Graphene capacitive screen and manufacturing method thereof

A production method and graphene technology, which are applied in the input/output process of electrical digital data processing, instruments, and data processing, etc., can solve the problems affecting the application of capacitive screens, insufficient flexibility, high and low temperature resistance, ozone resistance, ultraviolet resistance, and radiation resistance. Poor performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

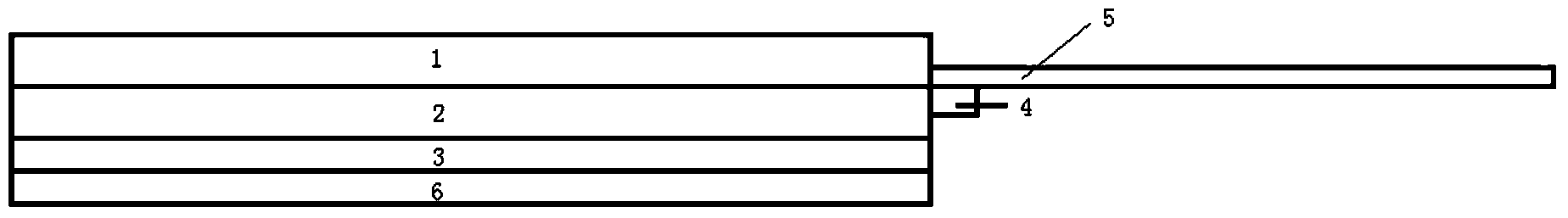

[0030] See figure 1 , the graphene capacitive screen in this embodiment is a capacitive screen with a layer of graphene circuit, and a graphene capacitive touch screen with a single-touch function. like figure 1 As shown, it includes a silicon base layer 1, a first graphene circuit layer 2, a first OCA adhesive layer 3 and a cover plate 6 arranged in sequence; and is connected to the first graphene circuit layer 2 by a first conductive double-sided adhesive layer 4 The FPC5. The thickness of the silica gel base layer 1 is 0.1 mm to 3 mm, and the composition of the silica gel can be changed to control the hardness and transparency as required; the thickness of the first OCA adhesive layer 3 is 0.025 mm to 0.175 mm; the thickness of the first conductive double-sided adhesive layer 4 is 0.03- 0.3mm. The cover plate 5 is one of silica gel, PET, PC, glass and PMMA. Different cover plate materials can meet different needs. Silicone cover plate: it is used to make an all-silicone ...

Embodiment 2

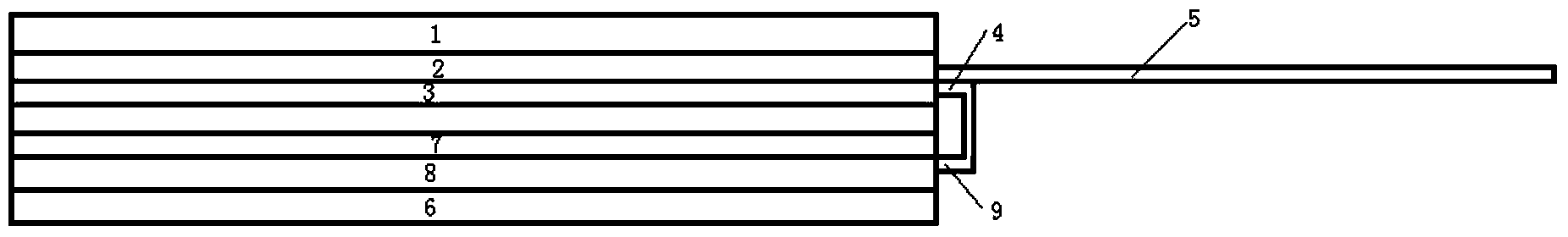

[0040] See figure 2 , which shows a graphene capacitive screen with two-layer graphene circuit layer and dual-touch function. Based on the principle of embodiment 1, it also includes a second graphene circuit layer 7, a second OCA adhesive layer 8 and a second conductive double-sided adhesive layer 9; the adjacent first OCA adhesive layer 3 and the second graphene circuit layer 7 A silica gel layer is arranged between them; the FPC4 is connected with two layers of graphene circuit layers through two layers of conductive double-sided adhesive layers.

[0041] By analogy, a graphene capacitive screen with a multi-touch function including multi-layer graphene circuit layers can also be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com