Roller of four-high rougher

A technology for roughing mills and rolls, which is applied to the rolls of rolling mills and the rolls of four-high roughing mills to achieve the effects of eliminating excessive contact pressure at the edge, preventing deviation, and improving the shape of the plate

Inactive Publication Date: 2010-09-22

SHANGHAI MEISHAN IRON & STEEL CO LTD

View PDF2 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

These technologies are only applicable to the finishing mill in which the work roll moves axially during rolling, and are not applicable to the roughing mill where the above-mentioned rolls are axially constrained

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

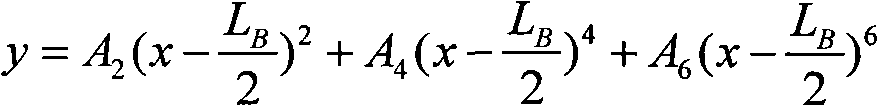

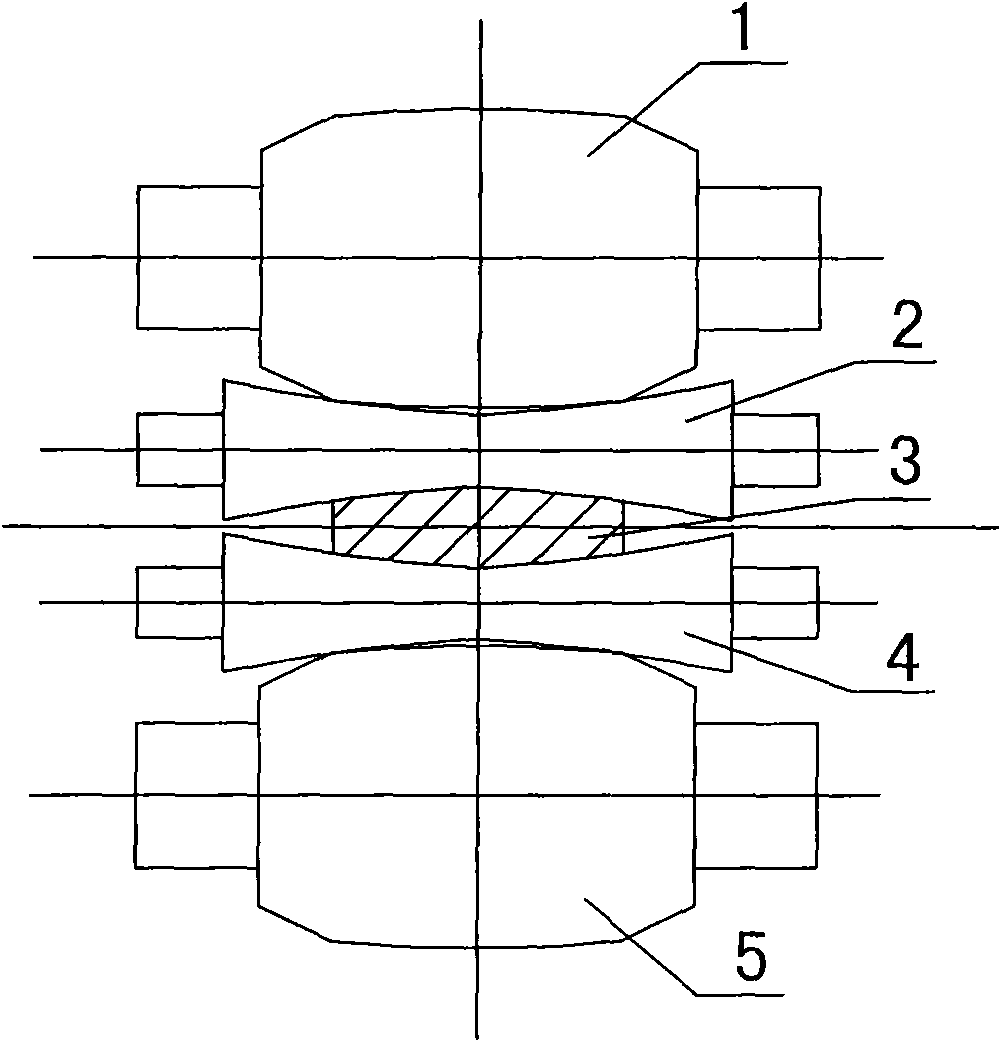

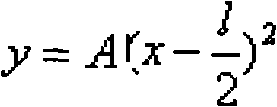

The invention relates to a roller of a four-high rougher, belonging to the technical field of a production process of hot rolled strips. The roller comprises two working rolls which symmetrically prop against a roughing mill and two supporting rolls which are in contact with the two working rolls, wherein the generatrix of the working rolls is a median-concave continuous curve determined by a curvilinear equation; and the generatrix of the supporting rolls comprises three sections, the middle section is a median-convex continuous curve determined by a polynomial equation, and the two end sections are symmetrical chamfer lines of an axial projected length L. The invention can inhibit the deviation of strip steel in the rough rolling process by the negative-convexity roll forming of the working rolls, equalize contact stresses among the rolls and eliminate the disadvantage of overlarge stress caused by the contact of the edges of the working rolls and supporting rolls, thereby prolonging the service cycle of the supporting rolls and improving the strip quality of an intermediate blank at the outlet of the roughing mill.

Description

technical field The invention relates to a roll of a steel rolling mill, in particular to a roll of a four-high rough rolling mill, and belongs to the technical field of hot-rolled plate and strip steel production technology. Background technique As far as the applicant knows, the rolls of the four-high roughing mill are all composed of back-up rolls on both sides and two work rolls that are in contact with the two back-up rolls respectively. During steel rolling, the strip passes between two work rolls. Practice has proved that the contact stress distribution between the cylindrical rolls of the existing four-high roughing mill is uneven, which easily leads to deviation, rapid wear at both ends, and affects the quality of the strip shape and the service life of the rolls. The search found that the application number is 95117449.5 and the name is "A Roll Shape with Axial Movement to Change Roll Gap Convexity and Variable Roll Gap Shape", and the application number is 20051...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21B27/02B21B29/00

Inventor 夏小明卞皓方少华

Owner SHANGHAI MEISHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com