Power chuck for turning hub

A wheel hub and power technology, applied in the field of power chucks for wheel hub turning, can solve the problems of affecting the machining efficiency of machine tools, heavy load, and difficulty in further increasing the spindle speed, so as to prolong the overhaul period and service period, improve service life, and surface The effect of smoothness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

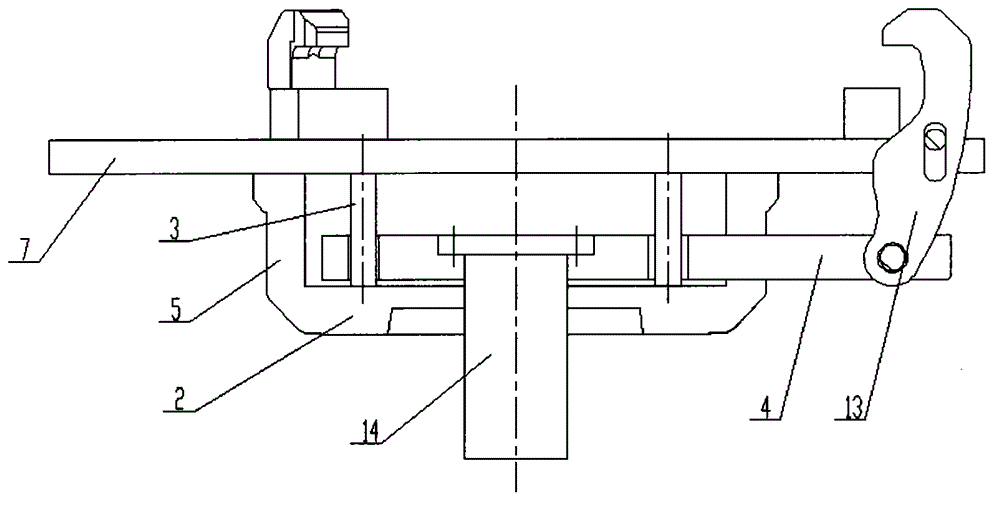

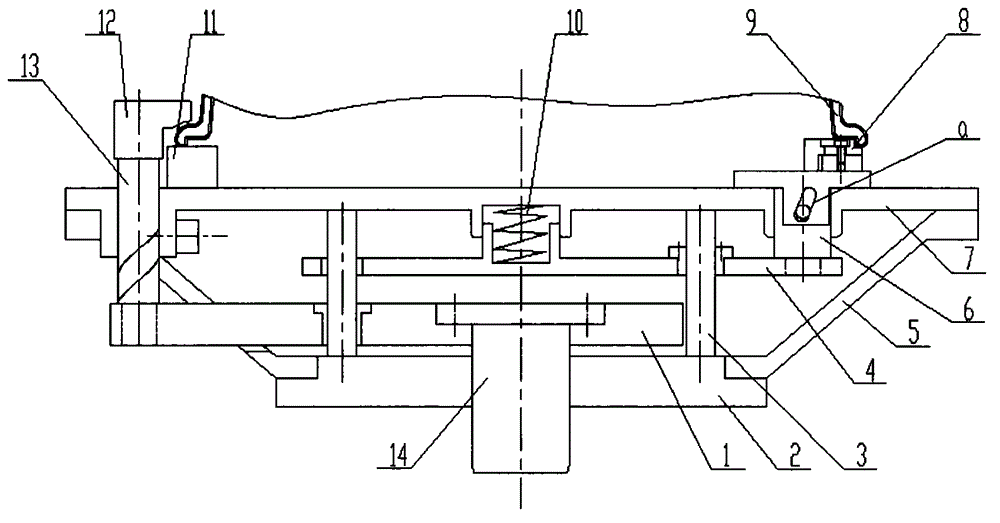

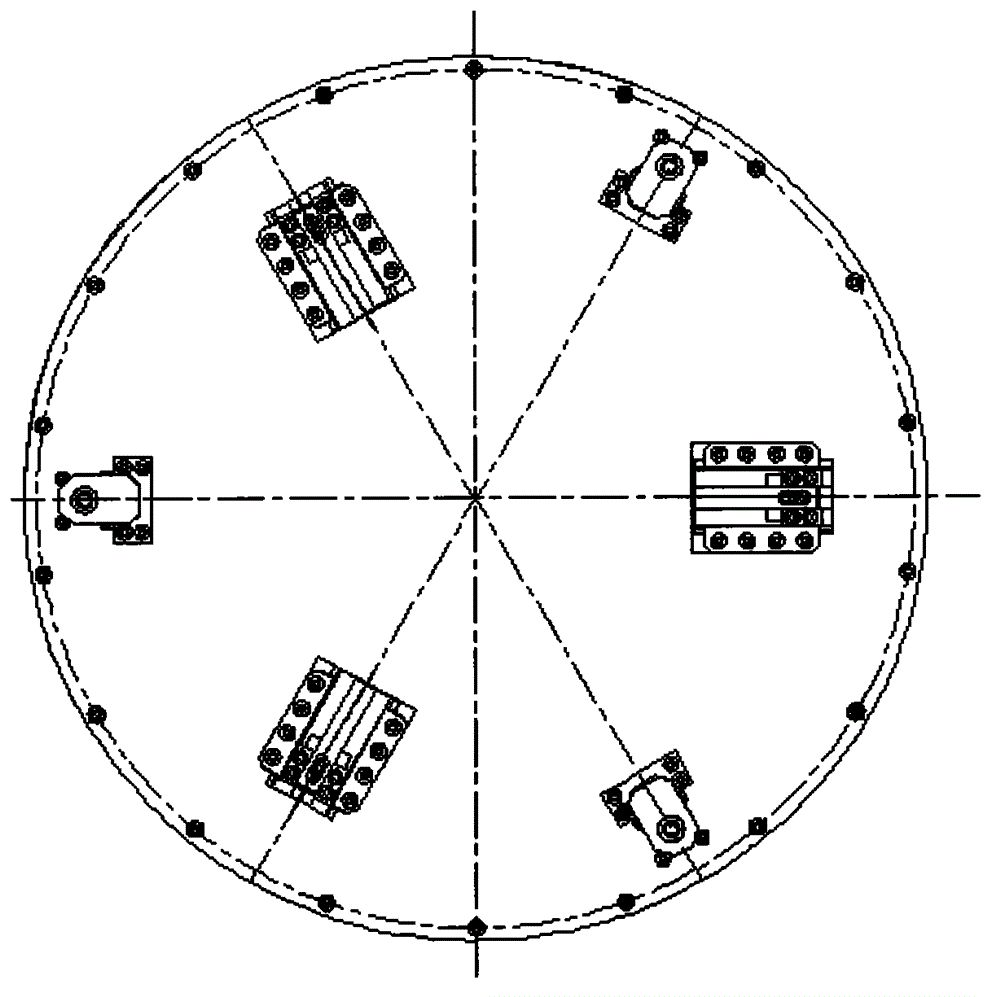

[0018] like Figure 2 to Figure 4 As shown, the wheel hub turning power chuck of the present invention is composed of a chassis 2, a support ring 5, a support guide rod 3 and an upper plate 7 to form its support structure, and the relative position of the chassis 2 and the upper plate 7 is formed by the support ring 5 and the support guide rod. 3 is fixed, and the central positioning frame 4 and the pressing claw pressing the connecting frame 1 are guided by the supporting guide rod 3 and can only move in the axial direction.

[0019] After the wheel hub is put in, the oil cylinder pulls the drive cylinder connecting shaft 14 to move downward, and the drive cylinder connecting shaft 14 is connected with the pressing claw pressing connecting frame 1, so that the pressing claw pressing connecting frame 1 moves downward, and the connecting frame 1 connected with it The axial pressing mechanism 13 makes the pressure claw 12 move downwards and also rotates around its own axis, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com