Method for preparing low-toxicity modified coal pitch for road building

A technology of coal tar pitch and coal tar pitch, which is applied in the field of preparation of low-toxicity modified coal tar pitch, can solve the problems of no discussion and explanation of performance, less application of ultraviolet irradiation method, influence on the performance of coal tar pitch, etc. The effect of recyclability and road performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

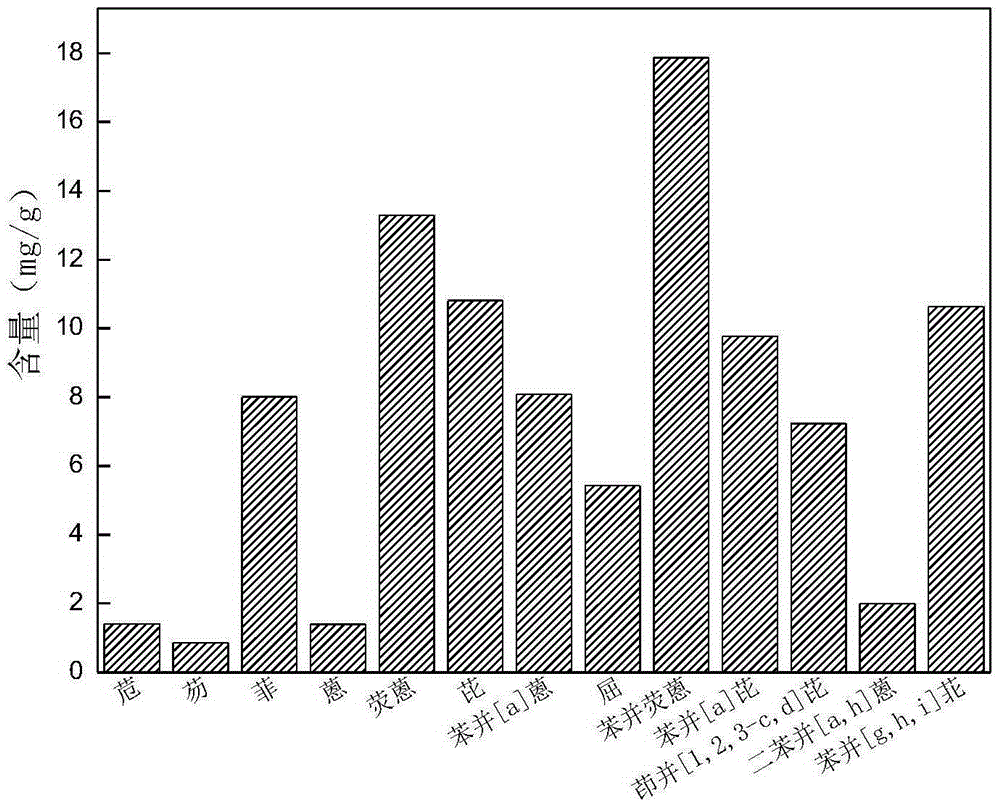

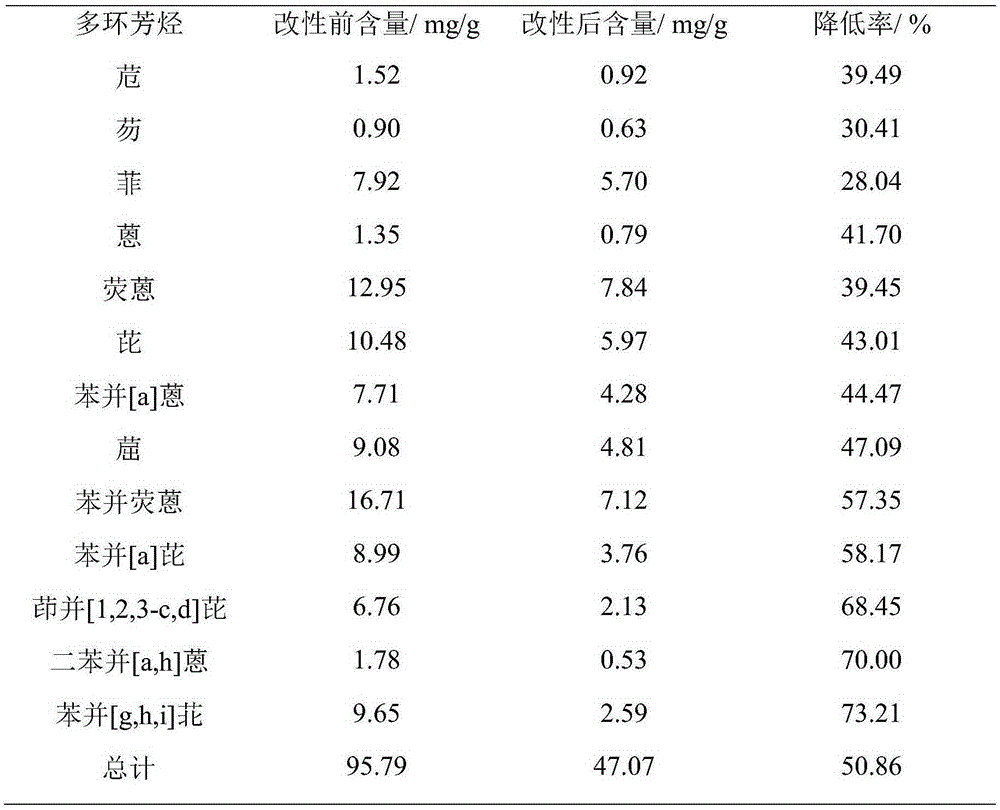

[0021] Mix 10 g of coal tar pitch, 4% modifier terephthalaldehyde, and 5% catalyst p-toluenesulfonic acid, add 50 mL solvent cyclohexane, and stir for reaction at room temperature for 4 hours. The content indicators of polycyclic aromatic hydrocarbons in the modified coal tar pitch are as follows:

[0022]

Embodiment 2

[0024] Mix 10 g of coal tar pitch, 8% modifier terephthalaldehyde, and 5% catalyst p-toluenesulfonic acid, add 50 mL solvent cyclohexane, and stir at room temperature for 4 hours. The content indicators of polycyclic aromatic hydrocarbons in the modified coal tar pitch are as follows:

[0025]

Embodiment 3

[0027] Mix 10g of coal tar pitch, 10% modifier terephthalaldehyde, and 5% catalyst p-toluenesulfonic acid, add 50mL solvent cyclohexane, and stir at room temperature for 4 hours. The content indicators of polycyclic aromatic hydrocarbons in the modified coal tar pitch are as follows:

[0028]

[0029]

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com