Patents

Literature

63results about How to "Reduce PAH content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

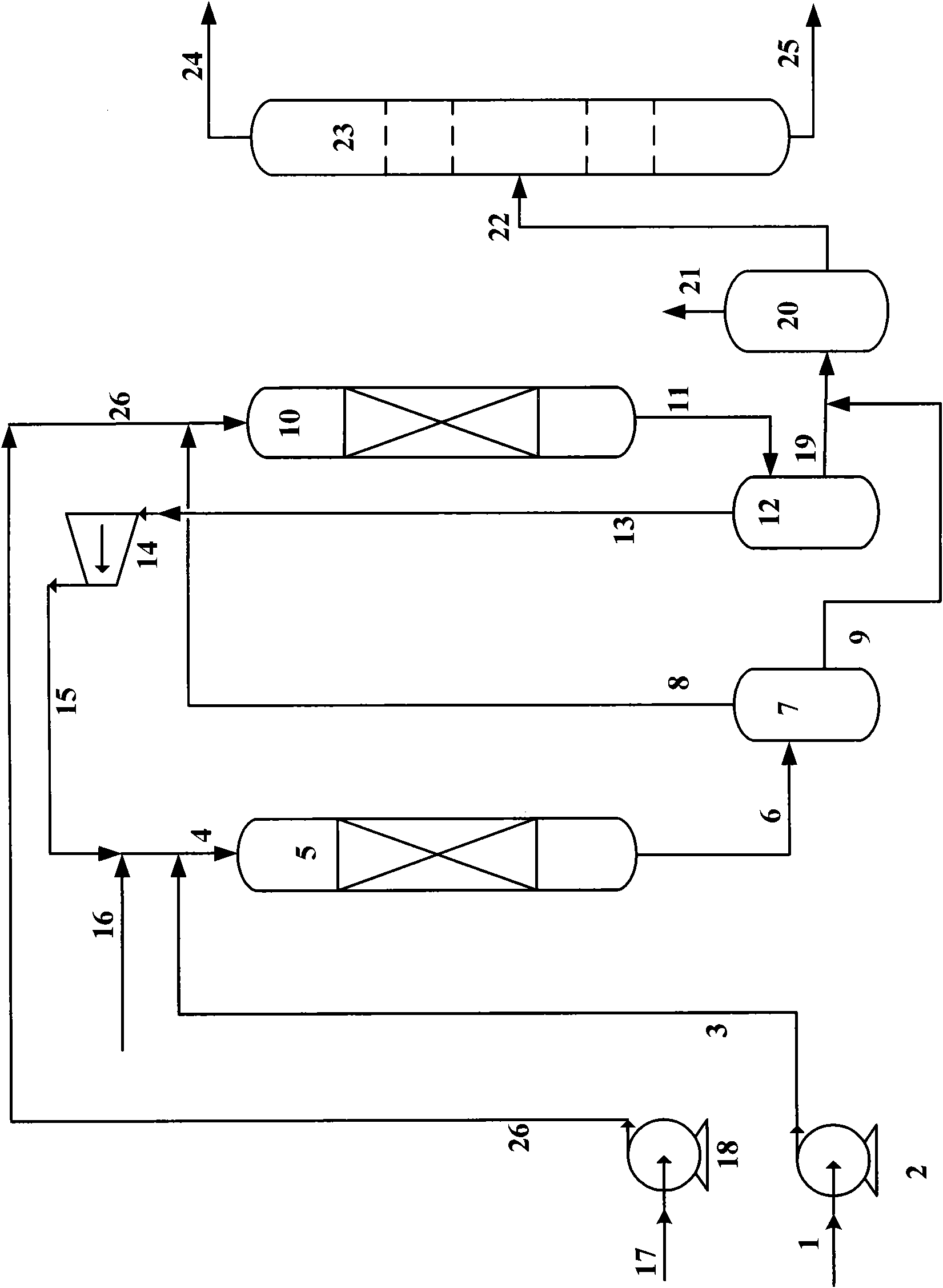

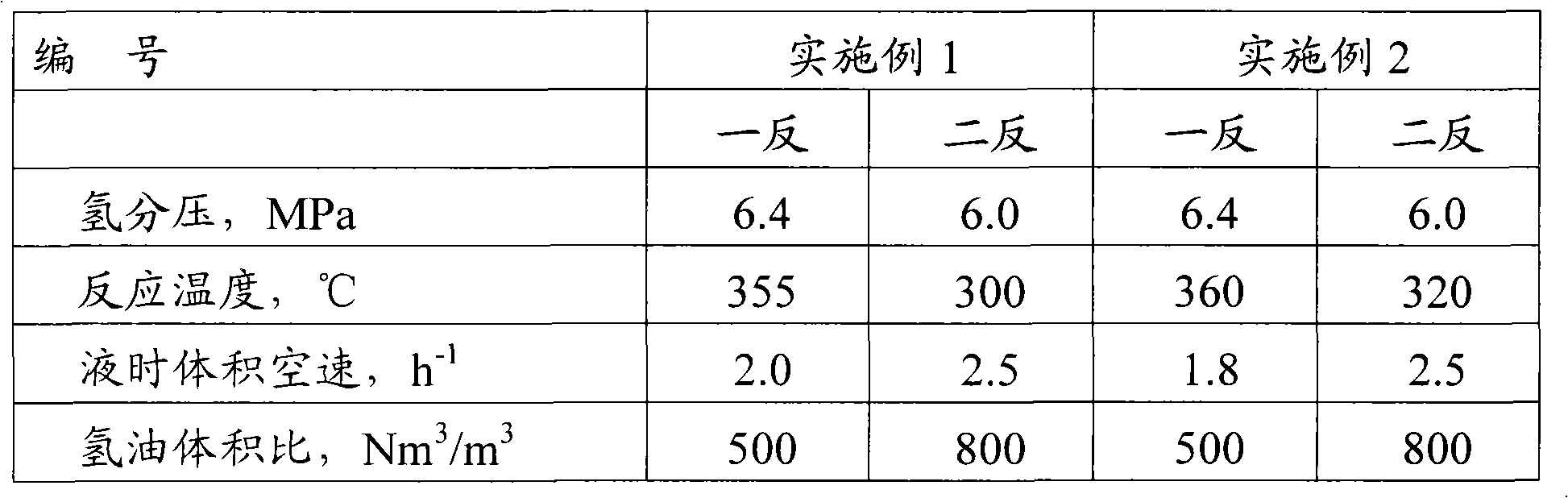

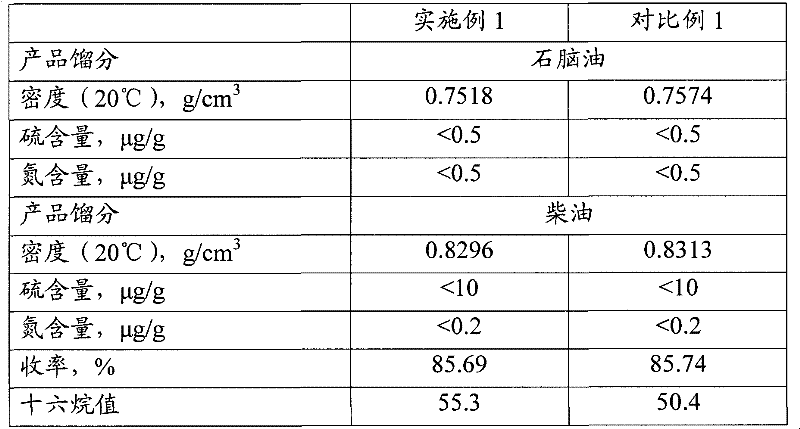

Combined hydrogenation method for mineral oil and animal and vegetable oil

ActiveCN101768469AReduce sulfur contentReduce PAH contentTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonVegetable oil

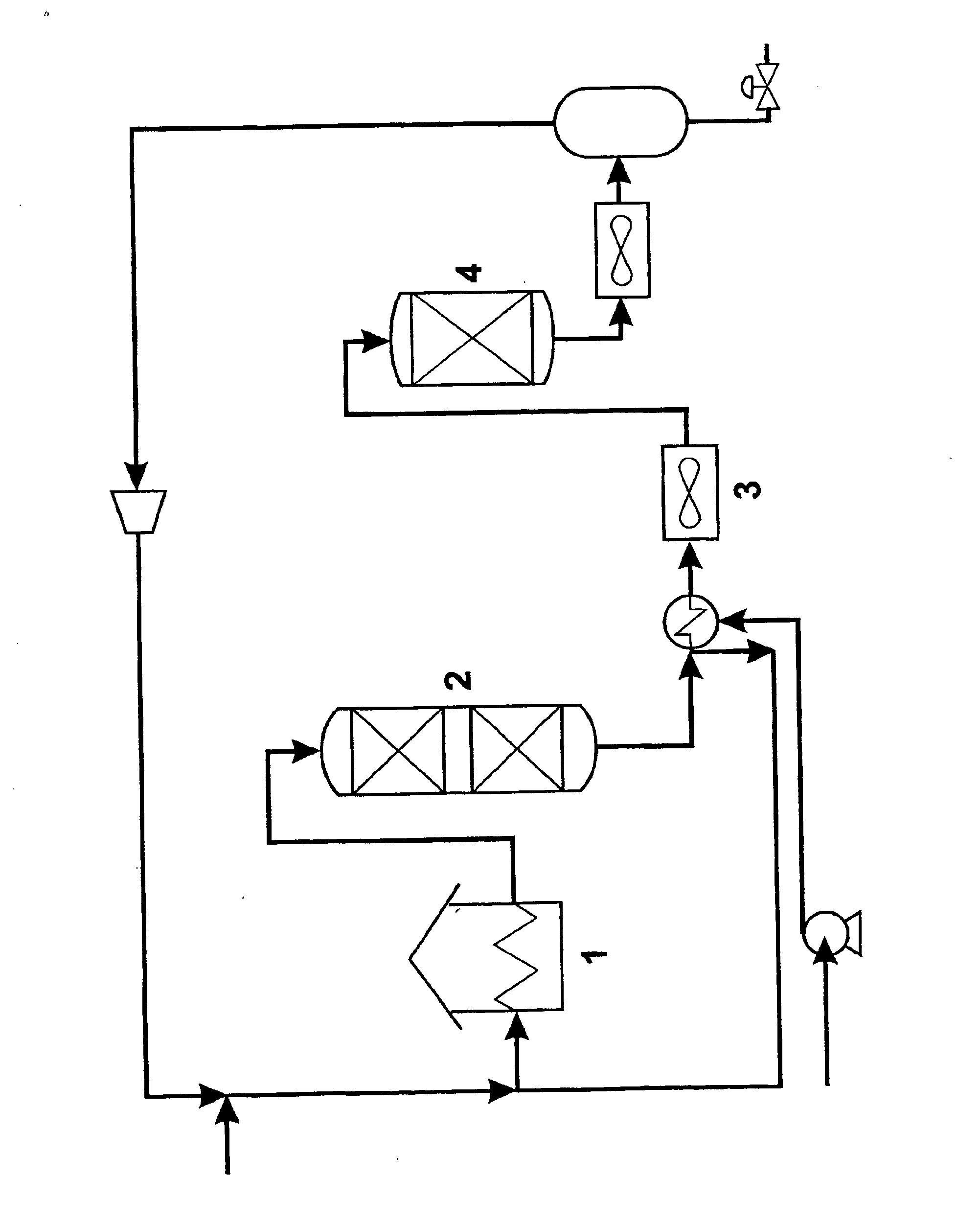

The invention relates to a combined hydrogenation method for mineral oil and animal and vegetable oil. In two hydrogenation reaction zones, high-sulfur mineral diesel oil distillate and animal and vegetable oil are respectively used as the raw materials and hydrogenated under different conditions, and the products are mixed to obtain a low-surfur or an even ultralow-surfur diesel oil product, wherein the gas-phase compound flow obtained in the first hydrogenation reaction zone is cycled to the second hydrogenation reaction zone, and the gas-phase compound flow obtained in the second hydrogenation reaction zone is cycled to the first hydrogenation reaction zone. The method can process high-sulfur mineral diesel oil distillate and vegetable oil. The method can be used for obtaining a clean diesel oil product with low sulfur content and high content of polycyclic aromatic hydrocarbon and cetane number under mild operating conditions. The invention saves the equipment and the operating procedure for regular sulfur supplement for hydrogenation of the vegetable oil, reduces the effect of water generated by the vegetable oil hydrogenation reaction on the activity of the hydrogenation catalyst, and prolongs the device operation period.

Owner:CHINA PETROLEUM & CHEM CORP +1

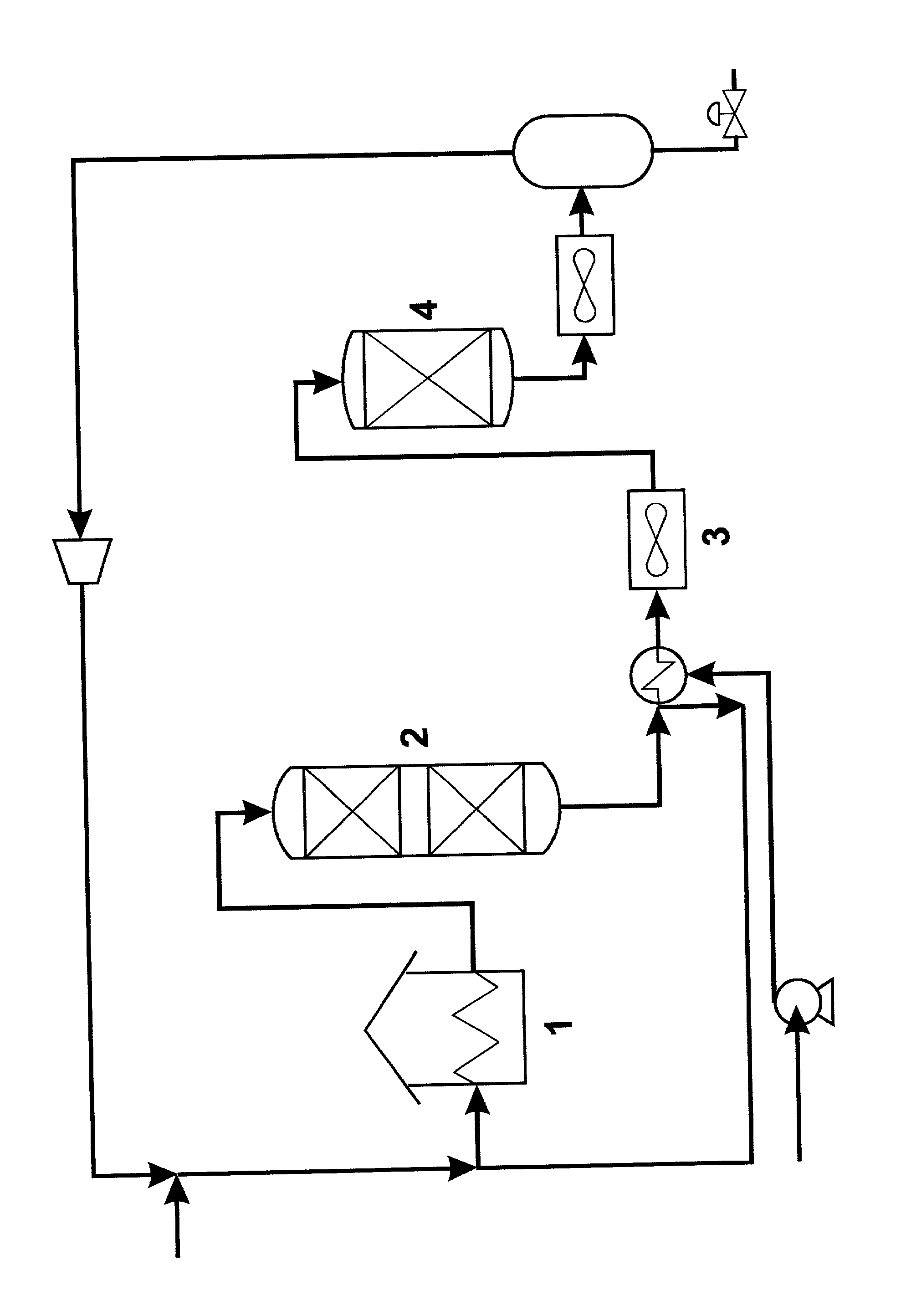

Process for reducing content of sulphur compounds and poly-aromatic hydrocarbons in a hydrocarbon feed

InactiveUS20010013484A1Slight additional investmentReduce contentHydrocarbon by hydrogenationLiquid carbonaceous fuelsPtru catalystSulphur compound

A process for reducing content of sulphur compounds and polyaromatic hydrocarbons in a hydrocarbon feed having a boiling range between 200° C. and 600° C., which process comprises in combination contacting the feed and hydrogen over a hydrotreating catalyst and hydrotreating feed at hydrotreating conditions, cooling the hydrotreated effluent and hydrogen-rich gas from the hydrotreating reactor contacting said effluent and hydrogen gas over a hydrotreating catalyst in a post-pretreatment reactor at a temperature sufficient to lower the polyaromatic hydrocarbon content.

Owner:HALDOR TOPSOE AS

Method for repairing polycyclic aromatic hydrocarbon polluted soil by using residual active sludge

InactiveCN102085529AReduce PAH contentContaminated soil reclamationPolycyclic aromatic hydrocarbonSludge

The invention relates to a combined method for repairing polycyclic aromatic hydrocarbon polluted soil and disposing residual active sludge of sewage treatment, and belongs to the technical field of environmental biology. The method mainly comprises the following steps of: mixing and composting the polycyclic aromatic hydrocarbon polluted soil, the residual active sludge and the biomass waste to obtain partial matured compost, and applying the compost to the polycyclic aromatic hydrocarbon polluted soil to repair. The method can effectively treat and dispose the residual active sludge and repair the polycyclic aromatic hydrocarbon polluted soil, and is simple in process and low in cost.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Process for reducing content of sulphur compounds and poly-aromatic hydrocarbons in a hydrocarbon feed

InactiveUS20050133411A1Reduce contentImprove performanceLiquid carbonaceous fuelsTreatment with hydrotreatment processesHydrogenSulphur compound

Owner:ZEUTHEN PER +1

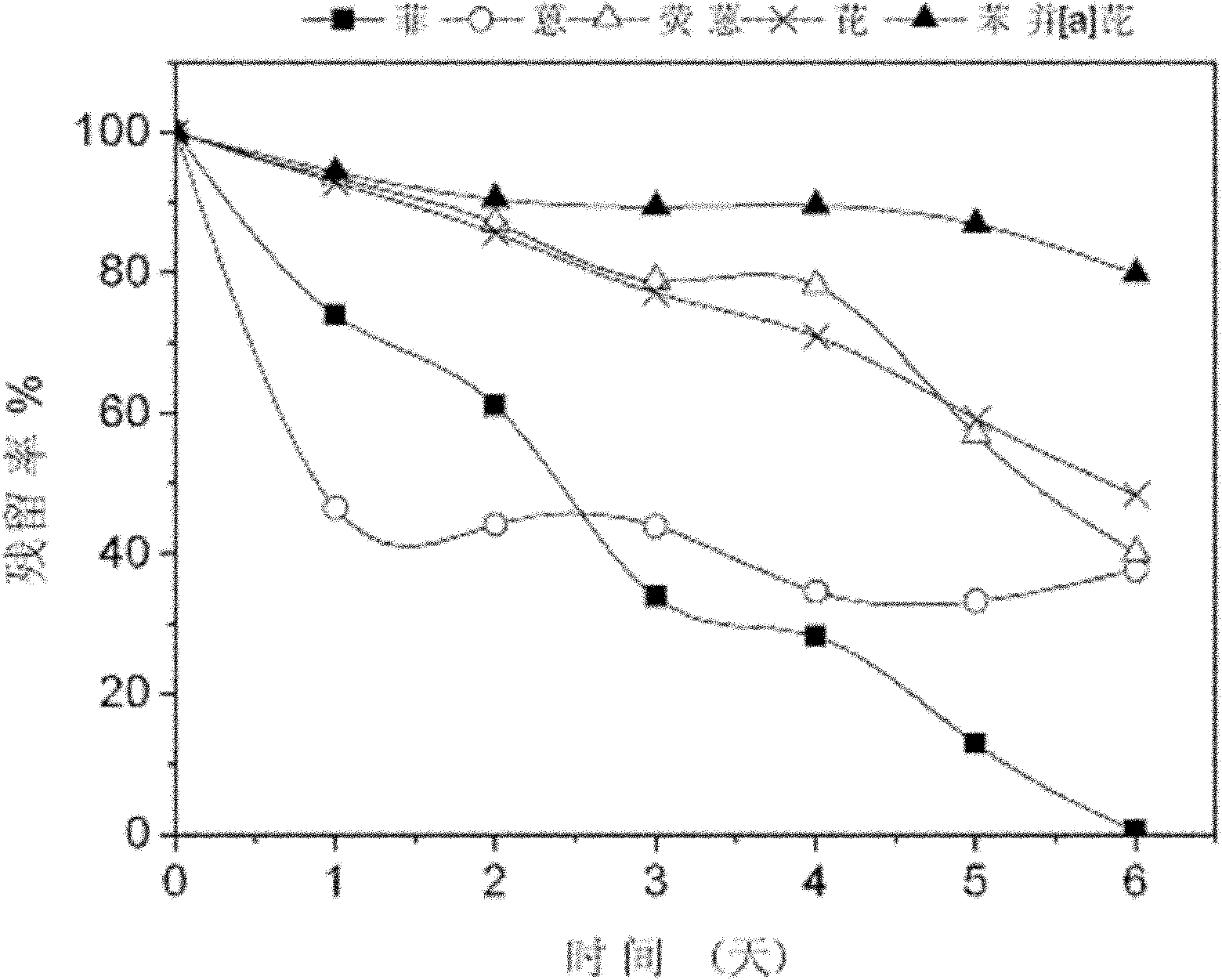

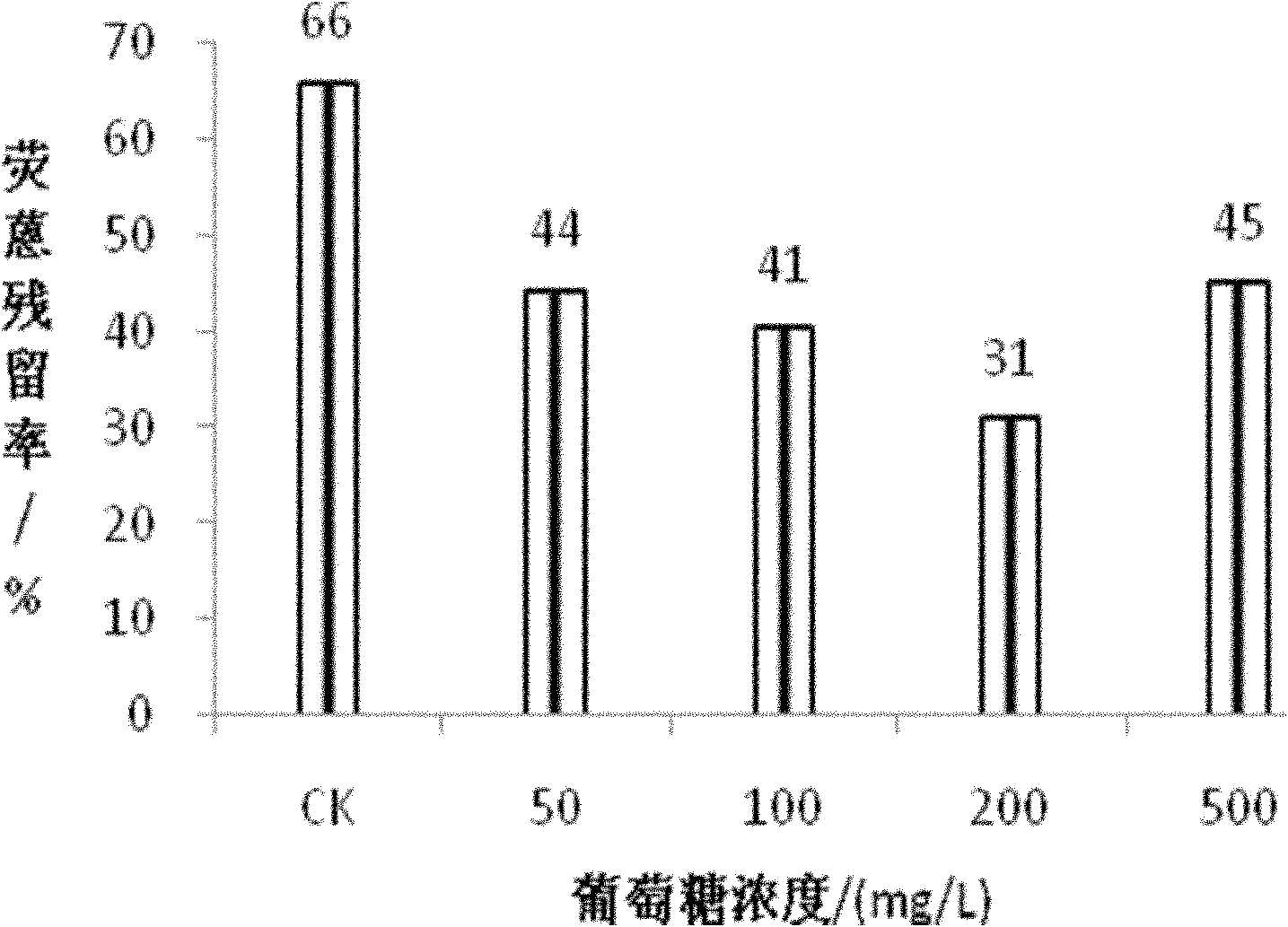

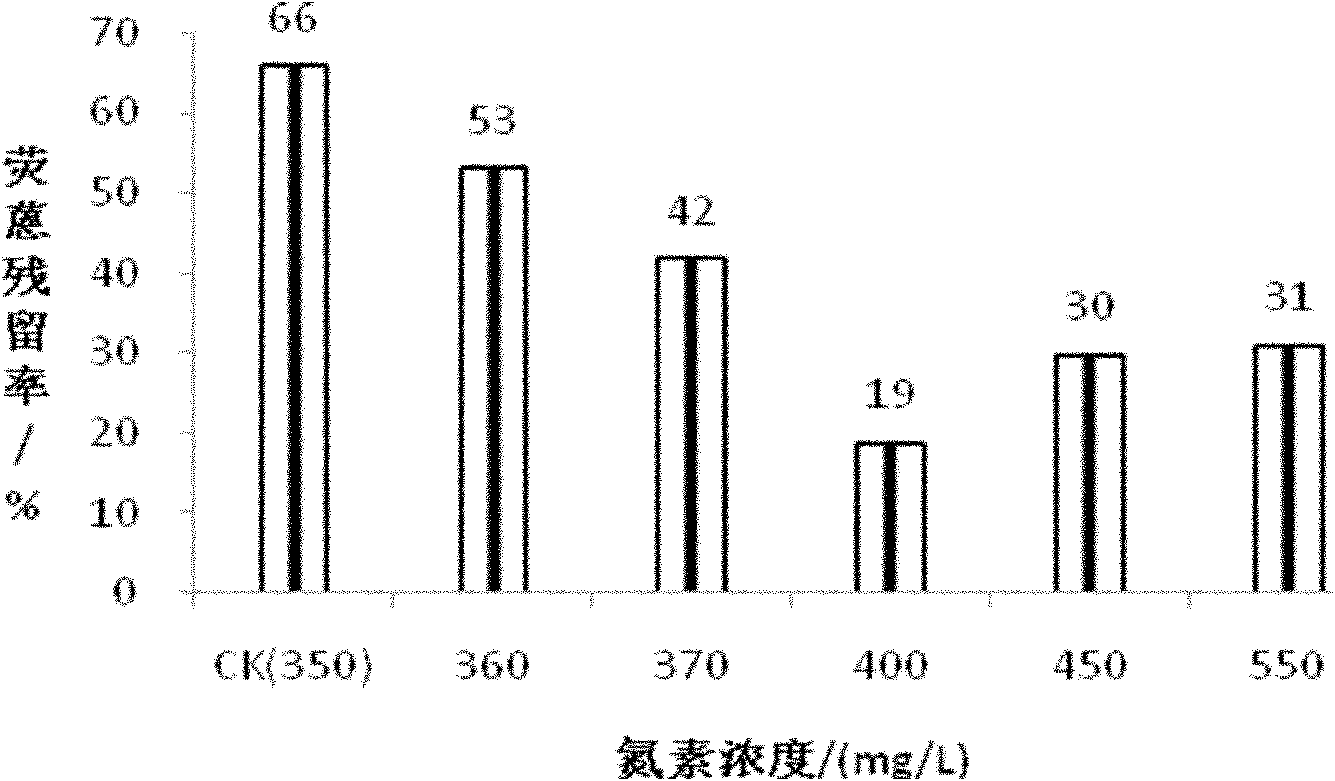

Sphingobium yanoikuyae and application thereof in degrading polycyclic aromatic hydrocarbon

The invention discloses a Sphingobium yanoikuyae and an application thereof in degrading polycyclic aromatic hydrocarbon. The Sphingobium yanoikuyae provided by the invention is named as LD29 with the strain collection number of CGMCC No.4400. The Sphingobium yanoikuyae LD 29 can grow and breed by respectively taking phenanthrene, anthracene, fluoranthene and pyrene as the only carbon source and energy source under the aerobic condition. In addition, the Sphingobium yanoikuyae LD 29 has a degrading effect on mixed polycyclic aromatic hydrocarbon, especially on pentacyclic benzopyrene [alpha] in the mixed polycyclic aromatic hydrocarbon. The Sphingobium yanoikuyae can be used for repairing soil and the water body polluted by the polycyclic aromatic hydrocarbon, and is quick, convenient and environmentally-friendly, and can be used for reducing the content of the polycyclic aromatic hydrocarbon in the environment, thereby providing new microorganism resources for bioremediation for polycyclic aromatic hydrocarbon pollution, and having an important value for environmental governance as well as considerable economic benefit and good social benefit.

Owner:CHINA AGRI UNIV

Method for making a liquid smoke coloring agent solution

InactiveUS6261623B1Lower the volumeExcellent color capability capabilityMeat/fish preservationAlcoholic beverage preparationLiquid smokePhysical chemistry

A liquid smoke coloring agent solution having total water miscibility, a benzopyrene content under about 5 ppb, and a pH above about 11, and a related method for making same by contacting liquid smoke with water and an alkaline agent. The liquid smoke coloring agent solution may be made from commercially existing liquid smoke compositions.

Owner:HICKORY SPECIALTIES

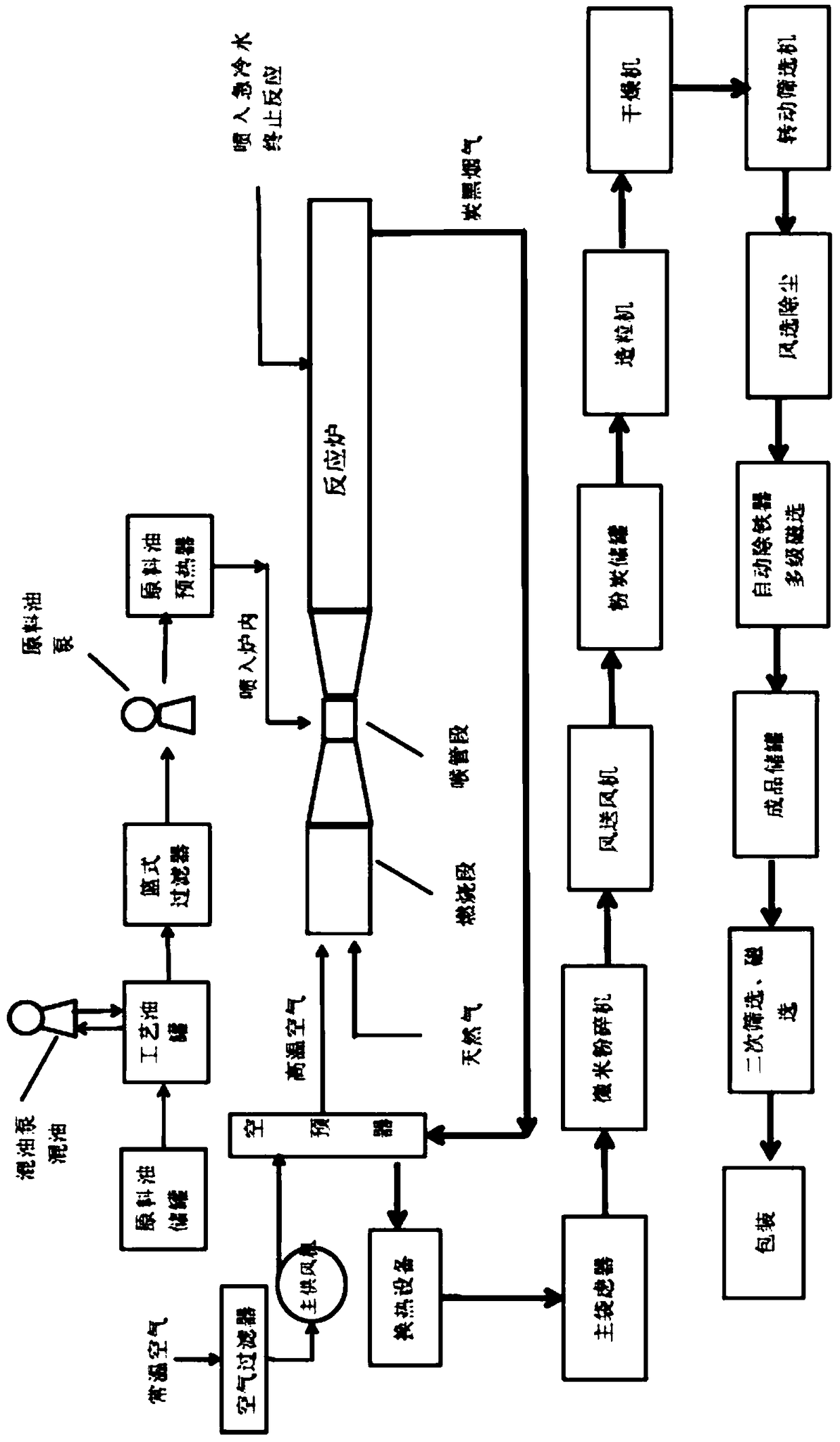

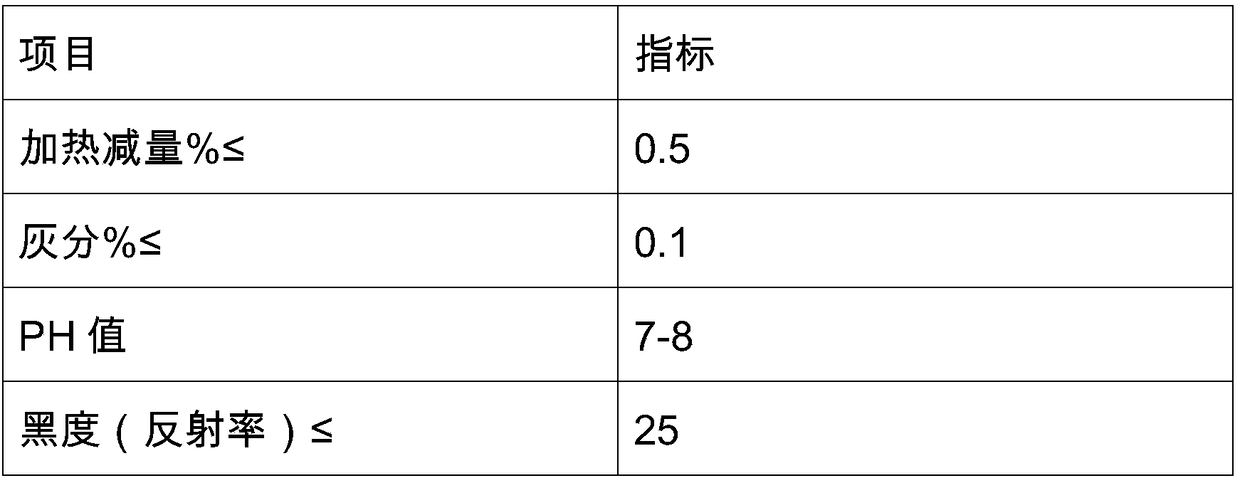

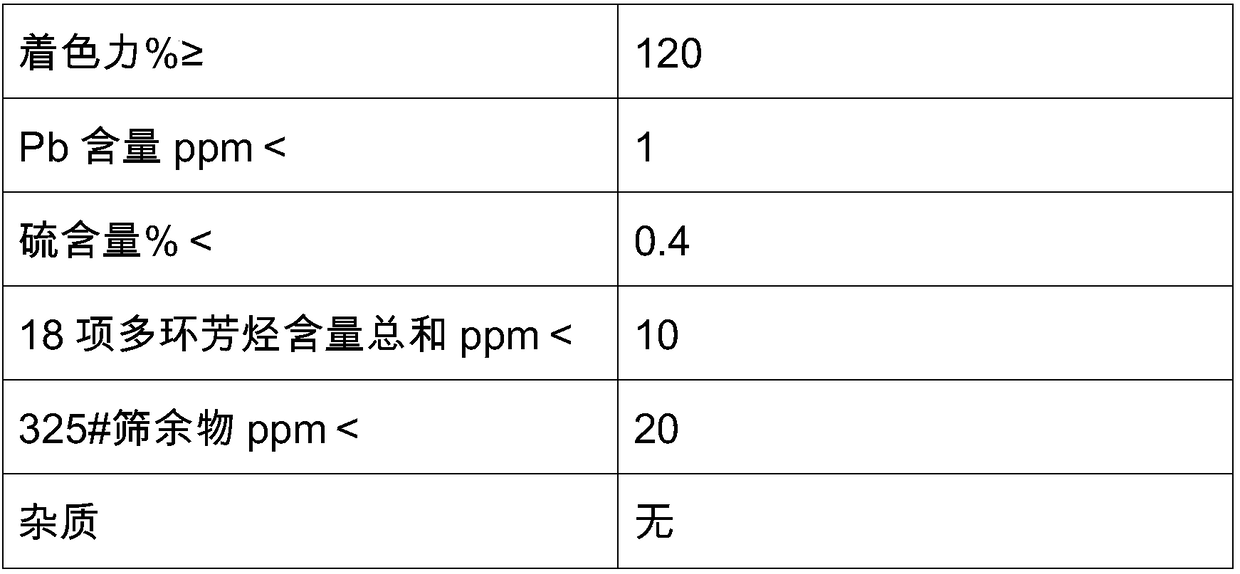

Method for producing carbon black for shielding material inside cable

The invention relates to a method for producing carbon black for a shielding material in a cable. The method comprises the steps that fuel gas and preheated air are input into a combustion section ofa reaction furnace, and the volume ratio of air to gas is (16 to 1) to (17 to 1), and the combustion temperature of the combustion section reaches 1850 DEG C to 1900 DEG C, the flue gas flow rate generated in the combustion section reaches 120 m / s to 150 m / s; preheated anthracene oil is pumped into a throat section of the reaction furnace, the flow rate of the anthracene oil is 3500 kg / h to 4200 kg / h, the quality index of the anthracene oil is that: the mass ratio of toluene insoluble matter is less than or equal to 0.2%, density rho 20 at 20 DEG C is 1.13 g / cm<3> to 1.15 g / cm<3>, viscosity E80 is less than or equal to 2, the water volume ratio is less than or equal to 1%, the fraction before 210 DEG C is less than or equal to 1%, the fraction before 360 DEG C is more than or equal to 60%;cold water is sprayed to a quenching section of the reaction furnace to terminate the reaction of the anthracene oil in high temperature environment, the reaction time of the anthracene oil is 0.2 sto 0. 3 s. The carbon black obtained by the method has a moderate nitrogen adsorption specific surface area and particle strength, a high purity of carbon black, a good dispersibility of carbon black,a high degree of structure, and a low volume resistivity when carbon black is combined with EVA.

Owner:山东联科新材料有限公司

Process for reduction of content of sulphur compounds and polyaromatic hydrocarbons in distillate fuels

InactiveUS20020117425A1Shorten the lengthIncrease cetane numberLiquid carbonaceous fuelsTreatment with hydrotreatment processesHydrogenBoiling point

A process for reducing content of sulphur compounds and polyaromatic hydrocarbons in a hydrocarbon feed having a boiling range between 120° C. and 450° C., which process comprises in combination contacting the feed and hydrogen over a hydrotreating catalyst and hydrotreating feed at hydrotreating conditions, cooling the effluent consisting of hydrocarbon, polyaromatic hydrocarbons, hydrogen sulphide and hydrogen-rich gas from the hydrotreating reactor, contacting said effluent and hydrogen gas over a hydrotreating catalyst in a post treat reactor at a temperature appropriate to lower the polyaromatic hydrocarbon content.

Owner:HALDOR TOPSOE AS

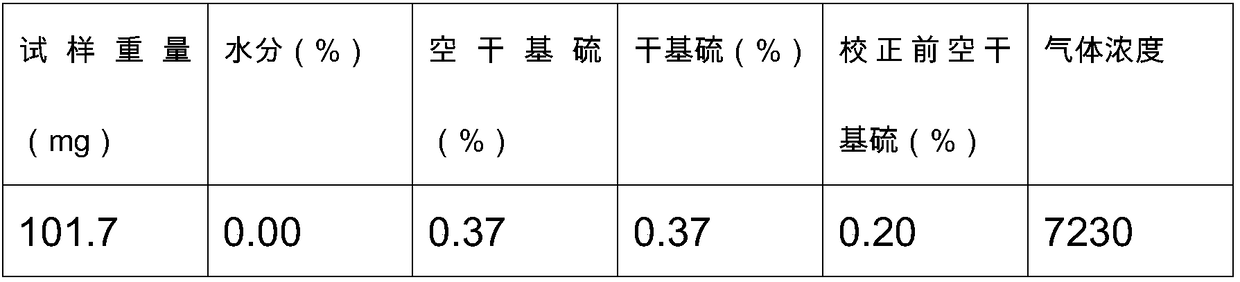

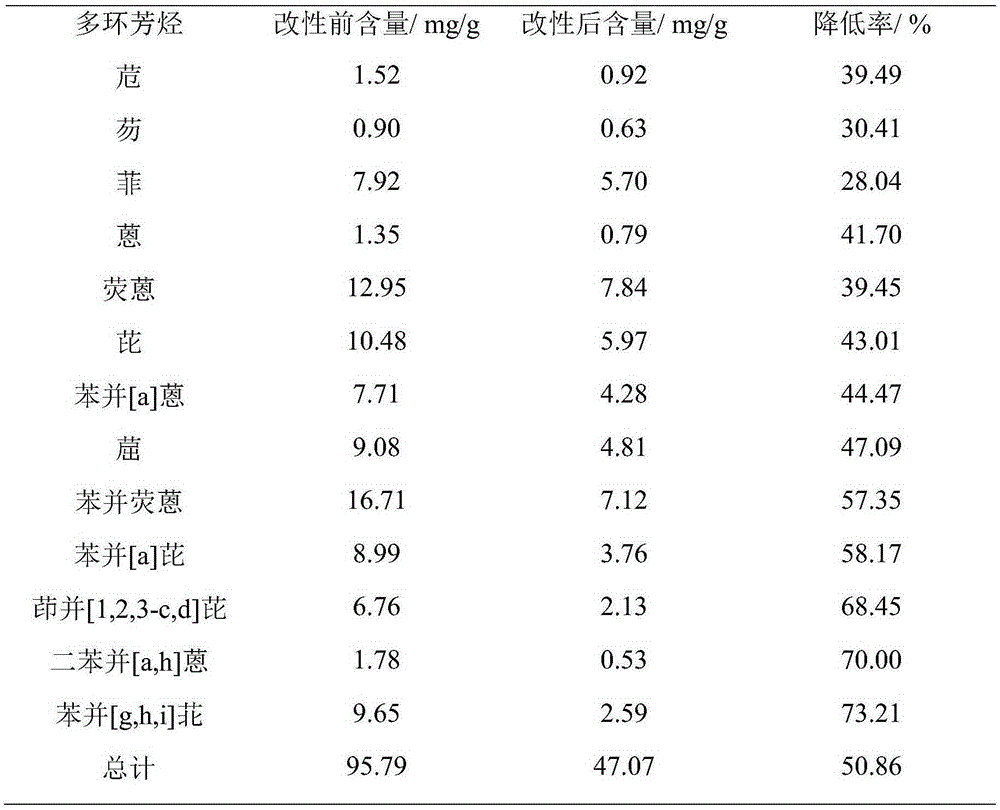

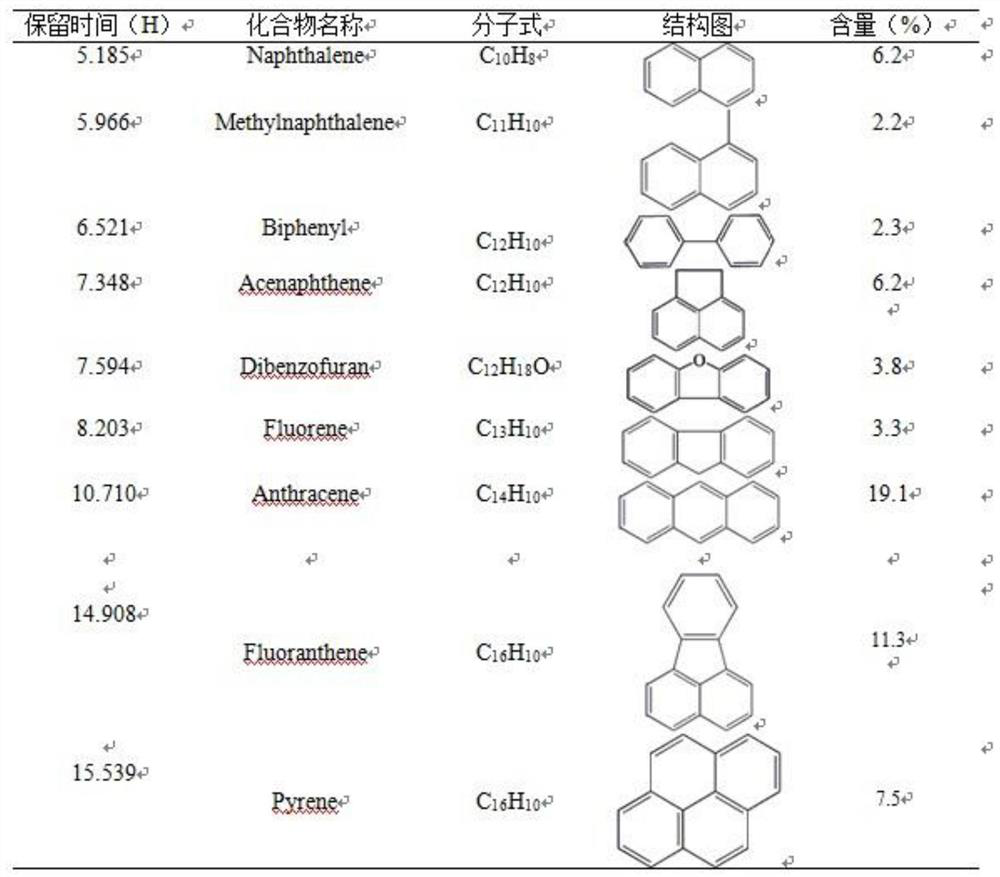

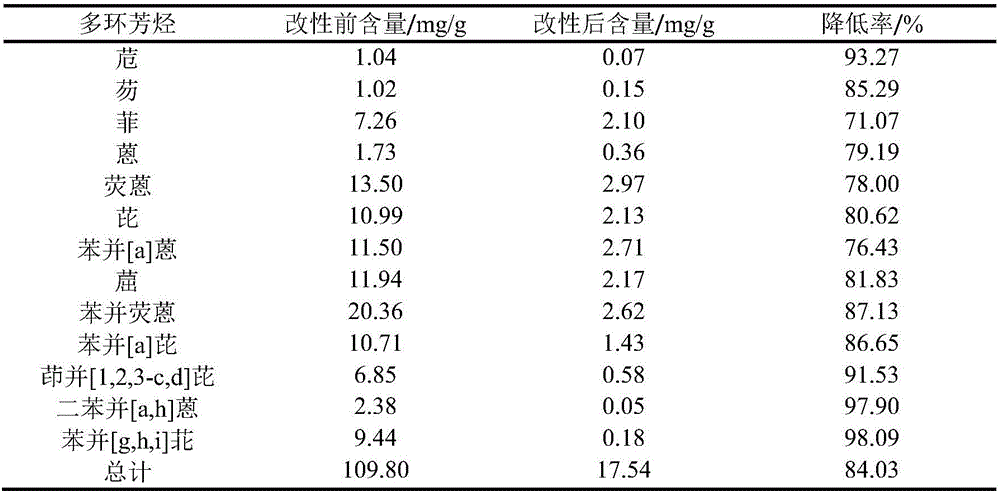

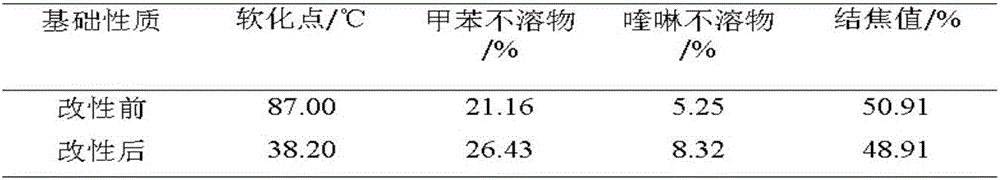

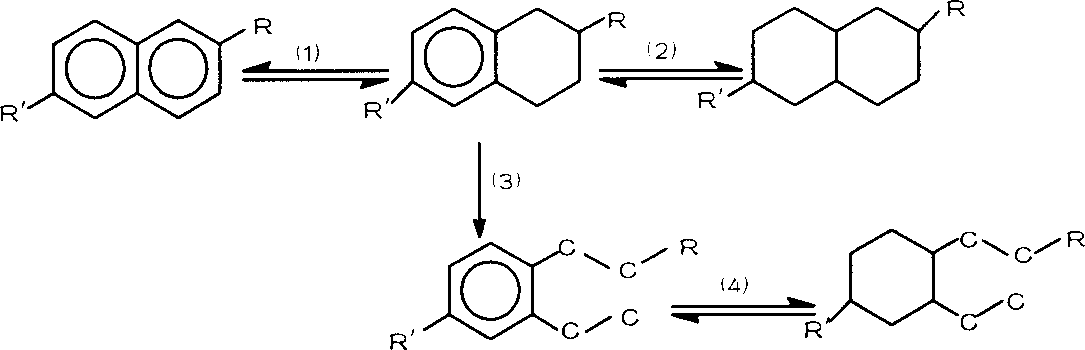

Method for reducing content of polycyclic aromatic hydrocarbons in coal tar pitch

ActiveCN104194357AReduce PAH contentLow modification costBuilding insulationsPolycyclic aromatic hydrocarbonCarcinogen

The invention discloses a method for reducing the content of polycyclic aromatic hydrocarbons in coal tar pitch. The method comprises the following steps: adding a potassium hypermanganate modifier into distilled water, and uniformly mixing to obtain a potassium hypermanganate solution; fully freezing original coal tar pitch at the brittleness temperature, grinding and screening to obtain coal tar pitch powder with the particle size of less than 80 meshes, adding the coal tar pitch powder into the prepared potassium hypermanganate solution at the normal temperature, and stirring at a constant speed for reaction at the room temperature to obtain modified coal tar pitch. The method is carried out at the normal temperature; the content of high-activity carcinogens, namely polycyclic aromatic hydrocarbon substances in the obtained modified coal tar pitch is greatly reduced; moreover, the process is simple to carry out, saves energy, reduces consumption, cannot cause secondary pollution and is easy for industrialized production.

Owner:TAIYUAN UNIV OF TECH

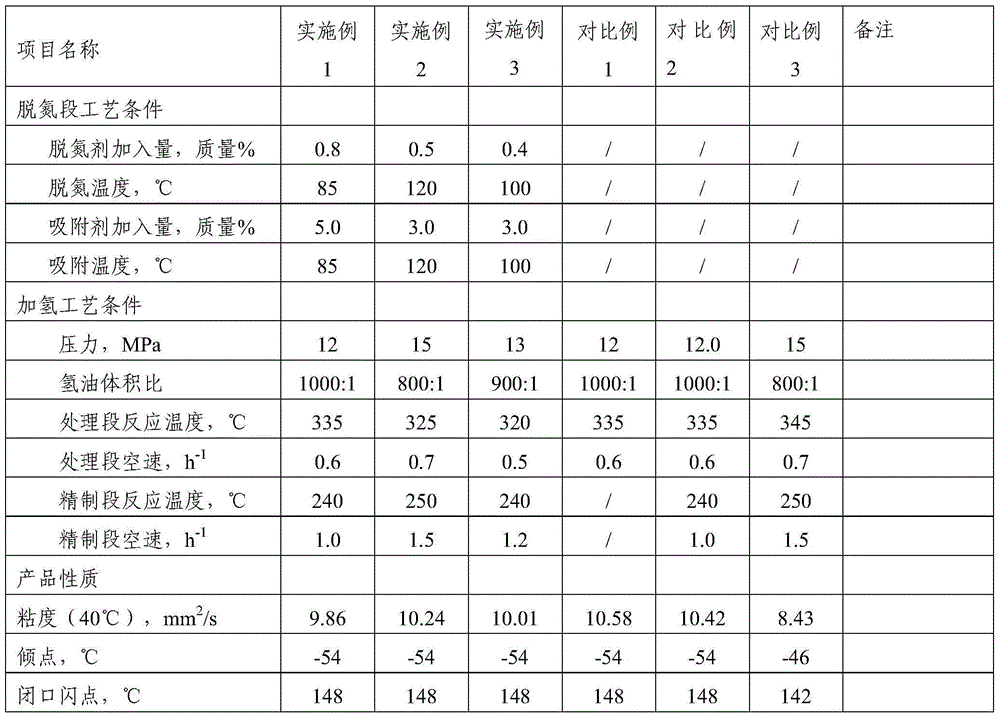

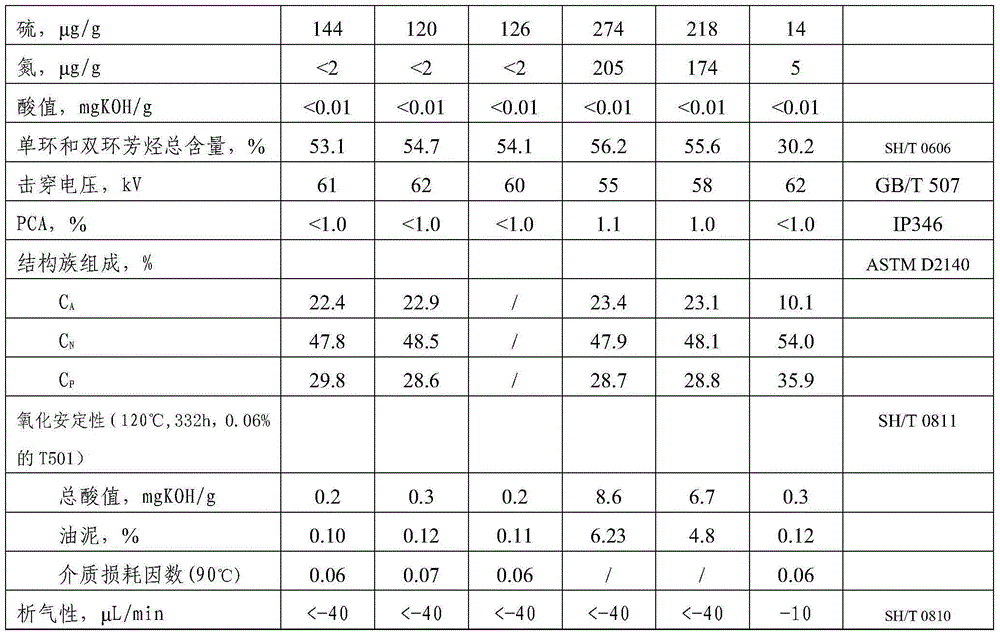

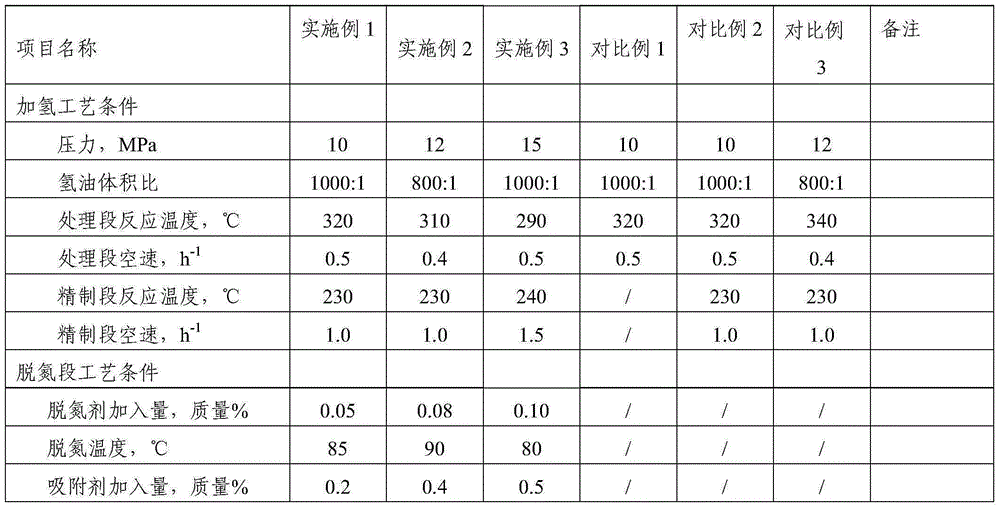

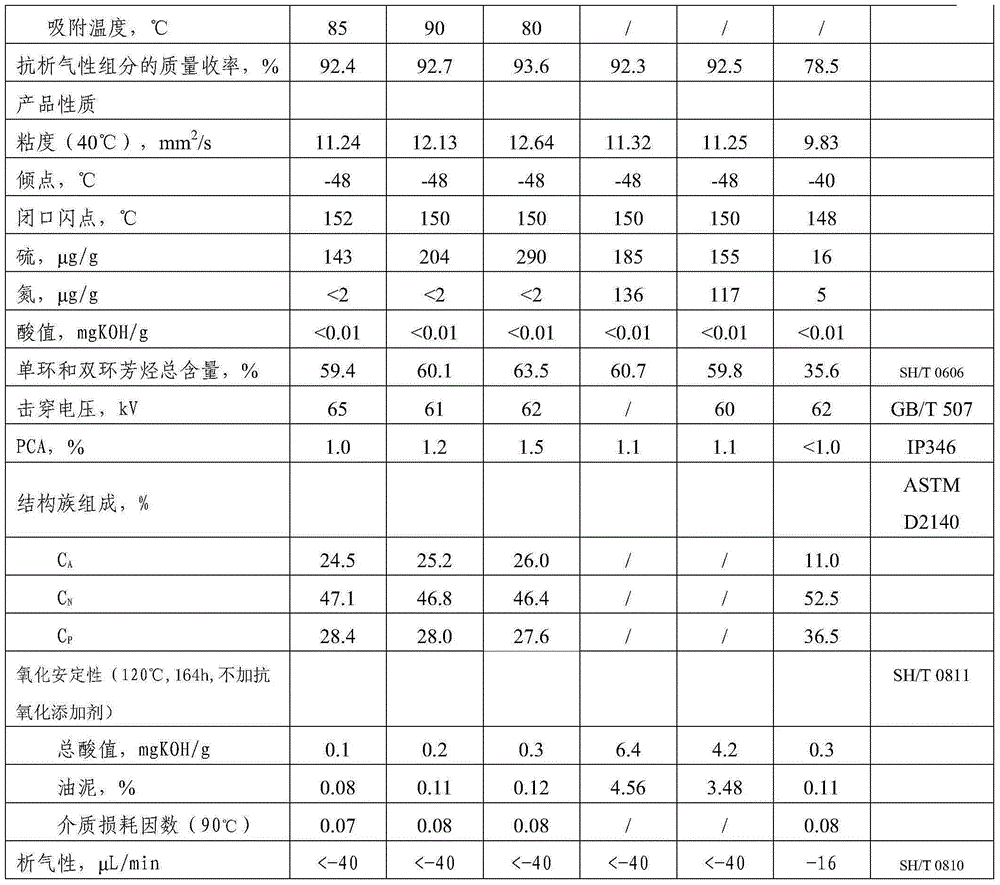

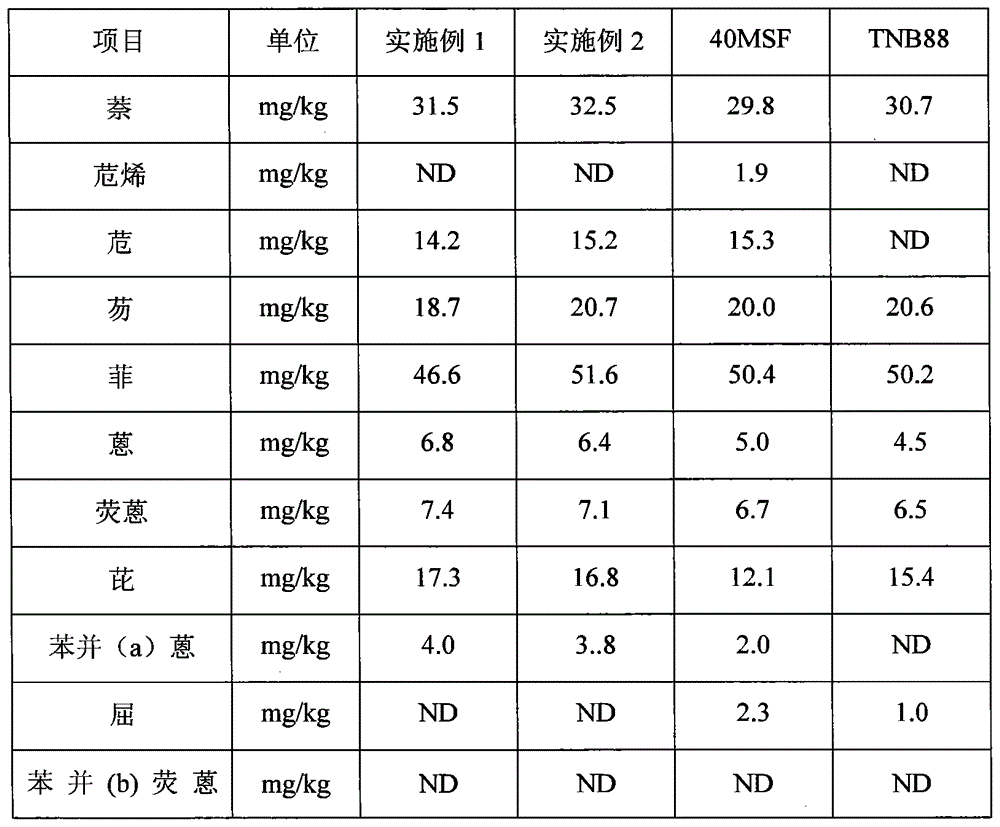

Transformer oil gassing-resistant additive and preparation method thereof

ActiveCN104862006AReduce sulfur contentReduce nitrogen contentTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonSulfur

The invention provides a transformer oil gassing-resistant additive and a preparation method thereof. The preparation method comprises steps as follows: extract oil refined by a naphthenic base transformer oil fraction solvent is taken as a raw material and is sequentially subjected to liquid phase denitrification processing and adsorption refining to obtain denitrified and refined oil; the denitrified and refined oil is subjected to hydroprocessing-hydrofinishing processing to obtain hydrofinished oil, the hydrofinished oil is redistilled, and distillate at the temperature higher than 280 DEG C is collected to obtain the transformer oil gassing-resistant additive. According to the method, the extract oil refined by the naphthenic base transformer oil fraction solvent with low additional value is taken as the raw material to prepare the transformer oil gassing-resistant additive with high additional value, and the transformer oil gassing-resistant additive has the characteristics of high content of monocyclic and dicyclic aromatic hydrocarbon, excellent gassing resistance, extremely low content of sulfur, nitrogen and polycyclic aromatic hydrocarbon, extremely low acid value and excellent oxidation stability and can be used in a blending component of high-grade transformer oil.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Transformer oil antigassing additive and preparation method thereof

ActiveCN104910959AHigh content of monocyclic and bicyclic aromaticsExcellent anti-gassing performanceTreatment with hydrotreatment processesSolvent refiningOxidation stability

The invention provides a transformer oil antigassing additive and a preparation method thereof. According to the invention, extract oil obtained by solvent refining of a cycloalkyl transformer oil fraction is adopted as a raw material, and is subjected to hydrotreating-hydrofinishing, such that hydrofinished oil is obtained; the oil is distilled; a fraction at the temperature higher than 280 DEG C is collected; and the fraction is subjected to liquid-phase denitrification treatment and then the fraction obtained after liquid-phase denitrification treatment is subjected to adsorption refining, such that the additive is obtained. With the method, the transformer oil antigassing additive with a high added value is obtained. The additive has the characteristics of high monocyclic and bicyclic aromatic hydrocarbon content, excellent antigassing performance, low sulfur content, low nitrogen content, low acid value, low polycyclic aromatic hydrocarbon content, and excellent oxidation stability. The additive can be used in a blending component of high-grade transformer oil.

Owner:CHINA NAT OFFSHORE OIL CORP +3

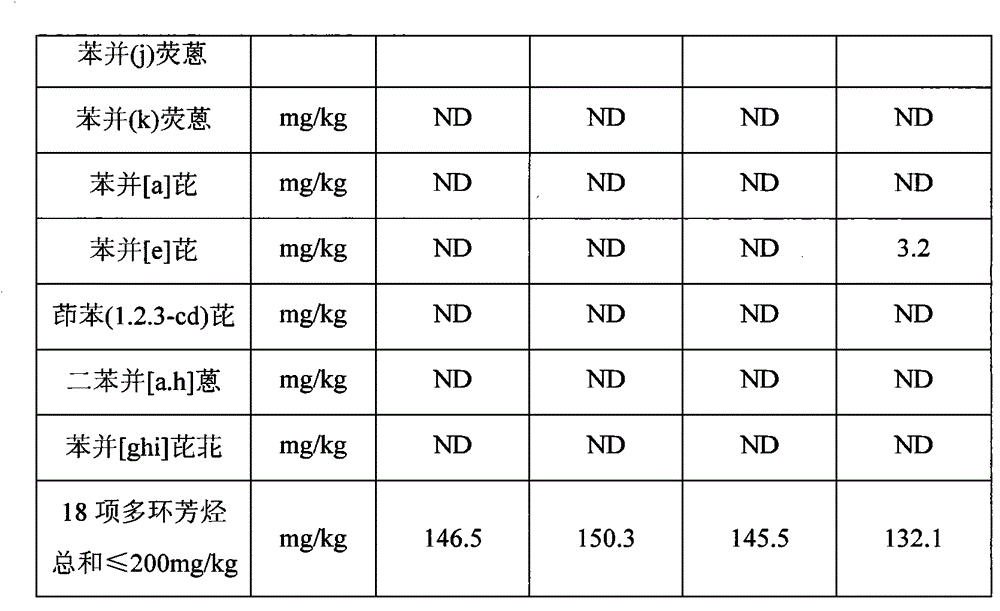

Environmental-friendly rubber homogenizing agent and preparation method thereof

ActiveCN104312084AHigh softening pointReduce carcinogensWorking-up pitch/asphalt/bitumen by chemical meansBuilding insulationsEnvironmental resistancePolycyclic aromatic hydrocarbon

The invention relates to an environmental-friendly rubber homogenizing agent. The environmental-friendly rubber homogenizing agent is prepared from the following components in parts by weight: 70-90 parts of modified petroleum asphalt, 10-30 parts of carbon-hydrogen resin and 1.5-2 parts of p-toluene sulphonic acid, wherein the modified petroleum asphalt is prepared from the following components in parts by weight: 70-90 parts of petroleum asphalt, 1.5-2 parts of phosphoric acid and 10-25 parts of a modifier. The environmental-friendly rubber homogenizing agent has the beneficial effects that comprehensively considering from environmental protection property and using property of a product, at higher temperature, air, the modifier and asphalt component generate chemical reaction in the uniformly mixing process by utilizing oxidation of the air and chemical modification of the modifier, and then the amount of polycyclic aromatic hydrocarbons carcinogen is reduced when the amount of softening point of asphalt is remarkably increased; selected formula system and preparation method can reach good effect, and the acquired homogenizing agent is low in polycyclic aromatic hydrocarbons content and accords with the requirement of European Union REACH Regulations; meanwhile, with the adoption of the environmental-friendly rubber homogenizing agent, blending uniformity of rubber can be remarkably improved, mixing quality is improved, and energy is saved, thus increasing technical content and added value of the product.

Owner:QINGDAO LINK OIL PROD

Production method of pigment carbon black applied to coating

InactiveCN109370267AQuality improvementImprove qualityPigmenting treatmentCoatingsAir preheaterCombustion chamber

The invention provides a production method of pigment carbon black applied to coating. A production technology of carbon black through an oil-gas furnace method specifically comprises the following steps: after filtering air, compressing the air through a Roots blower until the pressure is 0.16 to 0.19Mpa; heating to 700 to 750 DEG C through a high-temperature air pre-heater at 800 DEG C, and thenconveying the air into a combustion chamber; axially conveying natural gas with the flow of 400Nm<3> / h and the pressure of 75kpa into the combustion chamber to be mixed with hot air with the flow of5500Nm<3> / h; then sufficiently combusting and controlling the temperature of the combustion chamber to be 1850 to 1950 DEG C; enabling hot flue gas obtained by combustion to flow through a throat section of a reaction furnace at a high speed; spraying raw oil which is mixed with 20kg / h of an additive and has the flow of 1650kg / h into high-temperature flue gas from the throat section and carrying out cracking and polymerization reaction under the pressure of 65Kpa to generate the carbon black; finally, after sieving through a sieving machine with the size of 35 to 80 meshes, conveying a productinto a finished-product storage tank; and packaging to obtain the pigment carbon black. In a continuous production process, the quality of the carbon black is stable; and technical means including the raw oil, the high-temperature flue gas, temperature, pressure, ozone introduction and the like is combined to improve the quality of the pigment carbon black for the coating.

Owner:WUHAI BLACK CAT CARBON BLACK

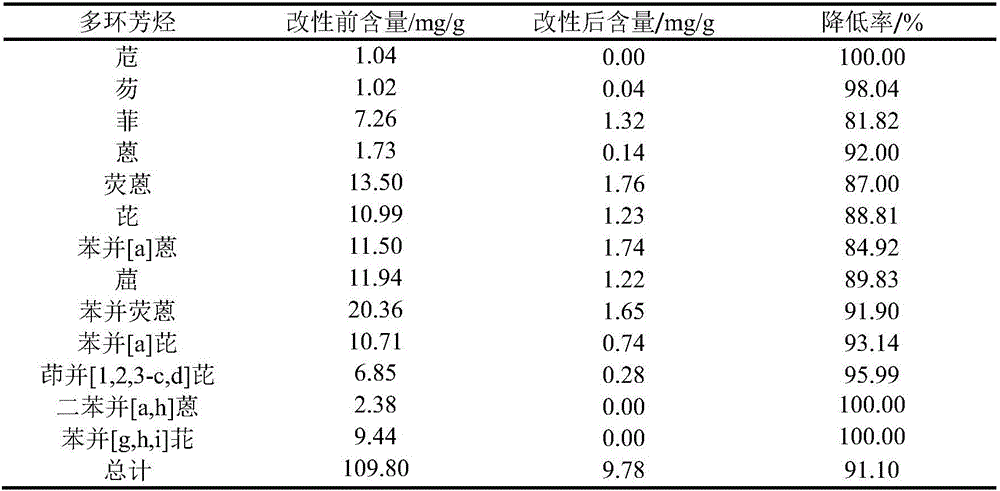

Method for preparing low-toxicity modified coal pitch for road building

ActiveCN105238429ABroaden the range of sourcesEasy to operateWorking-up pitch/asphalt/bitumen by chemical meansPolycyclic aromatic hydrocarbonDistillation

A method for preparing low-toxicity modified coal pitch for road building includes the steps that coal-tar pitch, terephthalaldehyde modifiers, p-toluenesulfonic acid catalysts and a cyclohexane solvent are fully dissolved, dispersed and continuously stirred for reaction; then, the cyclohexane solvent is recycled through pressure reduction distillation to obtain a coal pitch mixture, and the low-toxicity modified coal pitch for road building is prepared after vacuum drying. The method is simple in technology, low in modification temperature and little in modifier use amount, the solvent can be recycled, the content of 16 toxic polycyclic aromatic hydrocarbons detected by EPA in the modified coal pitch is greatly reduced, and the high-temperature coal pitch is modified into medium-temperature coal pitch.

Owner:TAIYUAN UNIV OF TECH

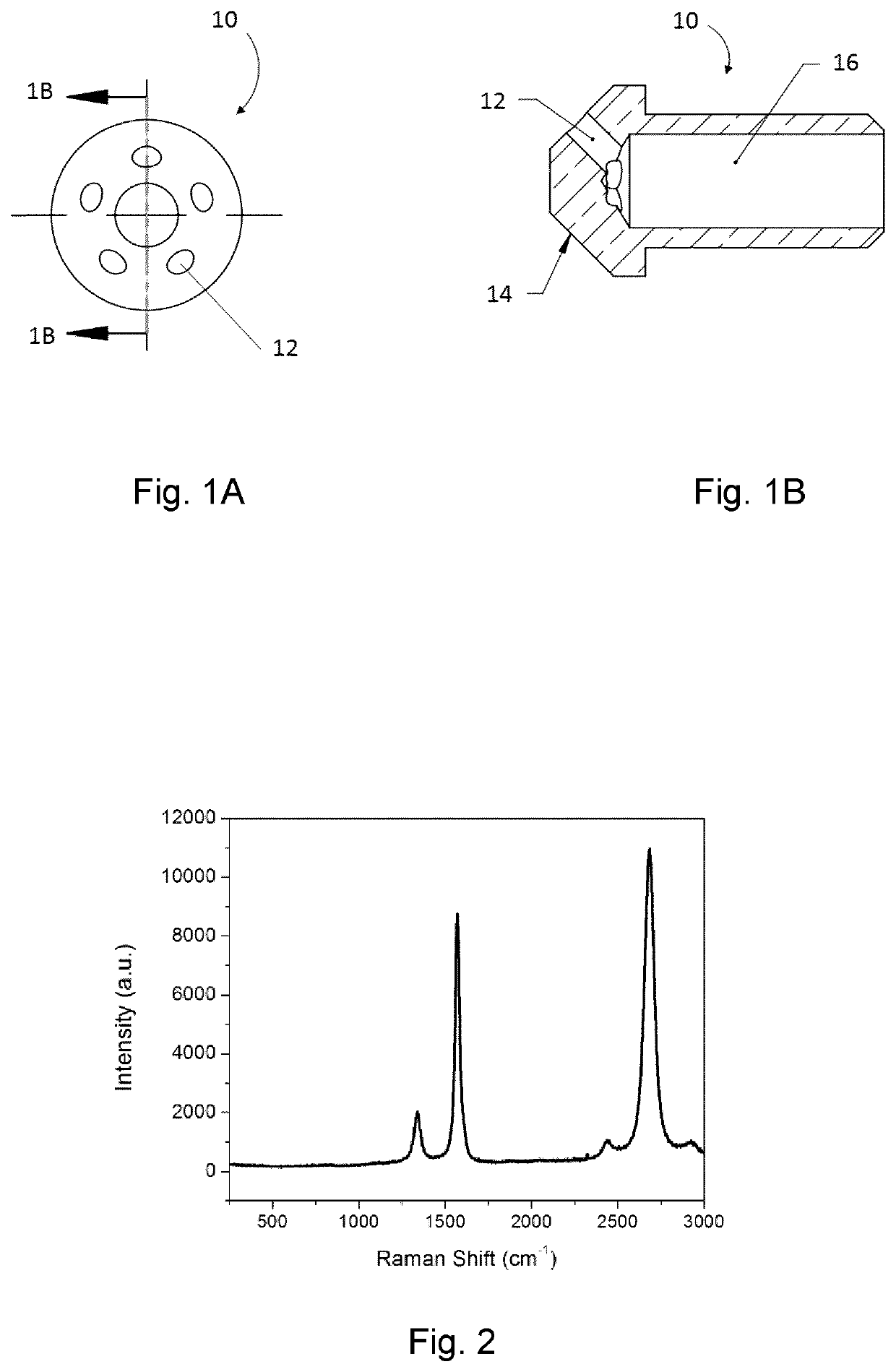

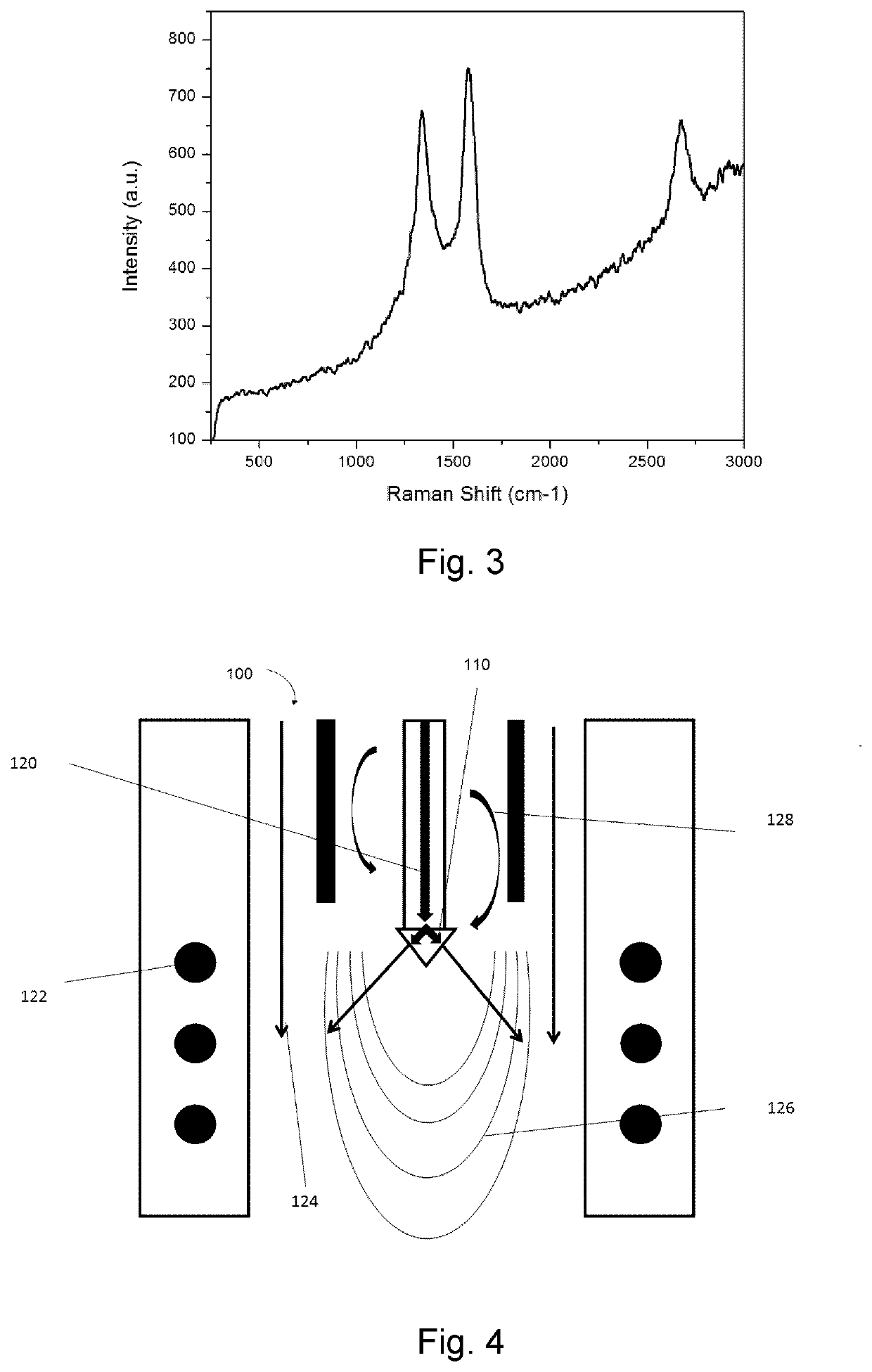

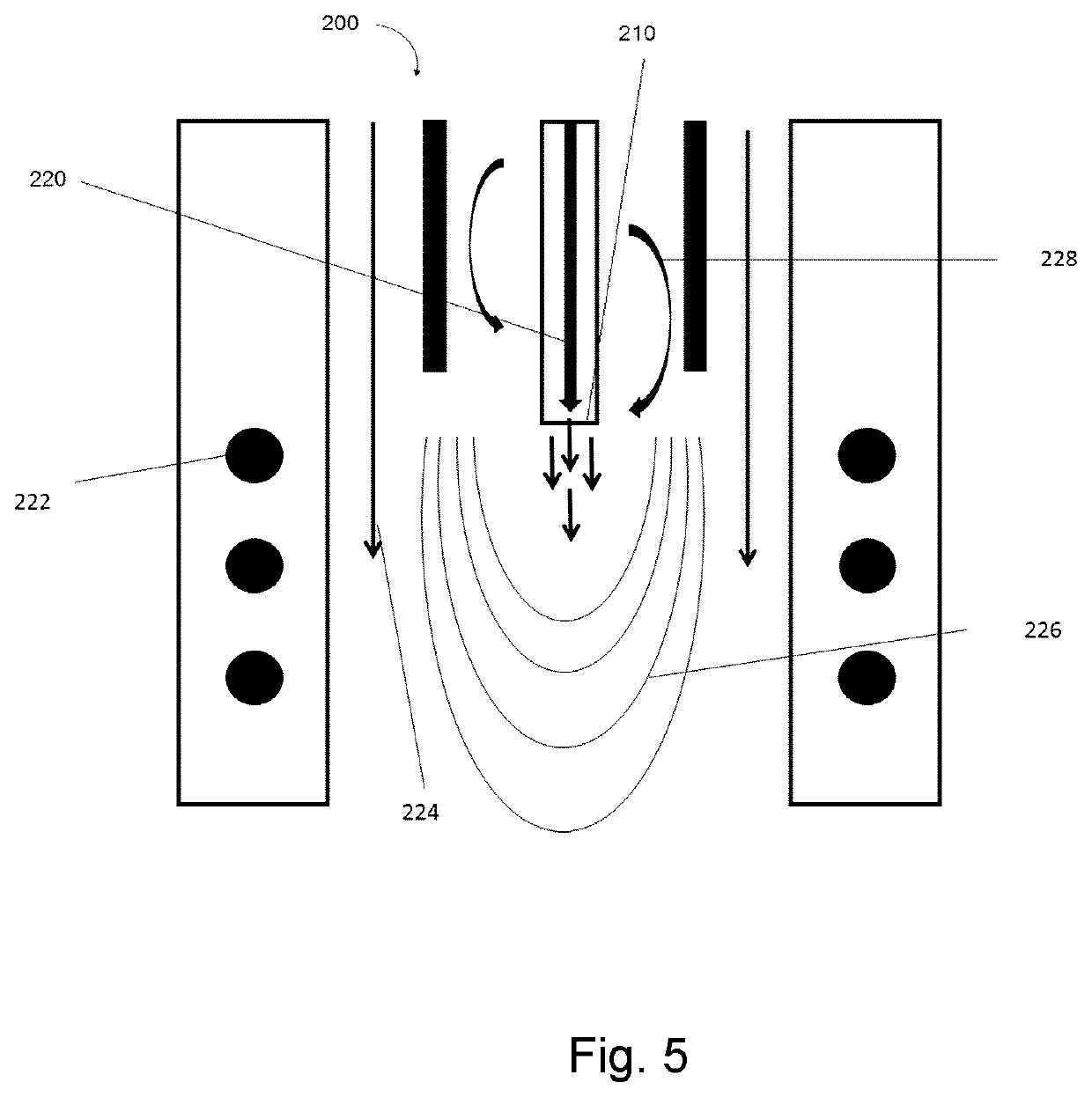

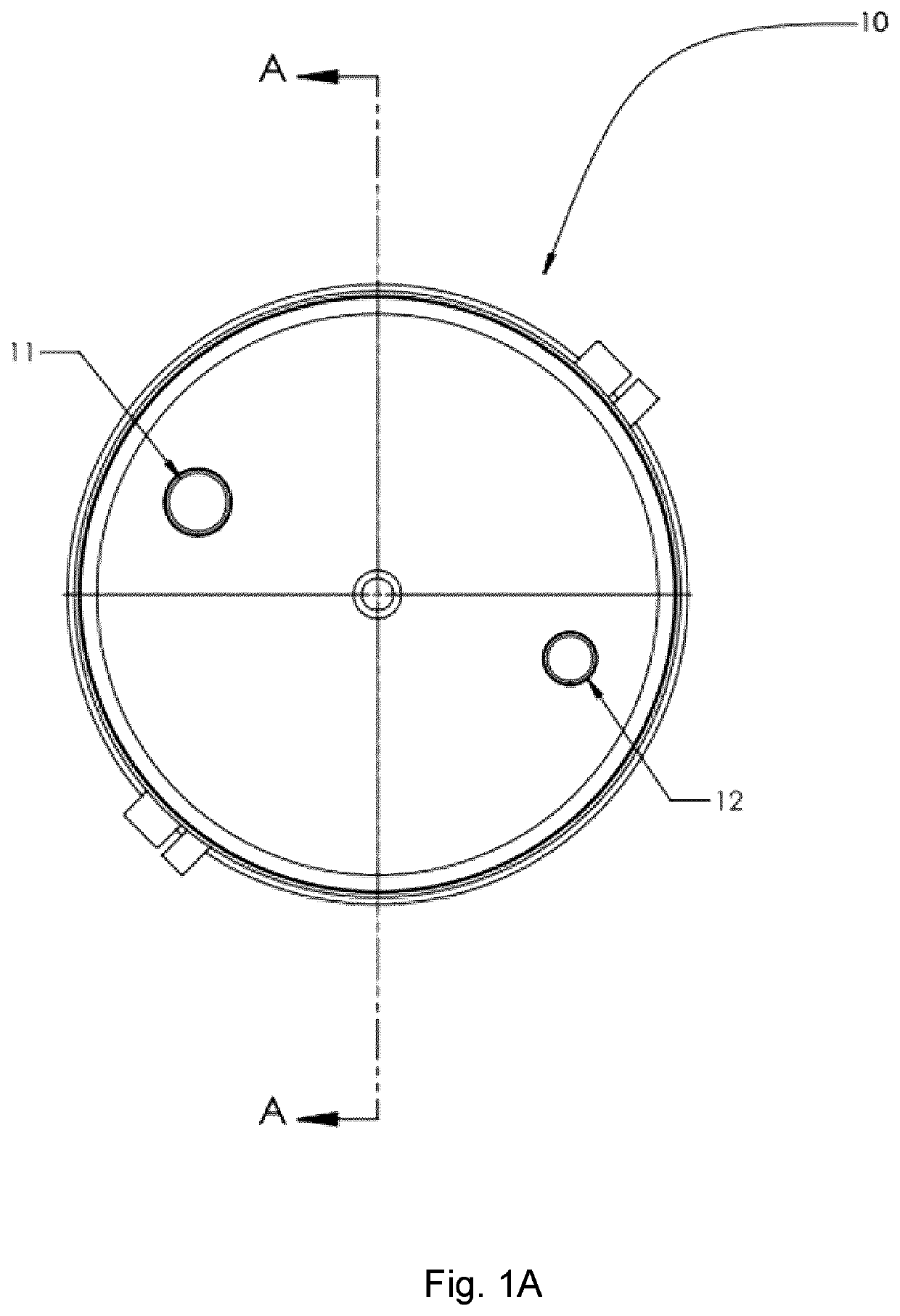

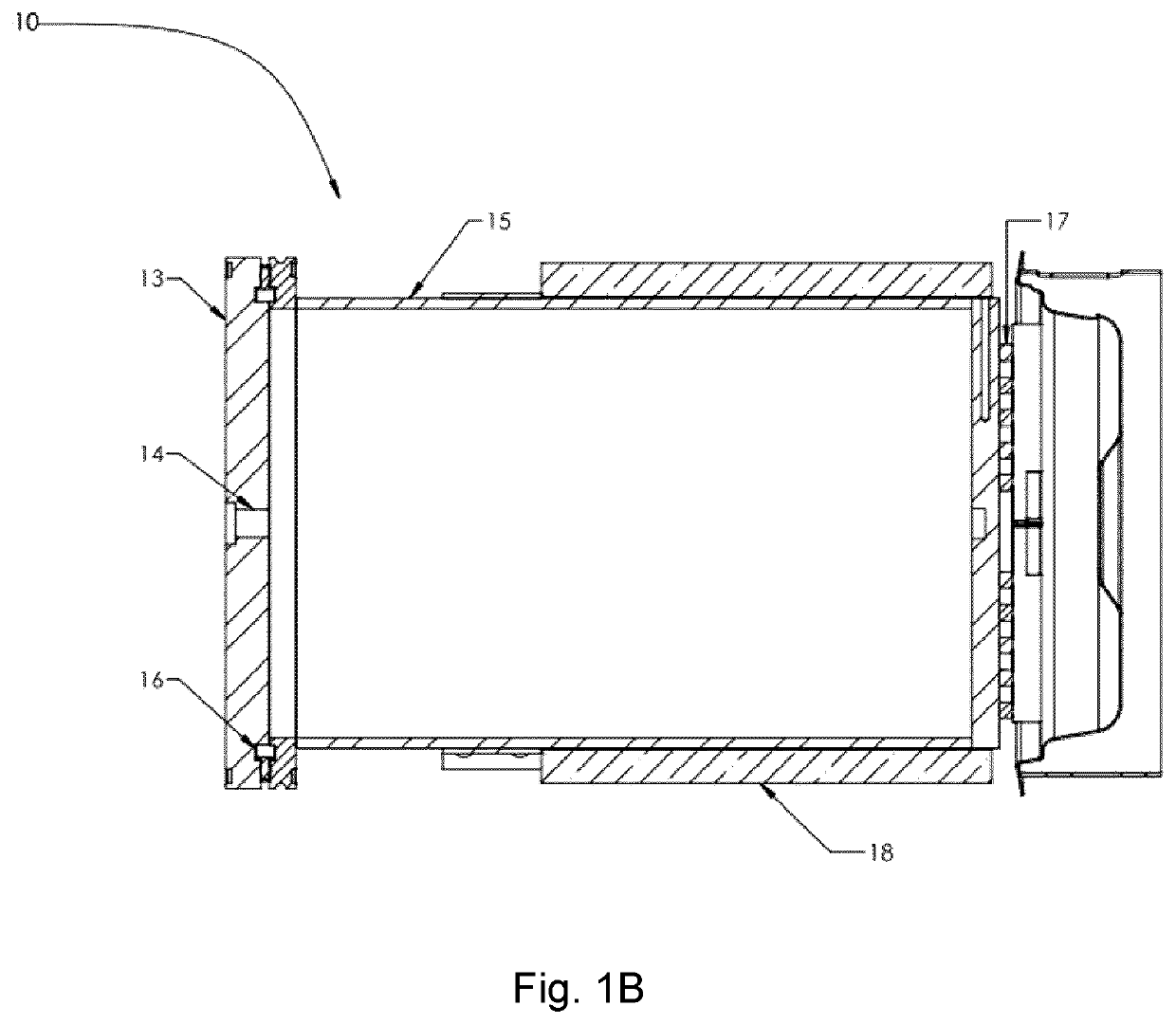

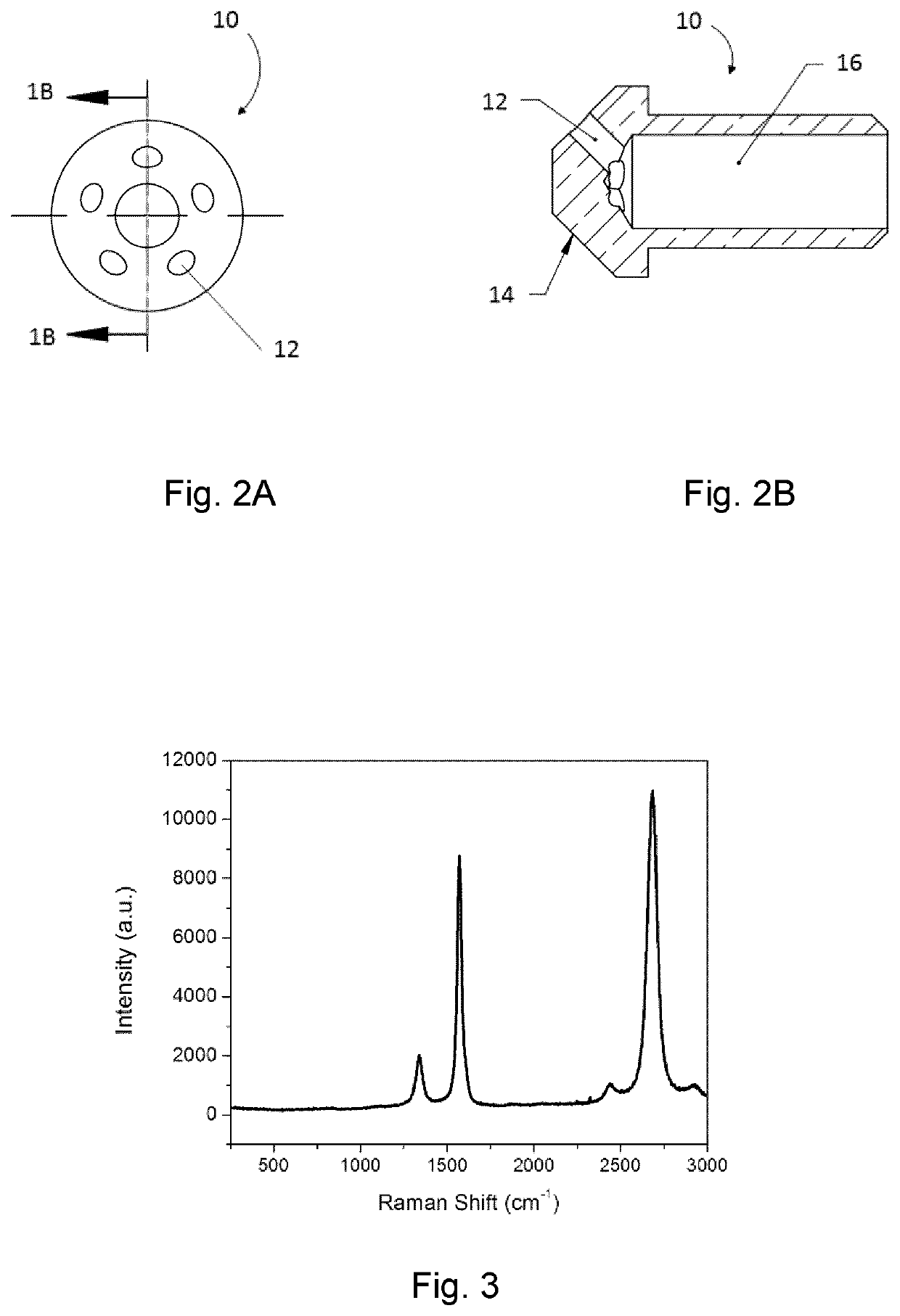

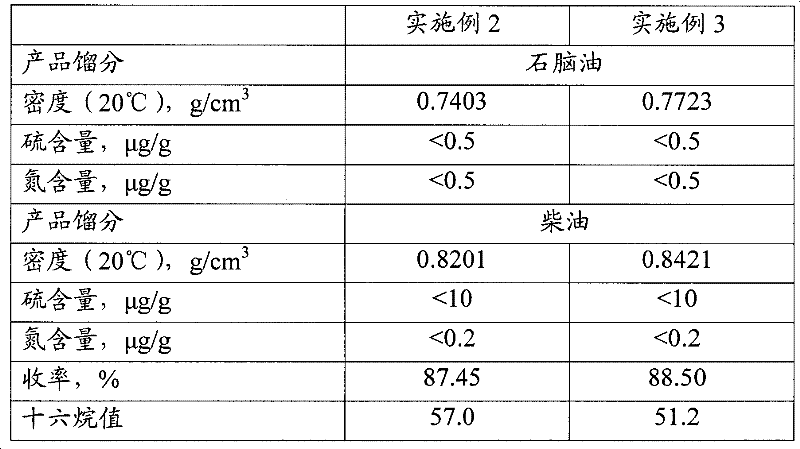

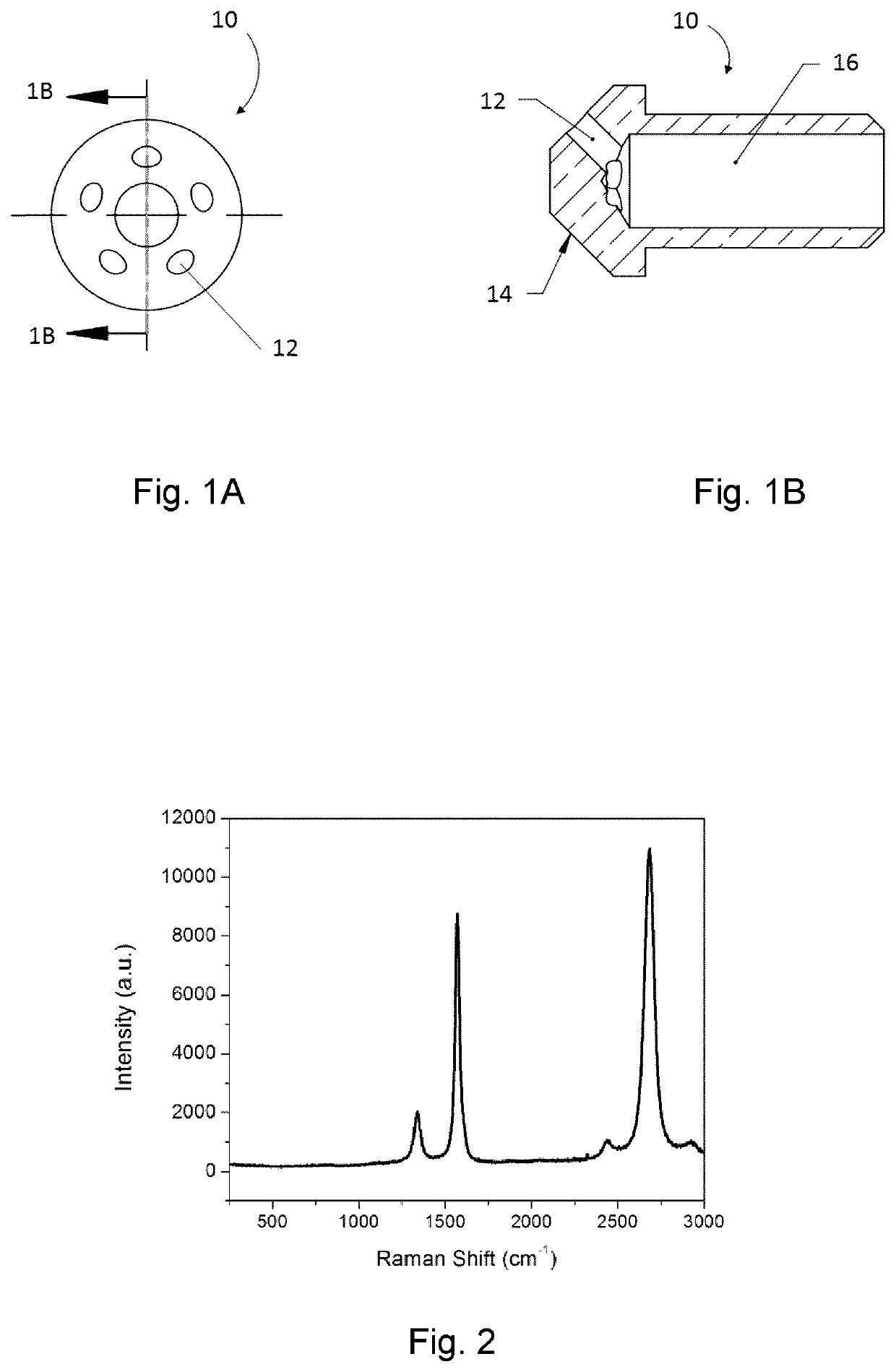

Plasma processes for producing graphene nanosheets

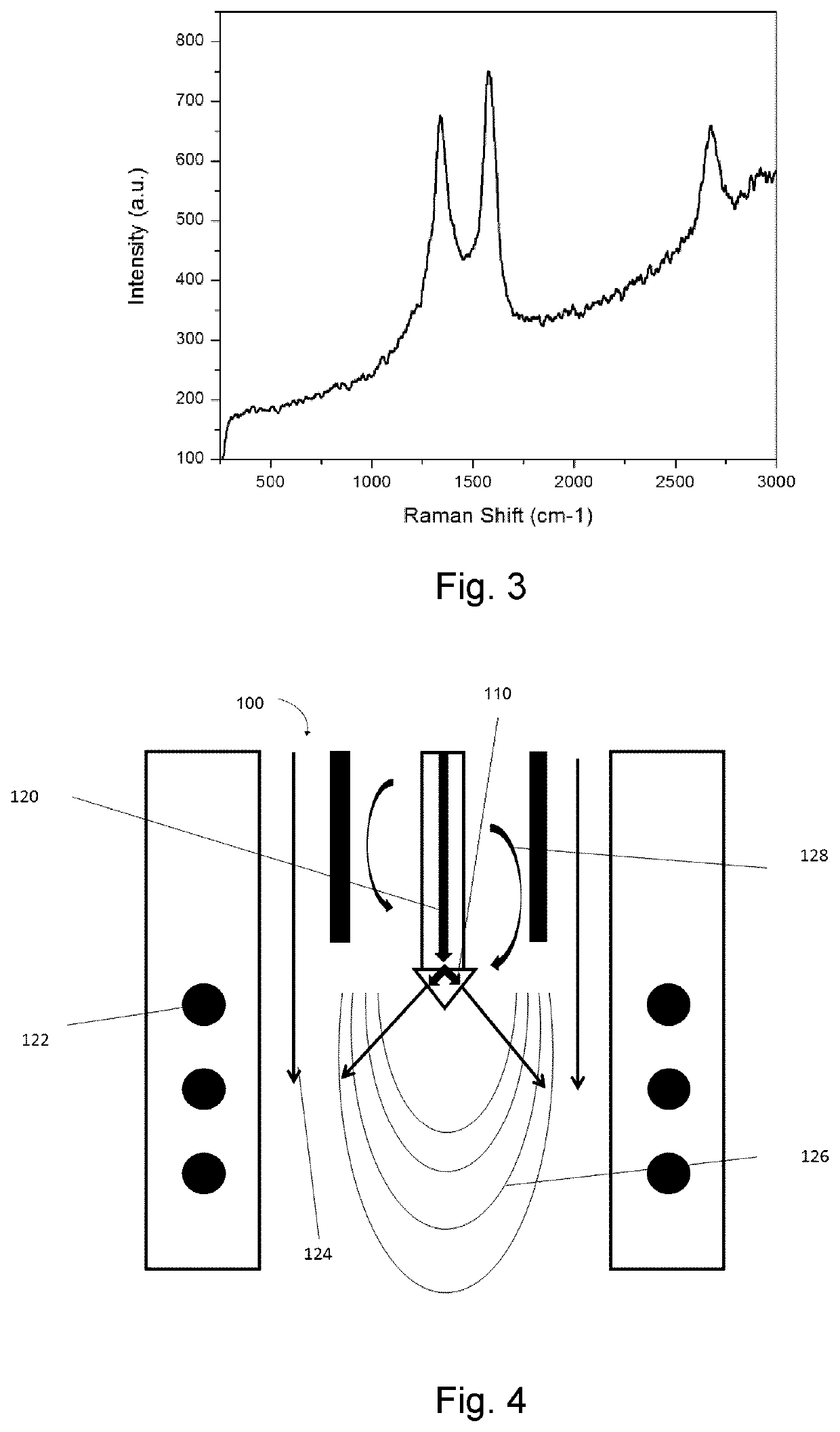

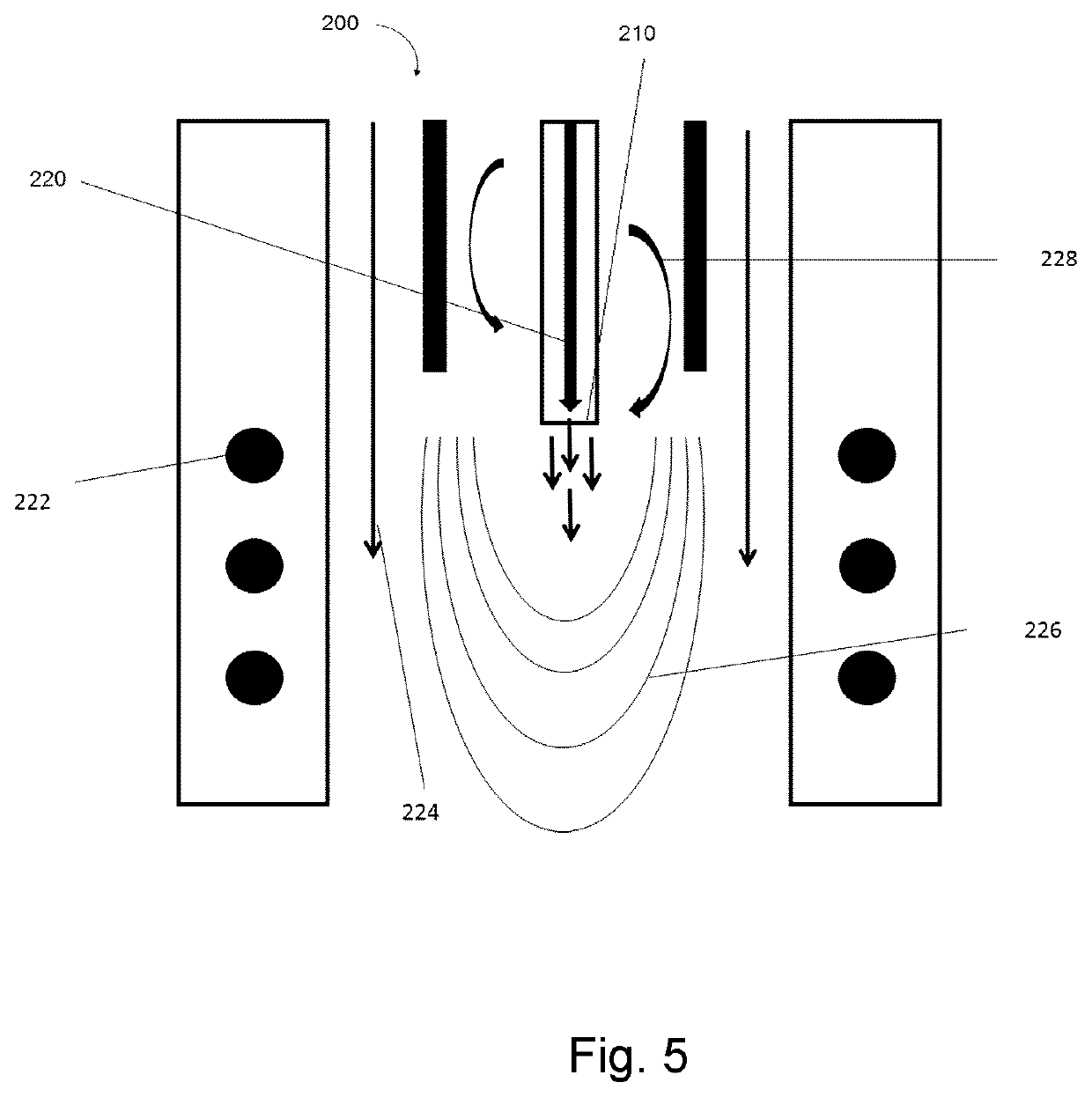

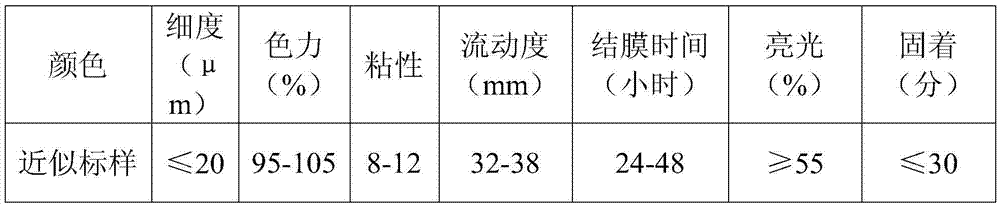

ActiveUS20200223698A1Safe handlingImprove productivityMaterial nanotechnologyGrapheneChemical physicsPhysical chemistry

Provided are plasma processes for producing graphene nanosheets comprising injecting into a thermal zone of a plasma a carbon-containing substance at a velocity of at least 60 m / s standard temperature and pressure STP to nucleate the graphene nano sheets, and quenching the graphene nanosheets with a quench gas of no more than 1000° C. The injecting of the carbon-containing substance may be carried out using a plurality of jets. The graphene nanosheets may have a Raman G / D ratio greater than or equal to 3 and a 2D / G ratio greater than or equal to 0.8, as measured using an incident laser wavelength of 514 nm. The graphene nanosheets may be produced at a rate of at least 80 g / h. The graphene nanosheets can have a polyaromatic hydrocarbon concentration of less than about 0.7% by weight.

Owner:RAYMOR IND INC

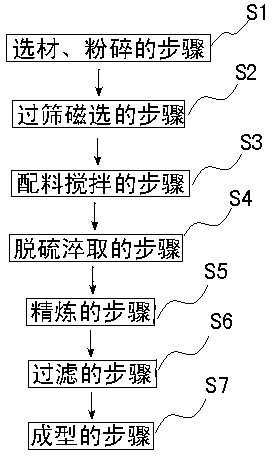

Production method and combination material formula of environment-friendly high-strength reclaimed butyl rubber

InactiveCN103275348AGuaranteed qualityReduce PAH contentPlastic recyclingChemical recyclingChemistryNational standard

The invention discloses a production method of environment-friendly high-strength reclaimed butyl rubber, which comprises the following steps: selecting good quality waste butyl rubber inner tube, and crushing into sheets; screening and magnetic separation; adding environment-friendly rubber softener and reinforcing agent for stirring so as to form a composition material; desulfuration and extraction; refining; filtering; and forming. According to the invention, the reclaimed butyl rubber is ensured in quality as good quality butyl rubber material is selected; the reclaimed butyl rubber conforms to requirements of environment-friendly laws and regulations of European Union as no contaminative rubber softener is added during the regeneration process, and also extracting process is added for extracting original rubber aromatic oil. The invention also discloses a composition material formula of the reclaimed butyl rubber. According to the invention, through improving formula processes and finely selecting raw materials, the tensile strength of the produced reclaimed butyl rubber is kept in the range of 8.5-9.5 MPa which is far higher than the national standard of being larger than or equal to 6.8 MPa.

Owner:NANTONG HUILI RUBBER +1

Combined remediation method of polycyclic aromatic hydrocarbon polluted soil

ActiveCN104492795ASimple stepsReduce PAH contentContaminated soil reclamationSubtilisinPolycyclic aromatic hydrocarbon

The invention belongs to the field of soil remediation, and discloses a combined restoration method of polycyclic aromatic hydrocarbon polluted soil, which comprises the following steps: (1) putting polycyclic aromatic hydrocarbon polluted soil in a bioreactor, adding water at room temperature, and stirring; (2) adding 5-30U of subtilisin to every gram soil of into the bioreactor, and stirring at 30 rpm; (3) while stirring, adding sodium palmitate and methyl palmitate into the bioreactor, and continuing stirring, wherein the sodium palmitate accounts for 3.5-5 wt% of the soil, and the methyl palmitate accounts for 0.8-1.6 wt% of the soil; and (4) adding cotton straw powder into the bioreactor (the cotton straw powder accounts for 1.5-4.5 wt%), continuing stirring for 2 hours, standing, separating the soil from water, and drying to obtain the remediated soil.

Owner:JIANGSU GAIYA ENVIRONMENTAL SCI & TECH CO LTD

Preparation method of asphalt material, asphalt material prepared by the same and application thereof

InactiveCN106520166ALow alpha benzopyrene contentReduce PAH contentWorking-up pitch/asphalt/bitumen by chemical meansBuilding insulationsBituminous materialsReaction temperature

The invention discloses a preparation method of an asphalt material, an asphalt material prepared by the method and application thereof. The preparation method comprises: carrying out purging reaction on an aromatic compound-containing raw material under inert gas purging to obtain an asphalt material. Specifically, based on the total mass of the aromatic compound-containing raw material, the flow rate of the inert gas is 0.5-10L / (min.kg), the purging reaction temperature is 380-440DEG C, and the purging reaction time is 1-10h. The asphalt material prepared by the preparation method provided by the invention can be applied to preparation of waterproof materials, anti-corrosion materials, electrode binders and automobile damping materials, and has very excellent environmental protection performance.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

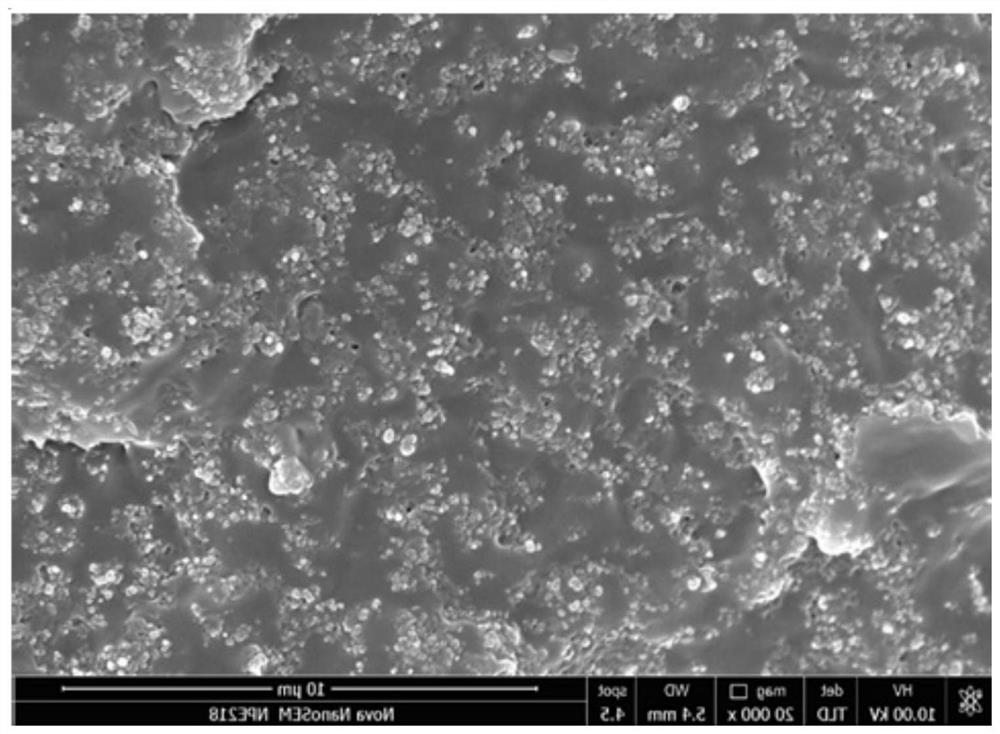

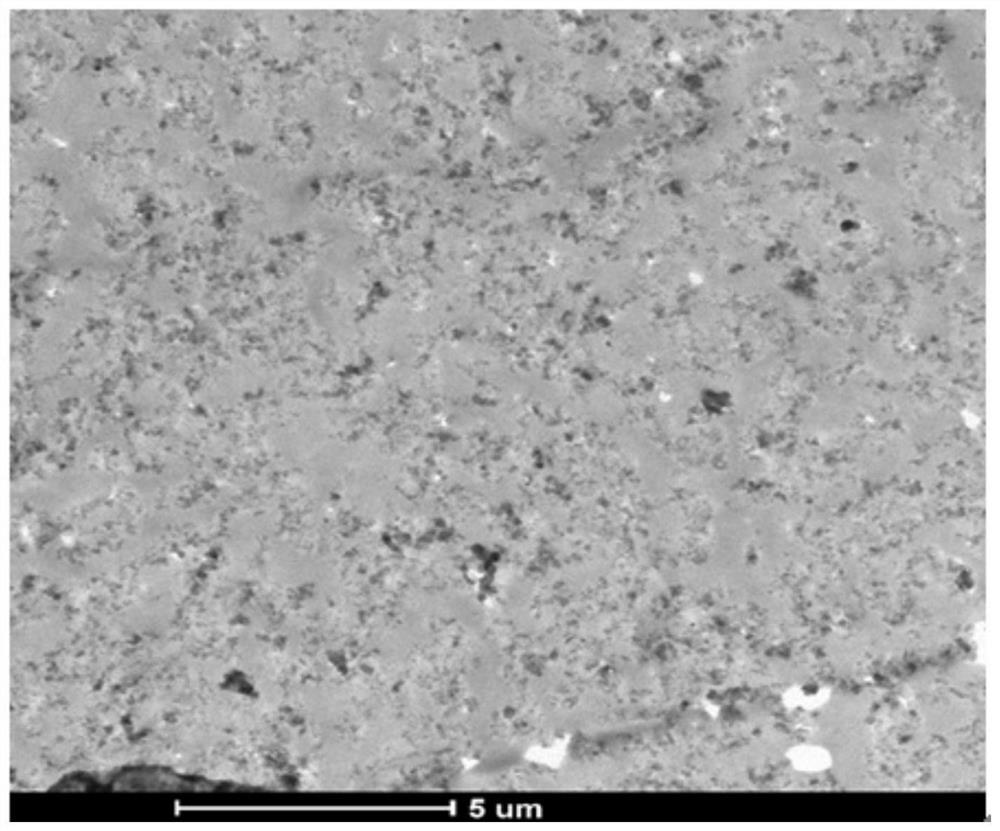

Production method of conductive carbon black for environment-friendly cable shielding material

ActiveCN112322077AHighly structuredModerate structurePigment physical treatmentElectric cablesElectrically conductive

The invention discloses a production method of conductive carbon black for an environment-friendly cable shielding material, and mainly relates to the field of carbon black production. The method comprises the steps of raw material control, raw material pretreatment, carbon black cracking preparation, carbon black collection, binder addition and granulation, carbon black drying and desorption, carbon black refining and volume resistivity test. The preparation method has the beneficial effects that the produced carbon black is good in high temperature resistance, good in electrical property athigh temperature, excellent in high-temperature extrusion property and higher in purity, and the use requirements of the environment-friendly non-crosslinked cable shielding material are fully met.

Owner:山东联科新材料有限公司 +1

Preparation method of environmentally friendly modified coal tar pitch

ActiveCN106336884AImprove performanceThe device is simple and easy to operateWorking-up pitch/asphalt/bitumen by chemical meansSolventCoal Tar Pitches

A preparation method of environmentally friendly modified coal tar pitch comprises the steps that medium-temperature coal tar pitch and a potassium hydrogen sulfate catalyst are mixed evenly, meanwhile an aprotic organic solvent low in boiling point and easy to recover and a 10-undecenal modifier are added to make the mixture fully dissolved, continuous stirring is performed at a certain rotation speed, and reflux condensation reaction is performed at the temperature of 30-70 DEG C for 1-8 hours; after reaction is completed, the aprotic organic solvent low in boiling point and easy to recover is recovered, aeration drying is conducted on the obtain solid substance for 24 hours, namely the environmentally friendly modified coal tar pitch is obtained. The operation process is simple, the usage amount of the modifier is small, the usage amount of the catalyst is also small, the reaction temperature is low, the solvent can be recycled, and the industrial production cost is low. The total content of 16 types of emphasized toxic polycyclic aromatic hydrocarbons, detected by coal tar pitch American EPA, in the coal tar pitch after modification is greatly reduced, and medium-temperature coal tar pitch is modified into low-temperature coal tar pitch.

Owner:TAIYUAN UNIV OF TECH

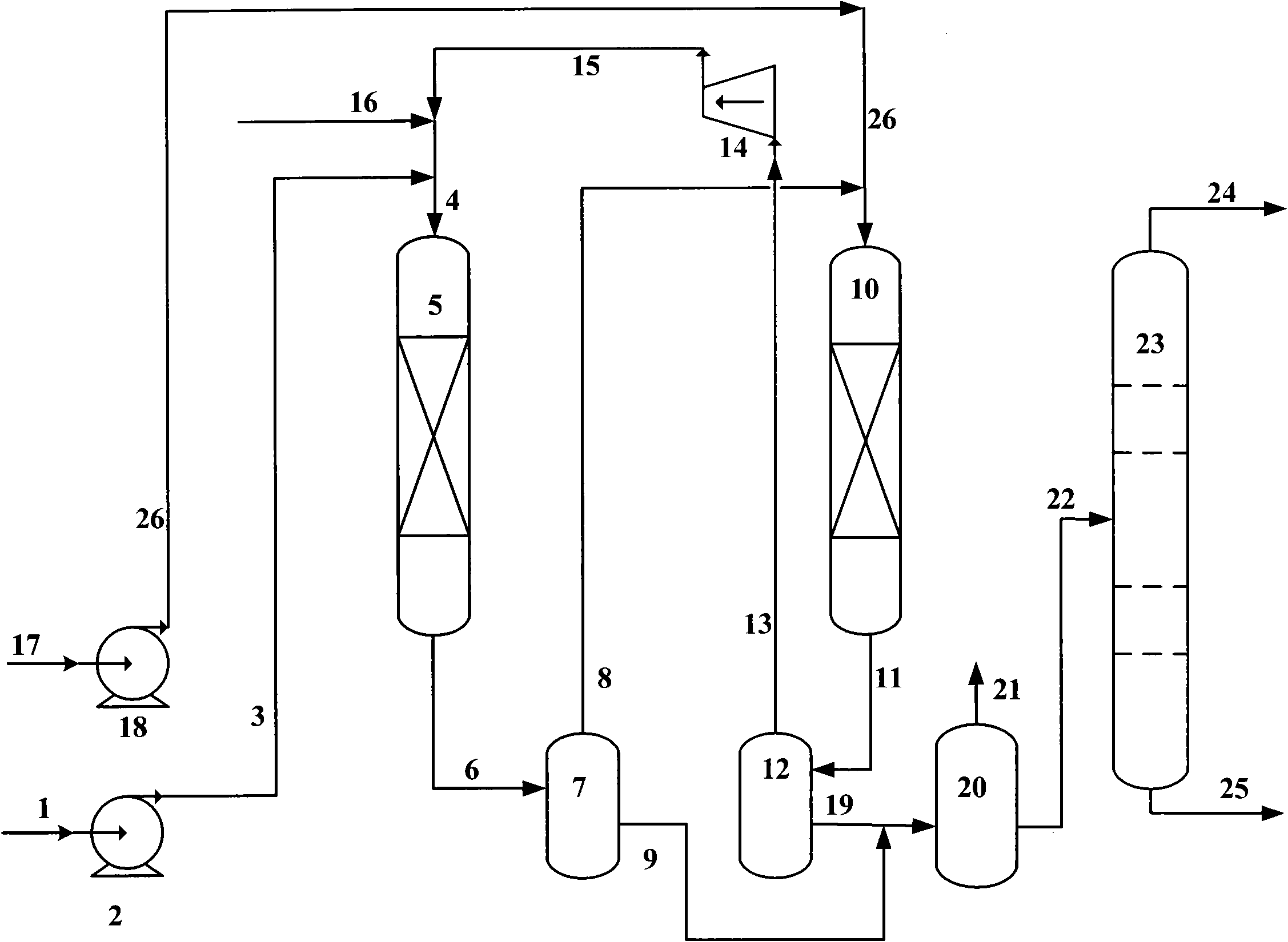

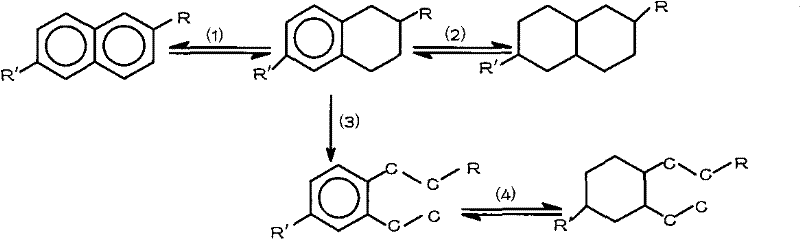

Diesel oil fraction hydrogenating modification process

ActiveCN1986747AIncrease cetane numberReduce PAH contentHydrocarbon oils refiningChemistryBoiling point

The diesel oil fraction hydrogenating modification process includes the contact of the mixture of material oil and hydrogen with the hydrotreating catalyst or the contact of the mixture of material oil and hydrogen with the hydrorefining catalyst and the hydrotreating catalyst successively, cooling and separating the reacted effluent, reusing the hydrogen-rich gas circularly, and fractionating the liquid product in the fractionating system to obtain diesel oil fraction and naphtha fraction. The process makes it possible to process inferior diesel oil fraction with banal boiling point in mild operation condition and can raise the cetane number greatly, lower the content of polycyclic aromatic hydrocarbon, S and N and reduce the density. In addition the process has high volume space velocity, low operation cost and high product yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Graphenic carbon nanoparticles having a low polyaromatic hydrocarbon concentration and processes of making same

Provided are graphene nanosheets having a polyaromatic hydrocarbon concentration of less than about 0.7% by weight and a tap density of less than about 0.08 g / cm3, as measured by ASTM B527-15 standard. The graphene nanosheets also have a specific surface area (B.E.T.) greater than about 250 m2 / g. Also provided are processes for producing graphene nanosheets as well as for removing polyaromatic hydrocarbons from graphene nanosheets, comprising heating said graphene nanosheets under oxidative atmosphere, at a temperature of at least about 200° C.

Owner:RAYMOR IND INC

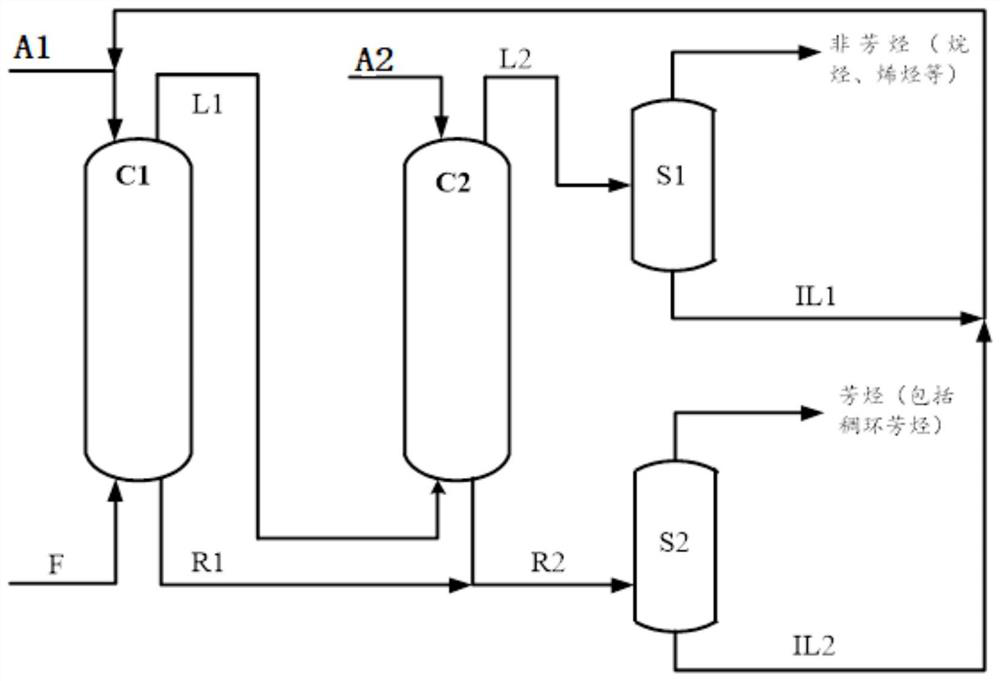

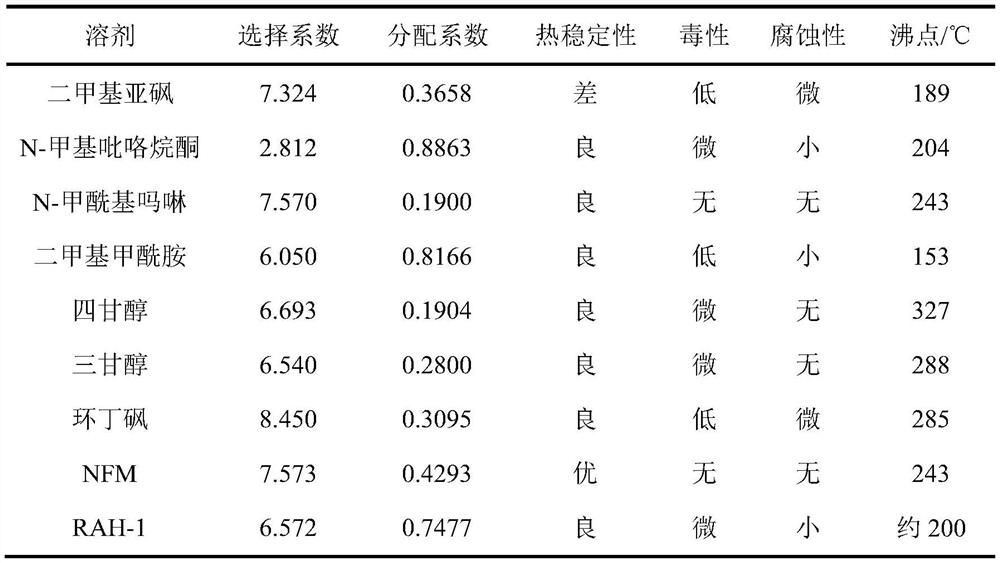

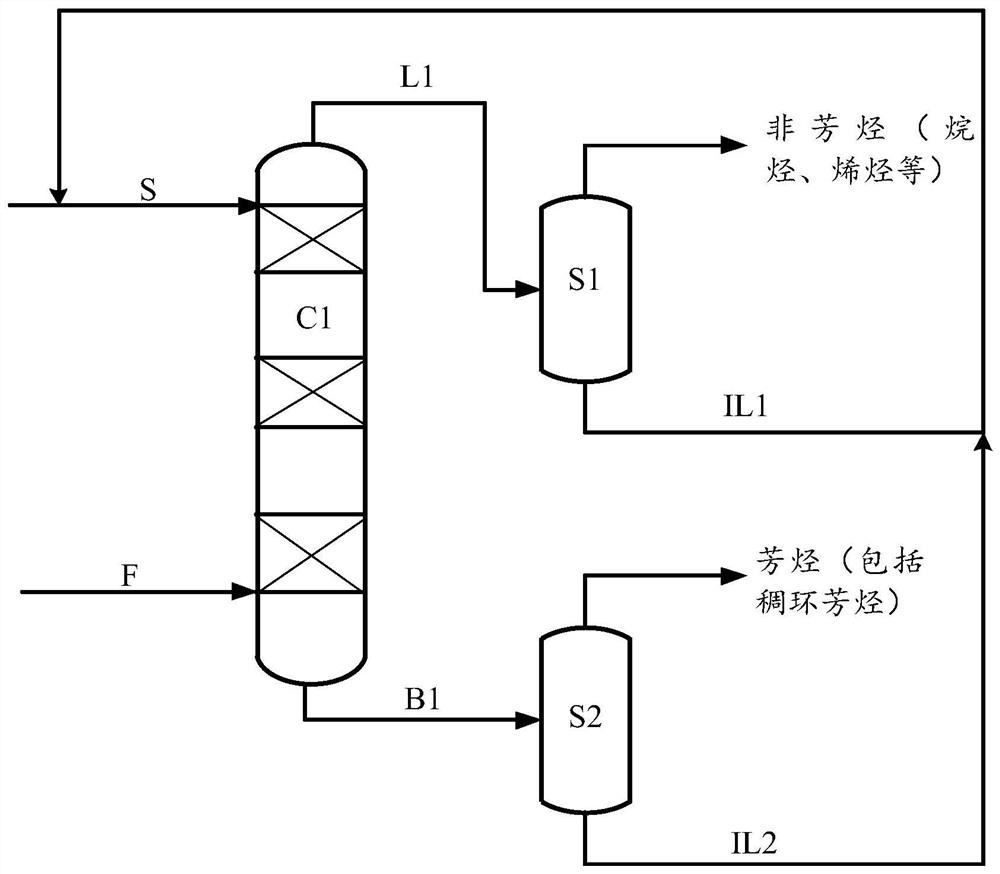

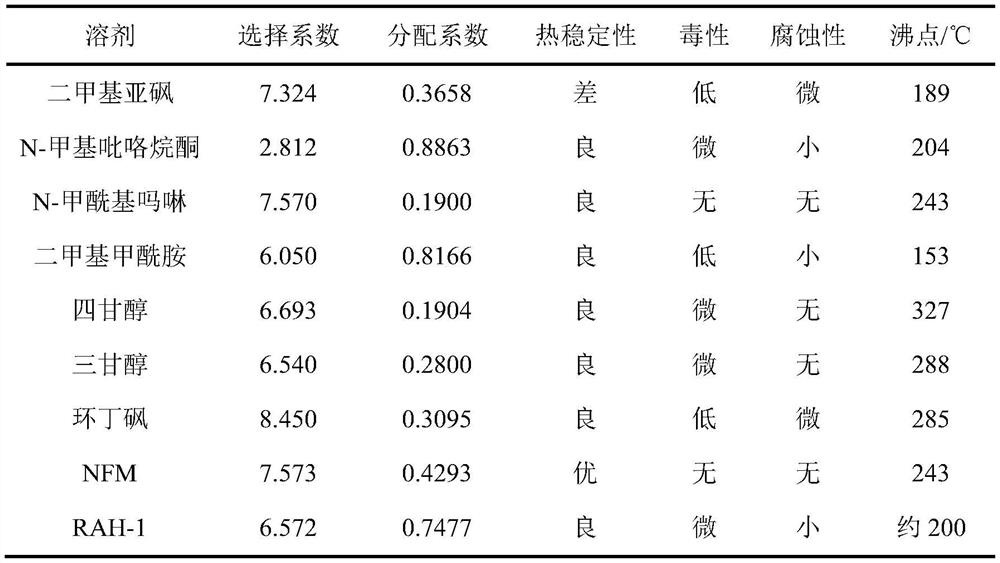

Multistage cross-flow extraction device and method for catalyzing diesel polycyclic aromatic hydrocarbon by using ionic liquid

PendingCN113185996AIncrease cetane numberSimple processHydrocarbon oils refiningHydrocarbon oils treatmentPolycyclic aromatic hydrocarbonAlkane

The invention discloses a multistage cross-flow extraction device and method for catalyzing diesel polycyclic aromatic hydrocarbon by using ionic liquid, and belongs to the technical field of chemical separation and purification. The efficient separation of the catalytic diesel polycyclic aromatic hydrocarbon mixture is realized by adopting a solvent multistage cross-flow extraction method and an extraction agent based on the ionic liquid. The method comprises the steps that catalytic diesel aromatic hydrocarbon to be separated enters a first-stage extractor (C1) from the bottom, an extracting agent A1 enters the first-stage extractor (C1) from the top, and the top of the first-stage extractor (C1) is connected to the bottom of a second-stage extractor (C2); an extraction agent A2 enters a second-stage extractor (C2) from the top, and the bottoms of the first-stage extractor (C1) and the second-stage extractor (C2) are connected with the middle of an extraction liquid flash tank (S2) for flash separation; and a material flow at the top of the second-stage extractor (C2) is connected to the middle part of a raffinate flash tank (S1) for flash separation. According to the method, the problem that the solvent and the raw materials are mixed and dissolved is solved, the yield of an oil product is increased, the purity of the separated oil product is high, and the diesel oil component with high cetane number and the aromatic hydrocarbon with low alkane content are obtained.

Owner:BEIJING UNIV OF CHEM TECH

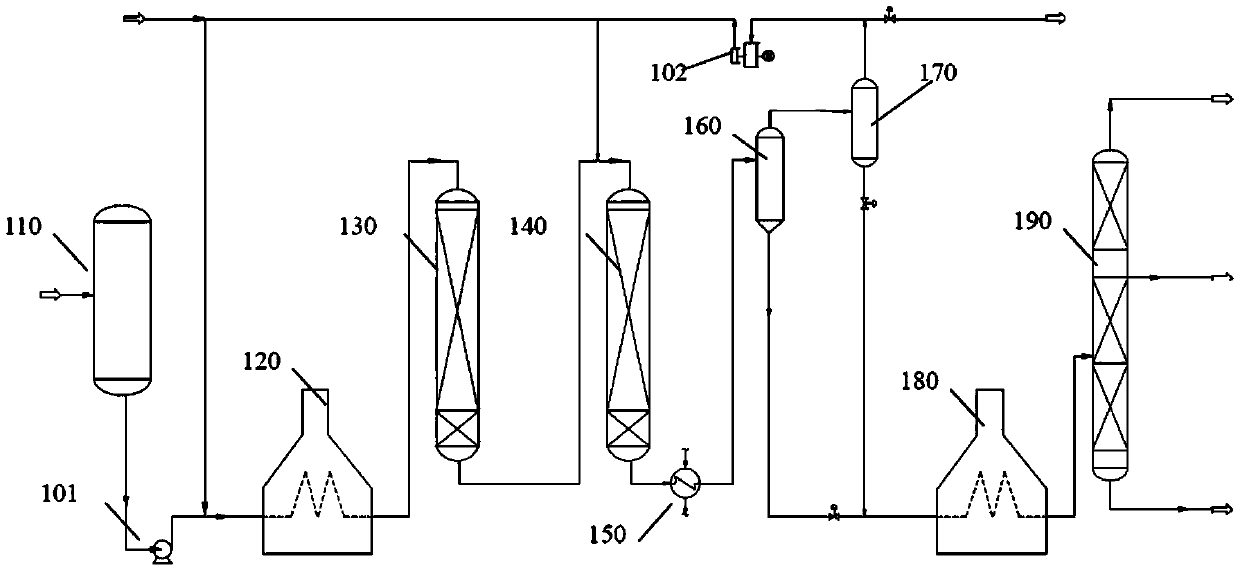

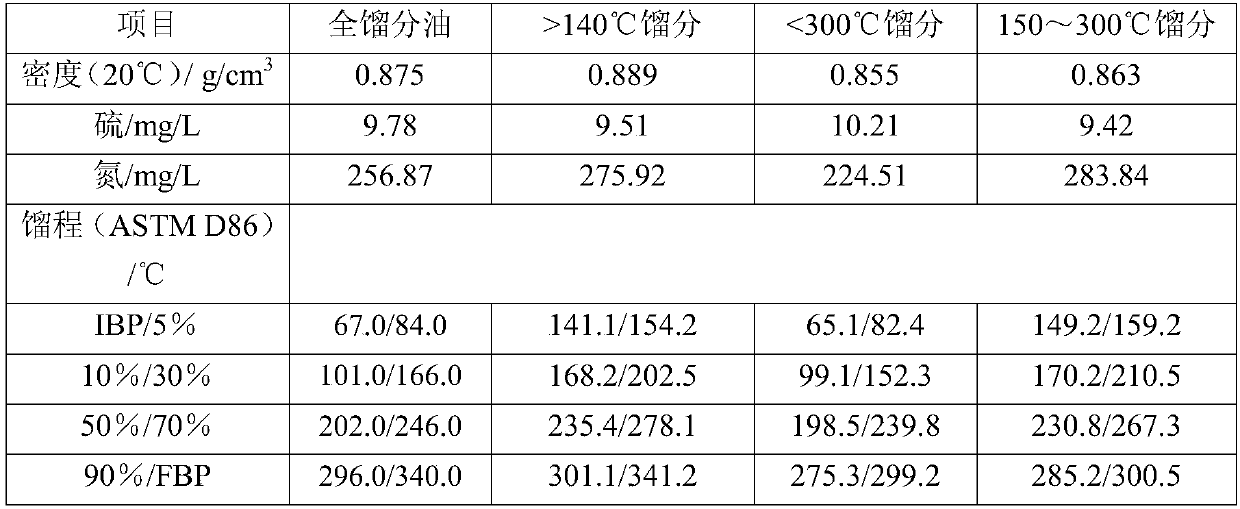

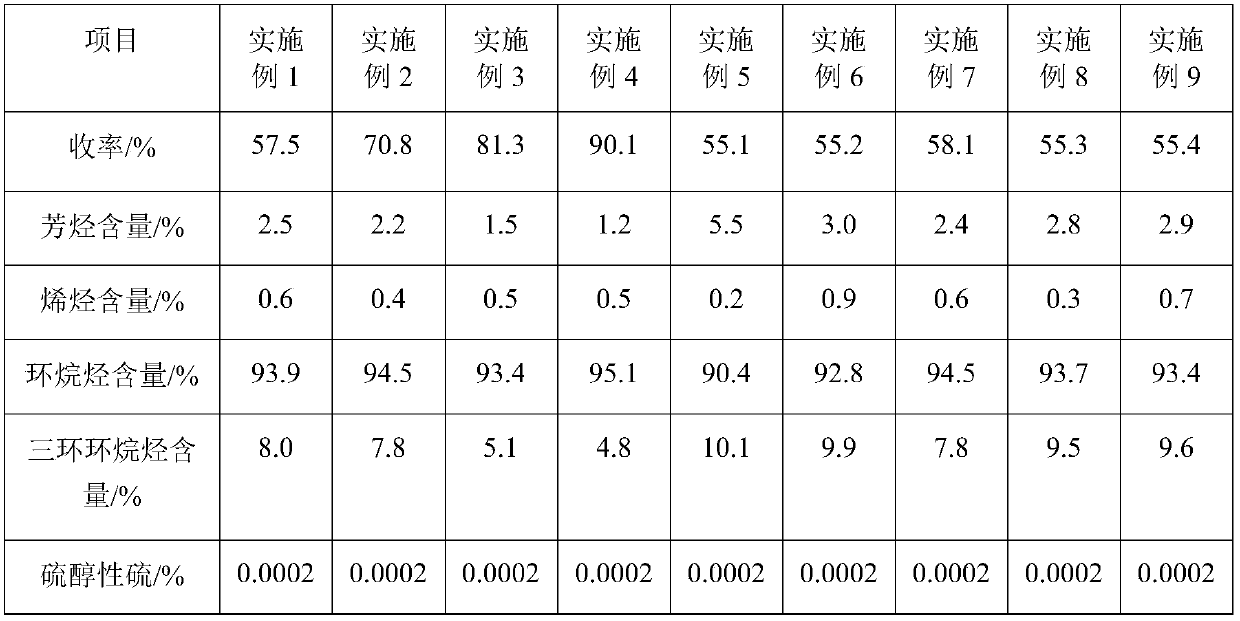

Coal-based high-density liquid fuel and preparation method thereof

ActiveCN109593553AImprove qualityHigh yieldTreatment with hydrotreatment processesLow nitrogenLiquid fuel

The invention discloses coal-based high-density liquid fuel and a preparation method thereof. The preparation method comprises the following steps: S1, contacting coal direct liquefied oil and hydrogen with hydrorefined catalyst to perform a hydrorefining reaction; S2, contacting the reaction effluent in the S1 with a hydrogen cracking catalyst to perform a hydro-upgrading reaction; S3, separatingand fractioning the reaction effluent in the S2 to obtain coal-based high-density liquid fuel, naphtha and diesel fraction. By applying the technical scheme, the coal-based high-density liquid fuel has the yield of 55 percent or more, the density of 0.85g / cm<3> or more and volume calorific value of close to 55 percent or more, and has the characteristics of low sulfur, low nitrogen, low aromatichydrocarbon, rich cycloalkanes, high flash point, high volume specific heat capacity, high thermal stability, good low temperature mobility and corrosion resistance.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

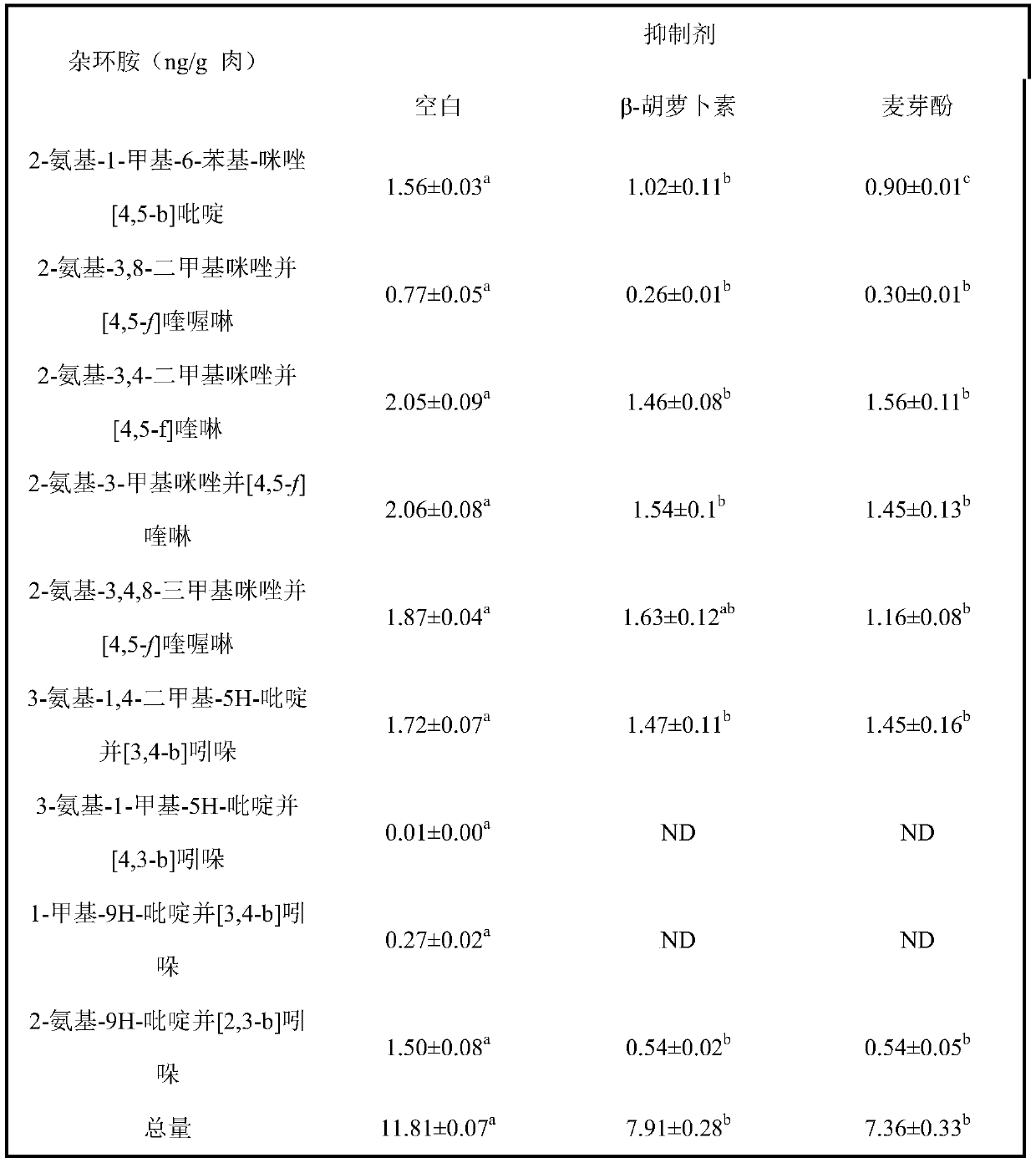

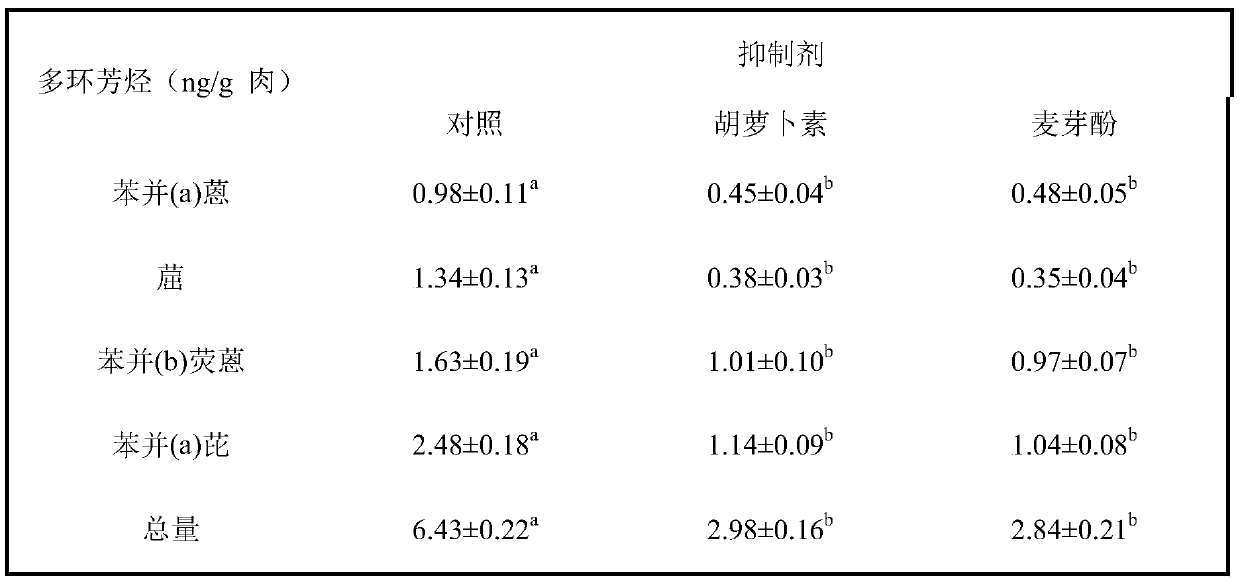

Inhibitor for controlling generation of heterocyclic amine and polycyclic aromatic hydrocarbon in beefsteak baking

PendingCN111436573AGenerate good effectNo side effectsLipidic food ingredientsBiotechnologyPolycyclic aromatic hydrocarbon

The invention discloses an inhibitor for controlling generation of heterocyclic amine and polycyclic aromatic hydrocarbon in beefsteak baking, and belongs to the technical field of food processing. The inhibitor is carotene or maltol, and the usage amount of the inhibitor is 0.08-0.12% of the mass of the steak. A specific use method comprises the following specific use operation steps: (1) uniformly smearing 0.1%-0.15% of an inhibitor on steak, wherein the inhibitor is carotene dry powder or maltol dry powder; (2) processing the steak by baking, wherein a cooking medium is olive oil or animalbutter, the baking temperature is 180-200 DEG C, and the baking time is 15-20 min. According to the processing method disclosed by the invention, the contents of heterocyclic amine and polycyclic aromatic hydrocarbon in baked steak can be remarkably reduced, and operation is simple and feasible. Meanwhile, the used inhibitor is safe and non-toxic and is low in cost, used equipment and materials are commonly seen in daily family life, and the daily eating requirements of consumers on safe and healthy meat products can be met.

Owner:HEFEI UNIV OF TECH +1

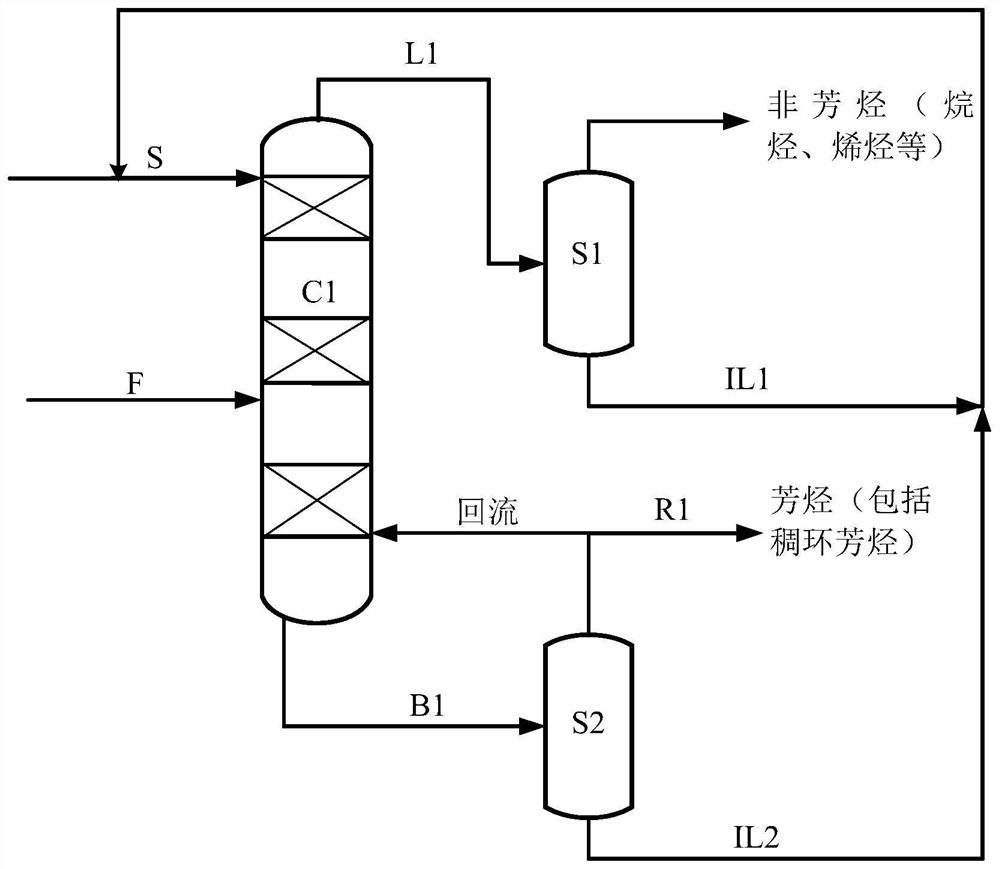

Multistage countercurrent extraction device and method for catalyzing diesel polycyclic aromatic hydrocarbon by using ionic liquid

PendingCN113201364AIncrease cetane numberSimple processTreatment with plural serial refining stagesPolycyclic aromatic hydrocarbonPhysical chemistry

The invention discloses a multistage countercurrent extraction device and method for catalyzing diesel polycyclic aromatic hydrocarbon by using ionic liquid, and belongs to the technical field of chemical separation and purification. Through a solvent multistage countercurrent extraction technology and an ionic liquid extraction agent, efficient separation of the catalytic diesel aromatic hydrocarbon mixture is realized. The method comprises the steps that a diesel aromatic hydrocarbon to-be-separated mixture enters a countercurrent mixed extraction tower (C1) from the tower bottom, an extraction agent S enters the countercurrent mixed extraction tower (C1) from the tower top, a material flow at the bottom of the countercurrent mixed extraction tower (C1) is connected with the middle of an extraction liquid flash tank (S2) for flash separation, a material flow at the tower top of the countercurrent mixed extraction tower (C1) is connected with the middle of a raffinate flash tank (S1) for flash separation, and extraction solvent outlets at the bottoms of the raffinate flash tank (S1) and the extract flash tank (S2) are connected with an extraction solvent circulating material flow at the extraction solvent feed port of the countercurrent mixed extraction tower (C1). The problem of miscibility of the solvent and the raw materials is solved, the yield of oil products is improved, and the product purity is high.

Owner:BEIJING UNIV OF CHEM TECH

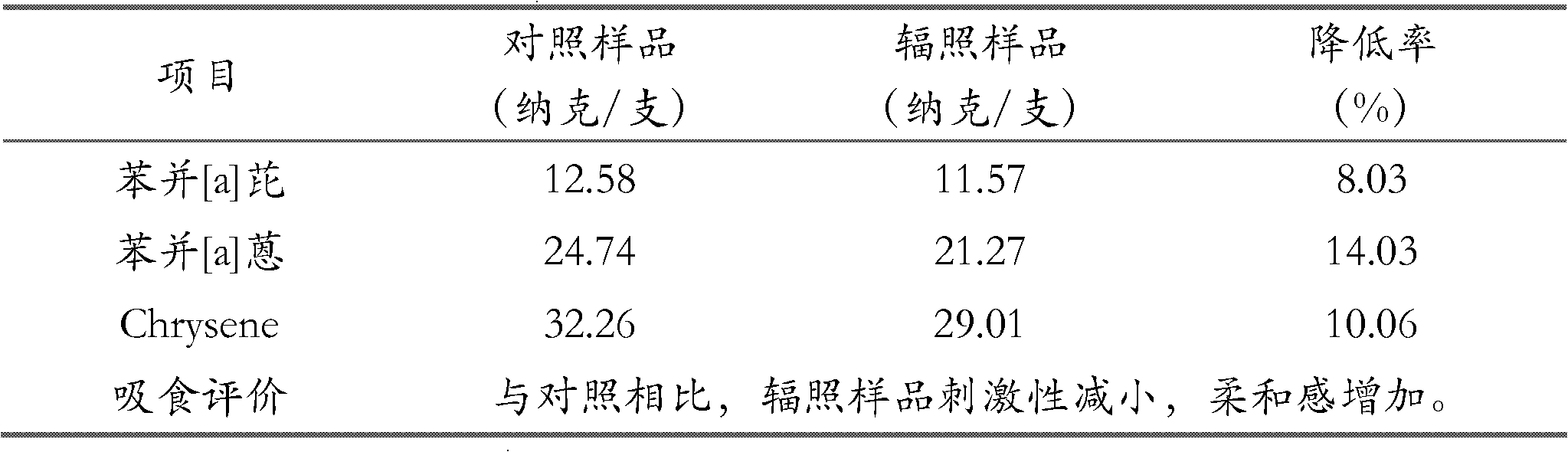

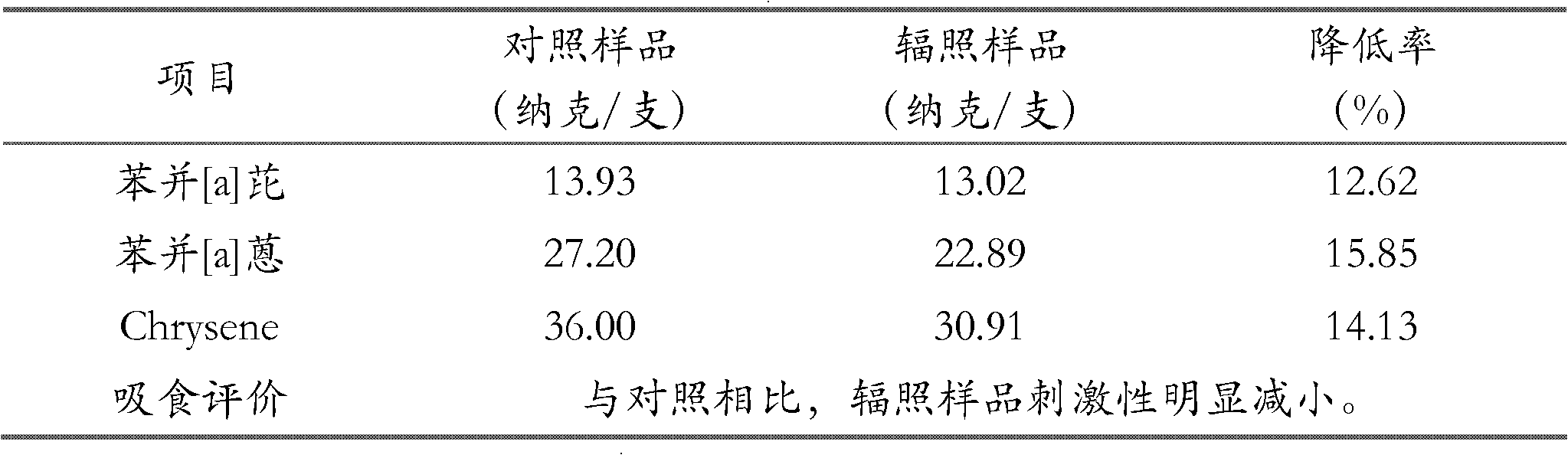

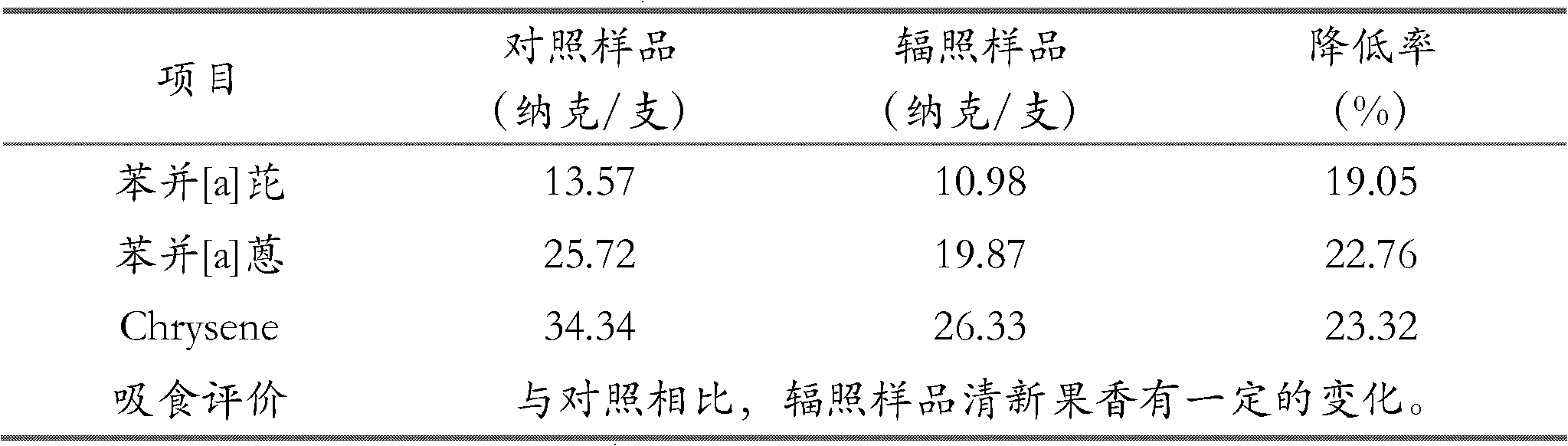

Method for reducing polyaromatic hydrocarbon content in tar of cigarette smoke

The invention discloses a method for reducing the polyaromatic hydrocarbon content in tar of cigarette smoke. The method comprises the steps: packaging tobacco leaves / finished products of cigarettes with cartons, wherein stacking thickness is 26-72cm and stacking density is 0.20-0.34g / cm<3>; and placing the tobacco leaf / cigarette carton on a conveyer at the conveying speed being 0.02-0.3m / s and irradiating the tobacco leaf / cigarette cartons with electron beams / X rays produced by an electron accelerator, wherein the electron accelerator has the energy being 5-10MeV, the beam flow being 0.3-20mA, the beam power being 10-20kW, the maximal scanning width being 100cm, the scanning frequency being 5-15Hz and the irradiation dose being 1-10kGy, the working temperature is set to be 5-35 DEG C, the tobacco leaf / cigarette cartons pass trough a scanning window of the electron accelerator twice to be irradiated, a distance between the center of each tobacco leaf / cigarette carton and the scanning window of the electron accelerator is 40-60cm during irradiation, and the ambient humidity is limited to be not more than 60% during working.

Owner:河南省科学院同位素研究所有限责任公司 +1

Hydrogenation method for increasing cetane number of diesel oil

ActiveCN102206510AReduce side chain scission reactionIncrease cetane numberTreatment with hydrotreatment processesAlkaneSide chain

Disclosed is a hydrogenation method for increasing cetane number of diesel oil. According to the invention, a reaction unit is provided with three sequentially arranged reaction zones; in a first reaction zone, a hydrobon catalyst I is filled and a hourly space velocity is 0.5 to 5.0 h <-1>; in a second reaction zone, a hydroupgrading catalyst is filled and a hourly space velocity is 1.0 to 8.0 h <-1>; in a third reaction zone, a hydrobon catalyst II is filled and a hourly space velocity is 1.5 to 12.0 h <-1>; the acidity of the hydrobon catalyst I is less than that of the hydrobon catalyst II. With the utilization of the method provided in the invention, cracking of open loops of annular aromatic hydrocarbons with more than two rings in the raw materials can be realized and the reaction of long-chain alkane cracking into short-chain alkane and the scission reaction of annular hydrocarbon with long side chains can be reduced; therefore, cetane number of diesel oil can be greatly increased under the condition that high yield of diesel oil is maintained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Plasma processes for producing graphene nanosheets

ActiveUS10793440B2Safe handlingImprove productivityMaterial nanotechnologyGrapheneChemical physicsPhysical chemistry

Provided are plasma processes for producing graphene nanosheets comprising injecting into a thermal zone of a plasma a carbon-containing substance at a velocity of at least 60 m / s standard temperature and pressure STP to nucleate the graphene nanosheets, and quenching the graphene nanosheets with a quench gas of no more than 1000° C. The injecting of the carbon-containing substance may be carried out using a plurality of jets. The graphene nanosheets may have a Raman G / D ratio greater than or equal to 3 and a 2D / G ratio greater than or equal to 0.8, as measured using an incident laser wavelength of 514 nm. The graphene nanosheets may be produced at a rate of at least 80 g / h. The graphene nanosheets can have a polyaromatic hydrocarbon concentration of less than about 0.7% by weight.

Owner:RAYMOR IND INC

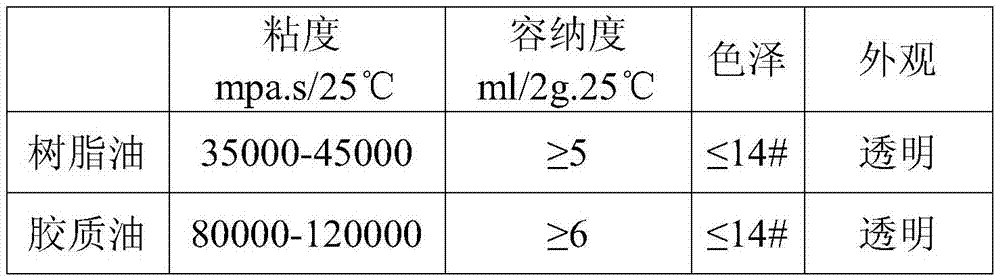

Environment-friendly plant oil-based ink used for offset printing

The invention belongs to the technical field of ink printing and particularly relates to environment-friendly plant oil-based ink used for offset printing. The ink is characterized by comprising the following ingredients in parts by weight: 30-34 parts of gummy oil, 25-39 parts of resin oil, 13-16 parts of a soya-bean oil solvent, 13-27 parts of color pigments, 0.5-2 parts of an additive and 0.8-2.5 parts of a drying agent. The ink provided by the invention has the beneficial effects that the ink is excellent in environmental friendliness, better in abrasion resistance and good in inking property, and has no toxicity, so that waste-paper deinking is easier, the printed volume is large, and the color is deep, abundant and bright. Therefore, the ink can be widely applied to color printing.

Owner:TIANJIN ANGEL CHEM GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com