Patents

Literature

43results about How to "Overcome the problem of uneven distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

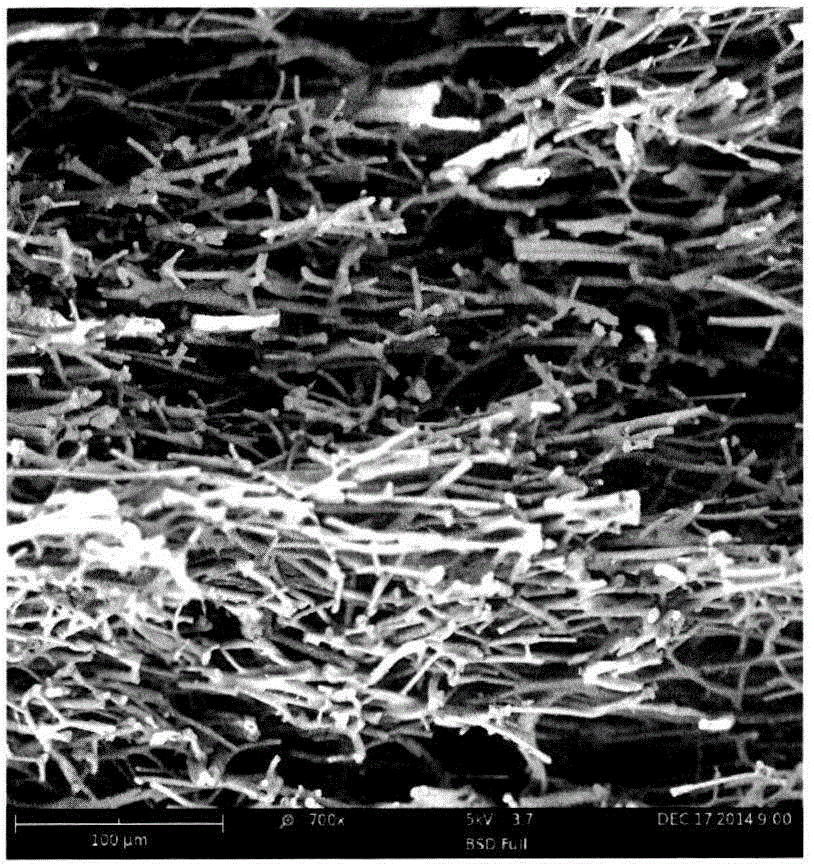

Environmental protection type base fibre film, and its mfg. process

ActiveCN1559176AHigh strengthLose weightOrganic fertilisersPlant protective coveringsAdhesiveEngineering

An environmental protection type bast fibre film which is air permeable and impervious is prepared from bast fibres through opening fibres, removing dust and impurities, carding, stripping for netting, airflow netting, chemical sticking by adhesive to become film, applying the hydrophobic agent onto its surfaces, and cold rolling.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

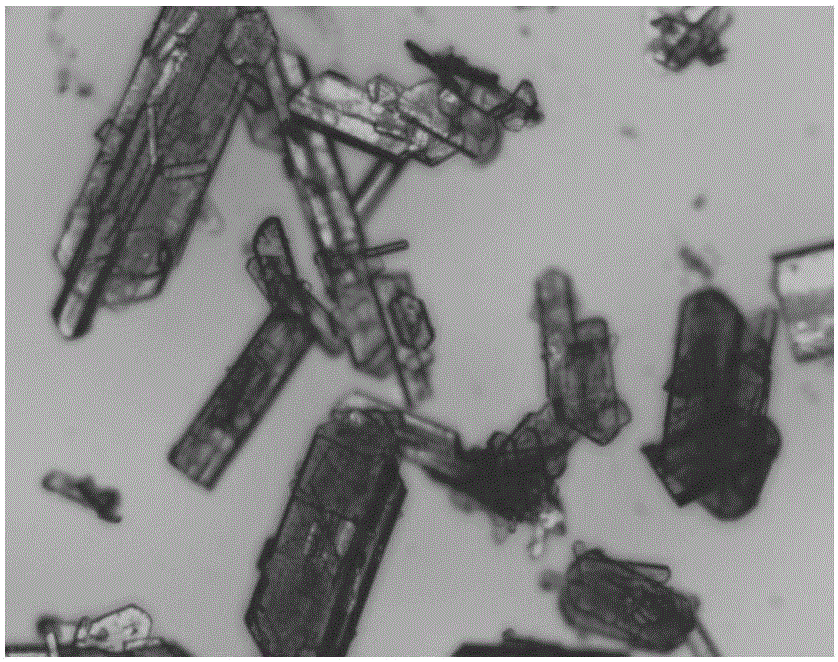

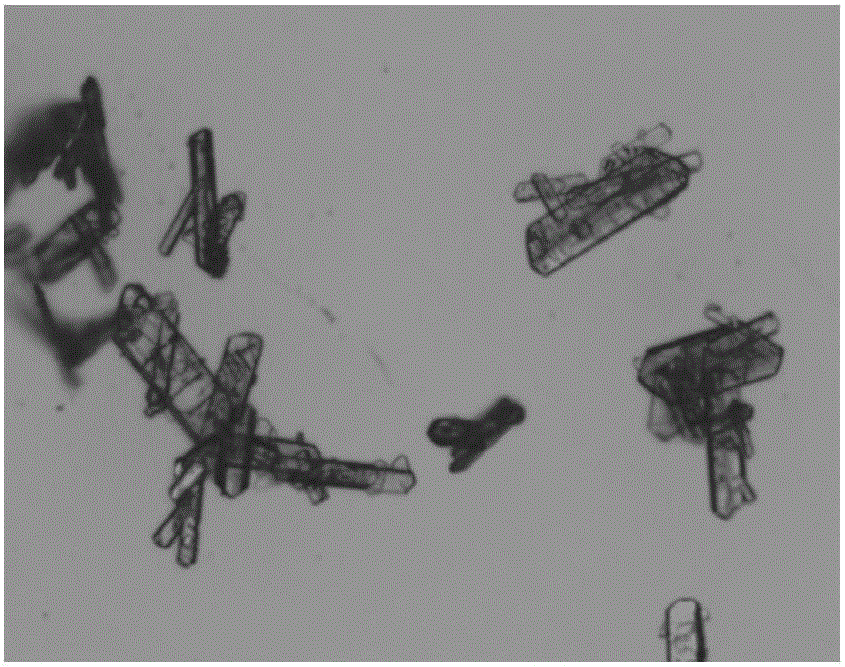

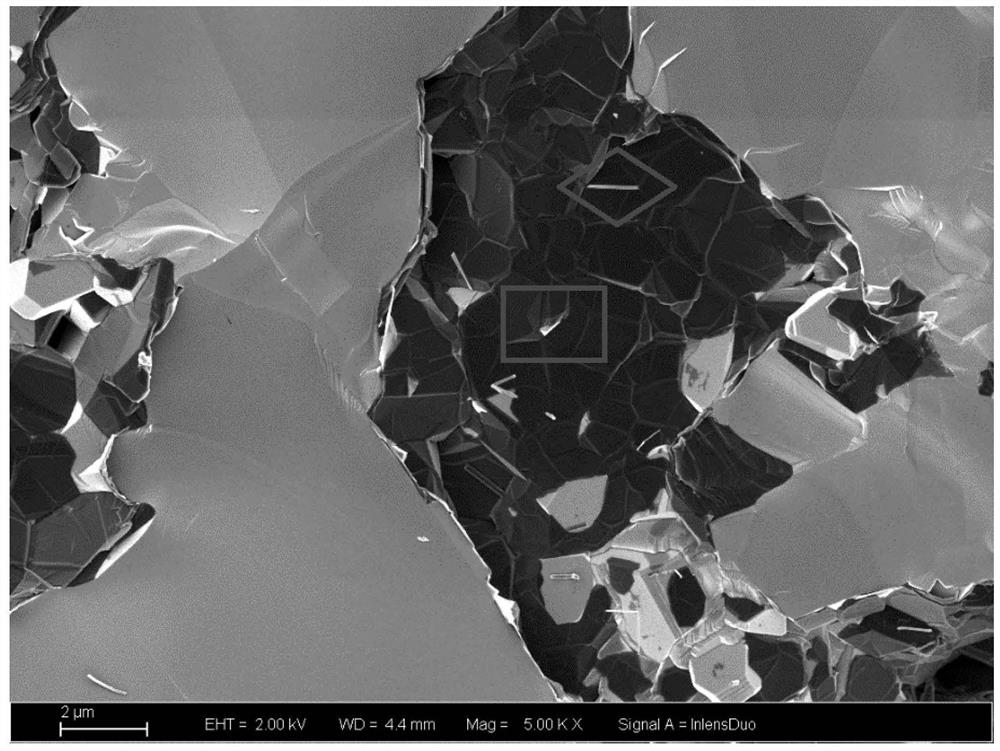

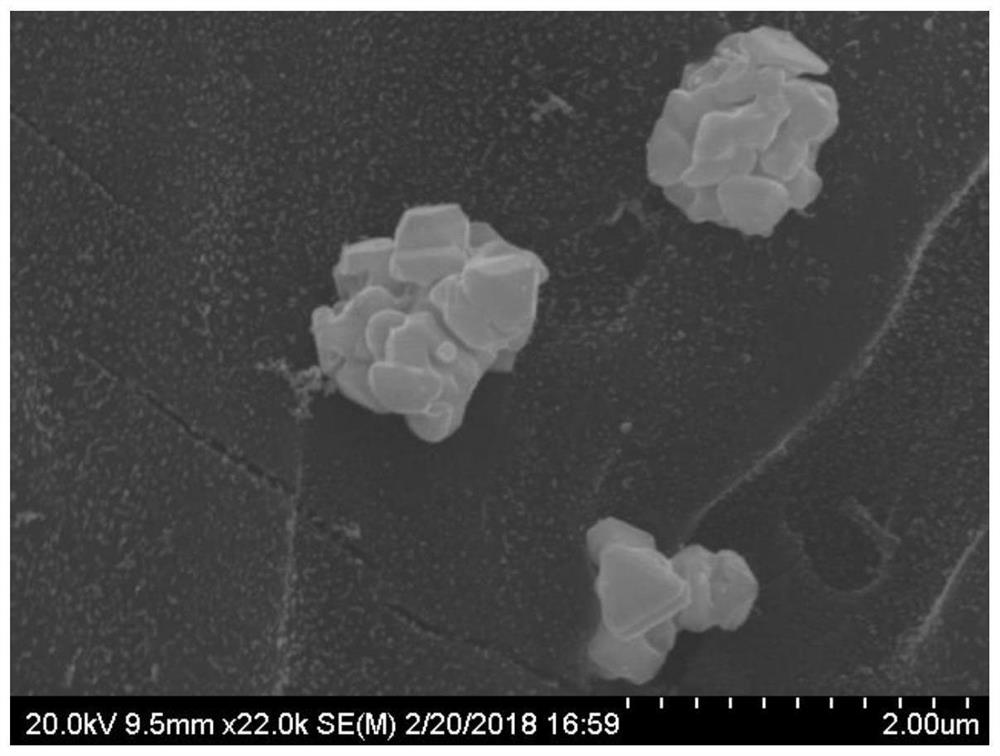

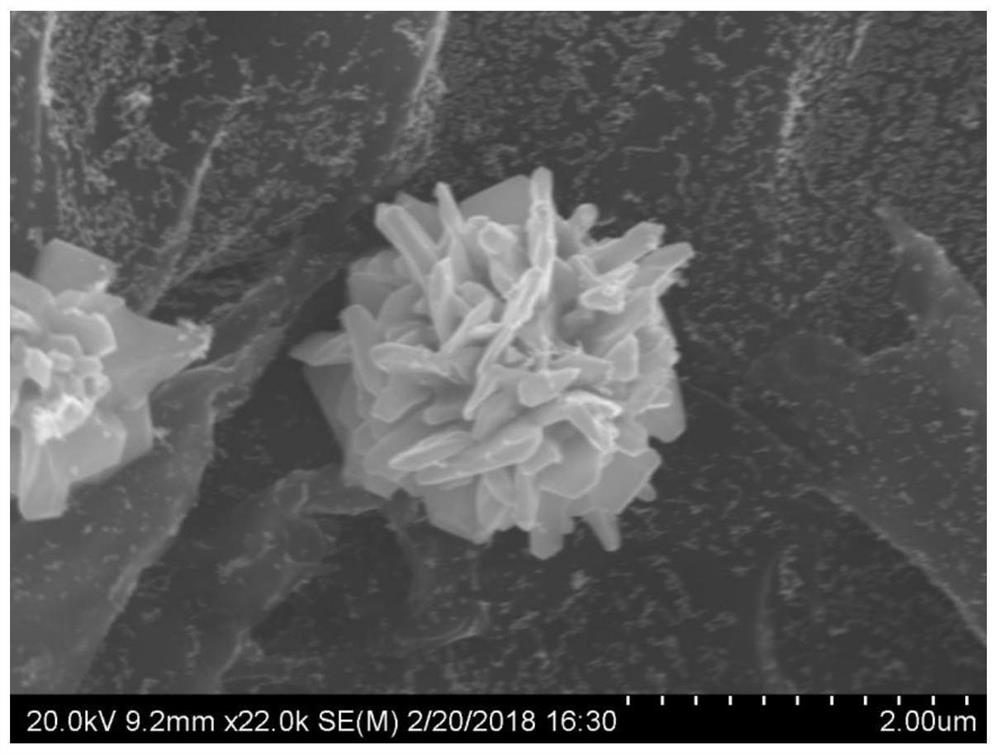

Rare earth alloy powder-modified Ti(C,N)-based metal ceramic and preparation method thereof

The invention discloses a rare earth alloy powder-modified Ti(C,N)-based metal ceramic and a preparation method of the metal ceramic. The metal ceramic comprises Co and Ni or at least two of components selected from Co, Ni as well as Fe as a bonding phase, Ti(C,N) as a basic hard phase and optionally at least one of metallic carbides; and a rare earth alloy powder modifier 0.1-3wt% of the total mass of the metal ceramic. The preparation method comprises treating a raw material through a wet-grinding and mixing process, a die-forming process, a vacuum-degreasing process and a low-pressure sintering process to prepare the rare earth alloy powder-modified Ti(C,N)-based metal ceramic. On the premise of keeping high hardness and high wear resistance, the Ti(C,N)-based metal ceramic prepared according to the invention has excellent comprehensive performance, can be greatly improved in strength and tenacity and can also be widely applied to various cutting tools and wear-resistant parts.

Owner:SICHUAN UNIV

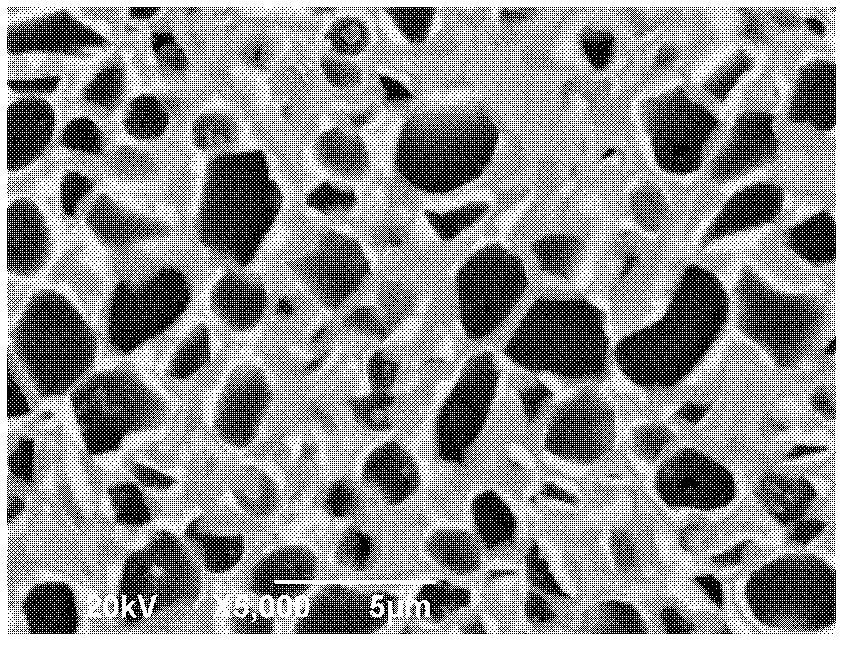

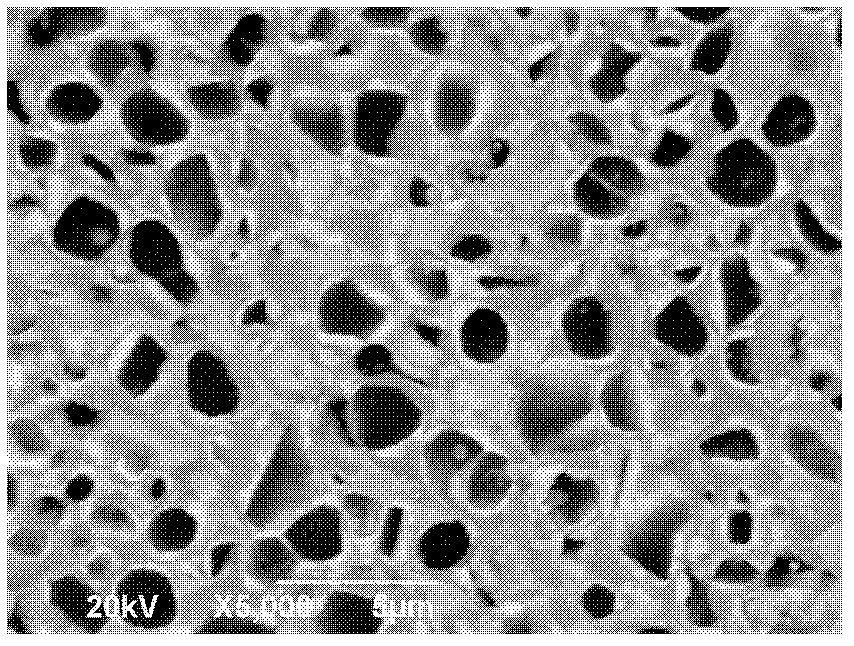

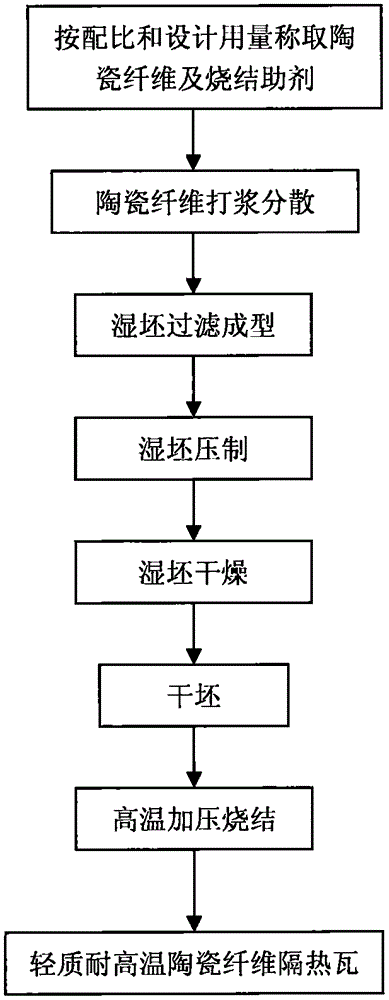

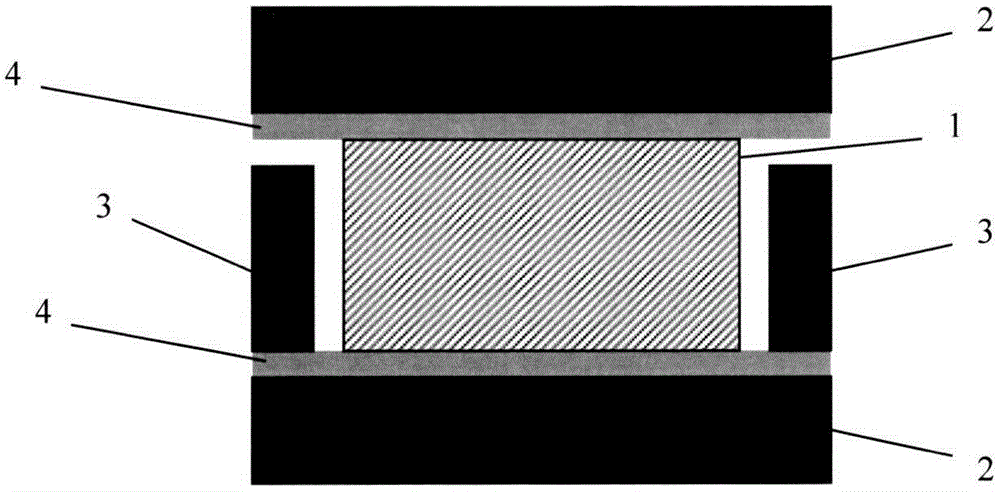

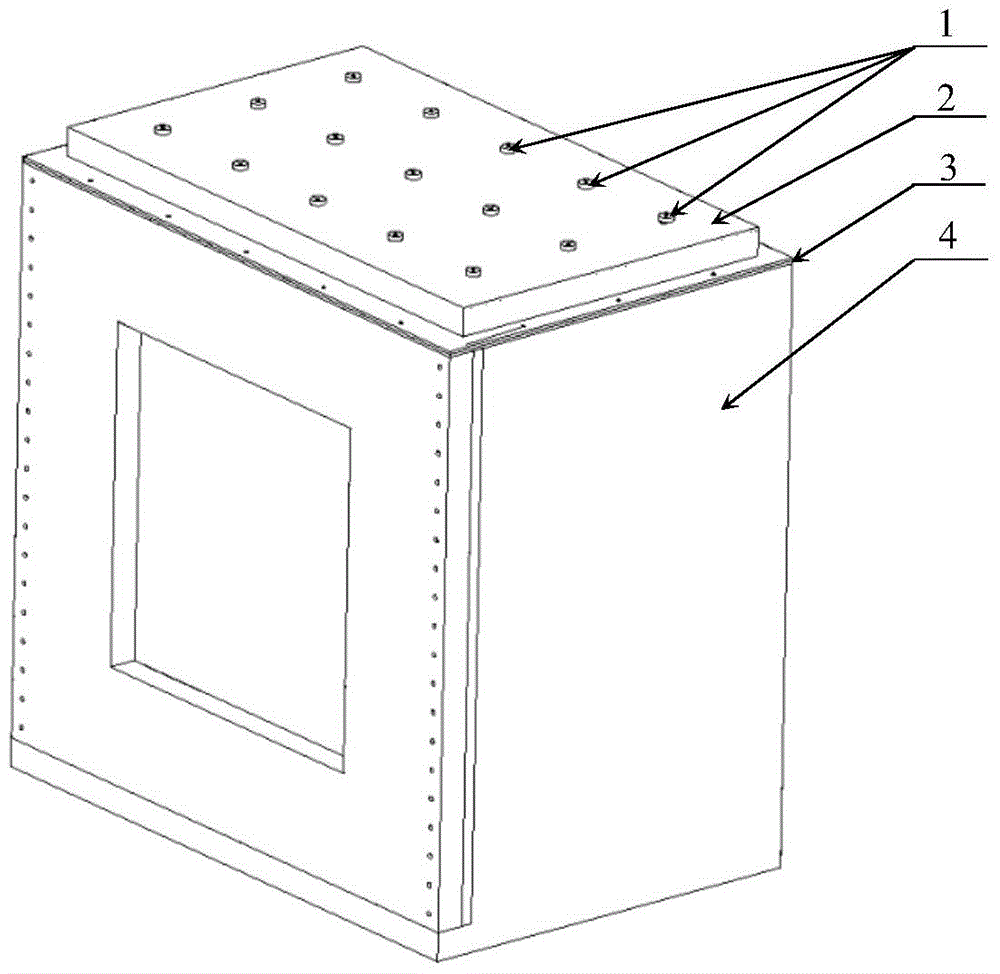

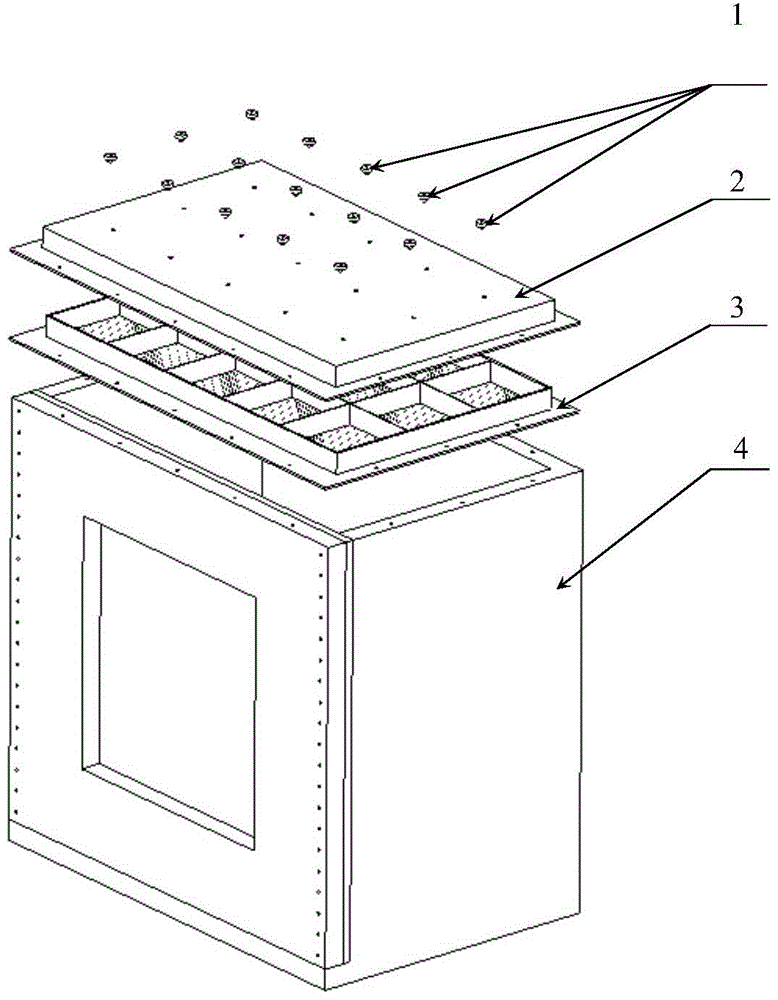

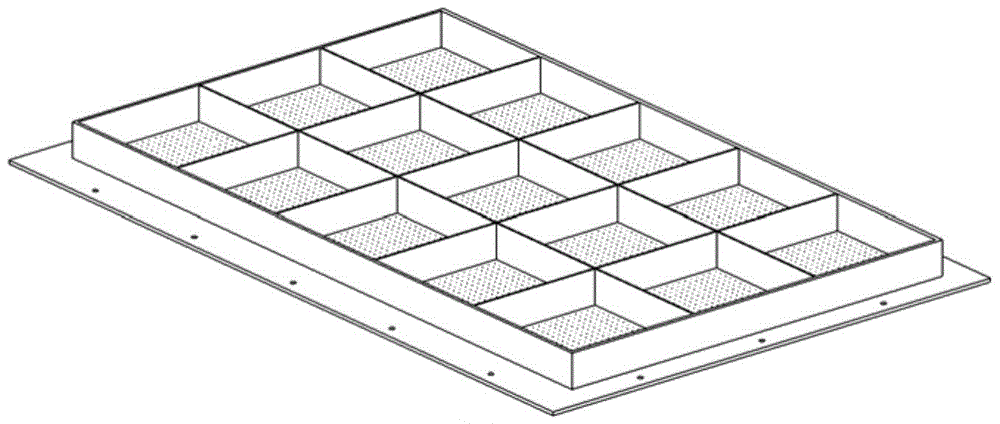

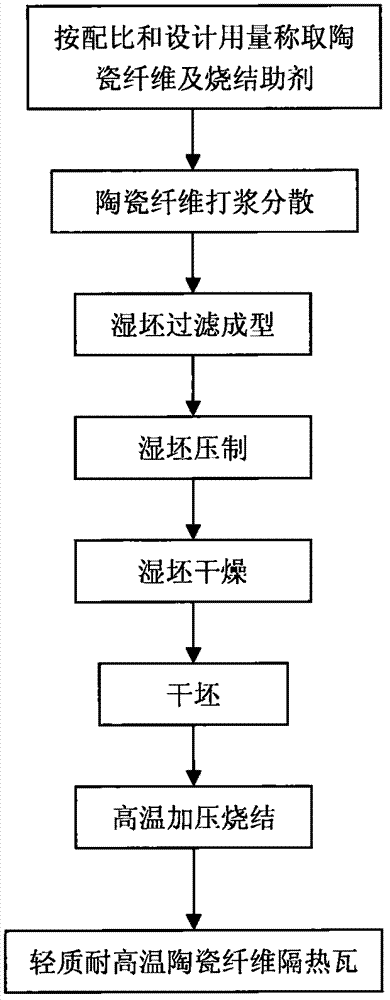

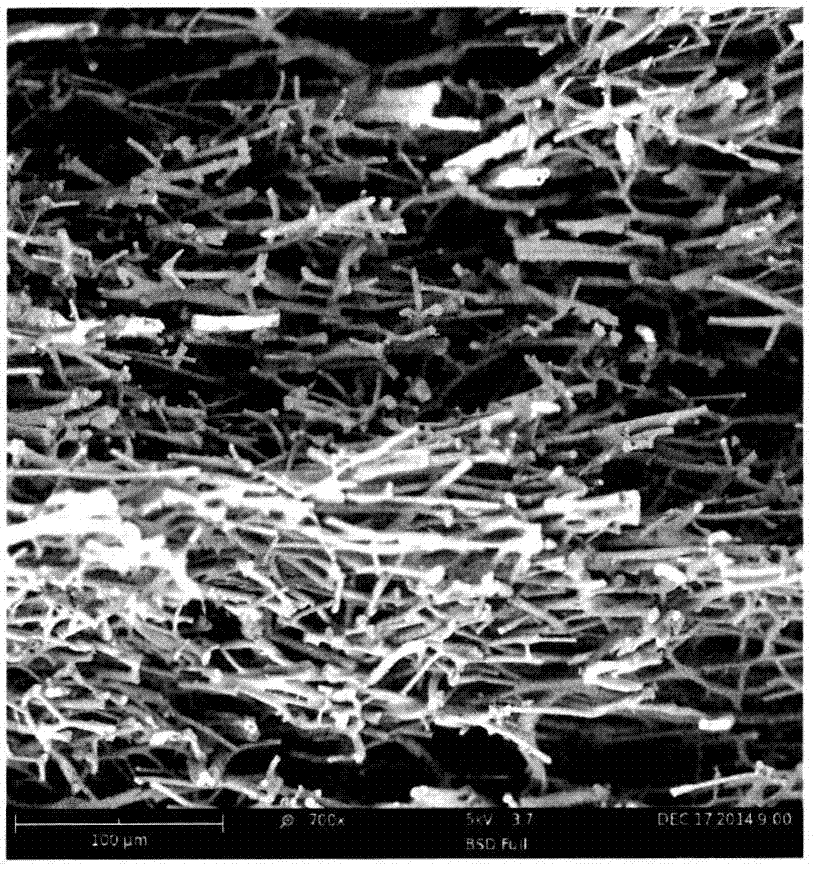

Light-weight, high temperature-resistance and heat-insulation ceramic fiber tile and making method thereof

ActiveCN105272322AOvercome the problem of uneven distributionImprove mechanical propertiesRoom temperatureSlurry

The invention relates to a light-weight, high temperature-resistance and heat-insulation ceramic fiber tile and a making method thereof. The heat insulation tile comprises ceramic fibers and boron oxide, wherein the ceramic fibers comprise quartz fibers, alumina fibers and yttrium oxide stabilized zirconia fibers. The making method of the light-weight, high temperature-resistance and heat-insulation ceramic fiber tile comprises the following steps: preparing a sintering aid suspension, preparing a ceramic fiber slurry, carrying out wet green body molding, drying the obtained wet green body, and carrying out pressurization sintering. The heat insulation tile has good heat insulation effect and mechanical performances, has light weight and resists high temperature; the density is controllable between 0.10g / cm<3> and 0.90g / cm<3>; the lowest apparent heat conduction coefficient at room temperature reaches 0.033W / (m.K); the compressive strength at room temperature is greater than 3.0Mpa; and the long-time use temperature can reach 1350DEG C.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

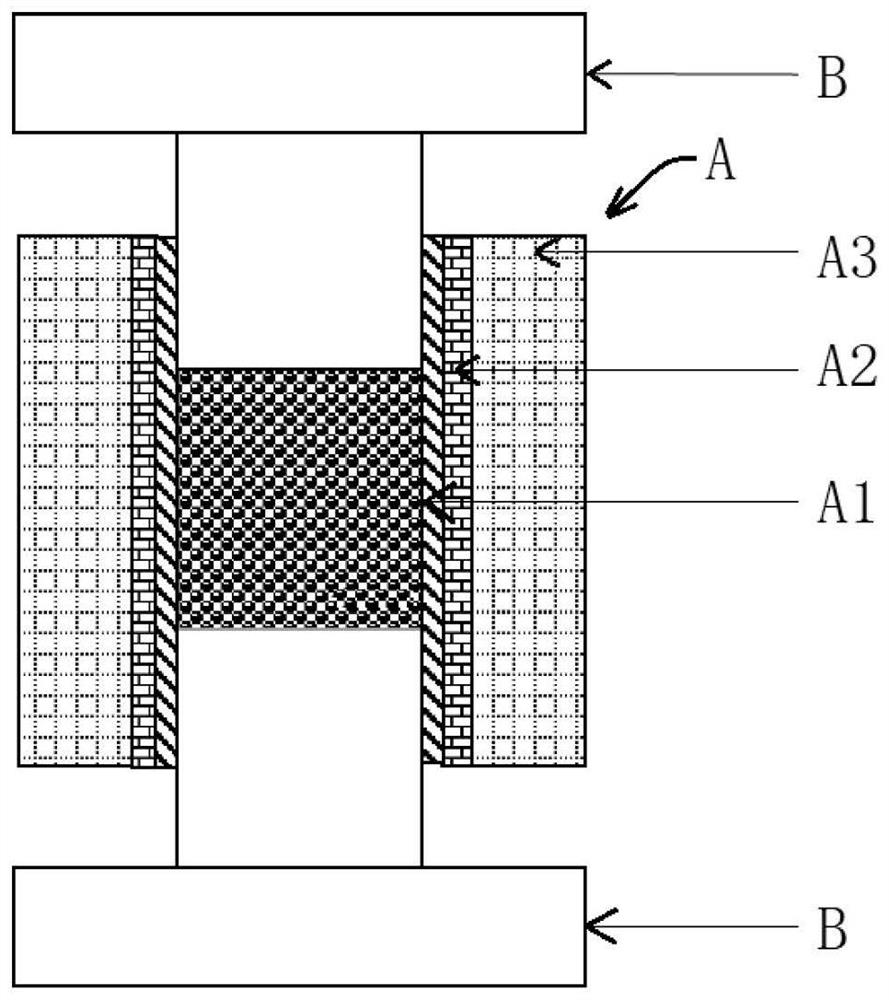

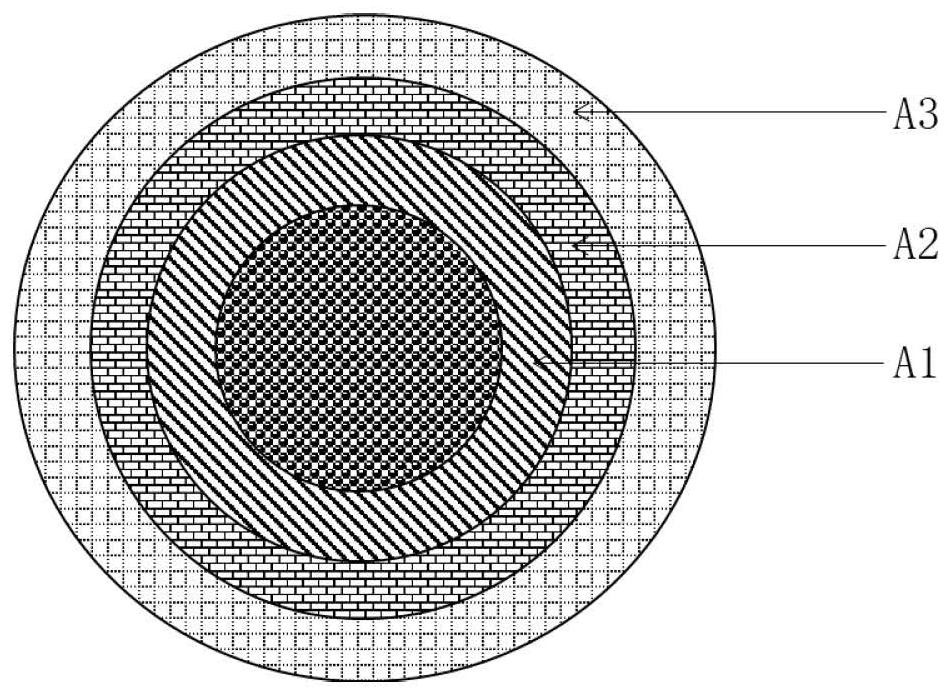

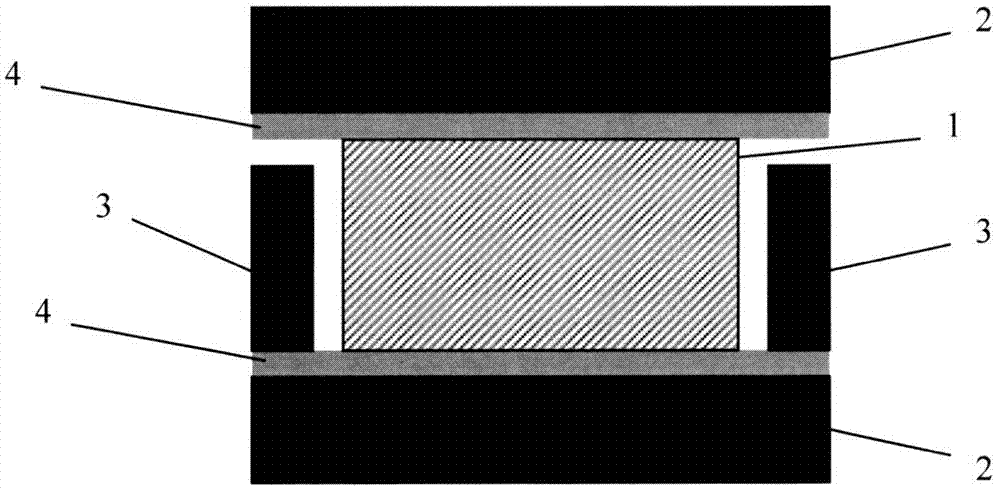

Method for preparing B4C-Al neutron-absorbing plate for spent fuel storage and transportation

ActiveCN102110484AControl criticalOvercoming reactivityNuclear energy generationReactors manufactureFuel tankInterfacial bond

The invention discloses a method for preparing a B4C-Al neutron-absorbing plate for spent fuel storage and transportation, which is implemented by adopting a frame rolling technique through the following steps: firstly, uniformly mixing a certain amount of B4C powder and Al matrix powder; then, carrying out mould pressing on the obtained mixture so as to obtain a compact green core body, sintering the compact green core body in a vacuum furnace, putting the sintered core body into an aluminum alloy frame, and sealing the aluminum alloy frame; and finally, rolling to obtain a plate. The process for preparing the neutron-absorbing plate is simple, the B4C is uniformly distributed into an Al matrix, and the B4C and the Al matrix have a good interfacial bond. The neutron-absorbing plate prepared by using the method disclosed by the invention is suitable for being used as a neutron-absorbing material in spent fuel tanks and transportation containers, thereby controlling the critical safetyof the spent fuel.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

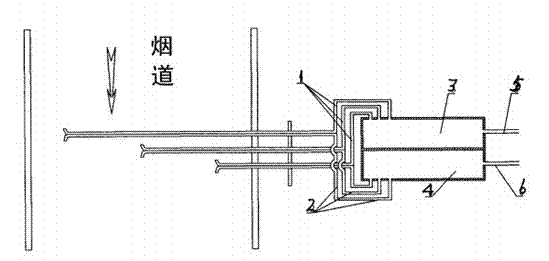

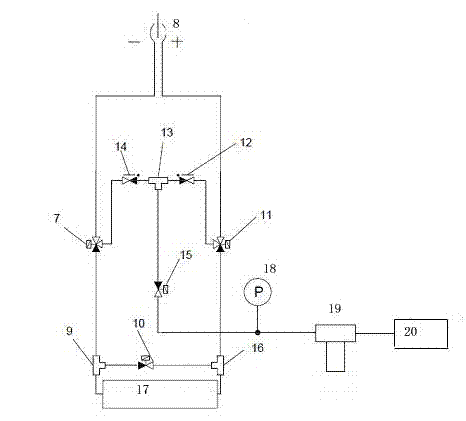

Integrated measuring device for multiple-point type flow velocity pressure temperature

ActiveCN103033289ASimple structureEasy to install on siteFluid pressure measurement by electric/magnetic elementsFluid speed measurement using pressure differenceFlue gasMultiple point

The invention discloses an integrated measuring device for multiple-point type flow velocity pressure temperature, and belongs to the technical field of flue gas flow velocity measuring devices. The integrated measuring device for the multiple-point type flow velocity pressure temperature comprises a gas circuit detection unit (8), a backflow calibration unit and a sensing measurement unit (17). An outlet of a dynamic pressure tube of the gas circuit detection unit (8) and an outlet of a static pressure tube of the gas circuit detection unit (8) are respectively connected with an air inlet of the backflow calibration unit. A temperature sensor of the gas circuit detection unit (8) is connected with the sensing measurement unit (17). Through the integrated measuring device for the multiple-point type flow velocity pressure temperature, multi-point measurement on the same pitot tube is achieved, flow velocity of a cross hatching line is directly outputted, accuracy of measurement of fuel gas flow velocity is improved, a gas circuit of a system is shortened, loss of backflow air supply pressure which is caused by the phenomenon that the gas circuit is too long is prevented, the backflow effect is enabled to reach an optimal level, and the gas circuit is prevented from being blocked by dust.

Owner:南京吉纳波环境测控有限公司

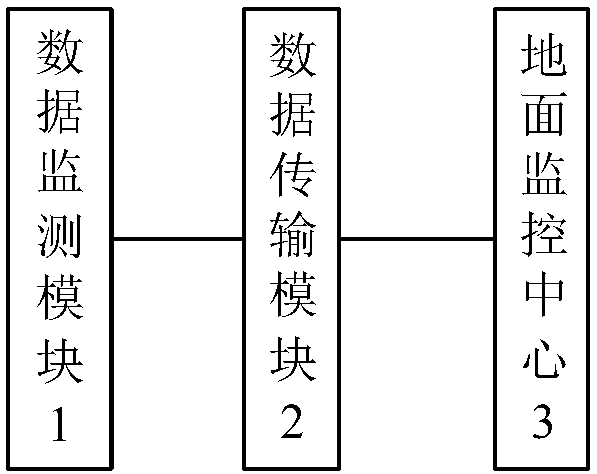

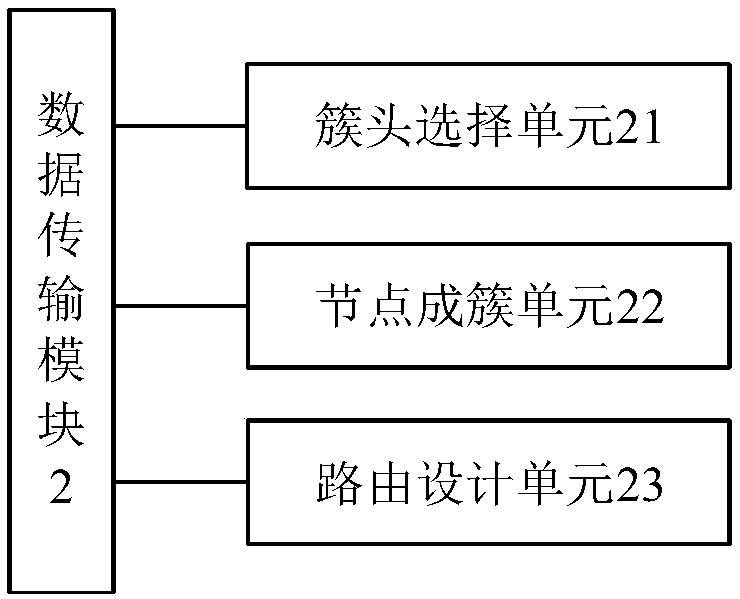

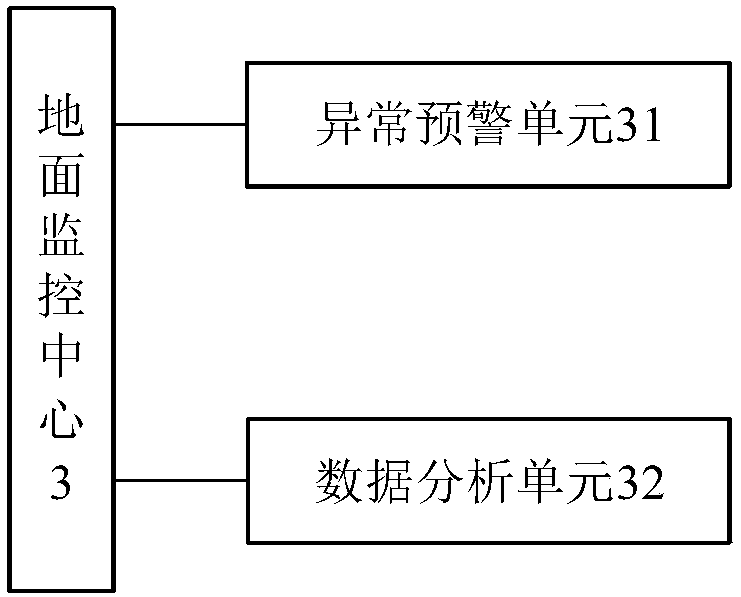

Mine surrounding rock monitoring system based on wireless sensor network

InactiveCN107484222AOptimizing Race ConditionsOptimize topologyPower managementMeasurement devicesLine sensorWireless mesh network

The invention discloses a mine surrounding rock monitoring system based on a wireless sensor network. The system comprises a data monitoring module, a data transmission module and a ground monitoring center. The data monitoring module is used for collecting characteristic changes resulting from surrounding rock stress change in an underground coal mining process, wherein the collection comprises temperature collection, pressure collection and slight vibration signal collection. The data transmission module is used for transmitting collected temperature, pressure and slight vibration signals to the ground monitoring center through adoption of a wireless sensor network technology. The ground monitoring center is used for analyzing geological condition according to the change of received monitoring data when underground mining is carried out and carrying out alarm when an abnormity occurs in the monitoring data. The system has the beneficial effects that through adoption of the wireless sensor technology, the security monitoring of mine surrounding rocks is realized; in the wireless sensor network, a cluster head in the network is selected through adoption of an improved LEACH algorithm; a cluster head competition condition is optimized; and the problem that cluster head nodes are not distributed uniformly is overcome.

Owner:潘金文

Water and fertilizer integrated fertilizer applying method for mangoes

InactiveCN106258141AImprove fertilizer use efficiencyReduce fertilizer useCalcareous fertilisersMagnesium fertilisersFertilizerBud

The invention discloses a water and fertilizer integrated fertilizer applying method for mangoes, which belongs to the technical field of agricultural irrigation and fertilizer application. The water and fertilizer integrated fertilizer applying method comprises the following steps of dissolving a water soluble fertilizer in water, and performing infiltration irrigation to soil at root zones, wherein the infiltration irrigation specifically comprises infiltration irrigation fertilizer application for mangoes at a flower bud differentiation period, infiltration irrigation fertilizer application for mangoes at a flowering period, infiltration irrigation fertilizer application for mangoes at a young fruit enlarging period, and infiltration irrigation fertilizer application for mangoes after being picked. Compared with a conventional fertilizer applying method, the water and fertilizer integrated fertilizer applying method disclosed by the invention has the advantages that the amount of the fertilizer is saved by 50% or above, the evaporation amount of water is notably reduced, and water is saved by 80%; the problem of pressure difference caused by a slope is solved, flow quantities of the water and the fertilizer on slopes and below the slopes are uniform, the growth vigours of tree bodies on the slopes and below the slopes are the same, and the yield is notably increased by 30% or above. An infiltration irrigation pipeline used for the method is buried underground, and farming operations of field weeding and insecticide spraying are not influenced.

Owner:上海国环生态科技股份有限公司

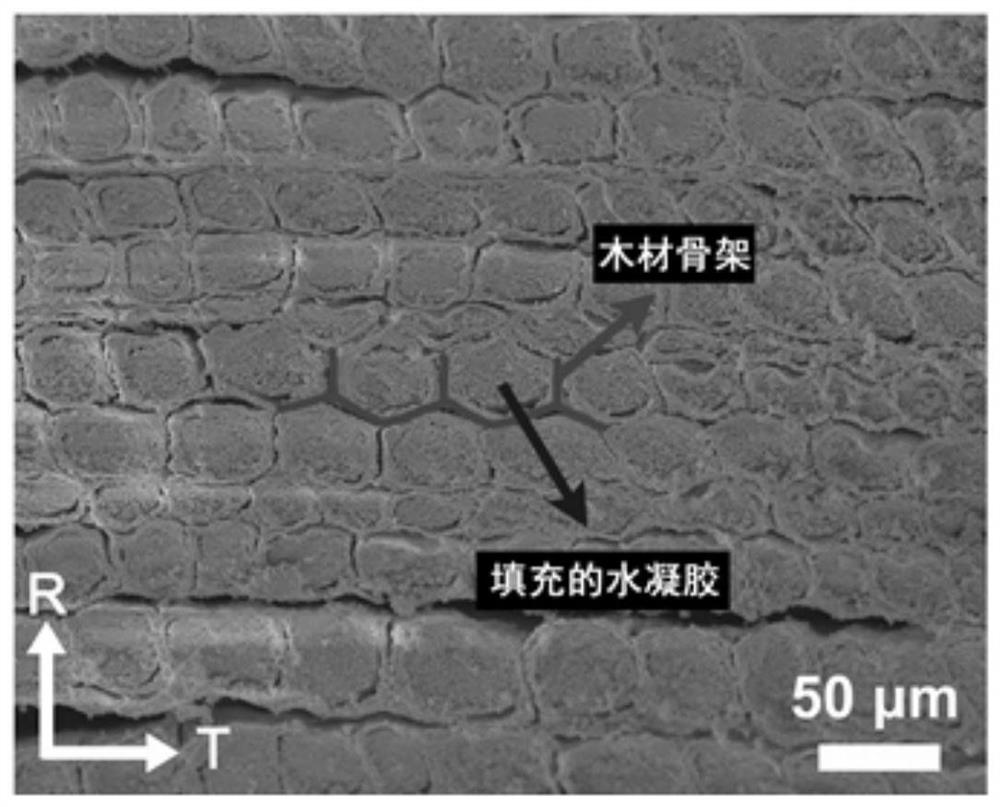

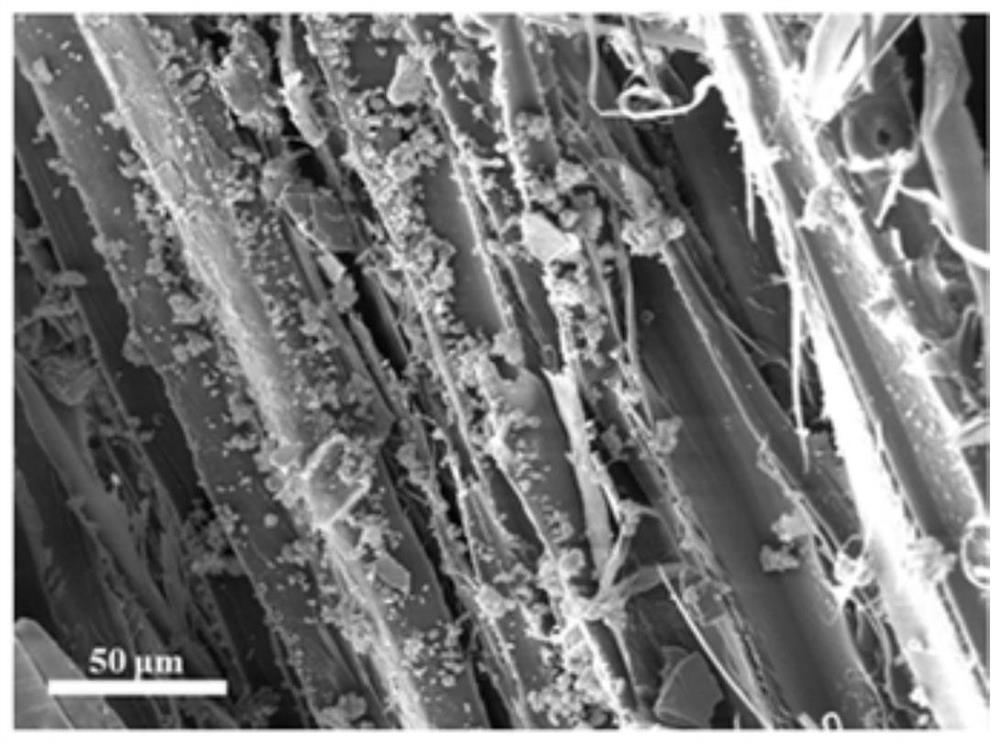

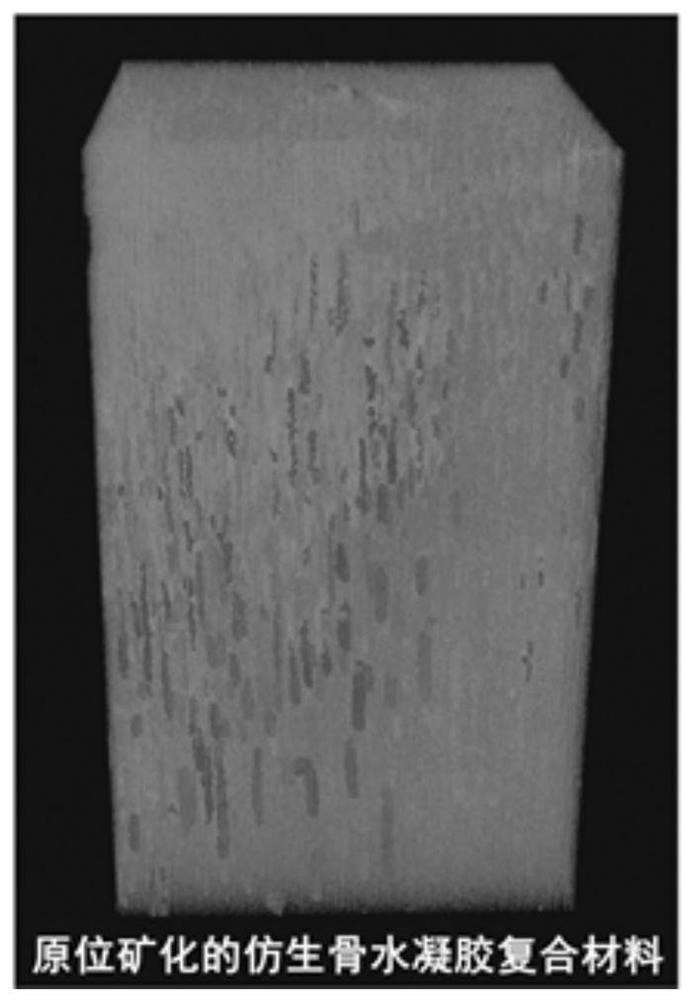

In-situ mineralized bionic bone hydrogel composite material with oriented structure as well as preparation method and application thereof

ActiveCN112402695APromote new bone growthGood osseointegration and mechanical stabilityTissue regenerationProsthesisOsteoblast adhesionMacromolecule

The invention relates to an in-situ mineralized bionic bone hydrogel composite material with an oriented structure as well as a preparation method and application thereof, which comprises a natural plant fiber template, natural polymer hydrogel directionally filled in the natural plant fiber template and hydroxyapatite directionally deposited in the natural plant fiber template. The hydrogel composite material has a three-dimensional porous structure and is anisotropic, which overcomes the problem of uneven distribution of hydroxyapatite particles in the hydrogel matrix; the material has super-strong tensile strength, compression strength, bending strength and toughness, and the mechanical properties are matched with those of hard bone tissues. The material is beneficial to induce pre-osteoblast adhesion and osteogenic differentiation, promote new bone growth, has good osseointegration and mechanical stability, and is suitable for large-area hard bone tissue repair; in addition, the material has adjustable surface activity, and fine adjustment and control of the structure and the surface can be achieved.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

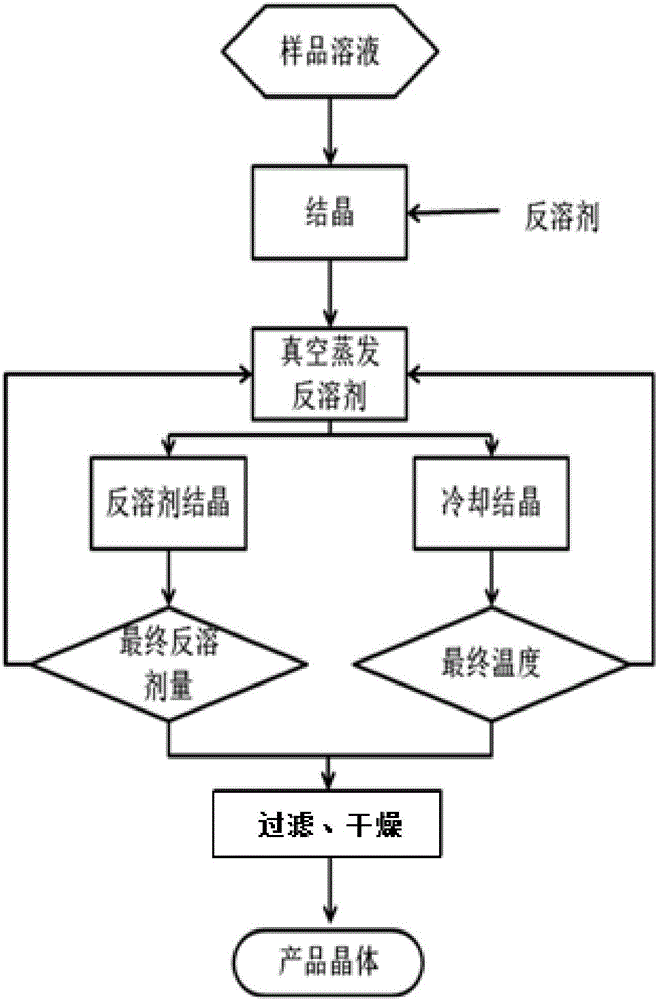

Crystallization method integrating anti-solvent crystallization, vacuum evaporation and cooling or anti-solvent crystallization

ActiveCN105031963AAchieve dissolutionLarge particle sizeSugar derivativesOrganic compound preparationAnti solventVacuum evaporation

The invention provides a crystallization method integrating anti-solvent crystallization, vacuum evaporation and cooling or anti-solvent crystallization. The method comprises the following steps: (1) preliminary anti-solvent crystallization: placing a to-be-crystallized amino acid material into a crystallizer, adding solvent water and allowing the material to be fully dissolved, carrying out heating to 30 to 80 DEG C, adding an anti-solvent into the crystallizer, carrying out full stirring, and allowing a part of the solute in the solution to be crystallized and separated out so as to obtain a to-be-crystallized material; (2) vacuum evaporation and cooling or anti-solvent crystallization: continuing stirring, subjecting an obtained solid-liquid system to evaporation under an absolute pressure of 20 to 60 kPa, cooling the obtained solid-liquid system or adding the same anti-solvent as in the step 1 so as to promote crystals to continue to grow, and repeating the step 2 for 1 to 3 times; and (3), filtering and drying: carrying out filtering, washing and drying so as to prepare a crystallization product. The method provided by the invention has the advantages of convenient and fast operation, high yield and easy realization of industrial scale production, and can obtain the crystallization product with narrow particle-size distribution and a large particle size.

Owner:肇东星湖生物科技有限公司

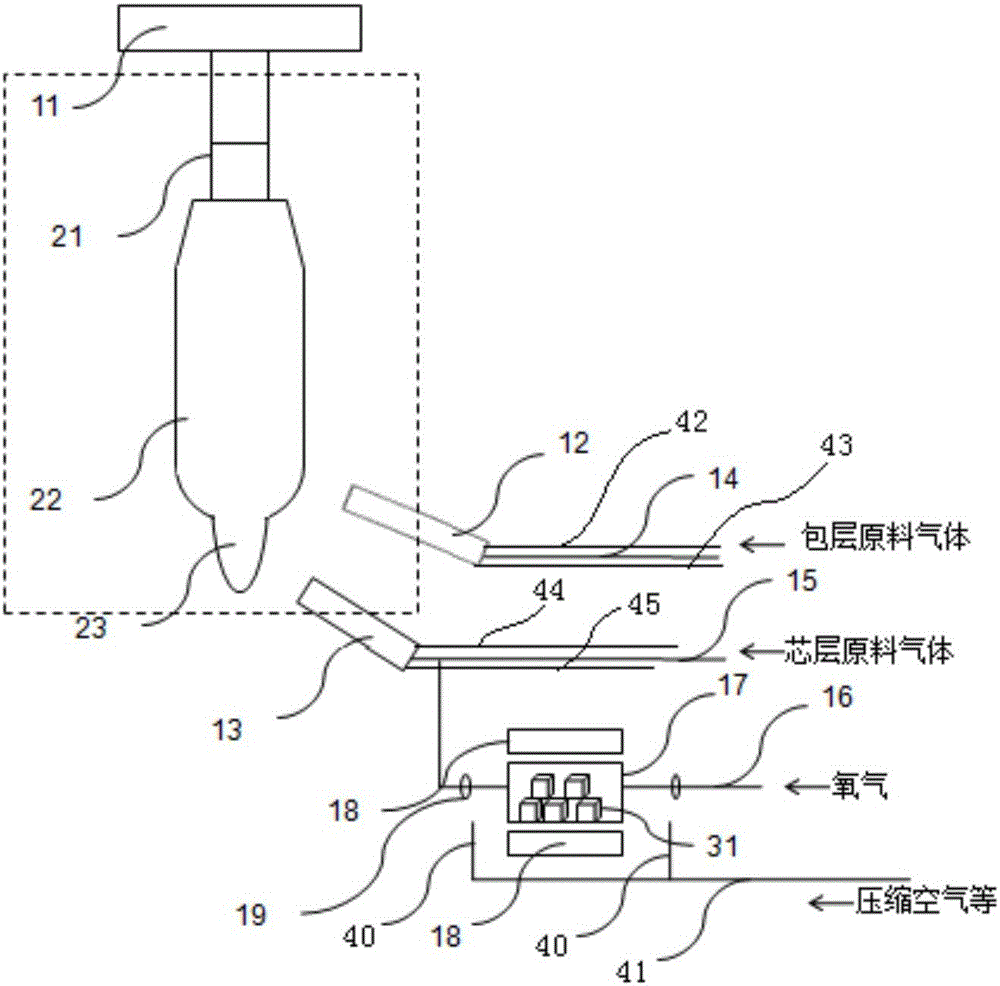

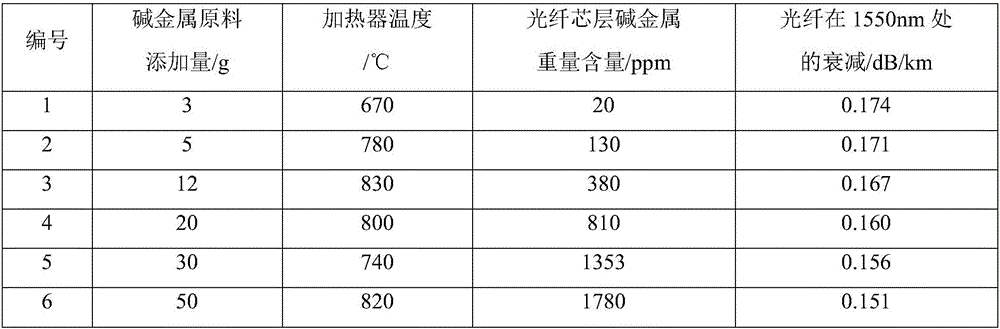

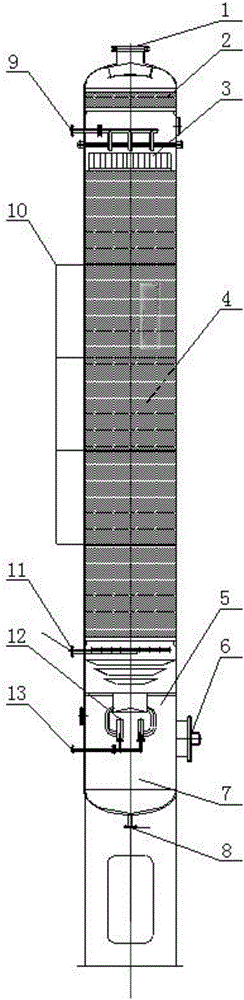

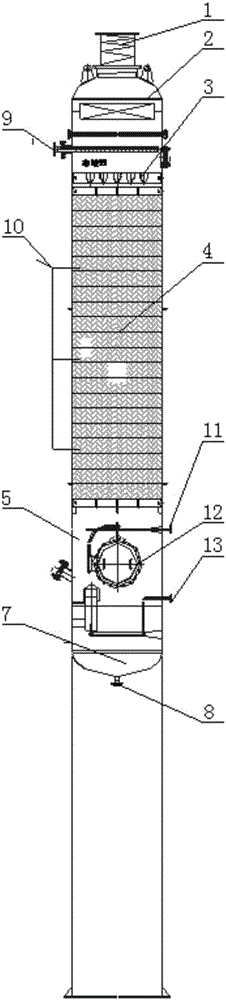

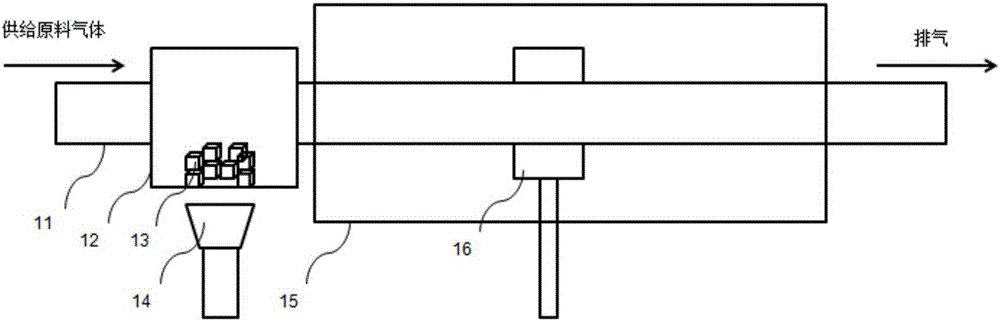

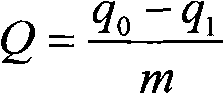

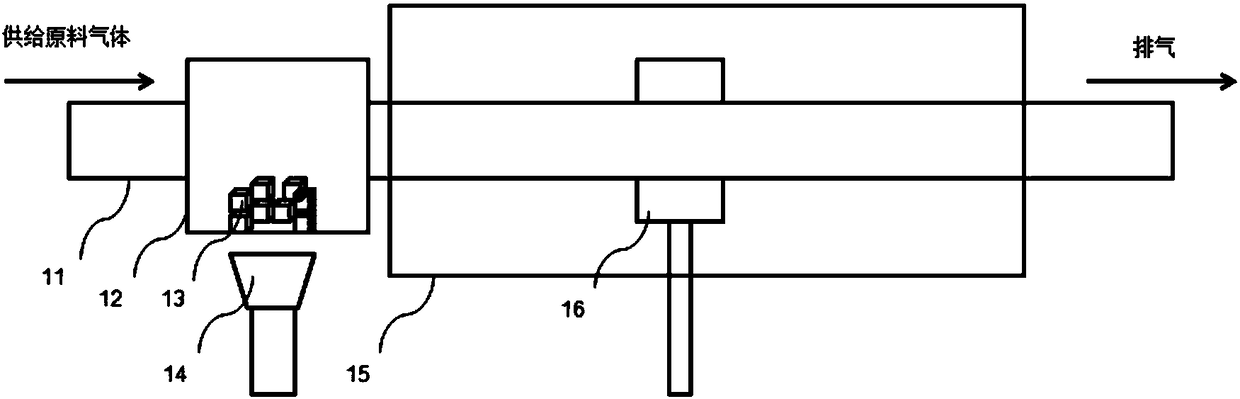

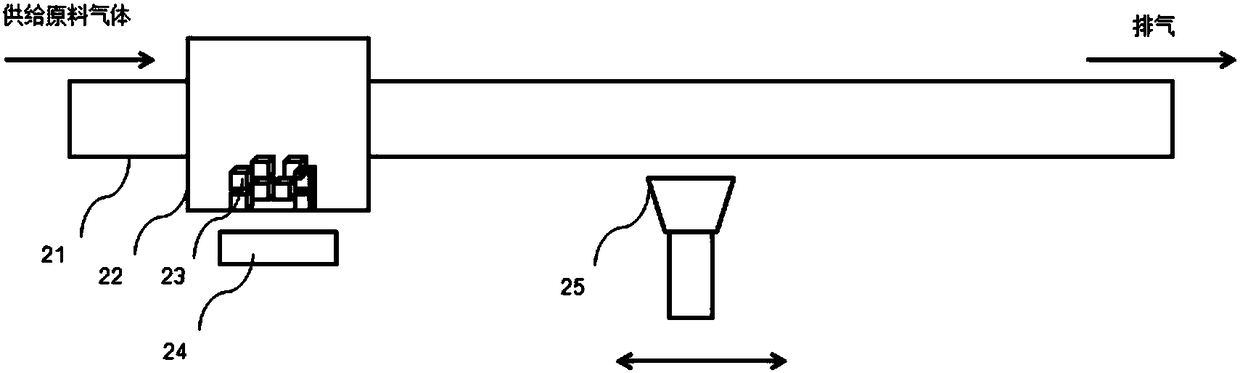

Production method of prefabricated fiber rod

ActiveCN106396362AEvenly distributed contentOvercome the problem of uneven distributionGlass deposition burnersDiffusion methodsContent distribution

The invention discloses a production method of a prefabricated fiber rod. The prefabricated fiber rod is produced through a vapor axial deposition technology. The method comprises the following steps: depositing a core layer by using a core layer blowtorch, and depositing a wrapping layer by using a wrapping layer blowtorch. The core layer blowtorch is connected with a core layer raw gas conveying pipeline, the wrapping layer blowtorch is connected with a wrapping layer raw gas conveying pipeline, the core layer raw gas conveying pipeline is connected with an oxygen conveying pipeline in parallel, the oxygen conveying pipeline is serially connected with a glass tube, and an alkali metal raw material is placed in the glass tube; the periphery of the glass tube is provided with a heater; and when the core layer is deposited, the heater and the oxygen conveying pipeline are started, oxygen carrying the alkali metal raw material volatilizing after being heated enters the core layer raw gas conveying pipeline, and deposits through the core layer blowtorch to form the alkali-doped prefabricated fiber rod core layer. Alkali metal doping is carried out in the deposition process of the core layer, and the content distribution of the alkali metal is uniform, so the problem of non-uniform distribution of the alkali metal in the glass tube in diffusion methods is solved, and the fiber attenuation is obviously reduced.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

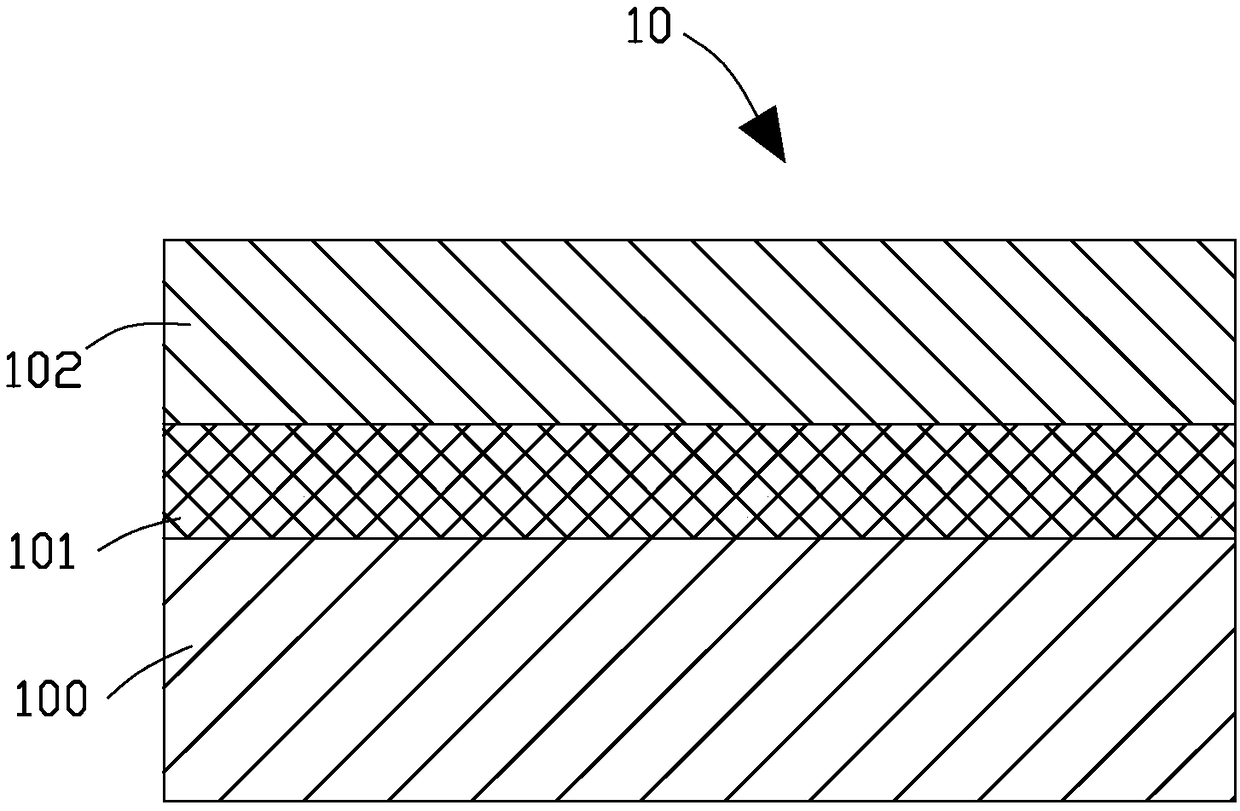

Graphene heat conducting member and preparation method thereof

ActiveCN110077048AOvercoming easy delaminationOvercome the thicknessLamination ancillary operationsGrapheneHeat conductingCvd graphene

The invention provides a graphene heat conducting member and a preparation method thereof. The preparation method of the graphene heat conducting member provided by the invention comprises the following steps: a) coating the surface of a graphene oxide film with organic liquid to form an organic liquid film, and then covering the surface of the organic liquid film with a graphite oxide film; spraying the organic liquid and covering with the graphite oxide film repeatedly until a desired thickness to obtain a composite precursor; b) cold-pressing the composite precursor to obtain a pressed body; c) performing heat treatment on the pressed body under an inert gas or reducing gas condition to obtain a heat-treated member; d) performing graphitization treatment and cold-pressing treatment on the heat-treated member to obtain the graphene heat conducting member. By adopting the preparation method provided by the invention, graphene members with high thickness can be prepared, the preparation process is simple and feasible, and facilitates large-scale production, and at the same time, the obtained product has high quality and achieves relatively good heat conduction effect.

Owner:CHONGQING YUNTIANHUA HIGH END NEW MATERIALS DEV CO LTD

Low-temperature deodorization and high-temperature deacidification process capable of inhibiting trans-fatty acid of peanut oil

ActiveCN106118875AReduce high temperature timeInhibitory conditionsFatty-oils/fats refiningEdible oils/fatsPlasticizerAcid value

The invention discloses a low-temperature deodorization and high-temperature deacidification process capable of inhibiting trans-fatty acid of peanut oil. The process specifically comprises the following steps: (1) degumming; (2) de-coloring; (3) carrying out low-temperature deodorization; (4) carrying out high-temperature deacidification. A packing tower is additionally arranged behind a plate tower of a deodorization and deacidification process, and an alkali refining neutralization reaction section is removed; oil is uniformly distributed in a thin film form and a manner of directly adding saturated steam from the bottom is adopted to effectively remove undesirable odor; high-temperature time of an oil product is shortened; two sets of packing deacidification towers are additionally arranged, wherein the temperature of the #1 deacidification tower is controlled to be 260 DEG C and is used for instantly distilling to remove a large part of acid value, and the temperature of the #2 deacidification tower is controlled to be 265 DEG C and is used for removing the acid value in the oil again, so that the acid value of finished-product oil is reasonably controlled; furthermore, the time of staying at a high-temperature section of the oil is short, the content of the trans-fatty acid is only increased by 0.2 percent to 0.3 percent and the acid value can be controlled to be about 0.1; the alkali refining neutralization section is removed so that the loss of neutral oil is reduced and the yield is improved; the consumption is reduced by about 0.03 percent to 0.05 percent by one acid value; meanwhile, a plasticizer and the acid value in the oil product can be effectively removed.

Owner:青岛天祥食品集团有限公司

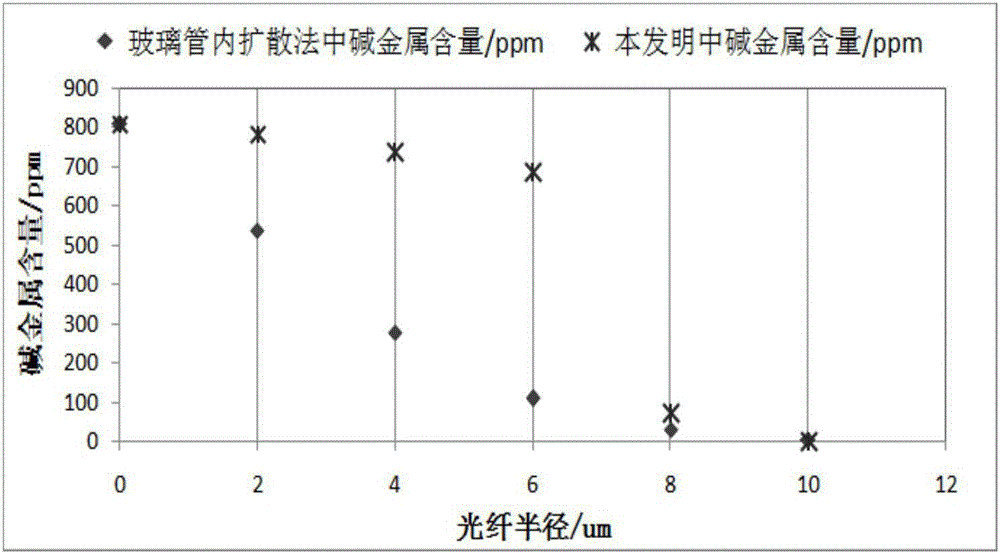

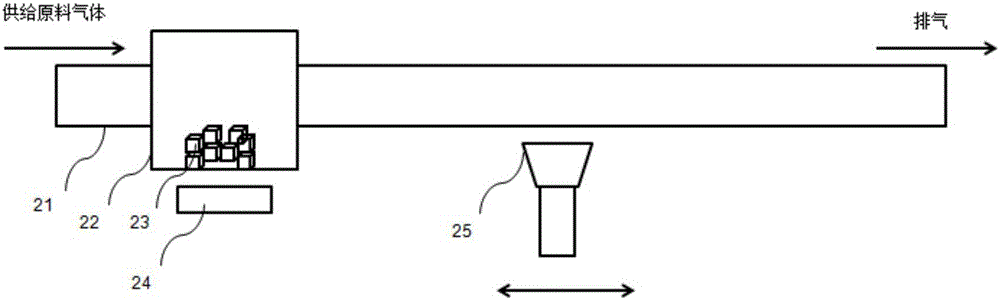

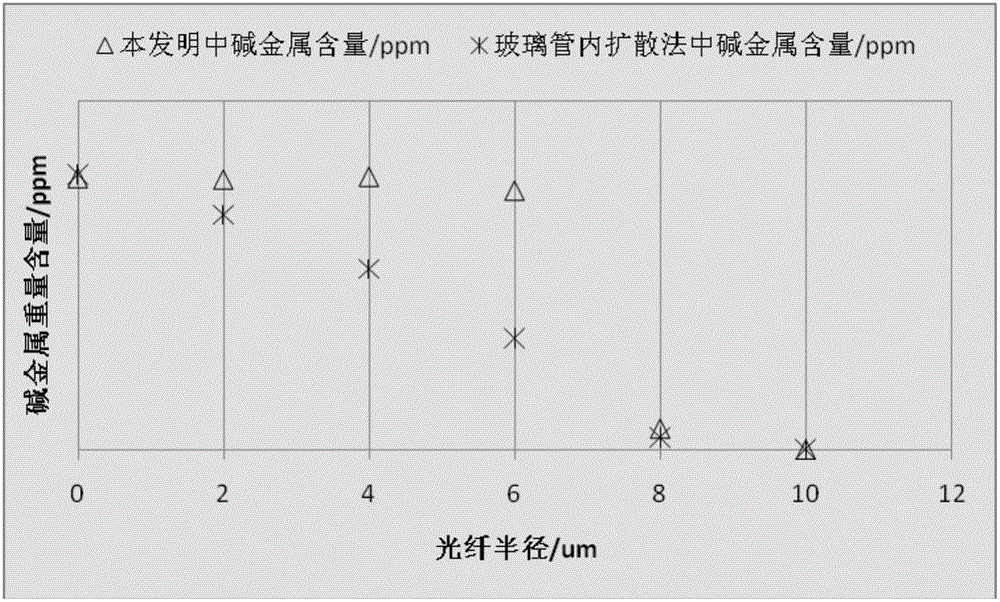

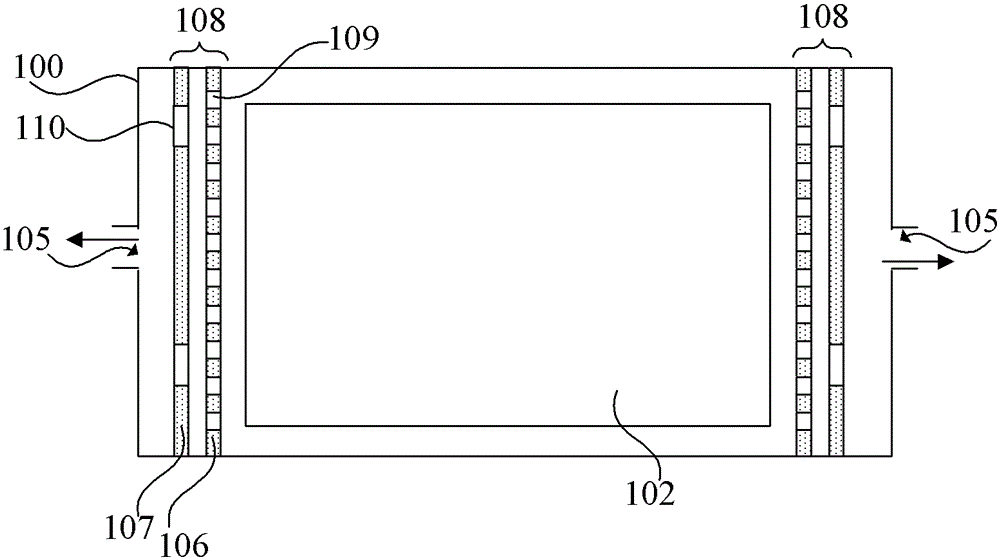

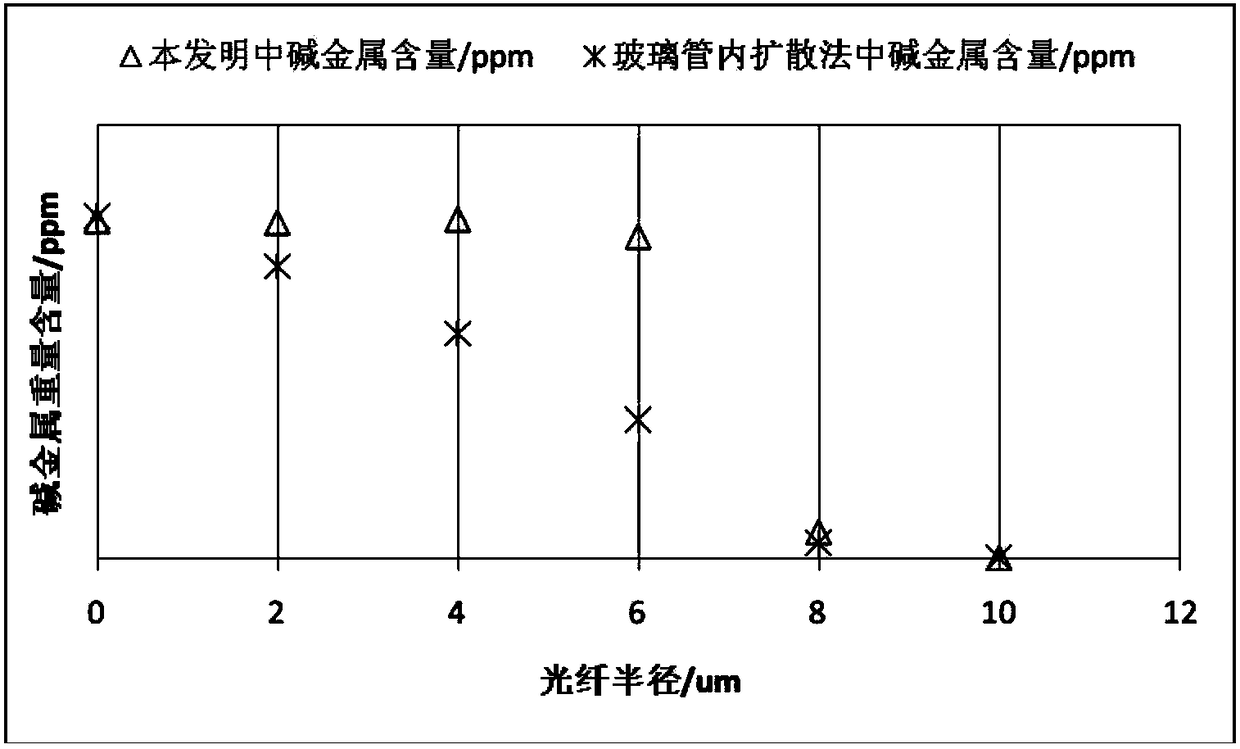

Optical fiber preform preparation method

ActiveCN106007359AEvenly distributed alkali metal contentOvercome uneven distribution of alkali metalsGlass making apparatusUltrasound attenuationContent distribution

The invention discloses an optical fiber preform preparation method. A core layer and a part of coating layer of an optical fiber preform are manufactured by adopting an in-tube vapor deposition process. The optical fiber preform preparation method is characterized in that a large-diameter glass tube is serially connected to a gas inlet end of a glass lining tube, an alkali metal raw material is arranged in the large-diameter glass tube, a heater is arranged on the periphery of the large-diameter glass tube, the heater is turned off in the process of depositing for forming the coating layer, and coating layer raw material gas enters the glass lining tube and deposits to form the coating layer; in the process of depositing for forming the core layer, the heater is turned on, core layer raw material gas carrying the alkali metal raw material volatilized due to heating enters the glass lining tube and deposits to form the core layer. The alkali metal doping in the optical fiber preform preparation method is preformed in the core preform deposition process, the alkali metal content distribution is evener, the problem of uneven alkali metal distribution in the glass tube by adopting a diffusion process can be solved, and optical attenuation can be obviously reduced.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Method for preparing B4C-Al neutron-absorbing plate for spent fuel storage and transportation

ActiveCN102110484BControl criticalOvercome the problem of uneven distributionNuclear energy generationReactors manufactureMetallurgy

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Catalyst for catalyzing and oxidizing carbon monoxide at low temperature and preparation method thereof

InactiveCN101879454AHigh catalytic oxidation activityExtended service lifeDispersed particle separationCatalyst activation/preparationActive carbonActivated carbon

The invention discloses a catalyst for catalyzing and oxidizing carbon monoxide at low temperature and a preparation method thereof. The catalyst comprises an active component Pd, additive Fe and a carrier, wherein the carrier is active carbon modified from chitosan; and the active component Pd and the additive Fe are loaded on the carrier. In the catalyst, the mass of the active component Pd is 0.5 to 3 percent of that of the carrier, and the mass of the additive Fe is 3 to 24 percent of that of the carrier. The preparation method of the catalyst comprises the following steps: adopting a step impregnation method, acidizing the active carbon, treating the acidized active carbon with chitosan solution, then sequentially soaking and absorbing the additive Fe and the active component Pd, filtering, washing and drying to obtain the catalyst. The catalyst is characterized by low precious metal content, high activity at low temperature, good moisture resistance property and the like.

Owner:CHINA AGRI UNIV

Shell and manufacturing method thereof

InactiveCN109023497AOvercome the problem of uneven distributionImprove bindingMetallic material coating processesElectrical apparatus casings/cabinets/drawersMaterials scienceCoating

The invention provides a shell. The shell comprises a base material and a coating arranged on the surface of the base material. A combination layer is further arranged between the base material and the coating and comprises continuous holes, and the holes are filled with part of the coating. The combination layer of the shell effectively improves the combination force between the base material andthe coating. The invention further provides a manufacturing method of the shell.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

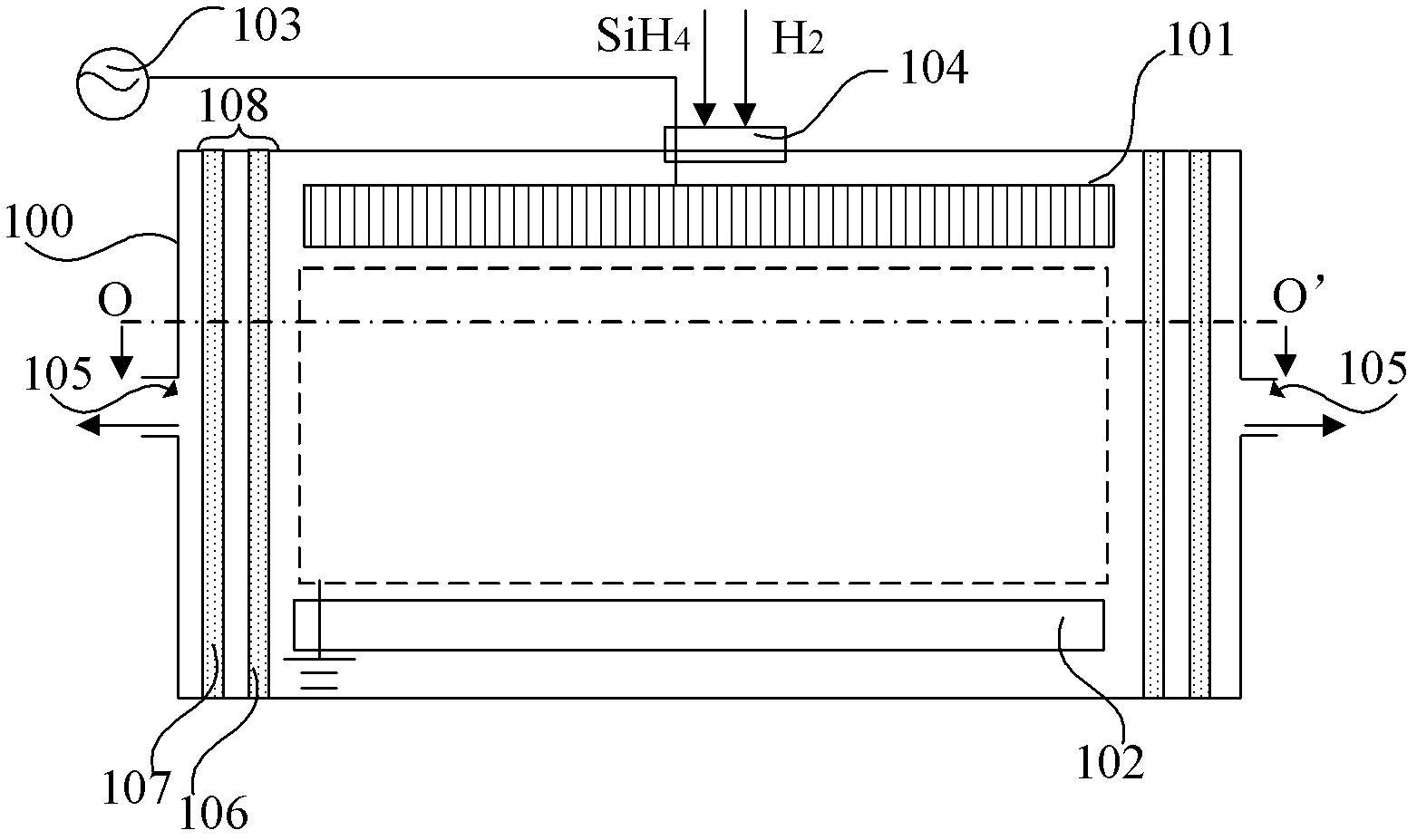

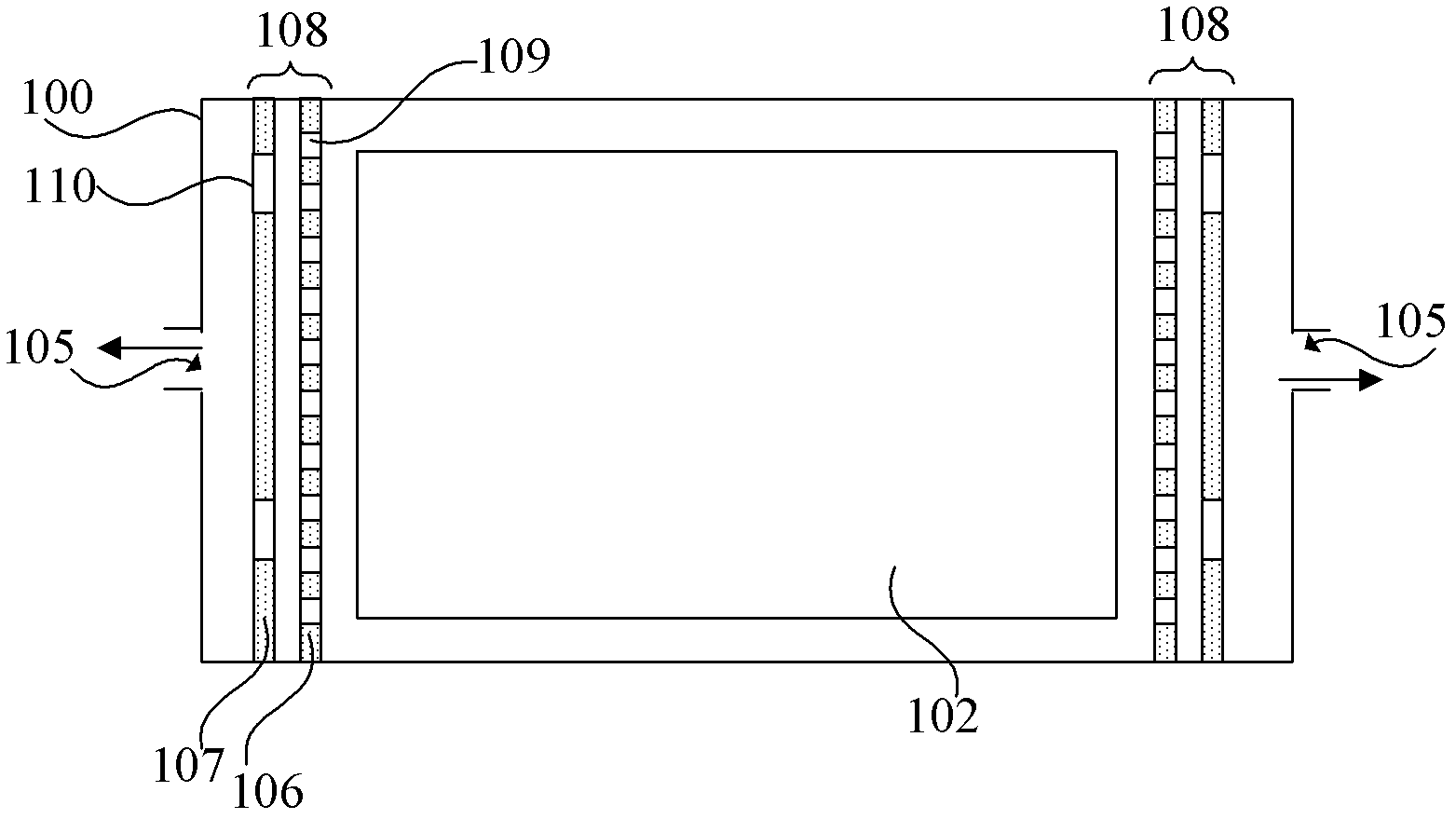

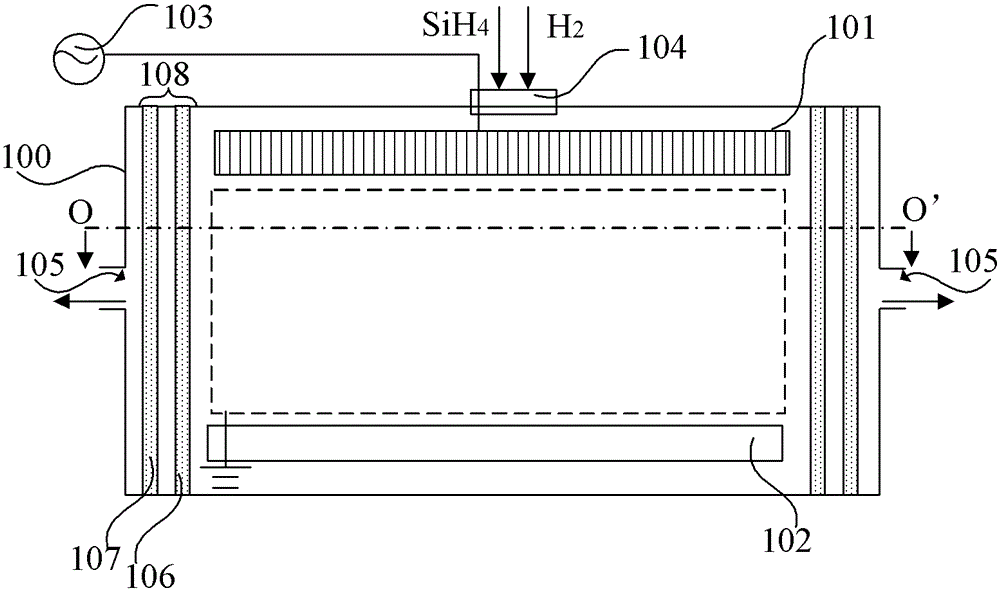

Plasma processing device

ActiveCN103132054AChange distributionReduce processing difficultyChemical vapor deposition coatingEngineeringCavity wall

The invention provides a plasma processing device. The plasma processing device comprises a processing cavity, wherein the processing cavity comprises a top wall, a bottom wall opposite to the top wall, and side walls formed between the top wall and the bottom wall. An air inlet device is arranged on the cavity wall of the processing cavity, air outlets are formed in the side walls, a process area is arranged in the processing cavity, an air outlet device is arranged among the process area and the air outlets, and the air outlet device at least comprises a first air outlet device and a second air outlet device. The first air outlet device is used for limiting plasma in the process area, and the second air outlet device is used for changing air distribution in the process area. The plasma processing device can improve uniformity of the air distribution.

Owner:理想万里晖真空装备(泰兴)有限公司

Boron carbide ceramic and preparation method and application thereof

ActiveCN112759408AEasy reunionOvercome the problem of uneven distributionArmour platesArmor-piercing shellCarbon nanotube

The invention discloses boron carbide ceramic and a preparation method and application thereof, and belongs to the technical field of weaponry. The preparation method of the boron carbide ceramic comprises the following steps: fully mixing boron carbide powder and carbon nanotubes in proportion, compacting and forming, then carrying out flash sintering-plasma sintering, and in the sintering process, generating nano-diamonds in situ from at least part of the carbon nanotubes, so as to obtain the boron carbide ceramic in which the carbon nanotubes and the nano-diamonds are uniformly distributed. The boron carbide ceramic prepared by the invention has the characteristics of high toughness, high hardness and high strength, can be used for bulletproof decks, and can resist multiple strikes of armor-piercing bullets and armor-piercing incendiary bombs.

Owner:SUZHOU FIRST ELEMENT NANO TECH

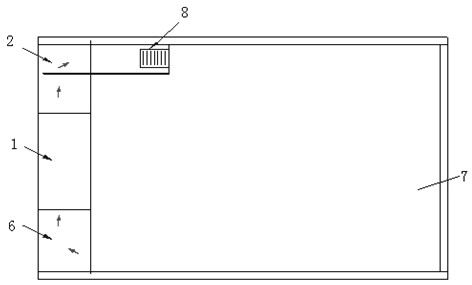

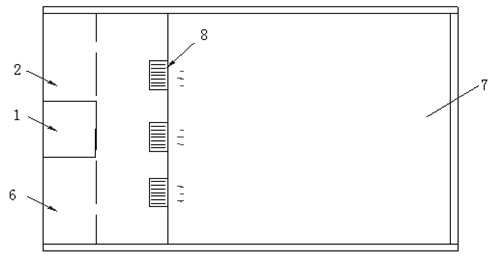

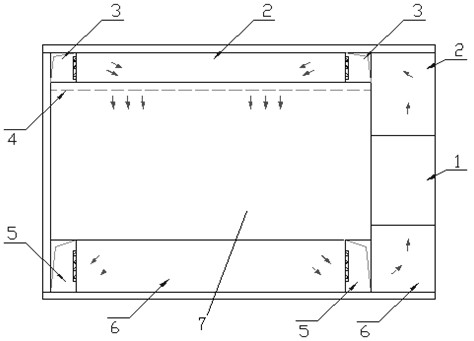

Lateral air supply and return treatment cabinet layout of refrigerator safety performance testing room and method thereof

InactiveCN102032625AOvercome wind resistance increaseOvercome the problem of uneven distributionDucting arrangementsLighting and heating apparatusAutomatic controlEvaporation

The invention relates to a lateral air supply and return treatment cabinet layout of a refrigerator safety performance testing room and a method thereof. The lateral air supply and return treatment cabinet layout of the refrigerator safety performance testing room comprises an air treatment cabinet and an environmental test chamber, wherein the air treatment cabinet is arranged on a side face of the environmental test chamber; the environmental test chamber is provided with a master air supply pipe and a master air return pipe which are symmetrically arranged up and down; and the master air supply pipe and the master air return pipe are connected with an air outlet and an air inlet of the air treatment cabinet respectively. The method comprises the following steps of: allowing air to flow through a coil pipe of the air treatment cabinet under the action of a fan in the air treatment cabinet; matching an evaporation coil pipe of the air treatment cabinet with an automatic control electric heating pipe for use to control air outlet temperature; distributing air to each air supply branch pipe after the air flows through the master air supply pipe; uniformly supplying the air into the environmental test chamber through an air supply perforated plate; gathering the ventilated air to the master air return pipe through air return branch pipes; and allowing the air to flow through the coil pipe in the air treatment cabinet to adjust temperature so as to finish circulation. Compared with the prior art, the layout and the method solve the problem of site limitation and meet the requirements of temperature, humidity and air speed inside the testing room at the same time.

Owner:ELECTROMECHANICAL PRODS DETECTING TECH CENT OF SHANGHAI ENTRY EXIT INSPECTION & QUARANTINE BUREAU

Catalyst for catalyzing and oxidizing carbon monoxide at low temperature and preparation method thereof

InactiveCN101879454BHigh catalytic oxidation activityExtended service lifeDispersed particle separationCatalyst activation/preparationActivated carbonActive component

Owner:CHINA AGRI UNIV

Environmental protection type base fibre film, and its mfg. process

ActiveCN1311733CHigh strengthLose weightOrganic fertilisersPlant protective coveringsAdhesiveEngineering

An environmental protection type bast fibre film which is air permeable and impervious is prepared from bast fibres through opening fibres, removing dust and impurities, carding, stripping for netting, airflow netting, chemical sticking by adhesive to become film, applying the hydrophobic agent onto its surfaces, and cold rolling.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

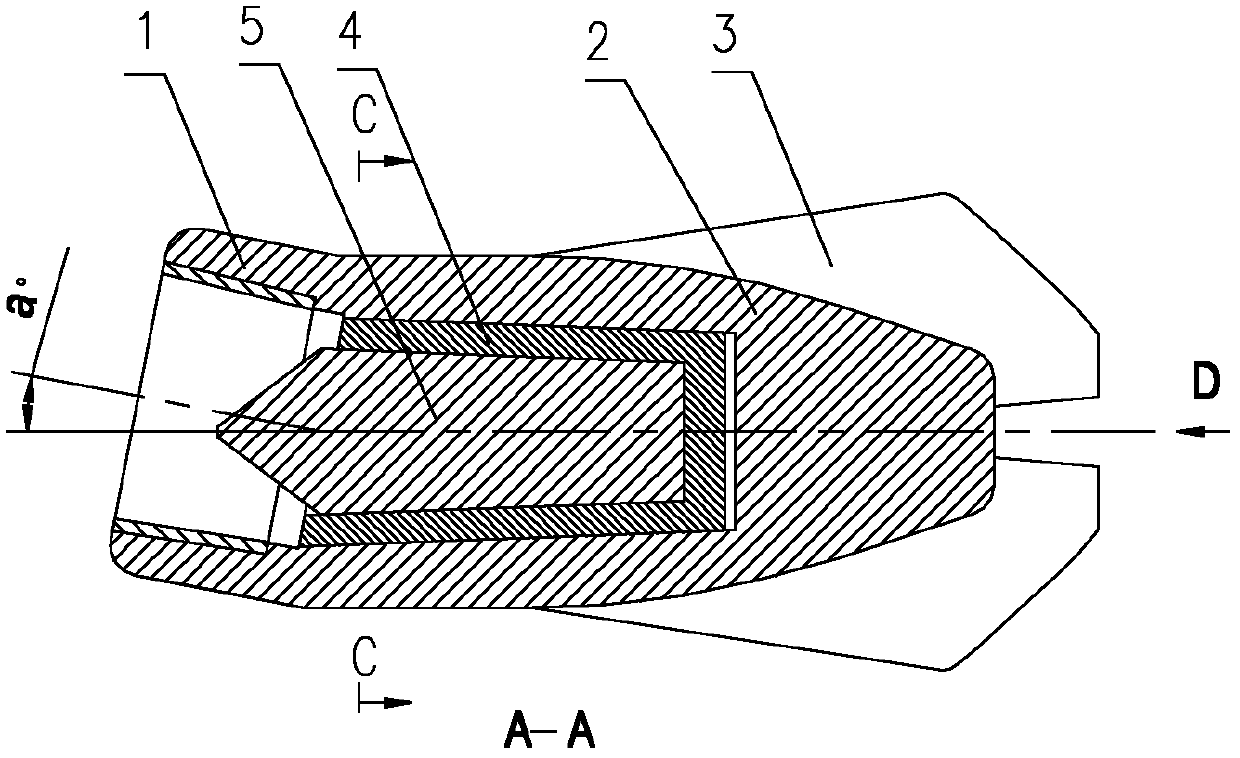

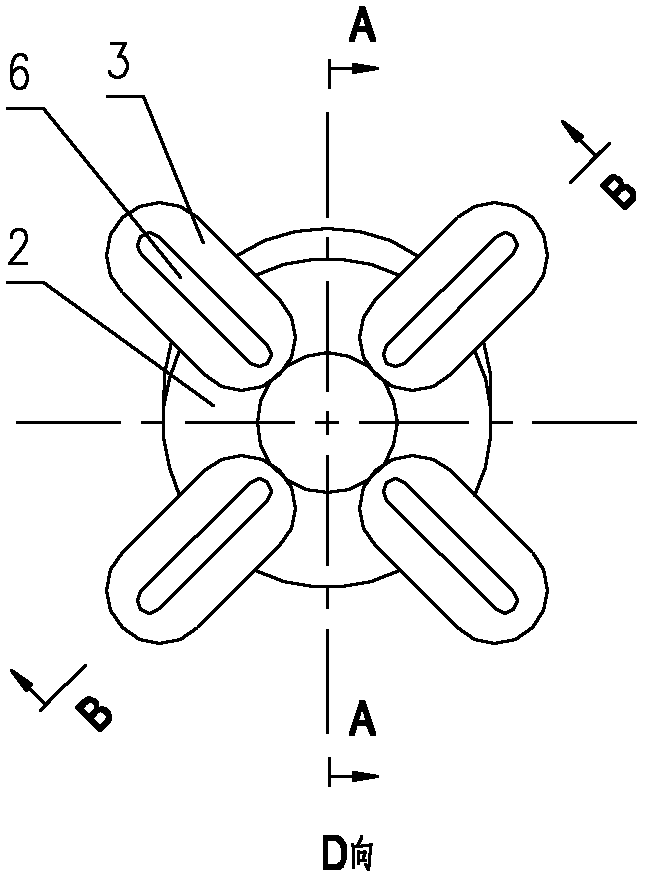

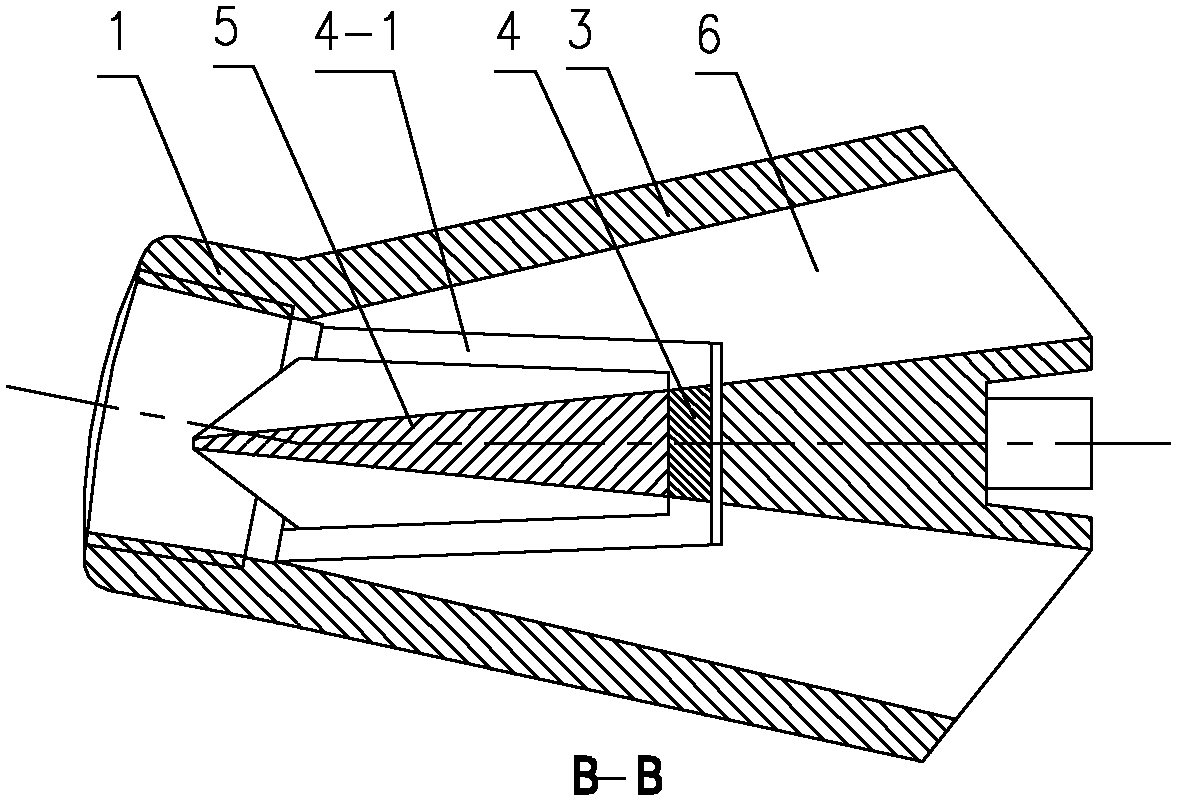

Nozzle for pulverized coal

InactiveCN103374639AOvercome the problem of uneven distributionEliminates the possibility of wear and tearBlast furnace componentsBlast furnace detailsCombustionEngineering

The invention provides a nozzle for pulverized coal in a structure with a wear-proof casing and a distributing cone inside. The distributing cone can distribute pulverized coal to spray pipes in design proportion according to layered flowing condition of pulverized coal in a spray gun, so that the problem of non-uniform distribution of pulverized coal in the prior art can be overcome. The wear-proof casing separates pulverized coal from the cone section of the nozzle, so that the probability that the inner wall of the cone section is worn by pulverized coal is completely eliminated. According to the nozzle for pulverized coal provided by the invention, the oxygen concentration and temperature of pulverized coal which is sprayed by a blast furnace can be remarkably improved when the pulverized coal reaches the tuyere outlet, the combustion of pulverized coal entering the inner wall of the blast furnace is greatly benefited, so that the combustion rate and quantity of pulverized coal can be further improved.

Owner:无锡市释珑能源科技有限公司

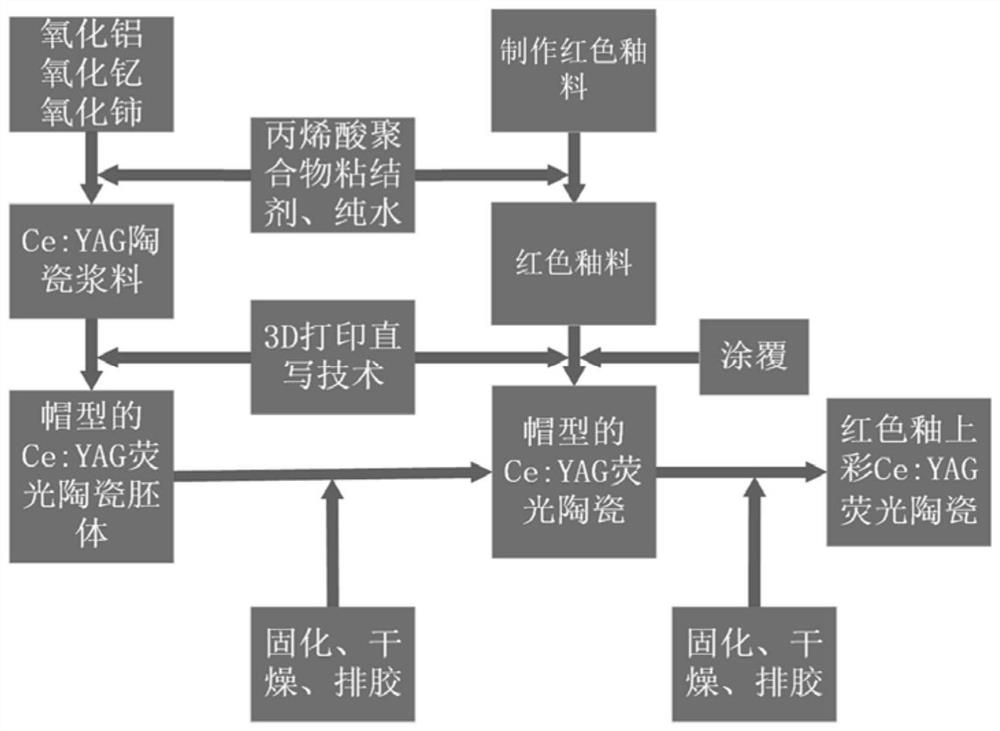

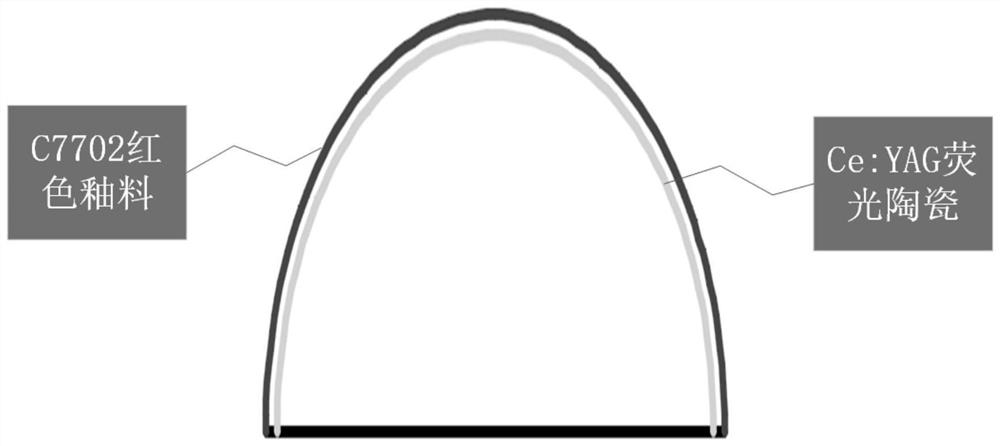

Preparation method of red overglaze color Ce:YAG fluorescent ceramic based on 3D printing

InactiveCN113754411AOvercome the problem of uneven distributionEvenly distributedAdditive manufacturing apparatus3d printGlaze

The invention discloses a preparation method of red overglaze color Ce:YAG fluorescent ceramic based on 3D printing. The method comprises the steps: firstly, printing weighed aluminum oxide, yttrium oxide and cerium oxide ceramic powder, a binder and pure water into a cap-shaped Ce:YAG fluorescent ceramic blank by virtue of a 3D printing direct writing technology, naturally curing, and carrying out drying treatment and glue discharging treatment, so as to obtain cap-shaped Ce:YAG fluorescent ceramic; and then coating the surface of the Ce:YAG fluorescent ceramic with the prepared red glaze slurry by adopting a 3D printing direct writing technology, and curing to obtain the red overglaze color Ce:YAG fluorescent ceramic. According to the preparation method, the uniform distribution of light is effectively improved, and the lighting effect is improved.

Owner:NANTONG UNIVERSITY

Catalyst for removing carbon monoxide in flue gas and preparation method thereof

ActiveCN109647385BImprove performanceOvercome the problem of uneven distributionGas treatmentDispersed particle separationActivated carbonPtru catalyst

Owner:GUODIAN SCI & TECH RES INST

Plasma treatment device

ActiveCN103132054BChange distributionReduce processing difficultyChemical vapor deposition coatingCavity wallPlasma processing

The invention provides a plasma processing device. The plasma processing device comprises a processing cavity, wherein the processing cavity comprises a top wall, a bottom wall opposite to the top wall, and side walls formed between the top wall and the bottom wall. An air inlet device is arranged on the cavity wall of the processing cavity, air outlets are formed in the side walls, a process area is arranged in the processing cavity, an air outlet device is arranged among the process area and the air outlets, and the air outlet device at least comprises a first air outlet device and a second air outlet device. The first air outlet device is used for limiting plasma in the process area, and the second air outlet device is used for changing air distribution in the process area. The plasma processing device can improve uniformity of the air distribution.

Owner:理想万里晖真空装备(泰兴)有限公司

A kind of preparation method of optical fiber preform rod

ActiveCN106007359BEvenly distributed contentOvercome the problem of uneven distributionGlass making apparatusUltrasound attenuationContent distribution

The invention discloses an optical fiber preform preparation method. A core layer and a part of coating layer of an optical fiber preform are manufactured by adopting an in-tube vapor deposition process. The optical fiber preform preparation method is characterized in that a large-diameter glass tube is serially connected to a gas inlet end of a glass lining tube, an alkali metal raw material is arranged in the large-diameter glass tube, a heater is arranged on the periphery of the large-diameter glass tube, the heater is turned off in the process of depositing for forming the coating layer, and coating layer raw material gas enters the glass lining tube and deposits to form the coating layer; in the process of depositing for forming the core layer, the heater is turned on, core layer raw material gas carrying the alkali metal raw material volatilized due to heating enters the glass lining tube and deposits to form the core layer. The alkali metal doping in the optical fiber preform preparation method is preformed in the core preform deposition process, the alkali metal content distribution is evener, the problem of uneven alkali metal distribution in the glass tube by adopting a diffusion process can be solved, and optical attenuation can be obviously reduced.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

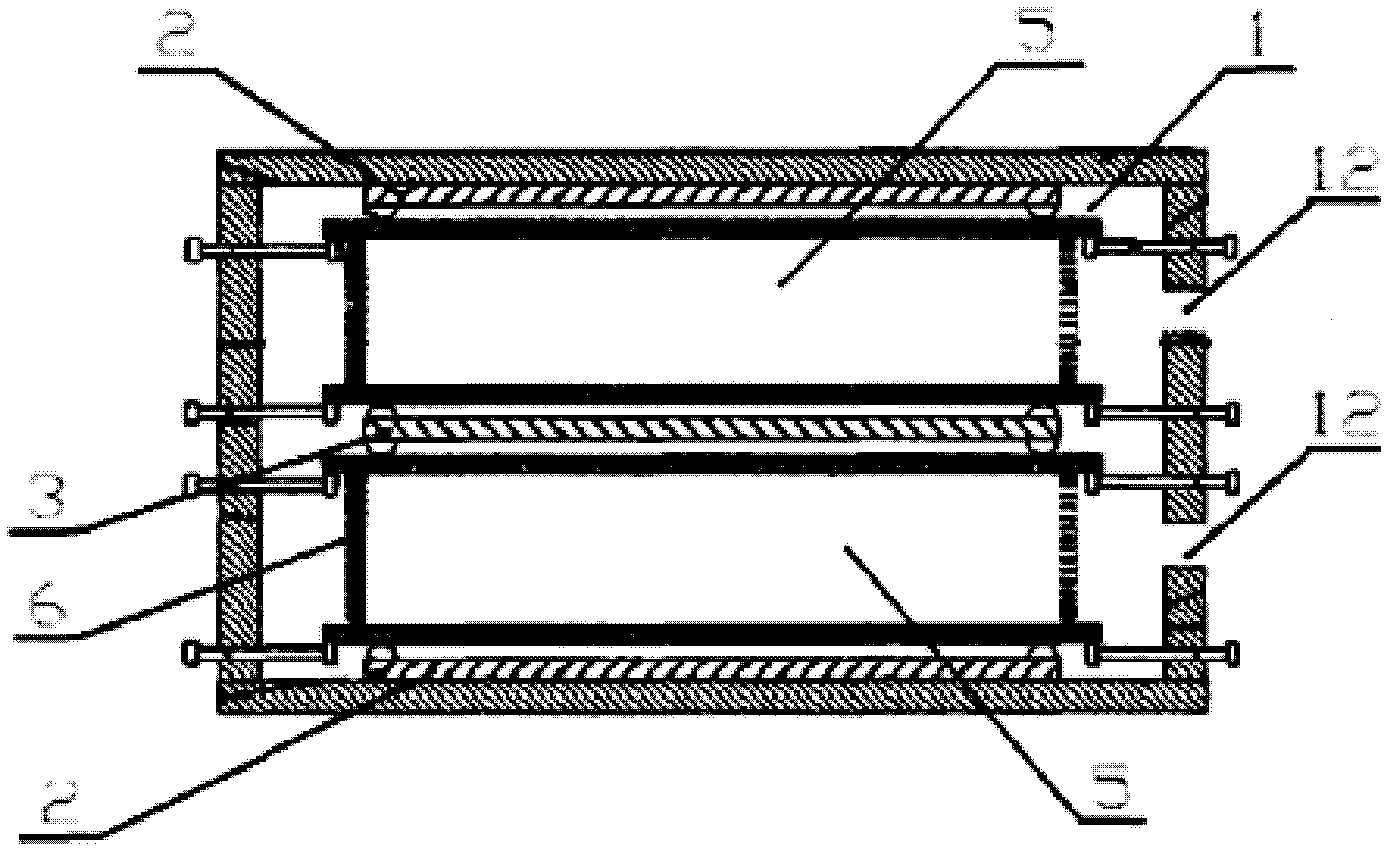

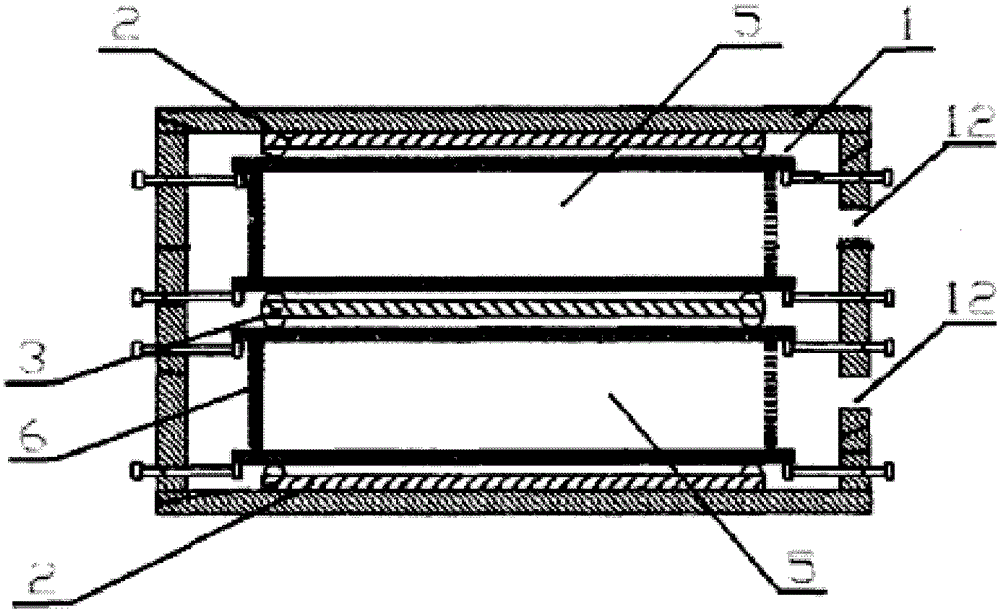

Geotechnical Centrifuge Rainfall Device

ActiveCN104101696BOvercome the problem of uneven distributionEven rainfallEarth material testingWater sourceAgricultural engineering

The invention discloses a geotechnical centrifuge rainfall device, which comprises a model box at the bottom, a rain plate is installed on the top of the model box, the bottom of the rain plate is a porous plate, and a lattice structure; the rain plate is buckled with a cover plate, and the cover plate is sealed on the lattice structure; the rain plate and the cover plate are connected to the model box by bolts; A plurality of rain chambers are formed between the plate and the cover plate, and a plurality of atomization nozzles are installed on the cover plate, each of the rain chambers corresponds to one atomization nozzle, and the atomization nozzles are arranged on Corresponding to the center of the top of the rain chamber, each of the atomizing nozzles is connected to a water source. The present invention atomizes the water through the atomizing nozzle and evenly sprays it in the rainfall chamber, which can overcome the problem of uneven distribution of water in the high centrifugal field; Uniform rainfall was achieved in the inner test area.

Owner:TIANJIN RES INST FOR WATER TRANSPORT ENG M O T +1

A light-weight and high-temperature-resistant ceramic fiber rigid heat-insulating tile and its manufacturing method

ActiveCN105272322BOvercome the problem of uneven distributionImprove mechanical propertiesRoom temperatureSlurry

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

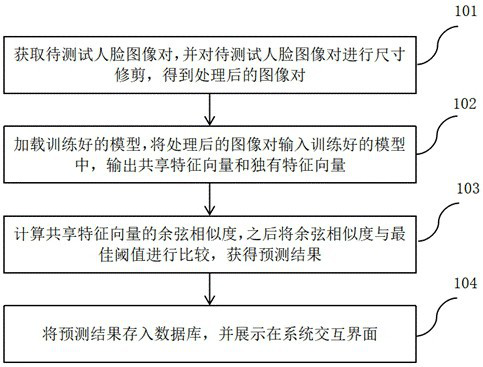

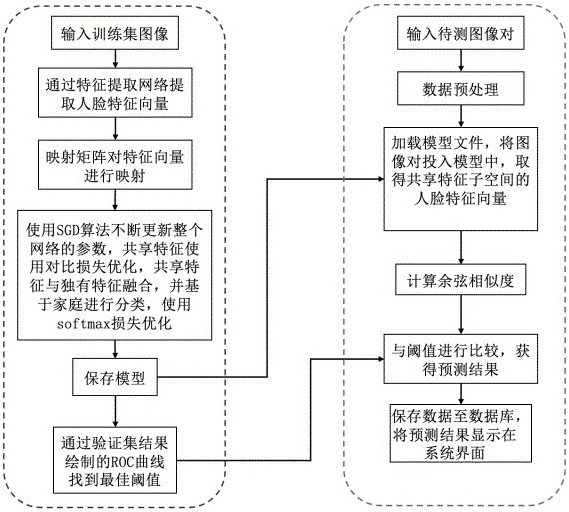

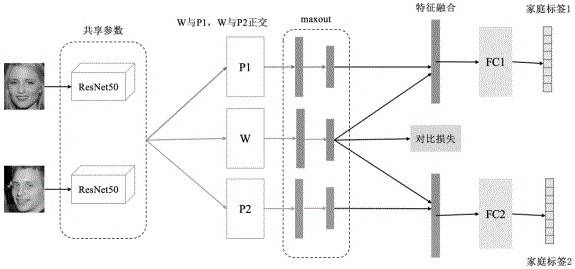

Method and device for automatic recognition of blood relationship based on face image analysis

ActiveCN113496219BImprove recognition accuracyOvercome the problem of uneven distributionCharacter and pattern recognitionCosine similarityFeature vector

This application proposes a blood relationship automatic recognition method and device based on face image analysis, which relates to the technical field of biometric feature recognition, wherein the method includes: acquiring a pair of face images to be tested, and performing size measurement on the pair of face images to be tested Trim to obtain the processed image pair; load the trained model, input the processed image pair into the trained model, and output the shared feature vector and unique feature vector; calculate the cosine similarity of the shared feature vector, and then convert the cosine The similarity is compared with the optimal threshold to obtain the prediction result; the prediction result is stored in the database and displayed on the system interface. The face blood relationship recognition model proposed by this application using the above scheme can better extract the inherent genetic features of the face, improve the robustness and discrimination of face blood relationship recognition, and effectively improve the accuracy of model recognition.

Owner:CAPITAL NORMAL UNIVERSITY

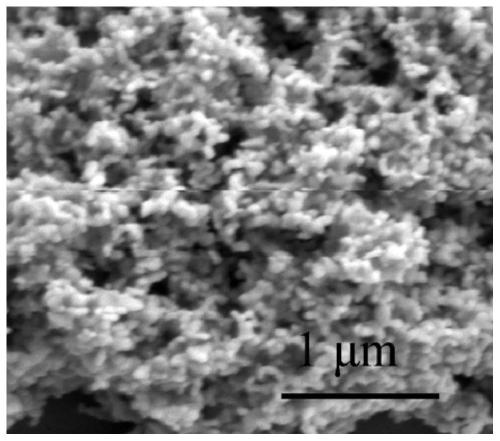

A kind of preparation method of magneto-optic holmium oxide transparent ceramic

ActiveCN108358635BImprove optical qualityOvercome the problem of uneven distributionOxide ceramicHolmium

The invention discloses a method for preparing transparent magneto-optic holmium oxide ceramic. The method comprises the following steps: preparing a holmium nitrate solution and an ammonium fluoridesolution; dropwise adding ammonia water to the holmium nitrate solution, and performing aging to obtain a white precipitate; filtering and washing the white precipitate, adding the filtered and washedwhite precipitate to the ammonium fluoride solution, and performing a reaction to obtain a rare earth holmium-based layered compound precursor containing a fluorion group; sequentially washing, drying, grinding and sieving the rare earth holmium-based layered compound precursor containing the fluorion group, and then calcining the precursor to obtain holmium oxide nano-powder; and sequentially performing pre-pressing and cold isostatic press molding on the holmium oxide nano-powder, performing high-temperature pressureless sintering on the cold isostatic press molded product, and machining the high-temperature pressureless sintered product to obtain the transparent holmium oxide ceramic. The method avoids the problem of non-uniform distribution of a fluoride additive, and the prepared holmium oxide ceramic has good optical performances.

Owner:NINGBO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com