Respectively moving and turning double-air-bag three degree-of-freedom 90/180 degree turnover machine

A technology with degrees of freedom and double airbags, applied in the direction of metal processing, etc., can solve the problems such as the structure or drive type can not be well applied to the overturning machine of large heavy-duty parts, and achieve the effect of simple structure, enhanced bearing capacity, and comprehensive functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

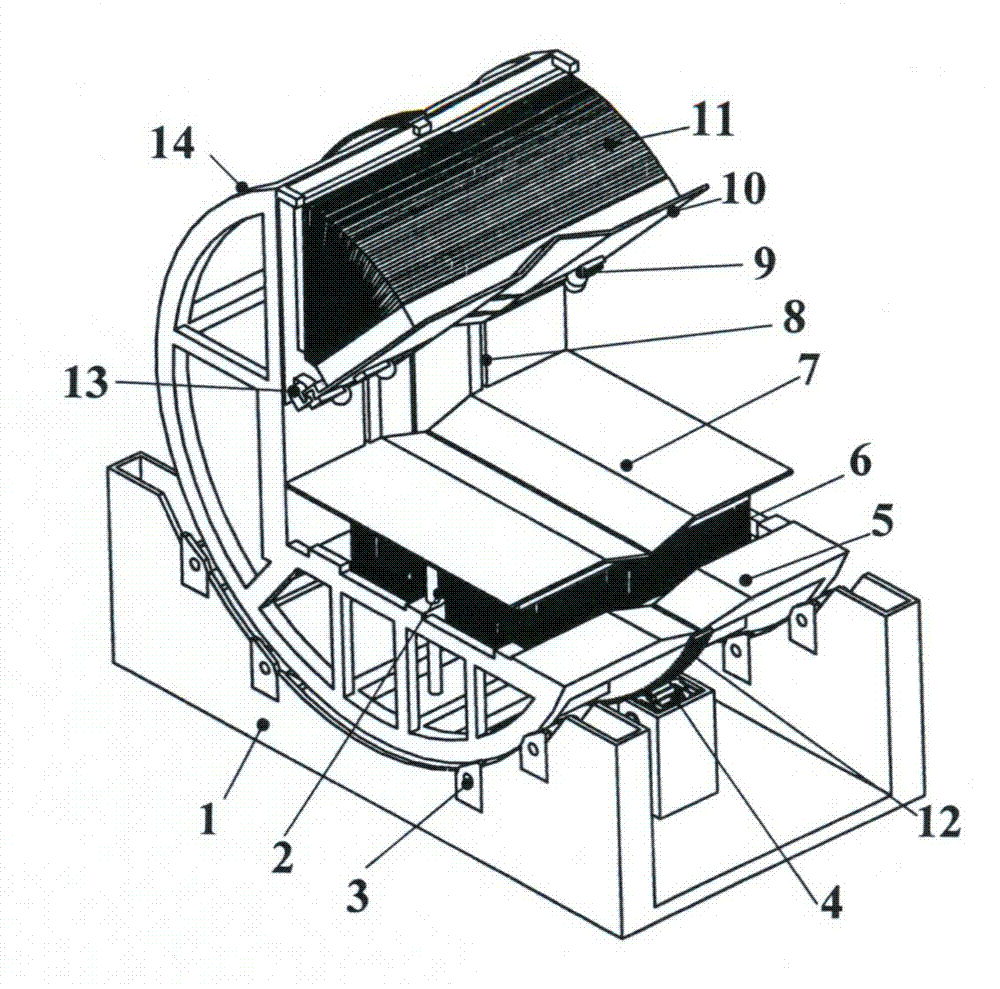

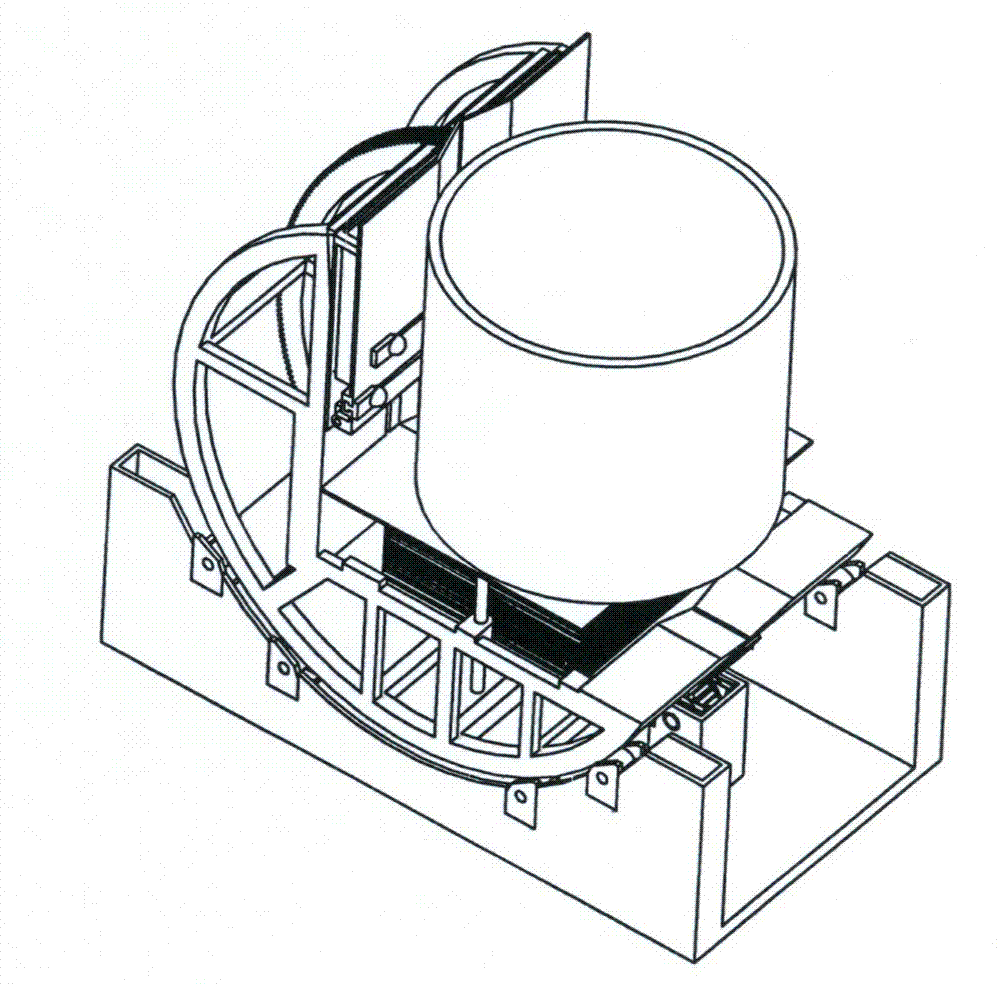

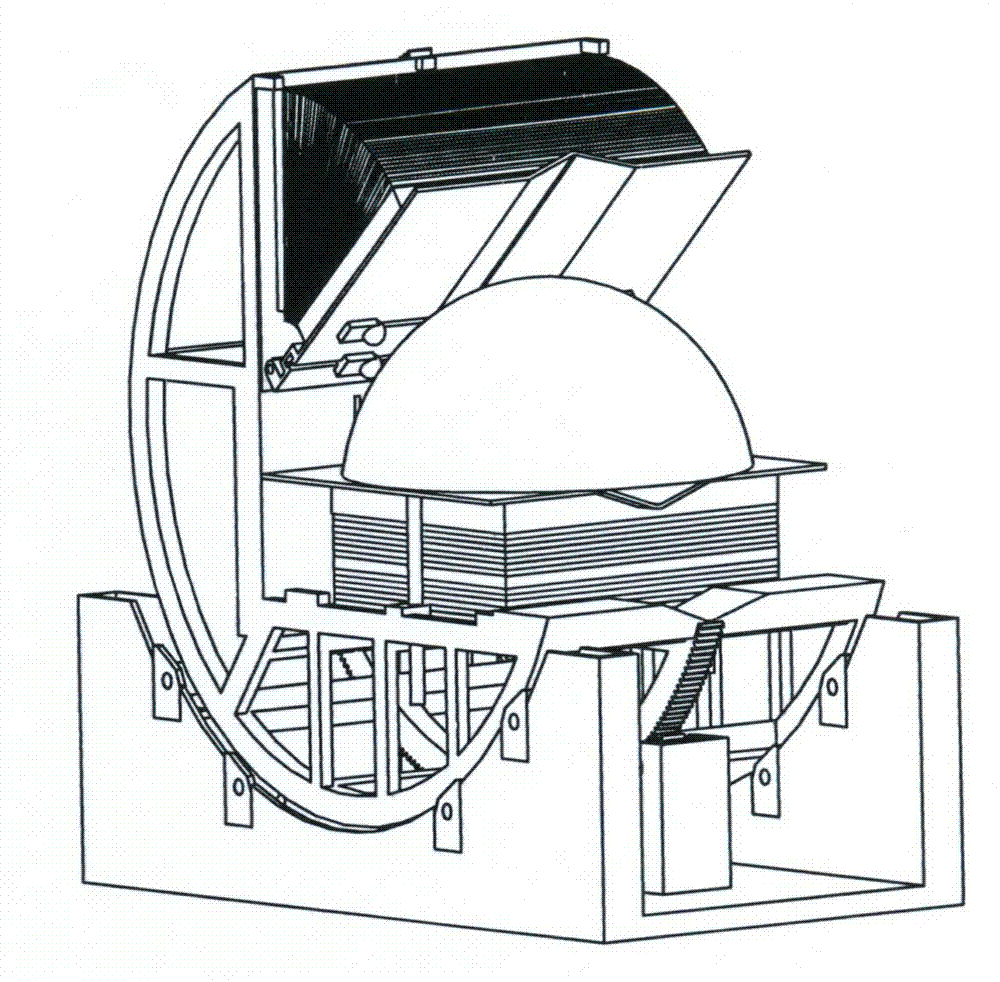

[0014] figure 1 It is an embodiment disclosed by the present invention. The turning machine is mainly composed of four parts: a machine base, a turning cart body, a turning workbench and a vertically moving workbench.

[0015] The machine base includes a base 1 , idlers 3 , and a turning drive gear 4 . Among them, the base 1 is a welded structure, and both ends of the axial direction are arc-shaped foundation roller tables parallel to each other formed by vertical support plates with concave arcs on the upper part. Four supporting rollers 3 are distributed, and the supporting rollers 3 and the arc-shaped basic roller table are positioned by rotating pairs. On the center line of symmetry of the base 1, a turning drive gear 4 is fixedly connected with a power transmission shaft, meshed with the arc-shaped car body ring gear 12, and is used to drive the turning big car body to realize rolling motion.

[0016] The overturned large vehicle body includes a cylindrical overturned v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com