Patents

Literature

321results about "Counter-pressure devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

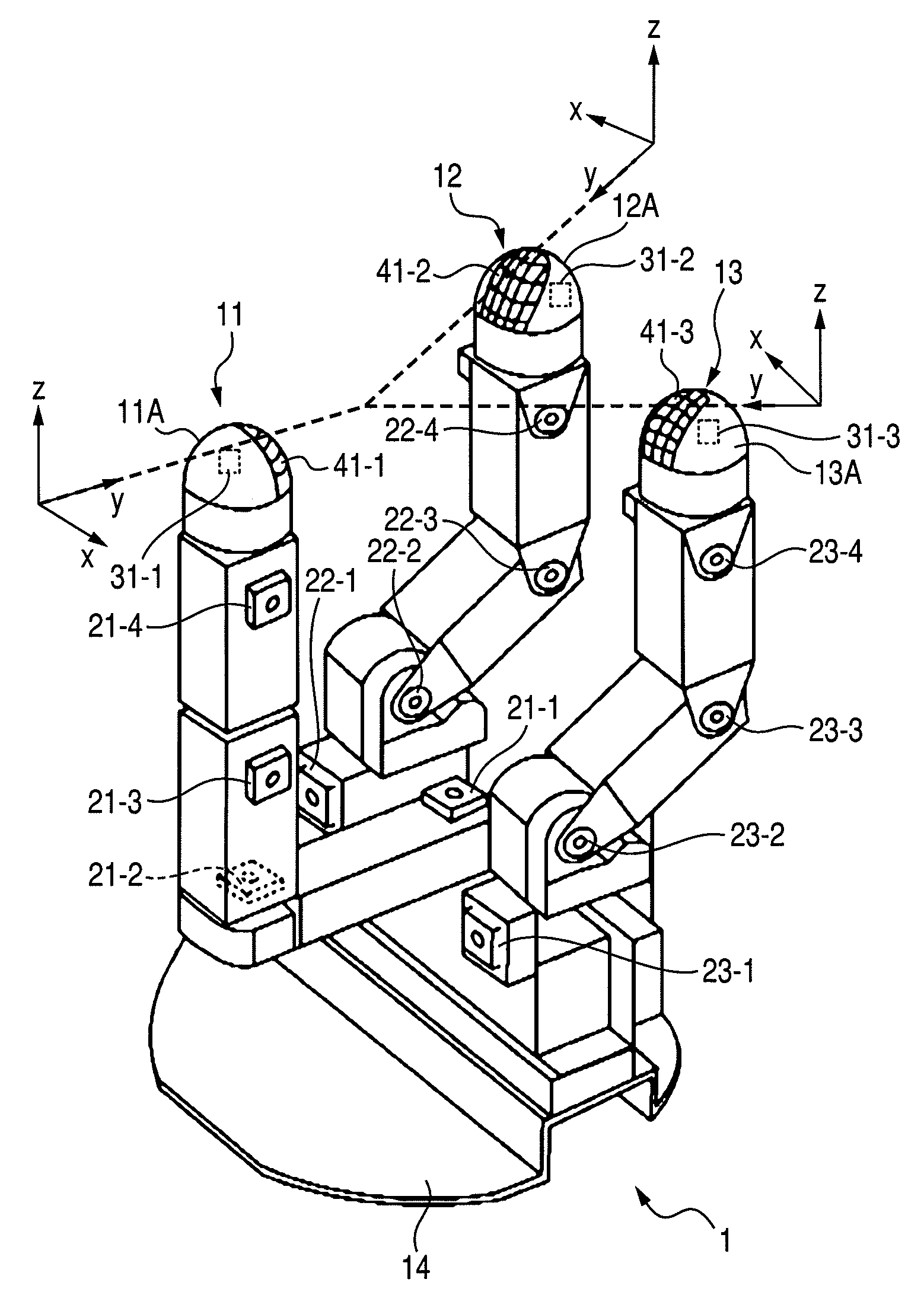

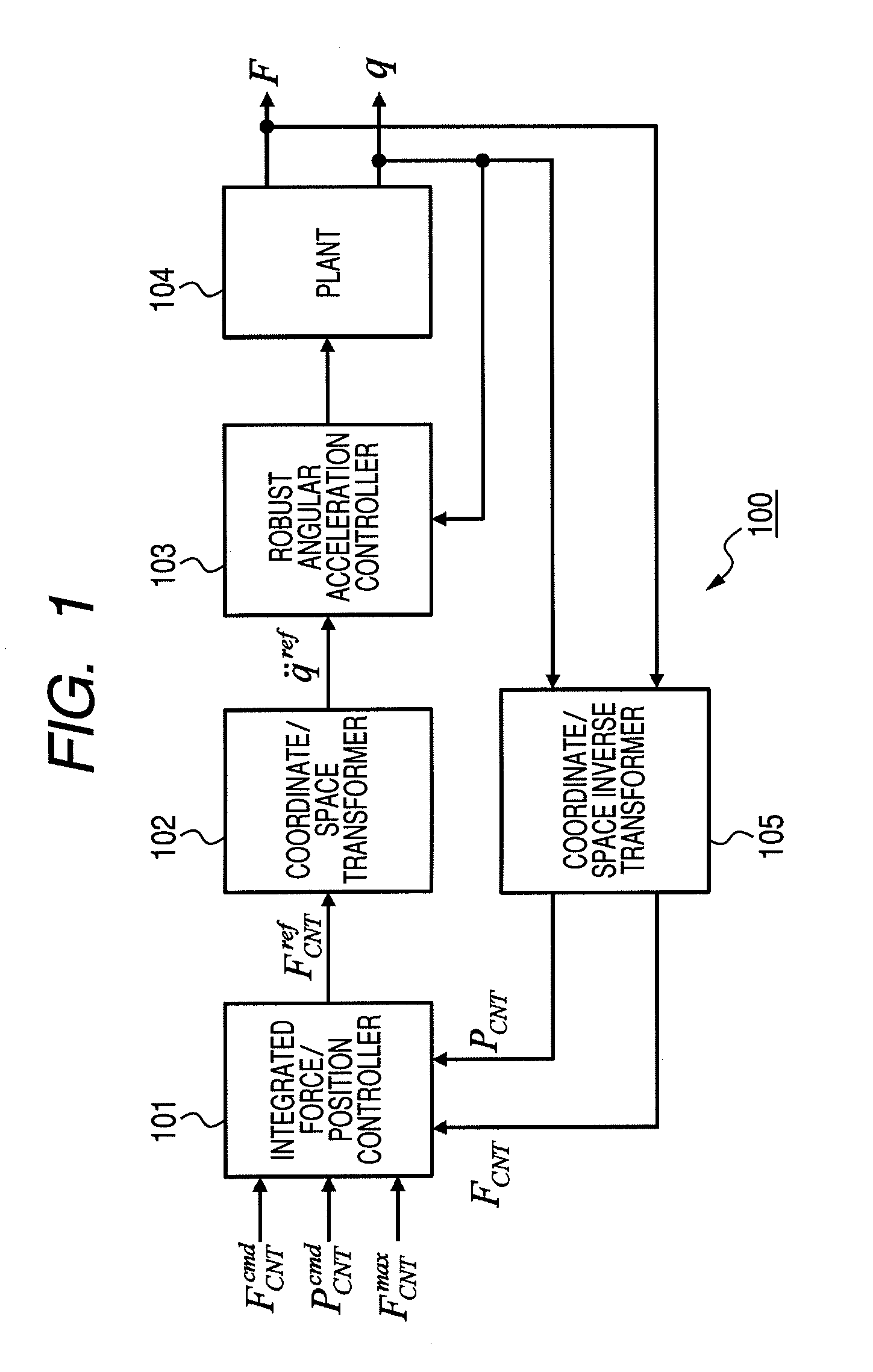

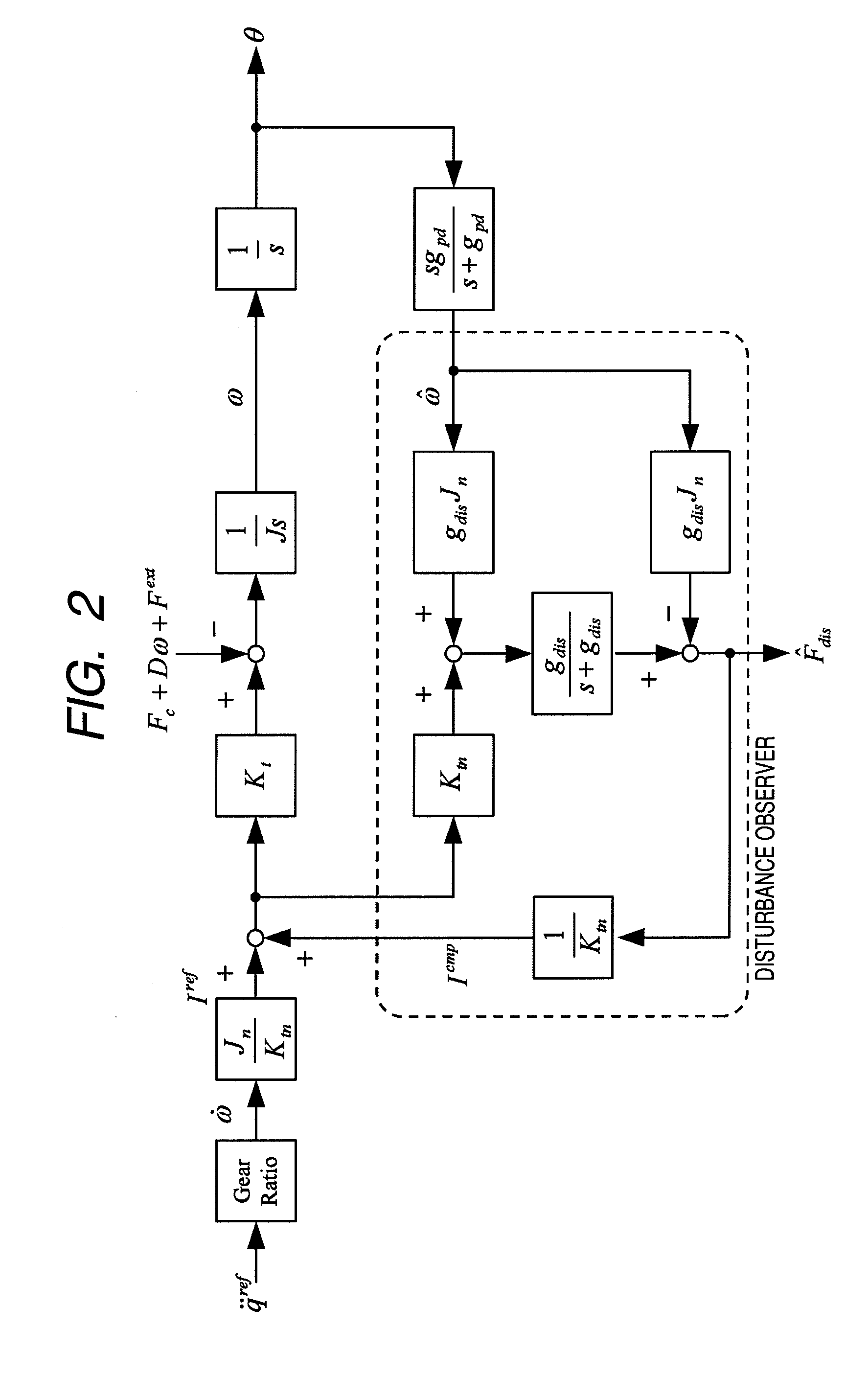

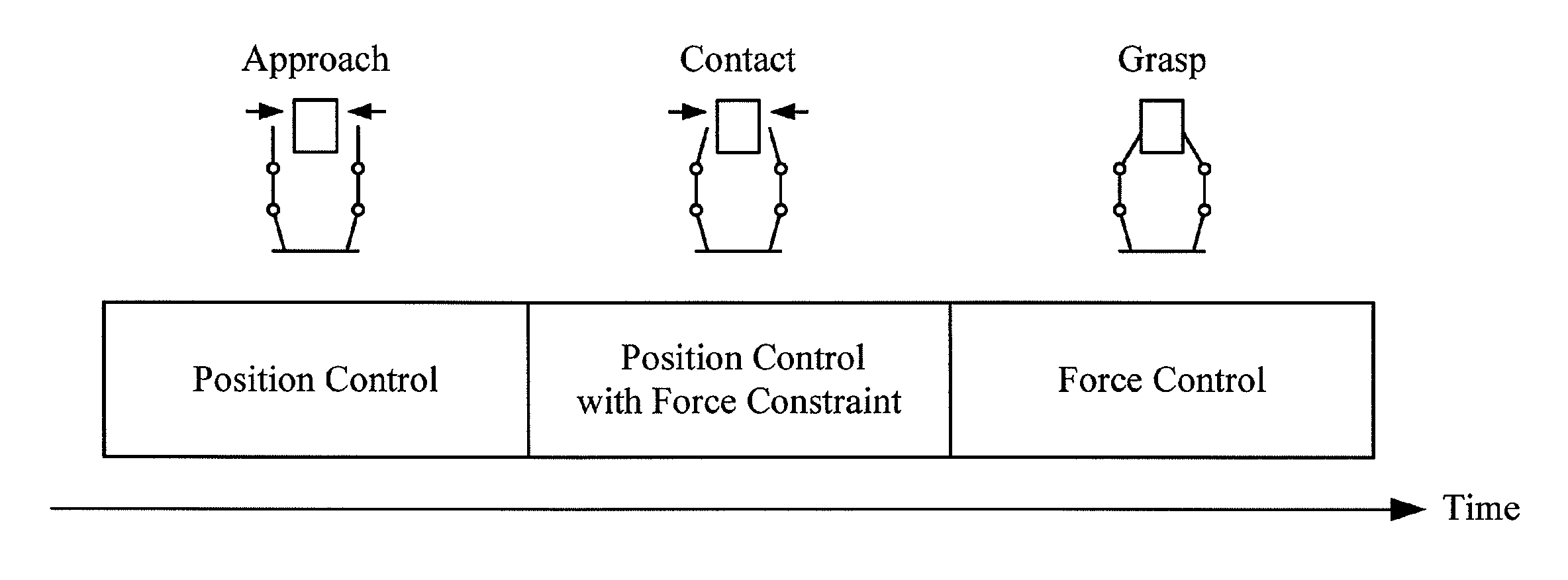

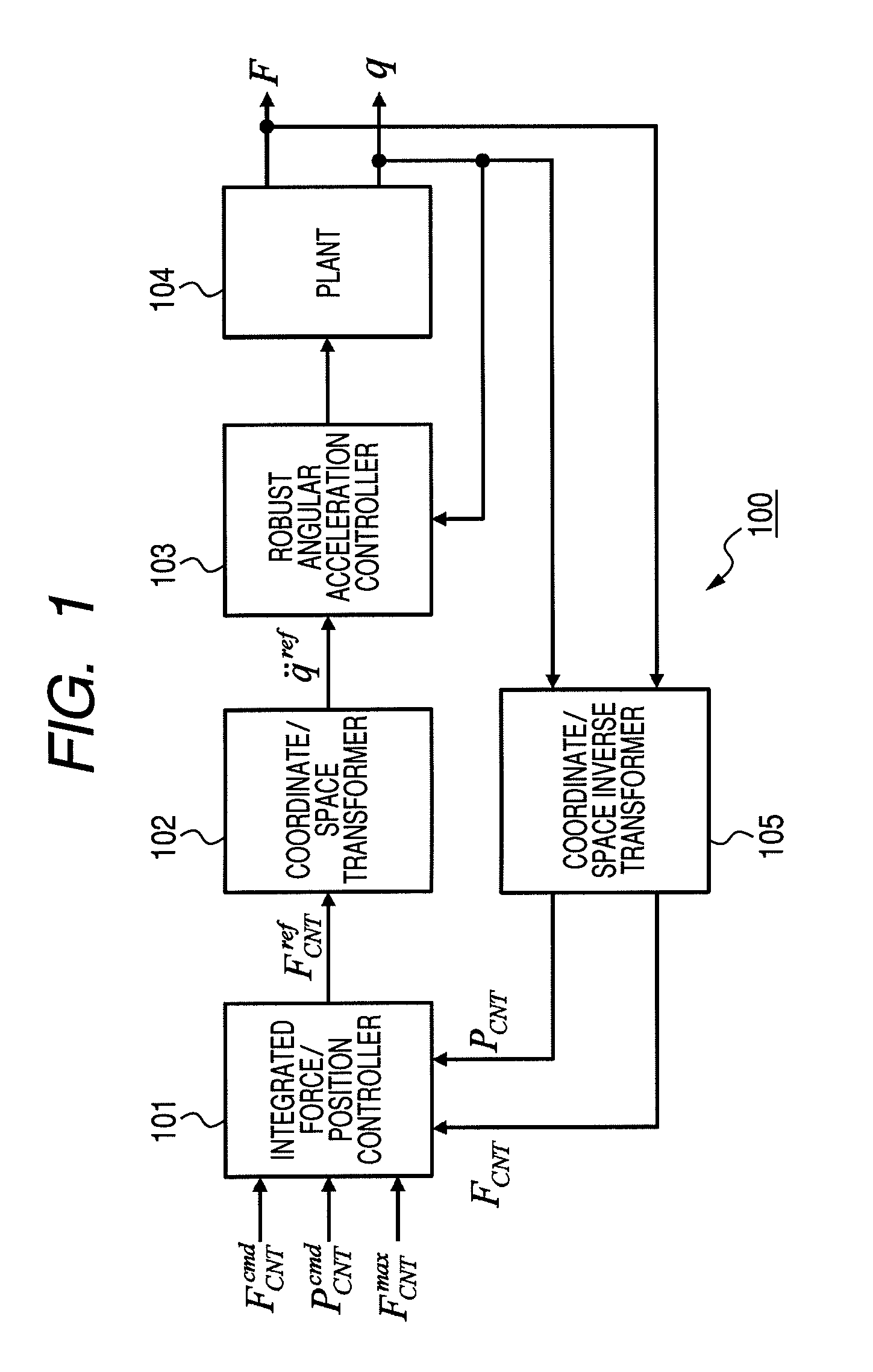

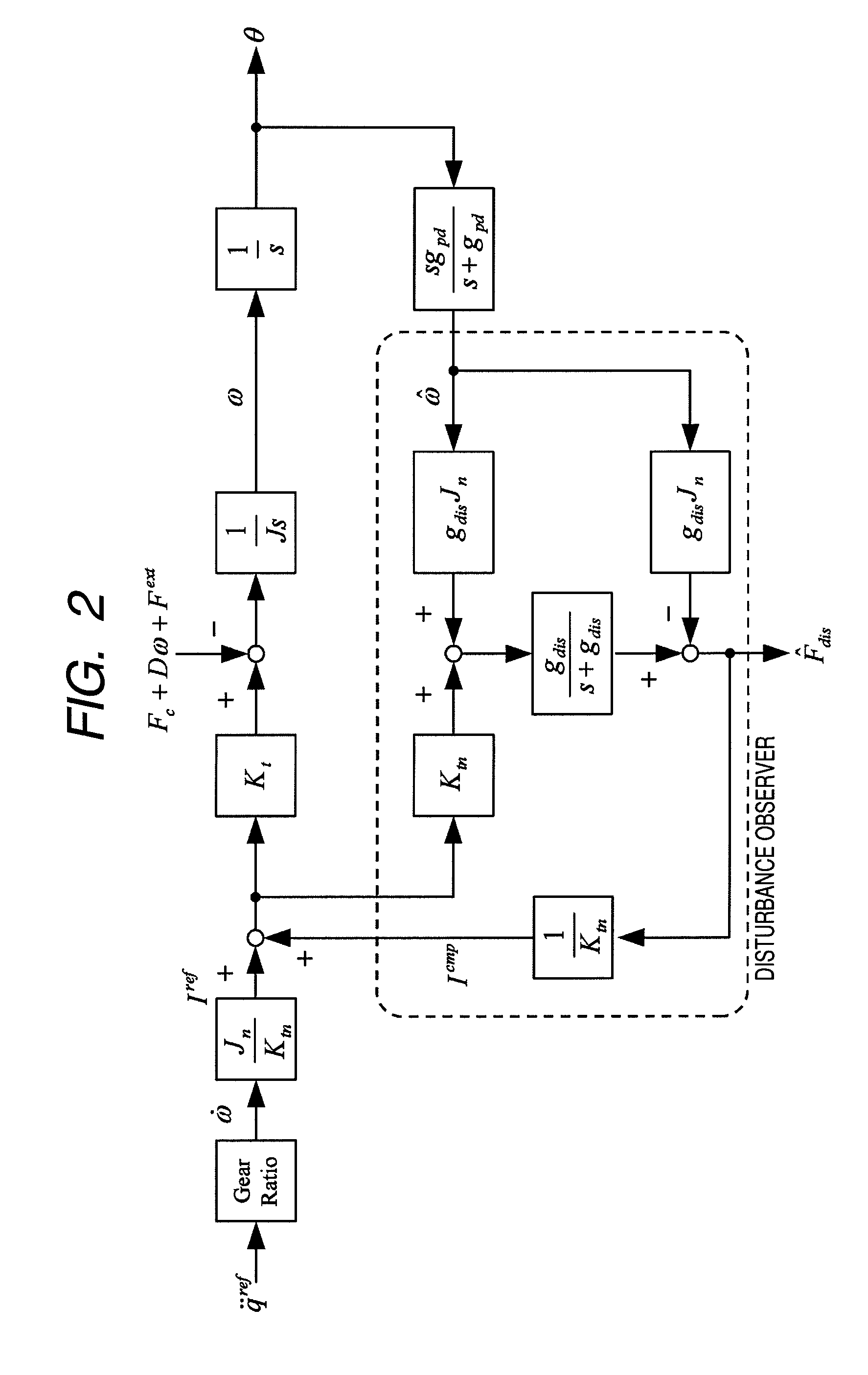

Robot apparatus and method of controlling the same

InactiveUS20090069942A1Easy to controlSmooth switchingProgramme-controlled manipulatorRoll force/gap control deviceMulti linkPosition control

A robot apparatus having a multi-link structure including a plurality of links and joints serving as link movable sections, and in which at least some of the links are driven by combination of position control and force control is disclosed. The apparatus includes: position control means for performing the position control on the links, which are driven by position control and force control; position control means with force constraint for placing the force control before the position control so as not to cause the magnitude of an external force to exceed a set value; force control means for performing the force control on the links; and integrated force / position control means for controlling driving of the joints by switching the position control means, the position control means with force constraint, and the force control means, and unifies the position control and the force control.

Owner:SONY CORP

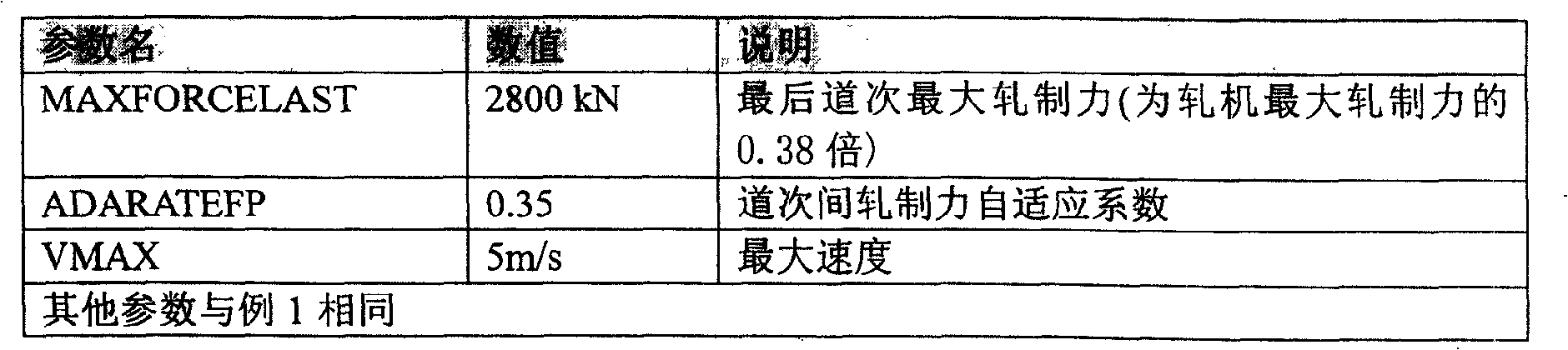

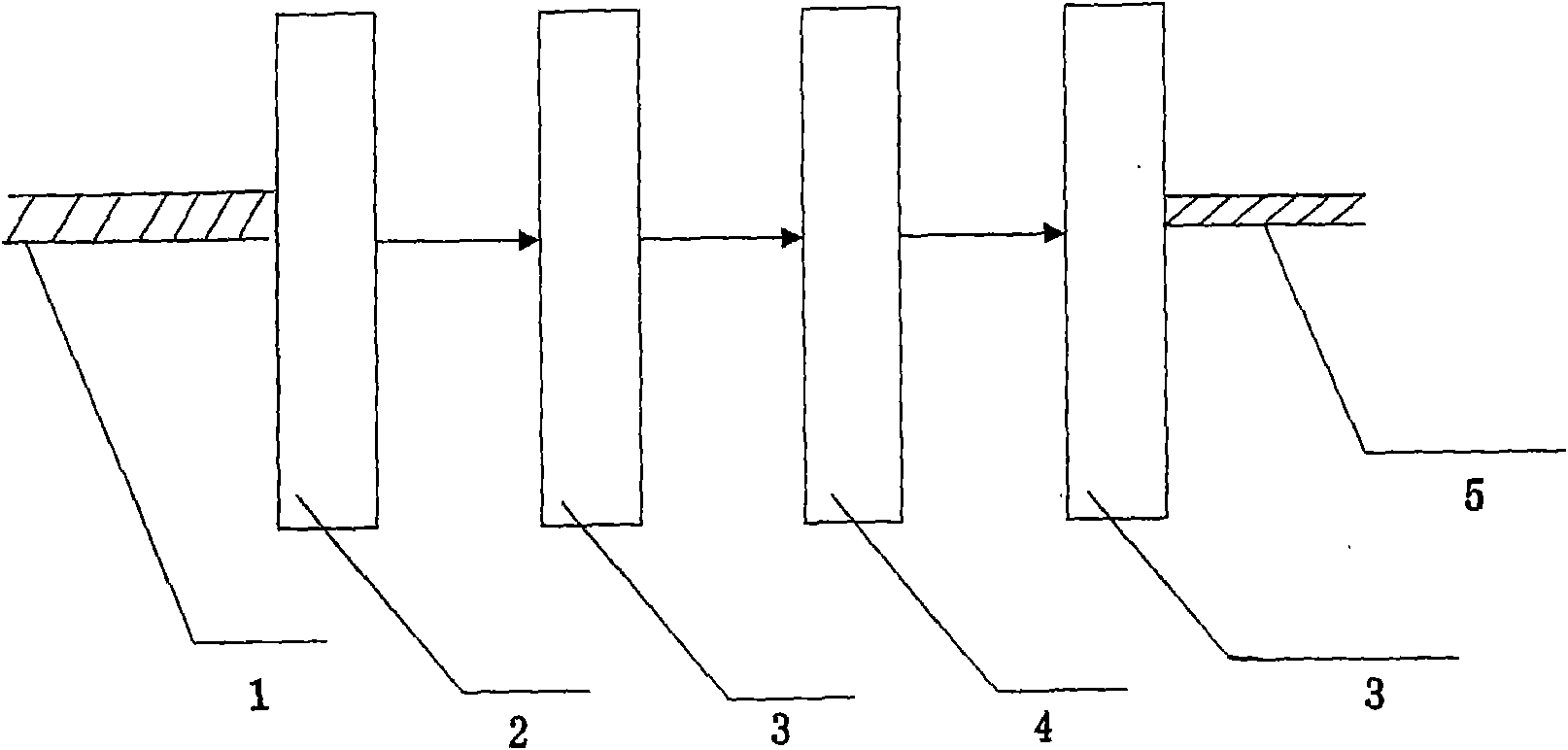

6mm steel plate rolling technique

InactiveCN101259482APrevent lateral movementStable rolling processRoll force/gap control deviceTemperature control deviceSheet steelEngineering

The invention provides a rolling technique for rolling a steel plate of 6mm by using a middle-thickness rolling mill which carries out corresponding settlements on the furnace discharge temperature of a stock, the stock thickness, rolling gates, an automatic gauge control, a rolling force, the self-adaptation coefficients of the rolling force between the gates, an opposite convexity and the matching between the linear speed of a transmission roller gate and the linear speed of the working roller of a rolling mill. The technique solves the problems of waves, bending, camber, frame scraping and waste rolling appearing in the plank stuffs during the testing rolling of 6mm plates of the existing middle-thickness rolling mill, leads the rolling to be stable and can manufacture qualified products in batch.

Owner:XINYU IRON & STEEL CO LTD

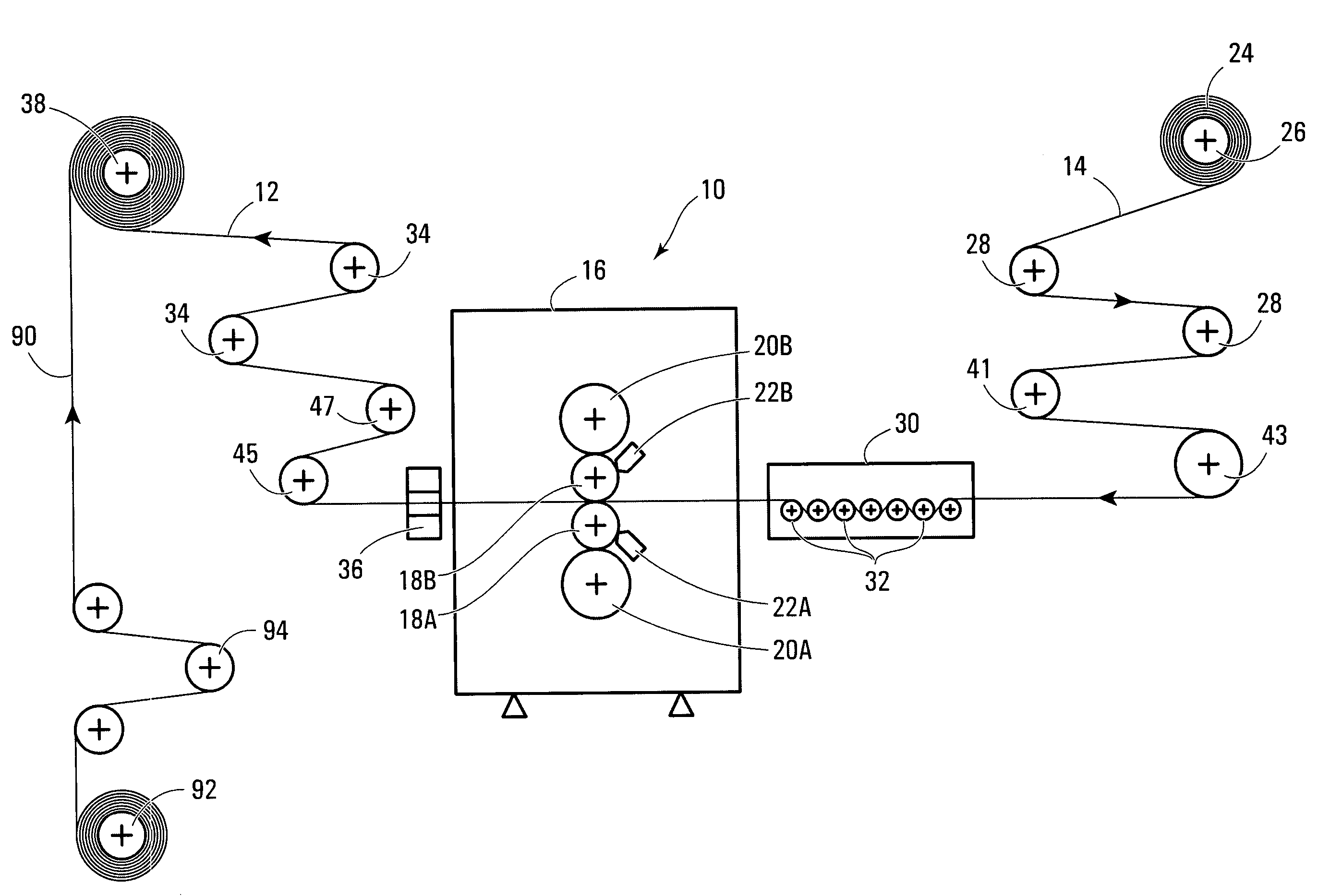

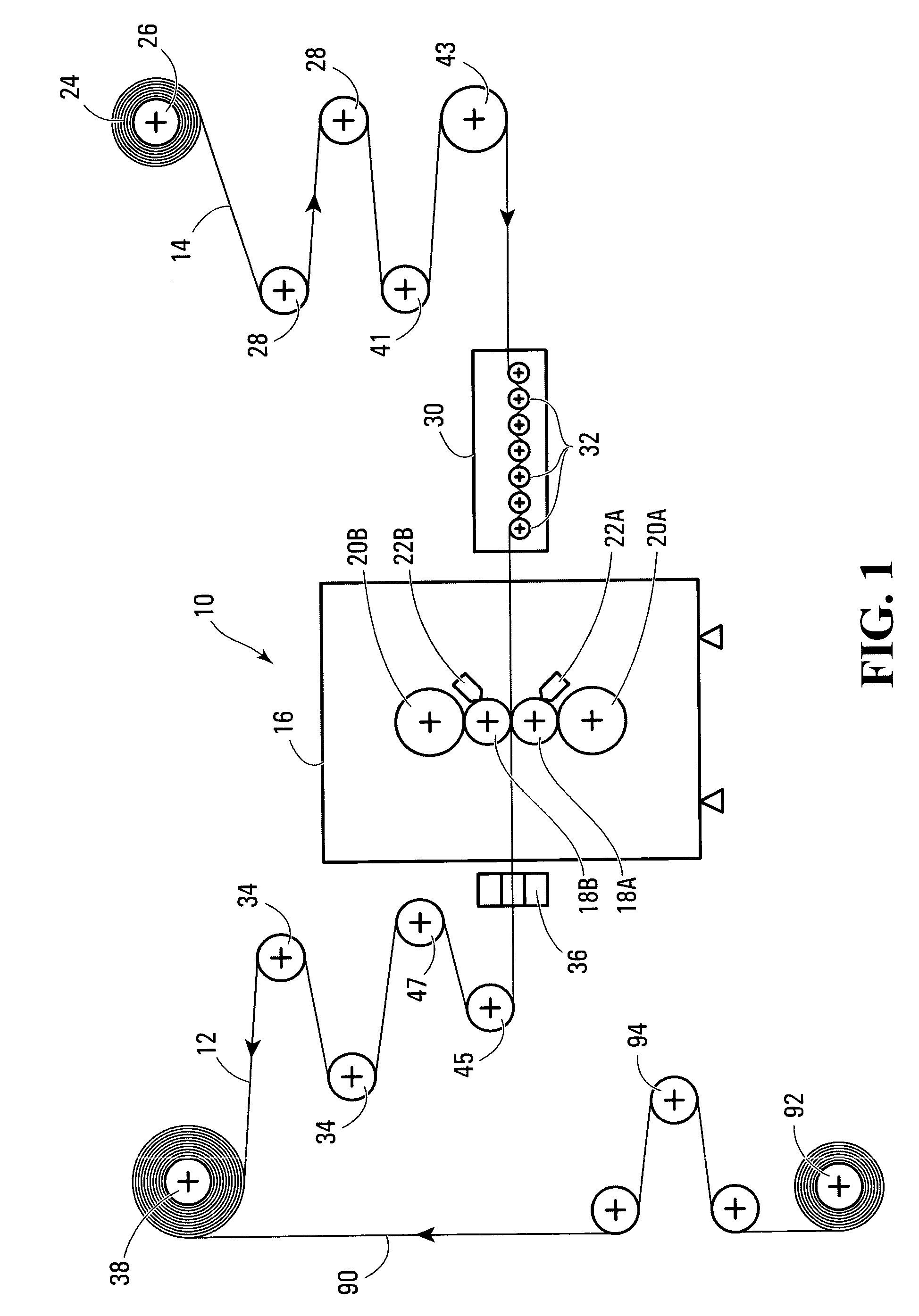

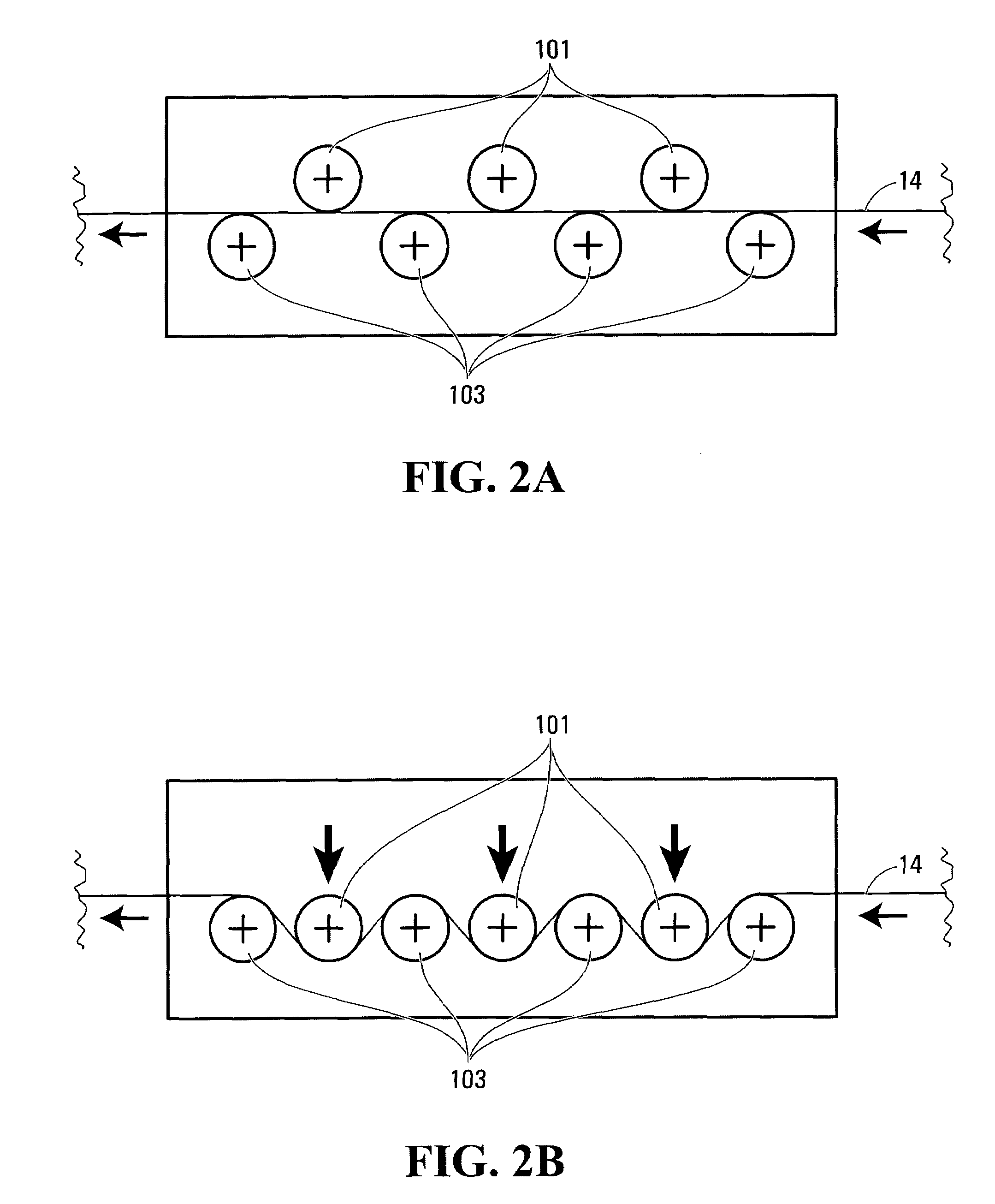

Lamination process and apparatus for alkali metals or alloys thereof

ActiveUS7513136B2Reduce thicknessElectrode rolling/calenderingRoll force/gap control deviceLithiumElectrical battery

An apparatus for and method of manufacturing lithium or lithium alloy anodes for electrochemical cells by a lamination process wherein a lithium or lithium alloy sheet is reduced into a thin lithium or lithium alloy film. The method and apparatus provide adjustments of the profile defined by the meeting surfaces of a pair of working rollers to compensate for thermal dilation of the working rollers or to compensate for irregular thickness of the lithium or lithium alloy sheet to control the shape and profile of the lithium or lithium alloy film being laminated.

Owner:BATHIUM CANADA

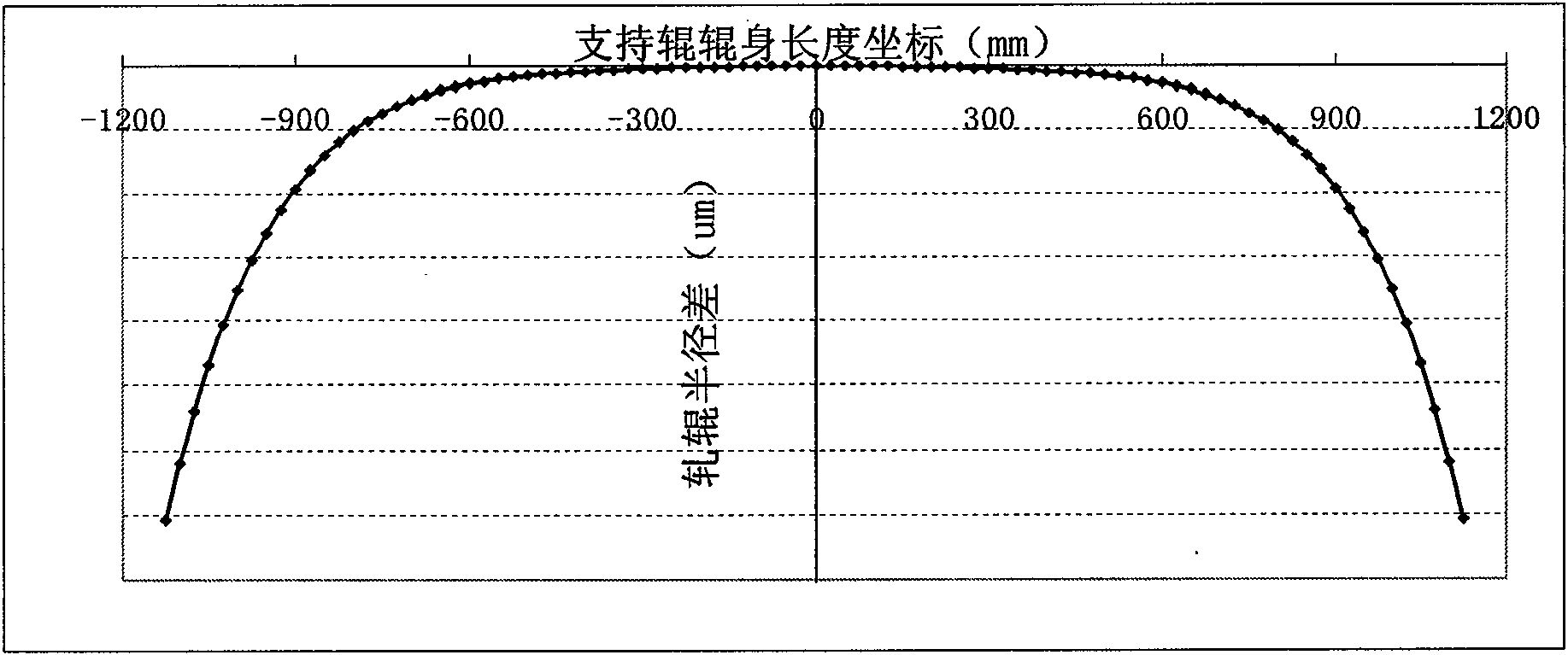

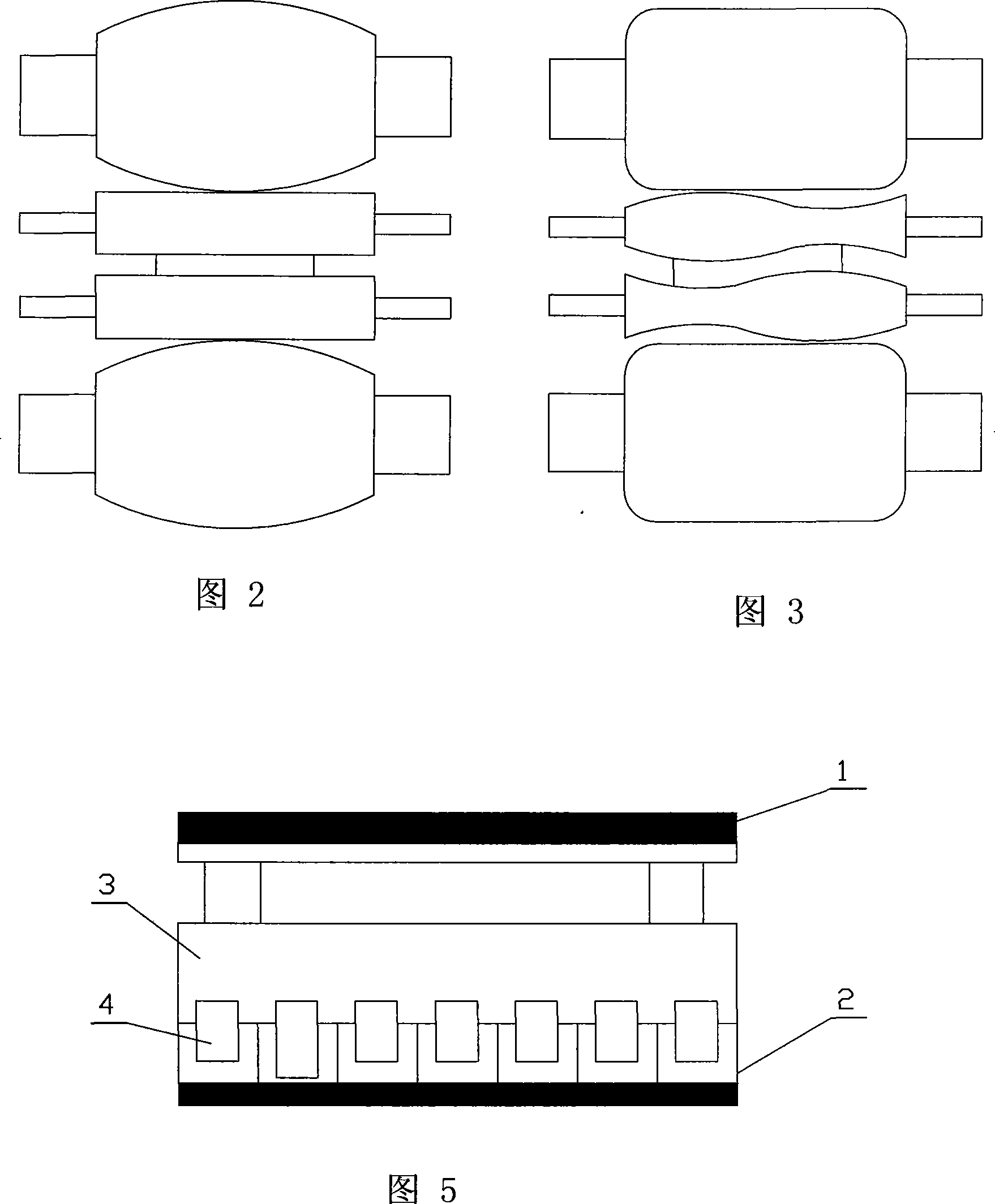

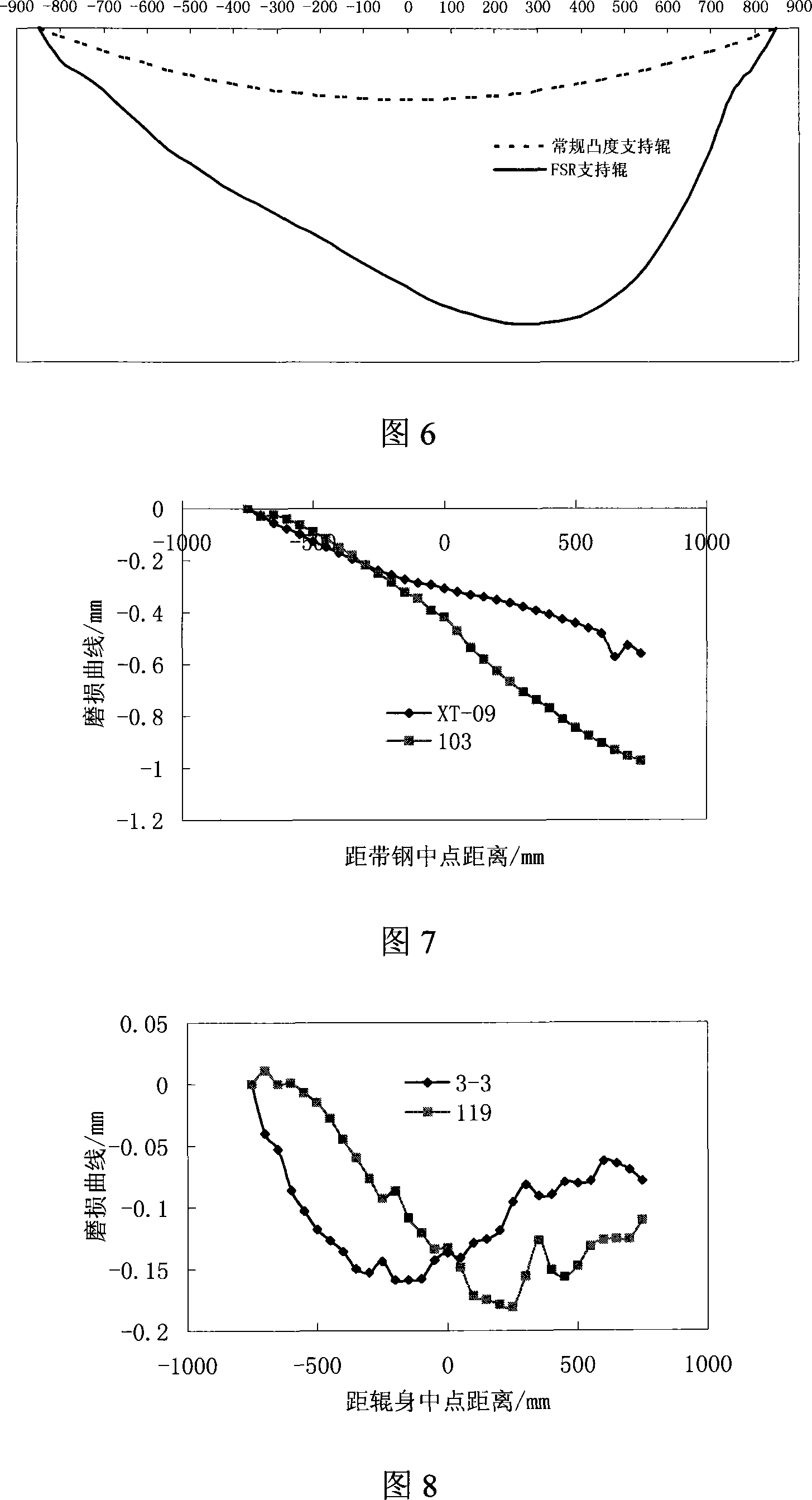

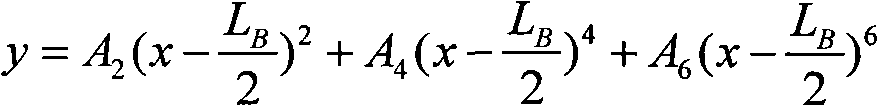

Method for configuring shape of supporting roll of four-high mill and shape of working roll thereof

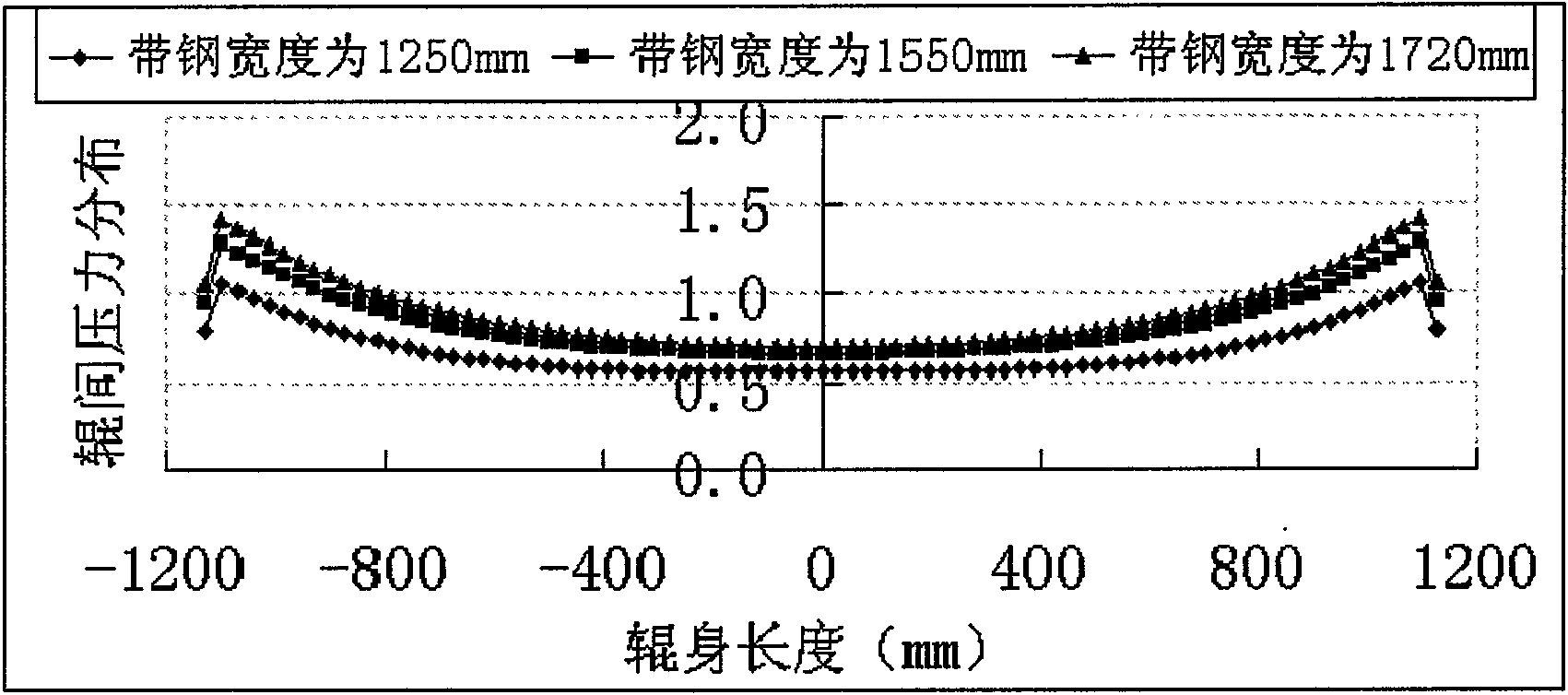

ActiveCN101554635ASolve peelingSolve the large amount of wear and tearCounter-pressure devicesRollsProduction lineStress concentration

The invention relates to a method for configuring the shape of a supporting roll of a four-high mill and the shape of a working roll thereof, belonging to the technical field of steel rolling. According to three types of width specifications of band steel which are most rolled by hot-rolling band steel production line, sixth-power polynomial supporting roll shape technology and second-power working roll shape curve are used for configuration so as to lead the contact length of the supporting roll and the working roll and the width of the rolled band steel to be fit. The method has the advantages of eliminating hazardous contact areas in which the parts of the two ends of the supporting roll with the flat roll shape and the working roll expand out of the edge of the band steel to generate large deflection and deformation, solving the problems that the stress concentration of the edges of the supporting roll and the working roll in a hot continuous mill for wide band steel causes stripping and the mill roll with the flat roll shape has large wearing capacity and is not even, reducing the consumption of the mill rill, saving energy, reducing consumption and reducing cost for rolling steel; and by the technical configuration of R2 working roll shape and the supporting roll shape, the invention solves the plate-shape problems that the middle blank generates negative convexity and the wedge shape is large, and improves the control precision of the shape of hot-rolled band steel.

Owner:SHOUGANG CORPORATION

Method for rolling precision stainless steel strips with Sendzimir rolling mill

InactiveCN101690940ALow investment costLow costRoll force/gap control deviceCounter-pressure devicesComputerized systemStrip steel

The invention discloses a method for rolling precision stainless steel strips with a Sendzimir rolling mill, which belongs to the field of stainless steel technology and steel rolling. In the method, a process regulation of rolling a strip with the thickness less than 0.3 mm is added on the basis of the prior rolling process regulations of a twenty high rolling mill; a computer system is adopted to perform control and rational roll system configuration so as to rationally assign the deformation rate of each pass and prevent the problems that strings of edge waves of the steel strip are drawn, or tension sides are ripped and broken, and string drawing easily occurs when the rolling mill is started; checking apparatuses, such as a thickness gauge, a plate shape gauge and the like, are corrected; and the surface conditions and the like of the rolled steel strip are checked in advance of two passes so as to comprehensively meet the requirements of producing the precision stainless steel strips of less than 0.3 mm. The method not only expands the rolling range of the twenty high Sendzimir rolling mill, but also can produce products with high value added and reduce investment cost of new precision rolling mills, and is good for producing and rolling the precision stainless steel strips with short time, higher speed and lower cost, and has great application and popularization values in the manufacturing industry.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Sheet rolling method and sheet rolling mill

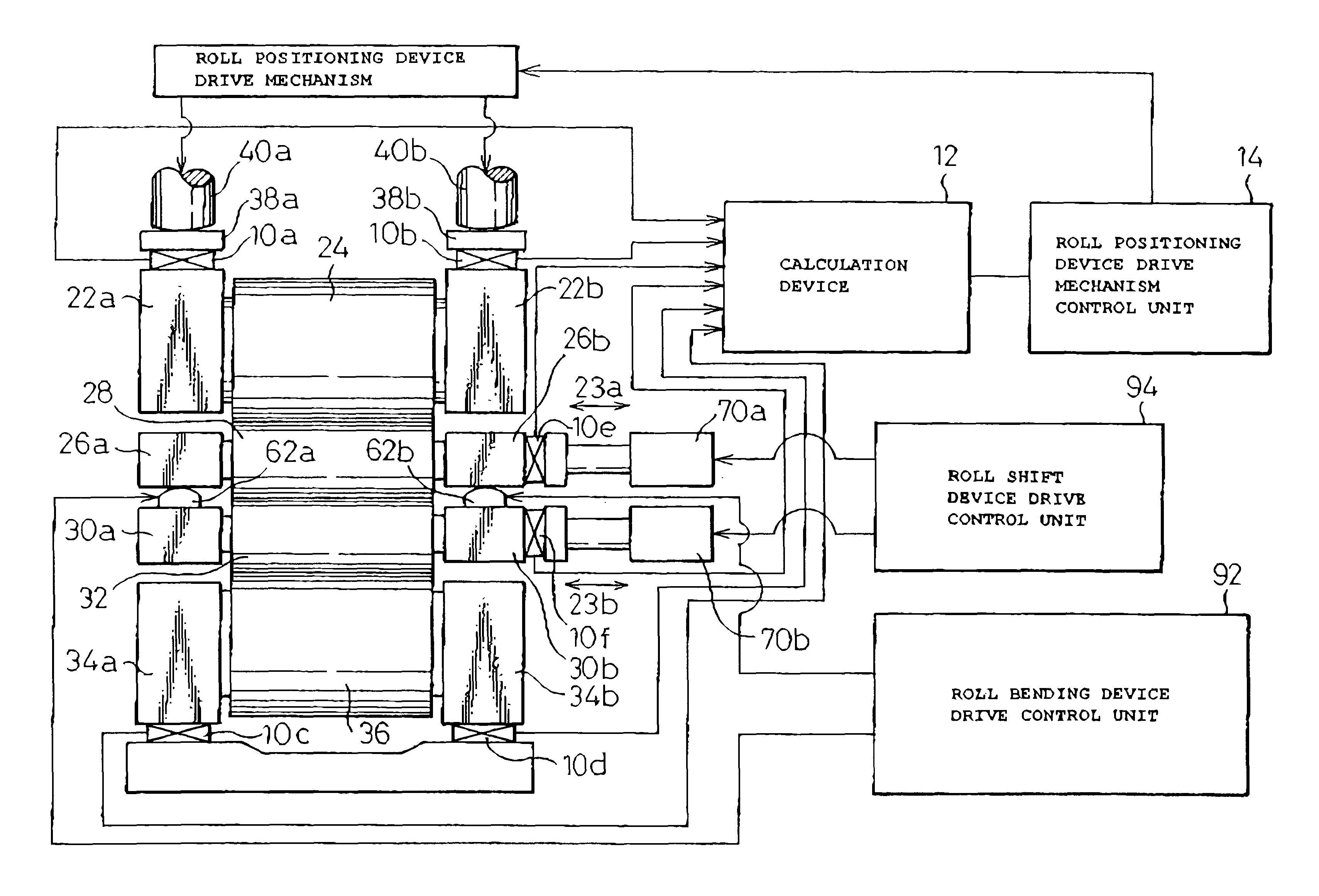

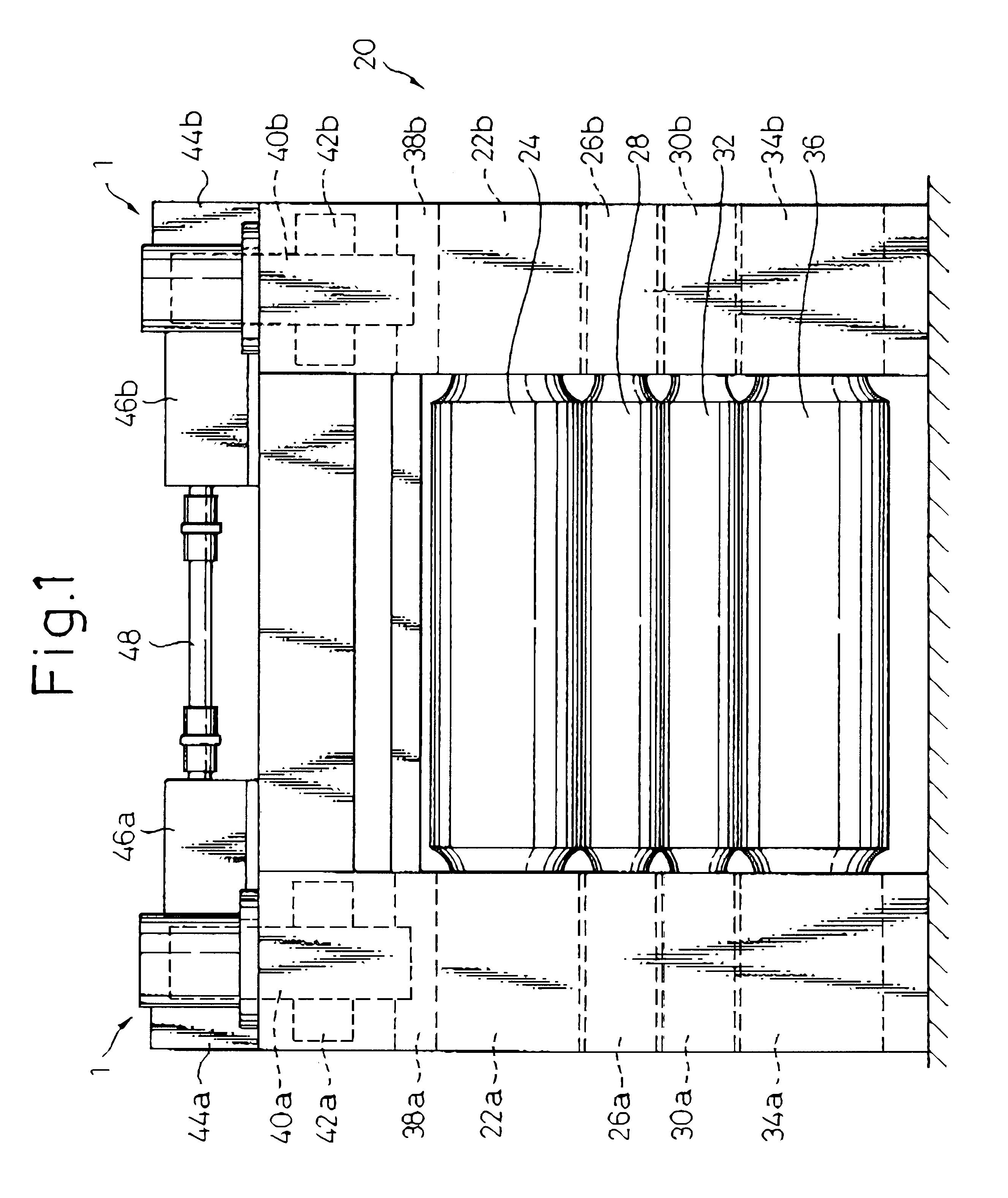

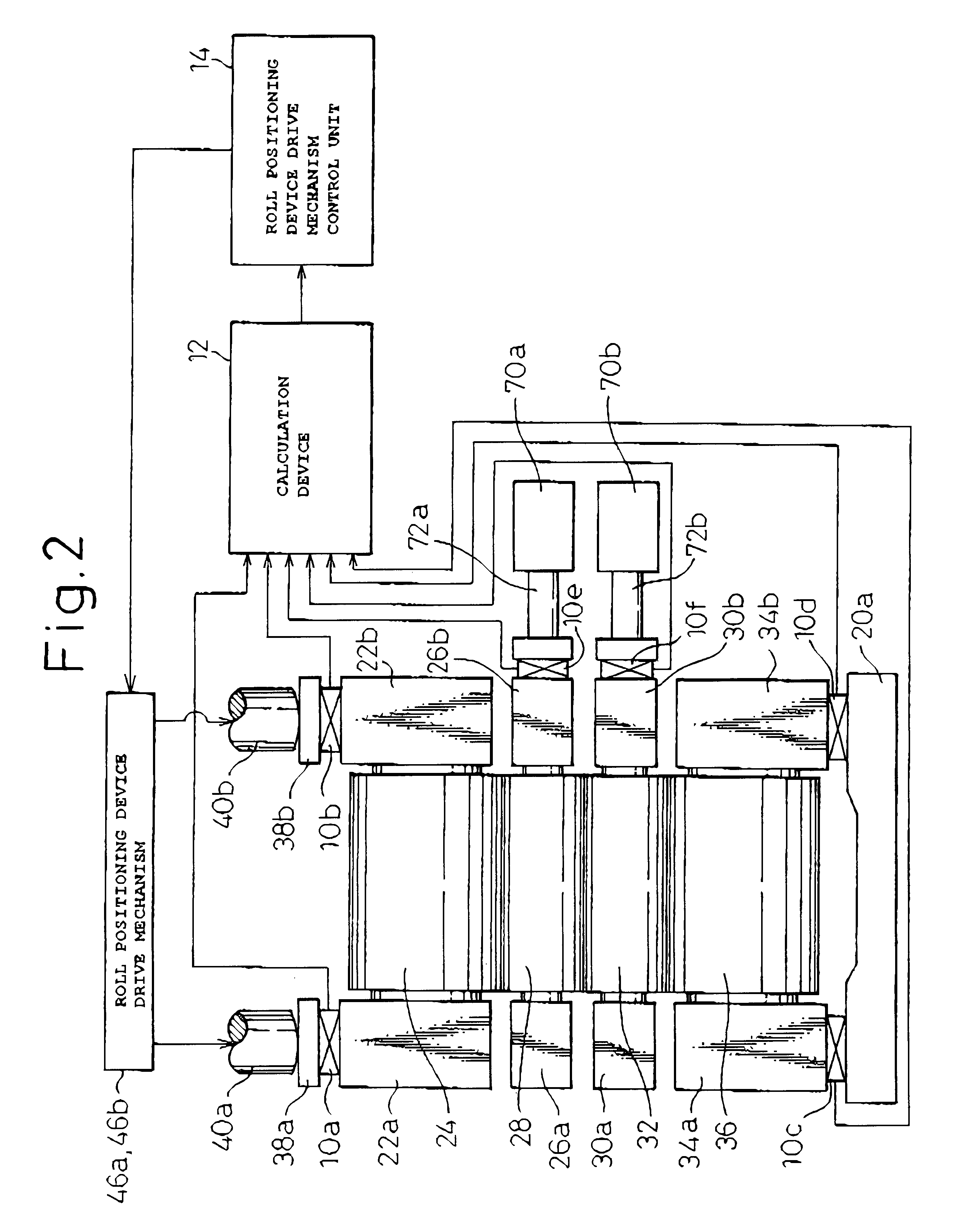

InactiveUS6401506B1Reduce distractionsDisturbance can be reduced negligibly smallRoll force/gap control deviceMetal rolling stand detailsStrip steelBackup roll

In a rolling method applied to a multi-roll strip rolling mill composed of not less than four rolls, one of the zero point of the roll positioning devices and the deformation characteristic of the strip rolling mill or alternatively both the zero point of the roll positioning devices and the deformation characteristic of the strip rolling mill are found from a measured value of the thrust counterforces in the axial direction of the roll acting on at least all the rolls except for the backup rolls in the kiss-roll tightening state and also from a measured value of the roll forces of the backup roll acting on the backup roll chocks of the top and the bottom backup roll in the vertival direction. According to the thus obtained zero point of the roll positioning devices or the deformation characteristic of the strip rolling mill, the setting and control of the roll forces is executed when rolling is carried out.

Owner:NIPPON STEEL CORP

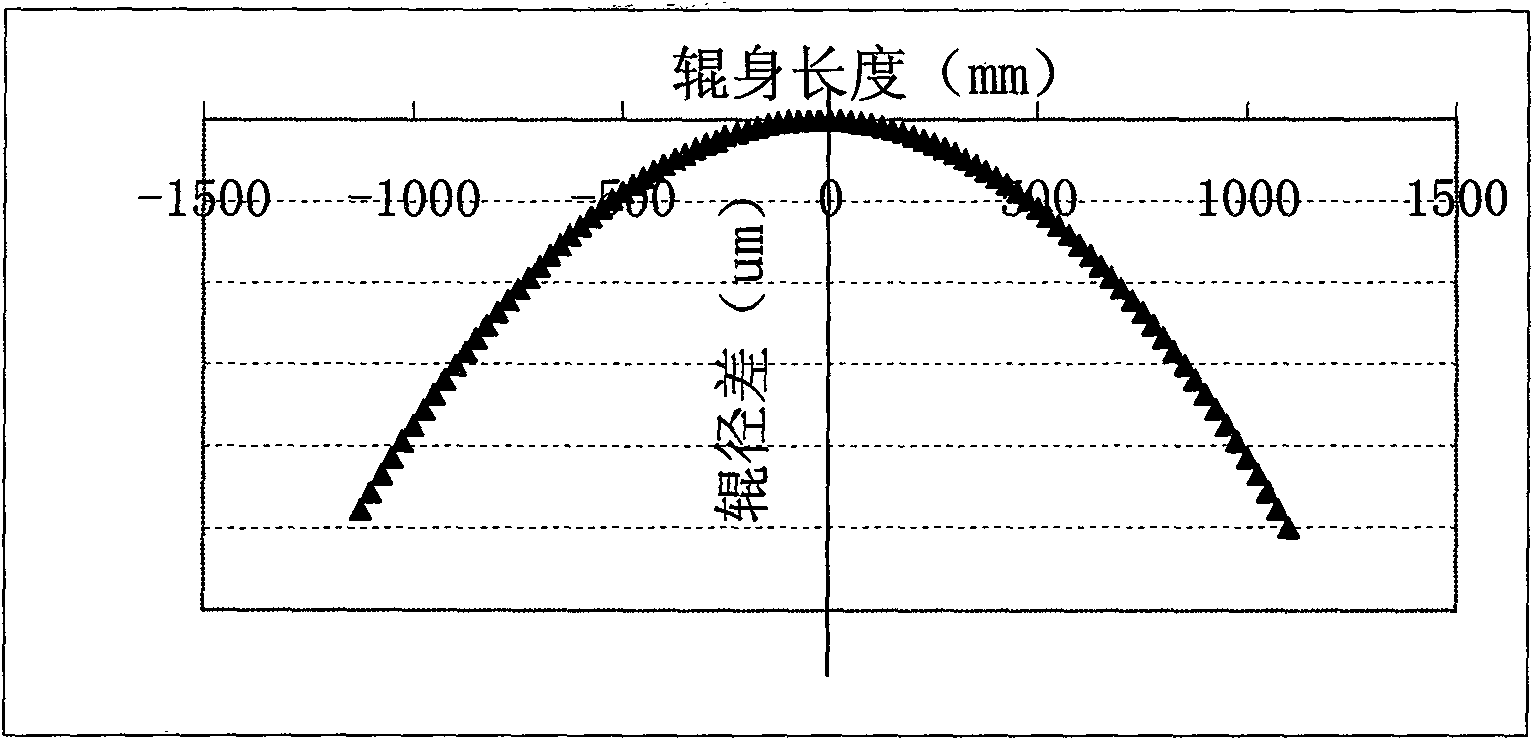

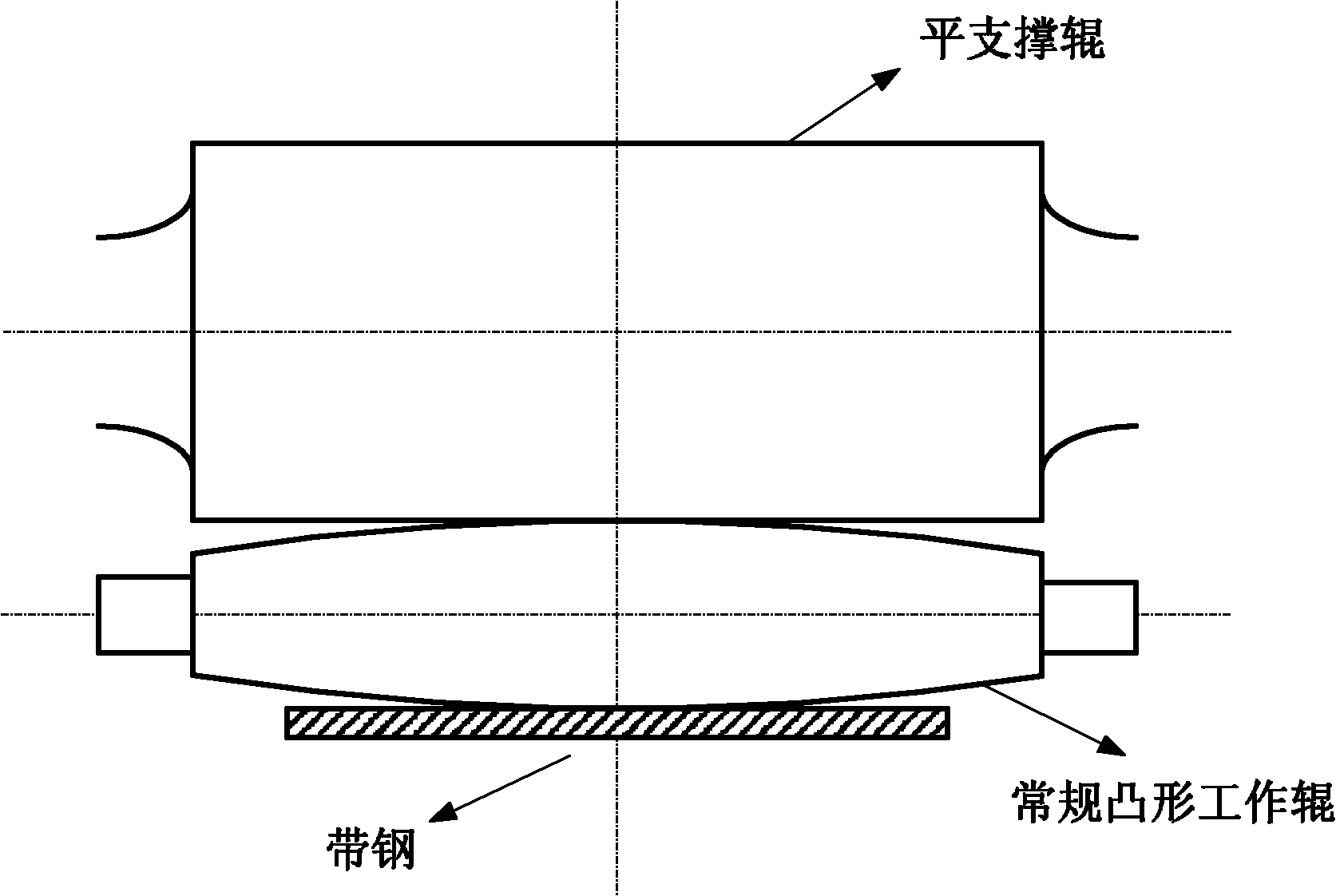

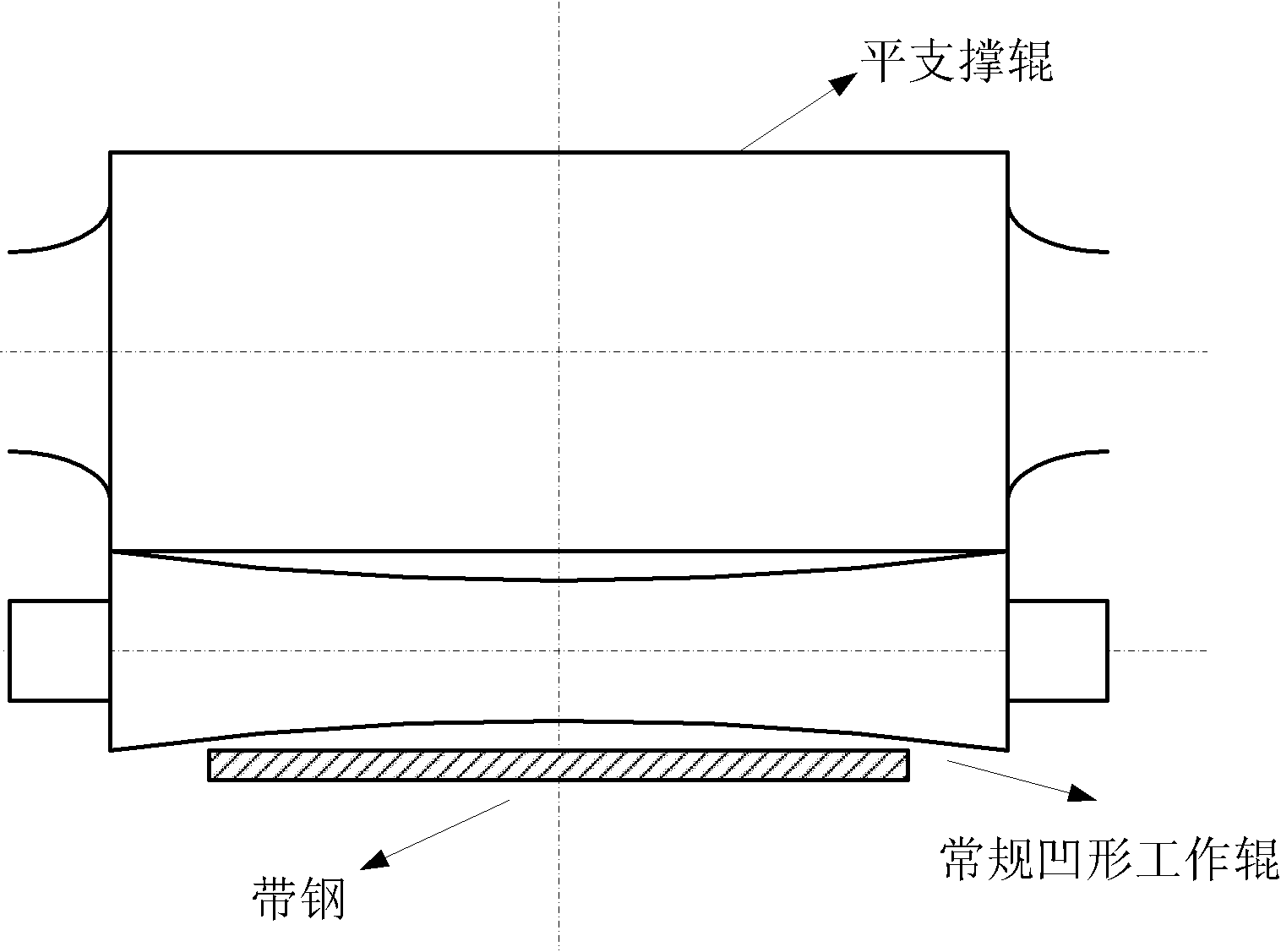

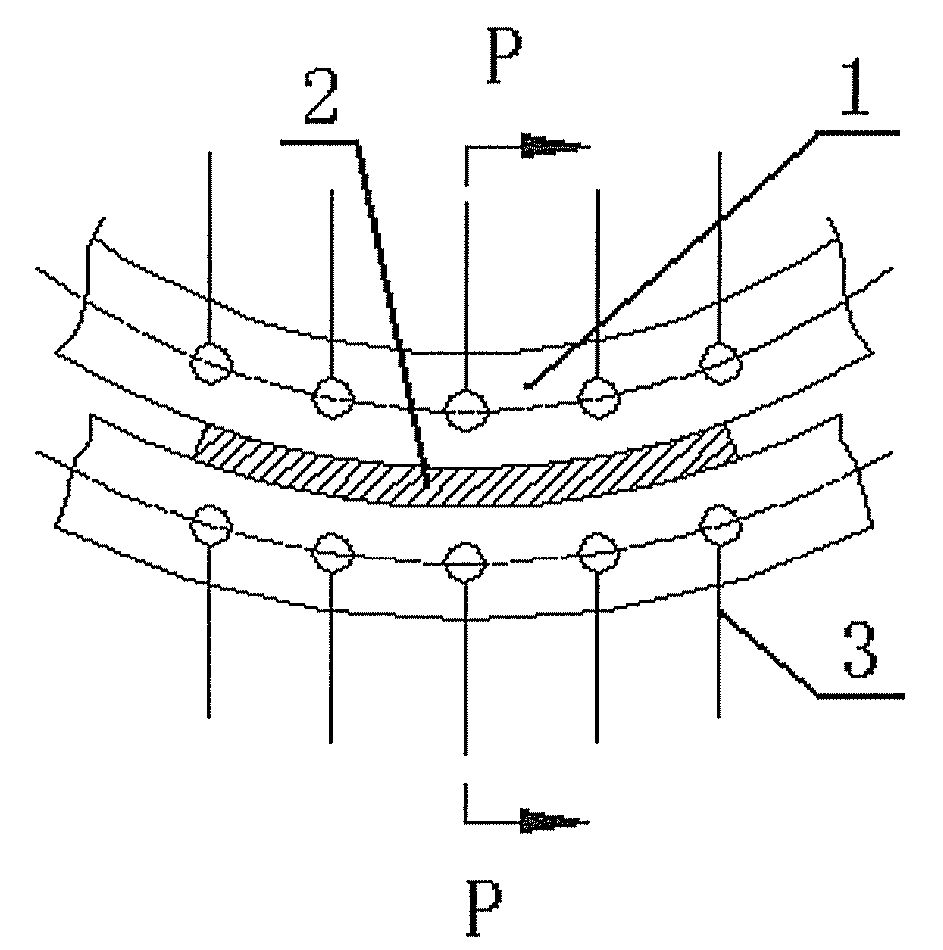

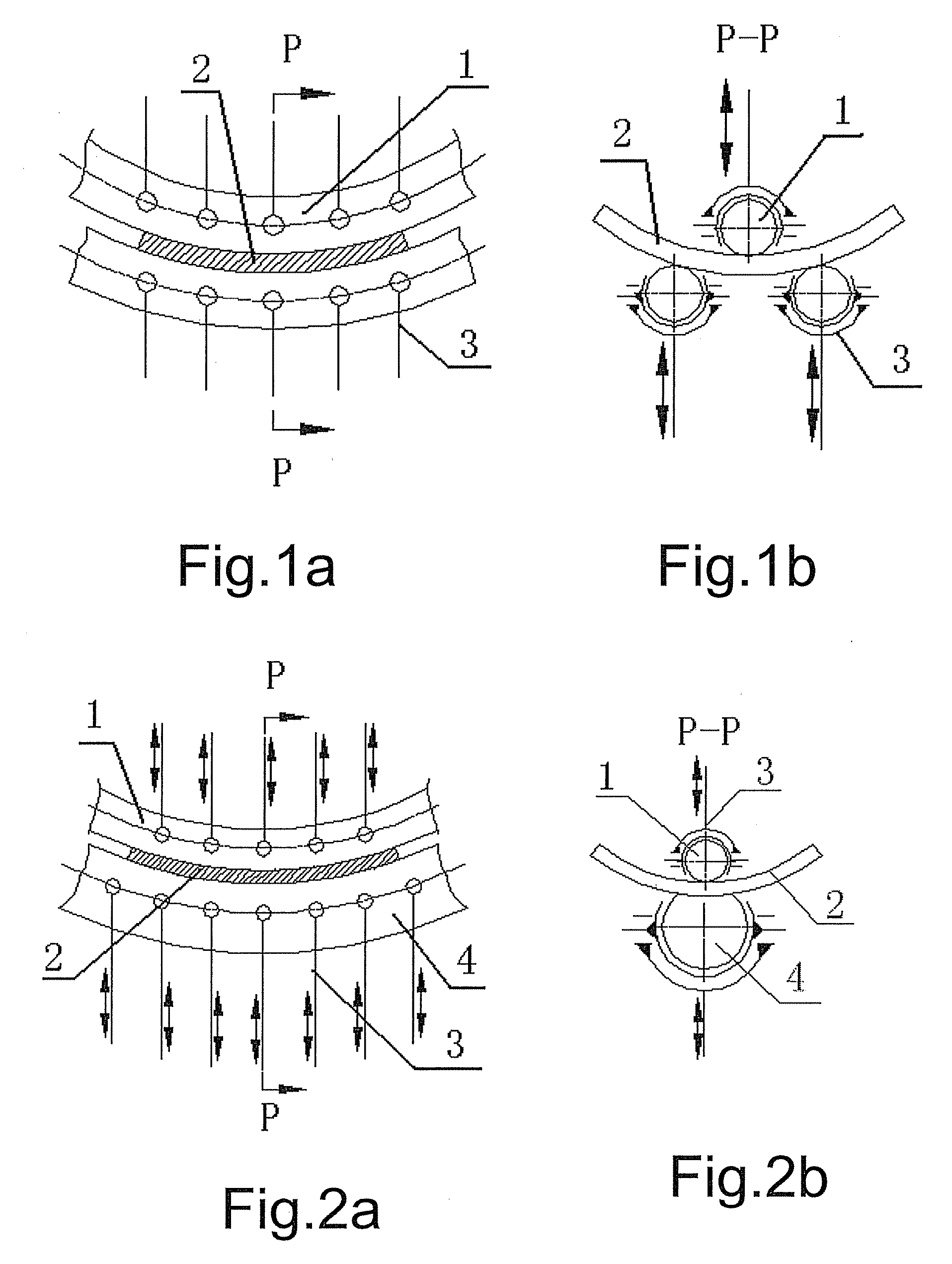

Configuration method of medium and heavy plate roll system with consideration of both rolling stability and cross-section shape

InactiveCN102009067ASuppression of rolling instabilityImprove controlCounter-pressure devicesRollsWork rollEngineering

The invention relates to a configuration method of a medium and heavy plate roll system with consideration of both rolling stability and cross-section shape, in particular to a fit way between a working roll and a supporting roll in different periods of service life of medium and heavy plate supporting roll. By comprehensively considering the impacts of a roll gap on the rolling stability and influencing factors of cross-section shape control, the invention provides the following scheme: the six-time polynomial curve supporting roll with big roll diameter at the middle and small roll diameter at two ends is adopted on a medium and heavy plate mill, and the six-time polynomial curve working roll with the small roll diameter at the middle and the big roll diameter at two ends is adopted for matching with the supporting roll; and the six-time polynomial curve working roll with the big roll diameter at the middle and the small roll diameter at two ends is adopted for matching with the supporting roll after abrasion during the later stage of the service life of the supporting roll. The configuration method of the roll system can solve the contradiction between the stability of medium and heavy plate rolling and the control of the cross-section shape, and the field application can obtain significant effects.

Owner:UNIV OF SCI & TECH BEIJING

Method for controlling shape of X80 pipeline steel hot rolling middle plate

ActiveCN101412042AScoop curvature reductionEasy to useRoll force/gap control deviceCounter-pressure devicesSurface coolingLine tubing

The invention relates to a method for controlling a plate shape of an X80 pipeline steel hot-rolled medium plate, which comprises a heating process, a roll crown matching process, a reduction schedule selecting process, a cooling control process and a straightening process. In the heating process, secondary heating temperature and soaking zone temperature are controlled; in the roll crown matching process, a working roll has a sinusoidal structure; the diameter of an upper roll is larger than that of a lower roll; period of a grinding roller and the crown of the working roll are determined by rolling capacity and plate width; in the reduction schedule selecting process, rolling pass and reduction ratio of each pass are distributed according to the thickness of a plate material during the process of precision rolling; in the cooling control process, water volume and pressure forming four cooling zones of a cooling bed, sheltering range of a controlled cooling edge part, proportion of upper surface cooling water and lower surface cooling water of a steel plate, distance from the steel plate surface are adjusted; and in the straightening process, positions of a guide-in roll and a delivery roll are reduced by positive and negative bowed roll straightening process. The method can greatly reduce the buckling rate of a high steel grade steel plate, improve the plate shape, improve production efficiency, and prolong service life of equipment.

Owner:SHAGANG GROUP

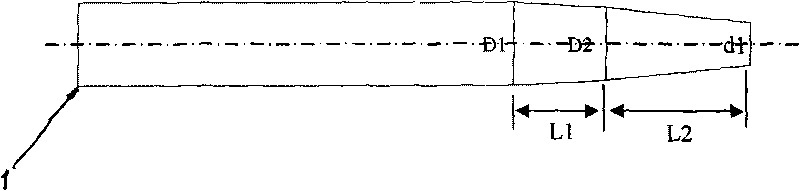

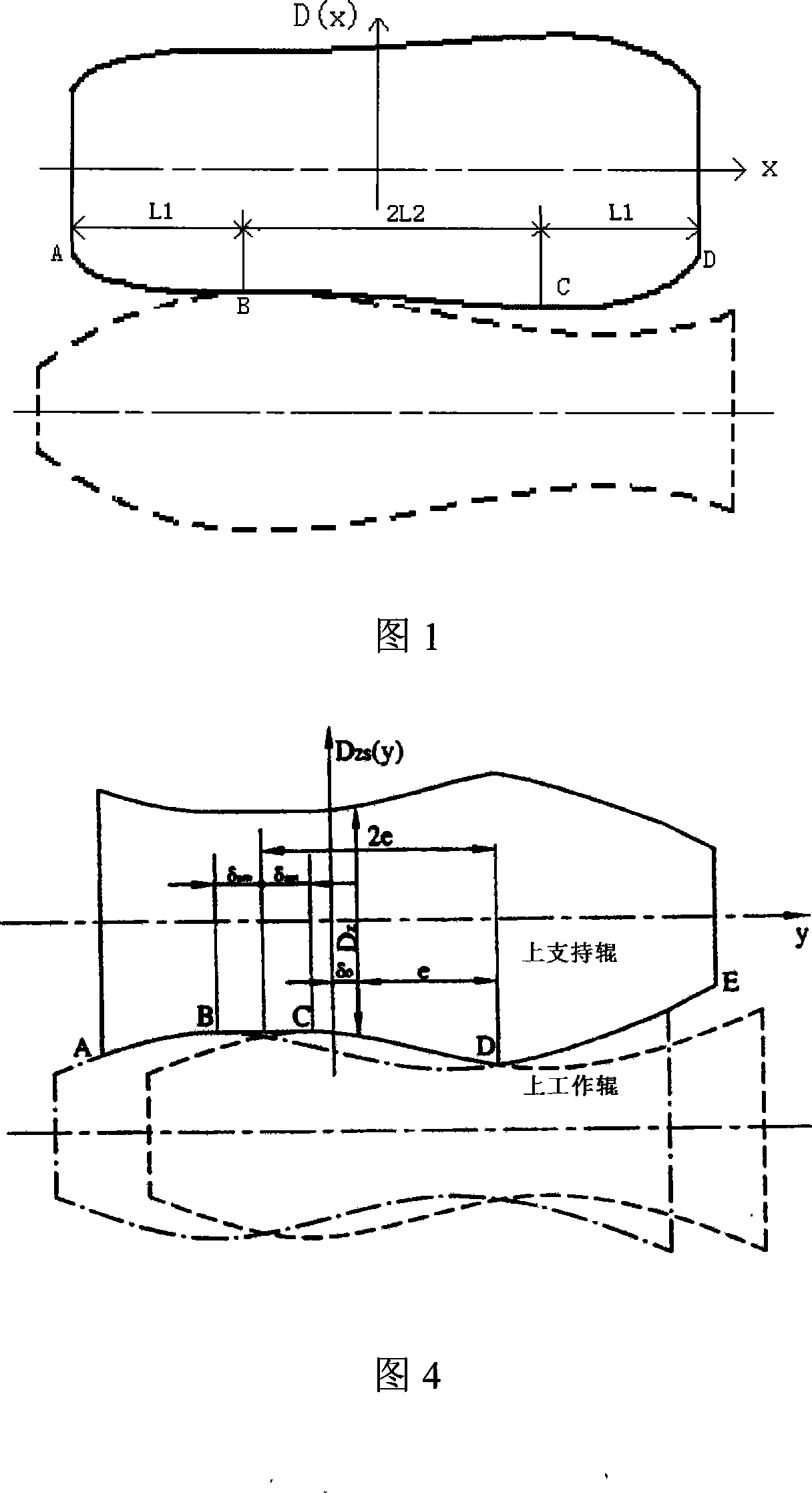

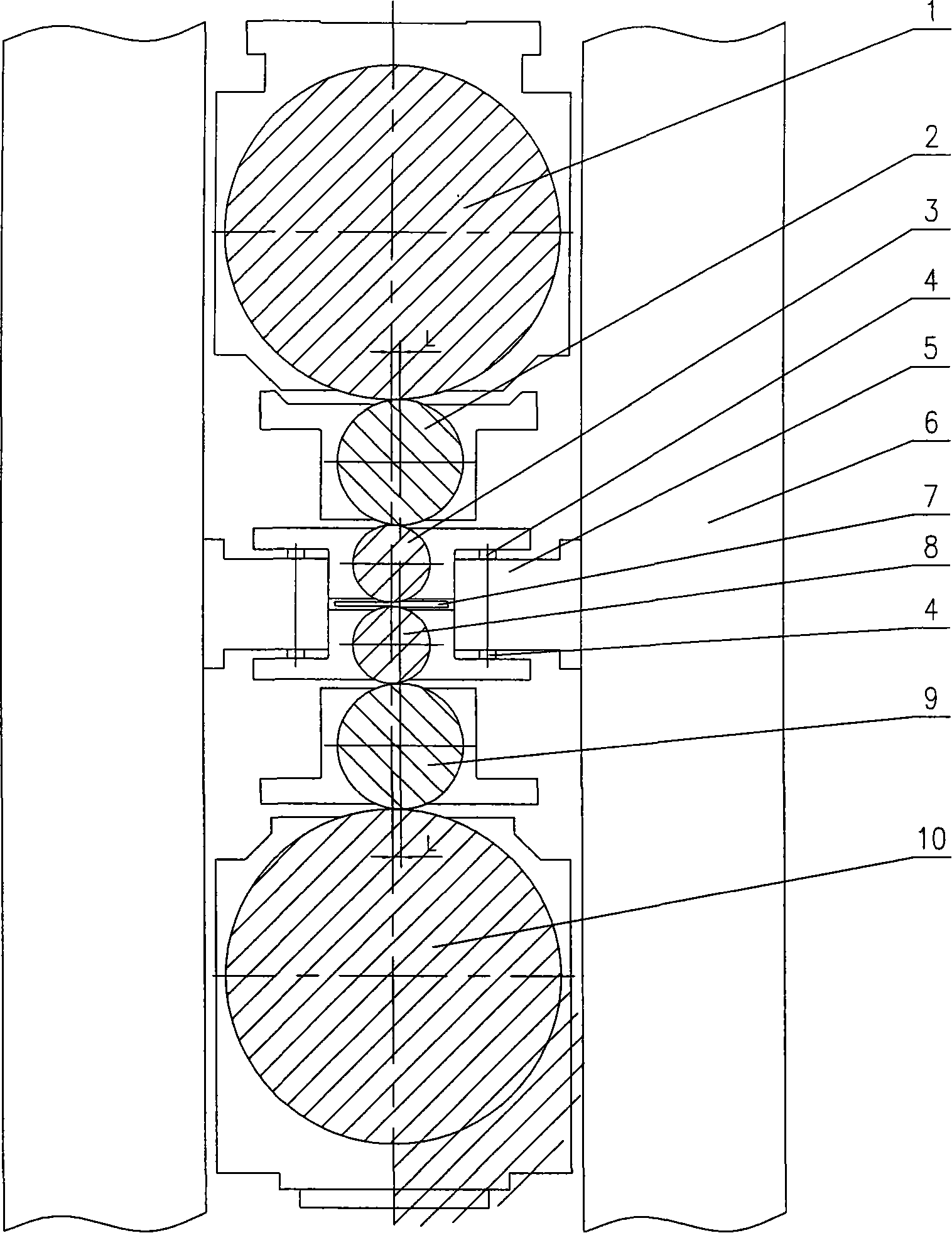

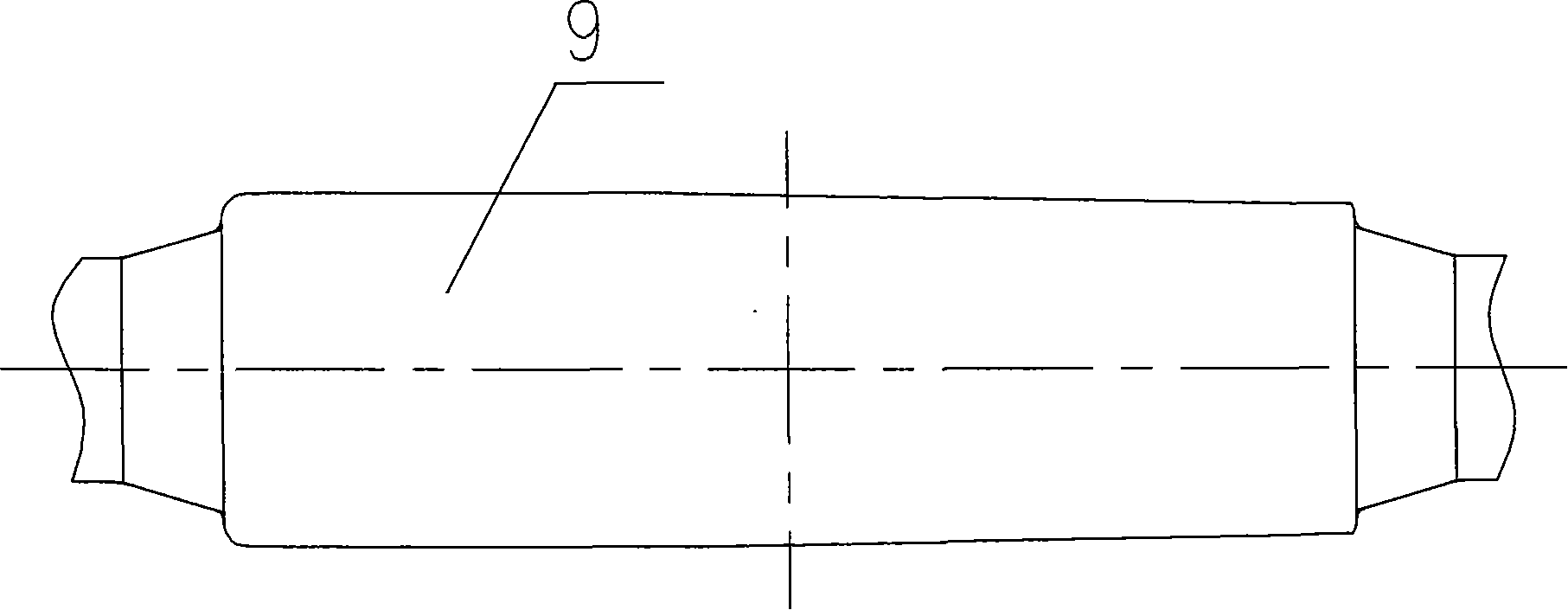

Continuous variational convexity degree rolling mill back-up shaft

InactiveCN101229560AExtended service periodImprove roll gap lateral stiffness characteristicsCounter-pressure devicesMetal rolling arrangementsContact pressureWork roll

The invention provides a continuously variable crown mill support roll to be matched with a roll curve of a continuously variable crown work roll. The roll shape is skew asymmetrical curve which essentially consists of a roll gap whole line contact curve section in the range of the strip width at the middle of the roll body and a contact line variable curve section at two ends of the roll; and the roll shape curves of an upper support roll and a lower support roll are the same but are arranged reversedly in an angle of 180 degrees The continuously variable crown mill support roll with the roll shape curve and the mill roll system with the continuously variable crown work roll can not only reduce uneven distribution and peak of the contact pressure between the roll, reduce or eliminate side spalling of the continuously variable crown mill support roll with normal crown, improve service cycle and service life of the support roll and reduce roll consumption of the support roll, but also overcomes harmful contact zone outside the rolled strip width and improves roll gap lateral rigidity of the mill and plate shape control efficiency of bending force, thereby improving plate shape quality of the rolling strip.

Owner:武汉钢铁有限公司 +1

Robot apparatus and method of controlling the same

InactiveUS8335591B2Smooth switchingProgramme-controlled manipulatorRoll force/gap control deviceMulti linkPosition control

A robot apparatus has a multi-link structure including a plurality of links and joints serving as link movable sections, and in which at least some of the links are driven by combination of position control and force control. The apparatus includes: position controller performing position control on the links, which are driven by position control and force control; position controller with force constraint placing the force control before the position control so as not to cause a magnitude of an external force to exceed a set value; force controller performing the force control on the links; and integrated force / position controller controlling driving of the joints by switching the position controller, the position controller with force constraint, and the force controller, and unifying the position control and the force control.

Owner:SONY CORP

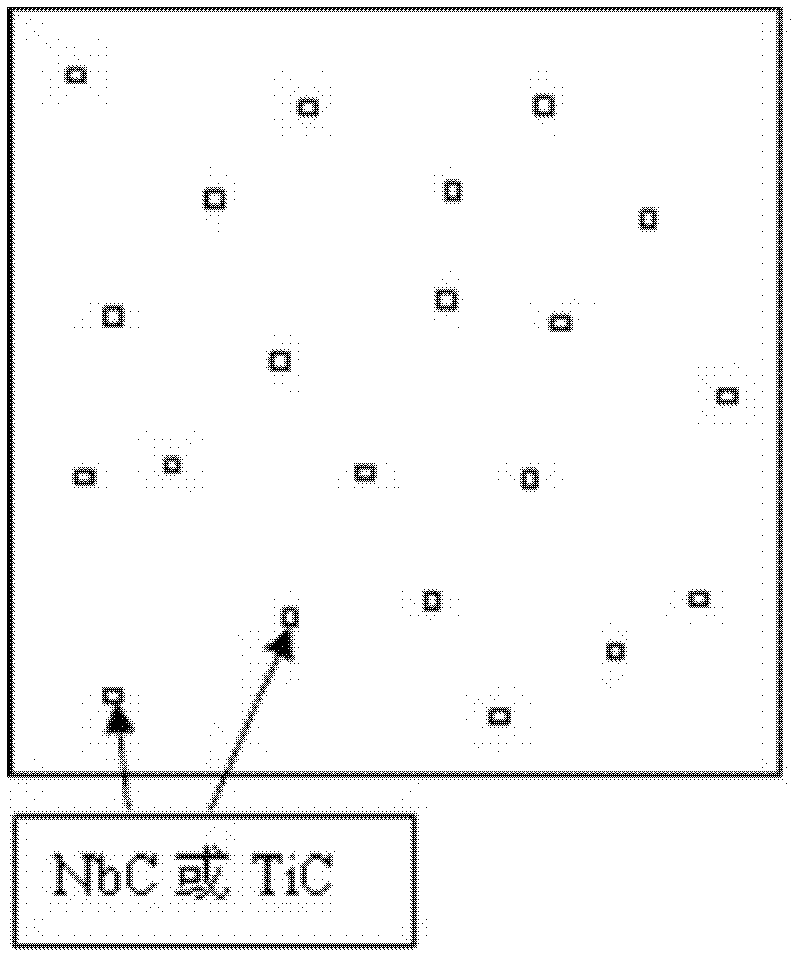

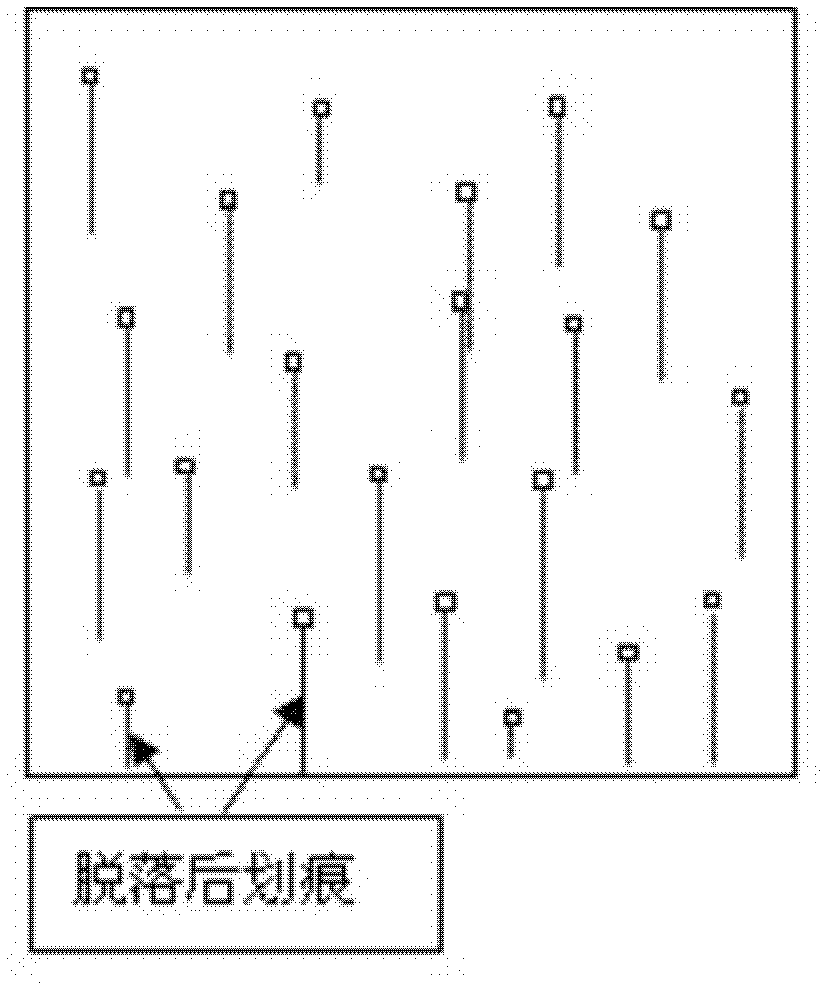

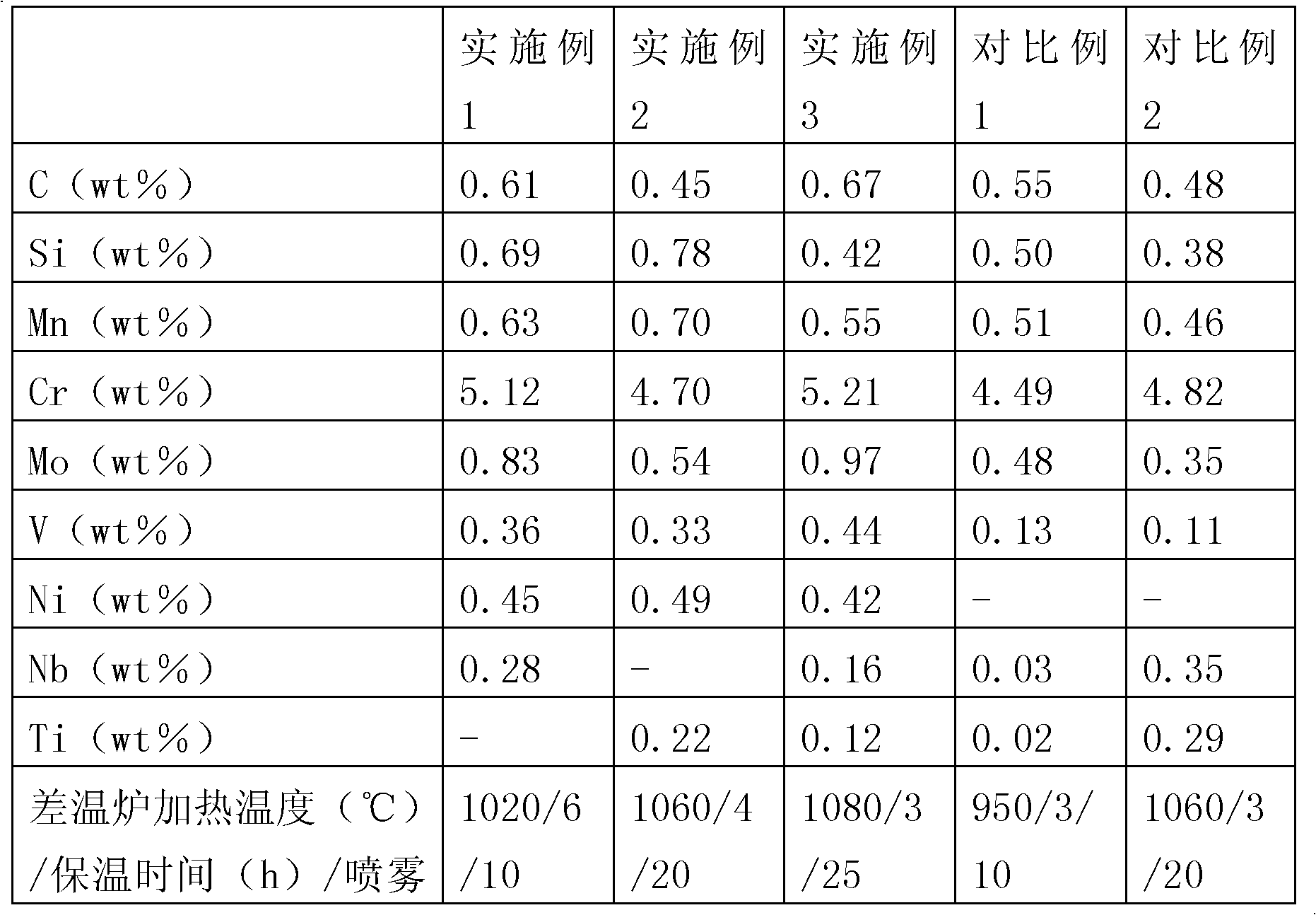

Supporting roller with roughness keeping capability and manufacturing method thereof

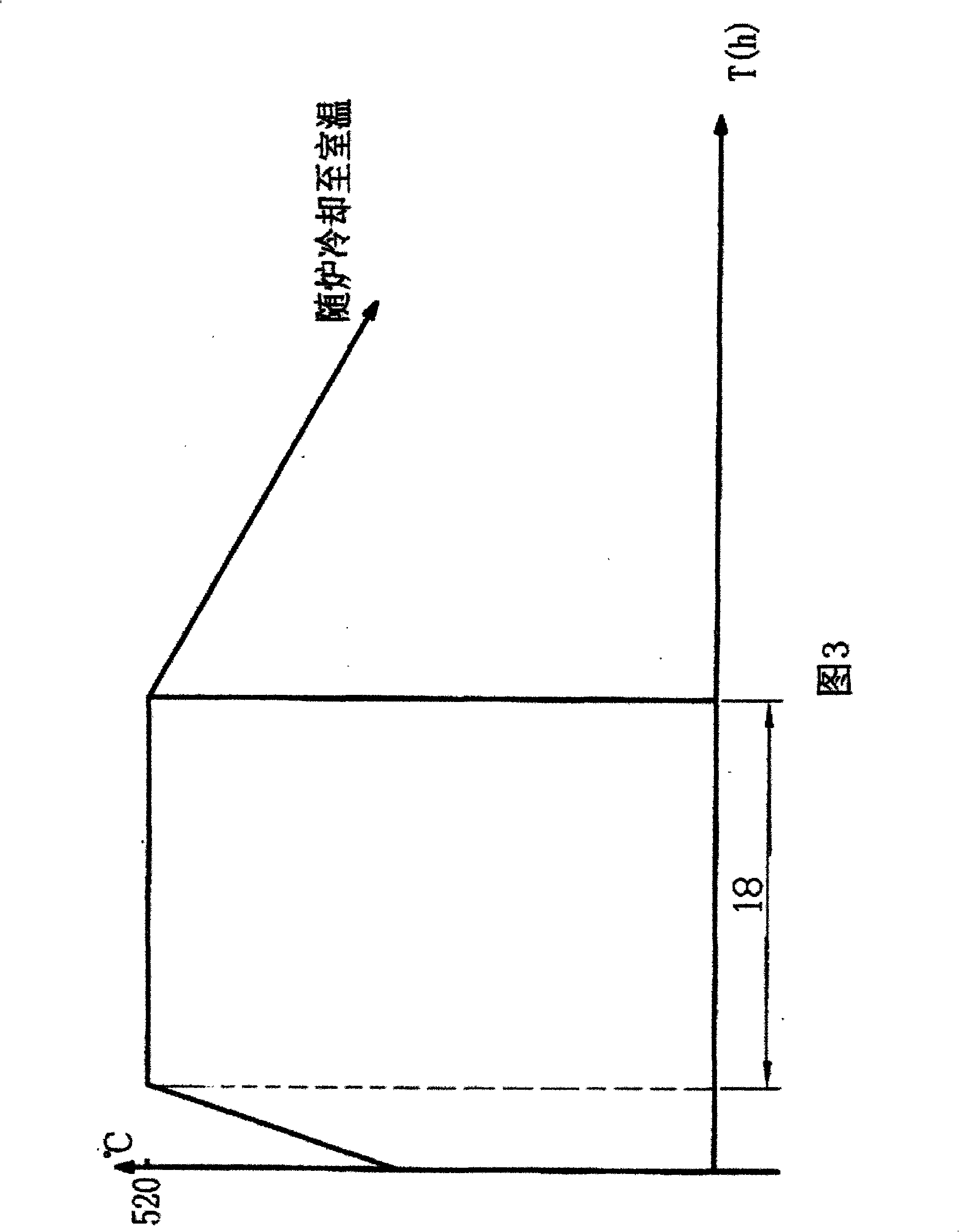

ActiveCN102634738AHigh roughness retentionIncrease productivityCounter-pressure devicesFurnace typesMetallurgy

The invention discloses a supporting roller with a roughness keeping capability, comprising the following chemical components in mass percentage: 0.40-0.70% of C, 0.40-0.80% of Si, 0.50-0.80% of Mn, 4.5-5.5% of Cr, 0.40-1.00% of Mo, 0.30-0.50% of V, 0.40-0.60% of Ni. The supporting roller further comprises one or two of 0.05-0.30% of Nb and 0.05-0.30% of Ti, and residual amounts of Fe and unavoidable impurities. The invention further discloses a manufacturing method of the supporting roller; and the roughness keeping capability of the manufactured supporting roller is greatly improved.

Owner:BAOSHAN IRON & STEEL CO LTD

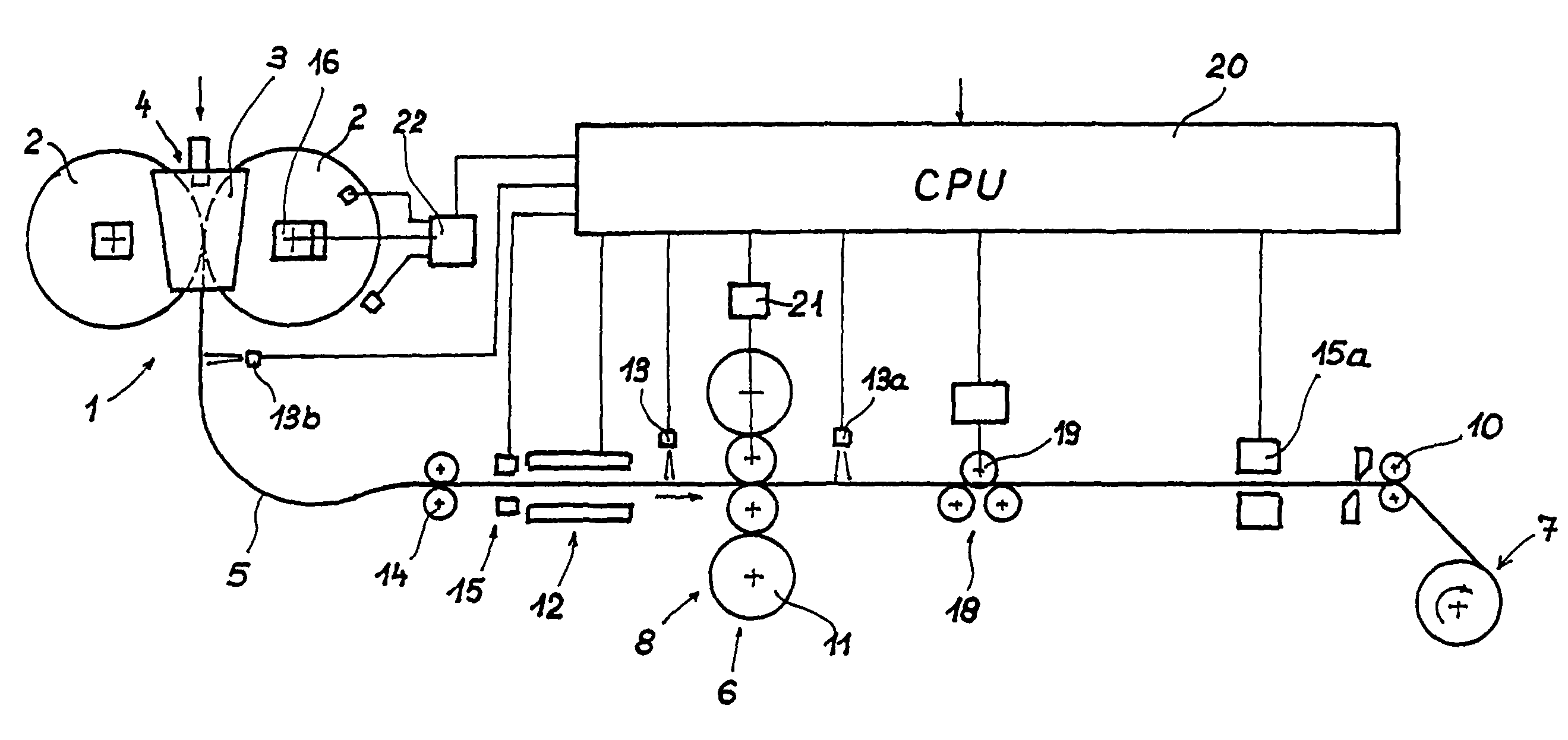

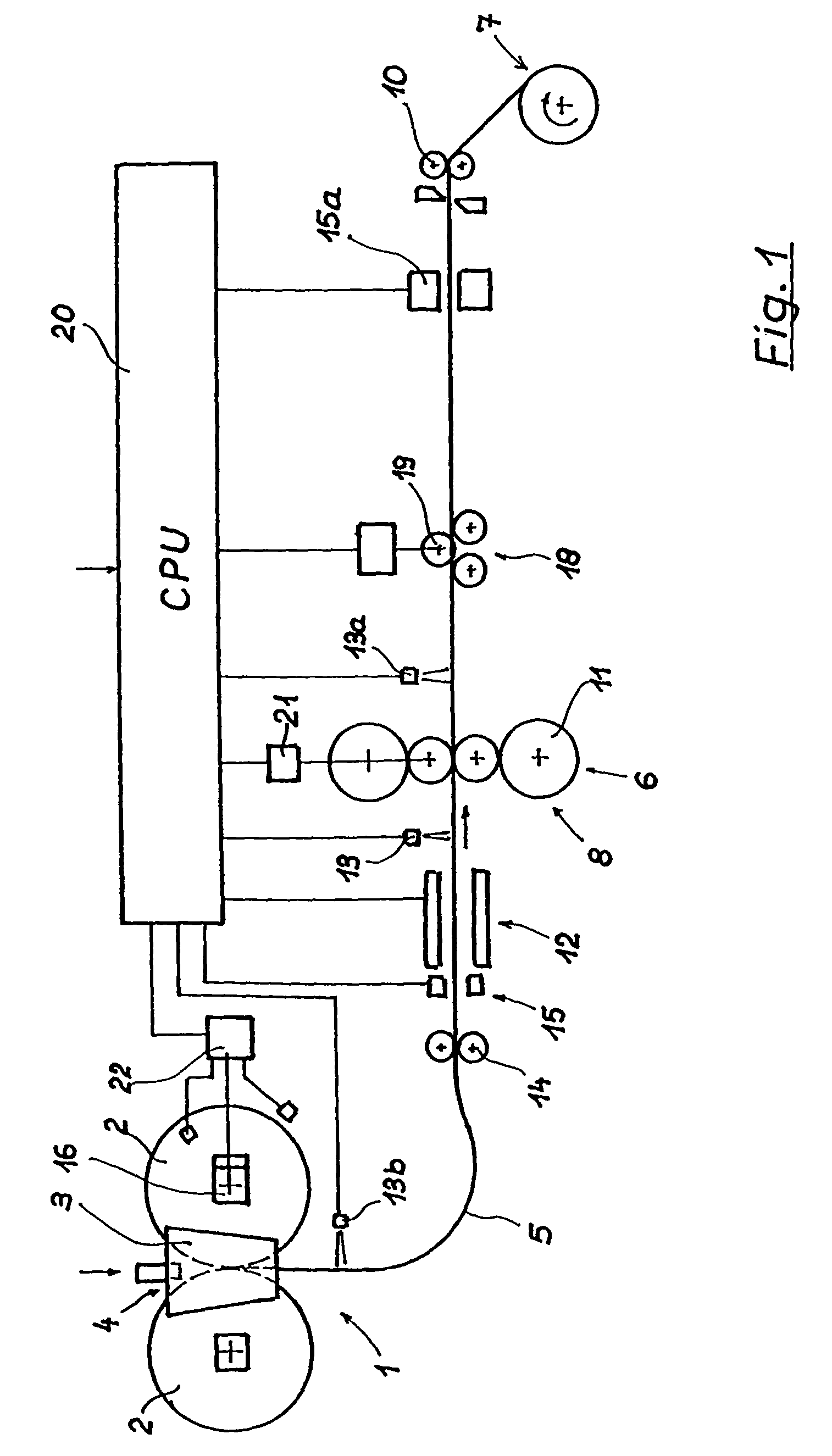

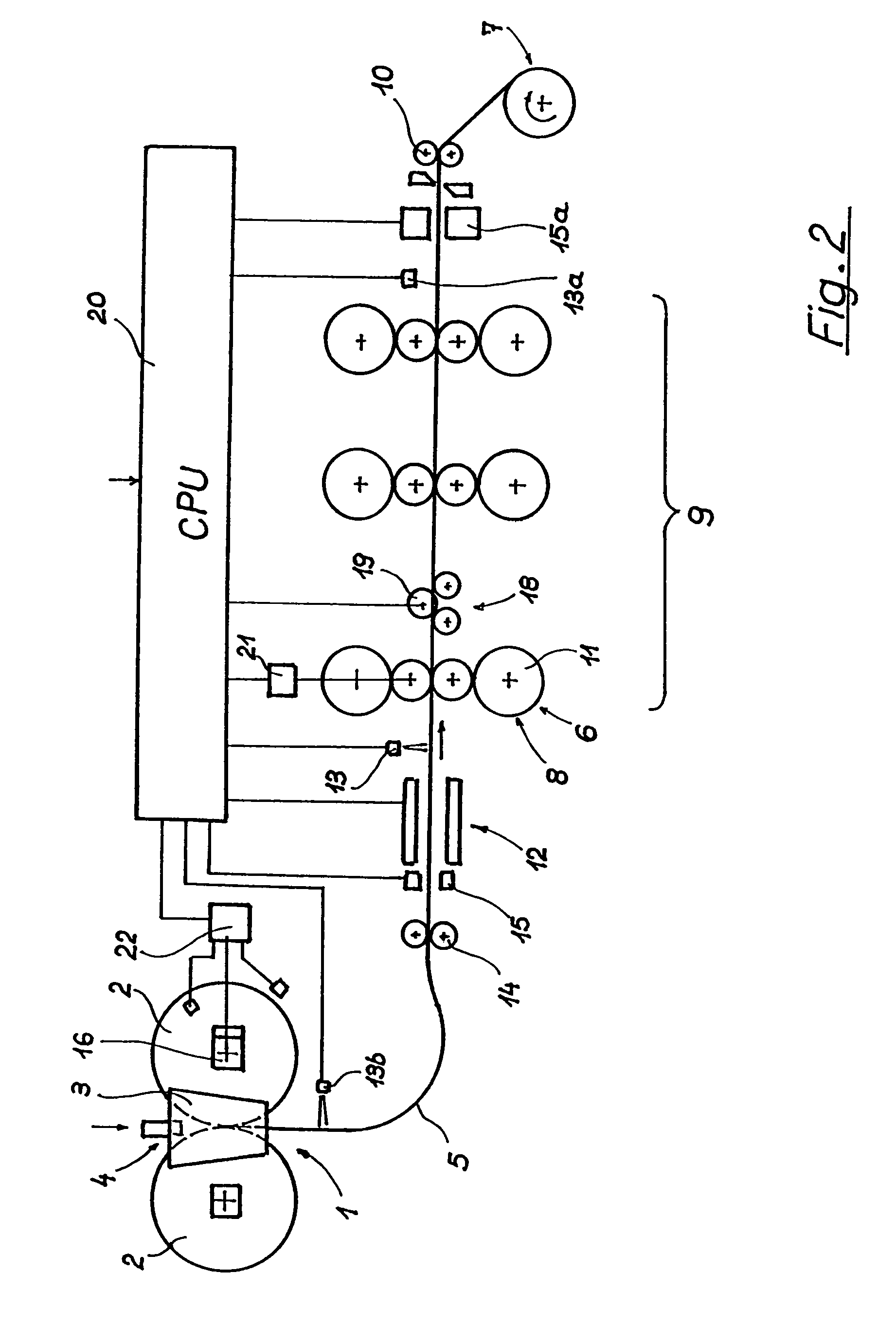

Process and apparatus for the continuous production of a thin metal strip

ActiveUS7963136B2Reduce flatness deviationImproved profileTemperature control deviceMetal rolling stand detailsThin metalThin slab

Processes for continuous production of a thin metal strip, in particular a steel hot strip, directly from a metal melt and with a strip cast thickness of <10 mm by the roll-casting process. The cast metal strip is fed for in-line thickness reduction, and then to a storage device. To achieve a high-quality, hot-rolled metal strip with flatness tolerances comparable to those which can currently be achieved in the production of hot-rolled metal strip from continuous-cast thin slabs or slabs, at cast thicknesses of between 40 and 300 mm, in a continuous production process starting directly from metal melt. With the low strip cast thickness, a flatness measurement is performed on the moving metal strip, and the measurement results of this flatness measurement are used to influence the flatness of the metal strip in a targeted way.

Owner:PRIMETALS TECH AUSTRIA GMBH

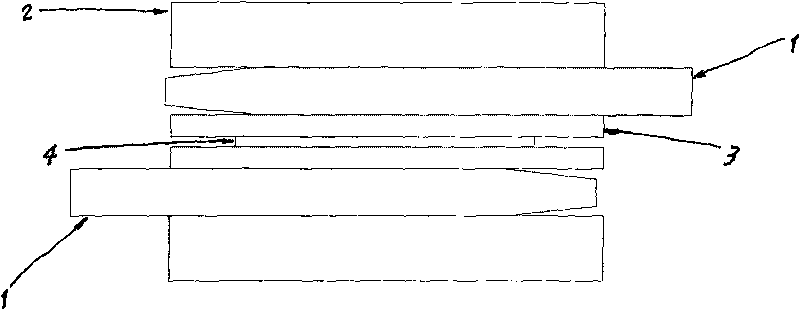

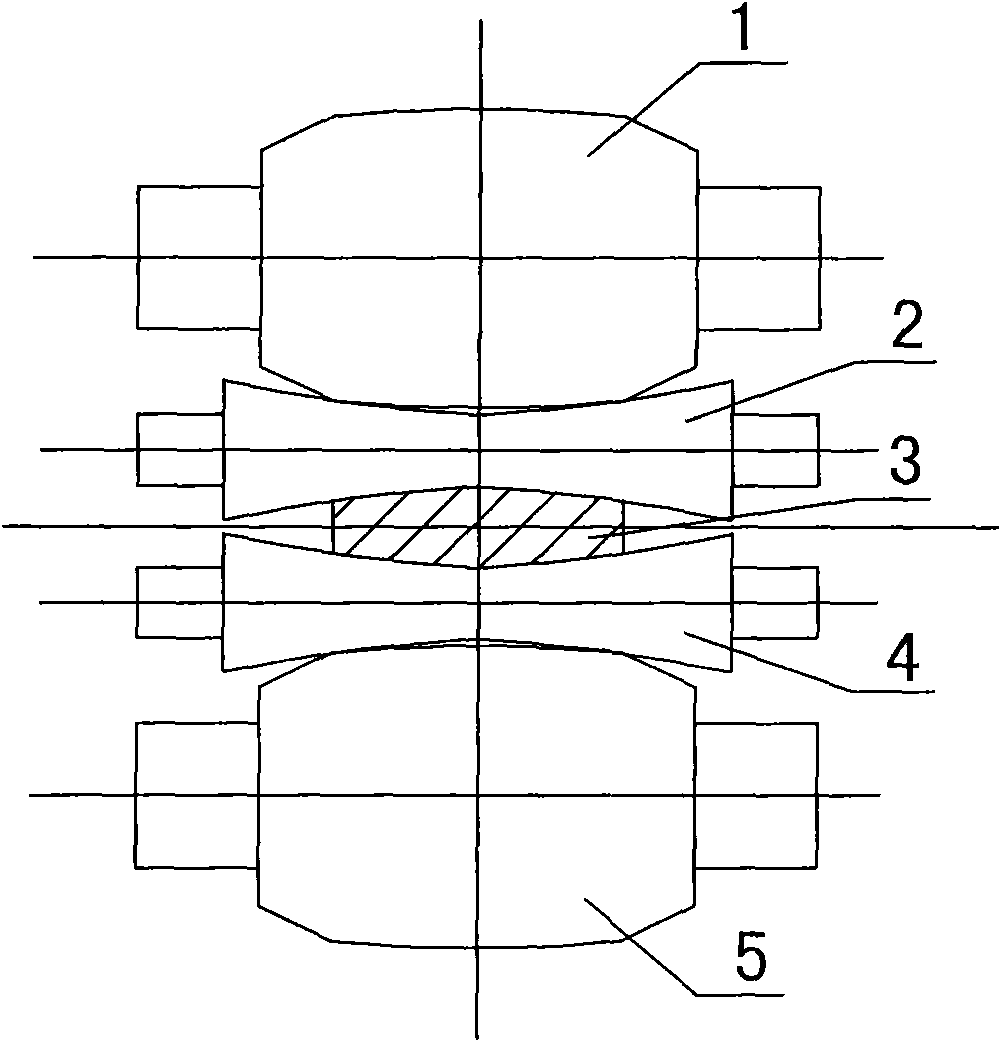

Roller of four-high rougher

InactiveCN101837369AExtended service periodImprove shape qualityCounter-pressure devicesRollsWork rollRoll forming

The invention relates to a roller of a four-high rougher, belonging to the technical field of a production process of hot rolled strips. The roller comprises two working rolls which symmetrically prop against a roughing mill and two supporting rolls which are in contact with the two working rolls, wherein the generatrix of the working rolls is a median-concave continuous curve determined by a curvilinear equation; and the generatrix of the supporting rolls comprises three sections, the middle section is a median-convex continuous curve determined by a polynomial equation, and the two end sections are symmetrical chamfer lines of an axial projected length L. The invention can inhibit the deviation of strip steel in the rough rolling process by the negative-convexity roll forming of the working rolls, equalize contact stresses among the rolls and eliminate the disadvantage of overlarge stress caused by the contact of the edges of the working rolls and supporting rolls, thereby prolonging the service cycle of the supporting rolls and improving the strip quality of an intermediate blank at the outlet of the roughing mill.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

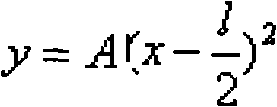

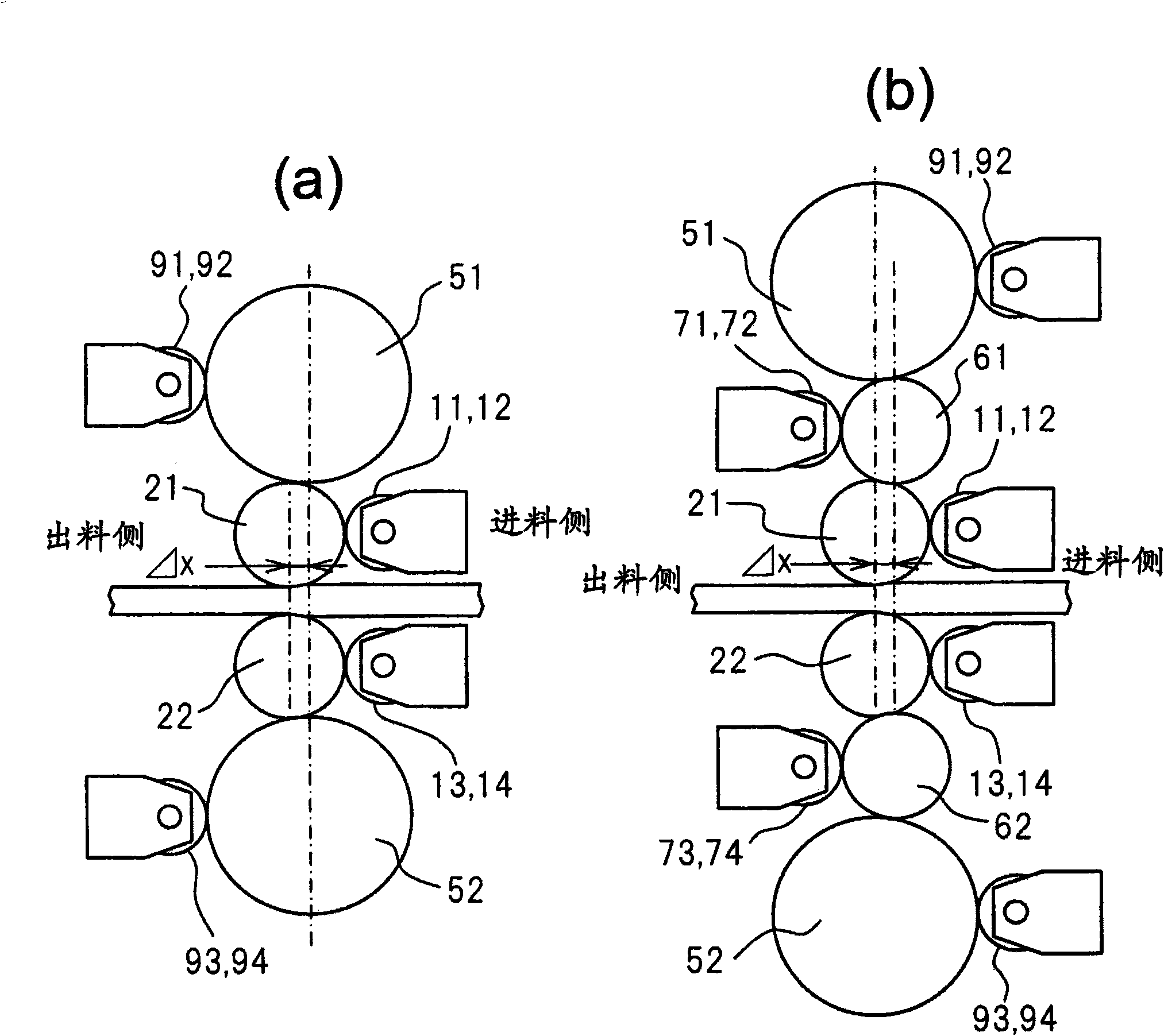

Roller device of cold calender

InactiveCN101249505AImprove reliabilityImprove stabilityMetal rolling stand detailsCounter-pressure devicesVertical planeRolling mill

The invention relates to a rolling device of cold rolling mill, which mainly comprises an upper support roller, an upper work roller, a lower work roller and a lower support roller, which are arranged in a same vertical plane, and an upper middle roller and a lower middle roller which are arranged in another vertical plane leaning to a direction opposite to the advancing direction of a first rolling length of a strip material. The rolling device is characterized in that the upper middle roller and the lower middle roller are arranged offset with respect to the upper support roller, the upper work roller, the lower work roller and the lower support roller. The surface portions of the upper middle roller and the lower middle roller are symmetrically fabricated to form a certain conical degree. The rolling device has the advantages of simple, compact and reasonable structure; convenient manufacture and improved reliability of the rolling mill due to no axial movement of the upper and the lower middle rollers; improved stability of the rolling mill due to the offset arrangement of the upper and the lower middle rollers with respect to the support rollers and the work rollers; and reduced diameter of the work rollers by adopting the middle rolls for transmission, so that the rolling device can roll ultrathin strip materials in the case of constant rolling force.

Owner:WUXI WUYE METAL ROLLING

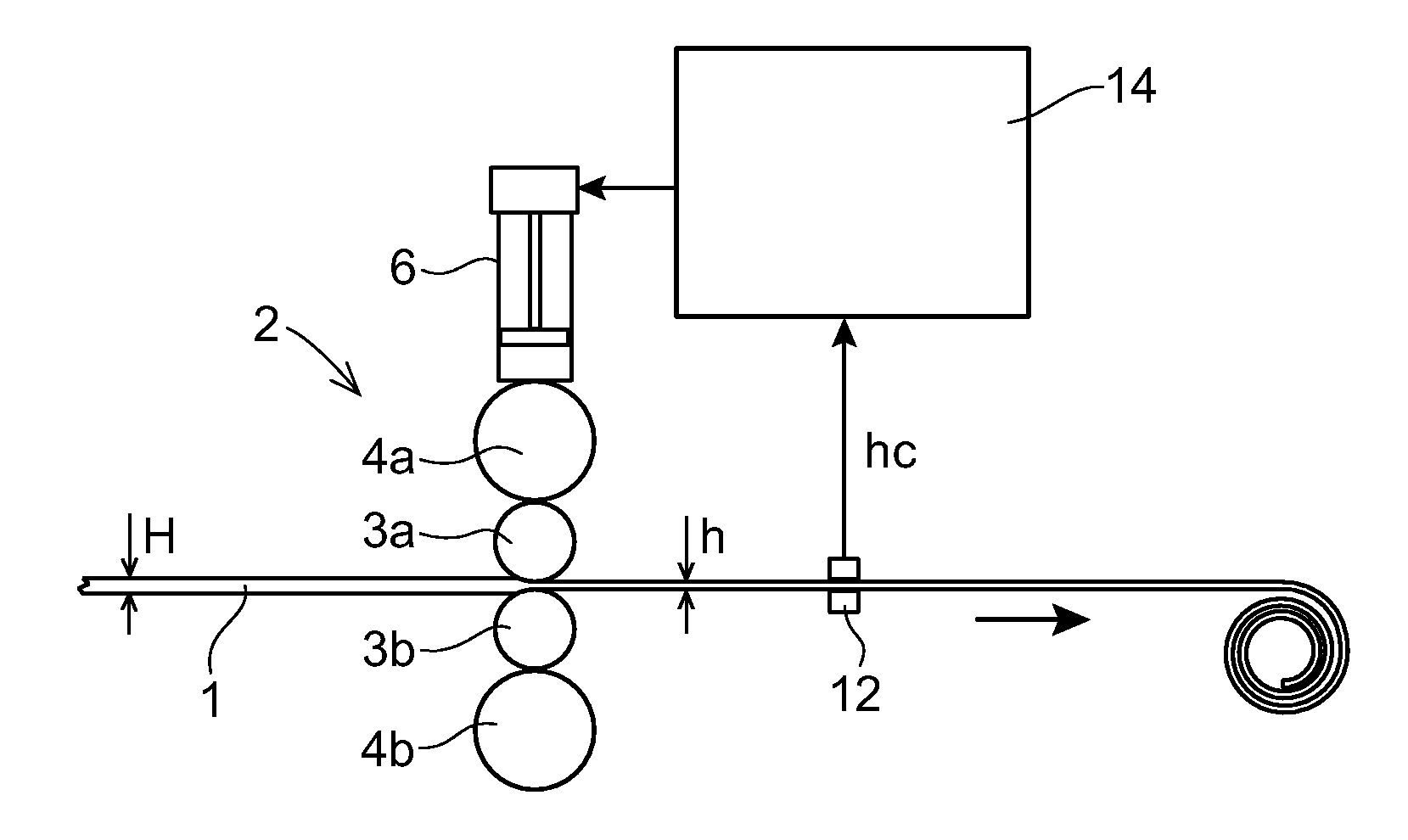

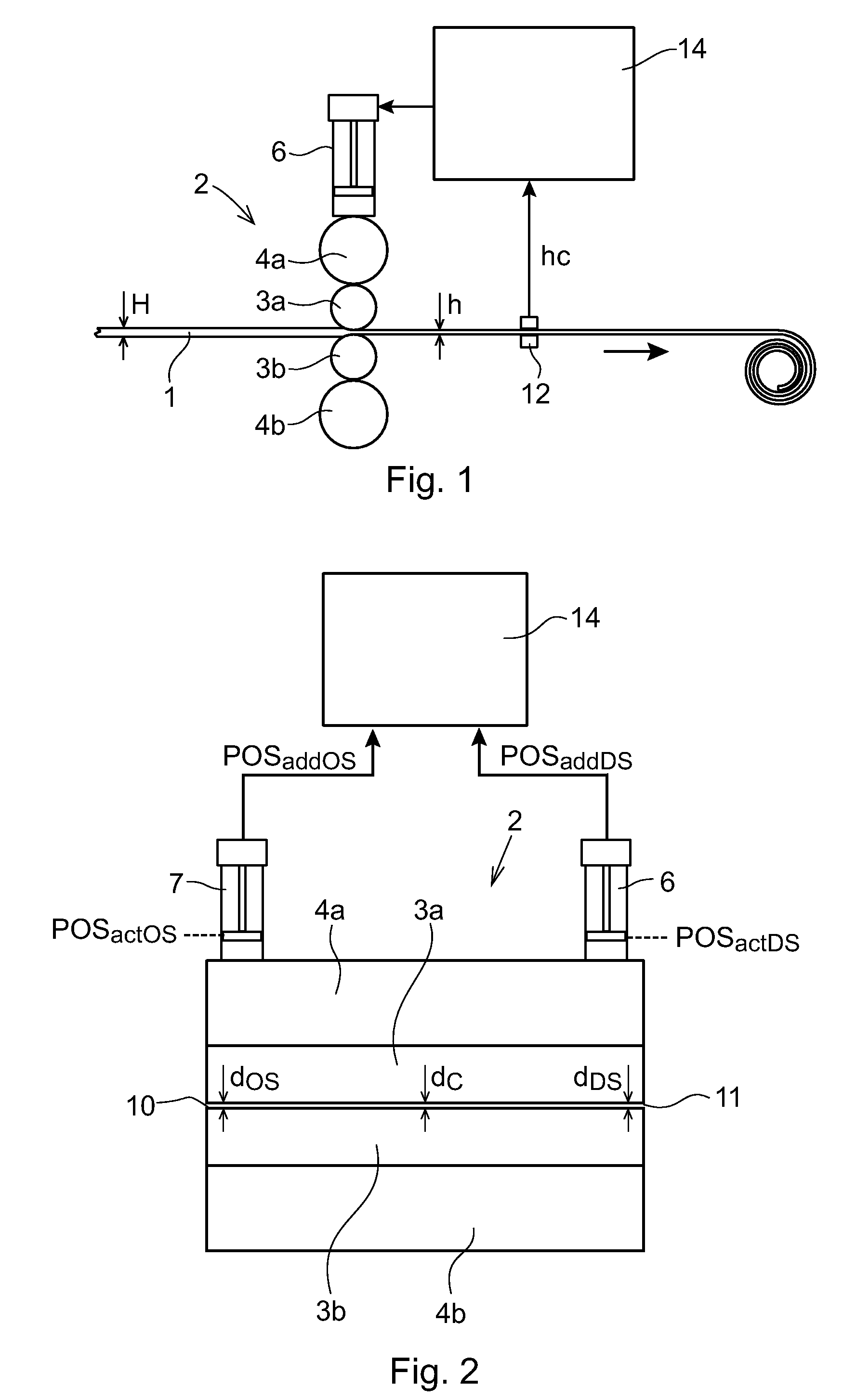

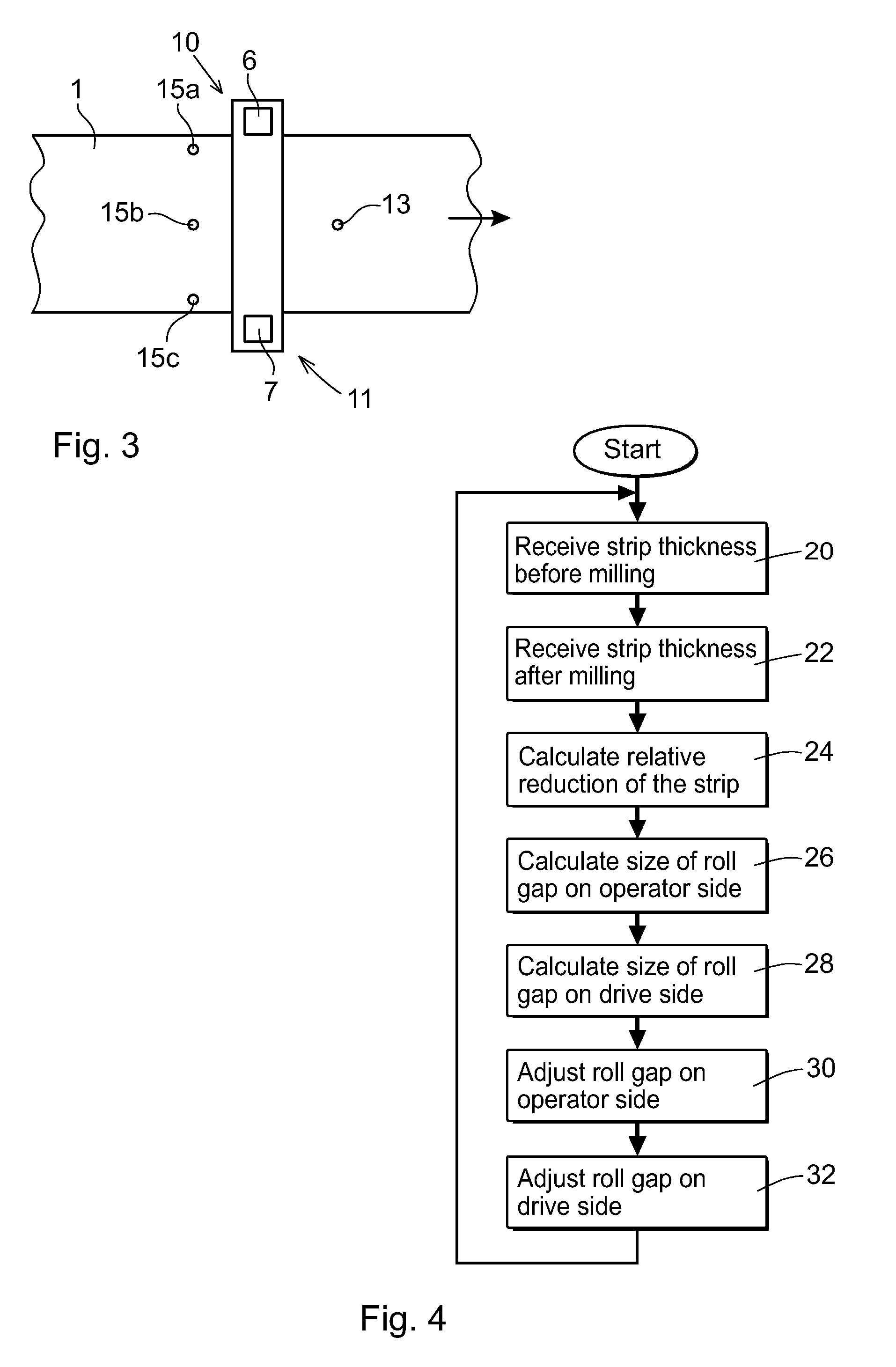

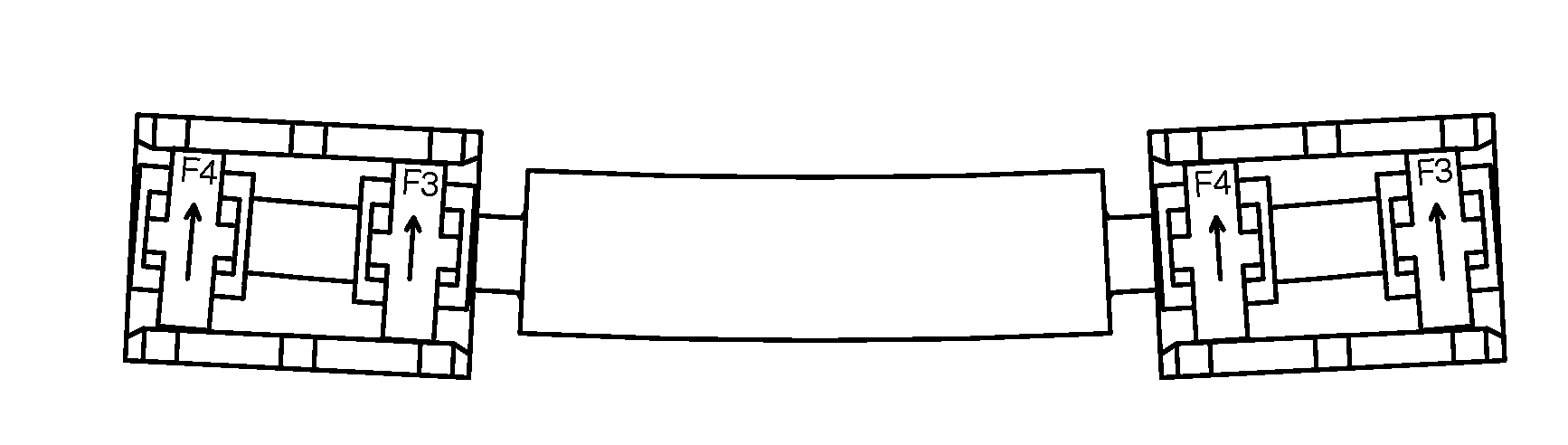

Method and device for controlling a roll gap

The invention relates to a method and a device for controlling a roll gap when rolling a strip (1) in a rolling mill including at least two rolls (3a-b,4a-b), and at least two roll gap actuators (6,7) that independently control the size of the roll gap. The device is adapted to receive information on the amount of wedge shape (POSactOS,POSactDS) in the strip thickness profile across the strip width, and to control said actuators, based on said information on the amount of wedge shape in the strip thickness profile, such that the relative reduction of the strip on both sides of the rolling mill become essentially the same.

Owner:ABB (SCHWEIZ) AG

Method for milling thin plate by four-high reversing cold mill

The invention relates to a method for milling a thin plate by a four-high reversing cold mill, which belongs to the technical field of cold-milling hard rolling plates. The method comprises the steps: pickling raw materials of a hot-milling rolling plate and coldly milling a pickled hot-milling rolling plate, wherein the milling steps comprise a first milling step and a second milling step; a milling plate which is obtained from the first milling step is annealed after the first milling step and is milled after being annealed so as to obtain a thin plate with the thickness of 0.18 mm to 0.23 mm, and the pickled hot-milling rolling plate with the thickness of 3 mm to 4 mm is milled into a milling plate with the thickness of 1 mm in the first milling step. The method for milling a thin plate by a four-high reversing cold mill can change the ultimate milling thickness of 0.23 mm into the ultimate milling thickness of 0.18 mm to 0.23 mm in the prior art.

Owner:CHANGSHU HUAYE STEEL STRIP

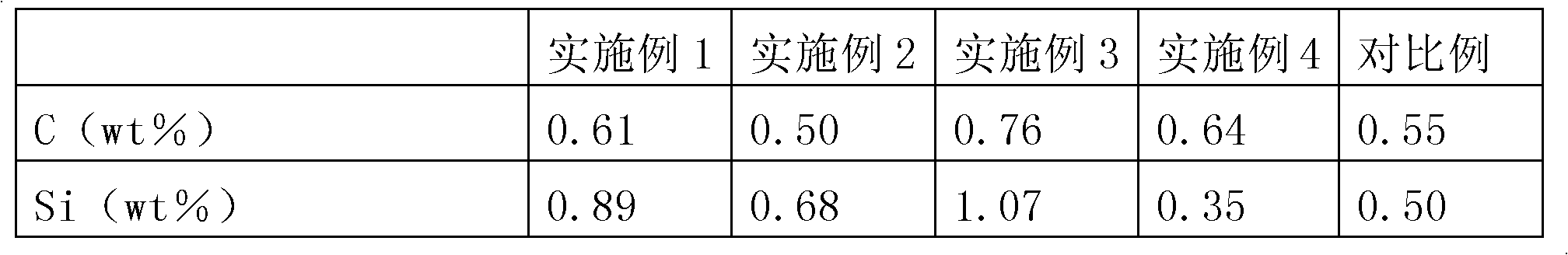

Support roll with high abrasion resistant performance and manufacturing method thereof

ActiveCN102618788ARich varietyIncrease particle hardnessCounter-pressure devicesMetal rolling arrangementsMetallurgyChemical constituents

The invention discloses a support roll with a high abrasion resistant performance, which comprises the following chemical constituents by weight percent: 0.38 to 0.85 percent of C, 6.1 to 10.0 percent of Cr, 0.4 to 1.5 percent of Mo, 0.15 to 0.8 percent of V, as well as one or more of 0.35 to 1.20 percent of Si, 0.35 to 1.00 percent of Mn, 0.4 to 0.8 percent of Ni, 0.4 to 0.8 percent of Co, and Fe and unavoidable impurities in balancing amount. The invention further discloses a manufacturing method of the support roll; and the rigidity and the abrasion resistance of the support roll produced according to the manufacturing method are greatly improved.

Owner:BAOSHAN IRON & STEEL CO LTD

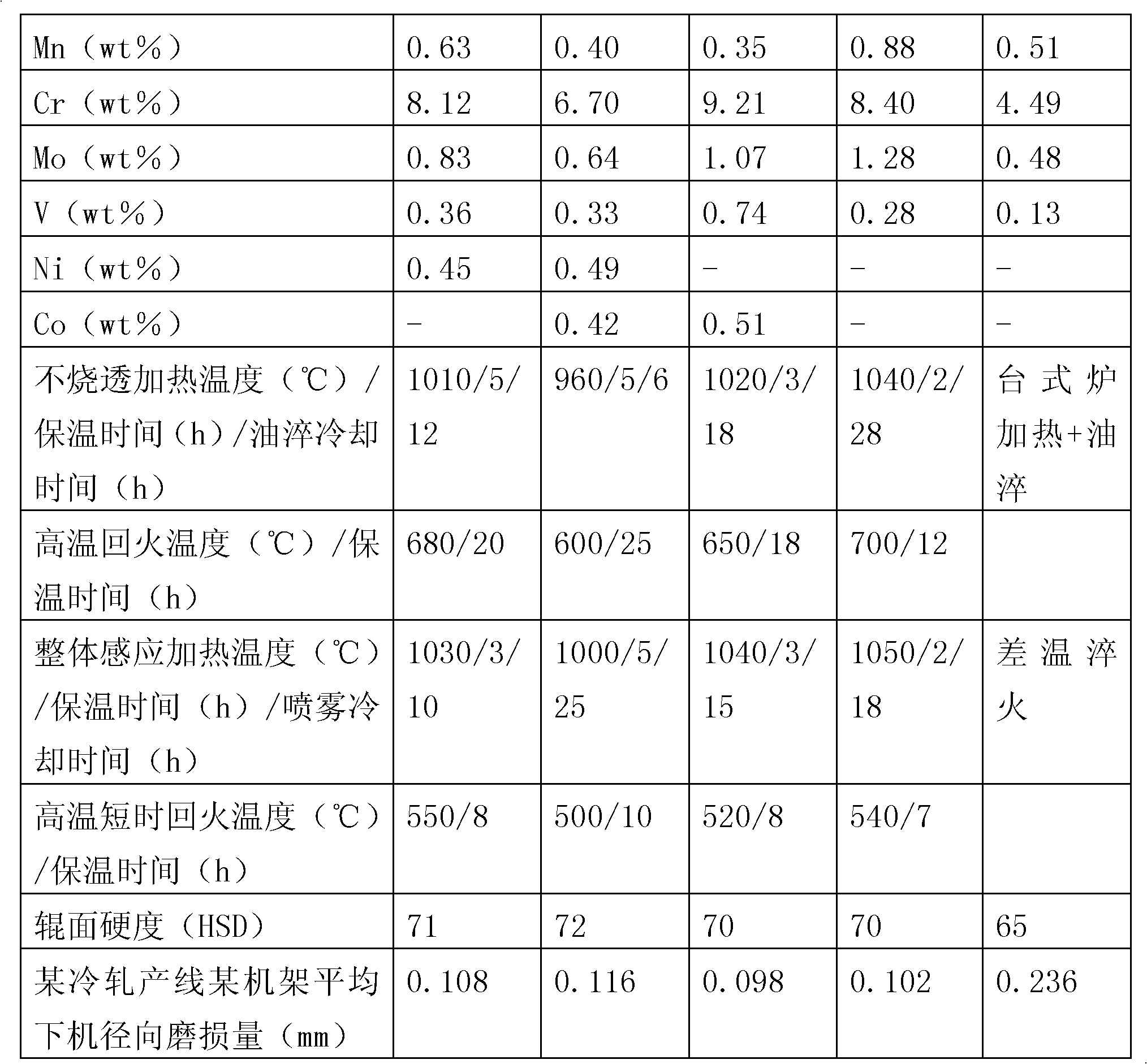

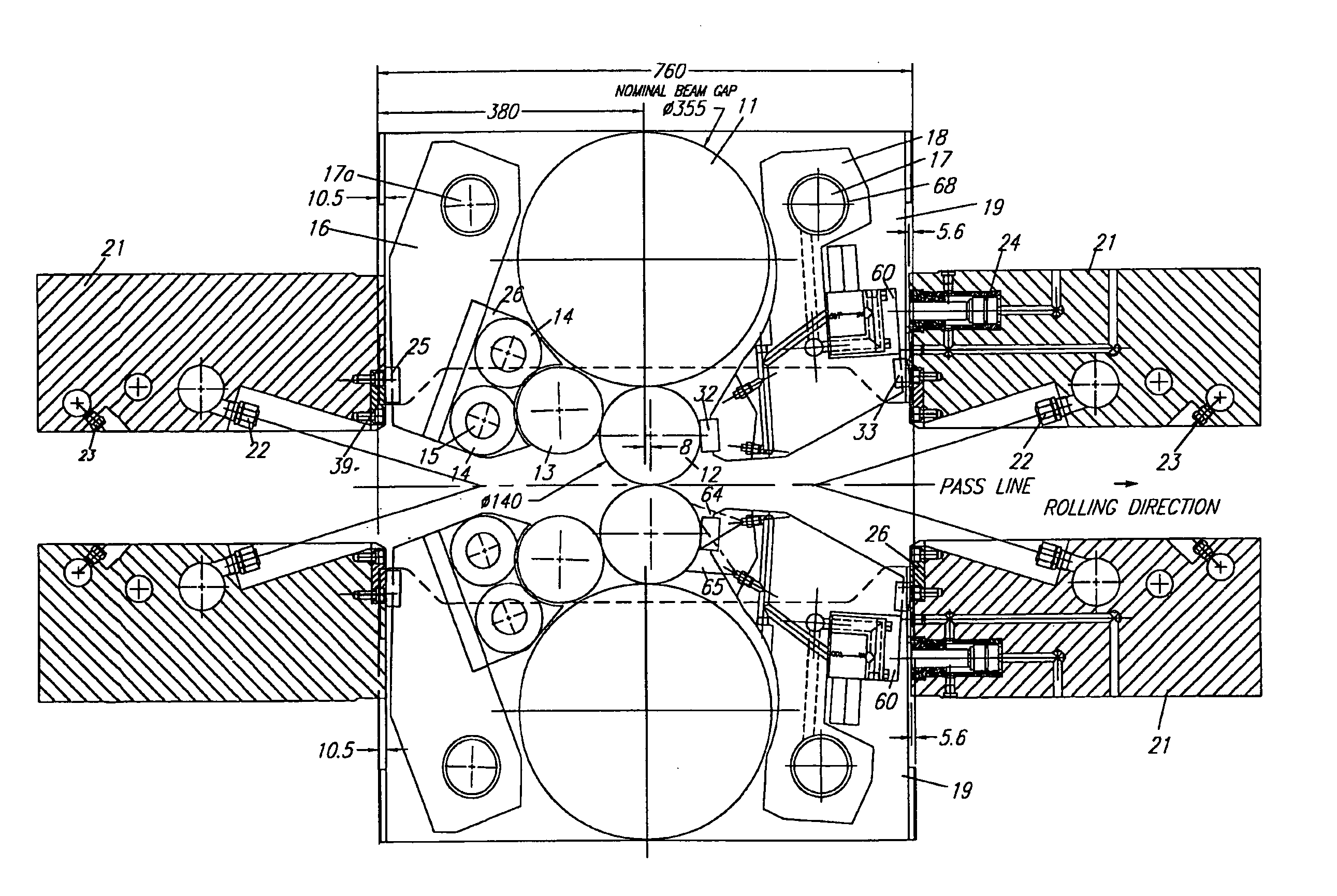

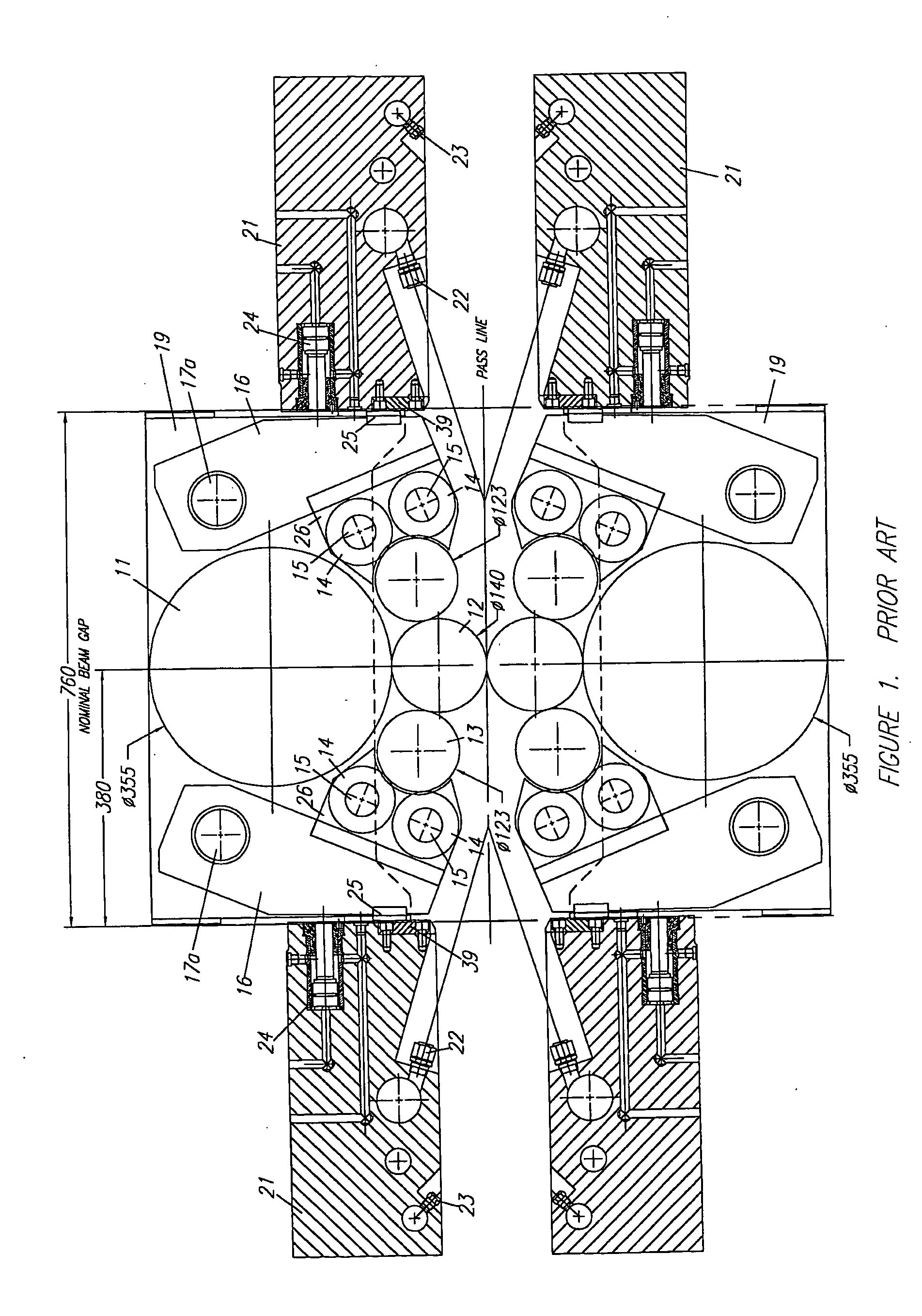

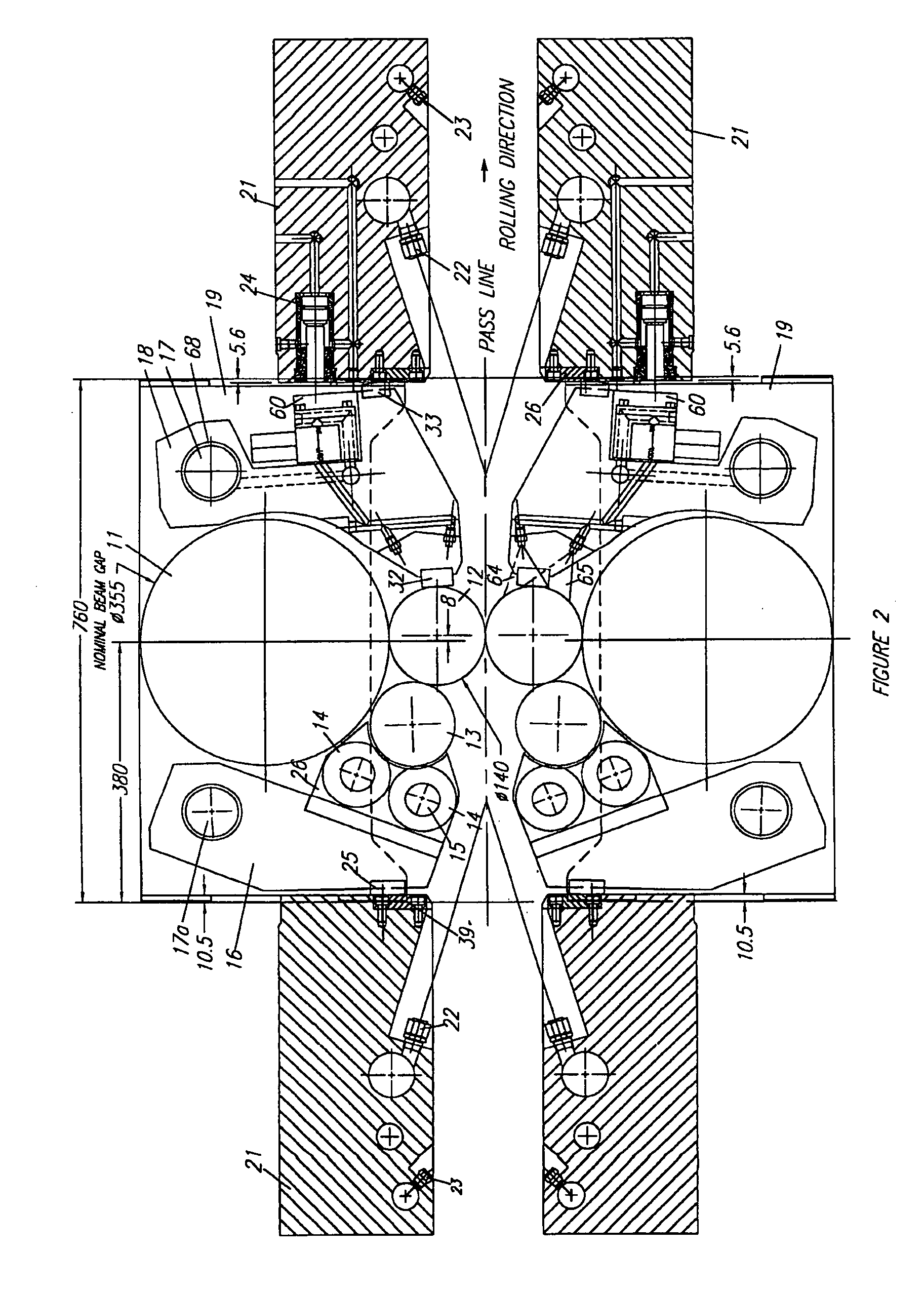

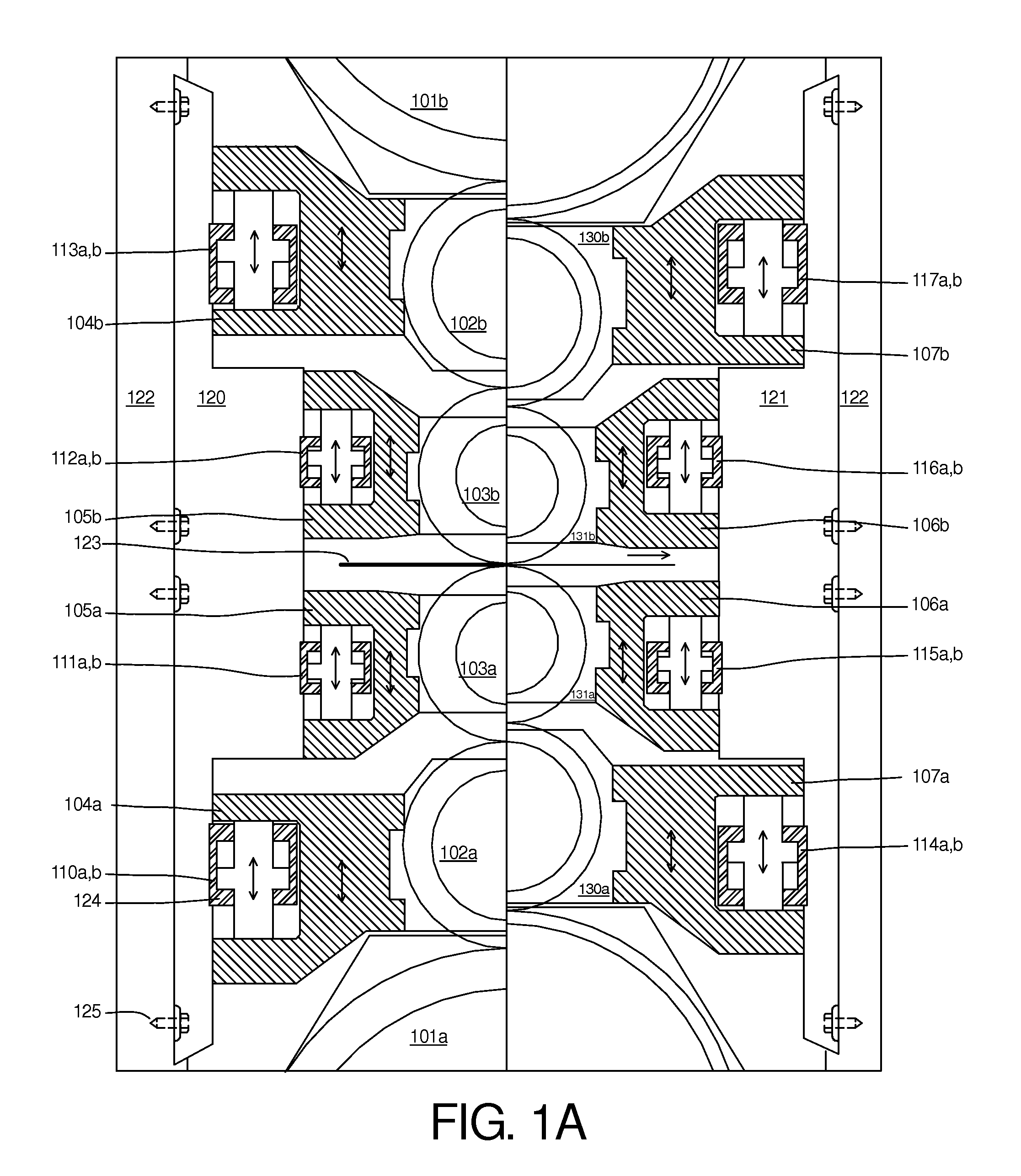

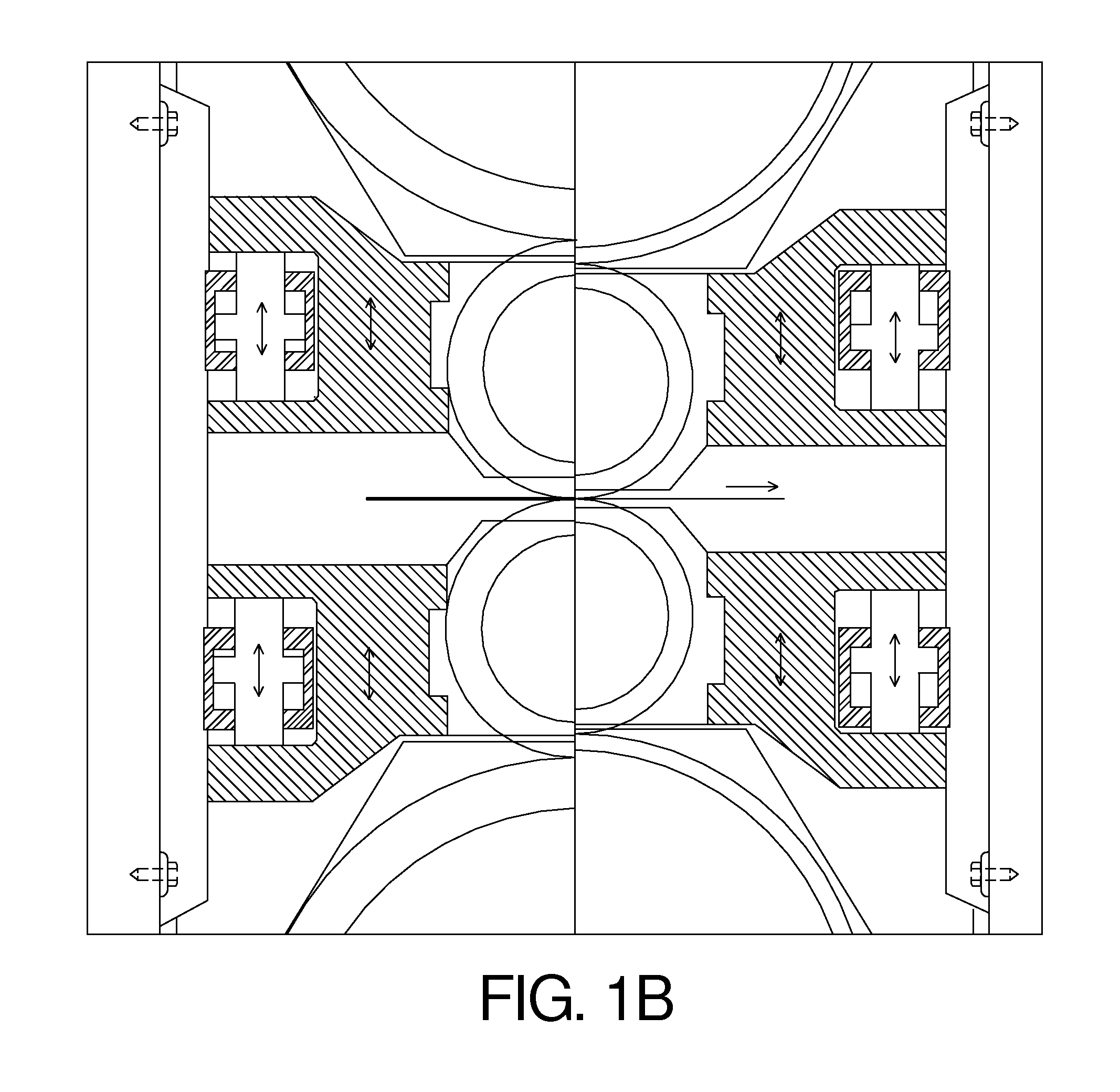

Prestressed Rolling Mill Housing Assembley With Improved Operational Features

InactiveUS20090158802A1High apparent mill stiffnessWide range of diameterRoll force/gap control deviceMetal rolling stand detailsWork rollPre stress

The present invention provides a Cluster mill which utilizes a Cluster mill gauge control system, has a high mill stiffness, a large work roll gap for threading, a rapid work roll gap opening, accurate roll force computation, side to side tilting, and utilizes work rolls over a much wider diameter range.

Owner:I2S

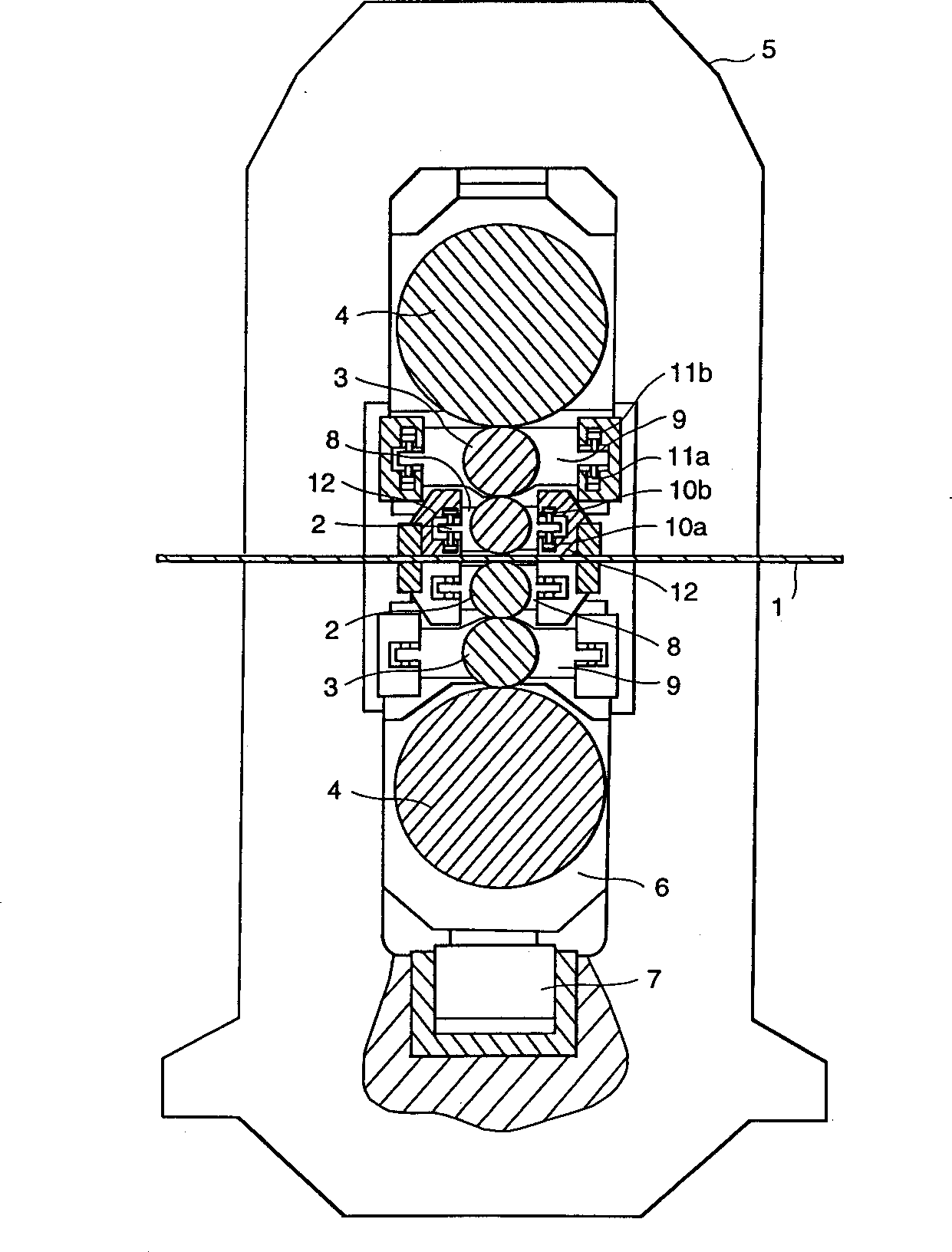

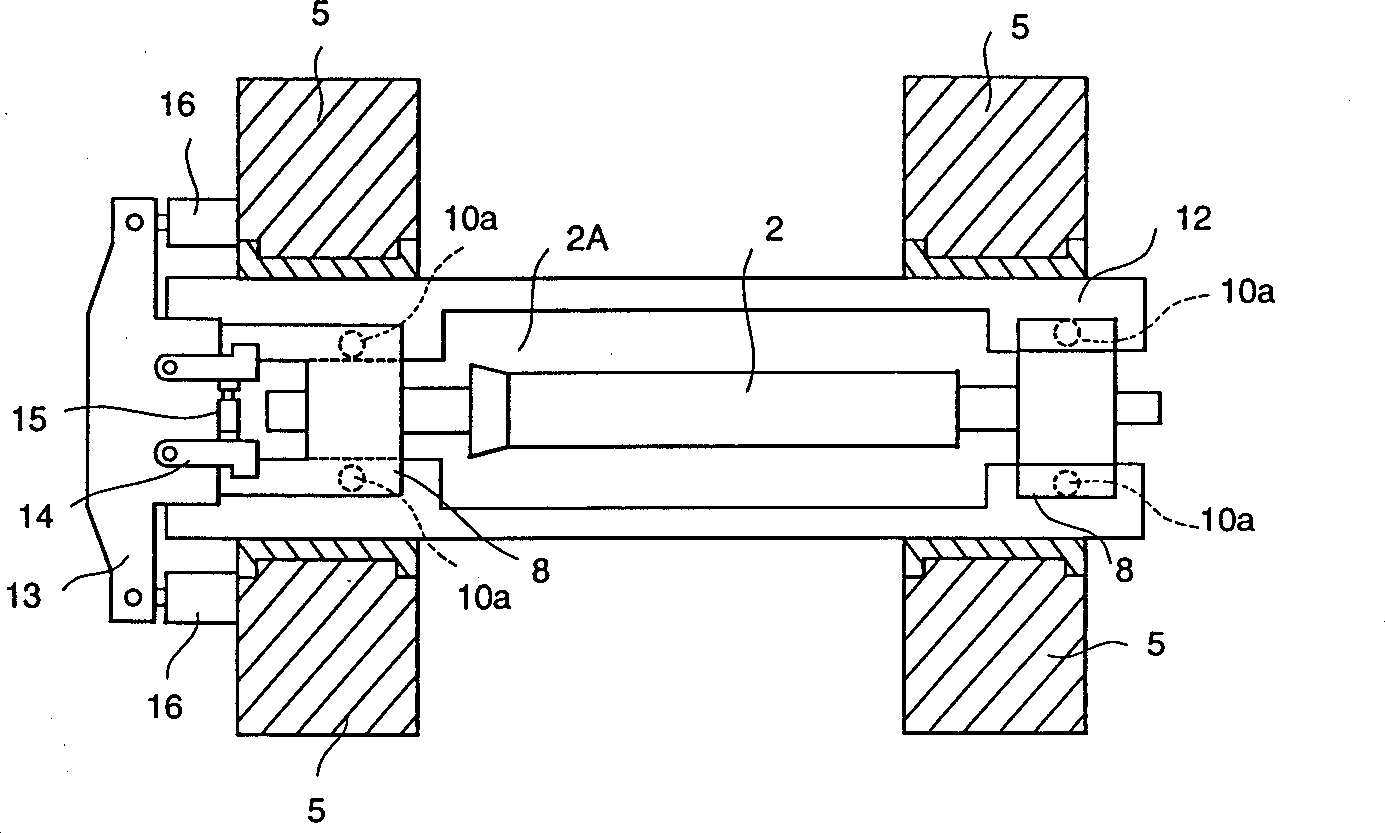

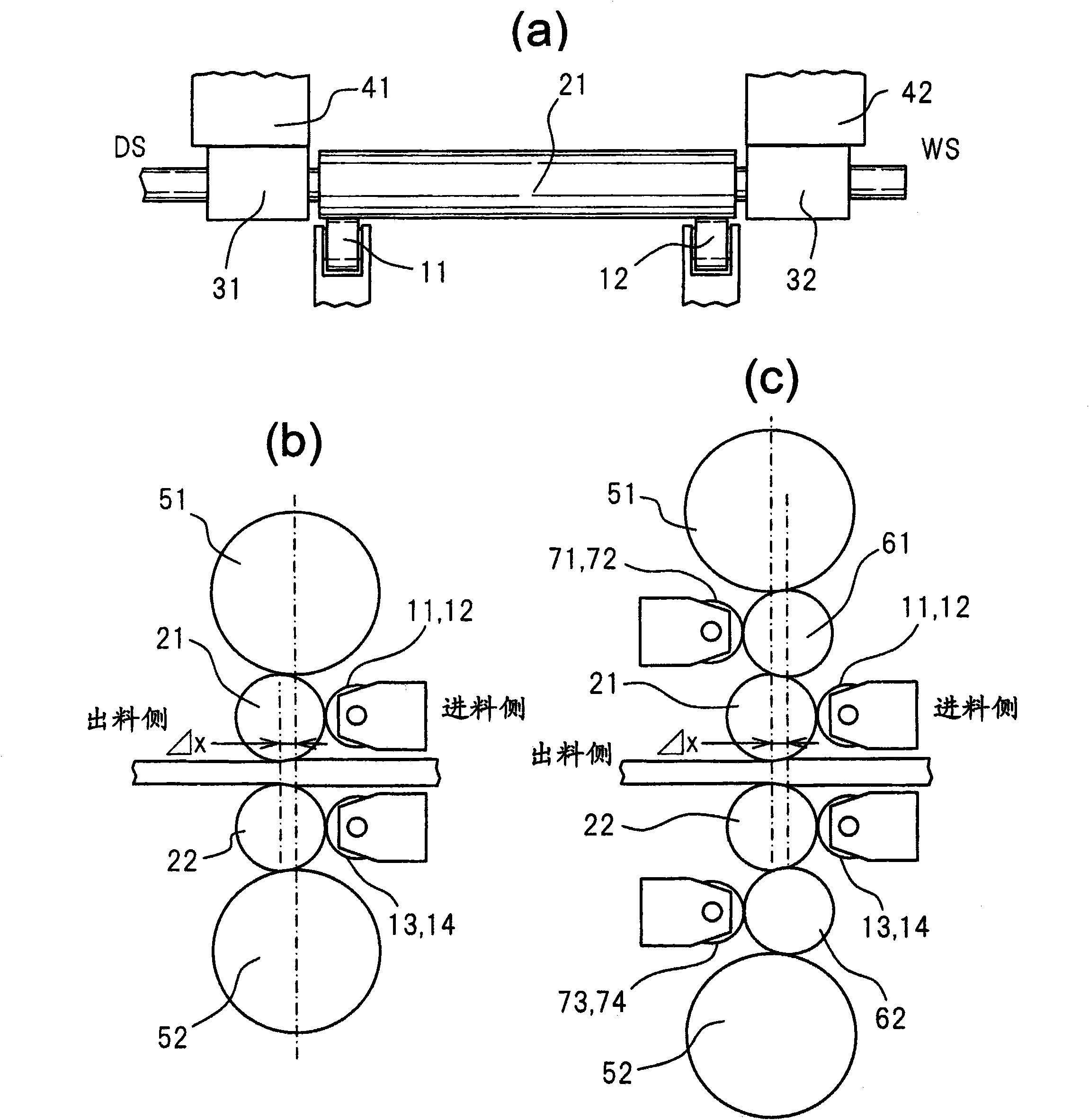

Cold-rolling mill and its rolling method

A 6-high rolling mill in accordance with the present invention wherein each of the working rolls 2 which are equipped with a shifting means has a locally gradually-thickened-toward-end part (or a local concave crown 2a) on one end of the roll, the working rolls 2 are disposed so that the locally gradually-thickened-toward-end parts of the working rolls 2 may be vertically symmetrically with a point, a decremental bender 10b which works to narrow the gap between the working rolls is provided as a first shape control means, both the local concave crowns 2a and the roll bender 10b are used to control thermal crowns, and an incremental bender 11a which controls bending of the intermediate rolls 3 is provided as a second shape control means which controls so that the center of a strip may have a concave crown.

Owner:HITACHI LTD

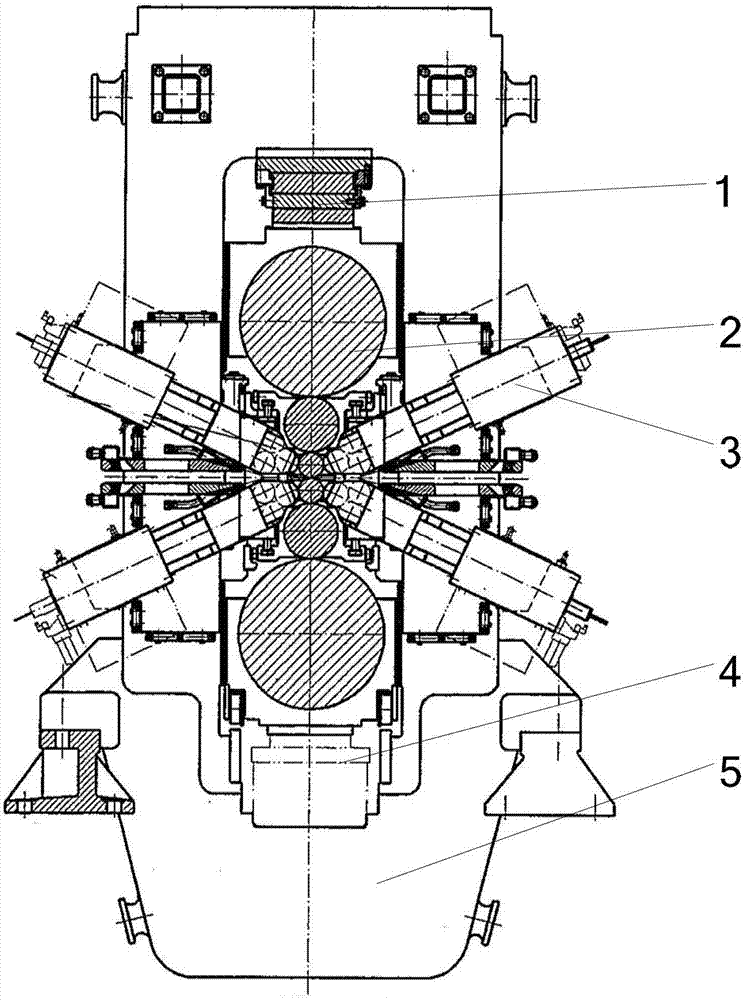

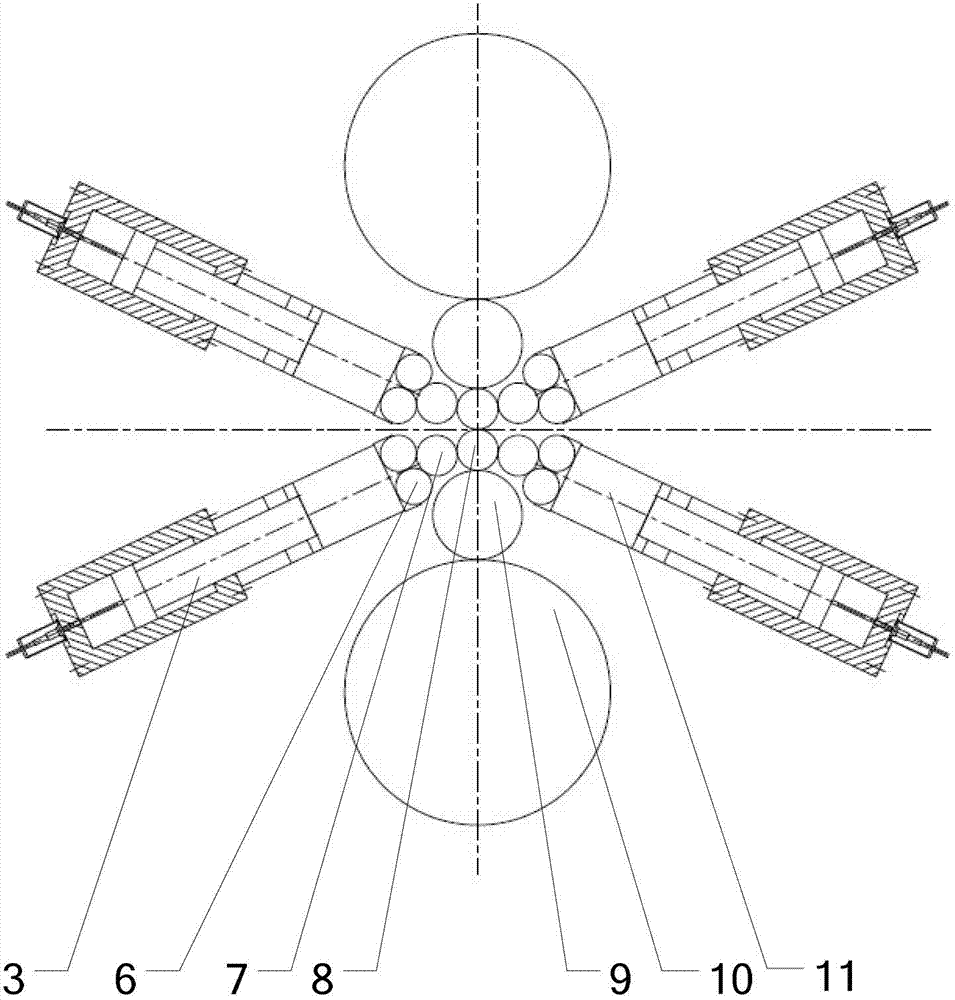

Eighteen-roller rolling mill structure

InactiveCN102886382AStrap for easy observationGuaranteed stiffness requirementsMetal rolling stand detailsCounter-pressure devicesEngineeringLubrication

The invention provides an eighteen-roller rolling mill structure. Side supporting devices of working rollers are respectively arranged in the front and at the back of as well as on and below a rolling mill machine frame assembly; each side supporting device comprises a side supporting bearing pedestal, a side roller and a side supporting roller; the side supporting device comprises a side driving cylinder which is provided with a displacement sensor and a servo valve for controlling the advancing and retreating positions of the side supporting device; when in a rolling work, the side supporting positions are set according to various technical parameters, so that the side deformation caused by the working rollers in a rolling process is counteracted and the rigidities of the working rollers are improved; with the adoption of the small-diameter working rollers and a side driving roller system mode, the demand of roller rigidity in the rolling process is ensured, and meanwhile, the rolling demand of an ultra-thin belt material is satisfied; and the rolling mill structure has the following advantages of high rolling mill opening degree, favorable lubrication for the roller and belt material, high speed, convenience to maintain equipment and low manufacturing cost of the equipment.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Side supported 6-high rolling mill

A 6-high rolling mill has work rolls which have offsets, relative to the intermediate rolls, such that during operation there is a net horizontal force acting to urge the work rolls into engagement with the support rolls whereby substantially all horizontal support of the work rolls is provided by the support rolls. Support pads are located proximal the rolls' side faces, without exerting any substantial force on the work rolls during operation.

Owner:T SENDERCHIMO

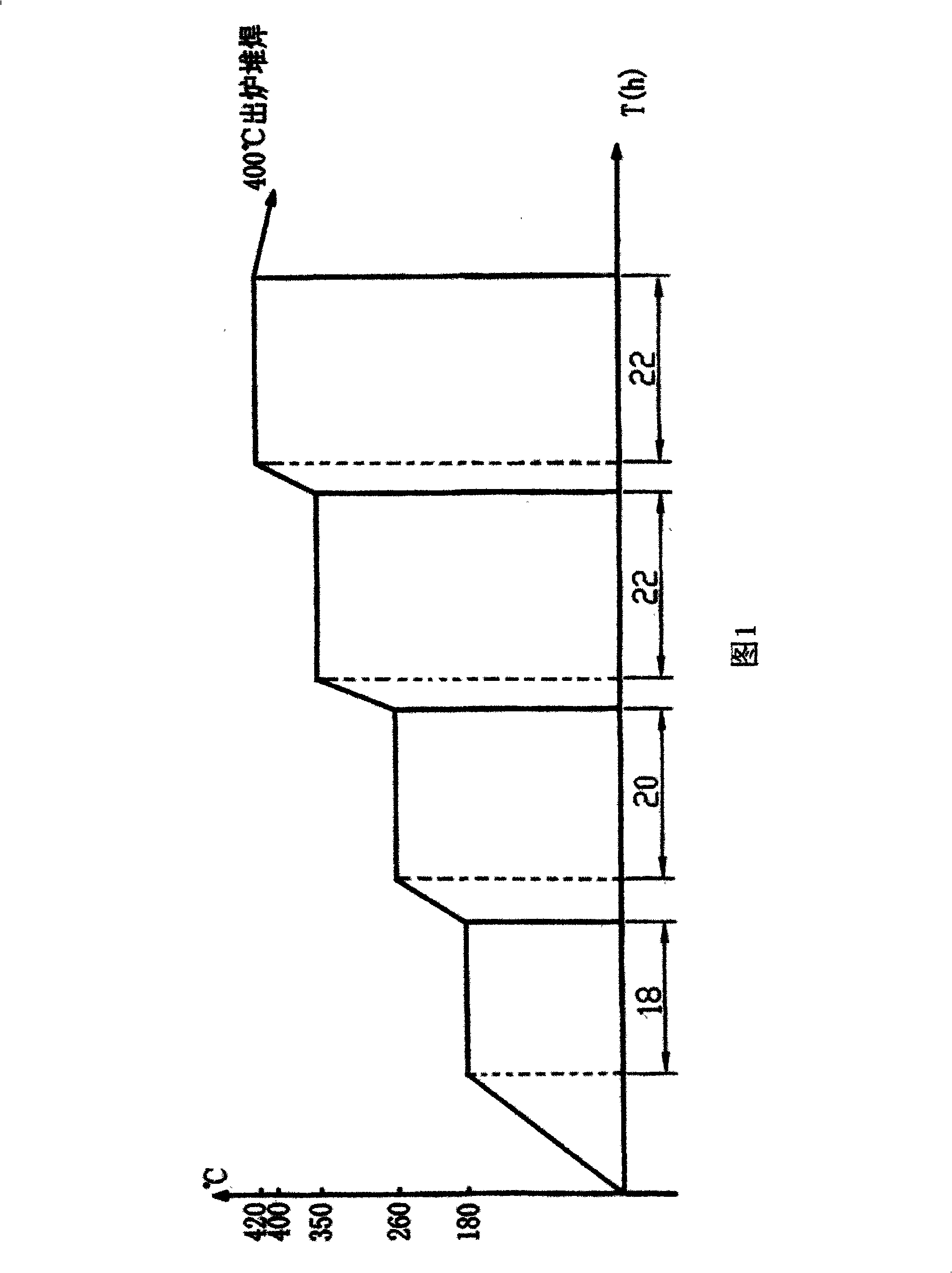

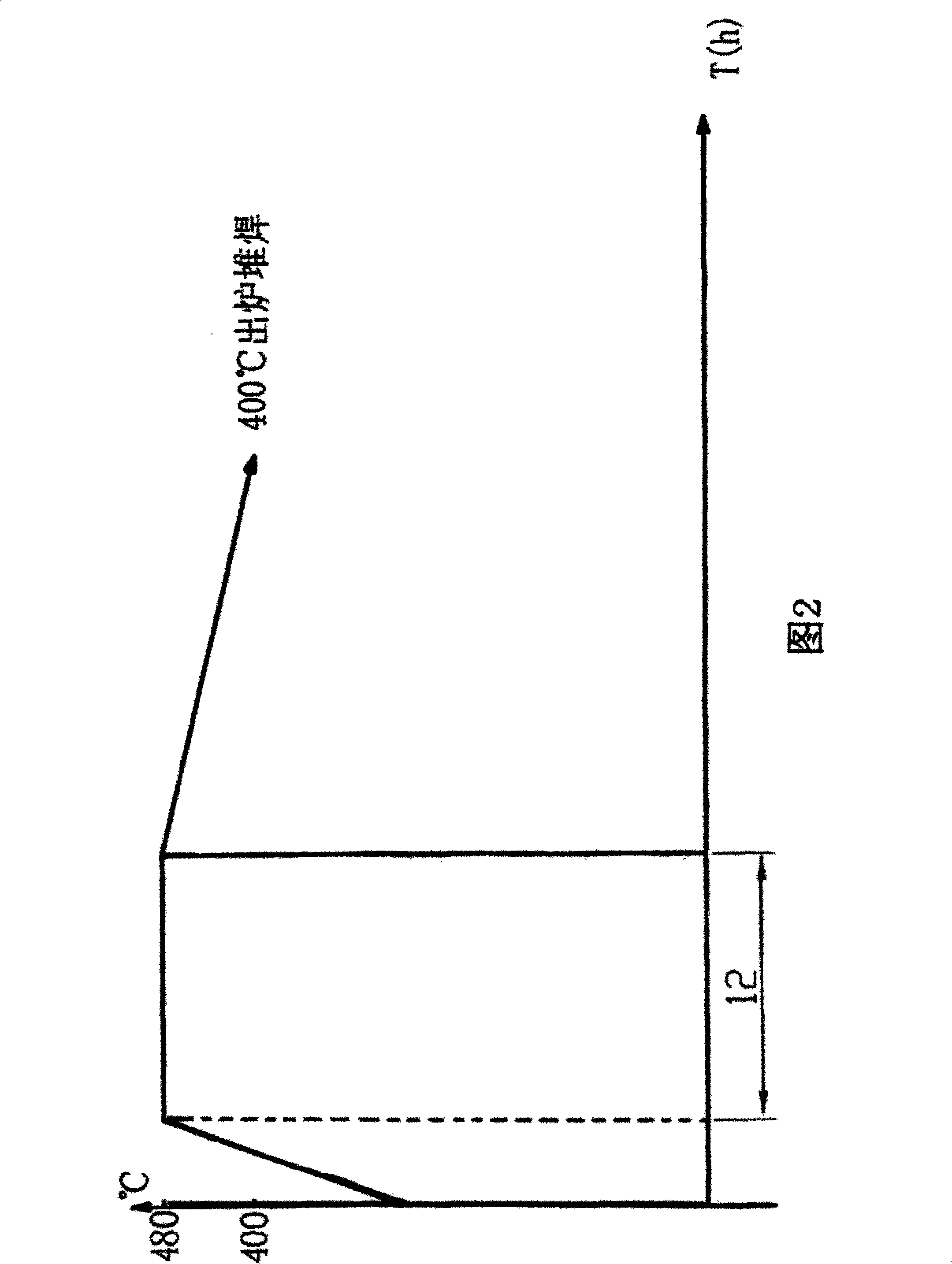

Renovation technique for phi2100í3400mm wrought steel support roll

InactiveCN101293300AEnsure homogeneityPreserve the quality of restorationCounter-pressure devicesArc welding apparatusHeat-affected zoneEngineering

The invention relates to the technical field for repairing an ultra-large type backup roll, in particular to a repair process of a forging steel backup roll with Phi2100* 3400mm. Firstly, welding is carried out on the rib of the backup roll: the roll body of the backup roll which needs to be welded is preheated to 250 DEG C, and the temperature is preserved for 10 hours; then the door of a furnace is opened, rib welding is carried out, zigzag welding is carried out every 100mm, and the length of the weld pass is 50-60mm; oxygen is used on the welded part immediately, and ethyne is used for warming the welded part until the welded part becomes blue. After the rib welding is finished, preheating treatment, temperature preservation treatment and destressing treatment are carried out respectively according to a heat treatment curve when the roll body of the backup roll is overlaid for making a bottom layer, a transition layer and a working layer. Compared with the prior art, in the technology of the invention, the influence on the service performance caused by the temperature circulation and change of a heat influencing region during the overlaying is considered, uniformity and penetration of preheating workpieces and uniformity of temperature between layers are guaranteed in the repair process, the blank in the repair rebirth field of the domestic ultra-large type backup roll is filled in. The time for repair is short, the service life is prolonged, and the cost is saved.

Owner:SHANGHAI SHIWEI WELDING IND

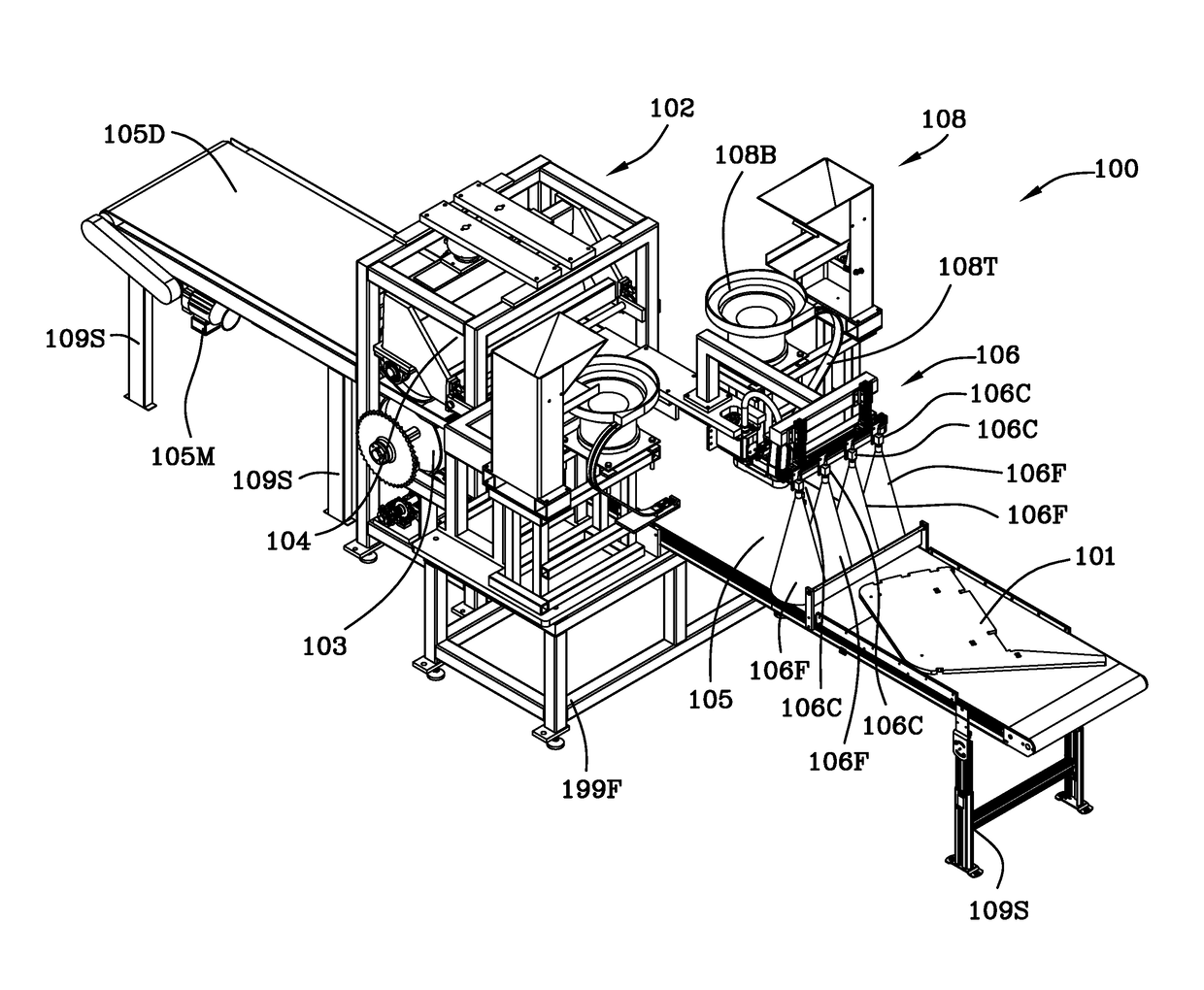

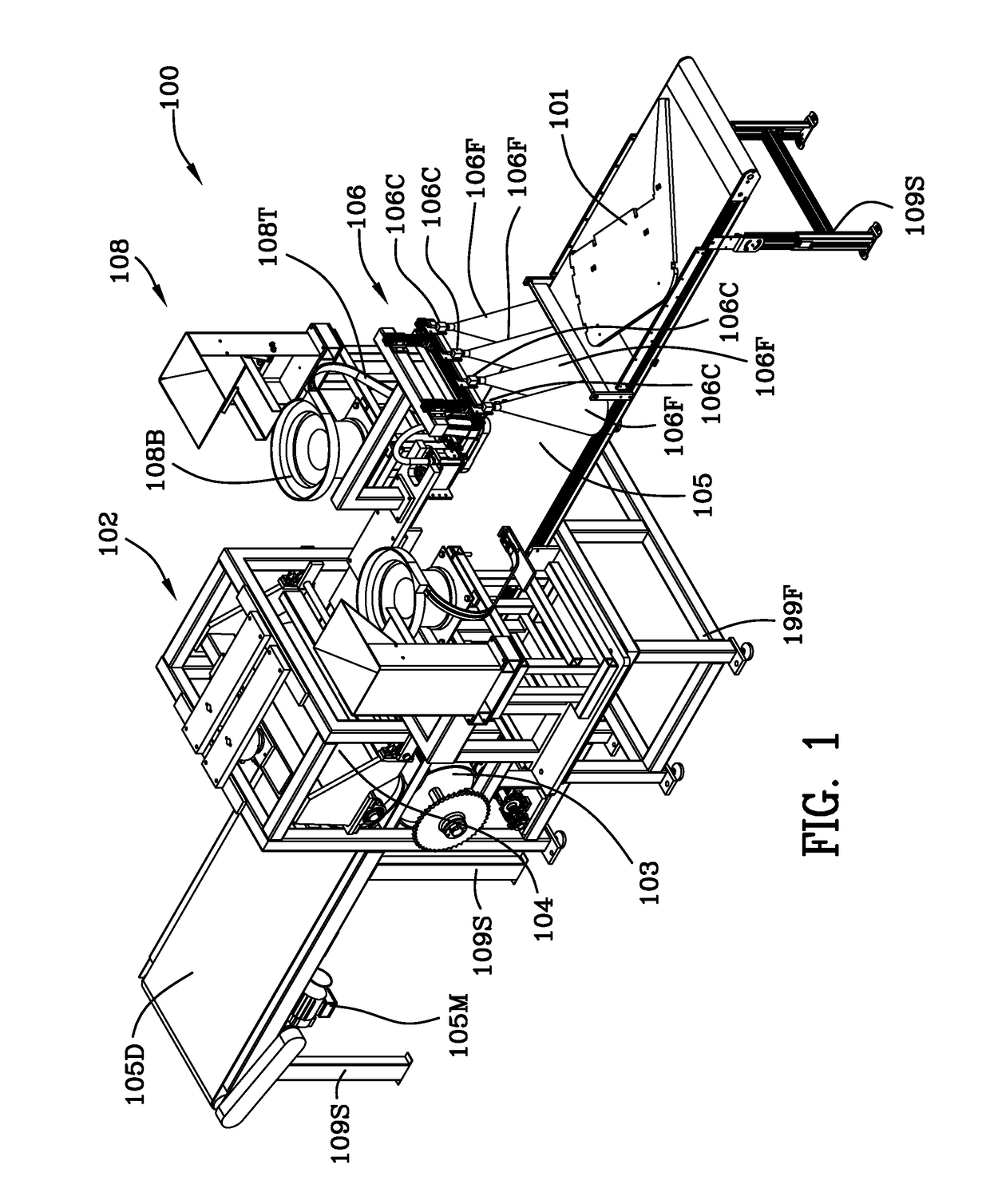

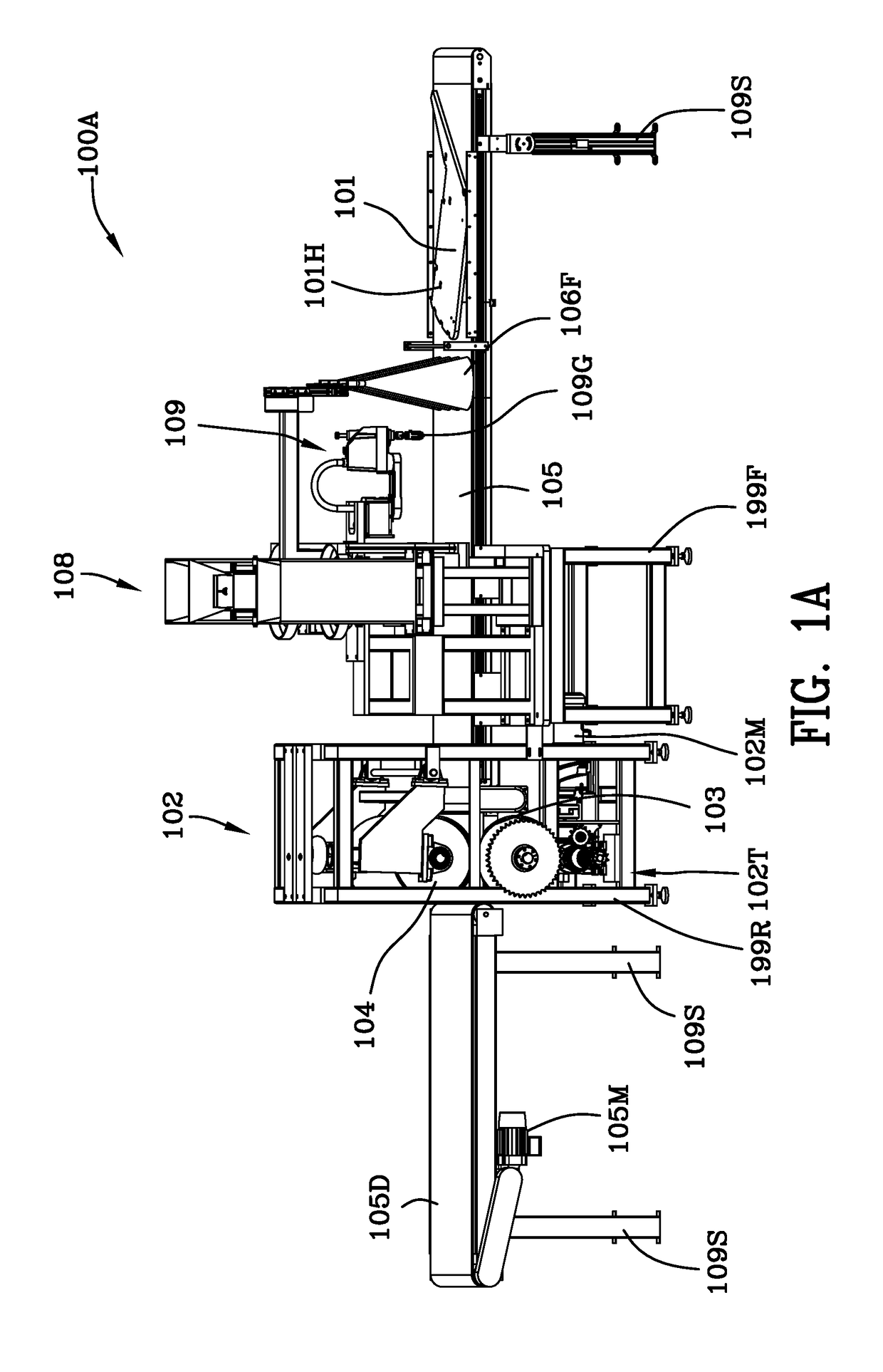

Insertable fastener installation apparatus and method

ActiveUS20180311775A1Reduce the risk of injuryReduce conductionProgramme-controlled manipulatorCounter-pressure devicesEngineeringFastener

An insertable fastener installation apparatus for a flat substrate has a thickness, T. A roller press station is used to press T-nuts into holes in the substrate. An optical vision system detects the location of the holes in the moving substrate and aligns the t-nuts with the holes. A computer controlled pick and place robot takes T-nuts from an escapement of a hopper feed system and aligns, but does not fully insert, the t-nuts in the substrate. A conveyor system feeds the substrates through the optical vision system, the pick and place robot station and the roller press station. A first roller is spaced apart from a second roller by a gap in the roller press station and the gap is less than the thickness of the substrate. The hopper feed system includes a bulk hopper, a bowl, a track and an escapement.

Owner:STAFAST PROD

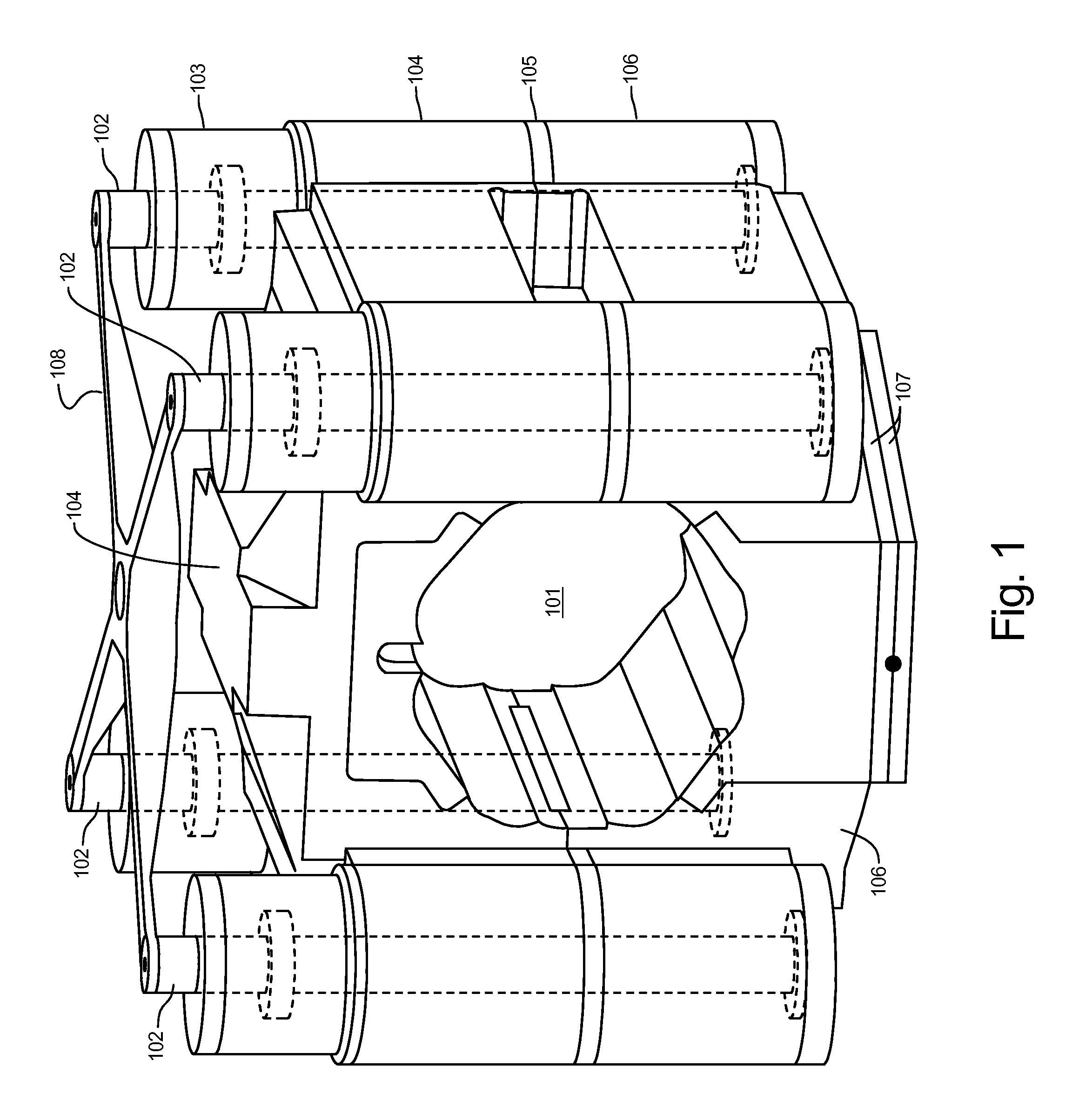

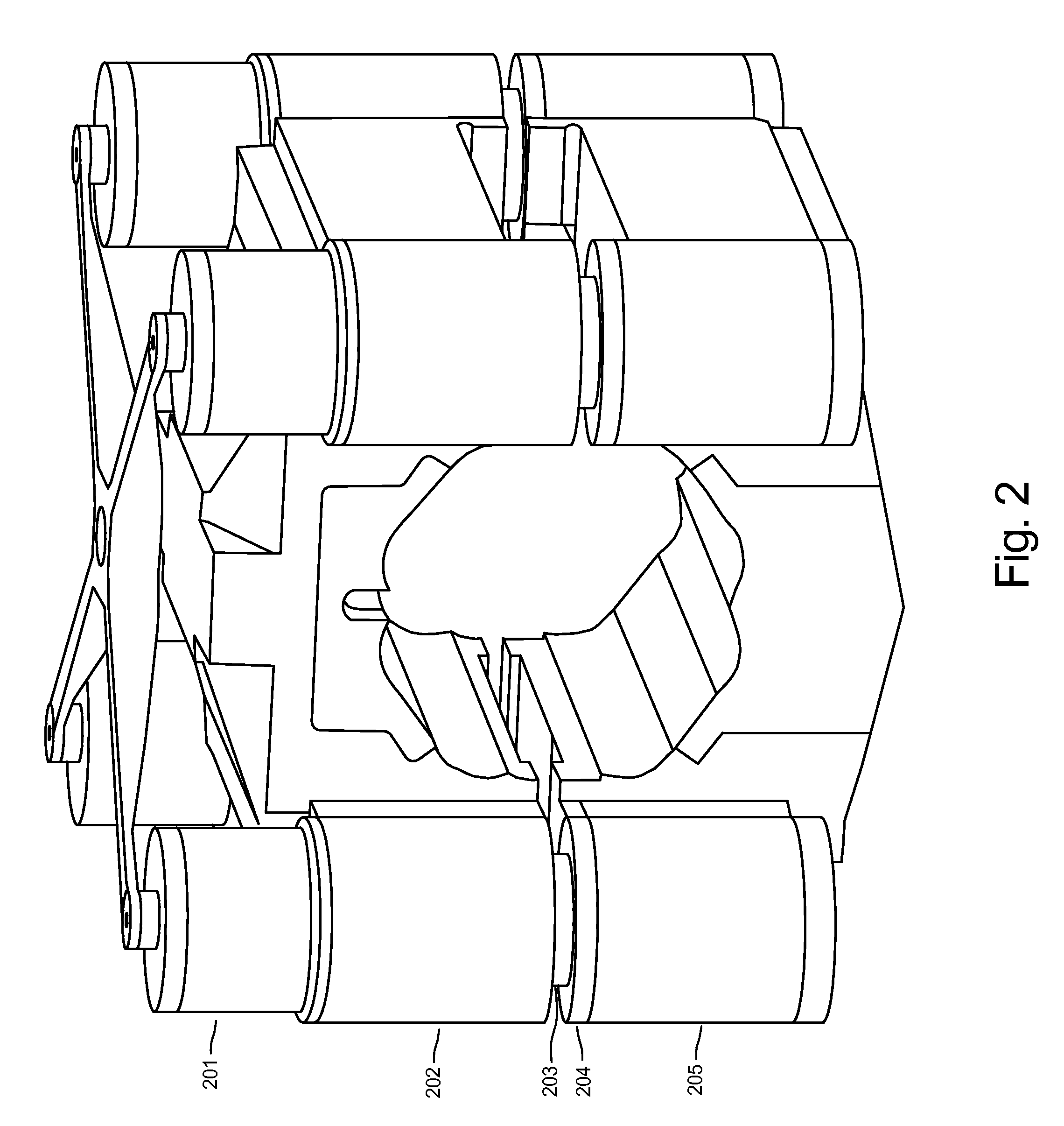

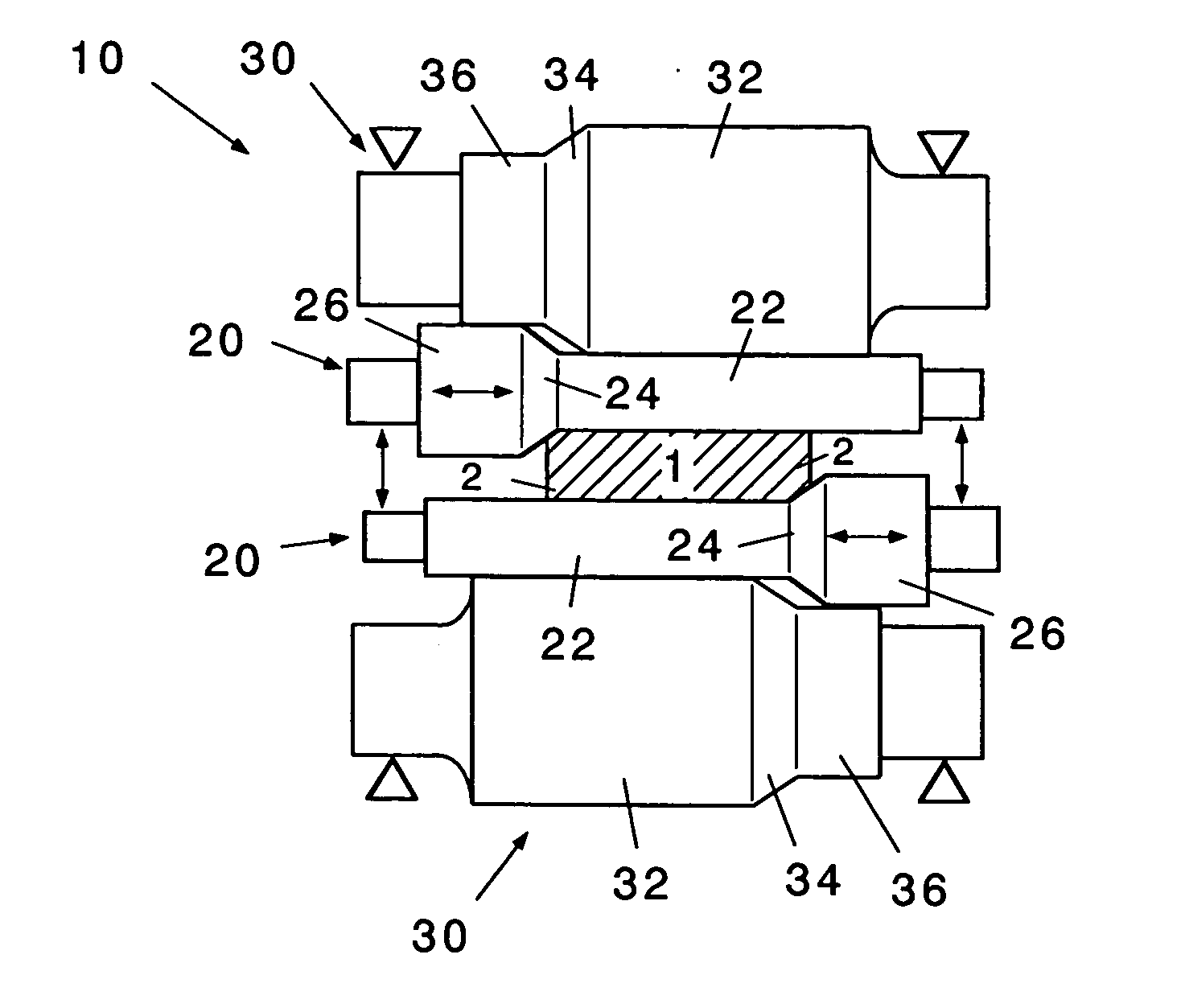

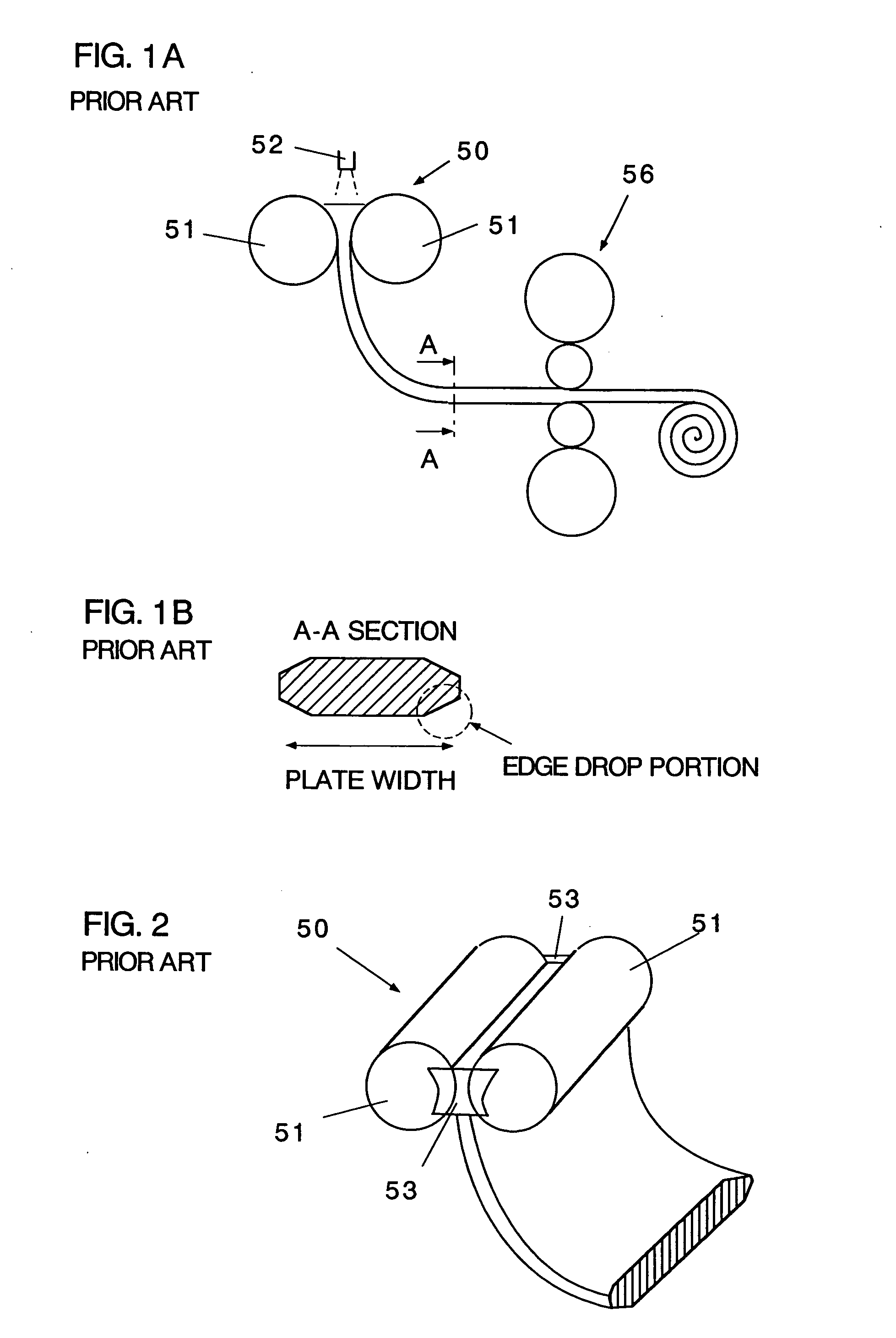

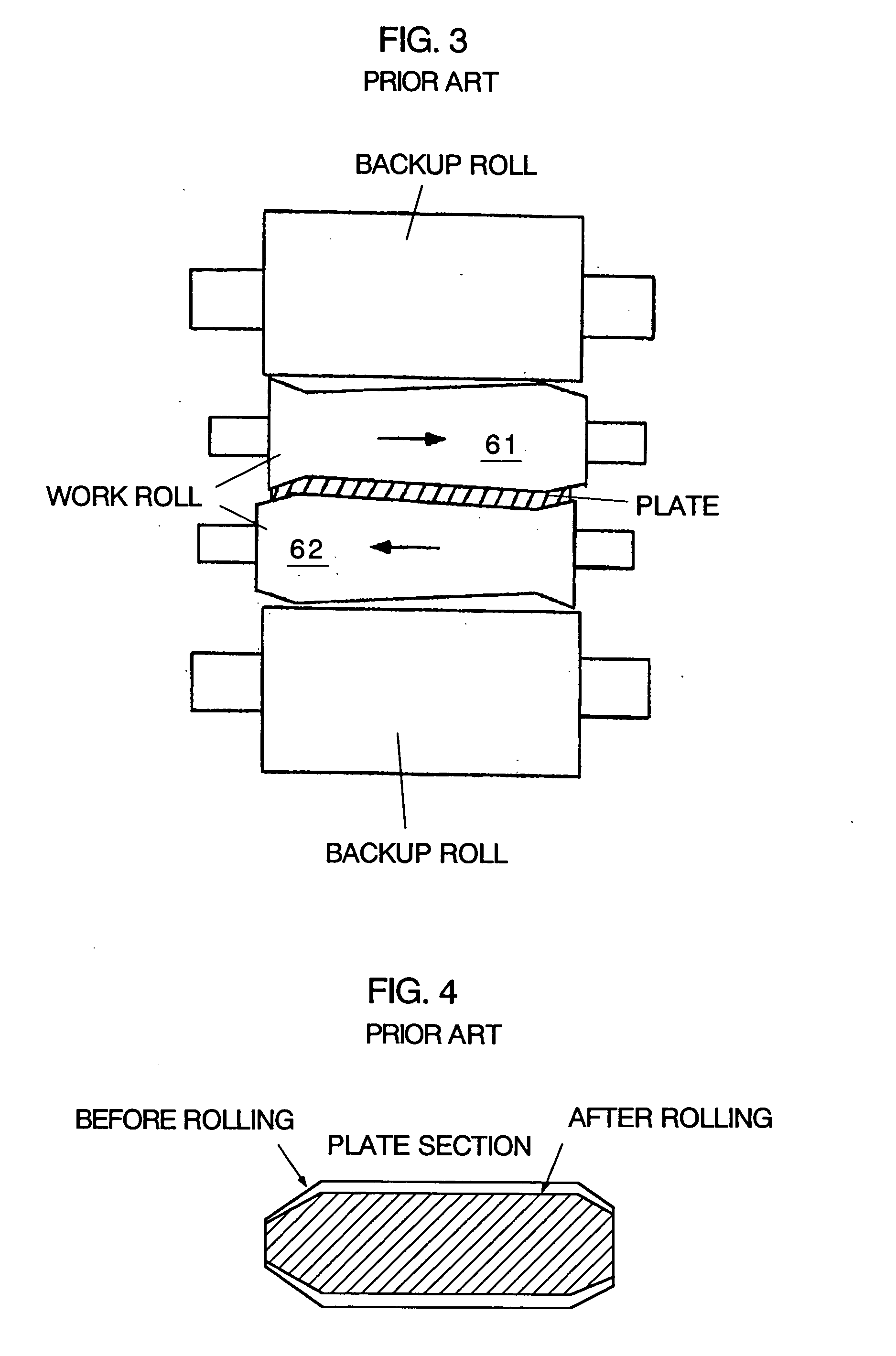

Apparatus for manufacturing band plate

ActiveUS20050044916A1Little resistanceMetal rolling stand detailsCounter-pressure devicesWork rollEngineering

An apparatus for manufacturing a band plate has a rolling mill that includes a pair of upper and lower work rolls that roll a slab material having edge drop portions at both ends thereof, and a pair of backup rolls that contact non-rolling side surfaces of the pair of upper and lower work rolls, respectively to prevent the work rolls from being deformed. The work roll includes a reverse taper portion where a roll diameter gradually increases towards a barrel end portion thereof corresponding to the edge drop portion. The upper and lower work rolls are configured to be shiftable individually in the axial direction thereof. The backup roll includes an escape portion whose diameter gradually decreases towards an axial end thereof so as not to contact the reverse taper portion of the work roll, within a shifting range of the work roll.

Owner:IHI CORP

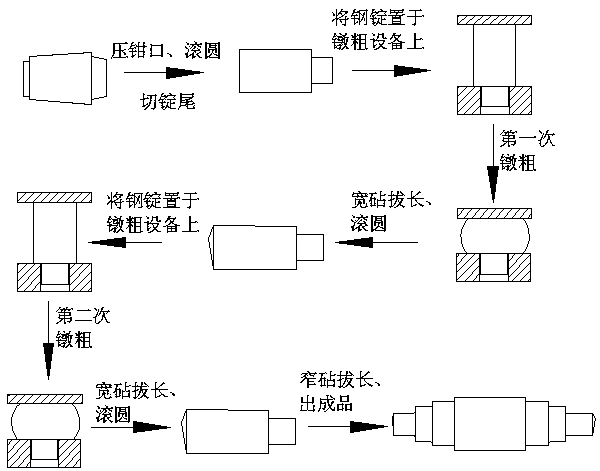

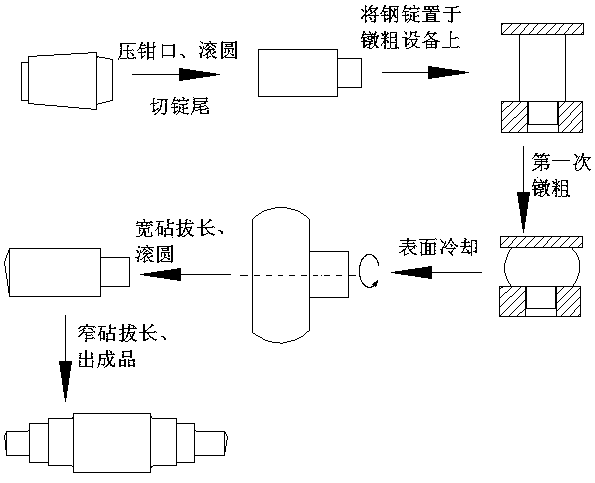

Forging method of large supporting roller forge piece

ActiveCN110405121ABroaden the limit upsetting rangeDense structure of forgingCounter-pressure devicesMetal rolling arrangementsIngotTemperature difference

The invention discloses a forging method of a large supporting roller forge piece, and relates to the technical field of free forging. The forging method comprises the following steps of pressing a riser of a steel ingot with a jaw, rounding an ingot body of the steel ingot and cutting off an ingot tail of the steel ingot to obtain a steel ingot blank; heating the steel ingot blank to 1220-1270 DEG C and preserving heat, wherein the heat preservation time is set according to the size of the ingot body of the steel ingot; upsetting the ingot body of the steel ingot until the ratio of H to D ranges from 0.37 to 0.50; uniformly cooling the surface of the steel ingot to 1000-1100 DEG C so as to enable the inside and outside of the ingot body to form a temperature difference; drawing the ingotbody of the steel ingot by adopting a wide flat anvil; and reheating the drawn blank, drawing out the step of each part of the forge piece to the designed size, cutting off water openings at the two ends of the steel ingot and riser leftovers and forming the finished product. According to the forging method, the effective compaction of a core of the steel ingot can be realized by means of one-timeupsetting and drawing, the technical problem that the large supporting roller forge piece usually needs two-time upsetting is solved, the kinetic energy consumption in the production process of the supporting roller is greatly reduced, and the product manufacturing period is further shortened.

Owner:CITIC HEAVY INDUSTRIES CO LTD

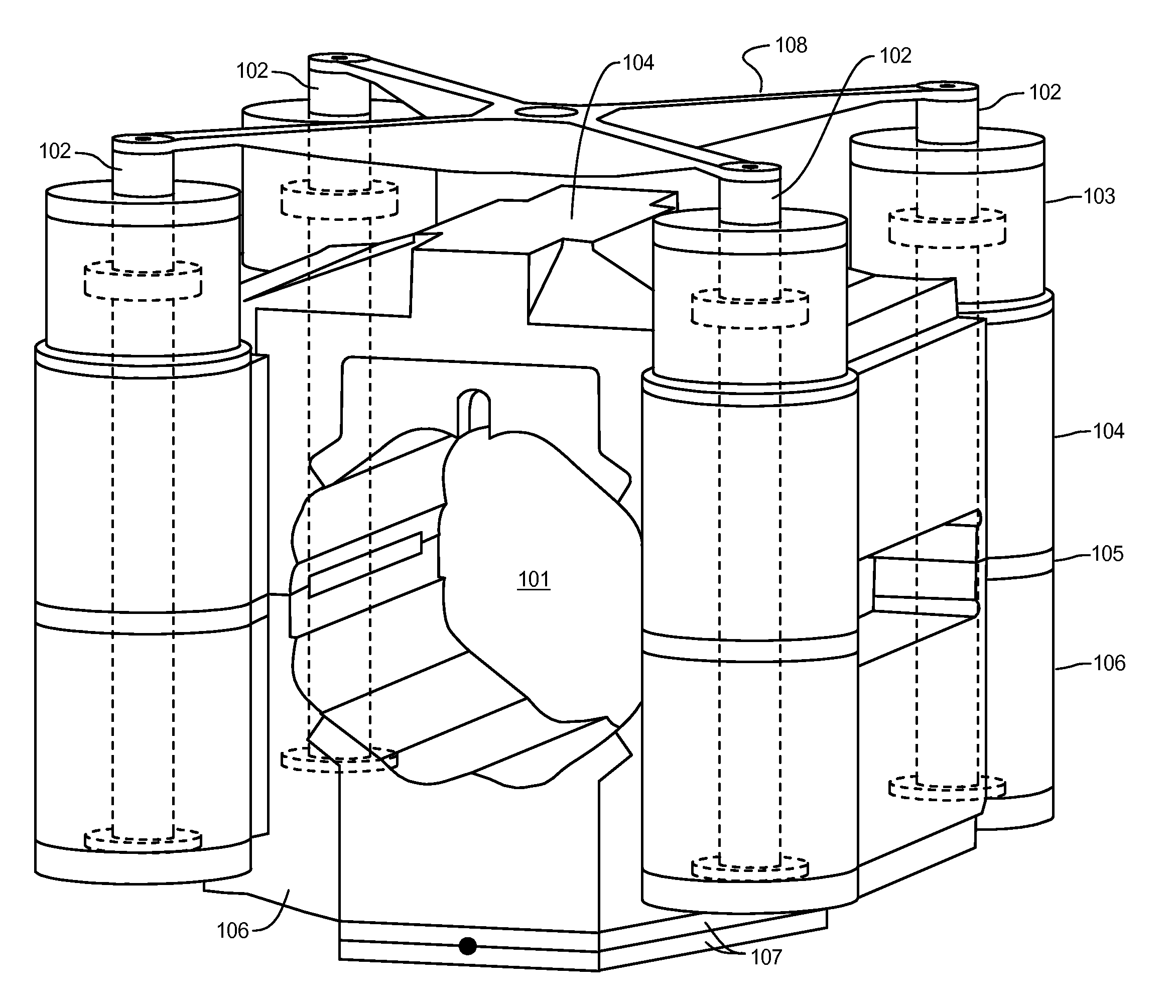

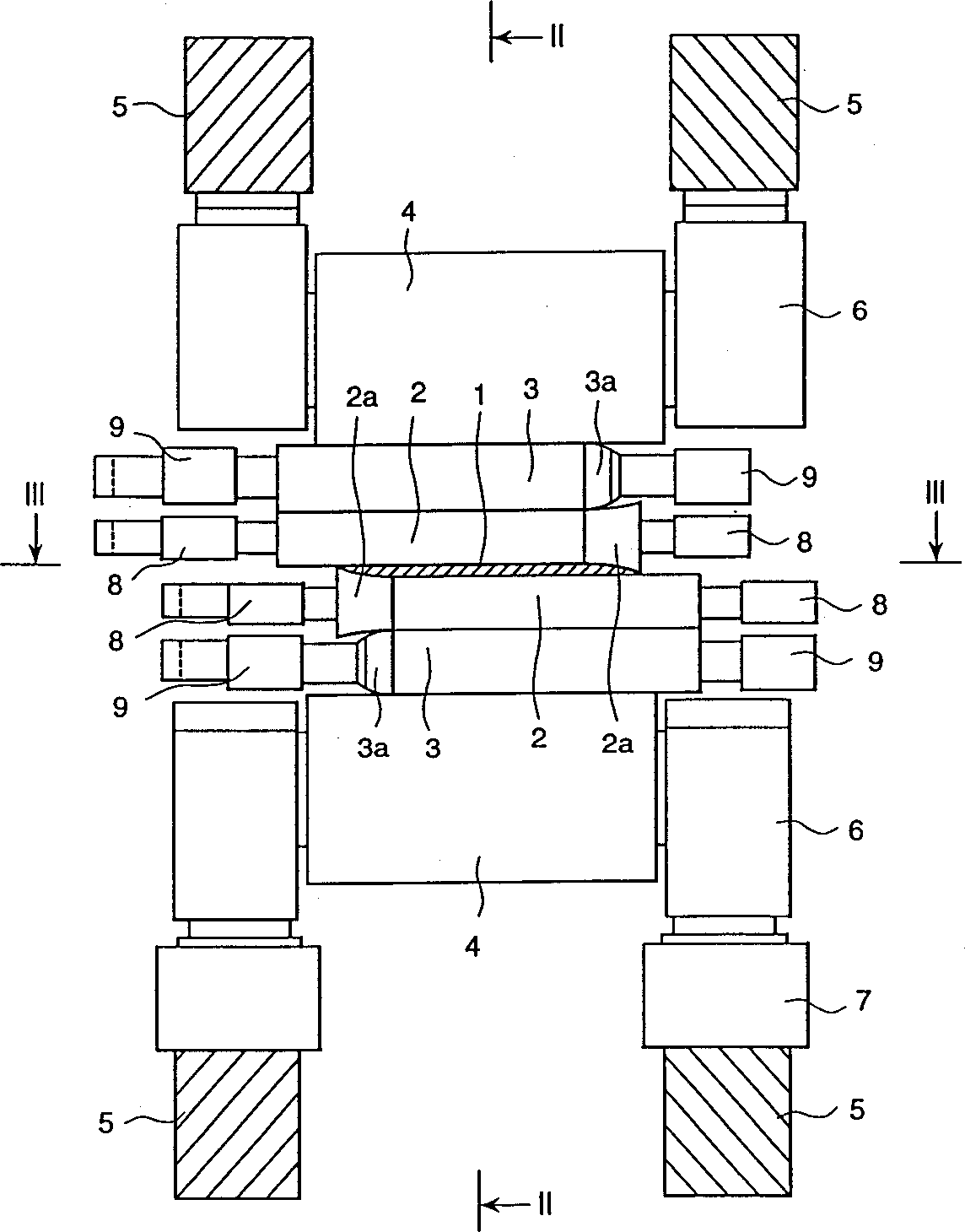

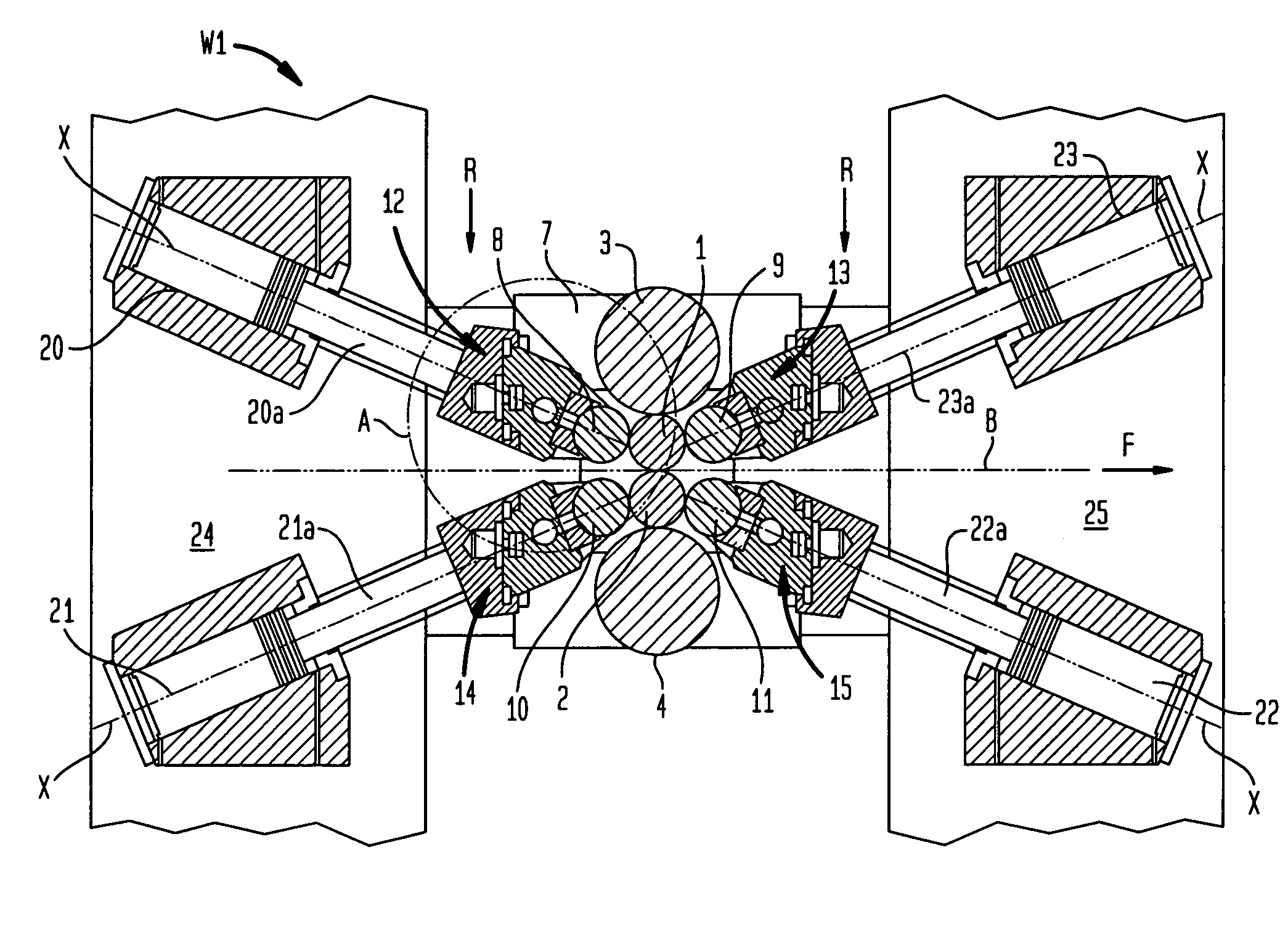

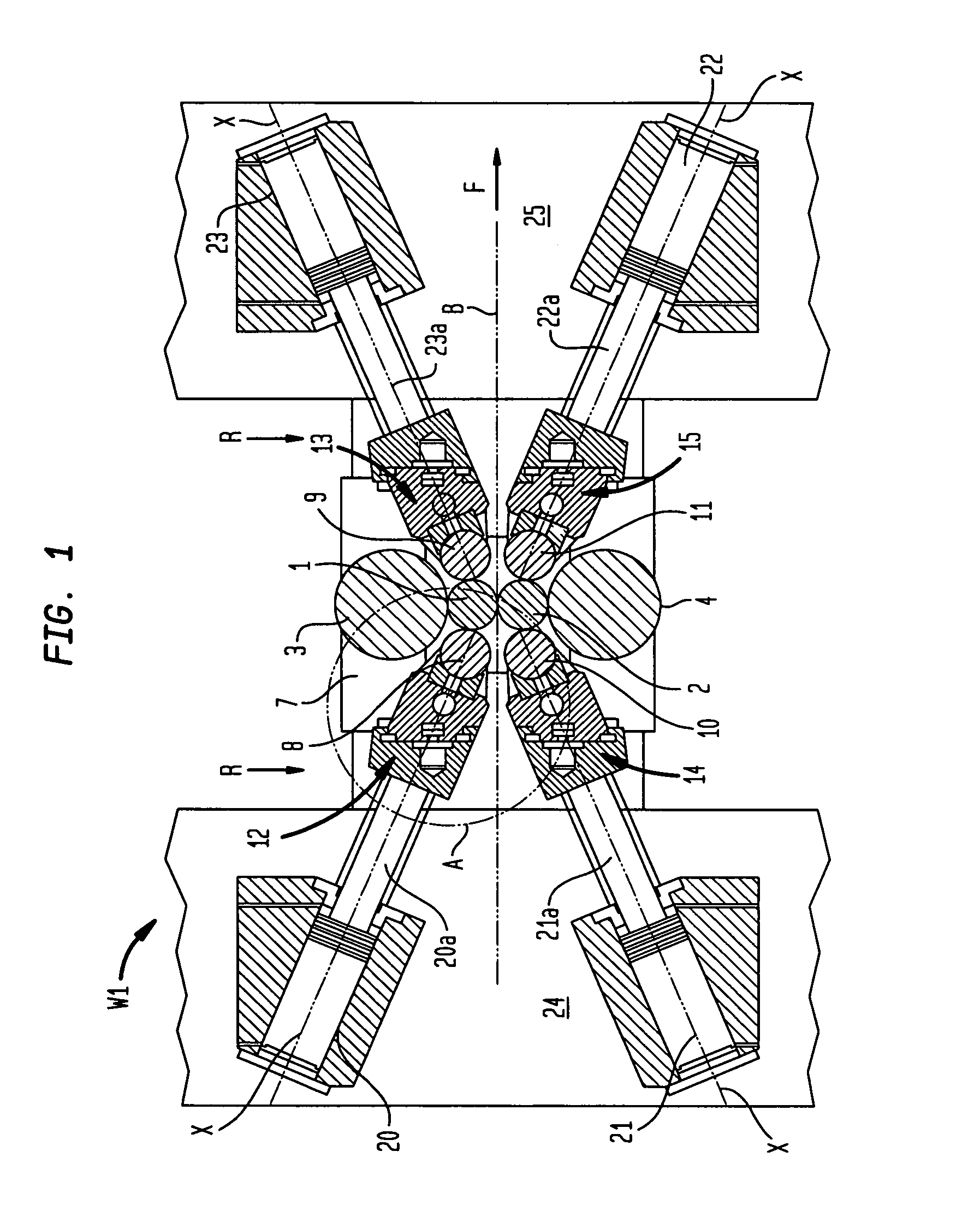

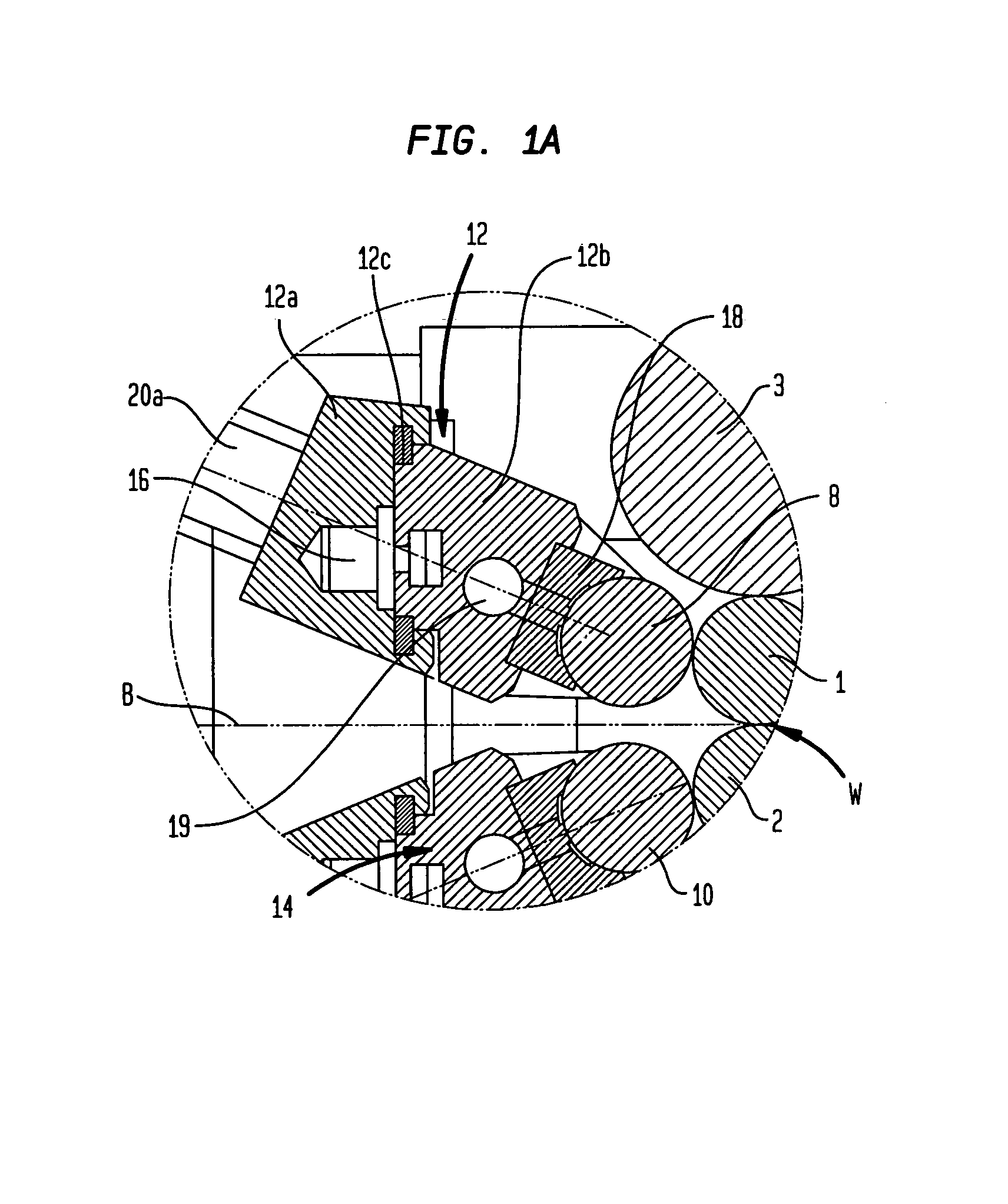

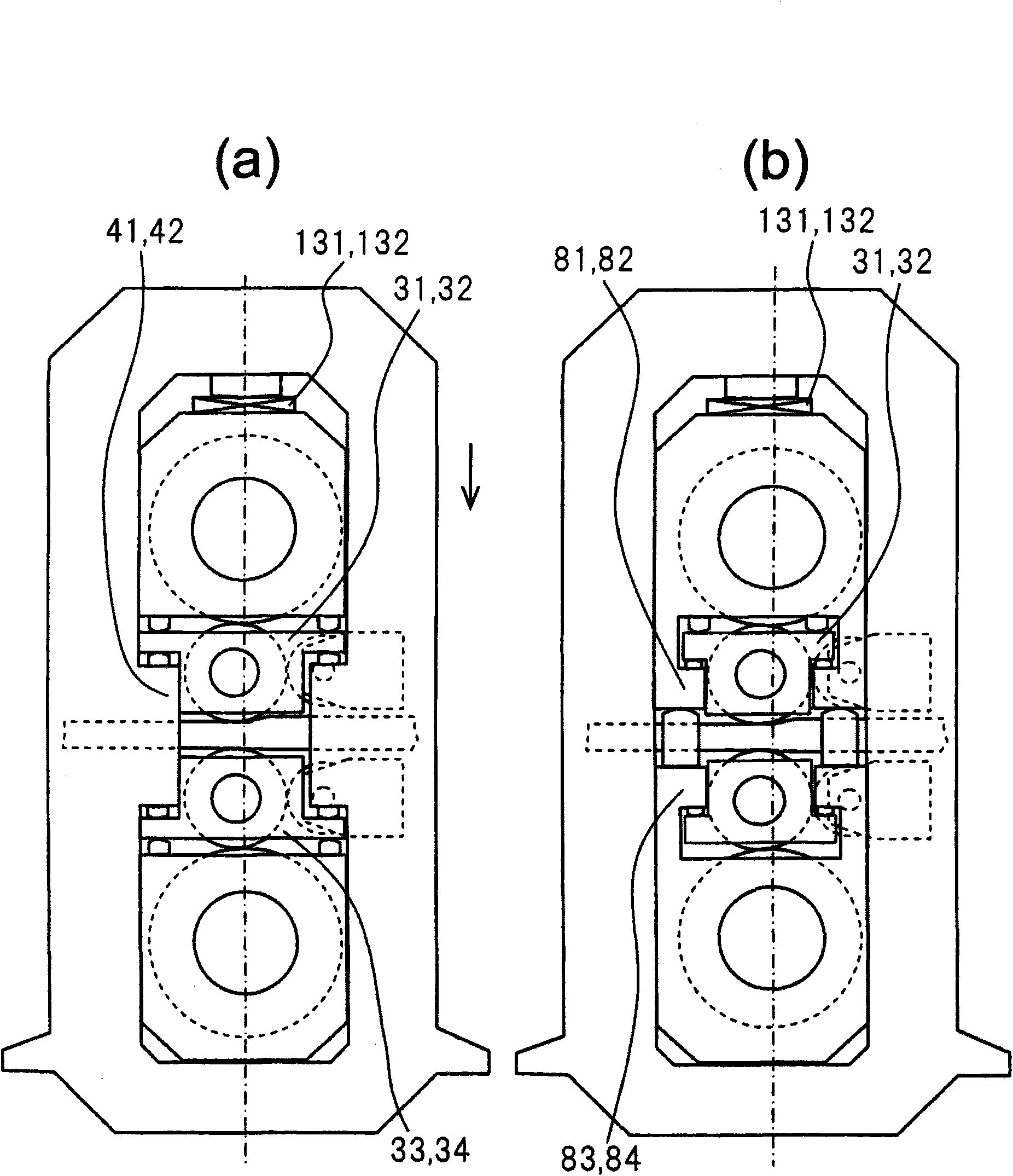

Roll stand

InactiveUS7104101B1Carry-out quickly and easilyMetal rolling stand detailsCounter-pressure devicesWork rollForce generation

The invention relates to a roll stand comprising a pair of work rolls 1, 2 for rolling a metal strip B, comprising back-up rolls 8, 9, 10, 11 which provide lateral support to their respectively allocated work rolls 1, 2, with support force directed towards the work rolls 1, 2 being able to be applied to said back-up rolls by means of a force generation device, and comprising support rolls or intermediate rolls 3, 4 which are borne by a chock which can be slid into the roll stand W1, W2 in the direction of the longitudinal axis of said chock 7, and wherein said chock can be withdrawn from said roll stand, with each support roll or intermediate roll supporting an associated work roll 1, 2 in a direction which is essentially perpendicular to the direction of movement of the metal strip B. In such a roll stand, changing of the rolls can be carried out more quickly and easily in that the back-up rolls 8, 9, 10, 11 can be positioned from an idle position in which they are arranged outside the region where the chock 7 of the support roll or intermediate roll 3, 4 moves during slide-in or withdrawal, to an operating position in which they rest against the work roll 1, 2.

Owner:SUNDWIG

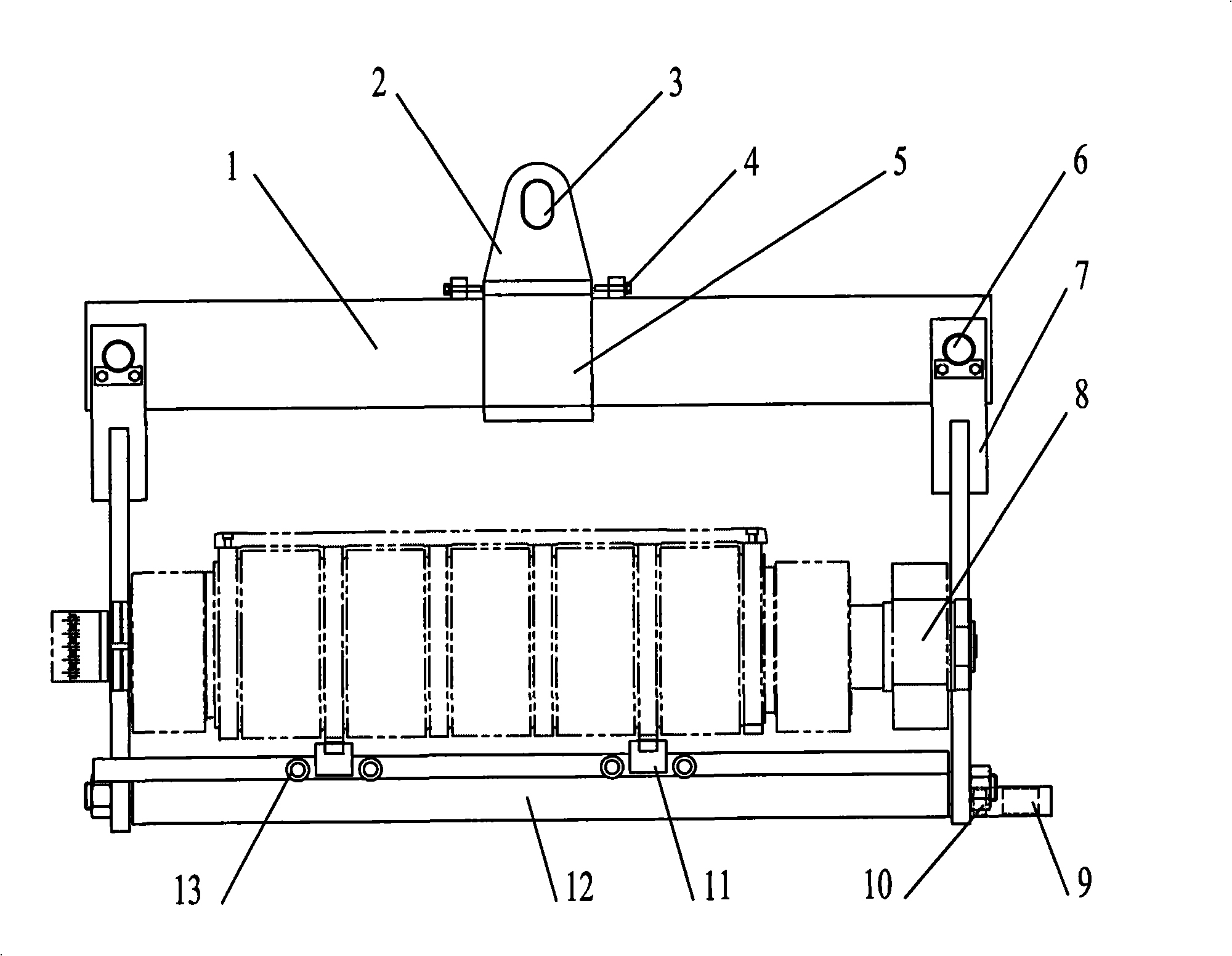

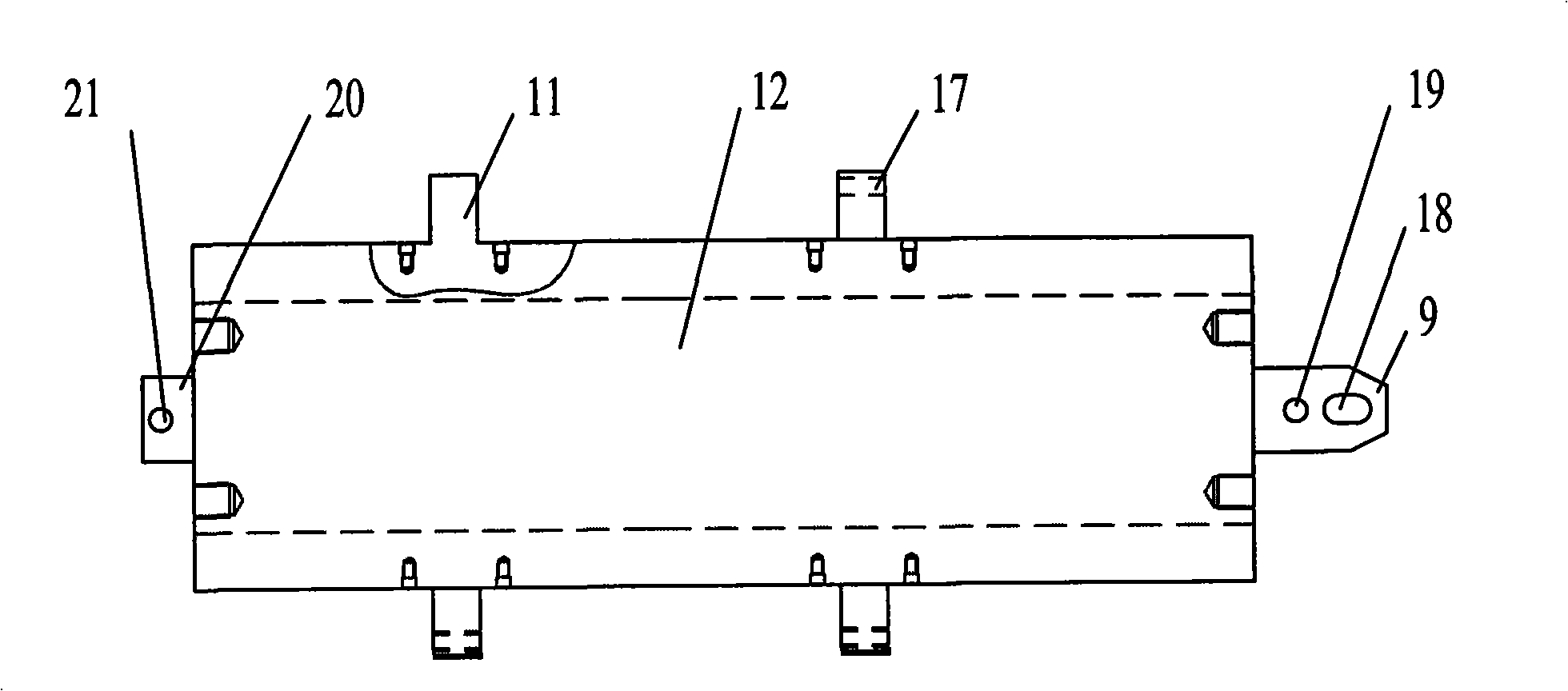

Upper back-up roll extractor of cluster roll

ActiveCN101352732AEasy to installEnsure safe liftingMetal rolling stand detailsCounter-pressure devicesEngineeringBackup roll

The invention relates to a roll changing device for up-backup rolls of a multi-roll mill. The roll changing device comprises a roll changing bracket, and also comprises a lifting tool for lifting the roll changing bracket, wherein, the lifting tool comprises a beam (1), a lifting lug (2) sheathed on the beam (1) and a swing lifting frame (7) connected with the two ends of the beam (1) by a pin roll (6); and a limit bolt (4) is respectively arranged at the two sides of the lifting lug (2) on the beam (1); the roll changing bracket comprises a carriage (12) and rollers (13) arranged on the carriage (12), the carriage (12) comprises a main body carriage and a side guide (11) which is provided with an upward prominence (17) respectively arranged on at least two end parts of two opposite sides of the main body carriage, and the rollers (13) are distributed at the two sides of the side guide (11). The roll changing device can simultaneously replace two bed rolls, and has the advantages of convenient operation and short roll changing time, and the production operation rate is improved.

Owner:CERI TECH

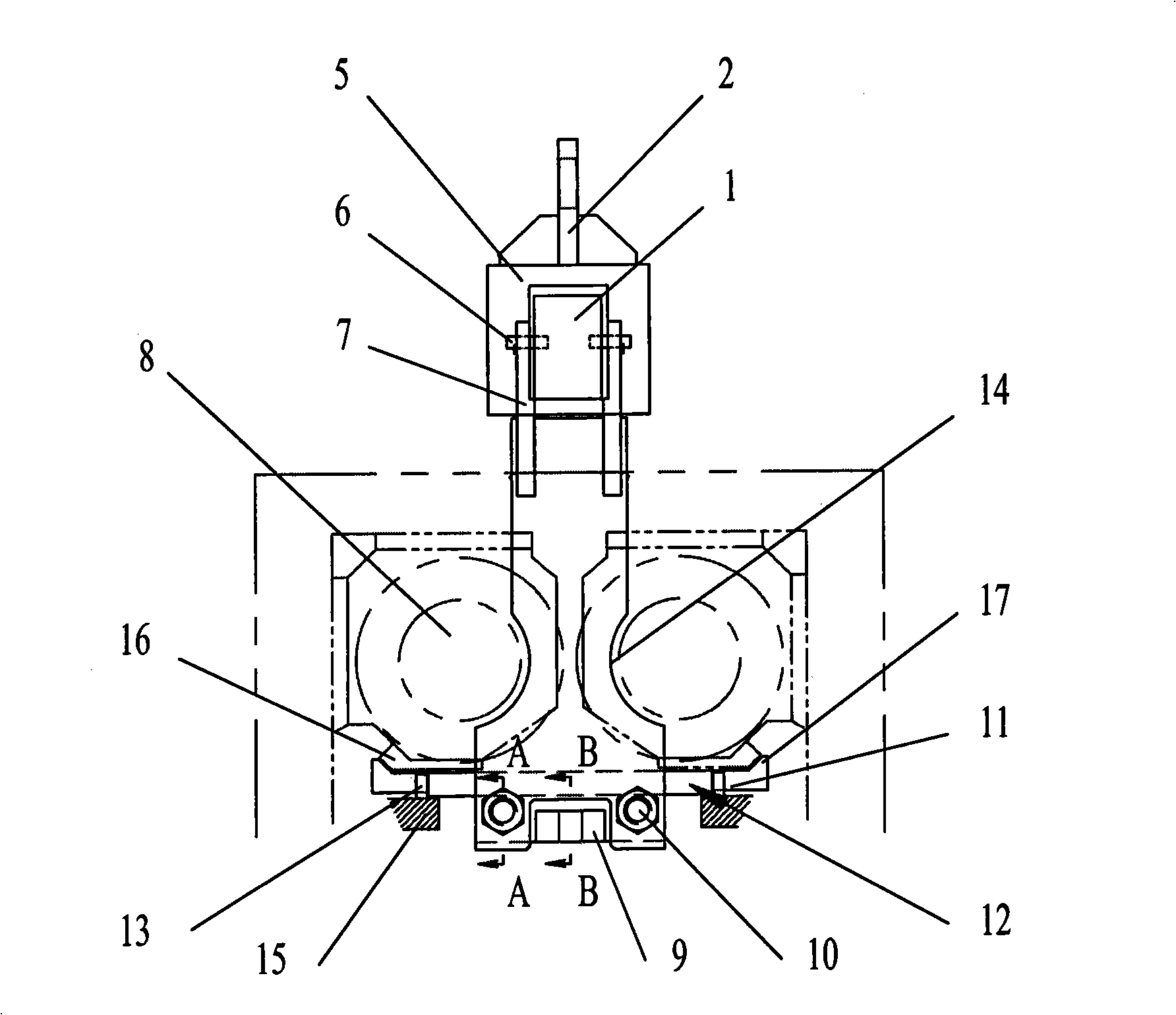

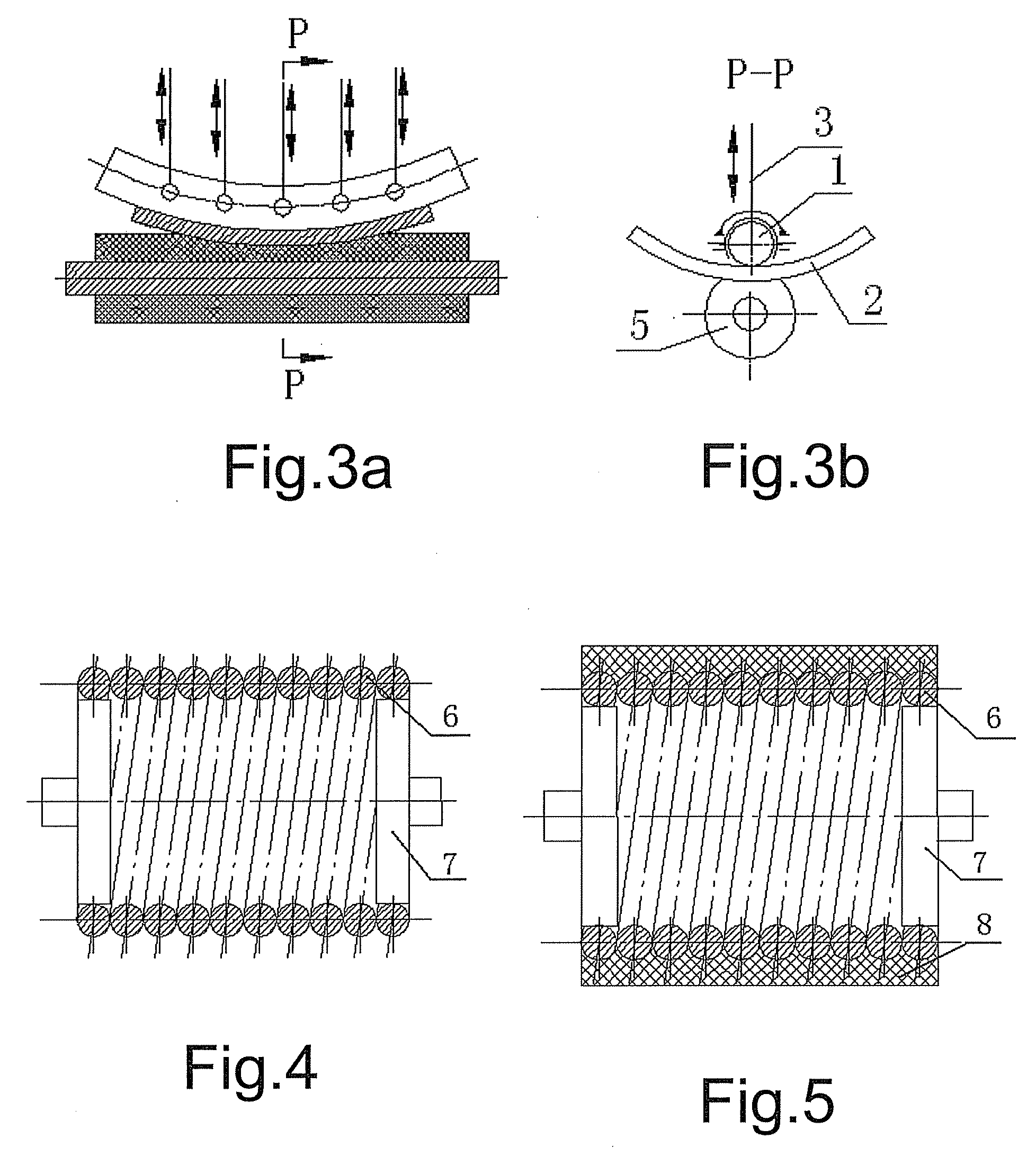

Flexible forming device for forming three-dimensional shaped workpieces

InactiveUS20090107199A1Increase productivityReduce manufacturing costWork manipulationCounter-pressure devicesEngineeringThree dimensional shape

Owner:JILIN UNIV

Plate rolling mill and plate rolling method

ActiveCN101918155ALarge deflectionConducive to loadMetal rolling stand detailsRoll mill control devicesWork rollElectric motor

Disclosed is a plate rolling mill wherein a kiss roll-tightening state such as zero point adjusting work before rolling, and deviations in offset of work rolls in the right / left or up / down directions of a rolling mill during rolling are eliminated, and such problems as warpage of a plate and meandering or camber caused by a thrust force produced between a work roll and a reinforcing roll are eliminated. The plate rolling mill comprises a pair of upper and lower work rolls being driven by an electric motor, a pair of upper and lower reinforcing rolls for supporting rolling reactions being loaded on to the work rolls by touching the work rolls, and a device for loading an external force substantially in the horizontal direction on to the upper and lower work rolls, respectively, characterized in that the external force in the horizontal direction being loaded on to the work rolls is in the same direction as the horizontal components of rolling reactions being loaded on to the work rolls by offset in the rolling direction, and the external force in the horizontal direction loaded on to the work rolls is supported by the project block of a rolling mill housing or a supporting member of a work roll chock. A plate rolling method using the plate rolling mill is also provided.

Owner:NIPPON STEEL CORP

Methods of Shifting and Bending Rolls in a Rolling Mill

InactiveUS20130104617A1Small rotationImprove bearing lifeMetal rolling stand detailsRolling equipment maintainenceWork rollBending force

An improved roll bending system is described for the work rolls and intermediate rolls in a six high mill. New bending blocks apply improved roll bending forces to the roll chocks, and additionally, are designed to move vertically and rotate, which provide important benefits to maintenance and enhance the rolling operation. Additionally, important related details to the mill operation and bending blocks provide operational improvements during roll changing.

Owner:I2S

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com