Production method of prefabricated fiber rod

An optical fiber preform and core layer technology, used in glass manufacturing equipment, manufacturing tools, glass deposition furnaces, etc., can solve problems such as uneven distribution and complex doping process, and achieve reduction in optical fiber attenuation, equipment use costs, and alkalinity. The effect of uniform distribution of metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

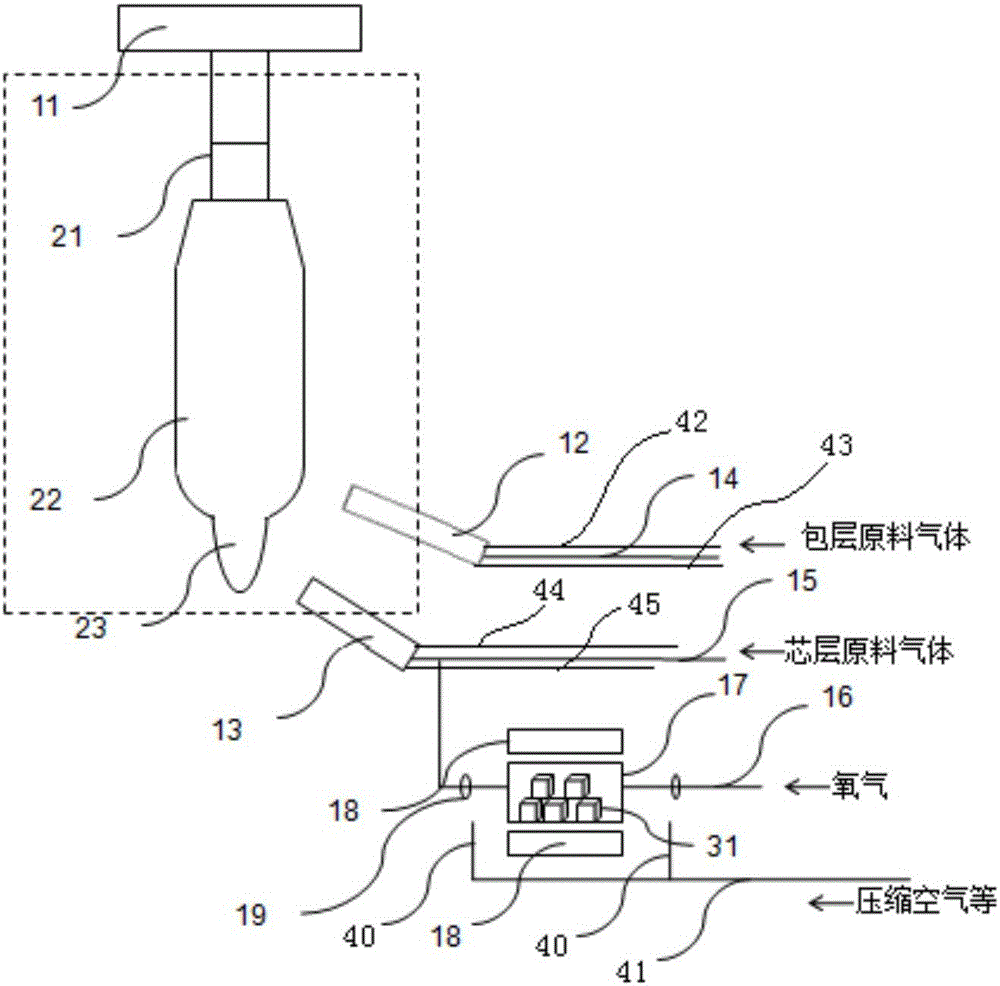

[0029] Such as figure 1 As shown, the optical fiber preform is manufactured through the VAD deposition process, the suspension mechanism 11 fixes the rod 21, the cladding raw material gas delivery pipeline 14 and the core layer raw material gas delivery pipeline 15 are respectively the cladding blowtorch 12 and the core layer blowtorch 13 continuous Supply raw material gas, cladding oxyhydrogen flame hydrogen supply pipeline 42, cladding oxyhydrogen flame oxygen supply pipeline 43 are respectively for cladding blowtorch 12 to continuously supply hydrogen and oxygen required by oxyhydrogen flame, core layer oxyhydrogen flame hydrogen supply pipe The pipeline 44 and the oxygen supply pipeline 45 for the core layer oxyhydrogen flame continuously supply the hydrogen and oxygen required for the oxyhydrogen flame to the core layer blowtorch 13 respectively, and the raw material gas ejected from the blowtorch 12 and the blowtorch 13 is generated after being reacted at a high temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com