Patents

Literature

68results about How to "Small deformability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous fibre enhancement polyurethane foam material and manufacturing method thereof

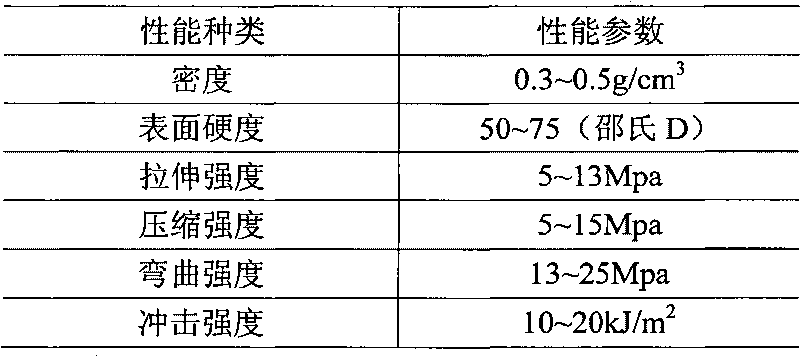

A continuous fiber reinforce polyurethane foaming material and a relative production method relate to a polyurethane foaming material, wherein the continuous fiber reinforce polyurethane foaming material has strong rigidity, strength and shock resistance to produce foaming polyurethane material with reinforced glass fiber, which eliminates breaking and premixing with any component of polyurethane, is directly mixed and immersed with polyurethane mixture in an immerser and is foamed and shaped continuously, and contains A, B and C components. A comprises polyatomic alcohol, foaming agent, catalyst, foaming stabilizer, chain extender and adjuvant, B is polyisocyanate, C is fiber material. The preparation method comprises mixing the materials of A in A pot, the materials of B in B pot, immersing fiber via an immerser with the mixture discharged from a high-speed pouring head, feeding immersed material into a continuous foaming mold to be foamed and solidified, cooling, removing mould, taking off and cutting to obtain final product.

Owner:厦门高特高新材料有限公司

Wood powder reinforced polyurethane wood-imitation material for furniture and production method thereof

The invention discloses a wood powder reinforced polyurethane wood-imitation material for furniture and a production method thereof. The mixture of polyether glycol, foaming agent, catalyst, stabilizing agent and fire retardant serves as a white material, polyisocyanate serves as black material, and wood powder filler with 80-100 meshes serves as the stabilizing agent, wherein, the mass ratio of white material to black material to wood powder is 112:112:7. The production method is as follows: respectively mixing the white material according to ratio to prepare composite polyether; adding wood powder to prepare wood powder / composite polyether mixture; then, adding the black material to prepare foaming mixture; and after injection molding and curing for 20 minutes, demolding to prepare the wood powder reinforced polyurethane wood-imitation material. The invention has the advantages that the compression strength and the shock resistance of the produced wood-imitation material and products are strengthened, wood texture effect is obvious, and density distribution is improved; the produced wood-imitation material and the product have stable size, small deformation and favorable heat insulation and sound insulation performance and are hard and ageing-resistant; flame retardant property can reach construction B2 grade, the product is environmentally-friendly and has low cost as well as favorable handling characteristics, such as sawing, digging, drilling, nailing, rubbing, sticking, coloring, coating and the like.

Owner:德华兔宝宝装饰新材料股份有限公司

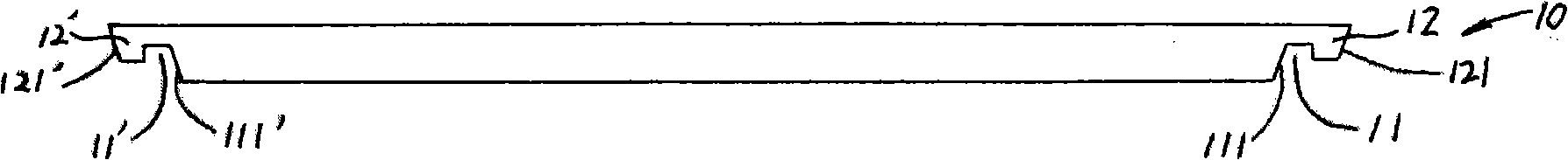

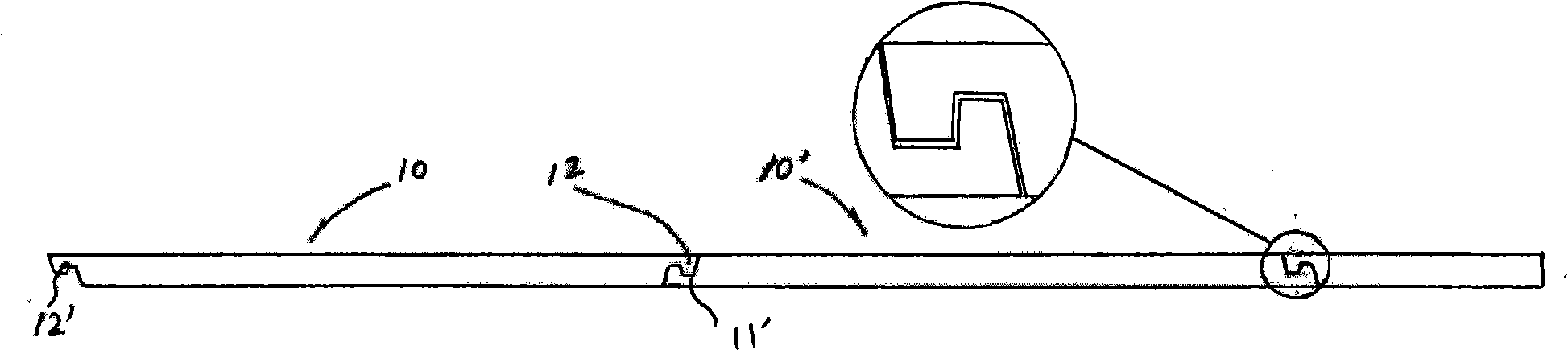

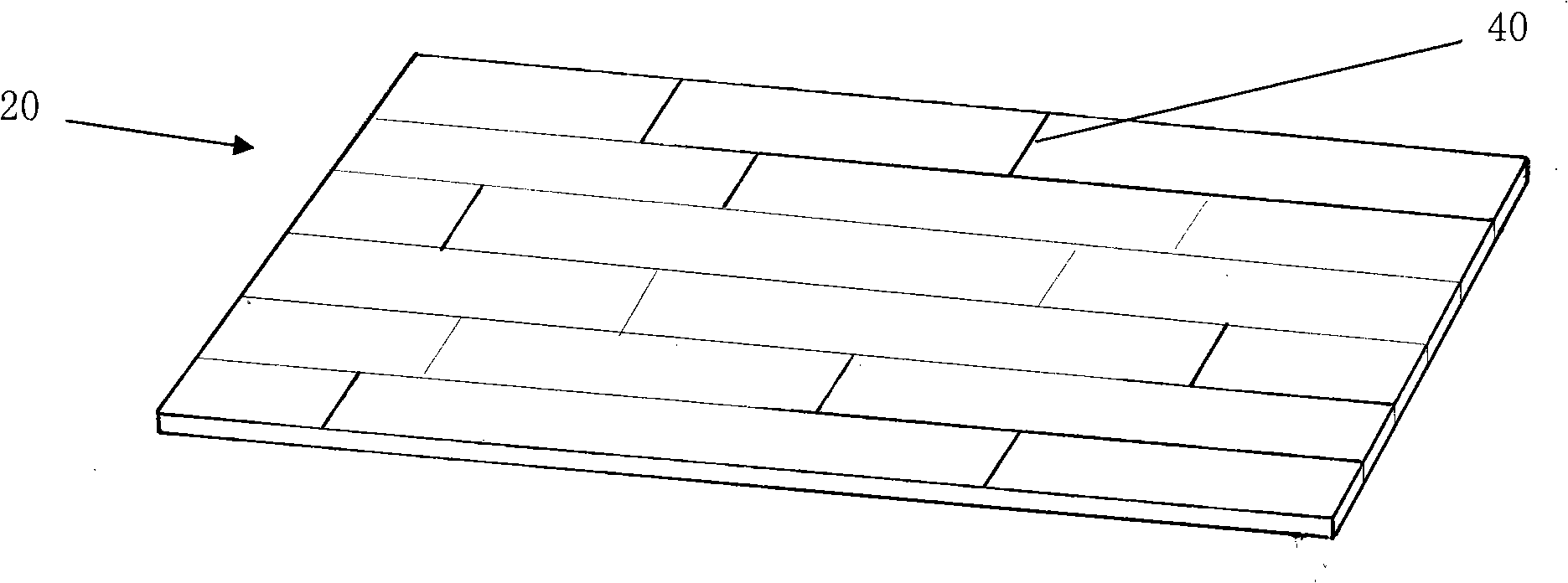

Seamless long bamboo sectional material

InactiveCN101294653ANovel structureWith horizontal pulling effectElongated constructional elementsWood treatment detailsEngineeringStructural engineering

Owner:SHANGHAI YUNSHENG BAMBOO & WOOD PROD

Production method of natural cellulose membrane

The invention discloses a production method of natural cellulose membranes, comprising the following steps: (a) immersion; (b) squeezing; (c) grinding; (d) maturing; (e) etiolation; (f) solution; (g) film formation; (h) desulfuration; (i) bleaching; (j) plastification; and (k) drying. The production method has the advantages of mild reaction condition, short spacings among the prepared natural cellulose membranes, stable expansion rate and tensile strength, proper stiffness and flexibility, better colour and luster, good transparence, high hygiene property, and the like, improves the surface property of paper through the plastification, in particular enhances the smoothness of paper surfaces, improves the printability, reduces the deformability of paper and the moisture absorption, thereby reaching the new requirement of modern printing and packaging.

Owner:绍兴柯德新材料股份有限公司

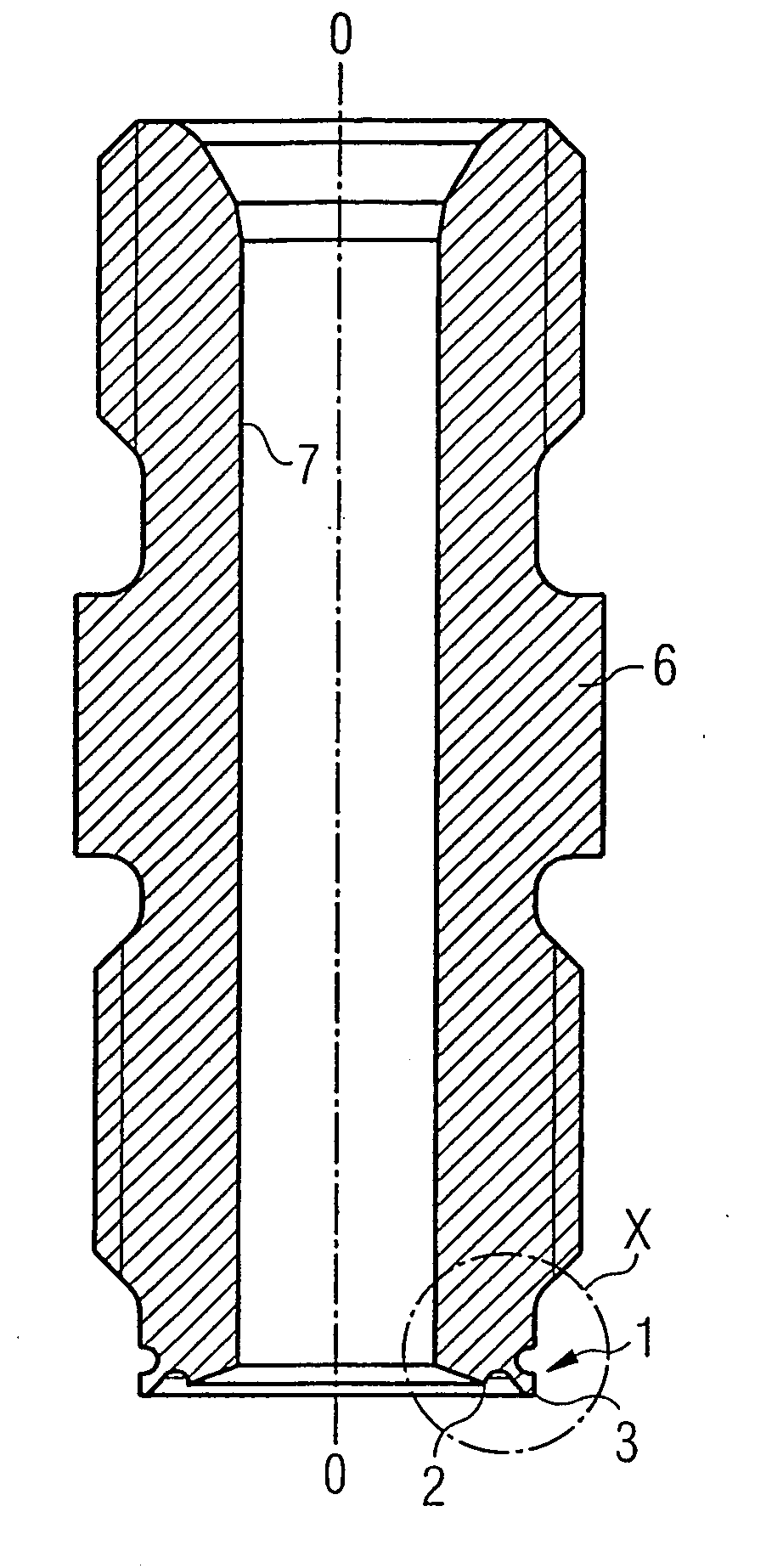

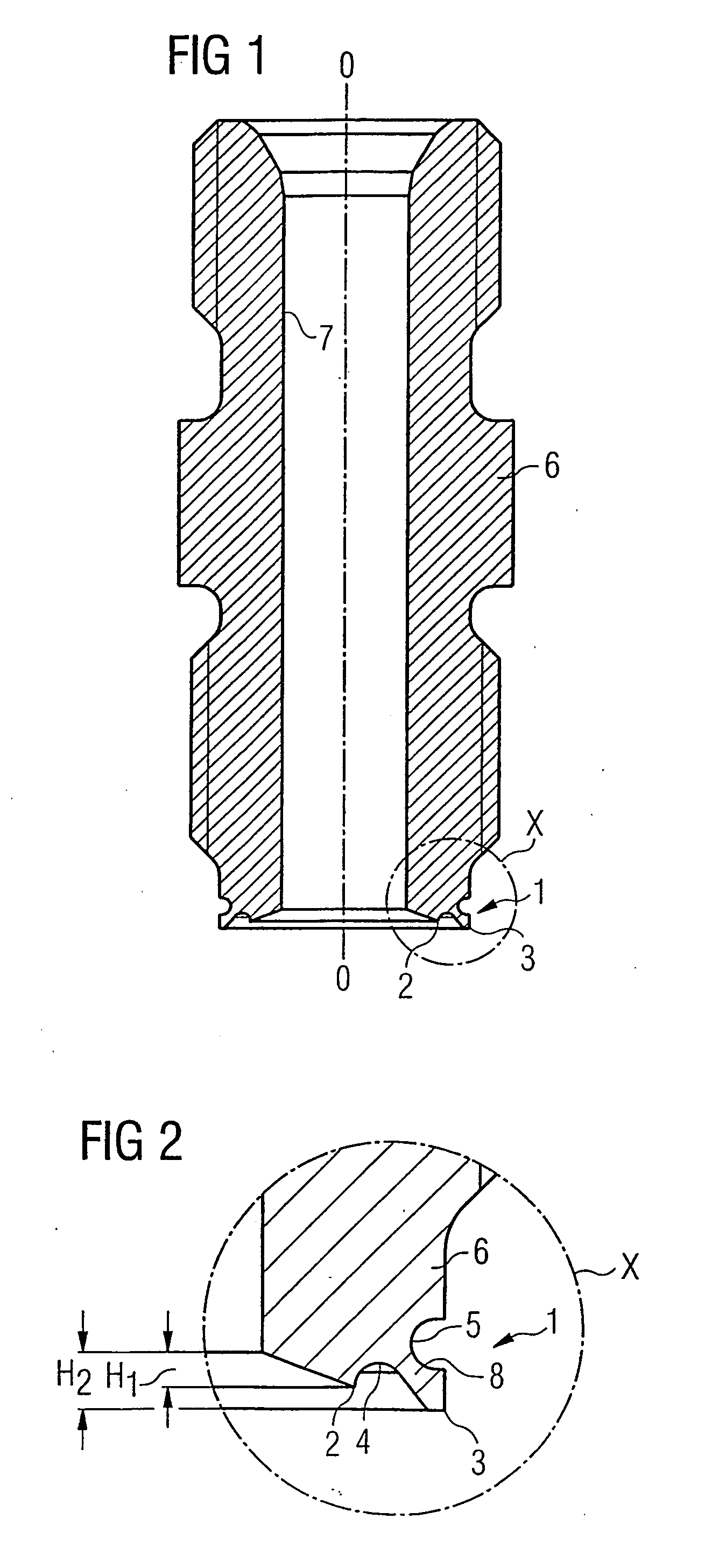

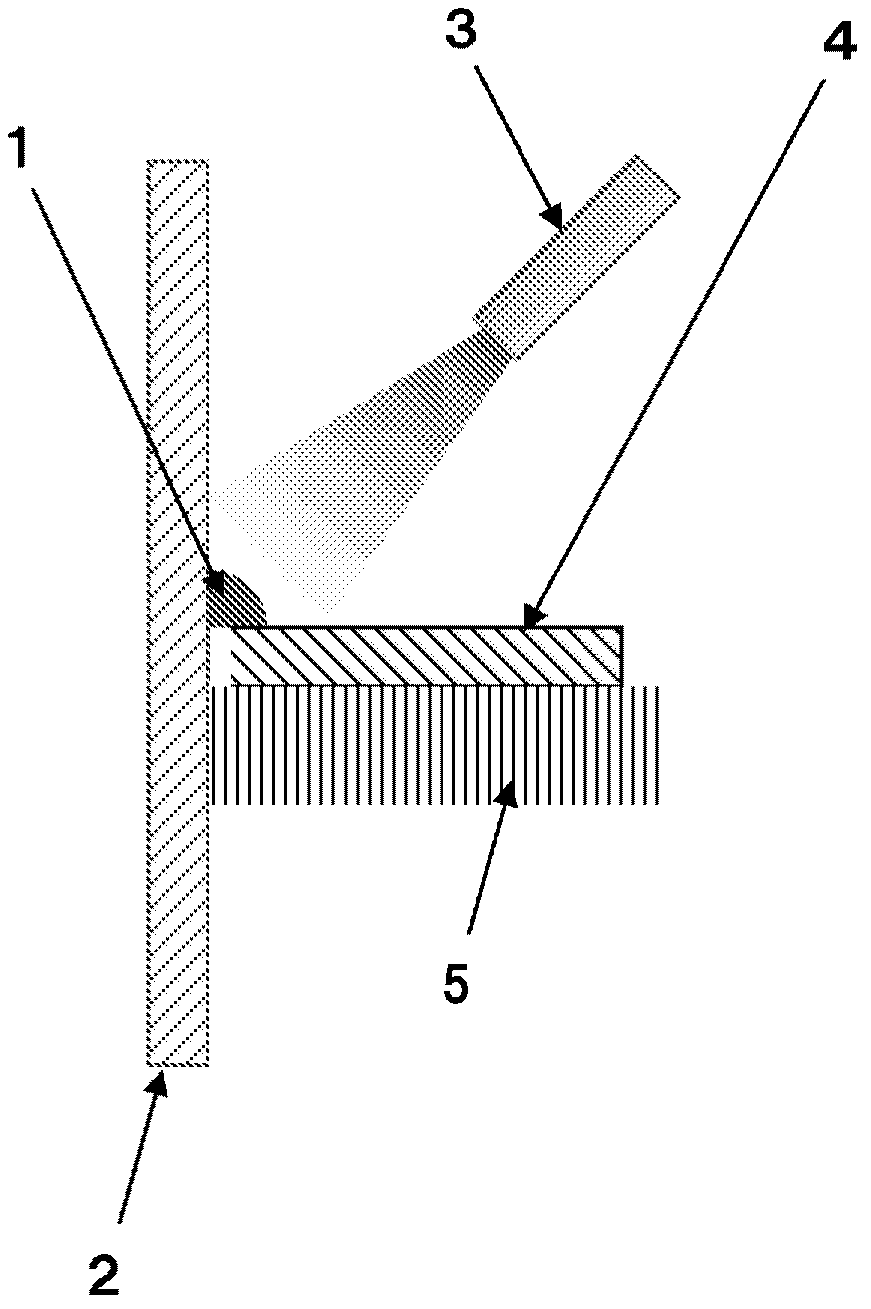

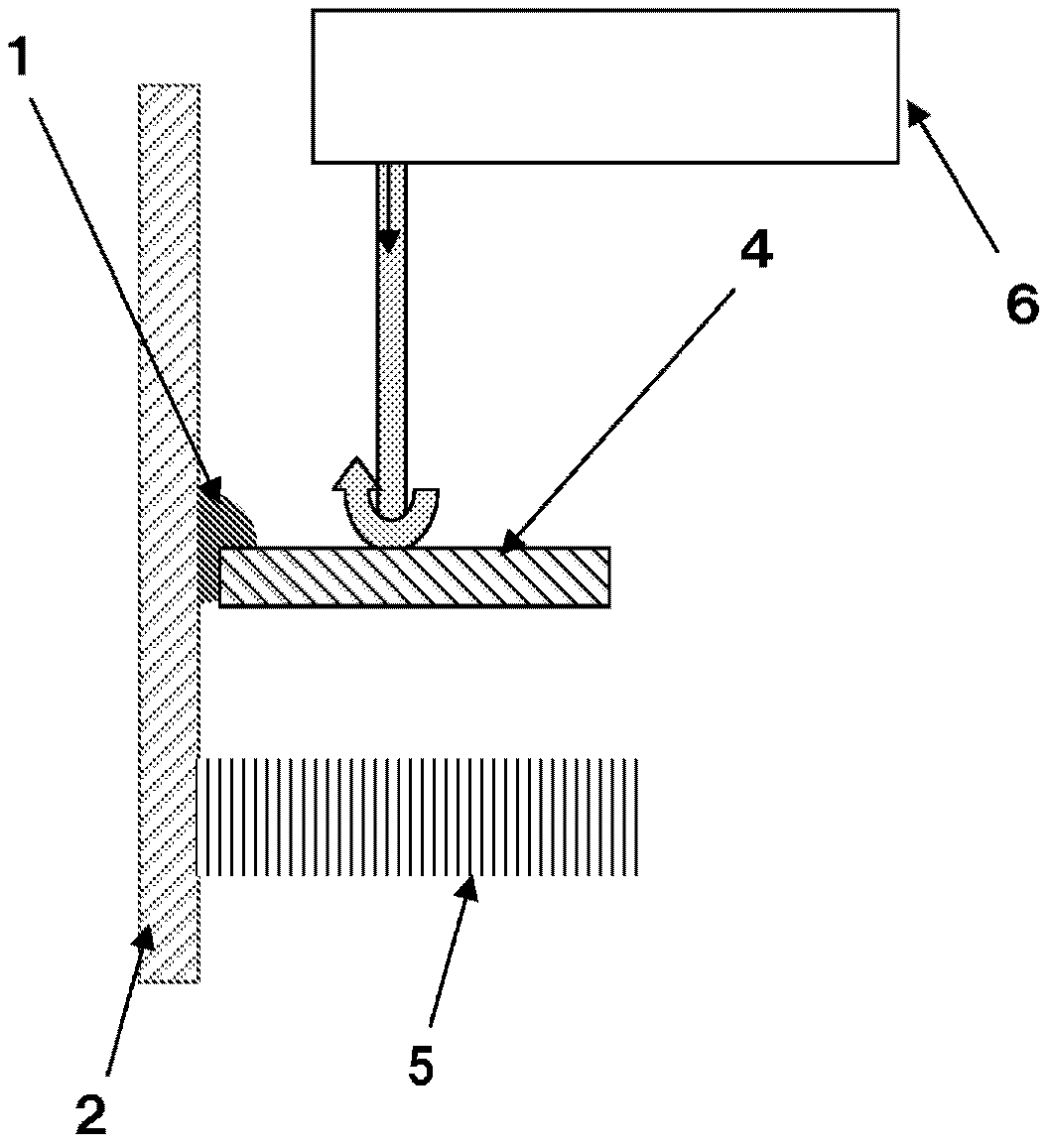

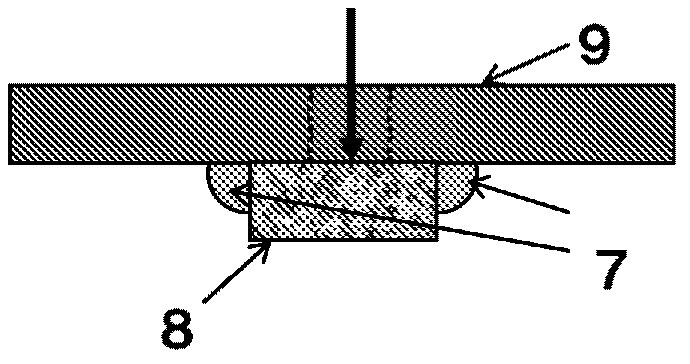

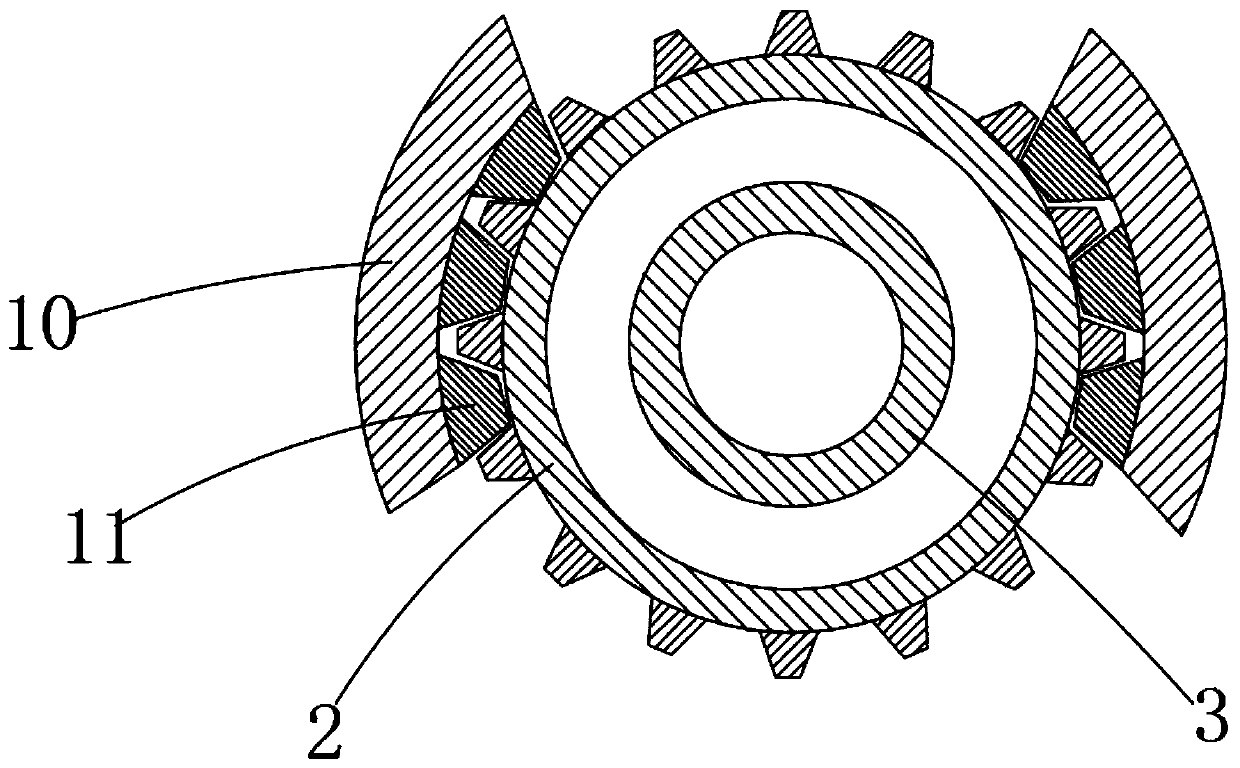

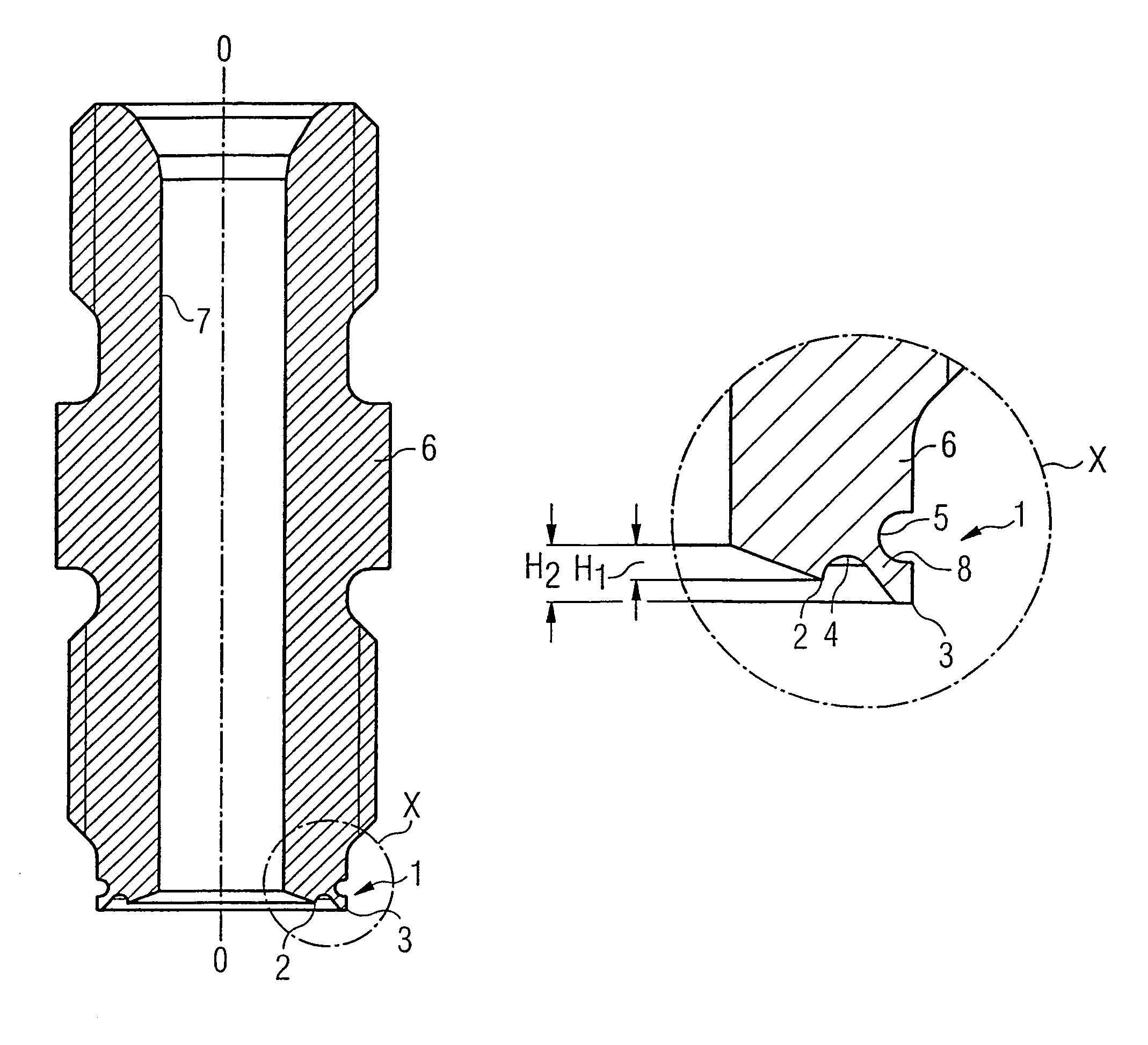

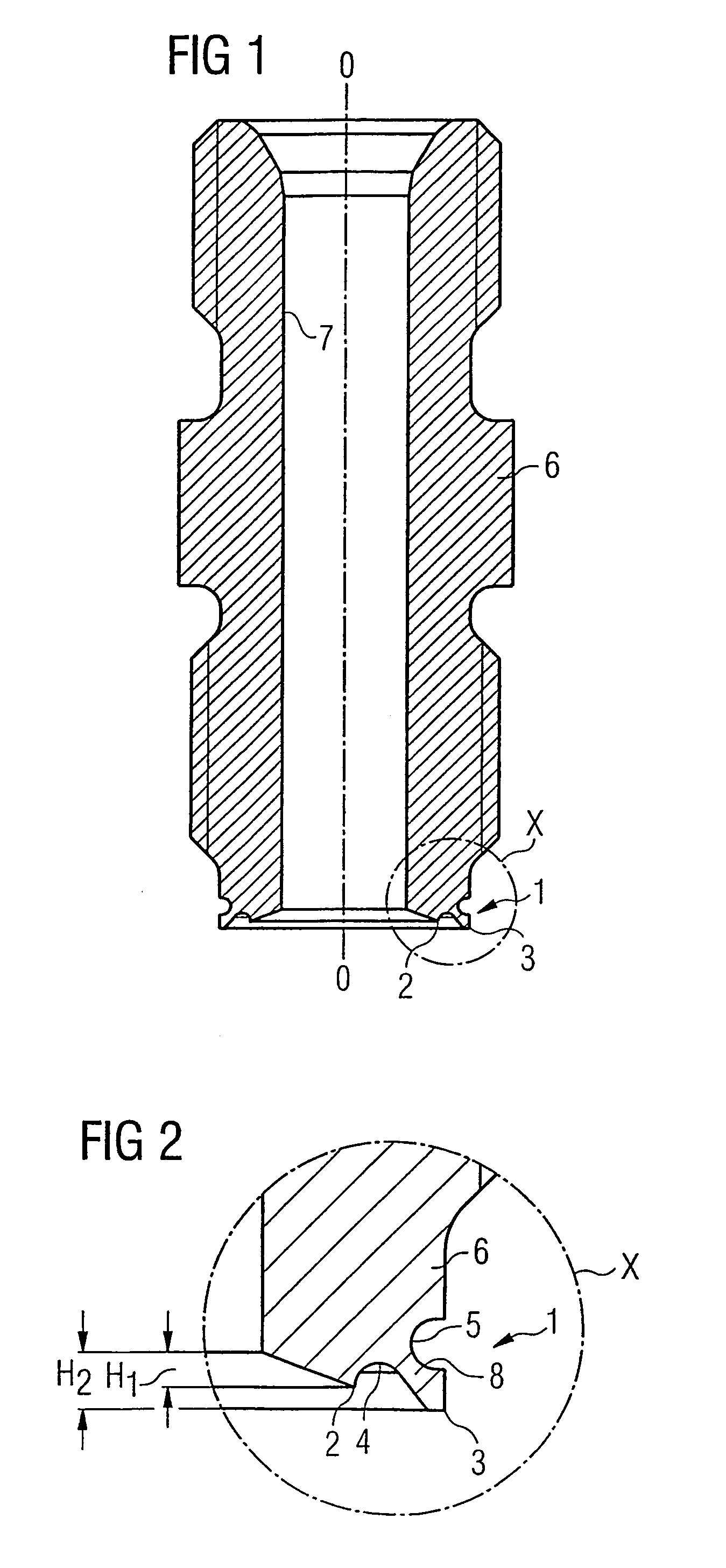

Sealing device for a high-pressure sealing of line junctions

InactiveUS20050082823A1Avoid damageSimple structureSleeve/socket jointsEngine sealsEngineeringHigh pressure

A sealing device (1) for a high-pressure sealing of line junctions comprises a cutting edge (2) and a protective edge (3). The cutting edge (2) permits a sealing of the line junction by means of plastic deformation. The protective edge (3) extends essentially parallel to the cutting edge (2) and projects beyond the cutting edge (2) in an axial direction 0-0 of the line.

Owner:CONTINENTAL AUTOMOTIVE GMBH

Method of producing a structure

InactiveUS7842218B2Improve mechanical propertiesSmall deformabilityCovering/liningsWallsAlkaline earth metalJoint compound

Producing a structure, in which: building elements are juxtaposed so as to define a space between said building elements; a joint compound composition is mixed with water so as to obtain a joint compound; said space is filled with said joint compound composition, without using a tape; and said joint compound is left to harden, wherein said joint compound composition includes: a) 50 to 60% of calcium sulphate hemihydrate; b) 5 to 15% of an organic binder in powder form; and c) 0.05 to 0.2% of a water repellent selected from the group consisting of oleic acid, stearic acid and their alkali metal or alkaline-earth metal salts.

Owner:CONTINENTAL BUILDING PROD OPERATING COMPANY

Preparation method of moisture-proof and flame-retardant plywood

ActiveCN110341262AImprove clearanceImprove retentionFireproof paintsAntifouling/underwater paintsHardnessFire prevention

The invention discloses a preparation method of a moisture-proof and flame-retardant plywood. The method includes: drying a set of veneers or a set of sliced veneers, then coating adjacent veneers orsliced veneers with an adhesive to prepare a slab, conducting cold pressing and hot pressing on the slab, and then performing shearing, edge sawing, surface finishing, sanding and polishing, and thenspraying primer and top coat. The product has bonding strength of 50-70MPa and a mould inhibition rate of 78.4-83.6%, accords with the GB50222 "fire prevention code for interior decoration design of buildings", meets the requirements of B1-C flame retardant grade, the inner flame tip height in 20s is 17-84mm, and the paint film hardness is 2-4H.

Owner:NANJING FORESTRY UNIV

Actinic radiation curable resin composition containing polyfunctional acrylate compound

ActiveCN103314023AImprove initial tack performancePrevent movementNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveDendrimerGlycerol Derivatives

The present invention provides a resin composition which serves as an adhesive for accurately fixing a component made of a material such as metal or plastic. This resin composition exhibits high initial adhesion to the material. In the durability tests including high-temperature and high-humidity test, the resin composition exhibits high holding power, and is rarely deformed even when heated under loading as well as when heated, thus inhibiting the movement of the part. An actinic radiation curable resin composition characterized by comprising (A) a polyfunctional acrylate compound having four or more (meth)acryloyl groups in the molecule, (B) a photocurable prepolymer, (C) a mono- or bi-functional (meth)acryloyl -containing monomer and (D) a photopolymerization initiator, said polyfunctional acrylate compound (A) being selected from the group consisting of (a1) glycerol derivatives, and linear or branched polymers thereof which each comprise ether skeletons as the connecting functional groups, (a2) trimethylolpropane derivatives, and linear or branched polymers thereof which each comprise ether skeletons as the connecting functional groups, (a3) monomeric pentaerythritol derivatives, and linear or branched polymers thereof which each comprise ether skeletons as the connecting functional groups, and (a4)dendrimers which contain ether or ester bonds and in which (meth)acryloyl groups are present at four or more terminals.

Owner:KYORITSU KAGAKU SANGYO KK

Production method of preservative natural cellulose membrane

ActiveCN102154812AMild reaction conditionsEasy to controlConjugated cellulose/protein artificial filamentsBleaching apparatusCelluloseChitin formation

The invention discloses a production method of a preservative natural cellulose membrane. The method comprises the following steps: a-(1) soaking, a-(2) squeezing, a-(3) crushing, a-(4) maturing, a-(5) yellowing and a-(6) dissolving the cellulose; b-(1) soaking, b-(2) squeezing, b-(3) crushing, b-(4) yellowing and b-(5) dissolving chitin; c-(1) mixing viscose; c-(2) forming a membrane; and c-(3) desulphurizing, c-(4) bleaching, c-(5) plasticizing and c-(6) drying the membrane. The reaction conditions of the method disclosed by the invention are mild; and the prepared preservative natural cellulose membrane has small space, stable elongation rate and tensile strength, proper stiffness and flexibility, relatively good color and luster and transparency, high hygiene property, antibacterial and bacteriostatic characteristics and the like.

Owner:绍兴柯德新材料股份有限公司

Joint compound composition for building elements and method of producing a structure

InactiveUS20090229736A1Improve mechanical propertiesSmall deformabilityCovering/liningsWallsAlkaline earth metalJoint compound

Producing a structure, in which: building elements are juxtaposed so as to define a space between said building elements; a joint compound composition is mixed with water so as to obtain a joint compound; said space is filled with said joint compound composition, without using a tape; and said joint compound is left to harden, wherein said joint compound composition includes: a) 50 to 60% of calcium sulphate hemihydrate; b) 5 to 15% of an organic binder in powder form; and c) 0.05 to 0.2% of a water repellent selected from the group consisting of oleic acid, stearic acid and their alkali metal or alkaline-earth metal salts.

Owner:CONTINENTAL BUILDING PROD OPERATING COMPANY

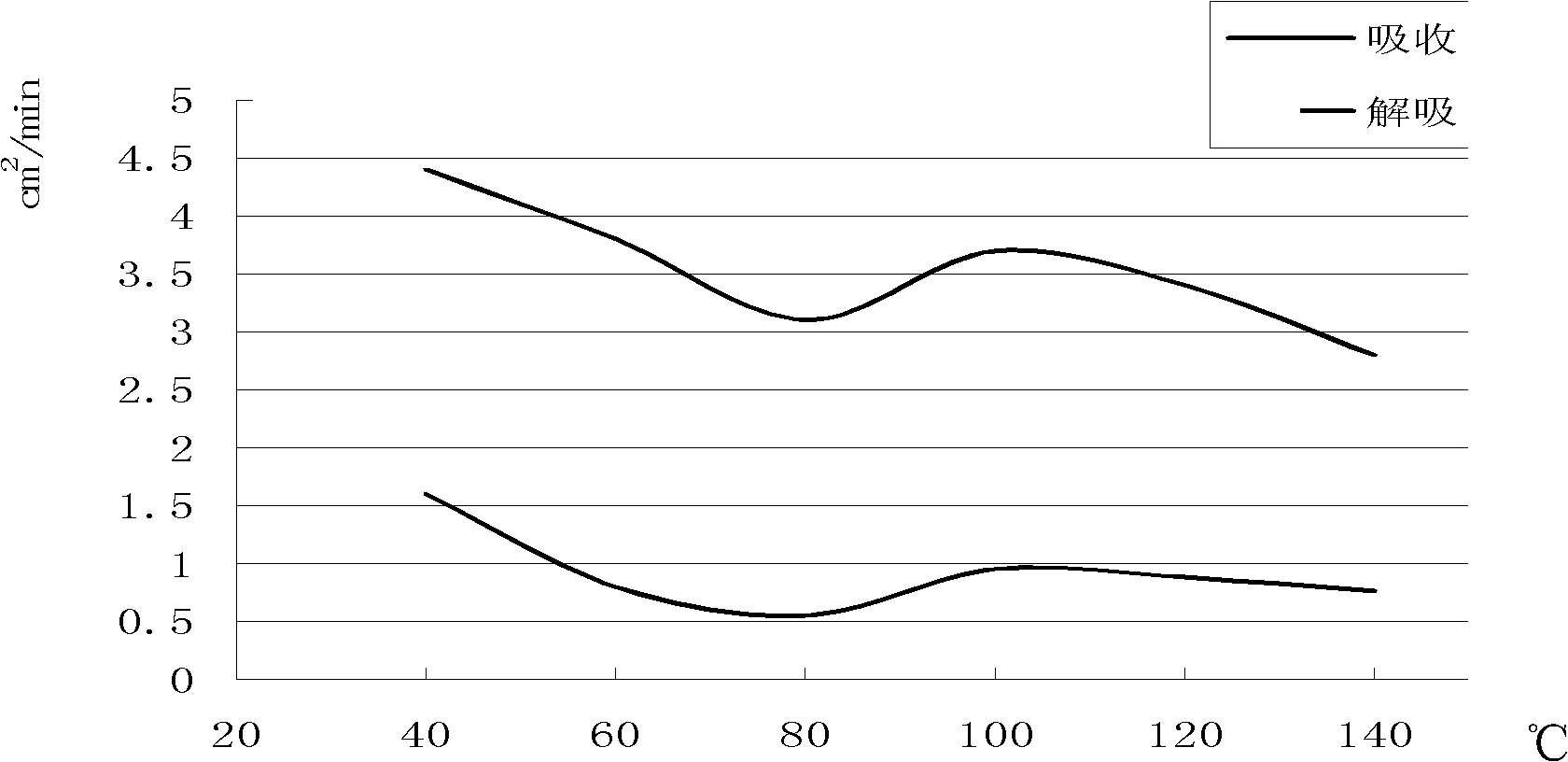

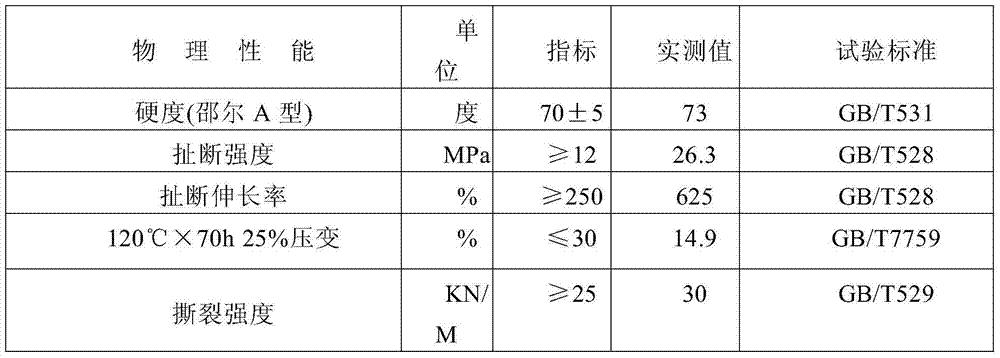

Bicycle tire tread rubber

InactiveCN104292514ASmall deformabilityLight in massSpecial tyresRolling resistance optimizationRolling resistanceStearic acid

The invention relates to the technical field of tires, and discloses a bicycle tire tread rubber which comprises the following raw materials in parts by weight: 80-90 parts of natural rubber, 10-20 parts of cis-1,4-polybutadiene rubber, 15-30 parts of plasticizer, 25-58 parts of silica white, 1-10 parts of vulcanizing agent, 1-20 parts of accelerator, 1-9 parts of zinc oxide, 0.1-2 parts of calcium carbonate, 1-10 parts of reinforcing agent cb, 0.1-2 parts of stearic acid, 2-5 parts of anti-aging agent aw, 2-5 parts of anti-aging agent 4010, 1-2 parts of paraffin and 1-10 parts of silane coupling agent. The bicycle tire tread rubber has the advantages of tear resistance, fatigue resistance, heat resistance, abrasion resistance, aging resistance, small deformability, light weight, favorable water absorptivity, long service life, low compressive heat generation and dynamic heat generation, small permanent deformation, favorable anti-slip property and small rolling resistance, and can well absorb shock load.

Owner:MINGGUANG RUITAI IND

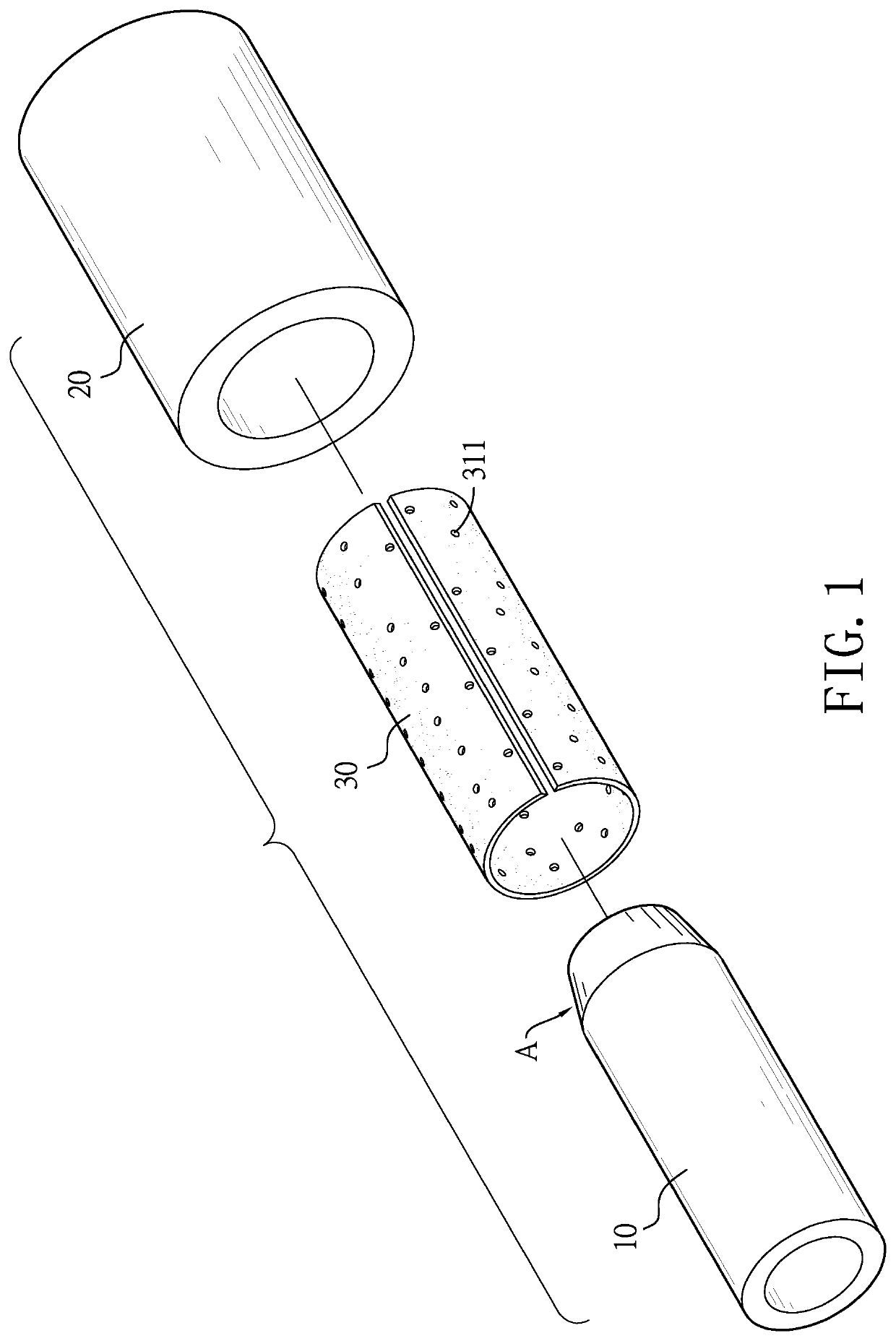

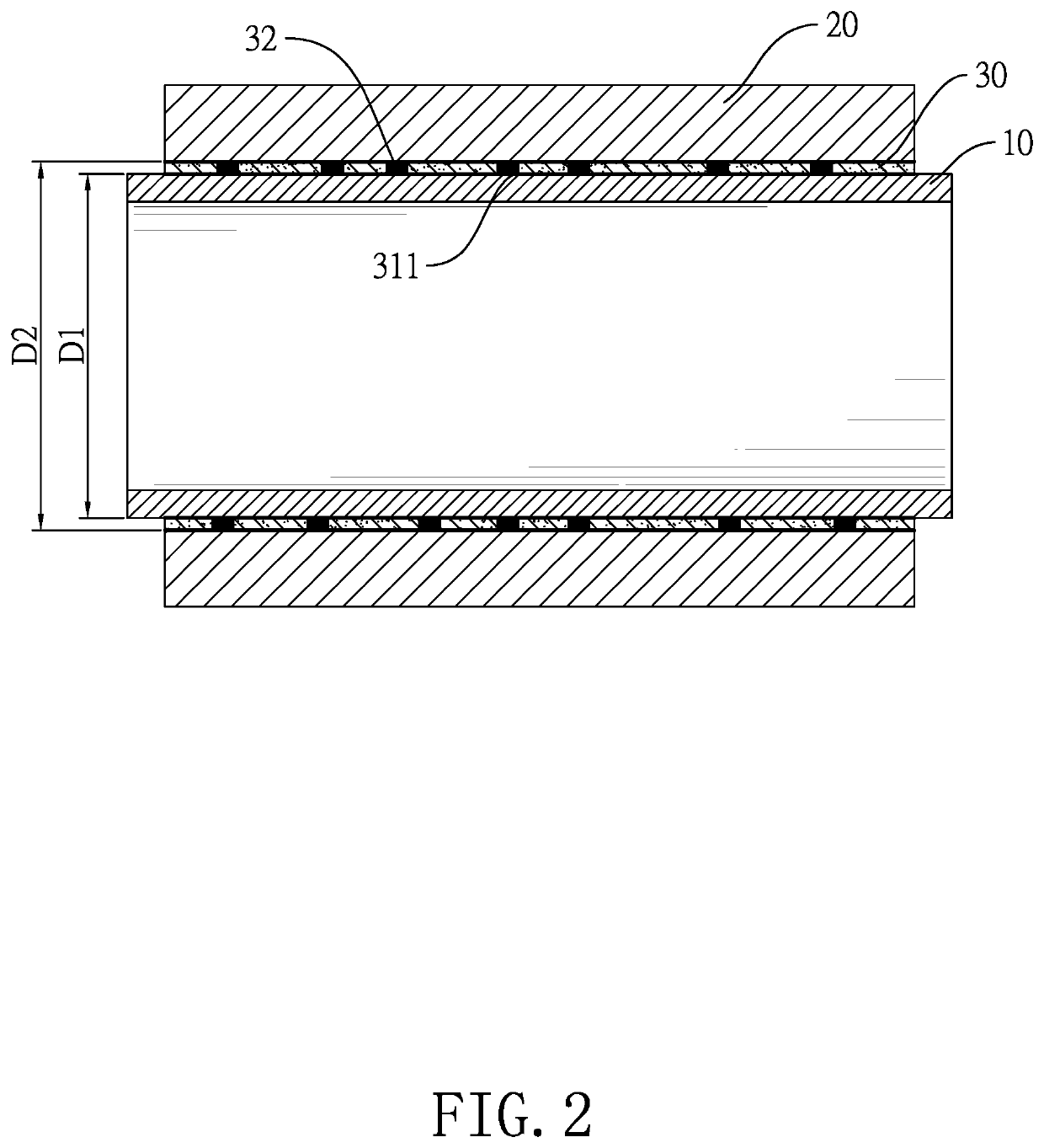

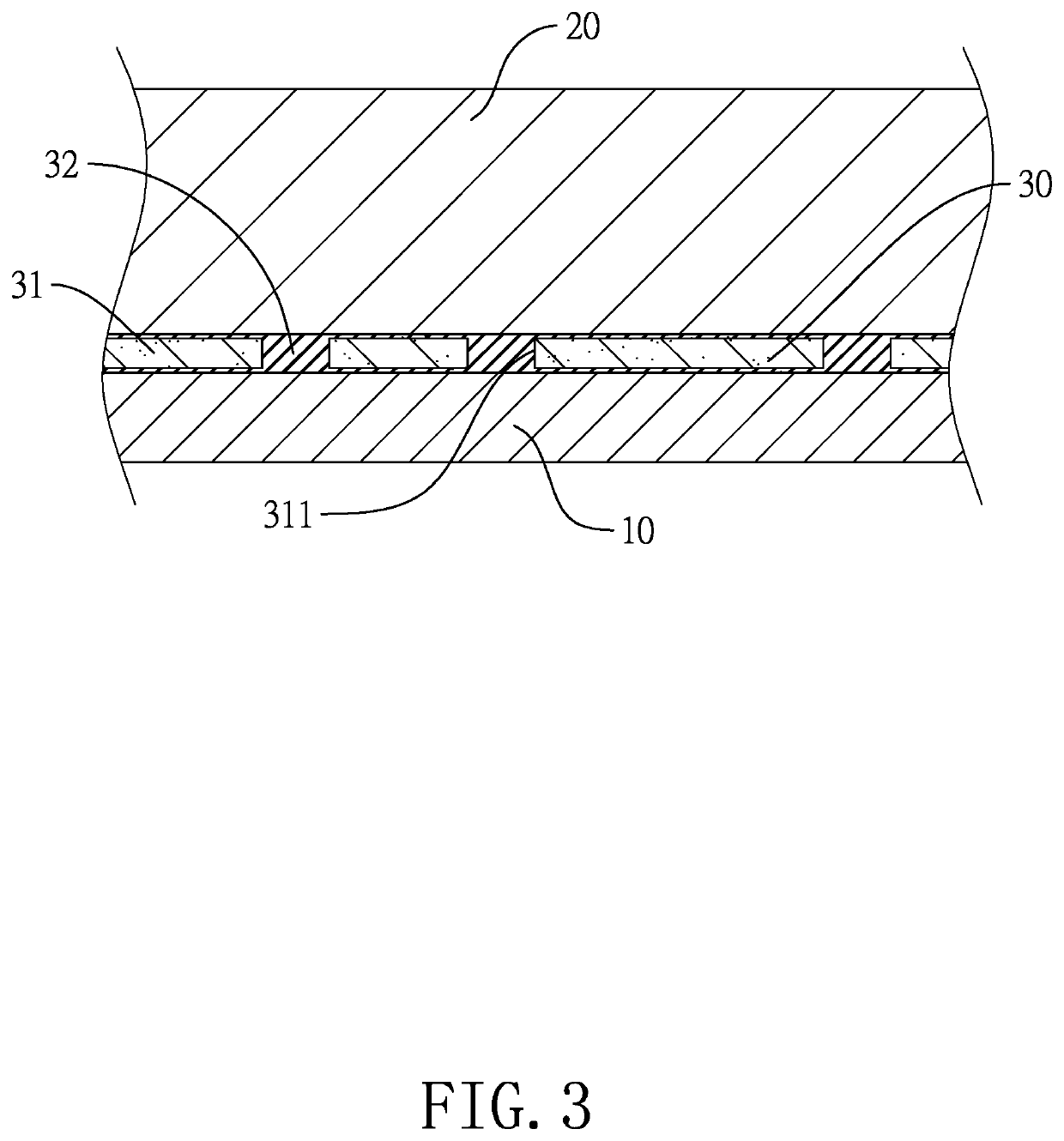

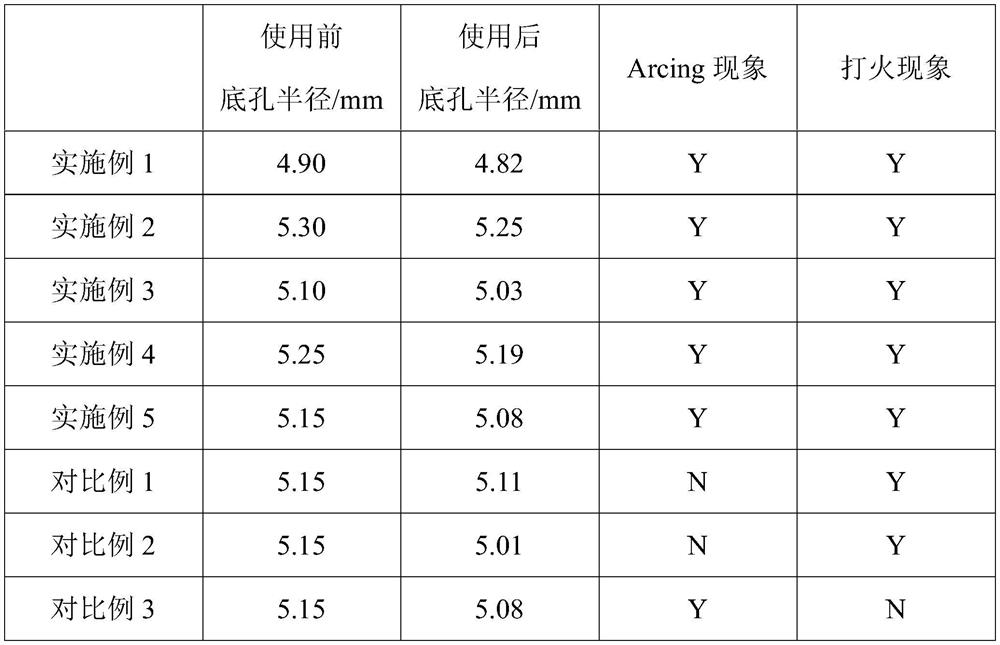

Rotatable sputtering target

ActiveUS20200203134A1Simple processMaintain joint strengthElectric discharge tubesVacuum evaporation coatingAdhesiveEngineering

A rotatable sputtering target has a target material, a back tube and a joint piece. The joint piece is disposed between the target material and the back tube. The joint piece has a compressible structure and an electrically and thermally conductive adhesive. Particularly, the compressible structure being a compressible blanket or a compressible sheet has multiple through holes and thus the electrically and thermally conductive adhesive is filled in the through holes and then directly formed between the target material and the back tube. Using the joint piece to joint the target material and the back tube not only maintains the joint strength but also elevates the tolerable power of the rotatable sputtering target, which can increase the sputtering efficiency.

Owner:OUMEIDA APPLIED MATERIALS TECH CO LTD +1

Preparation method of gradient functional ceramic

The invention relates to the technical field of ceramic preparation, particularly to a preparation method of gradient functional ceramic. According to the invention, slurry and the process parametersof 3D printing are optimized, and particularly, sintering additives in ceramic composite powder in the slurry and the exposure energy of 3D printing are optimized; a blank is printed by adopting exposure energy corresponding according to different slurry; the blank obtained by 3D printing is uniform and has high forming rate; and a ceramic formed by degreasing and sintering the blank under certainconditions is small in deformability, high in structural and dimensional precision, good in interlayer cohesiveness and high in density and bending strength. The gradient functional ceramic preparedthrough the method is high in forming efficiency and forming size precision; the structure of the gradient functional ceramic can be accurately regulated and controlled; functionalization is achieved;the material cost of the ceramic can be reduced; and production efficiency is improved.

Owner:GUANGDONG UNIV OF TECH

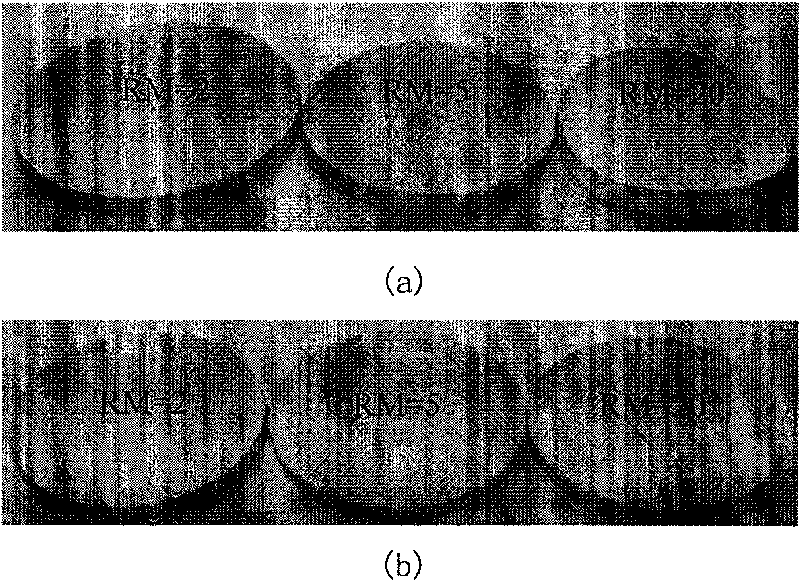

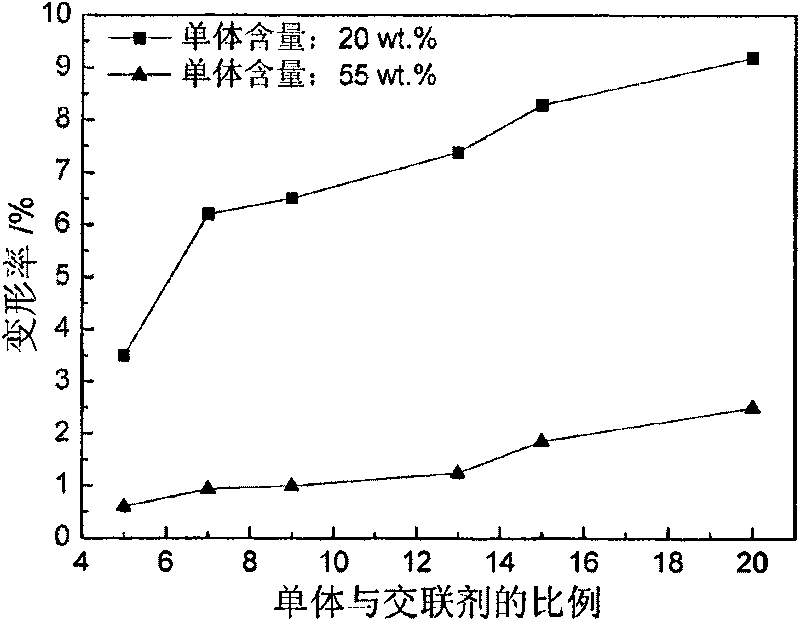

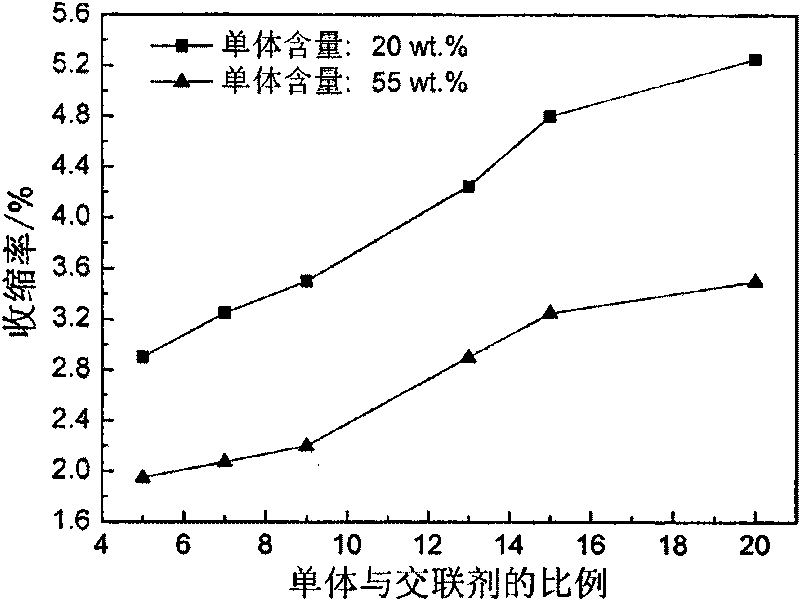

Method for controlling deformation of ceramic blank in gel casting process

InactiveCN101700676AEvenly distributedSmall deformabilityCeramic shaping plantsMethylene bisacrylamideMetallurgy

The present invention discloses a method for controlling the deformation of ceramic blank in the gel casting process which has the key point that in the gel casting process, the deformation of the ceramic blank is controlled in the drying process of the ceramic blank by controlling the content of monomer used for the gelling reaction and the proportion of the monomer to crosslinker in the slurry.The method is characterized in that acrylamide (AM) is used as the monomer and N, N'-methylene bisacrylamide (MBAM) is used as the crosslinker to prepare the slurry, the distribution of the gel network in the ceramic blank and the strength of the ceramic blank are controlled by controlling the content of the monomer used for the gelling reaction and the proportion of the monomer to crosslinker inthe slurry, and the problem of controlling the deformation of the ceramic blank in the drying process of the ceramic blank is solved.

Owner:XI AN JIAOTONG UNIV

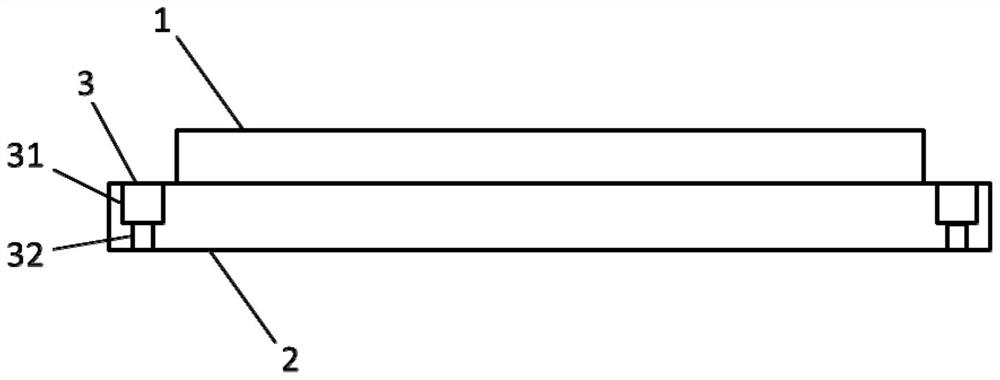

Anti-deformation titanium target material

InactiveCN111705301ASmall deformabilityEasy to disassembleVacuum evaporation coatingSputtering coatingEngineeringStructural engineering

The invention provides an anti-deformation titanium target material. The anti-deformation titanium target material comprises a back plate and a sputtering part connected with the back plate, the sizeof the sputtering part is smaller than that of the back plate, at least two mounting stepped holes are formed in the edge of the back plate, each mounting stepped hole comprises a counter bore and a bottom hole, and the ratio of the depth of the counter bore to the depth of the bottom hole is 1.25 to 1.55. The target material is small in deformability and easy to disassemble after being used, andthe sparking phenomenon is avoided in the using process.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

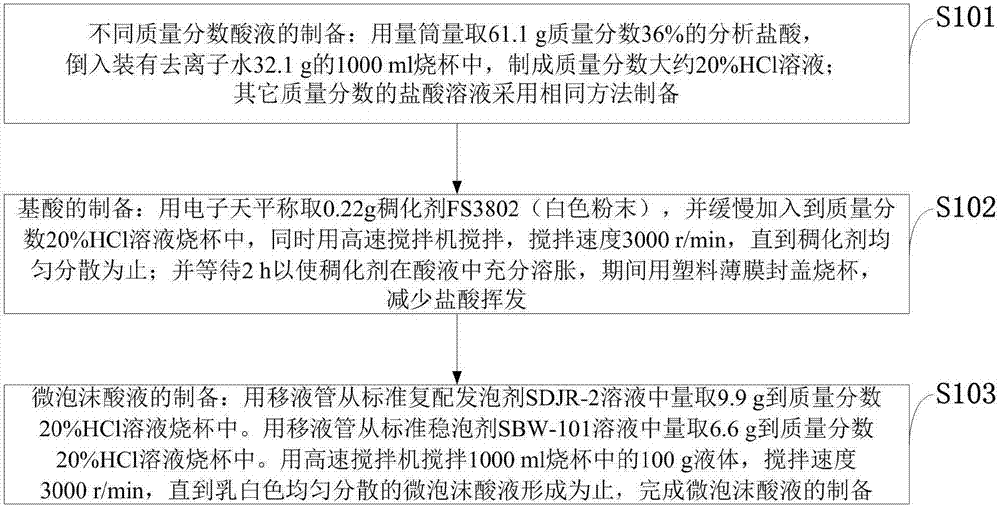

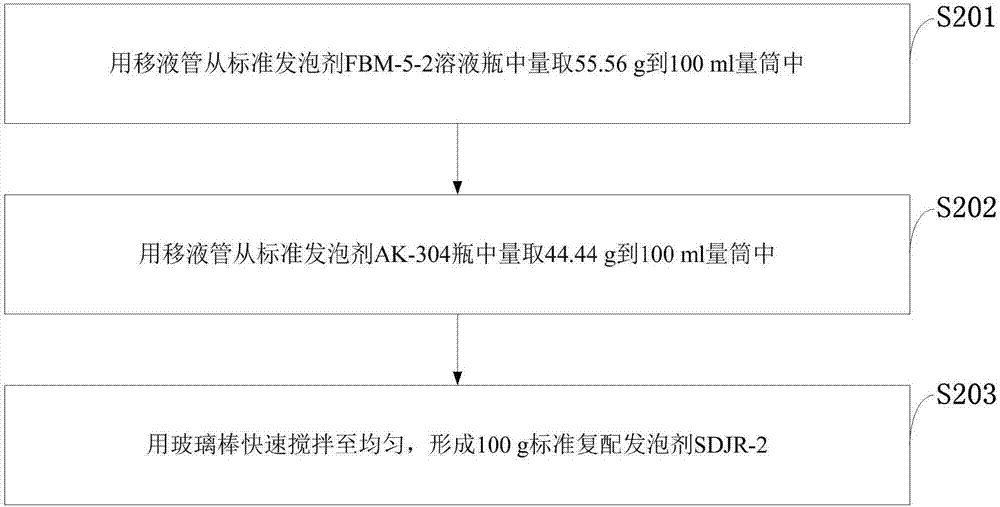

Microfoam acid liquid and preparation method thereof

The invention belongs to the technical field of foam acid and discloses microfoam acid liquid, constitution of a compound foaming agent of the microfoam acid liquid and a preparation method of the microfoam acid liquid. The microfoam acid liquid contains the following components in percentage by mass (100% in total): 10%-25% of HCl (hydrochloric acid), 0.36% of SDJR-2 (compound foaming agent), 0.24% of SBW-101 (foam stabilizer), 0.2% of FS3802 (thickening agent) and the balance of water, wherein the compound foaming agent SDJR-2 contains 55.56% of an FBM-5-2 foaming agent and 44.44% of an AK-304 foaming agent. The microfoam acid liquid has good properties of foaming, foam stabilization, viscosity maintenance, acid rock reaction retardance, temperature resistance, salt resistance, oil resistance, sand carrying and the like; by observing through an optical microscope, the microstructure and size of the microfoam acid liquid meet the dimensional requirement of microfoams; experimental evaluation shows that the microfoam acid liquid is a novel acid liquid system with excellent performance and has wide application prospects.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

A kind of lightweight ultra-high-strength concrete and its preparation method

The invention relates to a lightweight super-high-strength concrete and a preparation method thereof. The lightweight super-high-strength concrete comprises the following components in parts by weight: 630-650 parts of cement, 280-300 parts of ultrafine fly ash, 180-300 parts of 200 parts of silica fume, 100-120 parts of emery powder, 100-200 parts of floating beads, 150-200 parts of Peek plastic particles, 18-23 parts of organic polymer water-absorbing resin, 20-30 parts of polycarboxylate superplasticizer, 0.13- The water-to-binder ratio is 0.15, and the floating beads are divided into two particle size grades: 40‑100 mesh and 20‑40 mesh. The obtained lightweight ultra-high-strength concrete fully optimizes and improves the internal structure by the powder and aggregates mixed therein, greatly reduces the bulk density, improves the overall strength, has excellent performance, is simple to prepare, and is suitable for popularization.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

Disposable esophagus medicine applicator in department of gastroenterology

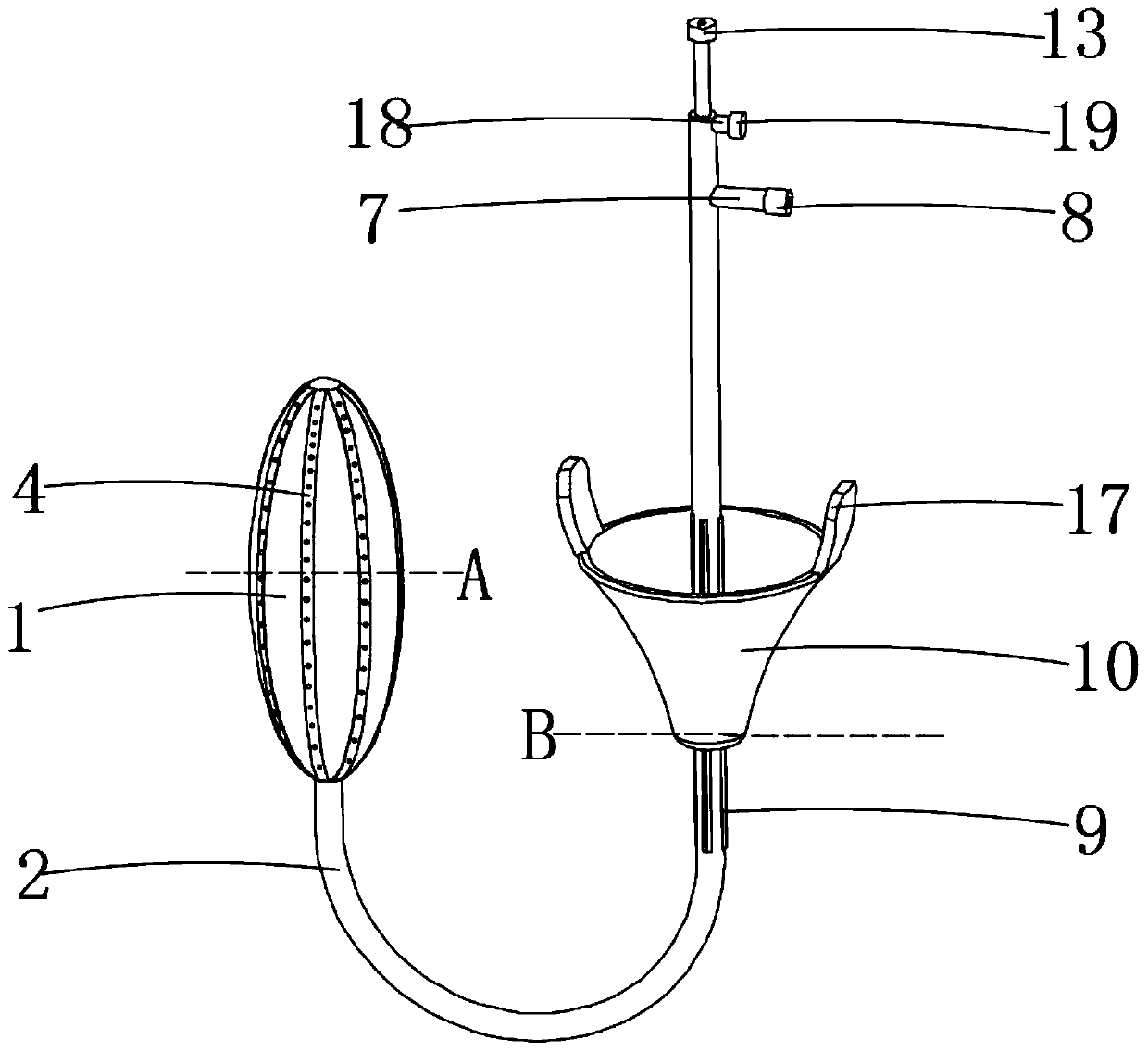

InactiveCN110711309AInjection achievedSyringe to achieve the injection of gasSurgeryMedical devicesSphygmomanometerEngineering

The invention relates to the field of a medical appliance, in particular to a disposable esophagus medicine applicator in department of gastroenterology. The disposable esophagus medicine applicator in department of gastroenterology comprises a silica gel air bag and an injector which are connected by a double-layer sleeve pipe, wherein the double-layer sleeve pipe comprises an outer pipeline andan inner pipeline arranged in the outer pipeline; and a plurality of groups of medical tough bars are respectively arranged on the curve surface side wall of the silica gel air bag. The disposable esophagus medicine applicator in department of gastroenterology has the advantages that the structure is simple; the cost brought by the use of a sphygmomanometer type latex air bag is reduced; in addition, by controlling the clamp blocks and conical clamp strips, the fixation of an elastic opening supporter and the double-layer sleeve pipe is realized; the displacement of the silica gel air bag dueto the swallowing of a patient can be avoided; the smearing effect is further improved; in addition, the operation and the use by a doctor are convenient; meanwhile, the medical tough bars have certain telescopic performance and can maintain the three-dimensional performance, so that the inner walls of the two sides of a medicine cavity cannot be in contact because the silica gel air bag becomes big, so that the deformation of the medicine cavity is reduced; further, medicine liquid can be conveniently injected into the medicine cavity; and the medicine liquid can be conveniently smeared ontothe esophagus position through a medicine leaking hole.

Owner:CHANGZHOU NO 2 PEOPLES HOSPITAL

Lightweight ultrahigh-strength concrete and preparation method thereof

The invention relates to lightweight ultrahigh-strength concrete and a preparation method thereof. The lightweight ultrahigh-strength concrete comprises, by weight, 630 to 650 parts of cement, 280 to300 parts of ultrafine fly ash, 180 to 200 parts of silica fume, 100 to 120 parts of carborundum powder, 100 to 200 parts of floating beads, 150 to 200 parts of Peek plastic particles, 18 to 23 partsof organic polymer water-absorbent resin and 20 to 30 parts of a polycarboxylate superplasticizer, the water-binder ratio is 0.13 to 0.15, the floating beads are divided into two particle size gradesof 40 to 100 meshes and 20 to 40 meshes. According to the obtained lightweight ultrahigh-strength concrete, the internal structure is fully optimized and improved by the doped powder and aggregate, the volume weight is greatly reduced, the overall strength is improved, the performances are excellent, the preparation is simple, and the lightweight ultrahigh-strength concrete is suitable for popularization.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

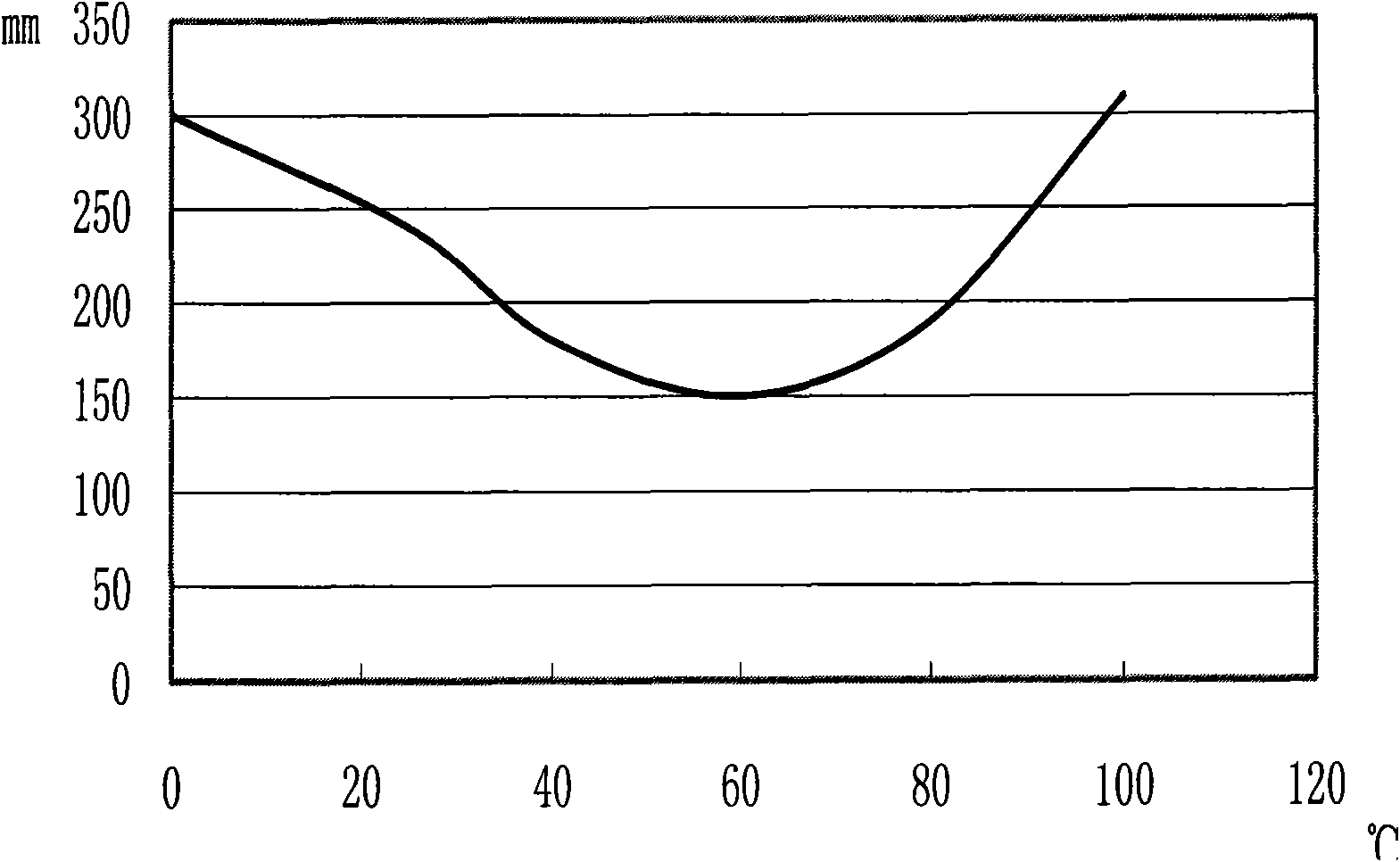

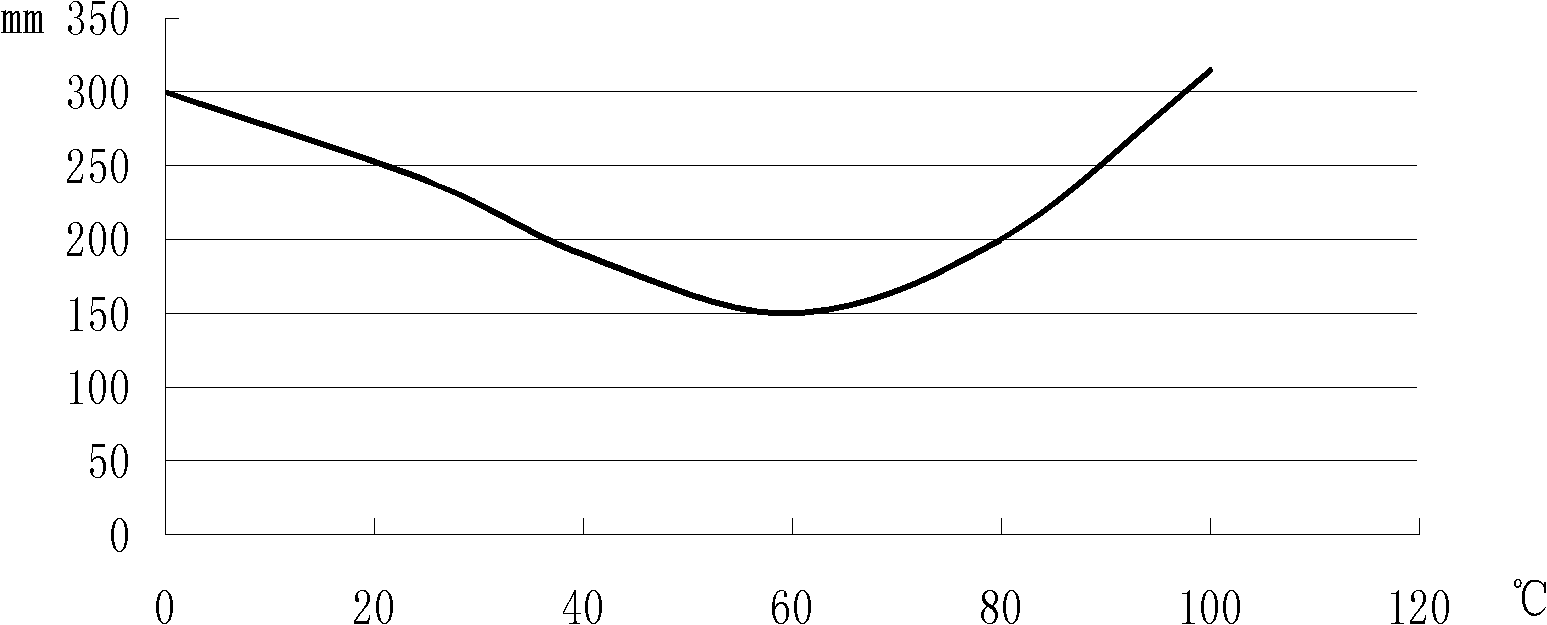

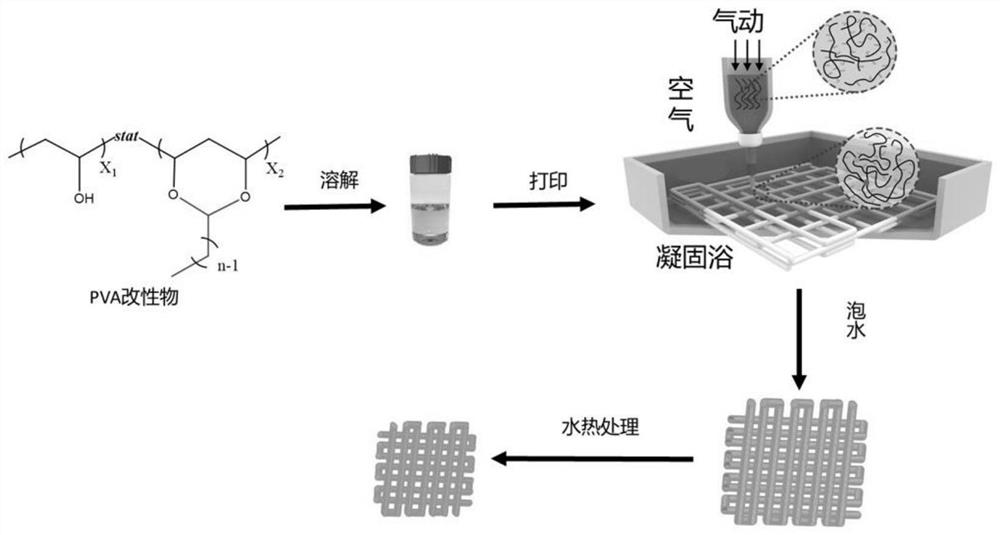

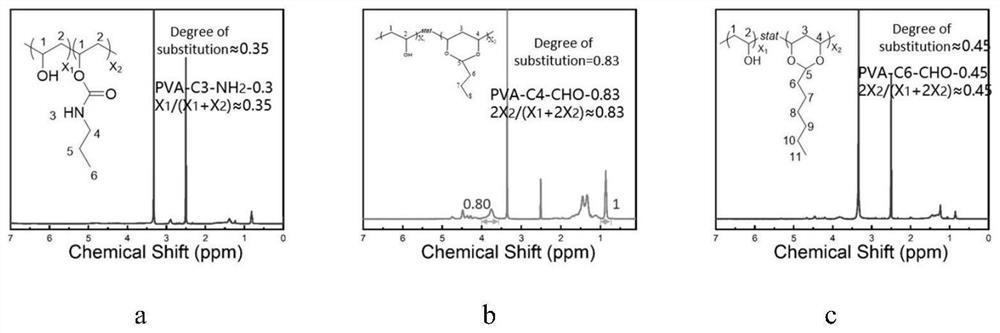

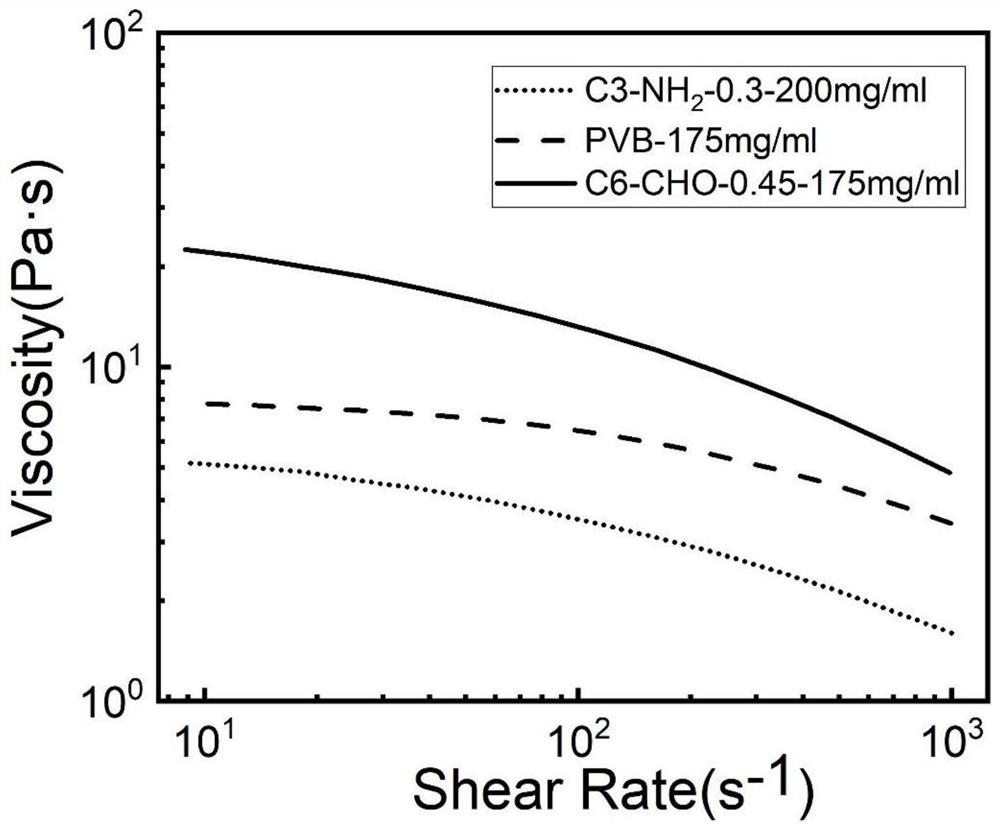

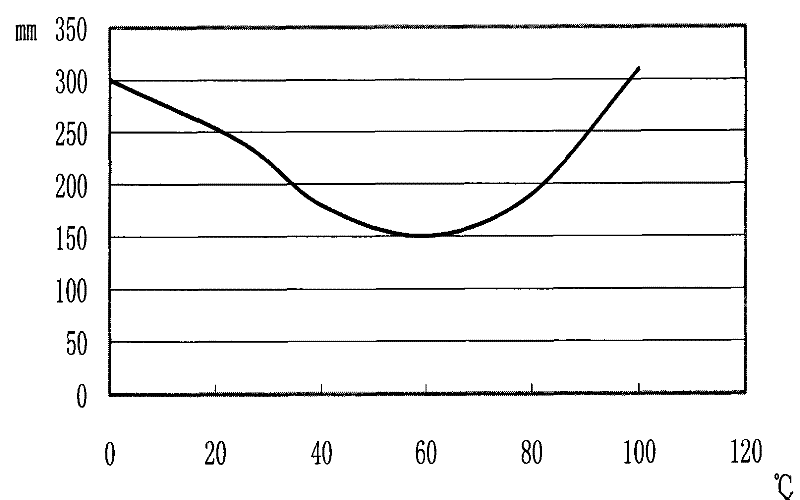

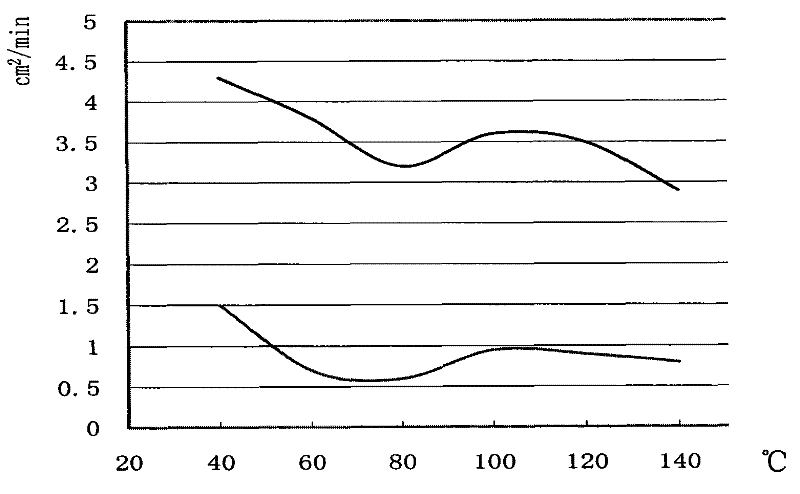

Method for controlling precision of extrusion type 3D printing polymer line width

ActiveCN113459505ASmall deformabilityHooke elastic behaviorAdditive manufacturing apparatus3D object support structures3d printAlkane

The invention relates to the technical field of 3D printing, in particular to a method for controlling precision of extrusion type 3D printing polymer line width. The method specifically comprises the following steps of dissolving short alkane chain grafted polyvinyl alcohol in an organic solvent to obtain a 3D printing solution, and performing 3D printing to obtain a printing sample; and soaking the printing sample in water and then placing in hot water for hydro-thermal treatment to obtain the 3D printing polymer. According to the method, the printing sample is subjected to hydro-thermal treatment, so that the size of the printing sample is reduced, and the reduction times of the printing sample are different under different hydro-thermal treatment temperature conditions, so that the reduction times of the printing sample can be controlled by controlling the hydro-thermal treatment temperature, and the technical purpose of controlling the line width precision of an extrusion type 3D printing polymer is achieved.

Owner:GUANGDONG UNIV OF TECH +1

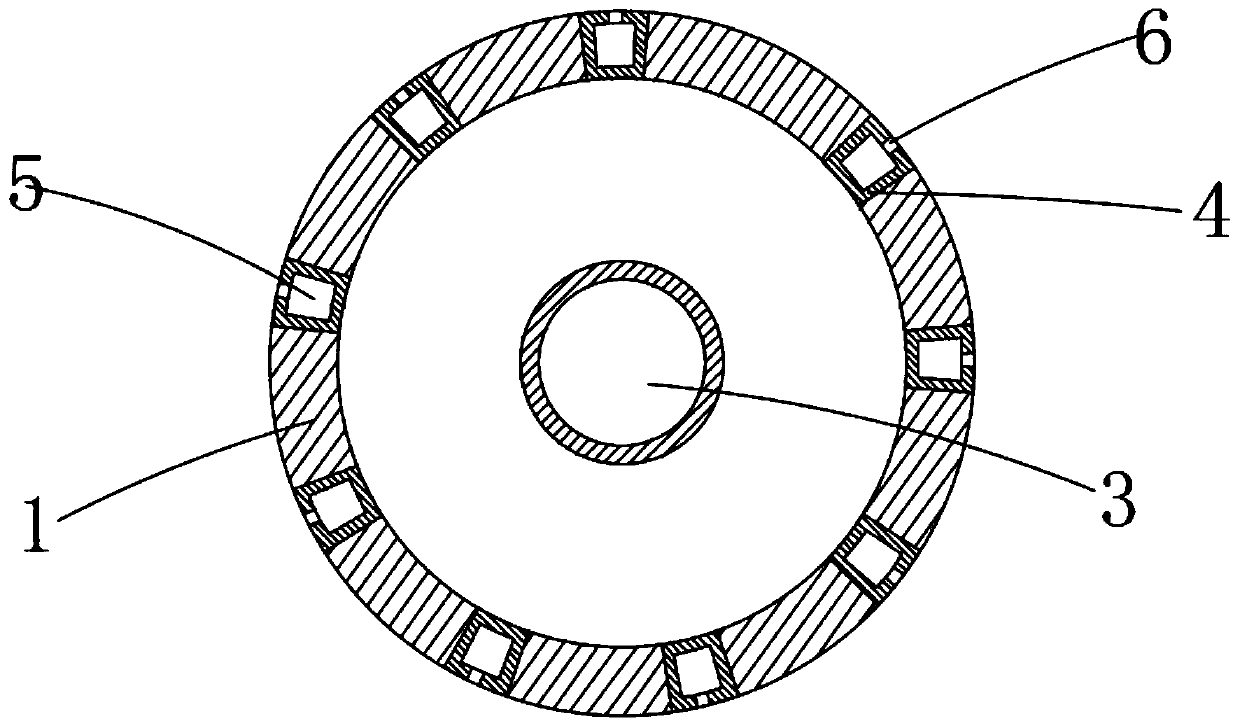

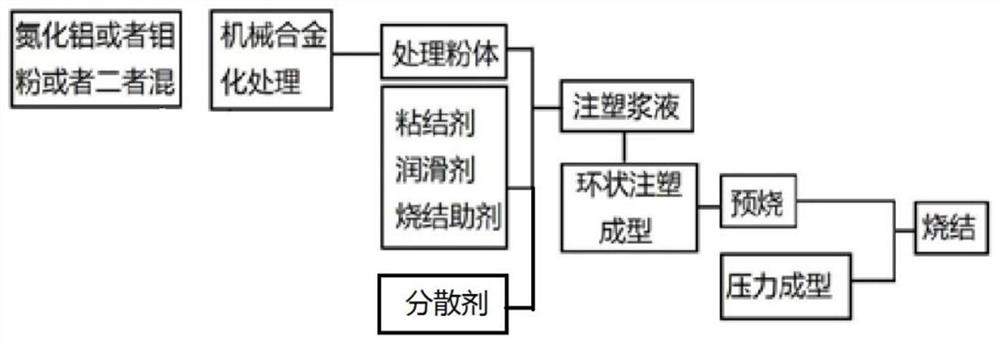

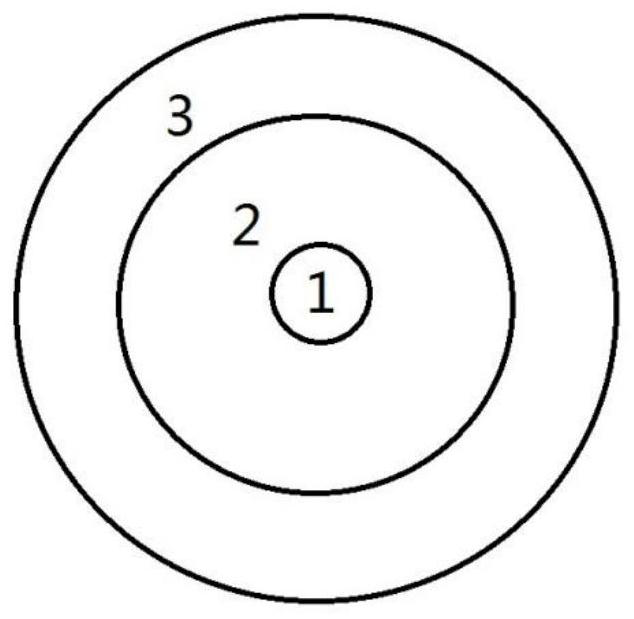

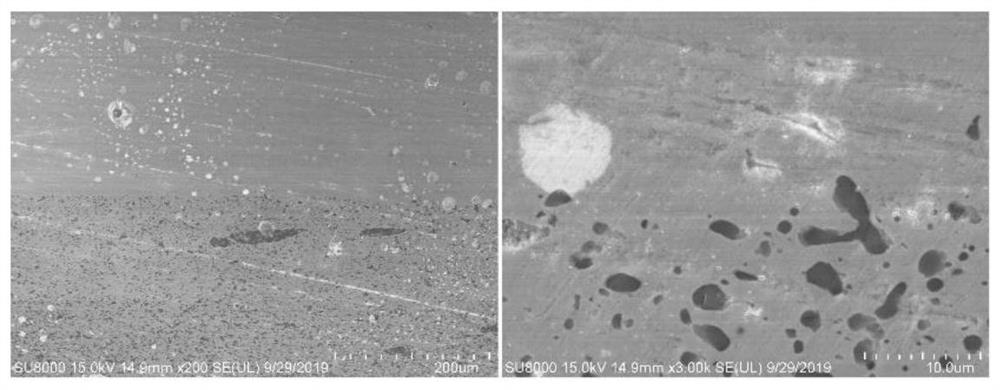

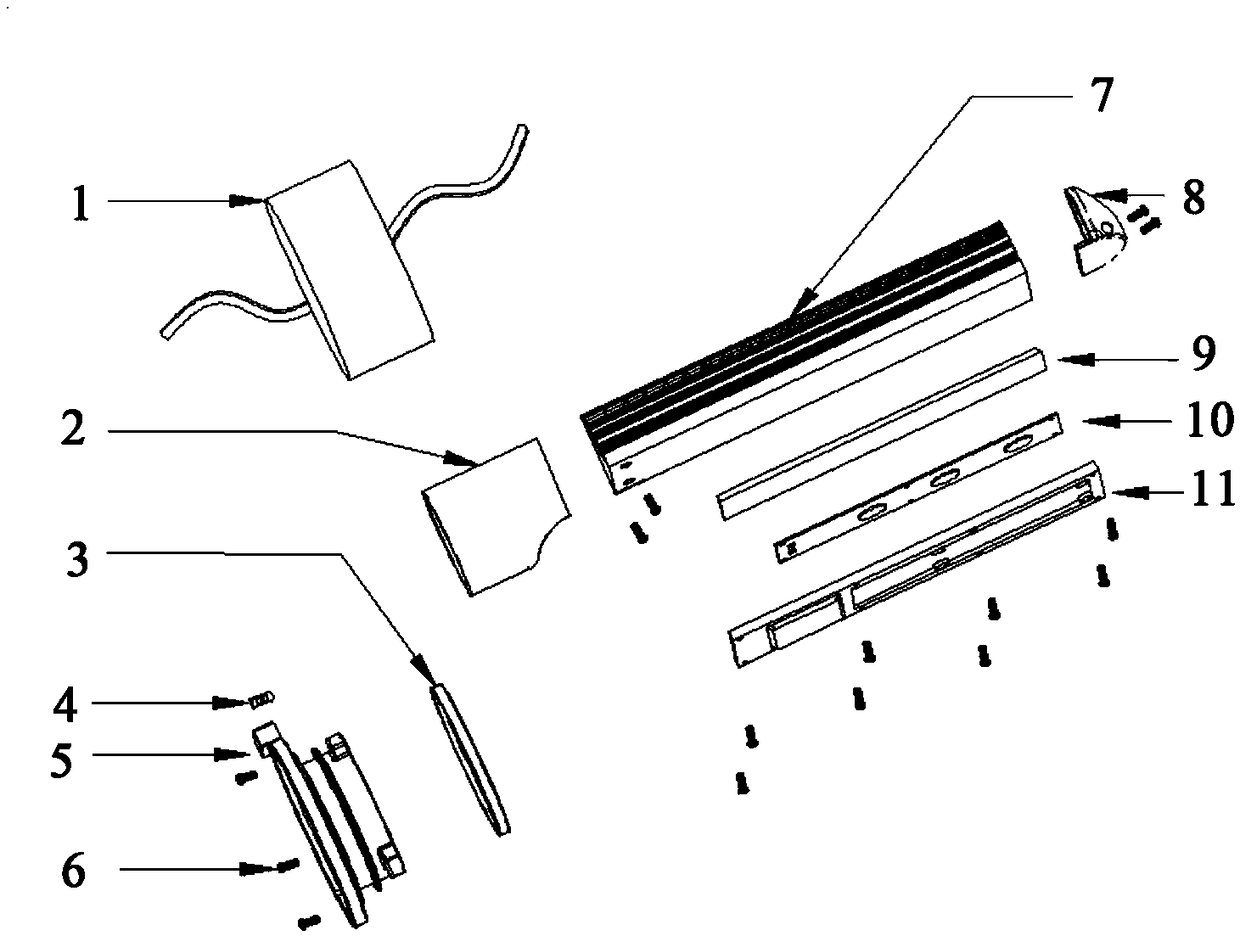

Annular metal-ceramic gradient material and preparation method thereof

ActiveCN112453410ASimple processLow costTransportation and packagingMetal-working apparatusGradient materialInjection moulding

The present invention relates to an annular metal-ceramic gradient material and a preparation method thereof. The structure the gradient material is annularly distributed from inside to outside, one ring is a gradient layer, and each gradient layer comprises the following components of, by weight, 88% to 90% of raw material powder, 2.25% to 3.3% of a dispersing agent, 2.8% to 3.22% of a binding agent, 4.32% to 5.4% of a lubricant and 0.54% to 0.86% of a sintering additive. According to different gradient layers, the raw material powder comprises pure ceramic powder, pure metal powder and mixture of powder of the pure ceramic powder and the pure metal powder in any mixing proportion. According to the annular metal-ceramic gradient material and the preparation method thereof, the number of layers is controlled through injection molding, the process is simplified, the cost is reduced, the molding efficiency is high, the deformability is small, the gradient components are uniformly distributed, the structural precision and the size precision are high, the interlayer cohesiveness is good, the density and the bending strength are high, and the production efficiency is improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

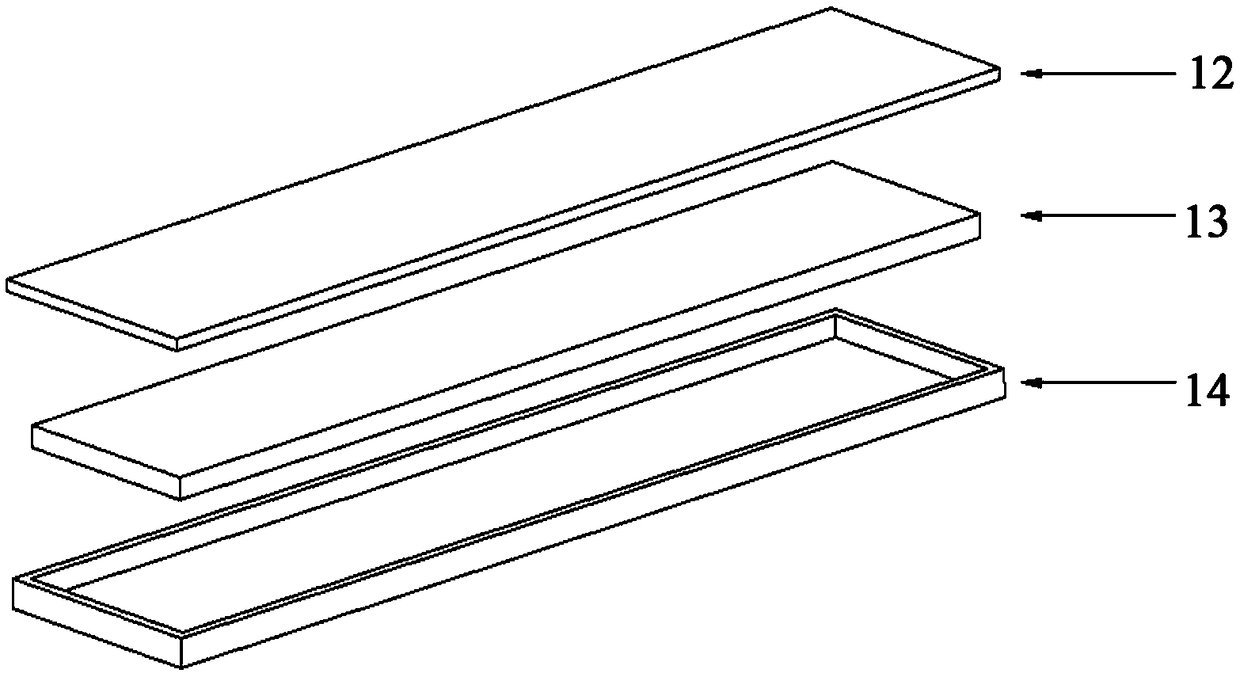

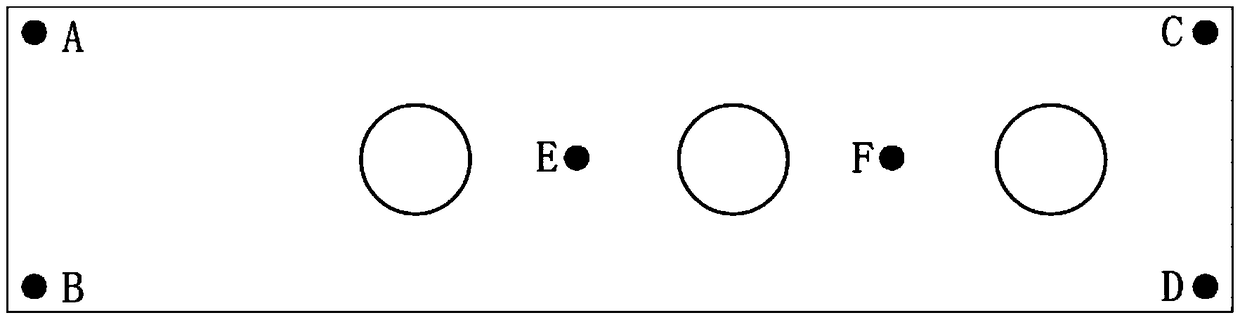

Graphene heat-radiating LED street lamp modulator tube

ActiveCN108730940AImprove heat transfer efficiencySmall deformabilityMechanical apparatusLighting heating/cooling arrangementsHeat conductingEngineering

The invention provides a graphene heat-radiating LED street lamp modulator tube. The graphene heat-radiating LED street lamp modulator tube comprises an LED light source, a heat-conducting temperatureequalization plate and a heat radiator; the heat-conducting temperature equalization plate is located between the LED light source and the heat radiator; and the heat-conducting temperature equalization plate comprises a packing seal and a reversible energy-storage material located in the packing seal. The LED street lamp modulator tube comprises the novel heat-conducting temperature equalizationplate, aiming at the situation that a COB light source has the increasingly high heat radiating requirement in the increasingly small closed space, the improved heat-conducting temperature equalization plate has the better heat storage and heat-conducting effects, thus the temperature of the whole LED street lamp modulator tube is maintained to be uniform, and the service life of the single COB light source is not affected by the excessively high local temperature.

Owner:明朔(北京)电子科技有限公司

Sealing device for a high-pressure sealing of line junctions

InactiveUS7134698B2Avoid damageSimple structureSleeve/socket jointsEngine sealsEngineeringHigh pressure

A sealing device (1) for a high-pressure sealing of line junctions comprises a cutting edge (2) and a protective edge (3). The cutting edge (2) permits a sealing of the line junction by means of plastic deformation. The protective edge (3) extends essentially parallel to the cutting edge (2) and projects beyond the cutting edge (2) in an axial direction 0-0 of the line.

Owner:CONTINENTAL AUTOMOTIVE GMBH

Production method of natural cellulose membrane

ActiveCN101628986BSmall difference between film websElongation stabilityCelluloseMoisture absorption

The invention discloses a production method of natural cellulose membranes, comprising the following steps: (a) immersion; (b) squeezing; (c) grinding; (d) maturing; (e) etiolation; (f) solution; (g) film formation; (h) desulfuration; (i) bleaching; (j) plastification; and (k) drying. The production method has the advantages of mild reaction condition, short spacings among the prepared natural cellulose membranes, stable expansion rate and tensile strength, proper stiffness and flexibility, better colour and luster, good transparence, high hygiene property, and the like, improves the surface property of paper through the plastification, in particular enhances the smoothness of paper surfaces, improves the printability, reduces the deformability of paper and the moisture absorption, thereby reaching the new requirement of modern printing and packaging.

Owner:绍兴柯德新材料有限公司

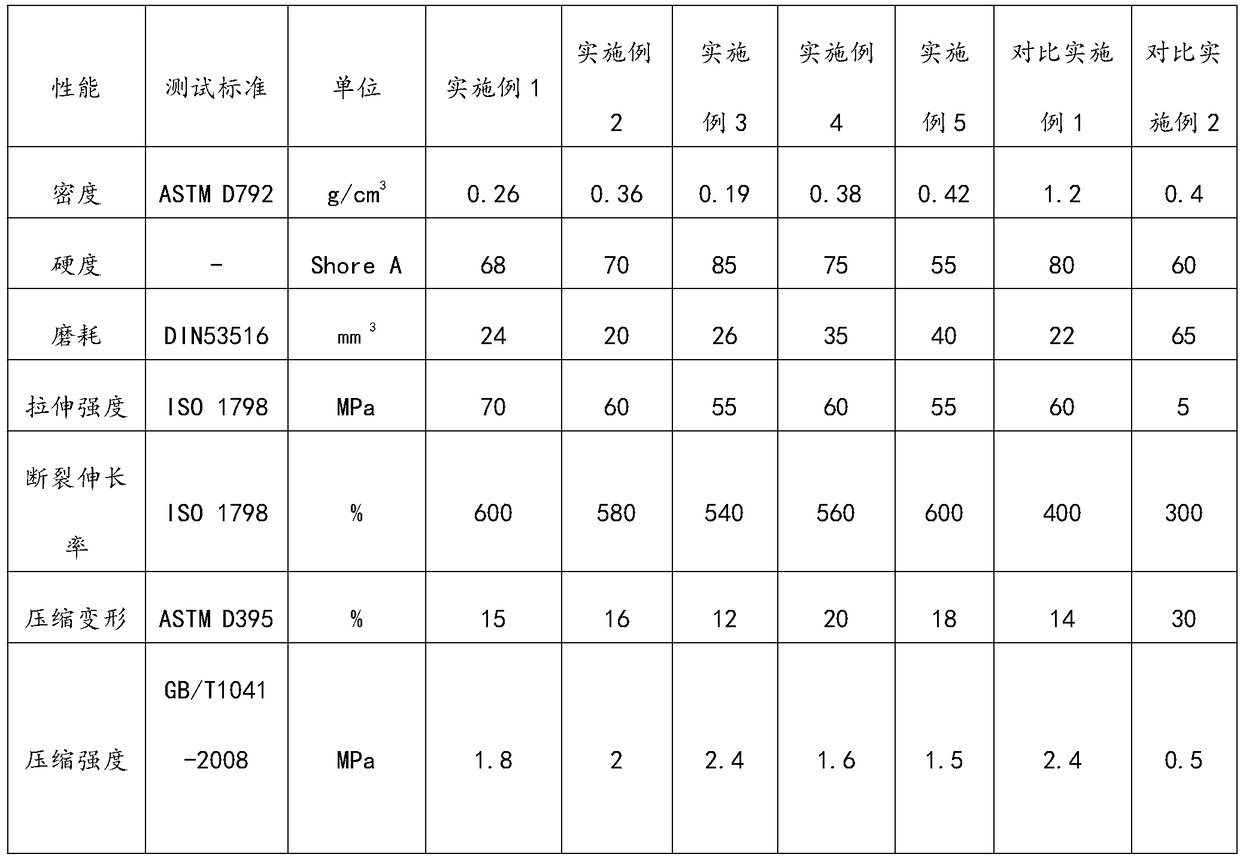

High load buffer material and preparation method thereof

The invention belongs to the field of chemical materials, and in particular relates to a high load buffer material and a preparation method thereof. The high load buffer material is prepared from thefollowing raw materials in percent by mass based on total weight of the raw materials: 10-95% of foamed particles and 5-90% of a castable polyurethane elastomer. The high load buffer material has a light weight, excellent mechanical properties and wear resistance as well as high compressive strength and relatively low compressive deformation and is simple in preparation method simultaneously.

Owner:MIRACLL CHEM

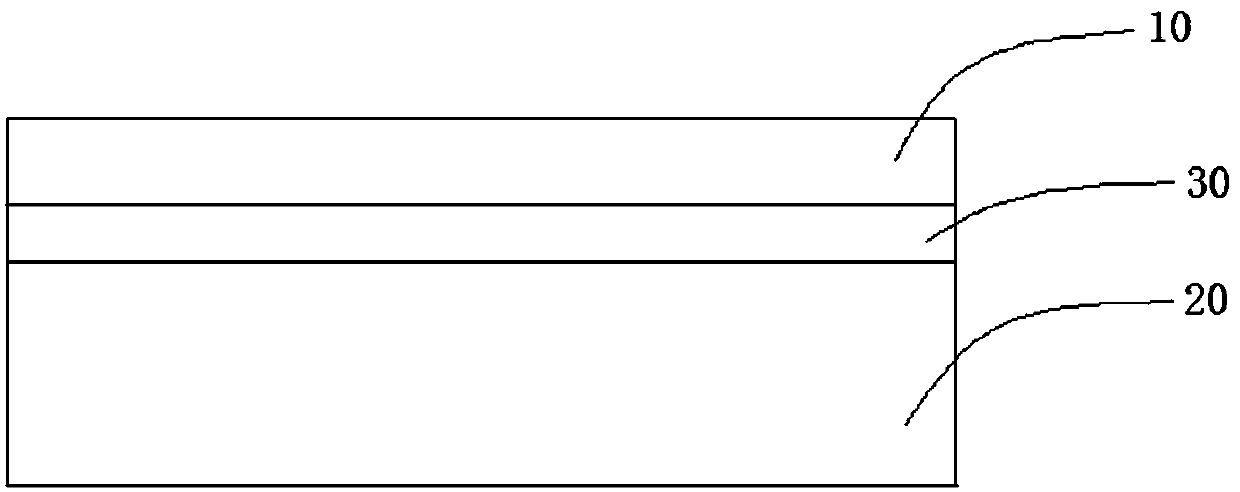

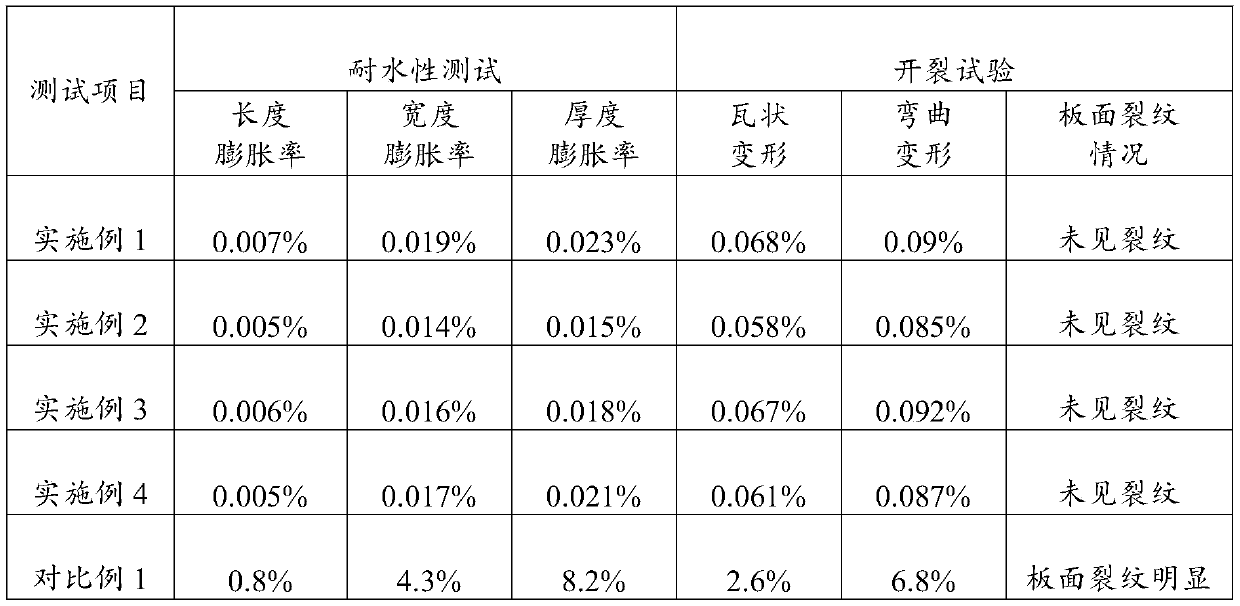

Modified wood veneer, modification method of wood veneer, wood veneer/stone plastic composite plate and preparation method of wood veneer/stone plastic composite plate

InactiveCN109648657AGood water resistance and plasticitySmall deformabilitySynthetic resin layered productsWood veneer joiningMaterials scienceWood veneer

The invention provides a modified wood veneer, a modification method of the wood veneer, a wood veneer / stone plastic composite plate and a preparation method of the wood veneer / stone plastic compositeplate, and relates to the technical field of plates. The modified wood veneer comprises a wood veneer base material and polymethyl methacrylate which coats the surface of the wood veneer base material and / or permeates into the wood veneer base material. By utilizing the modified wood veneer, the technical problem that a wood veneer in the prior art is prone to moisture absorption and deformationcan be relieved, and the technical effect of improving the stability of the wood veneer can be achieved.

Owner:ZHEJIANG DADONGWU GREENHOME WOOD CO LTD

Ceramic slurry reverse-pouring grouting molding method

Provide is a ceramic slurry reverse-pouring grouting molding method. The method comprises the following steps that a grouting head of a slurry conveying pipe is arranged vertically and upwards, a grouting hole in the bottom of a plaster mold is in butt joint with a vertically upward grouting head in a sealed mode, a grouting fluid is made to be injected into a mold cavity of the plaster mold from bottom to top, a small air hole is formed in the top of the plaster mold, and an iron nail is inserted into the small air hole, wherein the iron nail enables ceramic slurry to be prevented from overflowing and can achieve air releasing; the ceramic slurry can be injected into the plaster mold through a high pressure grouting machine with pressure, before half of the mold cavity is filled with the slurry, the grouting pressure is controlled to range from 1 kg to 1.5 kg, and after half of the mold cavity is filled with the slurry, the pressure is weakened slowly till the mold cavity is filled up; the pressure is kept till a green body of the inner wall of the mold cavity reaches the needed thickness, the pressure is relieved, the iron nail on the top of the plaster mold is pulled out, the ceramic slurry flows out completely and freely, after the green body in the mold cavity of the mold is dried and shrinks, demolding is conducted finally, and when demolding is conducted, the small air hole left by the iron nail is filled with same dry ceramic.

Owner:宜兴爱宜艺术陶瓷有限公司

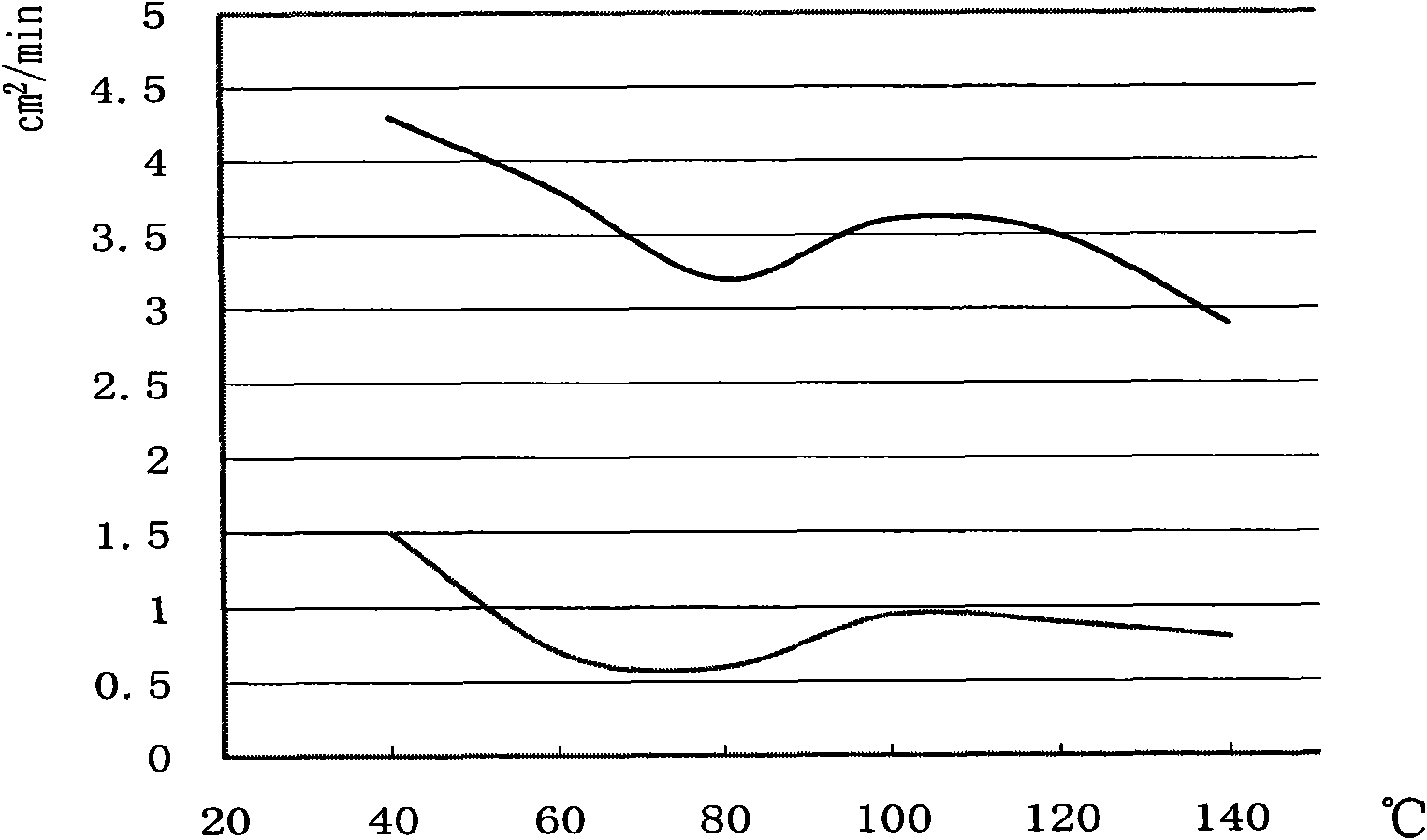

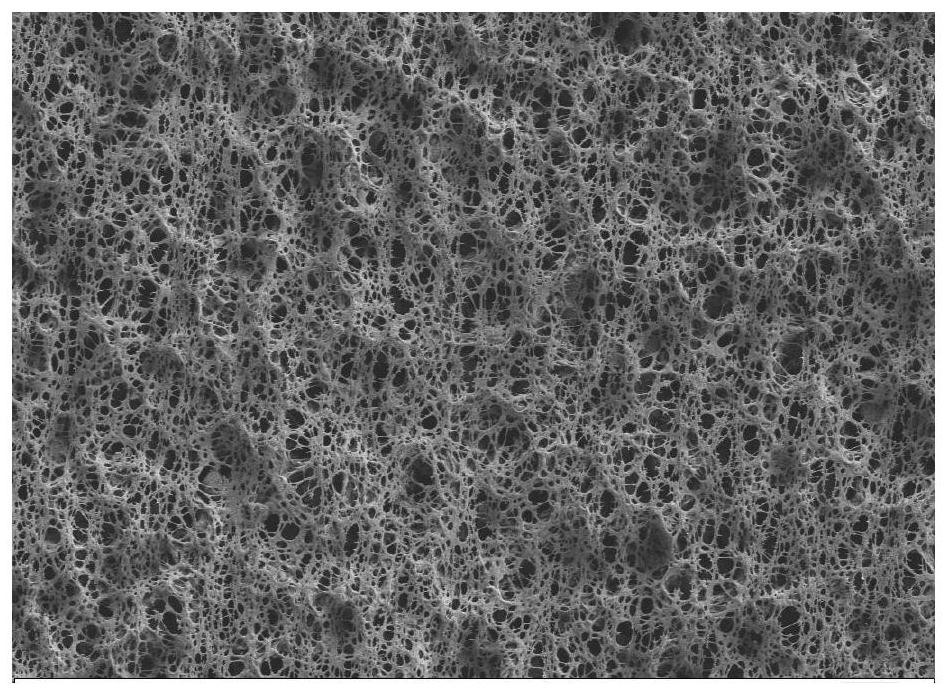

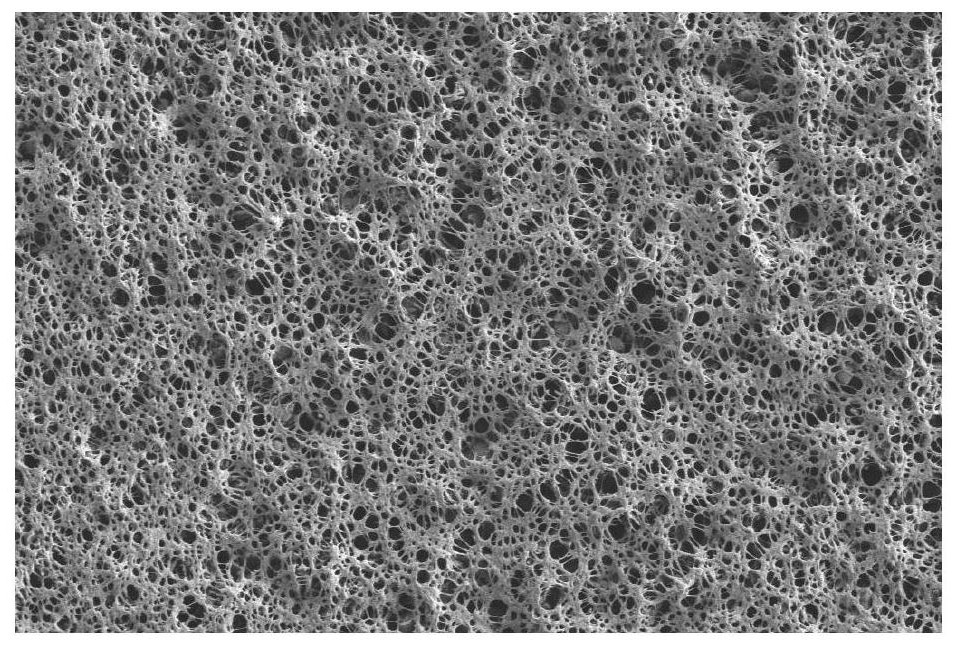

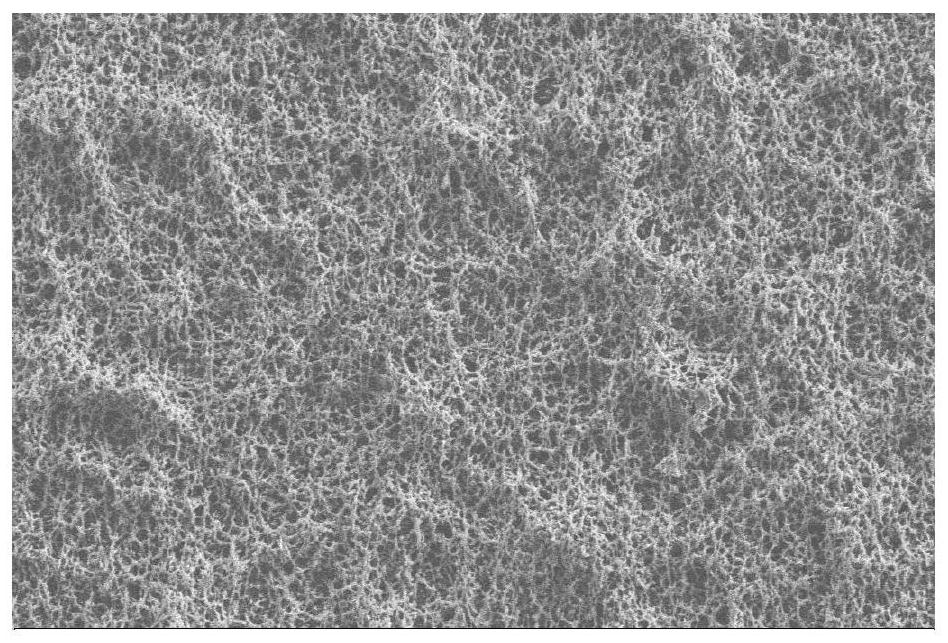

Coating method of lithium battery diaphragm, lithium battery diaphragm and lithium battery

InactiveCN111864158AReduce concentrationUniform pore size distributionCell component detailsSecondary cells servicing/maintenancePhysical chemistryLithium battery

The invention discloses a coating method of a lithium battery diaphragm, the lithium battery diaphragm and a lithium battery. The coating method comprises the steps of 1, preparing coating slurry; 2,uniformly coating the coating slurry on the surface of one side of a base membrane to obtain a coated diaphragm; 3, at the normal temperature of 25-30 DEG C, enabling the coated diaphragm to be subjected to 6-8 times of extraction and then subjected to 3-5 times of water washing, wherein the extract liquor is mixed liquor of water and NMP (N-methyl pyrrolidone), and in every two adjacent times ofextraction, the concentration of NMP in the extract liquor used in later extraction is 2-22 wt% less than that of NMP in extract liquor used in previous extraction; and 4, drying the coated diaphragmat the temperature of 30-65 DEG C after the extraction is finished. The lithium battery diaphragm obtained by the method is good in thermal stability.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

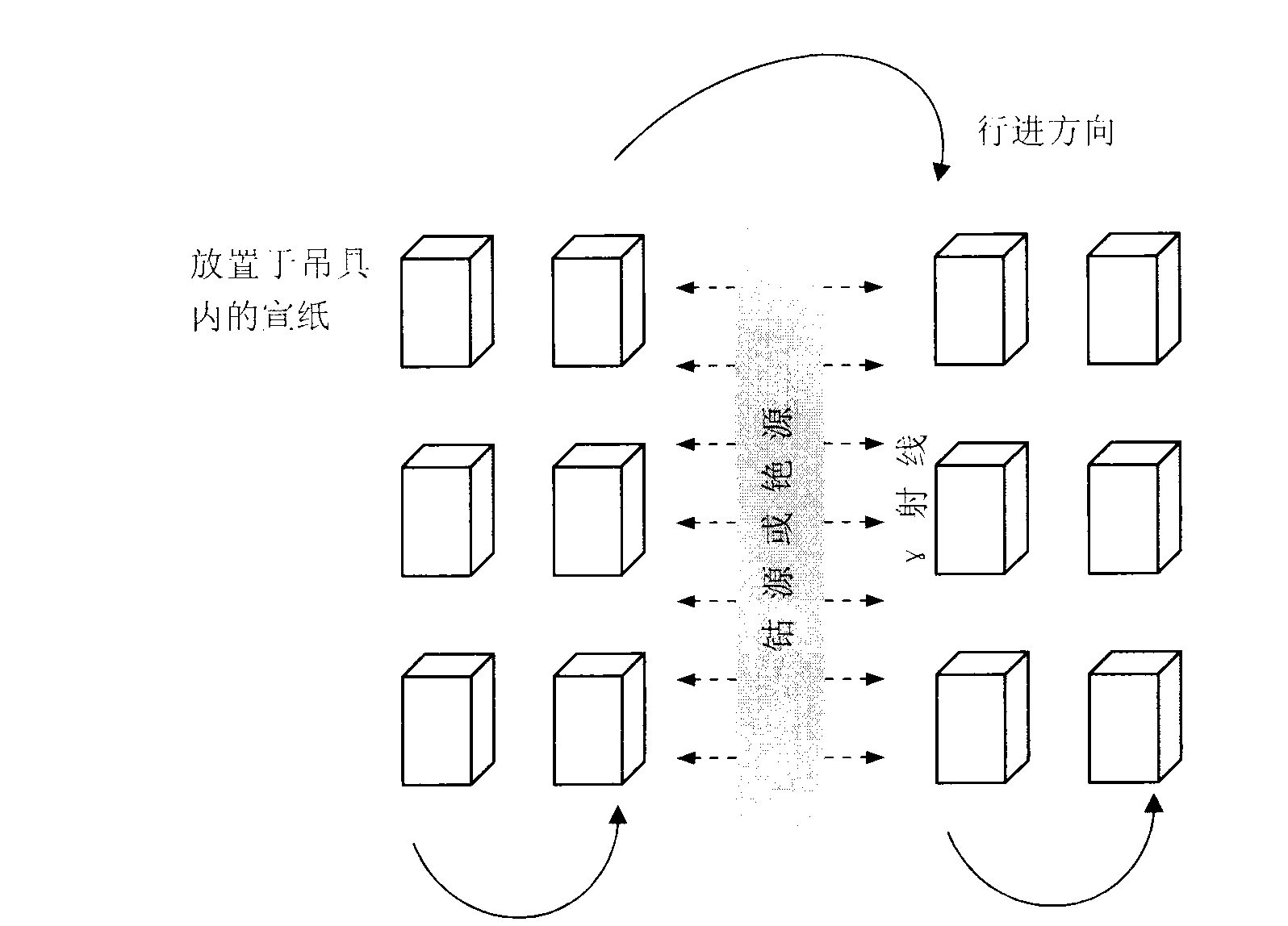

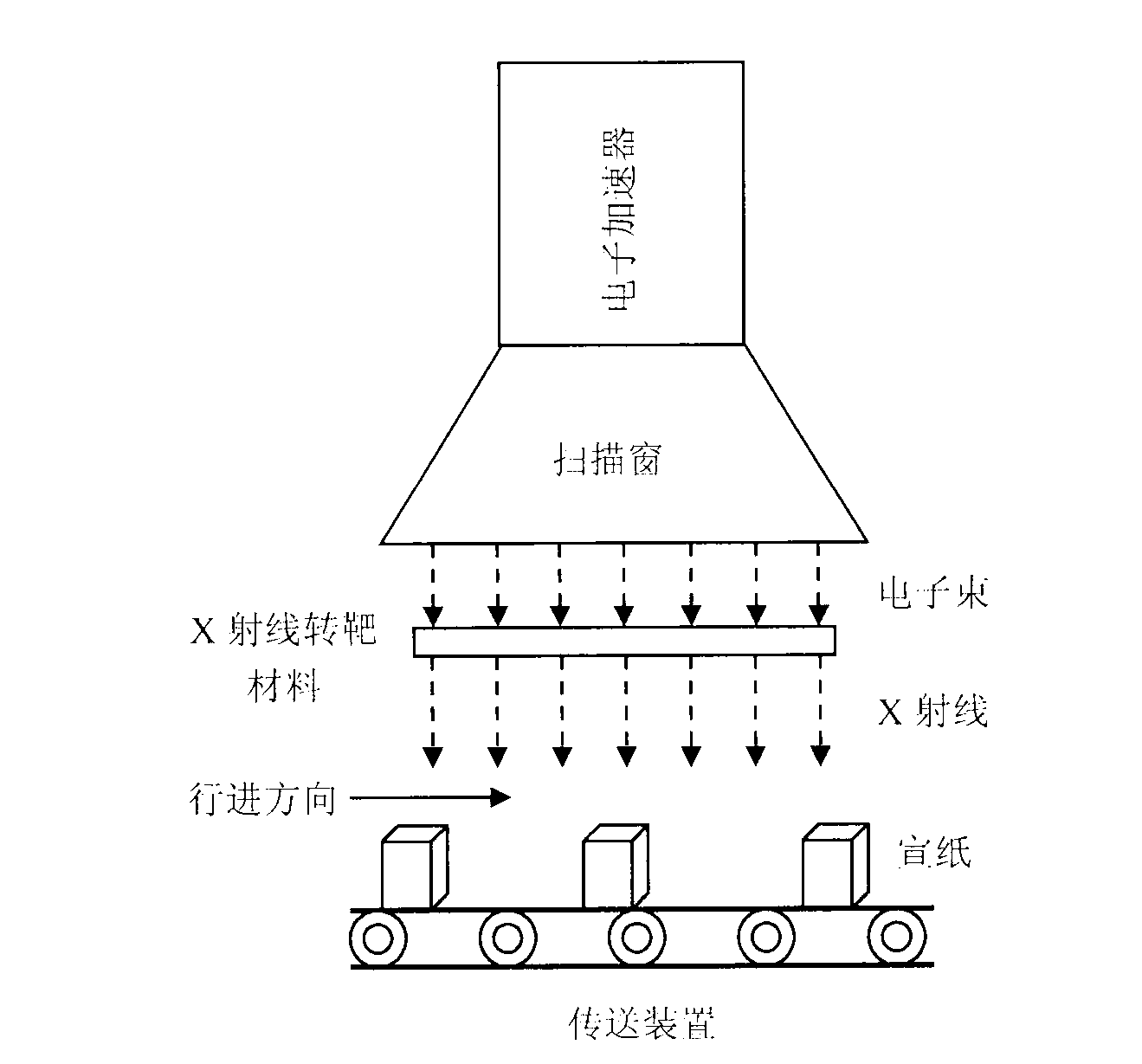

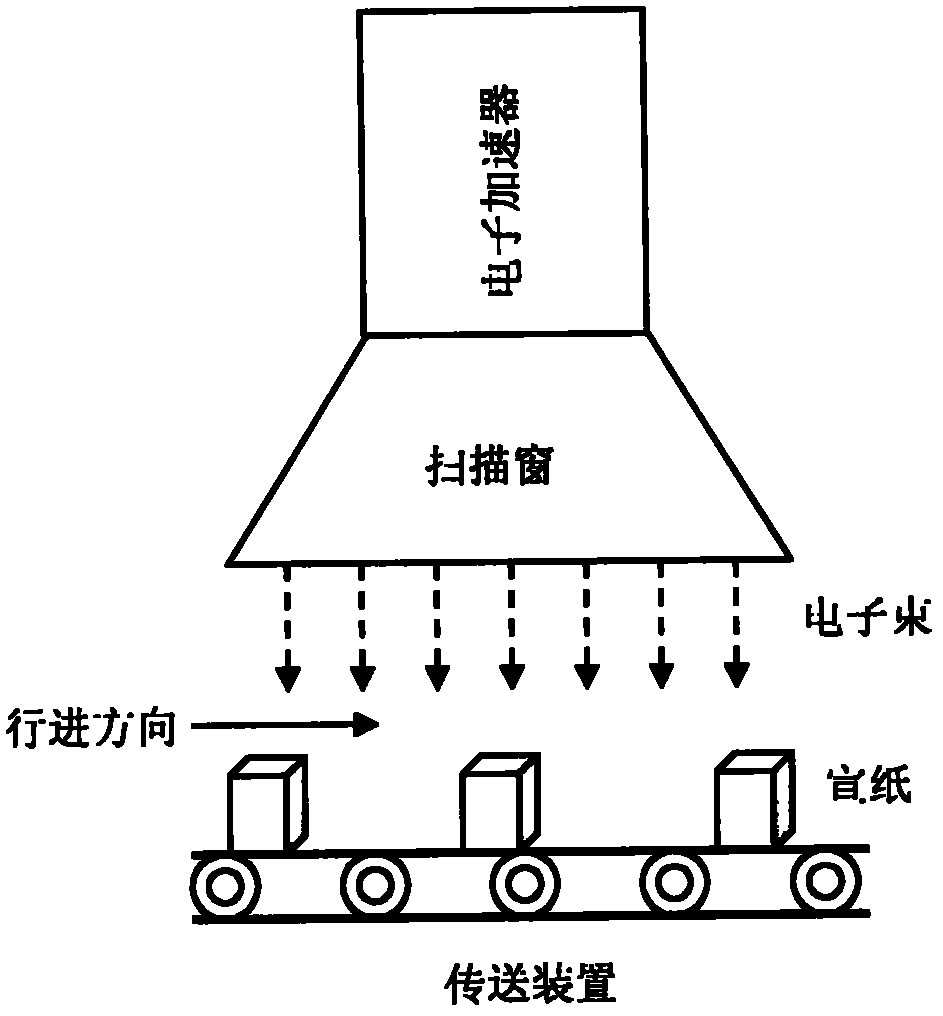

Method of using irradiation technology to improve performance of rice paper

InactiveCN103132390AFast penetrationUniform penetrationPhysical paper treatmentEngineeringIrradiation

The invention relates to a method of using irradiation technology to improve performance of rice paper. The method comprises the following steps: the rice paper is conducted with uniform irradiation by using irradiation radial. Irradiation dose is 0.1-100KGy. The method has the advantages of being quick in dealing speed and low in energy consumption. Ink embellishing of the rice paper can be improved quickly in a short time, deformation of the rice paper can be reduced and quality of the rice paper can be improved comprehensively.

Owner:天津市技术物理研究所有限公司

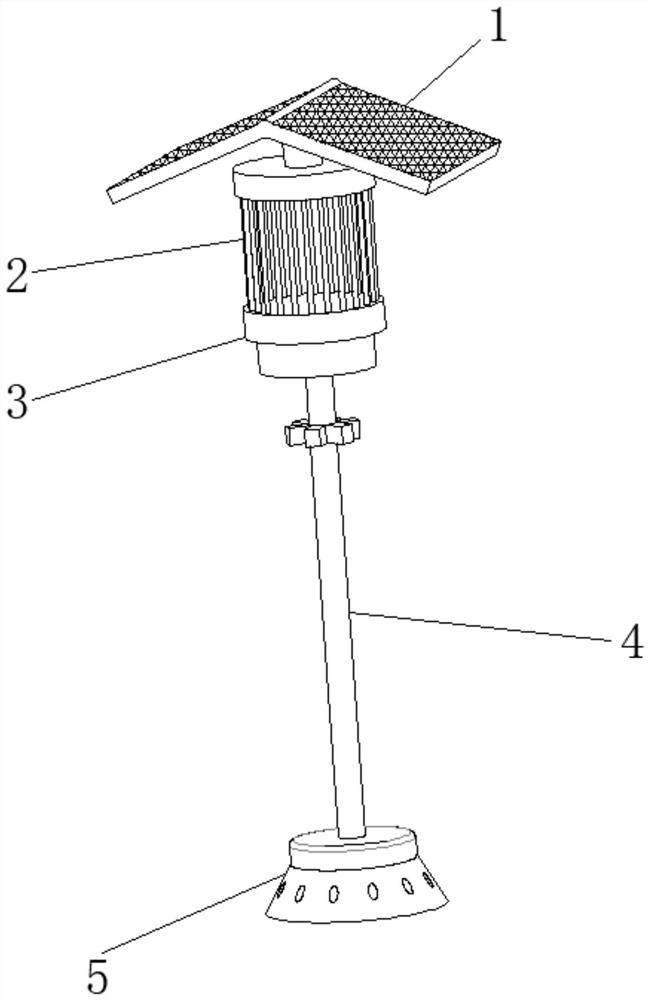

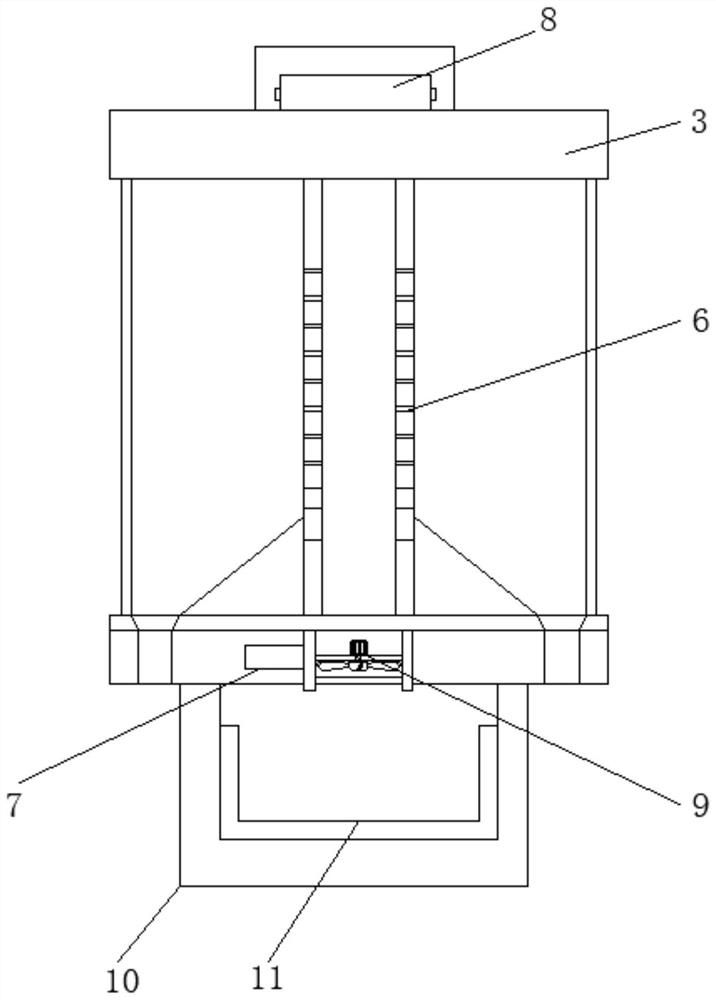

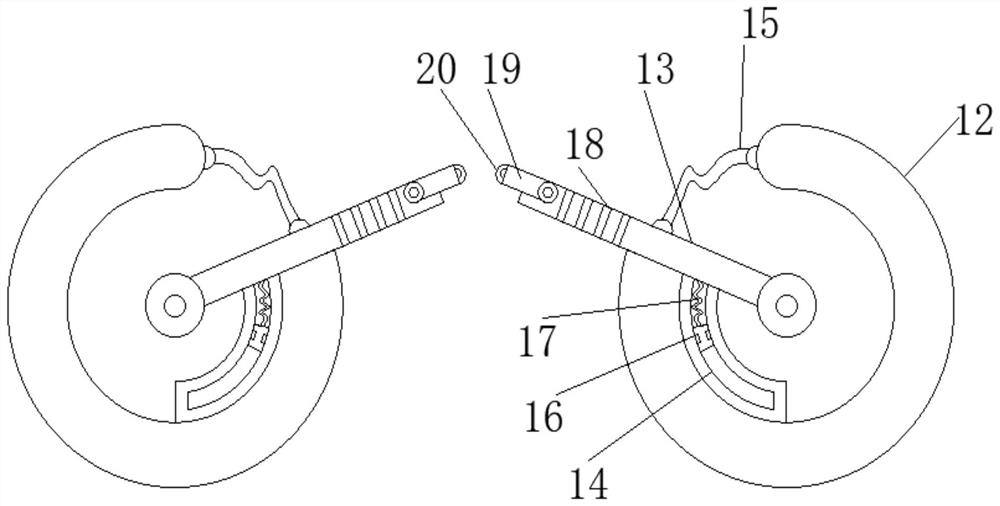

Trapping device

InactiveCN112825828APrevent escapeEasy to moveInsect catchers and killersTrappingStructural engineering

The invention provides a trapping device, and relates to the field of agricultural pest control. The trapping device comprises a solar panel, limiting rods, mounting plates, a supporting rod and a base, the solar panel is arranged above the mounting plates, the solar panel is fan-shaped, the limiting rods are arranged between the mounting plates, the limiting rods are annularly and uniformly distributed, the supporting rod is connected to the outer walls of the bottom ends of the mounting plates in a clamped mode, the bottom of the supporting rod is fixedly connected with the base, deinsectization mechanisms are arranged between the mounting plates, a cleaning mechanism is arranged at the bottom of each mounting plate, a guide plate is arranged on the inner wall of the bottom of each mounting plate, and a controller is arranged in each mounting plate. According to the trapping device, insects are prevented from escaping, the collecting effect is improved, meanwhile, the influence of the external environment can be reduced, the precision of the controllers is improved, the service life of the controllers is prolonged, volatilization of pheromones can be accelerated when a fan and an electric heating wire work, and therefore the trapping effect is further improved, and loss of electric energy is reduced.

Owner:苏州慧泽农业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com