Non-metallic cross-linking agent for ultra-high temperature fracturing fluid and fracturing fluid, as well as preparation and application

A non-metallic and cross-linking agent technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the tasks that affect the normal production and output of oil and gas reservoir reconstruction in oilfields, and cannot meet the requirements of low cost and low damage resistance of fracturing fluids. High temperature, rising guar gum prices and other issues, to achieve the effect of low cost, avoiding large damage, and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

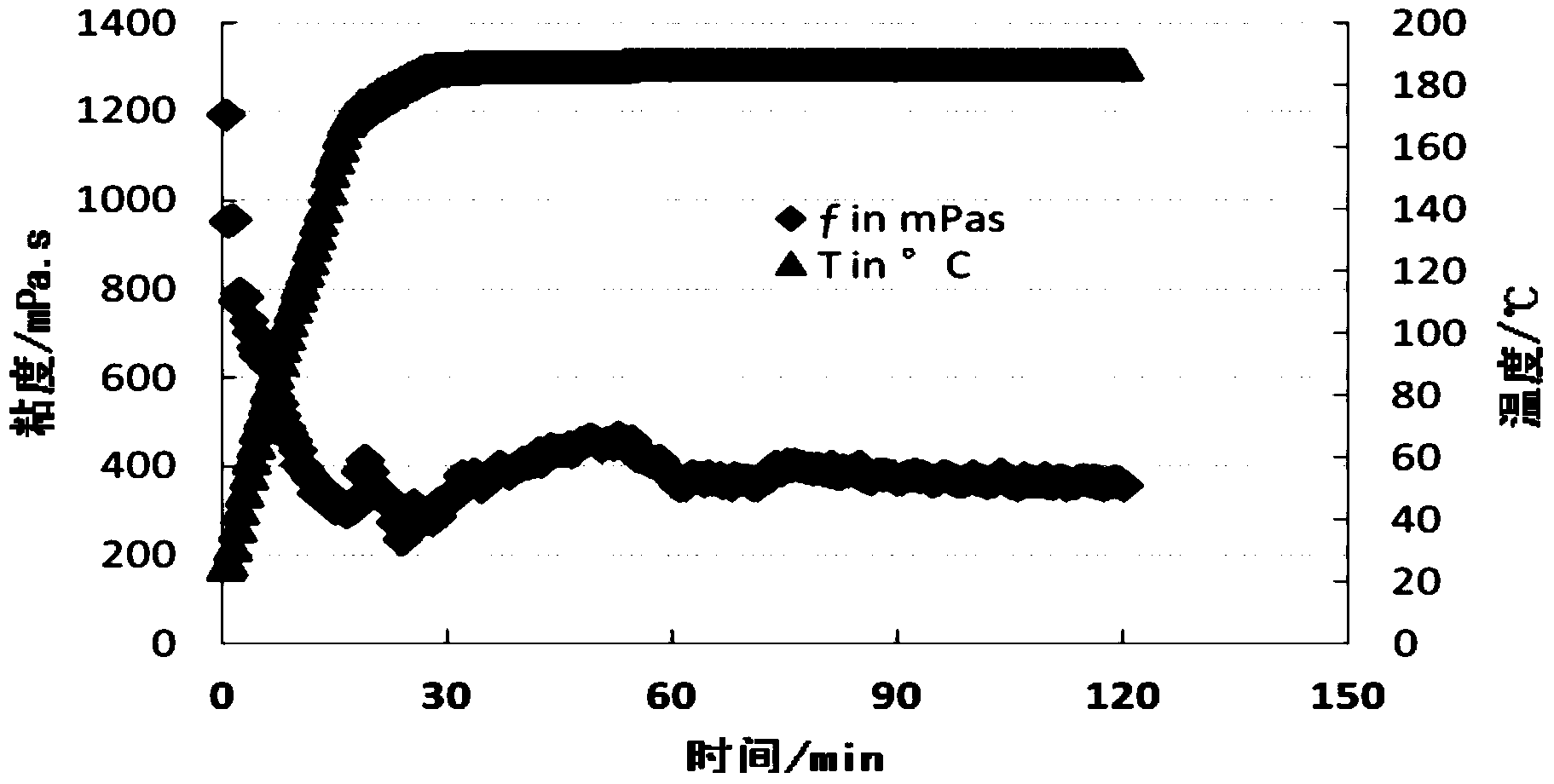

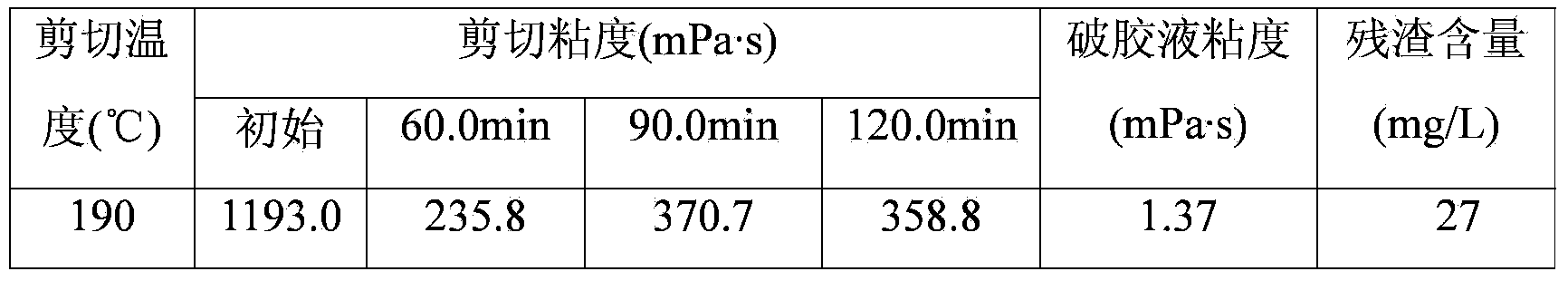

Embodiment 1

[0048]Synthetic polymer (prepared by reacting acrylamide and 2-acrylamide-2-methylpropanesulfonic acid at a mass ratio of 2:1 at 12°C for 4 hours, with a viscosity average molecular weight of 6.53 million) 0.4%, cross 0.25% of joint agent, 0.2% of lauryl ammonium chloride, 0.1% of demulsifier SP1690.1%, 0.05% of ammonium persulfate and the rest of the water prepare the ultra-high temperature fracturing fluid of the present invention (preparation method: add 0.4% Synthesize polymer thickener, stir 1.5 hours under 400r / min rotating speed, form uniform polymer aqueous solution; Add 0.2% lauryl ammonium chloride, 0.1% demulsifier, 0.05% ammonium persulfate, mix well and then add 0.25% cross-linking agent, after stirring for 2.5 minutes, an adjustable jelly fracturing fluid can be formed.)

[0049] Wherein the crosslinking agent is composed of: organic aldehyde hexamethylenetetramine 0.5%, organic phenol resorcinol 0.05%, organic alcohol isopropanol 5%, organic acid sulfamic acid 0...

Embodiment 2

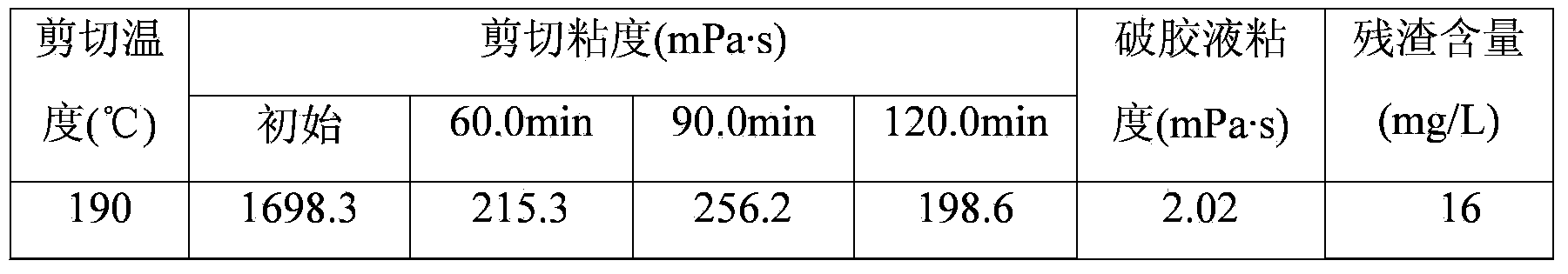

[0056] Synthetic polymer (prepared by reacting acrylamide and 2-acrylamide-2-methylpropanesulfonic acid at a mass ratio of 1:1 at 12°C for 4 hours, with a viscosity average molecular weight of 6.75 million) 0.8%, cross 0.25% of joint agent, 0.2% of lauryl ammonium chloride, 0.1% of demulsifier SP169, 0.05% of ammonium persulfate and the rest of the water prepare the ultra-high temperature fracturing fluid of the present invention (preparation method: add 0.8% synthetic Polymer thickener, stirred at 400r / min for 1 hour to form a uniform polymer aqueous solution; 0.2% lauryl ammonium chloride, 0.1% demulsifier, 0.05 % ammonium persulfate, mix well and then add 0.25% cross-linking agent, after stirring for 3.5 minutes, an adjustable jelly fracturing fluid can be formed.)

[0057] Wherein the crosslinking agent is composed of: 0.5% formaldehyde, 0.05% resorcinol, 5% n-butanol, 0.5% acetic acid, and the balance is water, prepared according to the following steps:

[0058] Add orga...

Embodiment 3

[0064] Synthetic polymer (prepared by reacting acrylamide and 2-acrylamide-2-methylpropanesulfonic acid at a mass ratio of 1.8:1 at 12°C for 4 hours, with a viscosity average molecular weight of 6.15 million) 0.8%, cross 0.25% of joint agent, 0.2% of lauryl ammonium chloride, 0.1% of demulsifier SP169, 0.3% of ammonium persulfate and the rest of the water prepare the ultra-high temperature fracturing fluid of the present invention (preparation method: add 0.8% synthetic Polymer thickener, stirred at 400r / min rotating speed for 1.5 hours to form a uniform polymer aqueous solution; in the uniform polymer aqueous solution, add 0.2% lauryl ammonium chloride, 0.1% demulsifier, 0.3 % ammonium persulfate, mix well and then add 0.25% cross-linking agent, after stirring for 4 minutes, an adjustable jelly fracturing fluid can be formed.)

[0065] Wherein the cross-linking agent is composed of: 0.5% of paraformaldehyde, 0.05% of resorcinol, 5% of isopropanol, 0.5% of formic acid, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com