A composite reinforced plugging slurry and plugging method

A technology of plugging slurry and base slurry, applied in chemical instruments and methods, earthwork drilling, drilling composition, etc., can solve the problem of gravity settlement, incomplete filling of cracks, and easy accumulation of plugging materials at the bottom of crack spaces, etc. problem, to achieve the effect of reducing the accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

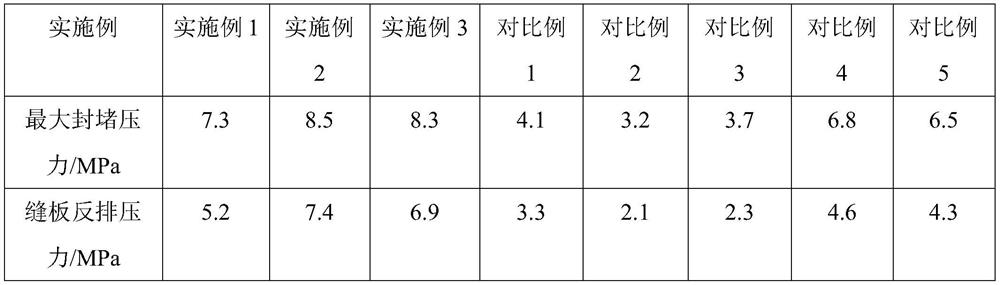

Examples

Embodiment 1

[0033] A composite enhanced plugging slurry, aiming at drilling fluid loss rate greater than 0 and less than or equal to 10.0m 3 Permeability leakage per hour, including the following raw materials by weight: 100 parts of base slurry, 6 parts of expandable plugging enhancer HJK-5(Ⅱ), 3 parts of inorganic plugging agent FDL, 3 parts of composite plugging agent, 1 part of thickener, 5 parts of consolidation agent A, 8 parts of consolidation agent B;

[0034] The base slurry is prepared by mixing sodium bentonite and water, and the mass content of the sodium bentonite in the base slurry is 4%.

[0035] The average particle size of the expandable plugging enhancer HJK-5(II) is 1.5-2.0mm.

[0036] The average particle size of the inorganic plugging agent FDL is 1.0-1.4mm, and the average density is 2.6 / cm 3 , the preparation method is as follows: mix mica flakes, expansive vermiculite, and shell fragments in a mass ratio of 1:1:2, and then grind and screen to obtain the inorganic...

Embodiment 2

[0043] A composite enhanced plugging slurry, aimed at drilling fluid loss rate greater than 10.0 and less than or equal to 25.0m 3 / h of fracture leakage, including the following raw materials by weight: 100 parts of base slurry, 12 parts of expandable plugging enhancer HJK-5 (Ⅱ), 5 parts of inorganic plugging agent FDL, 5 parts of composite plugging agent, 2.5 parts of thickener, 10 parts of consolidation agent A, 16 parts of consolidation agent B;

[0044] The base slurry is prepared by mixing sodium bentonite and water, and the mass content of the sodium bentonite in the base slurry is 4%.

[0045] The average particle size of the expandable plugging enhancer HJK-5(II) is 4.0-4.5mm.

[0046] The average particle size of the inorganic plugging agent FDL is 2.5-3.0mm, and the average density is 2.6g / cm 3 , the preparation method is as follows: mix mica flakes, expansive vermiculite, and shell fragments in a mass ratio of 1:1:2, and then grind and screen to obtain the inorga...

Embodiment 3

[0053] A composite enhanced plugging slurry, aiming at drilling fluid loss rate greater than 25.0 and less than or equal to 40.0m 3 / h fracture leakage, including the following raw materials by weight: 100 parts of base slurry, 15 parts of expandable plugging enhancer HJK-5 (Ⅱ), 8 parts of inorganic plugging agent FDL, 8 parts of composite plugging agent, 5 parts of thickener, 15 parts of consolidation agent A, 20 parts of consolidation agent B;

[0054] The base slurry is prepared by mixing sodium bentonite and water, and the mass content of the sodium bentonite in the base slurry is 4%.

[0055] The average particle size of the expandable plugging enhancer HJK-5(II) is 6.5-7.0mm.

[0056] The average particle size of the inorganic plugging agent FDL is 4.5-5.0mm, and the average density is 2.6g / cm 3 , the preparation method is as follows: mix mica flakes, expansive vermiculite, and shell fragments in a mass ratio of 1:1:2, and then grind and screen to obtain the inorganic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com