Coal-based high-density liquid fuel and preparation method thereof

A high-density liquid, coal-based technology, applied in the petroleum industry, hydroprocessing process, hydrocarbon oil treatment, etc., can solve the problems of low yield, complicated process route, low quality, etc., and achieve good low temperature fluidity and high volume Specific heat capacity, the effect of reducing the carbon deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

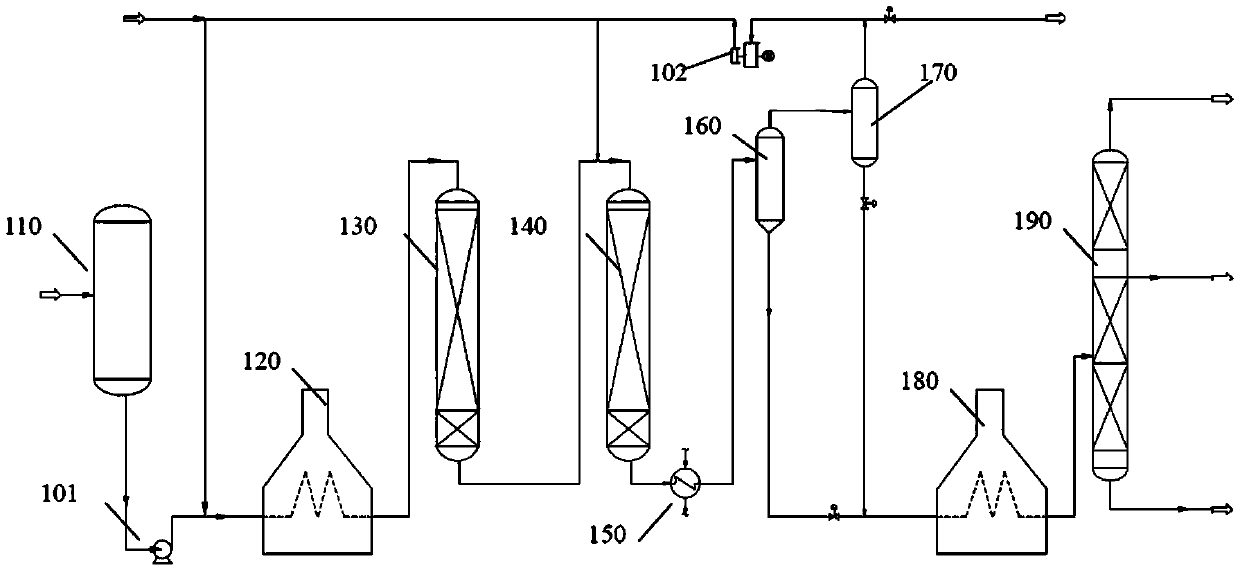

[0028] According to a typical embodiment of the present invention, a method for preparing coal-based high-density jet fuel is provided. The preparation method comprises the following steps: S1, after mixing the direct coal liquefied oil and hydrogen, contacting with a hydrofining catalyst to generate a hydrofining reaction; S2, contacting the reaction effluent in S1 with a hydrocracking catalyst to generate Hydrogenation reforming reaction; S3, the reaction effluent in S2 is separated and fractionated to obtain high-density liquid fuel, naphtha and diesel fractions.

[0029] Applying the technical scheme of the present invention, after the direct coal liquefied oil is subjected to the hydrofining reaction, hydrodeoxygenation, desulfurization, denitrogenation and aromatic hydrocarbon saturation reactions mainly occur, and heteroatoms are basically effectively removed during the reaction process, and the hydrogenated coal-based Oil can be used as a clean fuel, and most of the ar...

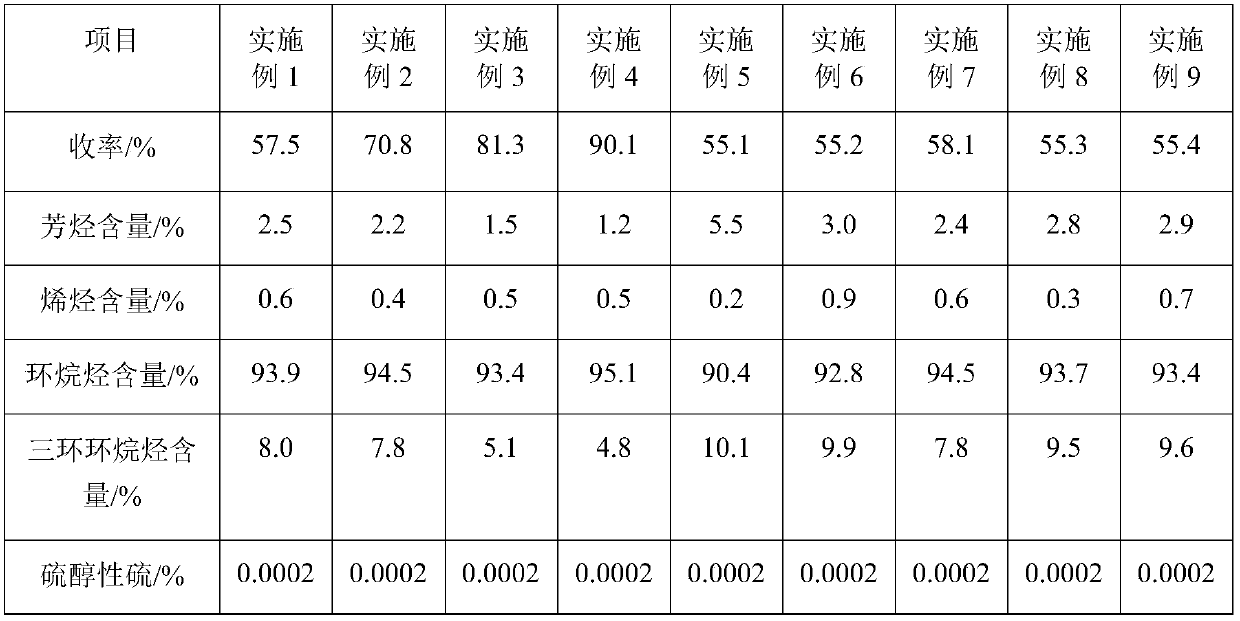

Embodiment 1

[0045] After the coal liquefied whole distillate oil is mixed with hydrogen, it enters the hydrofinishing reactor after preheating, and contacts with the hydrogenation protection catalyst RGC-1 and the hydrofinishing catalyst RNC-2, and the hydrofinishing reaction occurs to remove heteroatoms And the hydrogenation saturation reaction of aromatic hydrocarbons; the effluent from the hydrofinishing reactor enters the hydrogenation upgrading reactor, and contacts with the hydrogenation upgrading catalyst RCC-1 in the upgrading reactor, and the aromatic ring cracking ring-opening reaction occurs; the hydrogenation upgrading The effluent from the mass reactor is separated and fractionated to obtain naphtha fraction, high-density liquid fuel and diesel fraction.

[0046] The hydrogenation reaction (hydrofining and hydrogenation upgrading) conditions are: reaction pressure 13.7MPa, reaction temperature 370°C, volume space velocity 0.7h -1 , hydrogen oil ratio 700Nm 3 / m 3 .

Embodiment 2

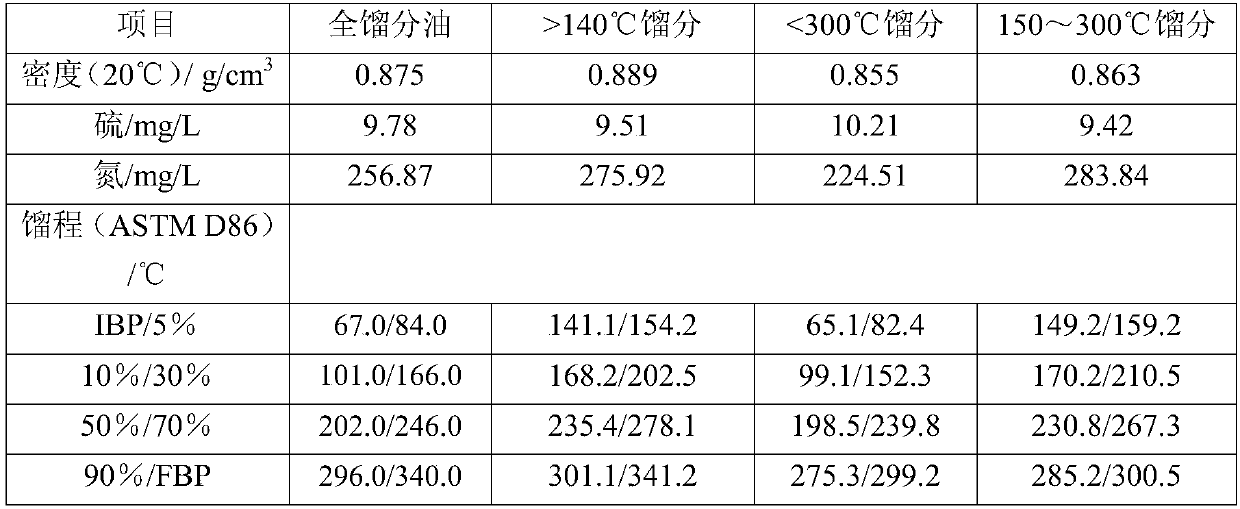

[0048] The process flow of Example 2 is the same as that of Example 1, the feedstock oil is >140°C coal liquefaction distillate, and the process conditions remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com