Patents

Literature

84results about How to "Formation damage is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Temperature-resistant and salt-tolerant foaming agent system for thermal recovery of heavy oil reservoir and preparation method

InactiveCN106753307AImprove solubilityImprove performanceDrilling compositionInorganic saltsSolubility

The invention relates to the technical field of heavy oil recovery, in particular to a foam agent system used for switching water drive into steam drive of a heavy oil reservoir or steam huff and puff to improve the oil recovery efficiency. According to the technical scheme, the temperature-resistant and salt-tolerant foaming agent system for thermal recovery of the heavy oil reservoir is characterized by comprising a foaming agent base, a foam stabilizer, a foam fixing agent, a foam promoter, an alkali substance, inorganic salt and a solvent. The foaming agent system can resist the temperature of 350 DEG C and has good thermal stability and better foamability; the foaming agent base in the system is lower than the critical micelle concentration and can produce more foam, the apparent viscosity is substantially increased, and the cost is saved; the foaming agent system has better solubility, causes little damage to formation and is environment-friendly.

Owner:NORTHEAST GASOLINEEUM UNIV

Reusable slippery water fracturing fluid for shale oil and gas reservoir

ActiveCN103275691ALow viscosityRapid Dispersion DissolutionDrilling compositionUniform systemWater quality

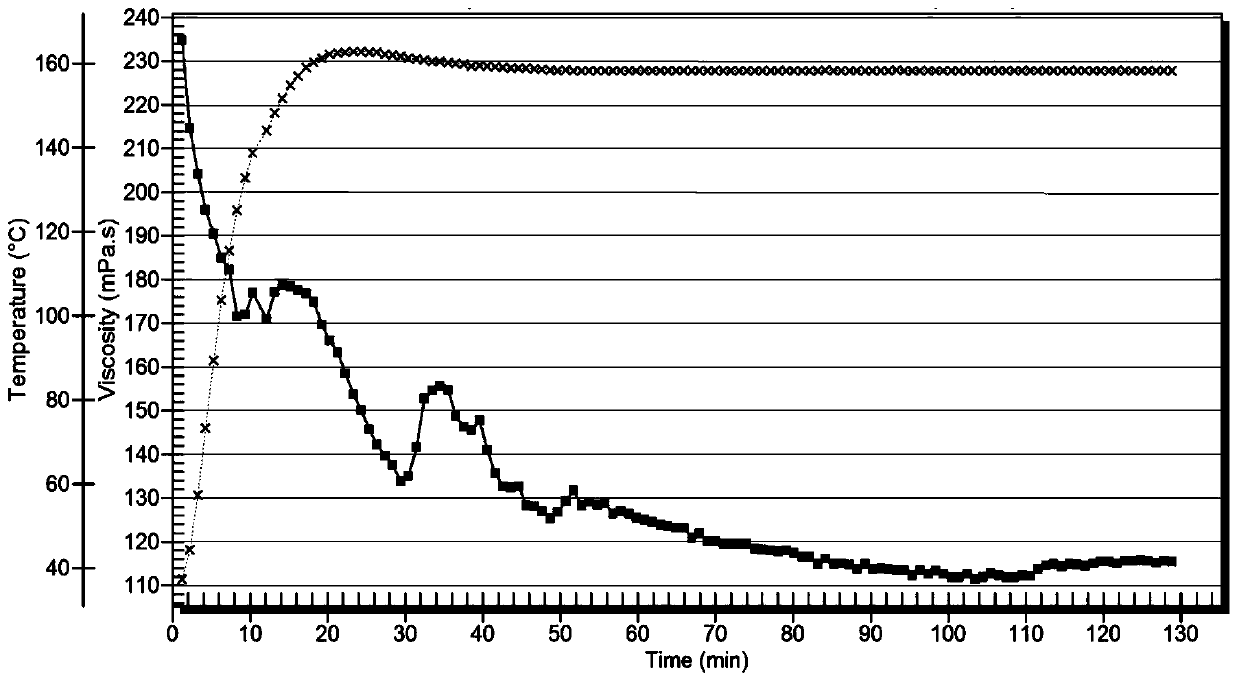

The invention discloses reusable slippery water fracturing fluid for a shale oil and gas reservoir. The reusable slippery water fracturing fluid for the shale oil and gas reservoir comprises the following components in percentage by weight: 0.02 to 0.08 percent of a resistance reducing agent, 0.7 to 1.5 percent of a discharge aid, 8 to 12 percent of an auxiliary discharge aid, 5 to 10 percent of an interfacial tension-reducing synergist, 0.05 to 0.1 percent of a clay stabilizer, 0.007 to 0.01 percent of a sterilizing agent, 0.04 to 0.06 percent of a scale inhibitor and the balance of water. The reusable slippery water fracturing fluid for the shale oil and gas reservoir has the beneficial effects that (1) the resistance reducing agent can be dispersed and dissolved quickly to form a uniform system, so the problem of difficulty in large-scale intermediate liquid preparation in a shale fracturing process is solved; (2) the slippery water fracturing fluid can be reused, so the treatment cost of return liquid is reduced; (3) the resistance reducing ratio of the slippery water is more than 75 percent, so large-displacement construction is realized, the requirement on pump injecting equipment is reduced, and the frictional resistance of the slippery water in a pipeline in a large-displacement fracturing construction process can be effectively reduced; and (4) the slippery water fracturing fluid has a wide application range, strong temperature adaptability and temperature adaptability, and low requirement on water quality.

Owner:PETRO KING OILFIELD TECH

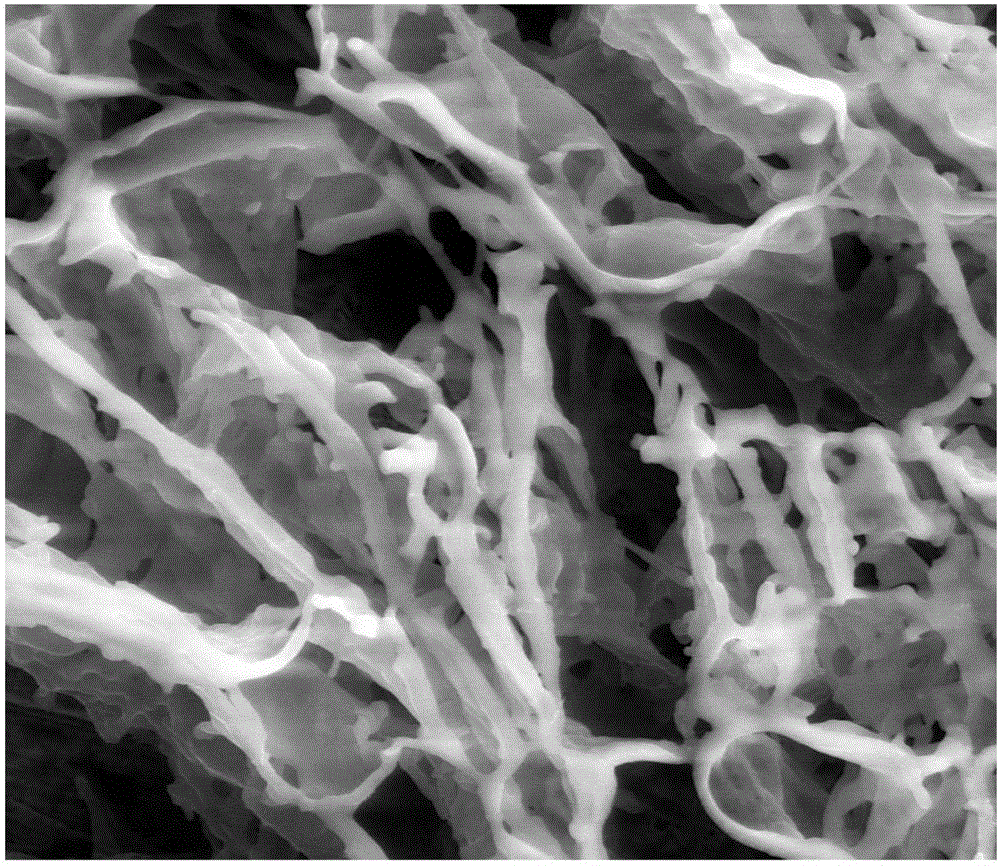

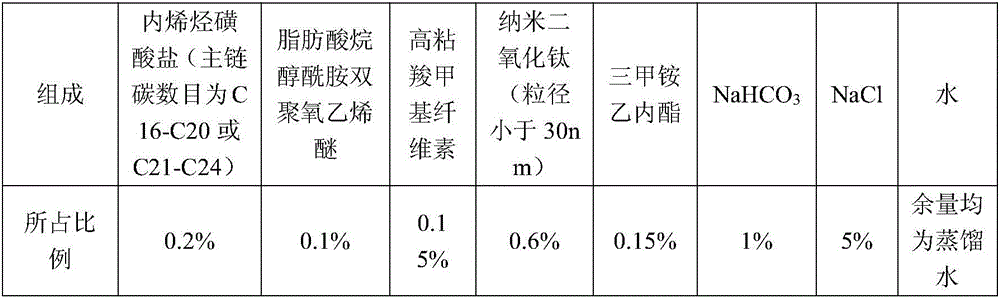

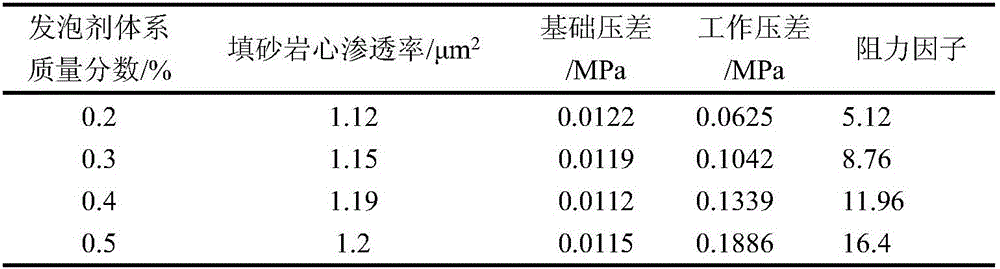

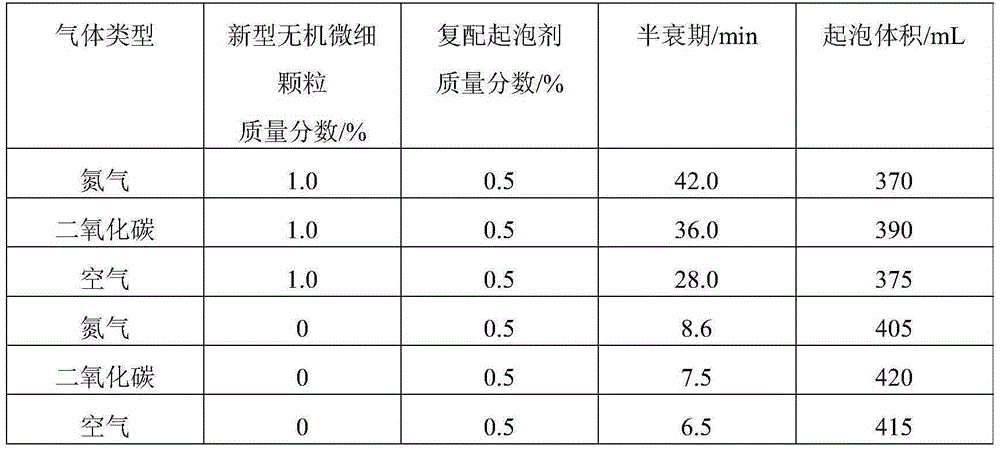

Novel inorganic fine particle enhanced foam system for oil and gas fields, and preparation method thereof

ActiveCN105238380AFormation damage is smallImprove performanceDrilling compositionFoaming agentGas phase

The invention relates to a novel inorganic fine particle enhanced foam system for oil and gas fields, and a preparation method thereof. The enhanced foam system comprises a gas phase and a liquid phase; the gas phase is nitrogen, carbon dioxide or air; the liquid phase comprises 0.2-0.8wt% of a foaming agent, 0.5-2.0wt% of novel inorganic fine particles, and the balance of water; and the novel inorganic fine particles are fine particles with the particle size being not greater than 2.5[mu]m, trapped and screened from air. The invention also provides the preparation method of the foam system. The enhanced foam system can be used to benefit efficient exploitation of oil and gas resources, can change the novel inorganic fine particles into valuables, reduces pollution of the novel inorganic fine particles to air environment, and has the advantages of low cost of the raw materials, simple preparation process, low operation cost, good oil and gas yield increasing effect, and high economic benefit.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

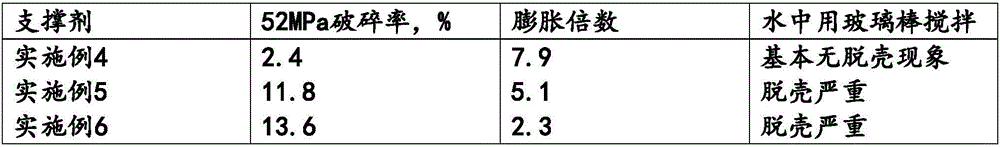

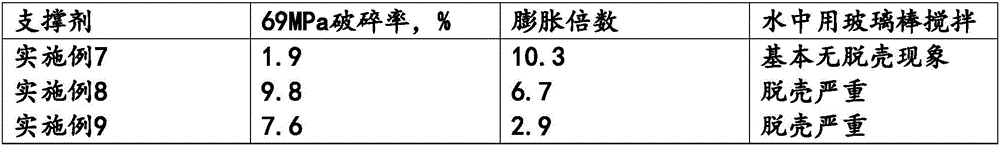

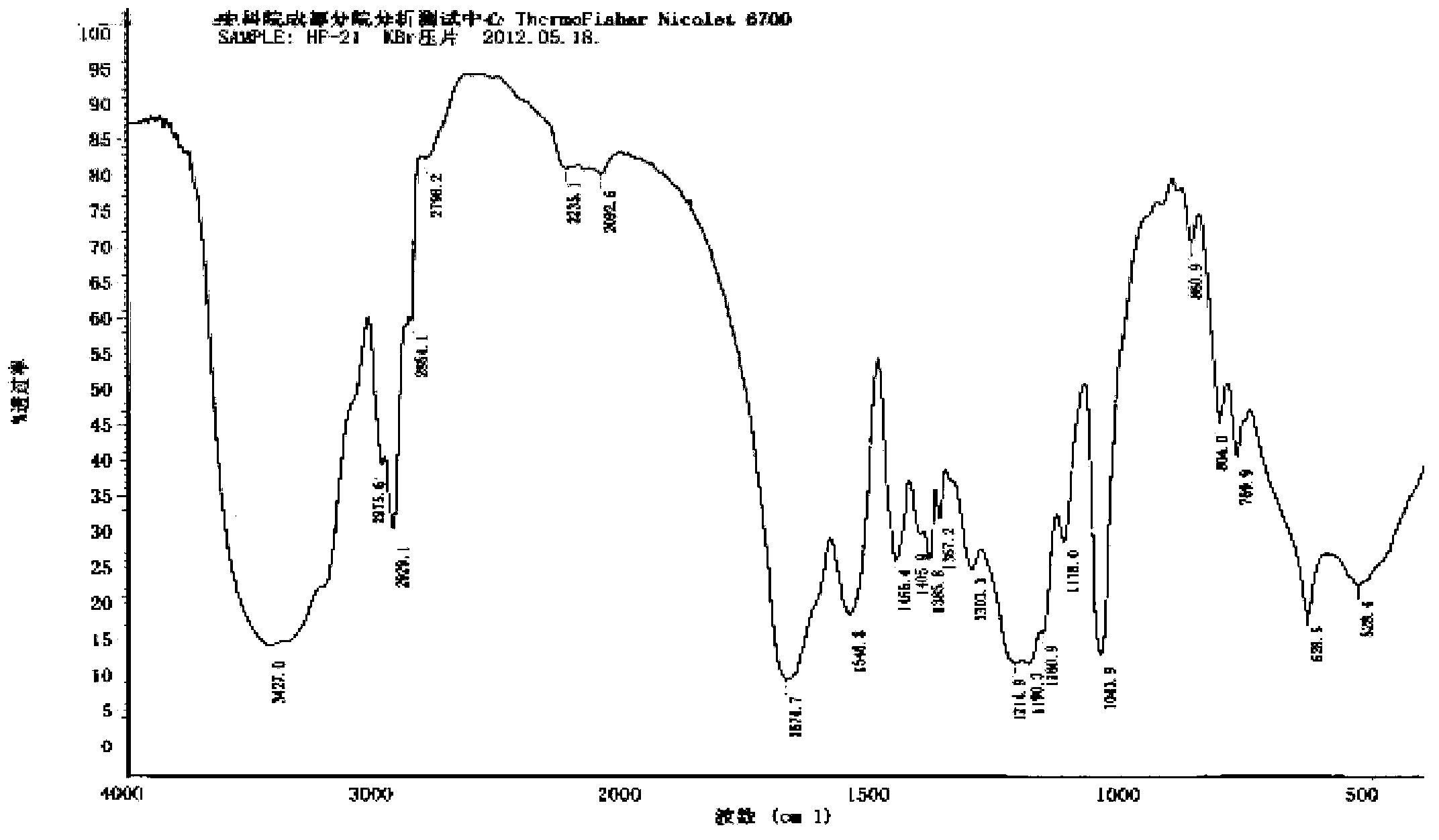

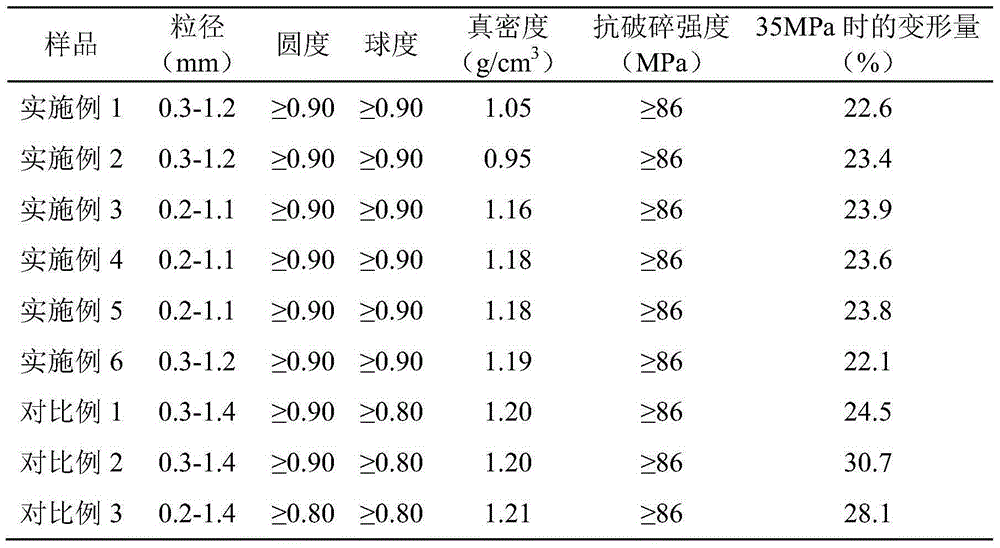

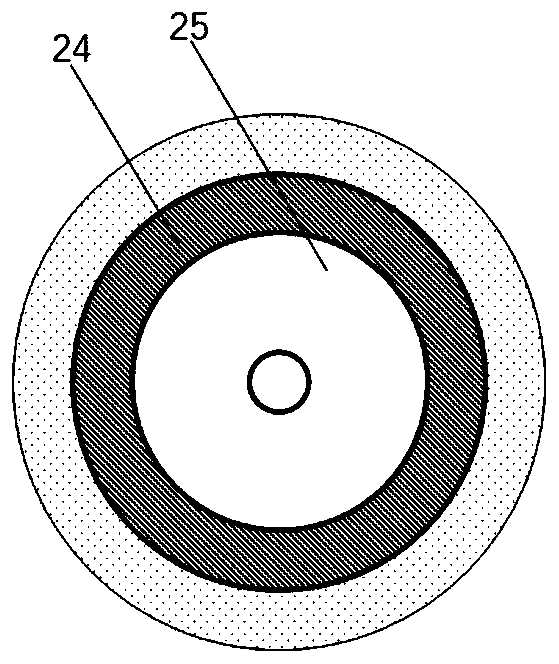

Water suspensible propping agent for oil and gas well fracturing and preparation method thereof

ActiveCN106675549AIncrease in sizeFormation damage is smallFluid removalDrilling compositionChemistryConstruction aggregate

The invention relates to a water suspensible propping agent for oil and gas well fracturing and a preparation method thereof. The water suspensible propping agent of the invention comprises a propping agent aggregate, an expansion layer and an interfacial transition layer arranged between the aggregate and the expansion layer, wherein the expansion layer comprises hydrogel dry powder and a binder for bonding the hydrogel dry powder and is swollen in water; and the interfacial transition layer comprises epoxy resin and / or thermoplastic phenolic resin as the interfacial transition layer resin.

Owner:PETROCHINA CO LTD +1

High temperature resistant cleansing emulsion or microemulsion fracturing fluid and preparation method thereof

ActiveCN102838980AIncrease contentReduce apparent viscosityProductsReagentsApparent viscosityPolymer science

The invention relates to a high temperature resistant cleansing emulsion or microemulsion fracturing fluid and a preparation method thereof. The emulsion fracturing fluid is composed of a continuous oil phase, a polymer (I)-containing dispersed water phase and an emulsifier. The preparation method of the emulsion fracturing fluid includes: preparing a mixed solution of the oil phase and the emulsifier, preparing a four-monomer containing water phase, conducting a polymerization reaction in the presence of an initiating agent, and other steps. The product provided in the invention has low apparent viscosity, and can dissolve rapidly. When the emulsion dissolves into gel, the emulsifier can have a synergistic effect with an association polymer, thus further improving and maintaining the viscosity, and helping to prevent leak-off and help flowback. An oxidation gel breaking way is employed for gel breaking, the gel can be completely broken, and the gel breaking solution has low viscosity and contains no residue. The emulsion fracturing fluid is easy to undergo flowback, and has low damage to the stratum.

Owner:CHINA PETROLEUM & CHEM CORP +1

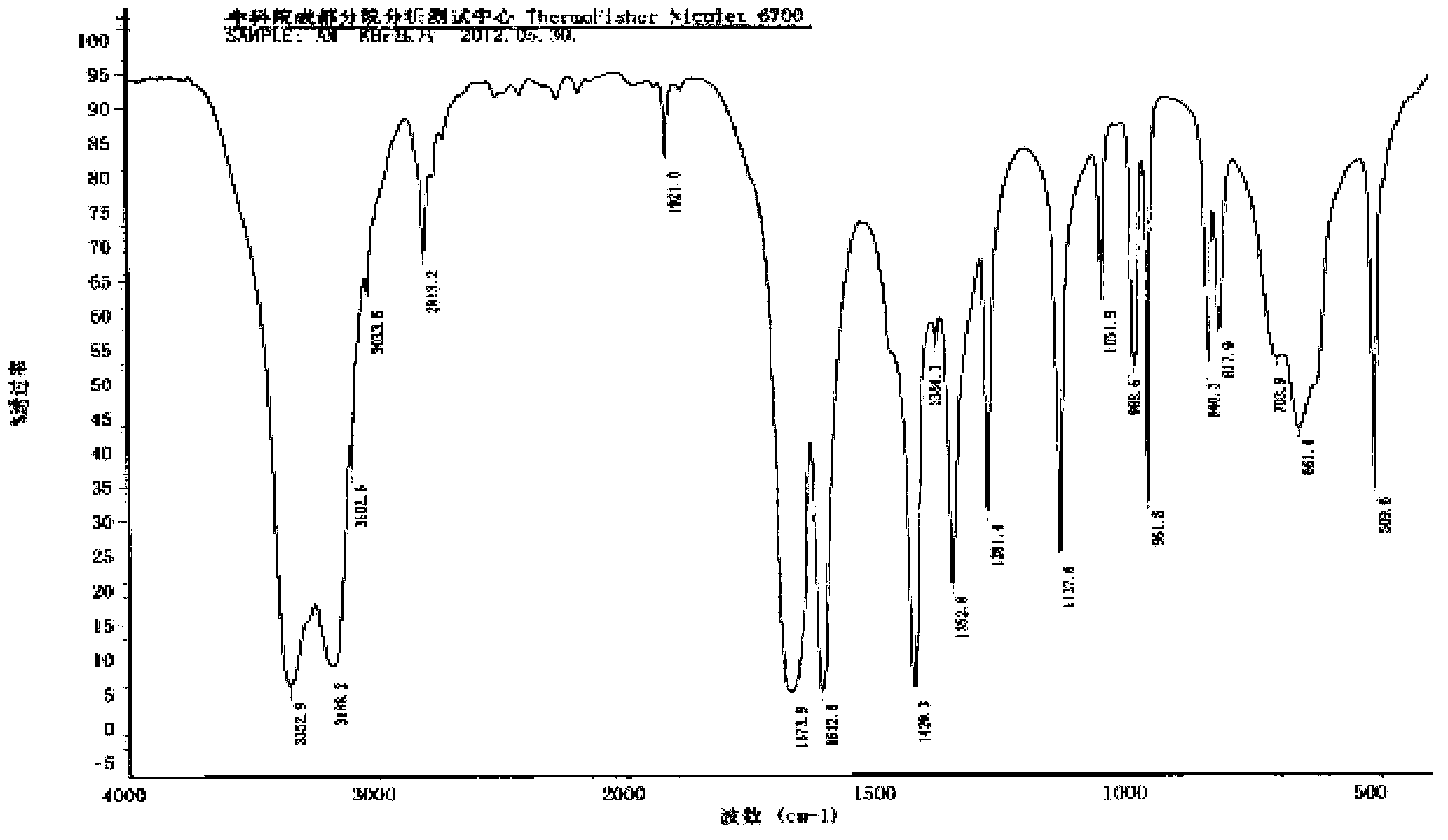

Thixotropic chemical sealing channeling agent

ActiveCN102181274AFormation damage is smallImprove construction safetyDrilling compositionSealing/packingChemistryCarbon black

The invention provides a thixotropic chemical sealing channeling agent. The sealing channeling agent comprises the following raw materials: 40 to 55 weight parts of iron rich low-carbon sulfur aluminate, 0.2 to 5.0 weight parts of sodium-based bentonite, 0.5 to 2.0 weight parts of fluid loss agent, 0.2 to 5.0 weight parts of white carbon black, 0.5 to 4.0 weight parts of cyclodextrin and / or starch and 30 to 50 weight parts of water. The chemical sealing channeling agent has the characteristics of strong adhesion and thermal stability, good durability, prominent cracking resistance and the like; the linear expansion rate reaches over 0.2 percent, the compressive strength reaches over 30MPa, and the shearing strength reaches over 10MPa; and by adding dispersant, fluid loss agent and thixotropic regulator, the sealing channeling agent has high thixotropic property and loss resistance.

Owner:PETROCHINA CO LTD

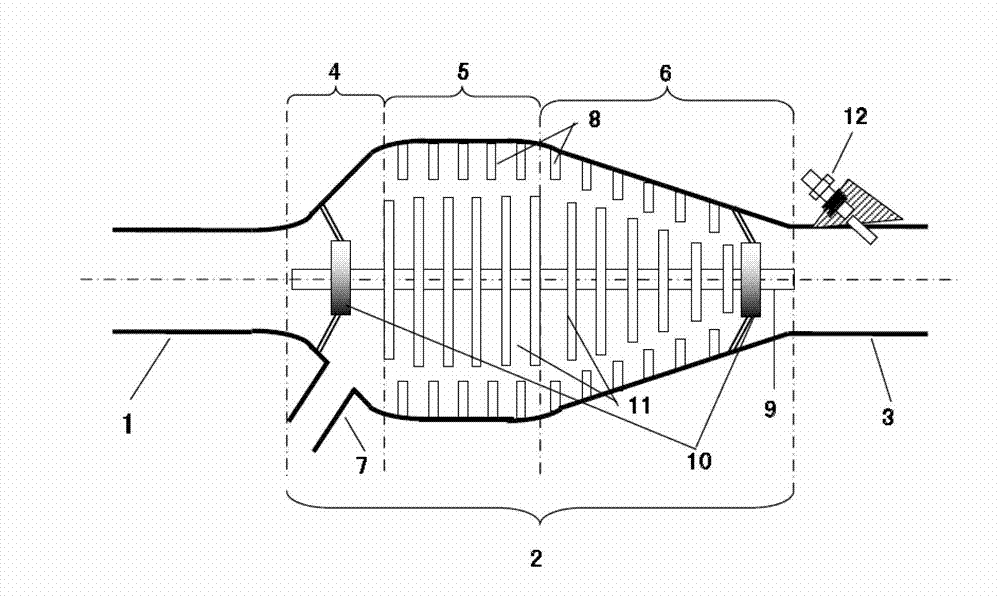

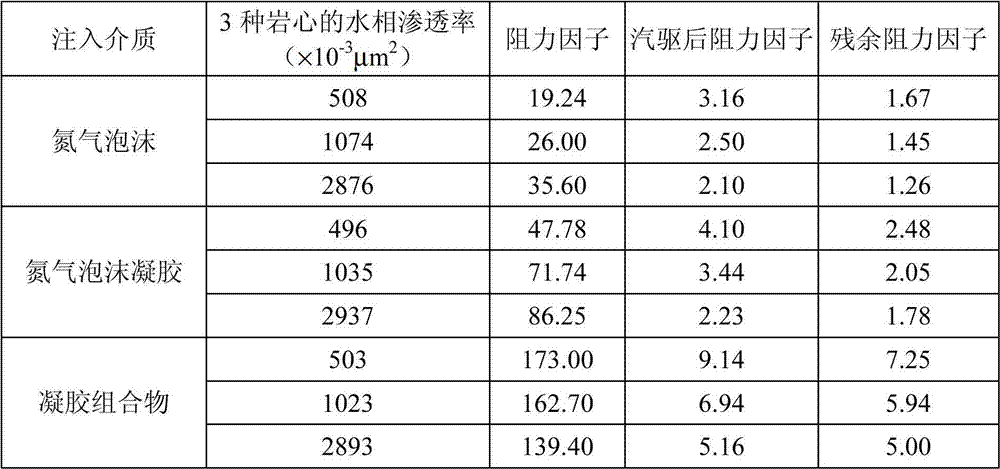

Gel composition and nitrogen-foamed gel composite temporary plugging agent containing same

ActiveCN103030916ASimple structureImprove stabilityFluid removalDrilling compositionFoaming agentChemical composition

The invention provides a gel composition and a nitrogen-foamed gel composite temporary plugging agent containing the same. The gel composition comprises the following components in percentage by mass: 1.0% of partially hydrolyzed polyacrylamide, 1.5% of formaldehyde, 0.5% of hydroquinone and the balance of water. The nitrogen-foamed gel composite temporary plugging agent comprises nitrogen and foamed gel, wherein the foamed gel is a mixture of the gel composition and a high-temperature-resistant foaming agent; and the volume ratio of the nitrogen to the foamed gel is (40-60):1. The invention also provides a coupled internal / external swirl foam generator which can be used as a facility for preparing the nitrogen-foamed gel composite temporary plugging agent. The invention also provides a method for inhibiting high-throughput-frequency well steam channeling interference of thick oil, which has the characteristics of small formation damage, strong selectivity for measures and the like and has the effect of gas energization.

Owner:PETROCHINA CO LTD

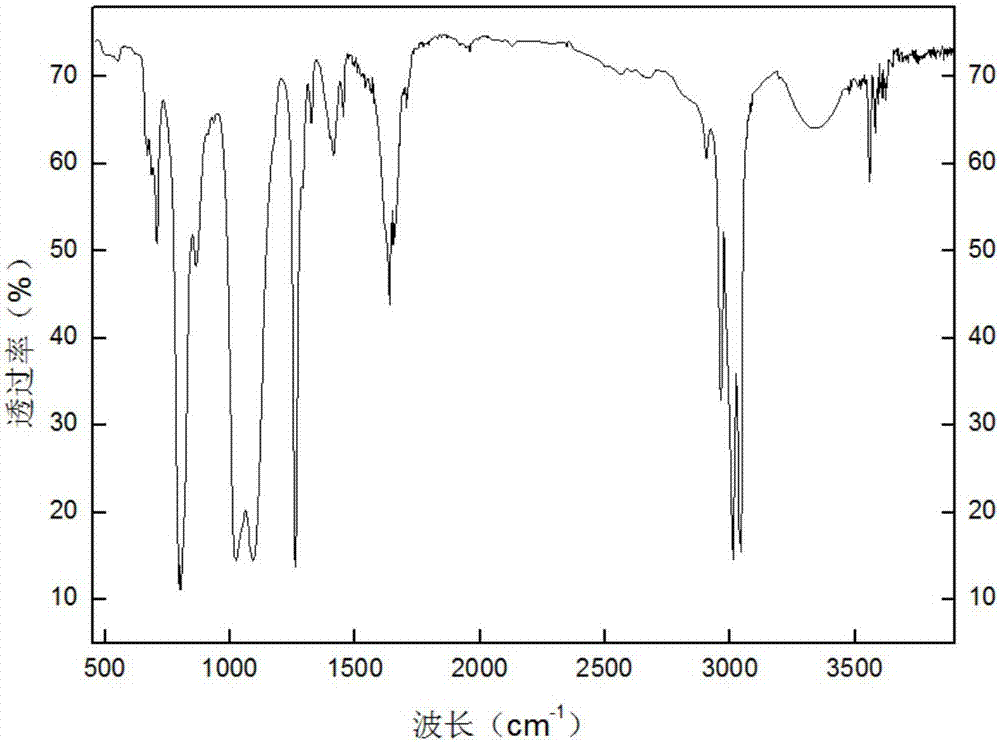

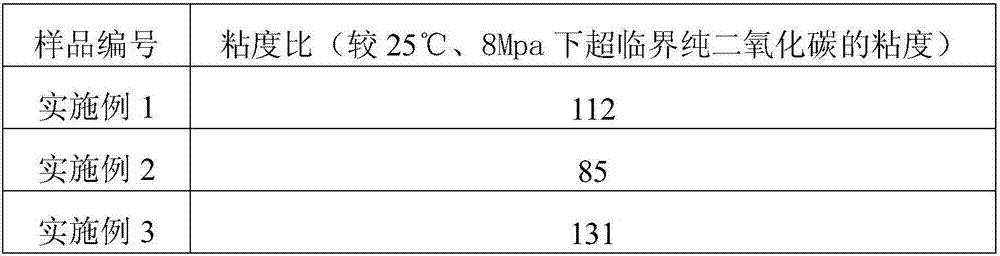

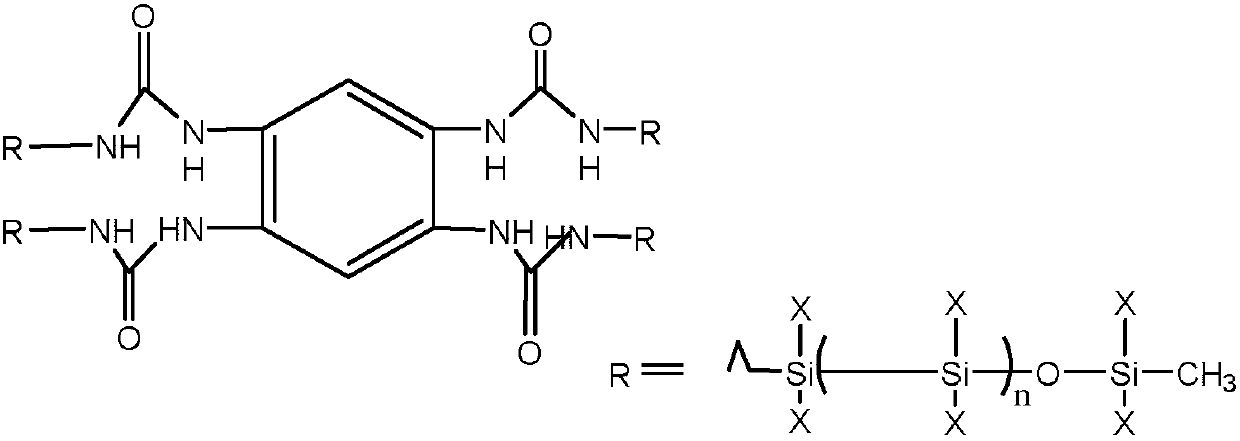

Preparation method of fracturing supercritical carbon dioxide thickener containing siloxane polymer

ActiveCN108003349AImprove fracturing effectImprove sand carrying capacityDrilling compositionBulk chemical productionSide chainSilanes

The invention relates to a preparation method of a fracturing supercritical carbon dioxide thickener containing a siloxane polymer. The method comprises the steps: carrying out a reflux reaction on anaminopropyl alkoxy silane hydrolysis product, tetravinyl tetramethylcyelo tetrasiloxane and other cyclosiloxane under the catalysis of an alkali to prepare aminopropyl-terminated vinyl side chain modified polydimethylsiloxane; then, carrying out an acylchloride reaction on the aminopropyl-terminated vinyl side chain modified polydimethylsiloxane and aroyl chloride to prepare an aroylamino-terminated side chain modified siloxane polymer; dropwise adding an organic solvent solution of chloroplatinic acid to make the aroylamino-terminated side chain modified siloxane polymer react with hydrosiloxane to obtain a product. The preparation method is high in monomer synthesis efficiency, the siloxane polymer serving as phenyl and acylamino in the fracturing supercritical carbon dioxide thickenerproduct is capable of improving the thickening effect, and when the dosage of the product is relatively low, the thickening performance is good, and the pollution to underground water and surface water of a stratum is reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Low-density composite proppant, preparation method and applications thereof

The present invention provides a low-density composite proppant, which is prepared by carrying out a polymerization reaction on an oil phase and an aqueous phase, wherein the oil phase comprises, by weight, 60-90 parts of a monomer, 5-25 parts of a cross-linking agent, 0.01-10 parts of a filler, 0.1-5 parts of an initiator and 0-2 parts of a filler dispersant, and the aqueous phase comprises, by weight, 90-100 parts of water, 0.1-5 parts of a dispersant and 0.1-5 parts of an inorganic salt. The present invention further provides a preparation method of the proppant, wherein the preparation method comprises: uniformly mixing the dispersant, the inorganic salt and the water to obtain the aqueous phase, uniformly mixing the monomer, the cross-linking agent, the initiator, the filler and the optional filler dispersant to obtain the oil phase, mixing the oil phase and the aqueous phase, carrying out a polymerization reaction at a certain temperature to obtain a polymerization product system, and post-treating the obtained polymerization product system. The present invention further discloses applications of the proppant or the proppant prepared according to the method in reservoir fracturing reforming.

Owner:CHINA PETROLEUM & CHEM CORP +1

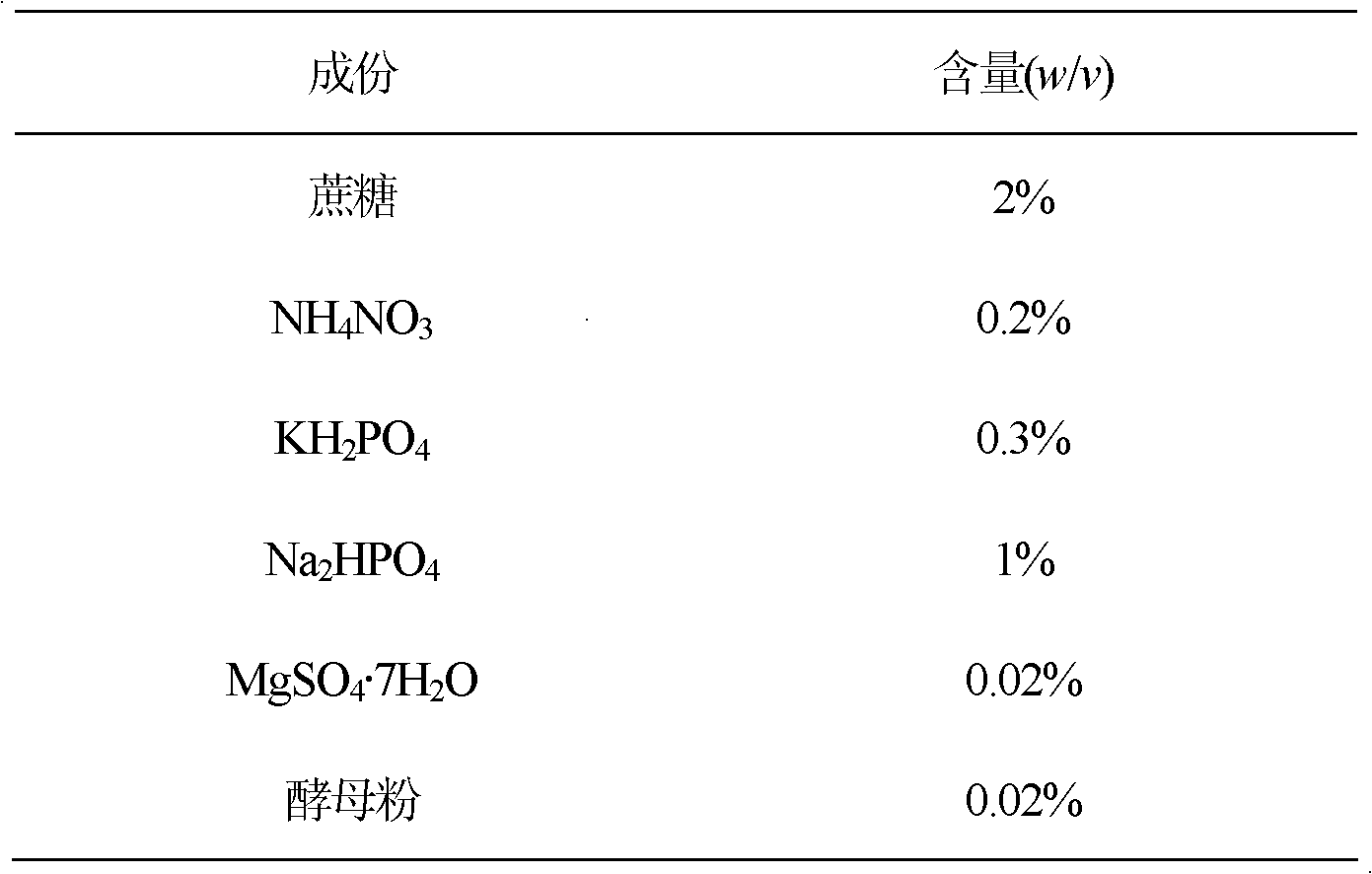

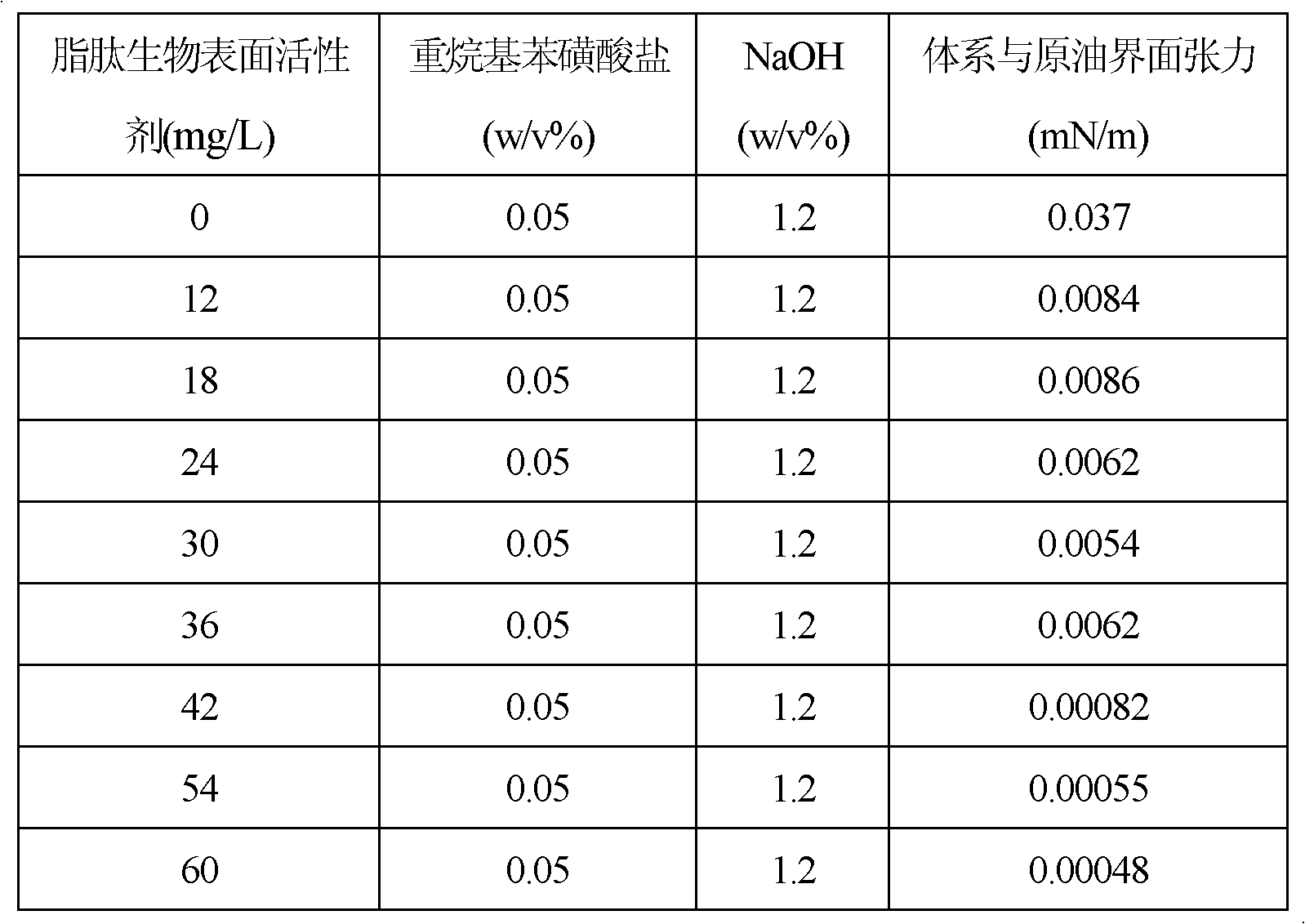

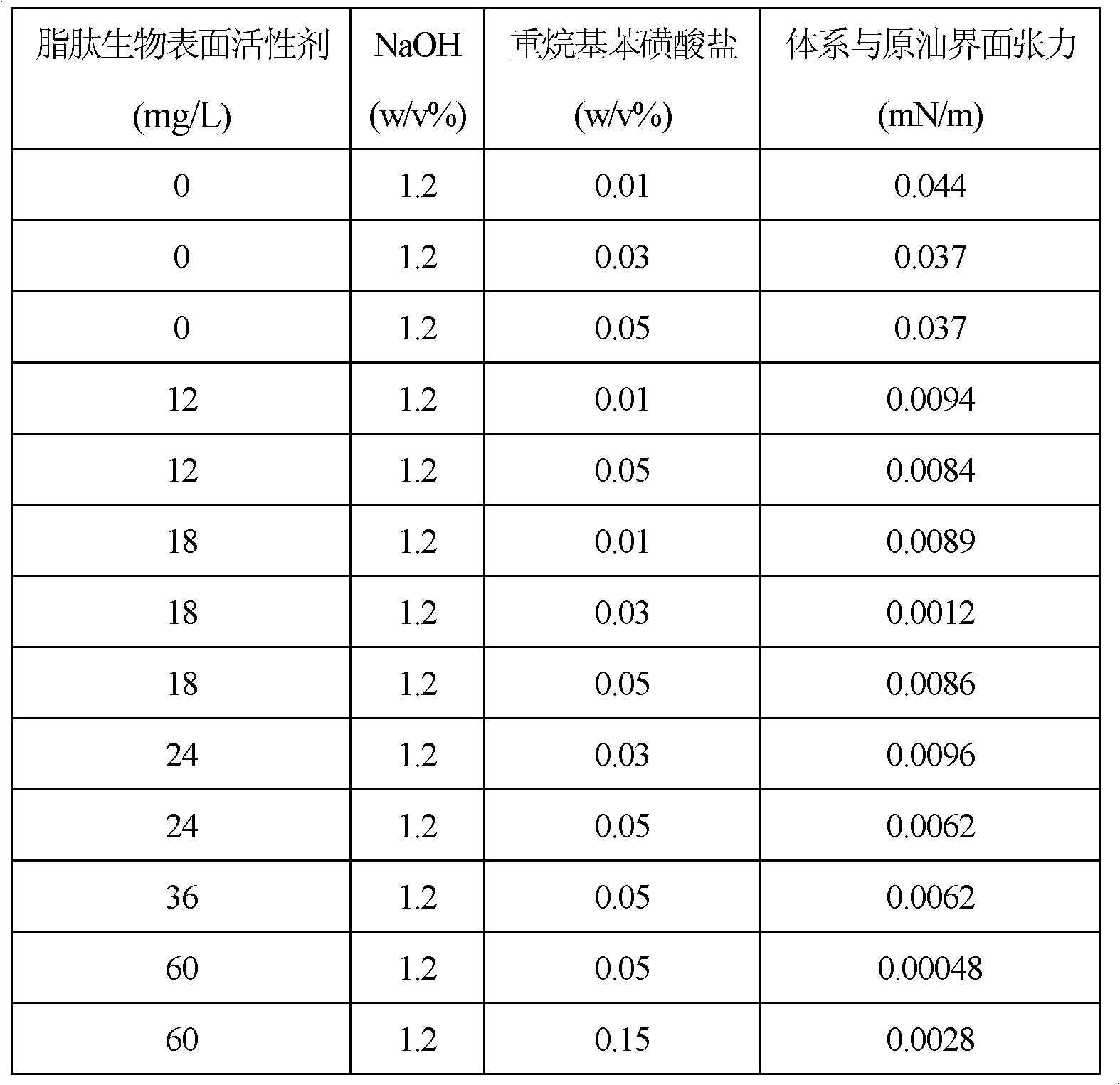

Composite flooding system containing lipopeptide biological surfactant and application thereof

InactiveCN102153998AReduce dosageHigh interface activityFluid removalDrilling compositionSulfonateSURFACTANT BLEND

The invention provides a composite flooding system containing a lipopeptide biological surfactant. The composite flooding system comprises the following components: 6 to 120 mg / L of lipopeptide biological surfactant, 0.01 to 0.30 w / v percent of heavy alkylbenzene sulfonate, and 0.5 to 5 w / v percent of alkali. The lipopeptide biological surfactant is introduced into the conventional composite system, so that the consumption of the alkali and the heavy alkylbenzene sulfonate is obviously reduced, the interfacial activity of the system is further enhanced at the same time, the activity range of the system is further enlarged, and the system is controlled and applied more easily.

Owner:EAST CHINA UNIV OF SCI & TECH

Low-injury sandstone acid used for acidification technology of oil well

InactiveCN101787269AFormation damage is smallIncrease penetrationDrilling compositionSolventHydroxycitric acid

The invention relates to a low-injury sandstone acid used for the acidification technology of an oil well. The low-injury sandstone acid comprises the compositions according to the mass percentage: 2-15% of hydrochloric acid, 0-10% of ammonium bifluoride, 0-10% of hydrogen nitrate, 0-8% of acetic acid, 8-18% of composite phosphonic acid, 0.5-5% of citric acid, 5-15% of acidulate corrosion inhibitor and 70-84% of water or additive water solution, wherein the additive water solution comprises the compositions according to the weight percentage: 0.5-5% of mutual solvent, 0.1-5% of demulsifying agent, 0-30% of clay stabilizer and 60-99.4% of water. The sandstone acid has the characteristics that the permeability of the oil well can be improved, the speed of reaction is slow and uniform, and the corrosion of the sandstone acid to the area near the oil well is nearly the same as that of the clean water.

Owner:XI'AN PETROLEUM UNIVERSITY

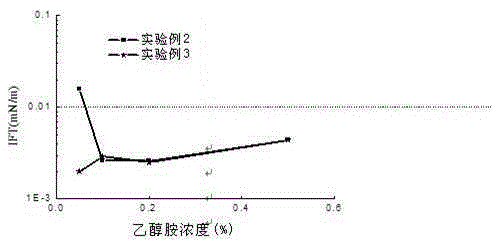

Organic base composite oil displacement system suitable for high-calcium oil reservoirs, and preparation method thereof

InactiveCN106433592AImprove oil displacement efficiencyEnhanced overall recoveryDrilling compositionOrganic baseWater soluble

The invention provides an organic base composite oil displacement system suitable for high-calcium oil reservoirs, and a preparation method thereof. The organic base composite oil displacement system comprises, by weight, 0.05-0.4% of an anionic surfactant or an anionic-nonionic mixed surfactant, 0.05-0.3% of a hydramine organic alkali, 0.1-0.3% of a water-soluble polymer, and the balance of water. The method for preparing the organic base composite oil displacement system suitable for high-calcium oil reservoirs from above raw materials comprises the following steps: 1, adding the water-soluble polymer into a first mixing container, adding water according to make the weight concentration of the water-soluble polymer reach 4500-5500 mg / L, controlling the temperature at 25-28 DEG C, stirring the polymer and water for 1.5-2.5 h, and slaking the polymer and water for 24-28 h to obtain a polymer mother liquor; 2, adding the hydramine organic alkali, the anionic surfactant or the anionic-nonionic mixed surfactant and remaining water into another mixing container, and stirring above materials at 25-80 DEG C for 10-30 min to obtain a mixed solution; and 3, adding the polymer mother liquor obtained in step 1 to the mixed solution obtained in step 2, and stirring the liquor and the solution for 20-40 min to obtain the organic base composite oil displacement system.

Owner:CHINA PETROLEUM & CHEM CORP +1

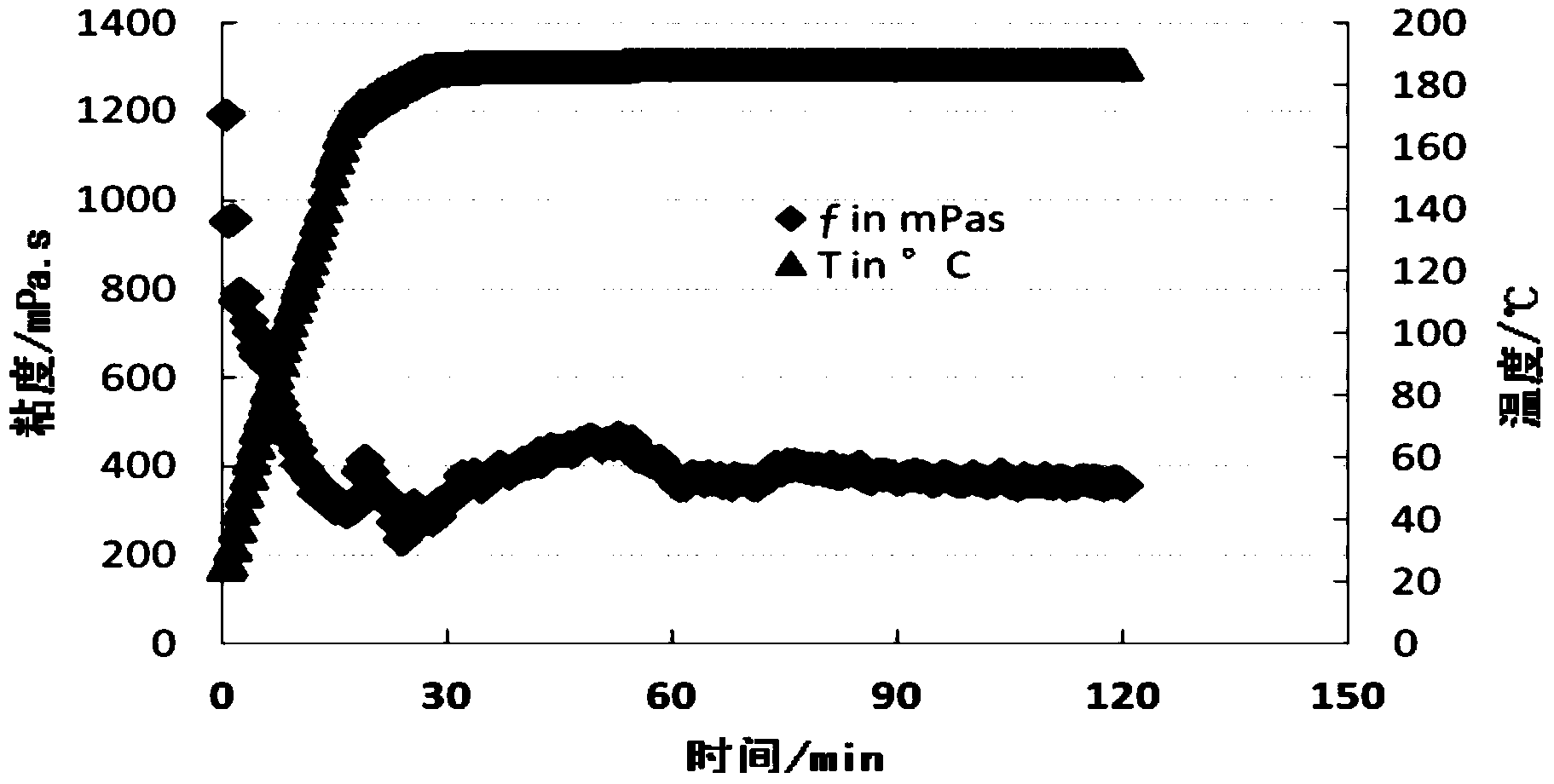

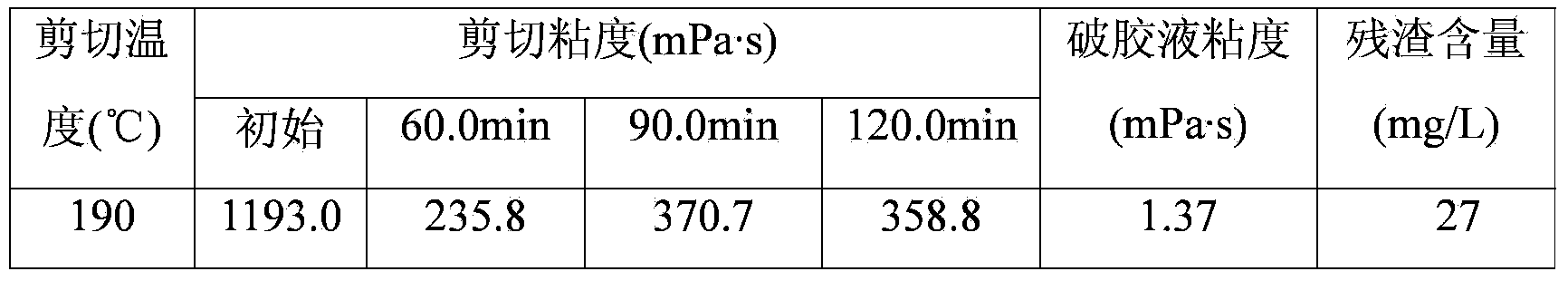

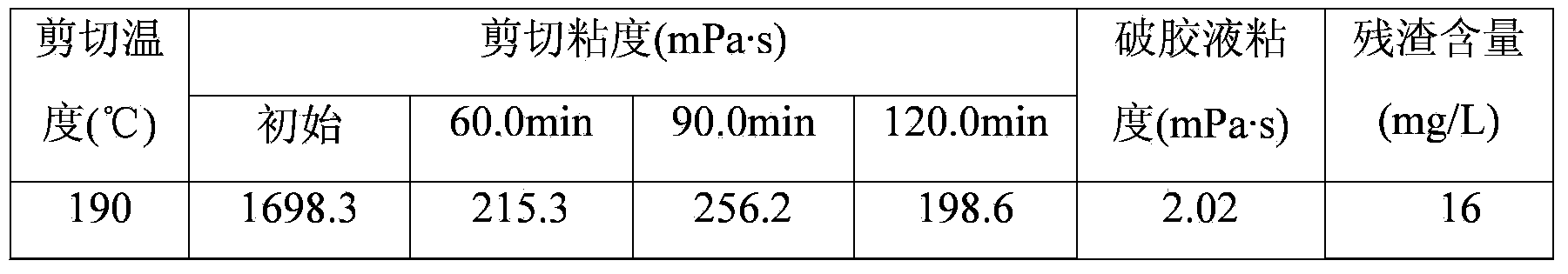

Non-metallic cross-linking agent for ultra-high temperature fracturing fluid and fracturing fluid, as well as preparation and application

ActiveCN104232071ALower working temperatureAvoid big disadvantagesDrilling compositionCross-linkOrganic acid

The invention provides a non-metallic cross-linking agent for ultra-high temperature fracturing fluid and the fracturing fluid, as well as preparation and application. The non-metallic cross-linking agent provided by the invention is mainly prepared from the following components in percentage by weight: 0.1-0.5% of organic aldehyde, 0.01-0.05% of organic phenol, 0-10% of organic alcohol, 0.05-0.5% of organic acid and the balance of water. The fracturing fluid provided by the invention has the advantages of small damage to the stratum, low cost, good temperature resistance and good gel breaking performance.

Owner:PETROCHINA CO LTD

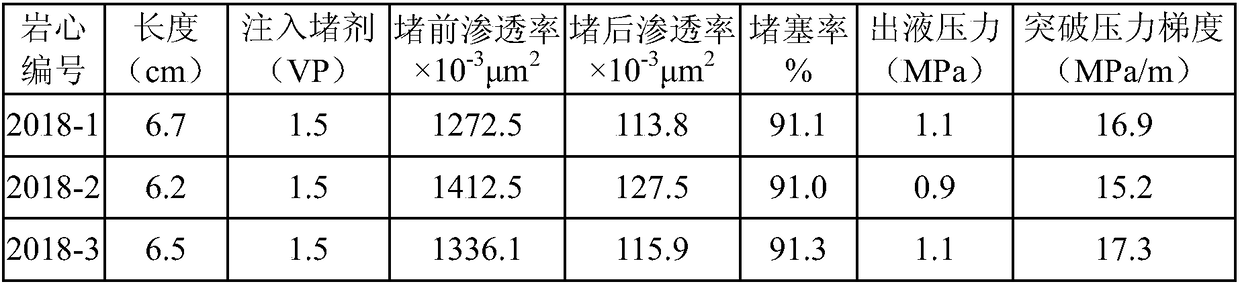

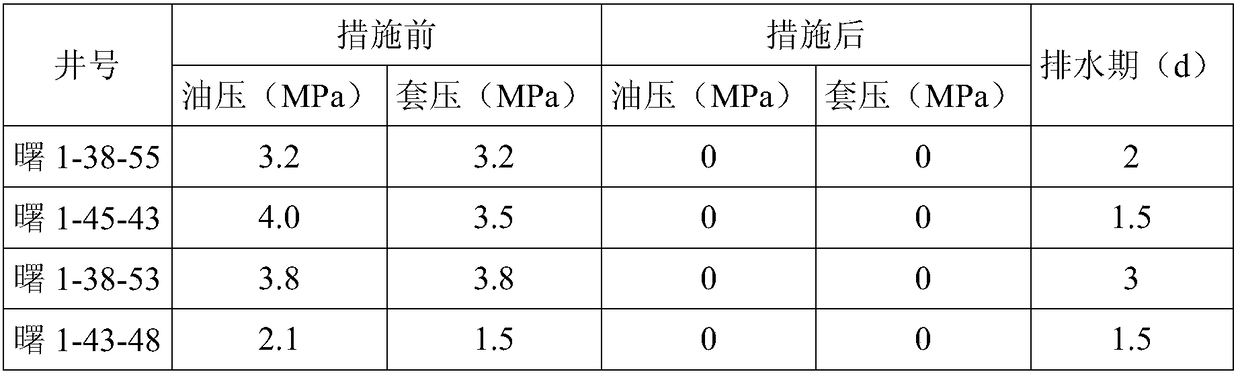

Solidified water temporary plugging well-killing working fluid and preparation method and draining method thereof

ActiveCN106833572AEasy to prepareSimple preparation processDrilling compositionSealing/packingWell killWorking fluid

The invention provides solidified water temporary plugging well-killing working fluid. The solidified water temporary plugging well-killing working fluid is prepared from 10 to 40 percent of solidified water system and 60 to 90 percent of anti-swelling stabilizing fluid, wherein the solidified water system is prepared from the following components in percentage by mass: 1.1 to 1.5 percent of main agent, 0.3 to 0.5 percent of solidification initiator and the balance of water. The preparation method of the working fluid comprises the following steps: 1), taking the main agent in an amount determined in a formula; 2) taking the solidification initiator and the anti-swelling agent in amounts determined in the formula; 3) injecting clear water into a container in an amount determined in the formula, adding the main agent and the solidification agent initiator in amounts determined in the formula in sequence, and uniformly stirring to obtain the solidified water system; 4) adding the anti-swelling stabilizing fluid in an amount determined in the formula to obtain the solidified water temporary plugging well-killing working fluid. A draining method combining acidifying-demulsifying and liquid nitrogen drainage is adopted. The working fluid is simple in preparation process, a colloid protective agent is not needed, the plugging efficiency is increased greatly, the plugging cost is lowered, damage to strata is reduced, and the problems of coexistence of collapse and leakage and low reservoir protection performance in a gas well construction process are solved. The solidified water temporary plugging well-killing working fluid has important practical significance to increase of the oil gas exploration and development speeds.

Owner:PETROCHINA CO LTD

Antifreeze clean fracturing fluid and preparation method thereof

ActiveCN108504346AImprove liquidityMeet construction requirementsDrilling compositionAlcoholWorking environment

The invention relates to antifreeze clean fracturing fluid which comprises the following components in percentage by weight: 2.0-15.0 percent of surfactant, 1.0-20.0 percent of water-soluble salt, 28.0-55.0 percent of alcohol and 36.0-55.0 percent of water. According to the different surfactants selected, the clean fracturing fluid is divided into two types. The first type of antifreeze clean fracturing fluid comprises the following components in percentage by weight: 2.0-5.0 percent of surfactant, 2.0-20.0 percent of water-soluble salt, 28.0-55.0 percent of alcohol and 38.0-55.0 percent of water, wherein the surfactant is at least one of zwitterionic surfactants of which a respective hydrophobic tail chain is an unsaturated dococyl hydrocarbyl chain. The second type of antifreeze clean fracturing fluid comprises the following components in percentage by weight: 9.0-15.0 percent of surfactant, 3.0-15.0 percent of water-soluble salt, 33.0-52.0 percent of alcohol and 36.0-50.0 percent ofwater, wherein the surfactant is at least one of zwitterionic surfactants of which a hydrophobic tail chain is an unsaturated octadecyl hydrocarbyl chain. The antifreeze clean fracturing fluid provided by the invention has the benefits that while the performance of the fracturing fluid is ensured, the freezing point of the fracturing fluid is reduced, and the low temperature-resistant use performance is improved, so that the antifreeze clean fracturing fluid still can be safely used in a working environment of below zero.

Owner:SICHUAN UNIV

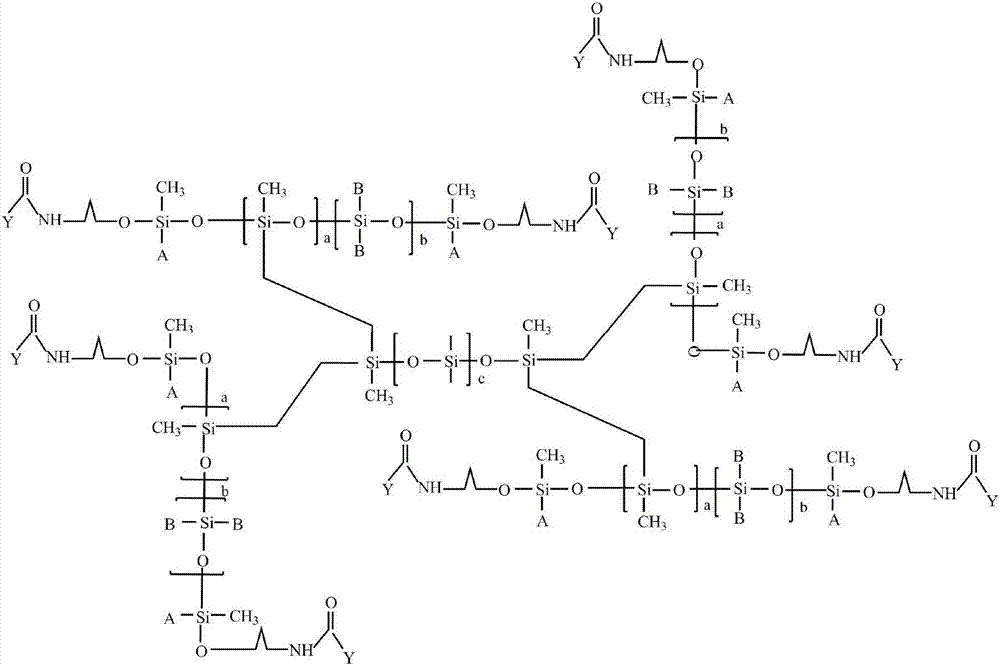

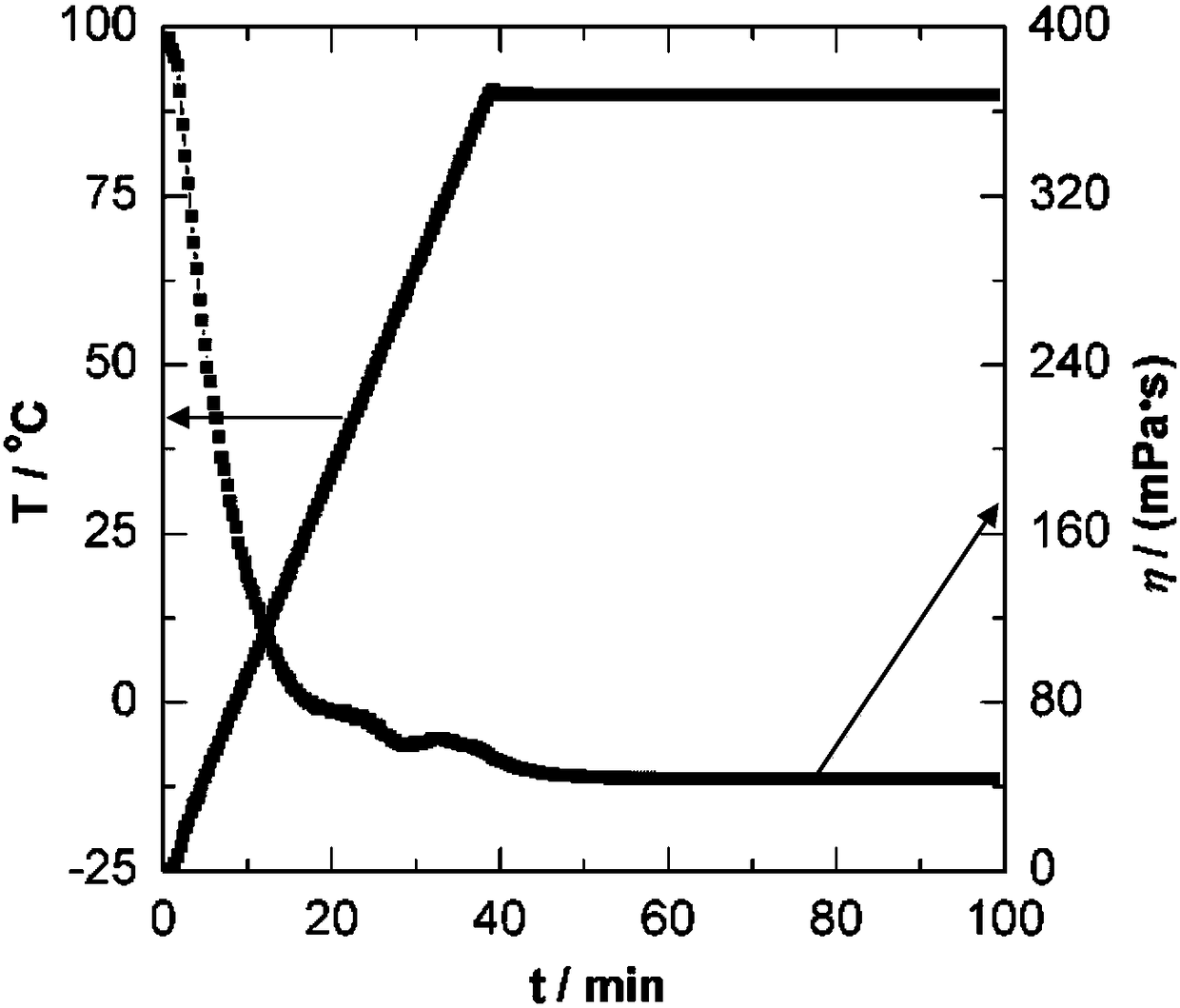

Preparation method of tetraphenylurea siloxane polymer supercritical carbon dioxide thickener

ActiveCN108034052AImproved ability to thicken supercritical carbon dioxideImprove solubilityDrilling compositionBulk chemical productionPolymer scienceTetrachloride

The invention provides a preparation method of a tetraphenylurea siloxane polymer supercritical carbon dioxide thickener. The method comprises the following steps: (1) azide and 1,2,4,5-benzenetetracarbonyl tetrachloride are reacted in order to obtain pyromellit azide; (2) cyclotetrasiloxane and monoamino propyl bis(alkyloxy) alkyl silane are hydrolyzed, and potassium hydroxide is added in order to obtain azeotropic backflow liquid; cationic resin is added into the azeotropic backflow liquid in order to obtain an amino side chain modified siloxane polymer; (3) the pyromellit azide and the amino side chain modified siloxane polymer are reacted in order to obtain the tetraphenylurea siloxane polymer. The tetraphenylurea siloxane polymer has good temperature resistance and pressure resistanceperformances, and can be used as the supercritical carbon dioxide thickener, which is suitable for realizing thickening performance under the conditions at different temperatures and pressures, and the polymer is used for fracturing and yield increase of oil fields.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Fire-flooding well self-degradable temporary plugging agent and preparation method and application thereof

ActiveCN109294541AEnhanced pumpabilityImprove temperature resistanceDrilling compositionReservoir typeCross-link

The invention provides a fire-flooding well self-degradable temporary plugging agent and a preparation method and an application thereof. By metering the total weight of the self-degradable temporaryplugging agent is 100%, the raw materials for preparing the self-degradable temporary plugging agent include: 0.3-0.8% of a main agent; 0.01-0.05% of a cross-linking agent; 0.5-2% of oil-solubility resin; 0.2-0.6% of fiber particles; 0.02-0.1% of a heat stabilizer; 0.1-0.5% of a fungicide; 0.2-0.6% of a cleanup additive; 1-3% of a fluid loss reducer; 0.001-0.004% of a slow release gel breaker, andthe balance of water. The fire-flooding well self-degradable temporary plugging agent has the characteristics of good pumping property, temperature resistance, simple preparation, and low cost, and the gel breaking time is adjustable, the sealing ability is strong, and the self-degradable temporary plugging agent is suitable for wide oil reservoir types, and is not easy to pollute the stratum andcan enter a deep part of the stratum, which can effectively solve the production problem of large gas production amount of the fire-flooding wells.

Owner:PETROCHINA CO LTD

Self-suspension propping agent and preparation method thereof

InactiveCN106675548AHigh compressive strengthTo achieve the suspension effectFluid removalDrilling compositionCross-linkPolymer science

A self-suspension propping agent and a preparation method thereof are disclosed. The propping agent comprises the following ingredients: aggregate, reinforced resin, a reinforced resin curing agent, secondary resin, a cross-linking agent, a thickening polymer material, a secondary resin curing agent and a dispersant. The self-suspension propping agent and a gel breaking method thereof realize high reverse discharging rate and cause little damage to stratum. In addition, the preparation is simple and cost is saved.

Owner:北京昆仑隆源石油开采技术有限公司

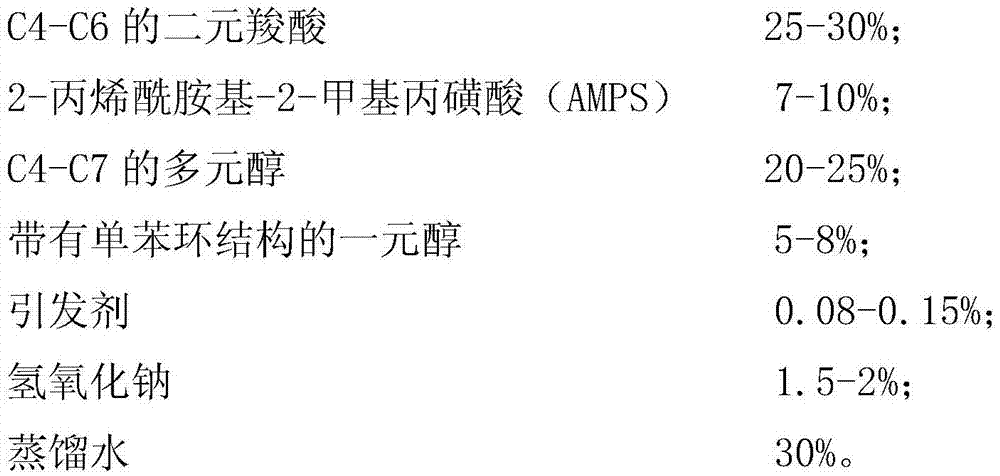

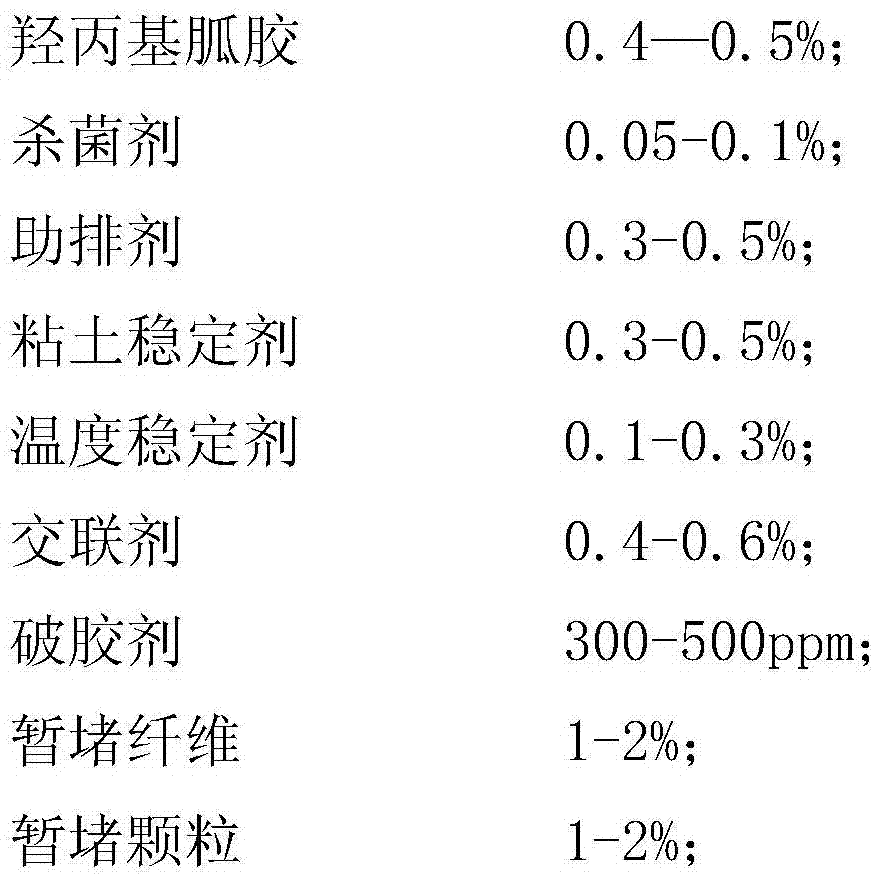

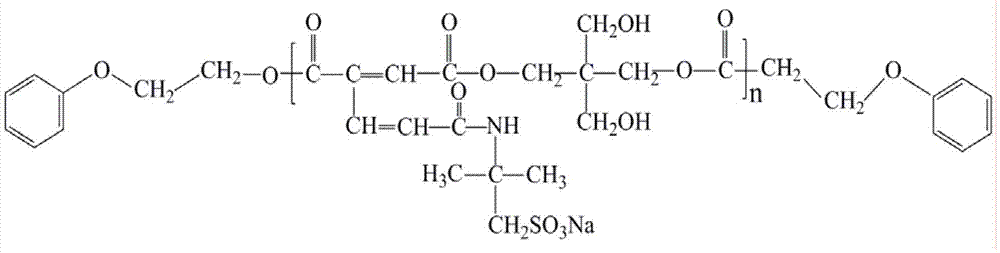

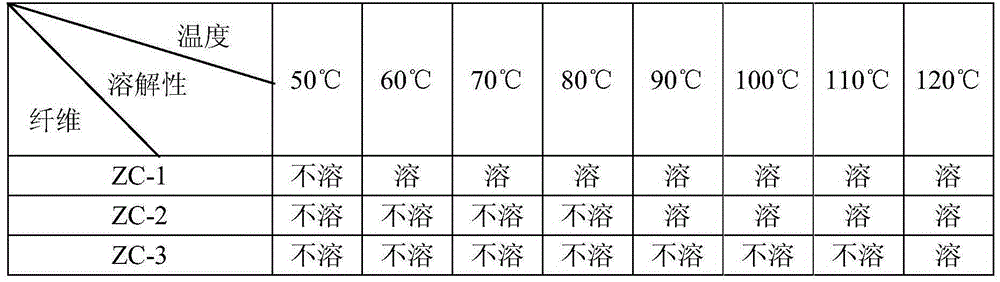

Soluble temporary plugging material for oil-gas well fracture, temporary plugging agent, fracturing fluid and preparation method thereof

ActiveCN105441049AGood temporary blocking steering effectFormation damage is smallDrilling compositionPolymer sciencePolyol

The invention discloses a soluble temporary plugging material for oil-gas well fracture, a temporary plugging agent, fracturing fluid and a preparation method thereof. The temporary plugging material is a polymer which is prepared from, by mass, 25-30% of C4-C6 dicarboxylic acid, 7-10% of 2-acrylamide-2-methyl propane sulfonic acid, 20-25% of C4-C7 polyatomic alcohol, 5-8% of monohydric alcohol with a single benzene ring structure, 0.08-0.15% of initiator, 1.5-2% of sodium hydroxide and 3% of distilled water. The temporary plugging material can be completely dissolved in fracturing fluid environments at different temperatures, and no solid residues exist.

Owner:四川安东油气工程技术服务有限公司 +1

Clean crushing liquid system

InactiveCN105273709ASimple recipeEasy to prepareFluid removalDrilling compositionCross-linkMaterial resources

The invention provides a clean crushing liquid system fit for prolonging the low-temperature and low-permeability reservoir of oil field. The clean crushing liquid system comprises the following components by weight percent: 0.3%-0.4% of thickening agent, 0.15%-0.2% of synergist, 0.5%-1.0% of anti-swelling agent, 0.1%-0.3% of gel breaker and the balance of water, wherein the hydrophobic group modified polyacrylamide and / or derivatives thereof is served as the thickening agent. Compared with the prior art, the clean crushing liquid system has the advantages that the clean crushing liquid is not cross-linked and belongs to non-cross-linking crushing liquid; the construction friction resistance is low; the anti-shearing ability is strong; the content of the residues after the gel breaking is low; the harm to the floor layer is small; the formula of the crushing liquid is simple; the preparation process is simple and convenient; a large amount of manpower and material resources can be saved during a crushing construction process.

Owner:YANCHANG OIL FIELD +1

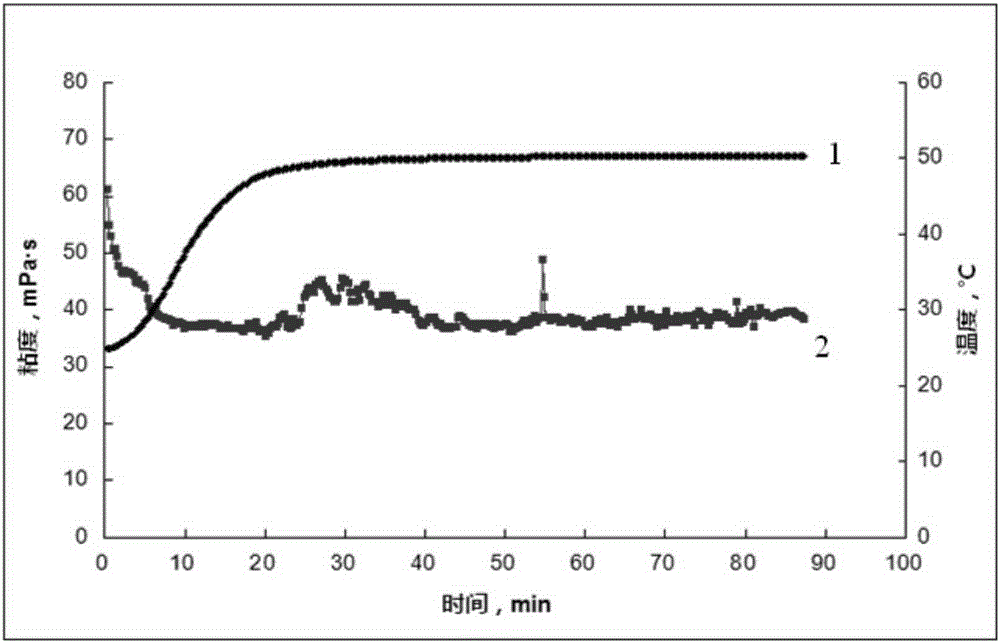

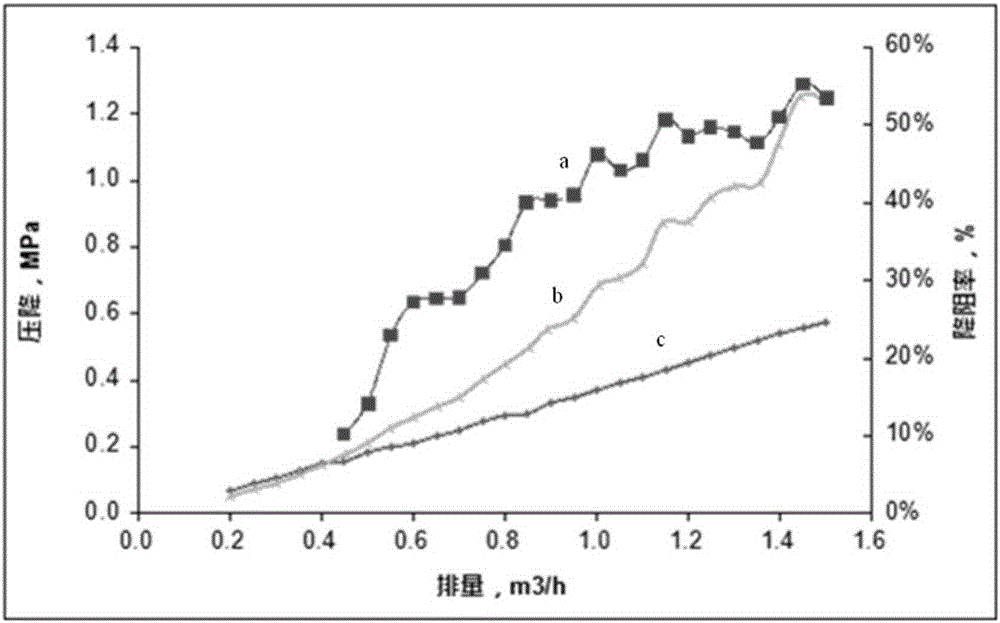

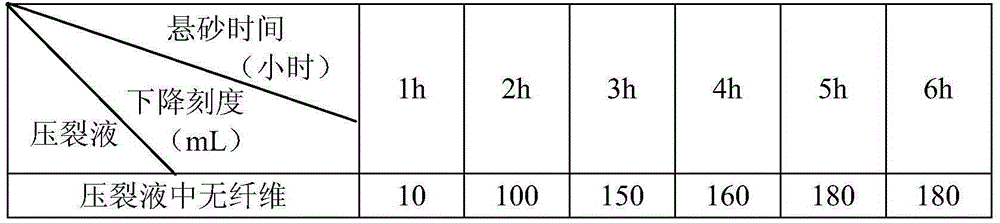

Degradable fiber, fracturing fluid with same and method for preparing fracturing fluid

The invention provides a degradable fiber, fracturing fluid with the same and a method for preparing the fracturing fluid. 50%-70% polyacid and 30%-50% polyhydric alcohol are subjected to polymerization reaction on the basis of the total weight of the degradable fiber at the temperature of 160-180 DEG C for 3-5 hours to obtain a polymer, and the polymer is subjected to jet flow, winding, wire drawing, secondary winding and shearing to obtain the degradable fiber. The fracturing fluid contains 0.10wt%-0.18wt% of the degradable fiber. The method for preparing the fracturing fluid with the degradable fiber includes the following steps of adding thickening agents and other reagents into water to obtain thickening agent aqueous solution; adding the degradable fibers into the thickening agent aqueous solution; and adding gel breakers and cross-linking agents into the thickening agent aqueous solution to obtain the fracturing fluid. The degradable fiber, the fracturing fluid and the method have the advantages that the degradable fiber can be used for preparing the fracturing fluid, accordingly, the sand carrying performance of the fracturing fluid can be improved, usage of the thickening agents for the fracturing fluid can be decreased, and formation damage can be reduced.

Owner:PETROCHINA CO LTD

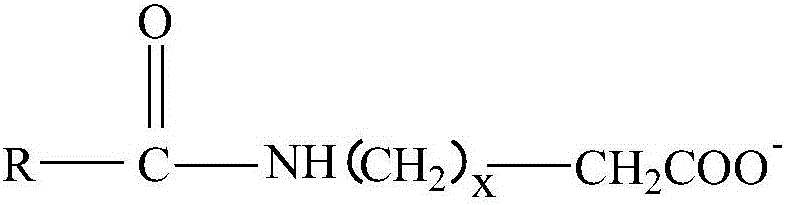

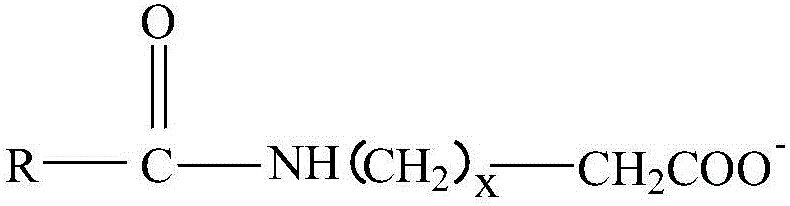

Surfactant fracturing fluid system and preparation method thereof

InactiveCN106118625AFormation damage is smallReduce pollutionDrilling compositionBetaineFracturing fluid

The invention discloses a surfactant fracturing fluid system, which is composed of the following components according to mass percentage: 0.3% to 0.5% of long-chain alkyl amidopropyl dimethyl amine oxide, 0.15% of long-chain alkyl amido betaine % ~ 0.4%, additives 0.1% ~ 0.2%, the balance is water. The invention also discloses a preparation method of the surfactant fracturing fluid system: dissolve the additive in water at normal temperature and pressure, then add long-chain alkylamide betaine and long-chain alkylamide propyl dimethyl Amine oxide, stir well, and serve. The surfactant fracturing fluid system of the present invention has low damage to the formation, less pollution, does not need to add chemical agents to break the gel, has a strong flowback ability, and the fracturing fluid residue content is almost zero, and can effectively stabilize clay and make fracturing The skin effect and oil layer pollution in the process are smaller, even close to zero pollution, which can more effectively increase the productivity of oil wells and achieve the purpose of fracturing oil and gas reservoirs. The preparation method of the invention is simple to operate, environment-friendly and suitable for large-scale industrial production.

Owner:YANCHANG OIL FIELD

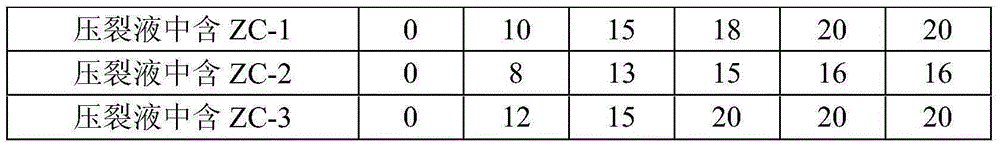

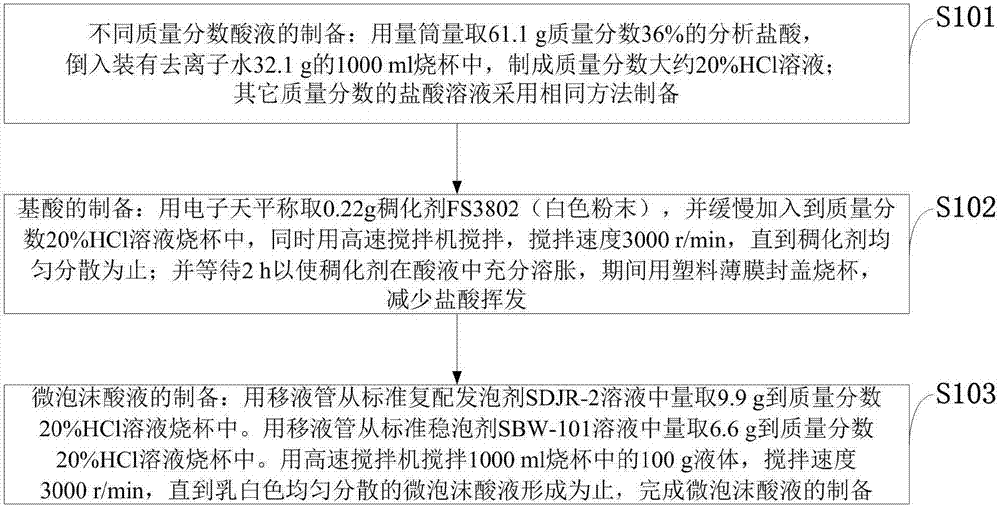

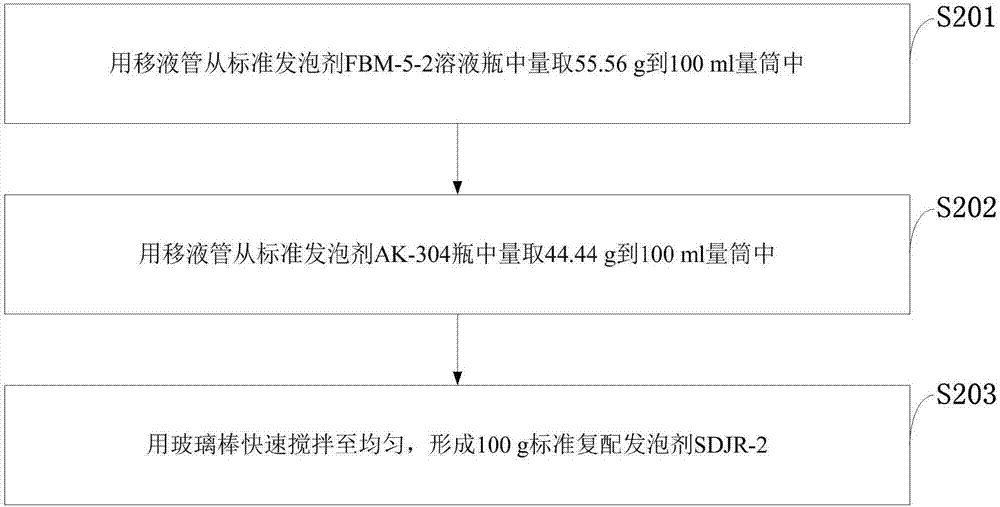

Microfoam acid liquid and preparation method thereof

The invention belongs to the technical field of foam acid and discloses microfoam acid liquid, constitution of a compound foaming agent of the microfoam acid liquid and a preparation method of the microfoam acid liquid. The microfoam acid liquid contains the following components in percentage by mass (100% in total): 10%-25% of HCl (hydrochloric acid), 0.36% of SDJR-2 (compound foaming agent), 0.24% of SBW-101 (foam stabilizer), 0.2% of FS3802 (thickening agent) and the balance of water, wherein the compound foaming agent SDJR-2 contains 55.56% of an FBM-5-2 foaming agent and 44.44% of an AK-304 foaming agent. The microfoam acid liquid has good properties of foaming, foam stabilization, viscosity maintenance, acid rock reaction retardance, temperature resistance, salt resistance, oil resistance, sand carrying and the like; by observing through an optical microscope, the microstructure and size of the microfoam acid liquid meet the dimensional requirement of microfoams; experimental evaluation shows that the microfoam acid liquid is a novel acid liquid system with excellent performance and has wide application prospects.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

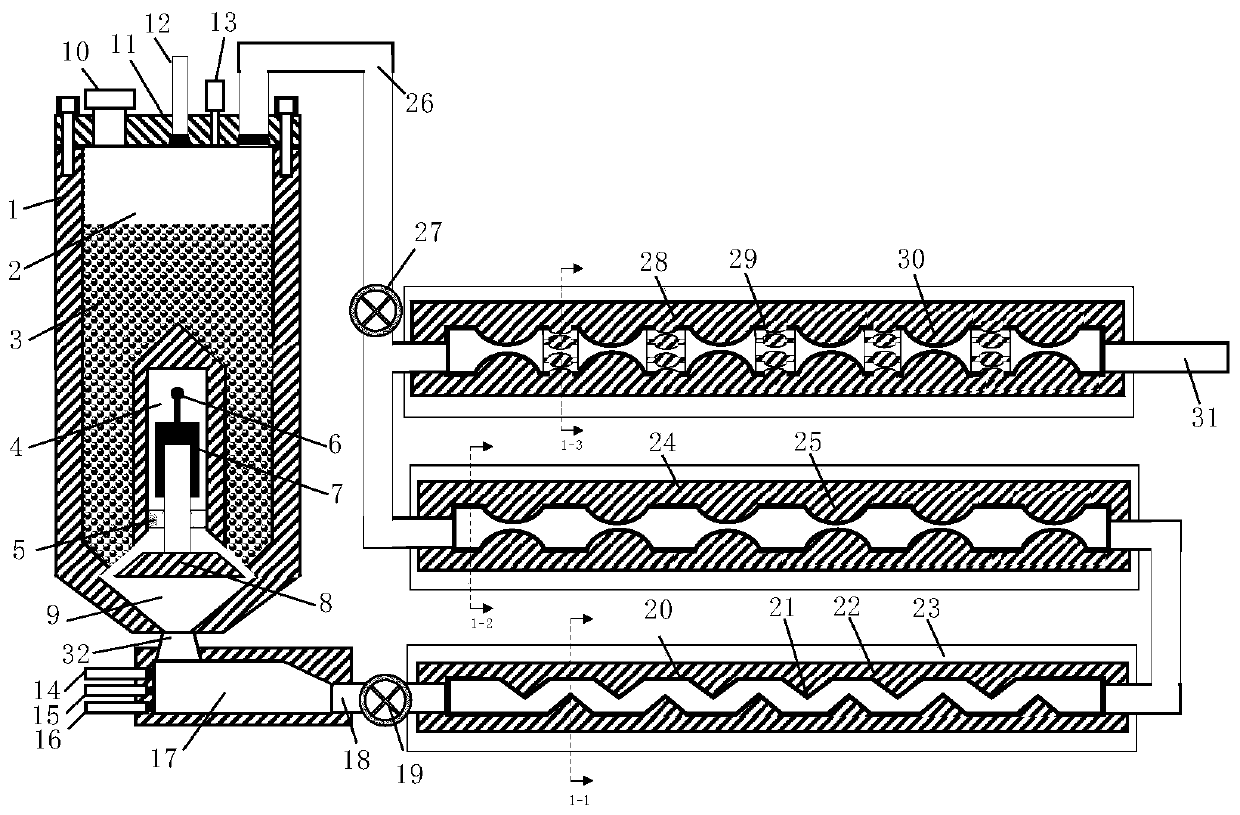

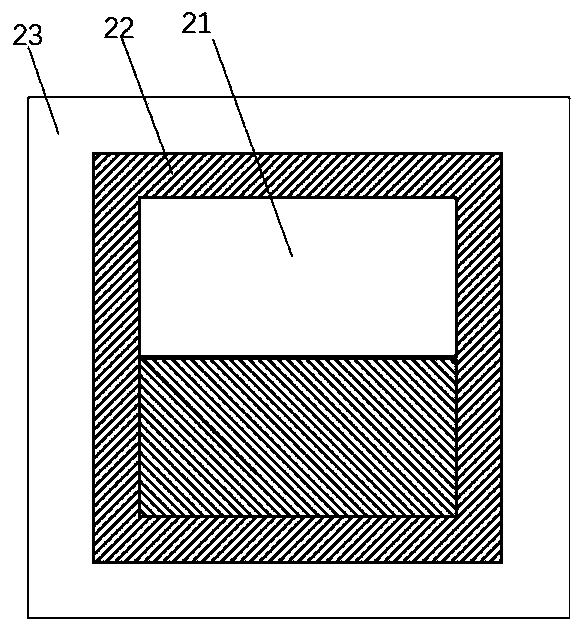

Anhydrous foam generator for shale oil and gas reservoir fracturing as well as application thereof

The invention discloses an anhydrous foam generator for shale oil and gas reservoir fracturing as well as application thereof. The anhydrous foam generator has the following structure: a sand adding port, a liquid CO2 second injection port and a safety valve are arranged at the top of a propping agent storage tank; the bottom of the propping agent storage tank communicates with a high-pressure gasand liquid mixer through a propping agent discharging pipe; the top of the propping agent storage tank communicates with a primary oscillator and a secondary oscillator through an exhaust pipe; a liquid CO2 first injection port, a N2 injection port and an anhydrous foam foaming agent injection port are formed in the side wall of the high-pressure gas and liquid mixer; and the side wall of the high-pressure gas and liquid mixer communicates with the primary oscillator through a liquid discharging pipe; and the primary oscillator, the secondary oscillator and a tertiary oscillator communicate with one another sequentially. According to the three tandem oscillation mode of the anhydrous foam generator, the anhydrous foam generator has the characteristic of efficient foaming, guarantees complete mixing of the liquid CO2, N2 and propping agent particles, enhances the foaming capability of the foaming agent for anhydrous foam fracturing, can generate uniform and compact anhydrous foam fracturing liquid, contributes to improving the fracturing efficacy and greatly reduces formation damage.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Slick water for tight sandstone reservoir, and preparation method thereof

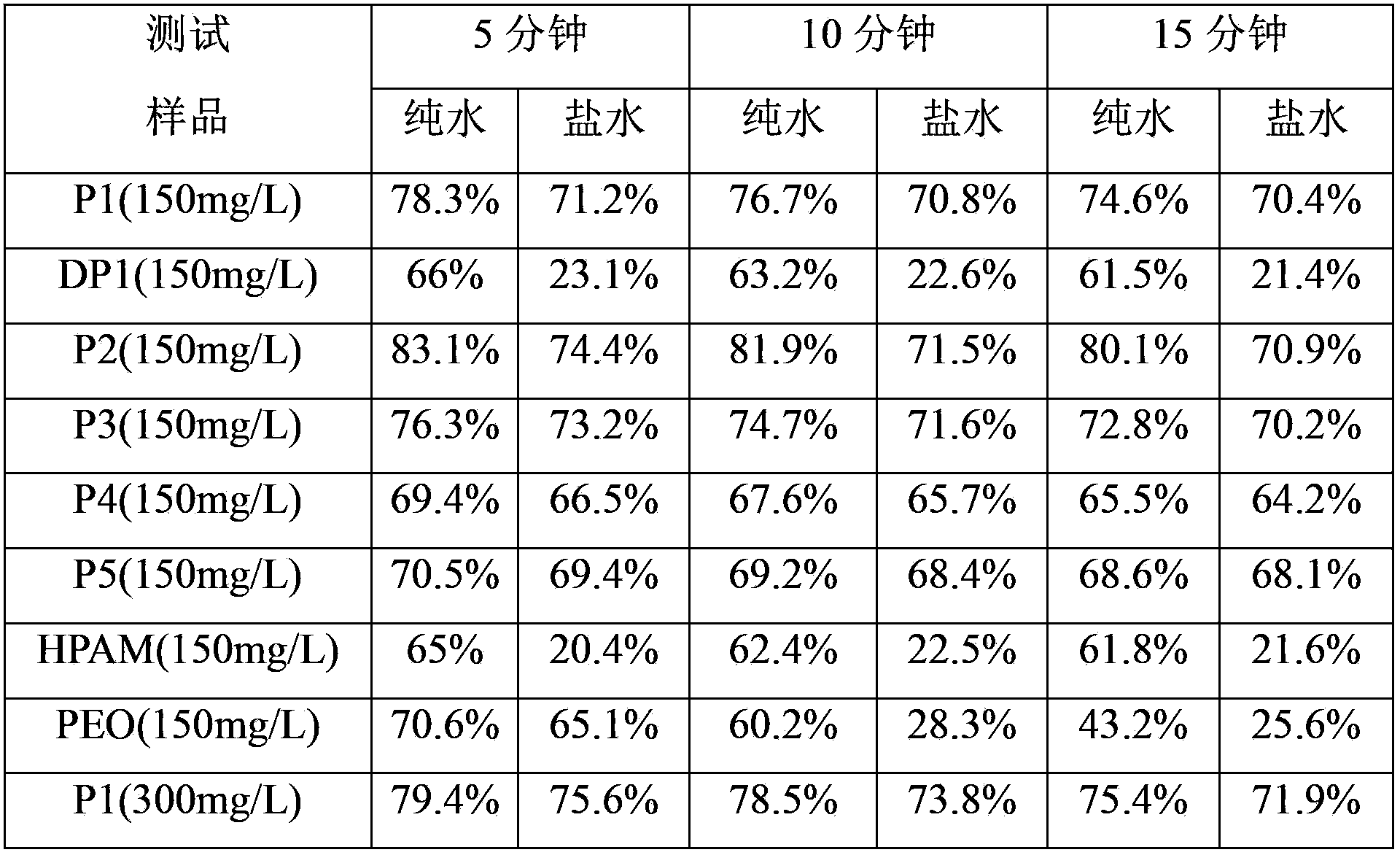

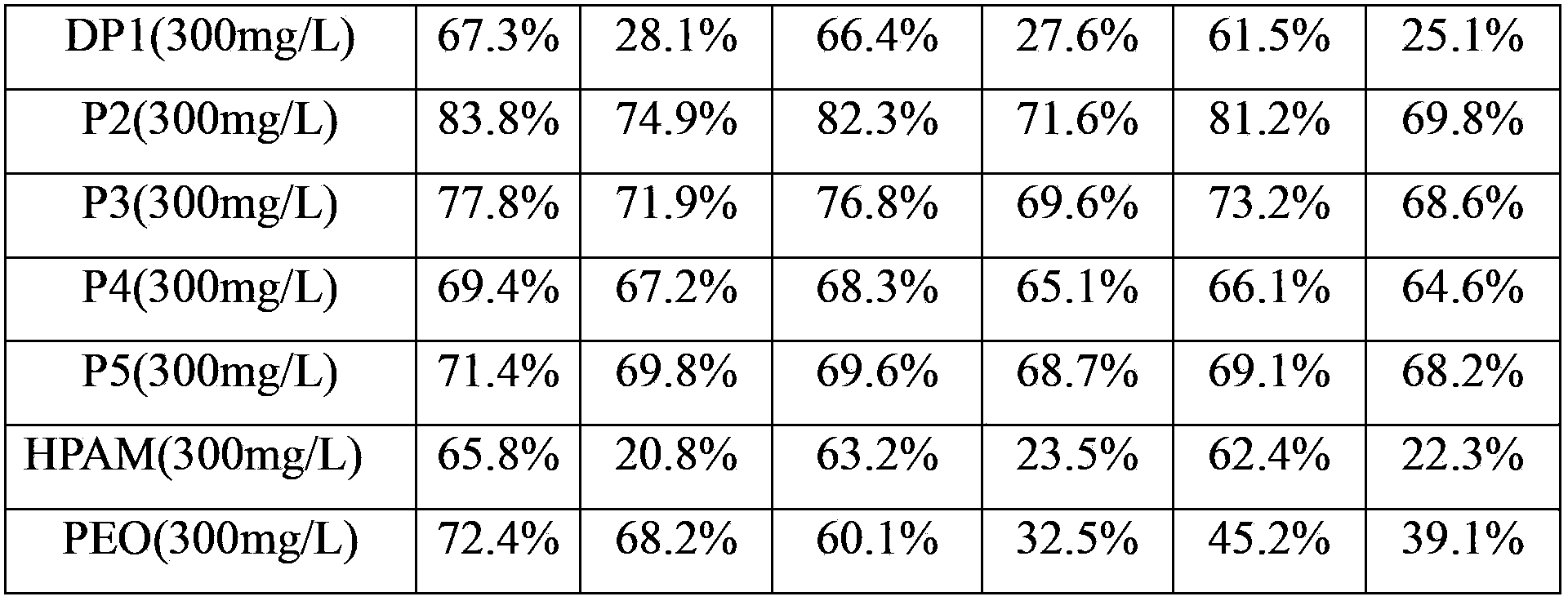

ActiveCN111218268AGood drag reduction effectReduce harmDrilling compositionReducing agentPetroleum engineering

The invention provides slick water for a tight sandstone reservoir, and a preparation method of the slick water. The slick water is prepared from the following components in percentage by mass: 0.05-0.15% of a resistance reducing agent, 0.05-0.3% of a cleanup additive, 0.05-0.5% of an anti-swelling agent, 0.01-0.5% of a bactericide and the balance of water, wherein the resistance reducing agent isa grafted copolymer of lignosulfonate and acrylamide, the cleanup additive is a microemulsion cleanup additive, the anti-swelling agent is potassium chloride or / and ammonium chloride, and the bactericide is formaldehyde or / and acrolein. According to the invention, based on the resistance reducing agent, the anti-swelling agent and the bactericide are considered in combination with selection of the cleanup additive, the proportions of all the components of the slick water are readjusted, the brand-new slick water suitable for the tight sandstone reservoir is developed, the drag reduction rateof the slick water exceeds 70%, damage to the reservoir is small, flowback is easy, compatibility is good, corrosion is not likely to happen, the preparation process is simple, and cost is low.

Owner:PETROCHINA CO LTD

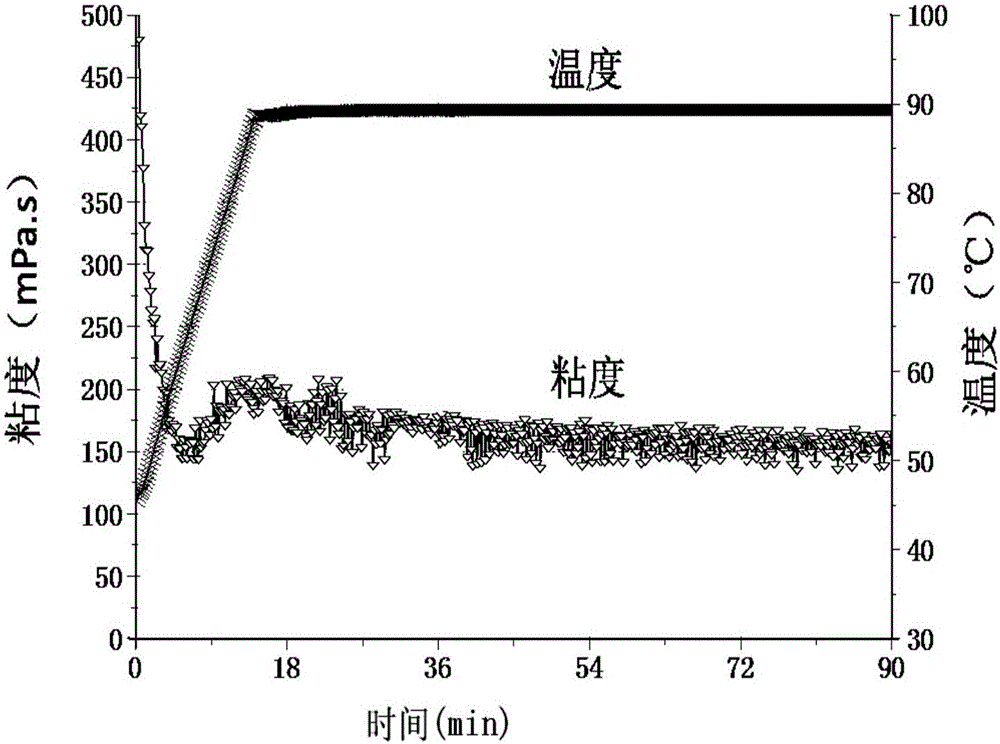

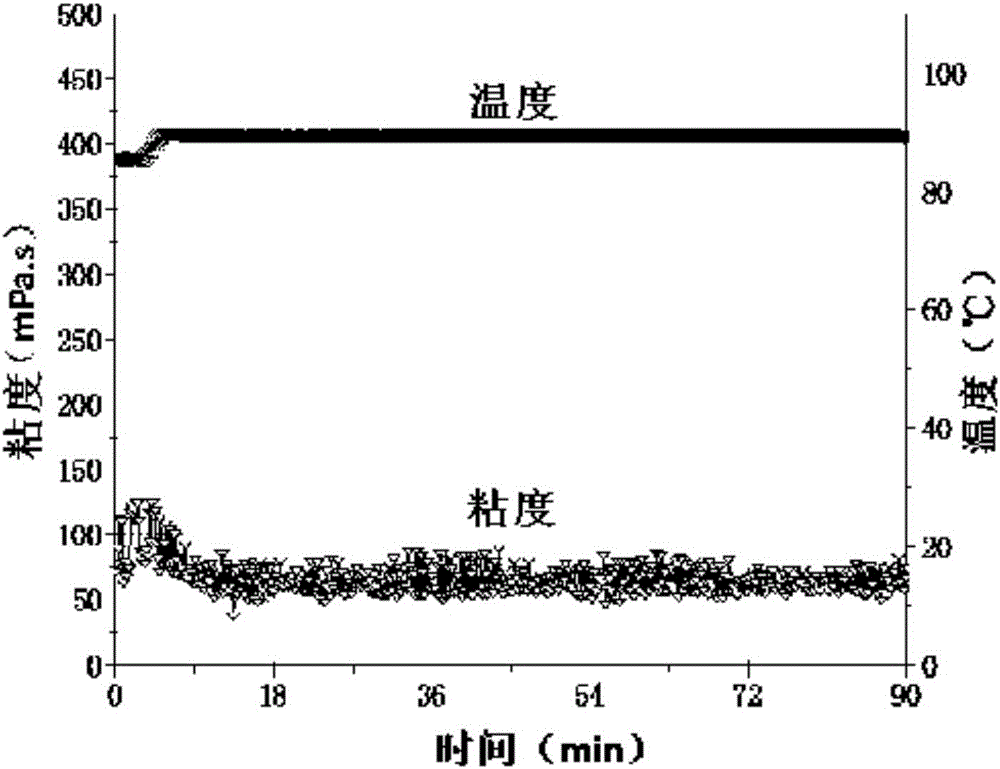

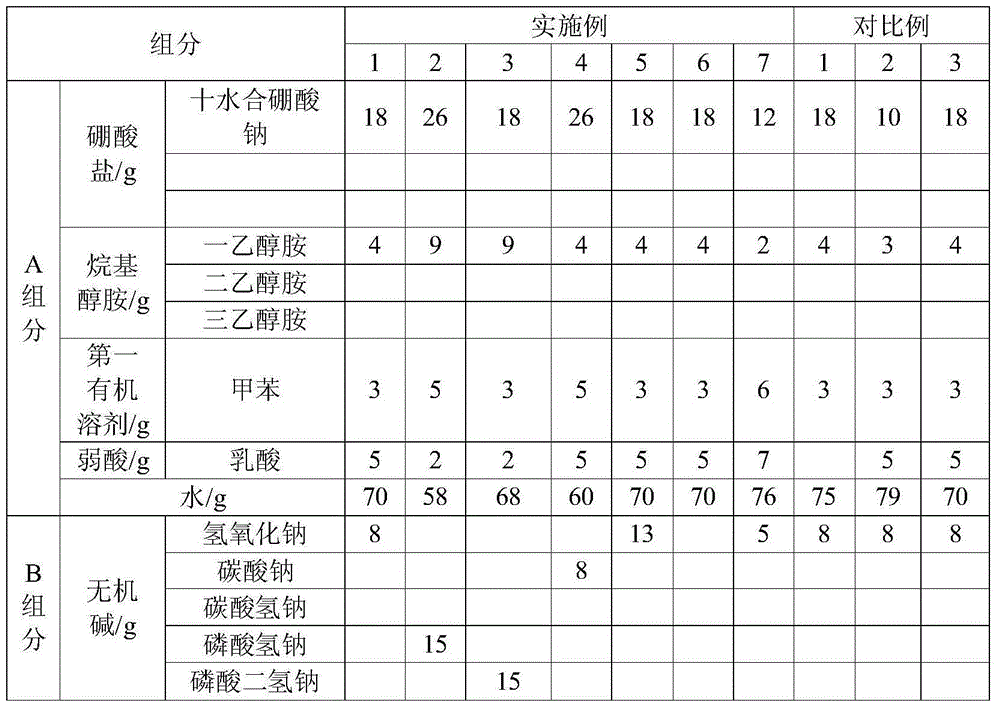

Cross-linking agent, hydroxypropyl guanidine gum fracturing fluid system and preparation method of hydroxypropyl guanidine gum fracturing fluid system

InactiveCN105062456AImprove heat resistanceImprove diversion capacityDrilling compositionCross-linkFracturing fluid

The invention provides a cross-linking agent, a hydroxypropyl guanidine gum fracturing fluid system and a preparation method of the hydroxypropyl guanidine gum fracturing fluid system. The cross-linking agent comprises an A component and a B component, wherein the A component comprises borate, alkyl alkylol amine, a first organic solvent, a first inorganic solvent and an acidic pH modifier; the B component comprises an alkaline pH modifier; the weight ratio of the A component to the B component is (2: 7)-(1: 5). The cross-linking agent provided by the invention is adopted to prepare the fracturing fluid system, so that the formation damage is reduced, the cost of a fracturing fluid is reduced, the fracturing effect is improved, besides, the concentration of a thickening agent is decreased, and the fracturing fluid property is guaranteed.

Owner:CHINA SHENHUA ENERGY CO LTD +1

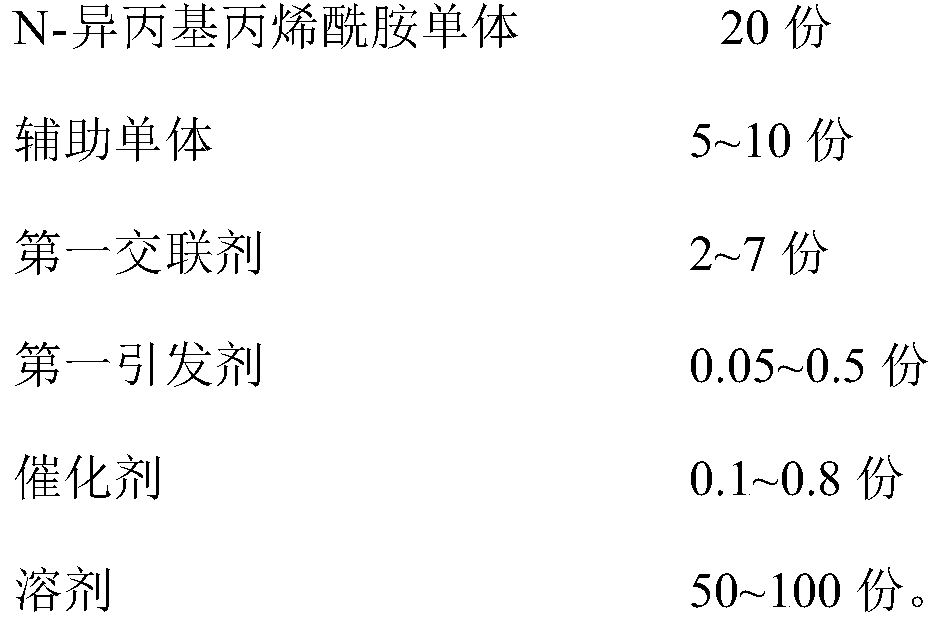

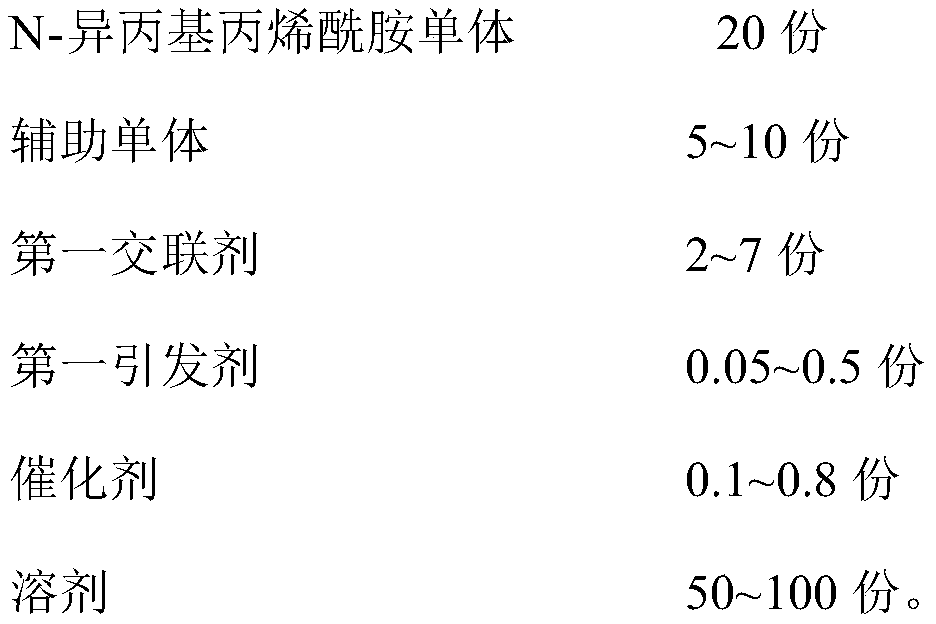

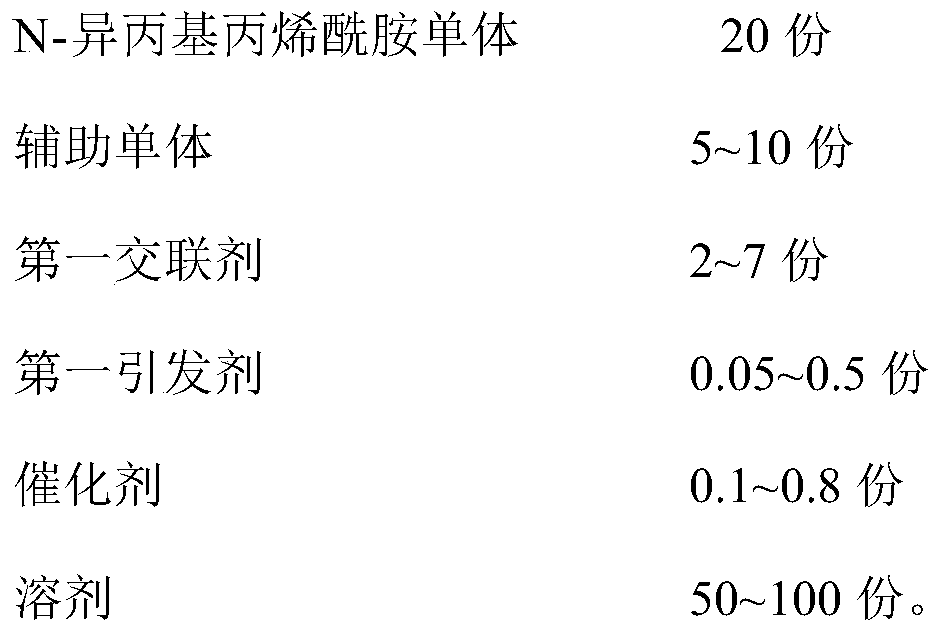

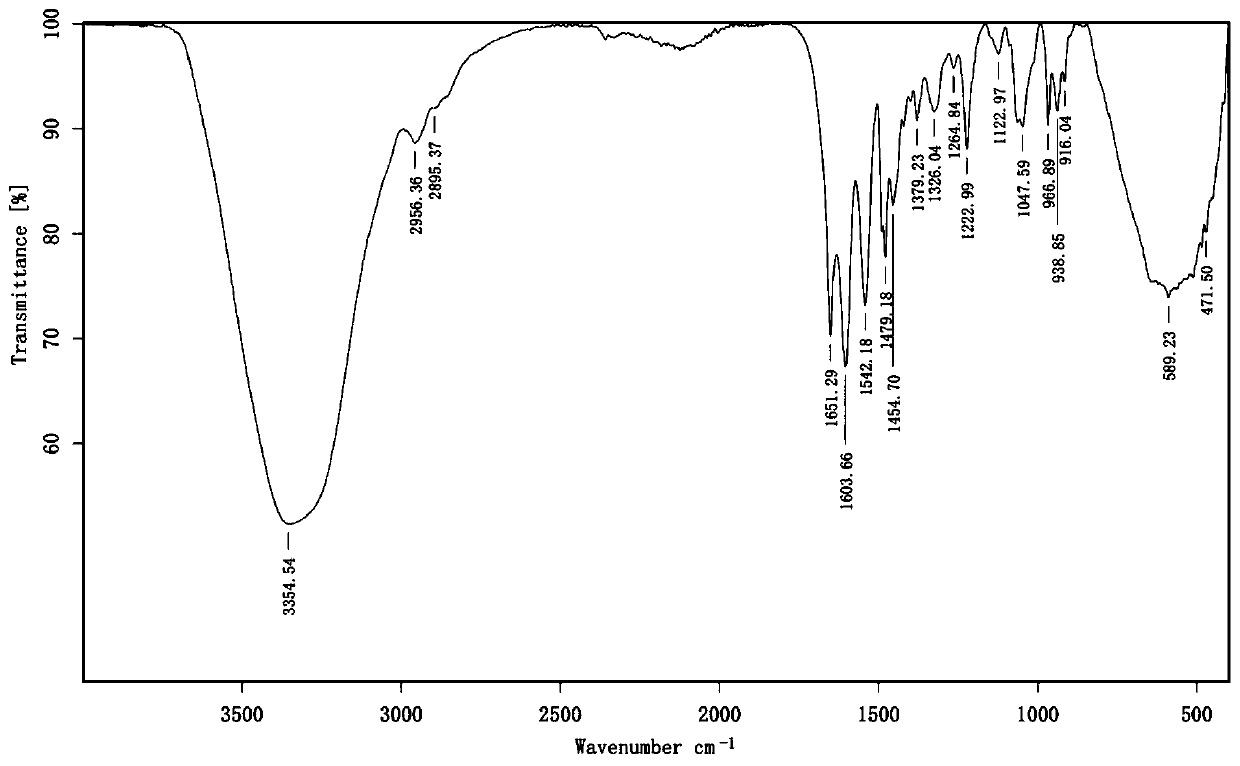

Repeated fracturing temporary plugging agent and preparation method thereof

InactiveCN110819325ARaw materials are widely availableLow costDrilling compositionPtru catalystIsopropyl

The invention discloses a repeated fracturing temporary plugging agent and a preparation method thereof, wherein the temporary plugging agent is prepared from the following components by weight: 20 parts of an N-isopropylacrylamide monomer, 5-10 parts of an auxiliary monomer, 2-7 parts of a first cross-linking agent, 0.05-0.5 part of a first initiator, 0.1-0.8 part of a catalyst and 50-100 parts of a solvent. According to the invention, the plugging strength and the response temperature of the temporary plugging agent can be remarkably improved through the first cross-linking agent, and the application range of the temporary plugging agent can be widened by adding the auxiliary monomer, so that the temporary plugging agent is suitable for medium-low-temperature reservoirs; and the preparation method has advantages of simple steps, convenience in operation, few reaction byproducts and low requirements on equipment.

Owner:BEIJING DADE GUANGYUAN PETROLEUM TECH SERVICE

Polyhydroxy thickener, high-temperature-resistant alcohol-based fracturing fluid system and application of high-temperature-resistant alcohol-based fracturing fluid system

ActiveCN111574989AImprove temperature resistanceImprove shear resistanceFluid removalDrilling compositionAlcoholCross linker

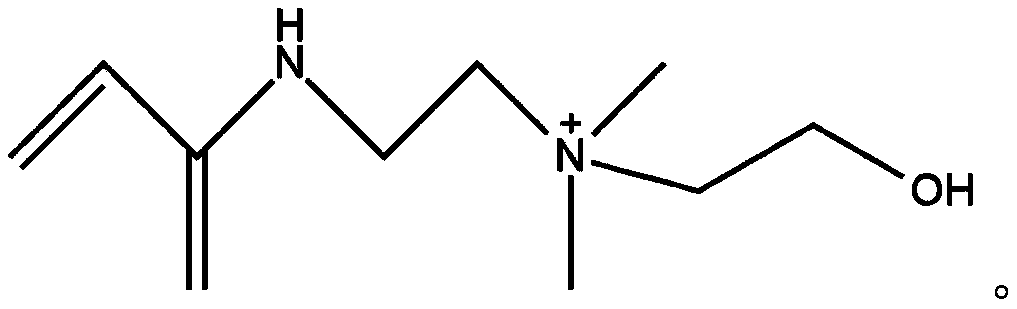

The invention discloses a polyhydroxy thickener and a high-temperature-resistant alcohol-based fracturing fluid system. The polyhydroxy thickening agent is formed by copolymerizing three monomers, namely acrylamide, N-vinylpyrrolidone and N-acrylamide propyl-N,N,N-dimethyl hydroxyethyl ammonium chloride, in an aqueous solution; and based on the total mass of the monomers, the mass ratios of acrylamide, N-vinylpyrrolidone and N-acrylamide propyl-N,N,N-dimethyl hydroxyethyl ammonium chloride are 40-85%, 5-35% and 3-25%, respectively. The high-temperature-resistant alcohol-based fracturing fluidsystem is prepared from the following raw materials: the polyhydroxy thickener, a composite cross-linking agent, a regulator, high-flash-point alcohol and water. According to the alcohol-based fracturing fluid system disclosed by the invention, the polyhydroxy thickening agent is introduced, so the alcohol-based fracturing fluid system has relatively high temperature resistance and shearing resistance, and can resist a temperature of 160 DEG C or above; by using the high-flash-point alcohol, the fracturing system is safer; and an alcohol / water ratio can be increased to 60% or above, even an anhydrous system with the alcohol / water ratio of 100% can be realized, so the fracturing fluid system has the advantages of high flowback rate, small stratum damage, safety, environment friendliness andthe like.

Owner:北京九恒质信能源技术有限公司

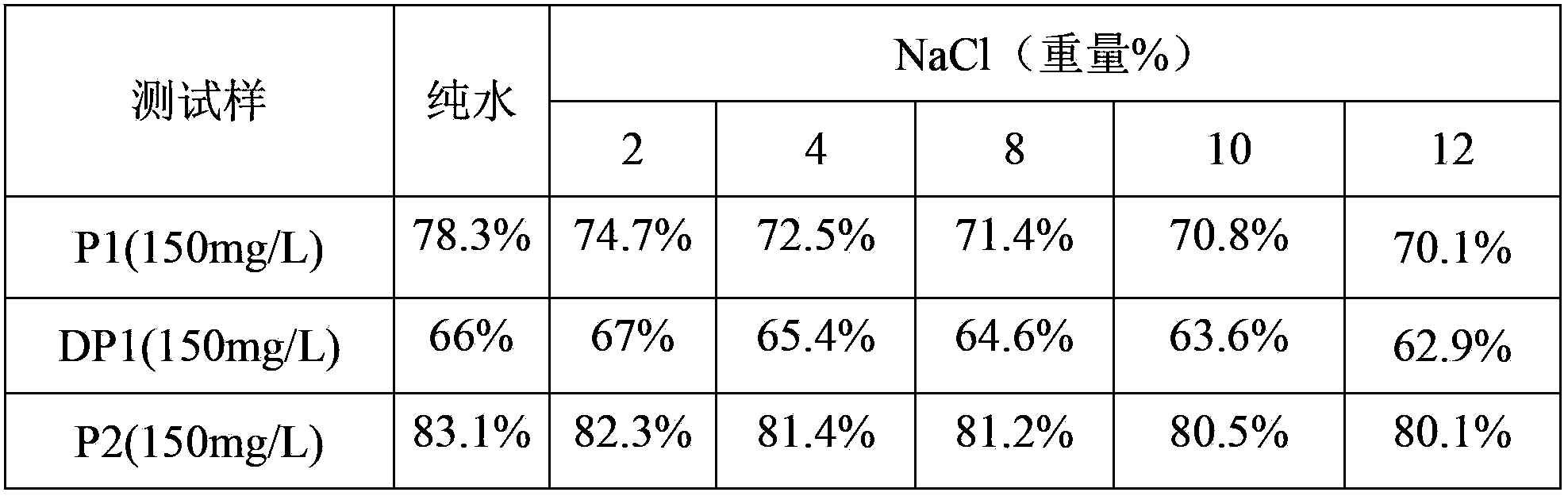

Acrylamide copolymer and preparation method and application thereof

ActiveCN103772601AHigh drag reduction rateGood compatibilityDrilling compositionPolymer scienceStructural unit

The invention discloses an acrylamide copolymer and a preparation method and application thereof. The acrylamide copolymer contains a structural unit A and a structural unit B, wherein the structural unit A is a structural unit shown as a formula (1) and / or a structural unit shown as a formula (2); the structural unit B is a structural unit shown as a formula (3) and / or a formula (4); the viscosity-average molecular weight of the acrylamide copolymer is 4,000,000-20,000,000. The acrylamide copolymer provided by the invention has high drag reduction efficiency, high shear resistance, high salt tolerance and high compatibility with clay inhibitors and bactericides. The formula (1), the formula (2), the formula (3) and the formula (4) are shown in the specification.

Owner:CHINA PETROLEUM & CHEM CORP +1

Protection liquid for oil well operation

InactiveCN104927812AReduce leakageImprove liquidityDrilling compositionChromium(III) hydroxideSulfite salt

The invention relates to the technical field of petrochemical industry, and concretely relates to a protection liquid for oil well operation. The protection liquid comprises 10-20wt% of acrylamide, 8-10wt% of chromium hydroxide, 10-20wt% of potassium carbonate, 10-20wt% of urea, 0.02-0.1wt% of dodecyl dimethyl benzyl ammonium chloride, 0.01-1wt% of anhydrous sodium sulfite, 10-20wt% of furfuryl alcohol, 0.01-0.02wt% of sodium hydroxide, 0.01-0.02wt% of glacial acetic acid and 0.1-0.5wt% of alkynoxymethyl amine. The purpose of the invention is to provide the protection liquid for oil well operation, with the advantages of simple construction and ideal performances.

Owner:荆春芳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com