Patents

Literature

183results about How to "Small permanent deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoplastic polyurethane elastomer foam material and preparation method thereof

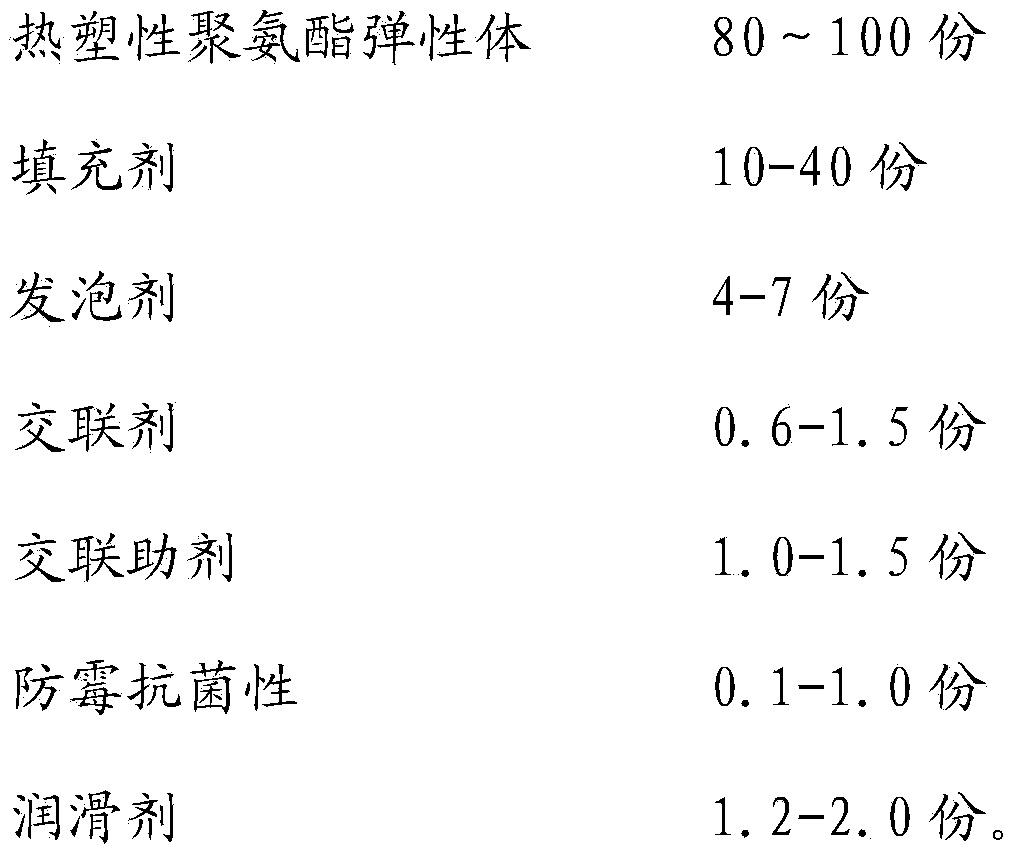

The invention discloses a thermoplastic polyurethane elastomer foam material, which is prepared from the following raw materials by weight: 80-100 parts of a thermoplastic polyurethane elastomer, 10-40 parts of a filler, 4-7 parts of a foaming agent, 0.6-1.5 parts of a cross-linking agent, 1.0-1.5 parts of a cross-linking assistant, 0.1-1.0 part of a mildew proof antibacterial agent and 1.2-2.0 parts of a lubricant. Adopting the above technical scheme, the invention has the beneficial effects of improving the foam expansion of the thermoplastic polyurethane foam material, expanding the scope of usage of the polyurethane foam material, and realizing compression deformation of a finished product produced from the thermoplastic polyurethane foam at no more than 35%, which is unmatched by an EVA foam material with equivalent foam expansion and similar elasticity. In addition, the foam material improves the performance of existing traditional foam materials, and solves the defects that polyester-type thermoplastic polyurethane elastomer has short service life, easily goes moldy on the product surface and generates mechanical performance loss in the field and damp and hot environment.

Owner:泉州三盛橡塑发泡鞋材有限公司

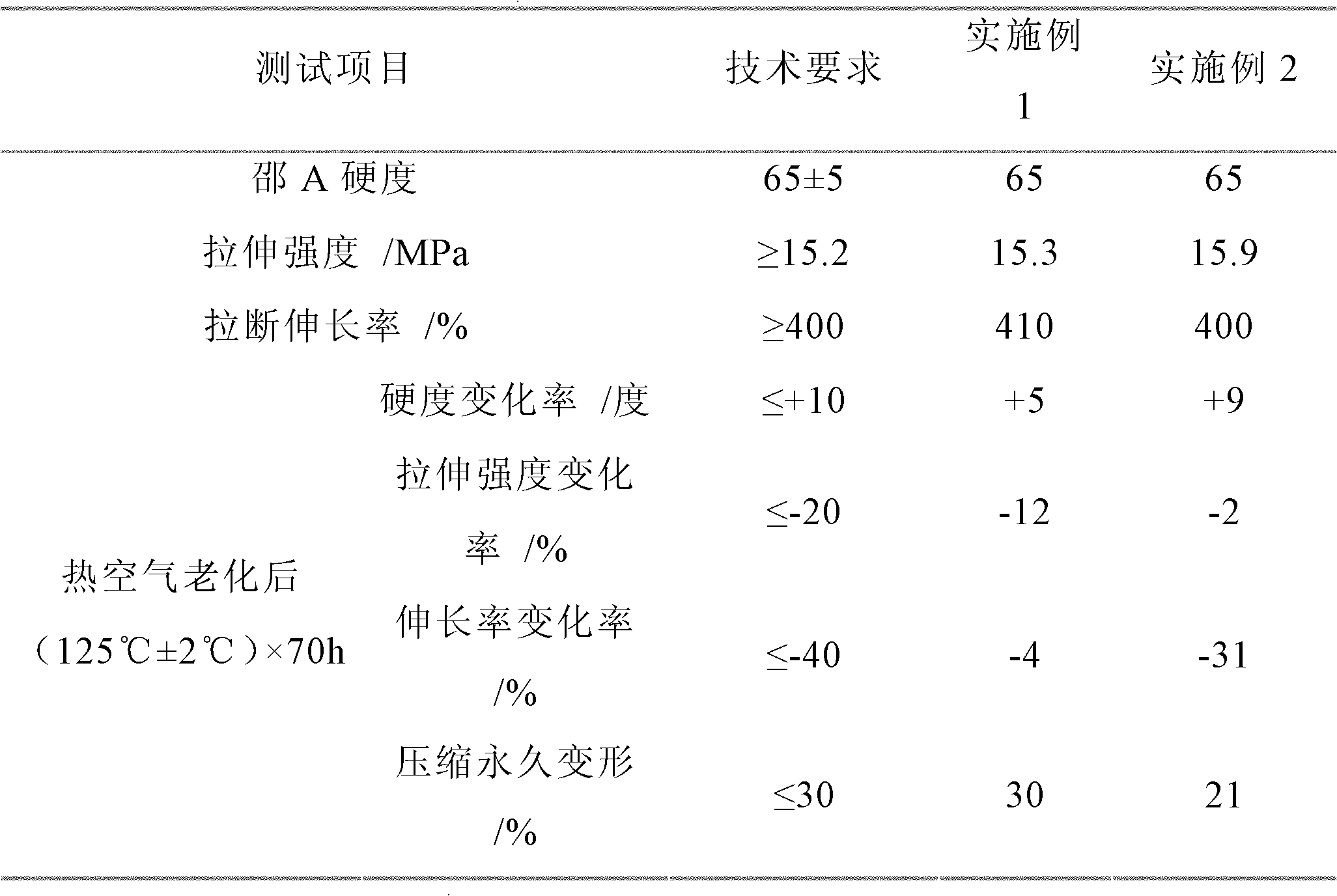

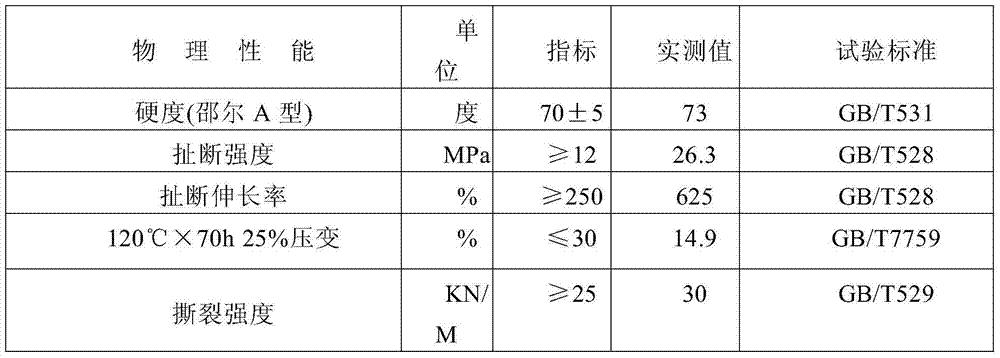

Ethylene propylene diene rubber composition and preparation method

The invention discloses an ethylene propylene diene rubber composition and a preparation method. The preparation method comprises the following steps of: firstly, performing after plastication on ethylene propylene diene rubber; then, adding zinc oxide, stearic acid, anti-aging agent, carbon black, plasticizers, accelerant, vulcanizer and the like in sequence; evenly mixing and then extruding a sheet; and preparing the sheet into the ethylene propylene diene rubber / carbon black nanometer composite material by adopting the after vulcanization process. Through adding various plasticizers and adopting special process treatment, the tensile strength of the ethylene propylene diene rubber composition disclosed by the invention is at least 15.2MPa, the elongation at break is at least 400 percent, and the compression set is lower than 30 percent under the condition of 125 DEG C*70h. The composite material can be used as a sealing article of rubber, especially a rubber sealing washer applied to a groove-type pipeline joint part of an automatic water spray fire extinguishing system, and thereby, a long-term sealing effect is ensured.

Owner:BEIJING RES & DESIGN INST OF RUBBER IND

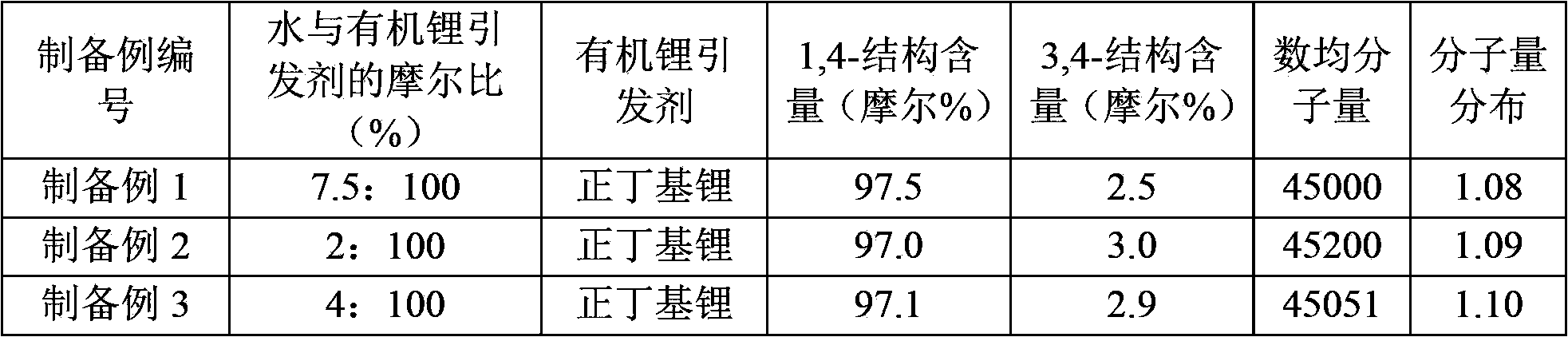

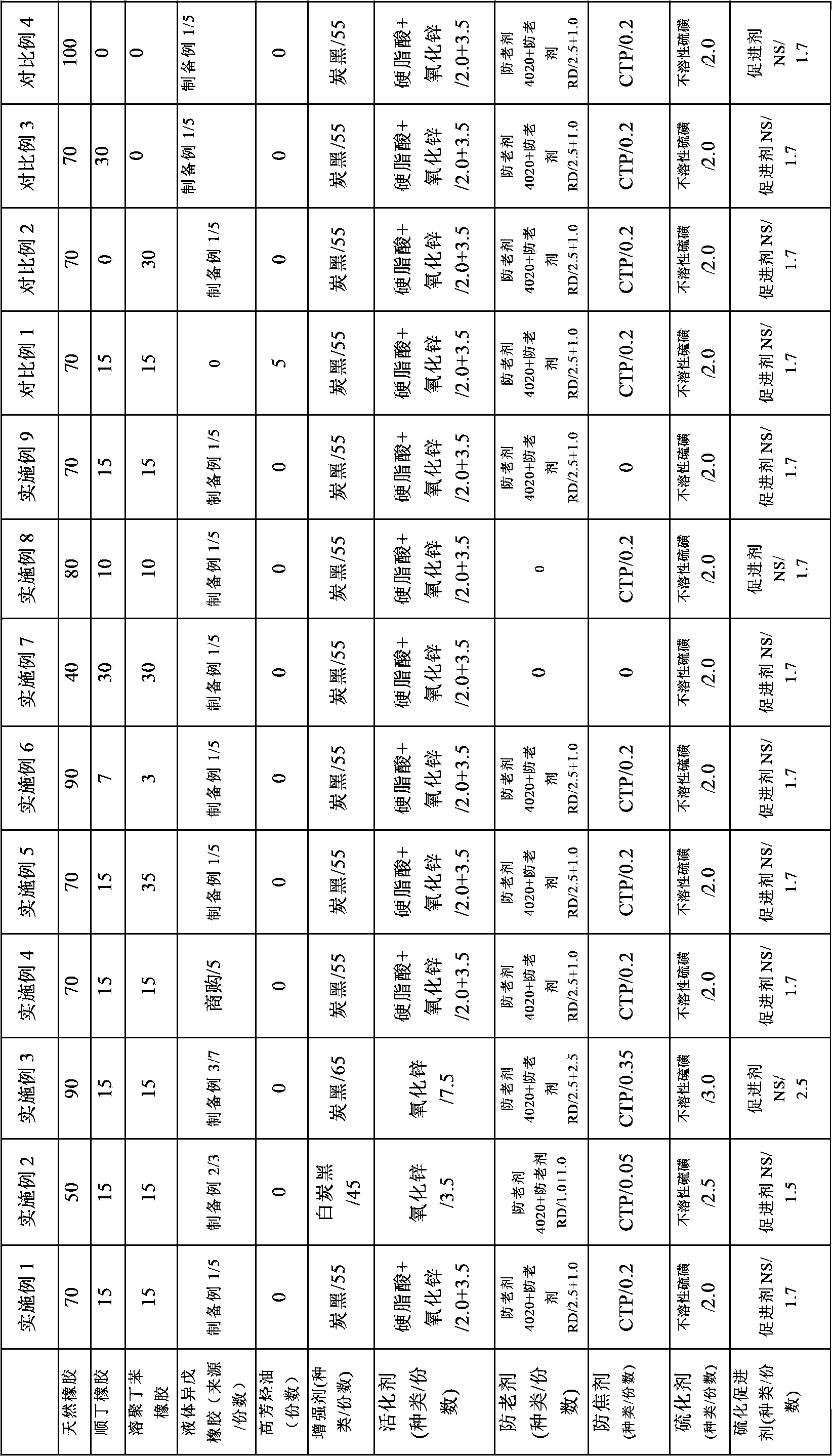

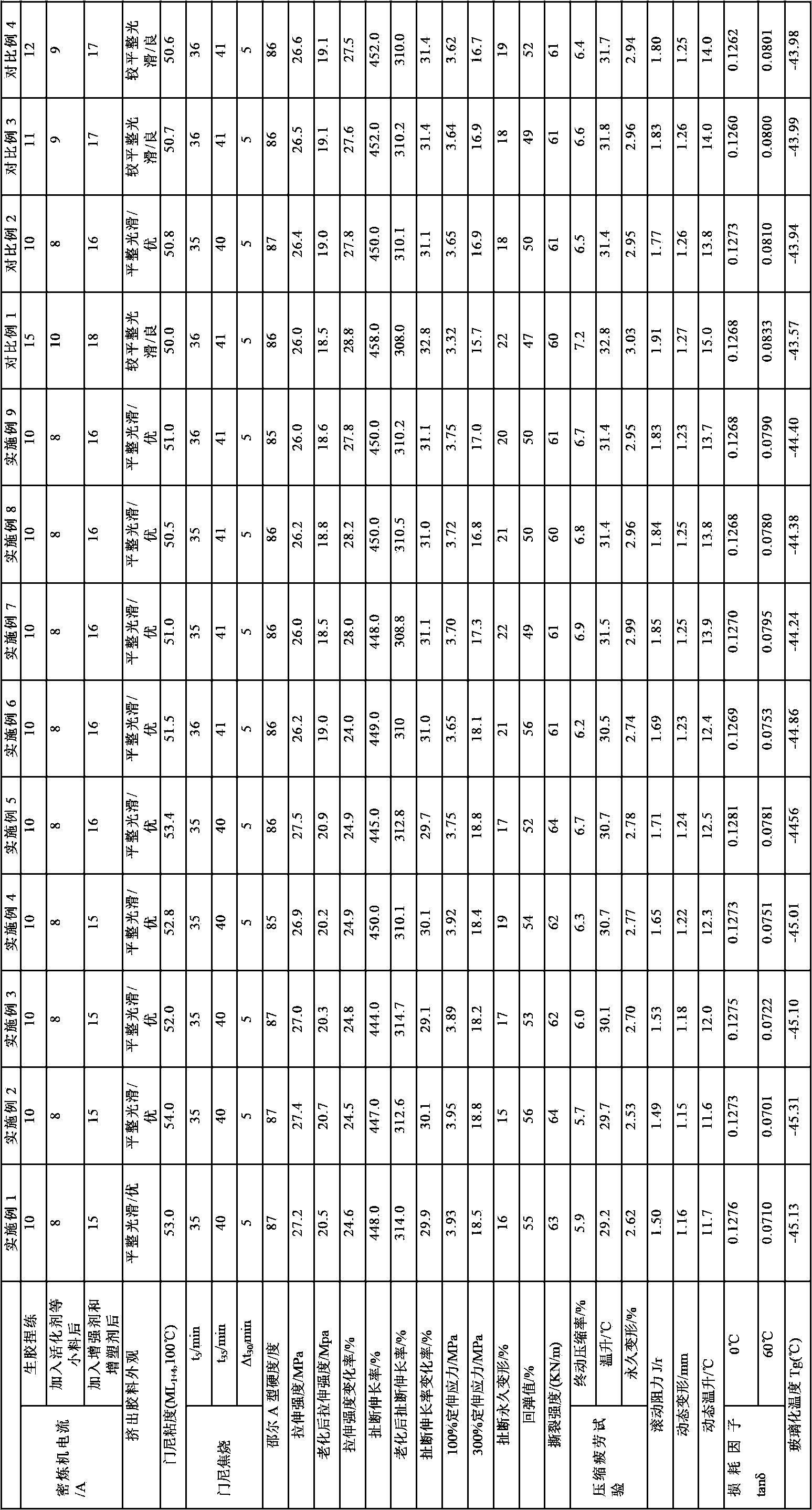

Rubber composition, tyre tread rubber and preparation method thereof

ActiveCN103788422AImprove securityEnsure safetySpecial tyresRolling resistance optimizationRubber materialRolling resistance

The invention relates to a rubber composition. The composition comprises a main body rubber, a vulcanizing agent, a vulcanization accelerator, an activator and a reinforcing agent. The composition also comprises liquid isoprene rubber. The main body rubber comprises natural rubber, butadiene rubber and solution polymerized styrene-butadiene rubber. The invention also discloses tyre tread rubber and a preparation method thereof. The tyre tread rubber provided by the invention is low in processing energy consumption, good in surface quality of extruding and calendaring rubber materials, good in physical and mechanical properties and ageing resistant property, and relatively small in compression set and heat generation, and can improve durability of the tyre and prolong the service life of the tyre. The tyre tread rubber provided by the invention has good wet skid resistance and low rolling resistance, can guarantee security of the tyre in a driving process and is benefit for energy conservation of the tyre.

Owner:CHINA PETROLEUM & CHEM CORP +1

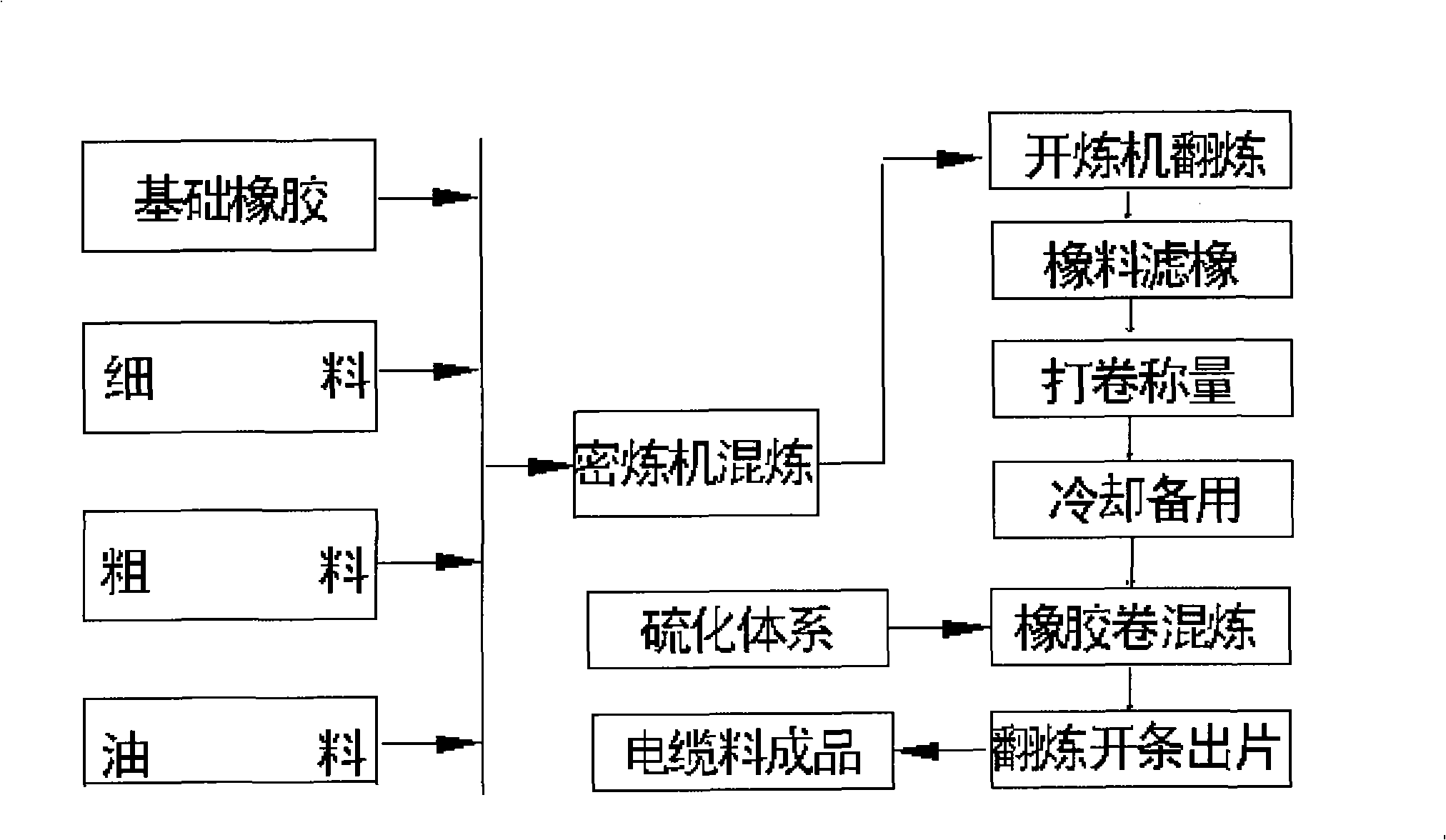

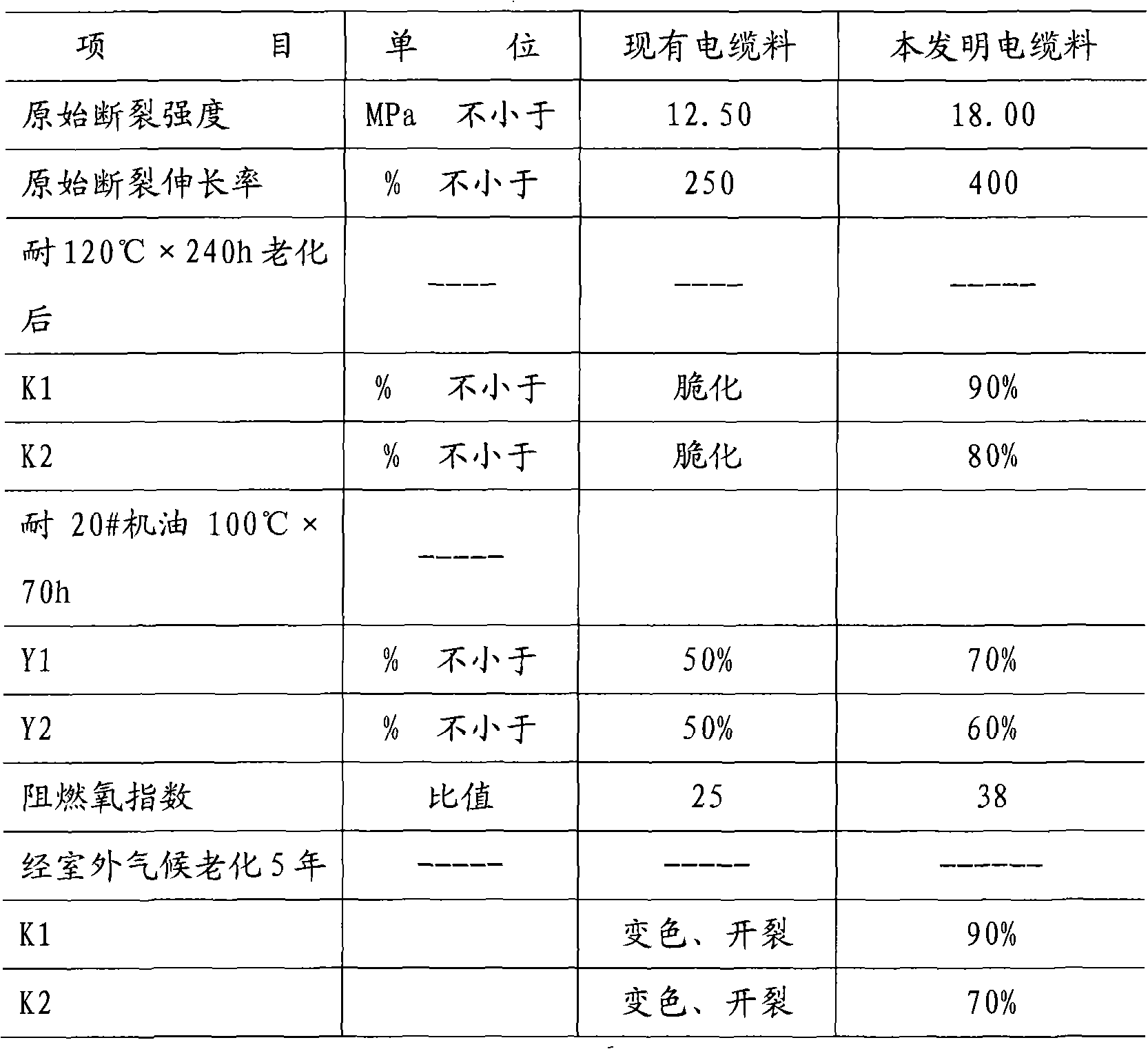

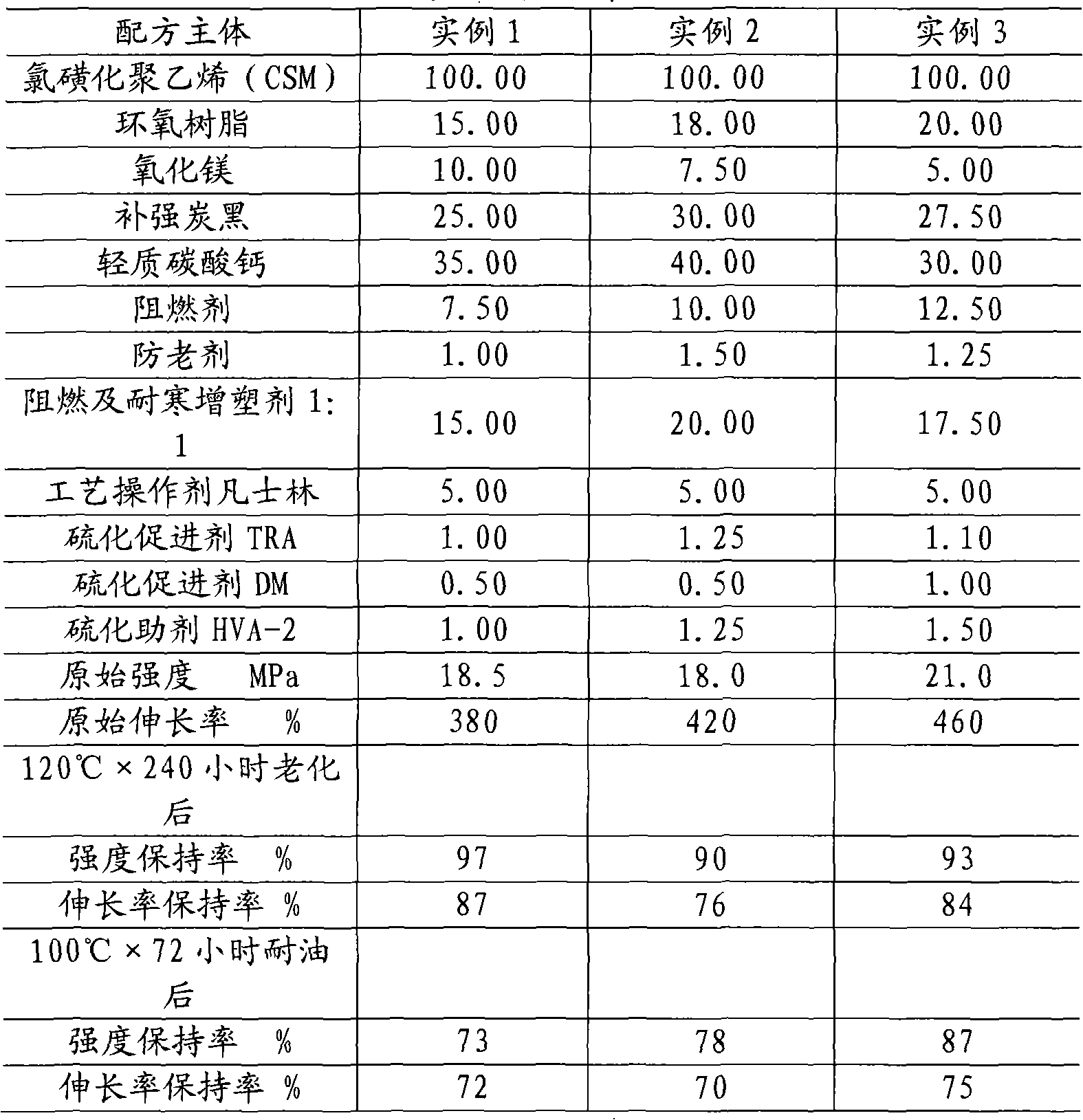

External rubber sleeve material of cable for wind power generation

InactiveCN101538391AEasy to operateImprove water resistanceInsulated cablesInsulated conductorsEpoxyVulcanization

The invention discloses an external rubber sleeve material of a cable used for wind power generation, comprising the following components by weight parts: 100.00 parts of chlorosulfonated polyethylene rubber, 15.00-20.00 parts of vulcanizing agent epoxy resin, 5.00-10.00 parts of magnesium oxide acid acceptor, 1.00-1.50 parts of vulcanization aid, 0.20-1.50 parts of vulcanization accelerator, 10.00-15.00 parts of fire-retardant plasticizer, 5.00-10.00 parts of cold resistant plasticizer, 30.00-40.00 parts of reinforcing agent, 40.00-50.00 parts of filling agent, 0.50-2.00 parts of anti-ageing agent, 0.50-2.00 parts of process operation agent, and 10.00-15.00 parts of flame retardant. The external rubber sleeve material of the cable used for wind power generation has the greatest advantages of extremely high physical and mechanical performance, excellent oil resistance and climate resistance, extremely softness and flame retarding, and the like.

Owner:ANHUI ZONGHENG HI TECH CABLE +1

Method of preparing thermoplastic elastomer compound material and product thereof

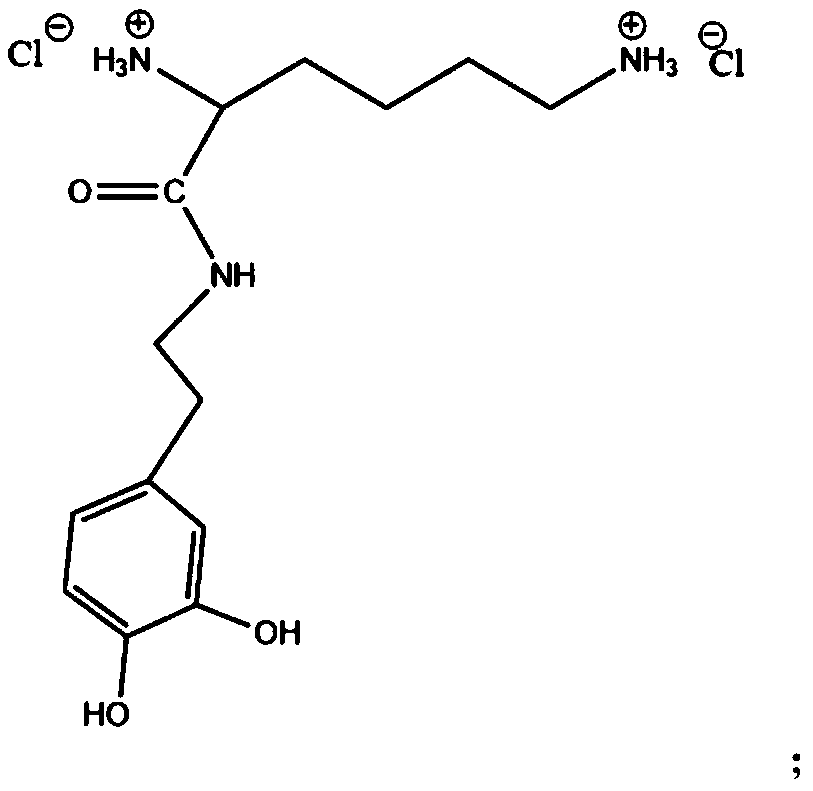

InactiveCN101550281AGood high pressure resilienceSmall permanent deformationThermoplasticInjection molding machine

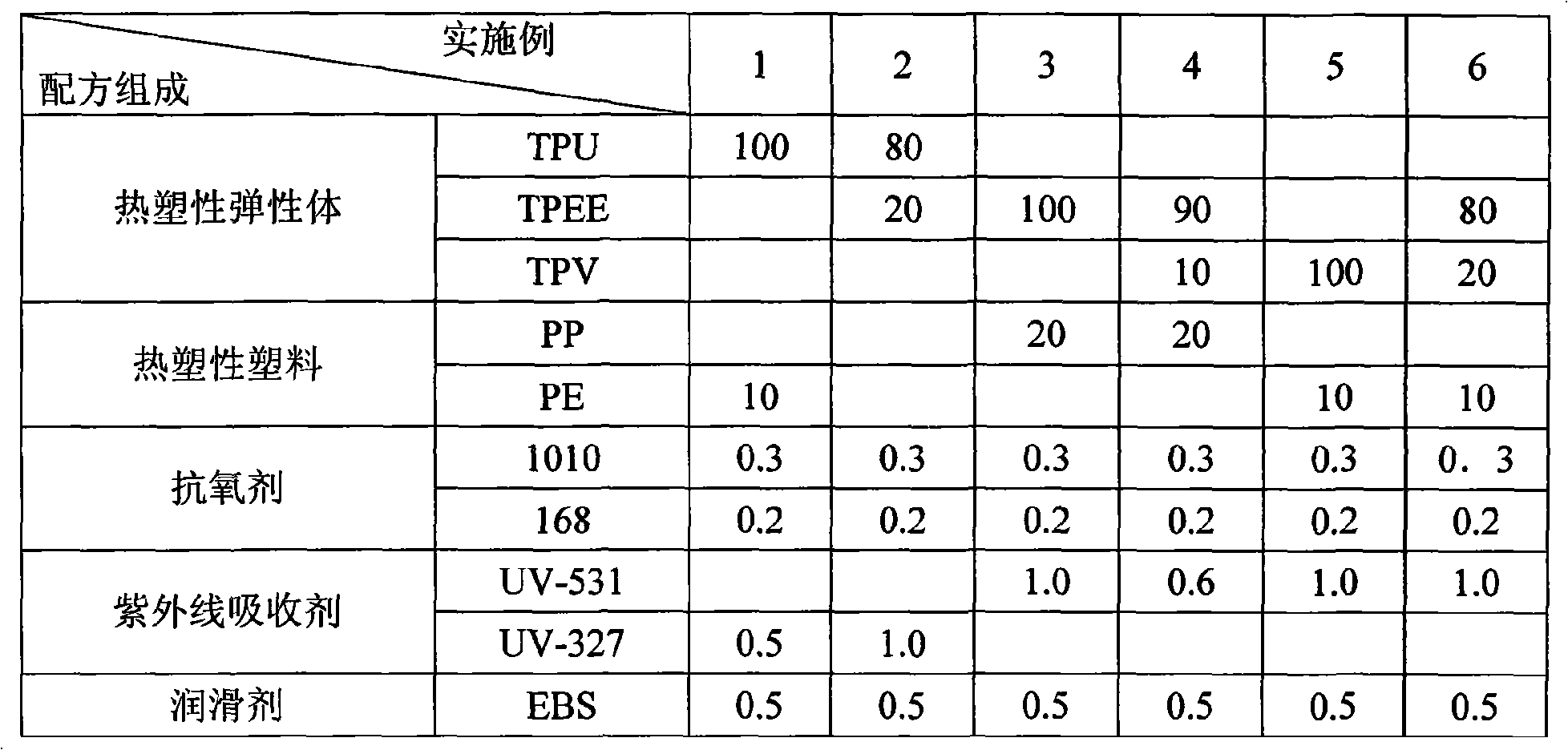

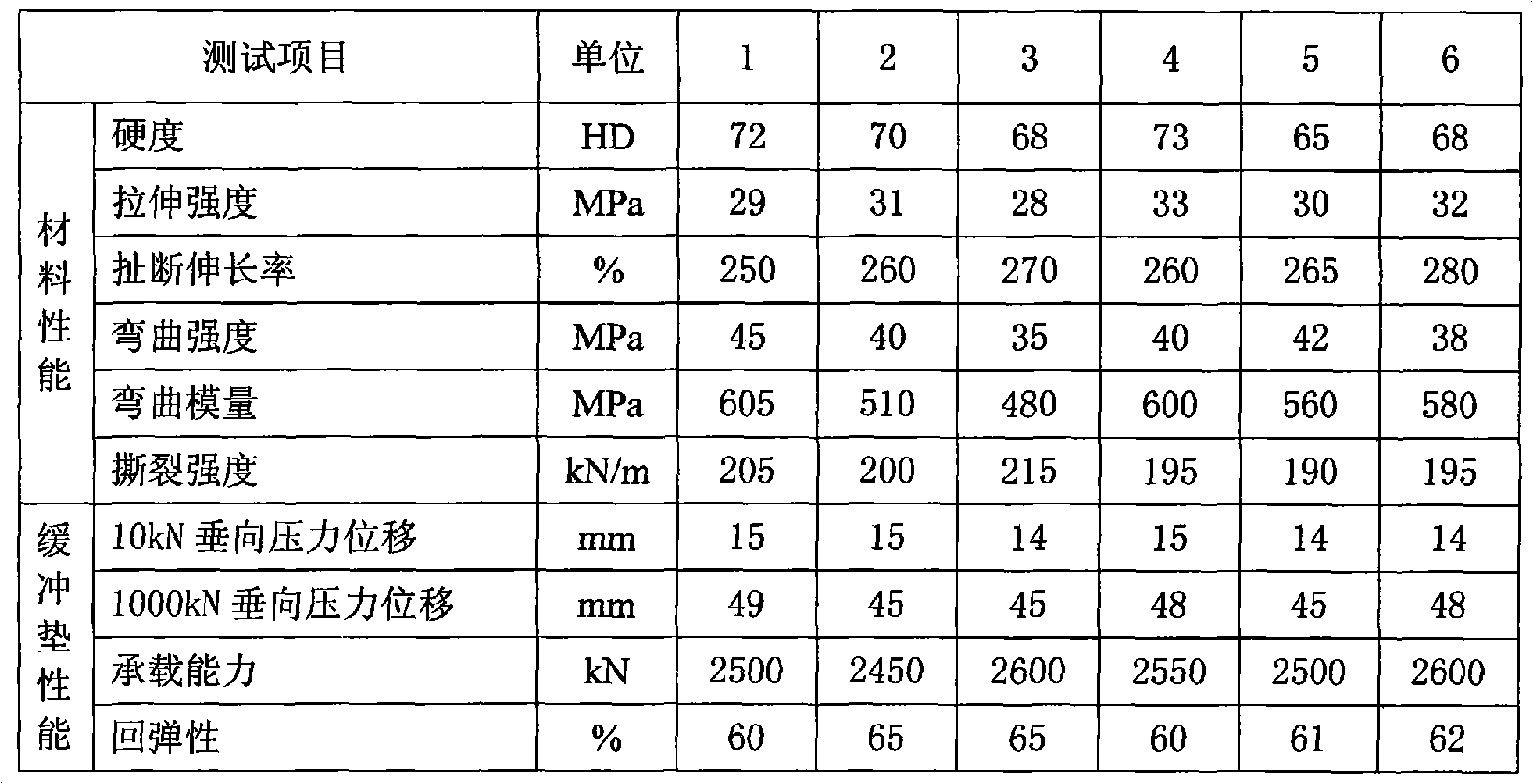

Method of preparing thermoplastic elastomer compound material and product thereof, applying post forming technics. The post forming technics is: first prepare the mold core by the method of injection molding or compression molding; then put the mold core into the mould and produce product with mold core by the compression molding method, taking the mold core out of the product by mechanical crushing, getting the product of hollow thermoplastic elastomer compound material. The post forming method includes following steps: 1) preparing the mold core by the injection molding of the compression molding method; 2) putting the mold core into the mould and producing product with the mold core by the injection molding method; 3) taking the mold core out of the product by mechanical crushing to get the hollow product. 4) the crushed mold core can be reclaimed for recreating use. The thermoplastic elastomer product prepared by the invention provided moulding preparation method is in formula (in mass parts proportioning): thermoplastic elastomer 100parts; thermoplastic plastics 1-50 parts; anti-oxidant 0.5-10 parts; ultraviolet absorbent 0.5-10 parts; lubricants 0.1-5.0 parts.

Owner:株洲时代工程塑料制品有限责任公司

Diatomite rubber reinforcing agent

The present invention, diatomite rubber reinforcing agent, relates to non-metal mineral product. The present invention features that diatomite is prepared into the diatomite rubber reinforcing agent to replace white carbon black. The rubber reinforcing agent with high quality and low cost is prepared with diatomite and through material selection, eliminating impurity, drying in kiln, crushing, wind selection and other technological processes.

Owner:马菊云

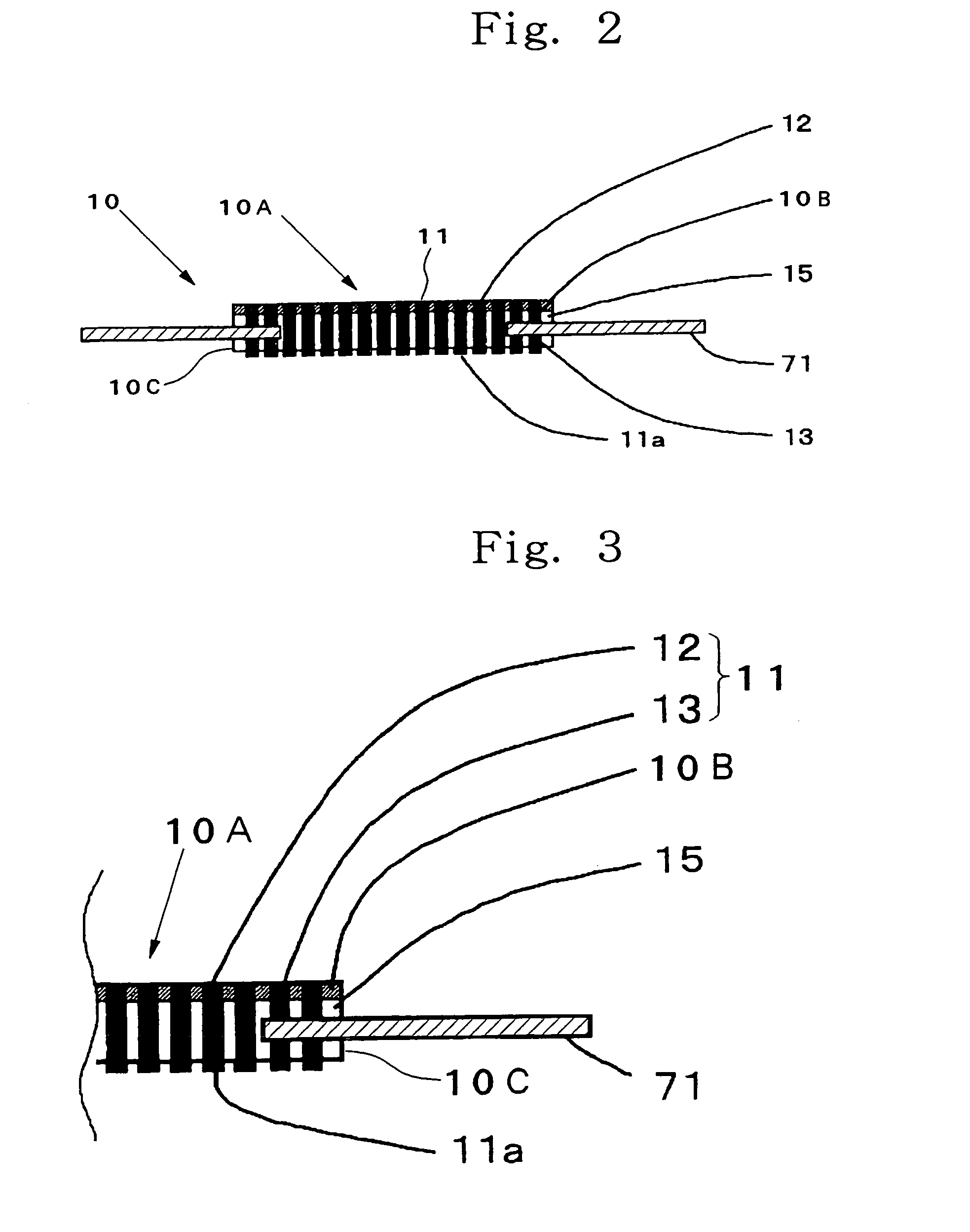

Anisotropic conductive connector and production method therefor and inspection unit for circuit device

ActiveUS7190180B2Necessary conductivity can be surely achievedImprove conductivityLine/current collector detailsElectrical measurement instrument detailsAnisotropic conductive filmSurface layer

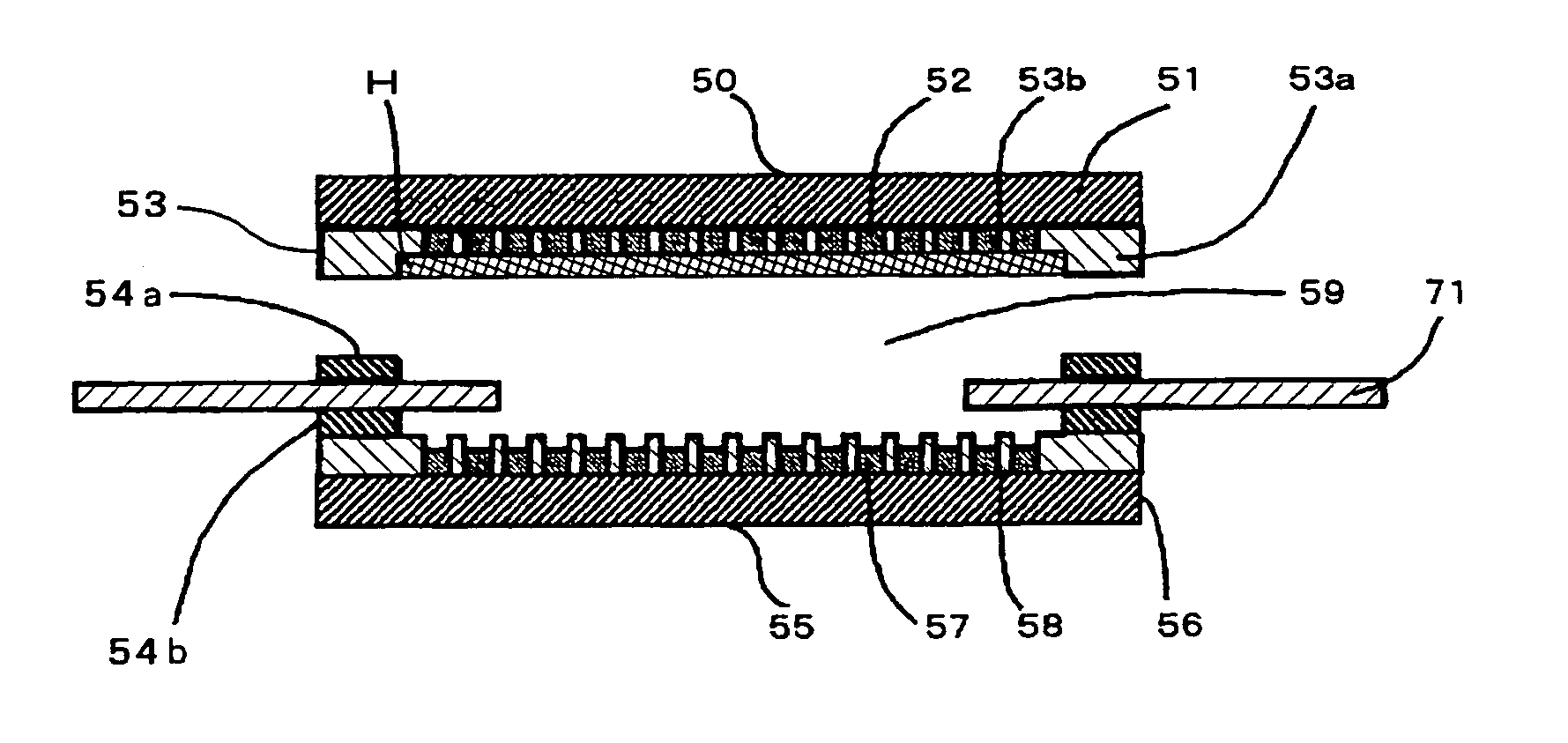

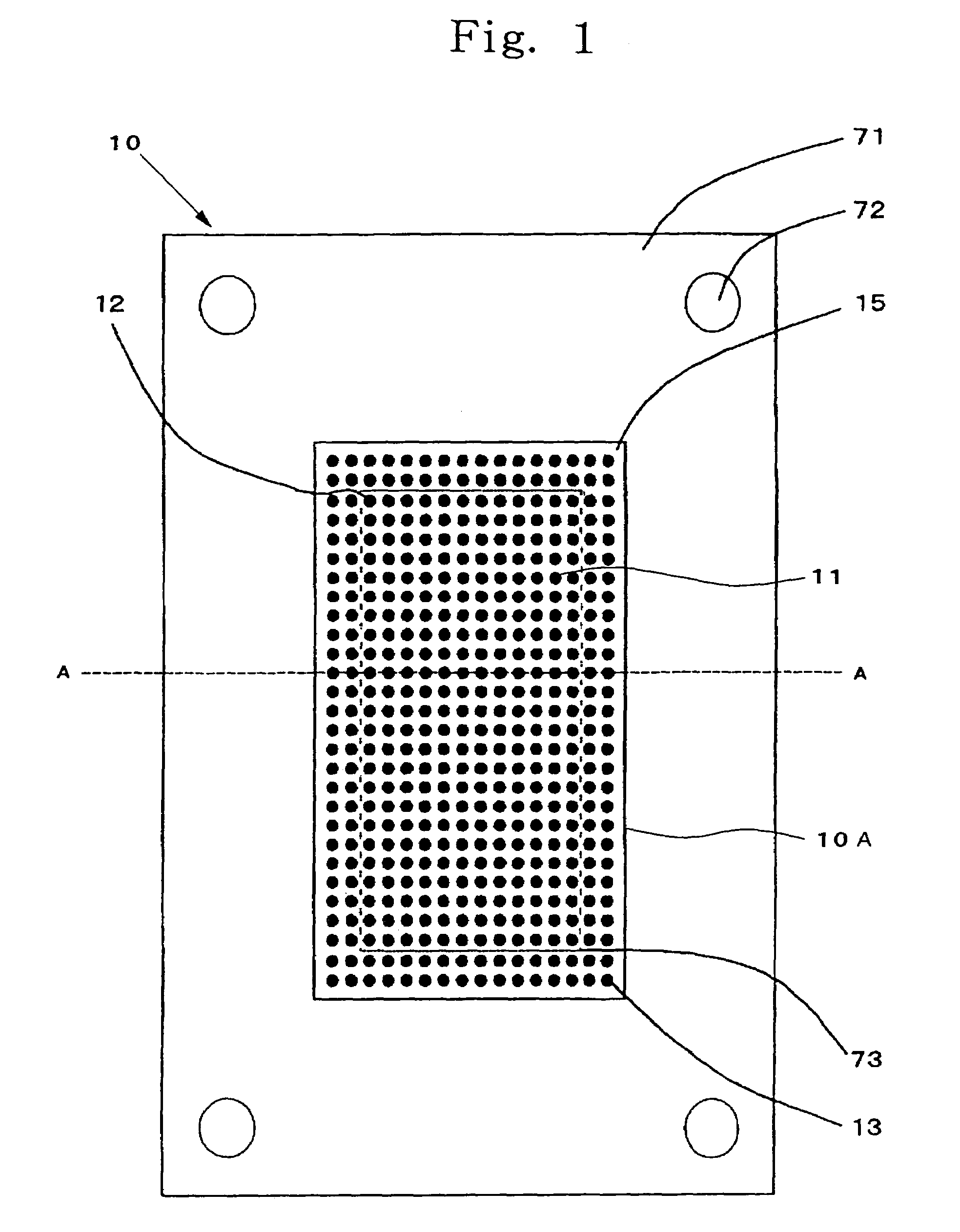

An anisotropically conductive connector, inhibits permanent deformation by contact of target electrodes to be connected with pressure and deformation by abrasion from occurring even if the target electrodes to be connected are those projected, achieves stable conductivity over a long period of time even when it is pressed repeatedly, and prevents or inhibits an object of connection from adhering, a production process thereof, and an inspection apparatus for circuit devices equipped with the anisotropically conductive connector. The anisotropically having an anisotropically conductive film, in which a plurality of conductive path-forming parts each extending in a thickness-wise direction of the film are arranged in a state mutually insulated by insulating parts. The anisotropically conductive film is formed by an insulating elastic polymeric substance, conductive particles exhibiting magnetism are contained in the conductive path-forming parts, and a reinforcing material formed of insulating mesh or nonwoven fabric is contained in a surface layer portion on one surface side of the anisotropically conductive film.

Owner:ISC CO LTD

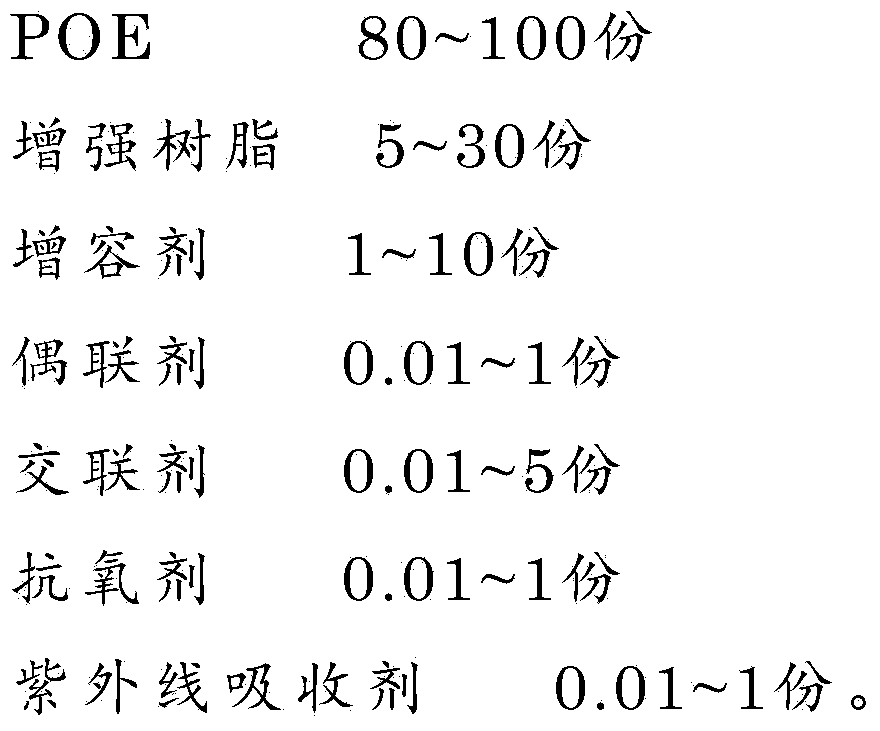

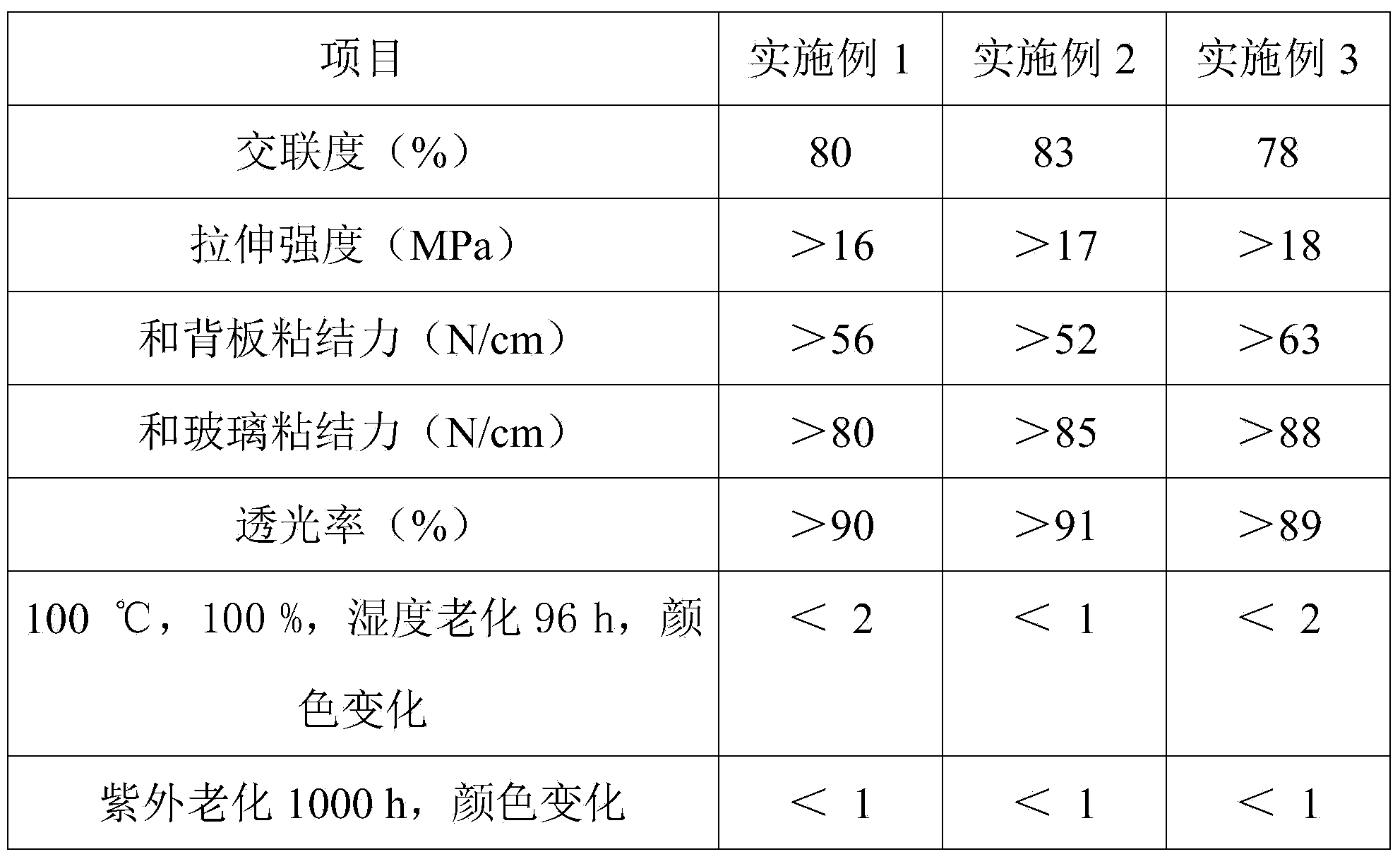

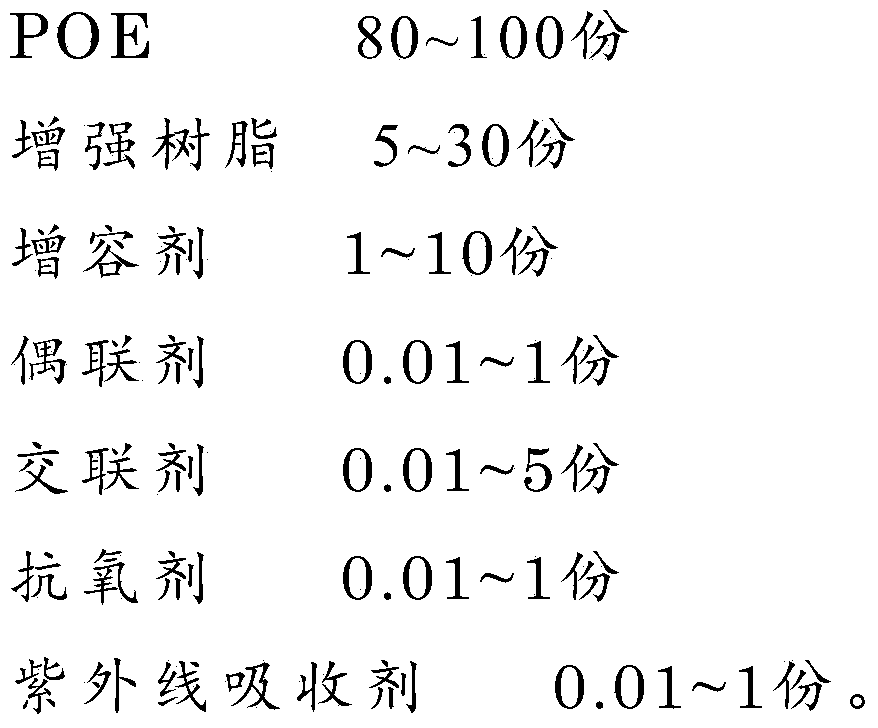

Intensified POE (Polyolefin Elastomer) photovoltaic packaging adhesive film as well as preparation process and application thereof

ActiveCN104231954AGood aging resistanceGuaranteed long service lifeNon-macromolecular adhesive additivesFilm/foil adhesivesChemistryPolyolefin

The invention discloses an intensified POE (Polyolefin Elastomer) photovoltaic packaging adhesive film which is prepared from the following raw materials in parts by weight: 80-100 parts of POE, 5-30 parts of intensified resin, 1-10 parts of a compatibilizer, 0.01-1 part of a coupling agent, 0.01-5 parts of a cross-linking agent, 0.01-1 part of antioxidant and 0.01-1 part of an ultraviolet absorbent. The adhesive film is high in tensile strength, high in aging resistance and resistant to yellowing, and the service life of a component can be prolonged.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

Method for preparing anti-freezing flame-retardant sheath

InactiveCN101649090AIncrease elasticitySmall permanent deformationInsulated cablesInsulated conductorsAnti freezingPolymer science

The invention relates to a process method for a sheath of a power transmission and transformation wire, in particular to a method for preparing an anti-freezing flame-retardant sheath. The method is characterized in that the anti-freezing flame-retardant sheath is prepared from the following raw materials in percentage by weight: 50 portions of base material, 1 portion of vulcanizing agent, 40 portions of strengthened plasticizer, 2 portions of antiager, 2 portions of damp-proof and moisture-proof separant and 5 portions of flame retardant. The anti-freezing flame-retardant sheath is preparedfrom novel high molecular materials, can protect power transmission and transformation wires, and can achieve the anti-freezing and flame-retardant effect.

Owner:陈志海

Process for producing ageing-resistant tire bladder sizing material

InactiveCN104017280AImprove thermal stabilityImprove antioxidant capacityMicrocrystalline waxProcess engineering

The invention discloses a process for producing an ageing-resistant tire bladder sizing material. The process comprises the steps of (1) respectively weighing chlorinated butyl rubber and chloroprene rubber, adding the rubber into an internal mixer, mixing for 1-1.5 minutes, then adding butyl rubber, performing primary mixing, adding zinc oxide, microcrystalline wax and carbon black after 2-3 minutes, mixing for 3-5 minutes, adding castor oil, mixing, discharging the rubber after 3-4 minutes, and performing open mixing; (2) filtering the primary mixed rubber in a rubber filter; (3) adding the filtered mother rubber into the internal mixer, performing secondary mixing, adding a vulcanizing agent after mixing for 1-2 minutes, and discharging the rubber after 1-2 minutes; (4) extruding the secondary mixed rubber into a shape required by a die pressing vulcanizing machine or an injection vulcanizing machine by adopting a cold feed extruder. The process disclosed by the invention is improved from the formula and the production process, so that the production efficiency of bladders is greatly improved, the problems of surface cracking, seam allowance cracking and short service life of a finished product under severe use conditions are solved, the qualification rate of the bladder product is greatly improved, and the service life of the bladder product is greatly prolonged.

Owner:东营金泰轮胎胶囊有限公司

High-wear resistance cable sheath material

ActiveCN103265738AGood physical propertiesDimensionally stableInsulated cablesInsulated conductorsWaxPolypropylene

The invention discloses a high-wear resistance cable sheath material. The high-wear resistance cable sheath material comprises the following raw materials by weight: 90 to 100 parts of chloroprene rubber DCR114, 10 to 20 parts of EPDM 4770R, 15 to 20 parts of nanometer bauxite, 20 to 30 parts of a modification filling material, 8 to 10 parts of dioctyl sebacate, 3 to 4 parts of polypropylene adipate, 4 to 6 parts of acetyl triethyl citrate, 2 to 4 parts of zinc oxide, 6 to 8 parts of chlorinated paraffin, 2 to 3 parts of antimony trioxide, 2 to 4 parts of triphenyl phosphite, 1 to 2 parts of the anti-aging agent MB, 1 to 2 parts of the promoter CZ and 0.8 to 1 part of sulphur. The cable sheath material produced in the invention has excellent physical properties, a stable dimension, low shrinking percentage, high tensile strength, great tearing strength, strong resilience and good resistance to oil, heat, burning, sunlight, ozone, acid and alkali and chemical reagents; and the modification filling material provided by the invention has good dispersibility and low surface tension, enables tensile strength and stress at definite elongation of the cable sheath material to be further improved, reduces heat generation and compression set, delays the ageing speed of the cable sheath material, is capable of resisting acid and alkali and allows production cost to be reduced.

Owner:ANHUI KANGLIYA CO LTD

Flame retardant cable sheath material

ActiveCN103265739AGood physical propertiesDimensionally stableRubber insulatorsInsulated cablesPolymer scienceCompression set

The invention discloses a flame retardant cable sheath material. The flame retardant cable sheath material comprises the following raw materials by weight: 97 to 100 parts of chloroprene rubber SN23, 10 to 15 parts of chlorinated polyethylene, 15 to 20 parts of hydrotalcite, 8 to 10 parts of magnesium carbonate, 18 to 25 parts of a modification filling material, 4 to 5 parts of trioctyl trimellitate, 3 to 4 parts of methylpentachlorostearate, 1 to 2 parts of an anti-aging agent ODA, 1 to 2 parts of a promoter TMTM, 1 to 2 parts of 3-aminopropyltrimethoxysilane, 3 to 4 parts of ethylene bis stearamide, 2 to 4 parts of aluminum tripolyphosphate, 1 to 2 parts of ferrocene, 1 to 2 parts of an anti-oxidant 168 and 1 to 3 parts of benzotriazole. The cable sheath material produced in the invention has excellent physical properties, a stable dimension, low shrinking percentage, high tensile strength, great tearing strength, strong resilience and good resistance to oil, heat, burning, sunlight, ozone, acid and alkali and chemical reagents; and the modification filling material provided by the invention has good dispersibility and low surface tension, enables tensile strength and stress at definite elongation of the cable sheath material to be further improved, reduces heat generation and compression set, delays the ageing speed of the cable sheath material, is capable of resisting acid and alkali and allows production cost to be reduced.

Owner:ANHUI KANGLIYA CO LTD

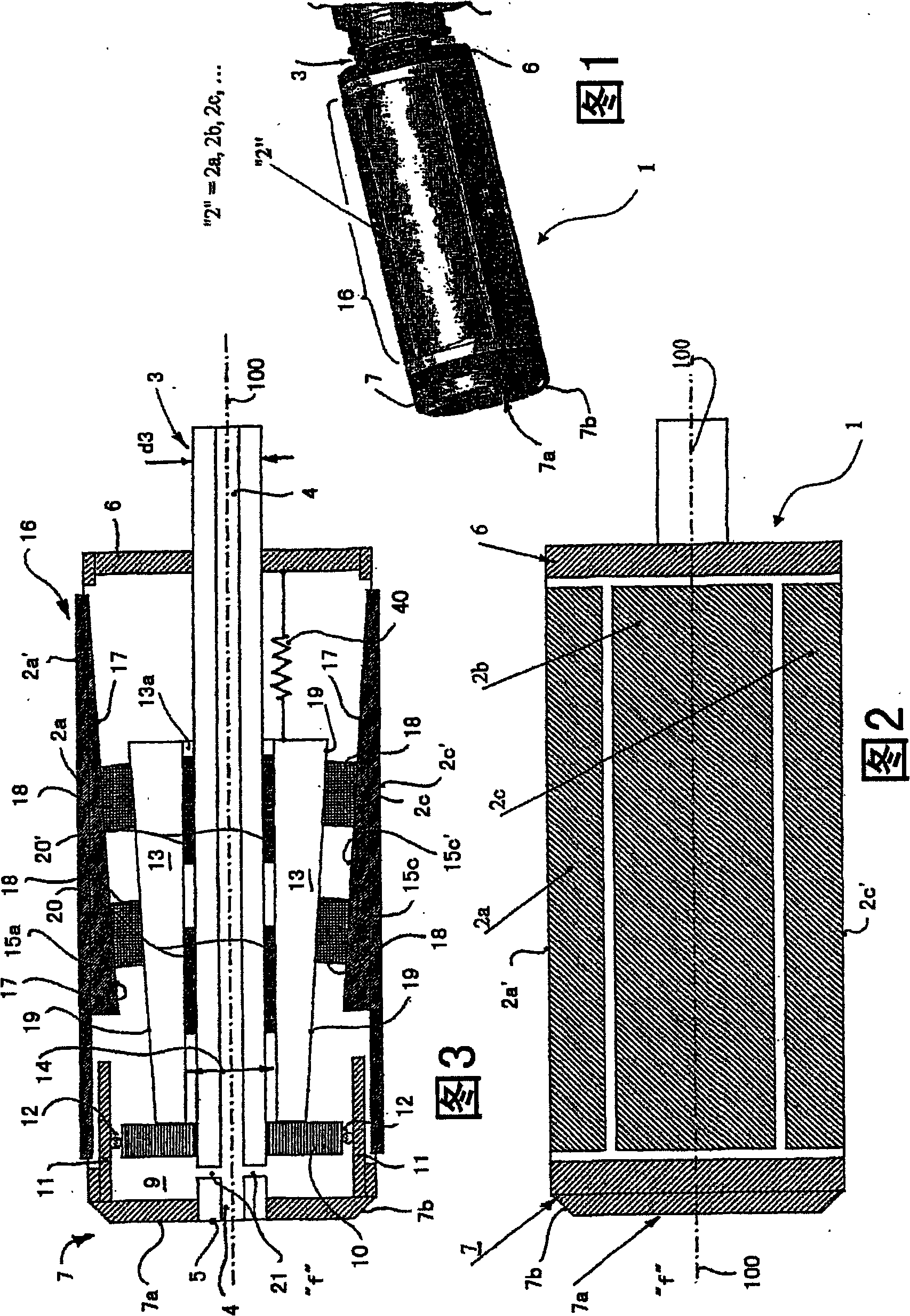

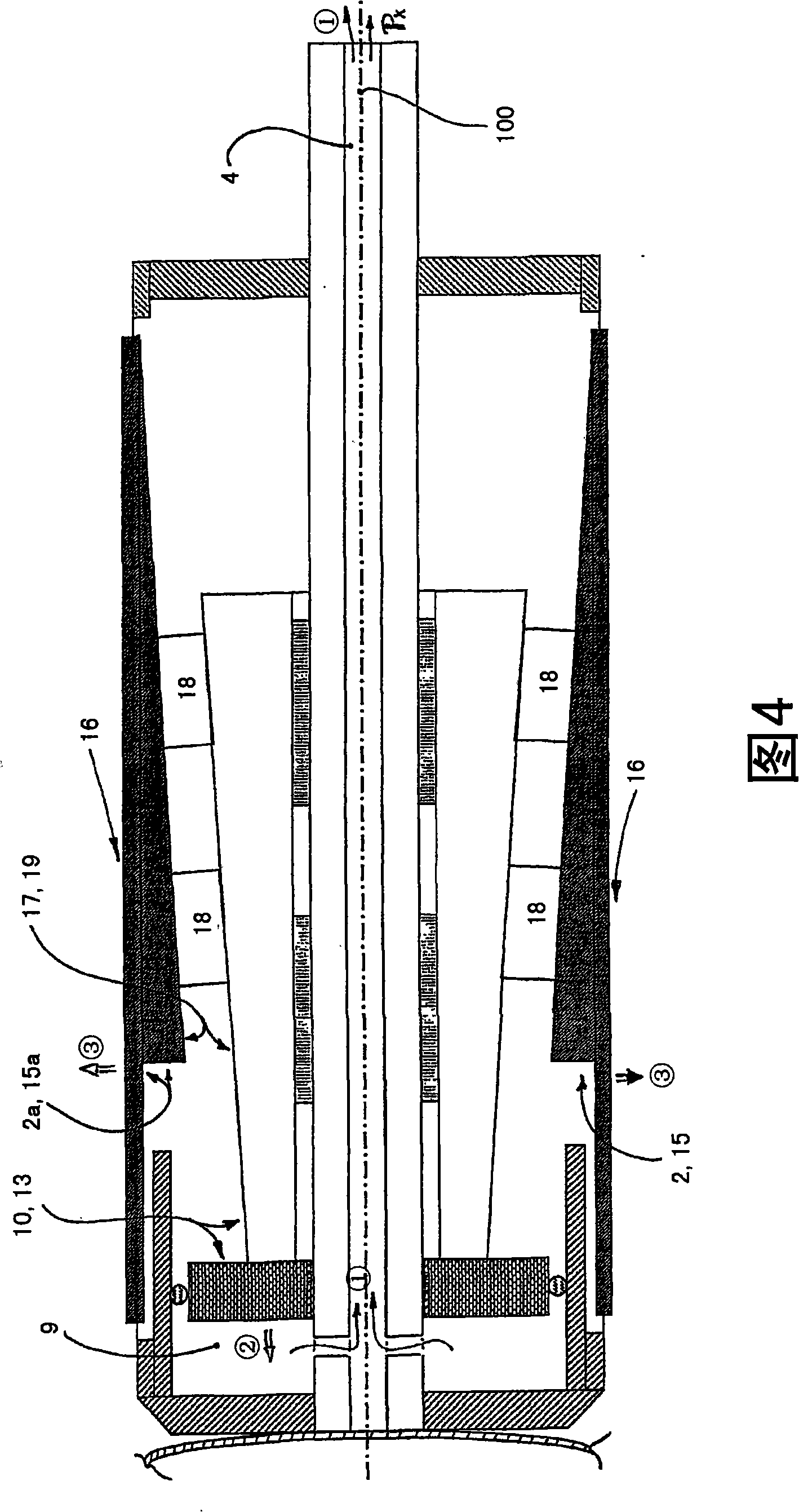

Mandrel used for digital printing on can members

ActiveCN101351340ASmall permanent deformationImprove accuracyRotary pressesDigital printingEngineering

Disclosed is a method for setting a beverage can as a rotationally symmetric hollow member embodied wherein the beverage can that is monolithically composed of a body and a bottom. The aim of the invention is to transmit accurate coupling and precise controlling of the movement of the mandrel to the hollow member. Said aim is achieved by providing several clamping segments (2; 2a, 2b, 2c) that form an outward-facing cylindrical clamping area (16) so as to grip an internal surface of the hollow member. The clamping segments are guided in a radially movable manner. A force transmitting mechanism (10, 13) that is arranged inside the mandrel (1) is used for synchronously controlling the radial movement of the clamping segments (2) such that a hollow member which is clamped by the clamping device can be accurately moved in a controlled fashion.

Owner:鲍尔欧洲有限责任公司

Asphalt concrete tracking-resisting modifier

The invention relates to a track resistant modifying agent used in asphalt concrete. The asphalt concrete track resistant modifying agent is characterized in that the asphalt concrete track resistant modifying agent consists of raw materials with the weight portion ration of 65 to 80 portions of low density polyethylene, 10 to 30 portions of anchoring agent, and 0 to 5 portions of activated rubber powder. The anchoring agent is petroleum resin or abietic resin. The invention has inexpensive price and excellent performance, and can improve the stability of the asphalt concrete at high temperature, enhance pavement bearing capacity and prolong service life of the pavement.

Owner:WUHAN UNIV OF TECH

Ageing resistant cable sheath material

ActiveCN103242574AGood physical propertiesDimensionally stableRubber insulatorsInsulated cablesCross-linkDispersity

The invention discloses an ageing resistant cable sheath material which comprises the following raw materials in parts by weight: 95-101 parts of neoprene A-30, 20-30 parts of nano calcium carbonate, 10-16 parts of modified filler, 6-9 parts of ethylene bis stearamide, 4-6 parts of epoxidized soybean oil, 15-20 parts of chlorinated polyethylene, 2-3 parts of diphenylamine, 10-15 parts of potassium feldspar powder, 2-4 parts of dibasic lead phosphate, 2-3 parts of antioxygen DSTP, 3-5 parts of barium stearate, 0.8-1 part of a cross-linking agent ATC, 0.8-1 part of an accelerant TMTD and 1-2 parts of dipentamethylenethiuram. The prepared ageing resistant cable sheath material has excellent performance, size stability, low shrinking percentage, has strong tensile strength, strong tearing strength, strong resilience force performance and also has good oil resistance, heat resistance, sunlight resistance, ozone resistance, acid / alkali resistance and chemical reagent resistance; and the modified filler has good dispersity and surface tension, can further improve the tensile strength and stress at definite elongation of the cable sheath material and reduce heating and compression set of the cable sheath material, is capable of slowing down the aging speed of the cable sheath material, resisting acid and alkali corrosion and reducing production cost.

Owner:ANHUI KANGLIYA CO LTD

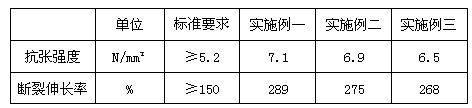

Multilayer condom containing modified polyurethane raw material and preparation method of multilayer condom

ActiveCN111072902AImprove surface propertiesImprove water resistanceMale contraceptivesPolymer scienceRosin

The invention provides a multilayer condom containing a modified polyurethane raw material and a preparation method of the multilayer condom. The preparation method of the condom comprises the following steps: (1) preparation of an inner-layer adhesive film: reacting polyisocyanate with a chain extender to obtain a fluorine-containing and silicon-containing polyurethane emulsion, and then forminga film to prepare the inner-layer adhesive film; (2) preparation of an intermediate layer adhesive film: blending polyisoprene rubber and a modified polyurethane emulsion to prepare the intermediate layer adhesive film; (3) preparation of an outer adhesive film: preparing rosin modified resin latex from maleated rosin through emulsion polymerization, and then blending the rosin modified resin latex with modified polyurethane emulsion and polyisoprene rubber emulsion to form a film; and (4) hemming, demolding and forming to obtain a finished product. The multilayer condom has the advantages ofno special smell, no anaphylactic reaction, high tensile strength, high elongation at break, good toughness, high resilience, good bacteriostasis effect on a plurality of common bacteria, efficient barrier performance on small molecules, good processing and production, and good application prospect.

Owner:眉山尤博瑞新材料有限公司

Modified building asphalt and production method thereof

InactiveCN101864182AGood dispersionHigh softening pointBuilding insulationsThermoplastic elastomerEconomic benefits

The invention relates to modified building asphalt and also relates to a production method of the modified building asphalt. The modified building asphalt consists of basis asphalt, depressurized residual oil, thermoplastic elastomer SBS, dispersing agent, padding material, anti-stripping agent and anti-aging agent. The production method is characterized in that the depressurized residual oil, the dispersing agent, the padding material, the anti-striping agent and the anti-aging agent are made into SBS mother material together with the thermoplastic elastomer SBS after being mixed, and then the SBS mother material and the molten basic asphalt are heated inside a reactor to generate the required modified building asphalt. The modified building asphalt which is prepared with the raw materials and the method has the advantages of difficult flowing at high temperature, difficult fracture at low temperature, good stability, low cost, good economic benefit and the like.

Owner:合肥宝盈新材料科技股份有限公司

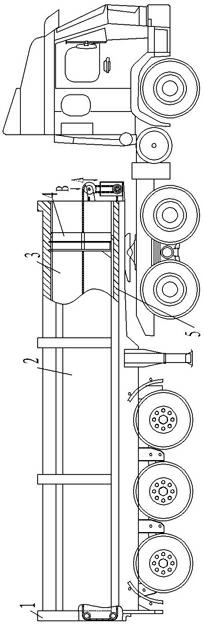

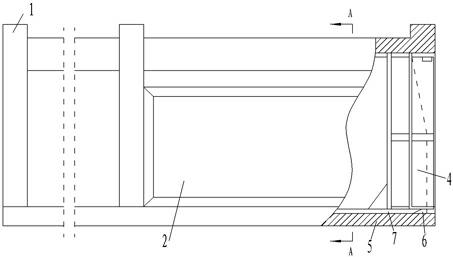

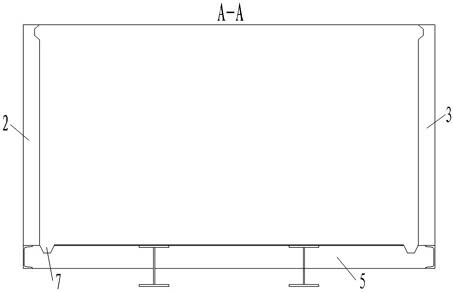

Horizontally pushing type dumper

InactiveCN102602319ALower center of gravityImprove stabilityVehicle with endless chains/beltsVehicle frameControl theory

The invention provides a horizontally pushing type dumper, which can move loaded cargoes backward as a whole to realize unloading. The horizontally pushing type dumper comprises a flat bottom type carriage; the flat bottom type carriage comprises a front breast board, a left side breast board, a right side breast board, a bottom board, front stand columns and rear stand columns; the carriage is internally provided with a push board which is in parallel to the front breast board; the left side breast board, the right side breast board and the bottom board are provided with longitudinal slideways or slide rails; correspondingly, the push board is provided with slide blocks or slide grooves; the left side breast board, the right side breast board and the bottom board form a movable pair with the push board; the push board can move backward and forward along the carriage under the drive of a push board driving device; when the cargoes are unloaded, the push board moves backward; and after the cargoes are unloaded, the push board moves forward to reset. According to the invention, when the cargoes are unloaded, the horizontally pushing type dumper does not need to lift the carriage and can unload the cargoes in the carriage completely only by moving the push board backward; unloading through tipping the carriage is changed to the unloading through horizontal movement, thereby promoting the cargo capacity and the vehicle stability and meanwhile reducing the probabilities that a vehicle frame suffers permanent deformation, and snap of welded joints happens in the carriage and an auxiliary frame.

Owner:LIANGSHAN TONGHUA SPECIAL PURPOSE VEHICLE

SBS (styrene-butadiene-styrene) modified asphalt and preparation method thereof

InactiveCN105838093AExtended service lifeImprove fatigue resistanceBuilding insulationsSulfurRoad surface

The invention discloses asphalt and in particular relates to SBS (styrene-butadiene-styrene) modified asphalt and a preparation method thereof. The SBS modified asphalt comprises 88.6-94.9% of matrix asphalt, 4-6% of SBS modifier, 0.1-0.4% of stabilizer and 1-5% of aromatic hydrocarbon oil, wherein the stabilizer is prepared from an accelerant TMTD and sulfur powder. The asphalt has good high and low temperature resistance in regions with larger temperature difference, better rut resistance and good elasticity and toughness, has the effect of improving the fatigue resistance of the pavement, has good strain capacity especially on severely overloaded high flow highways and can conduce to reducing permanent deformation of the pavement.

Owner:河南普天交通科技有限公司

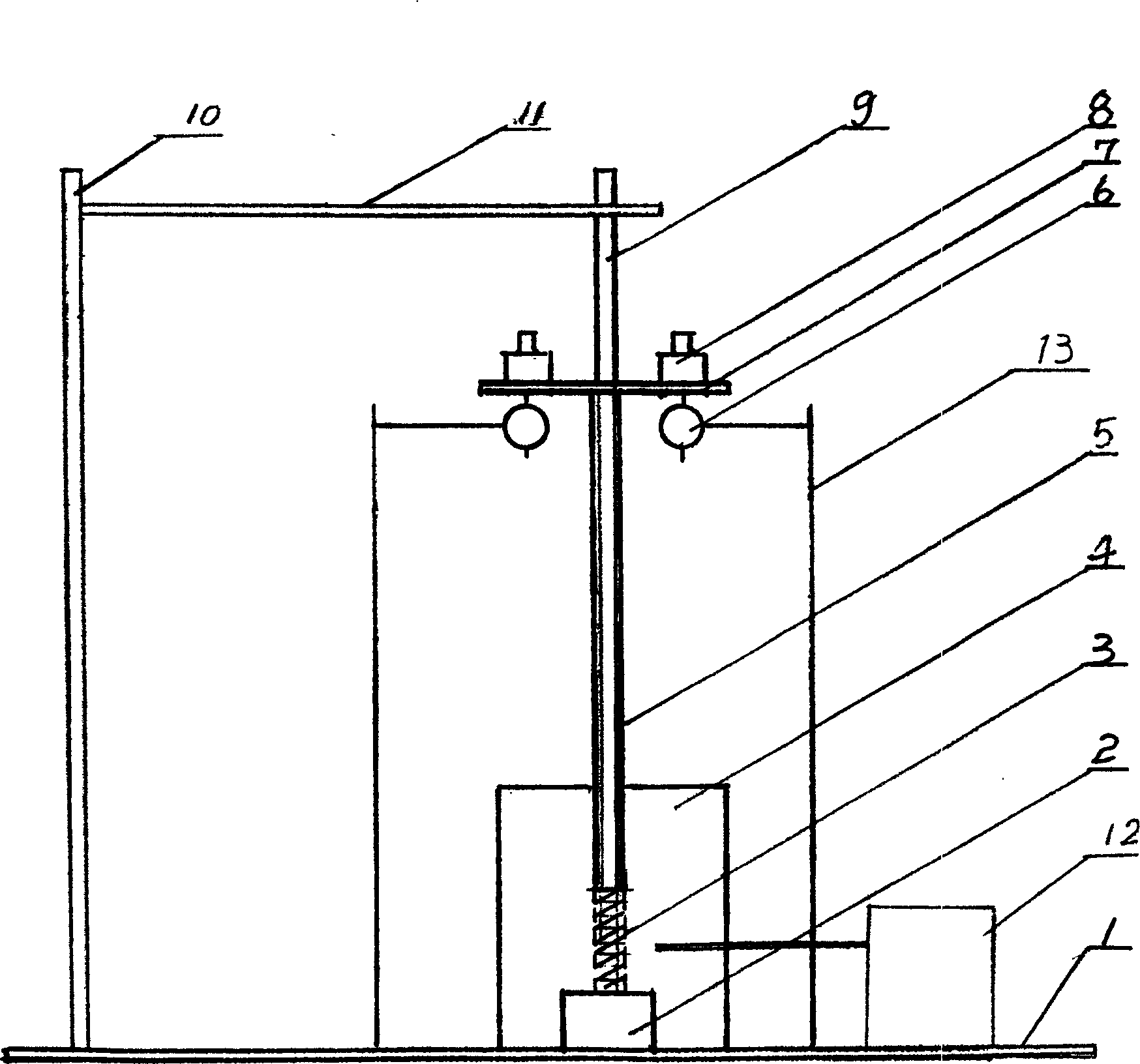

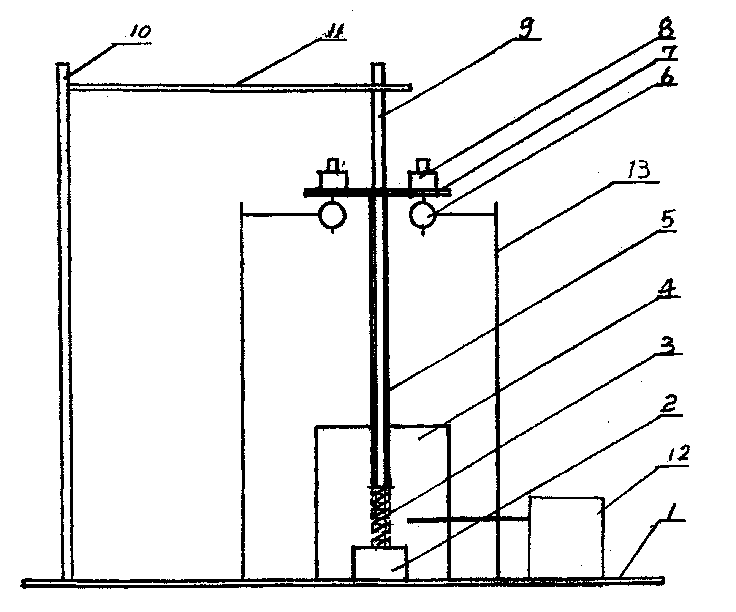

High temperature alloy spring for steam turbine steam locking and its processing method and detecting installation

InactiveCN1410688AImprove quality levelHigh thermal efficiencyLeakage preventionMachines/enginesQuality levelWorking temperature

The column type helical spring is made from Inconal X-750 (GH4145) alloy wire. The procedures for manufacturing the spring are as following: wrapping the semi-finished product of long coil of spring:cutting the long coil to single springs; washing the springs; carrying out the solid solution heat treatment; cutting end and adjusting the pitch, and carrying out the aging heat treatment. With the tests of rigidity and permangnet deformation in high temperature being completed, the finished springs are obtained. The device for testing rigidity of the spring includes the worktable, the electric stove and dial gauge etc. Testing indicates the performances of the spring: when the working temperature at 550 degree.C, the service life > or =25000 hr. The spring is easy to be assembled in the vapor lock.

Owner:DONGFANG TURBINE CO LTD

Efficient coating adhesive

InactiveCN103666337AAnti-agingWear-resistantNatural rubber adhesivesNon-macromolecular adhesive additivesAdhesiveAntioxidant

The invention discloses an efficient coating adhesive. The efficient coating adhesive comprises, by weight, 70-100 parts of a silicone acrylic emulsion, 50-90 parts of an elastic emulsion, 6-10 parts of nanometer calcium carbonate, 9-12 parts of PS, 11-32 parts of EVA, 20-21 parts of an adhesive, 10 parts of a foaming agent, 3-4 parts of a phosphite antioxidant, 10 parts of a carboxylic styrene butadiene emulsion, 10-14 parts of natural latex, 10-20 parts of a fire retardant, 5-20 parts of a film forming assistant, 20-30 parts of an acrylic emulsion, 1-2 parts of nanometer calcium carbonate and 1-3 parts of oxidized polypropylene ester. The efficient coating adhesive has the advantages of ageing resistance, wear resistance, corrosion resistance, high burning point, small permanent deformation, strong resilience, strong bonding force, low cost and the like.

Owner:QINGDAO HIBOUND CHENGYUAN PLASTIC

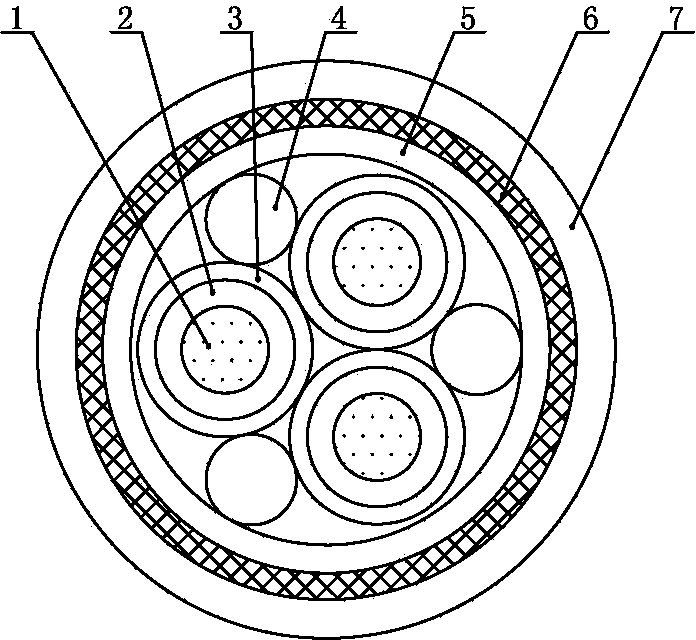

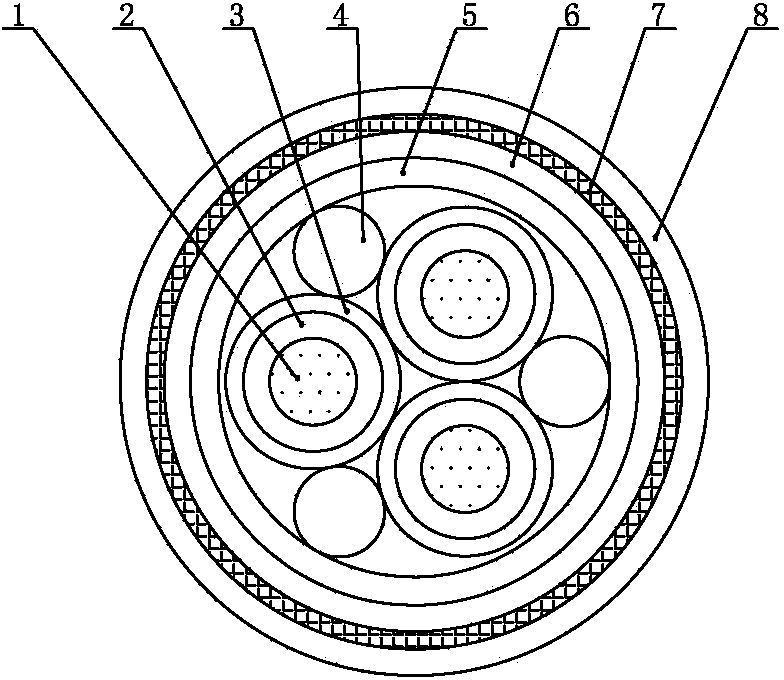

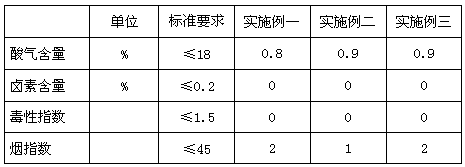

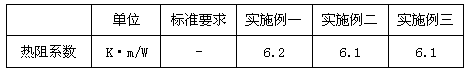

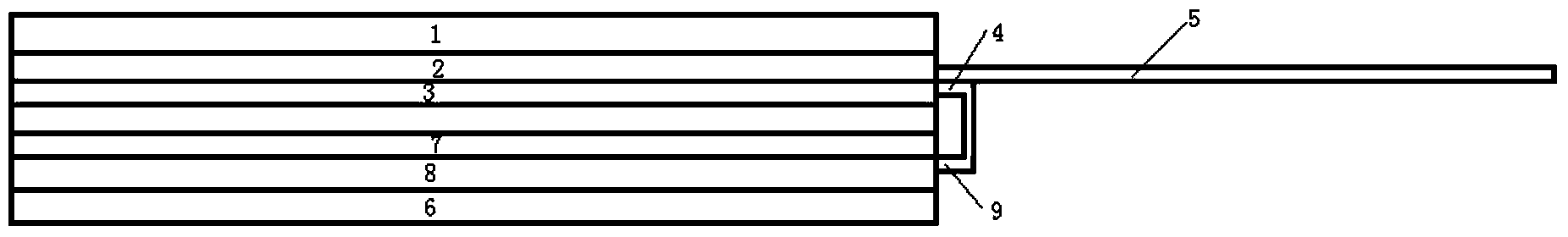

Vessel high-carrying-capacity low-surface-temperature-rise shielding cable and manufacturing method thereof

InactiveCN103474148AReduce the temperatureIncrease ampacityInsulated cablesCable/conductor manufactureCopper conductorGlass fiber

The invention relates to a vessel high-carrying-capacity low-surface-temperature-rise shielding cable and a manufacturing method thereof. A high-thermal-resistance-coefficient inflaming retarding fire-resistant insulating layer evenly wraps the periphery of a twisted copper conductor in a squeezing mode, a filament glass fiber woven reinforcement layer wraps the periphery of the high-thermal-resistance-coefficient inflaming retarding fire-resistant insulating layer to form shielding cable insulating cable cores, the shielding cable insulating cable cores are twisted to form a shielding cable core, and gaps among the shielding cable insulating cable cores are filled with high-thermal-resistance-coefficient inflaming retarding fire-resistant filling cores so that the cable core can be rounded off. A high-thermal-resistance-coefficient inflaming retarding fire-resistant longitudinal wrapping belt wraps the periphery of the shielding cable core, a shielding layer wraps the periphery of the high-thermal-resistance-coefficient inflaming retarding fire-resistant longitudinal wrapping belt, and a high-thermal-resistance-coefficient chemical crosslinking polyolefin outer sheath wraps the periphery of the shielding layer in a squeezing mode. According to the shielding cable, the temperature of the outer wall of the cable can be reduced, and the carrying capacity can be improved under the condition that the cross sections of conductors are the same.

Owner:JIANGSU YUANYANG DONGZE CABLE

Flexible vinyl in use for peristaltic

InactiveCN1727394AGood low temperature softness and light fastnessImprove resilienceFlexible pipesChemistryPliability

A soft polyvinyl chloride plastics for the tube of creeping pump is prepared from PVC resin, dioctyl phthalate (DOP), dioctyl adipate (DOA), diisononyl phthalate (DINP), epoxy soybean (or flaxseed) oil, stearate, organic phosphite and silicon oil. Its advantages are high elasticity, flexibility and stability.

Owner:威海威高创新有限公司

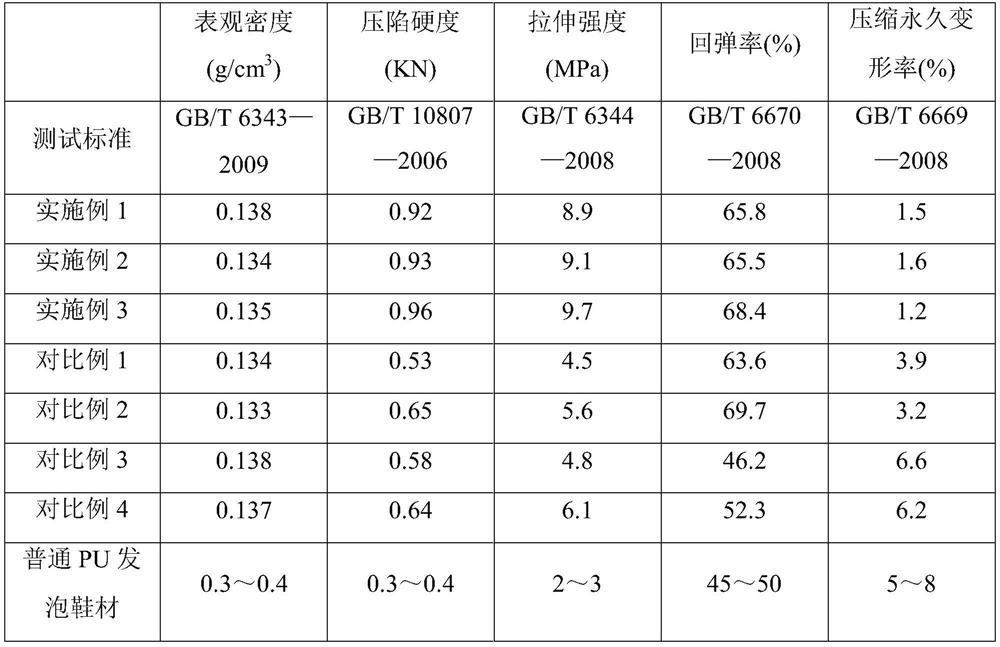

PU foaming shoe material capable of releasing negative ions and preparation method thereof

The invention discloses a PU foaming shoe material capable of releasing negative ions and a preparation method thereof. The PU foaming shoe material is prepared from the following raw materials in parts by weight: 70-80 parts of polyester polyurethane, 12-16 parts of ethylene-vinyl acetate copolymer, 5-7 parts of styrene-ethylene-butadiene-styrene block copolymer, 4-6 parts of a negative ion additive, 1.2-1.7 parts of 4-methylbenzenesulfonyl hydrazine, 0.45-0.55 parts of triethylene diamine, 0.08-0.12 parts of triallyl isocyanurate, 2-3 parts of talcum powder, 2-4 parts of titanium dioxide, 1-2 parts of zinc oxide, 2-4 parts of stearic acid and 1.5-2.7 parts of zinc stearate, wherein the negative ion additive is a mixture of opal powder and medical stone powder, and the mass ratio of opalpowder to medical stone powder is 1: (0.6-0.8). The PU foaming shoe material capable of releasing negative ions is small in density and light in weight; the indentation hardness is high, the tensile strength is high, and the mechanical property is good; the rebound rate is high, the compression set rate is low, the elasticity is good, and permanent deformation is not likely to happen in the usingprocess; and the overall performance is excellent.

Owner:ZHEJIANG SEMIR GARMENT CO LTD +1

Bicycle tire tread rubber

InactiveCN104292514ASmall deformabilityLight in massSpecial tyresRolling resistance optimizationRolling resistanceStearic acid

The invention relates to the technical field of tires, and discloses a bicycle tire tread rubber which comprises the following raw materials in parts by weight: 80-90 parts of natural rubber, 10-20 parts of cis-1,4-polybutadiene rubber, 15-30 parts of plasticizer, 25-58 parts of silica white, 1-10 parts of vulcanizing agent, 1-20 parts of accelerator, 1-9 parts of zinc oxide, 0.1-2 parts of calcium carbonate, 1-10 parts of reinforcing agent cb, 0.1-2 parts of stearic acid, 2-5 parts of anti-aging agent aw, 2-5 parts of anti-aging agent 4010, 1-2 parts of paraffin and 1-10 parts of silane coupling agent. The bicycle tire tread rubber has the advantages of tear resistance, fatigue resistance, heat resistance, abrasion resistance, aging resistance, small deformability, light weight, favorable water absorptivity, long service life, low compressive heat generation and dynamic heat generation, small permanent deformation, favorable anti-slip property and small rolling resistance, and can well absorb shock load.

Owner:MINGGUANG RUITAI IND

Ship and warship protection cable high in current carrying capacity and low in surface temperature rise and manufacture method thereof

ActiveCN103489525AReduce the temperatureIncrease ampacityRubber insulatorsPlastic/resin/waxes insulatorsCross-linkCopper conductor

The invention relates to a ship and warship protection cable high in current carrying capacity and low in surface temperature rise and a manufacture method thereof. A flame-retardant fire-resistant insulating layer high in thermal resistivity evenly wraps a stranded copper conductor in an extruding mode. A filament glass fiber woven reinforcing layer wraps the flame-retardant fire-resistant insulating layer high in thermal resistivity so as to form an electric cable insulating wire core. A plurality of electric cable insulating wire cores are mutually stranded to form an electric cable core. Flame-retardant fire-resistant padding high in thermal resistivity is filled into clearance between the electric cable insulating wire cores so as to enable the cable core to be round and neat. A flame-retardant fire-resistant longitudinal wrapping band high in thermal resistivity wraps the electric cable core. A chemical cross-linked polyolefin inner protection sleeve high in thermal resistivity wraps the flame-retardant fire-resistant longitudinal wrapping band high in thermal resistivity in an extruding mode. An armoured braid layer wraps the inner protection sleeve. A chemical cross-linked polyolefin outer protection sleeve high in thermal resistivity wraps the armoured braid layer. The high protection cable can reduce the temperature of the outer wall of cables, and can be improved in current-carrying capacity on the condition that section areas of conductors are the same.

Owner:江苏远桥电气科技有限公司

Graphene capacitive screen and manufacturing method thereof

InactiveCN104360778AImprove high temperature resistanceGood low temperature resistance (-40-60°C) performanceInput/output processes for data processingLaser etchingAdhesive

The invention discloses a graphene capacitive screen and a manufacturing method thereof. The capacitive screen comprises a silica gel basal layer, a first graphene circuit layer, and a first OCA layer which are arranged in sequence, and further comprises an FPC which is connected with the first graphene circuit layer through a first conductive double faced adhesive layer. According to the invention, the silica gel is selected and used as the substrate of the graphene, and adopted as an ultrathin structure to form a thin film of which the transparency is greater than 80%; the thin film is taken as a base material; the graphene material is transferred on the base material; a microcircuit is manufactured through a laser etching technique; the FPC is bound by utilizing conductive adhesive to form the capacitive touch screen provided with super soft characteristic.

Owner:2D CARBON CHANGZHOU TECH INC

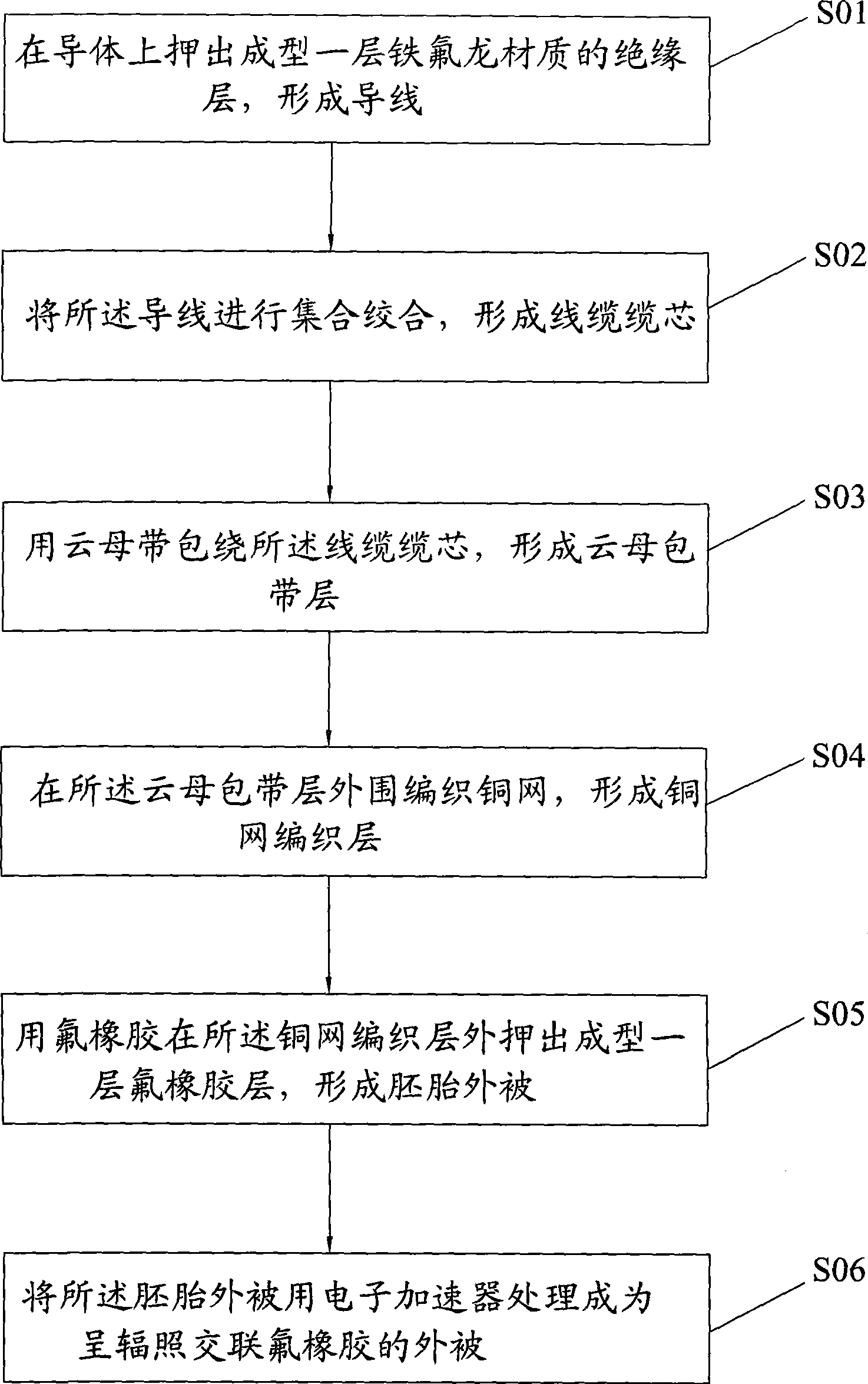

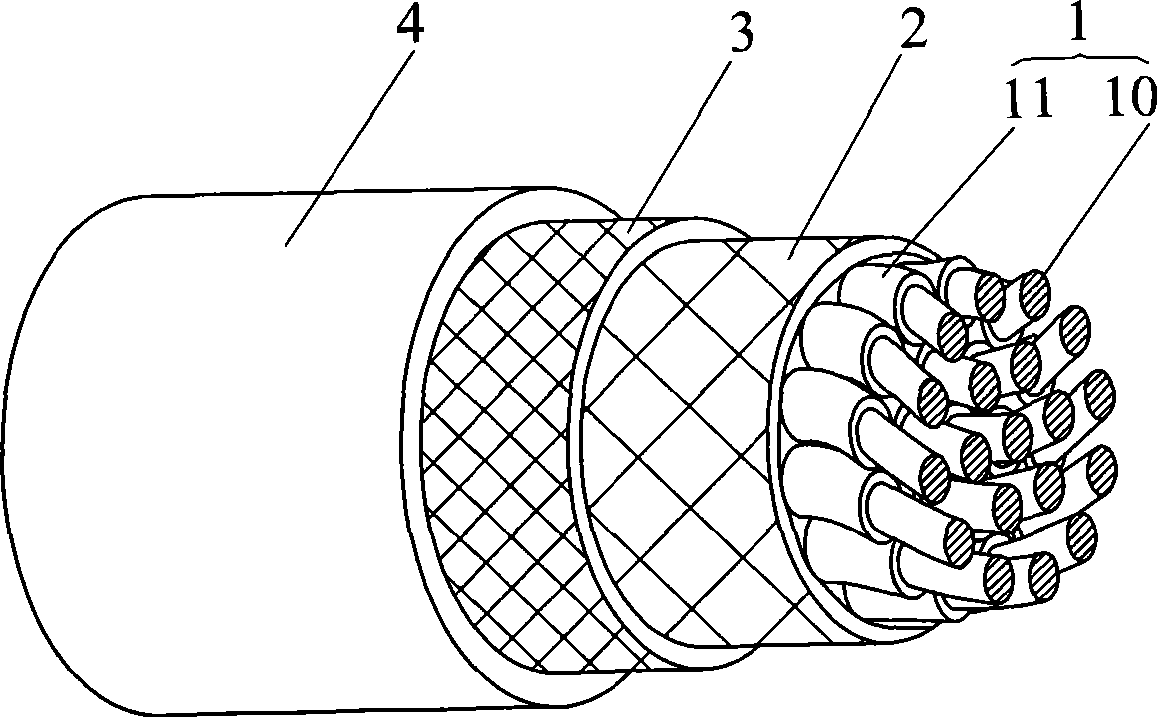

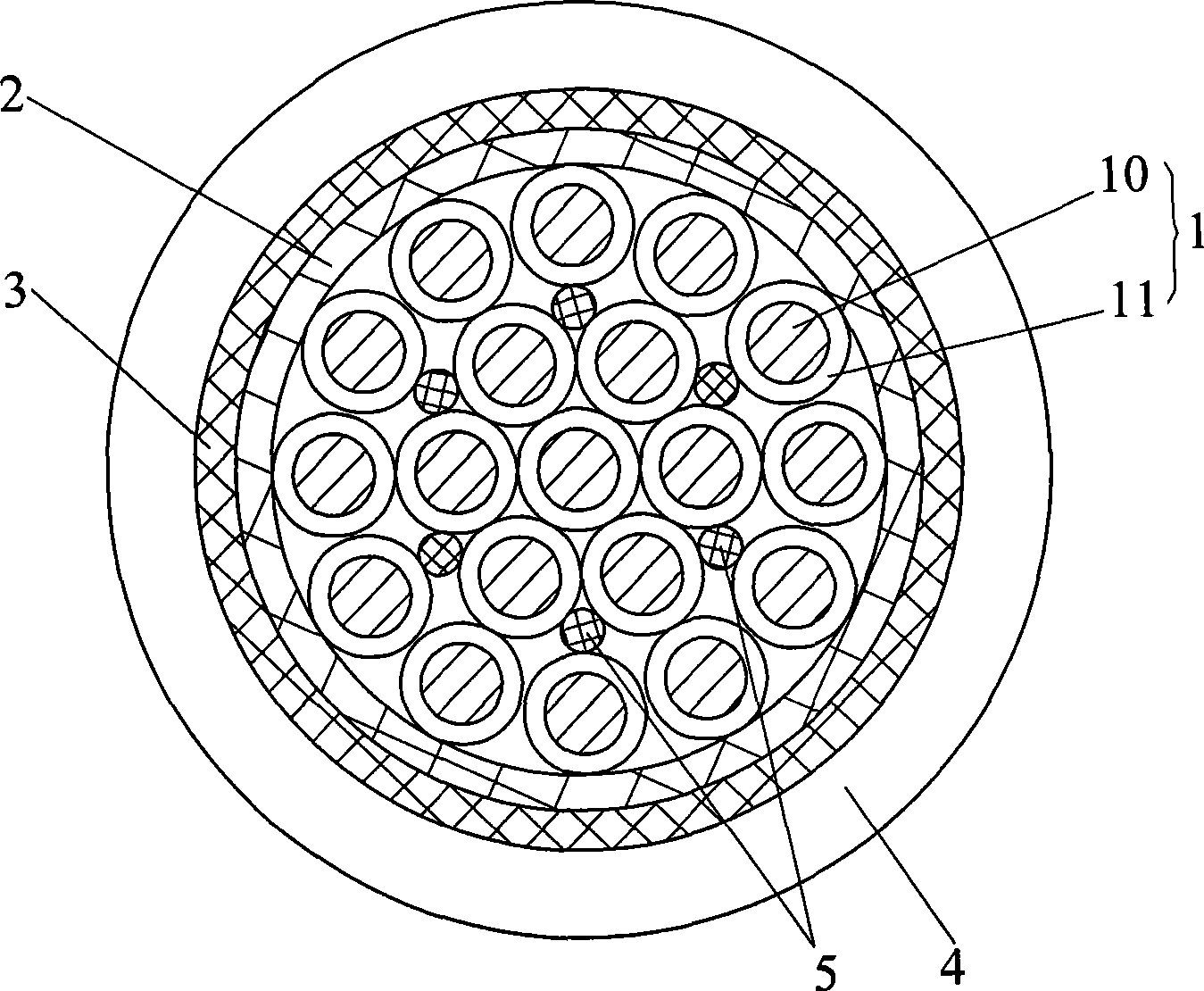

High temperature ultra-flexible electric cable and production method

InactiveCN101477847AImprove transmission performanceImprove high temperature resistanceFlexible cablesCable/conductor manufactureElectrical conductorUltraviolet

The invention discloses a manufacturing method of a high temperature cable with super flexibility. The method comprises the following steps: (1), an insulating layer with polytetrafluoroethylene material is extruded and formed on a conductor, and line conductors are formed; (2), the line conductors are centralized and intertwisted, and a cable core is formed; (3), a mica tape is used to wrap the cable core, and a mica belting layer is formed; (4), copper mesh is braided at the periphery of the mica belting layer, and a copper mesh braid ply is formed; (5), fluororubber is used to extrude and form a fluororubber layer outside the copper mesh braid ply, and an embryo covering is formed; and (6), by using an electron accelerator, the embryo covering is processed to an irradiation crosslinking fluororubber covering. The cable manufactured through the method is provided with the copper mesh braid ply, the mica belting layer and the irradiation crosslinking fluororubber covering, so that the cable has the advantages of good tensile strength, small resilience and permanent deformation, ozone resistance, ultraviolet radiation resistance, oil resistance, various chemical corrosion resistance, and good high temperature resistance and flexibility.

Owner:DONGGUAN NISTAR TRANSMITTING TECH CO

Highly oil-resistant chloroprene rubber sealing gasket and preparation method thereof

The invention discloses a highly oil-resistant chloroprene rubber sealing gasket comprising the following raw materials in parts by weight: 35-145 parts of chloroprene rubber CR1211, 20-25 parts of epichlorohydrin rubber, 10-20 parts of SG-2 type PVC (Polyvinyl Chloride) resin, 2-5 parts of tri(2-ethylhexyl)acetocitrate, 3-5 parts of dioctyl epoxy tetrahydrophthalate, 3-5 parts of dibutyl maleate, 1-2 parts of sodium alcohol ether sulphate, 30-40 parts of nano argil, 30-35 parts of carbon black N220, 30-35 parts of nano calcium carbonate powder and the like. The chloroprene rubber sealing gasket has excellent oil resistance and solvent resistance, is capable of satisfying the sealing requirement on an engine sump, and is easy to peel after being solidified, and cleanable and repairable without affecting dismounting and repairing.

Owner:ANHUI RONGDA VALVE

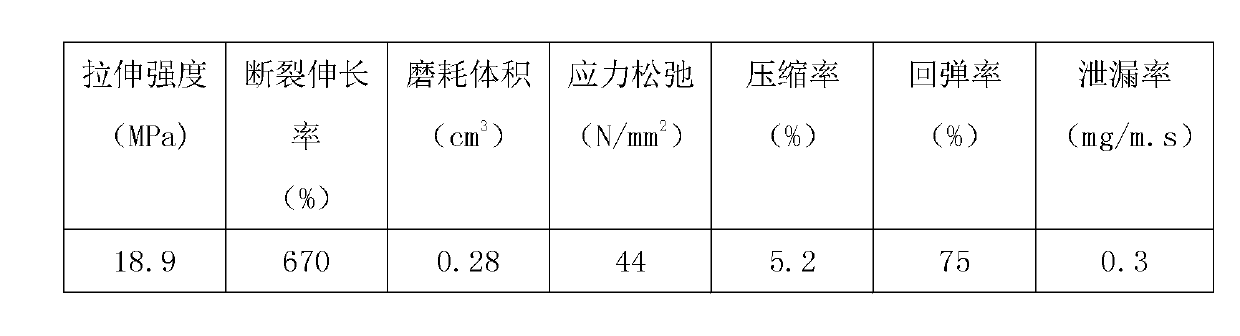

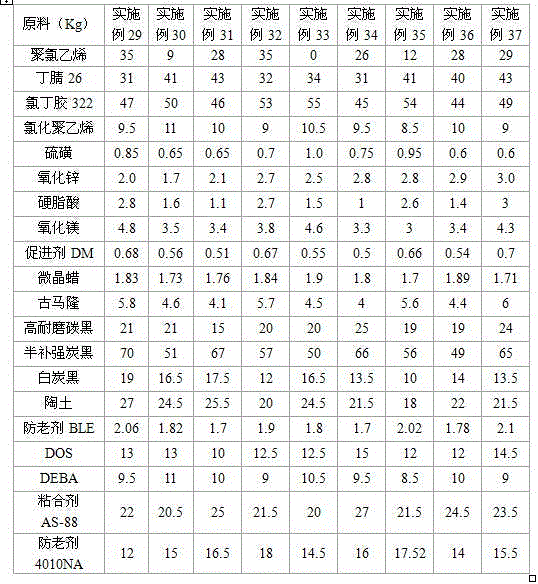

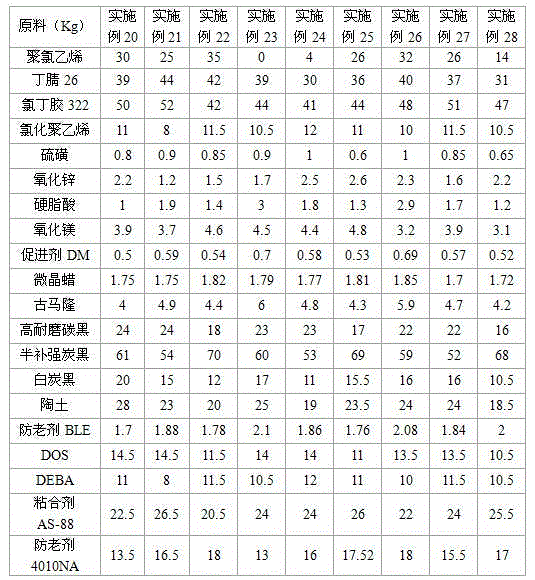

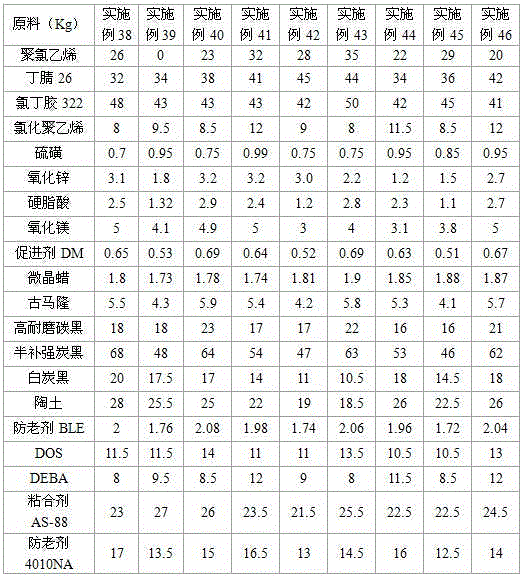

Ultralow-temperature woven/wound outer rubber mixed material for hydraulic rubber hoses

The invention discloses an ultralow-temperature woven / wound outer rubber mixed material for hydraulic rubber hoses, which is prepared from polyvinyl chloride, butyronitrile 26, neoprene 322, chlorinated polyethylene, sulfur, zinc oxide, stearic acid, magnesium oxide, an accelerator DM, microcrystalline wax, coumarone, high-wear-resistance carbon black, semi-reinforcing carbon black, white carbon black, argil, an anti-aging agent, dioctyl decanedioate, dibutoxyethyl adipate, an adhesive AS-88 and an anti-aging agent 4010NA. The outer rubber for hydraulic rubber tubes can greatly enhance the ultralow-temperature freezing resistance and aging resistance of the hydraulic rubber tube, increase the number of times of pulses in the product use process, lower the permanent deformation in the use process, avoid generating the phenomena of pinholes, liquid leakage and cracking in the use process and prolong the service life of the hydraulic rubber tube in an ultralow temperature environment; the low-temperature freezing resistance can reach -45 DEG C; and thus, the outer rubber is suitable for extremely cold regions.

Owner:LUOHE ZHONGYANG RUBBER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com