Preparation method of metal doped lithium manganese phosphate/graphene/carbon composite material

A carbon composite material, lithium manganese phosphate technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of poor cycle stability, attenuation, serious polarization, and low reversible capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

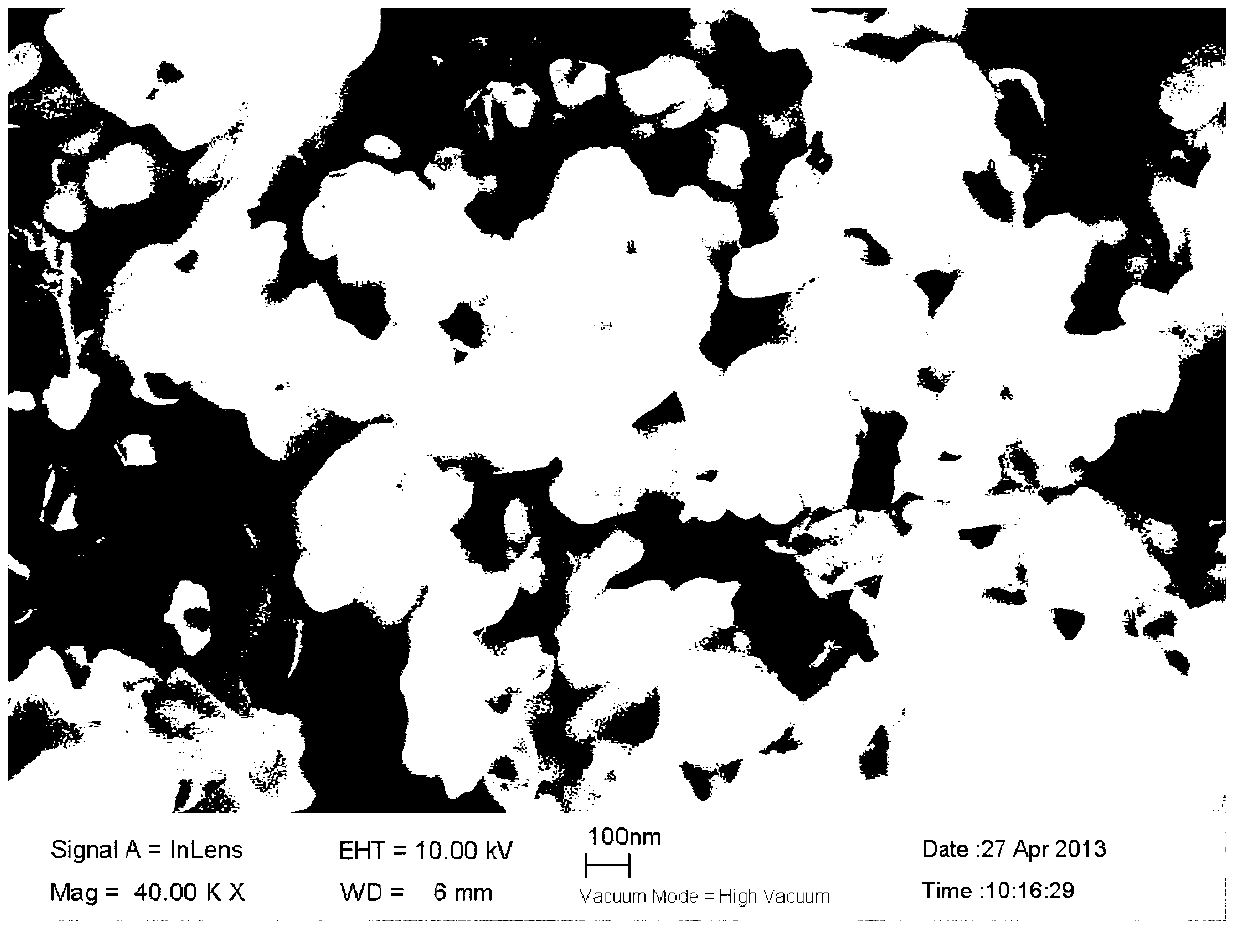

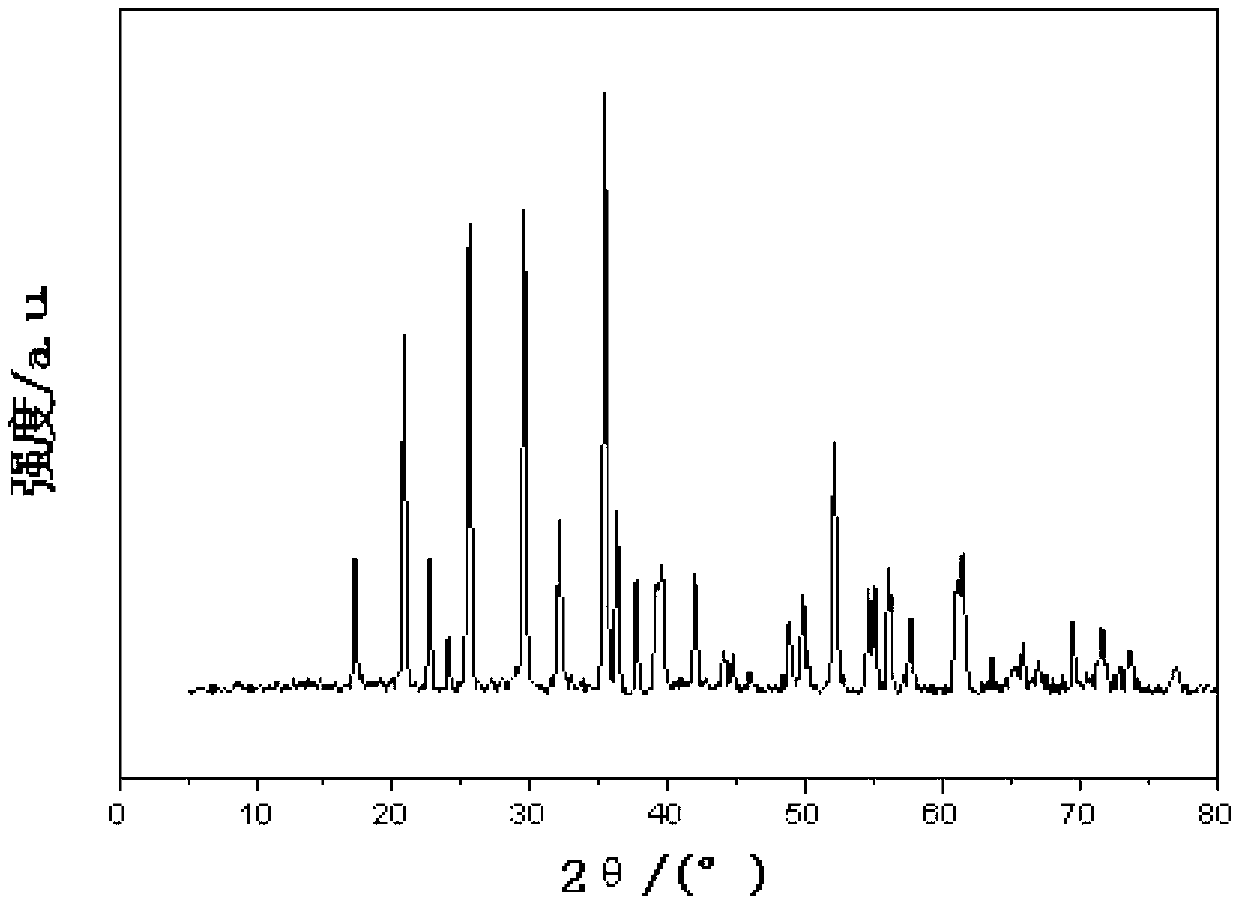

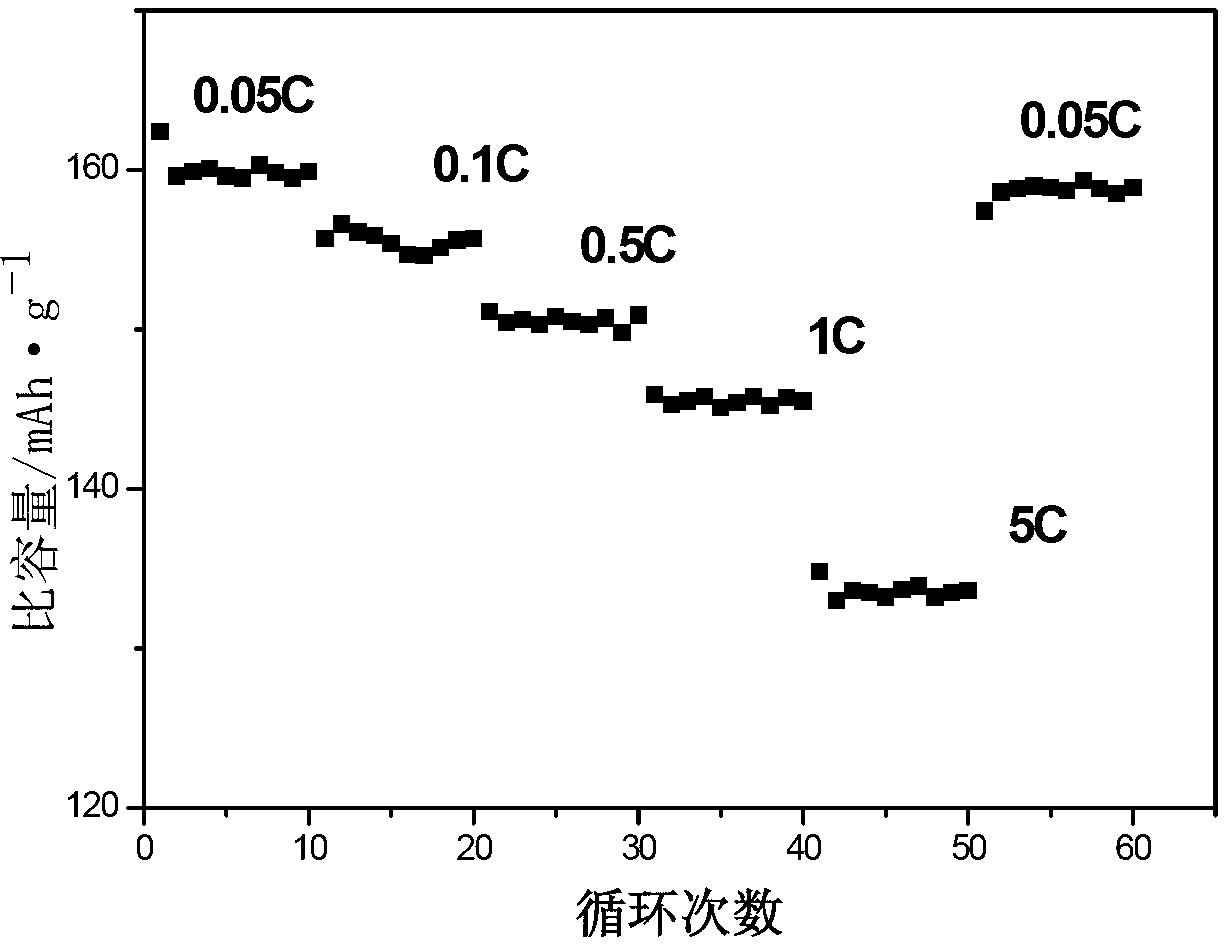

[0035] ①According to the theory of lithium manganese phosphate:graphene=1:0.005 mass ratio, disperse graphene (0.028g) in a mixture containing manganous sulfate (0.0288mol), ferrous sulfate (0.0072mol), phosphoric acid (0.036mol), ascorbic acid ( 0.01mol) of water and ethylene glycol at a volume ratio of 1:2 in a mixed solvent of 120ml, ultrasonically dispersed for 12h, and sheared at a speed of 10000r / min on a high-speed shear for 1h to fully disperse the graphene Uniform, called A liquid. Dissolve lithium hydroxide (0.108mol) in 120ml of a mixed solvent composed of water and ethylene glycol with a volume ratio of 1:2 to form liquid B, and then add it dropwise to liquid A to prepare the precursor of lithium manganese phosphate solution, wherein the concentration of lithium ions is 0.45mol / L. It is placed in a high-temperature and high-pressure reactor, and the filling capacity of the reactor is 60%. The lithium manganese phosphate / graphene composite material LiMn with graph...

example 2

[0041] ①According to the theoretical mass ratio of lithium manganese phosphate:graphene=1:0.03, disperse graphene (0.22g) in a mixture containing manganous sulfate (0.0456mol), magnesium sulfate (0.0024mol), phosphoric acid (0.048mol), ascorbic acid (0.0024 mol) and glucose (0.0133mol) in a mixed solvent of water and ethanol with a volume ratio of 1:2.5, ultrasonicated for 12 hours, and sheared for 1 hour at a speed of 10,000 r / min on a high-speed shearing machine to fully disperse graphene Uniform, called A liquid, called A liquid, the volume of A liquid is 200ml. Dissolve lithium hydroxide (0.144mol) in a mixed solvent composed of water and ethanol with a volume ratio of 1:2.5. The volume of the mixed solvent is 160ml. After dissolving, add it dropwise to liquid A to prepare the precursor of lithium manganese phosphate solution, wherein the concentration of lithium ions is 0.8mol / L. It is placed in a high-temperature and high-pressure reactor, and the filling capacity of th...

example 3

[0044] ① According to the theoretical mass ratio of lithium manganese phosphate: graphene = 1:0.01, disperse graphene (0.038g) in a mixture containing manganous acetate (0.0216mol), copper sulfate (0.0024mol), oxalic acid (0.0014mol) and glucose (0.01 mol) of water and polyethylene glycol 400 in a volume ratio = 5:6, after ultrasonication for 12 hours, and shearing for 1 hour at a speed of 10,000 r / min on a high-speed shearing machine, the graphene is fully dispersed and uniform. It is called liquid A, and the volume of liquid A is 80ml. Dissolve lithium dihydrogen phosphate (0.072mol) in a mixed solvent composed of water and polyethylene glycol 400 at a volume ratio of 5:6. The volume of the mixed solvent is 80ml. After dissolving, add it dropwise to liquid A to obtain phosphoric acid The precursor solution of lithium manganese, wherein the concentration of lithium ions is 0.45mol / L. It is placed in a high-temperature and high-pressure reactor, and the filling capacity of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com