Water electrolytic hydrogen production catalytic electrode of self-supporting metal-doped cobalt phosphide nano structure

A technology of metal doping and nanostructure, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., to achieve excellent catalytic activity and structural stability, broad application prospects, and the effect of efficient water electrolysis hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

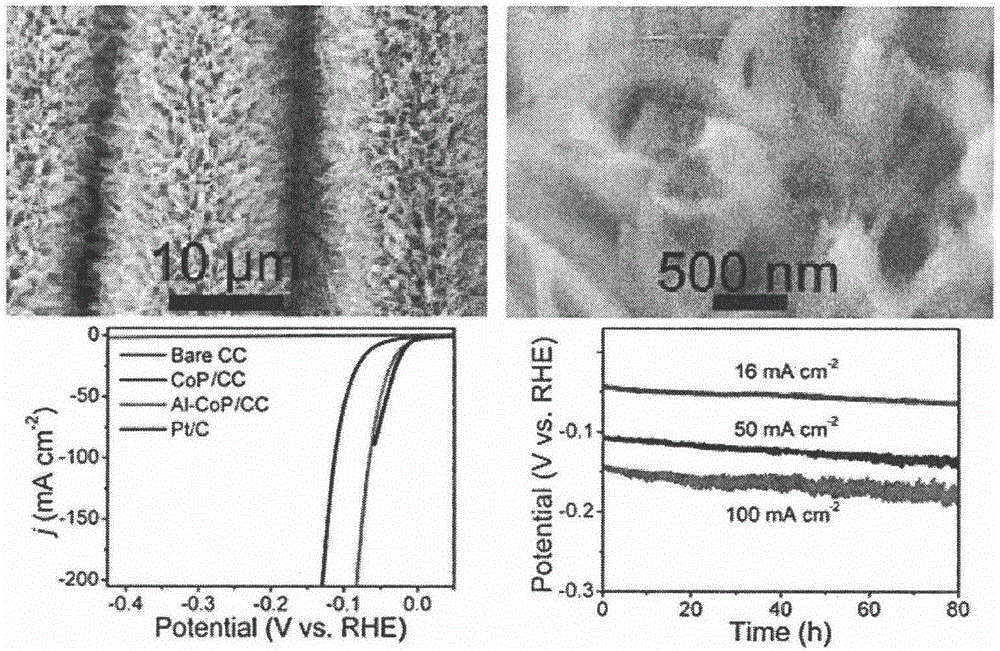

Embodiment 1

[0028] Step 1: Add 20 mL of distilled water to the PTFE liner, add 0.876 g of cobalt nitrate hexahydrate, 0.1125 g of aluminum nitrate nonahydrate, 0.148 g of ammonium fluoride and 0.60 g of urea and stir until the solids are completely dissolved.

[0029] Step 2: Put the collector carbon fiber cloth into the reaction kettle lining in step 1, and seal the polytetrafluoroethylene lining into a stainless steel mold, place it in a constant temperature drying oven under closed conditions and react at 120°C 6h.

[0030] Step 3: After the reaction is completed, cool down to room temperature with the furnace, then take out the carbon fiber cloth, wash it, and then place it in a vacuum drying oven and dry it at 50°C for 24 hours to obtain a precursor.

[0031] Step 4: Put the precursor prepared in Step 3 in a tube furnace and add sodium hypophosphite, and react at 280 ° C for 2 h in an argon atmosphere to obtain a self-supporting aluminum-doped cobalt phosphide nanoarray (Al -CoP / CC,...

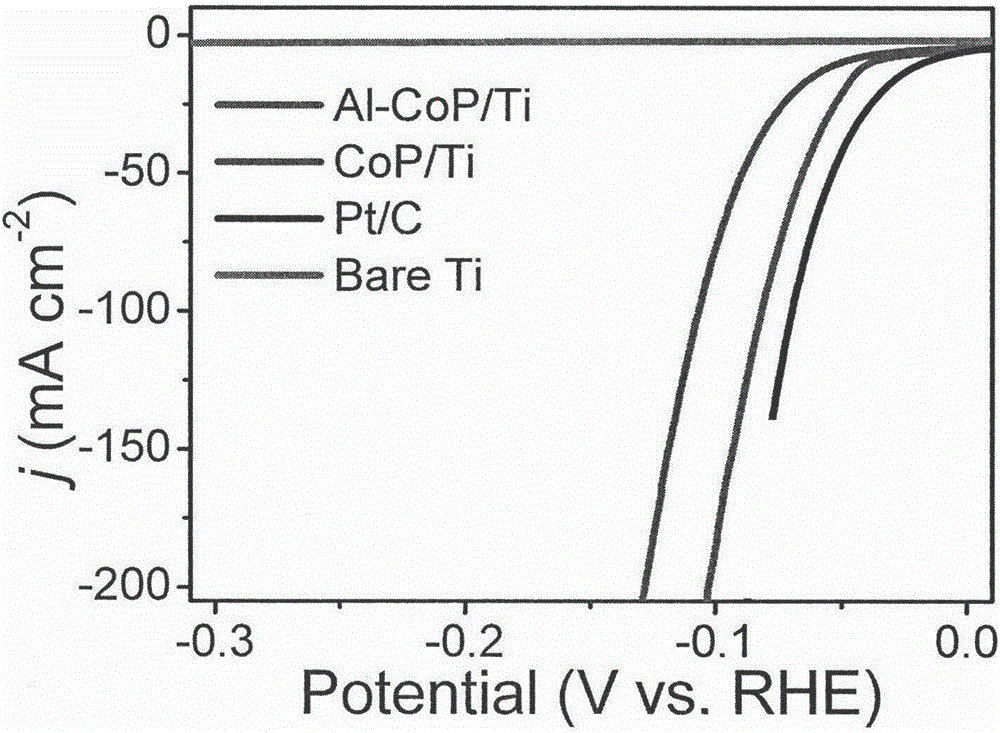

Embodiment 2

[0034] Step 1: Add 20 mL of distilled water to the PTFE liner, add 0.876 g of cobalt nitrate hexahydrate, 0.225 g of aluminum nitrate nonahydrate, 0.148 g of ammonium fluoride and 0.60 g of urea and stir until the solids are completely dissolved.

[0035] Step 2: Put the current collector titanium mesh into the reactor lining in step 1, seal the polytetrafluoroethylene lining into a stainless steel mold, place it in a constant temperature drying oven under closed conditions and react at 120°C 6h.

[0036] Step 3: After the reaction is completed, cool down to room temperature with the furnace, then take out the titanium mesh, wash it, and place the washed titanium mesh in a vacuum drying oven and vacuum-dry it at 40°C for 24 hours to obtain a precursor.

[0037] Step 4: Put the precursor prepared in Step 3 in a tube furnace and add potassium hypophosphite, and react at 300 °C for 3 h in an argon atmosphere to obtain a self-supporting aluminum-doped cobalt phosphide nanoarray (A...

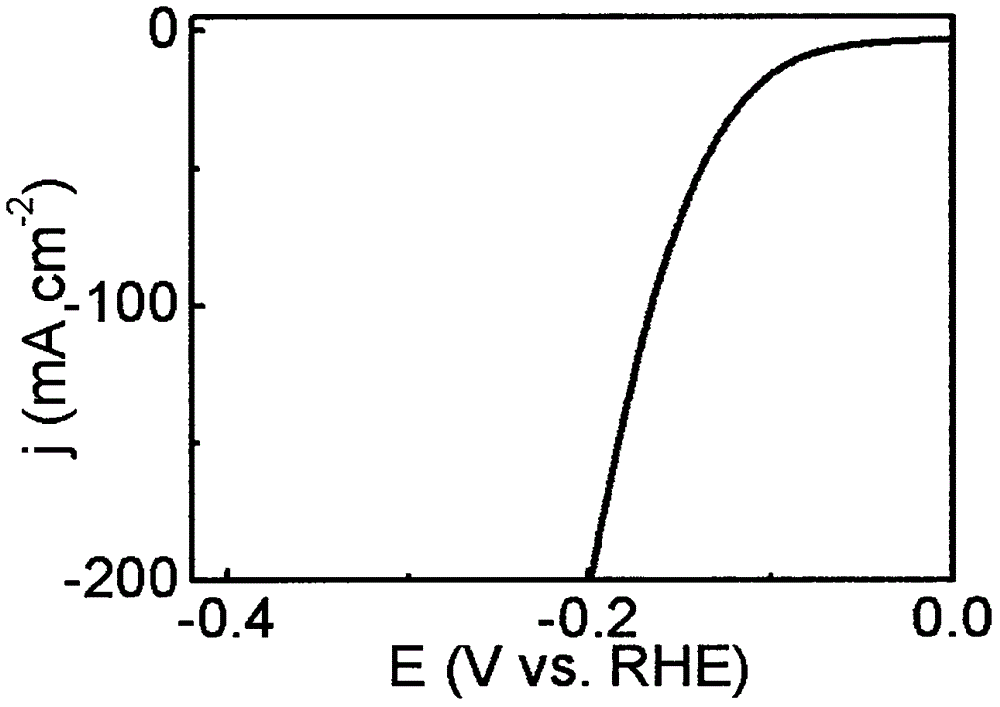

Embodiment 3

[0040]Step 1: Add 20 mL of distilled water to the PTFE liner, add 0.291 g of cobalt nitrate hexahydrate, 0.08524 g of copper chloride dihydrate, 0.093 g of ammonium fluoride and 0.30 g of urea and stir until the solids are completely dissolved.

[0041] Step 2: Put the collector foam nickel into the reactor lining of step 1, and seal the polytetrafluoroethylene lining into a stainless steel mold, place it in a constant temperature drying oven under closed conditions and react at 120°C 6h.

[0042] Step 3: After the reaction is completed, cool down to room temperature with the furnace, then take out the nickel foam, wash it, and then place it in a vacuum drying oven and dry it at 40°C for 24 hours to obtain a precursor.

[0043] Step 4: Put the precursor prepared in Step 3 in a tube furnace and add hypophosphorous acid, and react at 280°C for 3 hours in an argon atmosphere to obtain a self-supporting copper-doped cobalt phosphide nanoarray (Cu- CoP / NF).

[0044] Step 5: Use 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com