Patents

Literature

86results about How to "Guaranteed stiffness requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

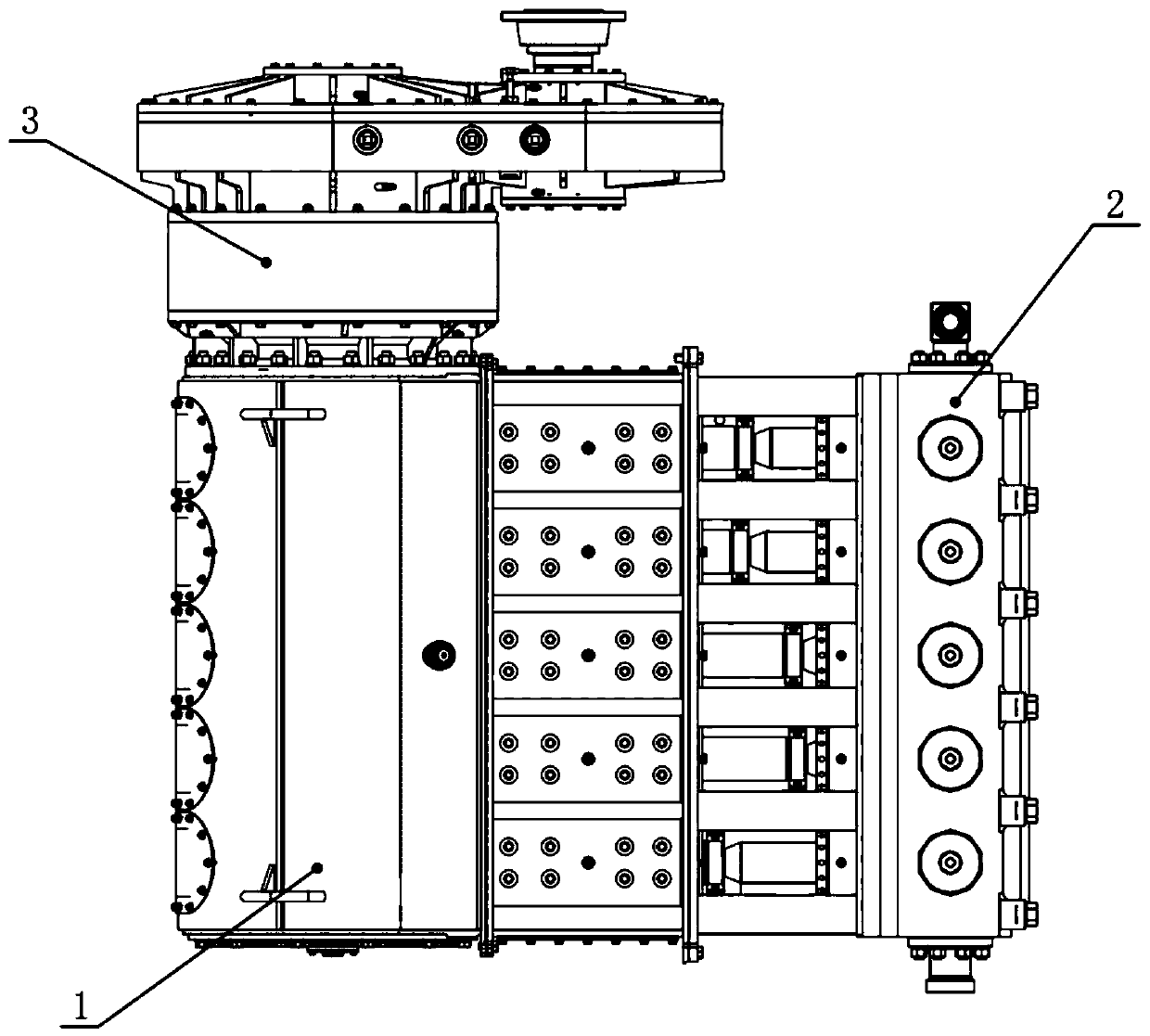

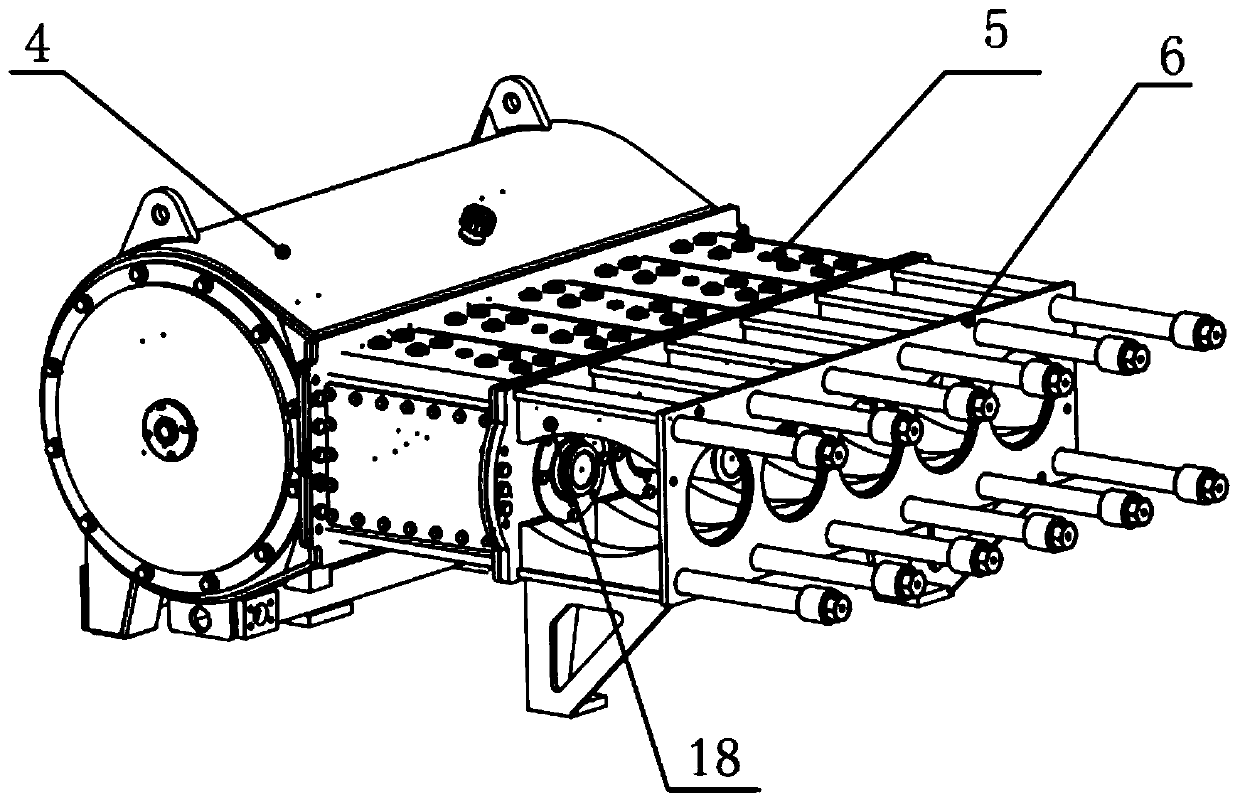

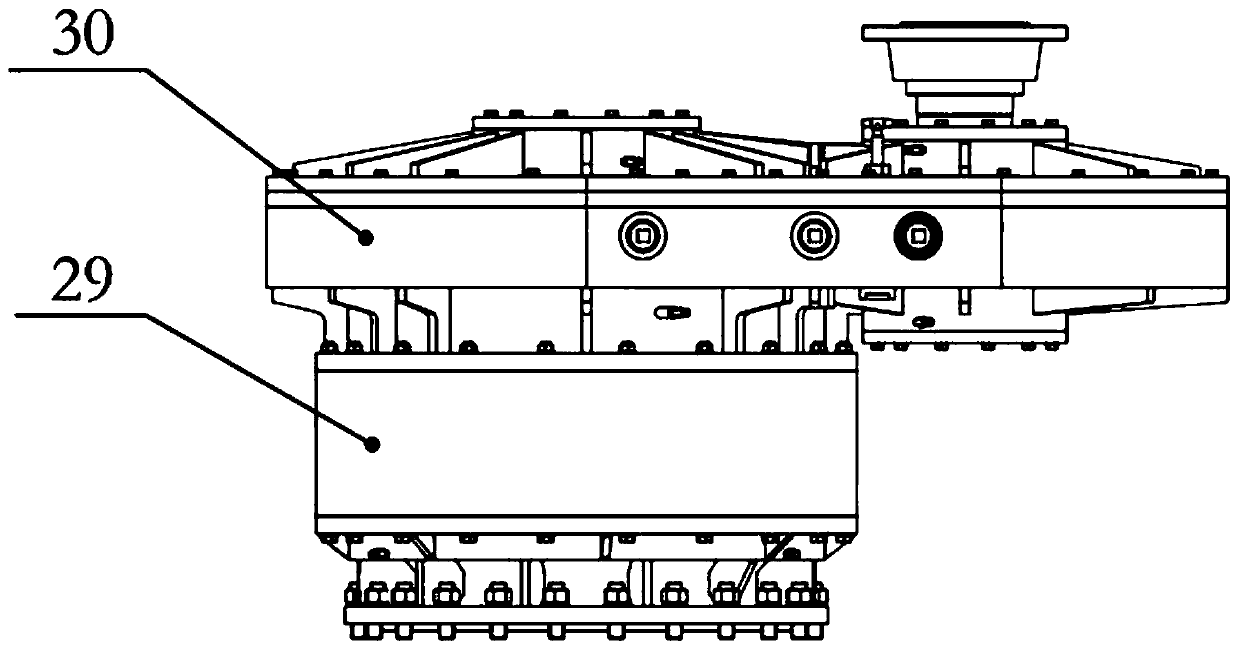

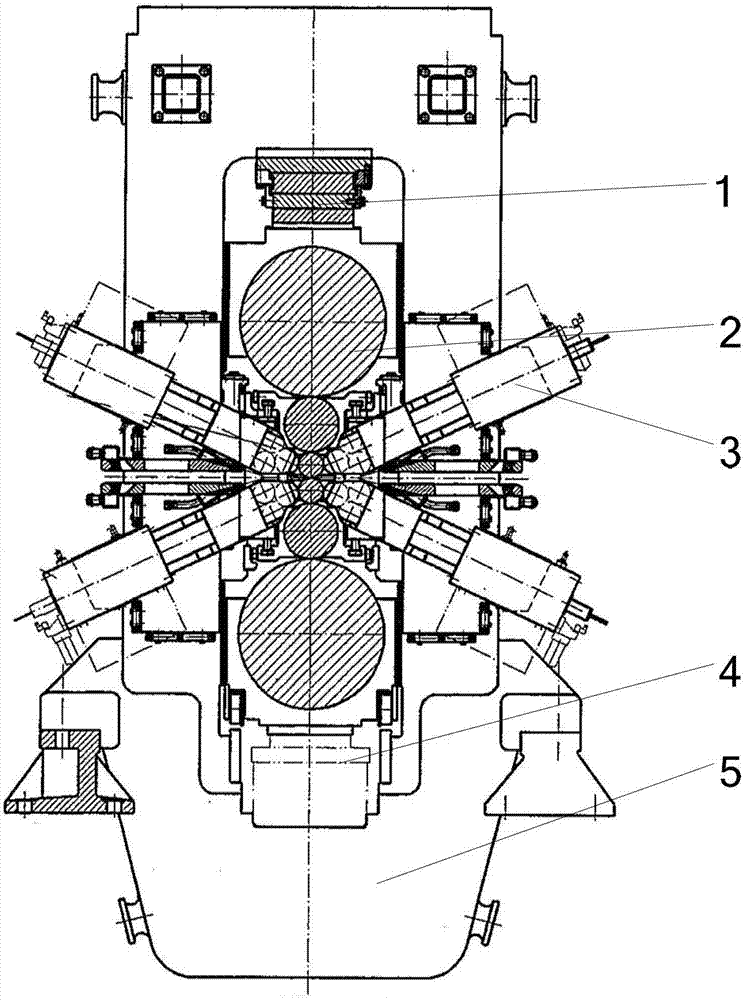

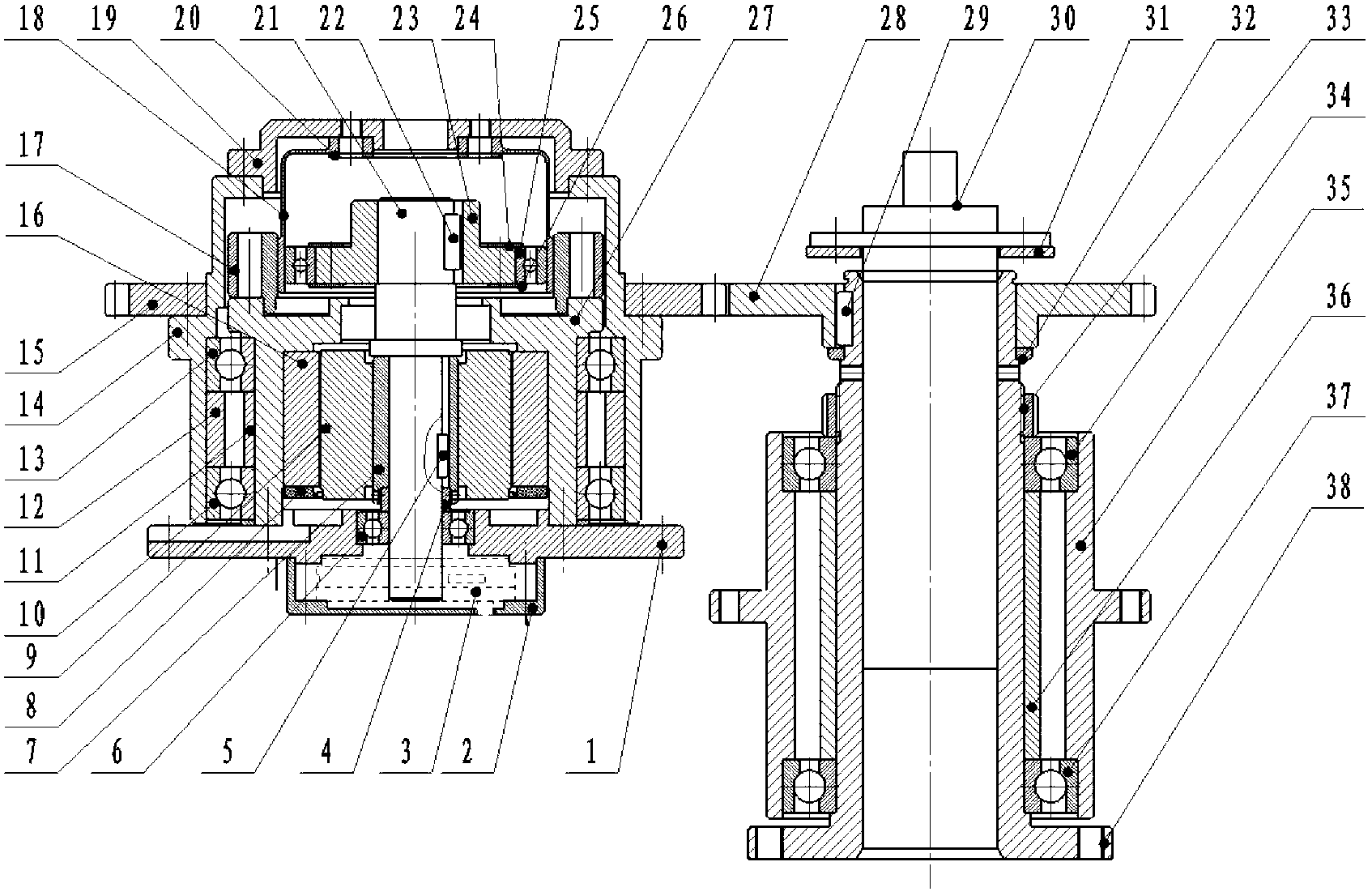

Super-power five-cylinder plunger pump

PendingCN109869294ALess equipmentSave on-site work spaceGearboxesPositive displacement pump componentsElectric driveCentre of rotation

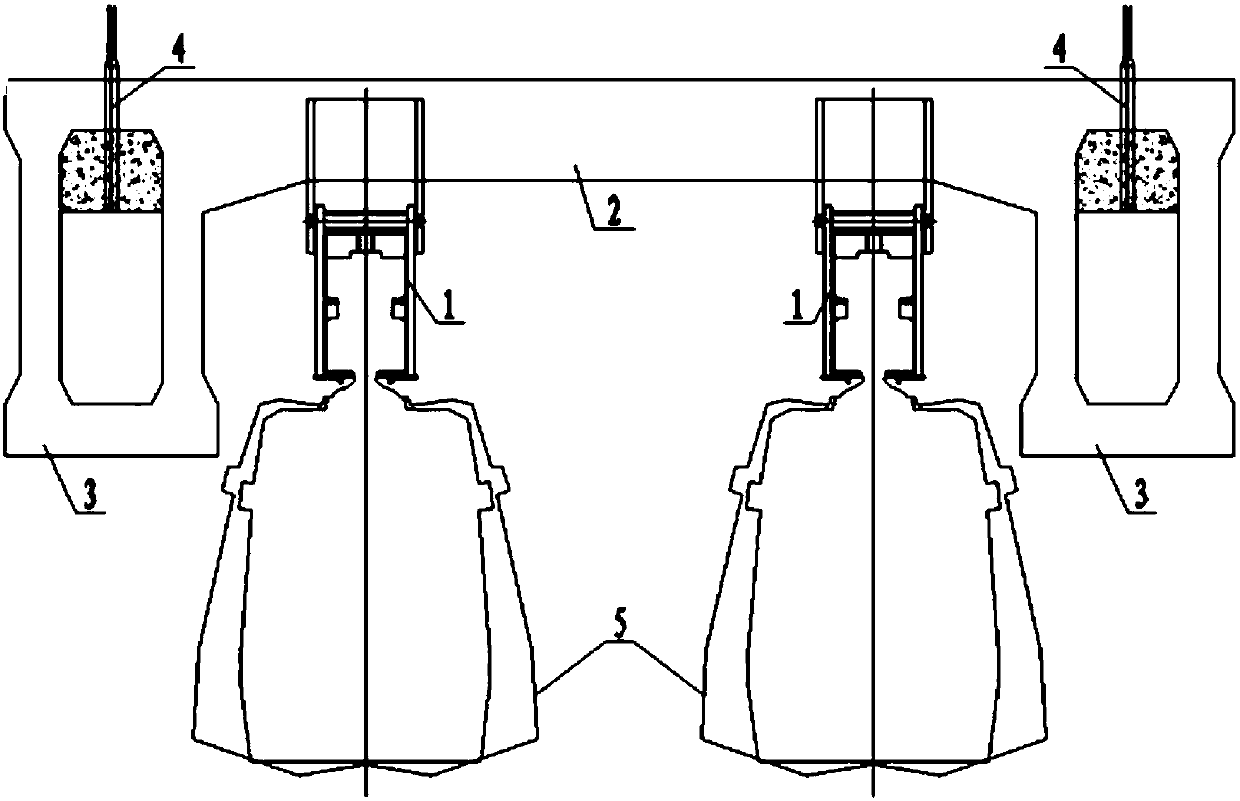

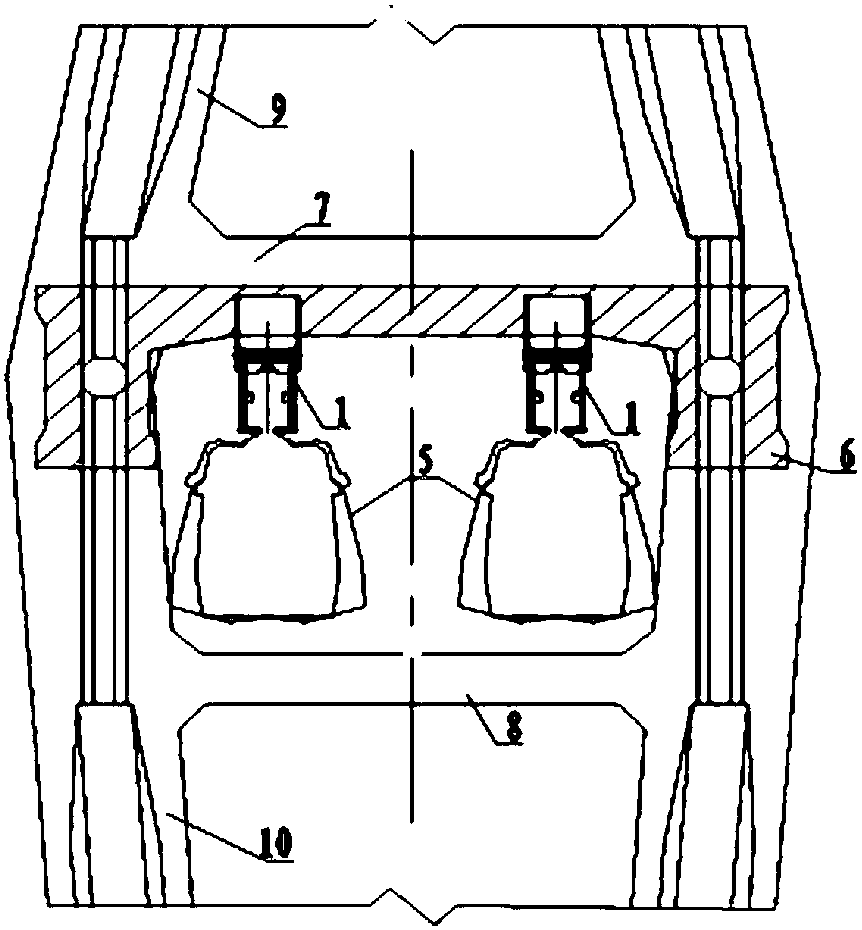

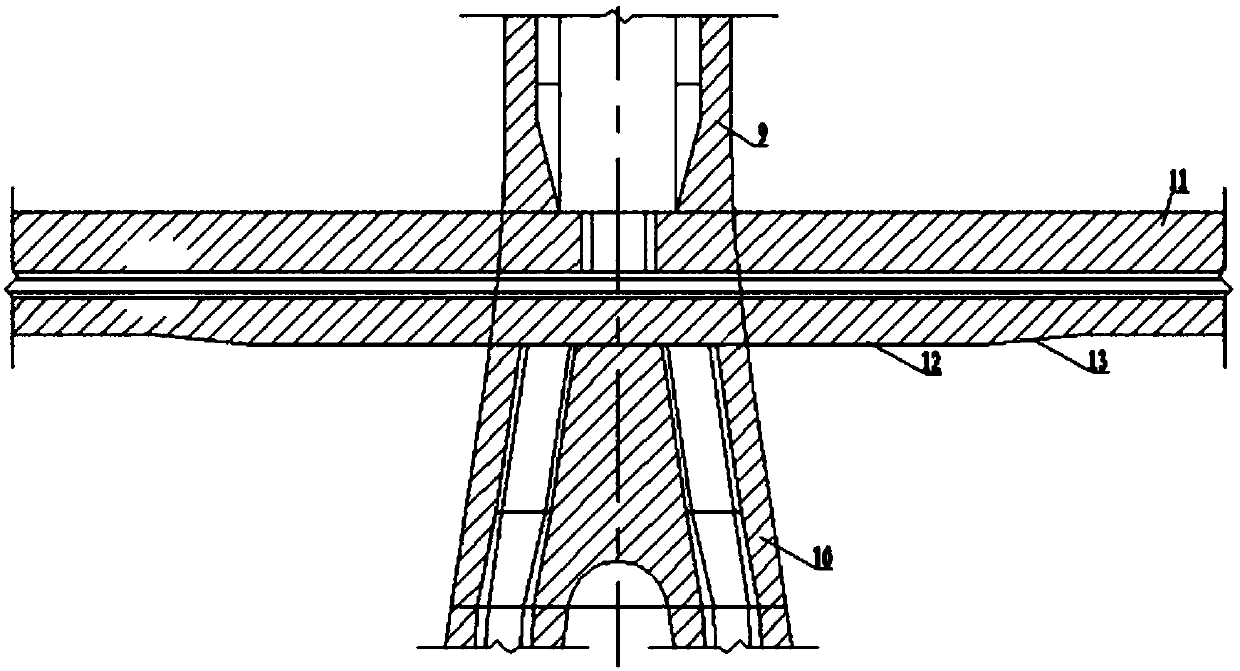

The invention discloses a super-power five-cylinder plunger pump. The super-power five-cylinder plunger pump comprises a power end assembly, a fluid-power end assembly and a reduction box assembly; the power end assembly adopting a sectional type structure design includes a crankshaft box body, a crosshead box body and a space-stop rack, one end of the crosshead box body is connected with the crankshaft box body, and the other end of the crosshead box body is connected with the space-stop rack; the fluid-power end assembly is arranged at one end of the space-stop rack, and the fluid-power endassembly passes through the space-stop rack and the crosshead box body in sequence and is connected with the crankshaft box body through bolts; and the reduction box assembly is connected with the crankshaft box body, a crankshaft in the crankshaft box body is forging alloy steel, the crankshaft includes six shaft necks and five crank threw, each crank throw is arranged between two adjacent shaftnecks, and the distance between the crank threw and the rotating center of the crankshaft is 110mm to 160 mm. The super-power five-cylinder plunger pump has the beneficial effects that the rated inputpower of the super-power five-cylinder plunger pump is 5000 hp, so that the problem that high-power motors cannot be matched with the plunger pumps of corresponding specifications in electric drive fracturing is solved, and the contradictions that the conditions in oil and gas well fields are limited and the matching of fracturing equipment is much is further solved at the same time.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH

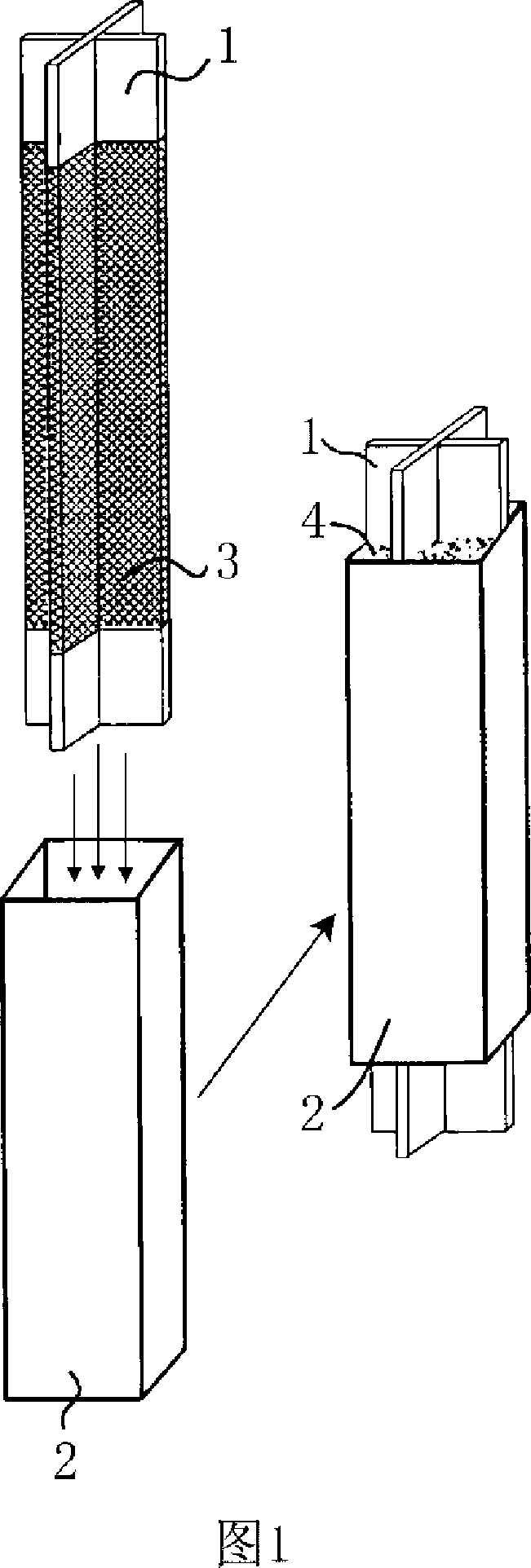

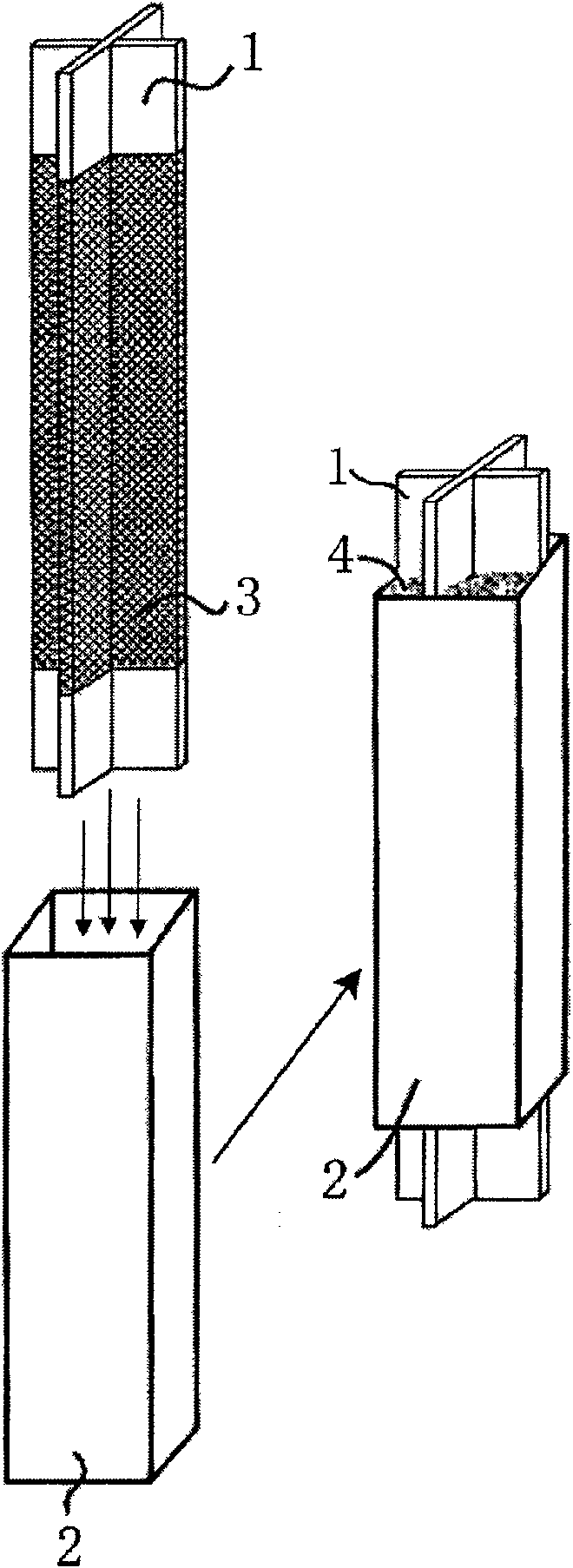

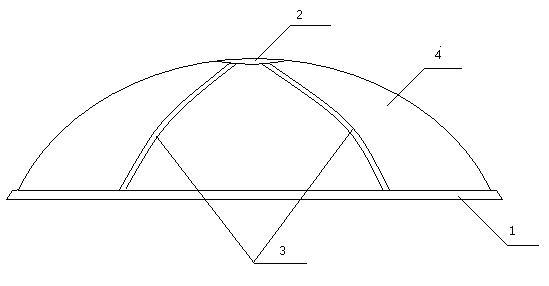

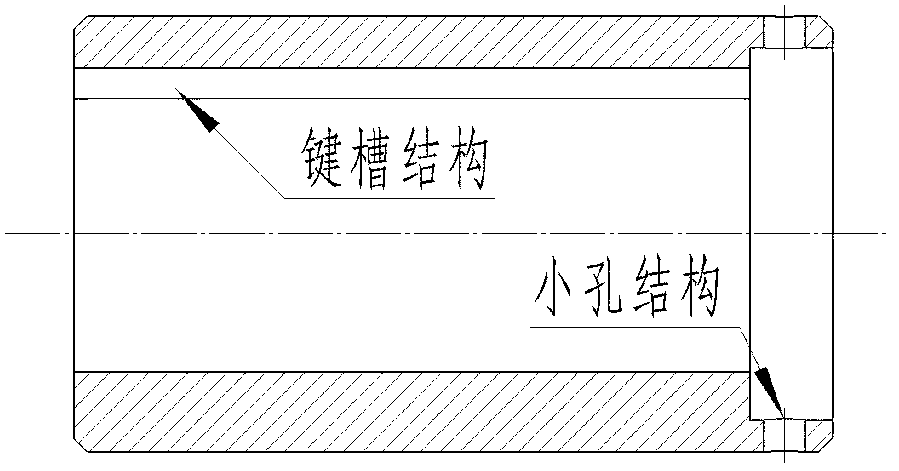

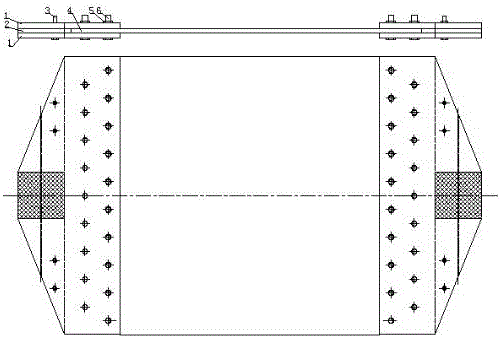

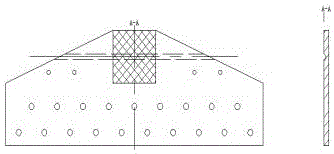

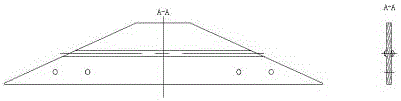

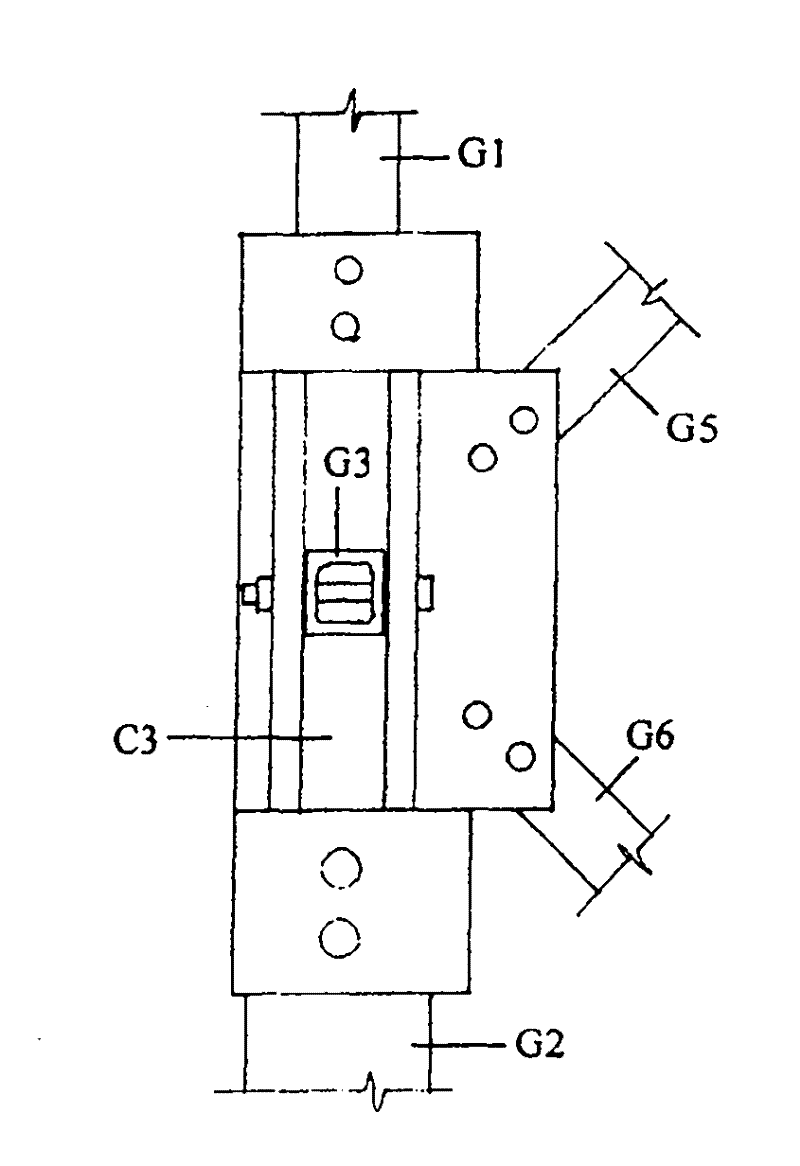

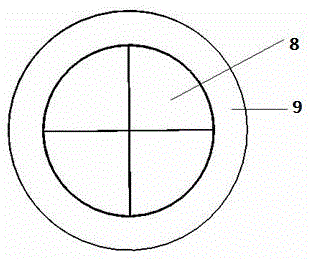

Double-layer bushing crisscross flexuosity restriction support with transverse diaphragm

InactiveCN101105054ASolve the problem of limited lateral expansionPossibility to avoid low-order bucklingShock proofingCruciformCompressible material

A cruciform buckling restrained brace with transverse partition double-layered bushing is provided. The core steel brace has a cruciform cross section, and comprises a middle segment (buckling segment) as major body with a smaller width, two distal end segments (extension segments), a transition segment between the buckling segment and the extension segment, and a transverse partition arranged in the middle of the buckling segment. Outer restraining steel bushings are positioned respectively at two sides of the transverse partition. An inner steel bushing is arranged between the outer restraining steel bushing and the core steel brace and has a cruciform cross section. The space between the inner steel bushing and outer restraining steel bushing is packed with fillers. An anti-adhesion material is coated tightly on the surface of the buckling segment and transition segment of the core steel brace, with a gap between the anti-adhesion material and the inner steel bushing and filled with a compressible material. The invention has the advantages of simple structure, low fabrication cost, suitability for streamline production, and wide application in high-rise buildings, towering buildings, and highway and railway bridges. The invention helps to increase the structural rigidity, improve the capacity of energy dissipation of the whole structure, and prevent earthquake disaster.

Owner:CHINA ACAD OF BUILDING RES +2

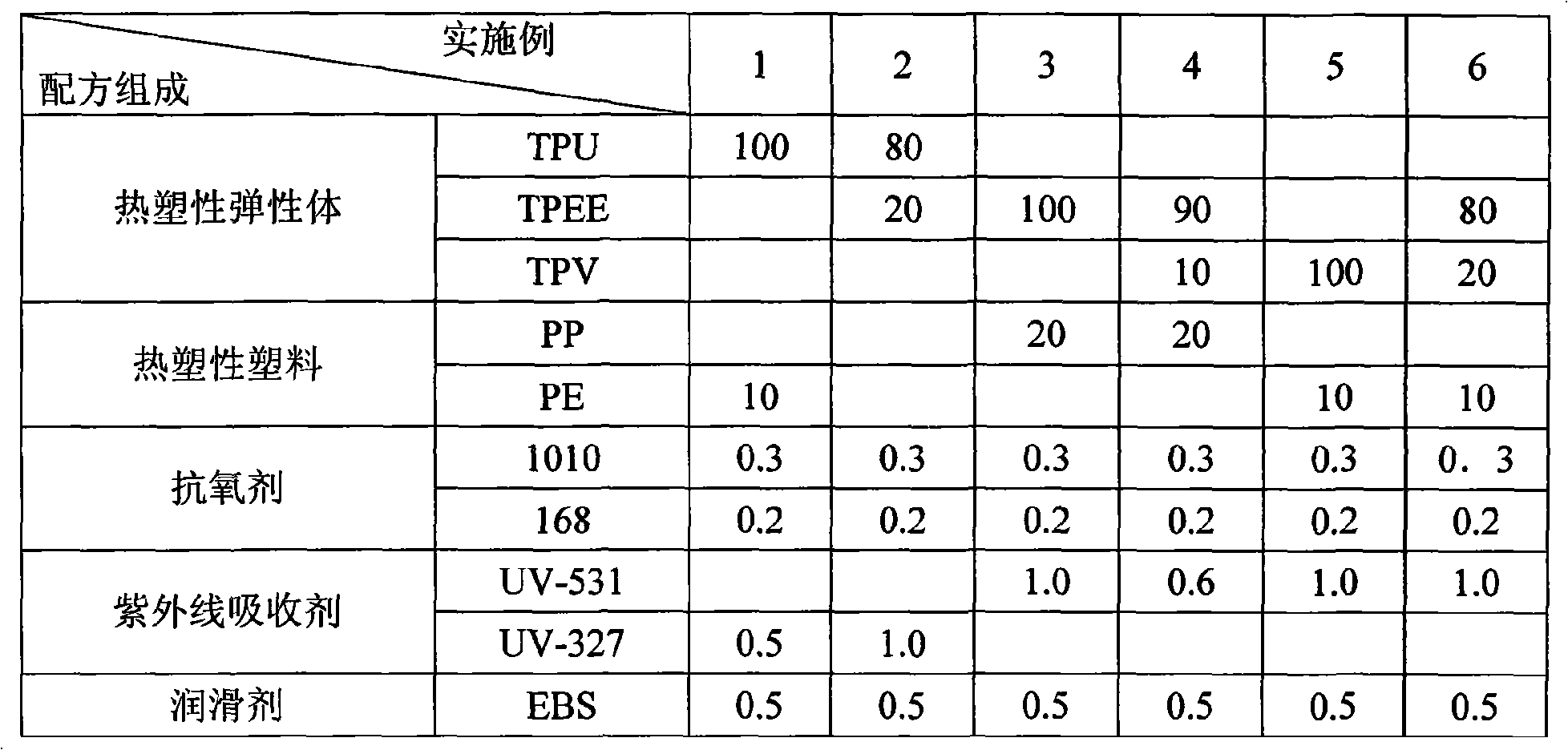

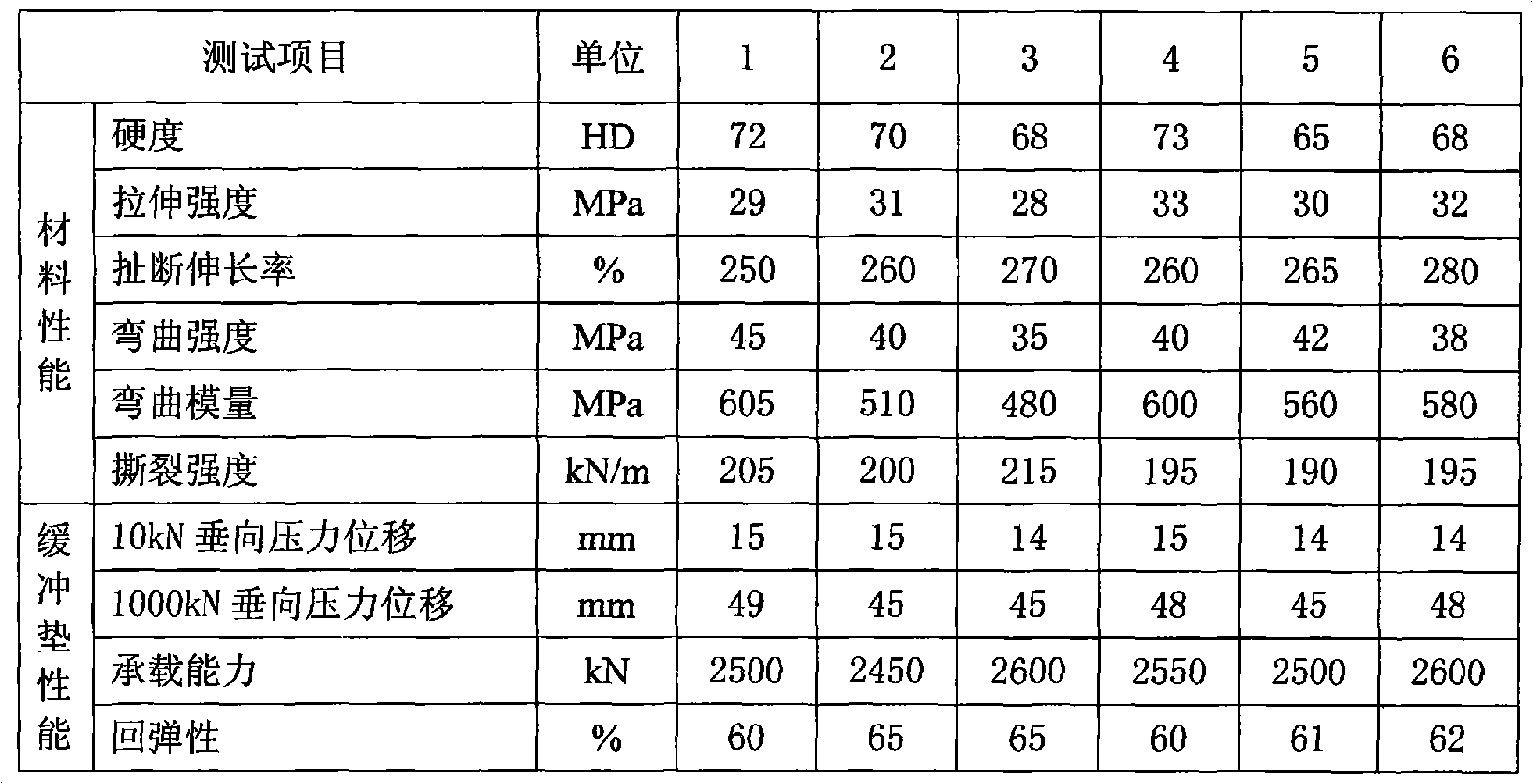

Method of preparing thermoplastic elastomer compound material and product thereof

InactiveCN101550281AGood high pressure resilienceSmall permanent deformationThermoplasticInjection molding machine

Method of preparing thermoplastic elastomer compound material and product thereof, applying post forming technics. The post forming technics is: first prepare the mold core by the method of injection molding or compression molding; then put the mold core into the mould and produce product with mold core by the compression molding method, taking the mold core out of the product by mechanical crushing, getting the product of hollow thermoplastic elastomer compound material. The post forming method includes following steps: 1) preparing the mold core by the injection molding of the compression molding method; 2) putting the mold core into the mould and producing product with the mold core by the injection molding method; 3) taking the mold core out of the product by mechanical crushing to get the hollow product. 4) the crushed mold core can be reclaimed for recreating use. The thermoplastic elastomer product prepared by the invention provided moulding preparation method is in formula (in mass parts proportioning): thermoplastic elastomer 100parts; thermoplastic plastics 1-50 parts; anti-oxidant 0.5-10 parts; ultraviolet absorbent 0.5-10 parts; lubricants 0.1-5.0 parts.

Owner:株洲时代工程塑料制品有限责任公司

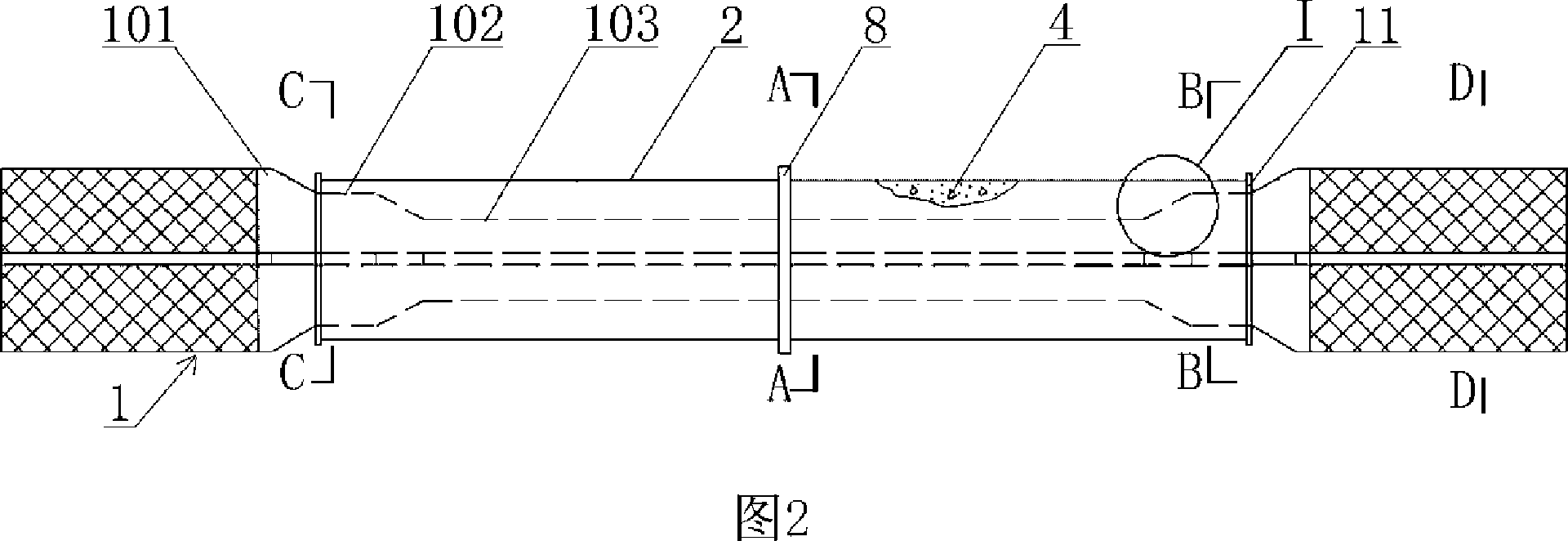

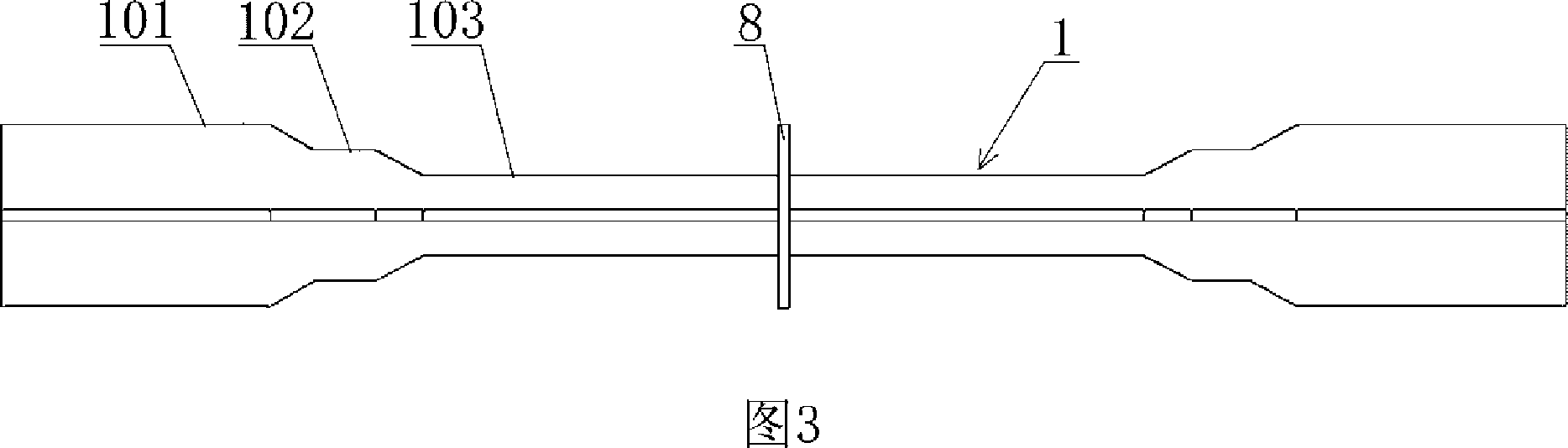

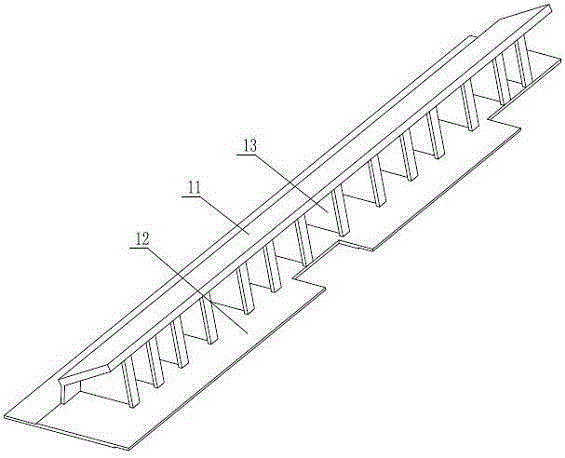

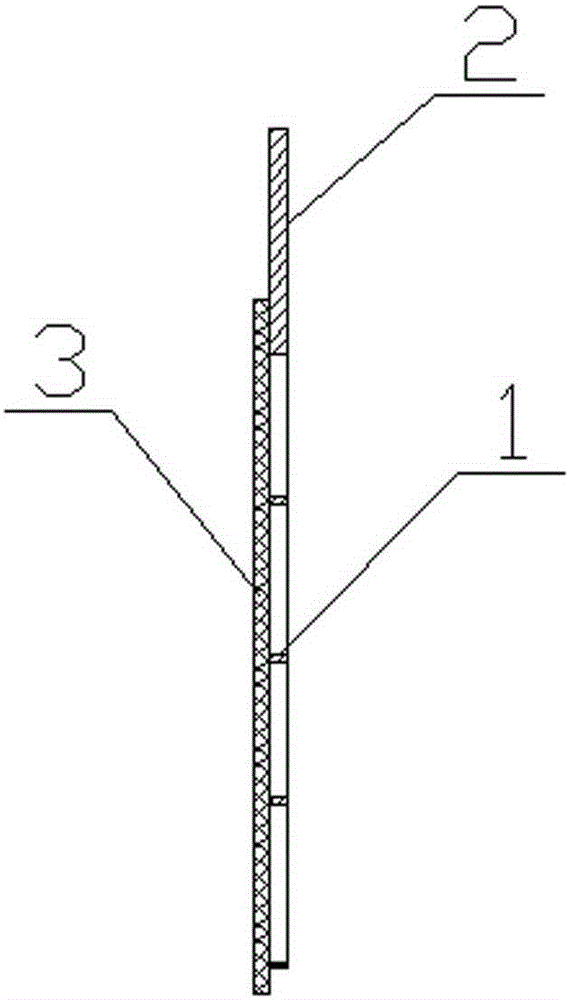

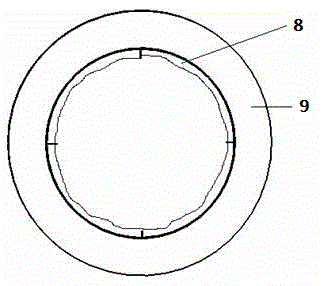

Double-layer bushing straight-line flexuosity restriction support with transverse diaphragm

InactiveCN100560884CSolve the problem of limited lateral expansionEliminates the problem of limited lateral expansionShock proofingCompressible materialCruciform

A linear buckling restrained brace with transverse partition double-layered bushing is provided. The core steel brace comprises a middle segment (buckling segment) as major body with a smaller width, two distal end segments (extension segments), and a transition segment between the buckling segment and the extension segment. The cross section of the buckling segment is shaped like the Chinese character 'Yi'. The cross sections of the transition segment and extension segment are cruciform. A transverse partition is welded in the middle of the buckling segment and provided outside with outer restraining steel bushings at two sides. An inner steel bushing is arranged between the outer restraining steel bushing and the core steel and has a linear cross section with respect to the buckling segment and a cruciform cross section with respect to the transition segment. The space between the inner steel bushing and outer restraining steel bushing is packed with fillers. An anti-adhesion material is coated on the surface of the core steel brace, with a gap between the anti-adhesion material and the inner steel bushing and filled with a compressible material. The invention has the advantages of simple structure, low fabrication cost, suitability for streamline production, and wide application in high-rise buildings, towering buildings, and highway and railway bridges.

Owner:CHINA ACAD OF BUILDING RES +2

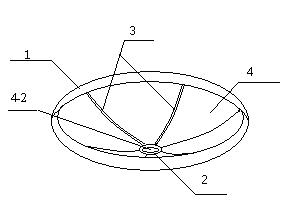

Reflecting surface of deployable antenna based on shape memory polymer and manufacturing method of skeleton structure thereof

ActiveCN101847786AReduce weightThe unfolding process is gentleAntenna adaptation in movable bodiesManufacturing engineeringMechanical engineering

The invention provides a reflecting surface of a deployable antenna based on a shape memory polymer and a manufacturing method of a reflecting surface piece thereof, which relate to a reflecting surface of a deployable antenna and a manufacturing method of a reflecting surface piece. The invention solves the problems of large weight, large volume, complicated structure and unsteady deployment andcontraction of a traditional deployable antenna used for spaceflight. The deployable antenna is formed by splicing an annular power component, an annular reinforcement component, a radial reinforcement component and a reflecting film. The manufacturing method of the reflecting surface piece comprises the following steps of: (1) designing a mold; (2) preparing a shape memory polymer material; (3) coating a fibre reinforced material by using the shape memory polymer material; (4) forming an uncured fibre-reinforced shape memory polymer blank; (5) putting the closed mold into a heating box and heating; and (6) demolding to obtain a skeleton structure taking the fibre-reinforced shape memory polymer as the material. The invention can be used as the reflecting surface of the deployable antennain the field of the spaceflight.

Owner:HARBIN INST OF TECH

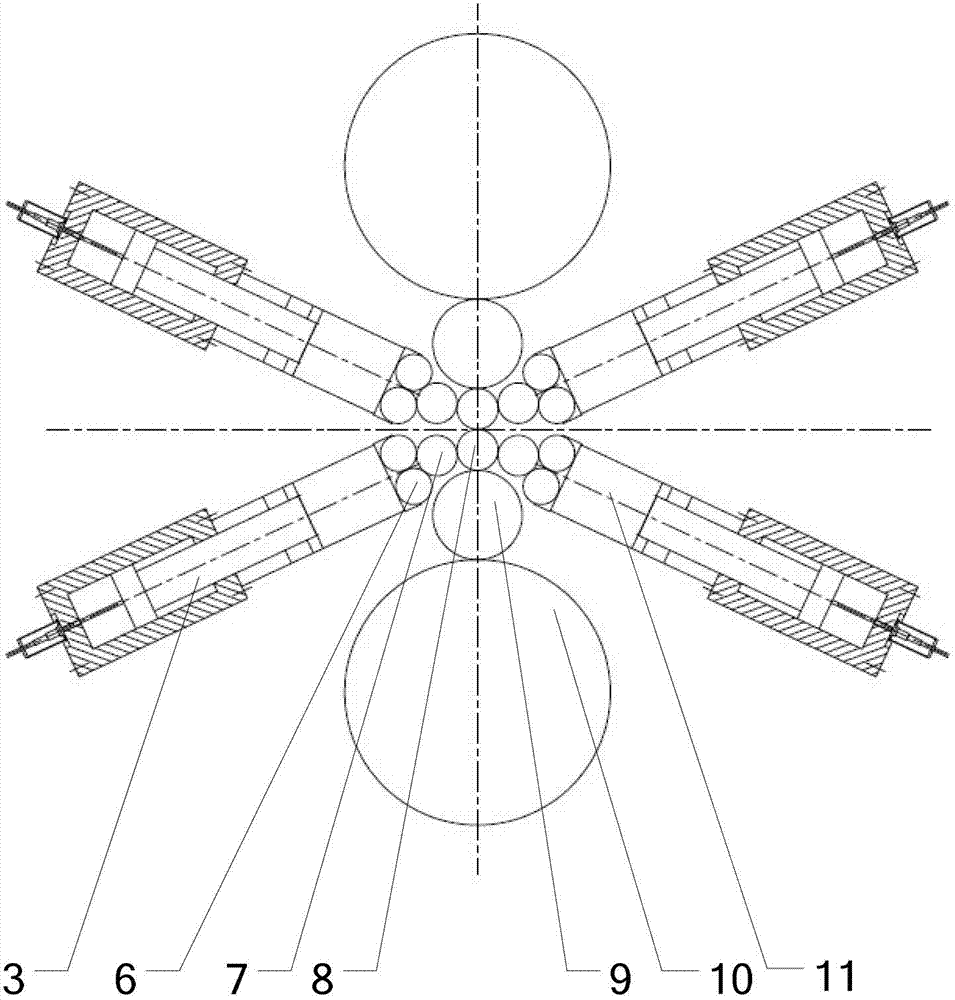

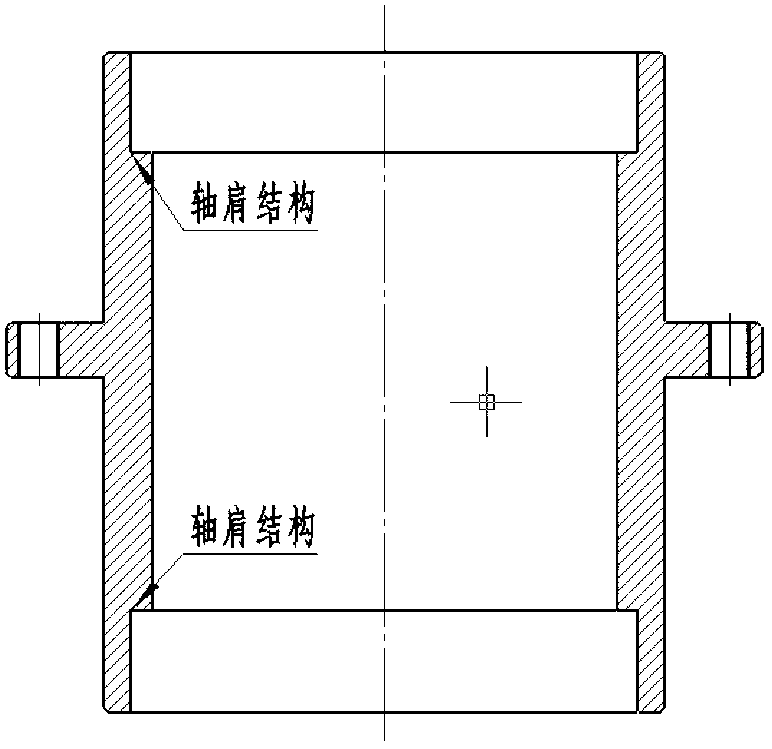

Eighteen-roller rolling mill structure

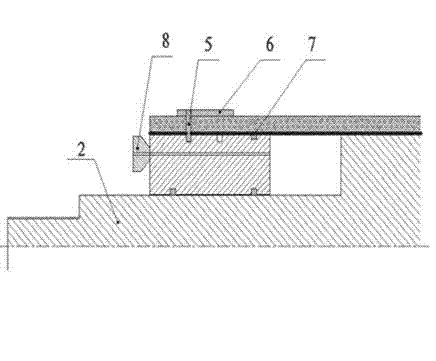

InactiveCN102886382AStrap for easy observationGuaranteed stiffness requirementsMetal rolling stand detailsCounter-pressure devicesEngineeringLubrication

The invention provides an eighteen-roller rolling mill structure. Side supporting devices of working rollers are respectively arranged in the front and at the back of as well as on and below a rolling mill machine frame assembly; each side supporting device comprises a side supporting bearing pedestal, a side roller and a side supporting roller; the side supporting device comprises a side driving cylinder which is provided with a displacement sensor and a servo valve for controlling the advancing and retreating positions of the side supporting device; when in a rolling work, the side supporting positions are set according to various technical parameters, so that the side deformation caused by the working rollers in a rolling process is counteracted and the rigidities of the working rollers are improved; with the adoption of the small-diameter working rollers and a side driving roller system mode, the demand of roller rigidity in the rolling process is ensured, and meanwhile, the rolling demand of an ultra-thin belt material is satisfied; and the rolling mill structure has the following advantages of high rolling mill opening degree, favorable lubrication for the roller and belt material, high speed, convenience to maintain equipment and low manufacturing cost of the equipment.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

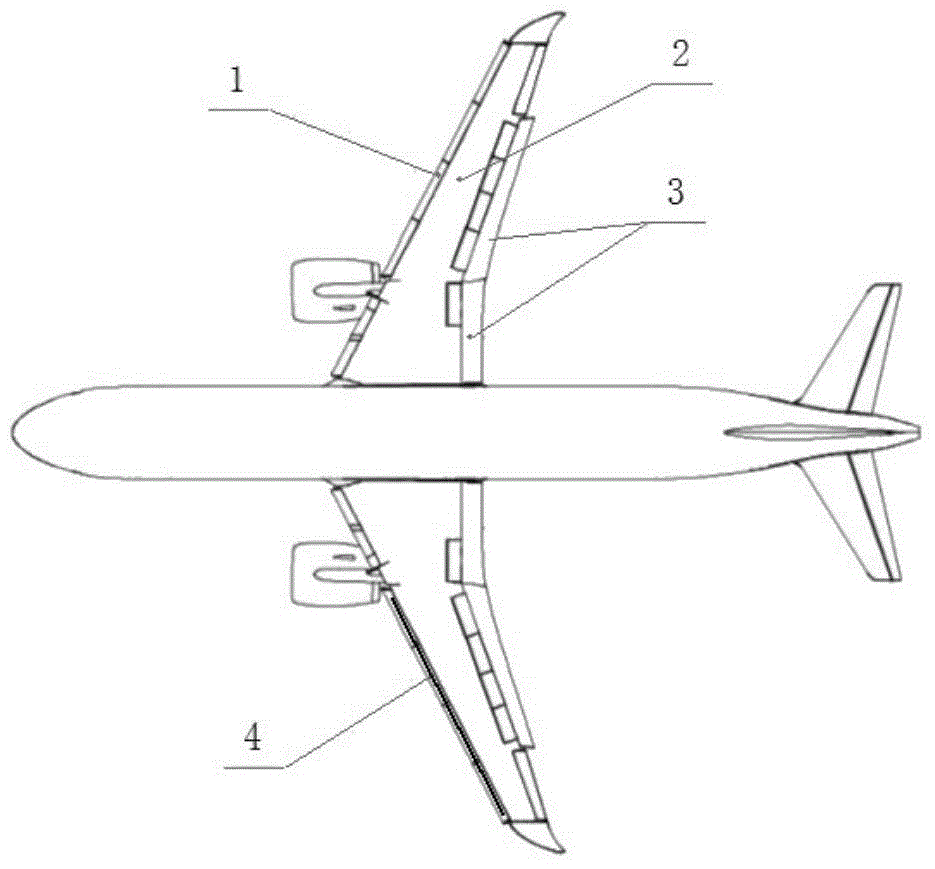

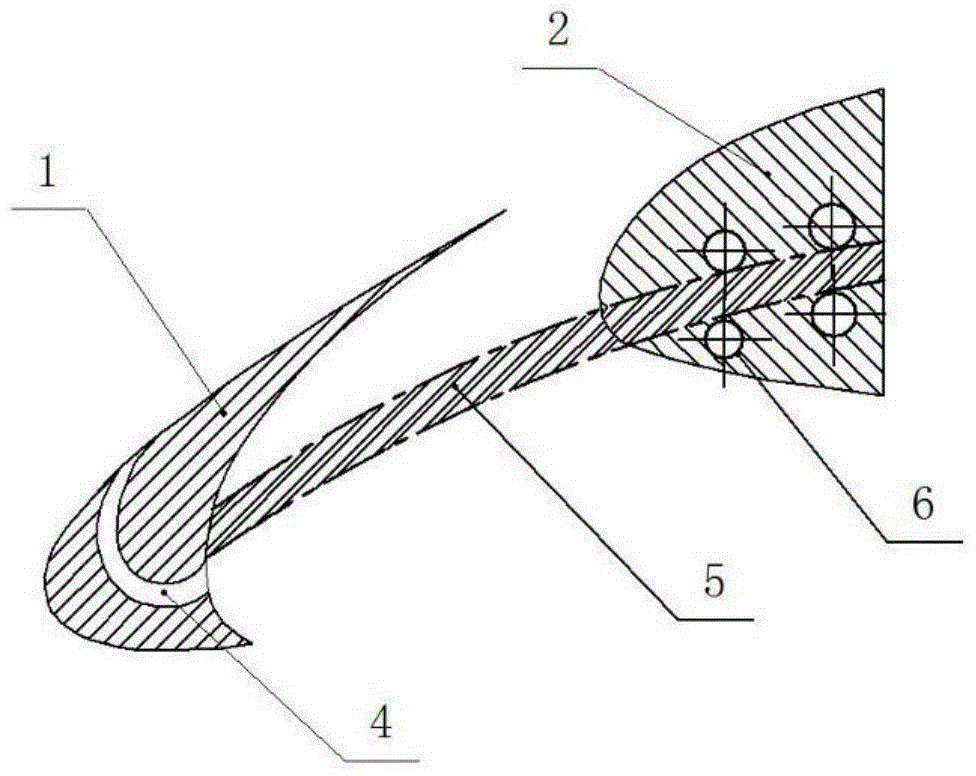

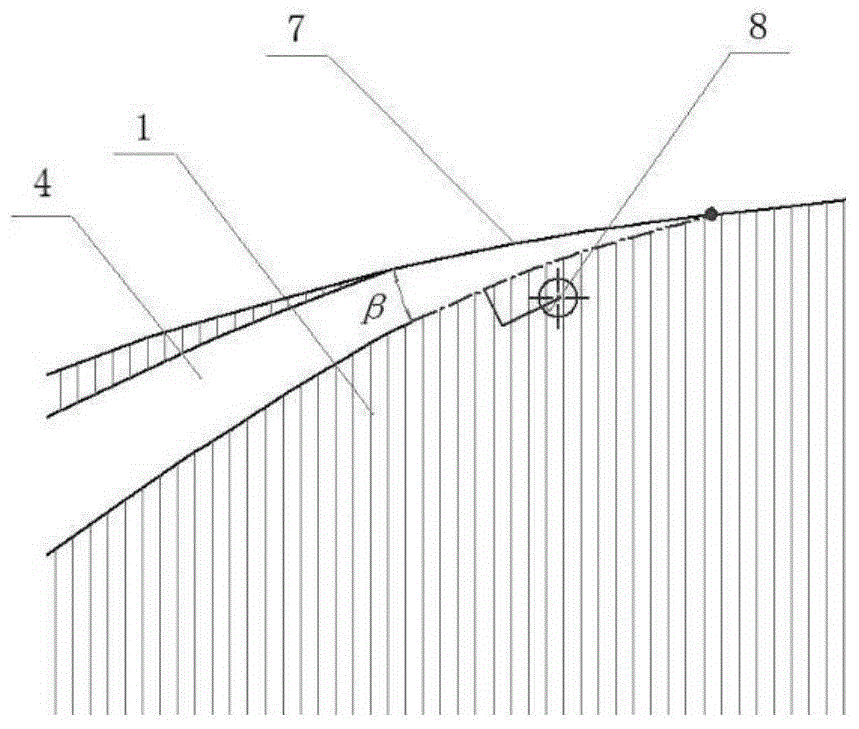

Leading-edge slat with drainage groove and designing method of drainage groove

InactiveCN104608919AImproved stall characteristicsImprove flight safetyWingsAir-flow influencersFlight safetyLeading-edge slats

The invention relates to a leading-edge slat with a drainage groove and a designing method of the drainage groove. By designing the drainage groove with a certain geometric shape, a wide inlet formed in the lower surface and a narrow outlet formed in the upper surface in the leading-edge slat, and by utilizing the pressure difference of the upper and lower surfaces of the leading-edge slat, an air flow with high pressure of the lower surface of the leading-edge slat is introduced into the upper surface of the leading-edge slat by virtue of the drainage groove and is blown out along the tangential direction of the upper surface of the leading-edge slat for blowing down a low-energy air flow piled on the upper surface of the leading-edge slat, repairing a damaged speed type of a boundary layer, lowering the thickness of the boundary layer and improving the ability of the boundary layer to resist adverse pressure gradient, and thus, separation of the air flow, around the leading-edge slat, is delayed, the stalling process of an aircraft is slow, variation of the aircraft lift after stalling is mitigated, and the stalling characteristic of the aircraft is alleviated. According to the invention, the leading-edge slat is applied to some civil aircraft and is capable of postponing the stall angle alpha stall of an aircraft body combination of equal-chord swept back wings of the aircraft by 1 degree when the aircraft is in a typical takeoff / landing state with the flight speed being mach number 0.20 and turning the aircraft into slow stalling from sudden stalling, and the lift variation after stalling is small, so that the stalling prewarning time is effectively prolonged, and the flight safety is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

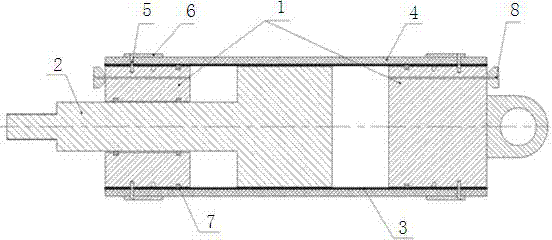

Lightweight high-strength carbon fiber composite hydrocylinder

InactiveCN103591078AIncrease productivityAvoid eccentricityFluid-pressure actuatorsResin matrixHigh intensity

The invention provides a lightweight high-strength carbon fiber composite hydrocylinder. The hydrocylinder comprises metal heads, a hydrocylinder piston, a metal liner formed by a hydrocylinder barrel, fixing parts, metal lantern rings and sealing rings, the metal liner is externally and integrally coated with a reinforcing layer formed by a carbon fiber composite, the metal lantern rings are sleeved outside the reinforcing layer which is formed by taking thermosetting resin as a matrix and carbon fiber as a reinforcement, and the thermosetting resin matrix accounts for 23-40% of the reinforcing layer by weight. Compared with all-metal hydrocylinders in the prior art, the lightweight high-strength carbon fiber composite hydrocylinder has the advantages that strength, rigidity and fatigue resistance of the hydrocylinder are all obviously improved under various working conditions, so that safety of the hydrocylinder is improved effectively, weight is reduced by 30-65%, and the objectives of mechanical pump truck weight reduction and complete truck cost reduction are achieved.

Owner:HENGSHEN

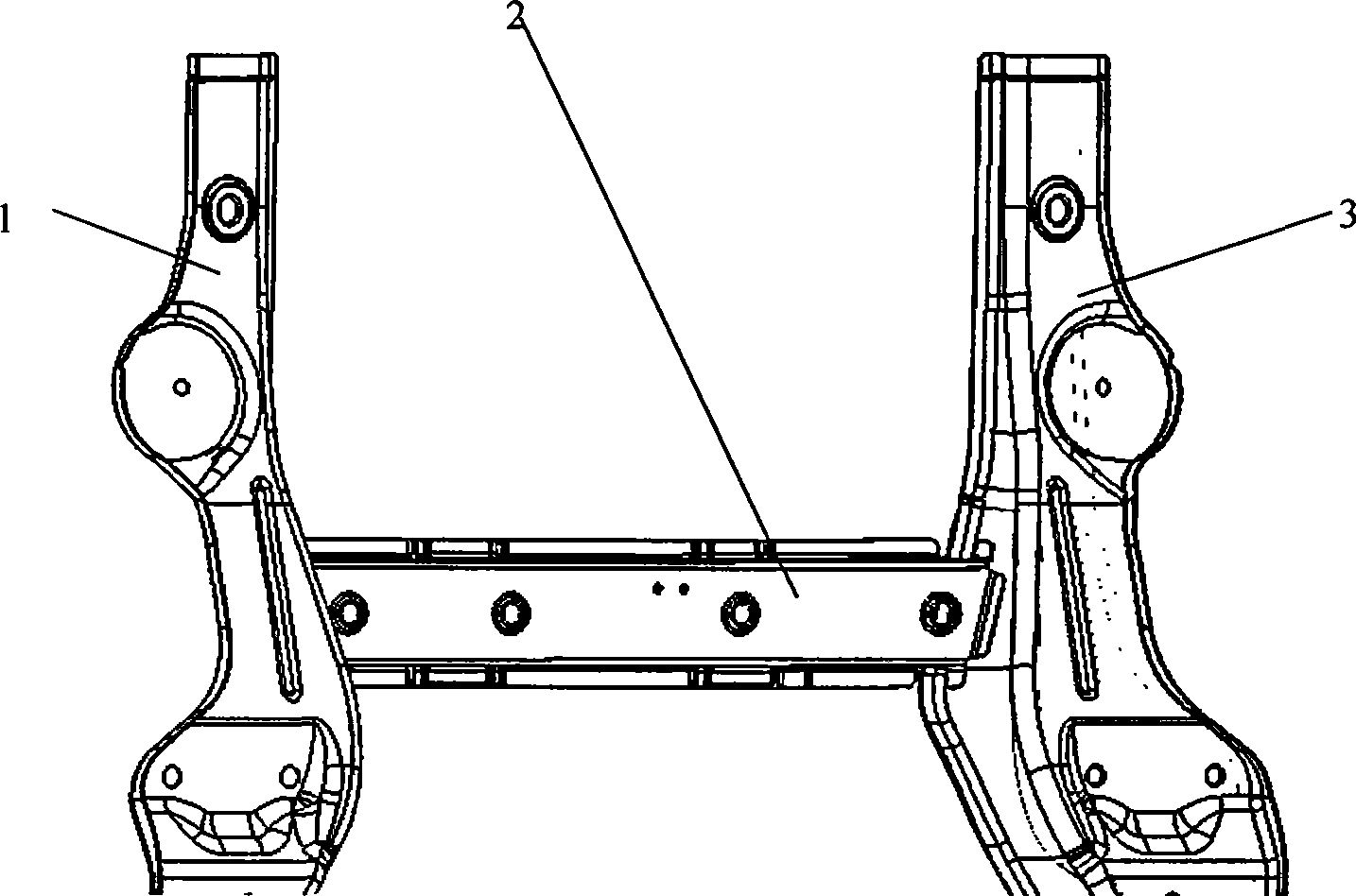

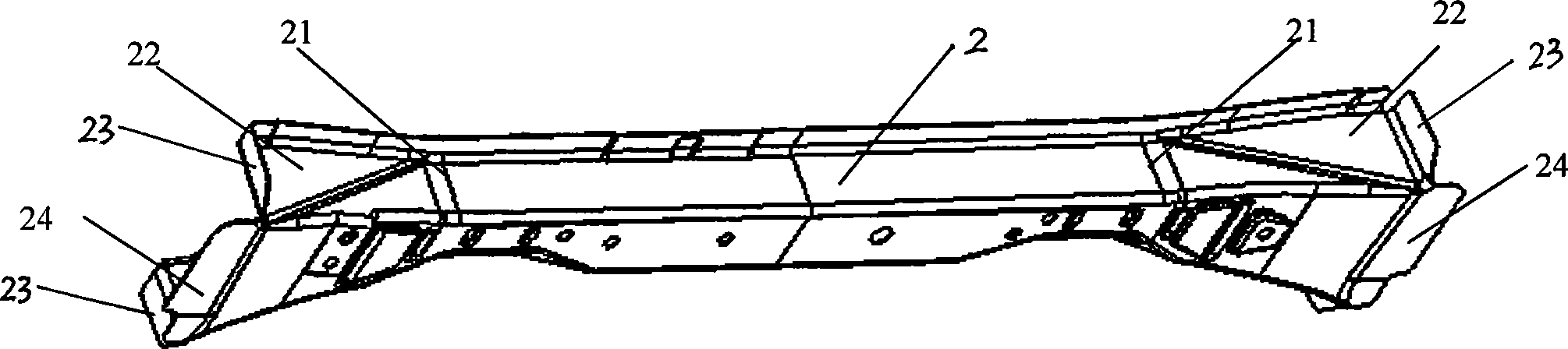

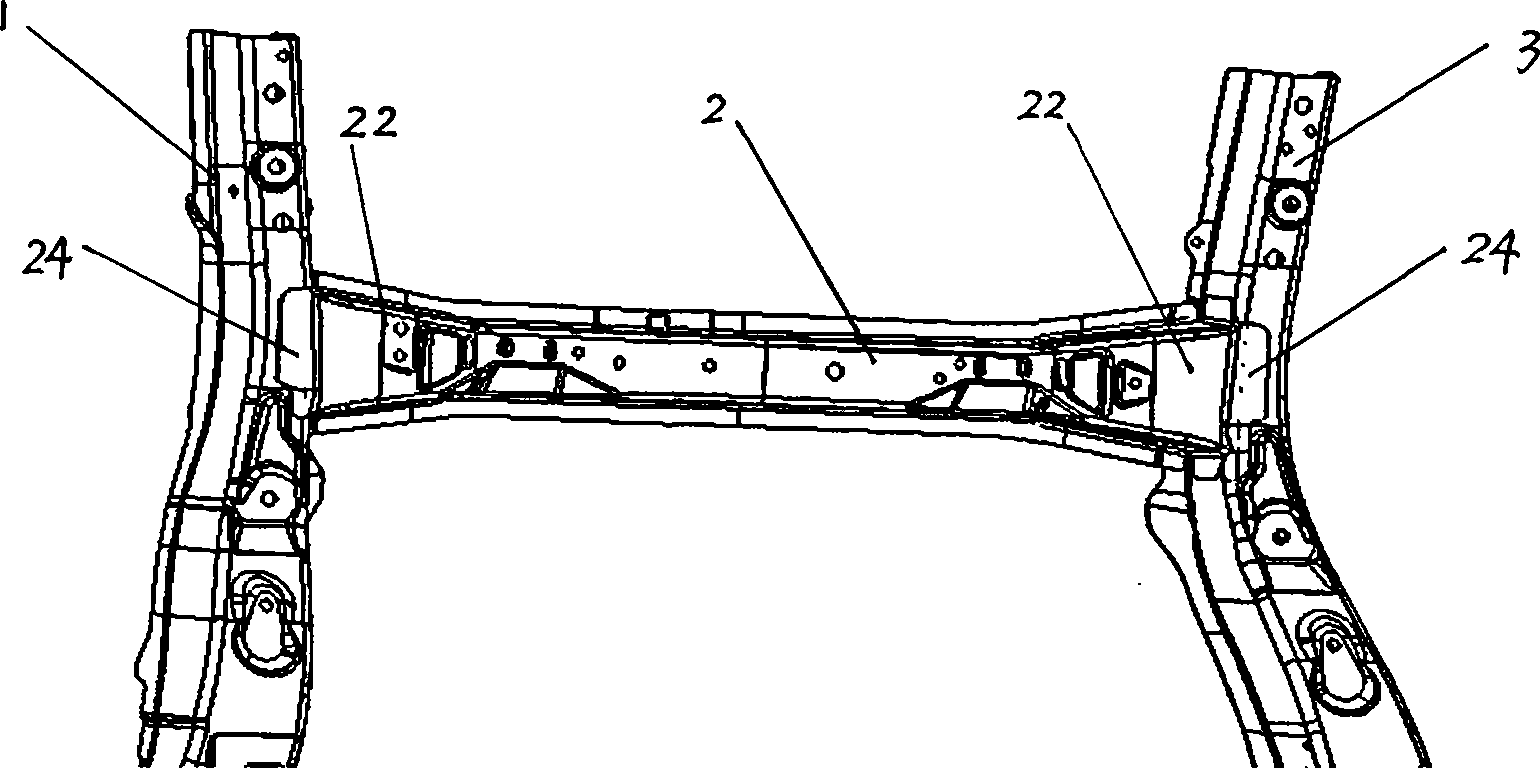

Bridging arrangement of vehicle beam and left-right longeron

InactiveCN101362480AWarranty Strength RequirementsGuaranteed stiffness requirementsUnderstructuresMedial surfaceStress concentration

The invention discloses a lapping structure of the horizontal beam and the left and right longitudinal beams of an automobile, wherein, the cross section of the horizontal beam is U-shaped and both ends of the horizontal beam are welded crosswise with the longitudinal beams through the lapping edge to form an H shape; both ends of the horizontal beam are flared with the width growing larger and larger. The edges of the end form two symmetrical rolling up lapping edges and a straight lapping edge, wherein, two symmetrical rolling up lapping edges lap on the medial surface of the two longitudinal beams, namely, the surface of the direction of Z subject to the coordinate system of the automobile; the straight lapping edge laps on the upper surface of the longitudinal beams, namely, the surface of the direction of X subject to the coordinate system of the automobile. The invention can successfully solve the problem that the processing kerf at the root of the weld edge and the parts lapping edge easily cracks due to the force transferring effect of the H-shaped lapping structure in the automobile structures and the concentrated stress at the root of the lapping parts, thus guaranteeing the requirement of overall intensity and stiffness of the structure.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

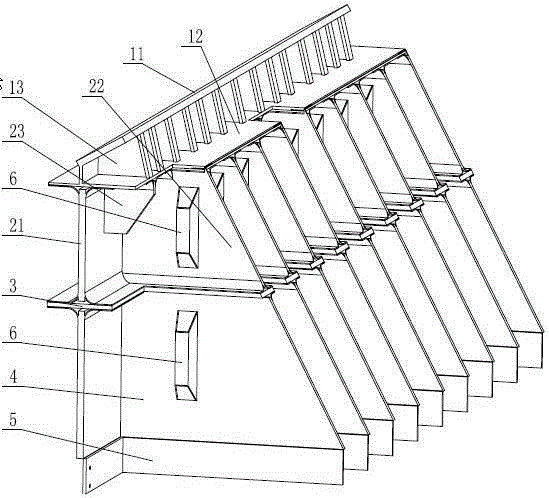

Harmonic wave speed reducing mechanism of inertance stabilizing tracking platform

ActiveCN103158884AHigh precisionReduce volumeAircraft componentsAxis–angle representationEngineering

Disclosed is a harmonic wave speed reducing mechanism of an inertance stabilizing tracking platform. The harmonic wave speed reducing mechanism of the inertance stabilizing tracking platform comprises a driving structure part, a harmonic wave transmission part and a transmission output structure part, wherein the driving structure part comprises a motor rotor assembly, a motor stator assembly, a motor shaft assembly and a motor installation assembly, the harmonic wave transmission part comprises a harmonic wave generator, a harmonic wave steel wheel and a harmonic wave flexible wheel, and the transmission output structure part comprises a transmission shaft assembly, a transmission shaft sleeve assembly and a lead wire slip ring assembly. Control of the degree of freedom of rotation is achieved through a driving structure, and power support is provided to movement of the platform. A harmonic wave transmission structure is a belt of the driving structure and a transmission structure, and driving of loads of different levels can be achieved through different gear ratios. Speed reduction and twist increase of an output shaft are achieved through a transmission output structure, and servo control of an angle movement of a transmission shaft is achieved according to a programming instruction. The harmonic wave speed reducing mechanism of the inertance stabilizing tracking platform is suitable for control of the inertance stabilizing platform and has the advantages of being large in transmission ratio, good in transmission rigidity, small in size of the driving unit, light in weight, simple in structure and the like. The harmonic wave speed reducing mechanism of the inertance stabilizing tracking platform is capable of improving carrying capacity and stabilization precision of the platform and is suitable for framework driving of aerial remote sensing and target tracking.

Owner:BEIHANG UNIV

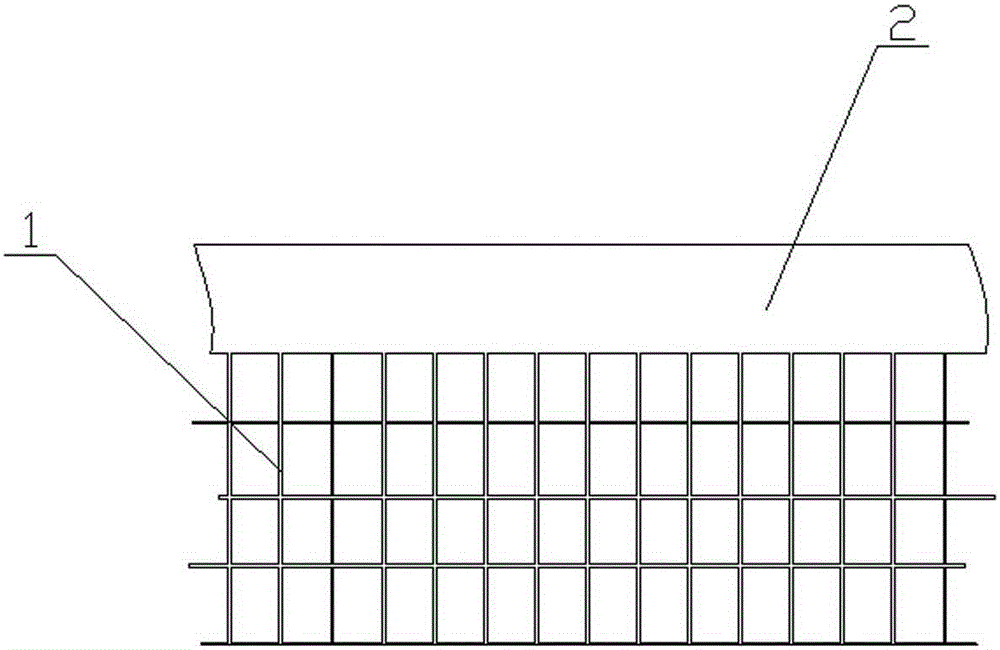

Two-layer plate frame type vibration damping base of composite structure

ActiveCN105217007AHigh strengthLow modulusNon-rotating vibration suppressionPropulsion power plantsElastic vibrationEngineering

A two-layer plate frame type vibration damping base of a composite structure comprises an equipment installation rigid base, an upper layer composite material plate frame, a middle layer rigid vibration-isolation panel, a lower layer composite material plate frame and a rigid connection transition plate which are sequentially distributed from top to bottom in the vertical direction. The upper end and the lower end of the upper layer composite material plate frame are fixedly connected with the equipment installation rigid base and the middle layer rigid vibration-isolation panel respectively, and the upper end and the lower end of the lower layer composite material plate frame are fixedly connected with the middle layer rigid vibration-isolation panel and the rigid connection transition plate respectively. By means of the two layers of composite material plate frames, a hard-soft-hard-soft-hard elastic vibration-isolation structure is integrally formed, characteristics of a composite material can be fully used, the dual aims of reducing vibration and noise and reducing the weight of the base are achieved on the premise that the rigidity and strength requirements of the vibration damping base structure are met, and low-frequency noise reduction can be achieved.

Owner:中国船舶重工集团公司第七〇二研究所

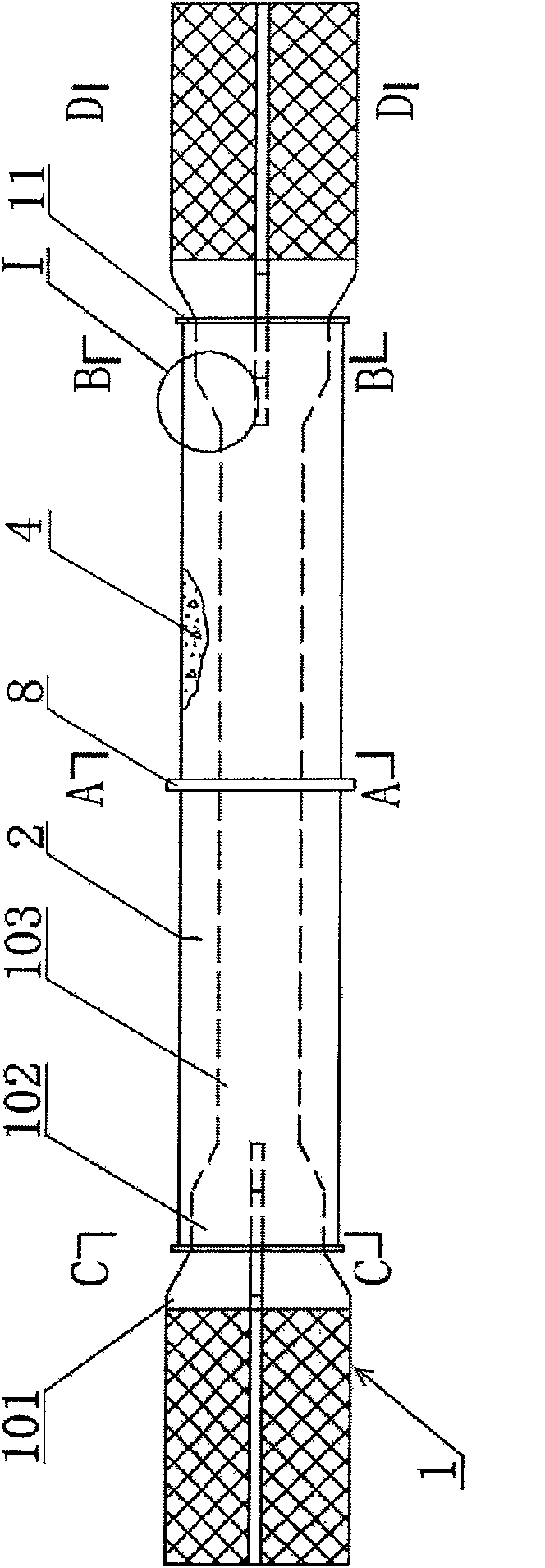

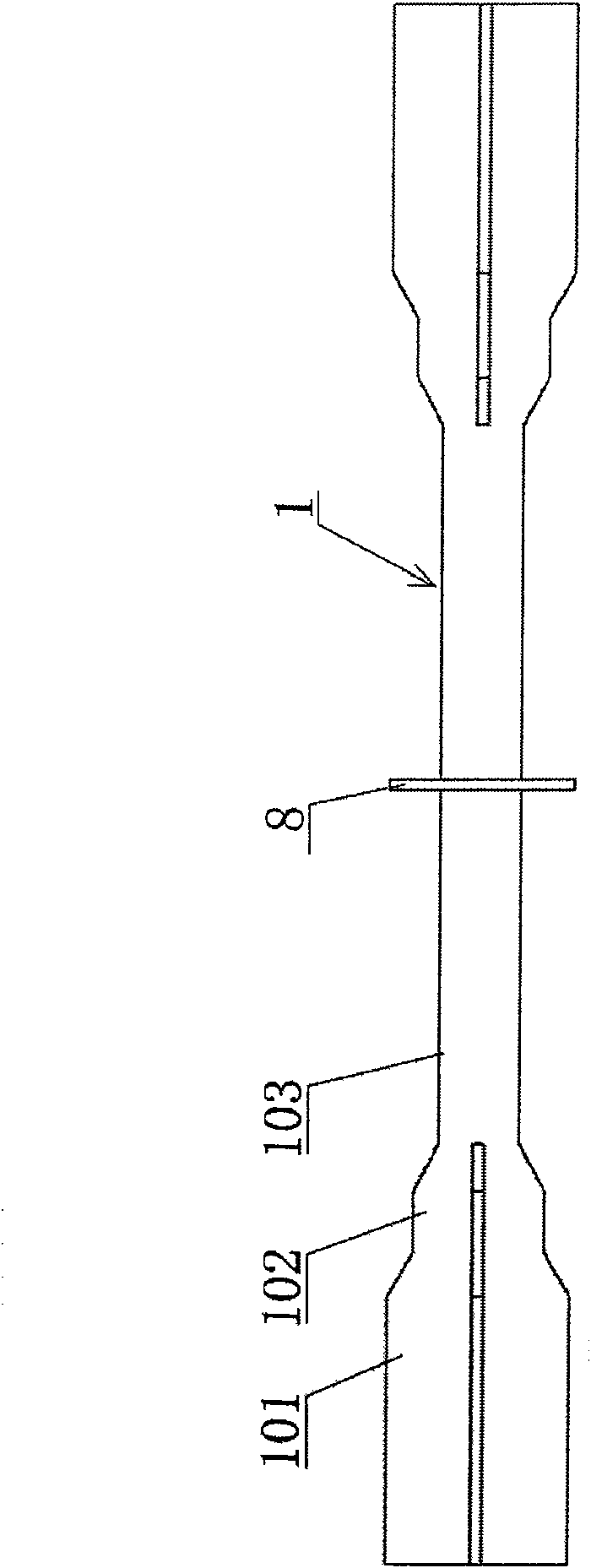

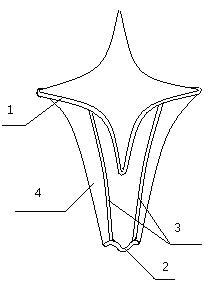

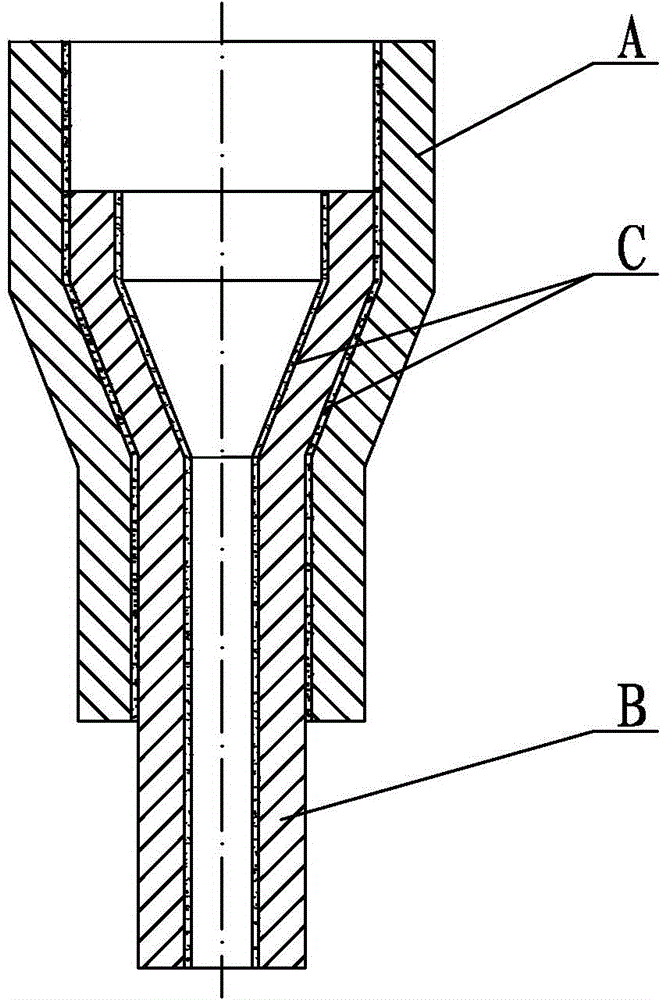

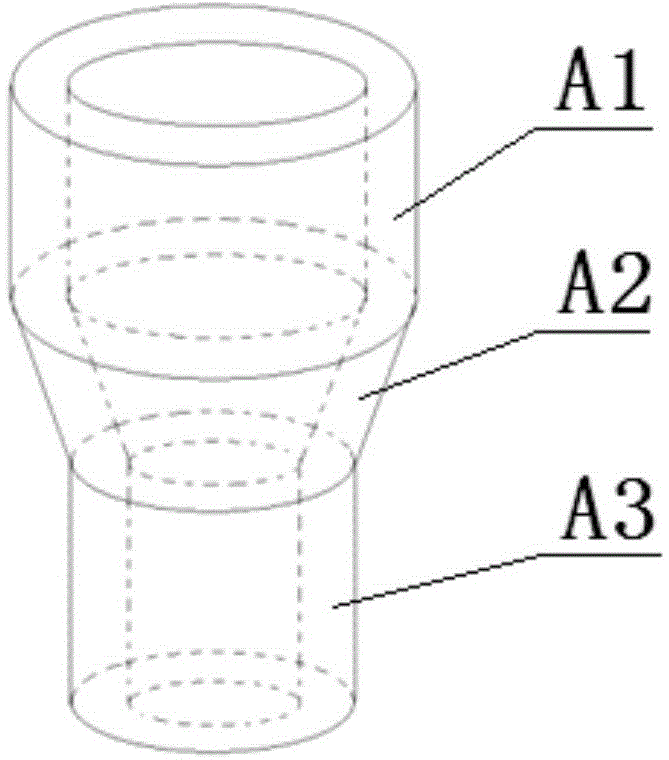

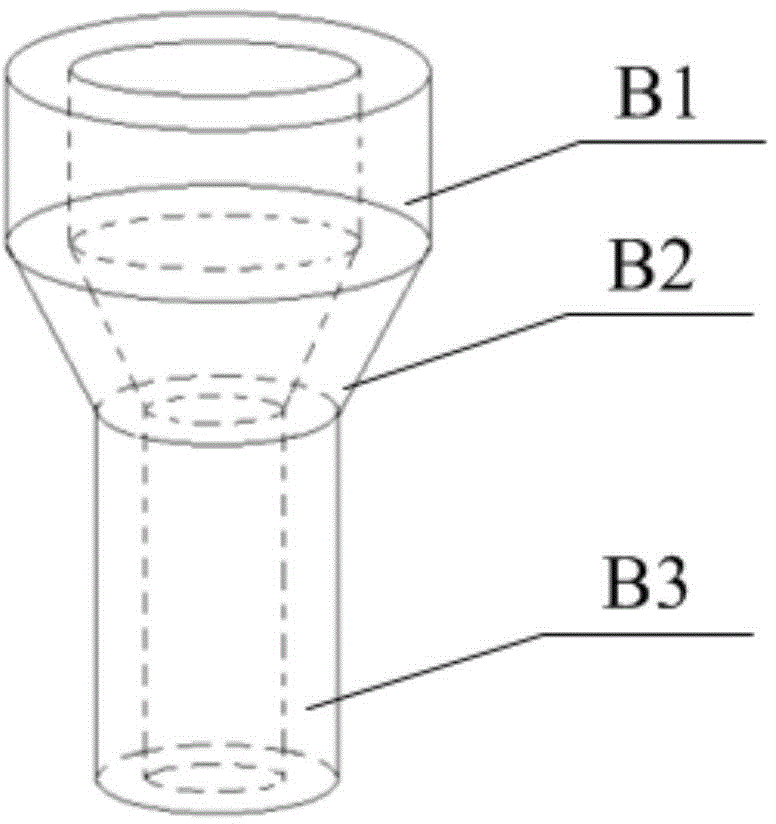

Intelligent bamboo-shaped releasing mechanism made of shape memory polymer composite material

ActiveCN104443438AReduce weightSimple structureCosmonautic vehiclesCosmonautic power supply systemsIntensifierEngineering

An intelligent bamboo-shaped releasing mechanism made of a shape memory polymer composite material aims to solve the problem that when a traditional space expansion mechanism releasing mechanism is unfolded, impact is generated, and accordingly atmosphere environments are polluted. The diameter of an inner lower straight tubular section is smaller than that of an inner upper straight tubular section, an outer sleeve intensifier is sequentially composed of an outer upper straight tubular section, an outer taper tubular section and an outer lower straight tubular section from top to bottom, the diameter of the outer lower straight tubular section is smaller than that of the outer upper straight tubular section, the outer sleeve intensifier is arranged on an inner sleeve driver in a sleeving mode, an inner upper straight tubular section is located in the outer upper straight tubular section, an inner taper tubular section is located in the outer taper tubular section, an inner lower straight tubular section is located in the outer lower straight tubular section, the upper end face of the inner upper straight tubular section is lower than that of the outer upper straight tubular section, the lower end of the inner lower straight tubular section is exposed out of the outer lower straight tubular section, the inner wall of the inner sleeve driver and the inner wall of the outer sleeve intensifier are each coated with a thermoelectric film, and the inner sleeve driver and the outer sleeve intensifier are both made of the shape memory polymer composite material. The mechanism is used for space expansion mechanisms in the field of aerospace.

Owner:HARBIN INST OF TECH

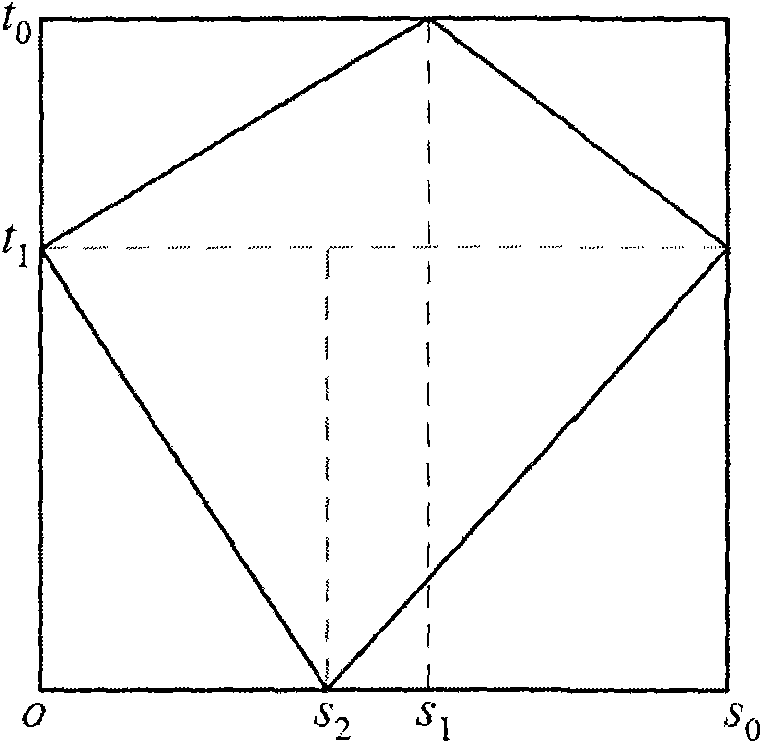

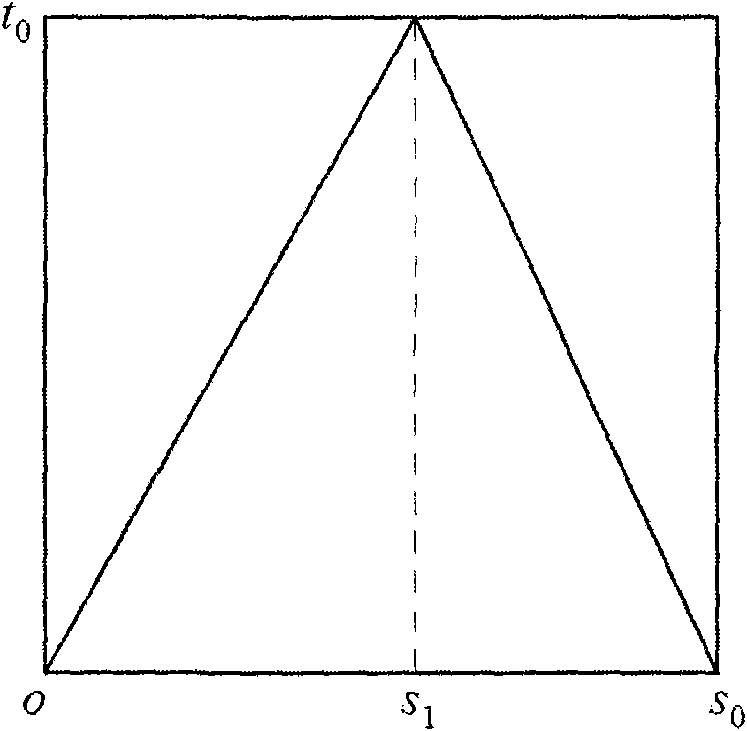

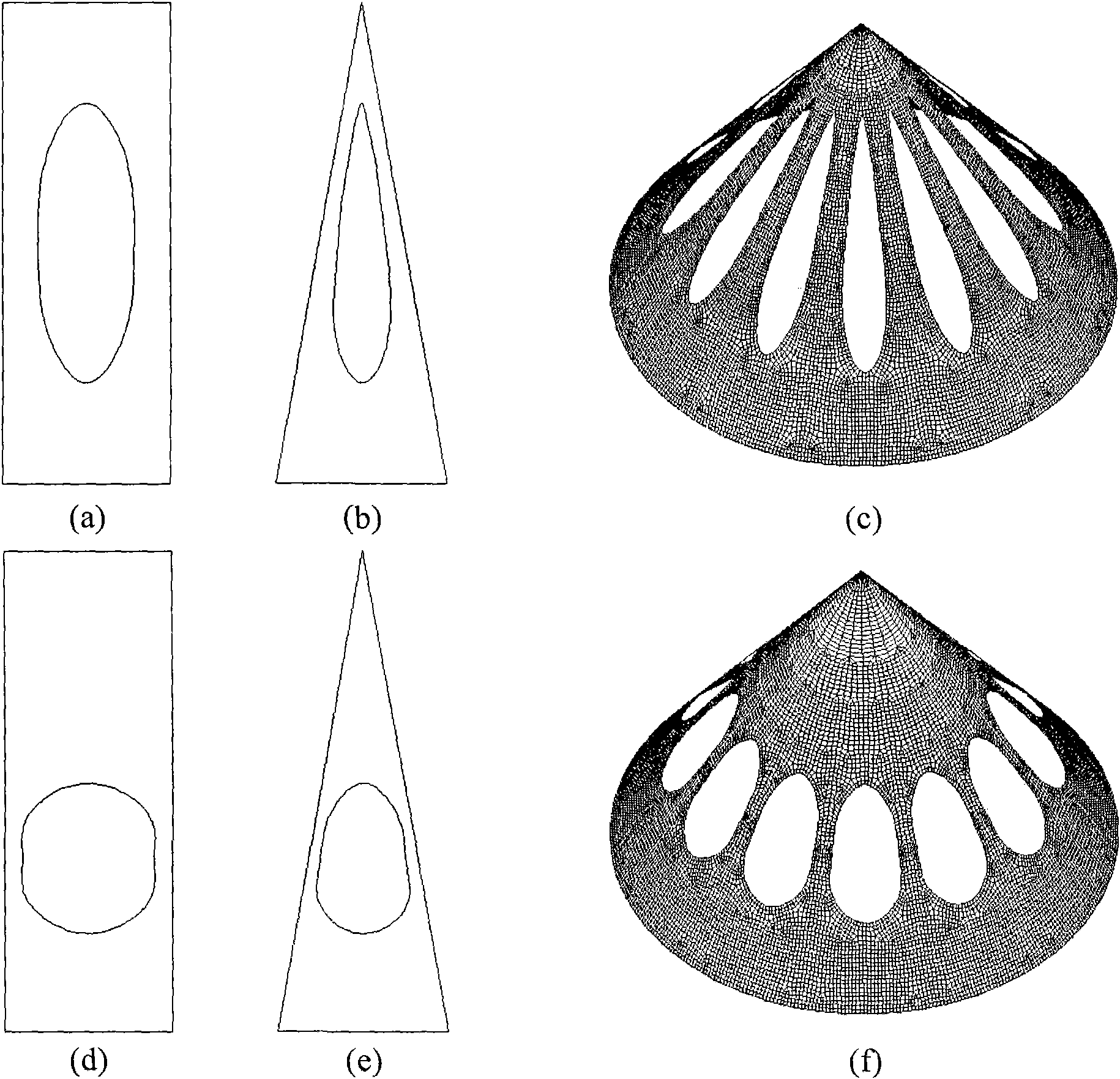

Space hole optimization design method of thin-wall curved-surface structure with holes

ActiveCN101840452AGuaranteed stiffness requirementsSpecial data processing applicationsElement modelCircular cone

The invention discloses a space hole optimization design method of a thin-wall curve-surface structure with holes, aiming at solving the technical problems that a fitted curve around a hole can not ensure to be always positioned on a given curve and a curve around a space hole is difficult to resolve and express in the hole optimization design on the conventional curved-surface structure. The method adopts design schemes that: design variables are defined on an internal parameter plane of a curve surface, and the space hole optimization design problem is equivalently simplified into a plane hole optimization design problem by adopting a parameter mapping method, therefore, the hole optimization design problem on any thin-wall curved-surface structures is solved, and compared with the prior art, the maximum equivalent stress of a finite element model of thin-wall conical curved-surface structures with holes and same size is greatly reduced.

Owner:JIANGSU SHUANGNENG SOLAR ENERGY +1

Quenching oil capable of enabling automobile plate spring to blacken automatically after quenched and quenching method thereof

ActiveCN105925768AWarranty Strength RequirementsGuaranteed stiffness requirementsFurnace typesMetallic material coating processesAntioxidantBase oil

The invention discloses quenching oil capable of enabling an automobile plate spring to blacken automatically after quenched and a quenching method thereof. The invention belongs to the field of metal heat treatment technology. The quenching oil comprises the following components, by weight, 35-40 parts of refined base oil, 7-10 parts of cooling catalyzed composite agent, 0.4-0.7 parts of blackening composite agent, 0.3-0.5 parts of brightening agent, 0.4-0.7 parts of surface activating agent and 0.02-0.03 parts of antioxidant. The effect is best when the maximum cooling speed of the quenching oil for the plate spring is about 110-120 DEG C / s and the using temperature is 65-70 DEG C. Under the above conditions, the strength and the stiffness of the quenched plate spring are greatly improved, at the same time the effect of the automatic surface blackening can be realized and a protective film formed on the surface is strong in adhesion and good in wear-resisting property. Once more surface coating and rust preventing treatment after the heat treatment can be reduced, so that the resources can be saved, the processes can be reduced and the efficiency can be improved.

Owner:马鞍山金泉工业介质科技有限公司

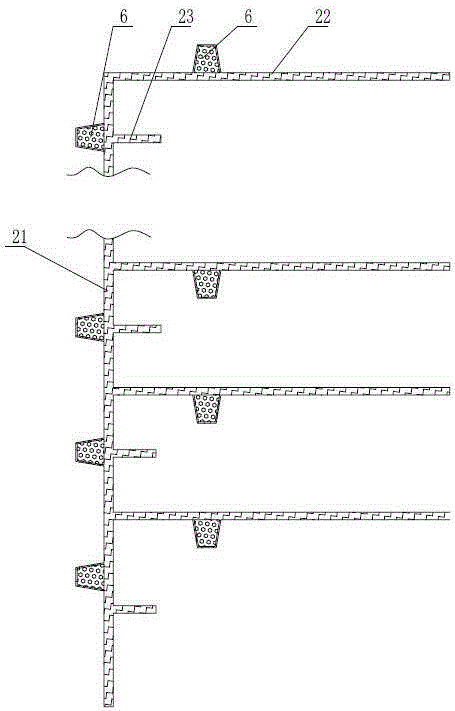

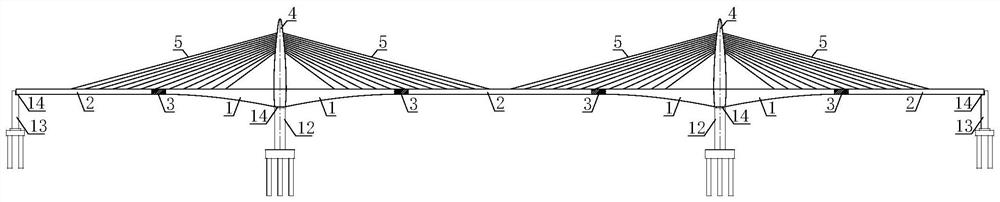

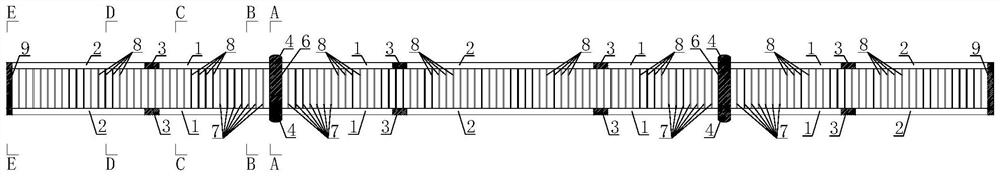

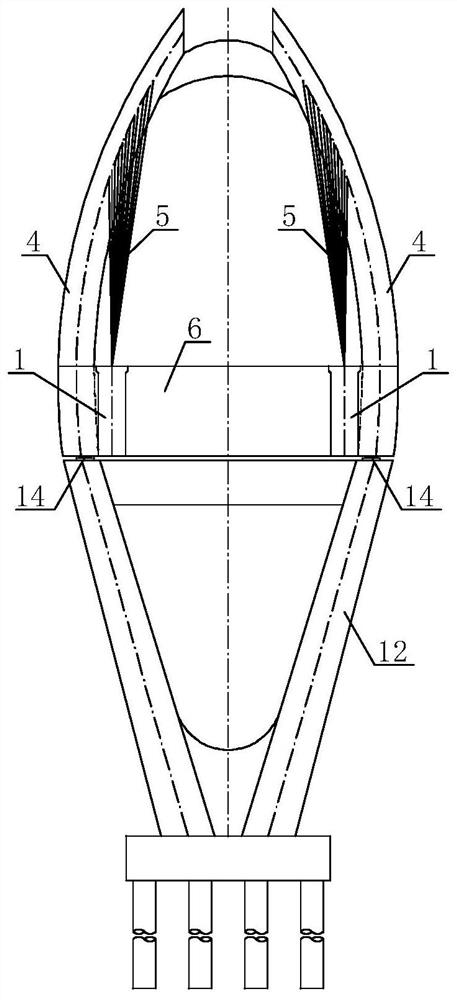

Suspended single-track large-span track beam system

ActiveCN107724225AAddress structural securityAddress structural requirementsBridge structural detailsTowerControl theory

The invention belongs to the technical field of track traffic and discloses a suspended single-track large-span track beam system. The suspended single-track large-span track beam system comprises a main beam and steel box track beams, wherein a longitudinal direction of the main beam extends along a front-rear direction; the main beam comprises a top beam and two side boxes; the two side boxes are parallel to each other and respectively arranged at the left and right ends at the bottom of the top beam; the left and right side boxes respectively penetrate through bridge towers on correspondingsides and are nested on the bridge towers on the corresponding sides, so that fixed connection between the bridge towers and the main beam is realized; in addition, each of the side boxes is respectively connected with the bridge tower on the corresponding side by virtue of a stay cable; two steel box track beams are arranged; a longitudinal direction of each of the steel box track beams extendsalong the front-rear direction; each of the steel box track beams is suspended on the top beam; and the two steel box track beams are positioned between the two side boxes. The suspended single-tracklarge-span track beam system disclosed by the invention has the characteristics of being simple in structure and clear in stress, and the requirements on structural safety and service function in thesuspended single-track large-span track beam are met.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

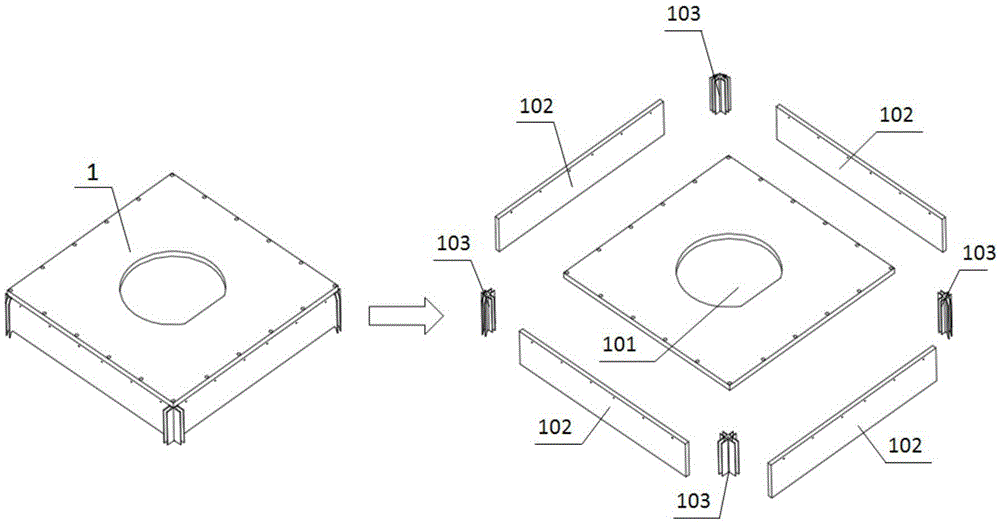

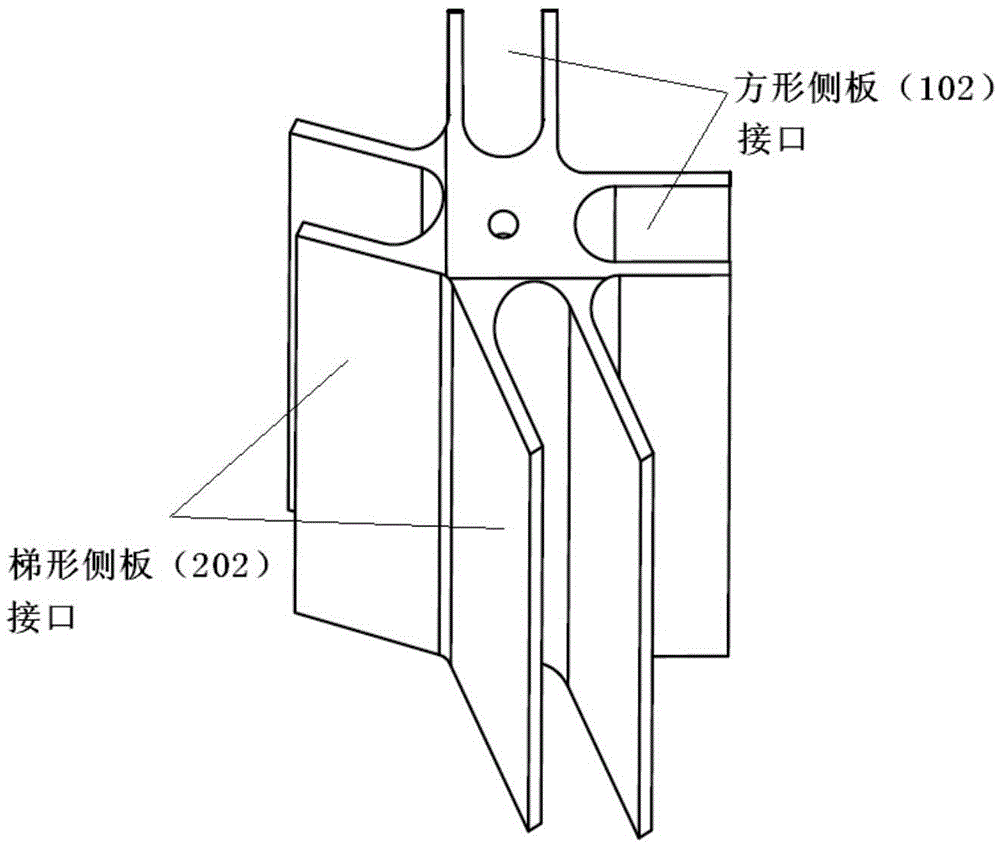

Spatial box type cabin structure

ActiveCN105539879AIncrease stiffnessHigh precisionCosmonautic vehiclesCosmonautic partsFlight vehicleEngineering

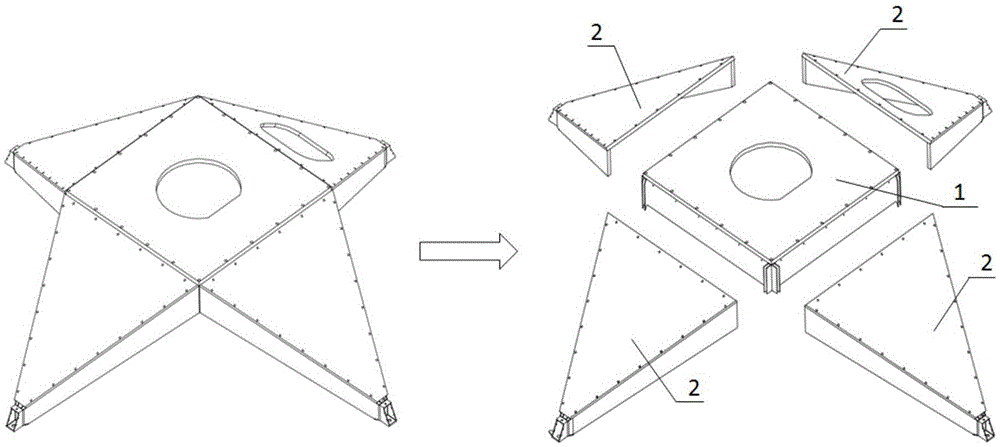

The invention relates to the field of spaceflight, is suitable for mounting high-accuracy mechanisms and high-accuracy equipment of a space exploration flight vehicle, and particularly relates to a spatial box type cabin structure. The spatial box type cabin structure comprises a square box body (1), namely a square box piece (1), and four triangular box bodies (2), namely four triangular box pieces (2), wherein the square box piece (1) is positioned in the center of the structure; the triangular box pieces (2) are uniformly distributed on four edges of the square box piece (1), and the four triangular box bodies (2) and the square box piece (1) are in the shape of forming spatial inclined angles; the spatial box type cabin structure adopts the whole configuration that the spatial box type cabin structure is gradually furled from top to bottom through the triangular box pieces (2) and is finally formed into a four-point support structure. The spatial box type cabin structure disclosed by the invention has the beneficial effects of being high in rigidity, high in accuracy, low in weight and the like.

Owner:SHANGHAI AEROSPACE SYST ENG INST

Fabrication method for negative plate of lead-acid storage battery

ActiveCN105226240AReduce weightThe strength does not decrease or even increaseLead-acid accumulator electrodesFiberCarbon fibers

A fabrication method for a negative plate of a lead-acid storage battery comprises grid fabrication and active substance filling and is characterized by comprising the following steps of: substituting the traditional framework of a negative plate grid by a conductive carbon fiber felt part; embedding a tab and conductive ribs onto the carbon fiber felt to form a novel grid; filling the interior and the surface of the novel grid with an active substance; and fabricating the negative plate. In the negative plate, lead dosage is reduced, the weight is favorably reduced, and an environment is protected; and particularly, the carbon fiber and the active substance are tightly combined, the contact area is large, the resistance is small, the utilization rate of the active substance is improved, the charging reception of the active substance is high, the sulphation is overcome, and the service life of the batter is prolonged.

Owner:SHUANGDENG GRP

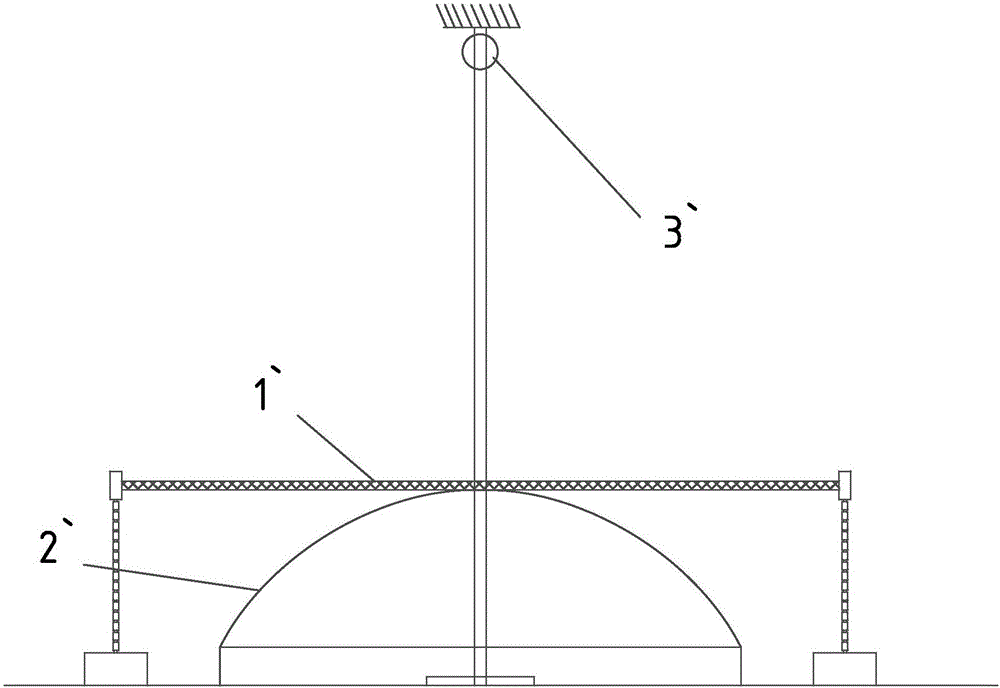

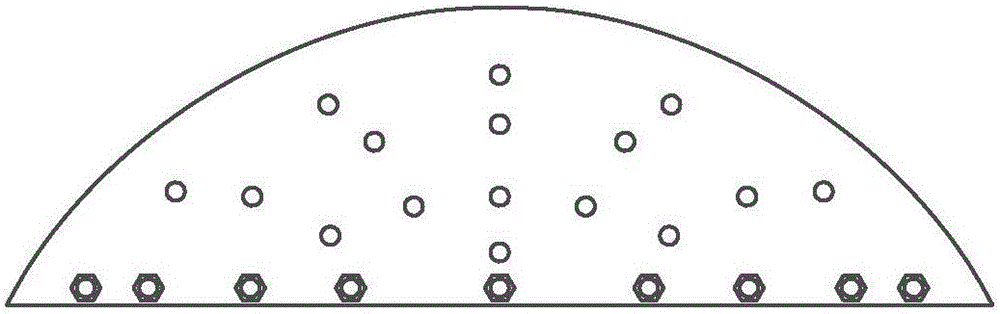

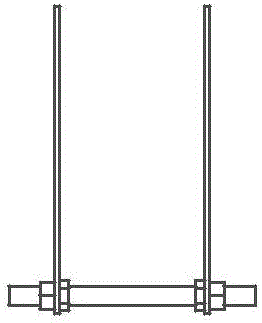

Novel device and method for testing minimum bend radius of ocean engineering flexibility pipeline and cable

ActiveCN105823398AFlexible loadingEasy to loadMechanical counters/curvatures measurementsEngineeringTraining set

The invention discloses a novel device for testing minimum bend radius of ocean engineering flexibility pipeline and cable. The device includes an anvil block, a horizontal slide rail, a tooth bar on the horizontal slide rail, an actuator for pushing the tooth bar to move along the horizontal slide rail, a pinion which coordinates with the tooth bar, a bull gear which coordinates with the pinion, a gear fixing rack for fixing the bull gear and the pinion, and a rope, wherein the anvil block includes an arc plate, a pipeline and cable bending support plate for fixing the arc plate, and a support truss structure. The invention also discloses a novel method for testing minimum bend radius of ocean engineering flexibility pipeline and cable. The novel device and method for testing minimum bend radius of ocean engineering flexibility pipeline and cable can realize that a greater radius of curvature of the pipeline and cable gradually and continuously transits to a smaller radius until the armoured steel wire for the pipeline and cable achieves the yielding state during the loading process, so that the novel device and method can guarantee that the minimum bend radius of the pipeline and cable can be accurately obtained through the test.

Owner:DALIAN UNIV OF TECH

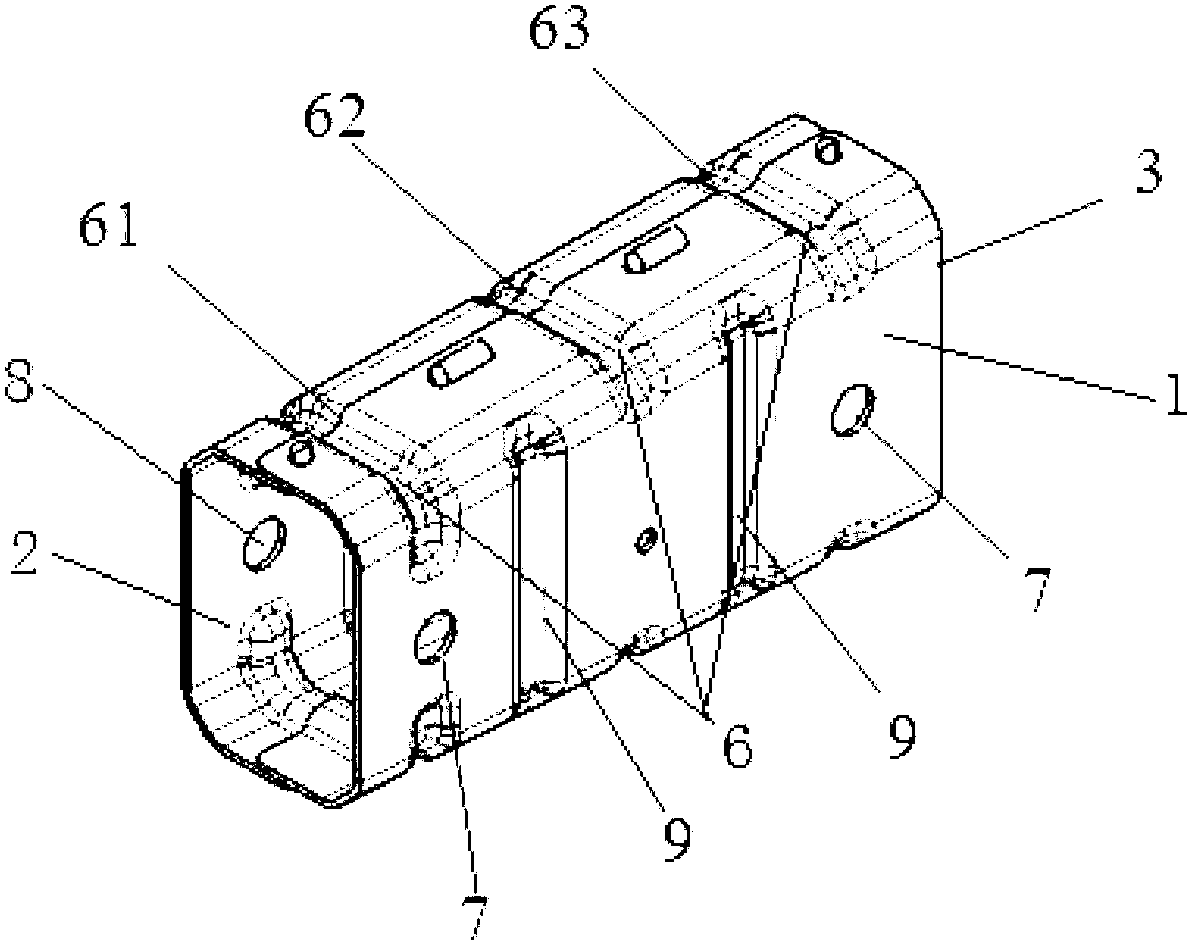

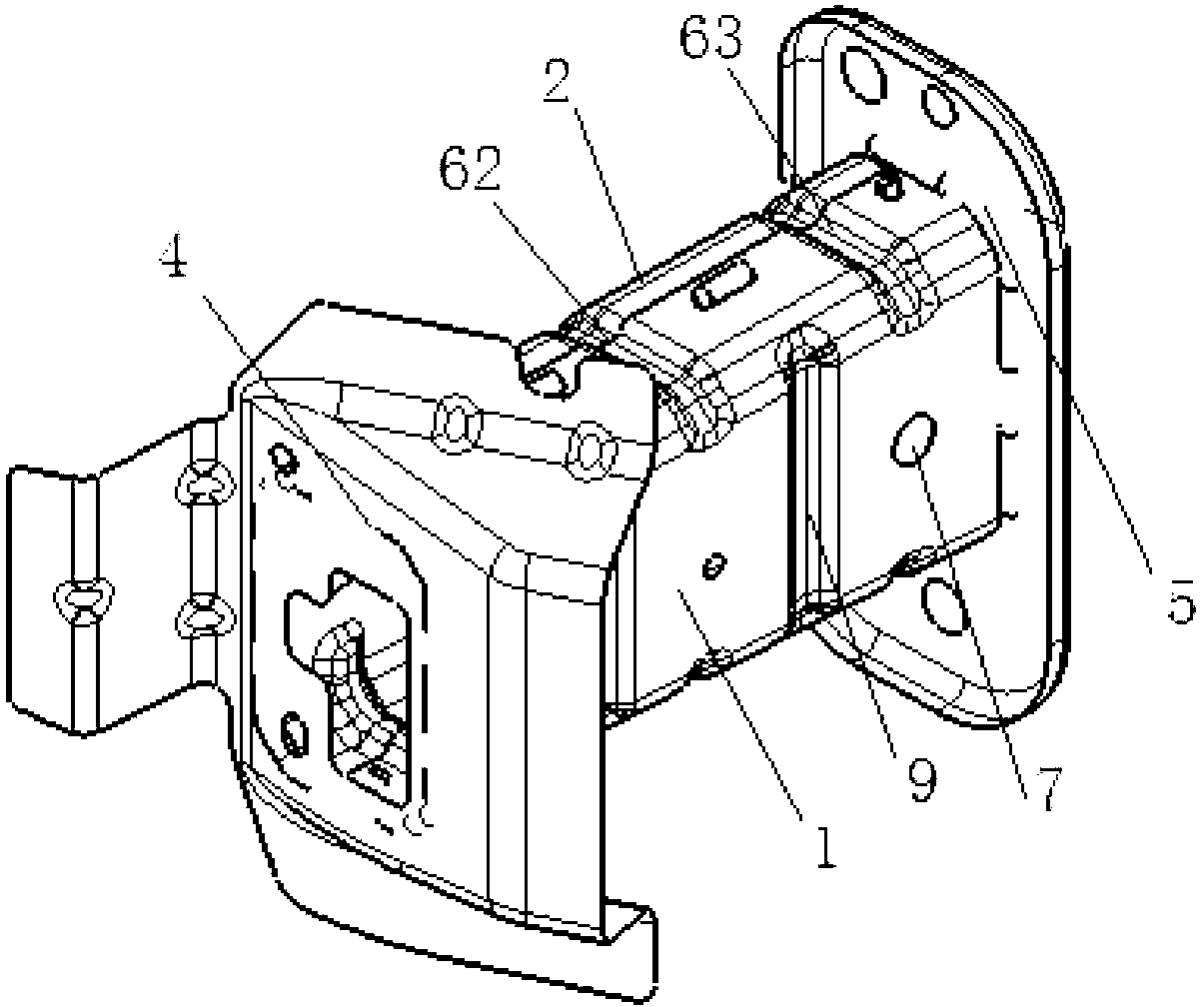

Automobile energy absorption box structure

InactiveCN103273962AImprove the collapse energy absorption effectEasy to produceUnderstructuresWave shapeOn board

The invention relates to an automobile energy absorption box structure. The automobile energy absorption box structure comprises an energy absorption box body (3) which is formed by a U-type energy absorption box outer board (1) and a U-type energy absorption box inner board (2) in a mutually lapped mode, a front end board (4) is fixedly arranged at the front end of the energy absorption box body (3), a rear end board (5) is fixedly arranged at the rear end of the energy absorption box body (3), a set of energy absorption bars (6) is symmetrically arranged on two lapped faces of the U-type energy absorption box outer board (1) and the U-type energy absorption box inner board (2), the energy absorption box body (3) is of a tapered structure, and the area of the cross section of the tapered structure is gradually increased in the direction from an automobile head to an automobile tail. The arrangement positions of the energy absorption bars (6) are overlapped with the wave shapes of crushing waves. The width of the energy absorption bars (6) is equal to the half wavelength of the crushing waves. The automobile energy absorption box structure is simple in structure and reasonable in design, can carry out collapse and energy absorption to the largest limitation, and can be widely applied to the field of automobile crashes.

Owner:CHERY AUTOMOBILE CO LTD

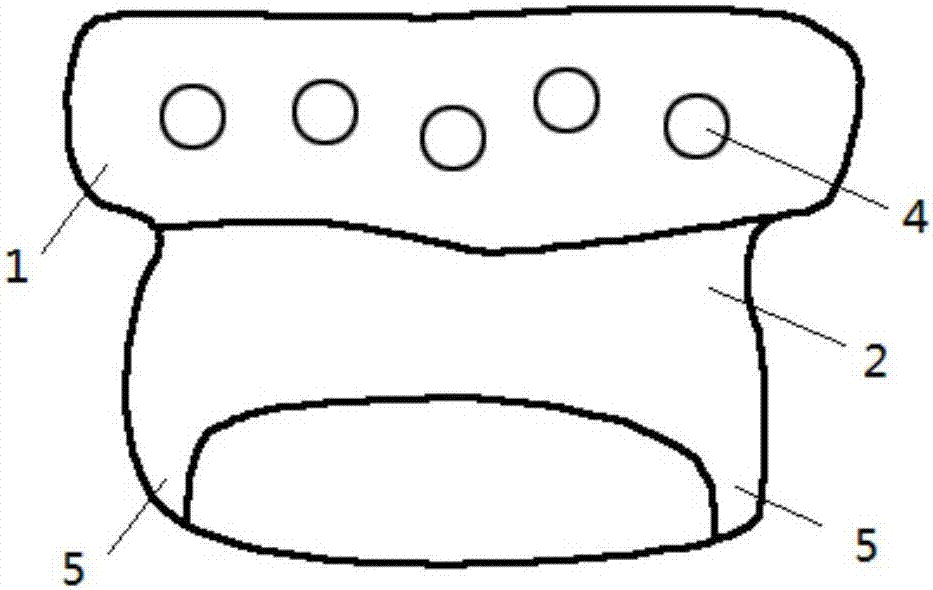

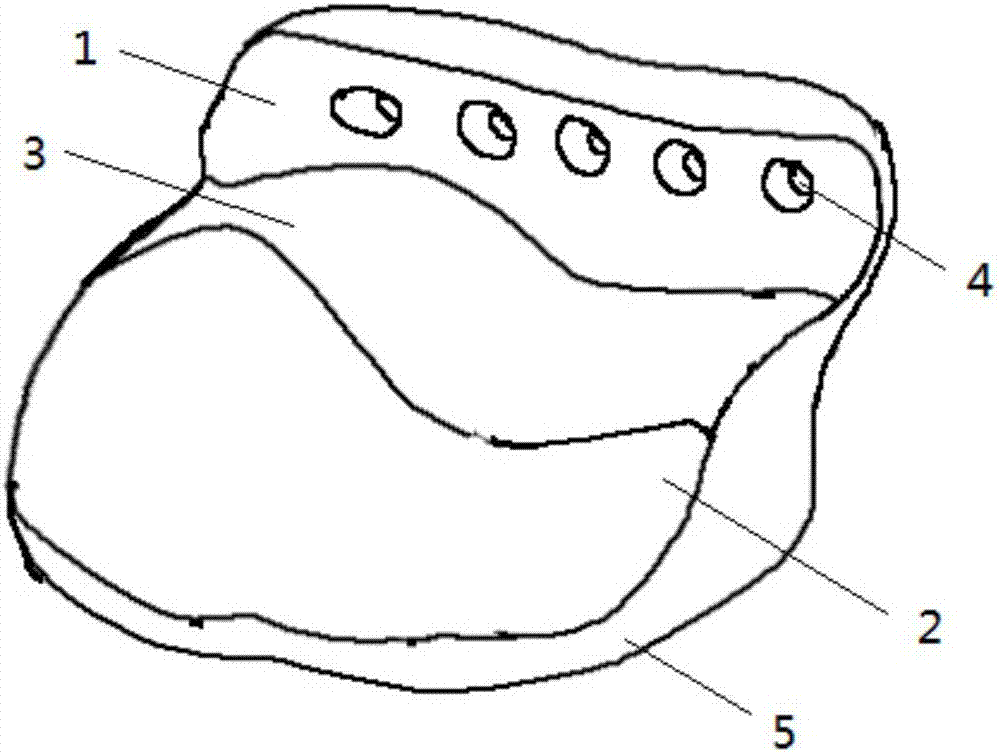

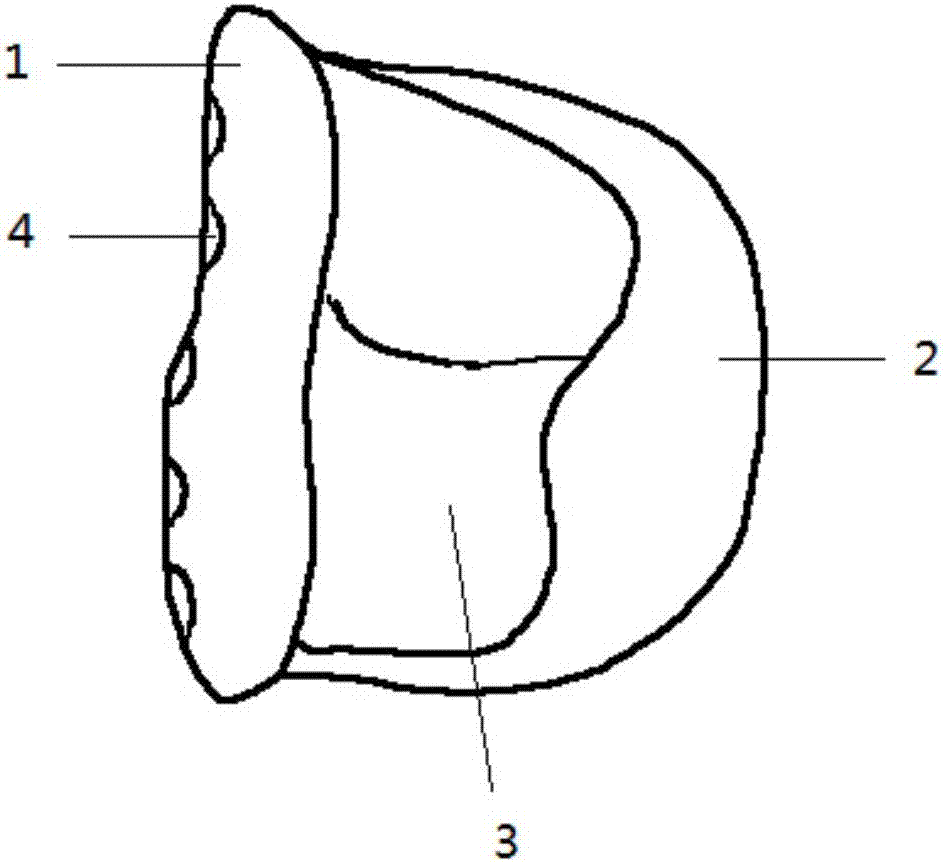

Personalized temporal-mandibular joint fossa implant

The invention discloses a personalized temporal-mandibular joint fossa implant which comprises an outer side retainer wing plate and a condyle process supporting surface, wherein the inner side face of the outer side retainer wing plate is in retaining fit with the outer side face of zygomatic arch of a patient; the lower edge of the outer side retainer wing plate and the condyle process supporting surface are connected into a whole; a top bulge is formed on the top surface of the condyle process supporting surface and positioned in a direction of the inner side face of the outer side retainer wing plate; the top surface of the condyle process supporting surface with the top bulge is attached to the temporal-mandibular joint fossa of the patient; the bottom surface of the condyle process supporting surface is attached to the lower condyle process head in a wrapped form; and the shape and size of the top bulge of the condyle process supporting surface and at least one of the width of the top surface and the width of the bottom surface of the condyle process supporting surface are in personalized matching according to the temporal-mandibular joint fossa and the lower condyle process head of the patient. The implant can be in close fit with the temporal-mandibular joint fossa of the patient, traumas and injuries of temporal-mandibular joint fossa implant surgery on peripheral tissues of the temporal-mandibular joint fossa can be reduced, and the joint fossa implant has high stability.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE +1

Wallboard structure fatigue testing machine clamp

InactiveCN105973696AReduce the influence of eccentricityWork reliablyStrength propertiesStress concentrationSoftware engineering

The invention provides a wallboard structure fatigue testing machine clamp. The traditional clamp is connected with a high-frequency fatigue testing machine through connecting bolts, but the wallboard structure fatigue testing machine clamp provided by the invention utilizes clamping head embossing processing, thereby greatly avoiding stress integration of a clamp body during loading, simplifying the device and facilitating operations. A clamp press plate and a connection plate are connected by utilizing a circular arc groove manner, thereby meeting the requirement of a testing machine on the rigidity of the clamp to the greatest extent; the clamp press plate and a test piece are connected through bolts, and a friction type connection manner is utilized, so that the bolts only exert connection and location functions without bearing a shearing force. According to the wallboard structure fatigue testing machine clamp, the wallboard structure fatigue test requirements and integral design requirements can be met, the structure is compact, the appearance is simple, and the machine is convenient to use and maintain.

Owner:HARBIN UNIV OF SCI & TECH

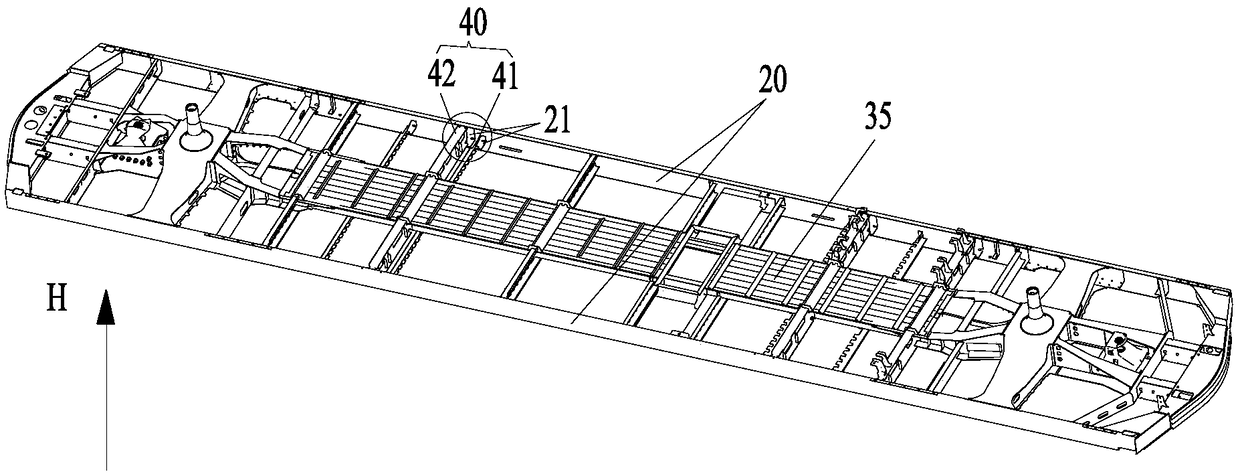

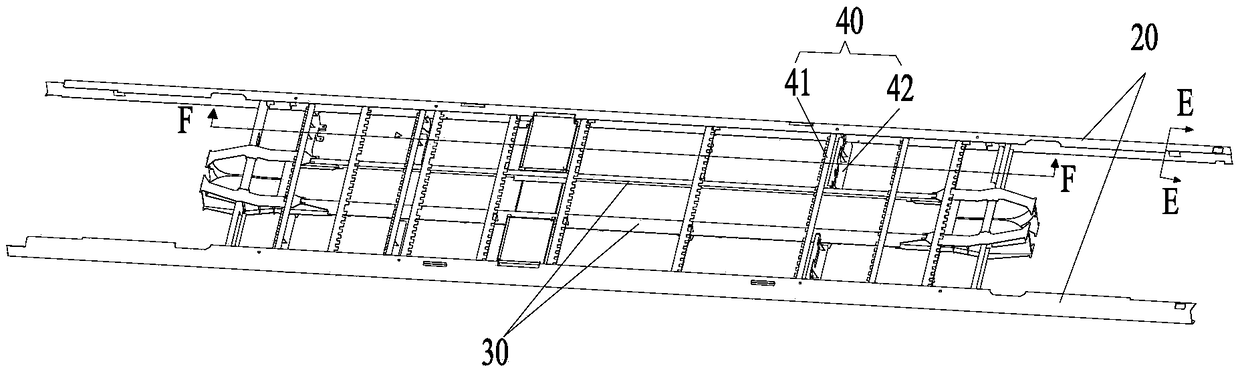

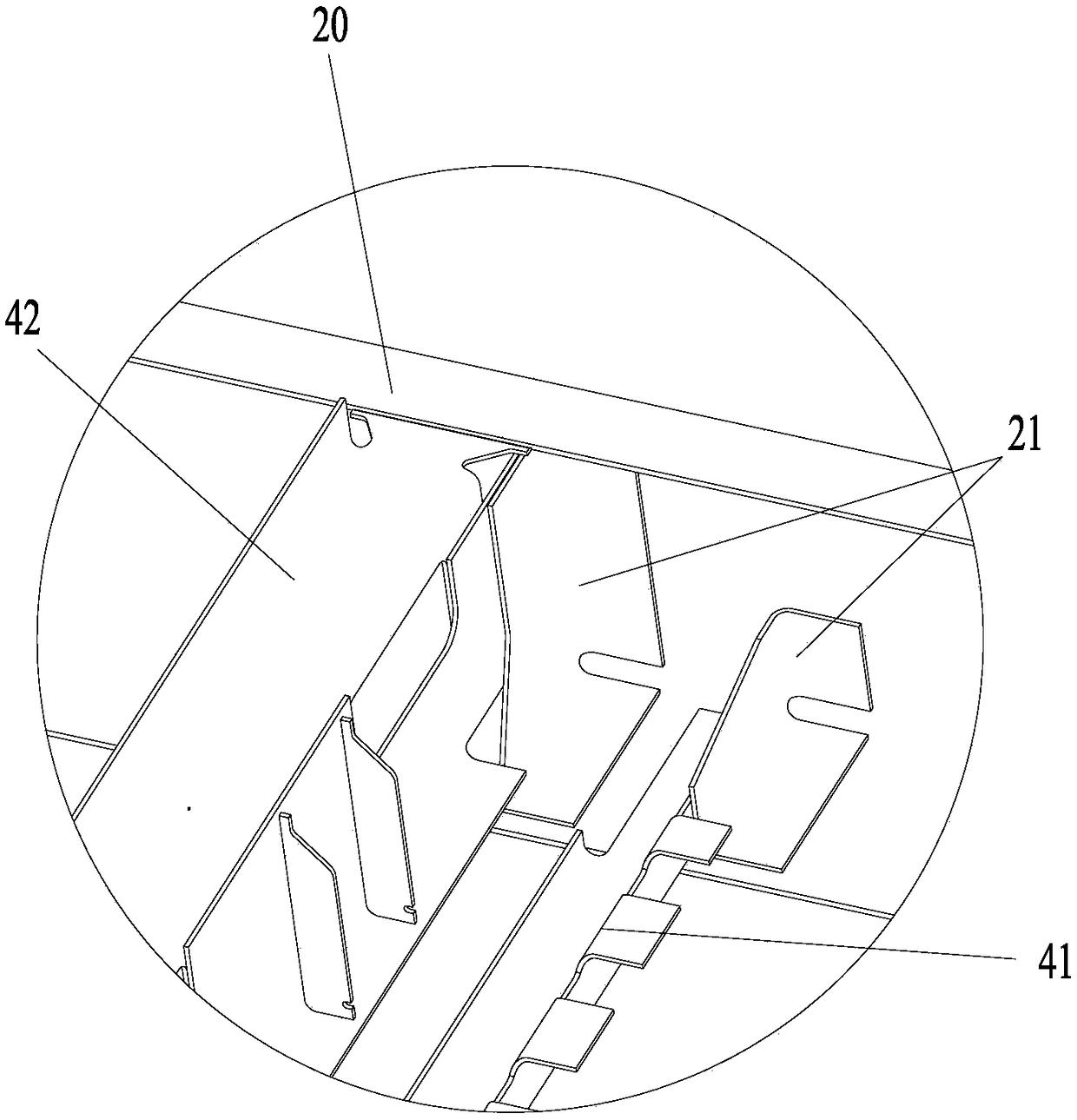

Underframe assembly of rail vehicle and rail vehicle

The invention provides an underfram assembly of a rail vehicle and a rail vehicle. The underframe assembly comprises two lower side beams arranged at intervals and a plurality of cross beams arrangedbetween the two lower side beams, the plurality of cross beams are arranged at intervals along the length direction of the lower side beams, at least one lower side beam is provided with a connectingseat, and at least one end of the cross beam is connected with the lower side beam through the connecting seat. By applying the technical proposal of the invention, the connecting strength between thecross beam and the lower side beam is increased by converting the connecting seat into surface contact, and the strength and the rigidity requirements of the underframe assembly are ensured.

Owner:CRRC QINGDAO SIFANG CO LTD

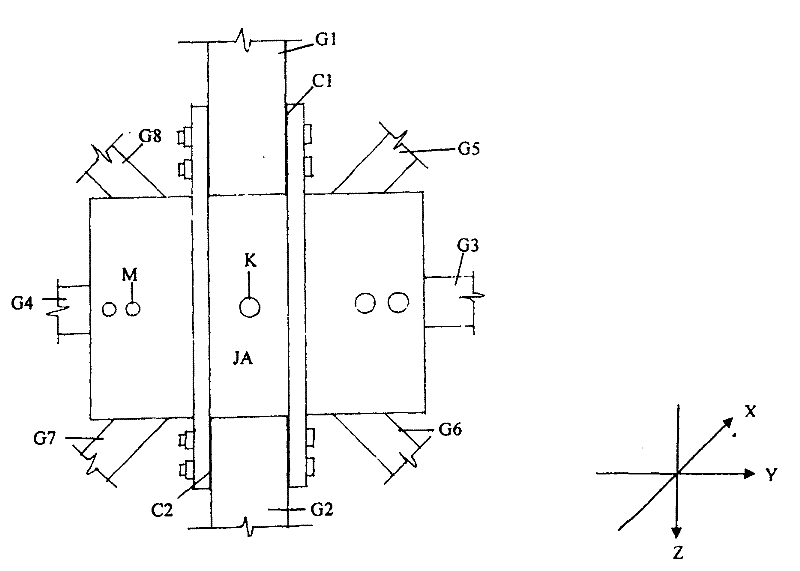

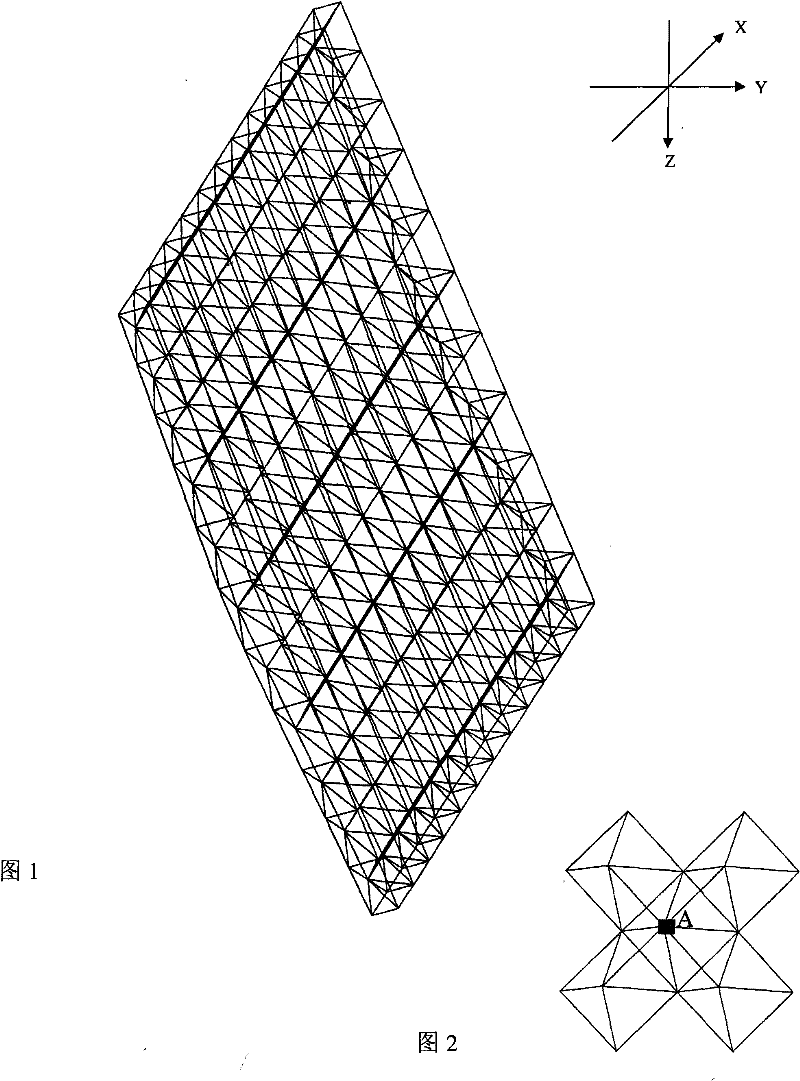

Body-like node aluminum alloy space truss structure

InactiveCN102304941AOutstanding FeaturesHighlight significant progressBridge structural detailsBuilding constructionsMaterials scienceAluminium alloy

A body-like node aluminum alloy space truss structure comprises all body-like space truss node bodies and all space truss chord members and web members, wherein the space truss node bodies are made of aluminum alloy materials, and the space truss chord members and the web members are made of the aluminum alloy materials and connected with the node bodies. The body-like node aluminum alloy space truss structure is characterized in that node body limb plates B1 and B2 connected to the space truss chord members in an X-axis direction are respectively arranged, or node body grooves C1 and C2 connected to the space truss chord members of the x-direction are arranged in positive and negative directions of the X axis located in the plane of the XY axes of the space truss according to requirements of connecting rods on each body-like node body; node body limb plates B3 and B4 connected to the space truss chord members in a Y-axis direction are respectively arranged or node body grooves C3 and C4 connected to the space truss chord members of the Y-direction are arranged in positive and negative directions of the Y axis located in the plane of the XY axes of the space truss; a node body limb plate B5 connected to the space truss web members G5 and G6 is arranged or a node body groove C5 connected to the space truss web members G5 and G6 is arranged in the plane of the space truss web members G5 and G6 at YZ side; and a node body limb plate B6 connected to the space truss web members G7 and G8 is arranged or a node body groove C6 connected to the space truss web members G7 and G8 is arranged in the plane of the web members G7 and G8 at (-Y)Z side. The space truss members converged at a node A(JA) and the space truss member ends corresponding to the node body limb plates are respectively provided with an opening so as to implant the node body limb plate, and the space truss member ends corresponding to the node grooves are directly implanted into the corresponding node grooves.

Owner:林娟

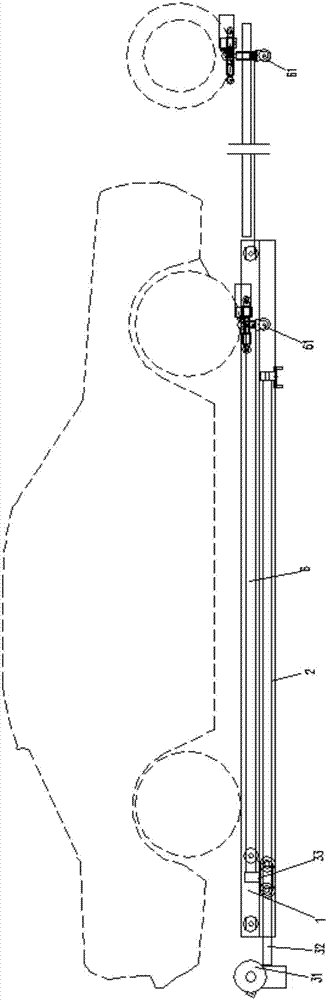

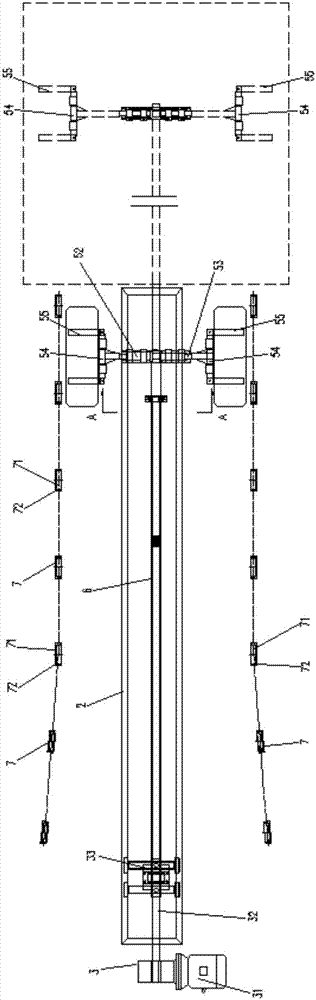

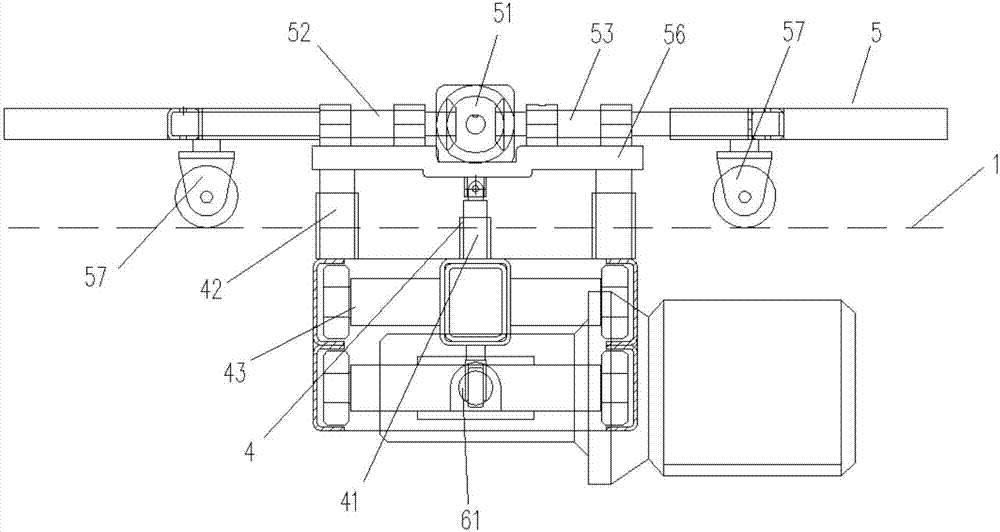

Mechanical carrying device for stereo garage

PendingCN107989435AEasy to operateStrong structural practicabilityParkingsParking spaceMechanical failure

The invention provides a mechanical carrying device for a stereo garage. The mechanical carrying device is provided with a carrying platform; guide rails are arranged in the middle of the bottom faceof the carrying platform, and a pushing mechanism located at the bottom of one end of the carrying platform is mounted on the guide rails after being matched with the guide rails; a jacking mechanismis arranged at the bottom of the other end of the carrying platform and connected with a wheel holding mechanism arranged at the upper plane of the other end of the carrying platform, and the pushingmechanism and the jacking mechanism are connected through a telescopic rod arranged at the bottom of the carrying platform; a vehicle is located on the carrying platform, and the wheel holding mechanism holds front wheels of the vehicle after being matched with the front wheels; and the front end of the vehicle is jacked up through the jacking mechanism, and the vehicle is pushed from the carryingplatform to a vehicle carrying plate or a parking space on the outer side of the carrying platform through the pushing mechanism. Automatic parking and pick-up of the vehicle are achieved, the manufacturing cost for vehicle parking and pick-up of the stereo garage is reduced effectively, the overall weight of the garage is reduced, the structure is simple, the mechanical failure rate is low, reliability is high, personal safety and vehicle safety are guaranteed, and the parking and pick-up time is reduced.

Owner:陕西通运易泊车位制造有限公司

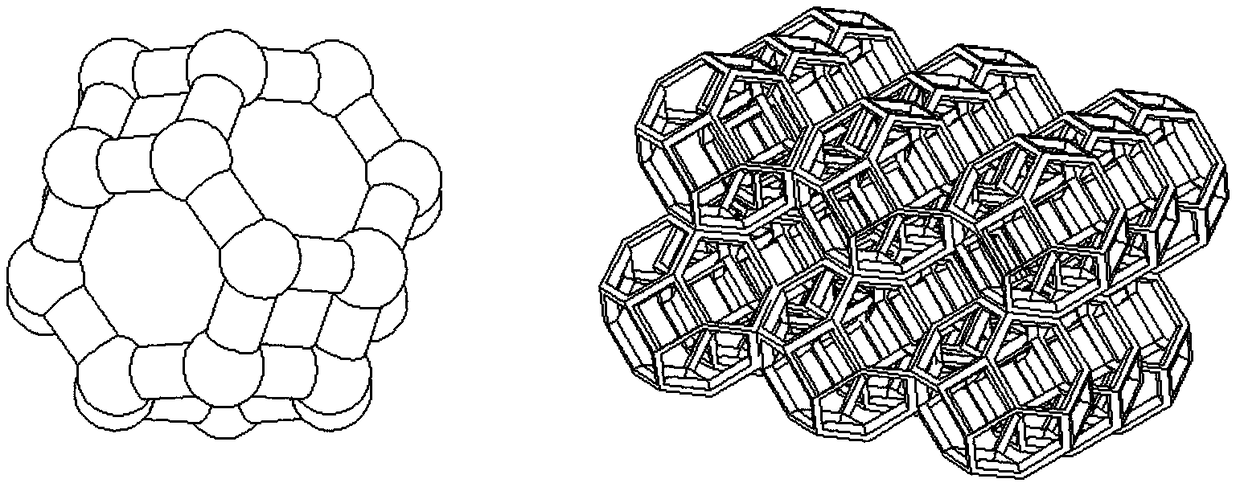

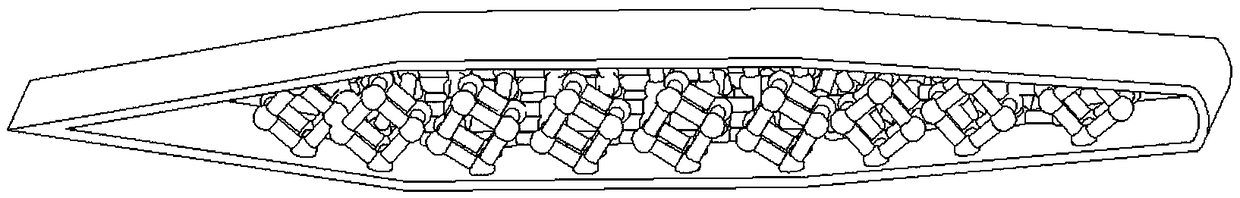

Structure design method of rotor wing paddle

InactiveCN109110125AReduce Design ComplexityShorten the design cycleFinal product manufactureGround installationsManufacturing technologyMetallic materials

The invention discloses a structure design method of a rotor wing paddle. The structure design method comprises the following steps: firstly, selecting a suitable lattice unit and a suitable engineering metal material; after selecting the lattice unit through a lattice unit mechanical analysis model, carrying out optimized design on the quantity of the lattice units in the paddle, geometric dimension of the lattice units and the distribution of the lattice units; after obtaining a lattice structure scheme meeting design requirements, directly preparing the paddle in an additive manufacturing manner. According to the structure design method disclosed by the invention, the design cost is reduced, the design period of the paddle is shortened, the complexity degree of manufacturing a paddle structure is extremely reduced, and a paddle manufacturing technology and flow are simplified; the production and manufacturing cost of the paddle is extremely reduced, the production and manufacturingefficiency of the paddle is improved, the strength can be increased, and the cost is reduced;; meanwhile, the strength and rigidity requirements of the structure can be ensured at the same time underthe condition that the weight of the material is the lightest; the recycling and utilization rate is high, the production cost is reduced, and industrial materials are saved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

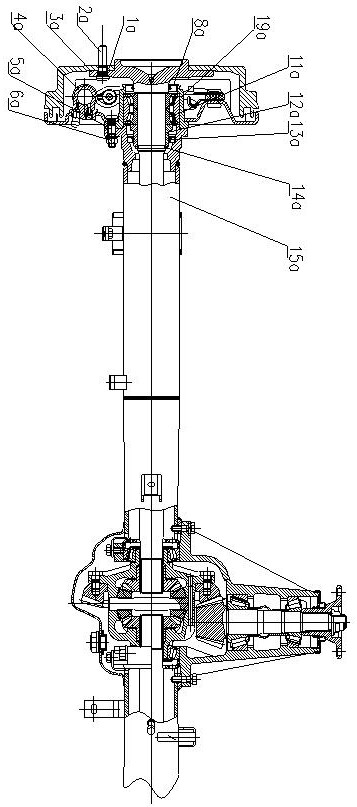

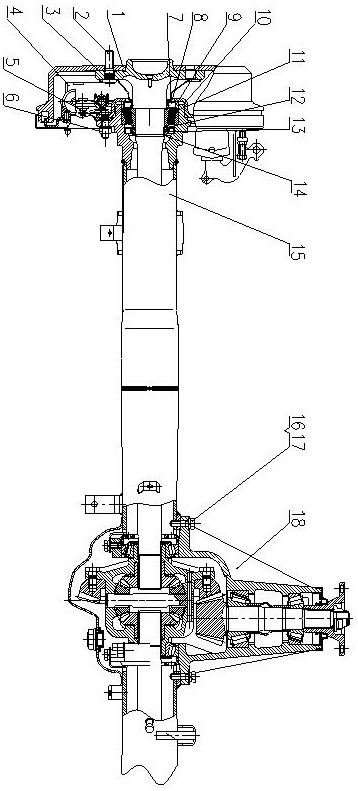

Drive axle based on half-shaft bearing novel installation system

PendingCN111619288APrevent leakageMeet the design lifeBraking element arrangementsAxle unitsStructural engineeringGear oil

The invention relates to a drive axle based on a half-shaft bearing novel installation system. A brake assembly is arranged on a rear axle housing assembly in a sleeving manner, and a half shaft assembly is mounted on the rear axle housing assembly. The drive axle is characterized in that a half shaft is sleeved with a half shaft bearing, a bearing bush is pressed on the outer side of the half shaft bearing, an inner oil seal is arranged on the surface of the bearing bush, a snap spring is arranged on the outer side of the bearing bush and fixed on the half shaft, an oil seal bush is arrangedon one side of the half shaft bearing, an outer oil seal is pressed on the inner diameter of the oil seal bush, and a bearing baffle is arranged on one side of the outer oil seal and presses and fixesthe half shaft bearing through a brake assembly; and an oil baffle disc is installed between the bearing baffle and the inner side end face of the half shaft, and a brake drum is installed at the endof the half shaft through half shaft bolts. The lightweight drive axle meets the design service life and the axial bearing capacity required by a whole vehicle, meanwhile, the hidden danger that a tapered roller bearing of the drive axle fails due to lack of lubricating grease is eradicated, and the potential safety hazard that gear oil leaks into a brake under extreme conditions to cause failureof a brake system is eradicated.

Owner:JIANGXI JIANGLING CHASSIS CO LTD

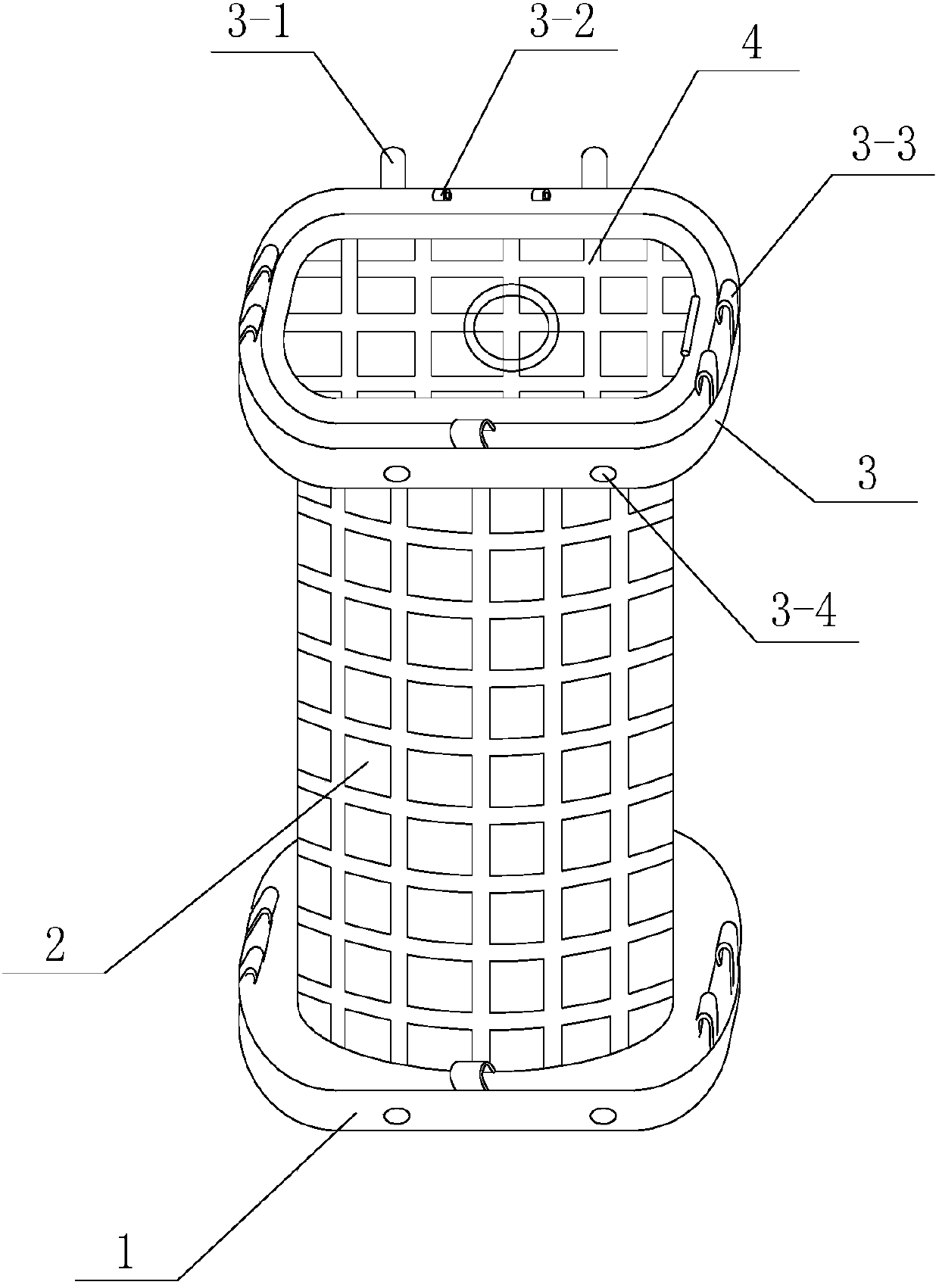

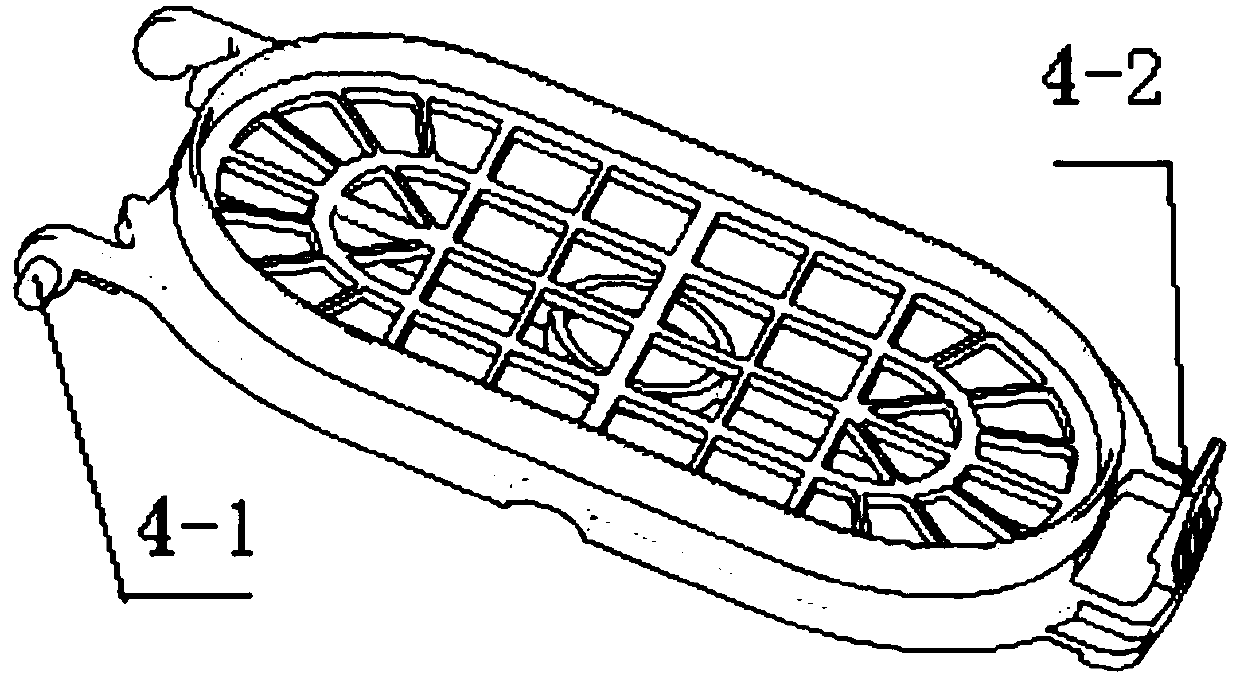

Oyster aquaculture device

InactiveCN107864906AReduce maintenance costsEasy to operateClimate change adaptationPisciculture and aquariaOysterLap joint

The invention discloses an oyster aquaculture device, which is formed by sequentially connecting a plurality of culture devices. Each culture device body comprises an upper cover, a cage body and a lower cover; each upper cover and each lower cover are respectively fixed to the upper end and the lower end of each cage body; two sides of each cage body are in lap joint with assembling columns through assembling holes; a detachable cover is arranged in the middle of each upper cover; one end of each detachable cover is rotatably connected with an inner wall of each upper cover through a rotary shaft and shaft hole connecting way; the other end of each detachable cover is connected with each upper cover through a clamping plate and clamping slot connecting way; positioning holes are formed inlong edges of one sides of the upper covers and the lower covers; positioning columns are arranged on long edges of the other sides, opposite to the positioning holes, of the upper covers and the lower covers; buckles are respectively arranged on two short edges and the long edges with the positioning holes of the upper covers and the lower covers; penetrating and sleeving holes are formed in thelong edges provided with the positioning columns. The oyster aquaculture device is convenient to assemble and disassemble, convenient to maintain, convenient to observe the individual situations in the culture device bodies, and low in logistics transportation cost, and the load of each cage is large.

Owner:刘云洲

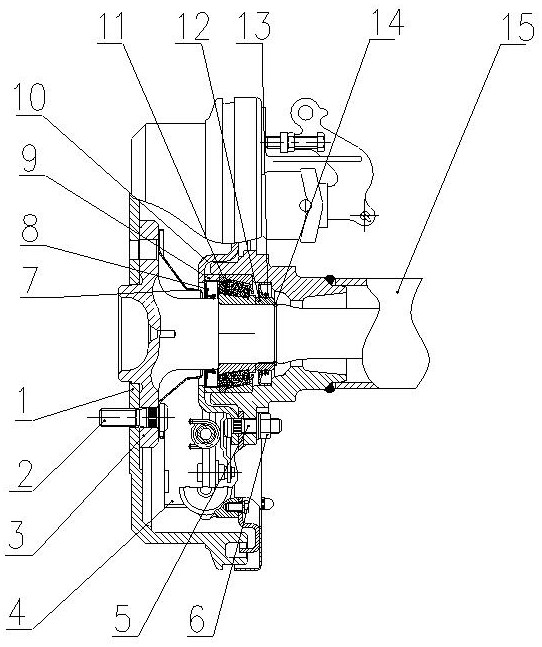

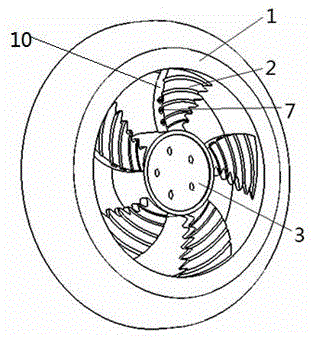

A valve and a wheel

InactiveCN103925389BImprove performanceGuaranteed stiffness requirementsDiaphragm valvesOperating means/releasing devices for valvesCar drivingHeat transmission

Owner:JIANGSU UNIV

Wide-width large-span hybrid beam extradosed cable-stayed bridge system and construction method thereof

PendingCN112982139AImprove carrying capacityLose weightCable-stayed bridgeBridge structural detailsArchitectural engineeringBridge deck

The invention discloses a wide-width large-span hybrid beam extradosed cable-stayed bridge system and a construction method thereof. The wide-width large-span hybrid beam extradosed cable-stayed bridge system comprises hybrid beams which are composed of concrete box girders and corrugated web steel box-concrete composite beams and arranged on two sides in a transverse bridge direction, wherein the concrete box girders are positioned on two sides of a middle fulcrum and are integrally poured with a bridge tower; the composite beams are located in side span and middle span; the concrete box girders and the composite beams are connected through a steel-concrete combined section; the steel-concrete combined section is formed by pouring combined section concrete in a corrugated web steel box; the hybrid beams are transversely composed of middle fulcrum concrete cross beams, truss type steel cross beams, I-shaped steel cross beams and end cross beams which are connected; a bridge deck is arranged on the hybrid beams; and the hybrid beams are supported by main piers and transition piers. The hybrid beam extradosed cable-stayed bridge system is reasonable in structural design, convenient to construct, good in using effect and capable of being used for wide and large-span bridges. Meanwhile, the invention further discloses a matched construction method. The matched construction method comprises the steps of bridge tower construction, concrete box girder construction, composite beam construction, steel-concrete combined section construction and the like. The construction method is complete, and construction progress is fast.

Owner:甘肃省交通规划勘察设计院股份有限公司

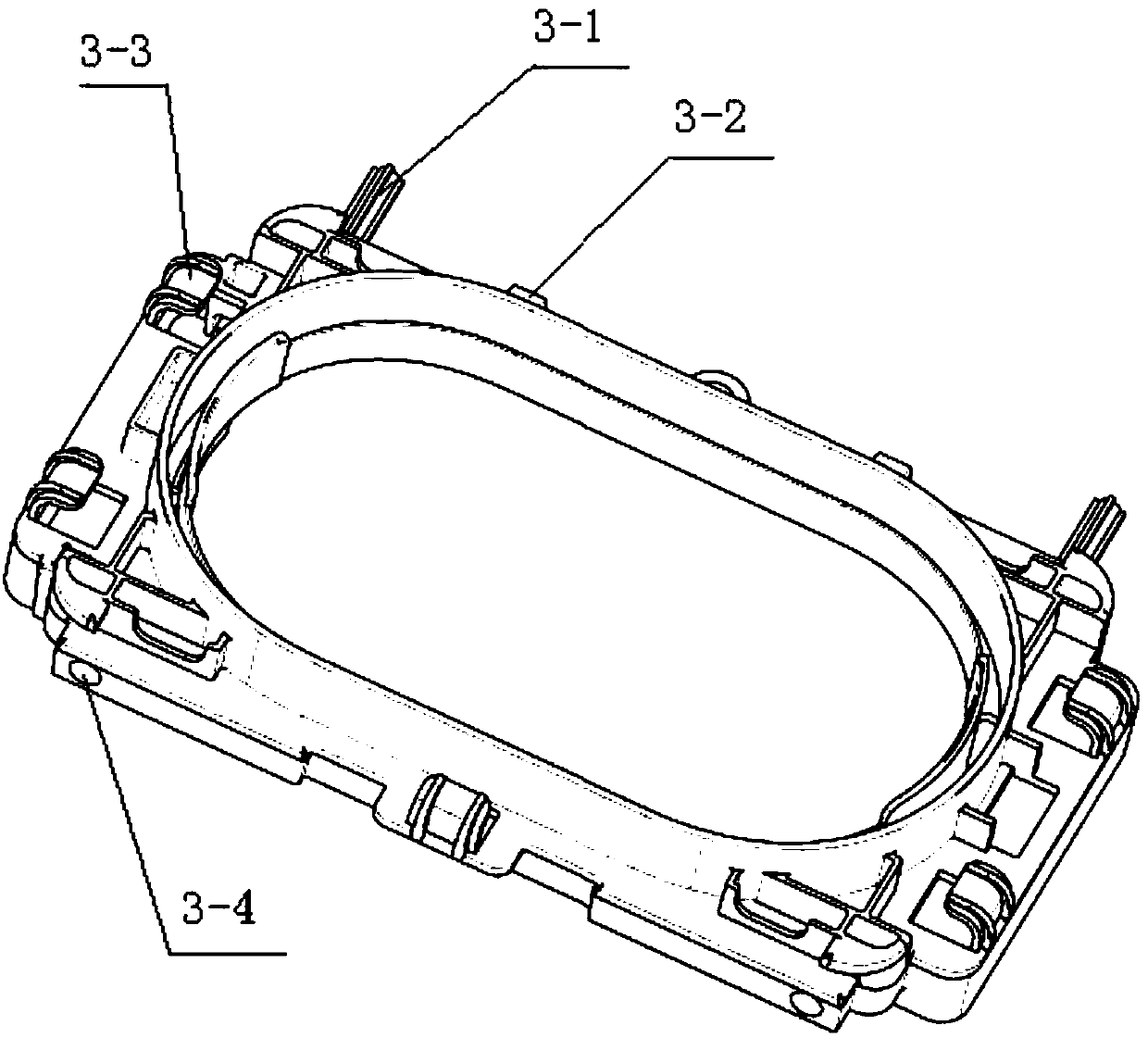

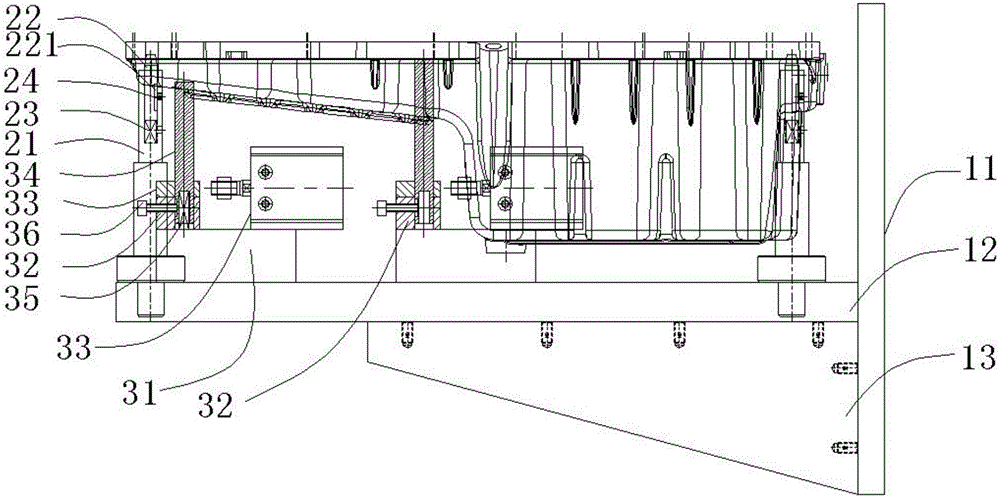

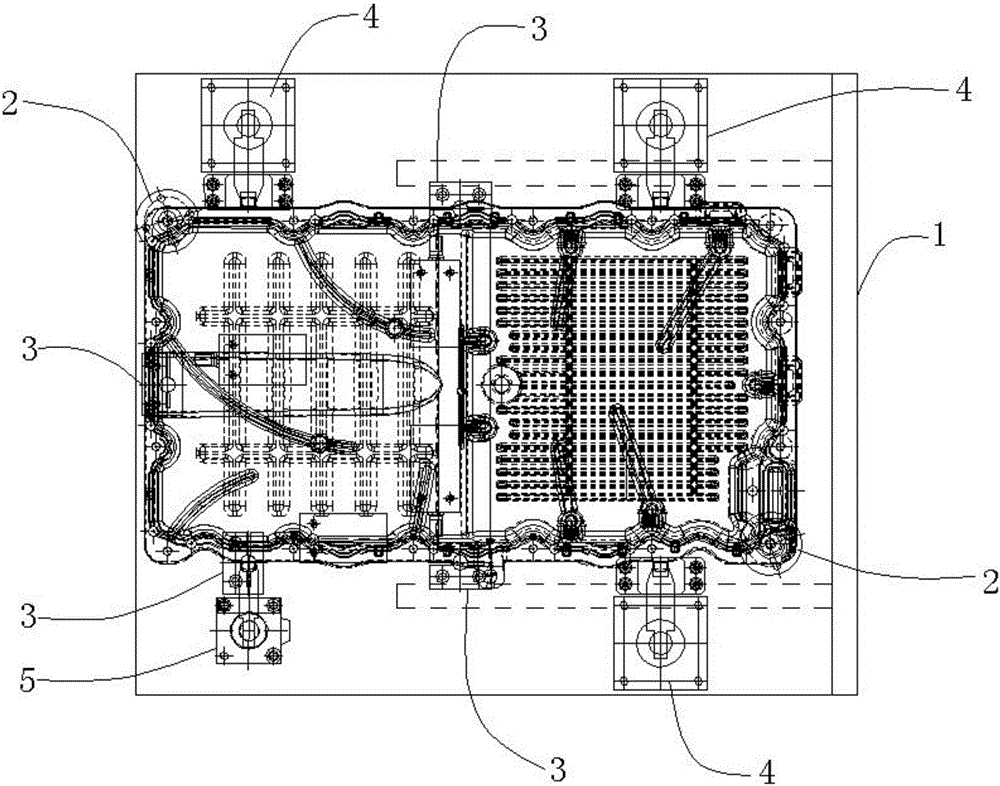

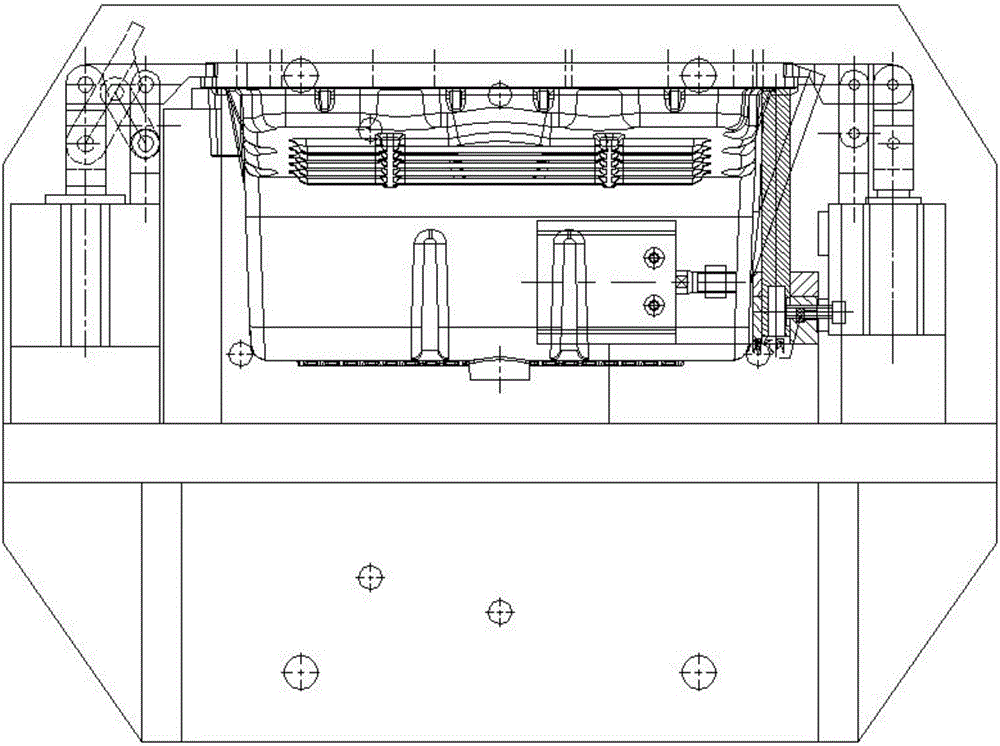

Oil pan machining device

The invention discloses a machining device for an oil pan, comprising a bracket assembly, a number of positioning pin assemblies, a number of support column assemblies, a number of support blocks and a number of pressure plate assemblies, the bracket assembly is used for The fixture is reliably installed in the processing equipment, the positioning pin assembly is located at the upper end of the bracket assembly, the positioning pin assembly and the support column assembly are all provided with floating devices, and the support column assembly, support block and pressing plate assembly are all located at the upper end of the bracket assembly and Distributed around the oil pan, the beneficial effect of this oil pan processing device is to achieve sufficient rigidity for the clamping of the oil pan parts during processing, effectively preventing the deformation of the oil pan parts by the clamping and the damage to the oil pan parts. The impact of machining accuracy improves the yield rate of parts processing. In addition, the clamping force is constant and fast, the efficiency is high, and the work intensity of workers is reduced.

Owner:苏州金澄精密铸造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com