Microfoam acid liquid and preparation method thereof

A technology of foam acid liquid and foam acid, which is applied in the field of foam acid, can solve the problems of low compressive plugging strength, high cost of construction equipment, and failure of plugging and turning, so as to simplify construction equipment and procedures, reduce formation damage, and achieve high The effect of stress resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

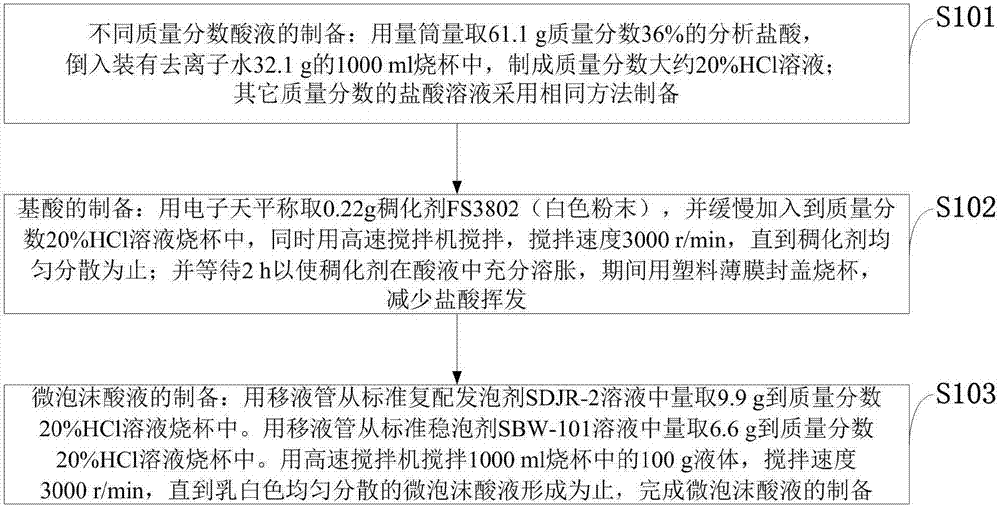

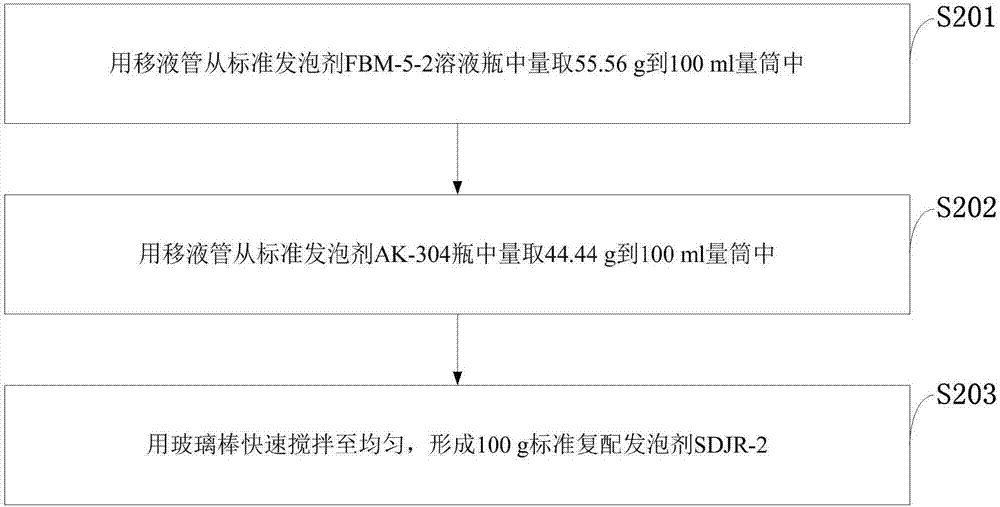

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0043] On the basis of fully researching and comparing the properties of foam acid and other acid liquids, and the understanding of the mechanism causing these differences, the present invention begins to think about which method to take to form a new acid liquid, which has some excellent characteristics of foam, such as It has important characteristics such as high viscosity, high energy, low gravity, and slow acid rock reaction, and at the same time has most of the characteristics of conventional acid liquids, such as water solubility, acid reaction, and compatibility with acidifying additives. Through the analysis of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com