Roller device of cold calender

A roll device, cold rolling mill technology, applied in the direction of roll, counter pressure device, metal rolling stand, etc., can solve the problems of high price, long manufacturing cycle, difficult processing, etc., to improve stability, improve reliability, Create convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

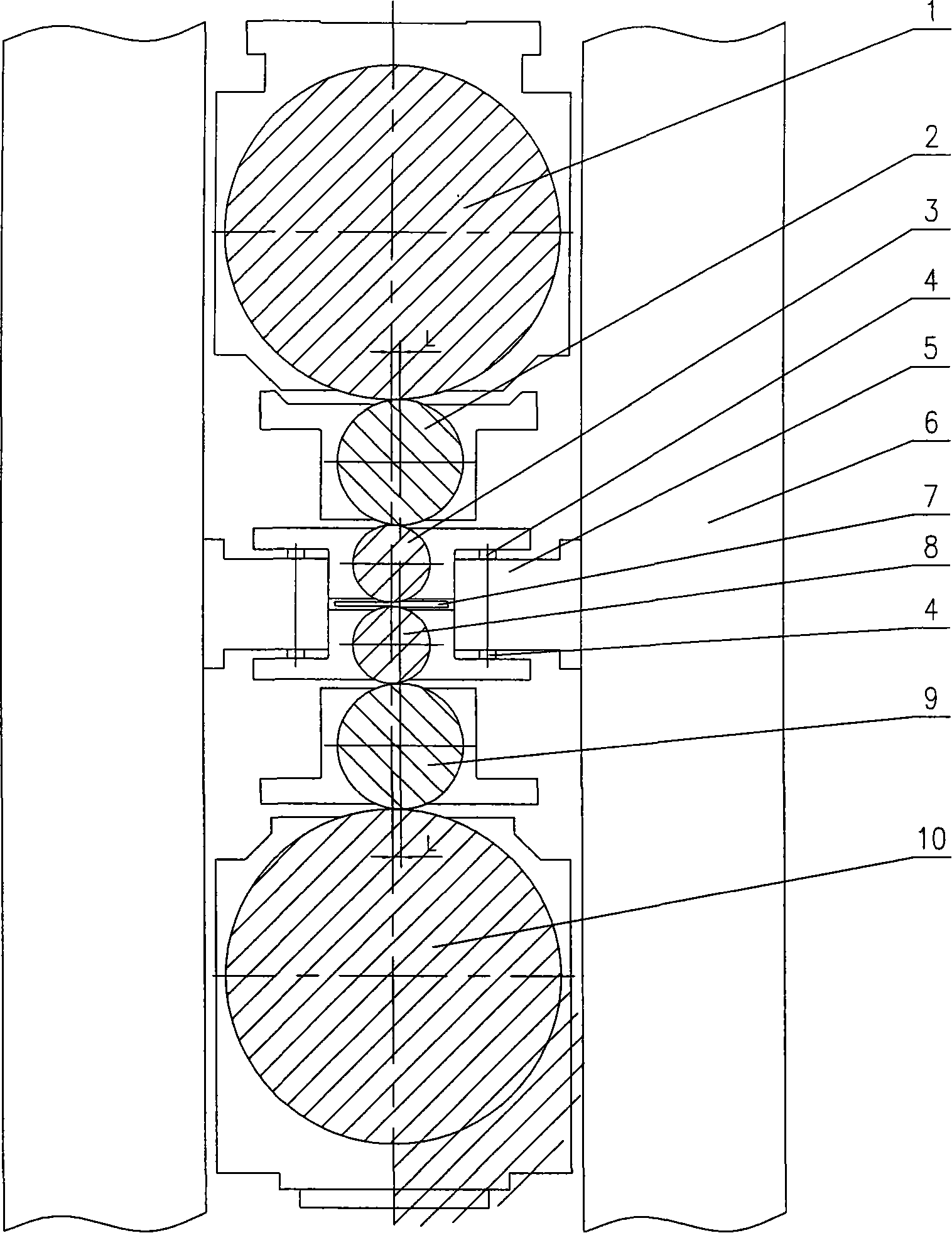

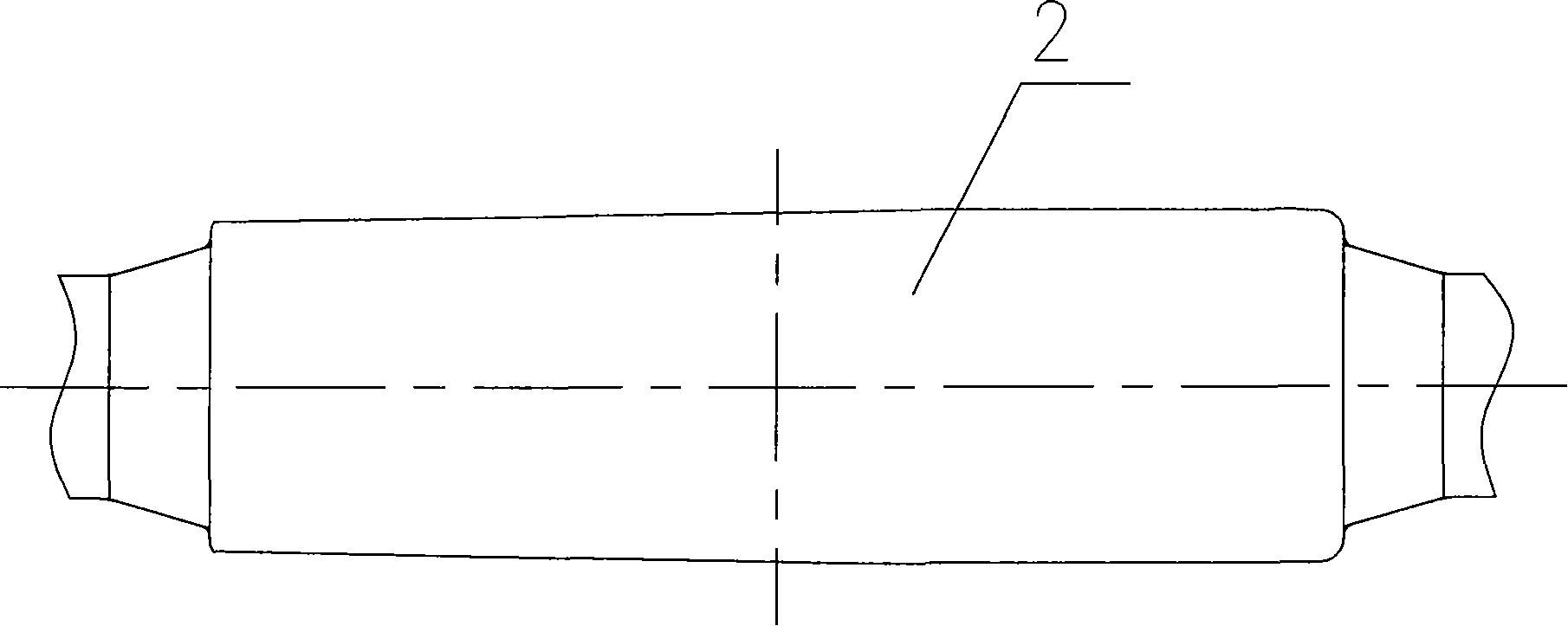

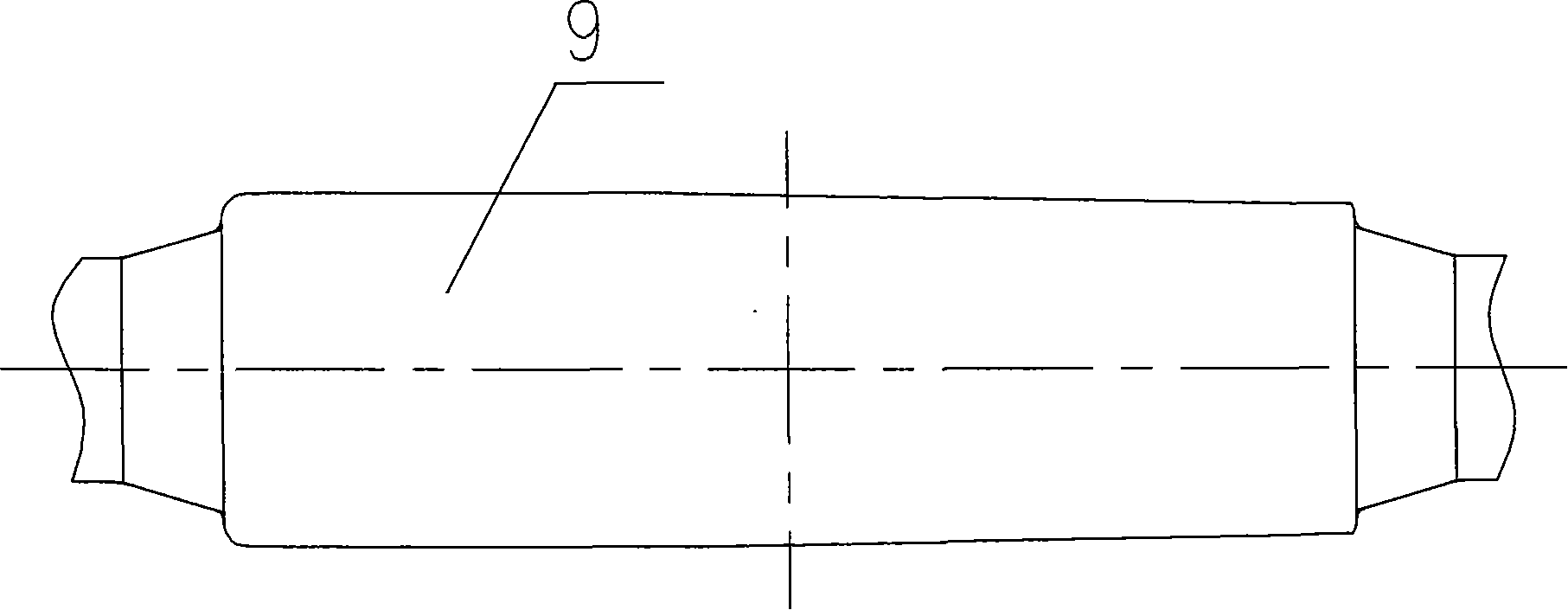

[0014] The present invention mainly consists of upper backup roll 1, upper intermediate roll 2, upper work roll 3, bending roll hydraulic cylinder 4, bending roll cylinder block 5, frame 6, strip 7, lower working roll 8, lower intermediate roll 9 and lower Support roller 10 etc. are made up. The present invention mainly adopts that the upper back-up roll 1, the upper work roll 3, the lower work roll 8, and the lower back-up roll 10 are arranged in the same vertical plane, and the upper intermediate roll 2 and the lower intermediate roll 9 are arranged in the first rolling process biased to the strip 7. In another vertical plane in the opposite direction of the forward direction; the upper intermediate roll 2 and the lower intermediate roll 9 are offset relative to the upper backup roll 1, the upper work roll 3, the lower work roll 8 and the lower backu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com