Method for producing carbon black for shielding material inside cable

A production method and internal shielding technology, applied in the direction of fibrous fillers, etc., can solve the problems of unstable product performance, dispersion, poor resistivity performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

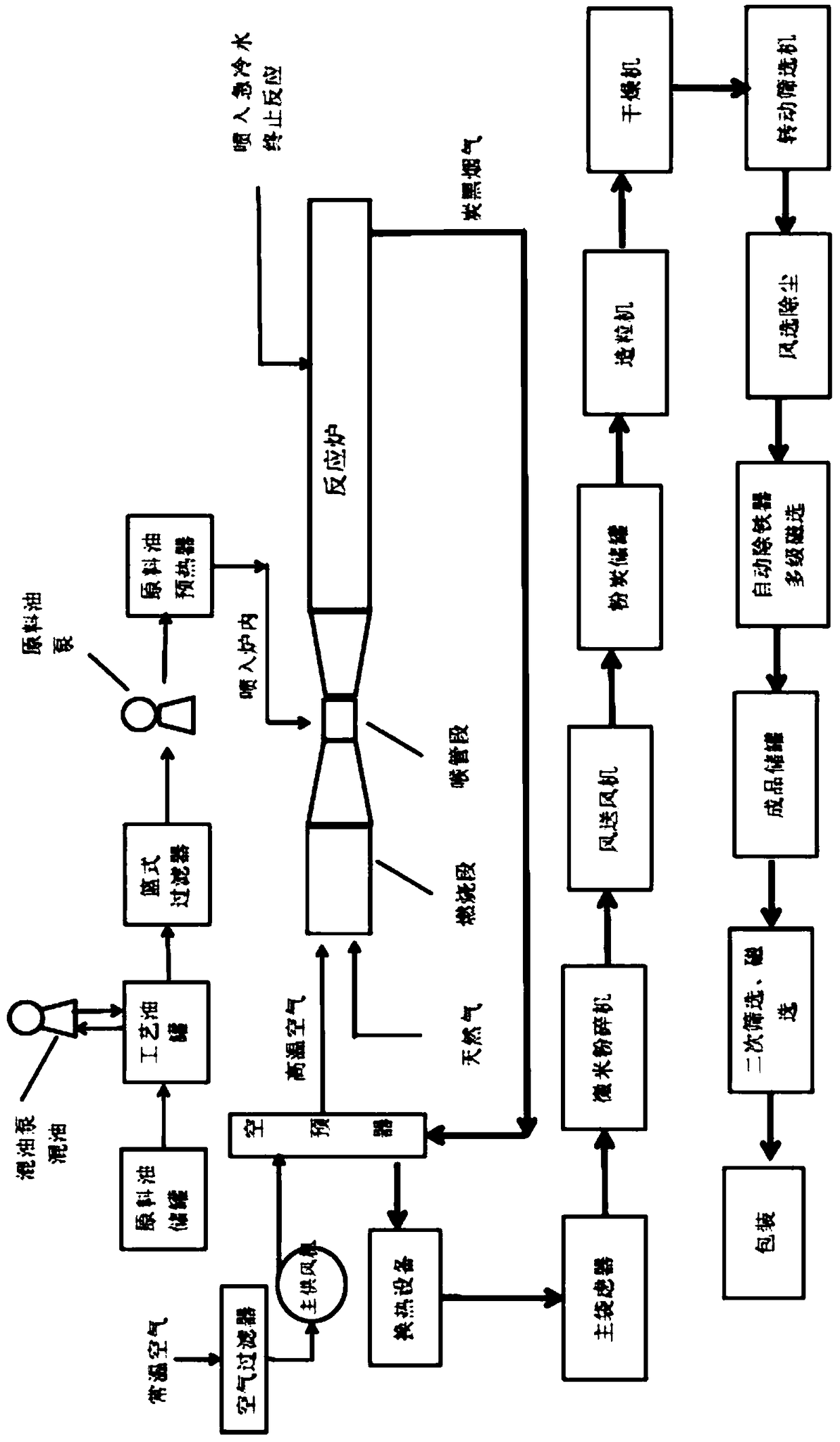

Method used

Image

Examples

Embodiment 1

[0040] The air is pressurized to 95kPa by a multi-stage centrifugal fan and preheated to 750°C. The flow rate is 17000Nm3 / h and enters the reaction furnace. The natural gas pressure is 108kPa and the calorific value is 8200kcal / m 3 According to the volume ratio, the ratio of air to natural gas is adjusted to 16:1, that is, the natural gas flow rate is about 1062Nm3 / h into the reactor, and the temperature in the combustion section of the reactor reaches 1900°C after mixed combustion.

[0041] The raw oil is left to settle, and then filtered through a basket filter to remove impurities in the oil, pressurized to 3.5MPa by a rotary jet pump, with a flow rate of 3500kg / h, and sent to a tube-and-tube heat exchanger to be heated to 180°C. Ten atomizing spray guns are sprayed into the reaction furnace along the radial direction of the reaction furnace in the throat section. The high-temperature flue gas flow rate generated in the combustion section reaches 140m / s, forming a shearing e...

Embodiment 2

[0047] The air is pressurized to 105kPa and preheated to 700°C by a multi-stage centrifugal fan, with a flow rate of 17500Nm 3 / into the reaction furnace, the natural gas pressure is 108kPa, the low calorific value is 8200kcal / m 3 According to the volume ratio, adjust the ratio of air to natural gas to 17:1 and adjust the flow rate of natural gas to about 1029Nm 3 / h enters the reaction furnace, and the temperature of the combustion section of the reaction furnace reaches 1850°C after mixed combustion.

[0048] The raw oil is left to settle, and then filtered through a basket filter to remove impurities in the oil, pressurized to 3.0MPa by a rotary jet pump, with a flow rate of 4200kg / h, and sent to a tube heat exchanger to be heated to 180°C. Ten atomizing spray guns are sprayed into the reaction furnace along the radial direction of the reaction furnace in the throat section. The high-temperature flue gas flow rate generated in the combustion section reaches 150m / s, which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com