Industrial intelligent optimization energy-saving system based on cement kiln fault diagnosis

A technology of fault diagnosis and intelligent optimization, which is applied in the direction of control/regulation system, general control system, test/monitoring control system, etc. It can solve the problems of inability to complete fault diagnosis of rotary kiln efficiently, quickly and accurately, difficulty in updating system knowledge, transparency, Problems such as rule expression are not refined, and the effect of extending the service period and service life, reducing costs, and optimizing design is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

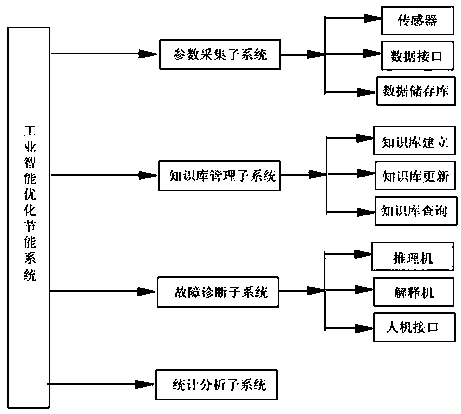

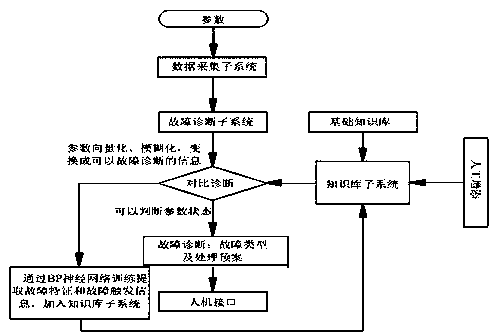

[0020] see figure 1 , the present invention is an industrial intelligent optimization energy-saving system based on cement kiln fault diagnosis, which consists of four parts: parameter acquisition subsystem, knowledge base management subsystem, fault diagnosis subsystem and statistical analysis subsystem, with the fault diagnosis subsystem as the core, With the support of the parameter acquisition subsystem and the knowledge base management subsystem, it is judged whether the parameter status is fault. Among them, the parameter acquisition subsystem includes sensors, data interfaces and data storage. Its function process is that the parameters of the cement kiln are collected by the sensors, stored in the database according to certain rules, and then transmitted to the fault diagnosis subsystem through the data interface after storage. The knowledge base management subsyst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com