Patents

Literature

32results about How to "Reduce plugging costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

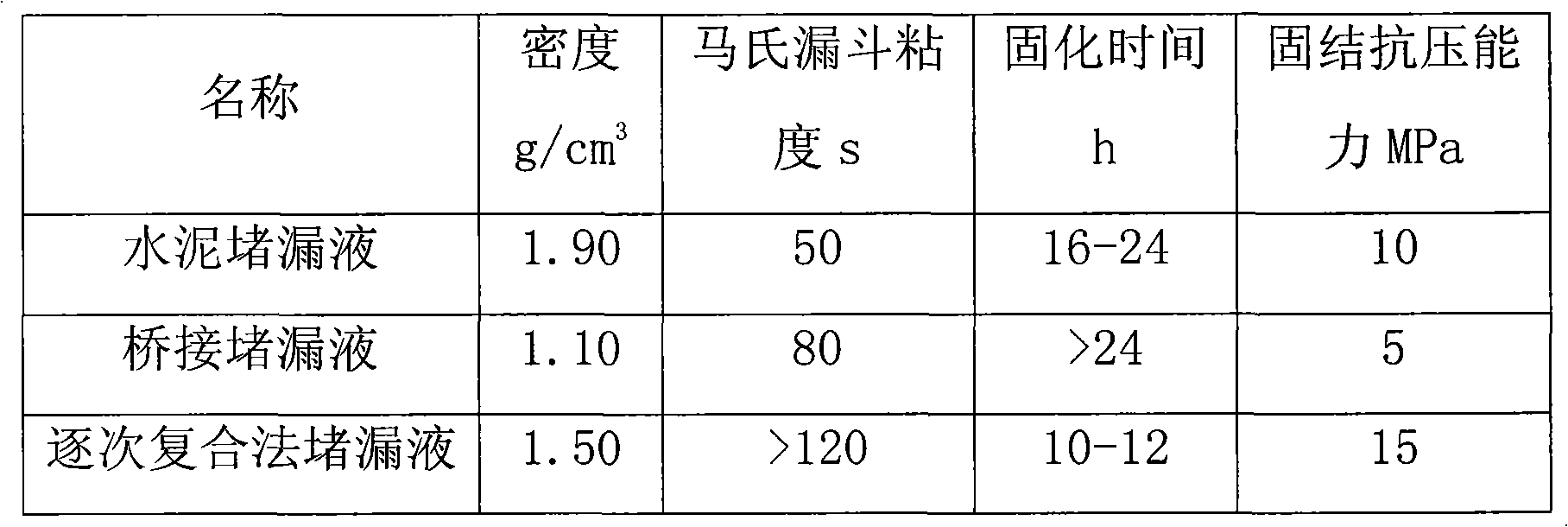

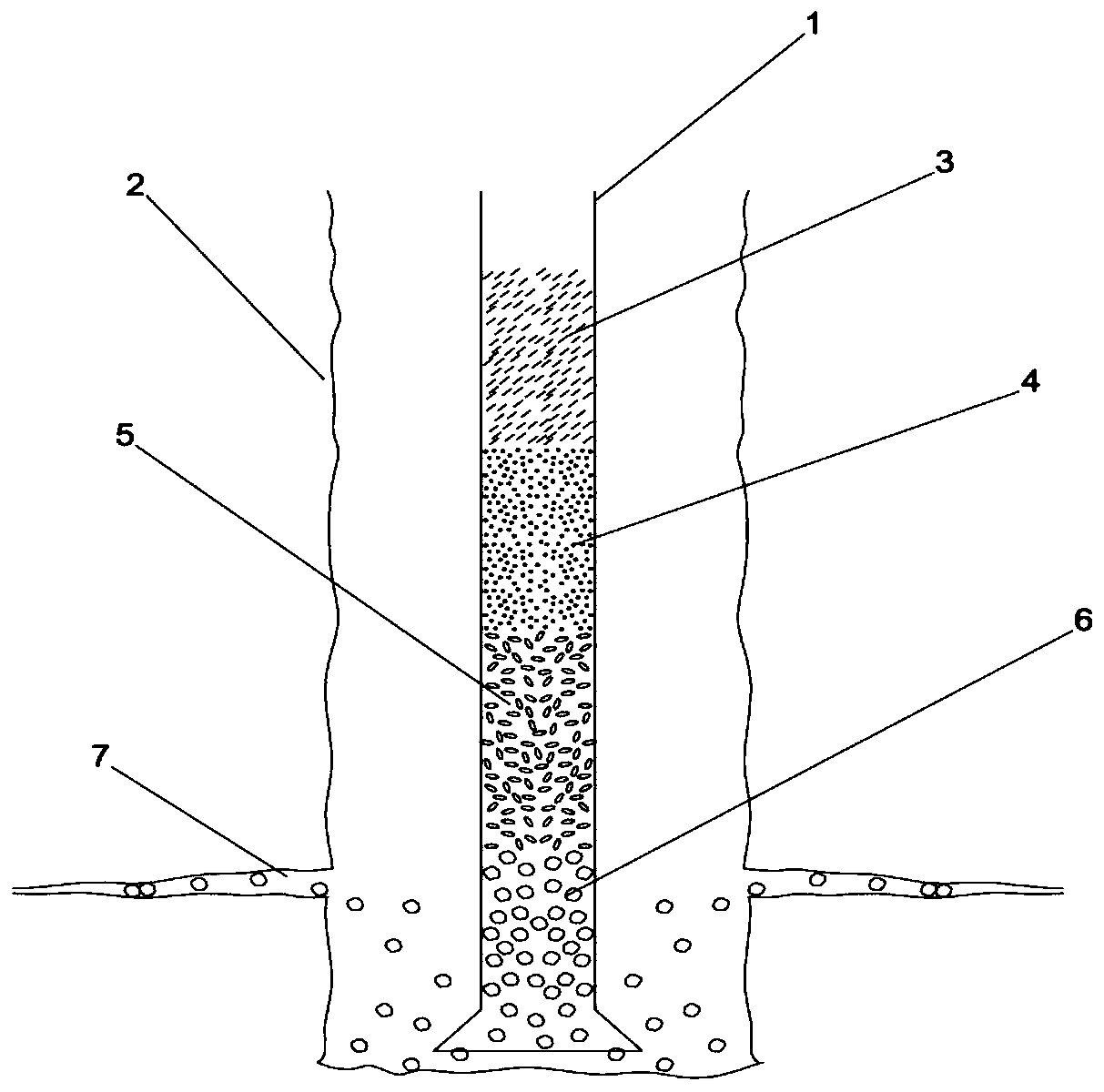

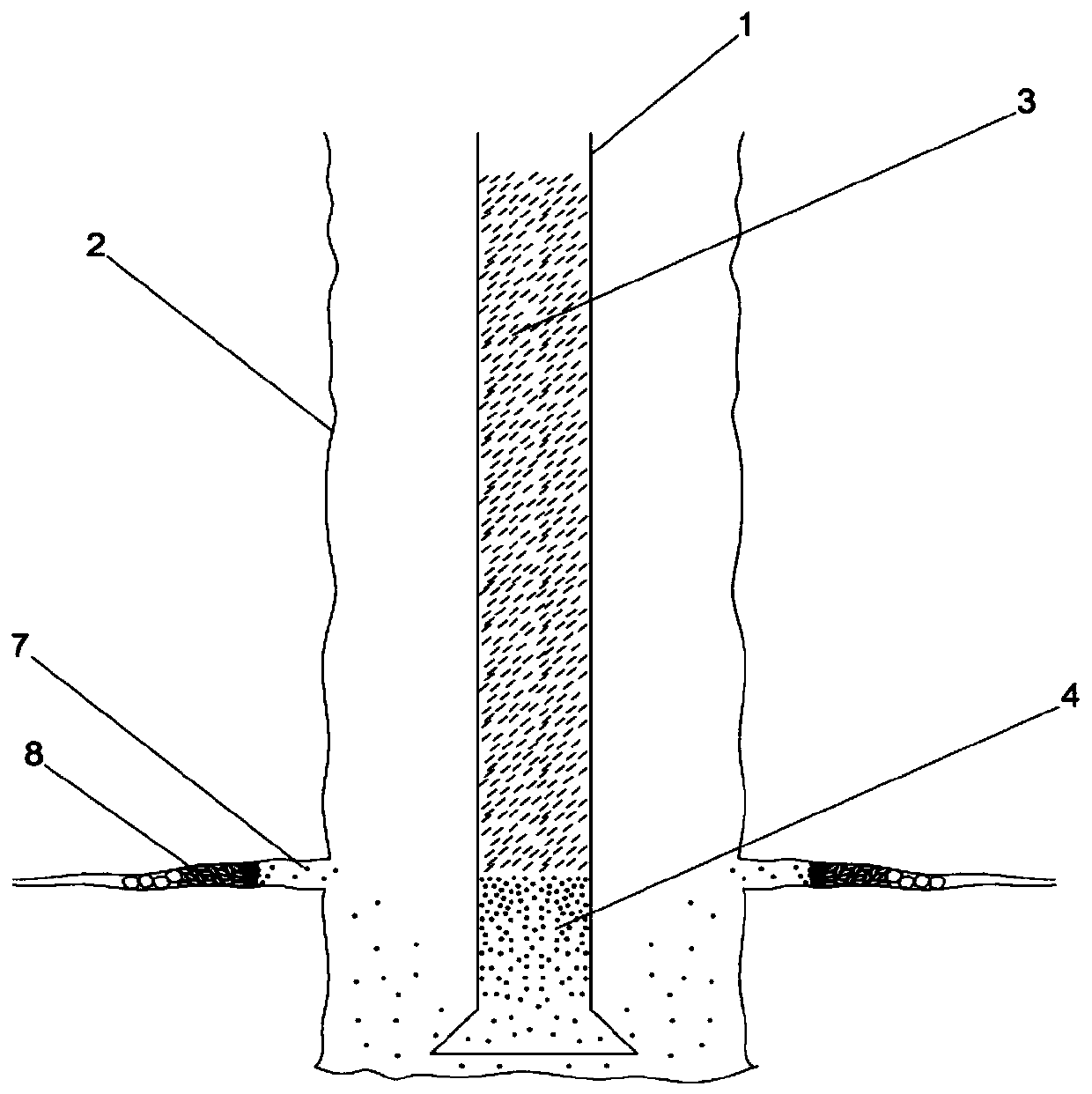

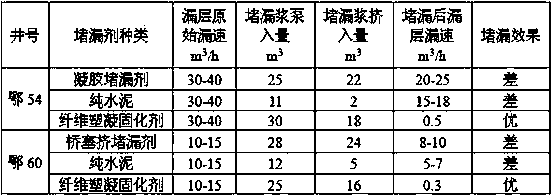

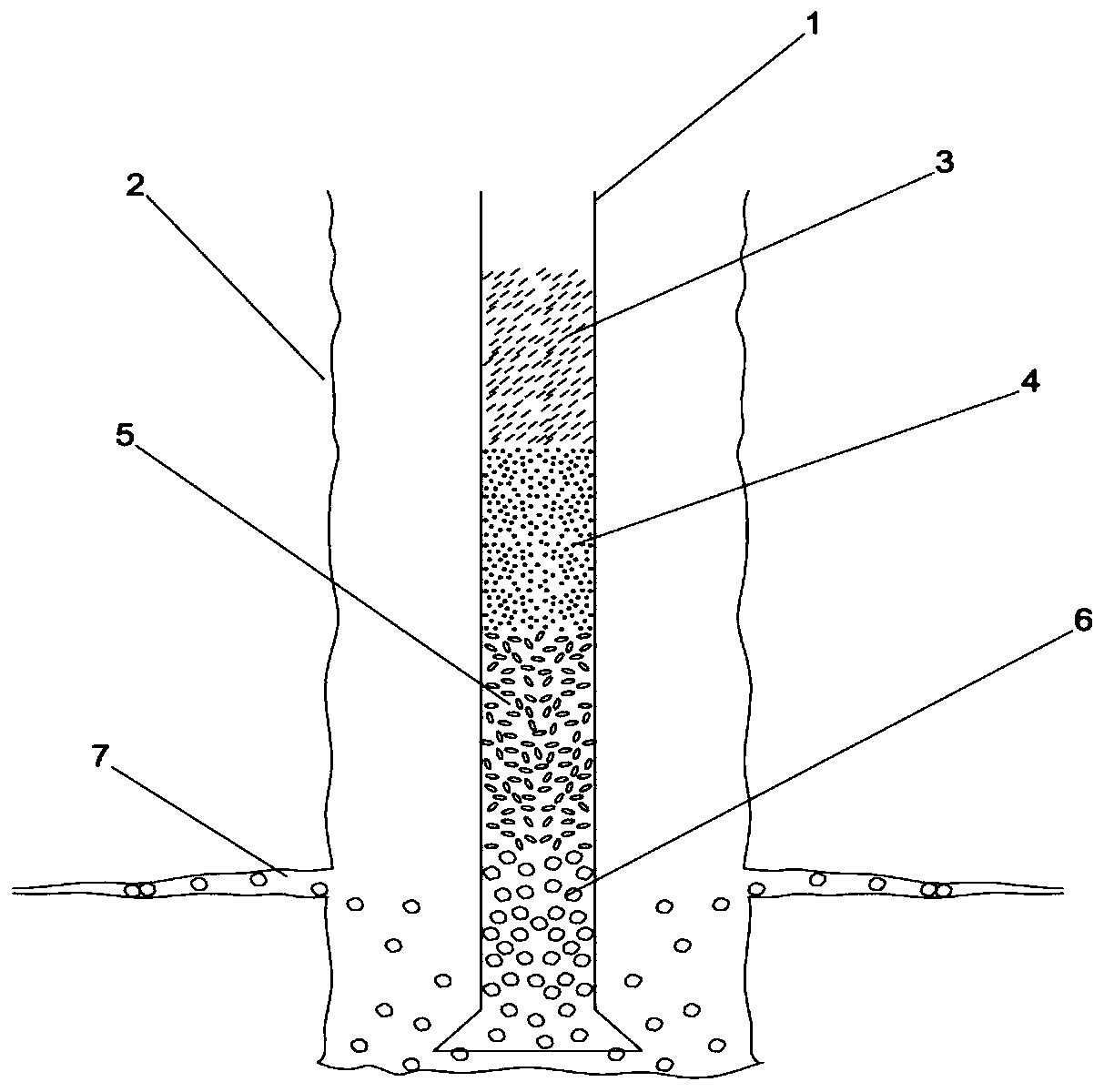

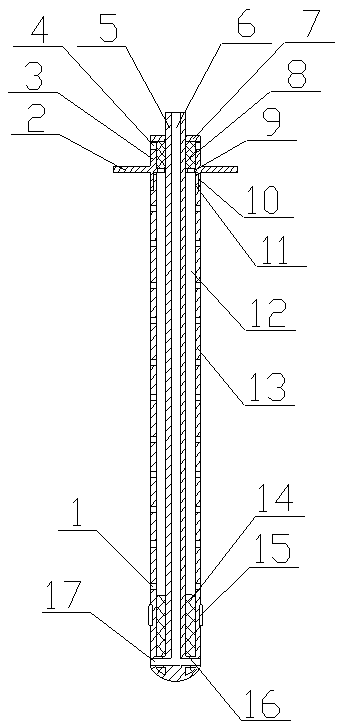

Successive-compounding-process based plugging method for well drilling

InactiveCN102434124AImprove pressure bearing capacitySolve the problem of low plugging success rateDrilling compositionSealing/packingWell drillingPorous medium

The invention discloses a successive-compounding-process based plugging method for well drilling. In the plugging method, a well-cementing cement pump or a mud pump is used for pumping two or more than two kinds of plugging fluids with different components and properties into an underground leakage zone successively in proportion. By means of the plugging method, the applicable range of the plugging fluids can be broadened, the loading capacity of a barefoot interval stratum can also be greatly increased, and the problem of low plugging success rate can be solved. According to the plugging method, a retention layer can be formed in porous media; the purpose of increasing the loading capacity and compressive strength of the stratum can be achieved by compounding the plugging fluids with different components and different properties; in addition, the construction process is simple, the plugging success rate is high, and the well drilling cost is effectively reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

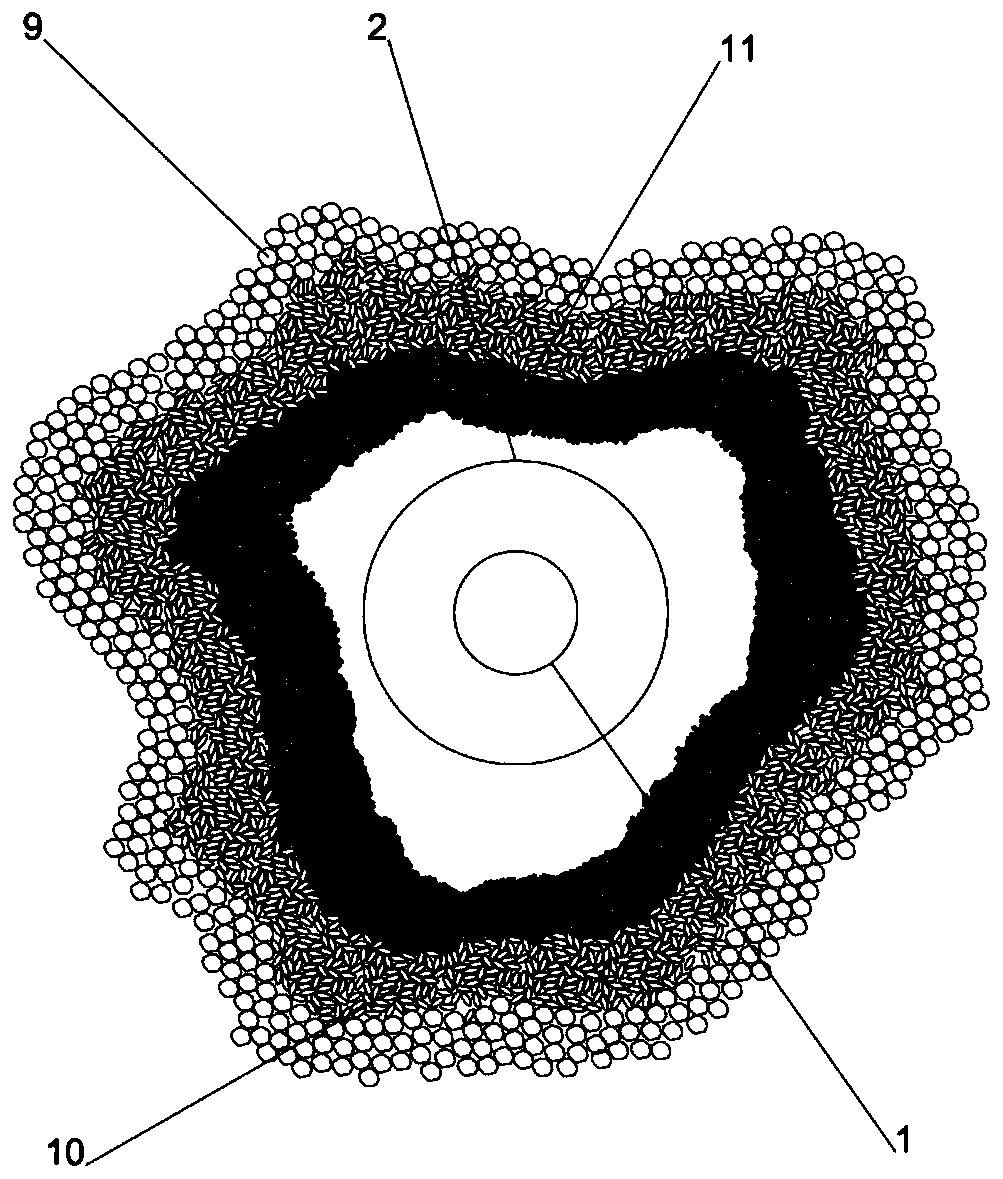

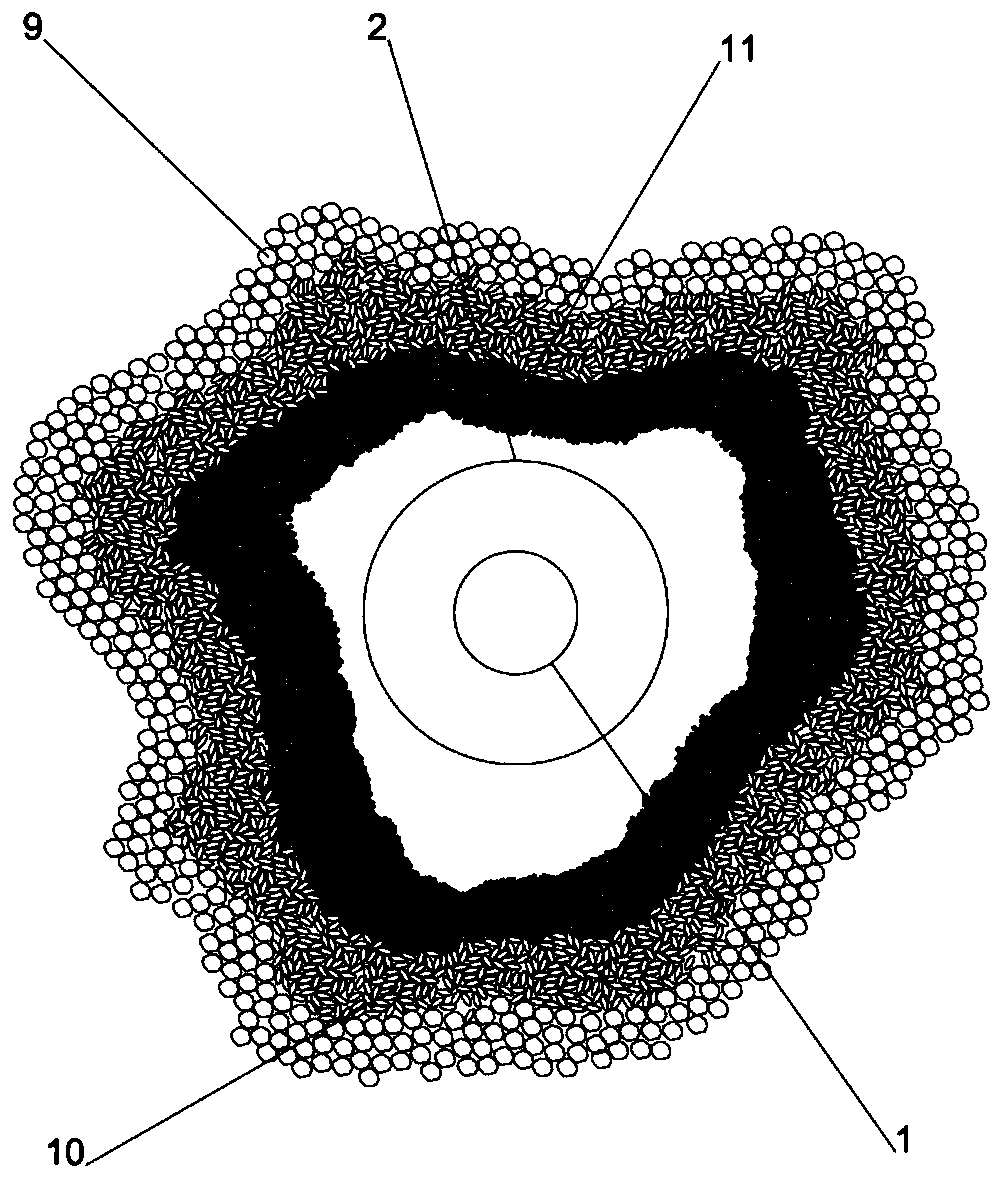

Multistage plug classification plugging method suitable for fissured stratum

The invention relates to a multistage plug classification plugging method suitable for a fissured stratum. The multistage plug classification plugging method includes the steps that first, the averageopening of fissures in the periphery of a well is determined to be D, bridging particles with the particle size being slightly smaller than D are used in first-stage plugging, the average particle size of the bridging particles is denoted as D<1>, the average particle size D<2> of plugging particles used in second-stage plugging is larger than D<1> / 4, and smaller than D<1>, and the particle sizeof each of the following stages of the plugging particles is successively determined through the same method until the average particle size D<n> of the last stage of the plugging particles is small enough to form a dense sealing layer; second, plugging grout only containing the bridging particles with the average particle size being D<1> is first injected through slugs to form a bridging particlelayer; third, plugging grout containing the plugging particles with the average particle size being D<2>-D<n-1> is injected in several times through a plurality of slugs to form a particle filling layer; and fourth, plugging grout with the average particle size of the plugging particles being D<n> is finally injected through the slugs to form the dense sealing layer. According to the multistage plug classification plugging method suitable for the fissured stratum, the principle is reliable, the fissures in the periphery of the well are more effectively sealed, the cost is saved, and the broadapplication prospects are achieved.

Owner:SOUTHWEST PETROLEUM UNIV

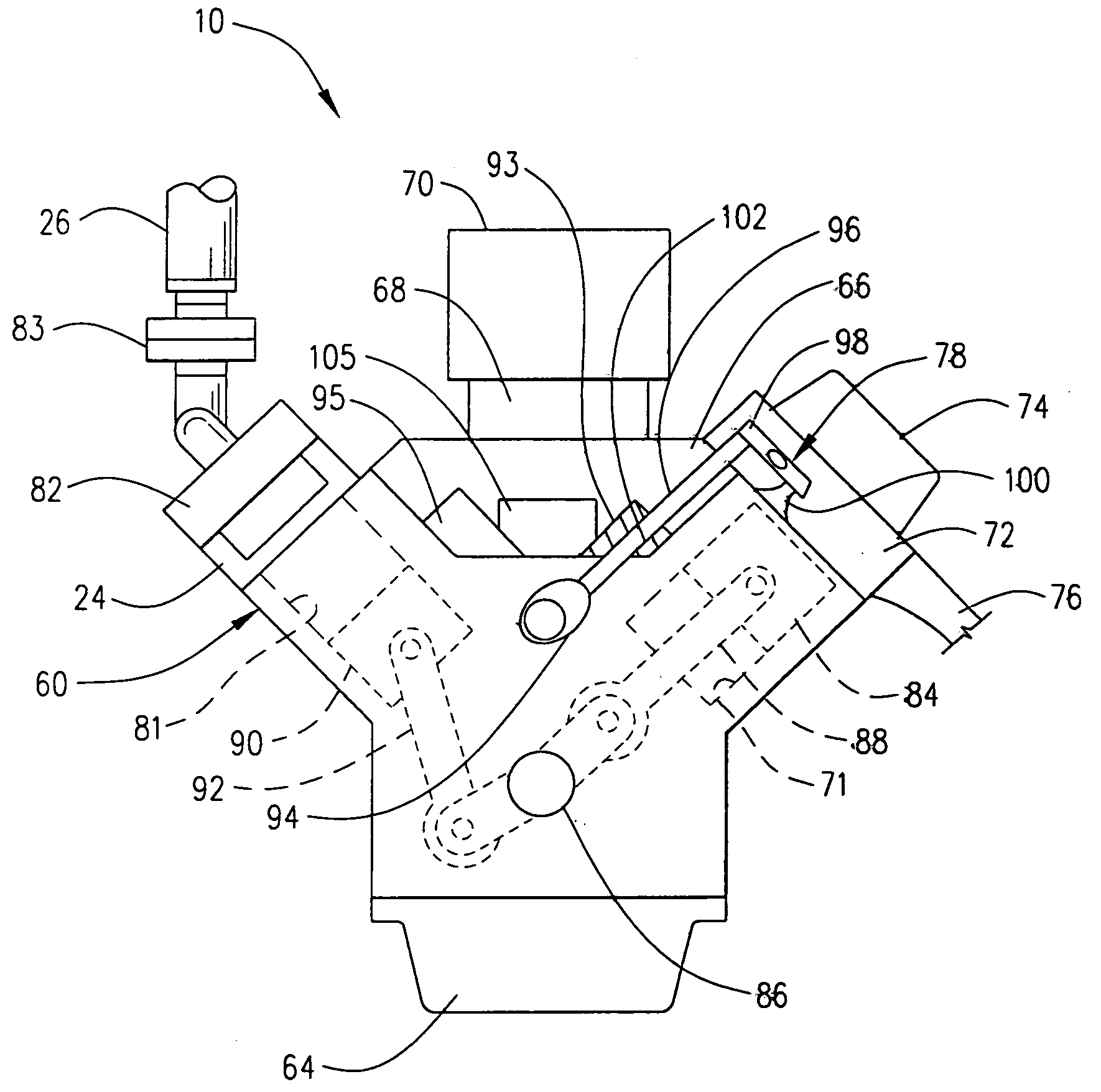

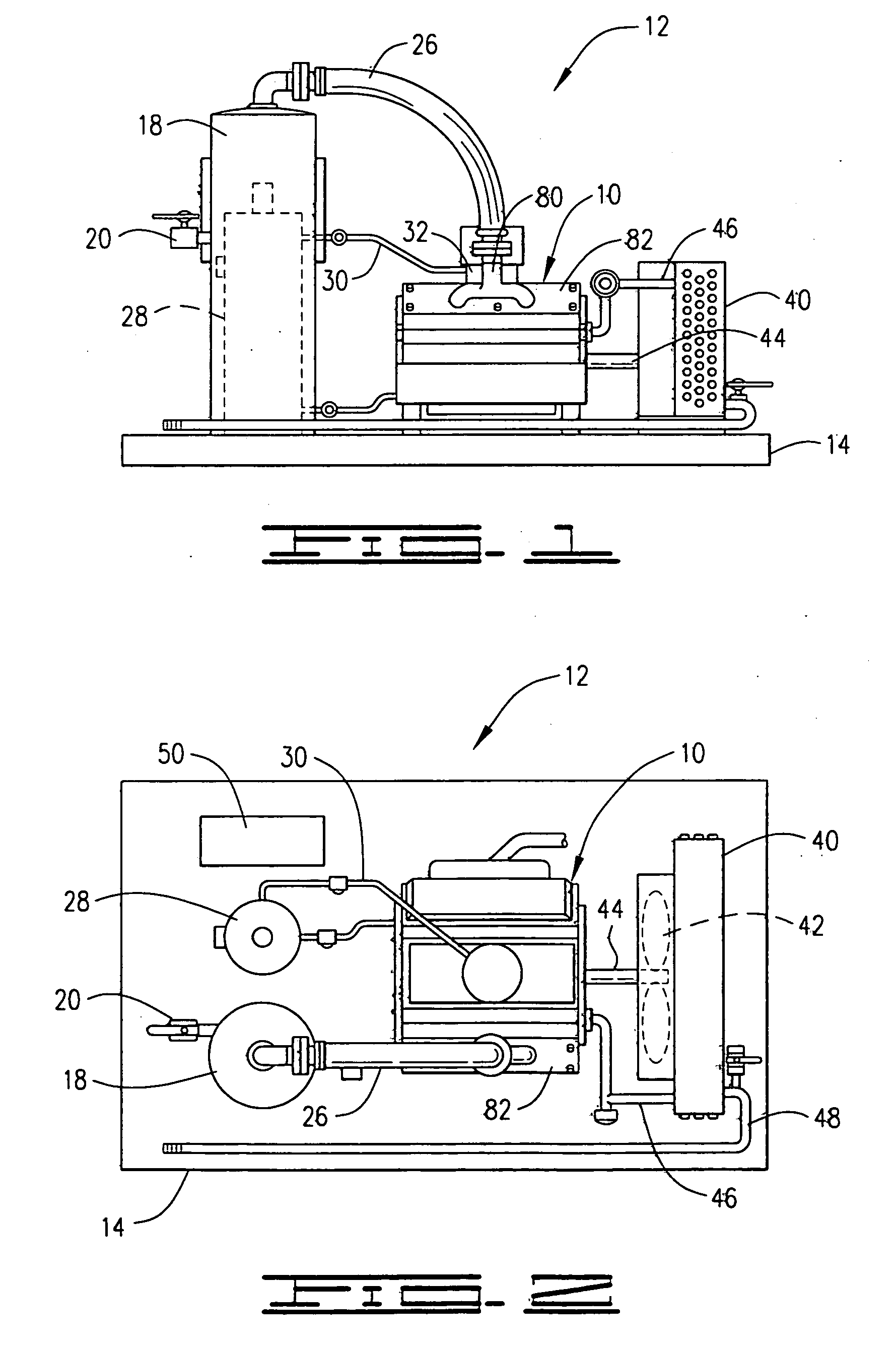

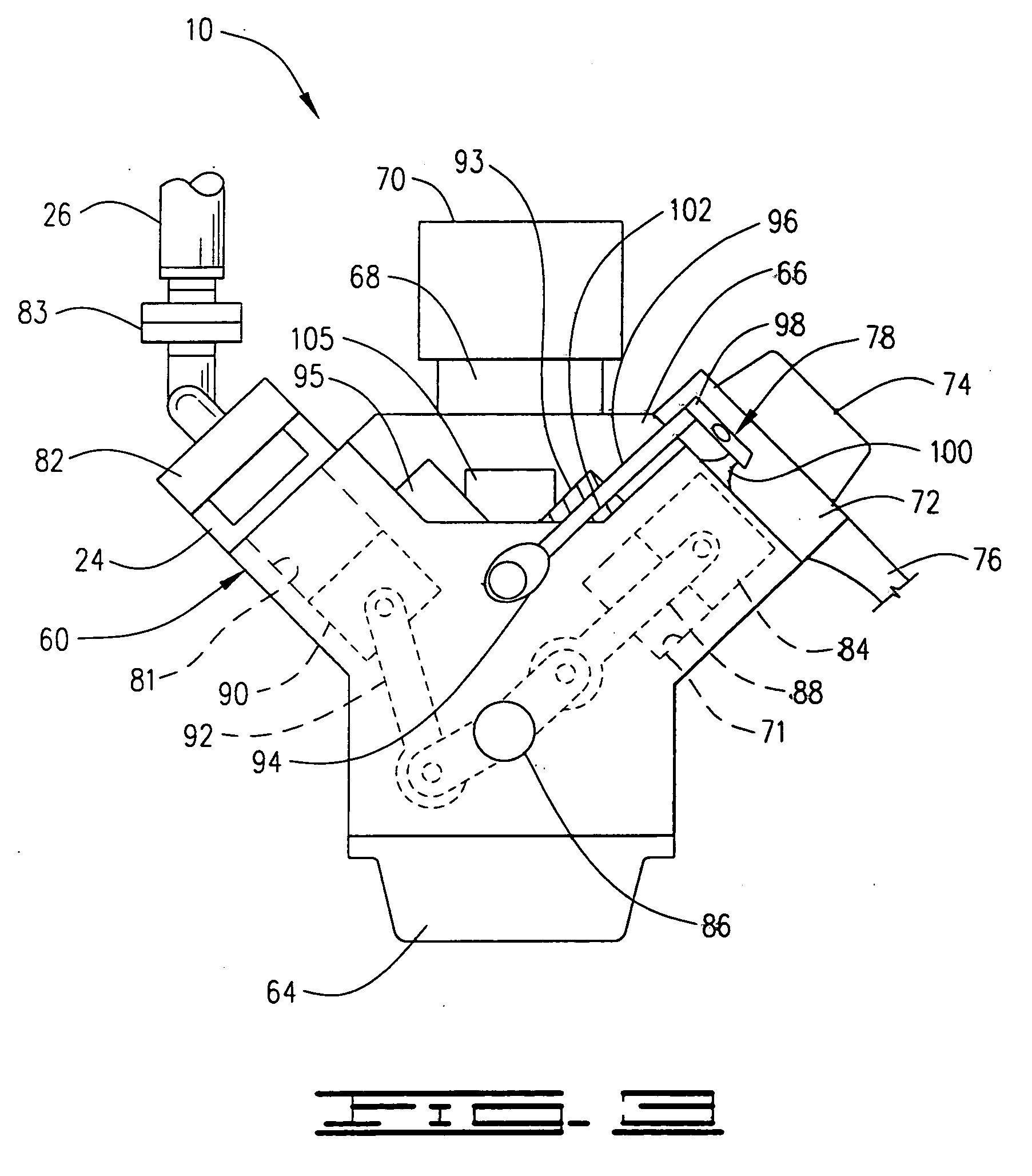

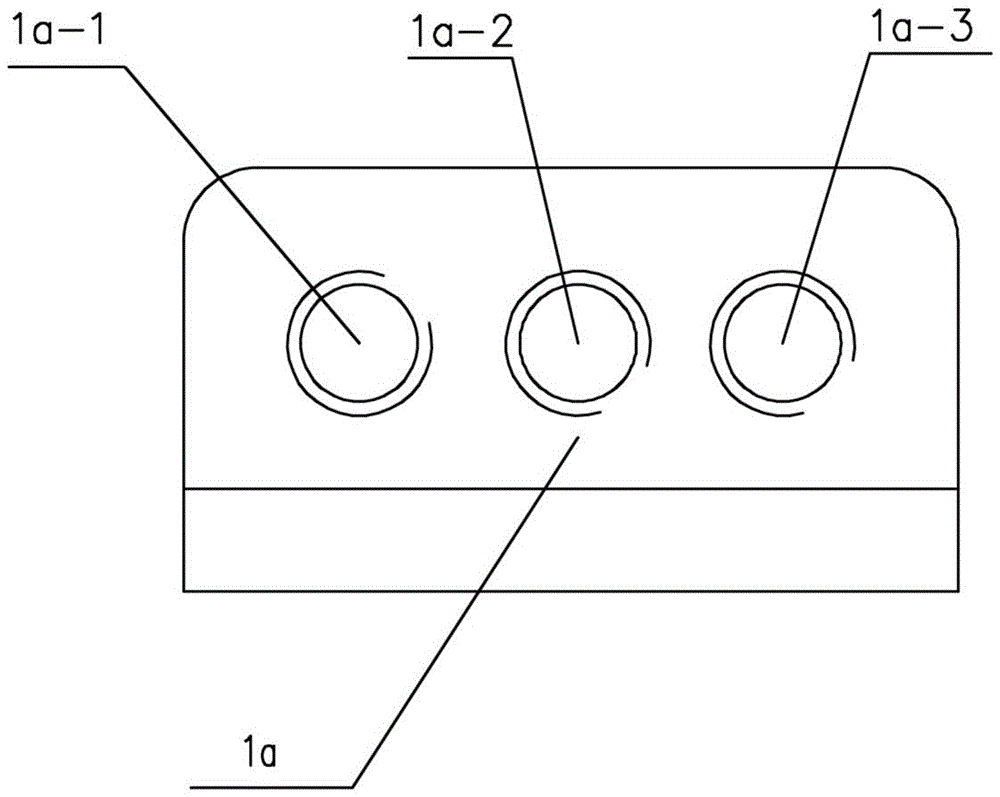

Cylinder block for integral gas compressor and internal combustion engine

InactiveUS20070079778A1Reduce plugging costsLow costCasingsCombustion enginesGas compressorExternal combustion engine

A cylinder block for an integral gas compressor and internal combustion engine. The cylinder block has a bank of compressor cylinders and a bank of engine cylinders, such as in a V-shaped configuration. Valve train openings are machined into the cylinder block adjacent to the engine cylinders so that engine valve train components, such as push rods, may be disposed therein. No valve train openings are machined into the cylinder block adjacent to the compressor cylinders; the block is left solid. A compressor utilizing the cylinder block is also disclosed.

Owner:COMPRESSCO INC

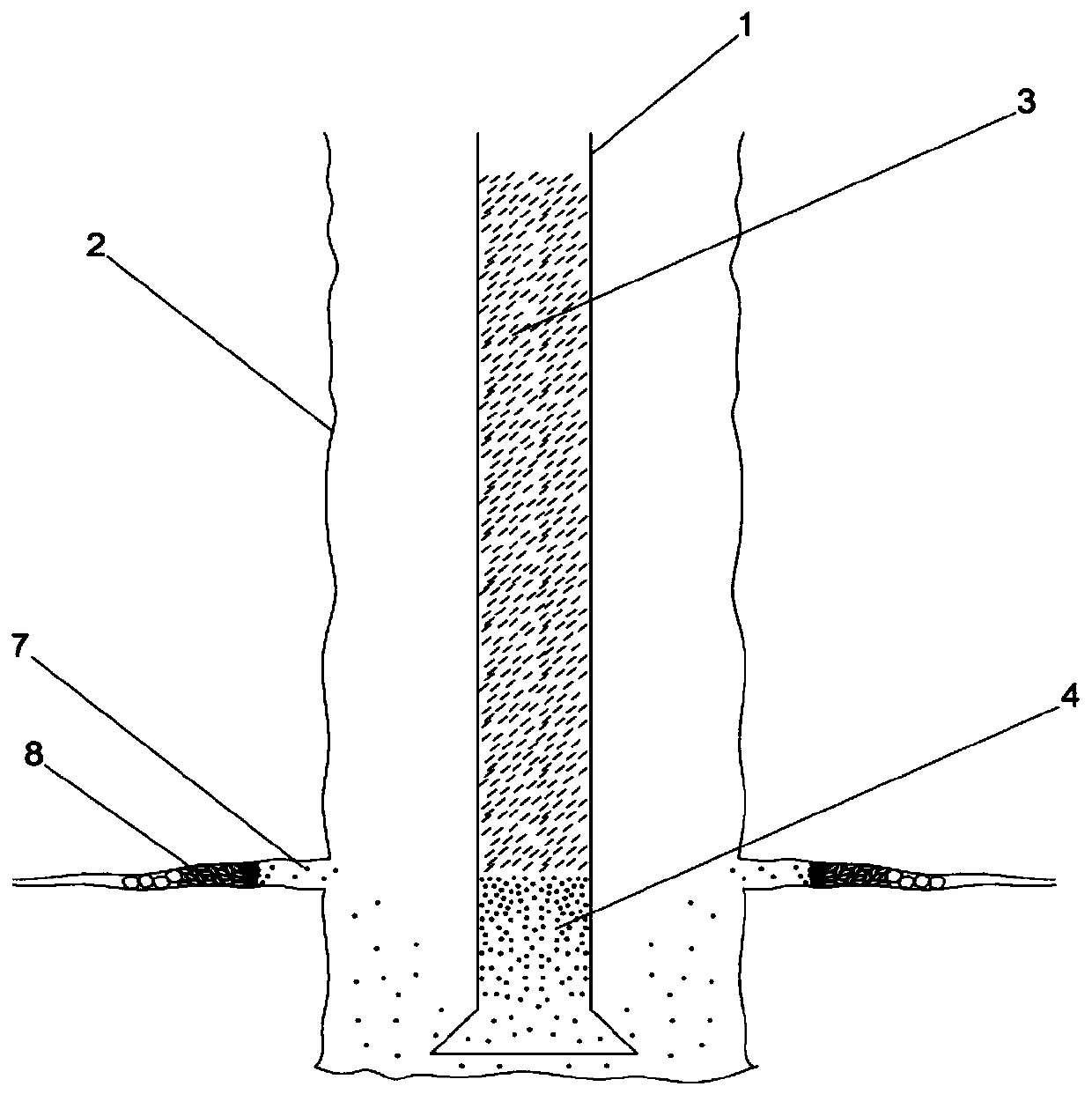

Plugging slurry for enhancing pressure-bearing capacity of leakage formation and preparation method thereof

ActiveCN106566499ASolve the problem of not being able to prepare plugging slurry with drilling team equipmentImprove pressure bearing capacityDrilling compositionSealing/packingFiberWell drilling

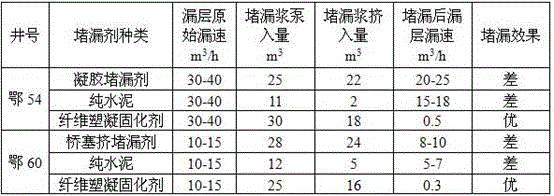

The invention provides plugging slurry for enhancing pressure-bearing capacity of leakage formation. The plugging slurry is composed of the following substances (by weight): 55-60% of a curing agent for fiber coagulation, 1-2% of asphalt powder for well drilling, 0.05-0.1% of an oil well cement defoamer and 38-45% of water. The invention also provides a plugging method capable of enhancing pressure-bearing capacity of leakage formation during petroleum drilling process. The method has a good plugging effect on medium and large-scale lost circulation and meets requirements of drilling construction and environmental protection. The plugging technology requires fewer types of chemical materials, and the method for preparation of the plugging slurry is simple. A pressure-bearing squeeze plugging method has strong operationality. The product has a good effect of plugging fractures and pores of a leakage zone and can obviously reduce lost circulation velocity of the leakage zone. Plugging time is greatly shortened and plugging cost is greatly reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

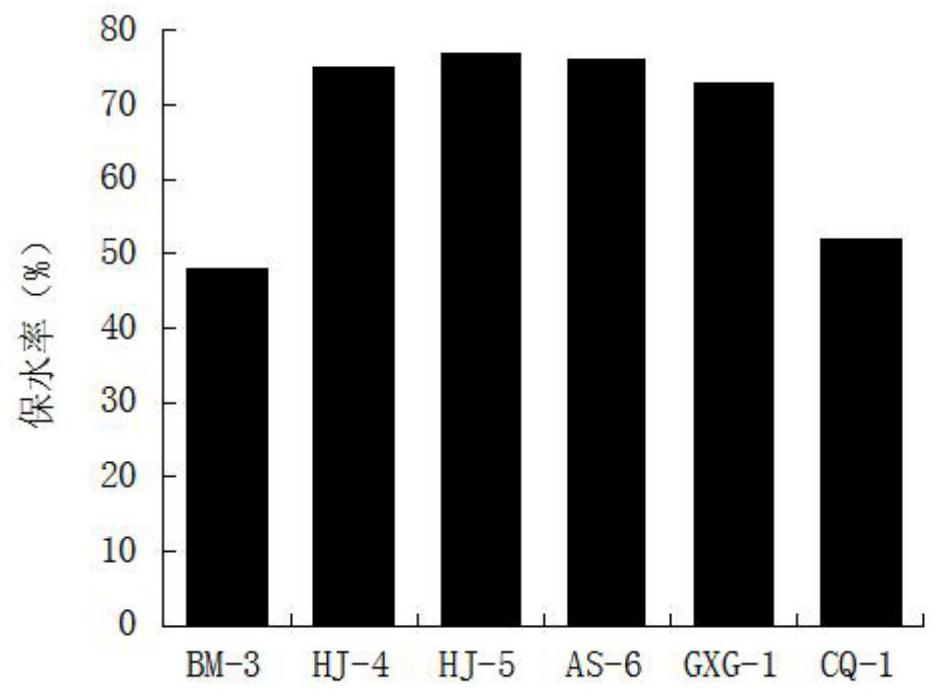

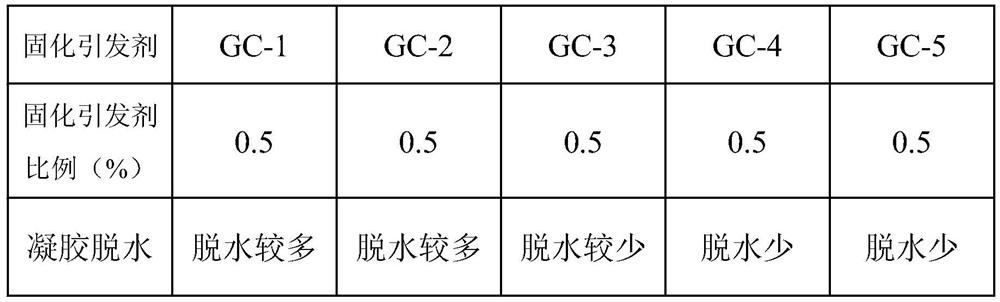

Solidified water temporary plugging well-killing working fluid and preparation method and draining method thereof

ActiveCN106833572AEasy to prepareSimple preparation processDrilling compositionSealing/packingWell killWorking fluid

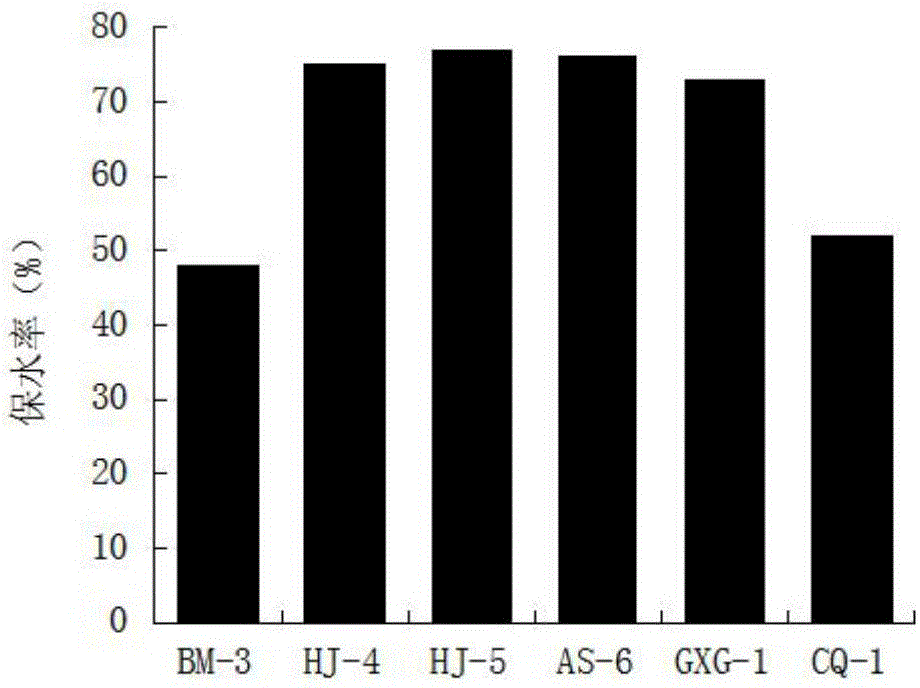

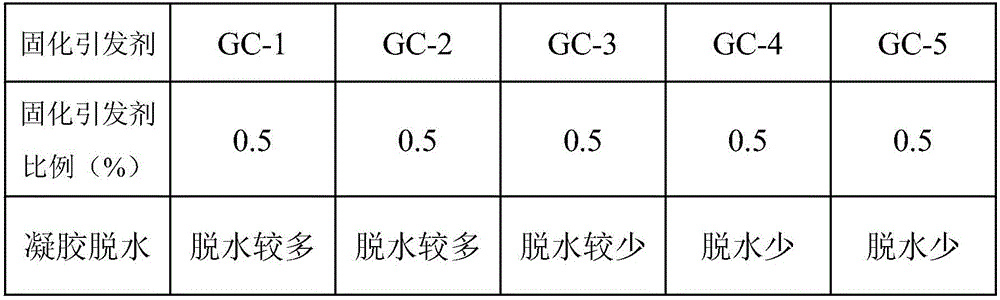

The invention provides solidified water temporary plugging well-killing working fluid. The solidified water temporary plugging well-killing working fluid is prepared from 10 to 40 percent of solidified water system and 60 to 90 percent of anti-swelling stabilizing fluid, wherein the solidified water system is prepared from the following components in percentage by mass: 1.1 to 1.5 percent of main agent, 0.3 to 0.5 percent of solidification initiator and the balance of water. The preparation method of the working fluid comprises the following steps: 1), taking the main agent in an amount determined in a formula; 2) taking the solidification initiator and the anti-swelling agent in amounts determined in the formula; 3) injecting clear water into a container in an amount determined in the formula, adding the main agent and the solidification agent initiator in amounts determined in the formula in sequence, and uniformly stirring to obtain the solidified water system; 4) adding the anti-swelling stabilizing fluid in an amount determined in the formula to obtain the solidified water temporary plugging well-killing working fluid. A draining method combining acidifying-demulsifying and liquid nitrogen drainage is adopted. The working fluid is simple in preparation process, a colloid protective agent is not needed, the plugging efficiency is increased greatly, the plugging cost is lowered, damage to strata is reduced, and the problems of coexistence of collapse and leakage and low reservoir protection performance in a gas well construction process are solved. The solidified water temporary plugging well-killing working fluid has important practical significance to increase of the oil gas exploration and development speeds.

Owner:PETROCHINA CO LTD

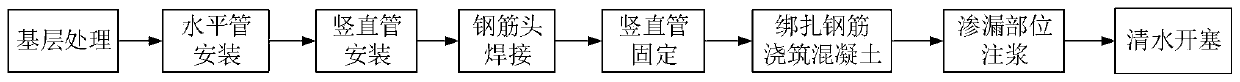

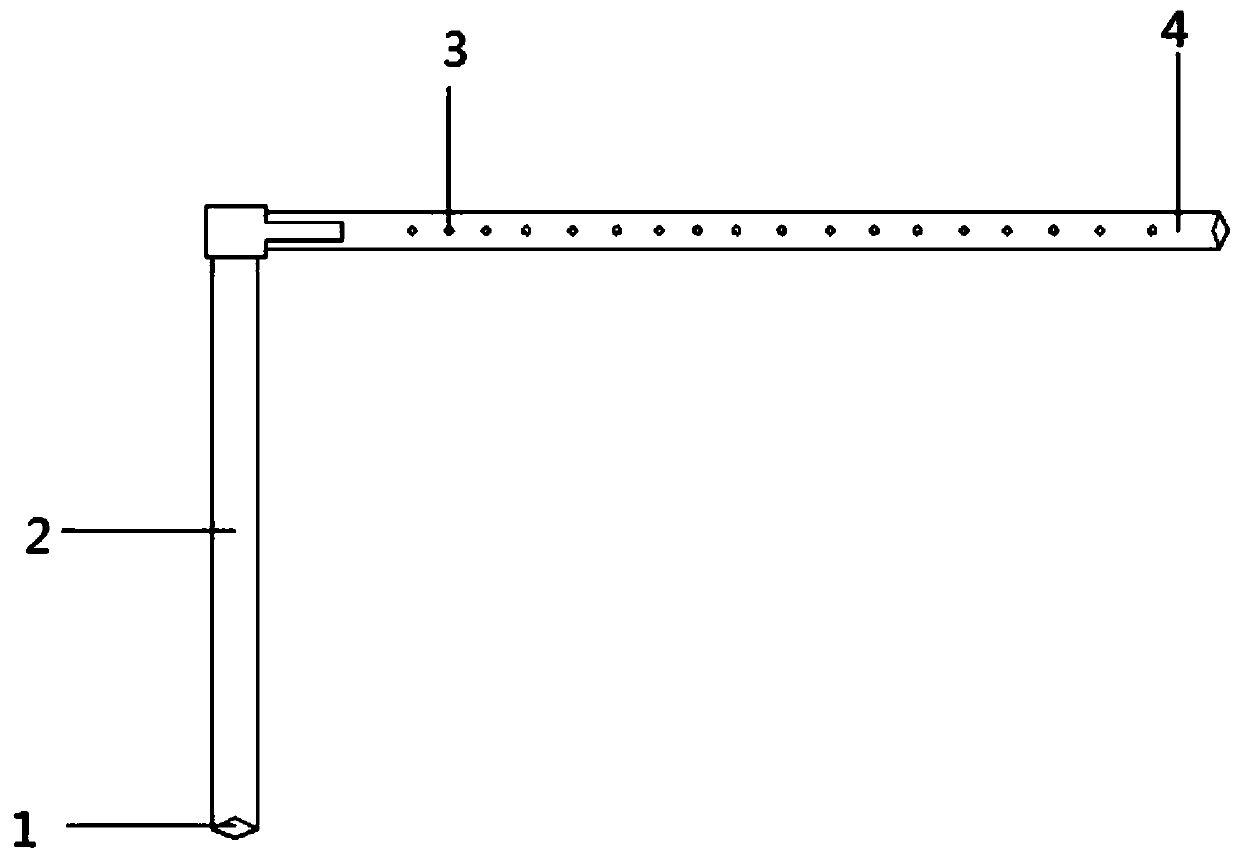

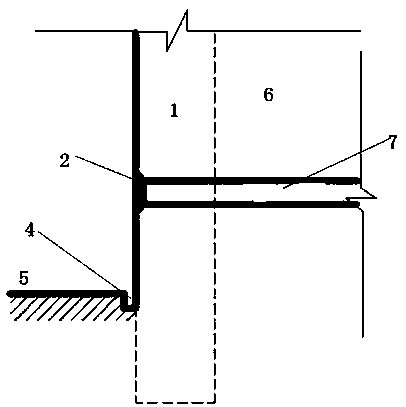

Anti-leakage construction method for foundation bottom plate, and building construction platform

InactiveCN109853629AAchieve the purpose of repeated useGuarantee the quality of pluggingArtificial islandsProtective foundationStructure of the EarthPlastic materials

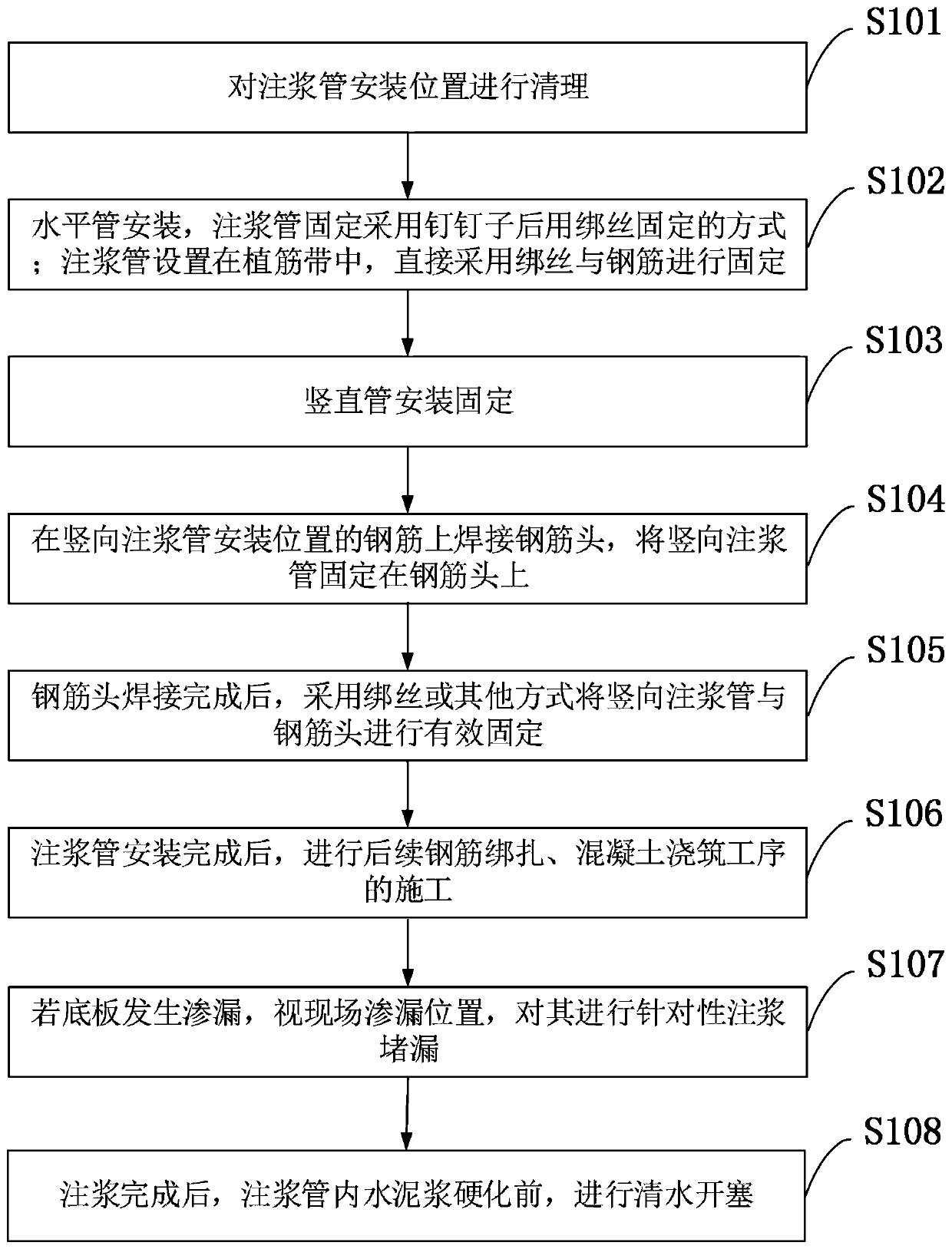

The invention belongs to the technical field of building construction, and discloses an anti-leakage construction method for a foundation bottom plate, and a building construction platform; before thebottom plate is poured, a horizontal grouting pipe is pre-embedded in a joint part of the bottom plate and an exterior wall, and then a vertical grouting mouth is left and placed on the upper portionof the foundation bottom plate; and leakage occurs on the bottom plate, grouting is performed on the inside of a reserved grouting mouth of a leakage part, after grout reaches the inside of the horizontal grouting pipe, the grout is grouted into a gap between the bottom plate and the exterior wall for plugging. After the grouting is completed, before cement slurry in the grouting pipe is hardened, a plug is opened with clean water, so that when the leakage occurs again in a later stage, the grouting can be performed again to achieve a purpose of repeated usage. Materials of the method and theplatform are plastic materials, are light and easy to fix, construction is performed before a reinforcing steel bar is bound, and a normal construction period is not completely affected; and the grouting pipe is simple in structure and low in cost, and economic benefit is good compared with other grouting leaking stoppage manners. If the leakage occurs on the bottom plate, the method performs targeted grouting and leaking stoppage, and is good in plugging effect.

Owner:ZHONGTIAN CONSTR GROUP

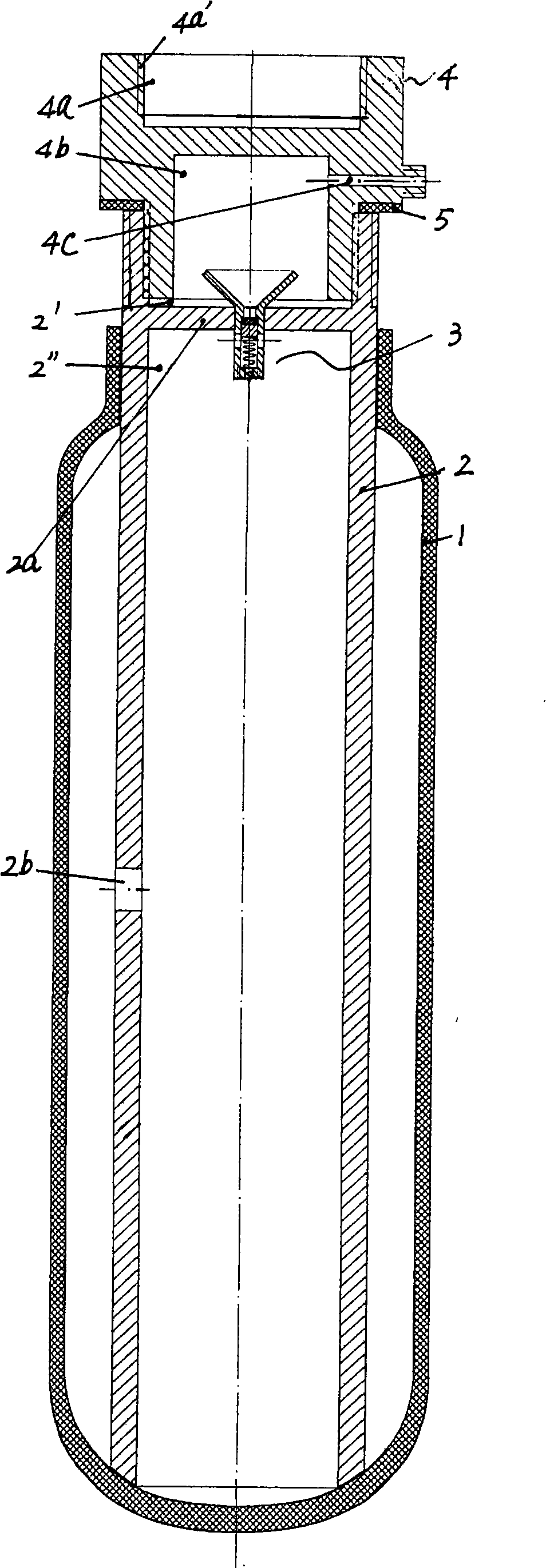

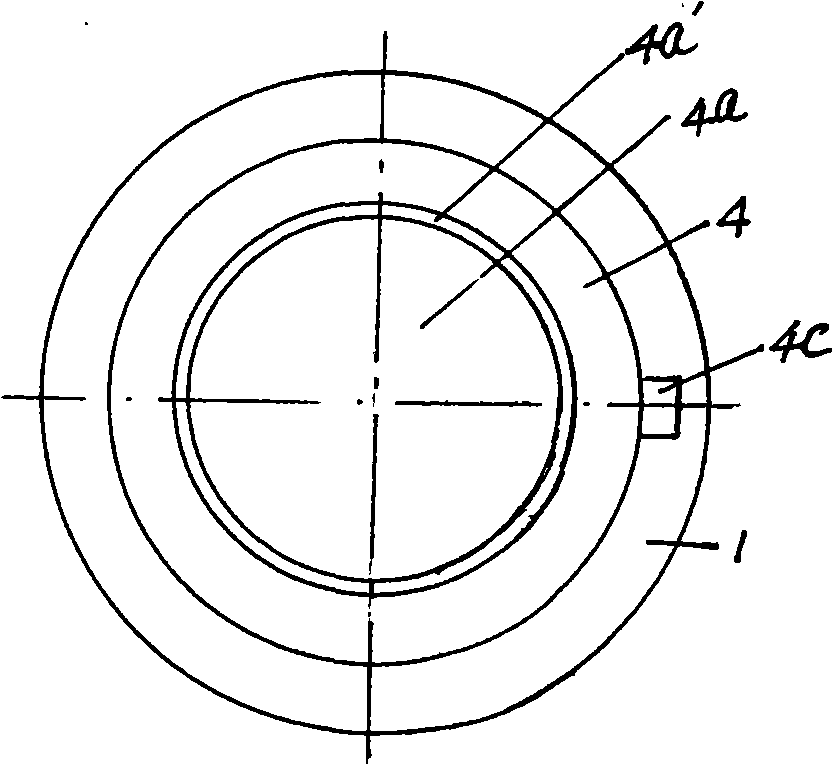

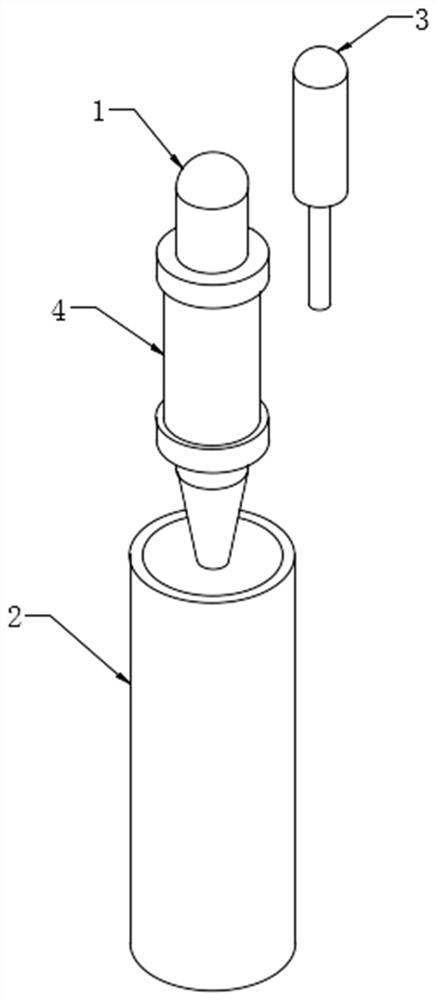

Quick plugging device

The invention discloses a quick sealer which is used for sealing a pipeline of an oil or gas well head and blowout and can be withdrawn conveniently if necessary afterwards to benefit the reuse of a well shaft. The quick sealer comprises an elastic air bag, a steel tube which is inserted into the air bag and connected on the opening end of the air bag by sealing, a clapboard which can divide the space of the steel tube into an upper space and a lower space which are not communicated with each other, a check valve which is provided for pressure air to enter the lower space of the steel tube from the upper space of the steel tube, and an air vent which can communicate the lower space of the steel tube and the air bag space; the outer tube wall and the inner tube wall of the steel bar, extending out of the air bag are both provided with screw sections and respectively connected with a jointer by screws; the jointer can be an air intake jointer or an air discharge joint. Therefore, the quick sealer solves the problems that damages to people and livestock exist in the implementation of the sealing by using a current combined sealing component only by a well killing method, the consumption of labor and materials and the loss of oil or gas are great, the pollution period is long, the pollution range is large, and the well shaft is not liable to repeated use after the sealing, etc.

Owner:寿国伟

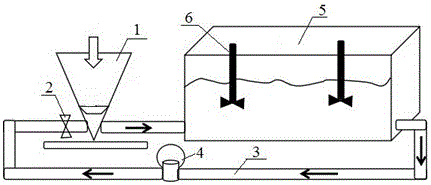

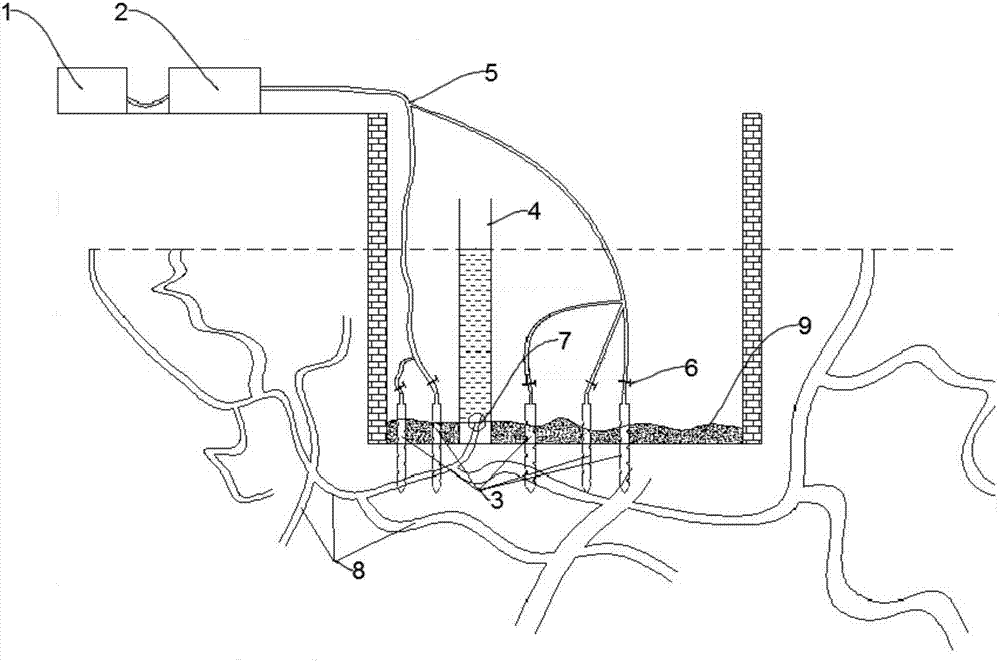

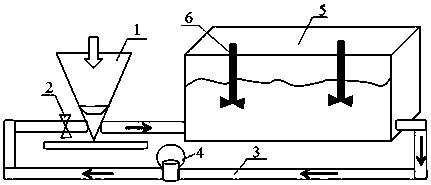

Karst area moving water treatment device and method

The invention relates to a karst area moving water treatment device and method. The device comprises a mixing machine, a grouting machine, grouting steel pipes and a hydraulic pressure balance pipe. The mixing machine is connected with the grouting machine. The grouting machine is connected with the multiple grouting steel pipes through grouting pipes. The grouting steel pipes are inserted into an excavated bedrock surface and used for injecting cement grout into karst pipelines. The hydraulic pressure balance pipe is inserted into a karst moving water outlet point in the excavated bedrock surface and used for balancing the hydraulic pressure. Compared with the practice that the grout is directly injected into the karst moving water outlet point, the karst area moving water treatment device and method have the advantages that the construction difficulty is lowered, the construction time is saved, and meanwhile, karst moving water overflowing can be fast stopped. In addition, the grout is greatly saved, the leaking stoppage cost is lowered, and the leaking stoppage effect is good.

Owner:NANCHANG RAILWAY ENG CO LTD OF CHINA RAILWAY 24TH BUREAU GRP CO LTD

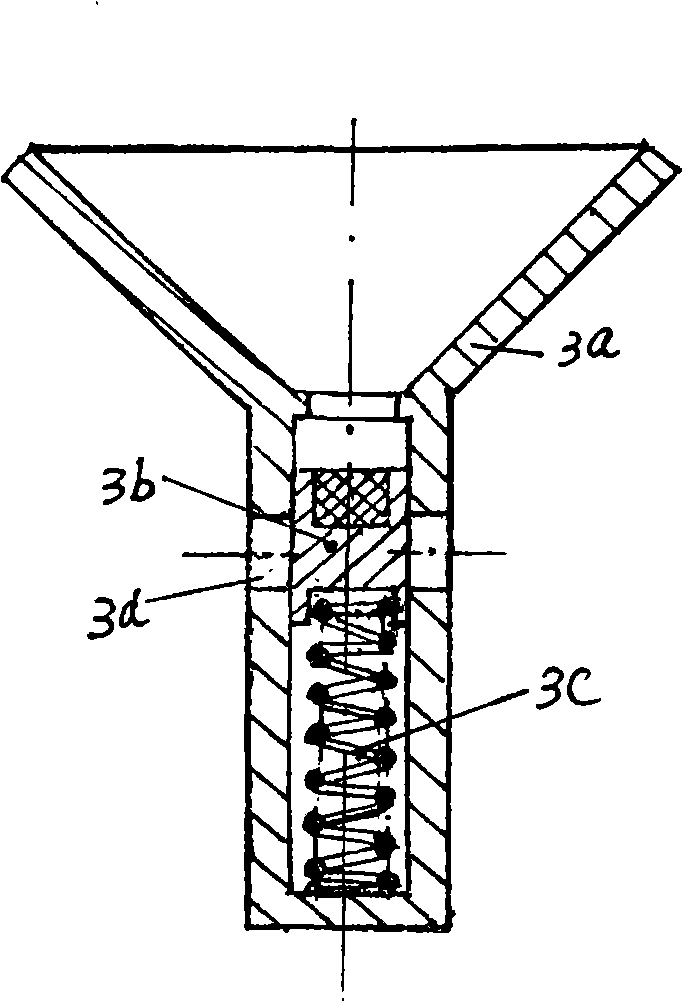

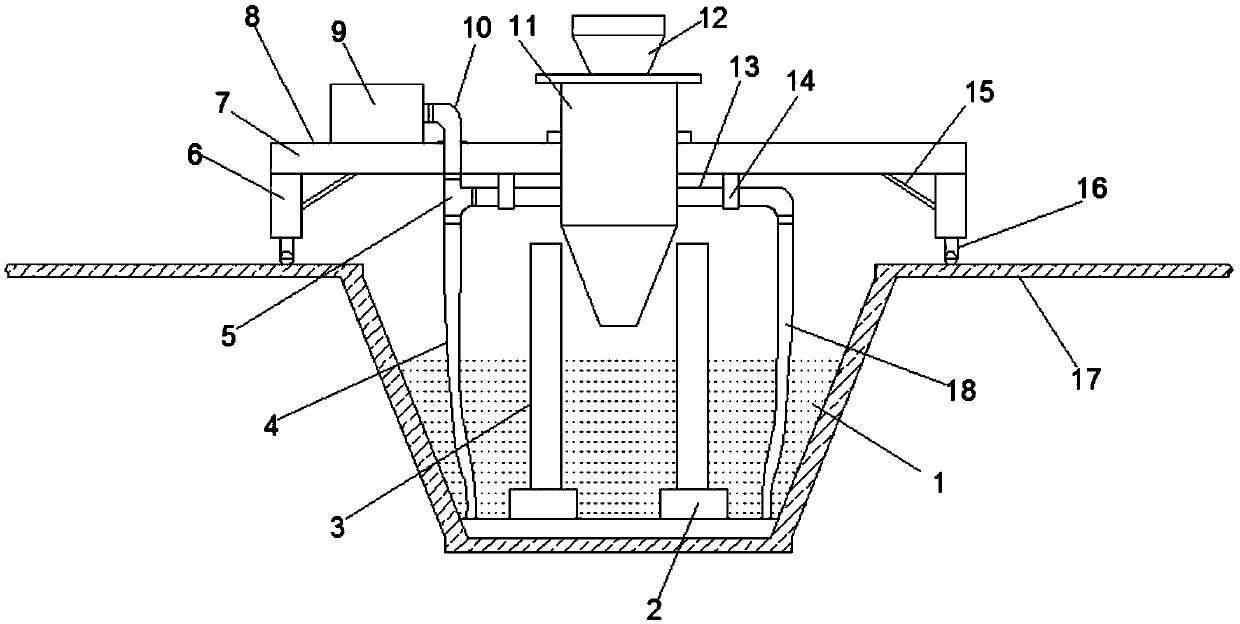

Civil engineering building backfilling device

PendingCN109537664AAvoid failureQuality improvementSoil-shifting machines/dredgersProtection layerBuilding construction

The invention discloses a civil engineering building backfilling device. The device comprises a foundation pit; a pair of bearing platforms are arranged at the bottom of the foundation pit, a frame column is arranged at the top end of each bearing platform in the height direction of the bearing platform, and a guide tool of the backfilling device is arranged above the foundation pit; and the guidetool comprises a horizontal frame, a funnel cavity and rolling wheels, wherein the funnel cavity is arranged at the center of the horizontal frame. The device has the beneficial effects that due to the arrangement of the guide tool, the defect of traditional soil throwing to backfill is overcome, the failure of a waterproof protection layer caused by earthwork impact is avoided, the quality and the efficiency of the backfilling soil are improved, the reworking is reduced, and the later plugging cost is reduced; in addition, water pumping pipes and a water pump are combined, the problem of water accumulation in the foundation pit area is solved, and meanwhile, the problem that due to the fact that the area of the backfilling area is narrow, a backfilling machine is inconvenient to pass through is solved; and the engineering is enabled to be carried out in a non-turbulent mode, the construction period is not affected, and the practicability is high.

Owner:安徽省人防建筑设计研究院

Sealing process of turbine rotor blade cover plate top hole of gas turbine

InactiveCN109261965AImprove conductivityImprove thermal conductivityIncreasing energy efficiencyEngineeringAlloy

The invention discloses a sealing process of a turbine rotor blade cover plate top hole of a gas turbine. The process comprises the steps that (1), top hole pre-processing is conducted; (2), a red copper bar cooperates with the top hole is prepared to be used as a lining; (3), the red copper bar is installed at the bottom of the top hole, sealing alloy powder is delivered into the top hole througha coaxial gas carrying powder delivering device to perform laser cladding process, and the path is single-passage and multi-layer; (4), the red copper bar is separated from the cover plate, and castmodification processing is conducted on the cover plate of which the top hole is sealed; (5), nondestructive examination is conducted on the cover plate on which cast modification is conducted. According to the sealing process, a traditional vacuum brazing process is abandoned, a laser cladding technology is adopted to seal the turbine rotor blade cover plate top hole of the gas turbine, metallurgical bonding is formed between the sealing alloy powder and the top hole inner wall, the bonding strength is high, the bonding does not easily fall in the using process, vacuum does not need to be ensured, the sealing cost is low, and the cladding quality is improved by multi-layer clading.

Owner:成都青石激光科技有限公司

Method for filling refracturing plugging agent into single rock core

InactiveCN103046895AReduce plugging costsEasy injectionFluid removalSealing/packingRock corePetrology

The invention discloses a method for filling a refracturing plugging agent into a single rock core. The method includes (a) first conducting manual gap building on the single rock core; (b) adding filling substances in a gap; (c) filling solution into the gap till pressure is constant; and (d) filling the refracturing plugging agent into the gap till the pressure is constant and finishing the whole filling process. By means of the method, the refracturing plugging agent is successfully filled into the single rock core, filling effect is good, the gap can be successfully blocked after injection, and blocking cost of the single rock core is greatly reduced.

Owner:罗涛

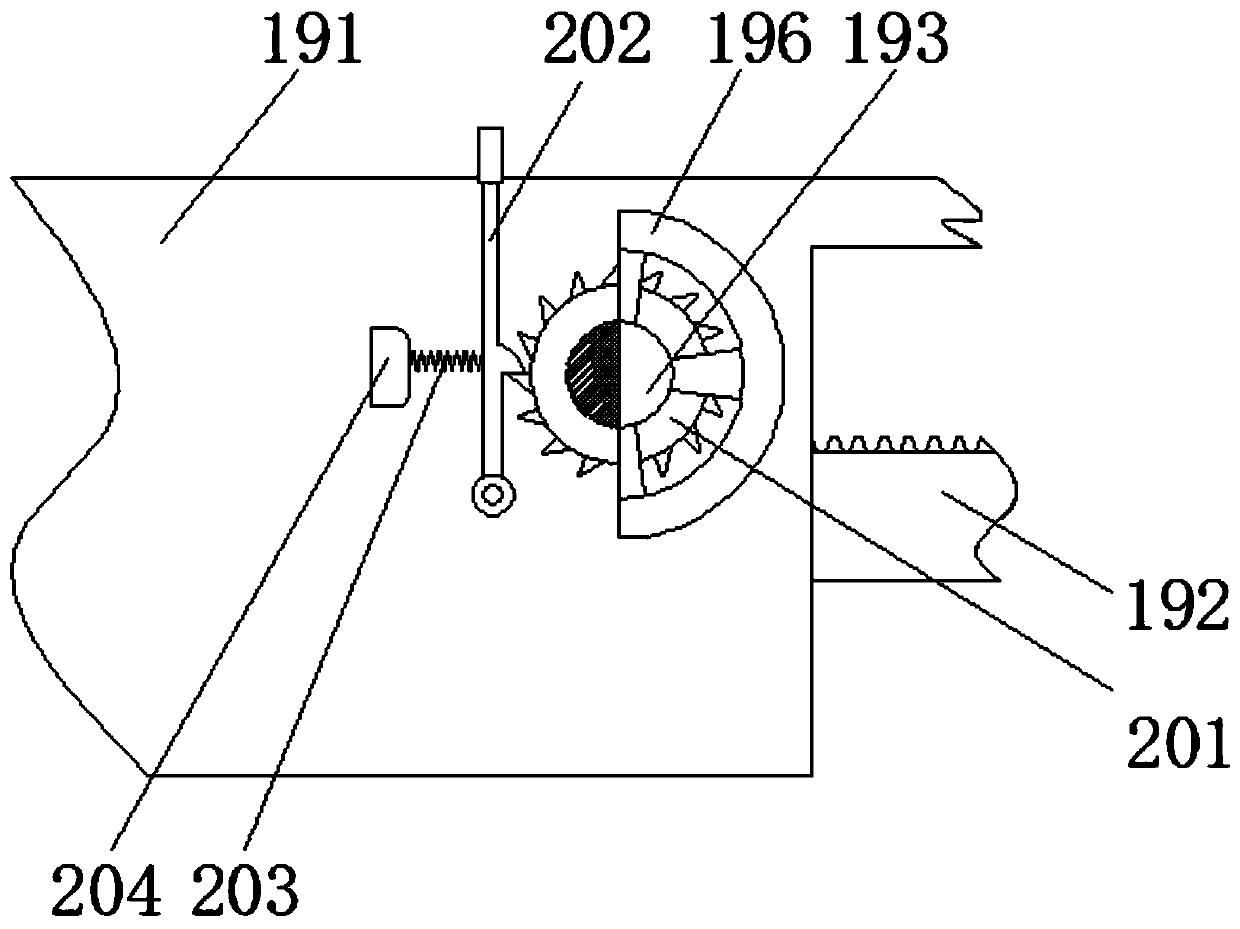

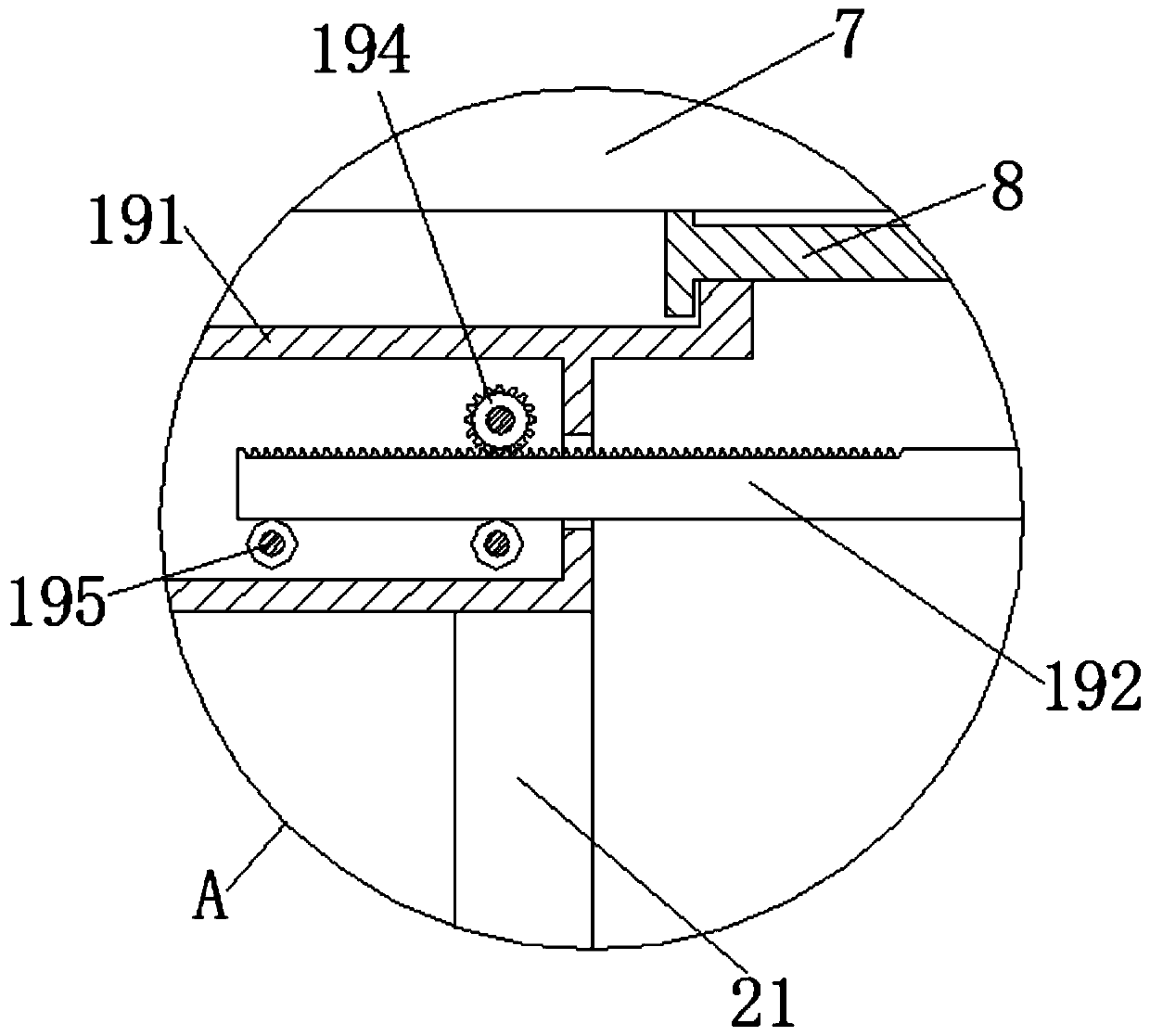

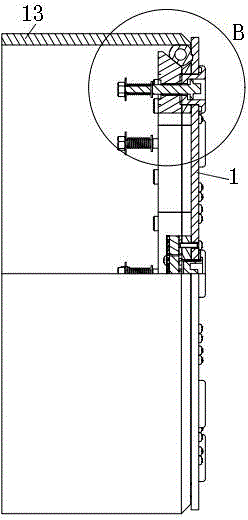

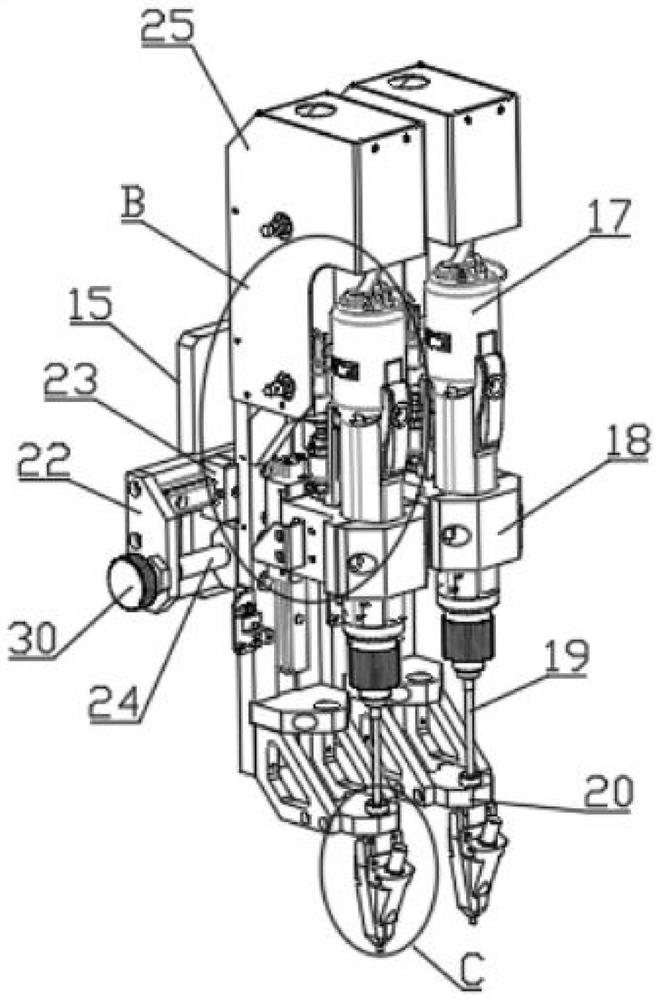

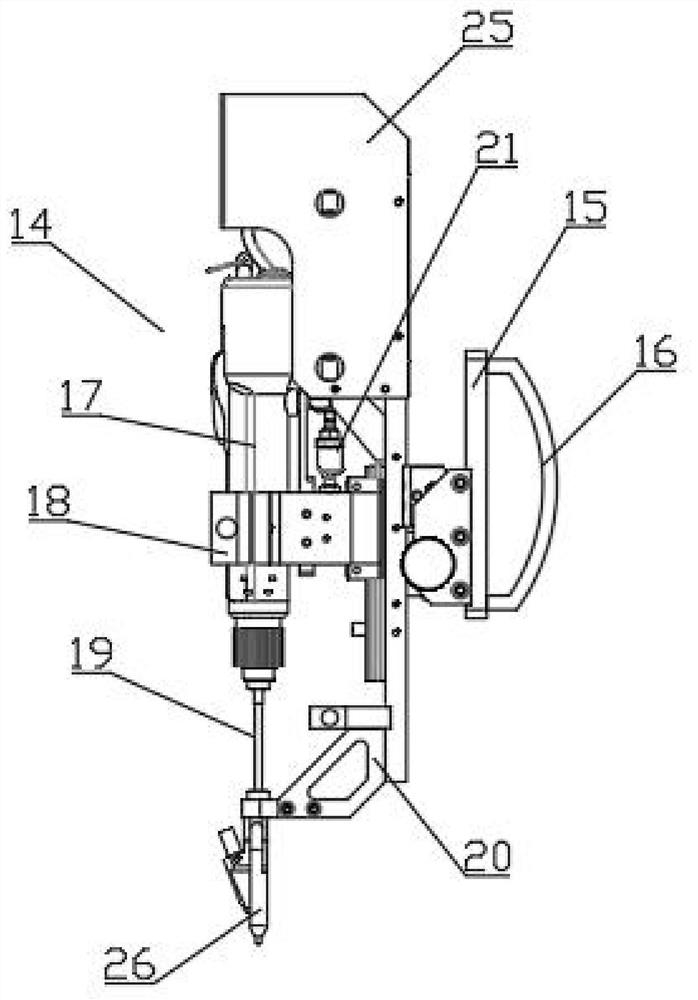

Pressure-regulating type perfusion plugging machine

The invention relates to the technical field of construction machinery, and discloses a pressure-regulating type perfusion plugging machine. The pressure-regulating type perfusion plugging machine comprises a gearbox, a gear set, a hand-held motor, a cam rotating disc, a connecting rod, a movable pull rod, a piston rod, a piston copper sleeve, a material cylinder, a check-back device, a pressure gauge, a conveying pipe, a metal pipe, an avocado head, a bidirectional switch, a material receiving bottle, a fixing seat, an adjusting device, a limiting device, a supporting leg and a movable leg, wherein the gear set is movably installed inside the gearbox. According to the pressure-regulating type perfusion plugging machine, through the arrangement of the adjusting device, the effective movable distance of the piston rod in the piston copper sleeve is changed, so that the size of slurry discharged from the piston rod during one time of reciprocation is changed, the slurry discharging pressure is further changed, the adaptability for cracks on different buildings and cracks of different positions and sizes can be effectively improved, and the adaptation range of the machine is increased; and meanwhile, suitable slurry pressure can effectively improve the safety of building crack filling, and the harm caused by excessive pressure can be reduced.

Owner:湖南古圣砖瓦科技有限公司

Quick stopper for long-distance pipeline

The invention relates to a quick stopper for a long-distance pipeline orifice. The quick stopper comprises a circular stopping blind plate, a plurality of flitches, an anti-theft gland, a sliding block, an anti-theft preloaded bolt, and an O-ring, wherein the flitches are sequentially distributed on the edge of the inner side of the circular stopping blind plate, and one surface of each flitch fits closely to the circular stopping blind plate; the other surface of each flitch is provided with a guide pin, and the anti-theft gland is arranged at the outer side of the circular stopping blind plate and sequentially penetrates through the circular stopping blind plate and the flitches; an axial groove is formed in the outside of a gland cover, and a through hole is formed in the bottom surface of the axial groove; the sliding block is slidably connected onto the guide pin, and a threaded hole corresponding to the through hole is formed in the sliding block; the tail part of the anti-theft preloaded bolt penetrates through the anti-theft gland, and is screwed out of the threaded hole of the sliding block, and then the anti-theft preloaded bolt is sleeved with a spring and then is positioned by a self-locking nut; the O-ring is arranged in a clamping slot formed between the circular stopping blind plate and an edge bevel of the sliding block. The quick stopper provided by the invention solves the problems that the stopping efficiency is low and the stopping cost is high, and the end face of a pipe section orifice is quickly stopped in the pipeline construction process. The quick stopper has an anti-theft function and a respiratory function, and is suitable for short-term use in long-distance pipeline construction.

Owner:祖宝华

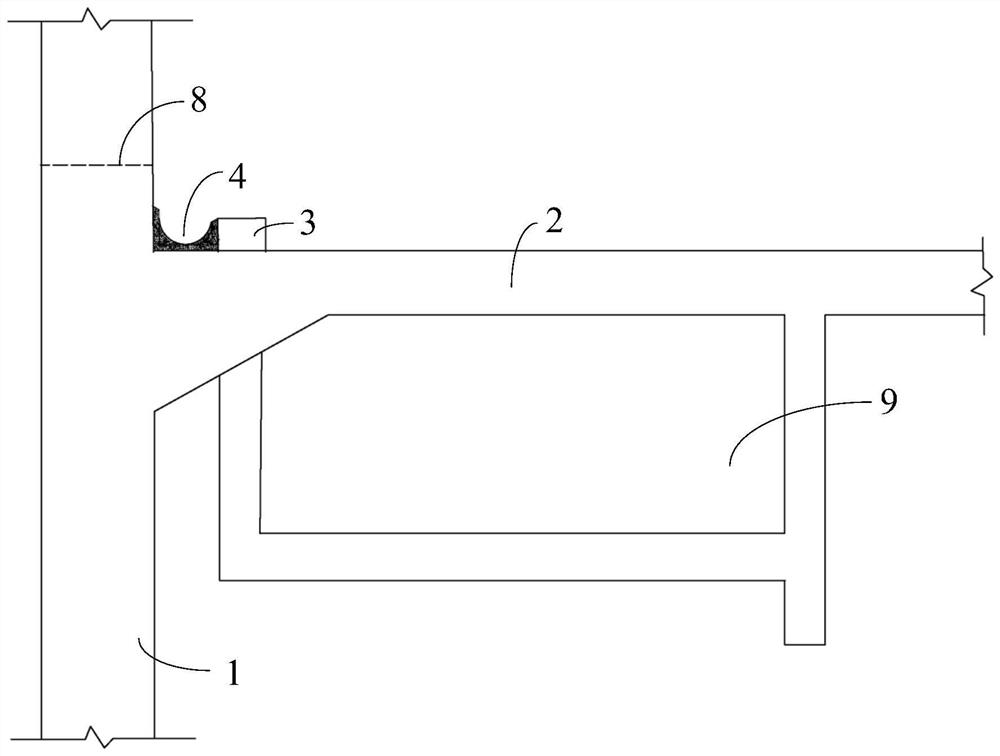

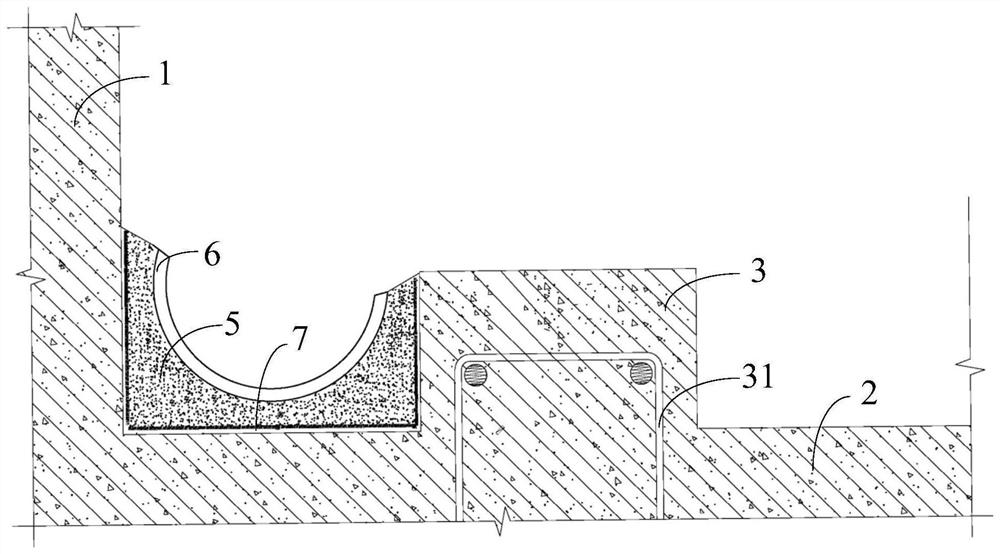

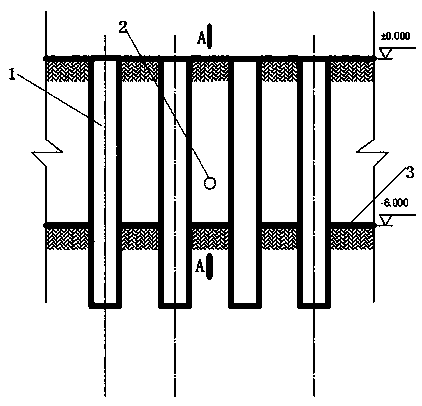

Subway station waterproof off-wall ditch structure and construction method thereof

PendingCN112854312AEasy dischargeGuaranteed waterproof performanceArtificial islandsProtective foundationStructural engineeringSubway station

The invention discloses a subway station waterproof off-wall ditch structure and a construction method thereof. The subway station waterproof off-wall ditch structure is arranged on a middle plate on one side of a side wall of a station and located below a construction seam in the side wall; the subway station waterproof off-wall ditch structure comprises a water retaining ridge arranged on the middle plate in the length extension direction of the side wall; a groove is formed between a water baffle and the side wall; a drainage pipeline which extends in the length direction of the groove and is provided with an opening in the upper end face is fixedly arranged in the groove; a space between the outer surface of the drainage pipeline and the inner wall of the groove is filled with waterproof mortar; and a waterproof structure layer is arranged between the waterproof mortar and the inner wall of the groove. According to the subway station waterproof off-wall ditch structure and the construction method thereof, the waterproof effect of an off-wall ditch is guaranteed through the waterproof structure layer, the drainage pipeline with the opening in the upper end face is convenient to install, the gradient is easy to adjust, water cannot make direct contact with the waterproof structure layer, the inner wall of the drainage pipeline is smooth, water drainage is facilitated, and the drainage effect of the off-wall ditch is guaranteed.

Owner:中建八局轨道交通建设有限公司

Plugging agent used for foundation pit row pile retaining wall and using method of plugging agent

ActiveCN110452671AImprove early strengthAvoid the risk of structural crackingFoundation engineeringDrilling compositionAluminateFiber

The invention discloses a plugging agent used for a foundation pit row pile retaining wall and a using method of the plugging agent, and relates to the technical field of building materials. The plugging agent comprises the following raw materials: 50-64% of an aluminate cement clinker, 6-10% of anhydrite, 2-16% of straw fibers, 4-16% of bentonite and 12-20% of walnut shell residues. The pluggingagent provided by the invention is inexpensive and has excellent durability. The invention also provides a using method of the plugging agent. The using method provided by the invention has simple construction operation, does not need to increase an engineering quantity and construction machine, and has low costs of plugging; and in addition, the walnut residues and short fibers prevent the plugging agent from flowing out through the action of ''bridged'', blocking, embedding, percolation and ''throat sticking'', and the plugging effect is significantly improved.

Owner:JIAHUA SPECIAL CEMENT

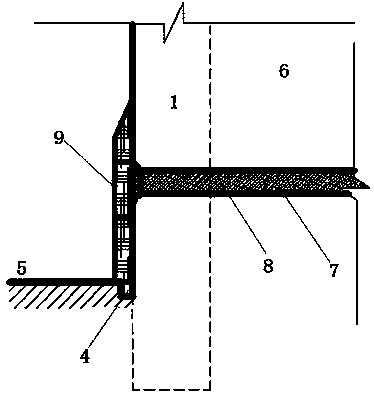

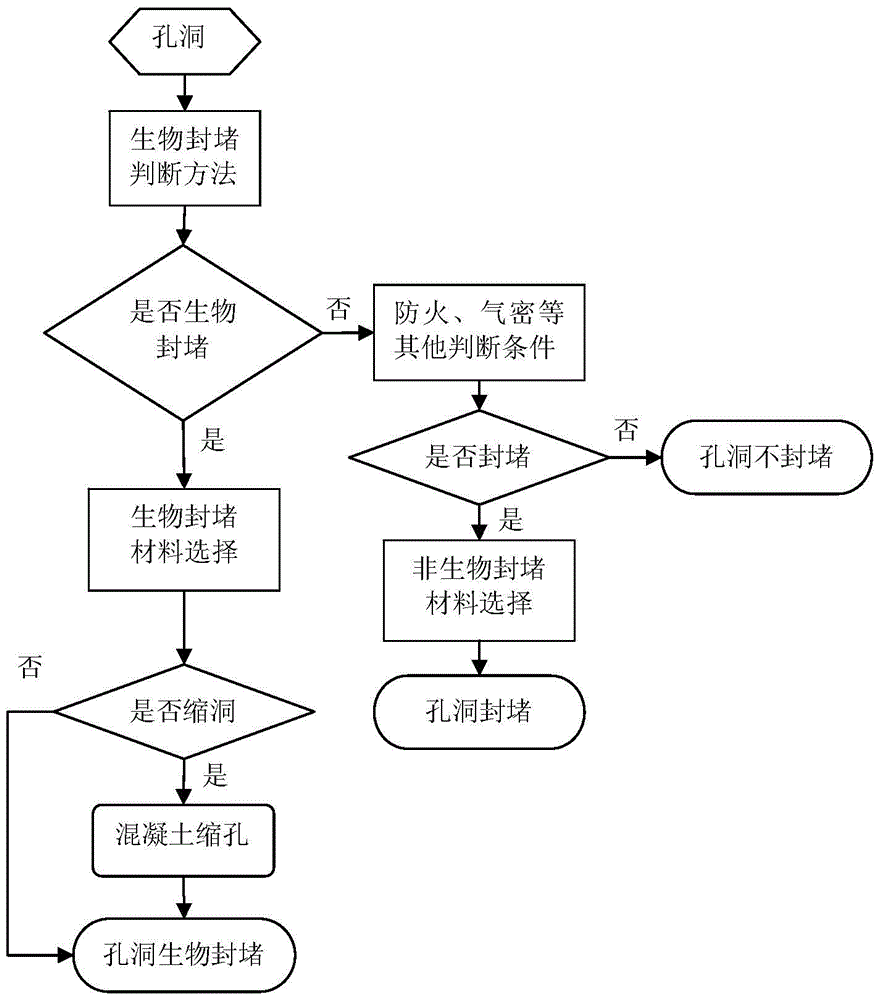

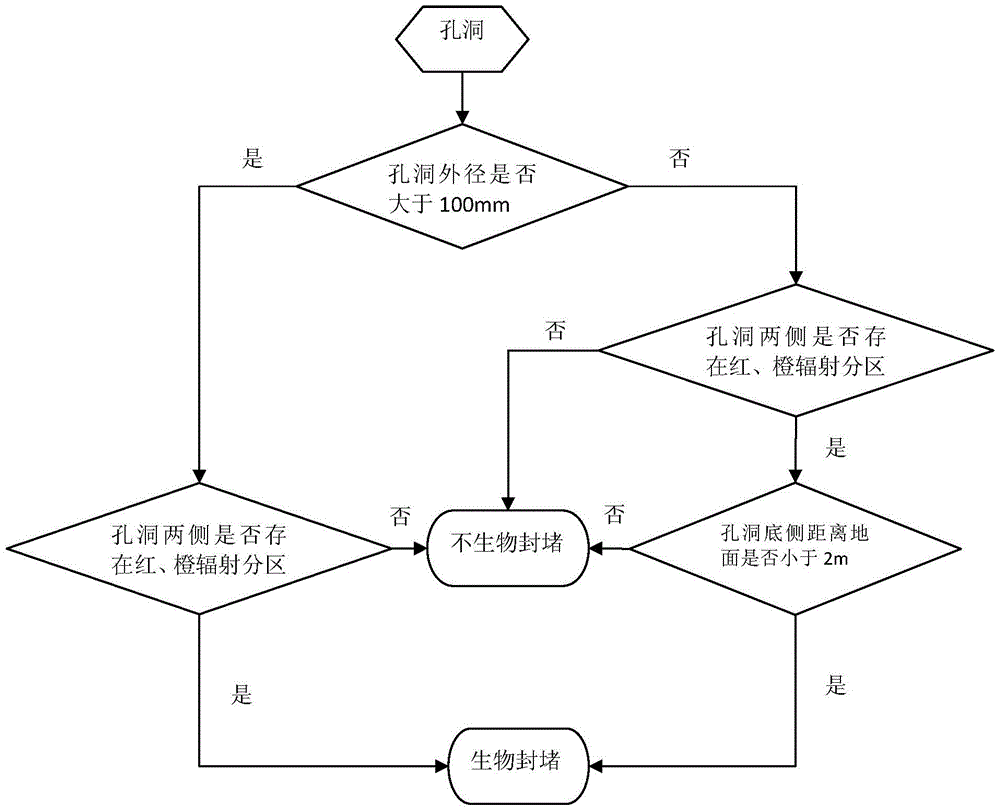

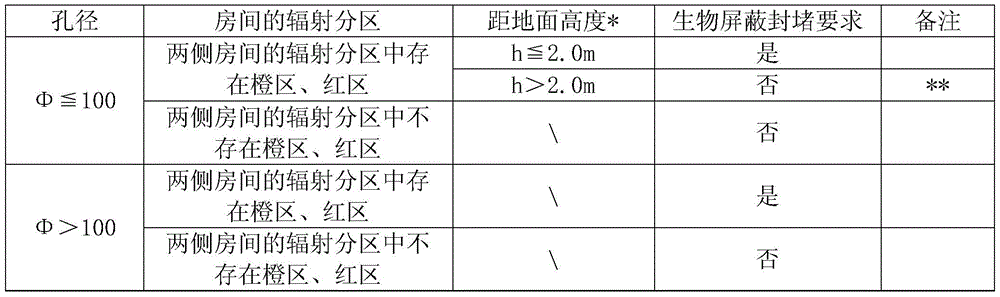

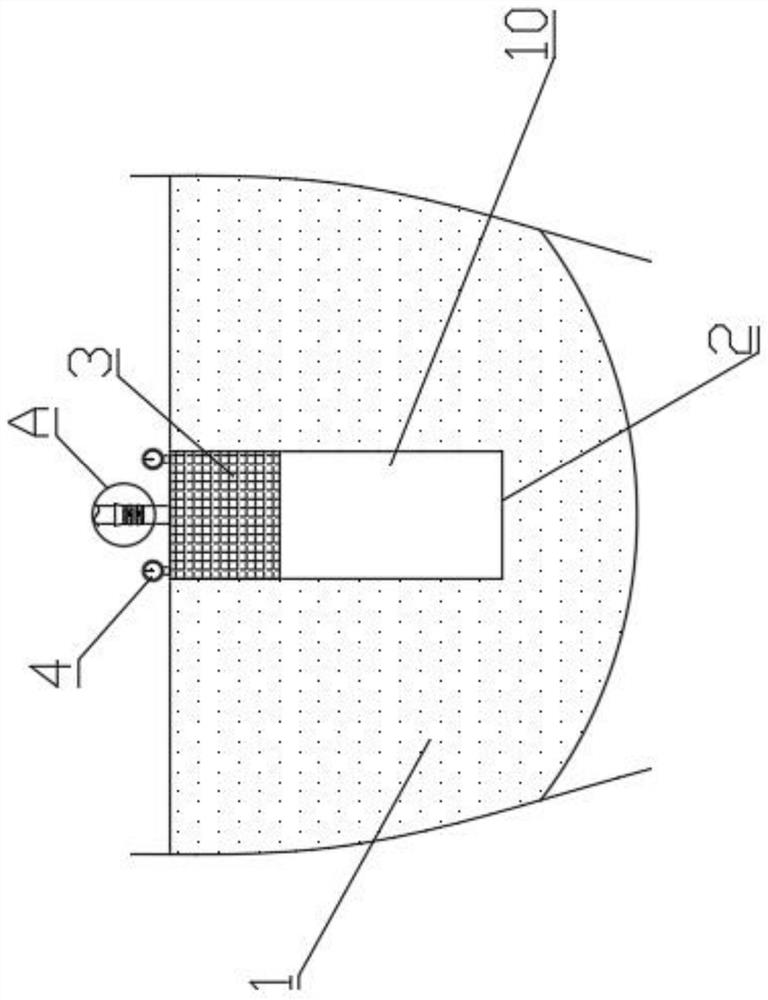

A biological sealing method for the hole in the wall of the nuclear island building of a nuclear power plant

ActiveCN104314186BAvoid misjudgmentReduce plugging costsBuilding insulationsIndustrial buildingsProcess specificationNuclear plant

The invention belongs to the design technology of nuclear power plants, and in particular relates to a biological sealing method for holes in walls of nuclear island workshops of nuclear power plants. The present invention first proposes a judgment method for quickly judging whether the hole in the wall of the nuclear island building of a nuclear power plant needs to be biologically sealed. The plugging process specification is a set of very operable standard procedures. Through this method, misjudgment of hole plugging due to different experience and judgment basis of staff can be avoided to the greatest extent, and the work’s impact on personnel qualifications and working hours can be reduced. The limitation of bio-sealing reduces the cost of bio-sealing and improves work efficiency at the same time.

Owner:CHINA NUCLEAR POWER ENG CO LTD

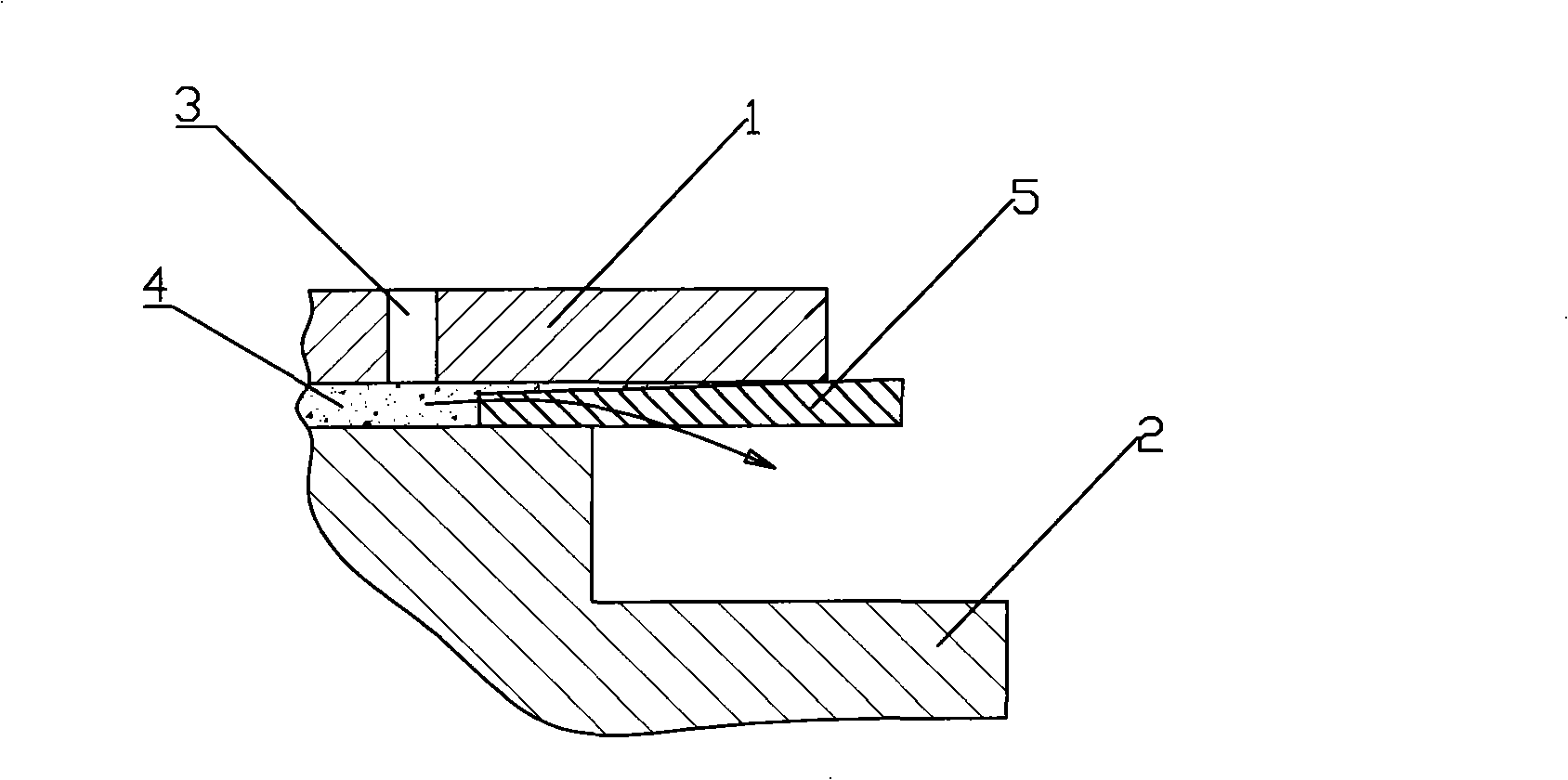

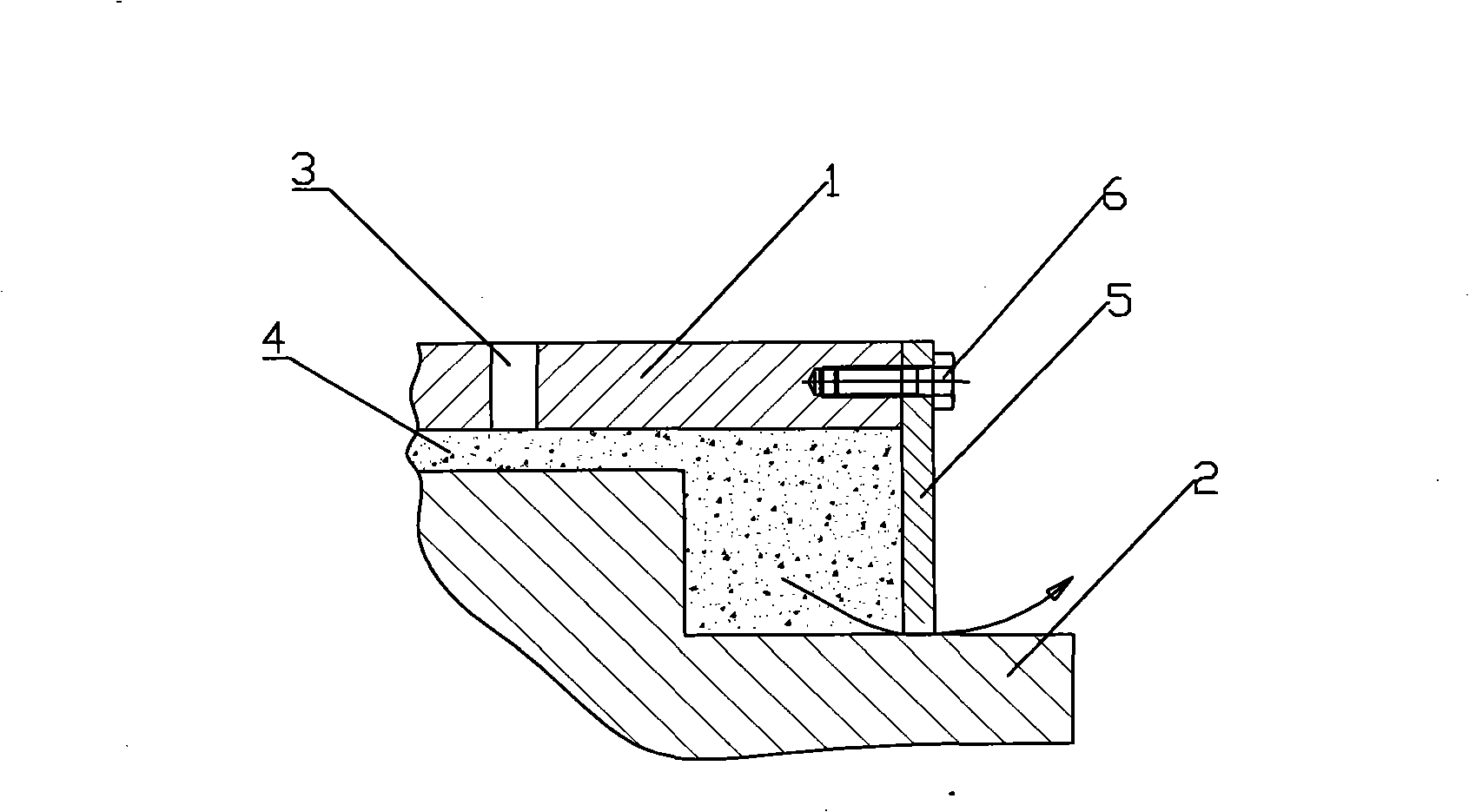

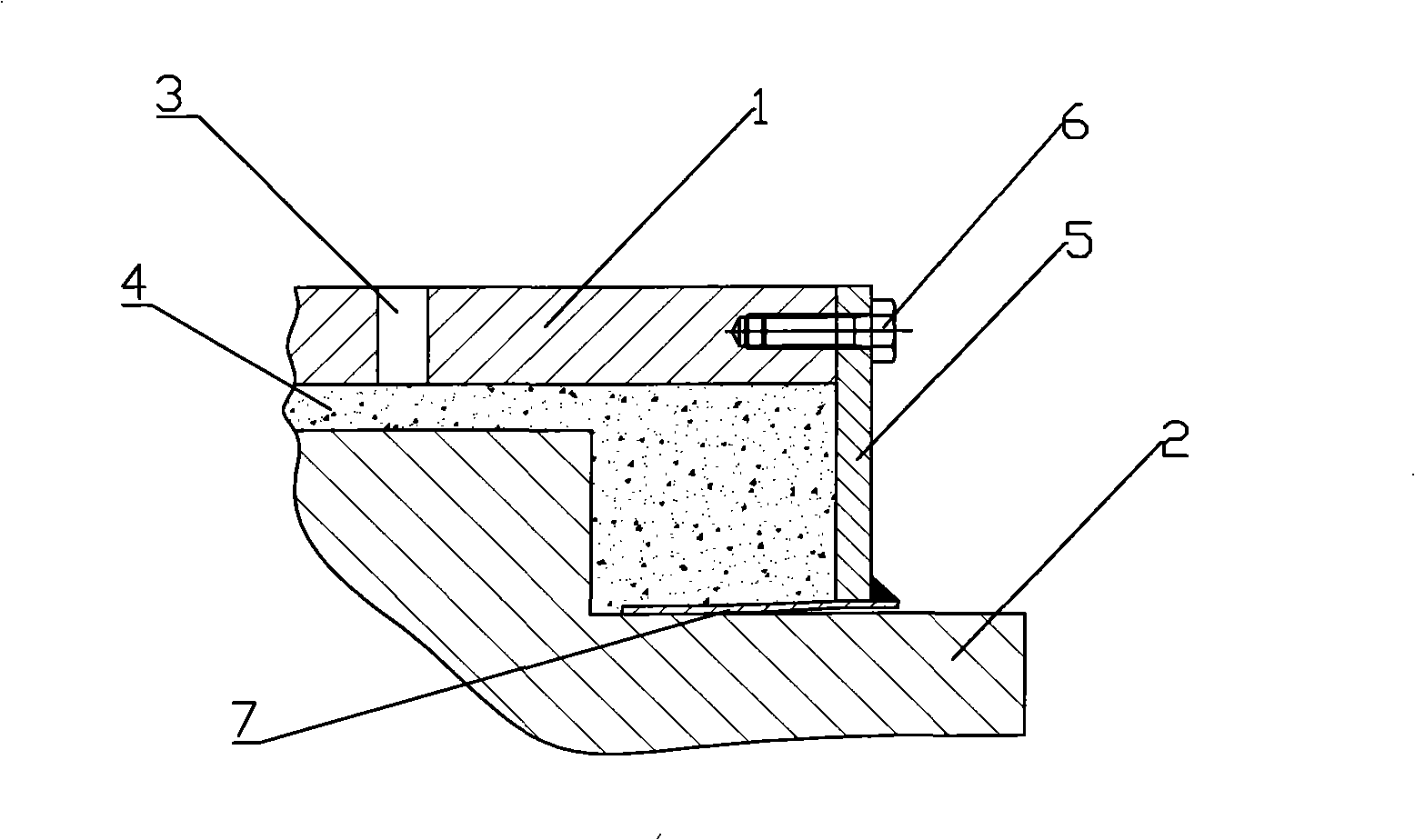

Leak stopping method and apparatus for special-shaped sealing surface under temperature and pressure

ActiveCN101487533BReduce the possibility of leaksImprove sealingEngine sealsEngineeringHigh pressure

The invention provides a plugging method with temperature and pressure for an exotic sealing face and a plugging device thereof. In the invention, a sealing basal body is provided with an exotic face and supported by a frame-shaped sealing structure member, the upper end of the sealing structure member is tightly pressed against the sealing body and the lower end thereof is closely contacted withthe sealing basal body by a lower self-sealing soft metal plate, one end of the upper self-sealing soft metal plate is weld on the frame-shaped sealing structure member, the non welding end is closely contacted with the sealing basal body, a sealing glue room is formed between the sealing body and the sealing basal body, a sealing room is formed between the frame-shaped sealing structure member and the sealing basal body, an glue injecting hole is arranged on the sealing body, and the plugging is carried out by injecting sealing glue into the sealing glue room from the glue injecting hole. The plugging method and plugging device of the invention adopt a two-stage self-sealing structure, have high sealing reliability, are applicable to plugging with temperature and pressure for high temperature and pressure system and equipment, and have low requirement for sealing structure member material, low sealing glue consumption and low plugging cost.

Owner:SHANXI SANHESHENG IND TECH

A plugging slurry for improving the pressure bearing capacity of lost formations and its preparation method

ActiveCN106566499BImprove pressure bearing capacitySolve the plugging problemDrilling compositionSealing/packingFiberWell drilling

The invention provides plugging slurry for enhancing pressure-bearing capacity of leakage formation. The plugging slurry is composed of the following substances (by weight): 55-60% of a curing agent for fiber coagulation, 1-2% of asphalt powder for well drilling, 0.05-0.1% of an oil well cement defoamer and 38-45% of water. The invention also provides a plugging method capable of enhancing pressure-bearing capacity of leakage formation during petroleum drilling process. The method has a good plugging effect on medium and large-scale lost circulation and meets requirements of drilling construction and environmental protection. The plugging technology requires fewer types of chemical materials, and the method for preparation of the plugging slurry is simple. A pressure-bearing squeeze plugging method has strong operationality. The product has a good effect of plugging fractures and pores of a leakage zone and can obviously reduce lost circulation velocity of the leakage zone. Plugging time is greatly shortened and plugging cost is greatly reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A multi-slug step-by-step plugging method suitable for fractured formations

ActiveCN110118073BPrevent leakageReduce wasteSolid waste managementDrilling compositionSlurryPellets

The present invention relates to a multi-slug staged plugging method suitable for fractured formations, comprising: step 1) determining the average opening of the fractures around the well as D, and using bridging particles with a particle size slightly smaller than D in the first-stage plugging. The average particle size is expressed as D 1 , the average particle size D of the plugging particles is used for the secondary plugging 2 greater than D 1 / 4, and less than D 1 , use the same method to determine the particle size of the following plugging particles in sequence, until the average particle size of the last stage of plugging particles is D n Small enough to form a tight plugging layer; step 2) first inject through the slug containing only 1 The plugging slurry of bridging particles forms a layer of bridging particles; step 3) injects the plugging particles with an average particle size of D through multiple slugs 2 ~D n‑1 plugging slurry to form a particle packing layer; step 4) use a slug to finally inject a plugging slurry with an average particle size of plugging particles Dn to form a tight sealing layer. The invention has a reliable principle, more effectively seals the cracks around wells, saves costs, and has broad application prospects.

Owner:SOUTHWEST PETROLEUM UNIV

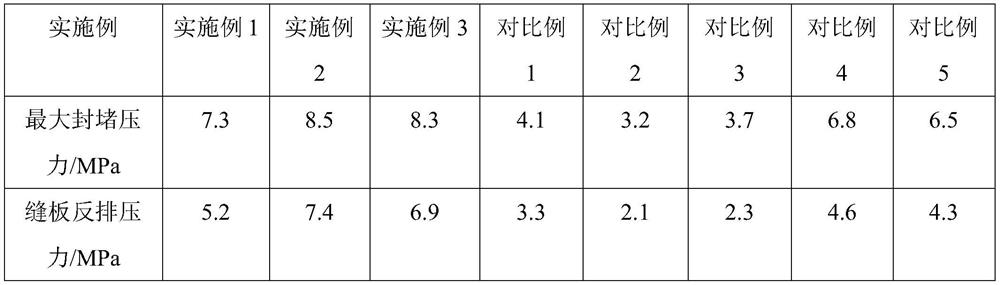

A composite reinforced plugging slurry and plugging method

ActiveCN111073615BSmall cross sectionSqueeze in effectivelyDrilling compositionSealing/packingProcess engineeringSlurry

The invention provides a composite strengthened plugging slurry and a plugging method, comprising the following raw materials in parts by weight: 100 parts of base slurry, 5 to 15 parts of expandable plugging enhancer HJK‑5 (II), and inorganic plugging agent FDL 2-10 parts, 2-10 parts of composite plugging agent, 0.5-8 parts of thickener, 5-20 parts of cementing agent A, and 5-25 parts of cementing agent B. The present invention adopts bridge plugging materials with different properties and particle sizes and carries out gradation research, so that the cracked leakage with different leakage volume can be used in a targeted manner, while saving the plugging cost, it has higher plugging efficiency and Plugging strength.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A solidified water temporary plugging and well killing working fluid and its preparation and drainage methods

ActiveCN106833572BEasy to prepareSimple preparation processDrilling compositionSealing/packingFluid phaseHydrology

The invention provides solidified water temporary plugging well-killing working fluid. The solidified water temporary plugging well-killing working fluid is prepared from 10 to 40 percent of solidified water system and 60 to 90 percent of anti-swelling stabilizing fluid, wherein the solidified water system is prepared from the following components in percentage by mass: 1.1 to 1.5 percent of main agent, 0.3 to 0.5 percent of solidification initiator and the balance of water. The preparation method of the working fluid comprises the following steps: 1), taking the main agent in an amount determined in a formula; 2) taking the solidification initiator and the anti-swelling agent in amounts determined in the formula; 3) injecting clear water into a container in an amount determined in the formula, adding the main agent and the solidification agent initiator in amounts determined in the formula in sequence, and uniformly stirring to obtain the solidified water system; 4) adding the anti-swelling stabilizing fluid in an amount determined in the formula to obtain the solidified water temporary plugging well-killing working fluid. A draining method combining acidifying-demulsifying and liquid nitrogen drainage is adopted. The working fluid is simple in preparation process, a colloid protective agent is not needed, the plugging efficiency is increased greatly, the plugging cost is lowered, damage to strata is reduced, and the problems of coexistence of collapse and leakage and low reservoir protection performance in a gas well construction process are solved. The solidified water temporary plugging well-killing working fluid has important practical significance to increase of the oil gas exploration and development speeds.

Owner:PETROCHINA CO LTD

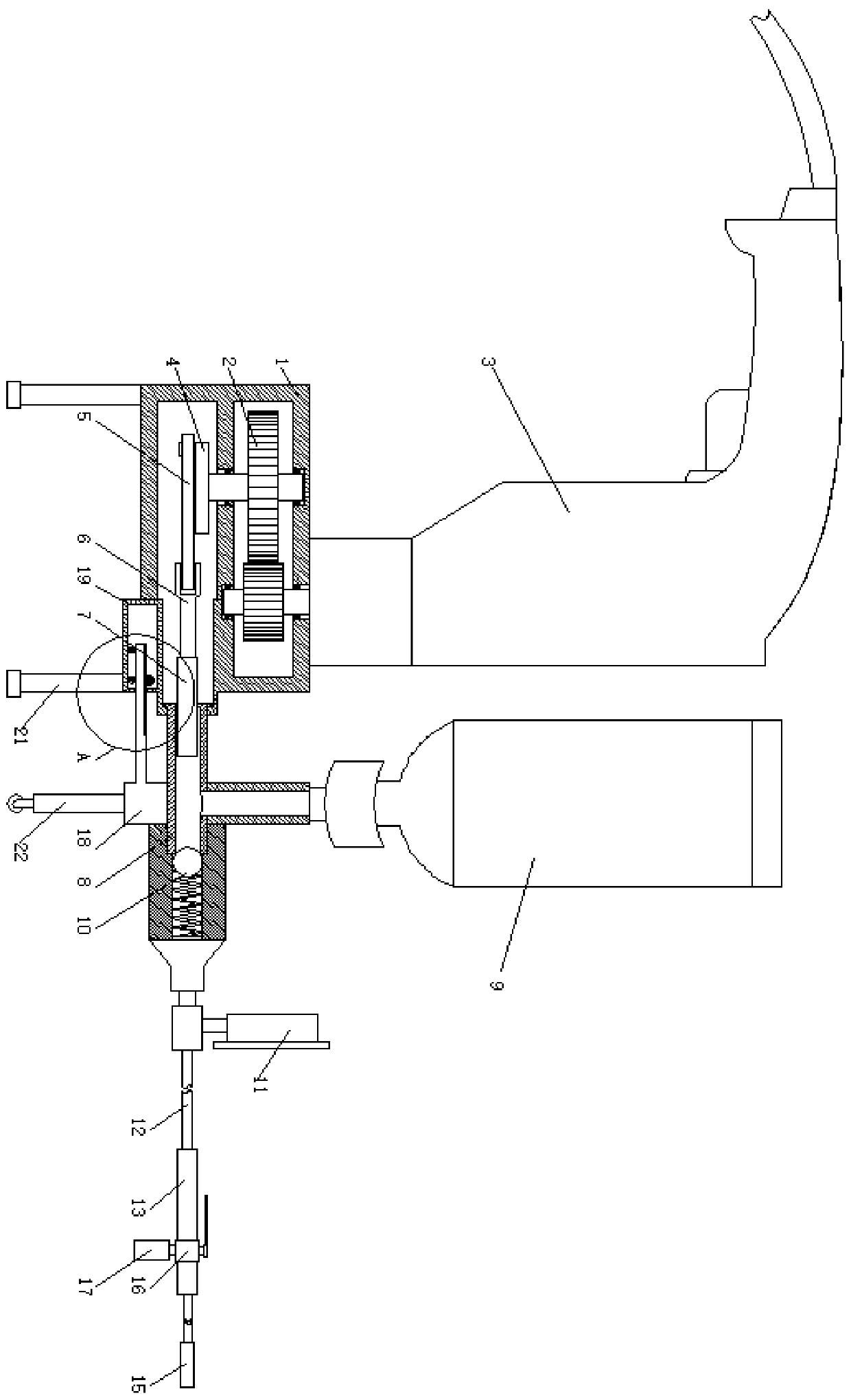

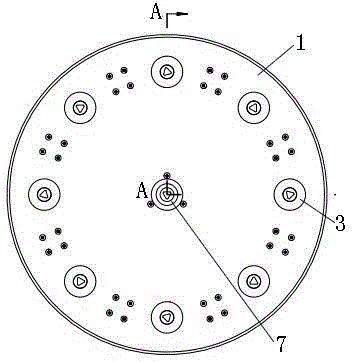

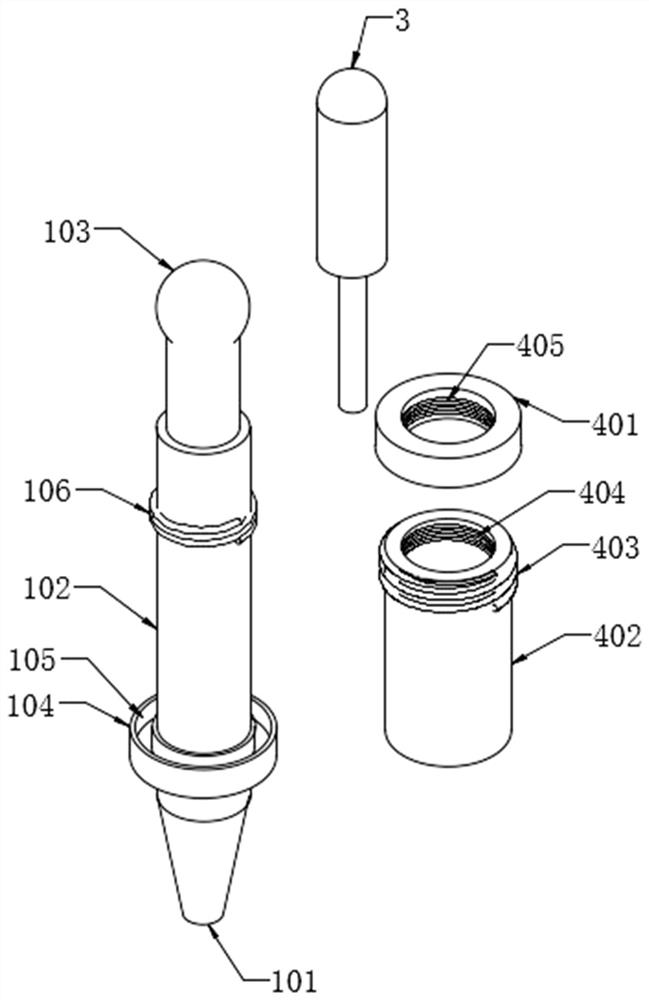

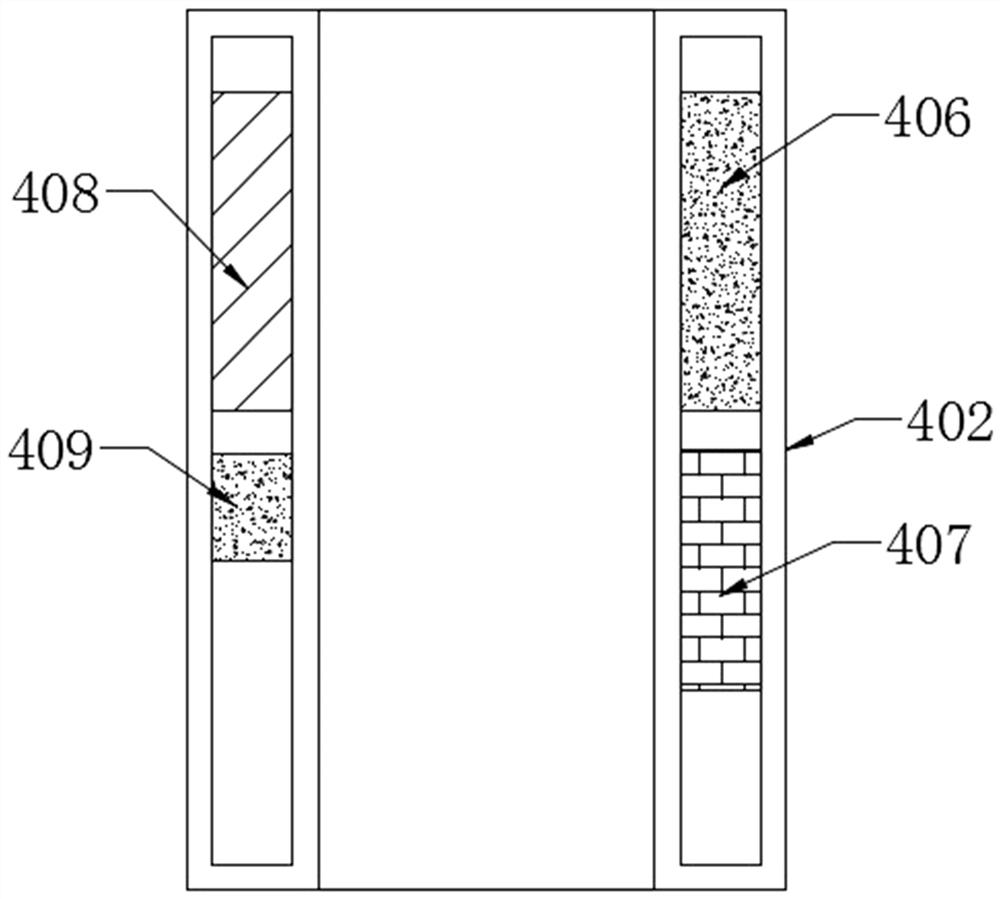

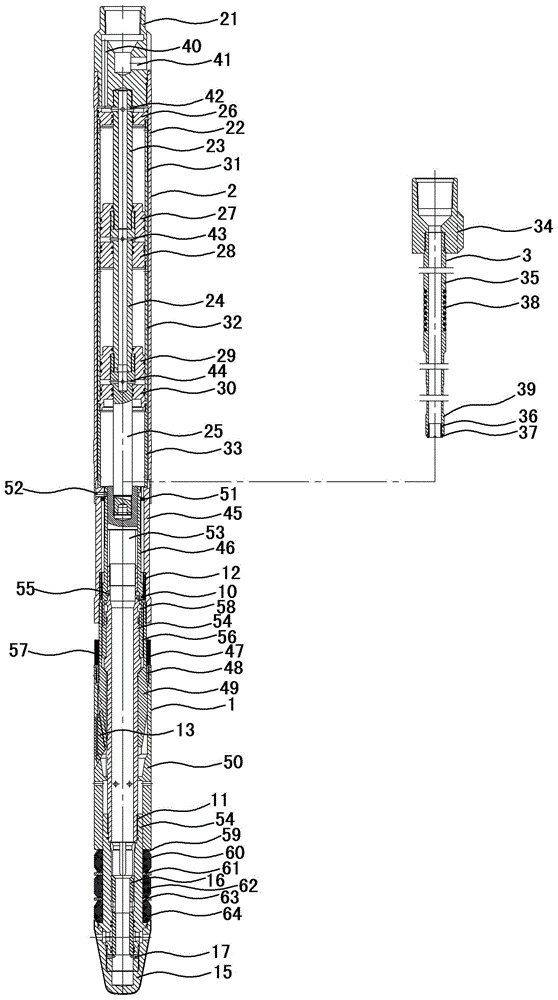

Temperature testing device used in cooperation with temporary plugging agent

InactiveCN113445995AReduce plugging costsConvenient fracturing pluggingConstructionsSealing/packingProcess engineeringTemperature testing

The invention discloses a temperature testing device used in cooperation with a temporary plugging agent, and relates to the technical field of temporary plugging agents. In order to solve the problems that existing oil well measurement work is tedious, a temporary plugging agent extrusion plugging device and a temperature measuring device are arranged separately, and consequently the plugging cost is increased, the scheme is provided; and the temperature testing device comprises a setting bridge plug mechanism and a temperature measuring mechanism. The temperature measuring mechanism is arranged on the circumferential side wall of the setting bridge plug mechanism in a sleeving manner and used for measuring the temperature in an oil well body, and an ash squeezing tool is arranged at one side of the setting bridge plug mechanism and used for being inserted into the setting bridge plug mechanism to convey the temporary plugging agent. The temperature testing device is novel in structure, the device does not need to be fed into the well through two-time hydraulic driving, the plugging cost is reduced, meanwhile, the condition that the temperature measuring device needs to be taken out back and forth and then fracturing plugging is conducted is avoided, fracturing plugging is convenient and fast, and use is convenient.

Owner:SOUTHWEST PETROLEUM UNIV

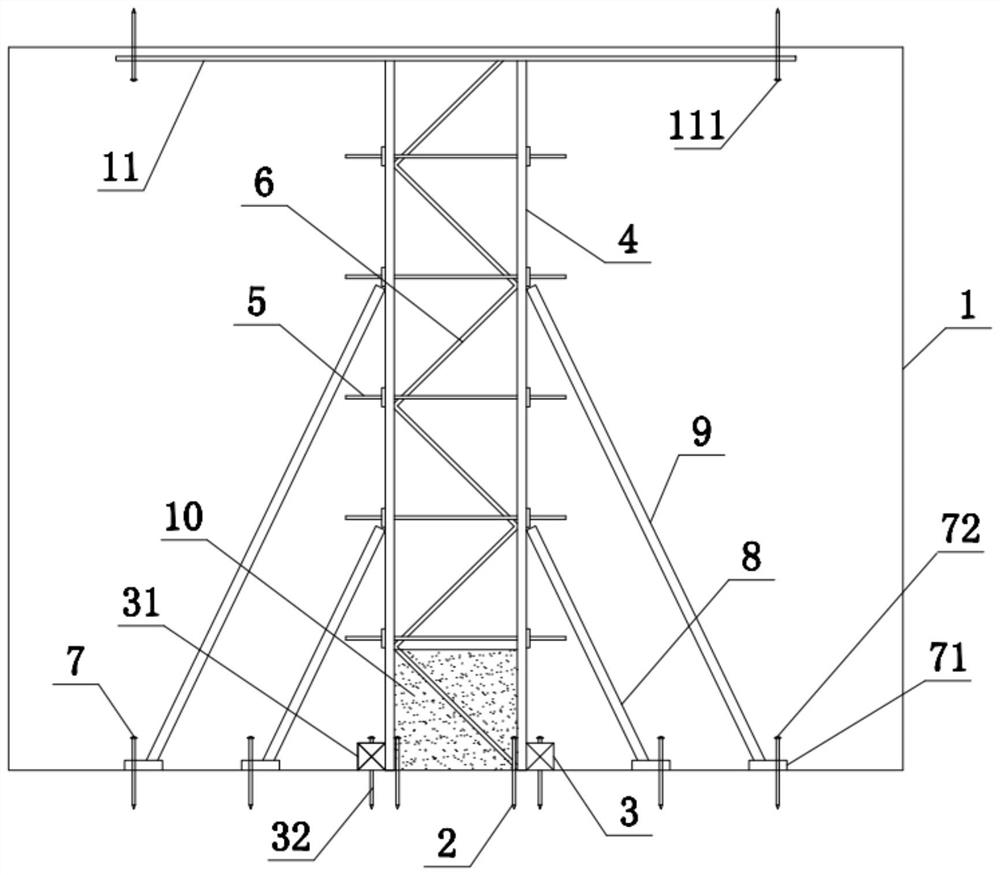

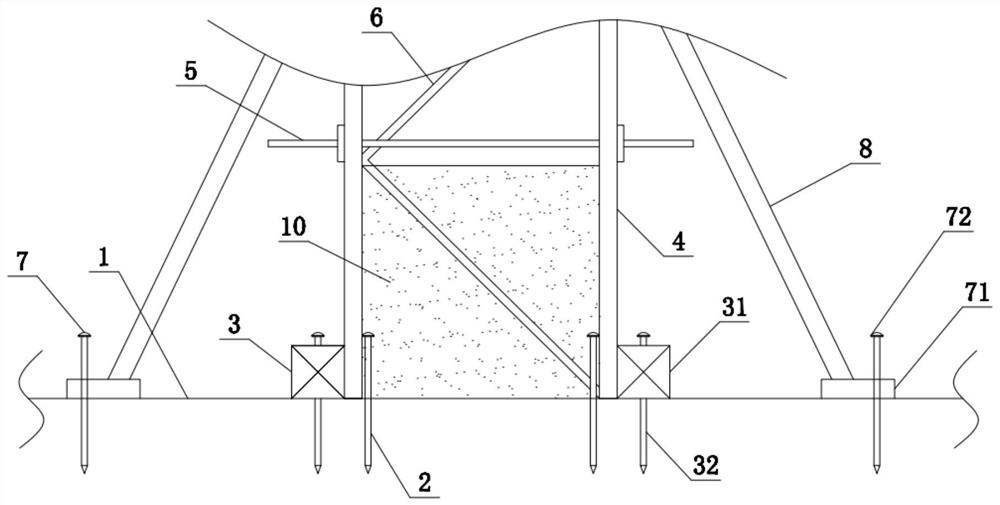

Air-raid shelter backfilling and plugging device and construction method thereof

PendingCN114197910AThe vibration method is denseHigh strengthArtificial islandsBuilding repairsSludgeStructural engineering

The invention provides an air-raid shelter backfilling and plugging device and a construction method thereof. The air-raid shelter backfilling and plugging device comprises a shelter body, a first stud is arranged on the inner side of the lower end in the shelter body, a positioning assembly is arranged at the lower end in the shelter body, and a formwork is movably connected to the interior of the shelter body through the first stud and the positioning assembly. The strength of the segmented concrete can be improved by additionally installing the angle steel framework, so that the segmented concrete can resist side pressure generated in the pouring process of the hole body backfill concrete, and when the segmented concrete is poured, the positions of the first supporting column and the second supporting column are stabilized through the installation assembly, so that the first supporting column and the second supporting column can stabilize the position of the formwork; and after subsection concrete pouring is completed, the formwork and the like can be removed for lower end plugging construction, materials are recycled, the plugging cost is greatly saved, and the backfilling mode is suitable for reinforcing the plugging device under the conditions that the geology of the bottom of the hole body is poor, and sludge exists and the like and suitable for hole body backfilling work under different actual conditions.

Owner:SHANGHAI BAOYE GRP CORP

One-time sealing device for building water leakage

The invention discloses a one-time sealing device for water leakage in a building, which is directly inserted into the wall body, not only capable of deodorizing and sterilizing, but also sealing water seepage gaps in the wall body through grouting. It can effectively improve the sealing efficiency of internal gaps in building walls and save costs. It is characterized in that the inner connecting pipe is placed on one end of the main body cylinder, the outer connecting pipe sleeve is placed on the inner connecting pipe, and is threadedly matched with the inner connecting pipe, and the pin cap is placed on the outer connecting pipe, and the pin cap is an annular plate-shaped structure , a rubber pad is placed on one side of the pin cap, and a hook is provided on the other side of the pin cap. The main body cylinder is provided with a plurality of diffusion holes in the axial direction, and the rubber ring is placed on the main body cylinder and is close to the main body. At the other end of the cylinder, the main cylinder is made of rigid material, the partition ring is placed on the inner ring of the pin cap, and a plurality of through holes are opened on the partition ring, one end of the connecting pipe is placed on the pin cap, and the connecting pipe is opened. The observation hole, the connecting pipe is built with a filter sponge, and the cover plate is placed on the connecting pipe.

Owner:徐州华显凯星信息科技有限公司

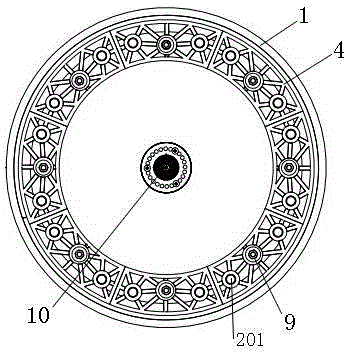

releasable anchor packer

ActiveCN104499988BReduce the difficulty of unanchoringEasily brokenSealing/packingEngineeringMechanical engineering

Owner:牡丹江金恒石油机械科技有限公司

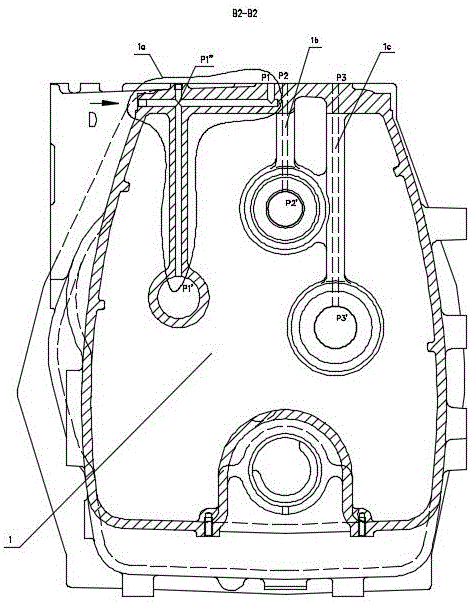

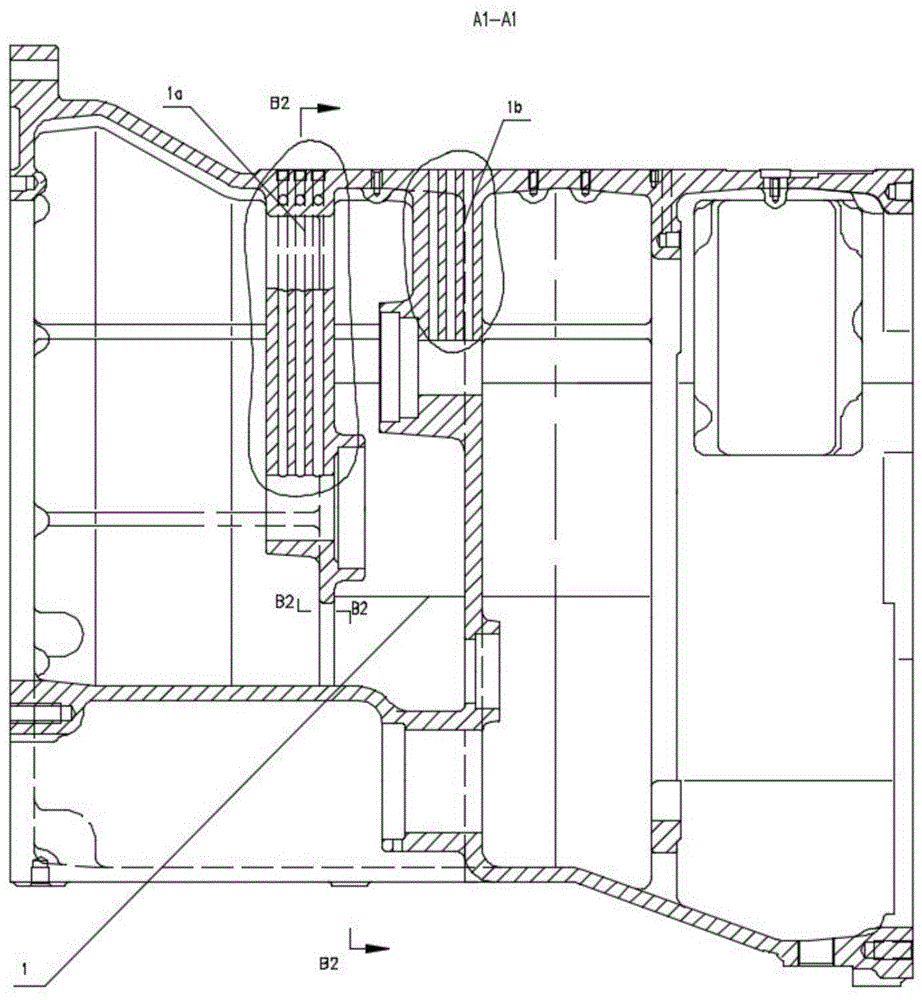

A leak detection and plugging assembly and plugging method for an oil passage hole of a tractor gearbox body

ActiveCN104482210BSolve the blocking problemImprove work efficiencyEngine sealsGearing detailsBodies oilAir filter

The invention provides a tractor gear box body oil way hole leakage detection plugging component and a plugging method, and belongs to the field of machine manufacturing. A plugging panel assembly is fixedly arranged at the upper part of a gear box body; the upper part of the plugging panel assembly is connected with a combination valve block component through a connection pipe; a threaded hole stop block assembly is fixedly arranged at the upper part of the gear box body and at one side of the plugging panel assembly; an internal expanding plug assembly is arranged in the gear box body; the other end of the internal expanding plug assembly is connected with an air filter through a connection pipe. By adopting the plugging component and the plugging method, the problem of difficulty in realizing leakage detection of a power shifting tractor gear box body can be effectively solved; the plugging component is simple in structure, high in detection efficiency, low in detection cost, and rapid and convenient to assemble; different parts can be detected; the component is high in universality and can detect different parts.

Owner:CHINA YITUO GROUP +1

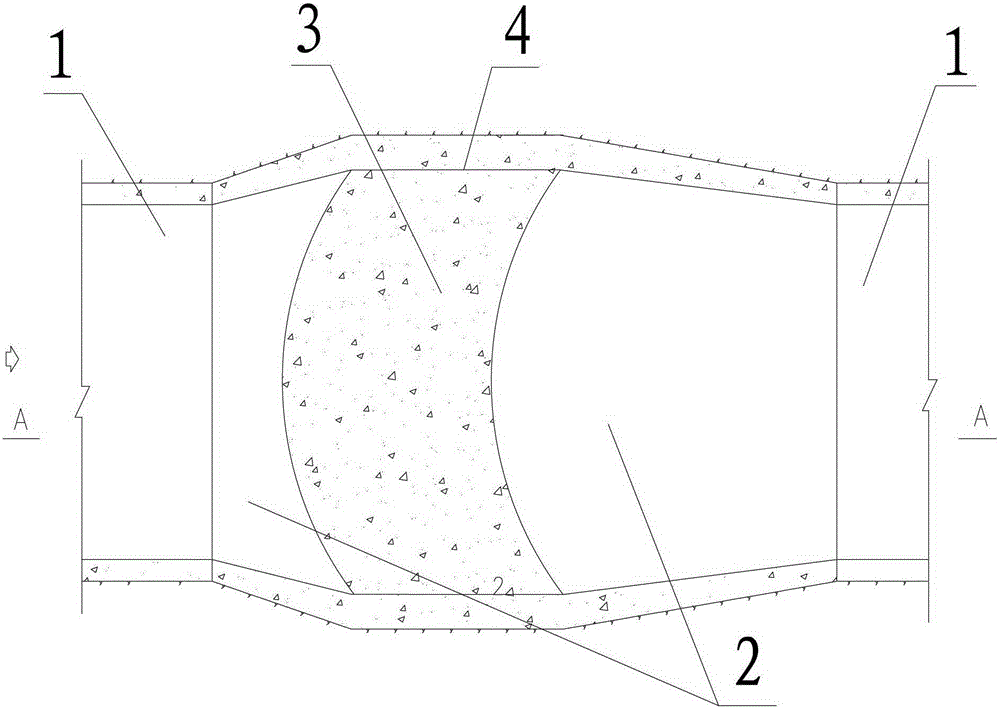

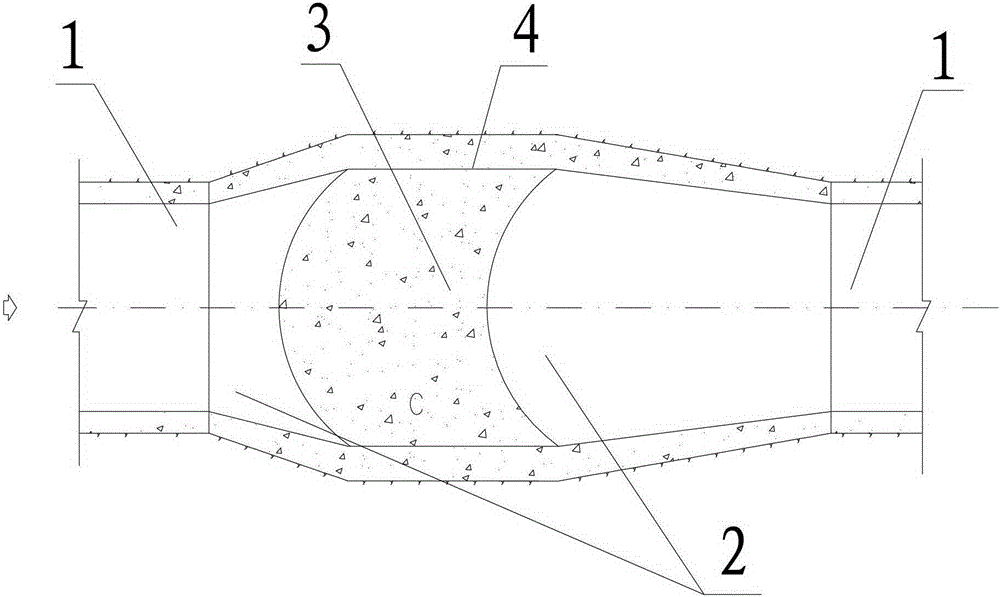

A sealing structure for diversion tunnel

ActiveCN103195032BImprove the blocking effectReduce the workload of plugging constructionWater-power plantsHydro energy generationHydraulic structureBuilding construction

The invention discloses a plugging structure, particularly discloses a plugging structure for a diversion tunnel and belongs to the technical field of hydraulic structure designing construction. The plugging structure is small in plugging construction work load and good in plugging effect. The plugging structure comprises the diversion tunnel arranged in a concealed body and a plugging body arranged in the diversion tunnel. A similar-oval plugging section with a longitudinal section smaller at two ends and larger in the middle is arranged on the diversion tunnel. The plugging body is a similar-oval plugging body matched with the shape of the similar-oval plugging section, and the similar-oval plugging body is arranged at the maximum cross section position of the similar-oval plugging section.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

New Technology of Deep Hole Blasting and Sealing

The invention discloses a new technology for sealing holes in deep hole blasting. The technology includes the following steps: firstly, a deep hole is opened at the construction site, and then two thirds of the explosive layer of the deep hole is filled with explosives; Set the grouting pipe on the rubber connecting sleeve, and then install the pouch by holding the handle on the pouch locker; put the pouch into the sealing section of the deep hole, and press the sealing material The water-cement ratio is 1:1 and the mixture is mixed, and the grouting pipe is connected to the grouting pump, and then the sealing material is injected into the pouch along the grouting pipe and the grouting pipe through the grouting pump, so that the pouch is bulged And block the hole-sealing section, stop the grouting when the pressure gauge shows that the pressure is 2MP, and then blast the hole-sealing material in the bladder 3 after solidifying for 20 minutes; the present invention solves the problem of punching holes; The blasting energy is concentrated; the construction process of workers is simplified, the construction time is shortened, the operation is simple, safe and reliable, the strength of the sealing material is guaranteed, and the advantages are economical and applicable.

Owner:SUZHOU JINDING SAFETY TECH CO LTD

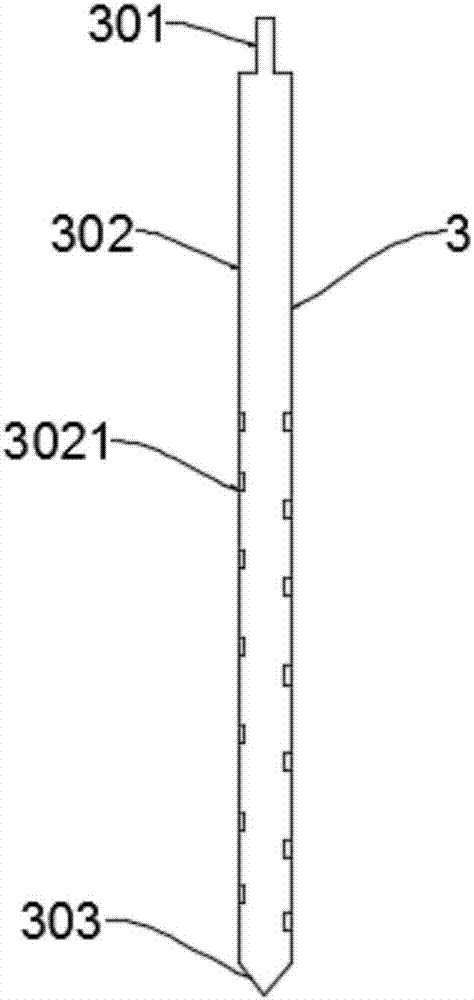

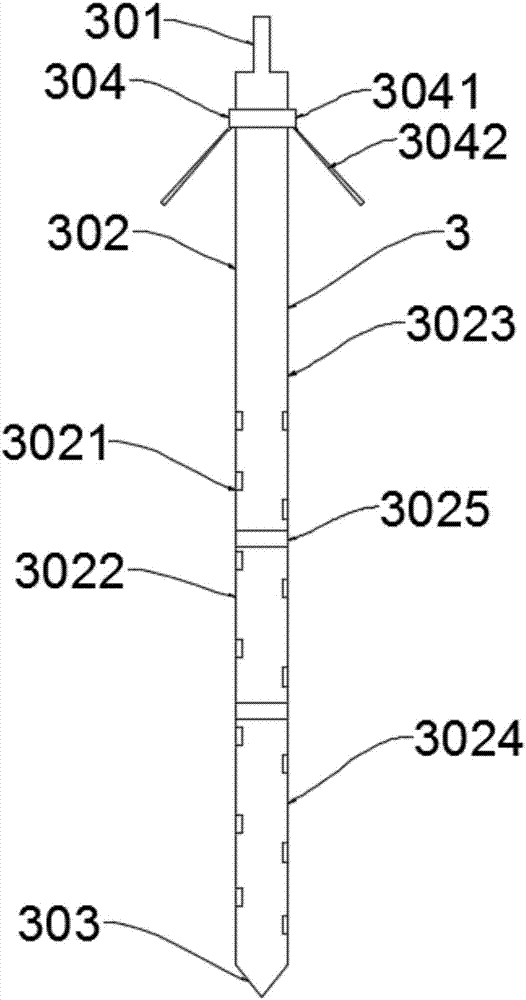

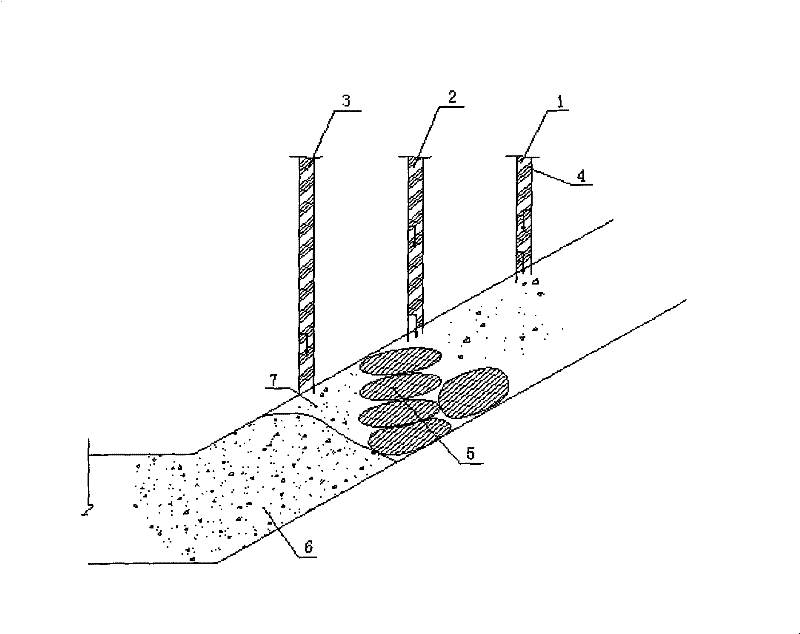

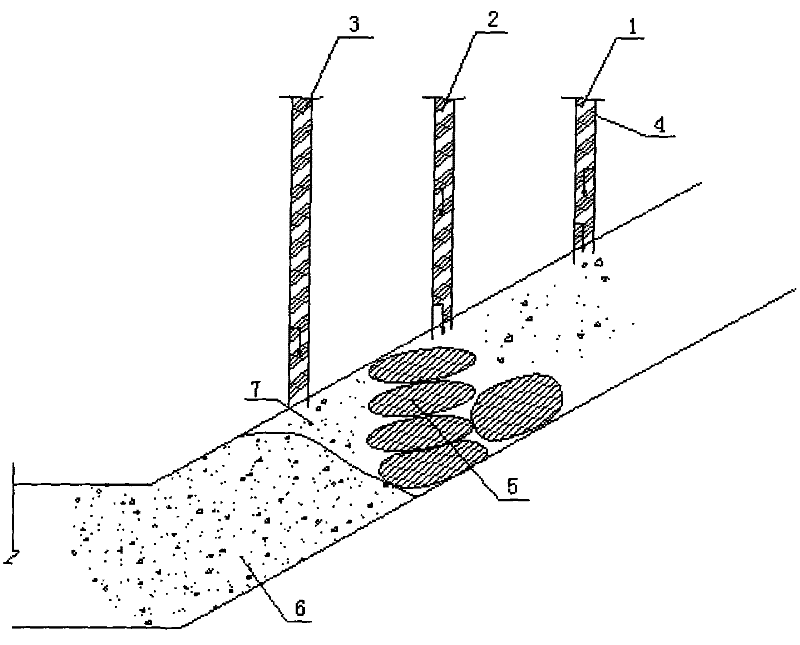

Deep imbedded underground water-permeable passage plugging method

ActiveCN101476336BStrong targetingImprove plugging efficiencyProtective foundationGeomorphologySlurry

The invention relates to a method for calking a deep underground nonwatertight channel, which adopts the technical proposal that the method comprises: measuring the flow velocity and the flow rate of leaked points of a main nonwatertight channel first; drilling three calking holes on the upstream, the midstream and the downstream of the nonwatertight channel, and selecting the particle diameter of calking materials to not more than one third of the aperture; using high-pressure blast to blow calking stone materials into an upstream hole; using the high-pressure blast to perform mold-bagged concrete calking on a midstream hole; using the high-pressure blast to throw the stone materials into a downstream hole for calking; and performing plaster slurry grouting on the upstream hole and the midstream hole after water seepage of the leaked points is obviously reduced until seeped water is completely calked. The method for calking the underground nonwatertight channel adopts a method for arranging the upstream hole, the midstream hole and the downstream hole and uses the stone materials, mold-bagged concrete and plaster slurry grouting to be combined with each other for calking the underground nonwatertight channel, has strong pertinence of drilling and calking, greatly improves the calking efficiency, and simultaneously reduces the calking workload and the calking cost.

Owner:CHINA GEZHOUBA GROUP CO LTD

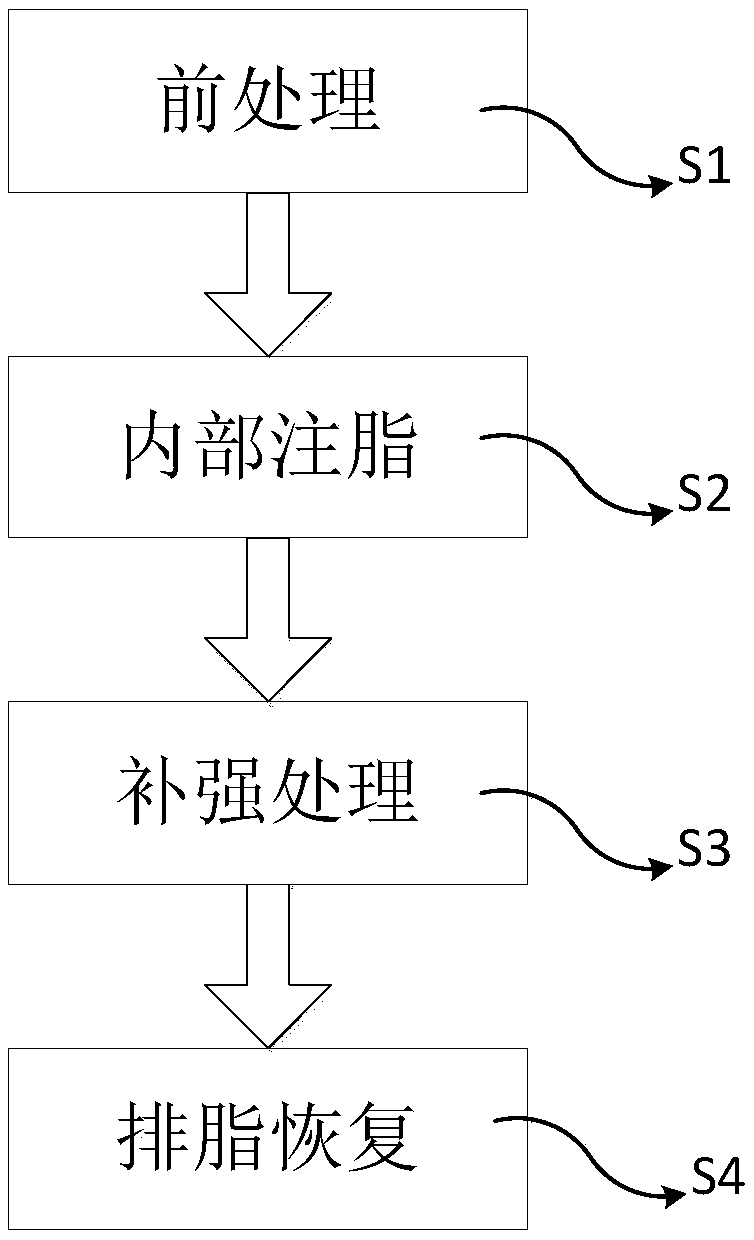

A method for sealing the leakage point between the branch port of the natural gas trunk pipeline and the root valve of the branch pipeline from the inside

The invention relates to a method for blocking the leakage points between natural gas main pipeline branch openings and a branch line pipeline root valve from the inside. The method comprises following steps that S1, pretreatment, wherein a branch line pipeline upper root valve and a downstream stop valve closest to the branch line pipeline upper root valve are closed, a pipeline between the two valves is emptied, and the emptied pipeline is dismounted from the root valve; S2, internal grease injecting, wherein a grease injecting and discharging device is arranged on an outlet of the root valve, seal grease is injected, and the leakage points are temporarily blocked; S3, reinforcing treatment, the leakage points are cleaned and ground from the outer portion of the pipeline, leakage stop cement gum is smeared and aligned, and after the leakage stop cement gum is completely hardened, a fiber cloth is used for winding the leakage point pipeline, and bonding is carried out through epoxy impregnating resin; S4, grease discharging recovery, wherein after seal grease is discharged, the root valve is closed, the grease injecting and discharging device is dismantled, an original pipeline isreassembled, and leakage stoop is finished. The method has the beneficial effects that a main pipeline is subject to conveying belt pressure leakage stop continuously, the method is simple, a large amount of emptying is not needed, the leakage stop cost is low, the damage to the environment is small, and the leakage stop effect is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com