Patents

Literature

1120 results about "Metal doped" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

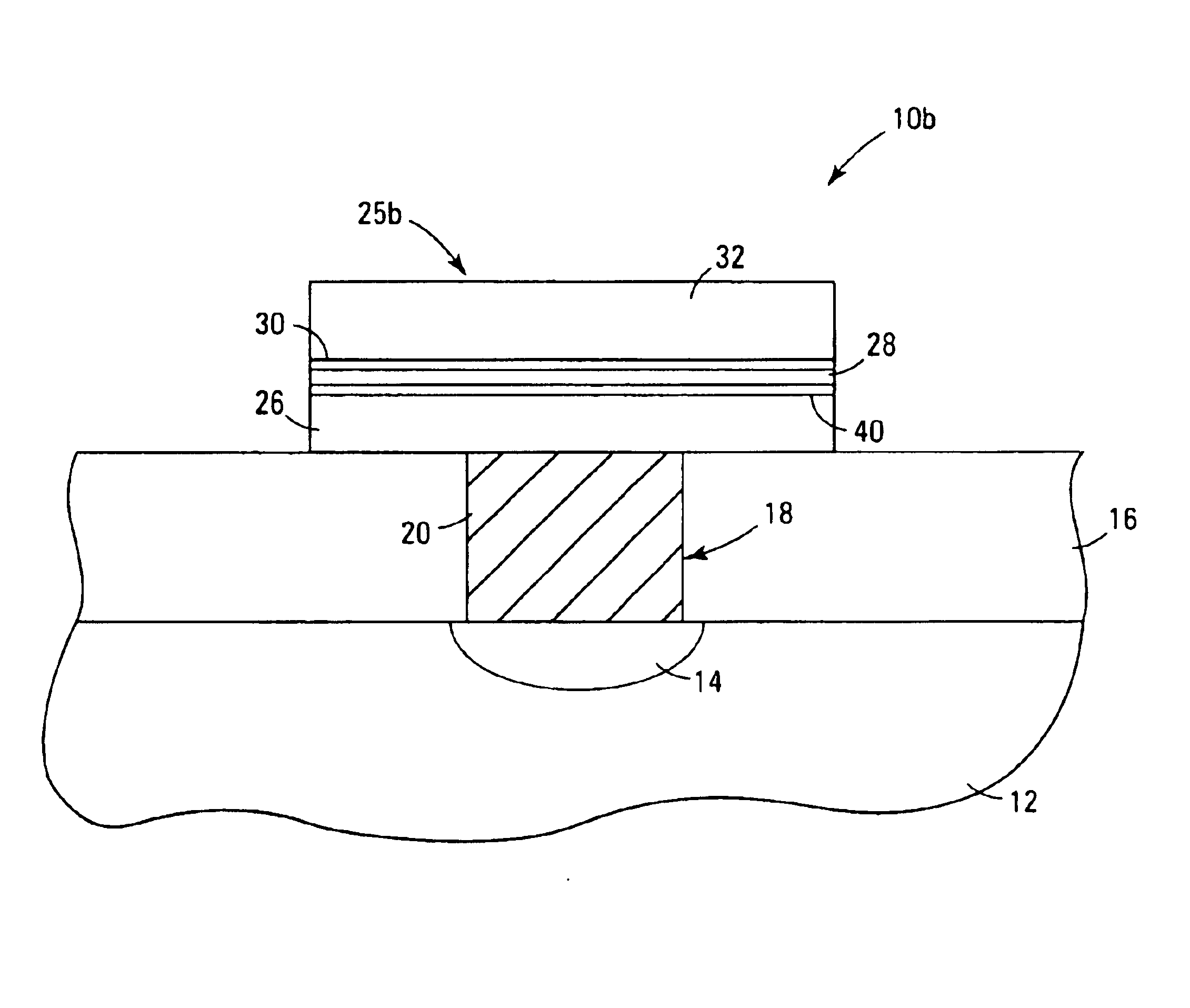

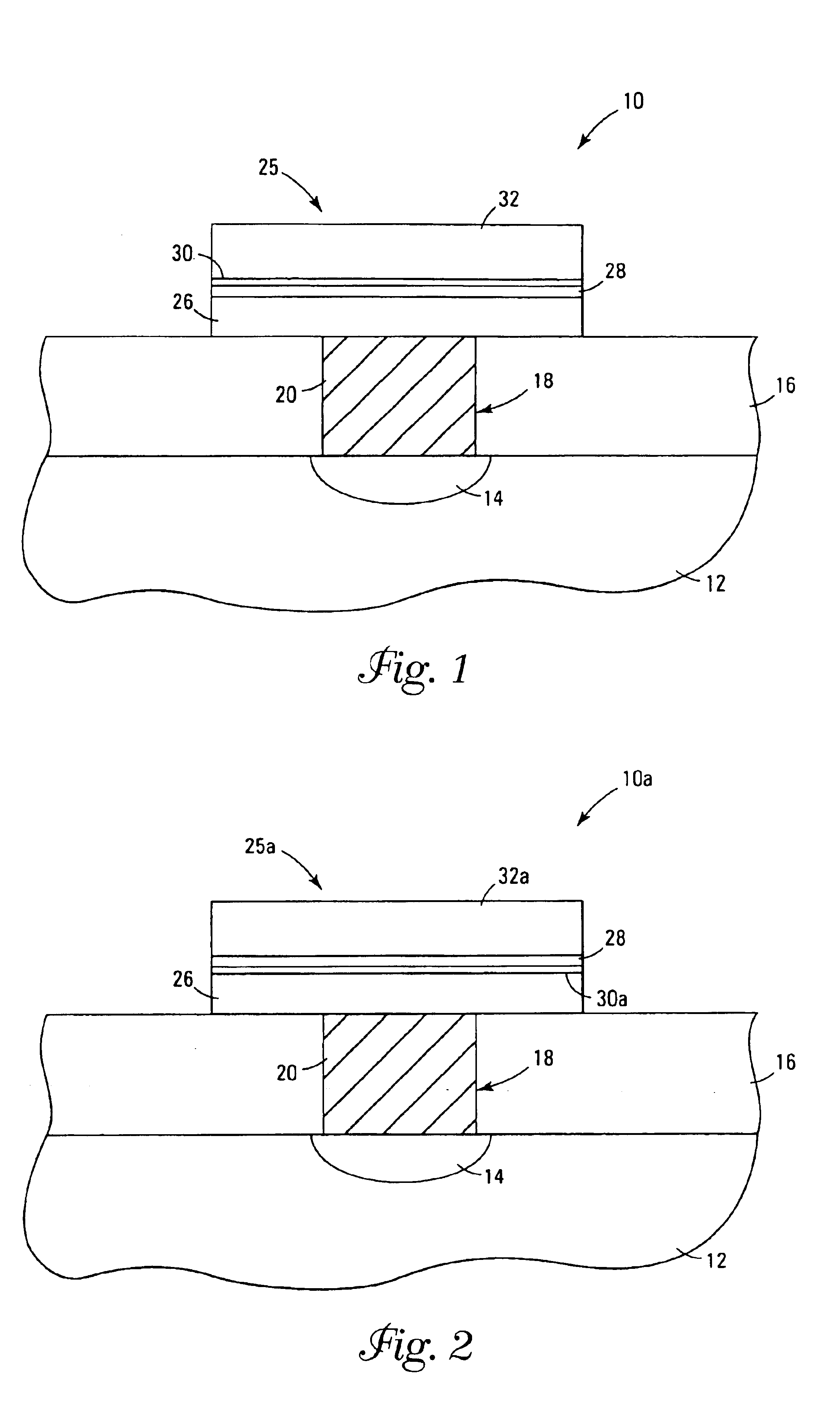

Systems and methods for forming metal-doped alumina

InactiveUS6984592B2Reduce decreaseEasy to controlSemiconductor/solid-state device detailsSolid-state devicesGas phaseOptoelectronics

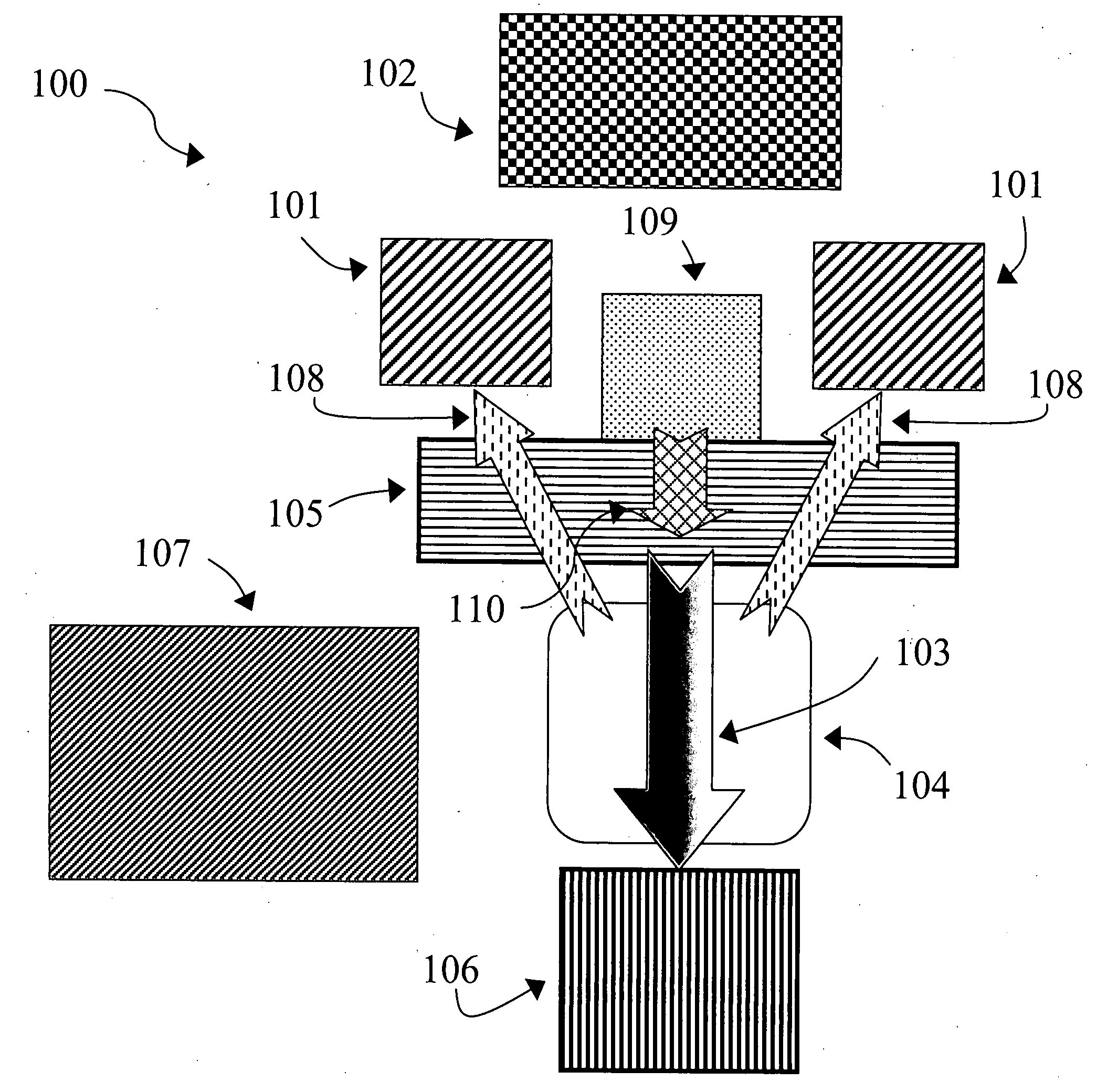

A method of forming (and an apparatus for forming) a metal-doped aluminum oxide layer on a substrate, particularly a semiconductor substrate or substrate assembly, using a vapor deposition process.

Owner:MICRON TECH INC

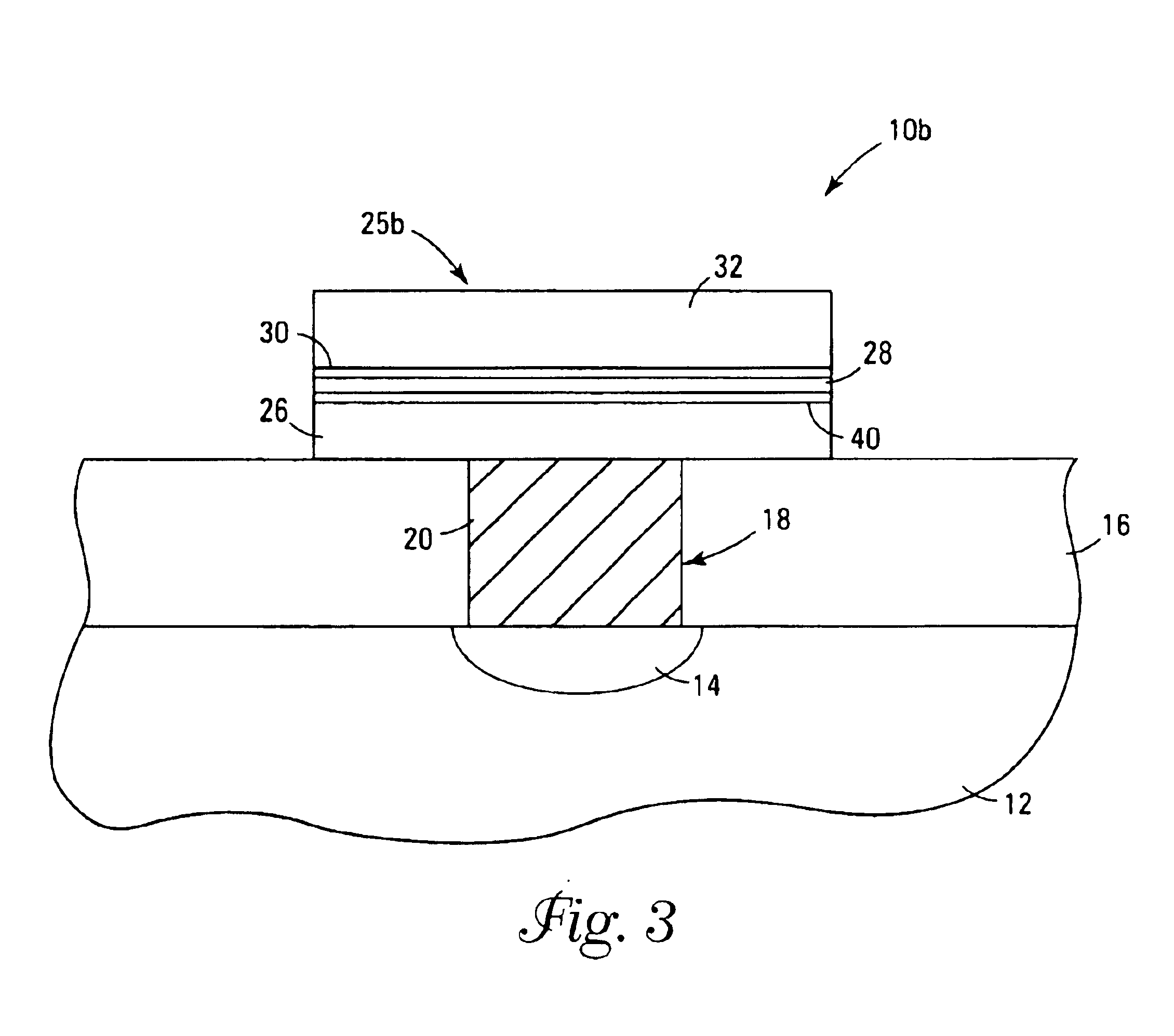

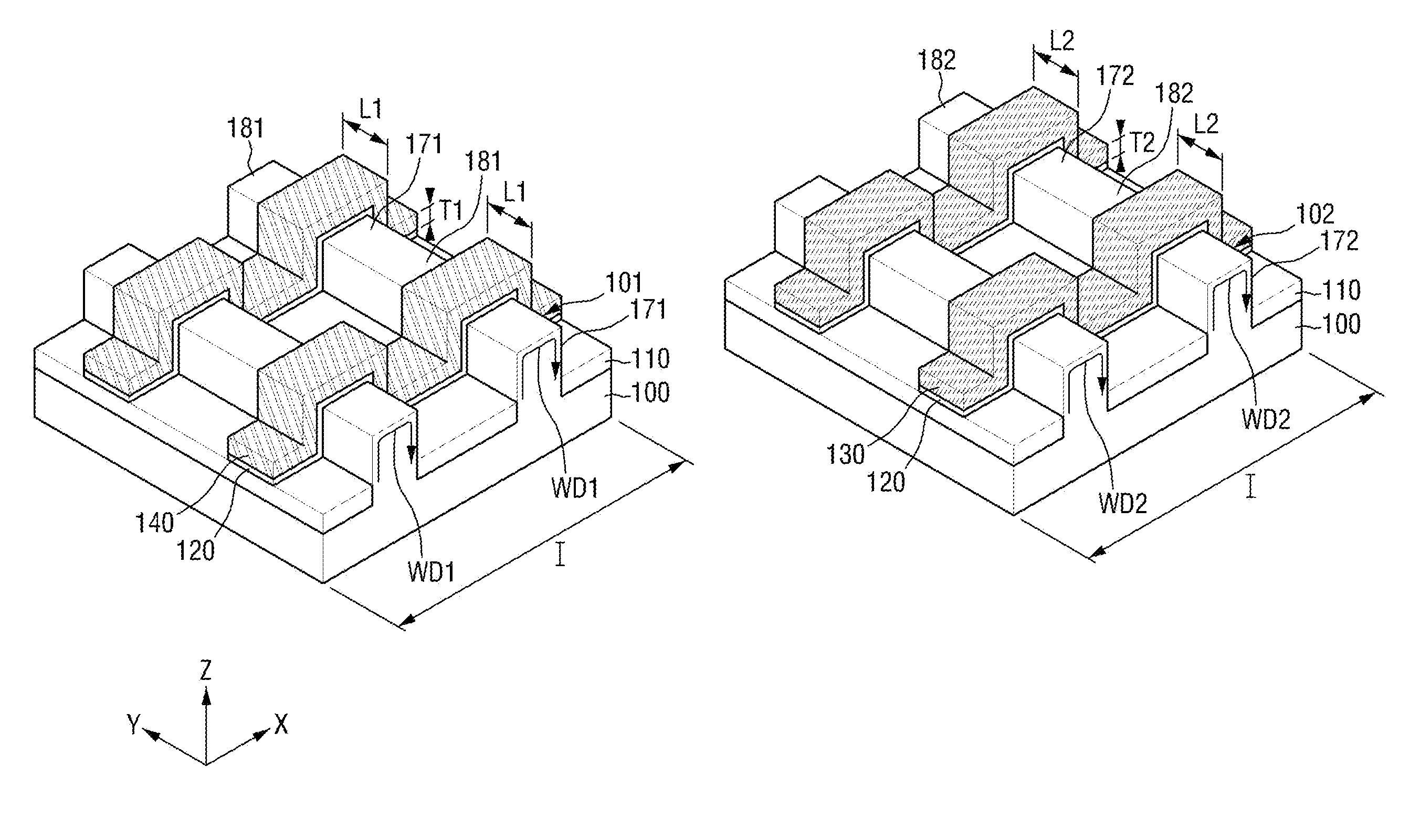

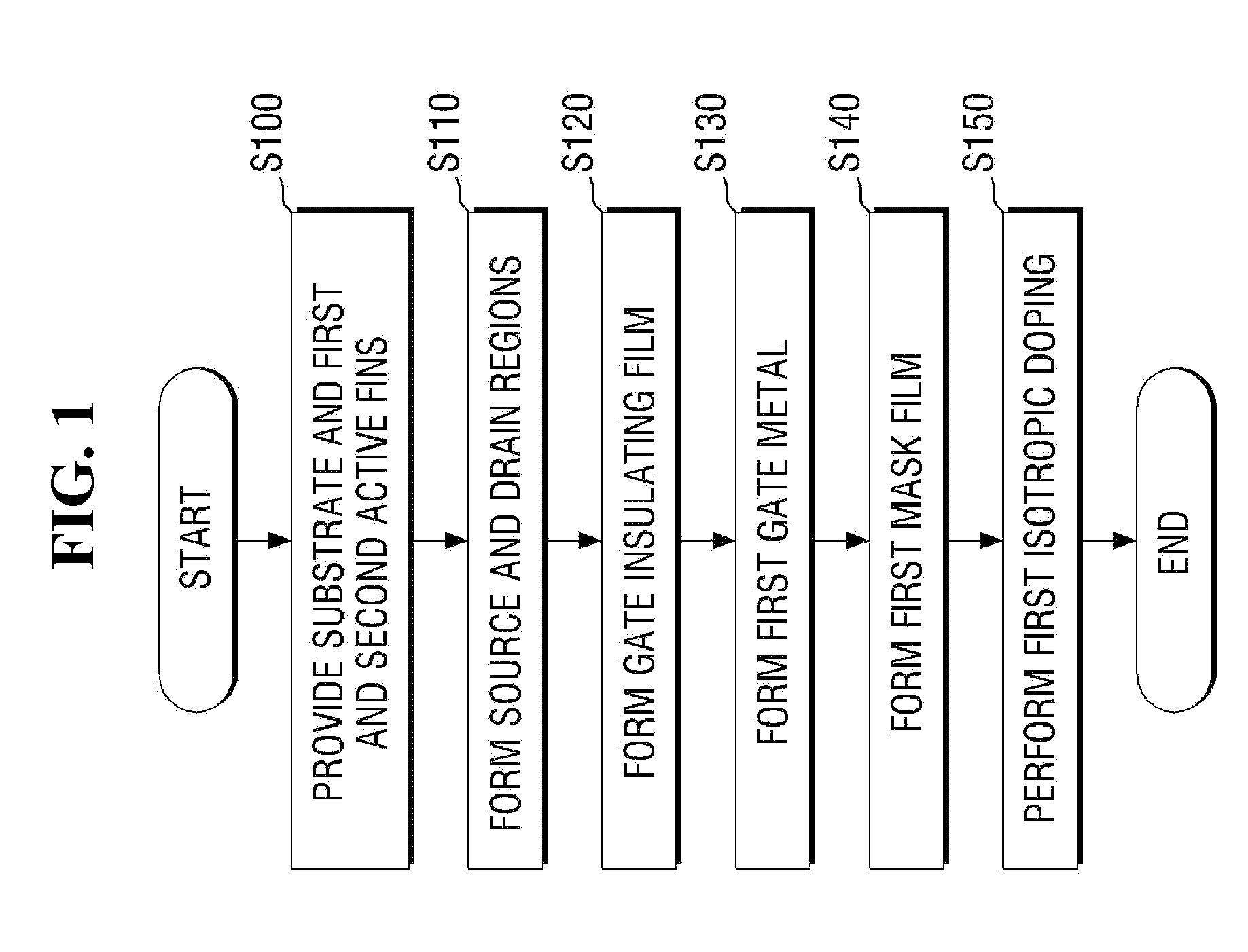

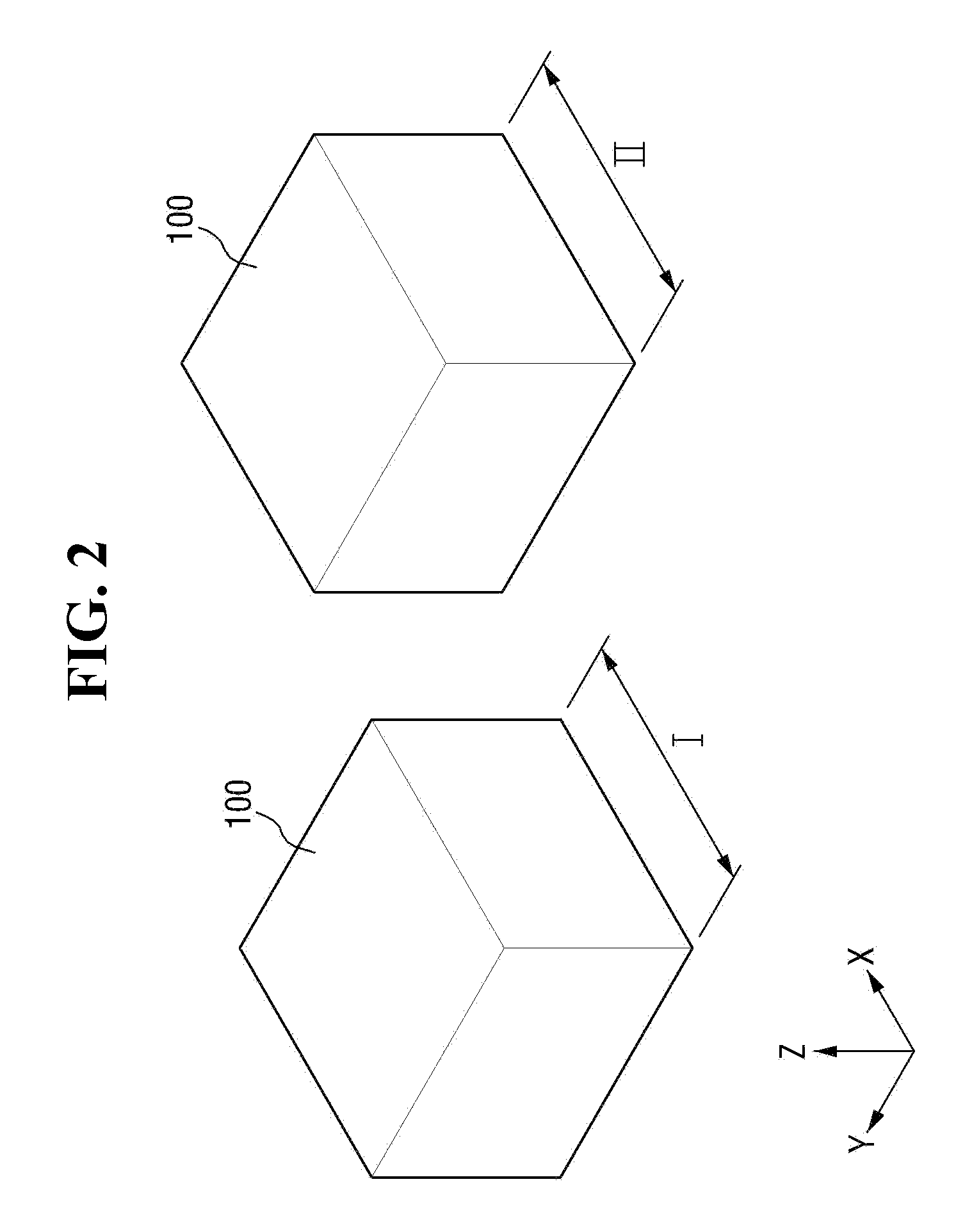

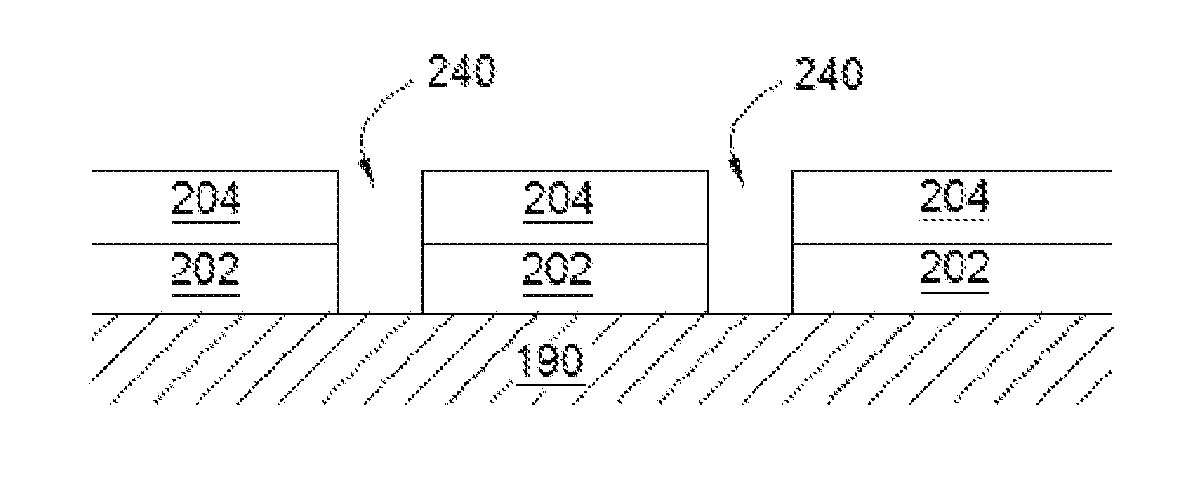

Semiconductor device and method of fabricating the same

A method of manufacturing a semiconductor device, a semiconductor device and systems incorporating the same include transistors having a gate metal doped with impurities. An altered work function of the transistor may alter a threshold voltage of the transistor. In certain embodiments, a gate metal of a first MOSFET is doped with impurities. A gate metal of a second MOSFET may be left undoped, doped with the same impurities with a different concentration, and / or doped with different impurities. In some embodiments, the MOSFETs are FinFETs, and the doping may be a conformal doping

Owner:SAMSUNG ELECTRONICS CO LTD

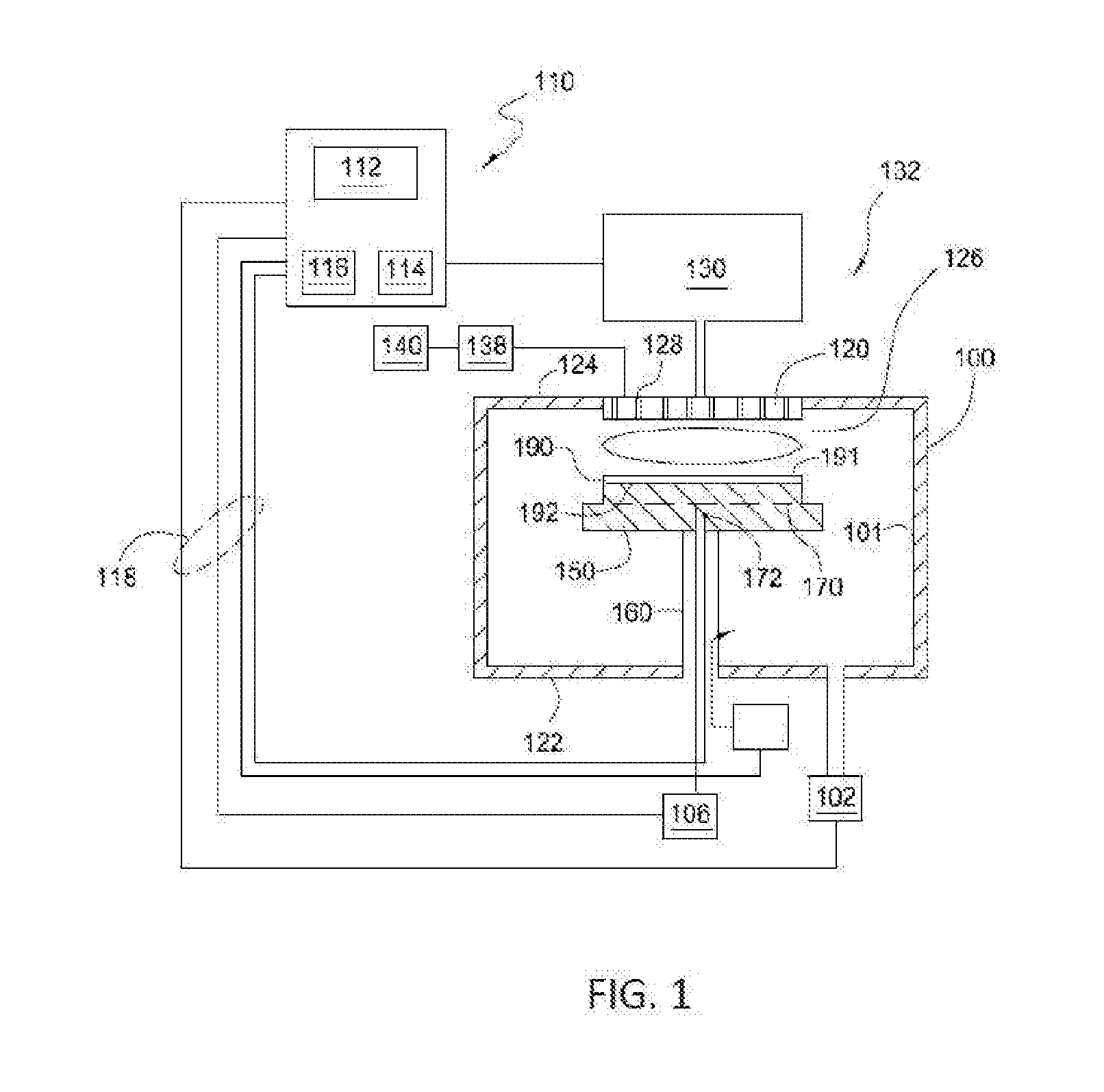

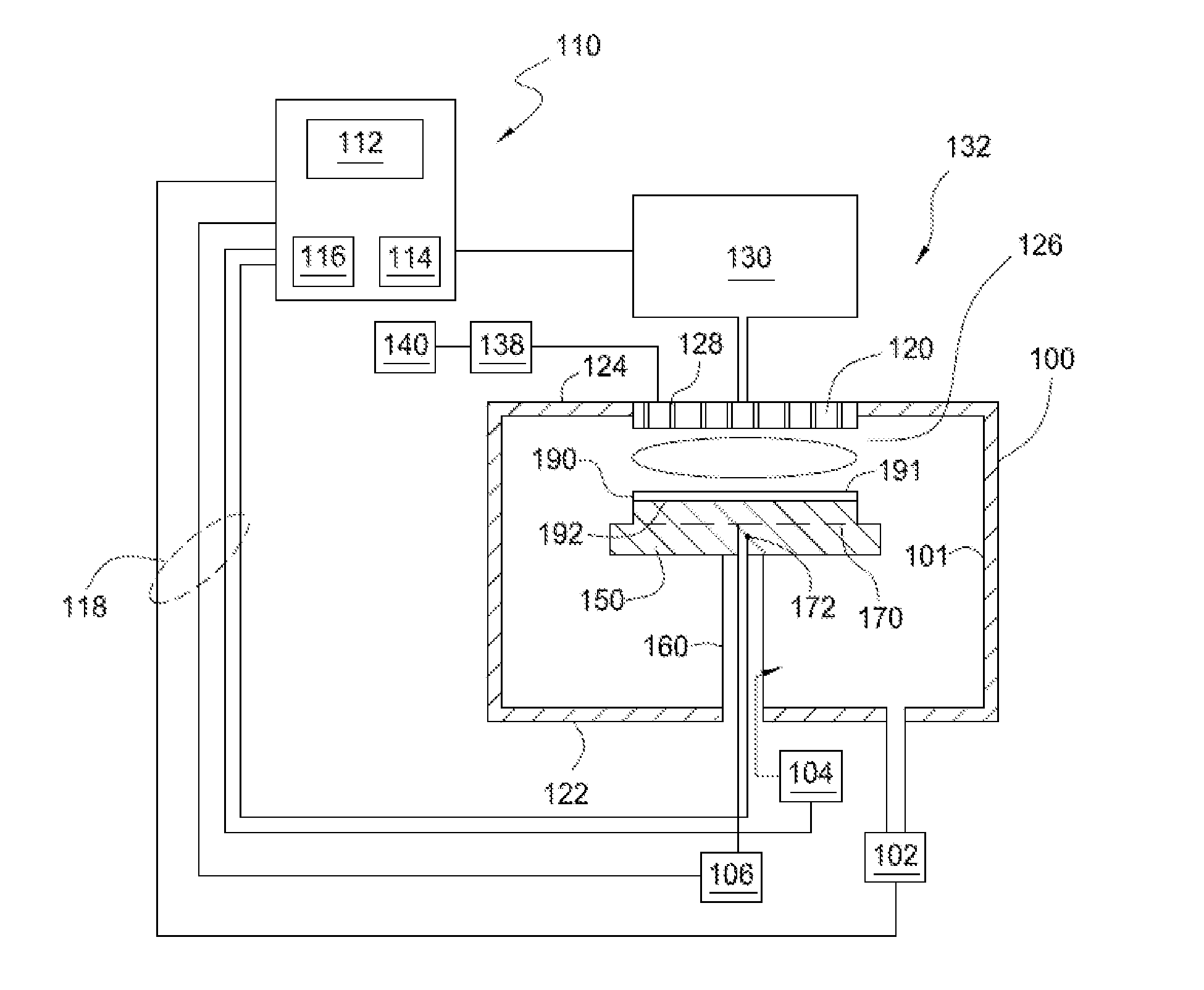

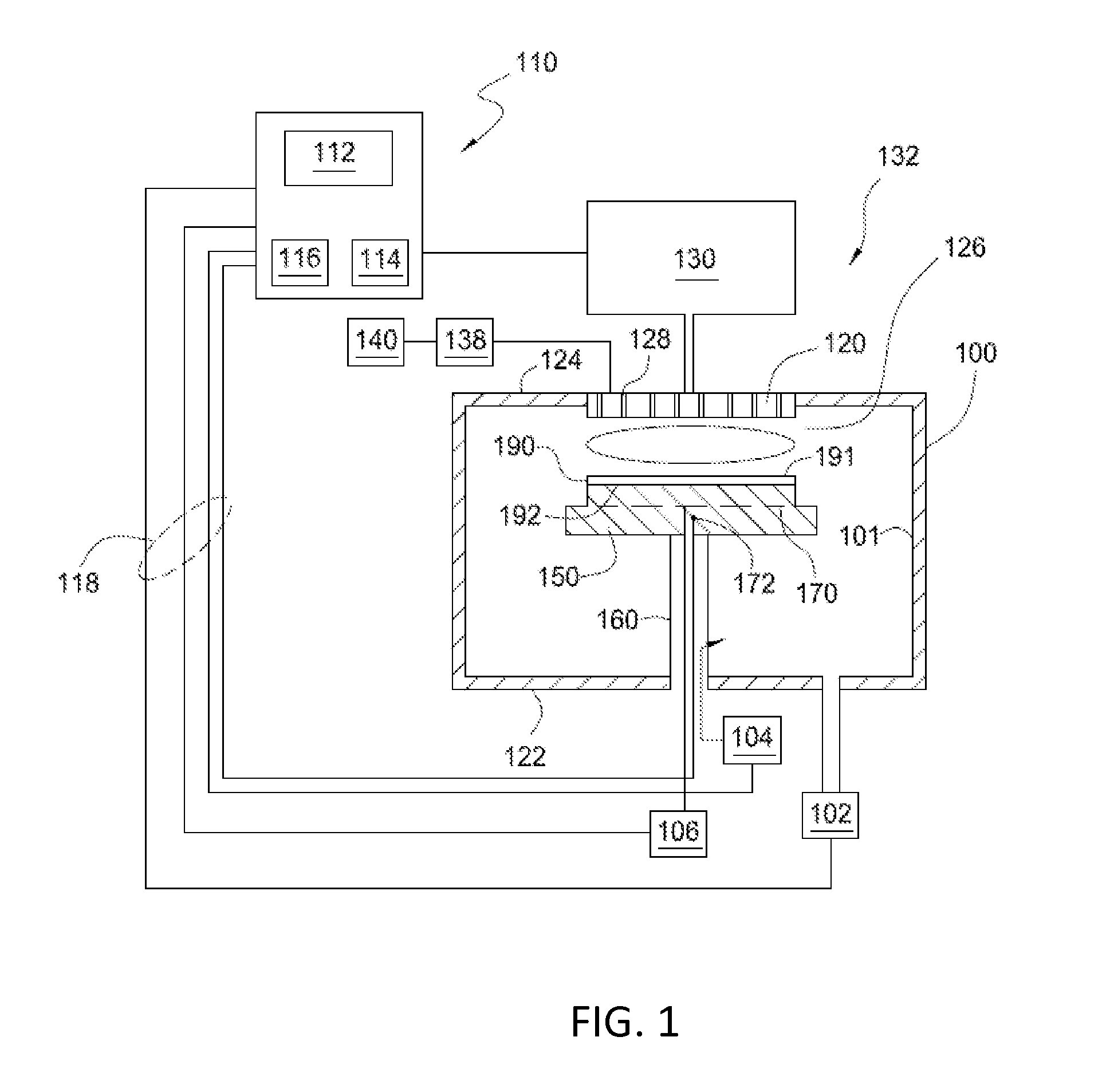

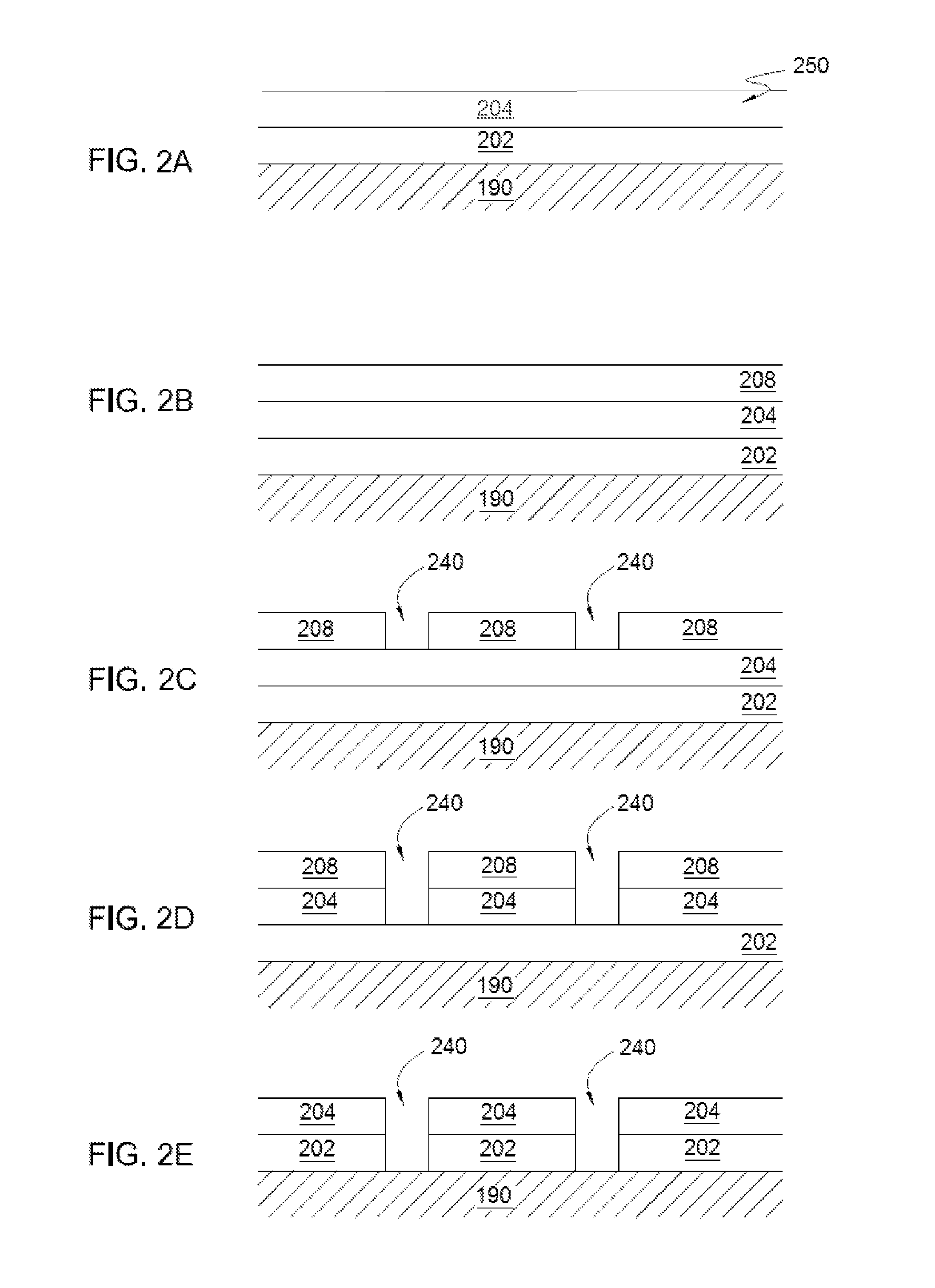

Plasma treatment to improve adhesion between hardmask film and silicon oxide film

The present disclosure relates to methods for improving adhesion between a hardmask layer and a subsequent layer on the hardmask layer. Particularly, embodiment of the present disclosure relates to methods for improving adhesion between a metal-doped amorphous carbon layer and a mask layer, such as a silicon oxide layer, a silicon nitride layer, or an amorphous silicon layer. One embodiment of the present disclosure includes performing a plasma treatment to the metal-doped amorphous carbon layer.

Owner:APPLIED MATERIALS INC

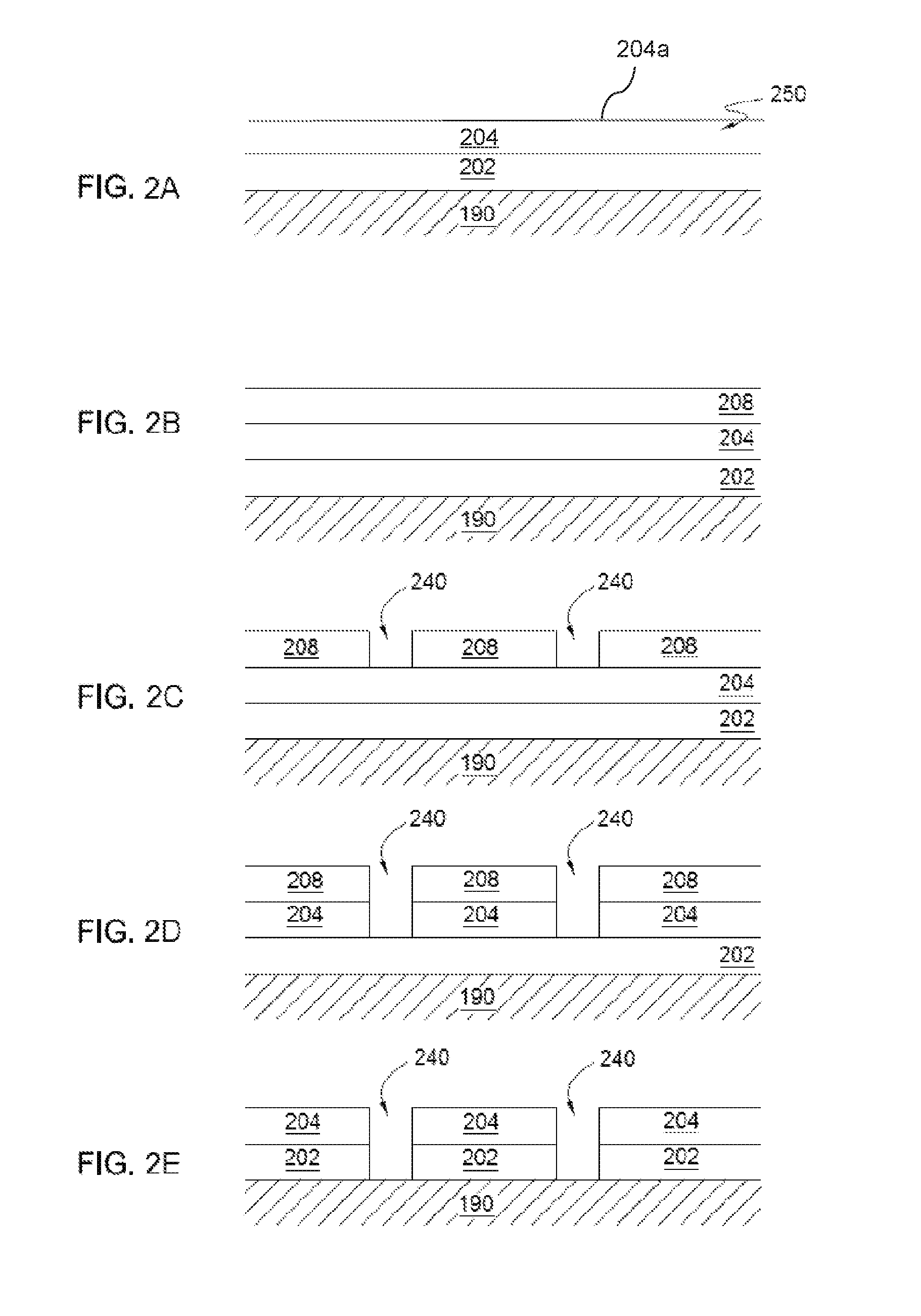

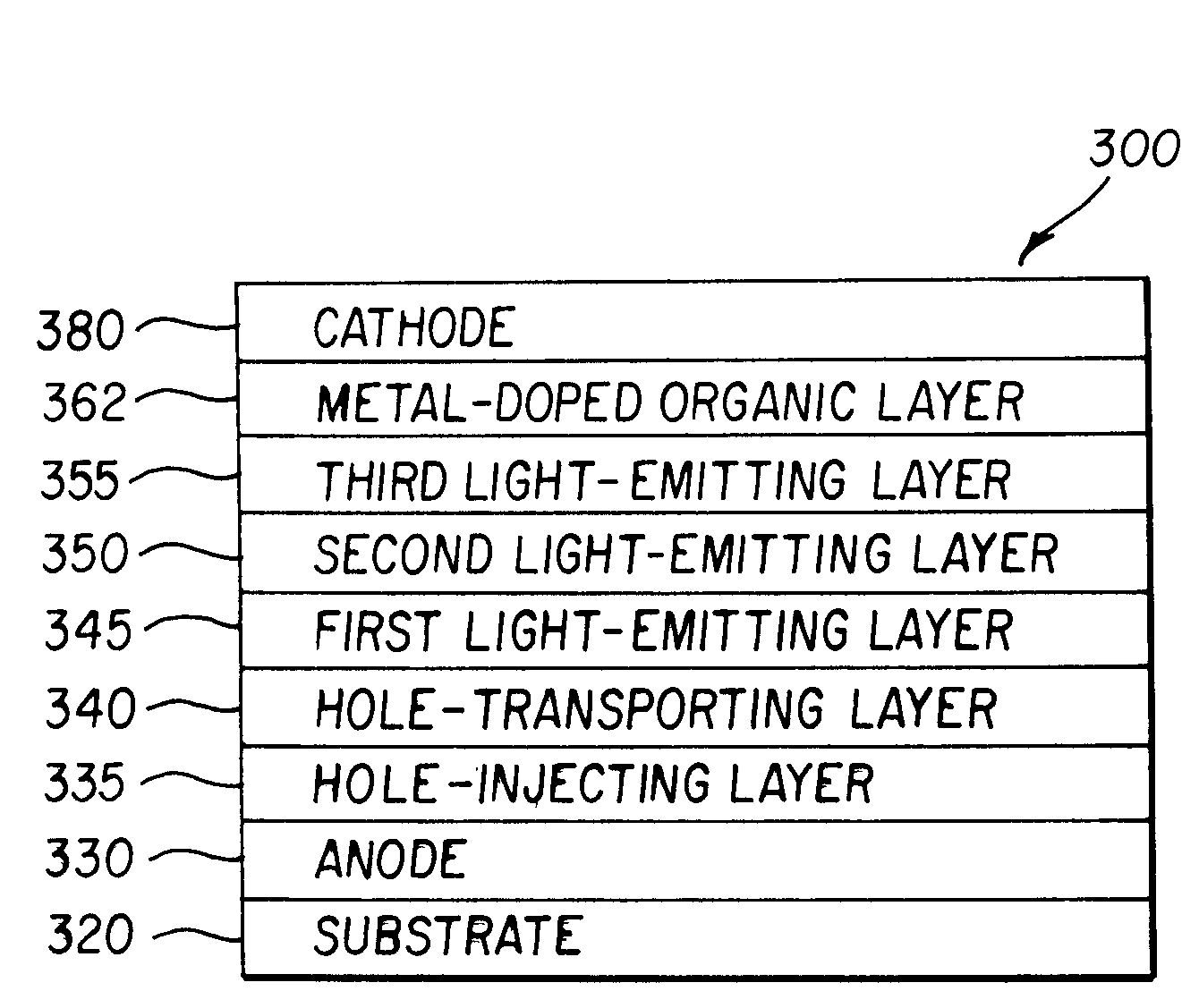

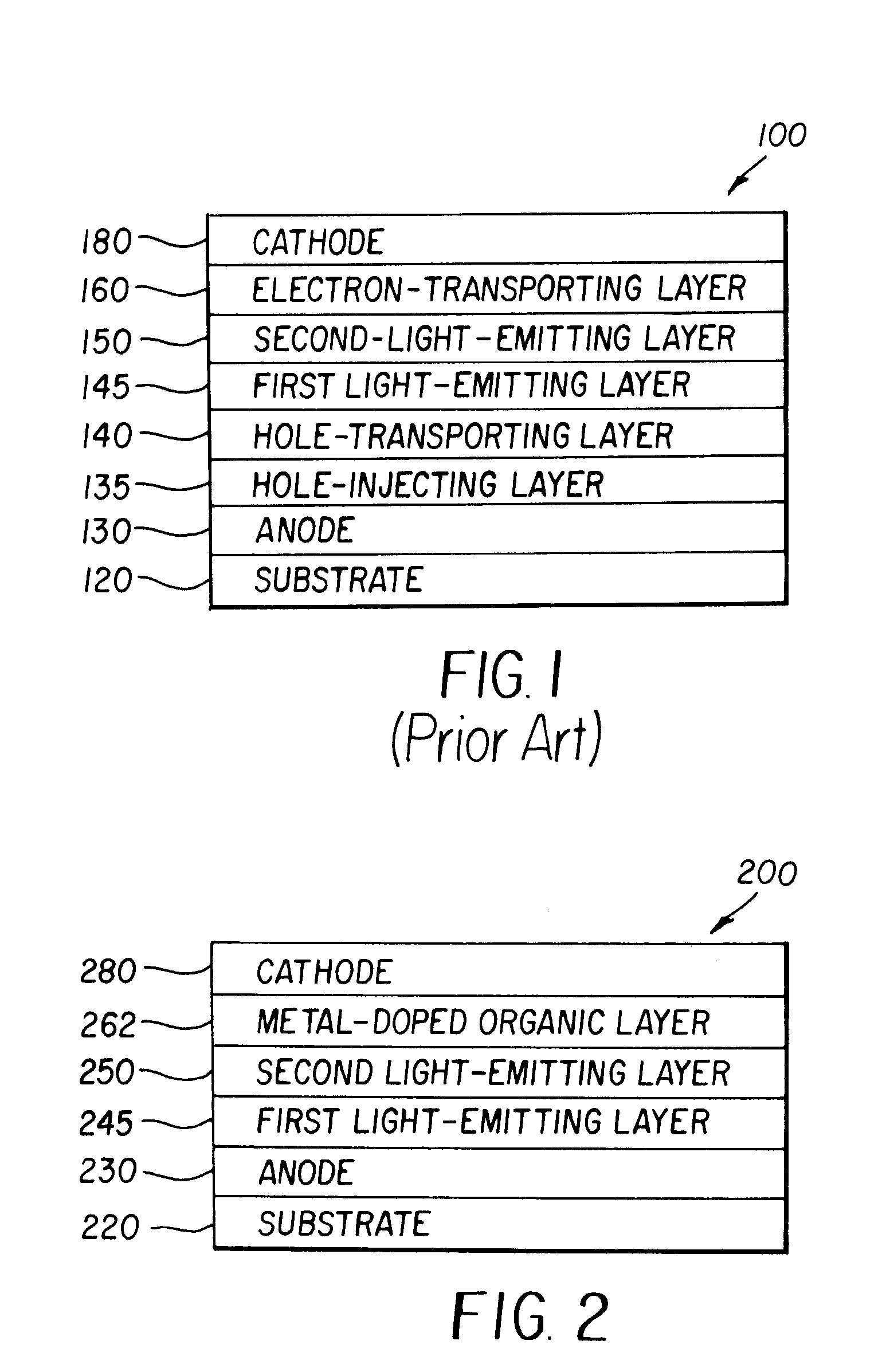

OLED device using reduced drive voltage

ActiveUS7192659B2High luminous efficiencyReduce the driving voltageIncadescent screens/filtersDischarge tube luminescnet screensOrganic layerEngineering

An OLED device includes an anode, a first light-emitting layer disposed over the anode, and a second light-emitting layer disposed over the first light-emitting layer. The device also includes a metal-doped organic layer containing an organic electron-transporting material and a low work function metal disposed over the second light-emitting layer, and a cathode disposed over the metal-doped organic layer.

Owner:GLOBAL OLED TECH

Multi-wavelength optical devices and methods of using same

Owner:VALENCELL INC

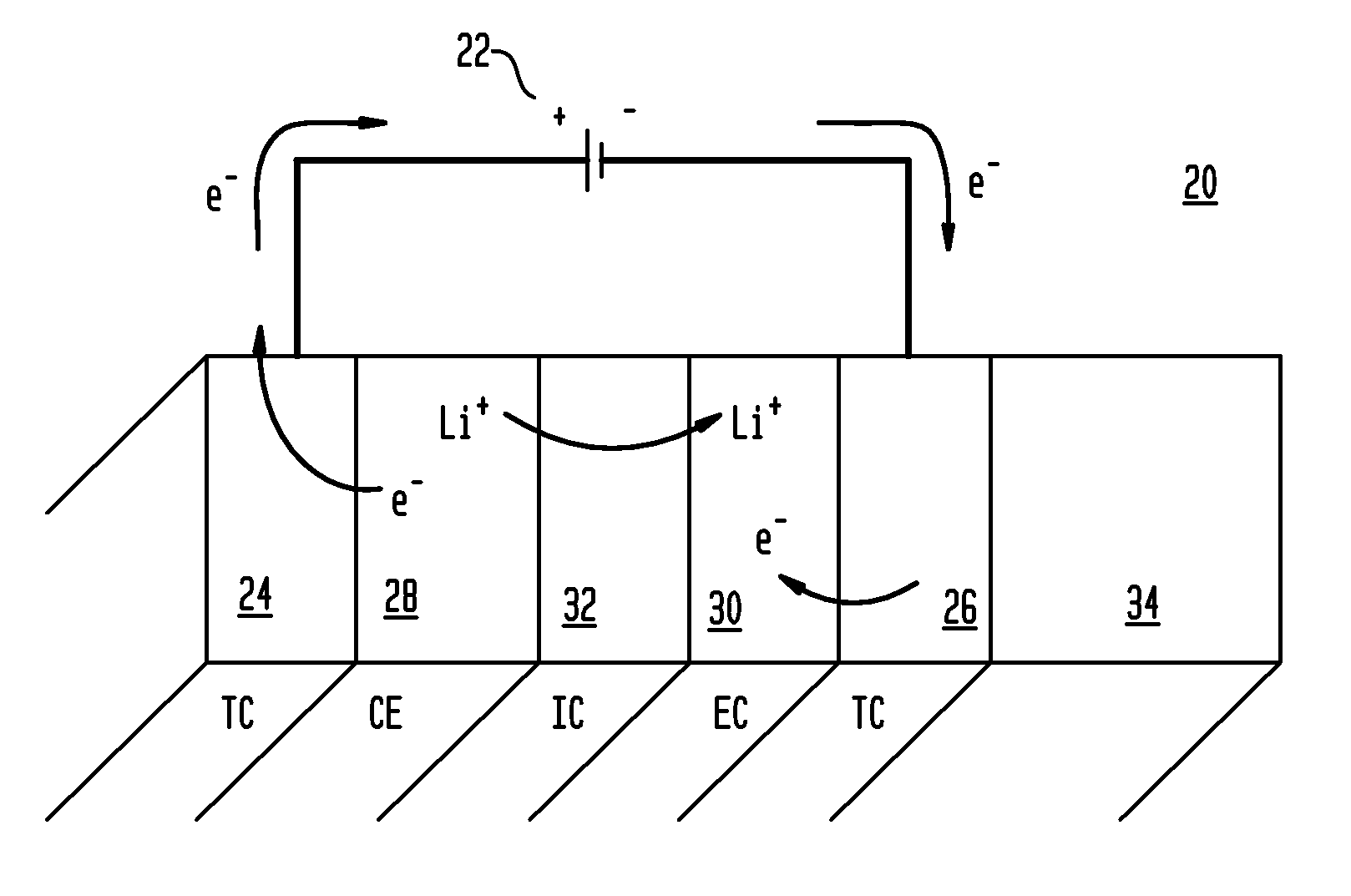

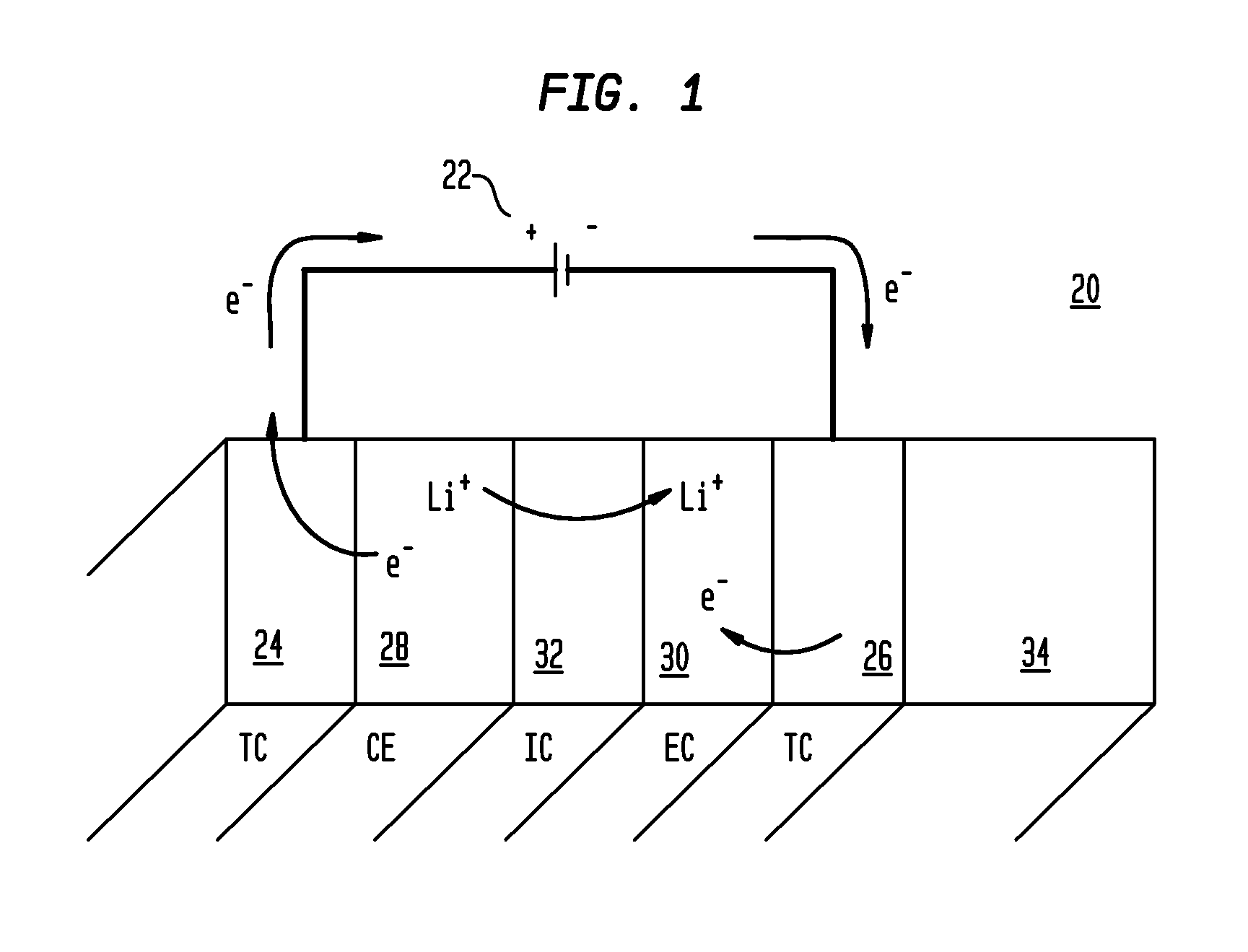

Electrochromic nickel oxide simultaneously doped with lithium and a metal dopant

An electrochromic device comprising a counter electrode layer comprised of lithium metal oxide which provides a high transmission in the fully intercalated state and which is capable of long-term stability, is disclosed. Methods of making an electrochromic device comprising such a counter electrode are also disclosed.

Owner:SAGE ELECTROCHROMICS +1

Method of forming chalcogenide comprising devices

InactiveUS6955940B2Semiconductor/solid-state device manufacturingDigital storageSulfurElectrode material

A method of forming a non-volatile resistance variable device includes forming a first conductive electrode material on a substrate. A metal doped chalcogenide comprising material is formed over the first conductive electrode material. Such comprises the metal and AxBy, where “B” is selected from S, Se and Te and mixtures thereof, and where “A” comprises at least one element which is selected from Group 13, Group 14, Group 15, or Group 17 of the periodic table. In one aspect, the chalcogenide comprising material is exposed to and HNO3 solution. In one aspect the outer surface is oxidized effective to form a layer comprising at least one of an oxide of “A” or an oxide of “B”. In one aspect, a passivating material is formed over the metal doped chalcogenide comprising material. A second conductive electrode material is deposited, and a second conductive electrode material of the device is ultimately formed therefrom.

Owner:MICRON TECH INC

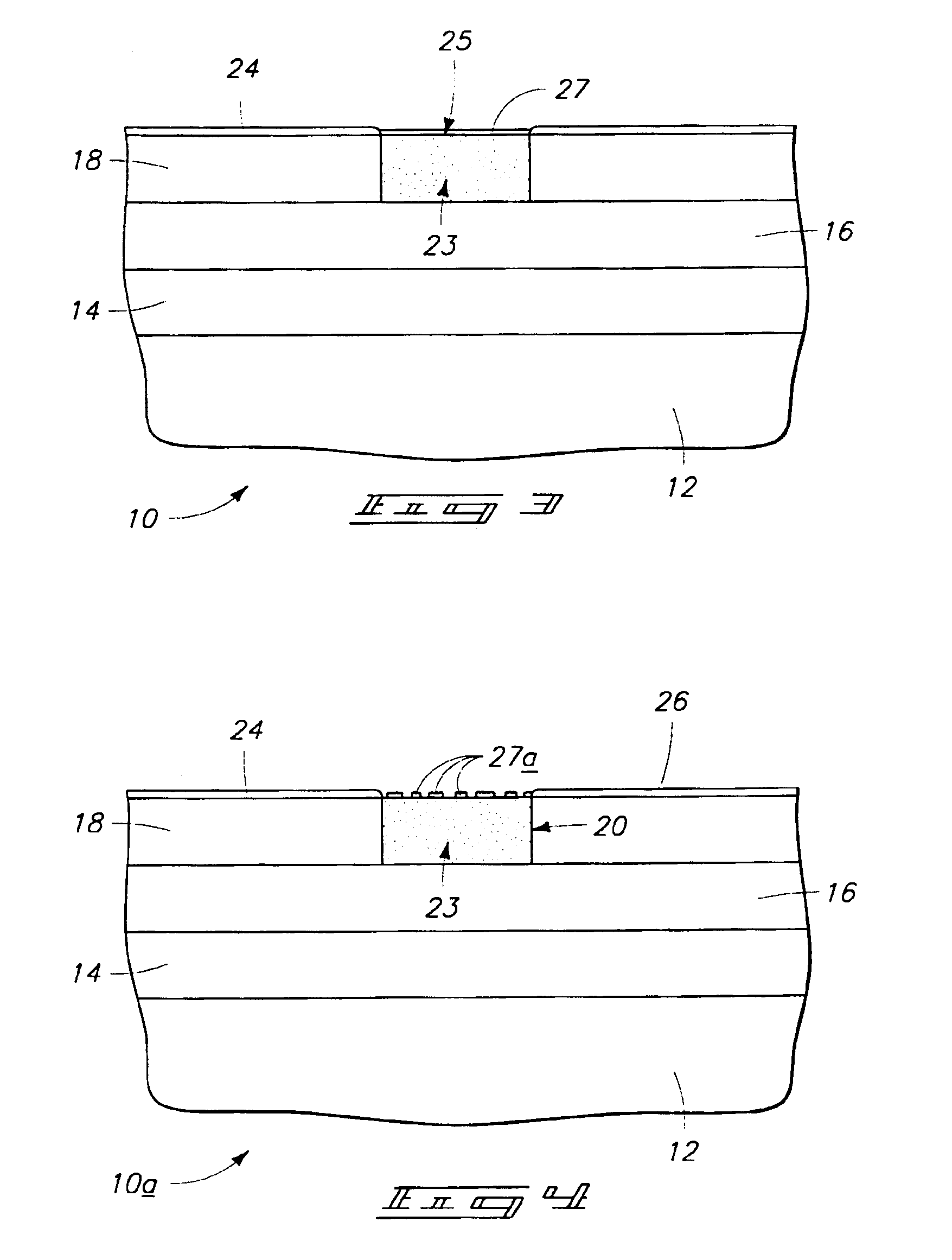

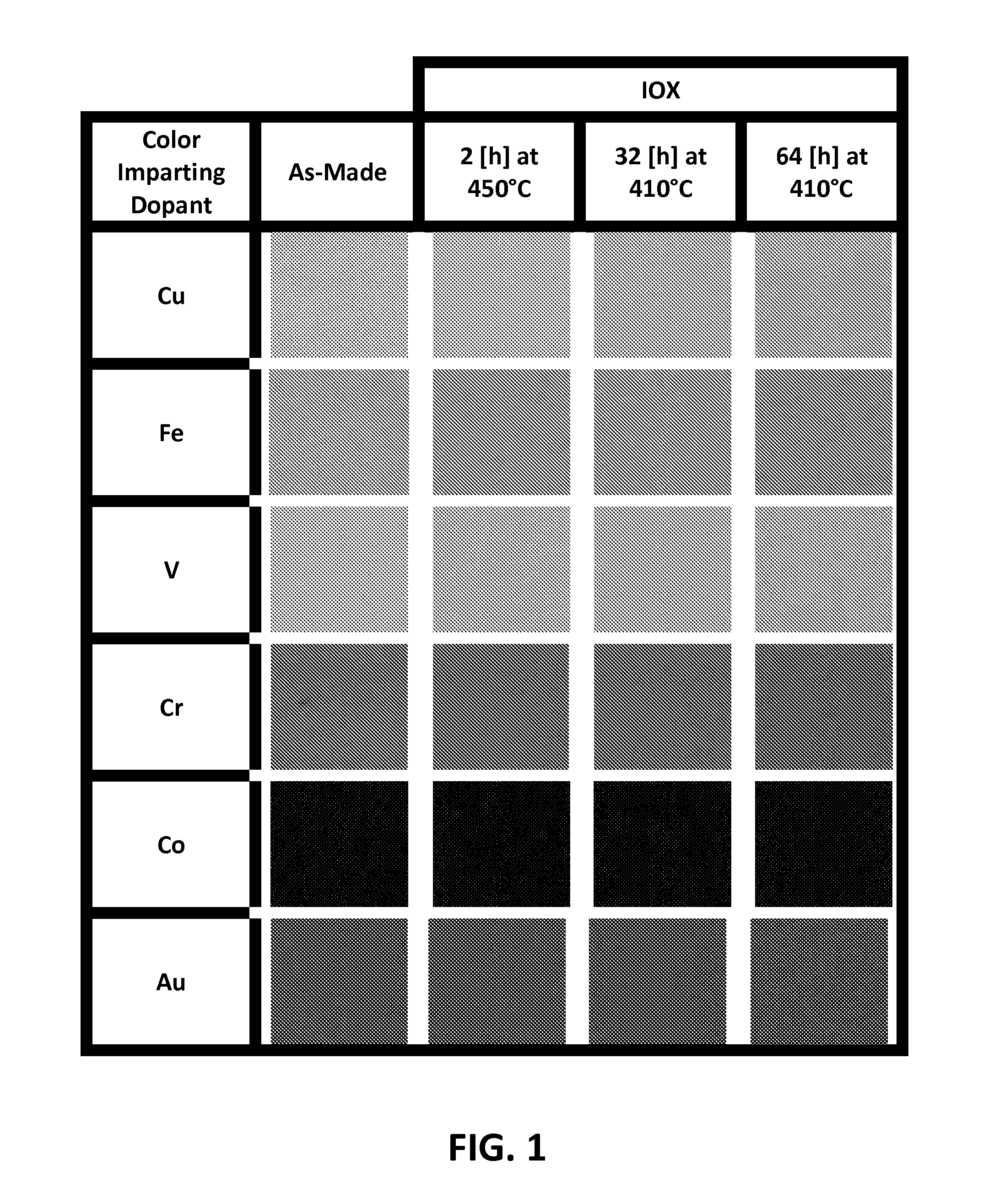

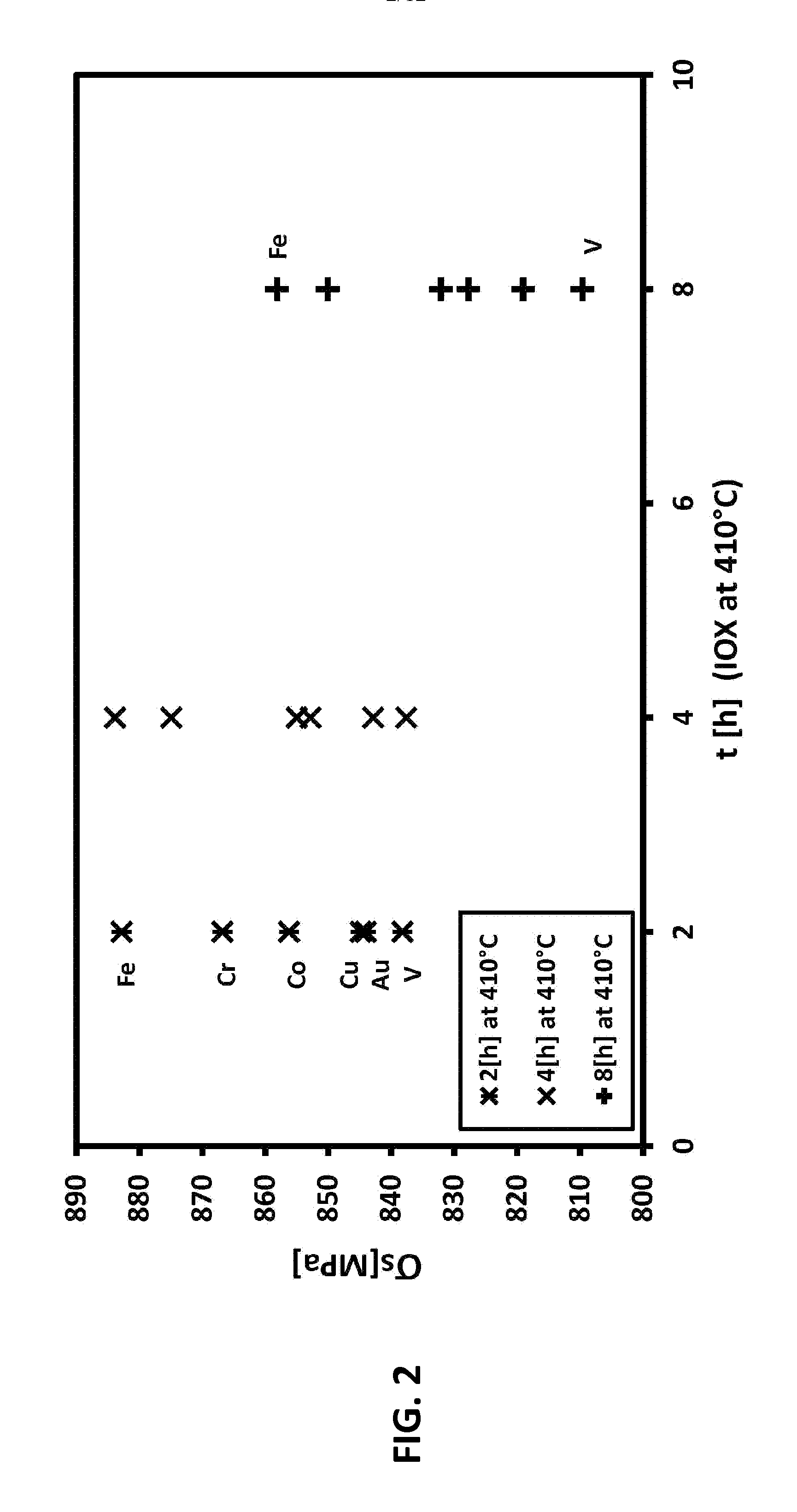

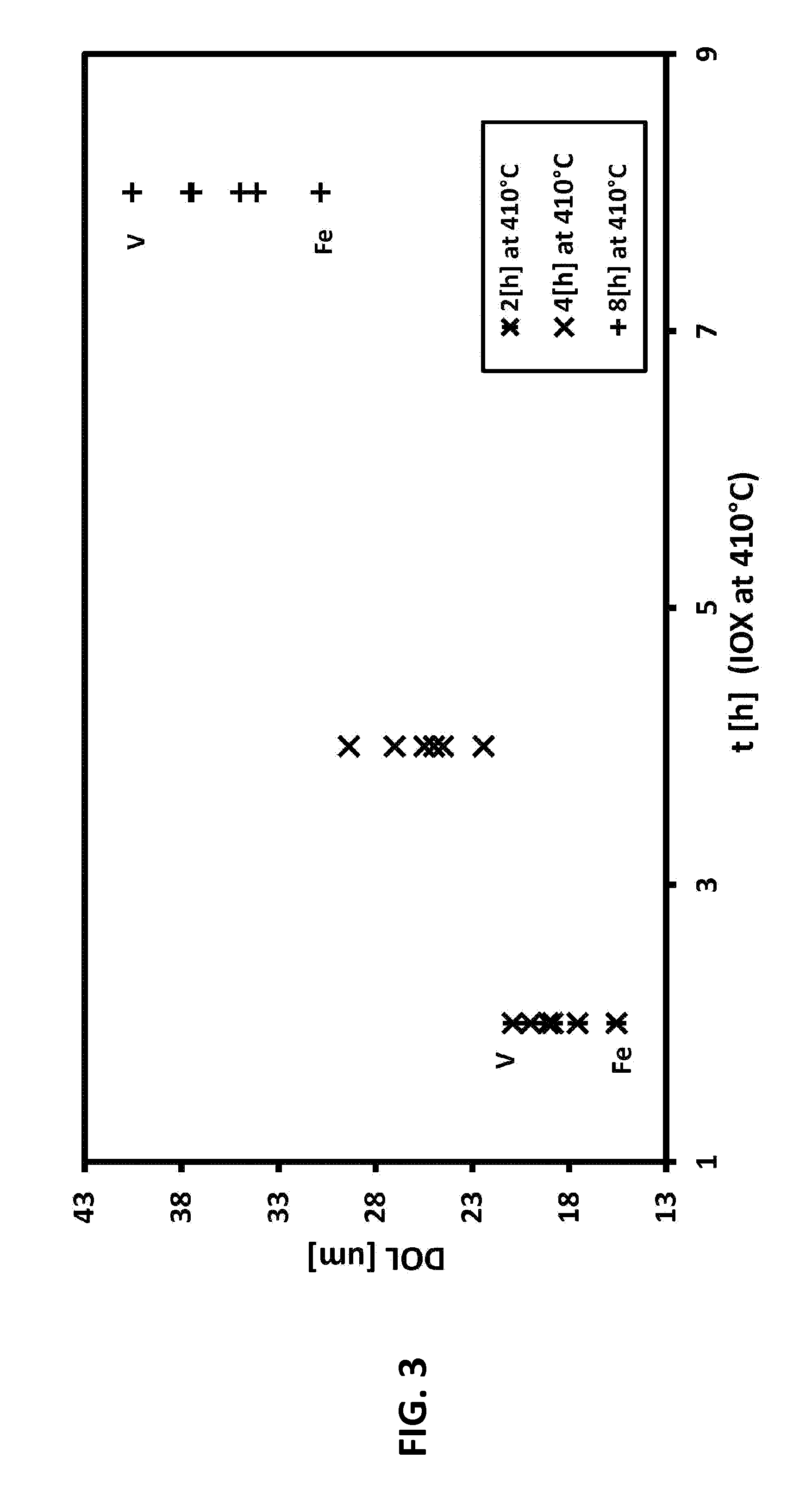

Colored alkali aluminosilicate glass articles

InactiveUS20130136909A1Synthetic resin layered productsGlass/slag layered productsDopantSilicate glass

A glass article including at least about 40 mol % SiO2 and, optionally, a colorant imparting a preselected color is disclosed. In general, the glass includes, in mol %, from about 40-70 SiO2, 0-25 Al2O3, 0-10 B2O3; 5-35 Na2O, 0-2.5 K2O, 0-8.5 MgO, 0-2 ZnO, 0-10% P2O5 and 0-1.5 CaO. As a result of ion exchange, the glass includes a compressive stress (σs) at at least one surface and, optionally, a color. In one method, communicating a colored glass with an ion exchange bath imparts σs while in another; communicating imparts σs and a preselected color. In the former, a colorant is part of the glass batch while in the latter; it is part of the bath. In each, the colorant includes one or more metal containing dopants formulated to impart to a preselected color. Examples of one or more metal containing dopants include one or more transition and / or rare earth metals.

Owner:CORNING INC

OLED device using reduced drive voltage

ActiveUS20050233166A1High luminous efficiencyReduce the driving voltageIncadescent screens/filtersDischarge tube luminescnet screensOrganic layerEngineering

An OLED device includes an anode, a first light-emitting layer disposed over the anode, and a second light-emitting layer disposed over the first light-emitting layer. The device also includes a metal-doped organic layer containing an organic electron-transporting material and a low work function metal disposed over the second light-emitting layer, and a cathode disposed over the metal-doped organic layer.

Owner:GLOBAL OLED TECH

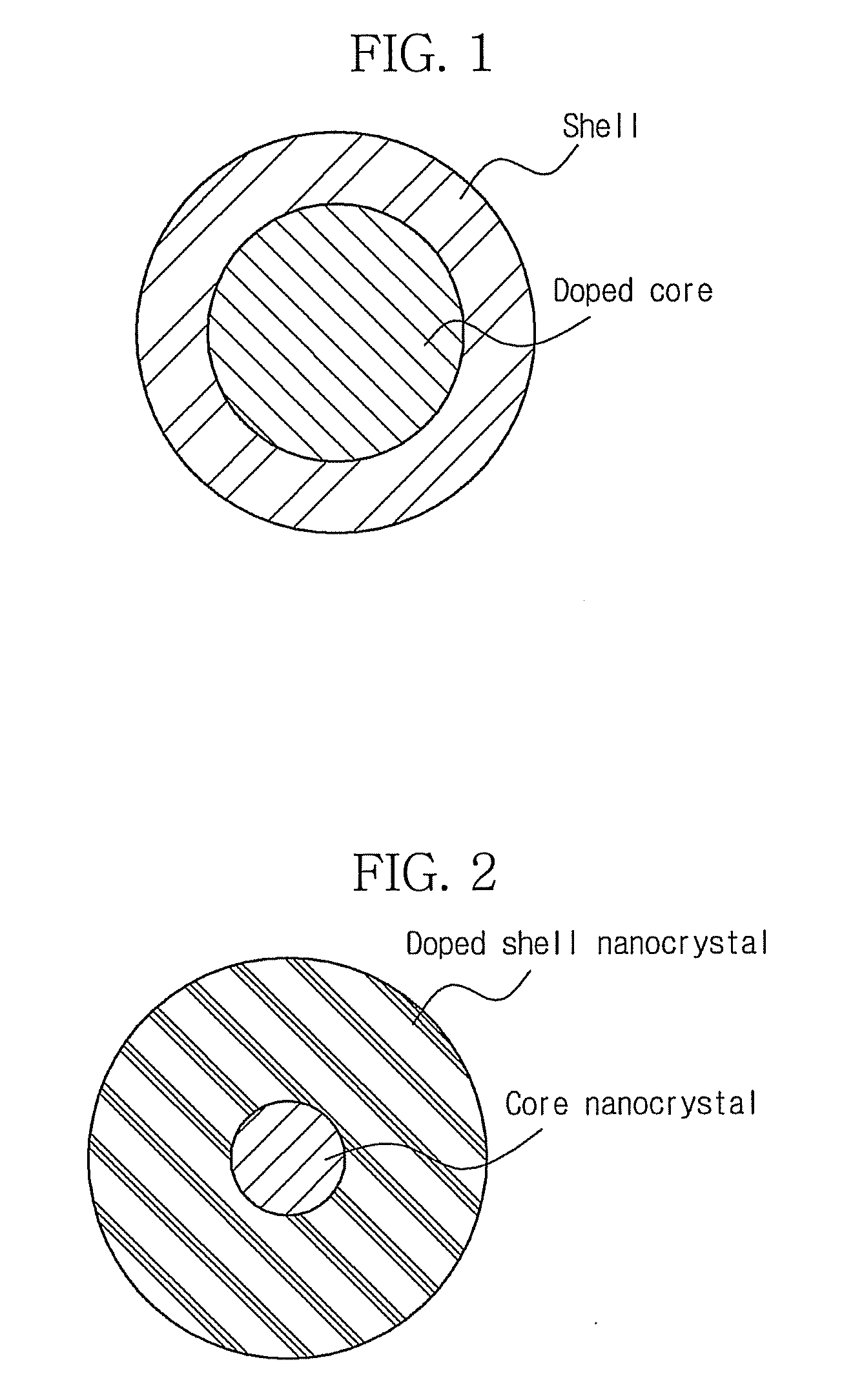

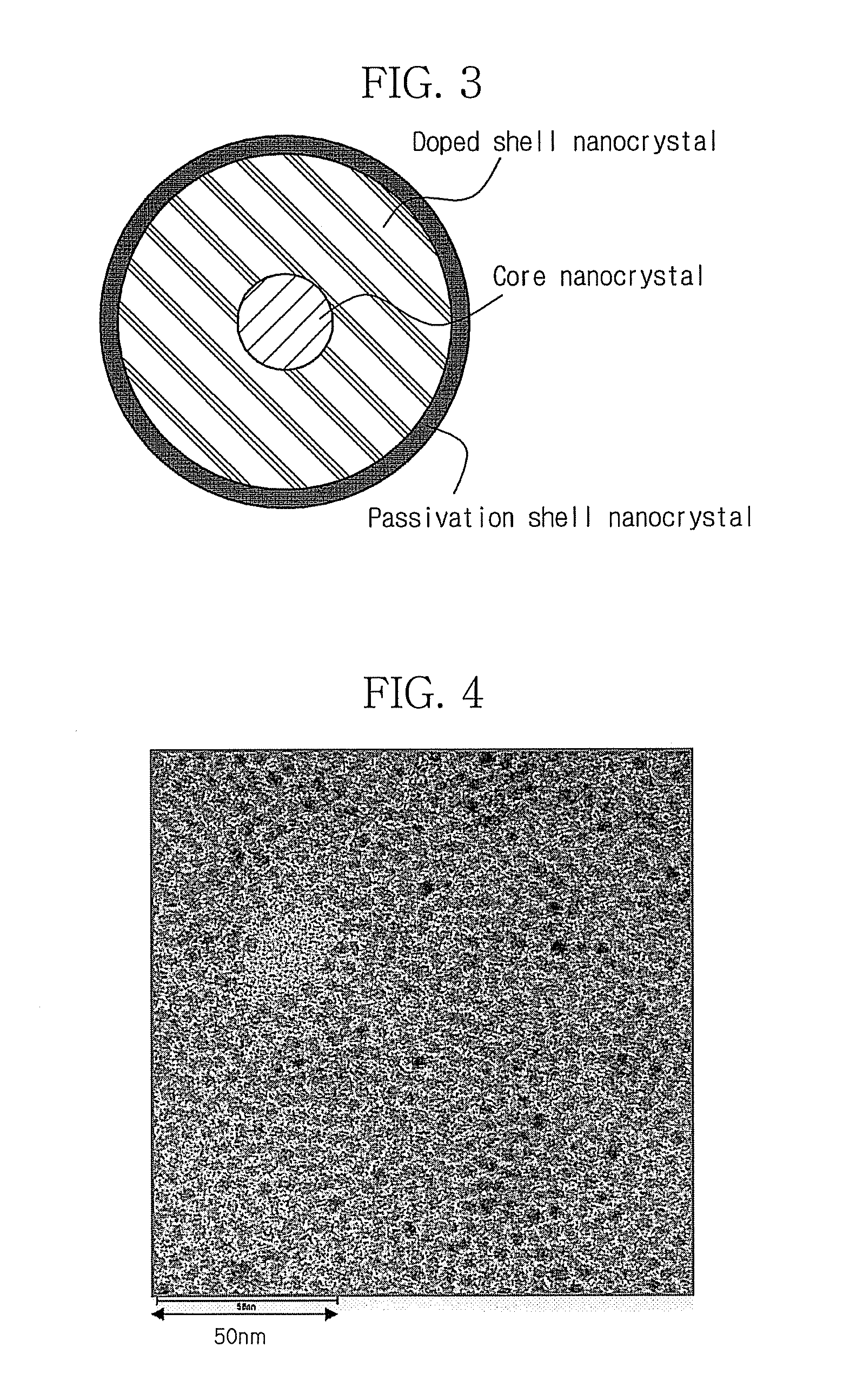

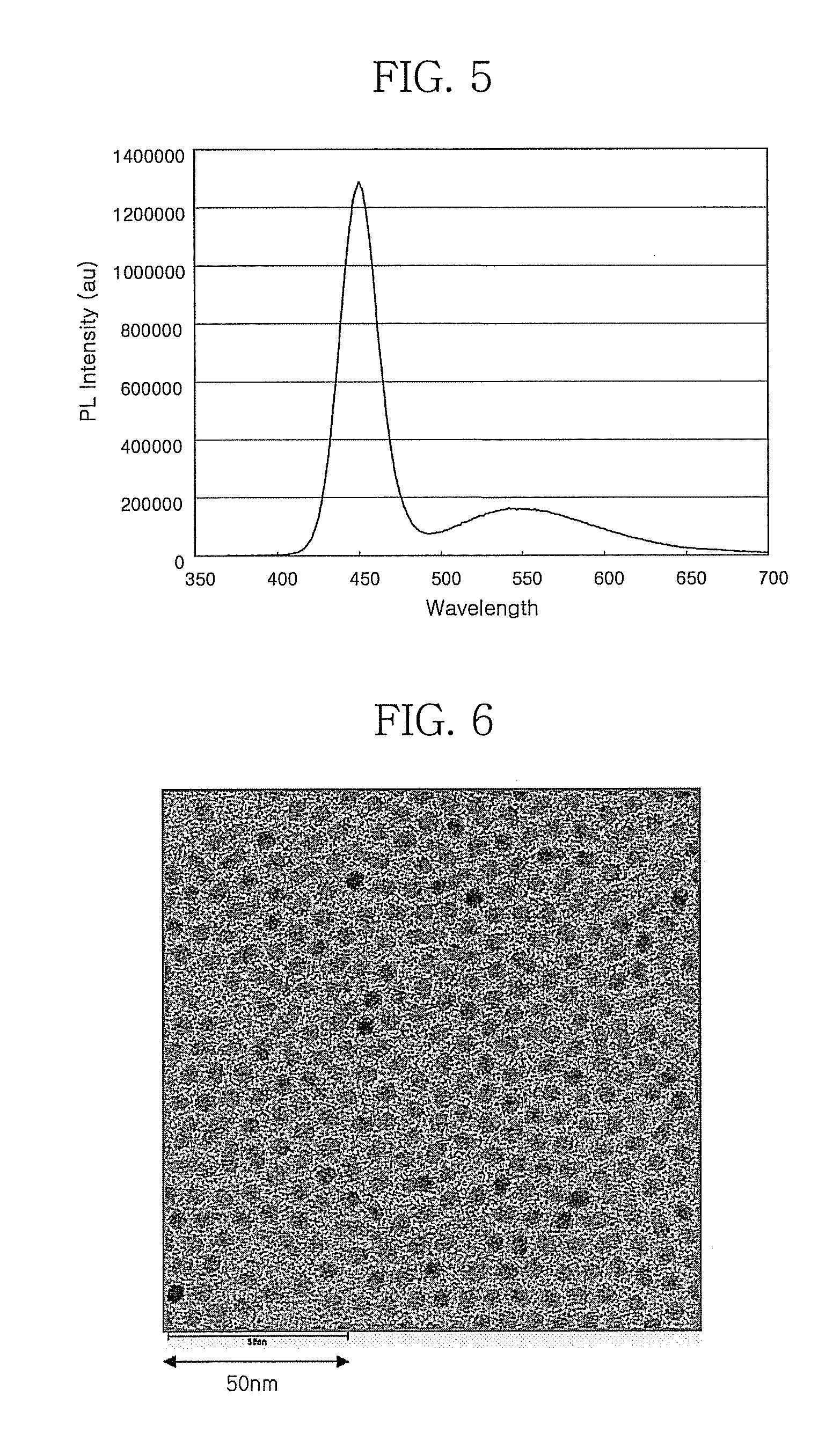

Core/shell nanocrystals and method for producing the same

InactiveUS20080305334A1Good reproducibilitySolve low luminous efficiencyMaterial nanotechnologyLiquid surface applicatorsNanocrystalCrystallinity

Disclosed herein are a core / shell nanocrystal and a method for producing the same. More specifically, disclosed herein are a core / shell nanocrystal comprising a metal-doped shell nanocrystal, and a method for producing the same. The core / shell nanocrystal comprises a core nanocrystal and a metal-doped shell nanocrystal formed on the core nanocrystal. Based on the structure, the core / shell nanocrystal exhibits superior crystallinity and high luminescence efficiency, enables easy control of the shape and size and can be produced in a simple manner.

Owner:SAMSUNG ELECTRONICS CO LTD

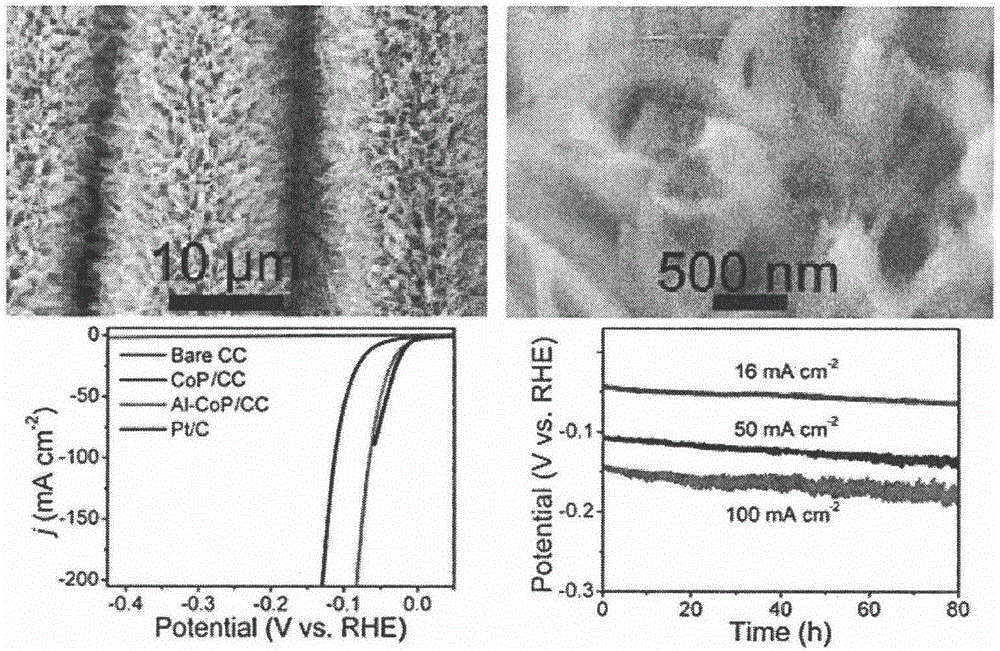

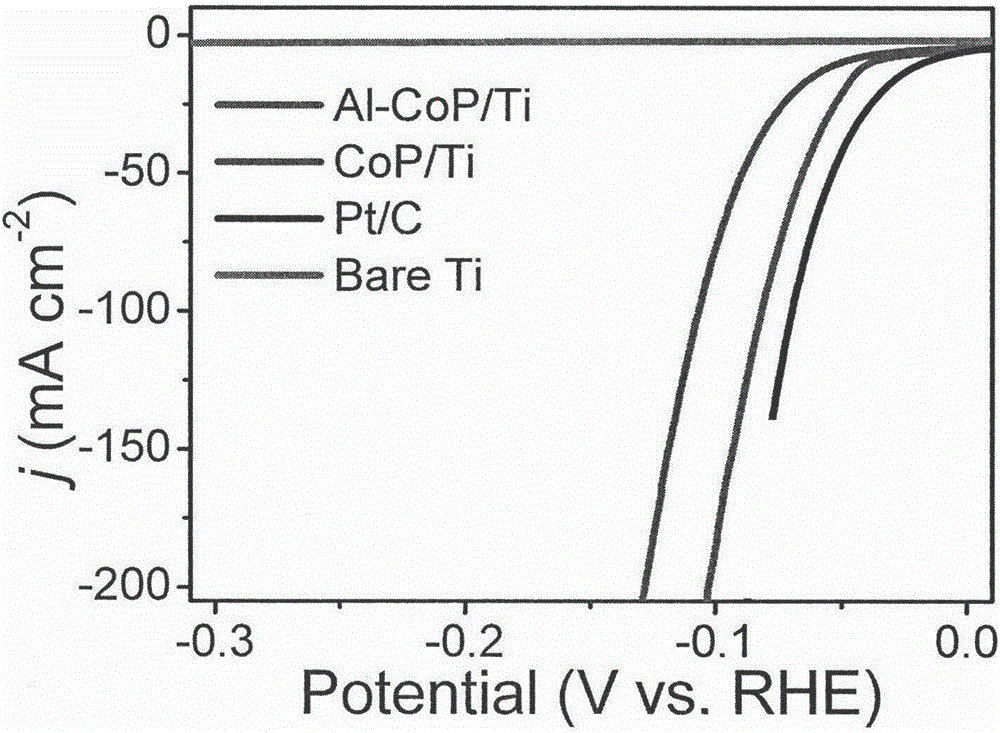

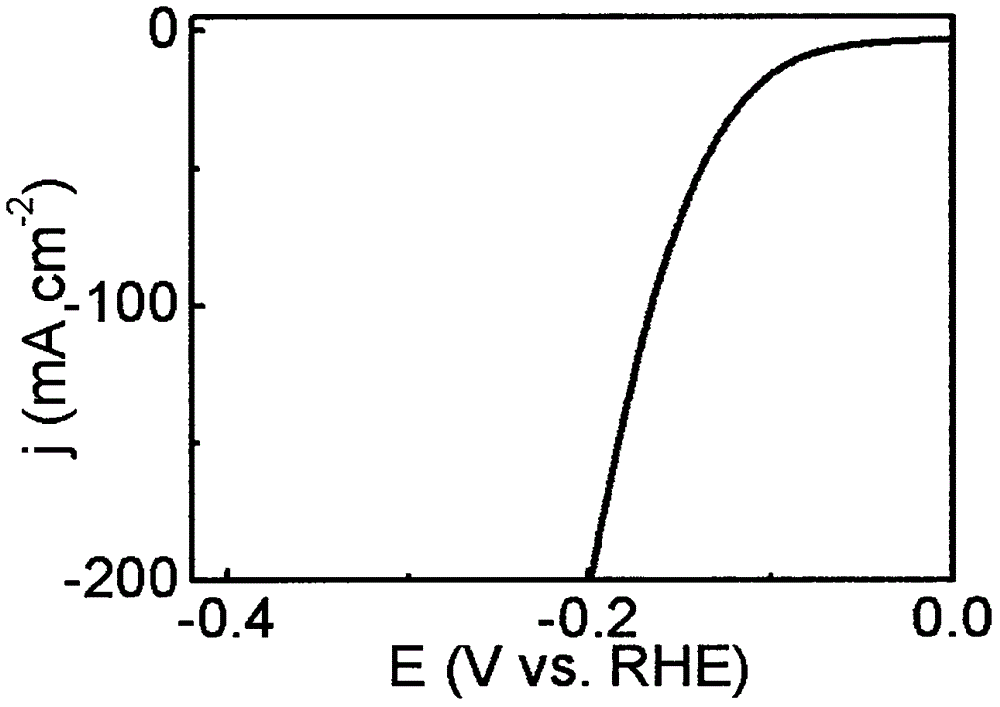

Water electrolytic hydrogen production catalytic electrode of self-supporting metal-doped cobalt phosphide nano structure

InactiveCN105839131AEfficient water electrolysis hydrogen productionGood activity and stabilityElectrodesNano structuringFuel cells

The invention discloses a preparation method for a self-supporting metal-doped cobalt phosphide nano structure and an application of the self-supporting metal-doped cobalt phosphide nano structure as a catalytic electrode in water electrolytic hydrogen production, and belongs to the technical field of hydrogen energy and fuel cells. According to the invention, a metal element is firstly used as a doping agent for introducing cobalt phosphide, in-situ growth, on the surface of a collector, of the cobalt phosphide is realized, the catalytic activity and the structural stability are improved, the problem that a powder catalyst needs a polymer binder for being effectively fixed on the surface of the electrode is solved, and therefore, the self-supporting metal-doped cobalt phosphide nano structure is suitable for large-scale industrial hydrogen production application.

Owner:成都玖奇新材料科技有限公司

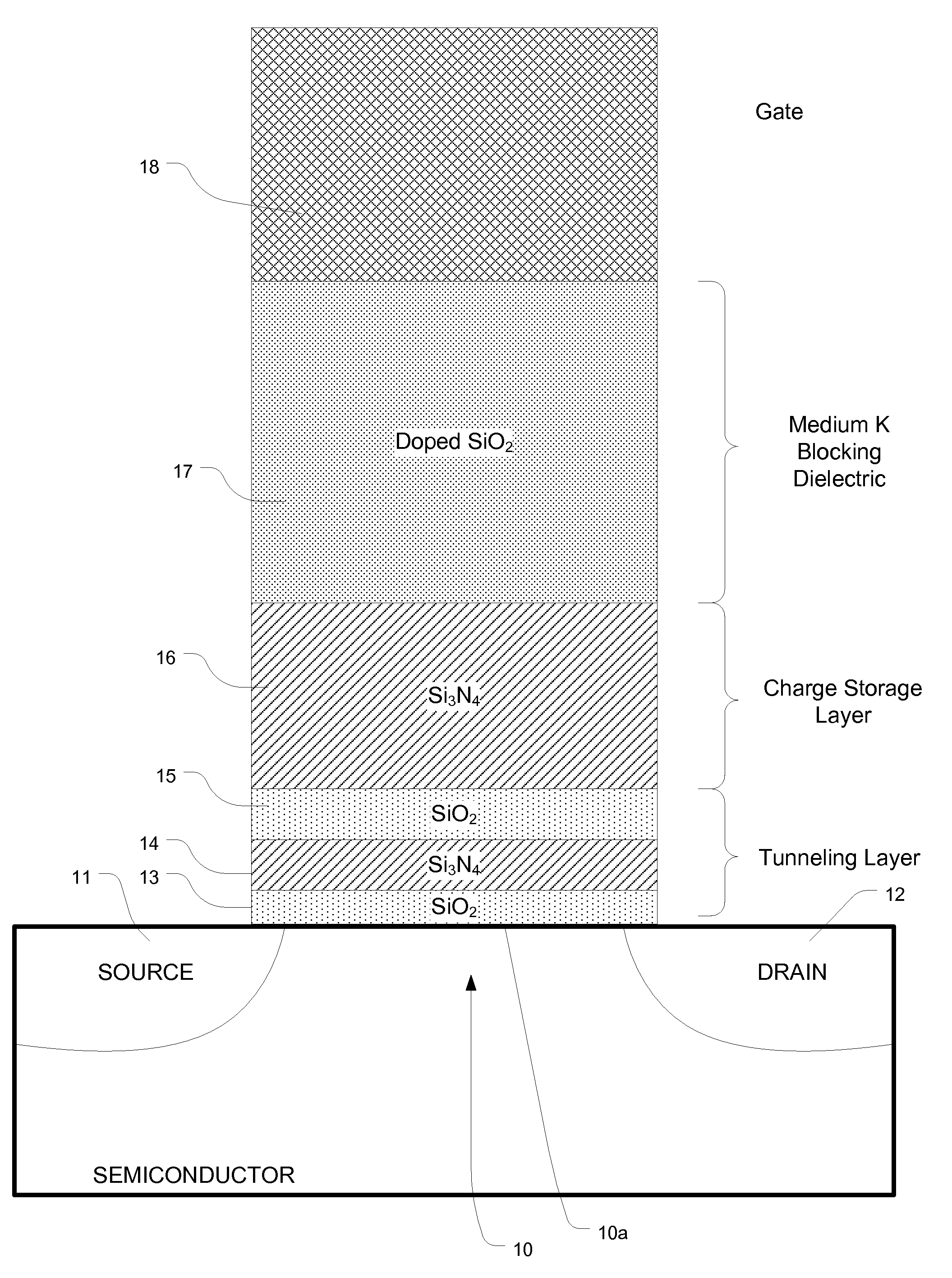

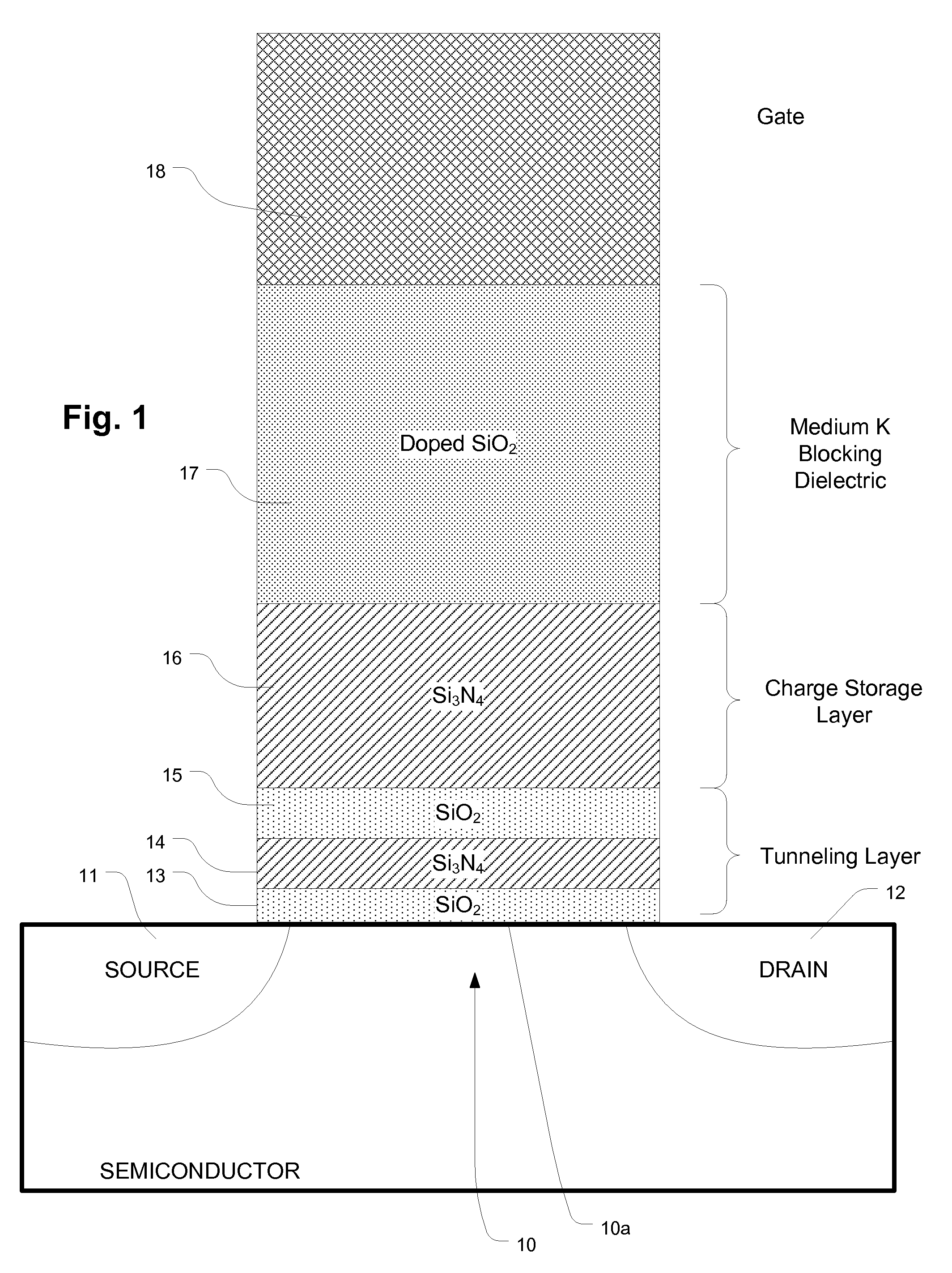

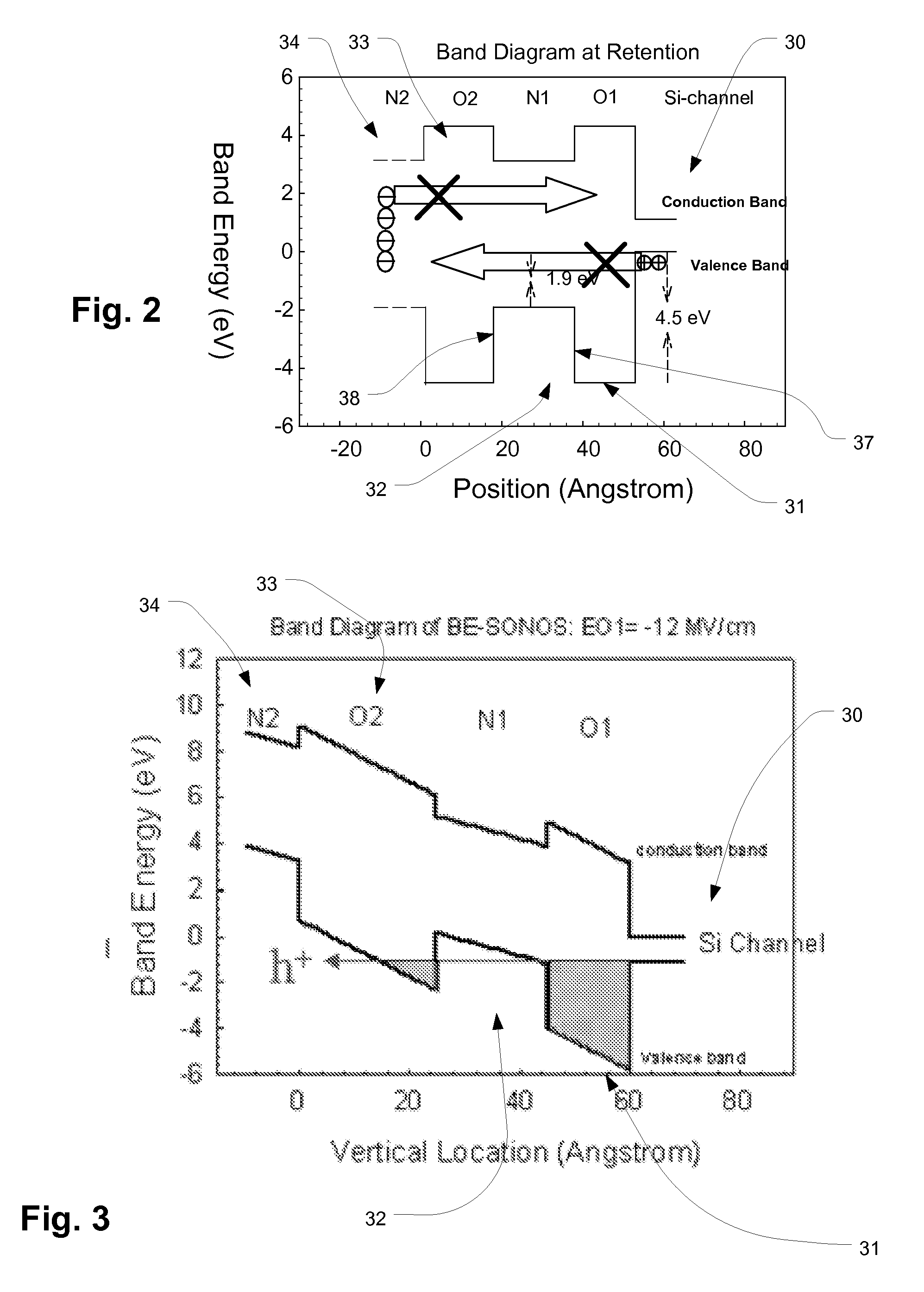

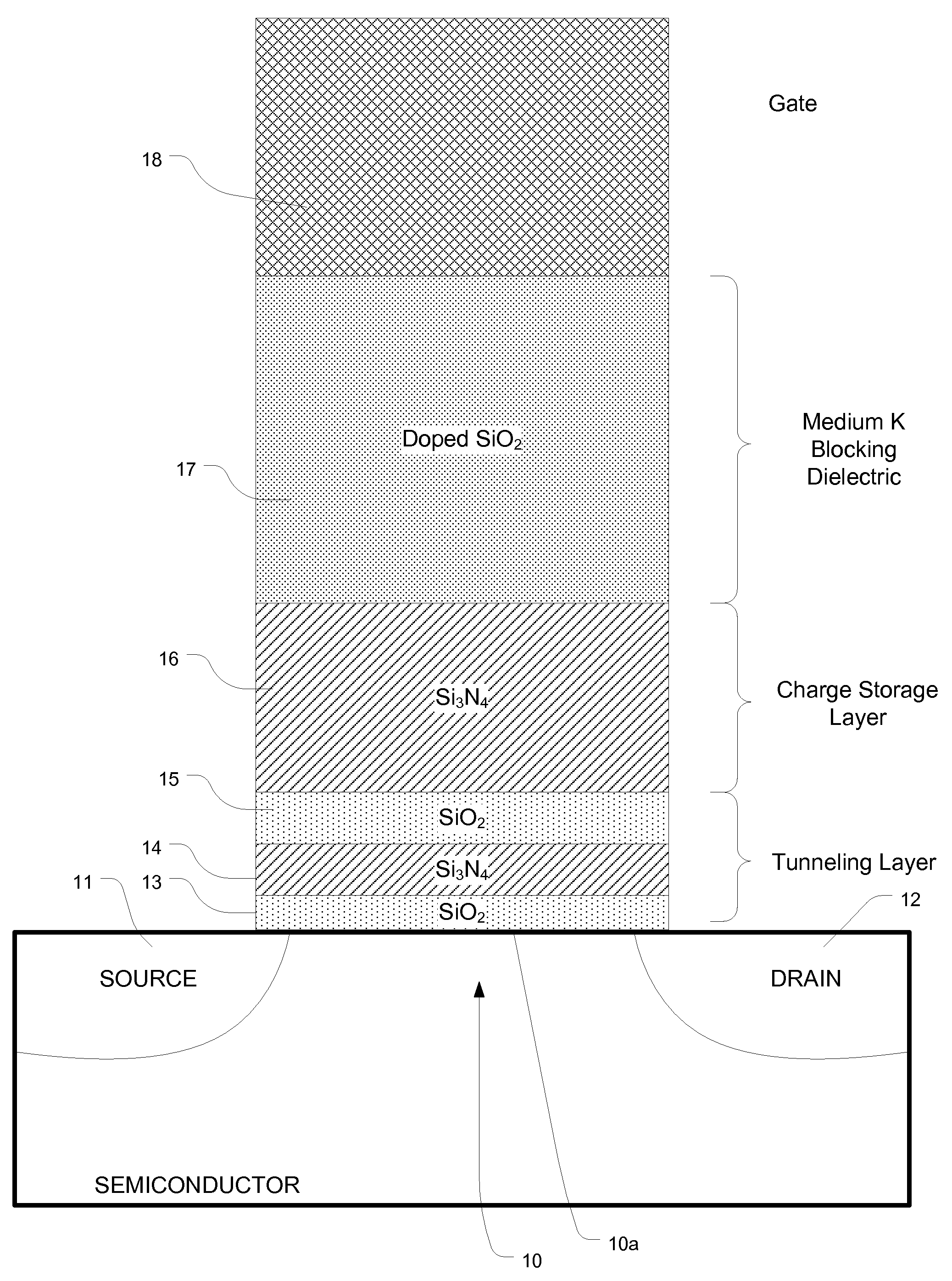

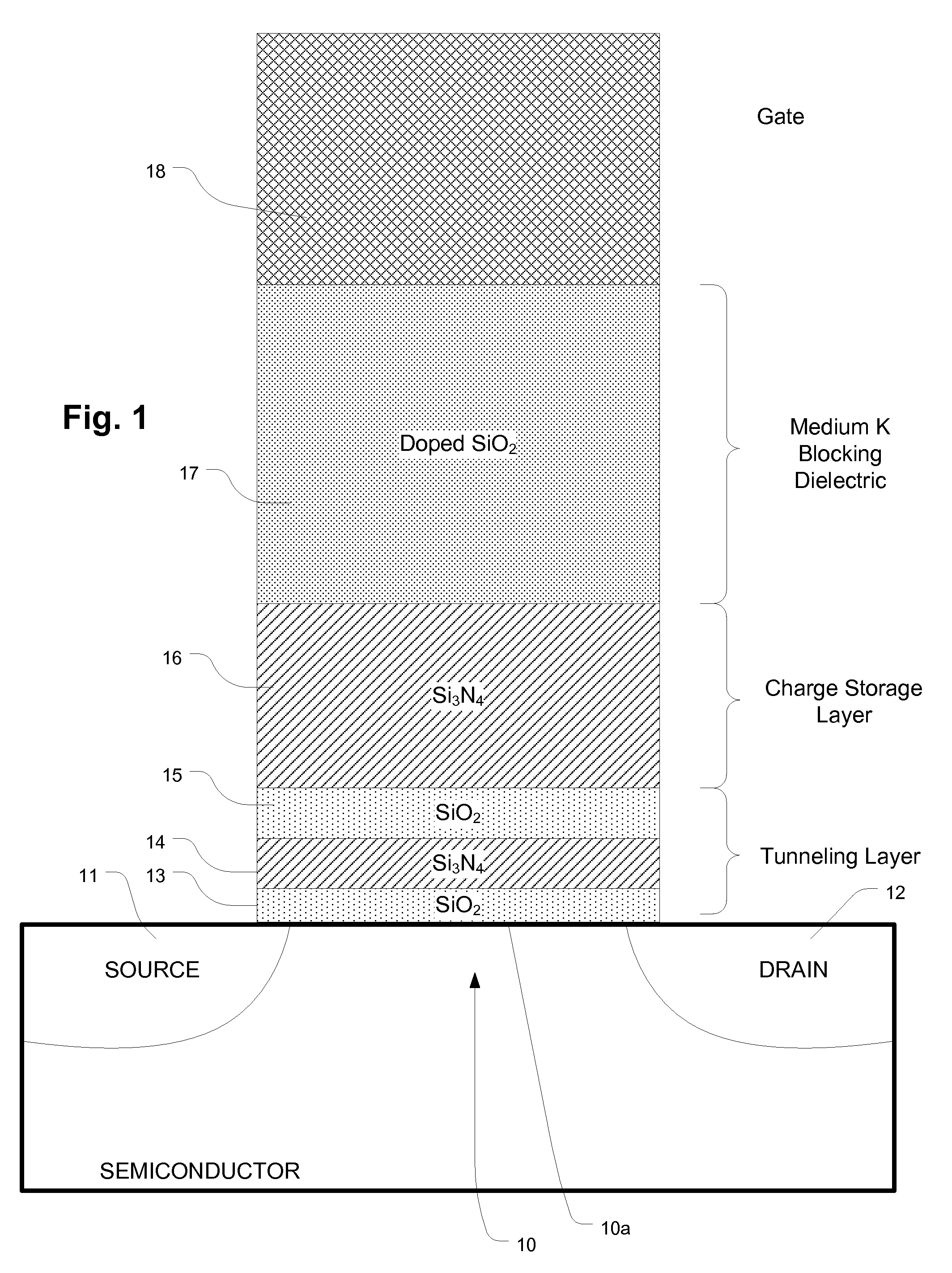

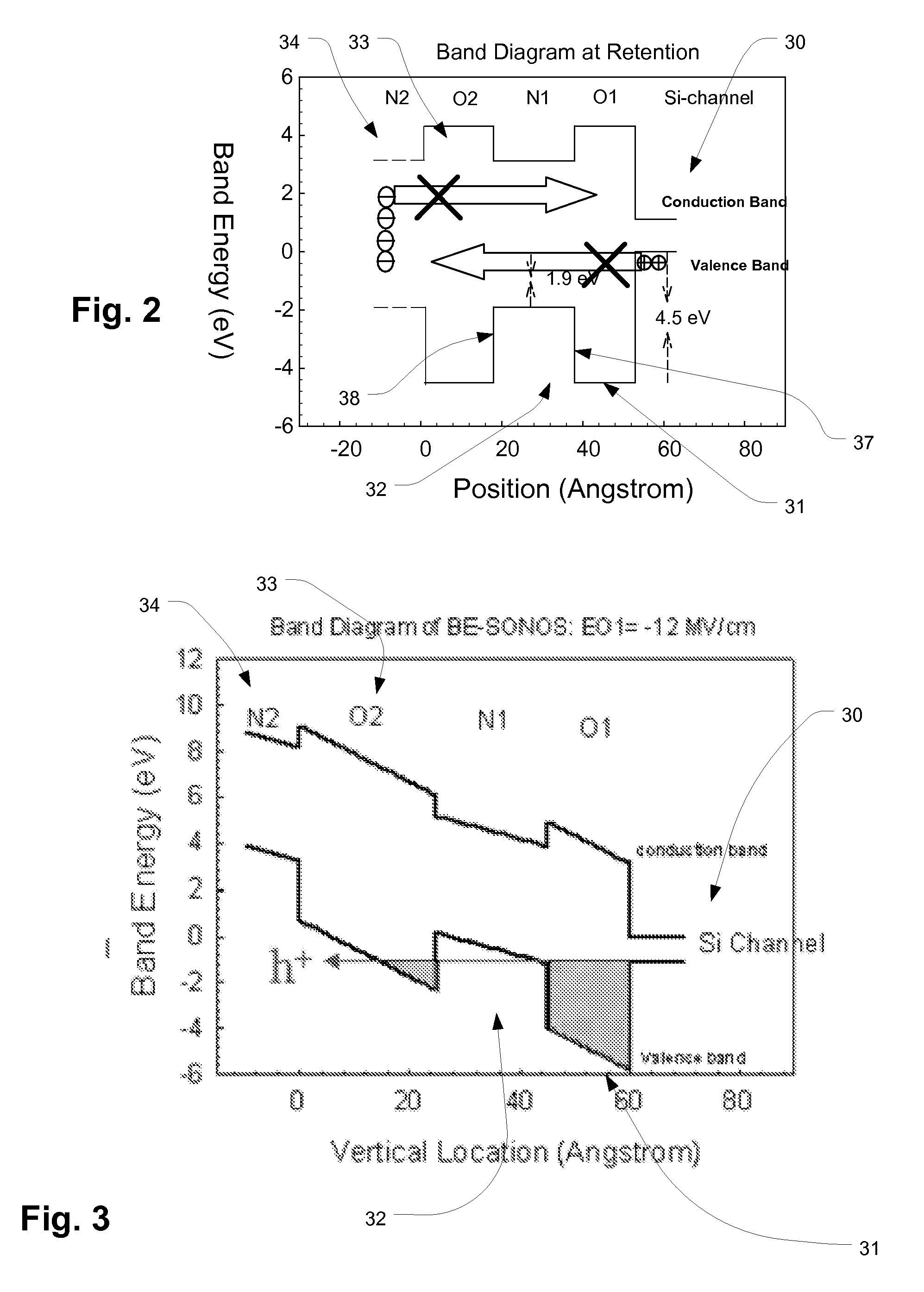

Blocking dielectric engineered charge trapping memory cell with high speed erase

ActiveUS7737488B2High barrier heightFast programmingSolid-state devicesRead-only memoriesDielectricTrapping

A band gap engineered, charge trapping memory cell includes a charge trapping element that is separated from a gate by a blocking layer of metal doped silicon oxide material having a medium dielectric constant, such as aluminum doped silicon oxide, and separated from the semiconductor body including the channel by an engineered tunneling dielectric.

Owner:MACRONIX INT CO LTD

Multilayered gradient diamond like nano composite coating for aluminum alloy piston and preparation method thereof

InactiveCN102092166AOvercome stressOvercome adhesionLayered productsVacuum evaporation coatingDiamond-like carbonSurface layer

The invention discloses a multilayered gradient diamond like nano composite coating for an aluminum alloy piston and a preparation method thereof. The coating consists of a piston matrix, a bottom adhesive layer, a middle transition layer and a surface layer in turn, wherein the bottom is provided with a metal Ti or Cr adhesive layer; the middle transition layer is metal nitride and a Si layer; and the surface layer is a metal-doped diamond like carbon film. The wear life of the coating is improved by more than 40 times compared with that of a single-layer diamond like coating with the same thickness directly formed on the surface of aluminum alloy, and the friction coefficient under the oil lubricating condition is stabilized to be 0.05. The piston with the diamond like coating has better comprehensive performance than a piston of which the skirt is treated by MoS2, and can meet the requirements on high speed, high efficiency and low emission of a modern engine.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

High efficiency transparent organic light emitting devices

InactiveUS6885149B2Improve efficiencyHighly efficient transparent cathodeSolid-state devicesSemiconductor/solid-state device manufacturingElectron injectionPhenanthroline

A highly transparent non-metallic cathode is disclosed that comprises a metal-doped organic electron injection layer that is in direct contact with a transparent non-metallic electron injecting cathode layer, such as indium tin oxide (ITO), wherein the metal-doped organic electron injection layer also functions as an exciton blocking or hole blocking layer. The metal-doped organic electron injection layer is created by diffusing an ultra-thin layer of about 5-10 Å of a highly electropositive metal such as Li throughout the layer. A representative embodiment of the highly transparent non-metallic cathode comprises a layer of ITO, a layer of 2,9-dimethyl-4,7-diphenyl-1,10-phenanthroline (BCP), which acts as an electron injection, exciton blocking, and hole blocking layer, and an ultra-thin layer of lithium, which degenerately dopes the layer of BCP, improving the electron injecting properties of the BCP layer. This cathode is demonstrated for use in an OLED having a transparency of about 90% or higher combined with a device external quantum efficiency of about 1% or higher.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Blocking dielectric engineered charge trapping memory cell with high speed erase

ActiveUS20090039416A1Fast programmingImprove reliabilitySolid-state devicesRead-only memoriesDielectricTrapping

A band gap engineered, charge trapping memory cell includes a charge trapping element that is separated from a gate by a blocking layer of metal doped silicon oxide material having a medium dielectric constant, such as aluminum doped silicon oxide, and separated from the semiconductor body including the channel by an engineered tunneling dielectric.

Owner:MACRONIX INT CO LTD

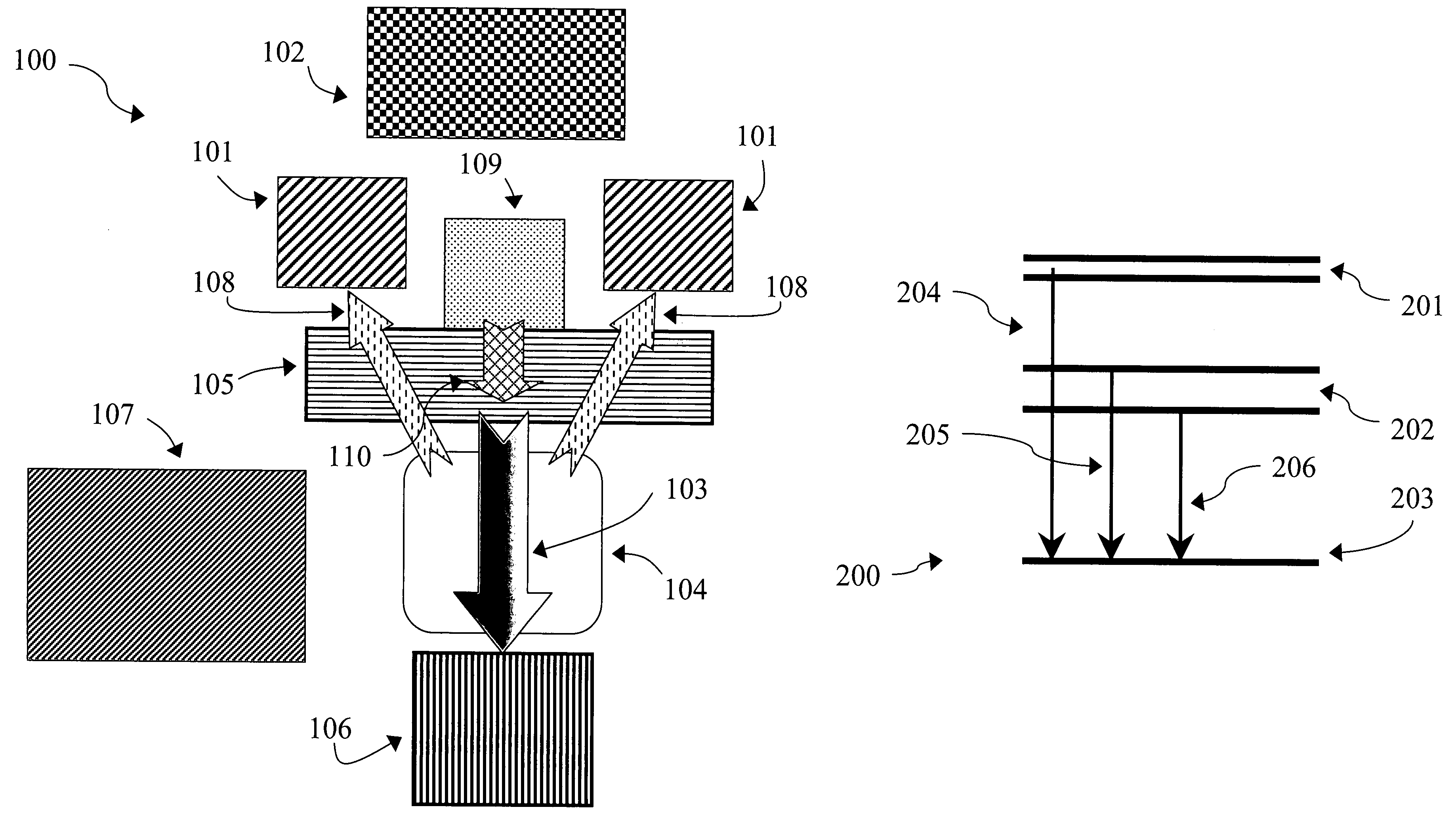

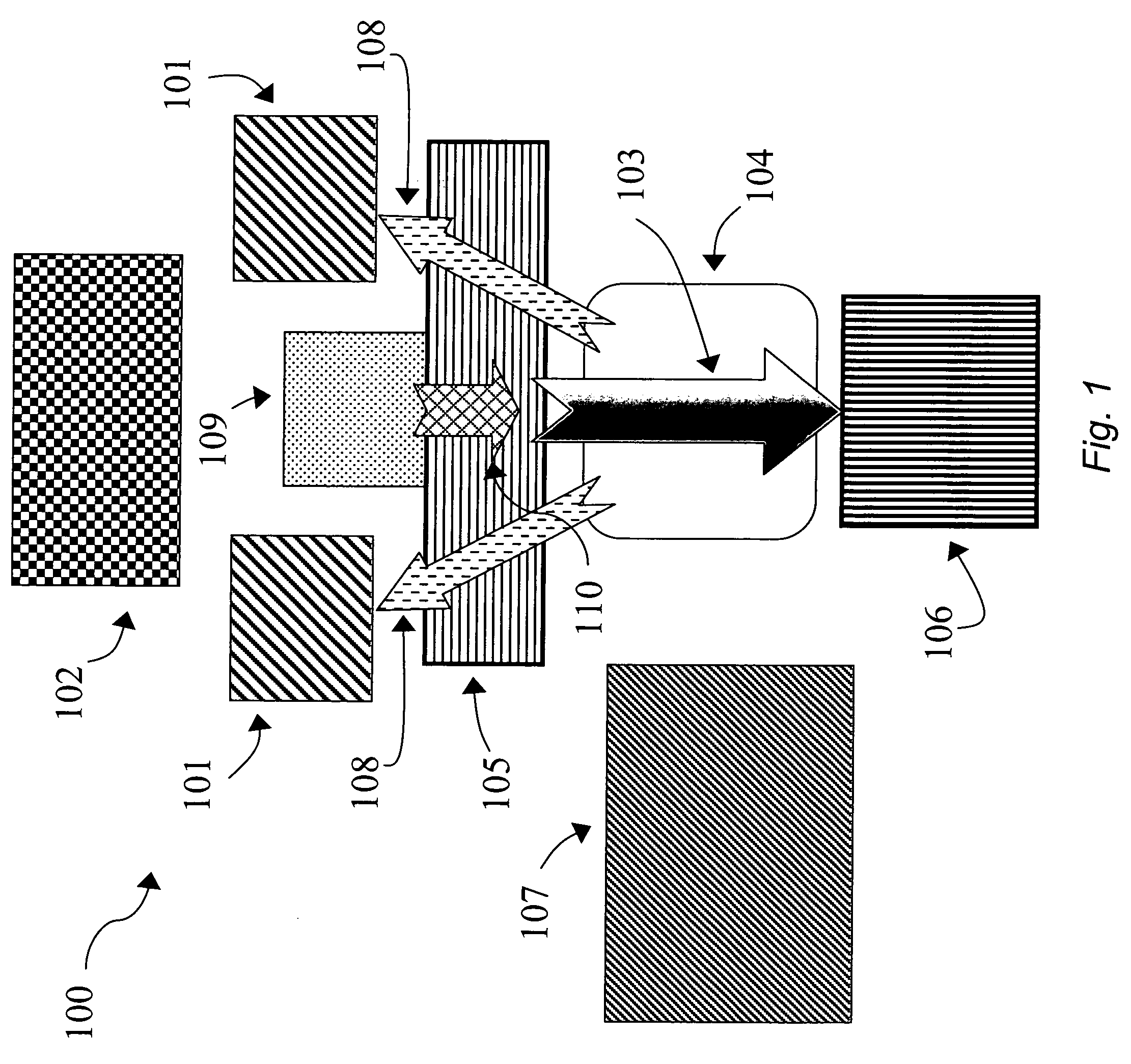

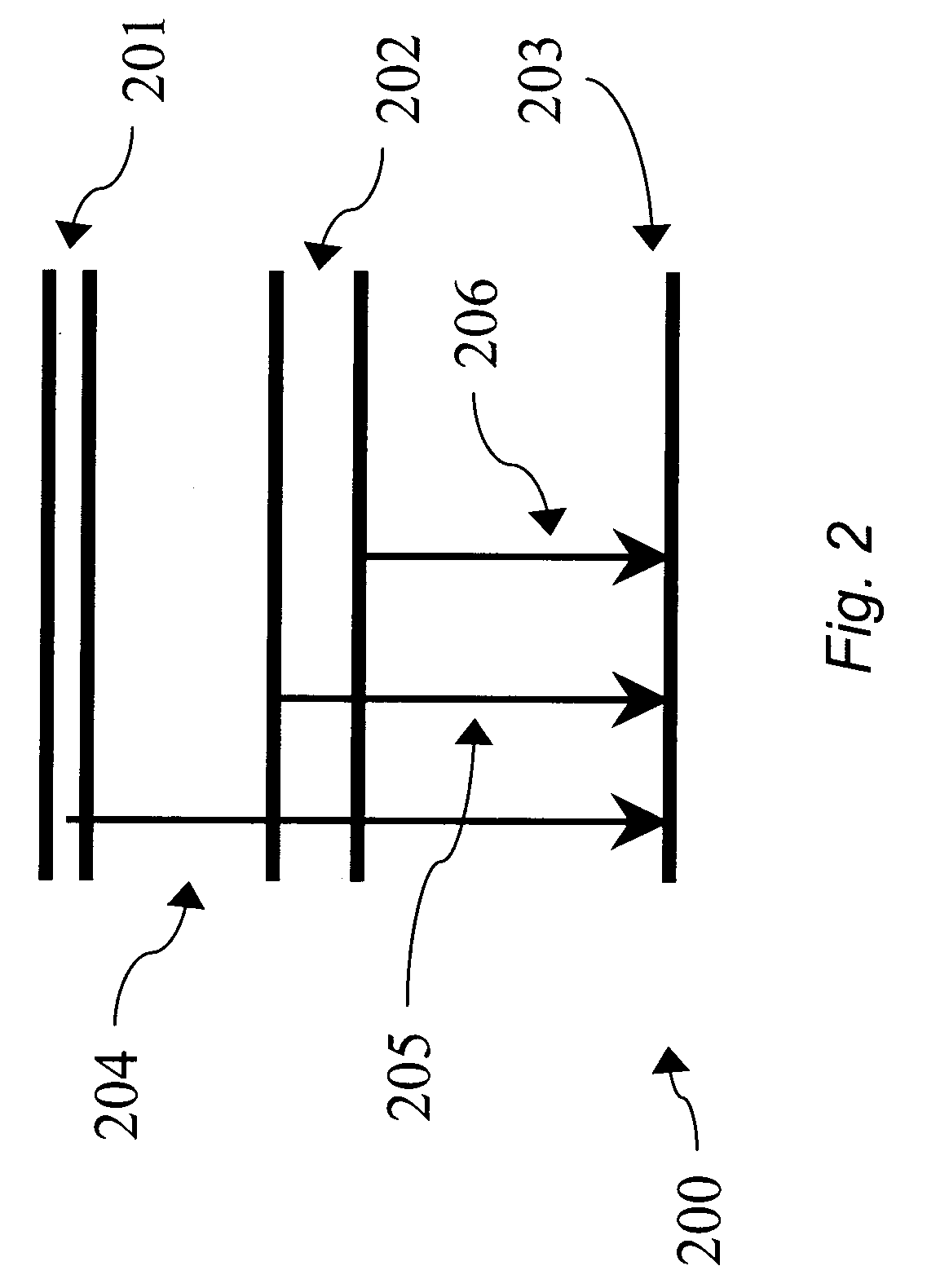

Multi-wavelength optical devices and methods of using same

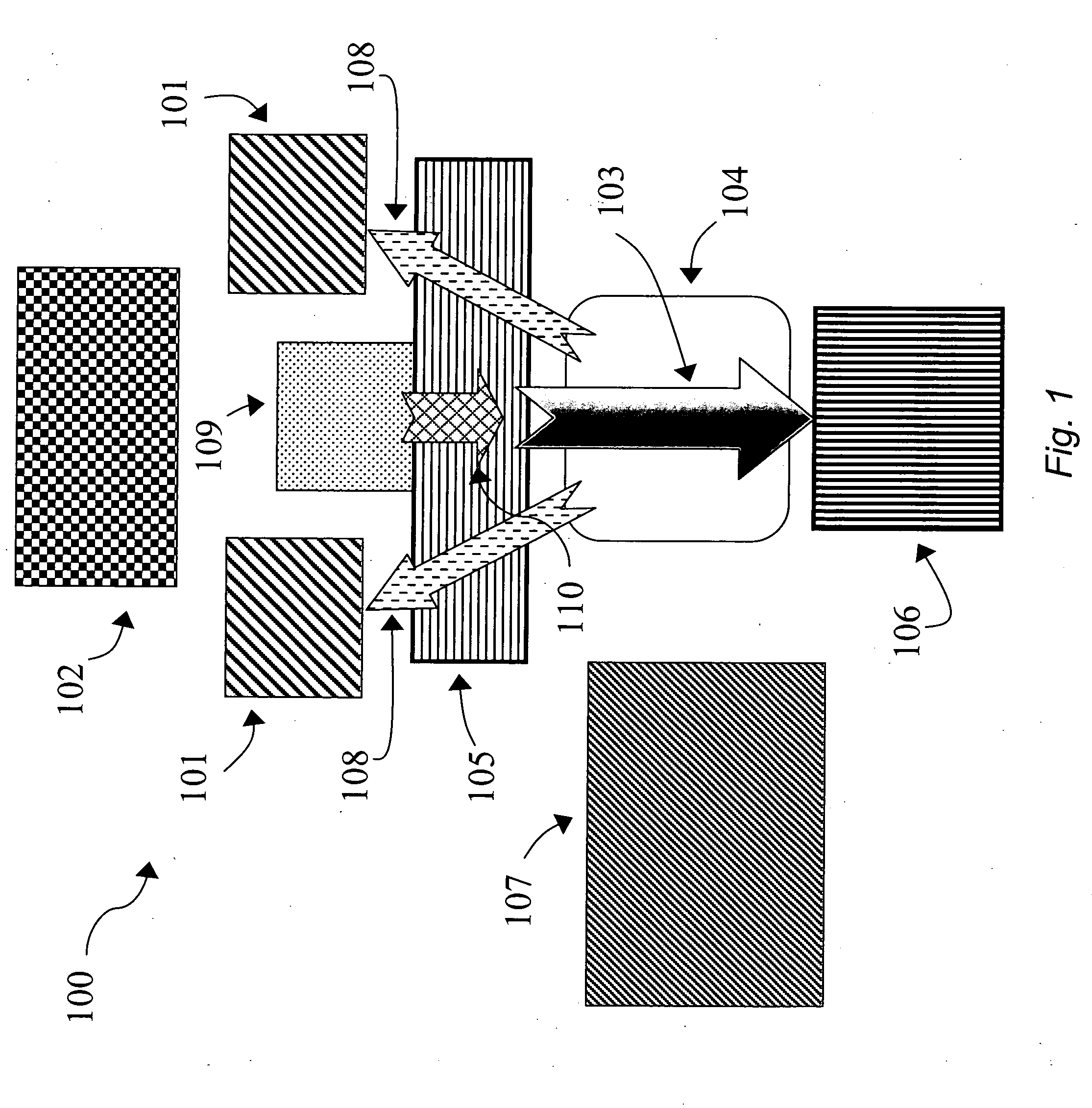

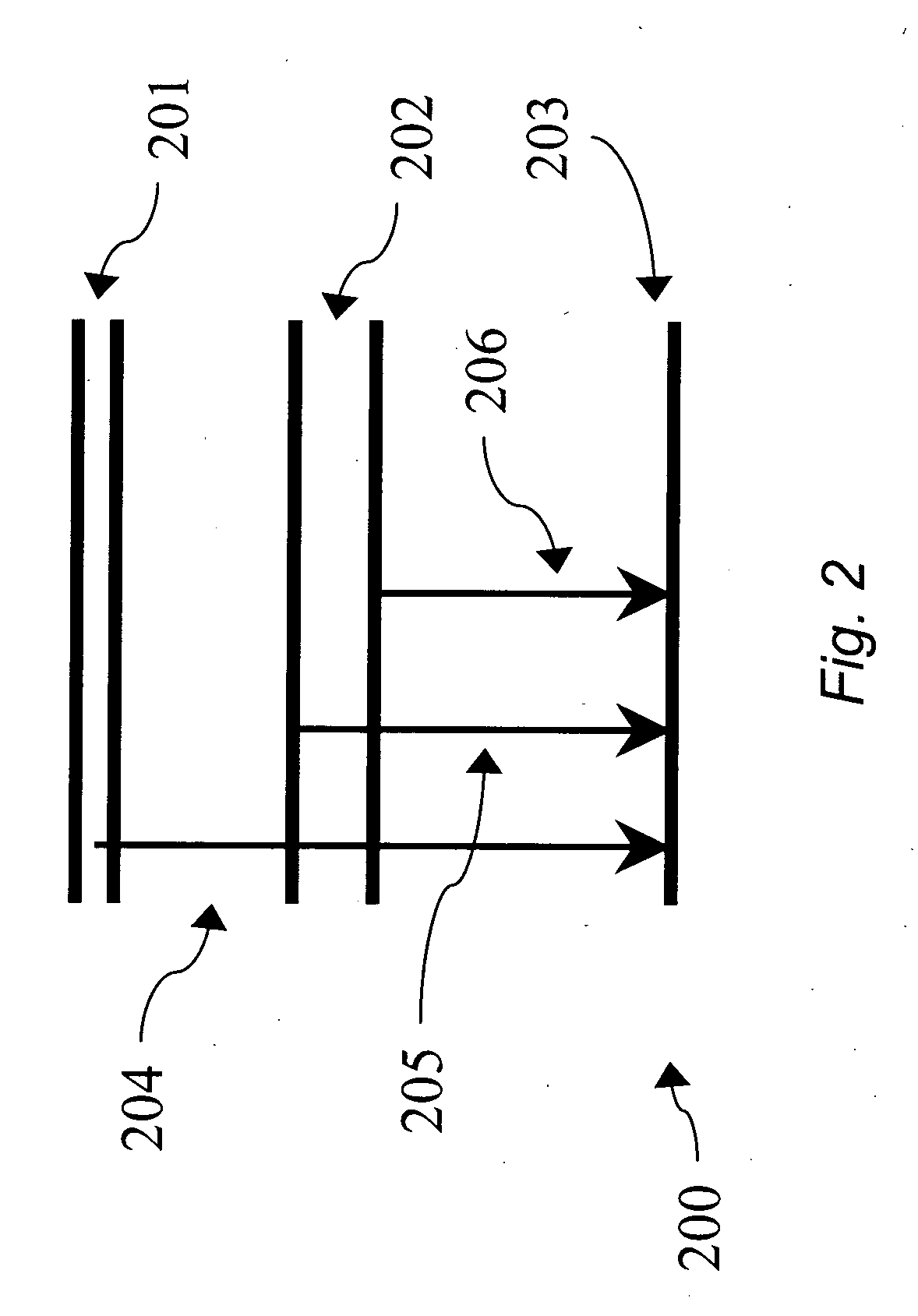

InactiveUS20100049017A1Radiation pyrometryScattering properties measurementsRare earthElectromagnetic radiation

Multi-wavelength optical apparatus includes an optical emitter, and an energy transition layer positioned adjacent to the optical emitter. The energy transition layer generates multi-wavelength electromagnetic radiation when monochromatic light from the optical emitter passes therethrough. The energy transition layer includes a plurality of luminescent films, and each film is configured to luminesce at a respective different wavelength range when monochromatic light from the optical emitter passes therethrough. The plurality of luminescent films may be arranged in contacting face-to-face relationship or may be arranged in an array. The luminescent films may include rare-earth doped oxides, phosphors, metal-doped oxides, rare-earth doped nitrides, nanostructures, and / or nanostructured films, etc. The optical emitter may be a light emitting diode (LED), a laser diode (LD), an organic light-emitting diode (OLED), a resonant cavity light emitting diode (RCLED), and / or an edge-emitting diode (EELED).

Owner:VALENCELL INC

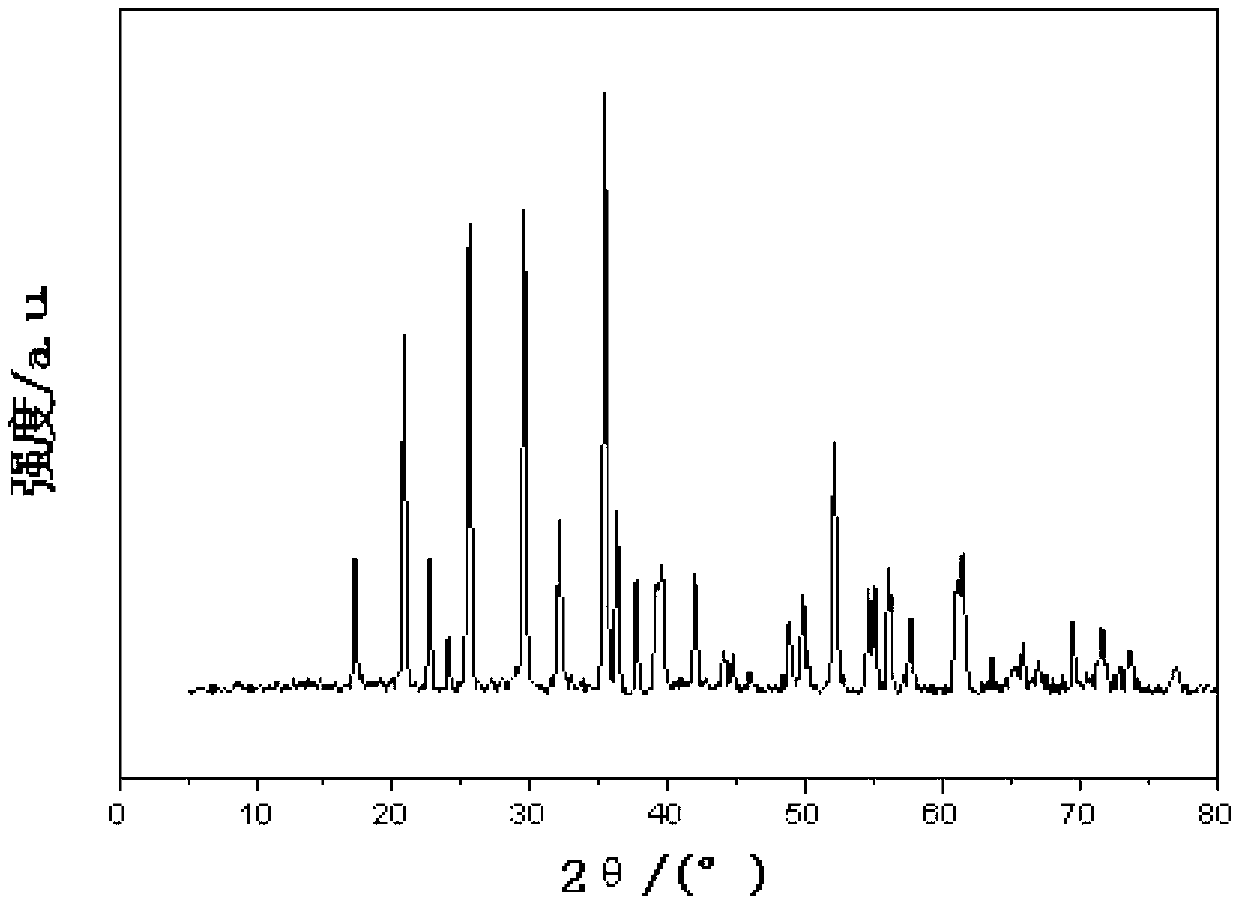

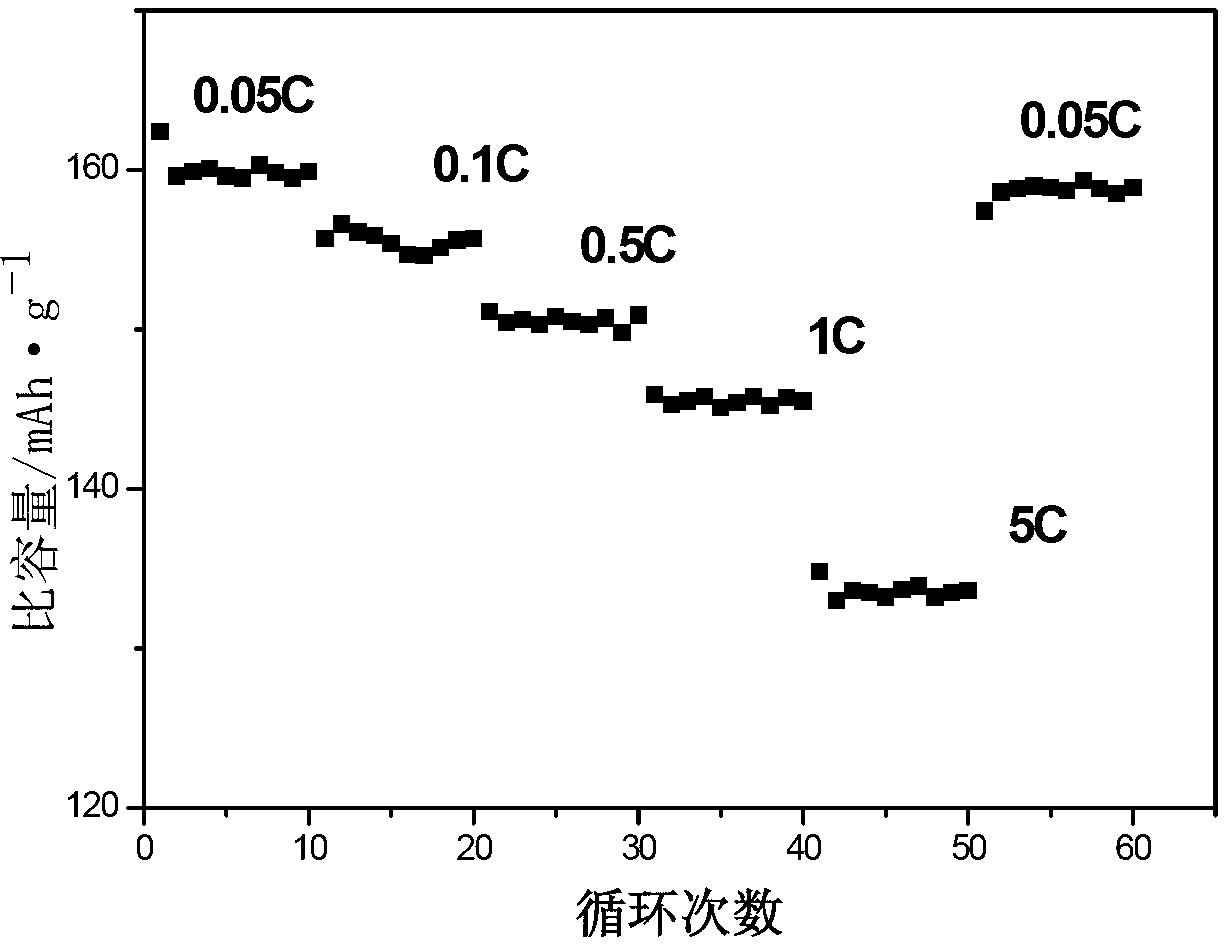

Preparation method of metal doped lithium manganese phosphate/graphene/carbon composite material

ActiveCN103346319AImprove electrochemical performanceReduce polarizationCell electrodesCarbon compositesSolvothermal reaction

The invention discloses a preparation method of a metal doped lithium manganese phosphate / graphene / carbon composite material. By adopting the method, the graphene is added in the preparation process of the lithium manganese phosphate to replace partial conductive carbon black; and a precursor which is a mixture of three solutions is transferred to a reaction tank and is subjected to solvothermal reaction at 160-300 DEG C for 1-20 hours to obtain the graphene in-situ composite lithium manganese phosphate material. According to the preparation method disclosed by the invention, the surface-contact compounding of graphene and lithium manganese phosphate is achieved by taking advantage of the flexibility characteristic of graphene, and the electronic conductivity of the lithium manganese phosphate is improved by taking advantage of the extremely high conductivity of graphene. By adopting the preparation method disclosed by the invention, not only is the intrinsic electronic conductivity of the composite material improved, but also a graphene film layer with extremely high conductivity is uniformly coated on the surface of the lithium manganese phosphate material, the graphene and the conductive carbon black together form a three-dimensional conductive network, and therefore the electrochemical performance of the lithium manganese phosphate material is obviously improved, and the composite material can be used as the anode material of a lithium ion battery.

Owner:HEBEI UNIV OF TECH

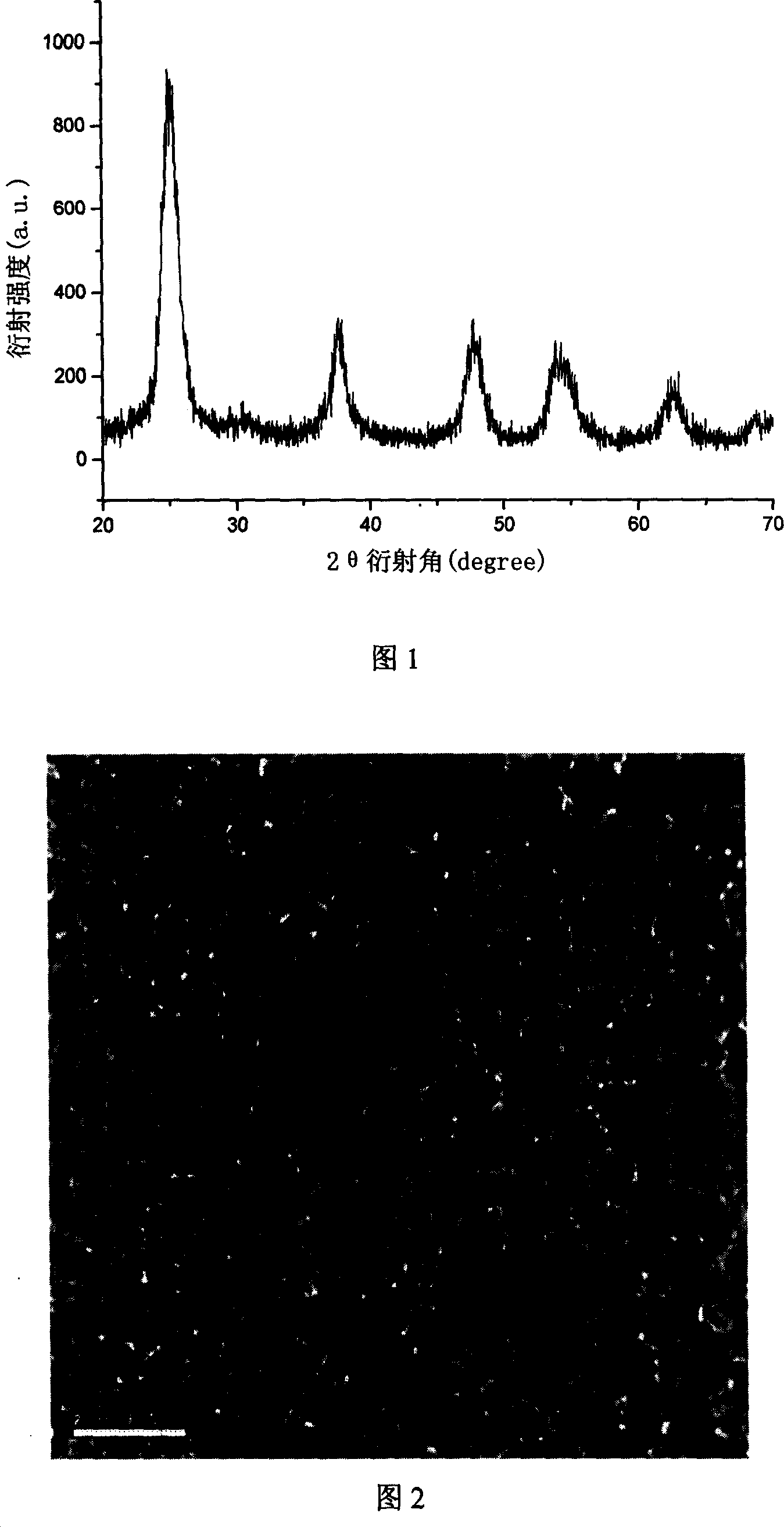

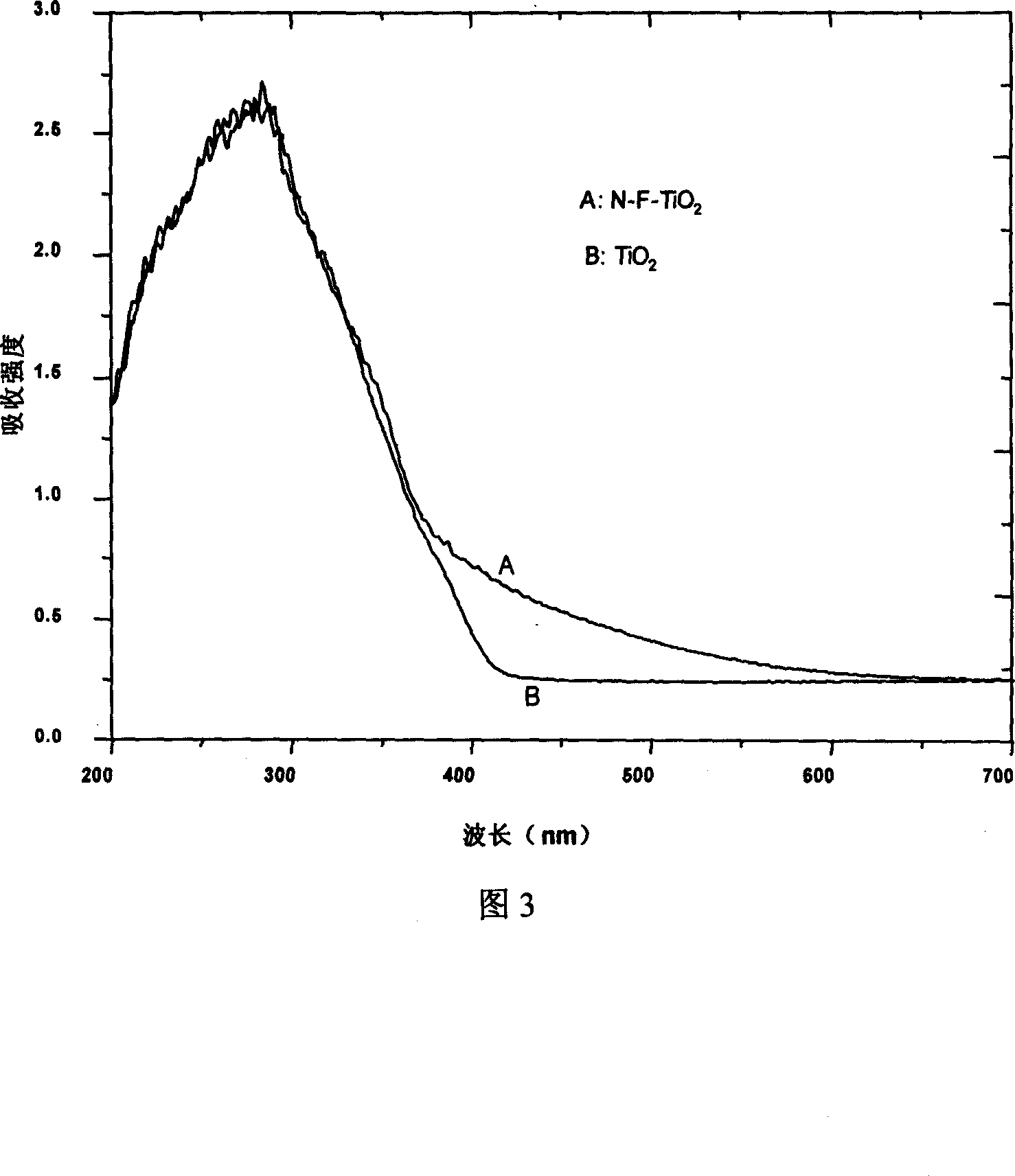

Multi element daged-anatase type TiO2 collosol photo catalyst and its preparation method

InactiveCN100998937AGood water solubilityIncrease industrial outputPhysical/chemical process catalystsSolventNonmetal

A multiple elements doped anatase-type TiO2 sol photocatalyst features that its solvent is water or the mixture of water and unitary or binary alcohol, and its sol contains non-metal doped anatase-type TiO2 nanoparticles, and has a formula: TiO2-x-yAxBy, where x=0.0-0.1, y=0.0-0.1 and A or B is one or more of non-metal halogens or N-family elements. Its preparing process includes such steps as hydrolyzing organic or inorganic Ti source, doping, dispergating, and hydrothermal crystallizing.

Owner:SOUTH CHINA UNIV OF TECH

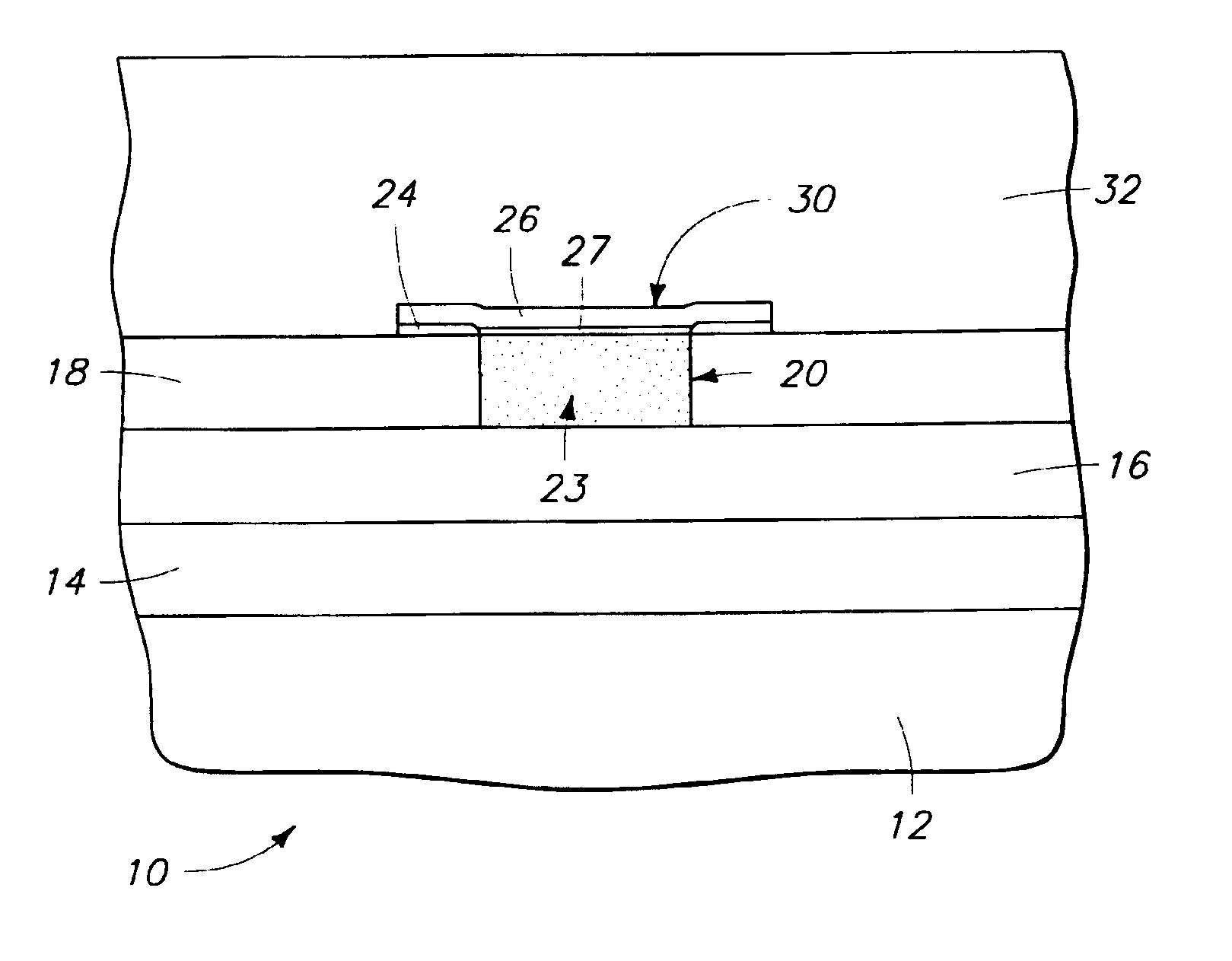

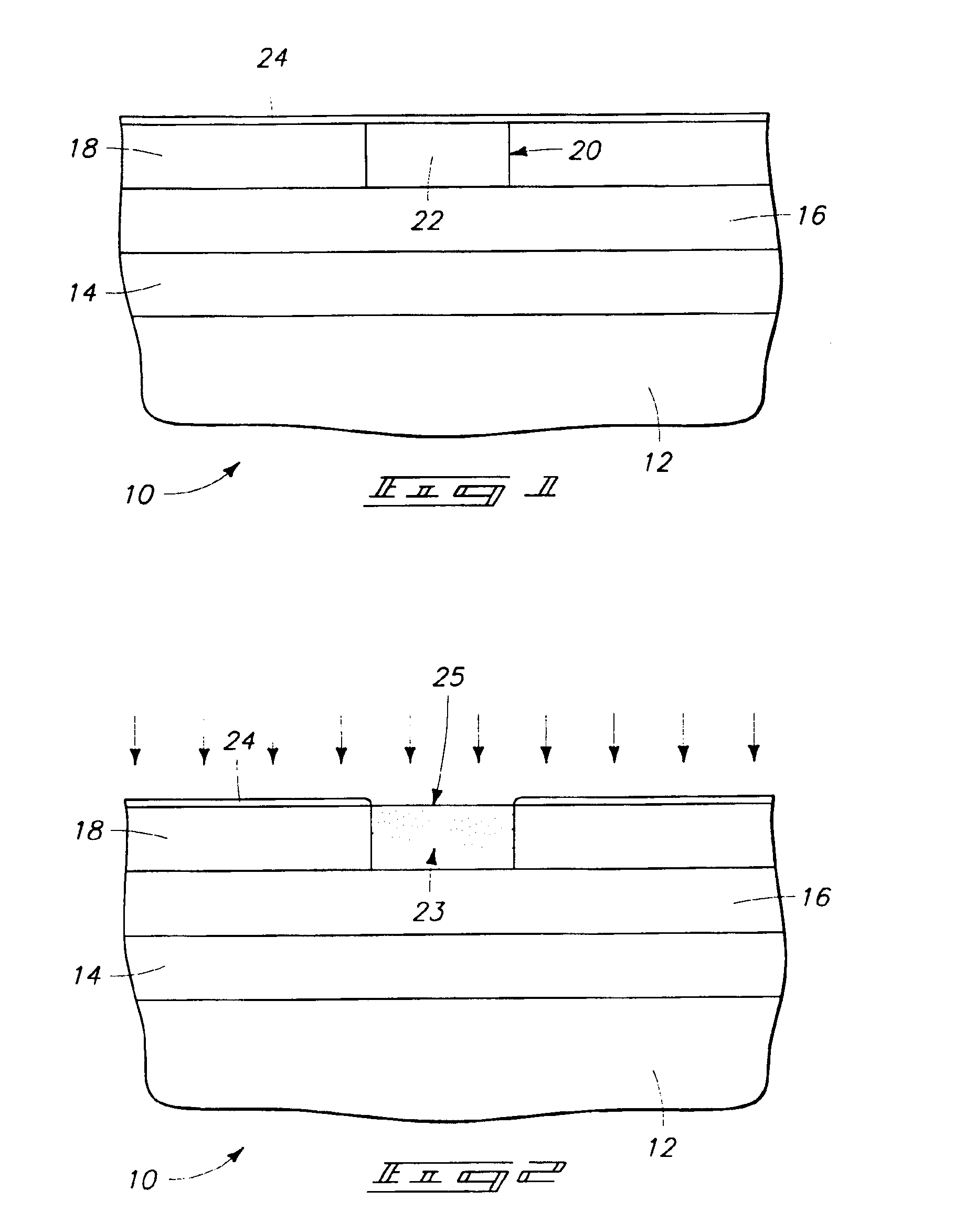

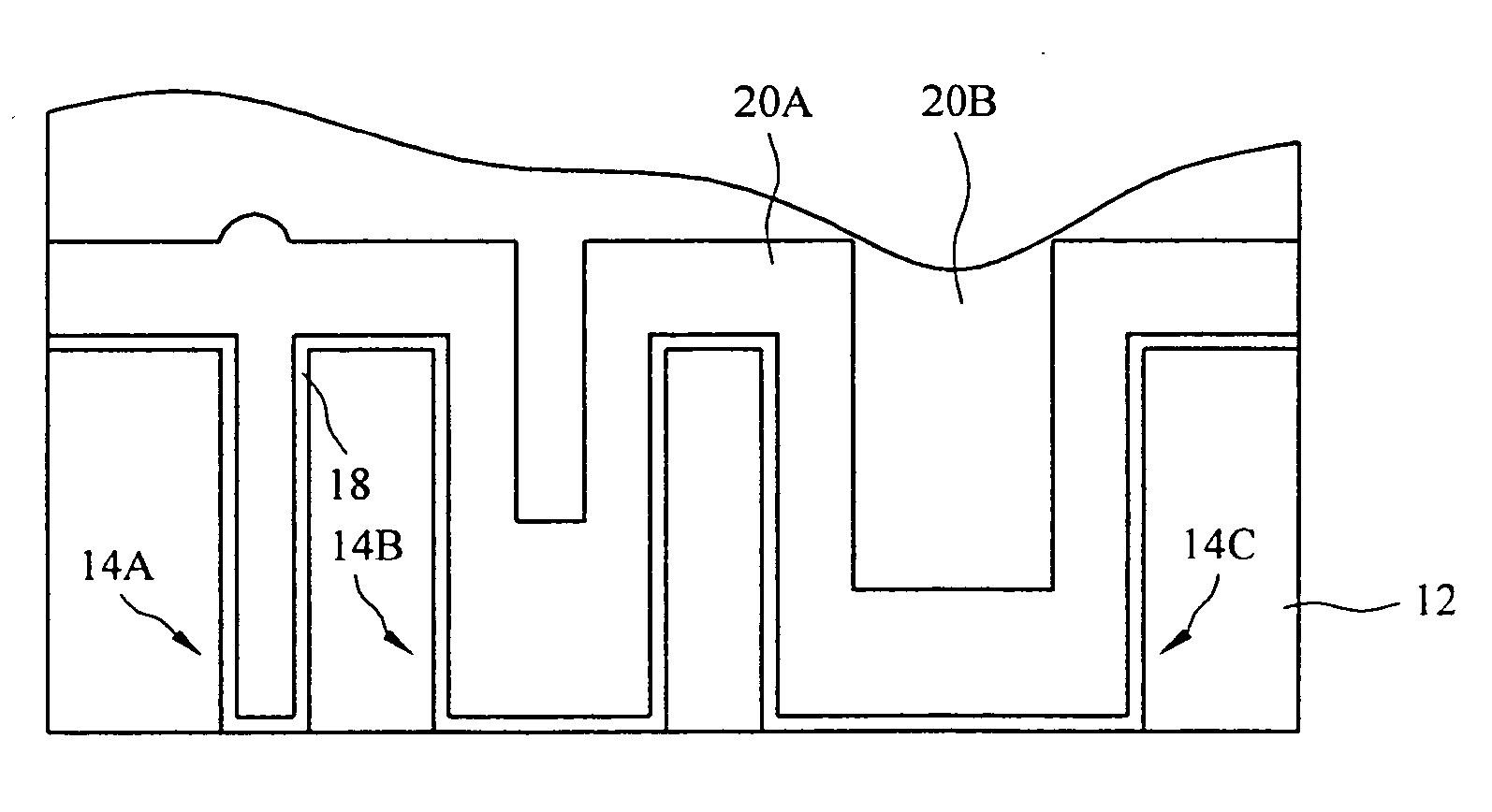

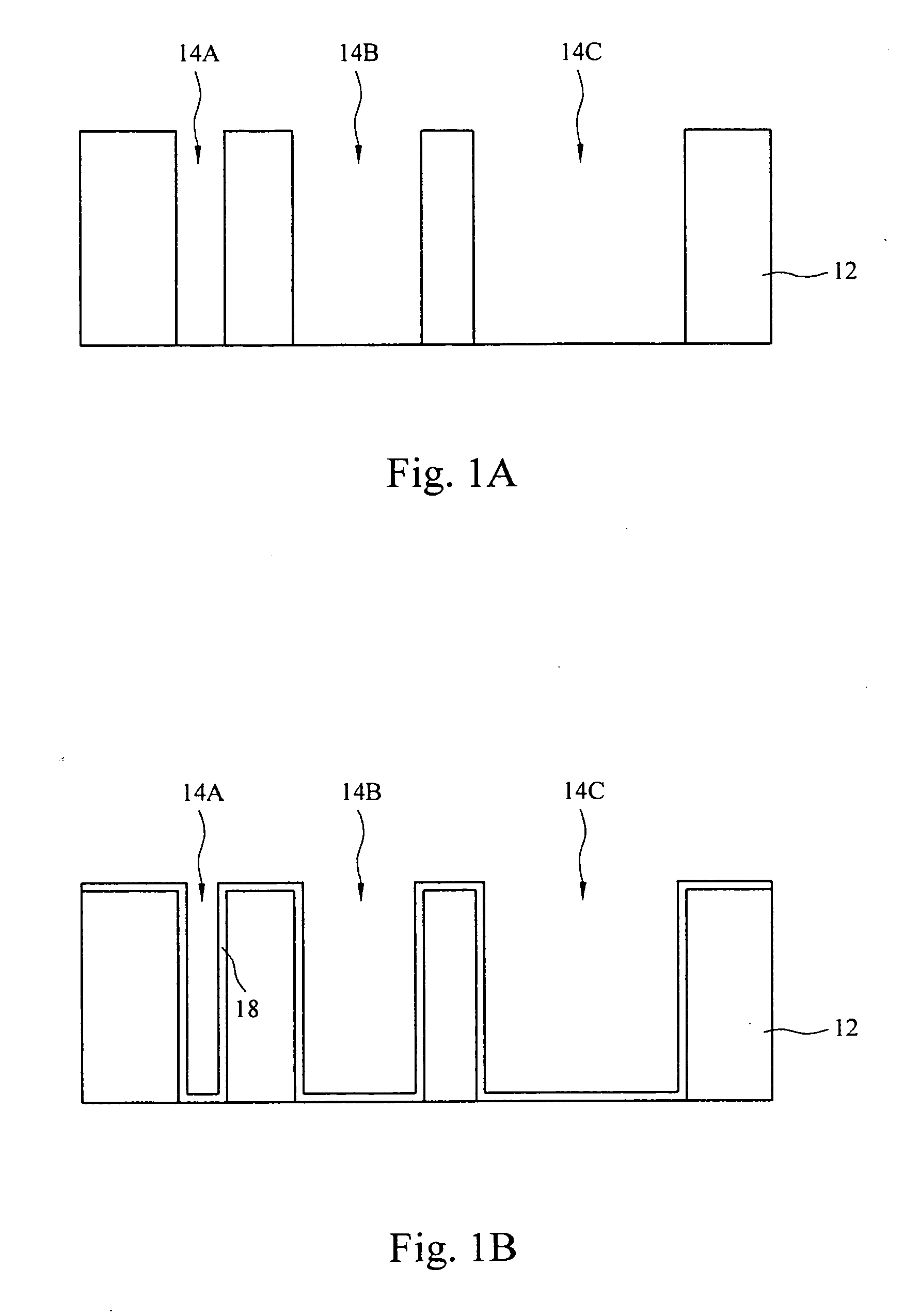

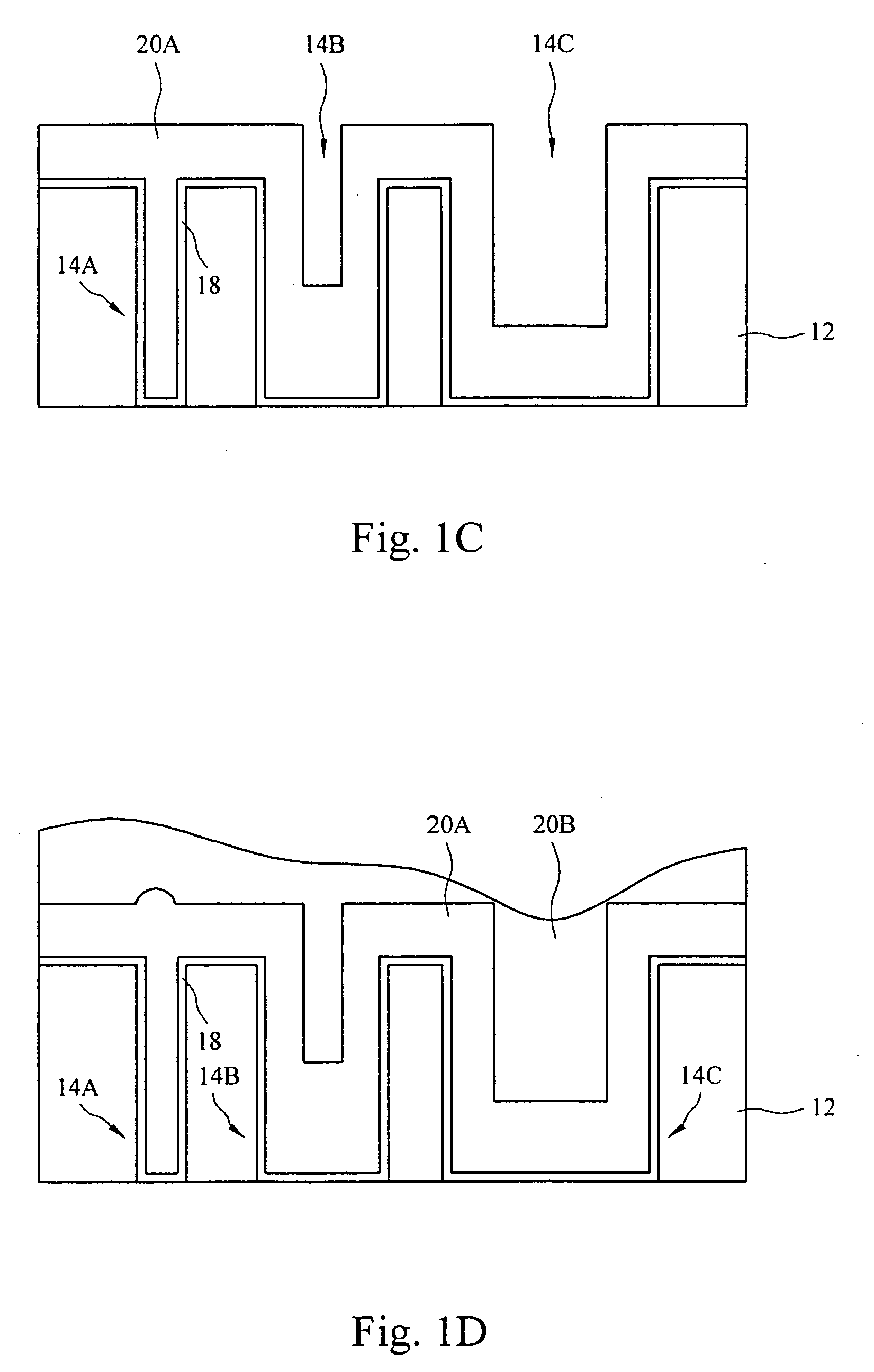

Differentially metal doped copper damascenes

InactiveUS20060091551A1Improve the immunityAcceptable resistivitySemiconductor/solid-state device detailsSolid-state devicesDopantCopper

A method of forming a copper filled semiconductor feature having improved bulk properties including providing a semiconductor process wafer having a process surface including an opening for forming a semiconductor feature; depositing at least one metal dopant containing layer over the opening to form a thermally diffusive relationship to a subsequently deposited copper layer; depositing said copper layer to substantially fill the opening; and, thermally treating the semiconductor process wafer for a time period sufficient to distribute at least a portion of the metal dopants to collect along at least a portion of the periphery of said copper layer including a portion of said copper layer grain boundaries.

Owner:TAIWAN SEMICON MFG CO LTD

PVD nano composite ceramic coating screw and method for manufacturing same

InactiveCN101518935ASolve pollutionIncreased microhardnessLayered productsVacuum evaporation coatingCarbon filmDiamond-like carbon

The invention provides a PVD nano composite ceramic coating screw. A screw substrate (7) is coated with a coating (6) consisting of a bonding layer, a primary wear-resistance layer and a lubricating layer sequentially. The method for manufacturing the screw comprises the following steps: firstly, depositing a 50 to 100 nanometer thick transitional metal bonding layer at an air pressure of 0.1 Pa; secondly, depositing a 2 to 5 micrometer thick composite ceramic layer as the primary wear-resistance layer at a temperature of between 350 and 400 DEG C, a voltage of between -50 and -200 volts and an air pressure of 0.2 to 1Pa; and finally, depositing a 1 to 3 micrometer transitional metal doped diamond carbon film layer as the lubricating layer at a temperature of between 100 and 150 DEG C, a voltage of between -50 and -150 volts and an air pressure of 0.1 to 0.5Pa. Compared with the prior art, the screw has the advantages of having lubricating performance, along with high hardness (more than 40GPa Hv hardness) and excellent wear resistance (friction coefficient about 0.1). The method is free from pollution and the coating has strong adhesive force.

Owner:舟山市汉邦机械科技有限公司

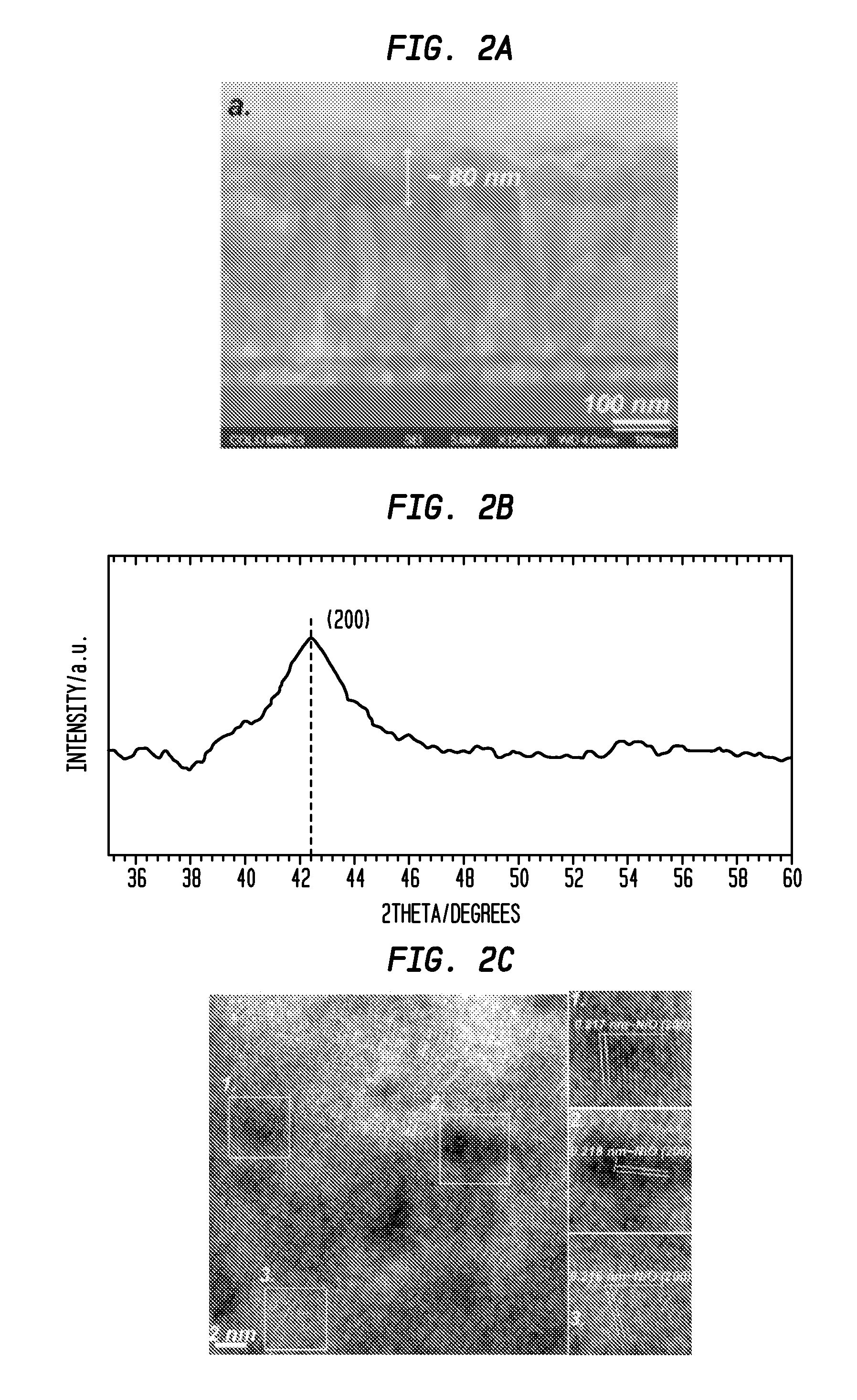

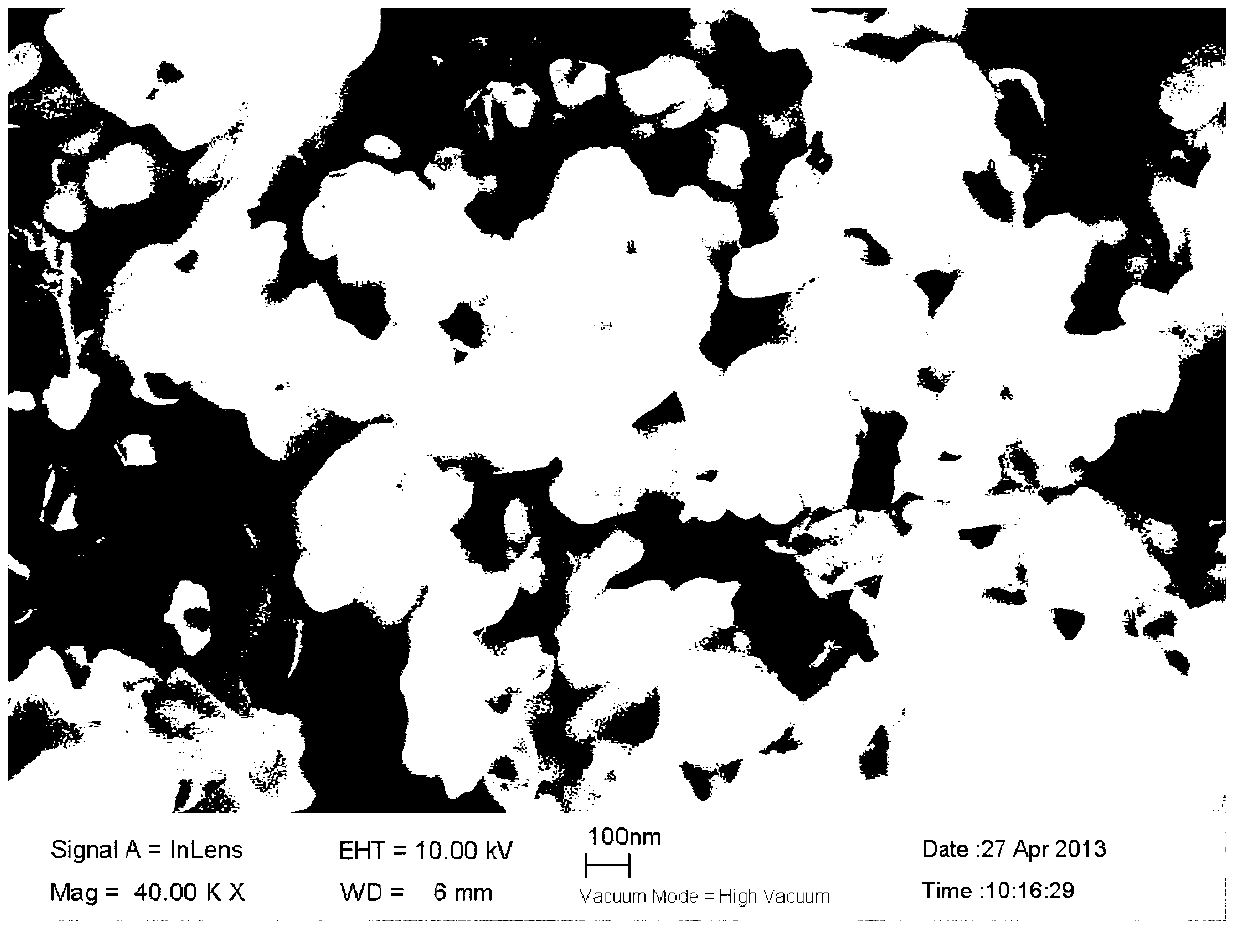

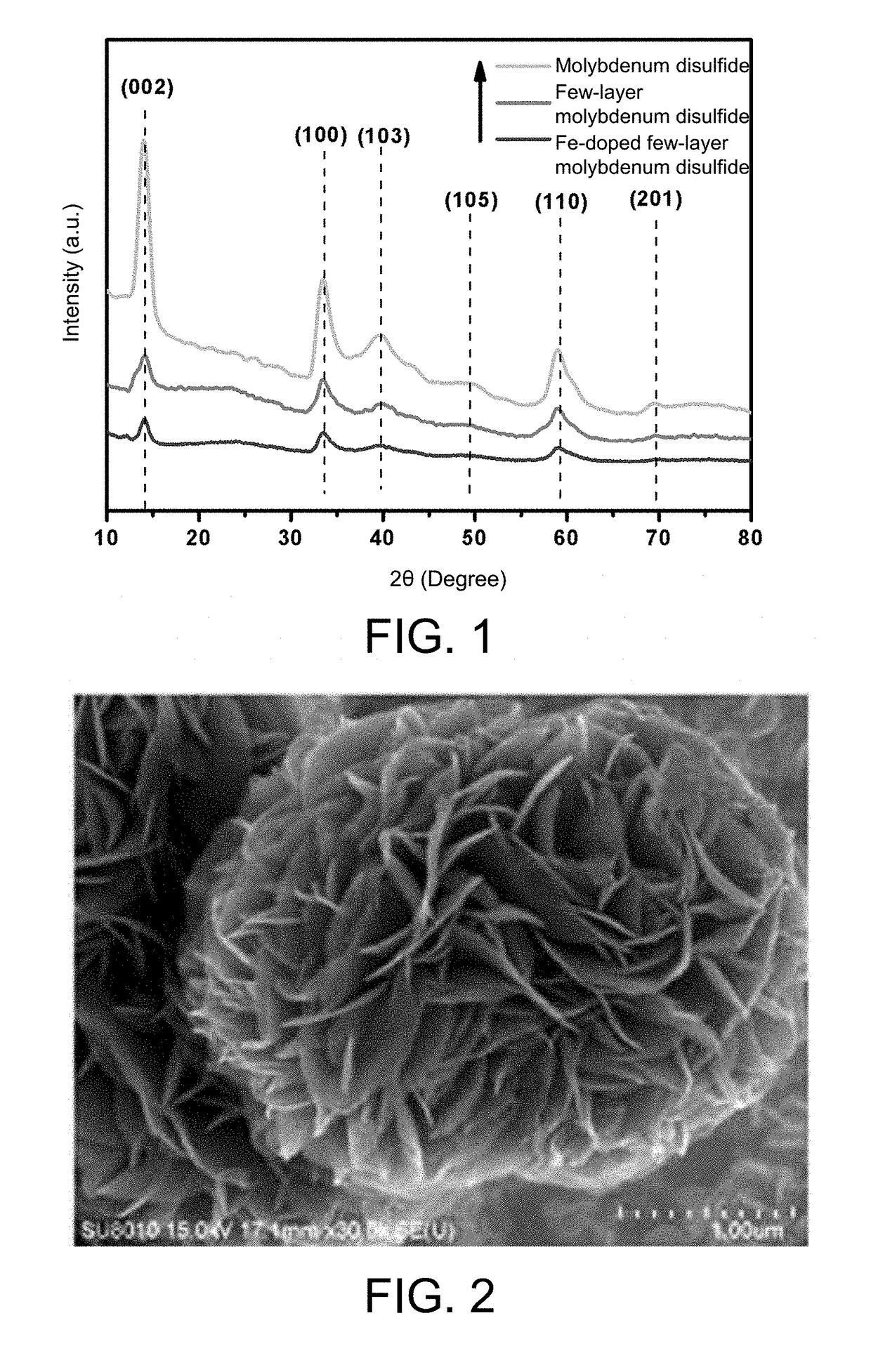

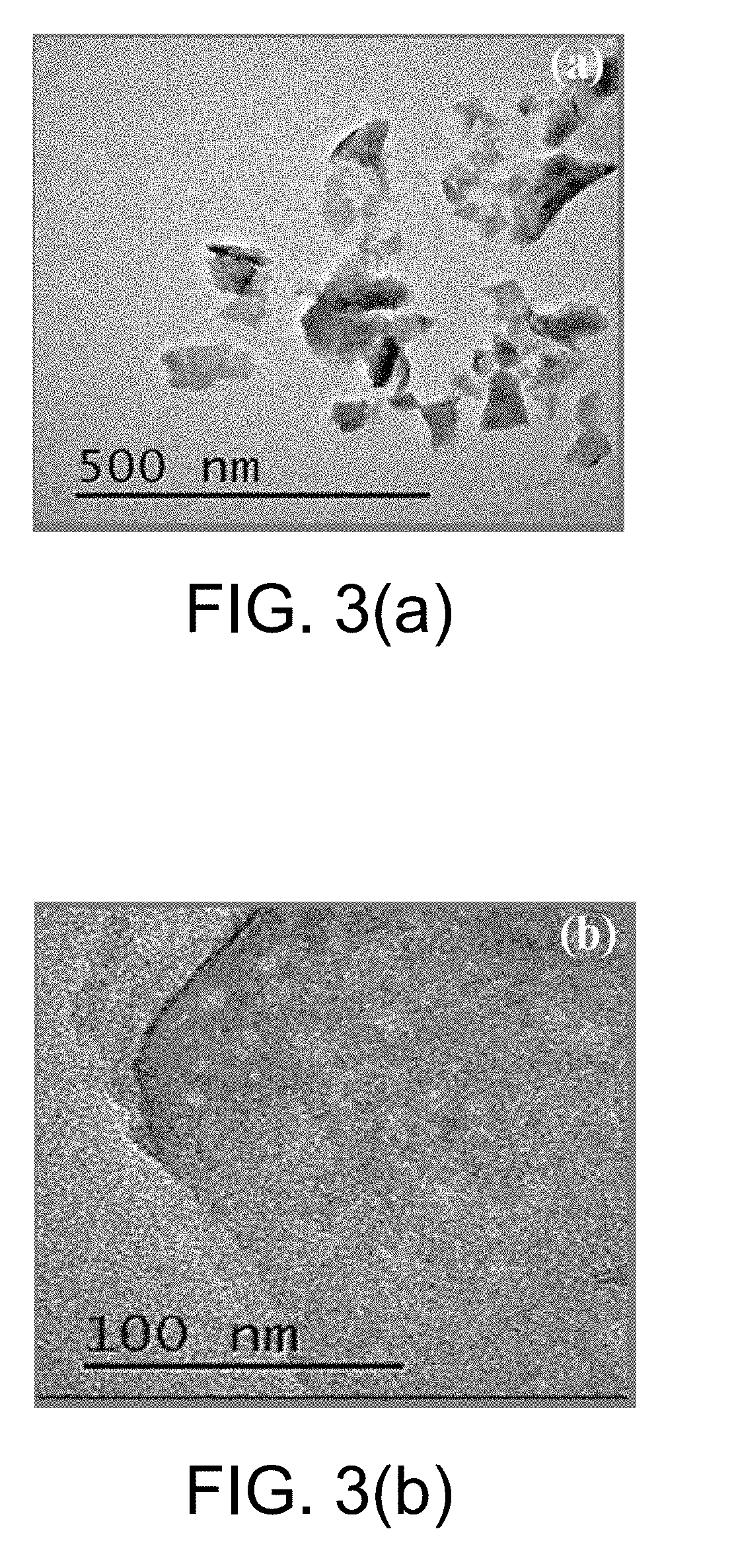

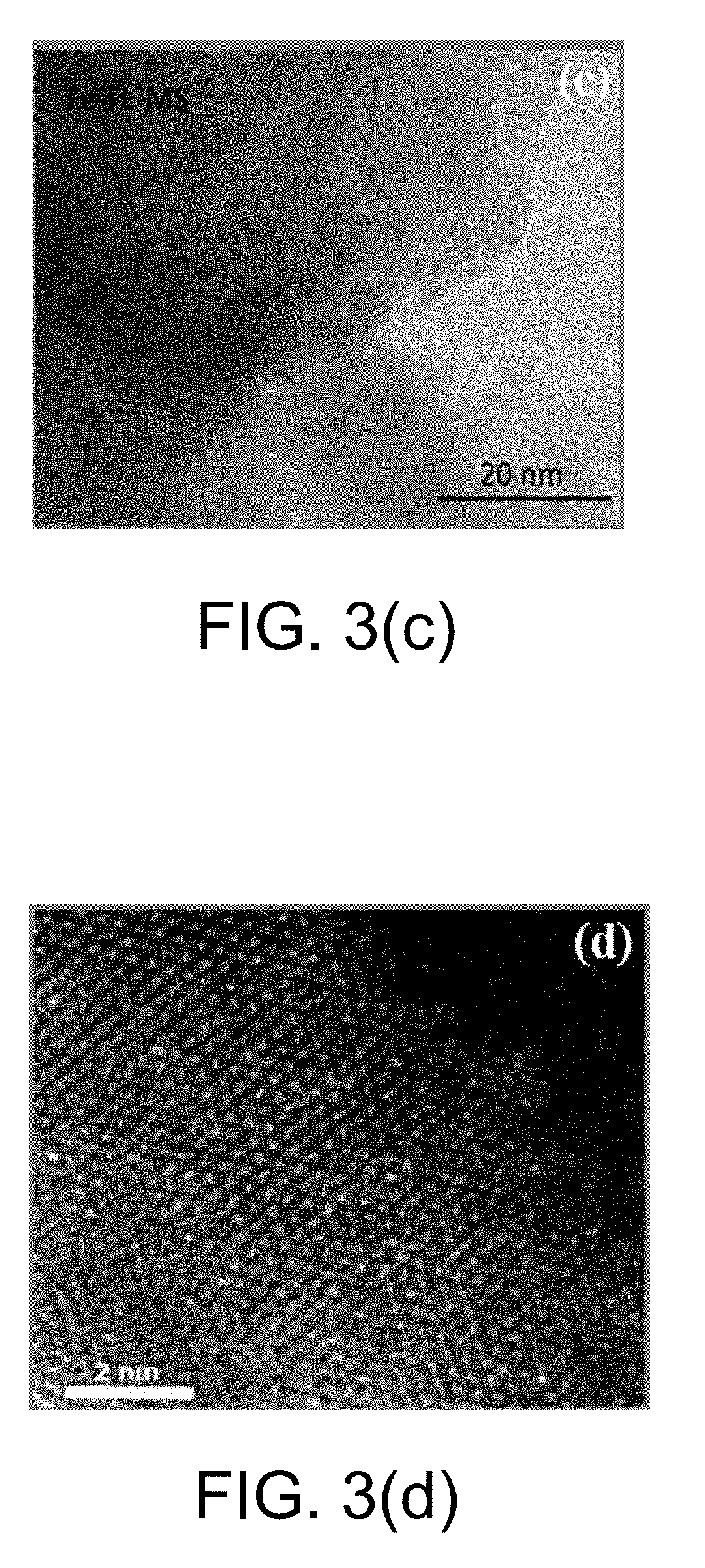

Monatomic metal-doped few-layer molybdenum disulfide electrocatalytic material, preparing method thereof, and method for electrocatalytic nitrogen fixation

ActiveUS20190030516A1Readily availableLow costHeterogenous catalyst chemical elementsCatalyst activation/preparationFaraday efficiencySelective reduction

The present invention provides a monatomic metal-doped few-layer molybdenum disulfide electrocatalytic material, a preparing method thereof, and a method for electrocatalytic nitrogen fixation. The material has a few-layer ultra-thin and irregular flake-like microstructure with a length and a width of nanometer scale. A doping metal in the monatomic metal-doped few-layer molybdenum disulfide electrocatalytic material is dispersed in a form of single atoms. When the catalyst is used in electrochemical reduction of N2, a Faradic efficiency in selective reduction of N2 into NH4+ is 18% or above, and stability of the catalyst is better.

Owner:HUAZHONG NORMAL UNIV

Deposition of metal doped amorphous carbon film

Embodiments of the present disclosure relate to a metal-doped amorphous carbon hardmask for etching the underlying layer, layer stack, or structure. In one embodiment, a method of processing a substrate in a processing chamber includes exposing a substrate to a gas mixture comprising a carbon-containing precursor and a metal-containing precursor, reacting the carbon-containing precursor and the metal-containing precursor in the processing chamber to form a metal-doped carbon layer over a surface of the substrate, forming in the metal-doped carbon layer a defined pattern of through openings, and transferring the defined pattern to an underlying layer beneath the metal-doped carbon layer using the metal-doped carbon layer as a mask. An etch hardmask using the inventive metal-doped amorphous carbon film provides reduced compressive stress, high hardness, and therefore higher etch selectivity.

Owner:APPLIED MATERIALS INC

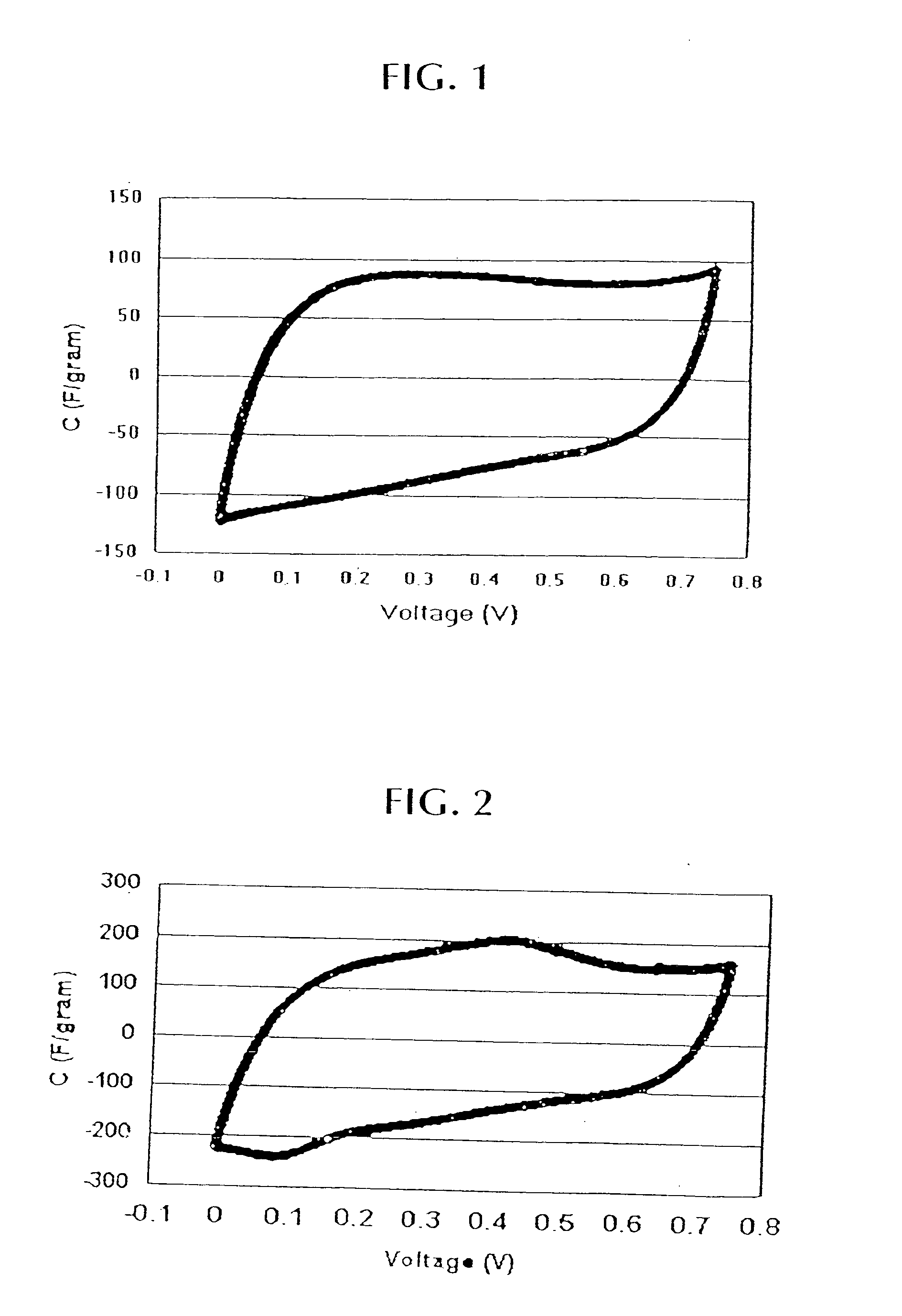

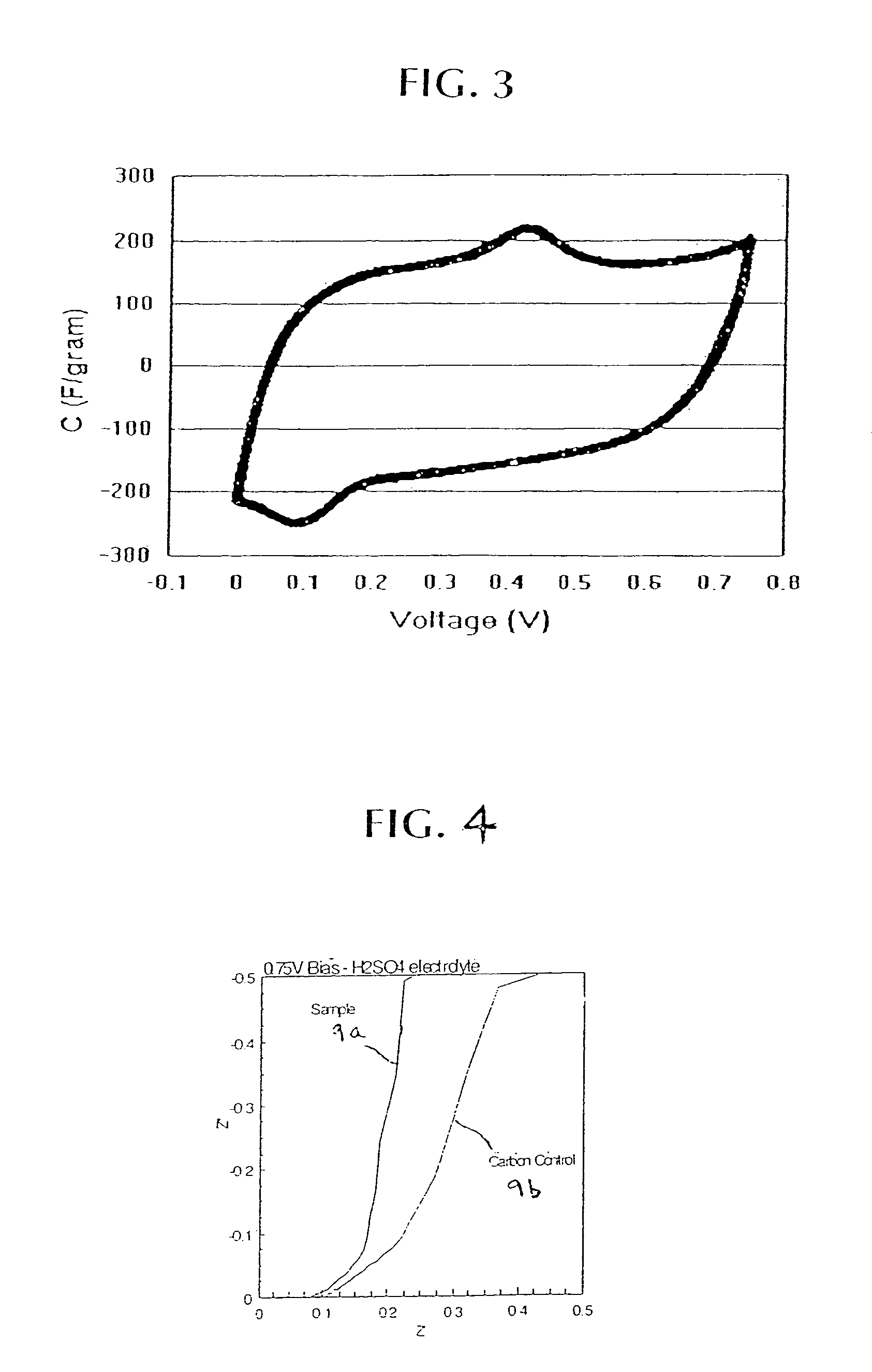

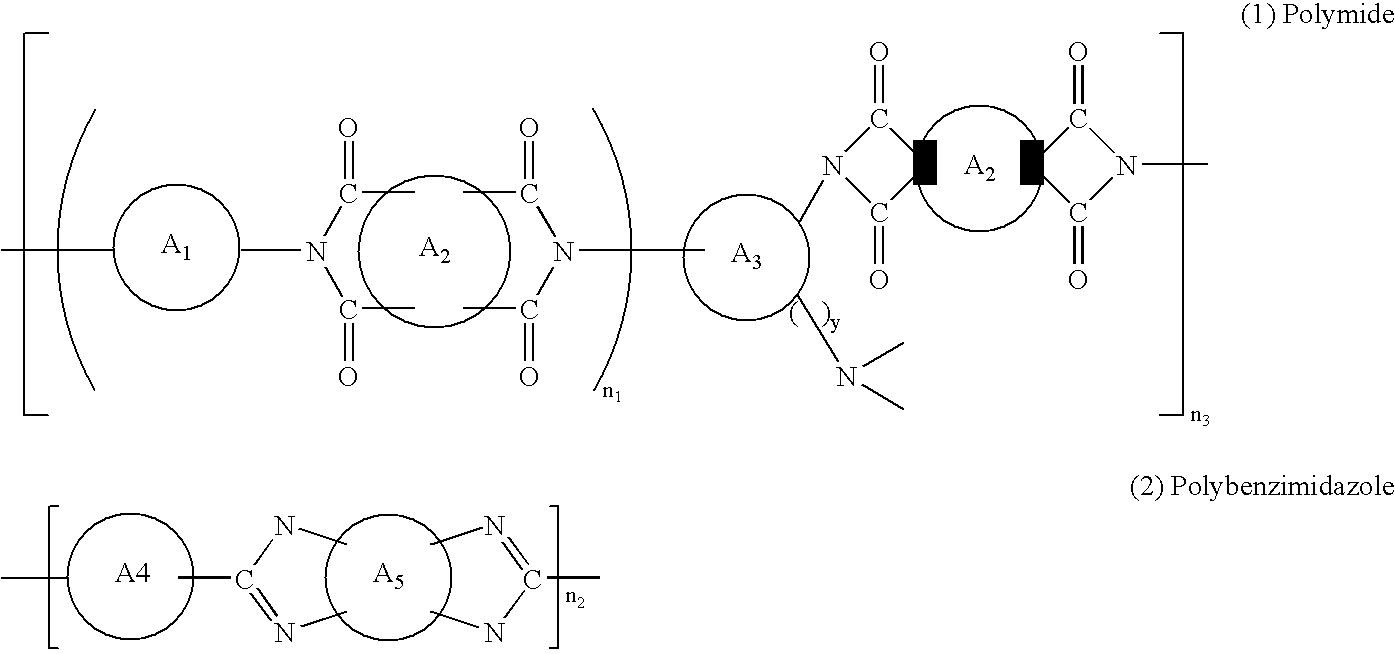

Processes for producing monolithic porous carbon disks from aromatic organic precursors

InactiveUS20060033226A1Material nanotechnologyElectrode thermal treatmentCarbon compositesPorous carbon

Disclosed are processes for producing monolithic and metal doped monolithic porous carbon disks from prepolymer organic precursors in the powder form composed of either or both polyimide and polybenzimidazole. The powders are consolidated (compressed) into disks and then pyrolyzed to form the desired porous carbon disk. Porous carbon-carbon composite disks are also prepared by adding carbon to the prepolymer organic precursors.

Owner:ELECTROMATERIALS

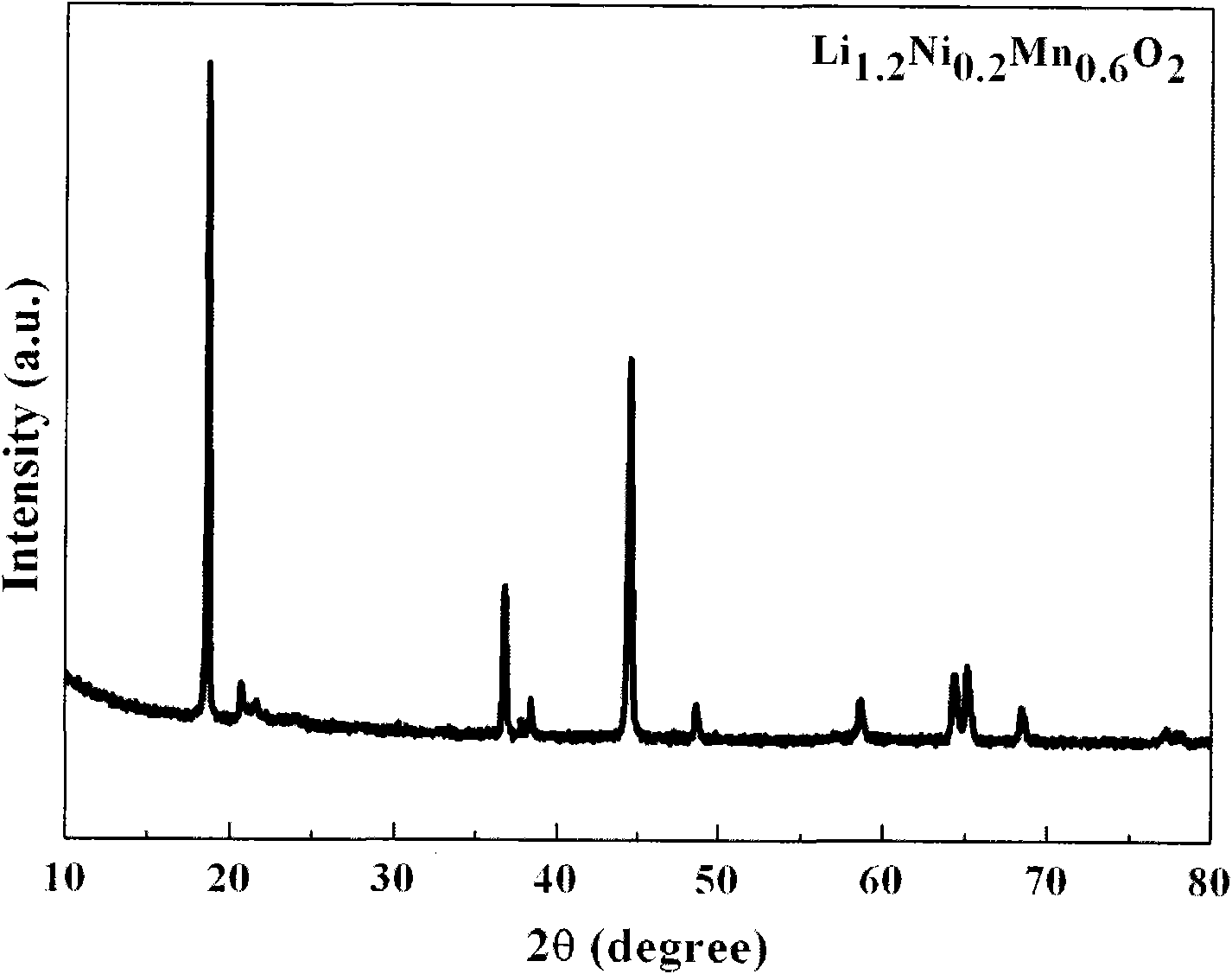

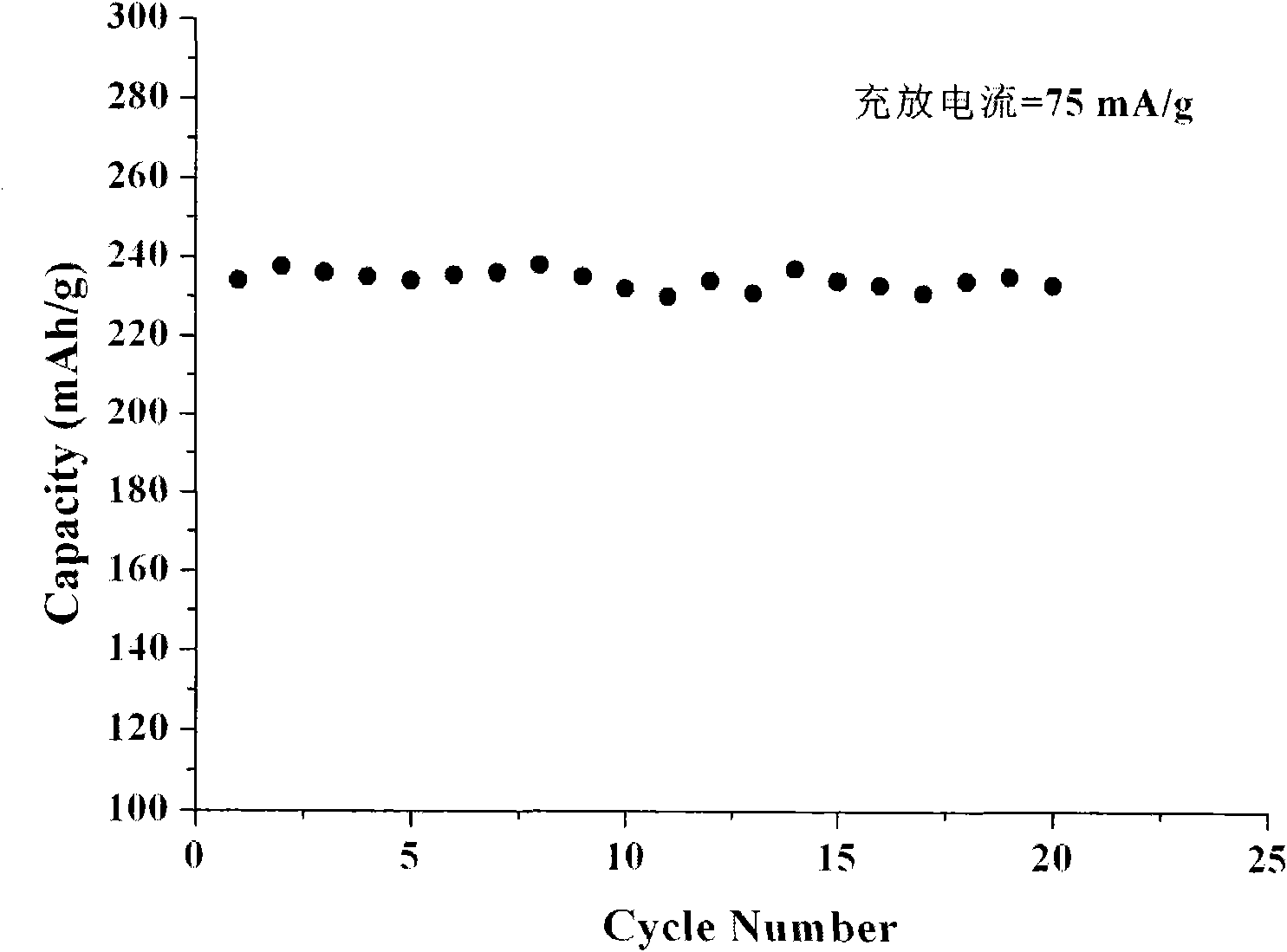

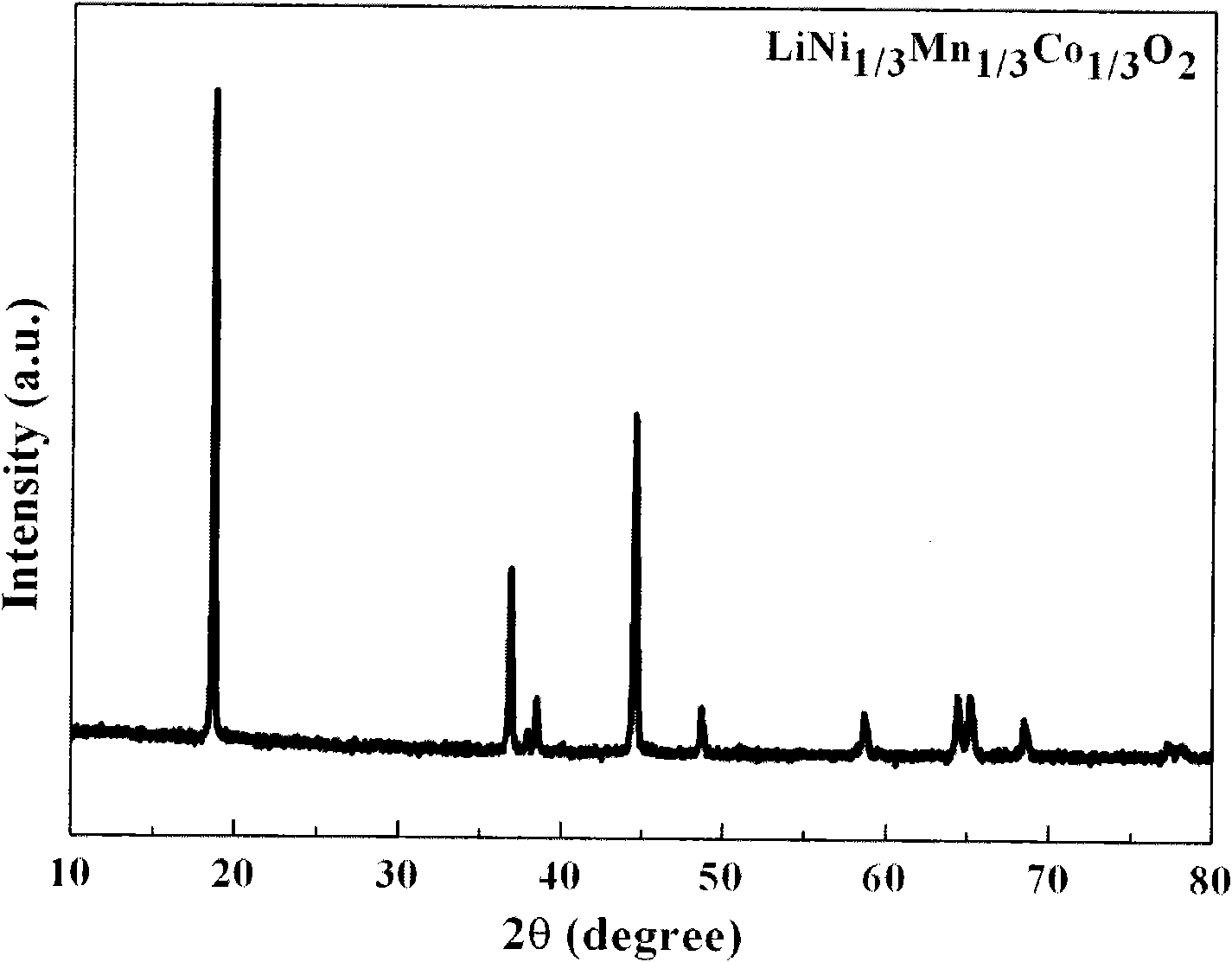

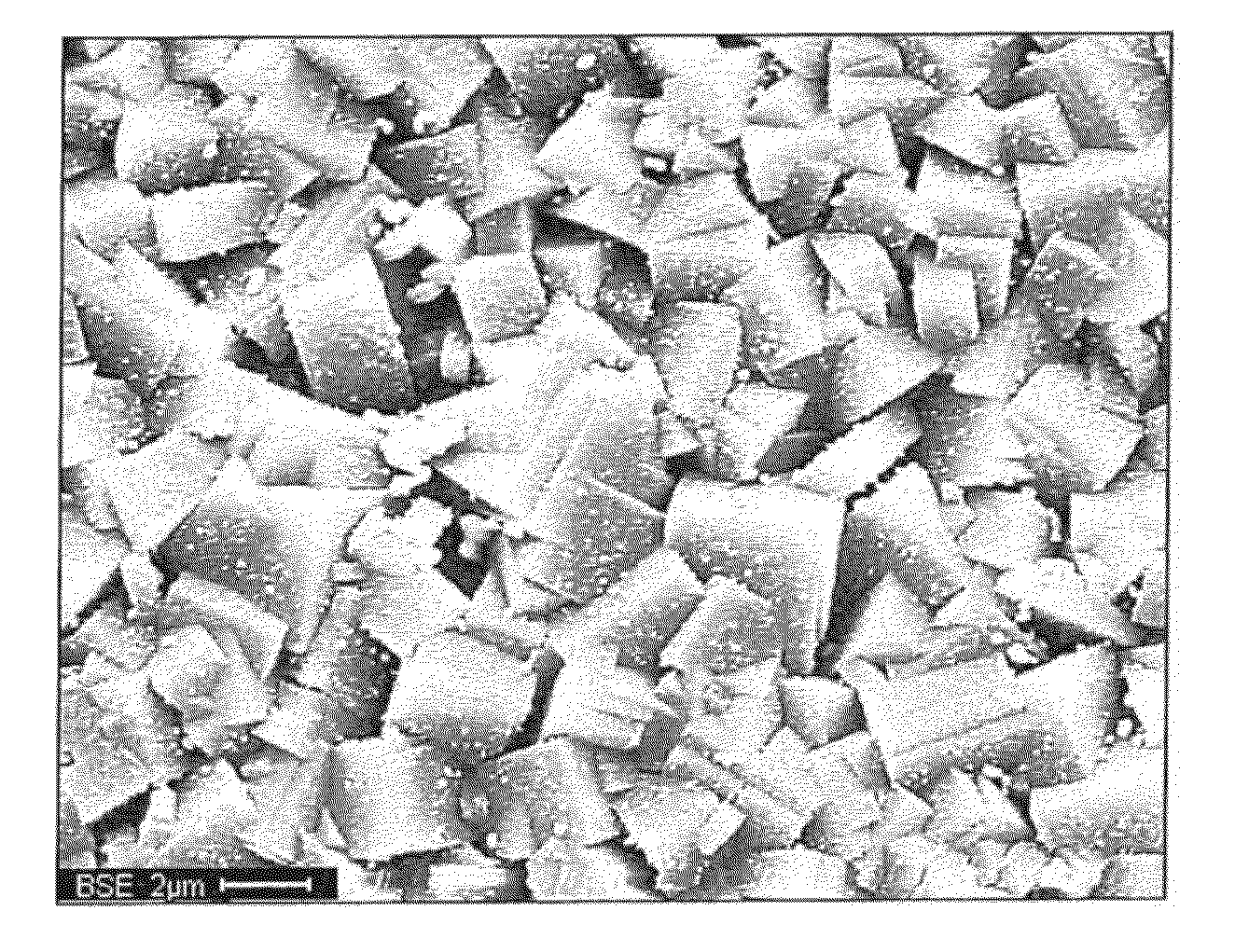

Method for preparing lithium battery anode material lithium transition metal composite oxide

InactiveCN101916843ASolve the problem of uniform and orderly arrangementUniform average particle sizeCell electrodesTransition metal atomsComposite oxide

The invention discloses a method for preparing a lithium battery anode material lithium transition metal composite oxide, which comprises the following steps of: uniformly mixing transition metal mixed M salt and metal doped M' salt in accordance with a stoichiometric proportion in a mechanical mode; calcining at high temperature to form the transition metal composite oxide; performing secondary mechanical mixing on the transition metal composite oxide and the lithium salt; and calcining at high temperature to prepare the lithium transition metal composite oxide. By adopting a secondary mechanical mixing-solid-phase sintering process, the method solves the problems that a pure-phase quaternary lithium transition metal composite oxide cannot be synthesized by the traditional dry mixing solid-phase sintering process, and the improved wet mixing-solid-phase sintering method cannot make lithium and transition metal atoms uniformly and sequentially arranged; the lithium battery anode material lithium transition metal composite oxide has the advantages of no impurity phase, and uniform average grain diameter and excellent cycle performance of the product; and the preparation method has the advantages of simpleness, low production cost and suitability for industrial production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

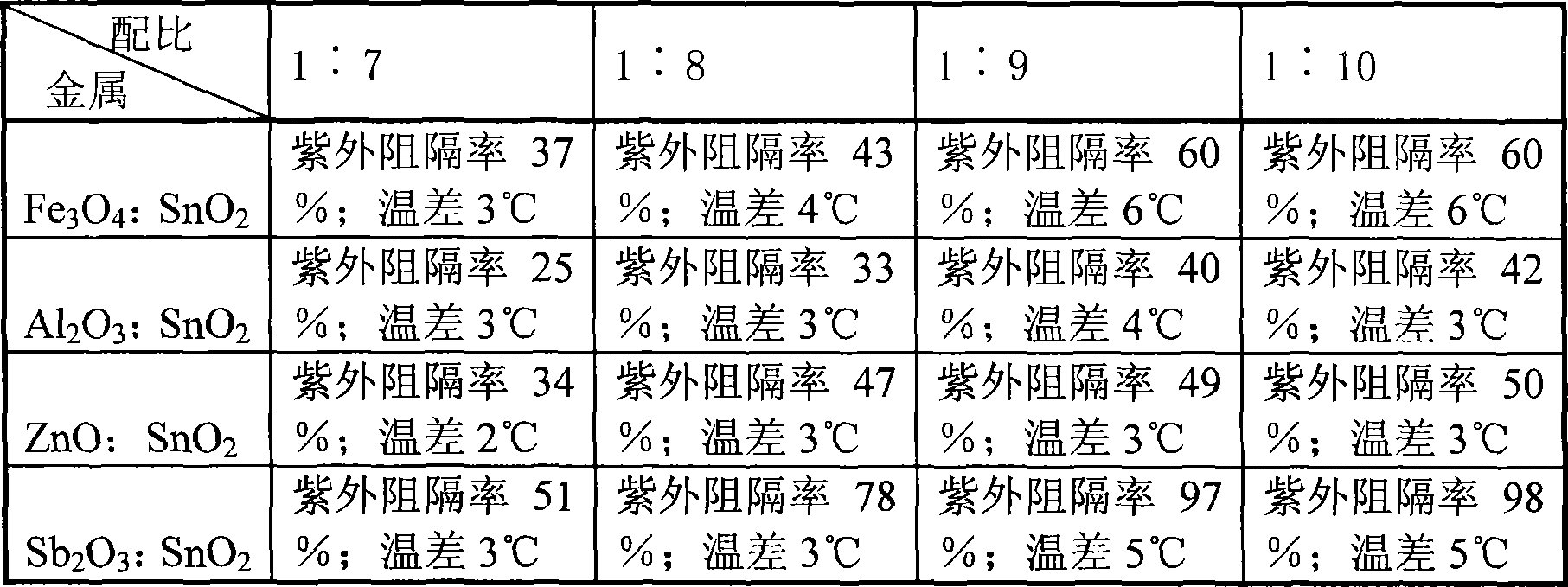

Method for preparing non-toxic visible ultraviolet heat insulating UV coating material

InactiveCN101423676AEasy to keep freshEasy to storeFlexible coversWrappersPolyesterUltraviolet lights

The invention relates to a method for preparing a nontoxic visible ultraviolet and heat insulation UV coating for food packaging and belongs to a composite material for packaging and the field of a photocuring technology. The invention relates to a white carbon black and metal doped tin oxide nanometer powder body composite ultraviolet photo-cured coating which can improve the capacity of ultraviolet insulation and heat insulation; the coating mainly comprises a photosensitive oligomer, an active thinner, a light evocating agent, white carbon black and metal doped tin oxide, a filler and an additive. The UV coating material has innocuity and harmlessness, can obstruct ultraviolet light of over 97 percent and infrared light of over 80 percent in daylight, has functions of transparence, heat insulation, sterilization and uneasy gleization, is in particular suitable for a visible plastic food packaging bag, a transparent polyester food vessel and the like, is convenient to keep food fresh and store food, prolongs guarantee period of food and reduces the deterioration and waste of food. The UV coating is not added with an organic solvent, is favorable for environmental protection, and has convenient construction and obvious environmental, social and economic benefits.

Owner:JIANGNAN UNIV

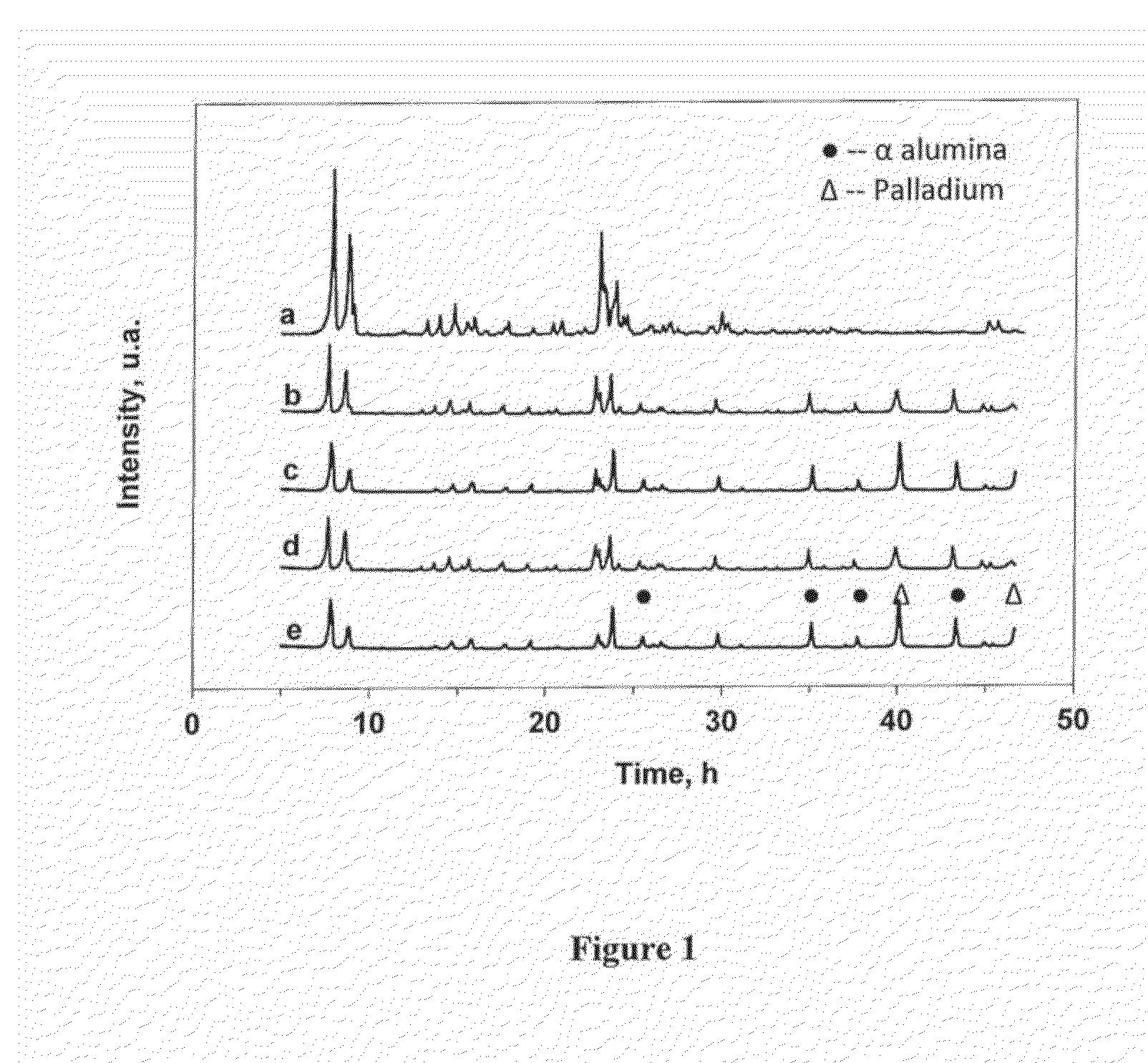

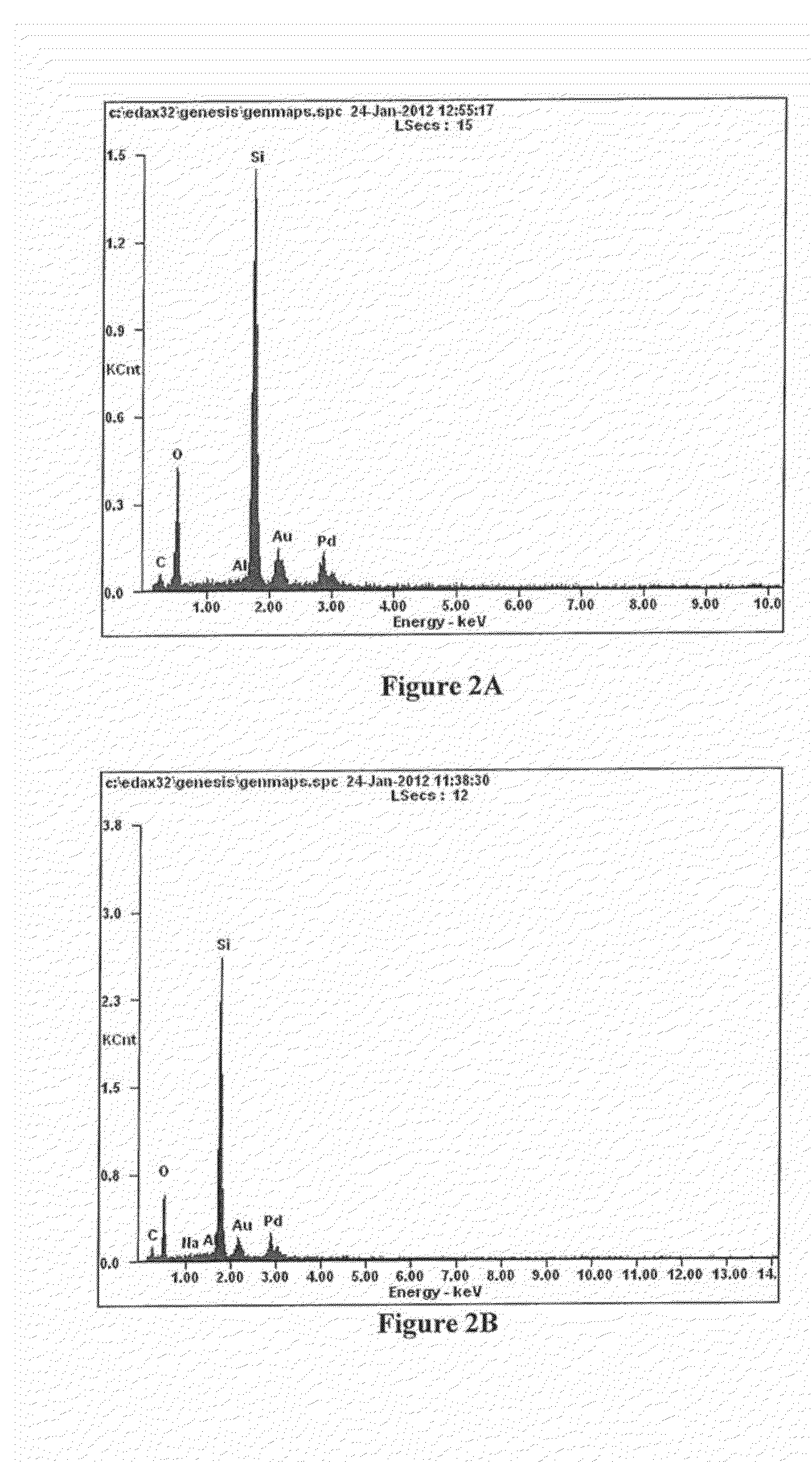

Metal doped zeolite membrane for gas separation

The present invention discloses composite inorganic membranes, methods for making the same, and methods of separating gases, vapors, and liquids using the same. The composite zeolite membrane is prepared by TS-1 zeolite membrane synthesis, and subsequent palladium doping. In the composite zeolite membrane synthesis, two different methods can be employed, including in-situ crystallization of one or more layers of zeolite crystals an a porous membrane substrate, and a second growth method by in-situ crystallization of a continuous second layer of zeolite crystals on a seed layer of MFI zeolite crystals supported on a porous membrane substrate. The membranes in the form of disks, tubes, or hollow fibers have high gas selectivity over other small gases, very good impurity resistance, and excellent thermal and chemical stability over polymer membranes and other inorganic membranes for gas, vapor, and liquid, separations.

Owner:BETTERGY

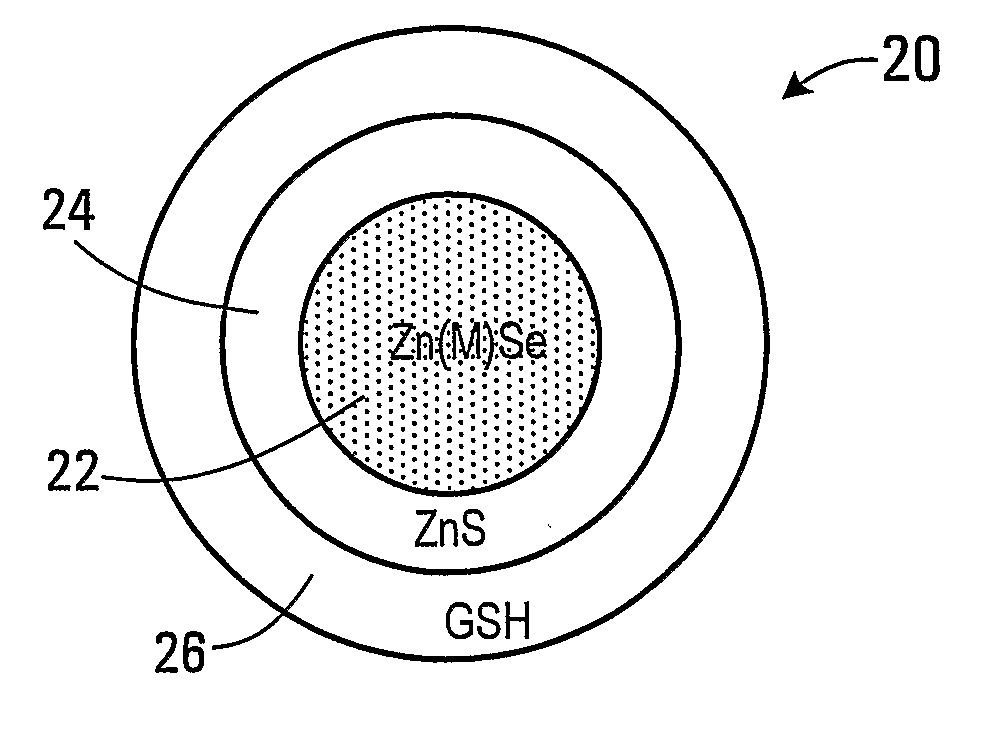

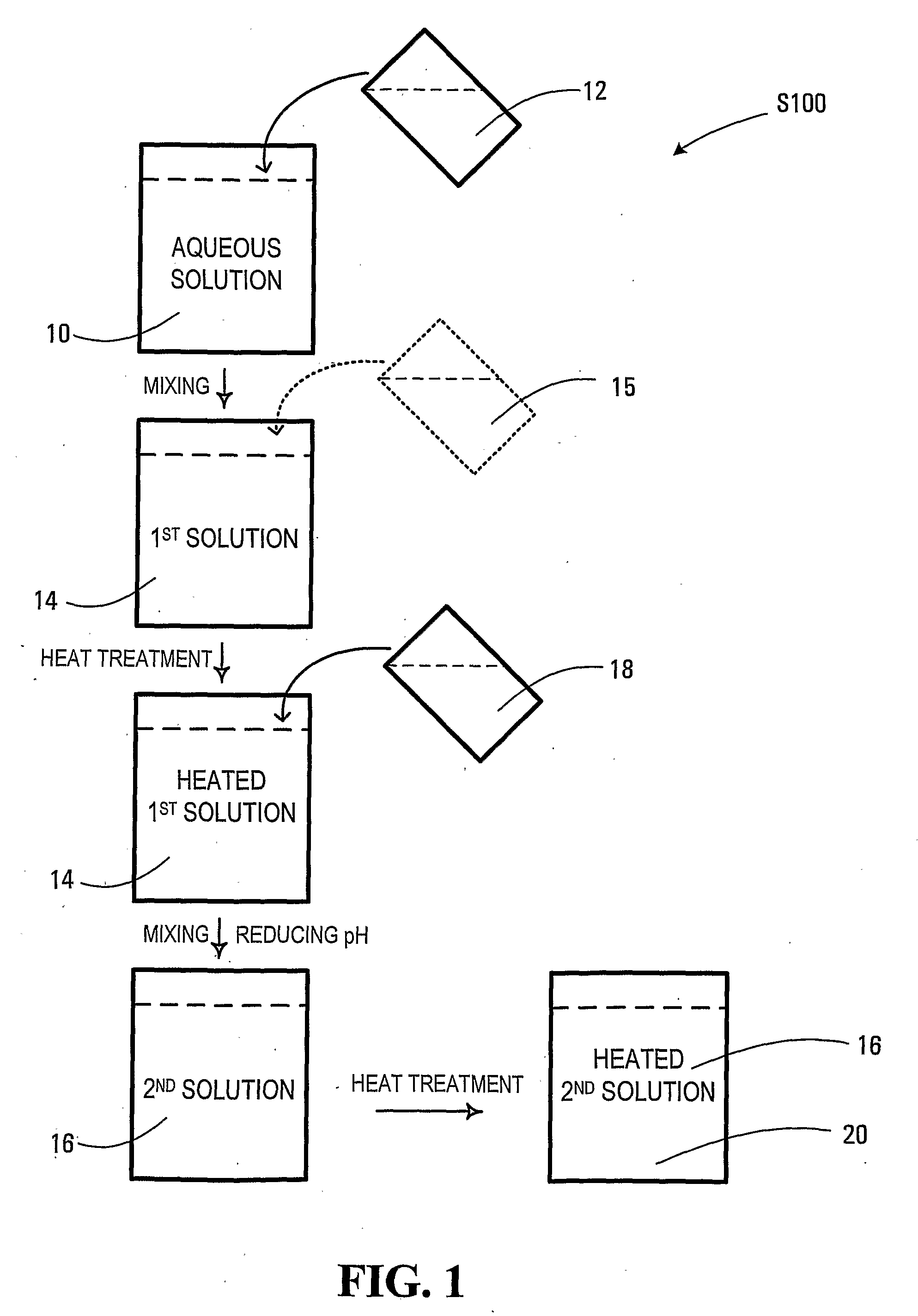

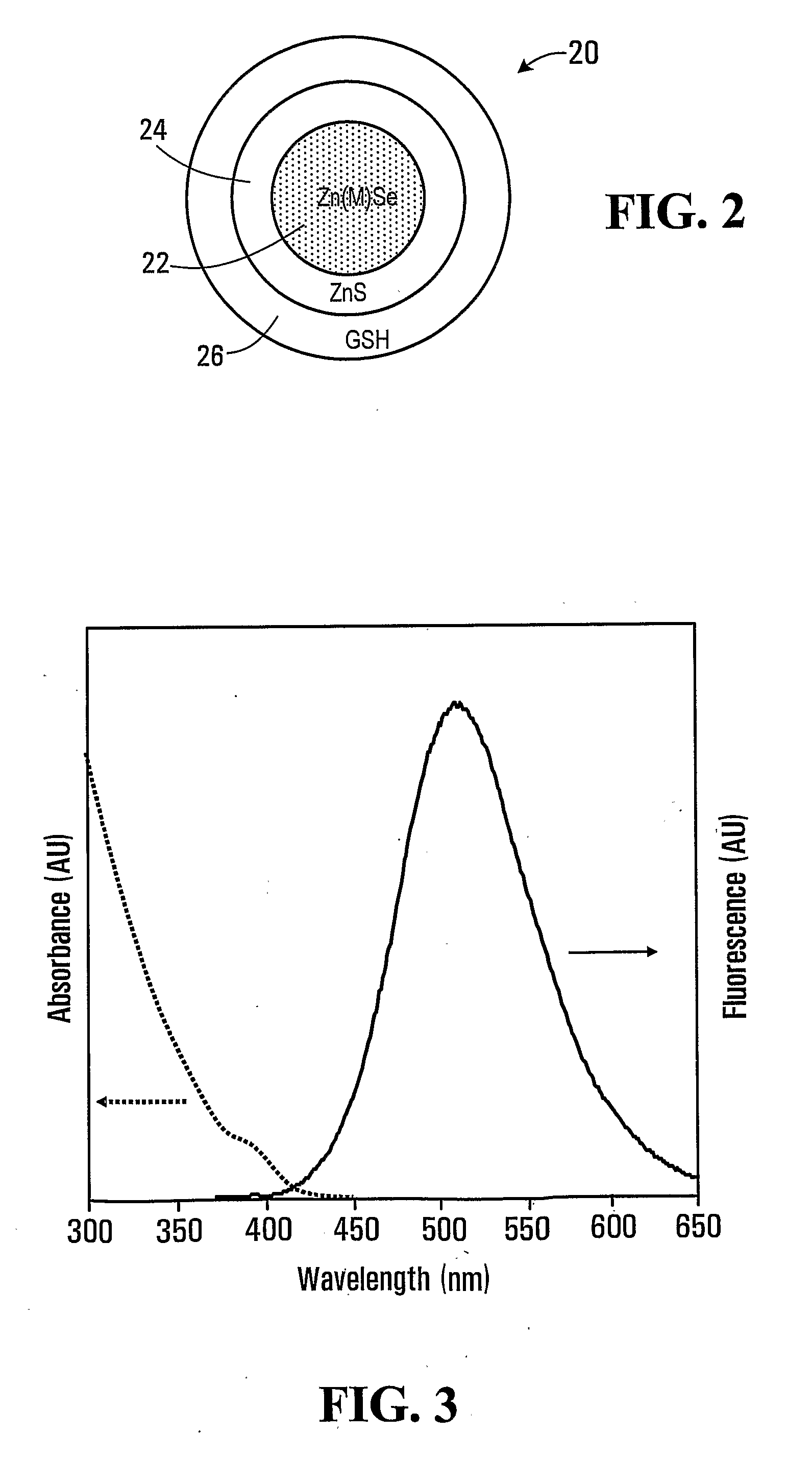

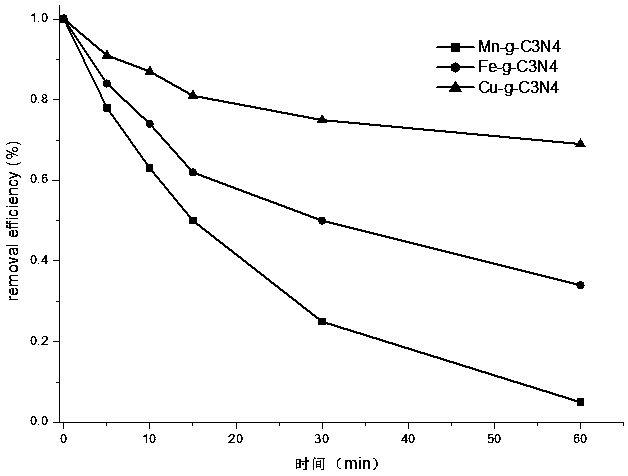

Forming glutathione-capped and metal-doped zinc selenide/zinc sulfide core-shell quantum dots in aqueous solution

InactiveUS20100316797A1Reduce the temperatureMaterial nanotechnologyPolycrystalline material growthZinc selenideSe element

In a process of forming a capped crystal structure, a precursor solution is heated. The solution comprises a mixture of zinc (Zn) precursor, selenium (Se) precursor, precursor for a dopant, glutathione (GSH), and water. The dopant comprises a transition metal (M). The molar ratio of Zn:Se in the solution may be about 10:3 to about 10:5. The solution is heated for a first period sufficient to allow Zn(M)Se crystal core to form. After the first period of heating, more zinc precursor and GSH are added to the heated solution, and the solution is heated for a second period sufficient to form ZnS crystal shell on the Zn(M)Se crystal core. GSH is added in a sufficient amount to form a GSH layer around the Zn(M)Se / ZnS quantum dot.

Owner:AGENCY FOR SCI TECH & RES

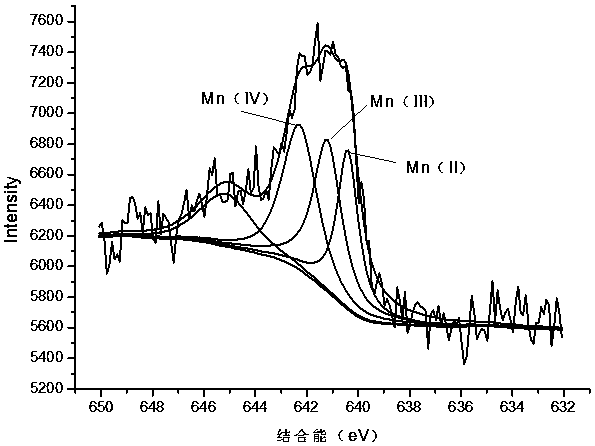

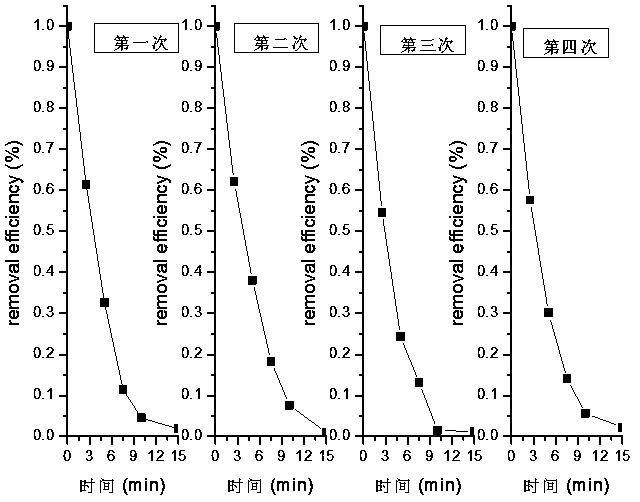

Preparation method and application of graphite-phase carbon nitride-based heterogeneous Fenton-like catalyst

InactiveCN108380235AEvenly dopedGood ability to catalyze PMS to degrade PPCPs pollutants in waterWater contaminantsCatalyst activation/preparationSynthesis methodsMuffle furnace

The invention relates to a preparation method and application of a graphite-phase carbon nitride-based heterogeneous Fenton-like catalyst. The graphite-phase carbon nitride-based heterogeneous Fentoncatalyst is a metal-doped g-C3N4 composite material. The preparation method comprises the following steps: proportionally mixing metal salt and urea without any pretreatment to the metal salt and theurea, adding an obtained mixture into a ceramic crucible, wrapping the mouth of the crucible with aluminum foil, covering with a crucible cover, putting into a muffle furnace, and calcinating in a programmed heating manner without need of any inert protective gas during calcination; and naturally cooling a calcinated product to room temperature, then taking out and grinding to obtain the needed material. The graphite-phase carbon nitride-based heterogeneous Fenton catalyst is applied to organic wastewater treatment. By a one-step synthesis method of the metal-doped g-C3N4 Fenton catalyst, various precursors are not required to be dissolved in advance and then dried by freezing or evaporating so as to be uniformly mixed, and a metal element can be uniformly doped only by controlling a heating program, so that the obtained material has relatively high ability of catalyzing PMS to degrade PPCPs pollutants in water.

Owner:TONGJI UNIV

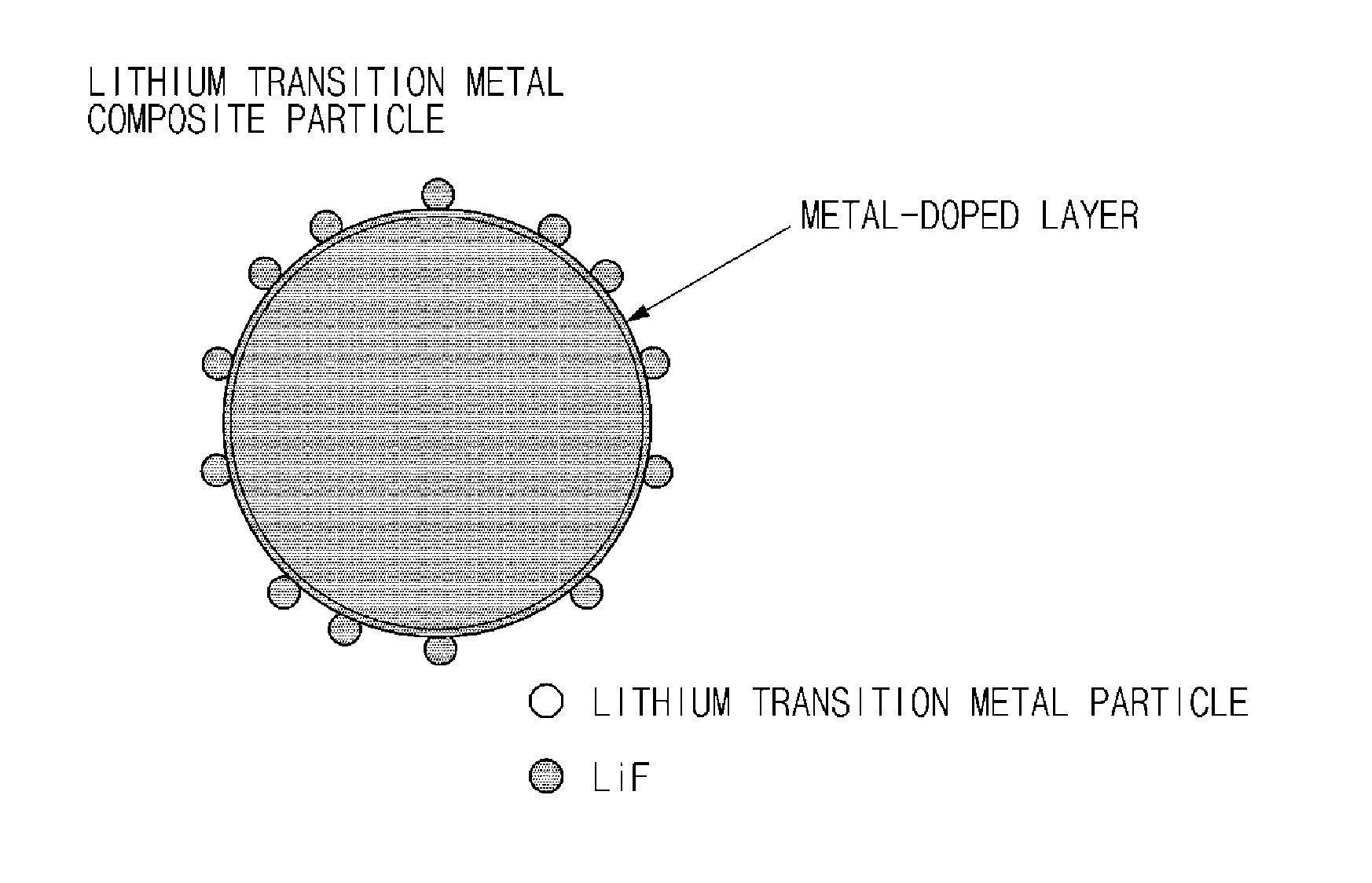

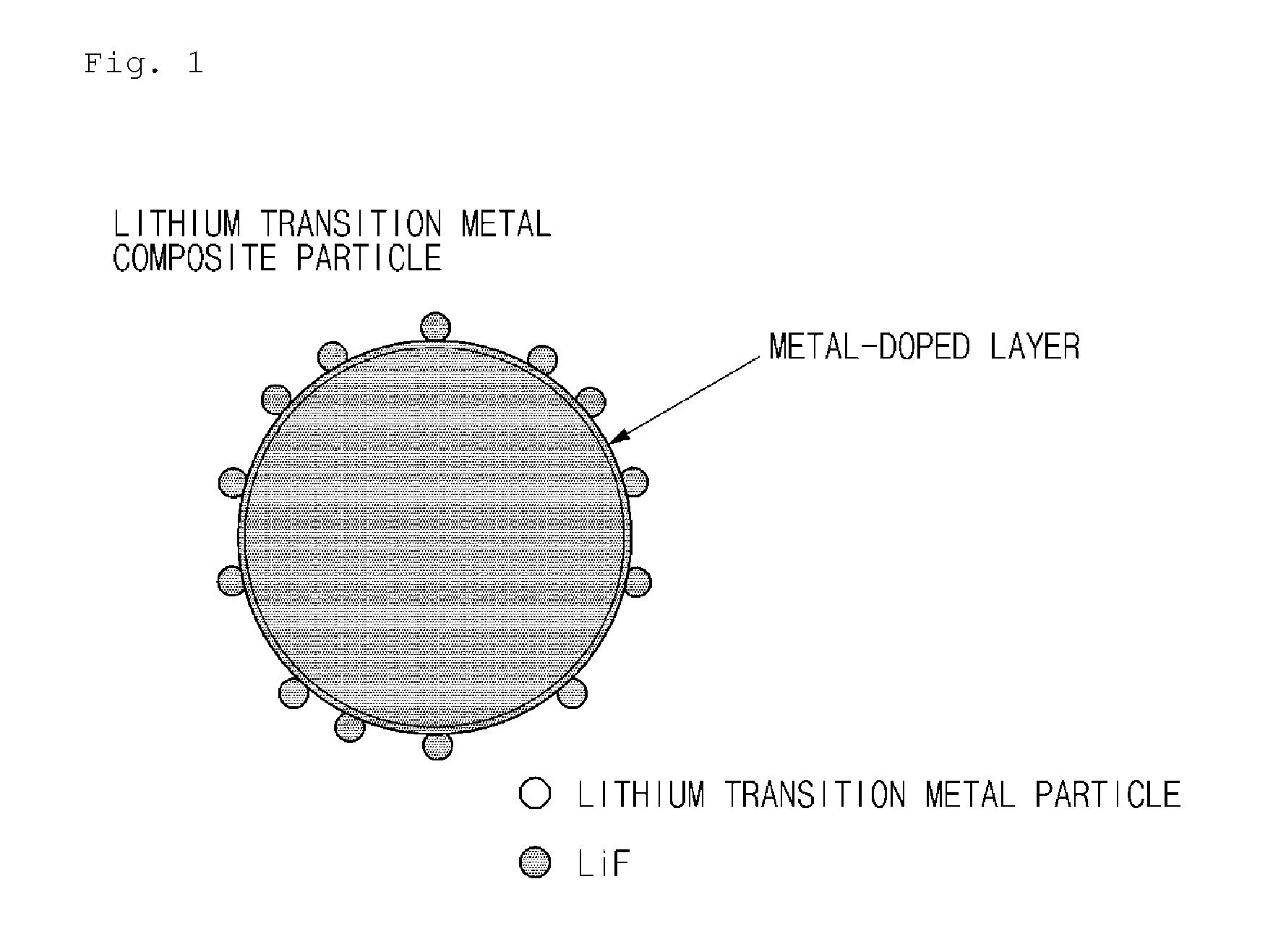

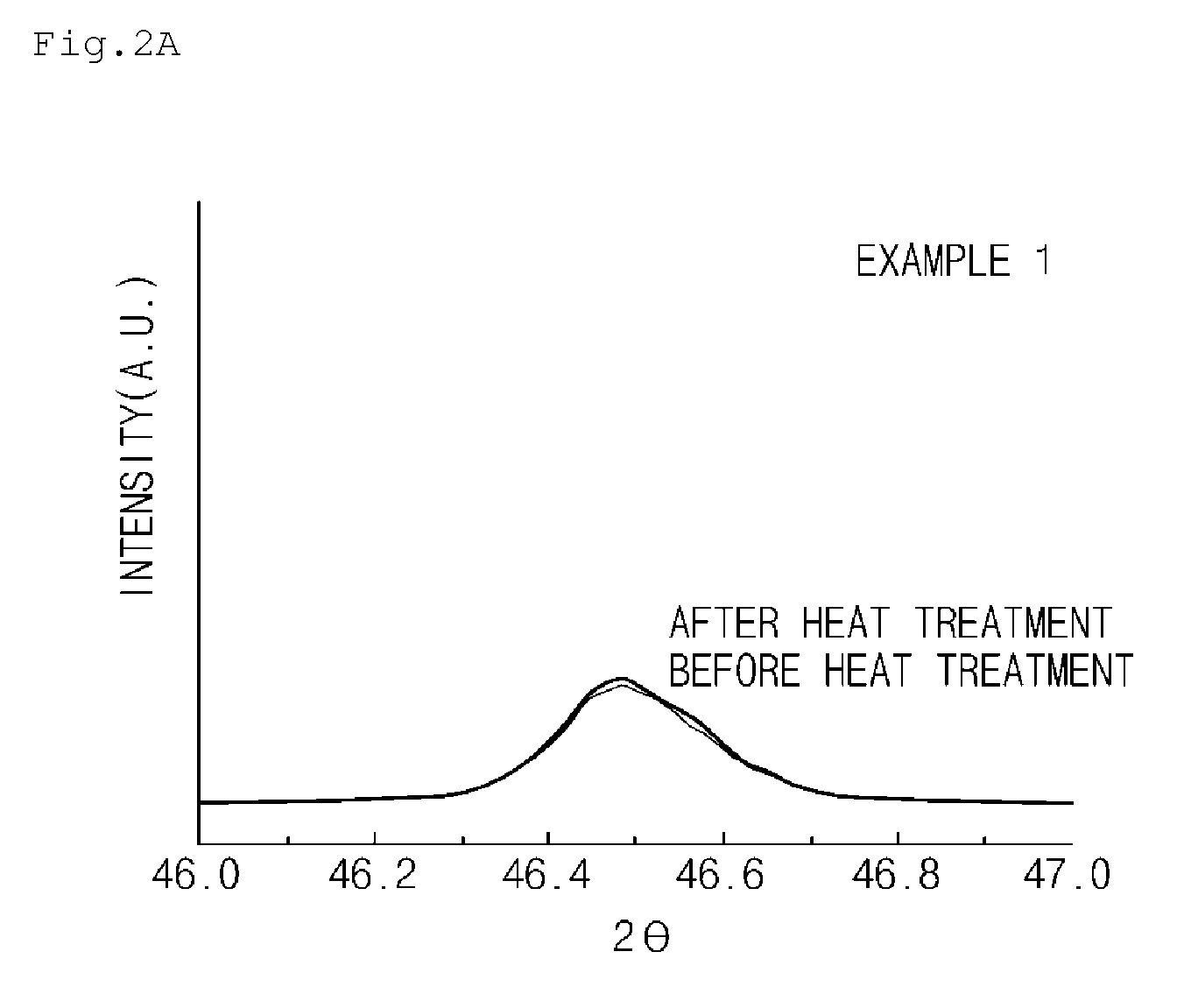

Lithium transition metal composite particles, preparation method thereof, and cathode active material including the same

ActiveUS20150147655A1Reduce the amount requiredInhibit side effectsPositive electrodesNon-aqueous electrolyte accumulator electrodesLithiumPhysical chemistry

Provided are lithium transition metal composite particle including a lithium transition metal oxide particle, a metal-doped layer formed by doping the lithium transition metal oxide particle, and LiF formed on the lithium transition metal oxide particle including the metal-doped layer, a preparation method thereof, and a lithium secondary battery including the lithium transition metal composite particles.

Owner:LG ENERGY SOLUTION LTD

Method for preparing metal doped TiO2 nanocrystal particles

InactiveCN104190416AHas visible light catalytic activityGood suspensionMetal/metal-oxides/metal-hydroxide catalystsLight ActivityAqueous solution

The invention discloses a method for preparing metal doped TiO2 nanocrystal particles. The method comprises the following steps: dispersing a titanium source in a metal ion aqueous solution, hydrolyzing to obtain metal ion doped hydrated titanic acid precipitation, dispersing the metal ion doped hydrated titanic acid precipitation in a hydrogen peroxide aqueous solution, and hydrothermally reacting to obtain the metal doped TiO2 nanocrystal particles. The method for preparing the metal doped TiO2 nanocrystal particles, which is disclosed by the invention, can be used for preparing metal doped monodisperse and suspended TiO2 nanocrystal particles with visible-light activity, and the method has a good application prospect in the fields of photocatalytic air purification, photocatalytic water treatment and the like.

Owner:李建明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com