Cold-rolling mill and its rolling method

A technology of cold rolling mills and rolling mills, which is applied in the direction of rolling mill control devices, metal rolling, metal rolling, etc., and can solve problems such as strip shape deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0101] Several embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

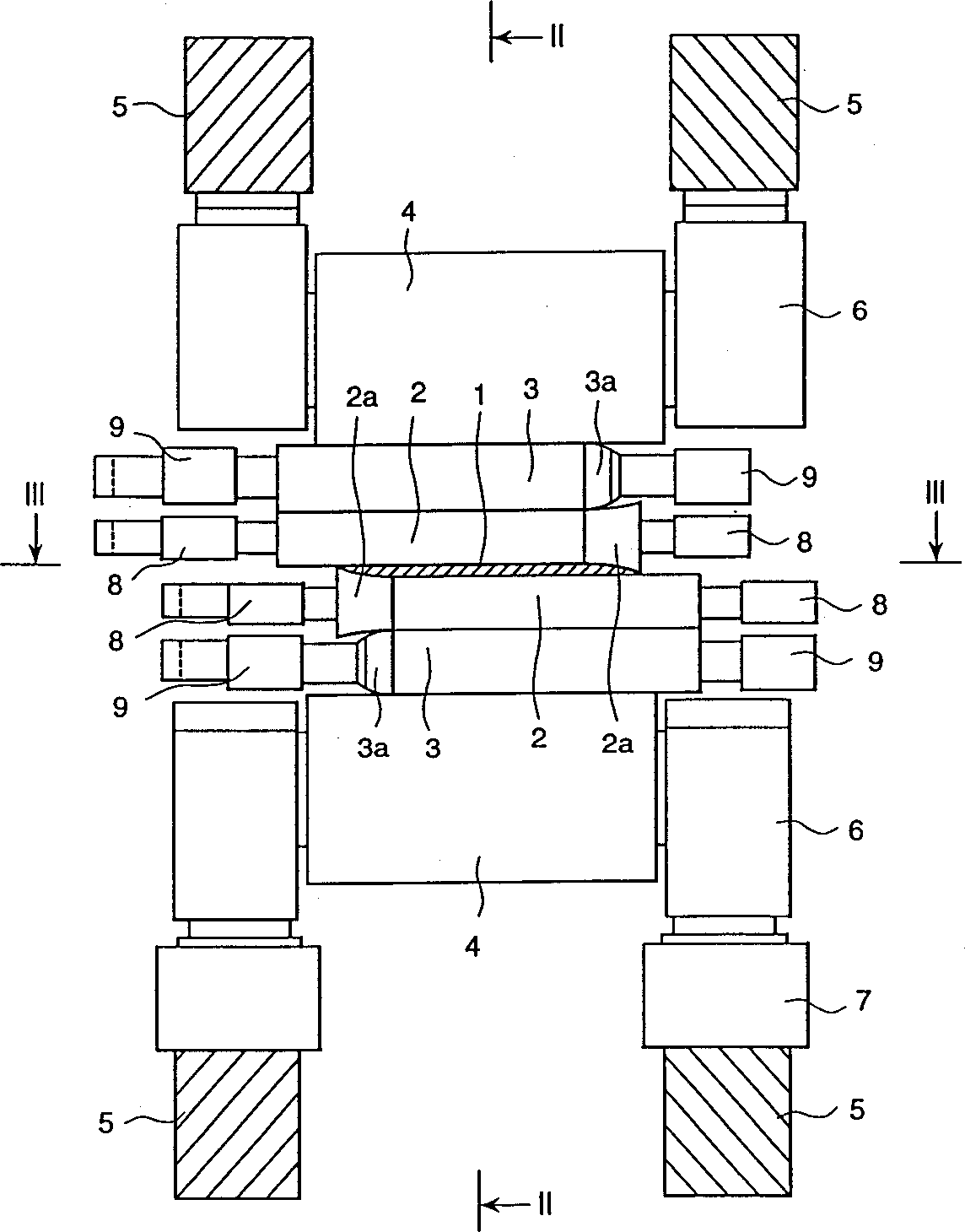

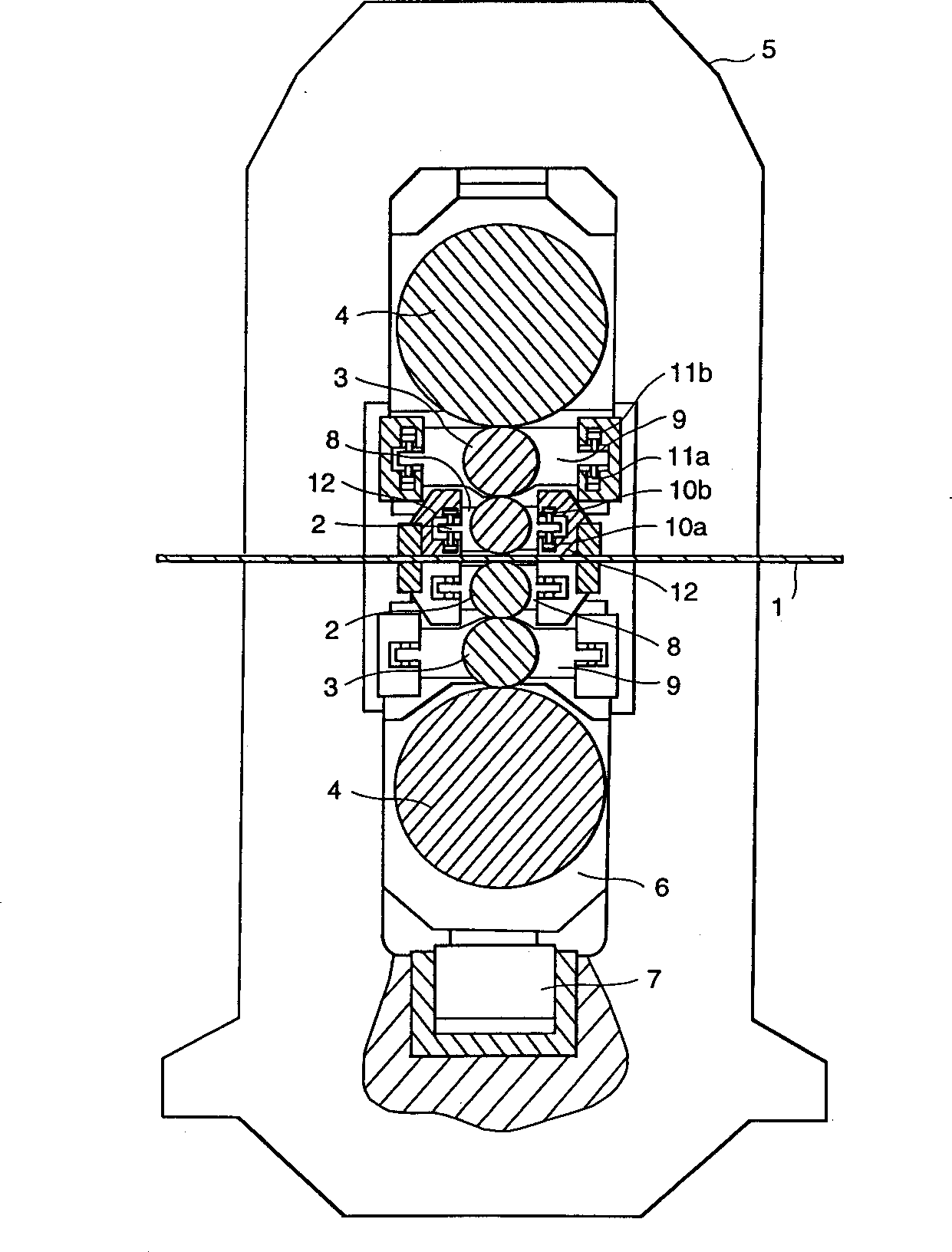

[0102] figure 1 A vertical front sectional view of a six-high rolling mill (cold rolling mill) showing one embodiment of the present invention.

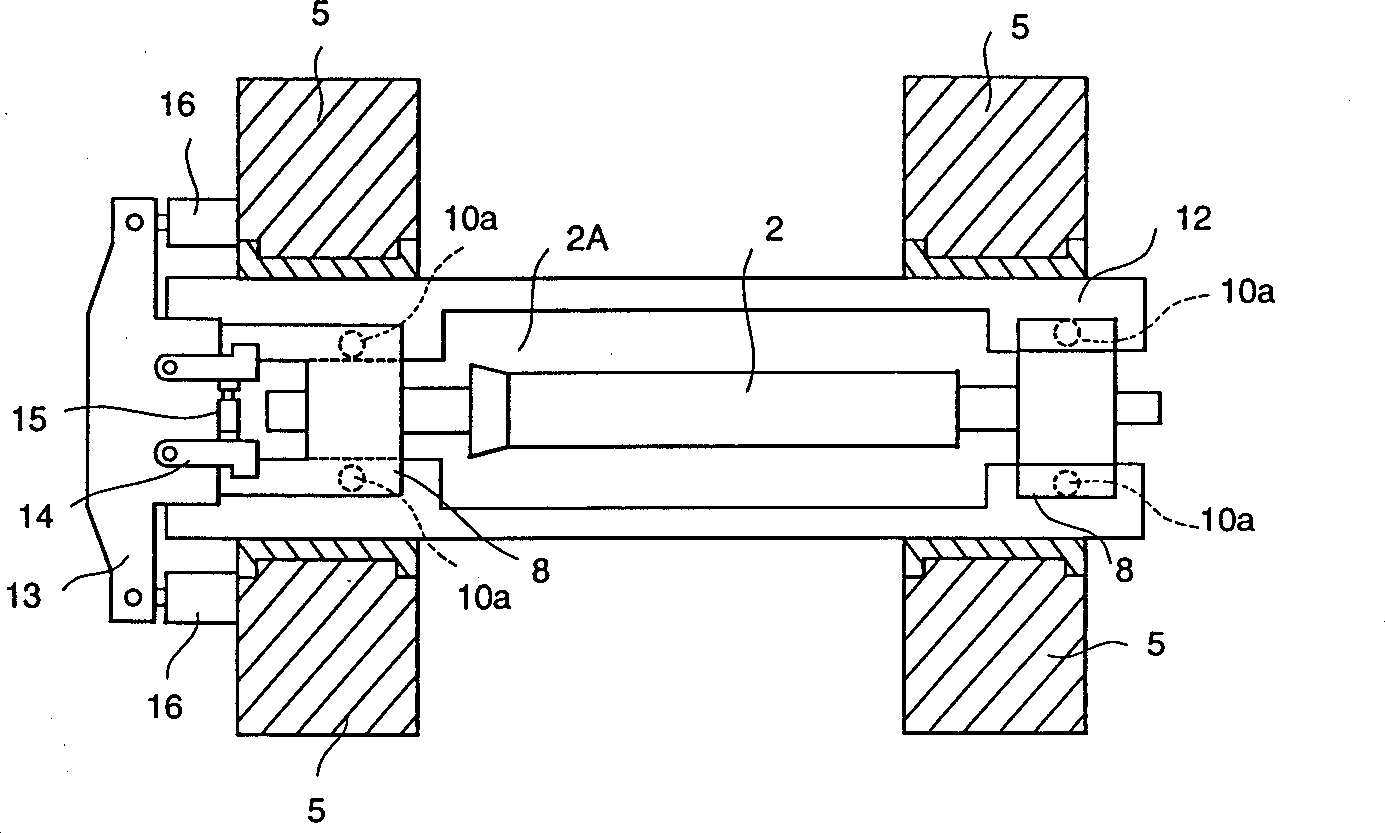

[0103] figure 2 with image 3 respectively show along the figure 1 Cross-sectional views of lines II-II and III-III of the embodiment.

[0104] exist Figure 1~3 Among them, the six-high rolling mill has a work roll 2 that directly contacts the strip 1 and rolls the strip 1, an intermediate roll 3 that contacts the work roll 2, a backup roll 4 that contacts the intermediate roll 3, and a back-up roll 4. Bearing box 8, and the frame 5 supporting each roll by bearing box 8. The hydraulic jack 7 positioned on the bottom of the frame 5 makes the bearing housing 6 of the support roll 4 rise and fall to adjust the pressure applied to the strip 1 . The work roll 2 and the intermediate roll 3 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com