Carbon monoxide conversion process

A carbon monoxide, process technology, applied in the field of carbon monoxide conversion process, to achieve the effect of broadening the use conditions and broadening the source range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The raw material gas is a self-combined gas, in which the volume fraction of hydrogen is 64%, the volume fraction of carbon monoxide is 20%, the volume fraction of carbon dioxide is 10%, and the volume fraction of methane is 12%.

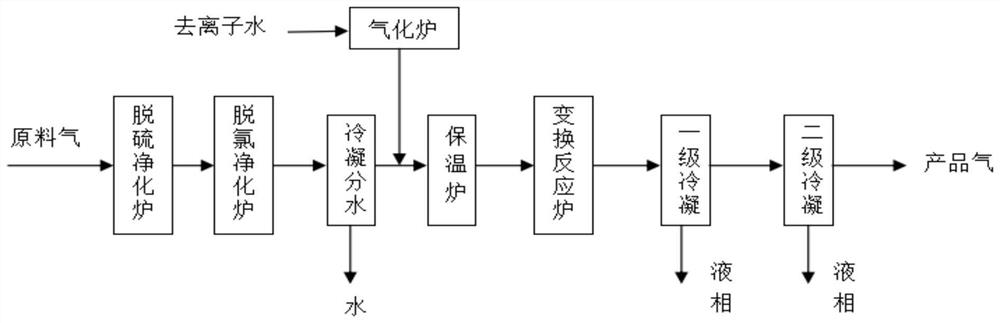

[0039] A schematic diagram of the carbon monoxide shift process is shown in figure 1 , the carbon monoxide shift process comprises the following steps:

[0040] (1) Raw material gas purification: The raw material gas passes through the desulfurization and dechlorination reactors controlled at a pressure of 3.0Mpa and a temperature of 240°C in sequence. The crude desulfurization catalyst A is zinc oxide, and the fine desulfurization catalyst B is a mixture of cobalt-molybdenum catalyst and iron oxide , the volume ratio of A:B is 1.5:1, and after cooling by the water cooling system and gas-liquid separation, the purified feed gas with a sulfide concentration of 0.08ppm and a chloride concentration of 0.04ppm is obtained;

[0041] (2) Water vap...

Embodiment 2

[0047] The raw material gas is coke oven gas, in which the volume fraction of hydrogen is 60%, the volume fraction of carbon monoxide is 10%, the volume fraction of carbon dioxide is 3%, the volume fraction of methane is 18%, and the hydrocarbon is 3%.

[0048] The carbon monoxide shift process includes the following steps:

[0049] 1) Purification of raw material gas: The raw material gas passes through the desulfurization and dechlorination reactors with a pressure of 2.5Mpa and a temperature of 200°C. The crude desulfurization catalyst A is a mixture of zinc oxide and activated carbon, and the fine desulfurization catalyst B is a cobalt-molybdenum catalyst. : B volume ratio is 2.0:1, and then after cooling by water cooling system and gas-liquid separation, the purified raw material gas with sulfide concentration of 0.05ppm and chloride concentration of 0.01ppm is obtained;

[0050] (2) Water vaporization: deionized water is pumped into the vaporizer with a temperature contr...

Embodiment 3

[0056] The raw material gas is the product gas of Inner Mongolia lignite gasification in the laboratory, which contains hydrogen volume fraction of 56%, carbon monoxide volume fraction of 15%, carbon dioxide volume fraction of 14%, methane volume fraction of 5%, and hydrocarbons of 6%.

[0057] The carbon monoxide shift process includes the following steps:

[0058] 1) Purification of raw material gas: The raw material gas passes through the desulfurization and dechlorination reactors with the pressure controlled at 3.0Mpa and the temperature controlled at 240°C. The crude desulfurization catalyst A is a mixture of zinc oxide and activated carbon, and the fine desulfurization catalyst B is a cobalt-molybdenum catalyst and oxidation Iron mixture, the volume ratio of A:B is 1.8:1, after cooling by water cooling system and gas-liquid separation, the purified raw material gas with sulfide concentration of 0.02ppm and chloride concentration of 0.01ppm is obtained;

[0059] (2) Wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com