Vanadium and titanium containing cold rolling non-oriented electrical steel and preparation method thereof

A technology of oriented electrical steel and rough rolling, which is applied in the field of metallurgy, can solve the problems of small selection range of smelting raw materials, increase production costs, unfavorable utilization of recycled steel, etc., and achieve the effects of suppressing adverse effects, promoting use, and reducing precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

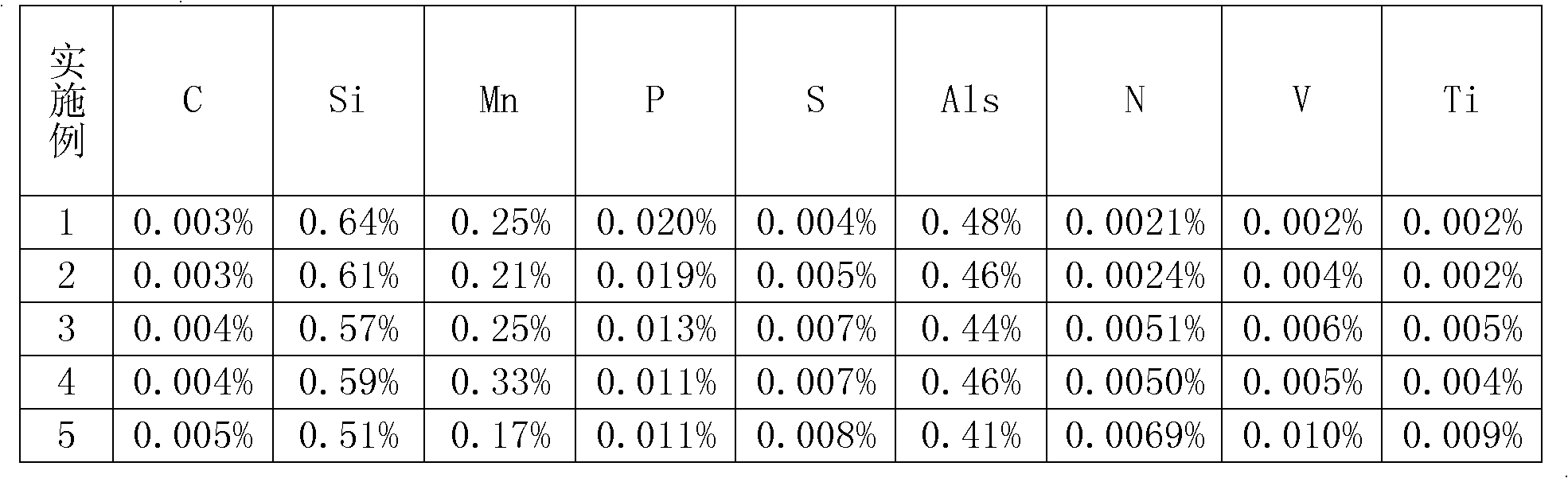

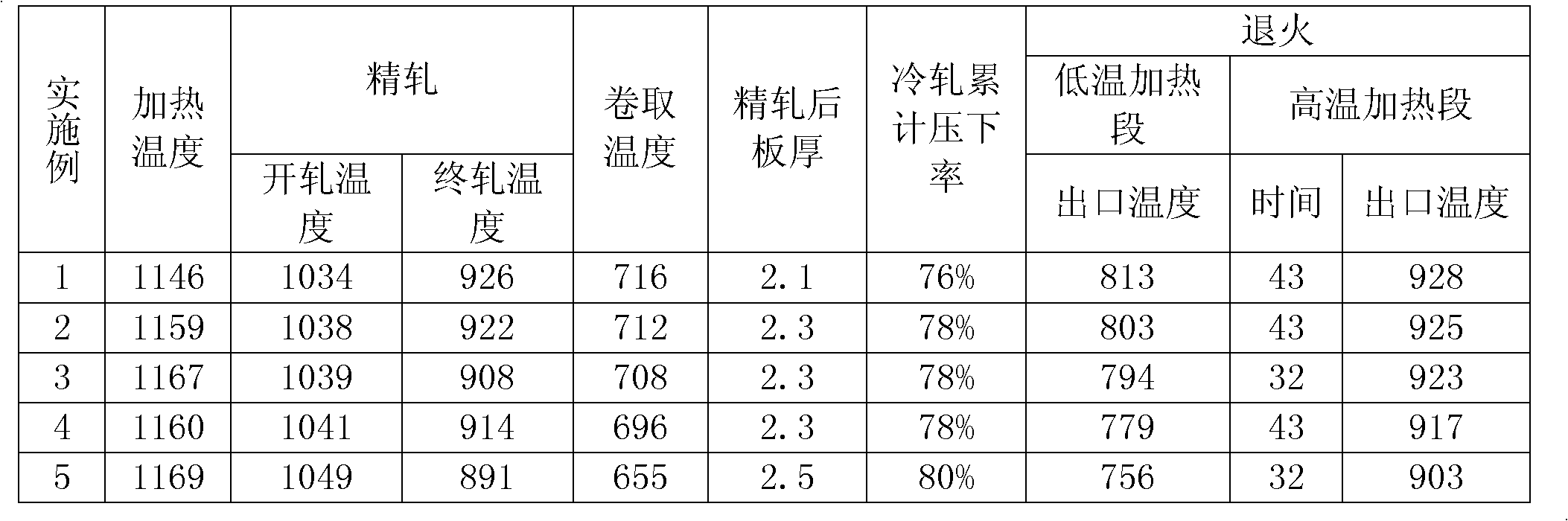

[0032] In a factory, an engineering test was carried out according to the composition design and process design of the present invention, and the production grade was 50PW700 non-oriented electrical steel, and other processes except the explained process parameters were carried out according to the existing requirements.

[0033] The equipment includes a 120-ton LD converter, a hot continuous rolling unit including five-pass rough rolling and six-stand finish rolling, and a galvanizing / continuous annealing dual-purpose unit. The specific production process is as follows: steel billet, heating, rough rolling, finishing rolling, coiling, cold rolling, annealing. During the production process, the descaling water of other passes except the second and fourth passes is turned on in the rough rolling step, and a set of dephosphorization water is set between the rough rolling and the finishing rolling. The specific chemical composition is shown in Table 1, the process parameters are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com