Solidified water temporary plugging well-killing working fluid and preparation method and draining method thereof

A technology of solidifying water and working fluid, applied in the field of drilling fluid research, which can solve the problems of poor reservoir protection performance and coexistence of gas well collapse and leakage, and achieve the effects of great environmental protection, reduced formation damage, and high anti-swelling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

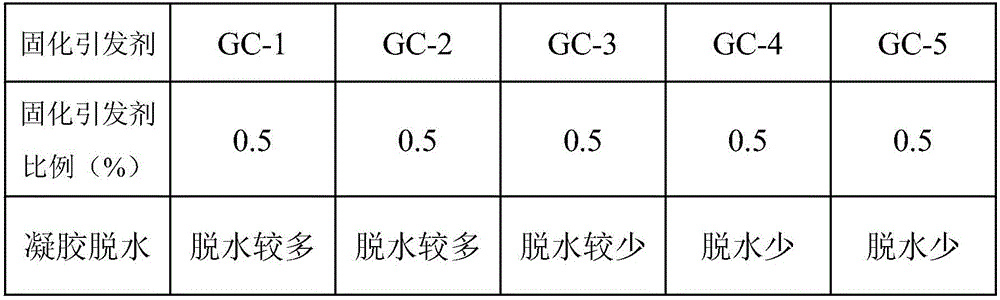

[0030] In order to overcome the problems of co-existence of collapse and leakage and poor reservoir protection performance during gas well construction in Longdong area, the invention provides a solidified water temporary plugging and well killing working fluid, which includes 10-40% solidified water system and 60-90% % anti-swelling stabilizing liquid, the solidification water system is composed of the following components according to the following mass percentage: 1.1-1.5% main agent, 0.3%-0.5% curing initiator, and the balance is water.

[0031] The preparation method of the above-mentioned solidified water temporary plugging and killing working fluid comprises the following steps:

[0032] 1) Take the main agent of formula quantity;

[0033] 2) take the curing initiator and anti-swelling agent of formula quantity;

[0034] 3) Pour the formula amount of clear water into the container, add the formula amount of main agent and curing initiator in sequence, and stir evenly t...

Embodiment 2

[0038] On the basis of Example 1, a solidified water temporary plugging and killing fluid includes a solidified water system and an anti-swelling stabilizing fluid. The injection amount of the liquid accounts for 60% to 90% of the wellbore volume, and the solidified water system is composed of the following components in the following mass percentages: 1.1% to 1.5% of the main agent, 0.3% to 0.5% of the curing initiator, and the balance is water; the main agent is a polyacrylate modified water-absorbent resin grafted with hydroxyethyl cellulose, and the grafting rate of hydroxyethyl cellulose is 20-40%, and the preparation method of the modified water-absorbent resin includes the following Steps: a) Dissolve 10-15g of hydroxyethyl cellulose in 50-75ml of distilled water, add 150ml of dispersion medium and 7.5ml of dispersant while stirring; b) slowly add 150-350ml of polyacrylate neutralizing solution, 0.5 g initiator and 10-15g cross-linking agent, heat up to 65°C, and react ...

Embodiment 3

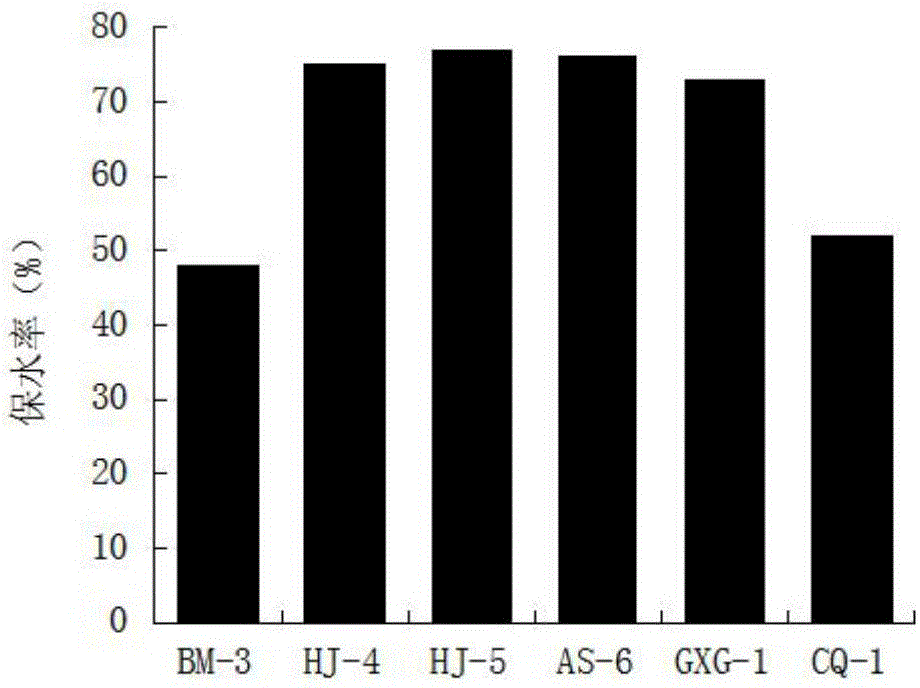

[0065] This example provides a low-damage solidified water temporary plugging and well killing working fluid. Polyacrylate-modified water-absorbing resin-20 grafted with hydroxyethyl cellulose is selected as the main agent; triethanolamine is used as the curing initiator, and high-efficiency clay Anti-swelling agent S-403 is used as an anti-swelling agent, and it is formulated into an anti-swelling stable liquid with a mass percentage of 1%. The high-efficiency clay anti-swelling agent S-403 is an existing product, purchased from Shengdu Petroleum, Dongying City Technology Co., Ltd.; take 98% of clear water into the container, add the above-mentioned 1.5% of the main agent and 0.5% of the curing initiator in turn, and stir evenly to obtain the solidified water system. The dosage of the solidified water system is 3-5m 3 , the amount of anti-swelling stabilizer is 20-40m 3 It is the temporary plugging and killing fluid for the required solidified water.

[0066] Experiments sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com