Method of preparing thermoplastic elastomer compound material and product thereof

A technology of thermoplastic elastomers and composite materials, which is applied to the molding of thermoplastic elastomer composite materials for rolling stock and its products. The application fields of the above materials can solve the problems of limiting the service life of products, affecting the safety of vehicles, and poor aging resistance. , to achieve the effects of low production cost, convenient processing, and good high-pressure resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific embodiments.

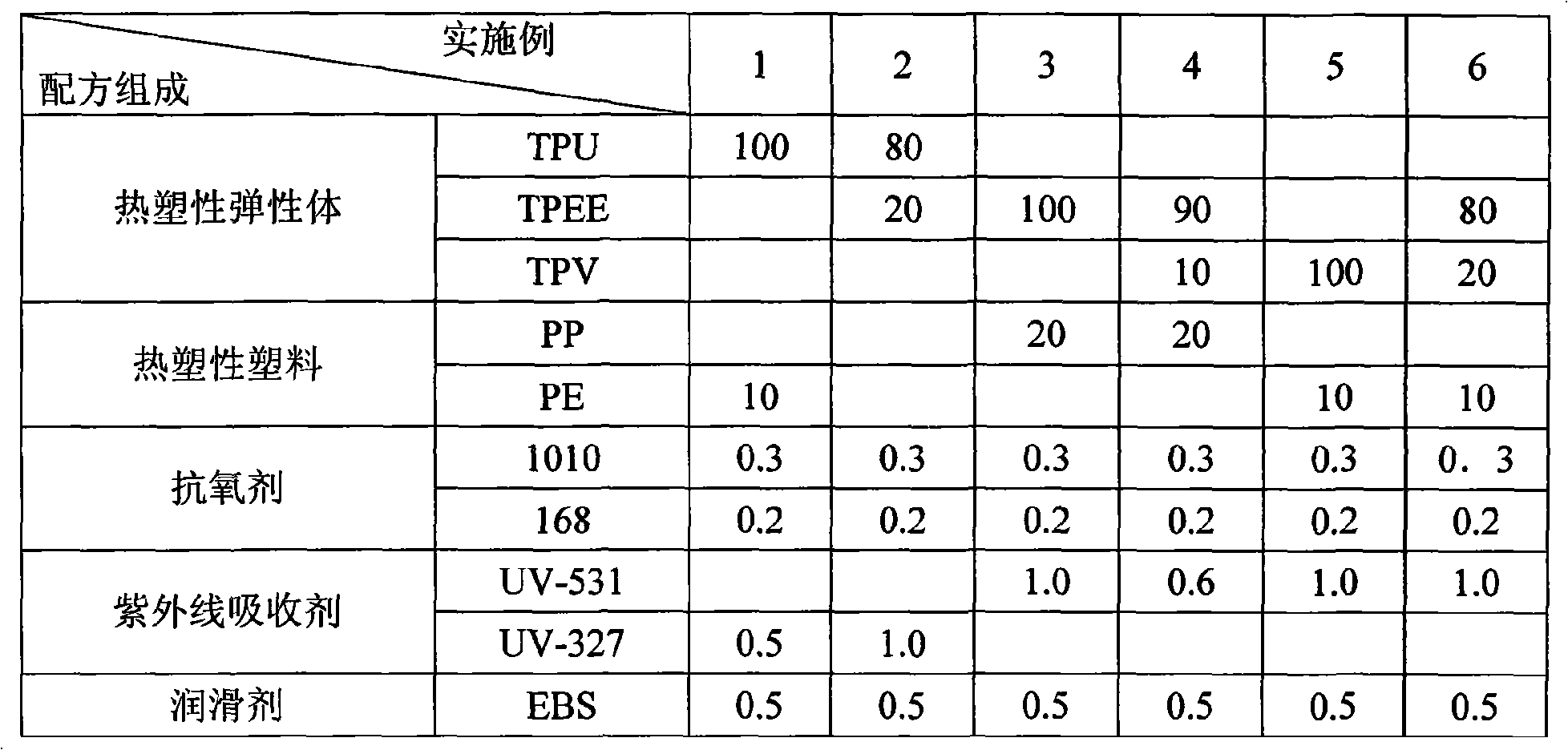

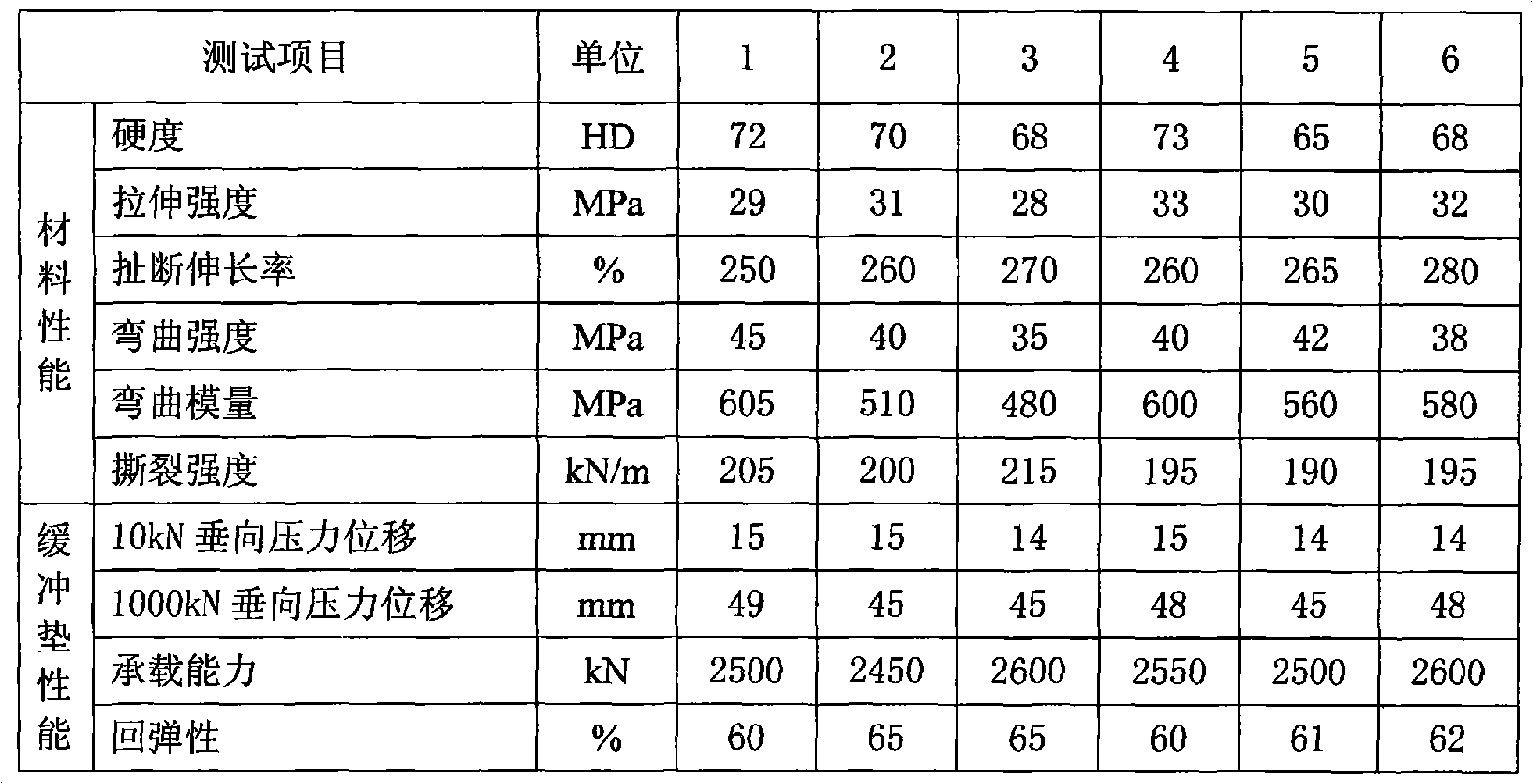

[0020] The formula composition of embodiment one to embodiment six is as table 1.

[0021] As can be seen from the table, the present invention is a production method and material of a thermoplastic elastomer composite material, and the formula of its material is (proportioning by mass parts):

[0022] 100 parts of thermoplastic elastomer;

[0023] Thermoplastic 1-50 parts;

[0024] Antioxidant 0.5-10 parts;

[0025] 0.5-10 parts of ultraviolet absorber;

[0026] 0.5-50 parts of other additives;

[0027] Described thermoplastic elastomer is selected from polyurethane TPU, polyester elastomer TPEE, vulcanized rubber (TPV), and described thermoplastic is selected from polybutylene terephthalate (PBT), polyethylene (PE) and polypropylene (PP).

[0028] The antioxidant is selected from hindered phenolic antioxidants 1010, 1076, 300, 4426, phosphite antioxidant 168, thio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com