Bicycle tire tread rubber

A technology for tire treads and bicycles, which is applied to special tires, tire parts, vehicle parts, etc. It can solve problems that affect the service life of tires, bias tire bulging, delamination, etc., and achieve low rolling resistance, long service life, small mass effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

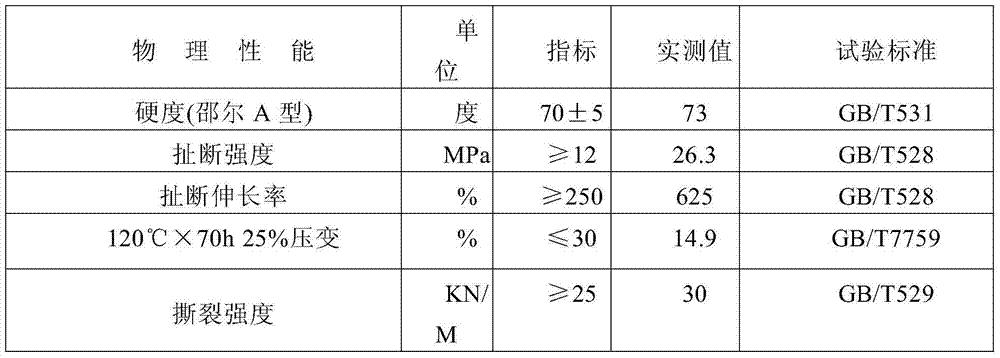

Image

Examples

Embodiment 1

[0014] A bicycle tire tread compound, comprising the following raw materials in parts by weight: 90 parts of natural rubber, 20 parts of butadiene rubber, 30 parts of plasticizer, 58 parts of white carbon black, 10 parts of vulcanizing agent, 20 parts of accelerator, oxidation 9 parts of zinc, 2 parts of calcium carbonate, 0 parts of reinforcing agent cb, 2 parts of stearic acid, 5 parts of anti-aging agent aw, 5 parts of anti-aging agent 4010, 2 parts of paraffin, 10 parts of silane coupling agent.

[0015] The production method of the present embodiment: natural rubber, butadiene rubber, plasticizer, white carbon black, accelerator, zinc oxide, calcium carbonate, reinforcing agent cb, stearic acid, antioxidant aw, antioxidant 4010, paraffin , the silane coupling agent is mixed evenly for the first mixing; then add the vulcanizing agent and accelerator, carry out the second mixing, and vulcanize.

Embodiment 2

[0017] A bicycle tire tread compound, comprising the following raw materials in parts by weight: 80 parts of natural rubber, 10 parts of butadiene rubber, 15 parts of plasticizer, 25 parts of white carbon black, 1 part of vulcanizing agent, 1 part of accelerator, oxidation 1 part of zinc, 0.1 part of calcium carbonate, 1 part of reinforcing agent cb, 0.1 part of stearic acid, 2 parts of anti-aging agent aw, 2 parts of anti-aging agent 4010, 1 part of paraffin, 1 part of silane coupling agent.

Embodiment 3

[0019] A bicycle tire tread compound, comprising the following raw materials in parts by weight: 85 parts of natural rubber, 15 parts of butadiene rubber, 18.5 parts of plasticizer, 35 parts of white carbon black, 1.5 parts of vulcanizing agent, 3 parts of accelerator, oxidation 1.5 parts of zinc, 0.3 parts of calcium carbonate, 2 parts of reinforcing agent cb, 0.3 parts of stearic acid, 3 parts of anti-aging agent aw, 3 parts of anti-aging agent 4010, 1.5 parts of paraffin, 3.5 parts of silane coupling agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com