Patents

Literature

260 results about "Solvent refining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

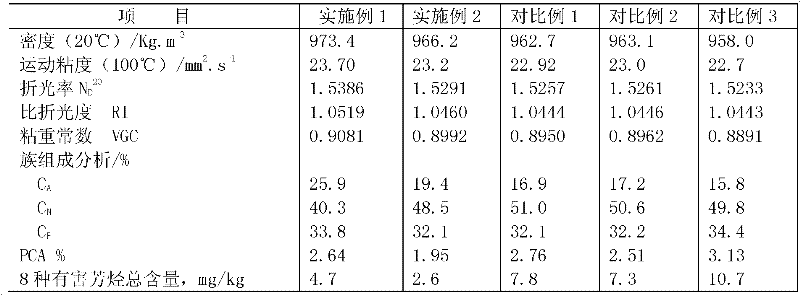

Method for producing high-arene environment-friendly rubber oil

The invention relates to a method for producing high-arene environment-friendly rubber oil. The method comprises the steps of taking heavy-solvent extract oil of a lubricating-oil solvent-refining device as raw material, adding an auxiliary agent to the raw material and then refining solvent, wherein the heavy-solvent extract oil has the flash point higher than 200 DEG C, the kinematic viscosity greater than 15.0 mm<2> / s at 100 DEG C and the CA value greater than 35.0 percent; the auxiliary agent is single-hydrocarbon or light-hydrocarbon oil with low density, low viscosity and boiling point between 80 and 300 DEG C; the solvent is N-methyl pyrrolidone, phenol or furfural; a refining tower has the temperature between 50 and 100 DEG C on the top and has the temperature between 30 and 100 DEG C on the bottom; and the mass ratio of the raw material to the auxiliary agent to the solvent is 1.0:0.1-0.5:2.0-5.0. Refined oil is high in arene content; the CA value of the refined oil is above 19.0 percent; the arene content of the refined oil is greater than 50.0 percent; the PCA content of the refined oil determined by an IP346 method is less than 3.0 percent; the benzopyrene of the refined oil is less than 1 PPM; and the total content of eight specific polyaromatic hydrocarbon is less than 10 PPM.

Owner:PETROCHINA CO LTD

Process for forming magnesium alloy ultra-fine thin-wall tube used for degradable blood vessel bracket

The invention provides a figuration technology of superfine magnesium alloy thin-walled tube for degradable vascular bracket. The characteristics of its major technique is adding yttrium to pure magnesium, mixing RE, Al, Ca, Mn, Sb, Zn, and Zr, smelting through gas shield smelting + reduction iron solvent refining method to obtain ingot casting of magnesium alloy, performing hot extrusion, distortion and solution treatment, intercepting certain length as workpiece for subsequent processing, processing one end to tubular form and the other end to clubbed form, heating the pipe end, and tugging through multiple tracks to obtain superfine thin-walled tube with diameter of 2-10mm, wall thickness of 0.20-1mm.Its advantage is overcoming limitation of figuration technology such as pressing, has low cost, uniform wall thickness and tissue, and good mechanical property.

Owner:SHENYANG POLYTECHNIC UNIV

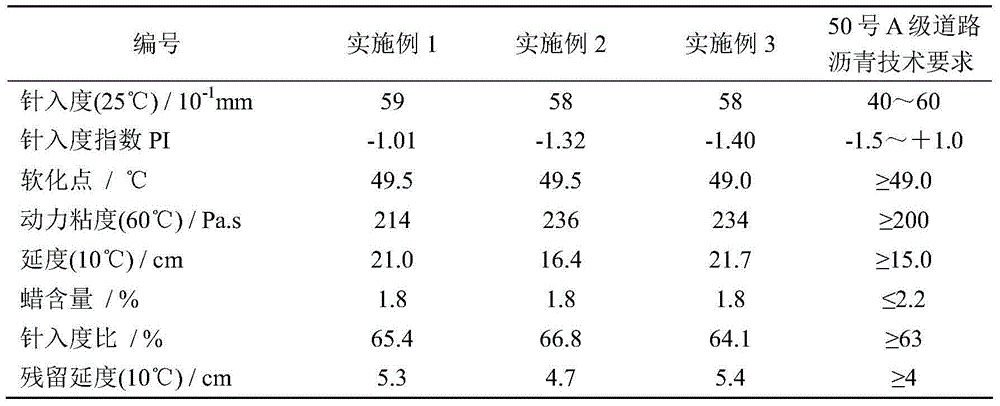

Low-strength and high-grade road asphalt and preparation method thereof

ActiveCN103554926AImprove use valueImprove performanceBuilding insulationsAging resistanceDistillation

The invention discloses low-strength and high-grade road asphalt. The low-strength and high-grade road asphalt comprises the following components in parts by weight: 25 to 75 parts of vacuum residue, and 25 to 75 parts of one or more of deoiled asphalt, extract oil from solvent refining, and unimproved hard vacuum residue, wherein the vacuum residue is the vacuum residue prepared by introducing catalytic oil into the bottom of an atmospheric distillation column and then transferring into a reduced-pressure distillation column together with atmospheric residue to improve by reduced-pressure distillation. The invention also discloses a preparation method of the low-strength and high-grade road asphalt. By adopting the low-strength and high-grade road asphalt, the problem due to the dependence on types of crude oil can be solved, and the problem of the prior art that the high-grade road asphalt produced by catalytic slurry oil is poor in ageing resistance also can be solved; the low-strength and high-grade road asphalt with high additional value can be produced through the catalytic slurry oil with low additional value. In addition, the preparation method is simple in process and low in cost.

Owner:CHINA PETROLEUM & CHEM CORP

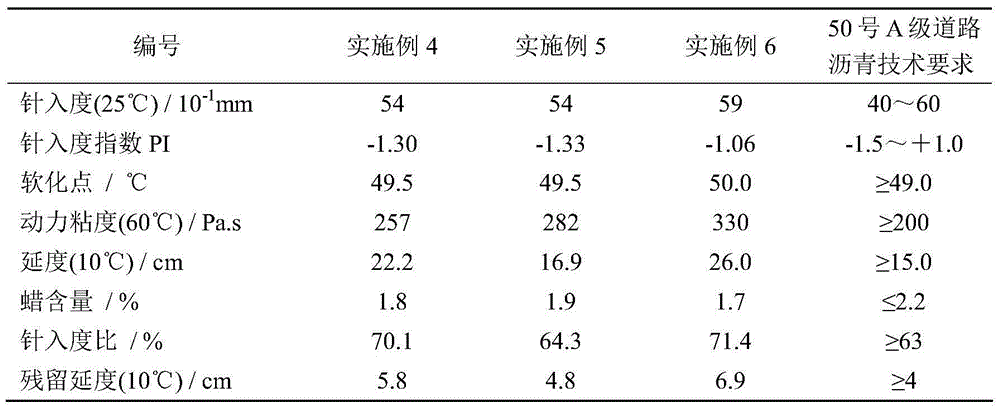

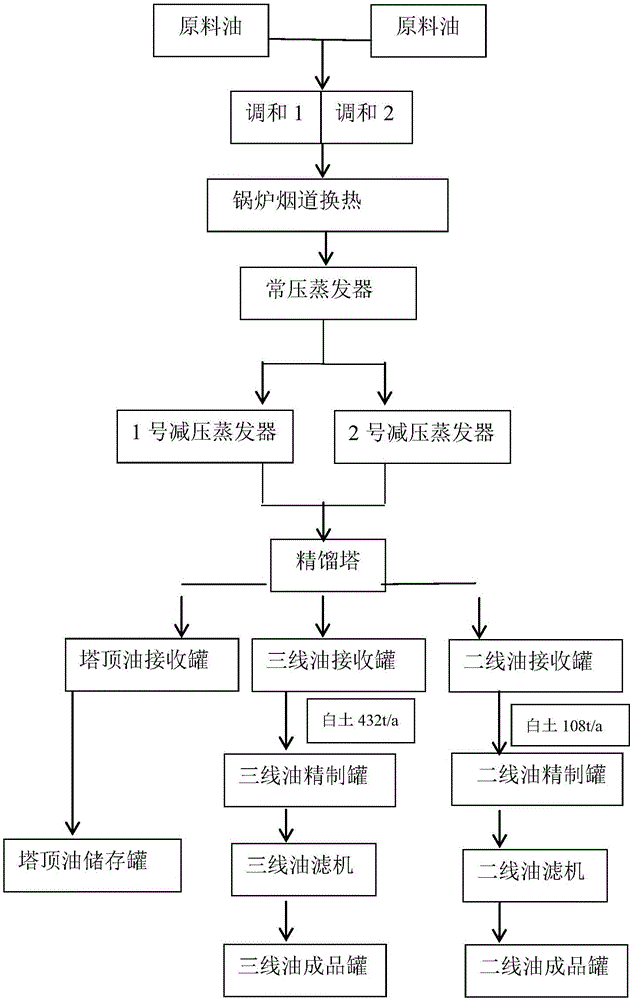

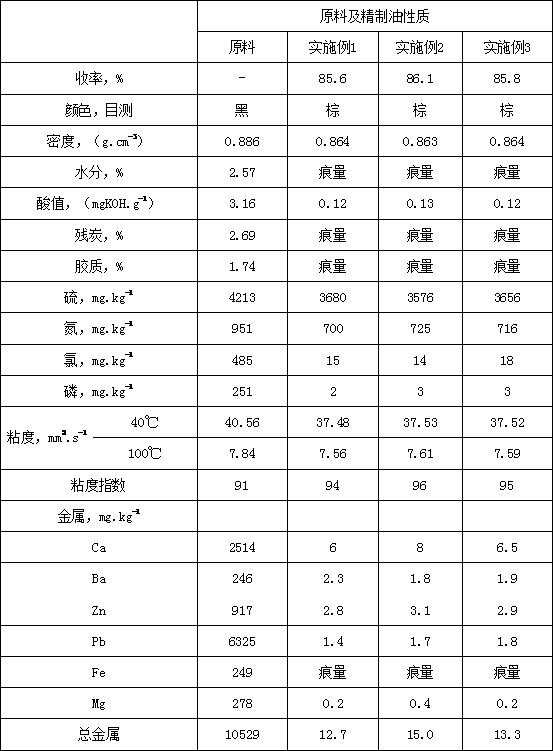

Method for regenerating base oil by waste oil

InactiveCN106833736AAvoid wastingImprove protectionTreatment with plural serial refining stagesLubricant compositionDistillationFuel oil

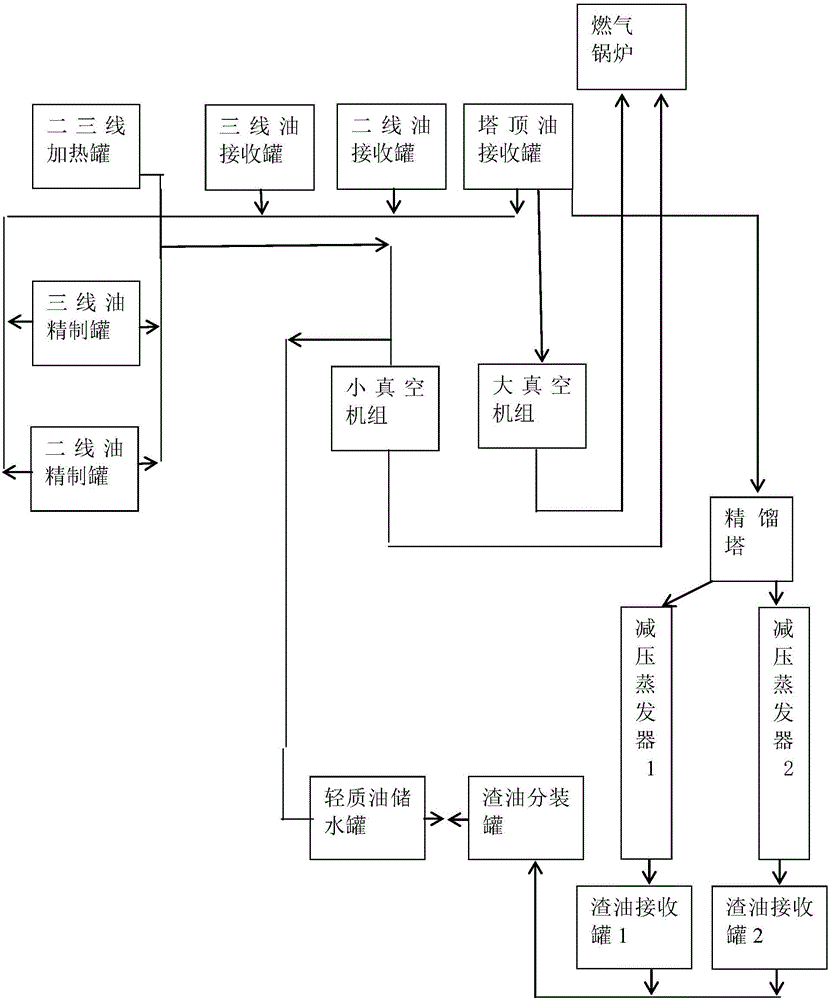

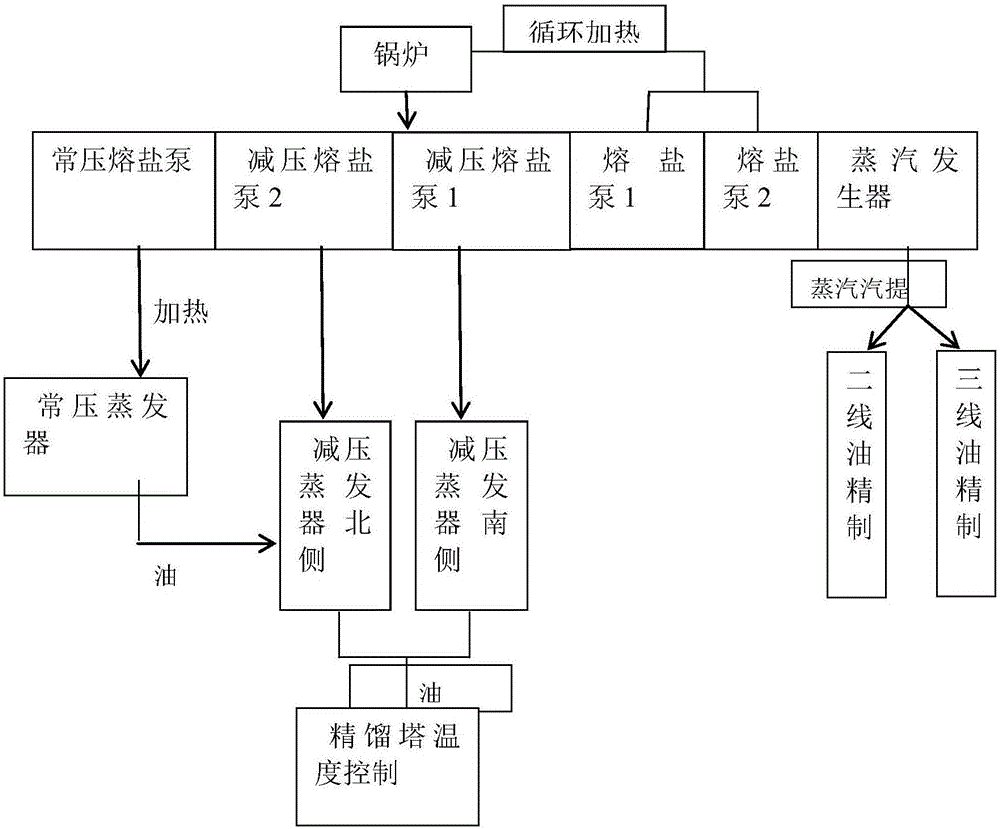

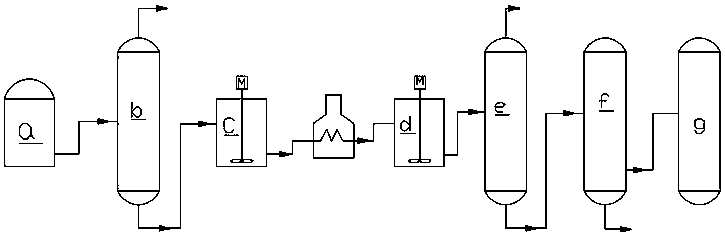

The invention discloses a method for regenerating base oil by waste oil, belonging to the technical field of waste oil regeneration. The problems that the waste oil regeneration rate is low, the oil quality of regenerated oil is poor, the environment is polluted and the like in the prior art are solved. The method for regenerating the base oil by the waste oil comprises a raw material pretreating part and a solvent refining part; wherein the raw material pretreating part comprises three phases of prefractionation, reduced pressure distillation cutting and molecular distillation; the solvent refining part comprises the steps of extraction, refined solution recovery, extracted solution recovery and solvent recovery; the molecular distillation refers to the process that tower bottom oil of a reduced pressure distillation tower is fed into a short-path distiller, and separating fuel oil and residues through two-stage molecular distillation under the condition that the pressure is 0.001 to 100Pa. The method provided by the invention is suitable for regenerating the base oil by the waste oil.

Owner:山东铂铠环保科技有限公司

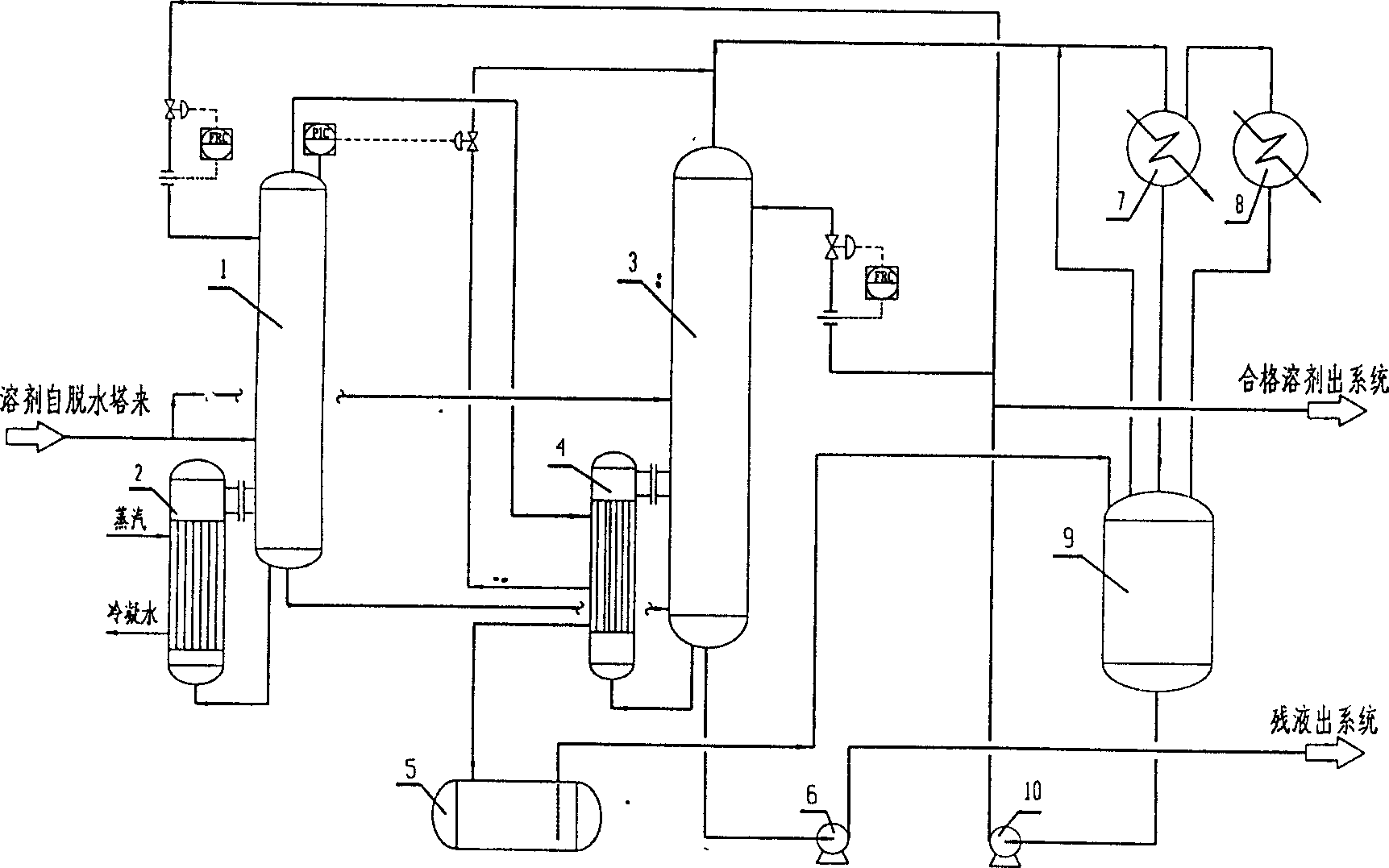

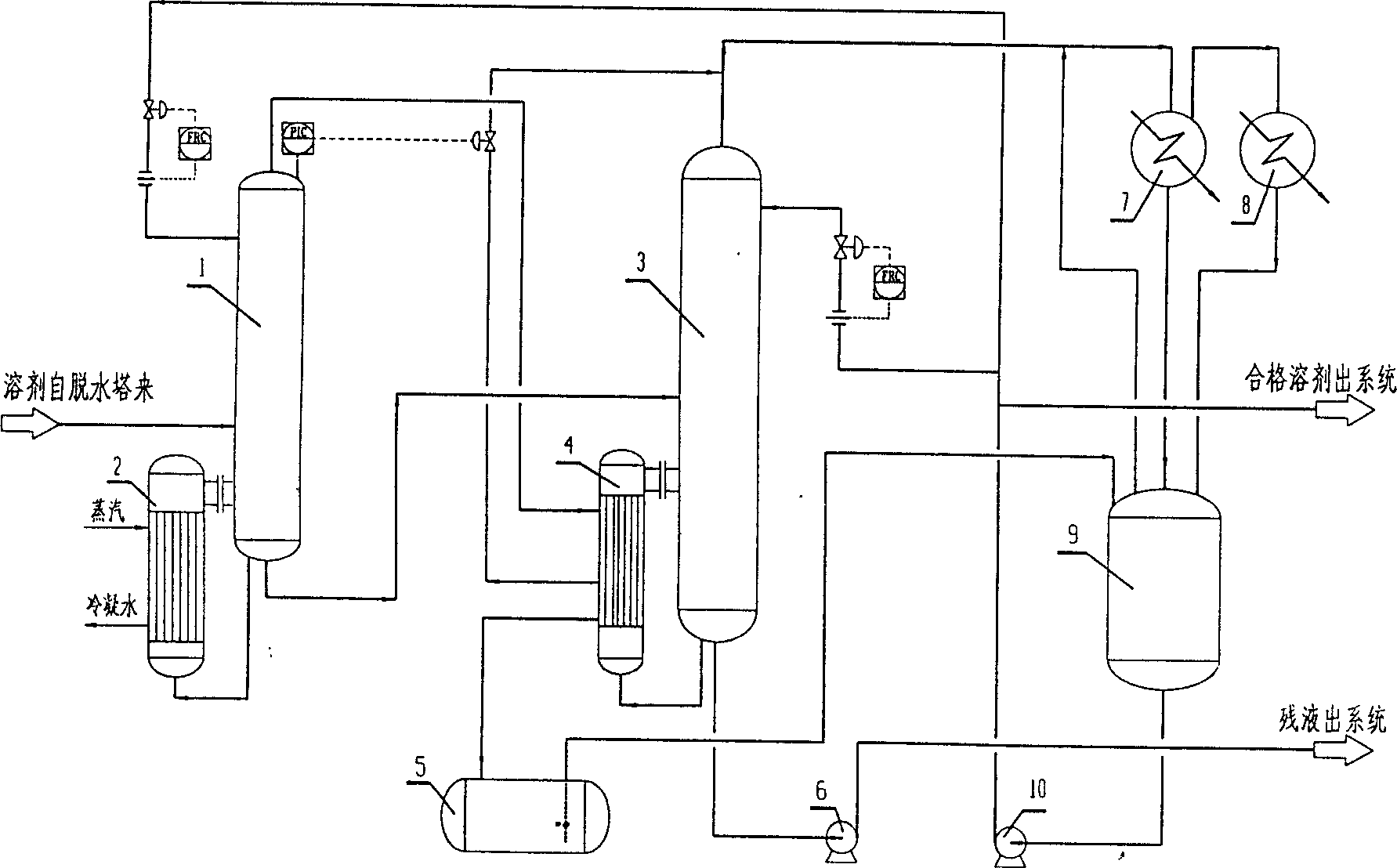

Refining and reclaiming technology of tail gas absorption solvent in production of toluene diisocyanate

InactiveCN101870666AContinuous and stable feedingContinuous and stable dischargeDispersed particle separationDistillation purification/separationToluene diisocyanateGas phase

The invention relates to a refining and reclaiming technology of a tail gas absorption solvent in the production of toluene diisocyanate (TDI). The solvent containing little phosgene, toluene diisocyanate and di-Et-1,3-benzenedicarboxylate (DEIP) performs two-stage refinement in an atmospheric refining tower and a vacuum refining tower, and a falling-film evaporator and a storage tank are arranged between the two towers. The overhead non-condensable gas phase of the atmospheric refining tower is returned to a phosgene absorption tower to recycle phosgene, the refined solvent is drawn from theside of the atmospheric refining tower, the temperature of the tower bottom is controlled to be 3-8 DEG C higher than the boiling point of the solvent, the discharged material of the tower bottom enters the falling-film evaporator, the evaporating temperature is 20-30 DEG C higher than the boiling point of the solvent, the unevaporated material enters the storage tank for storage, the material inthe storage tank performs batch vacuum rectification under the absolute pressure of 0.1-0.25bar, and the unevaporated residual material enters the residue evaporator of a TDI device to recycle TDI and DEIP. By using the solvent refining technology provided by the invention, the useful components in the solvent can be completely recycled, and the technology has the advantages of simple and stable operation and lower cost and energy consumption.

Owner:QINGDAO UNIV OF SCI & TECH +1

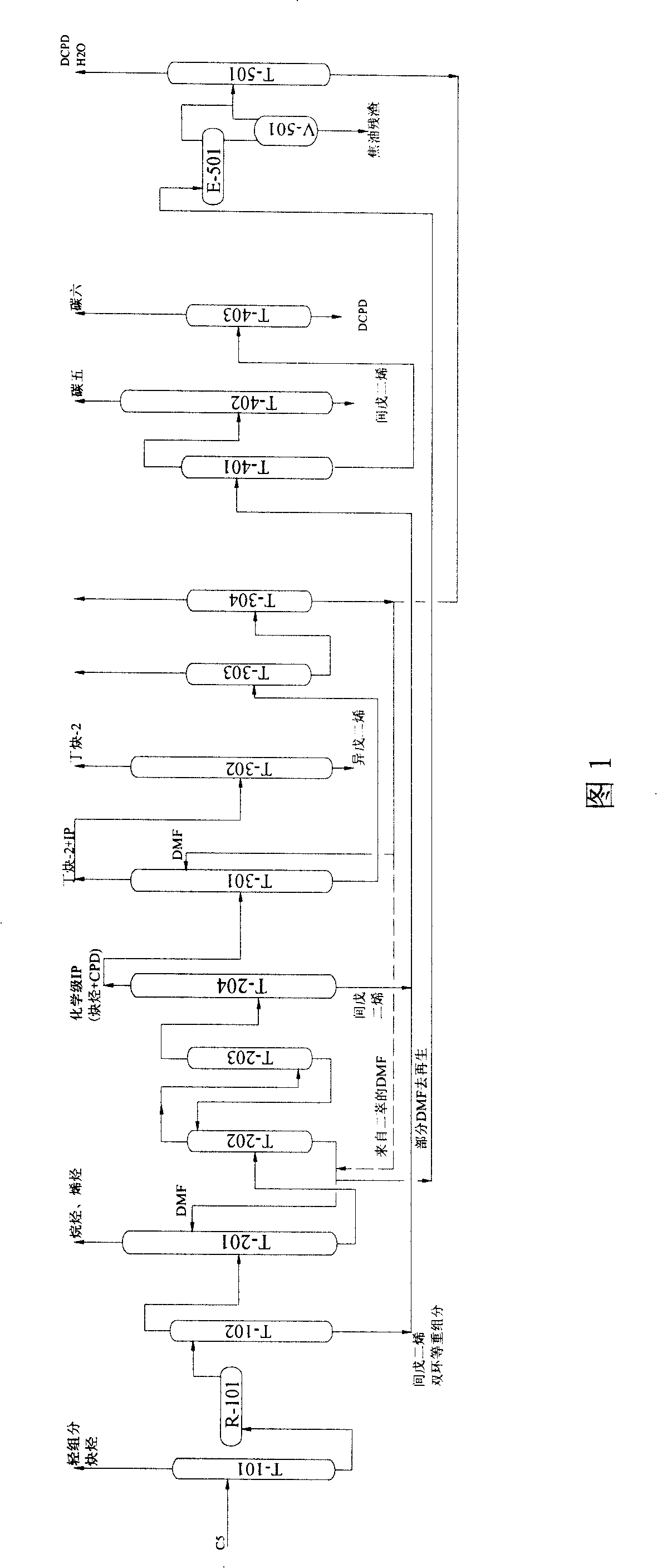

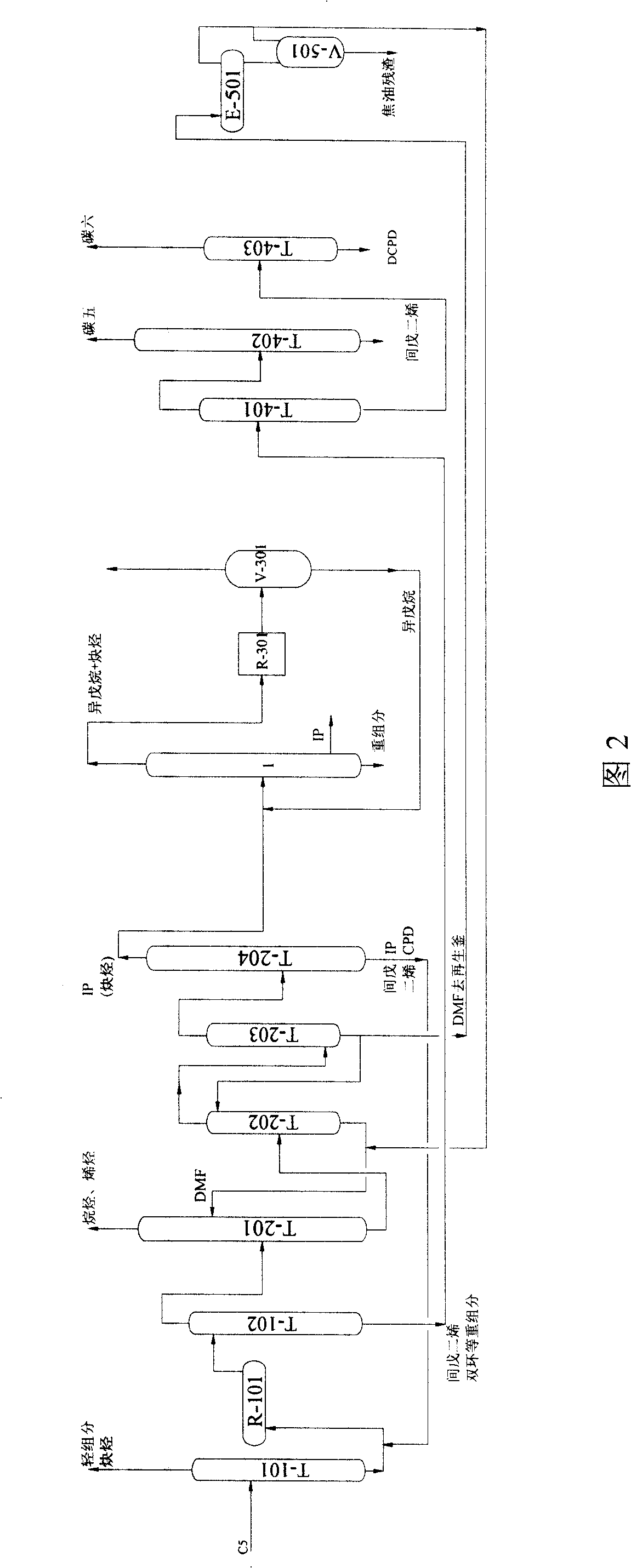

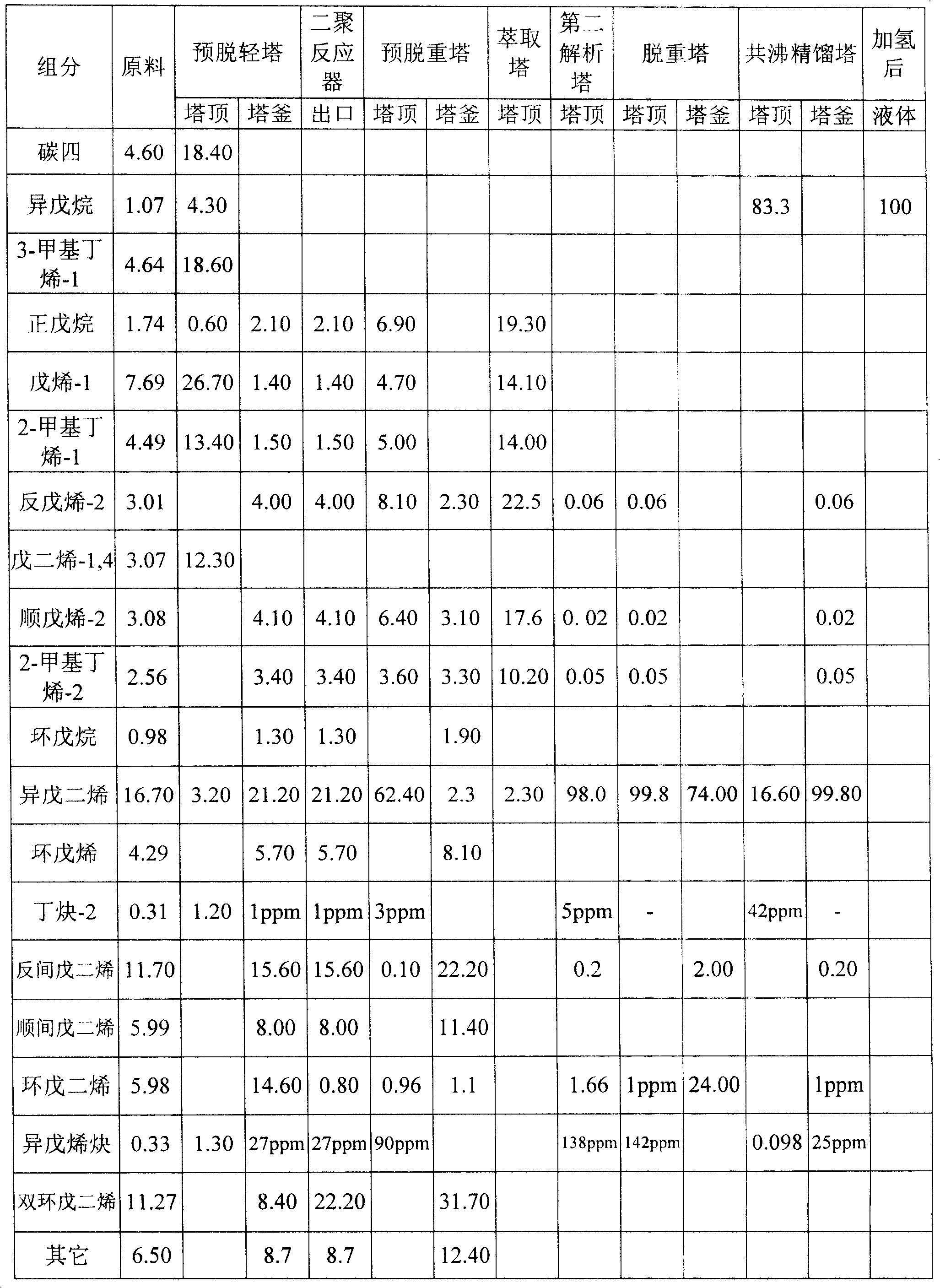

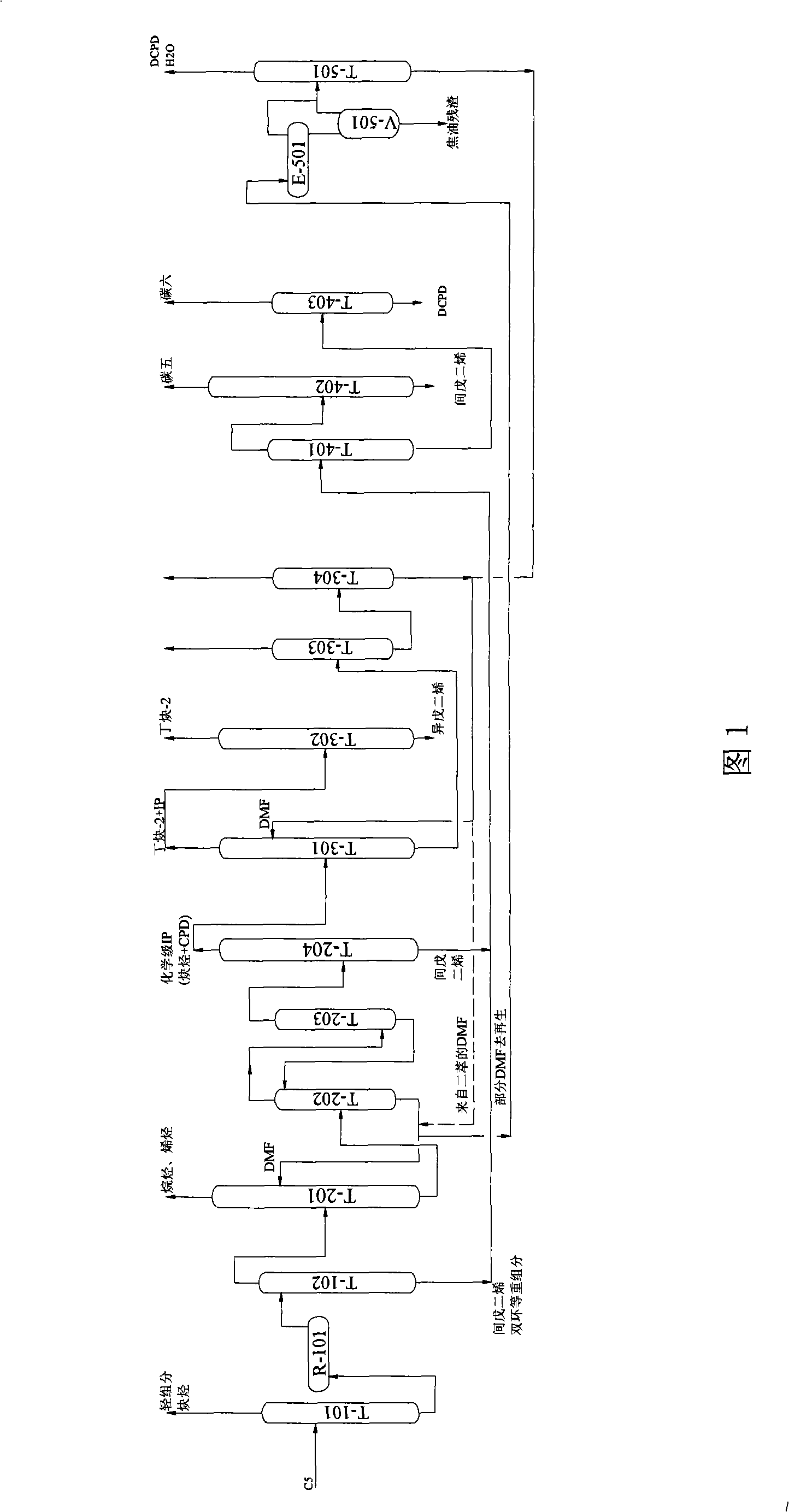

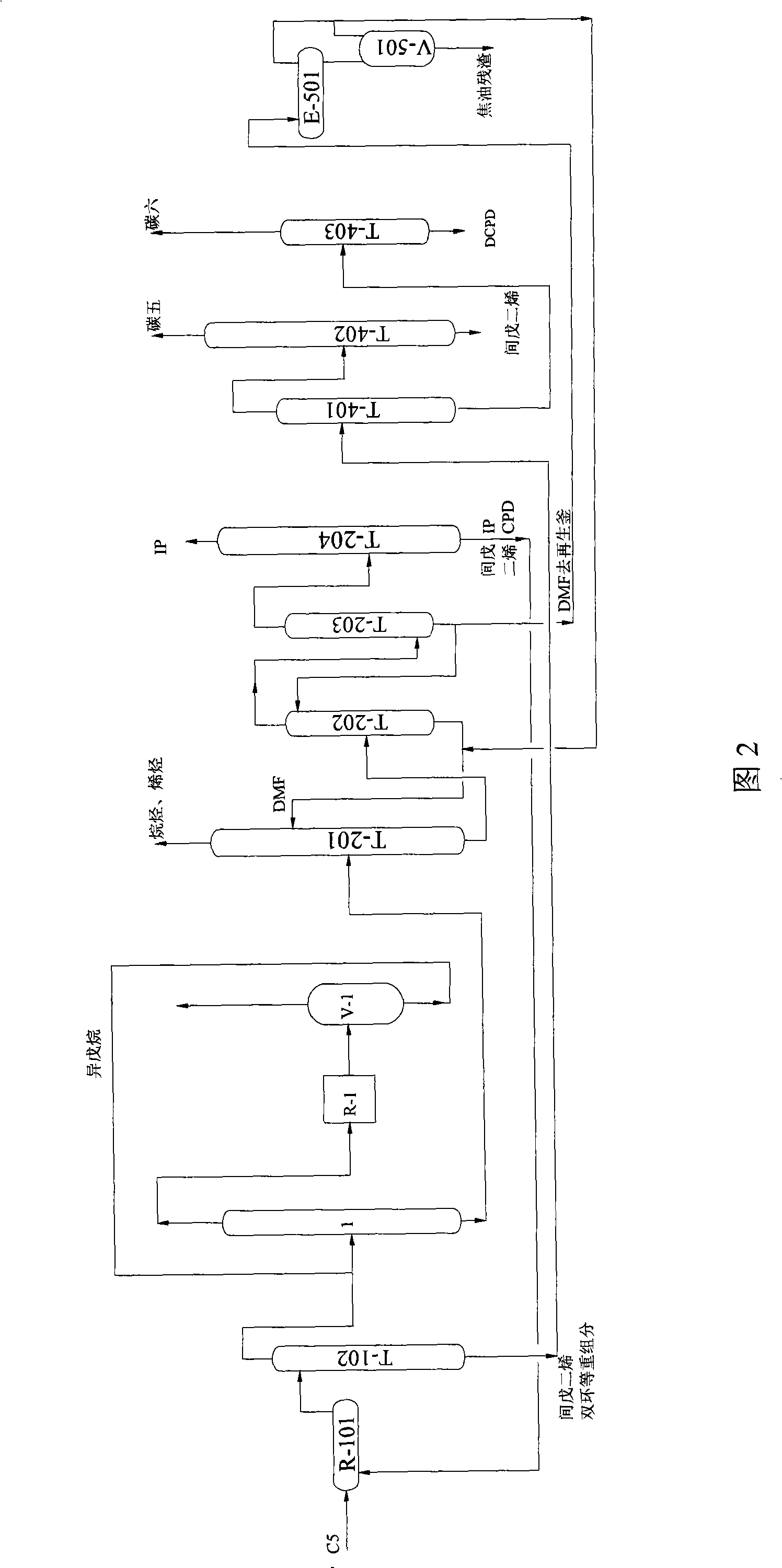

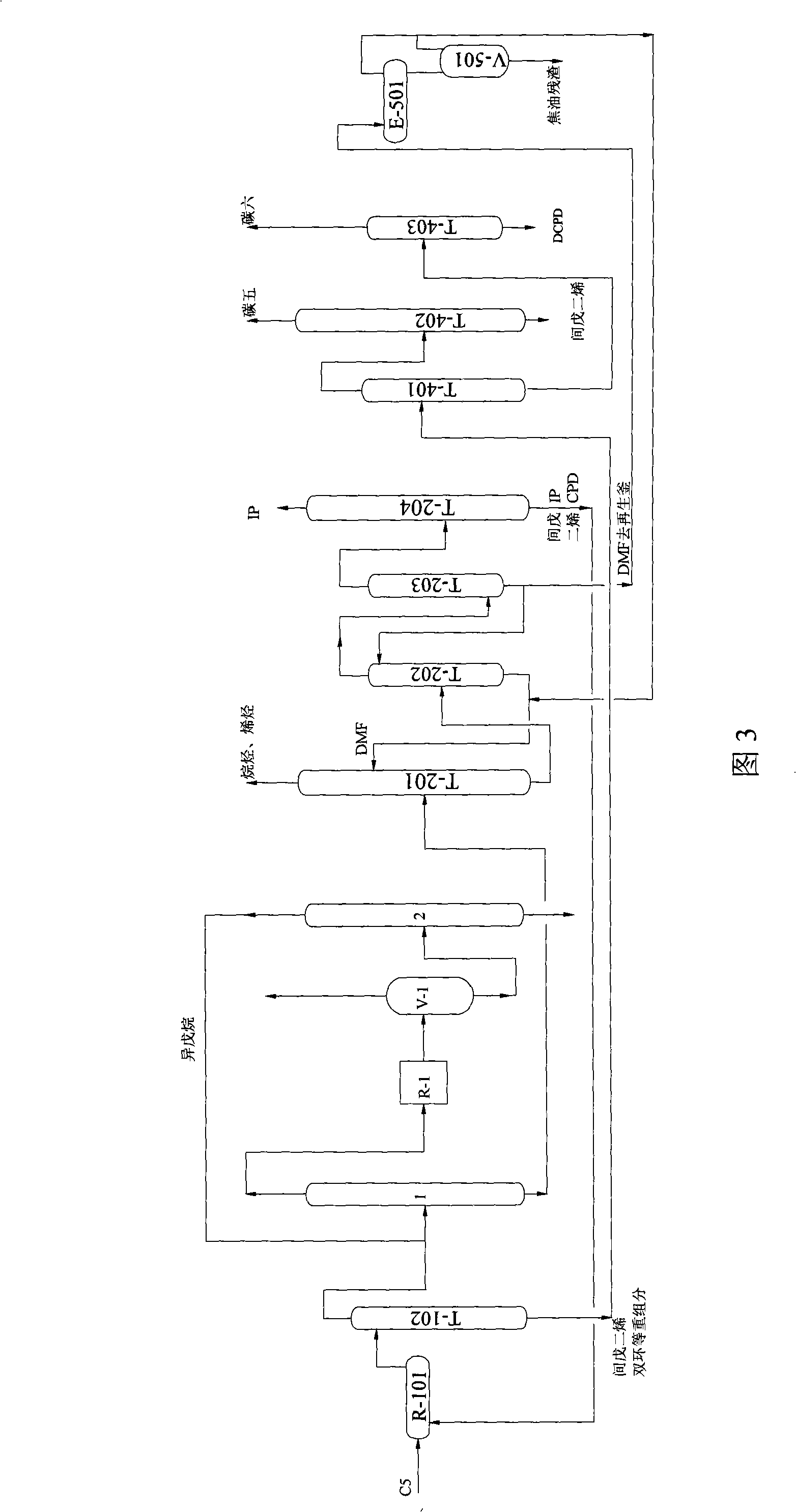

Method for one-section abstraction distillation separation cracking carbon 5-cut fraction

The invention relates to a section of extracting, rectifying, separating and cracking 5 carbon stream which belongs to the technical field of separating 5 carbon stream, and provides a method of a section extracting, rectifying, separating and cracking 5 carbon stream in order to solve the problems of a second extraction unit in the existing carbonium 5 separation process, such as high energy consumption, complex operation, harsh operation demand and big extraction solvent loss, etc.; the method adopts distillation method to remove isoprene and uses an azeotropy distillation method to remove alkyne; a polymerization grade isoprene product is obtained with no need of two times extraction and the second extraction unit and a solvent refining tower are omitted. The method of a section extracting, rectifying, separating and cracking 5 carbon stream is simple in operation, easy in operation and low in production cost; the energy consumption of the polymerization grade isoprene product unit of the invention is about 20 percent of the existing second extraction unit in the same treating load of the raw material; m-pentadiene is produced from a pre-deheavy tower kettle and does not enter an extraction and distillation unit; the throughput of the extraction and distillation tower, an absorption tower and a de-heavy tower is reduced by 50 percent with the energy consumption being reduced by 50 percent correspondingly, and construction cost and production cost are reduced largely. .

Owner:CHINA PETROLEUM & CHEM CORP +1

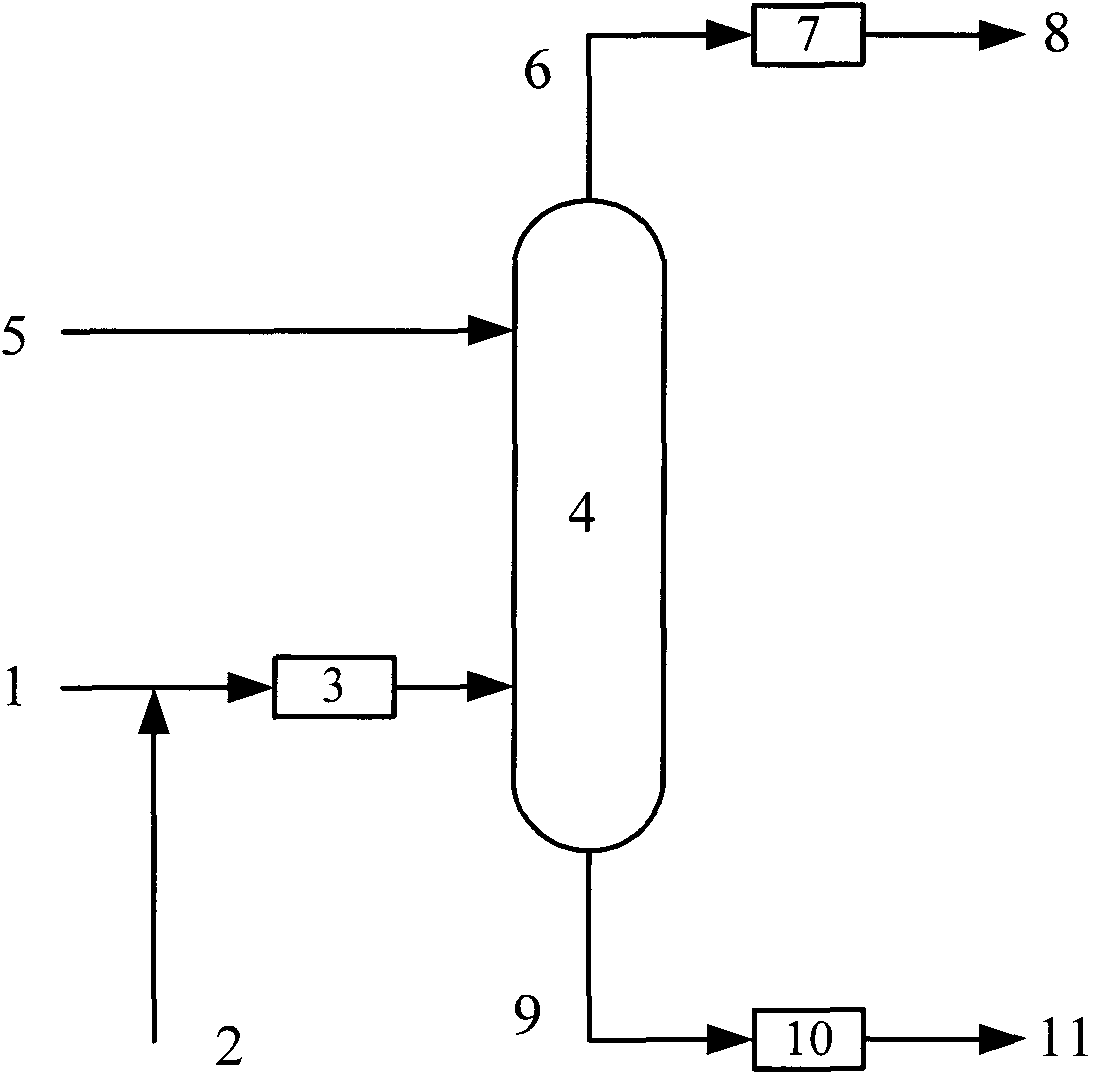

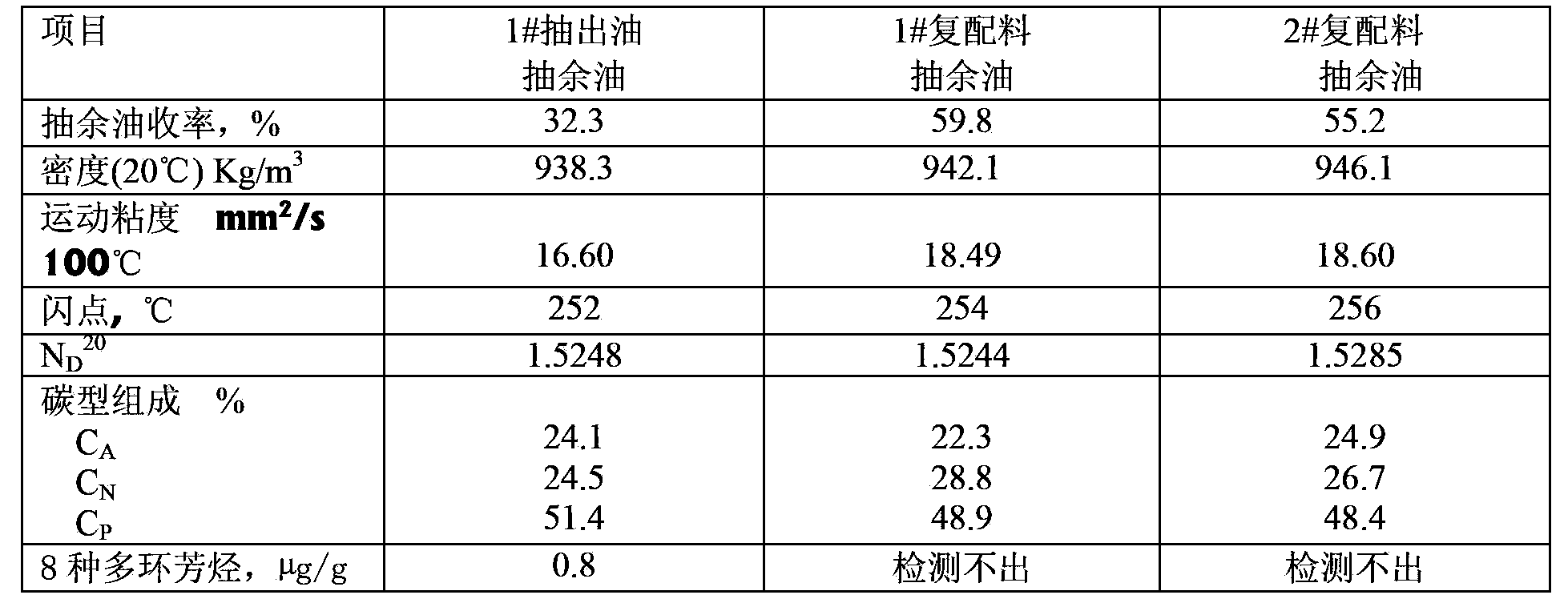

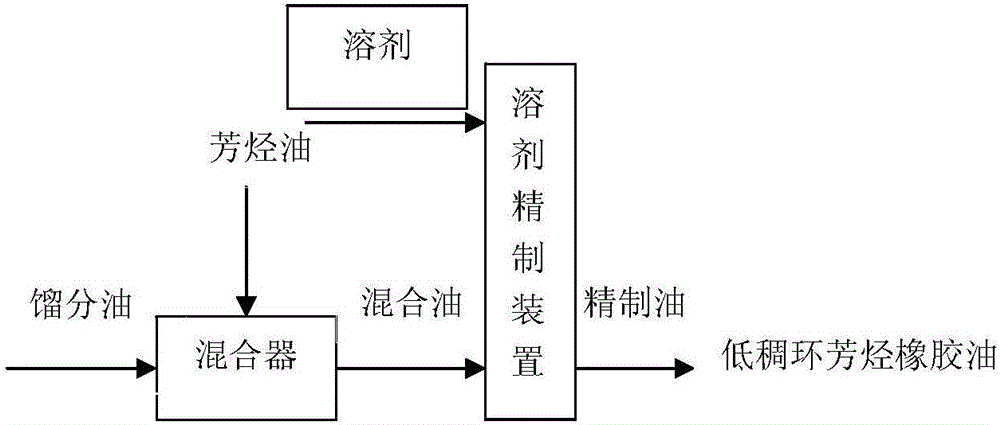

Preparation method for distillate aromatic extract (DAE)

The invention relates to a preparation method for DAEs, comprising the following steps that: raw oil and a diluting solvent are mixed, the mixed solution enters into an extraction tower and contacts with an extraction solvent in the extraction tower, and raffinate oil is separated from raffinate, wherein the raw oil is extract oil obtained by solvent refining and / or de-waxing oil of the extract oil, the diluting solvent contains a main solvent, the extraction solvent contains the main solvent and an anti-solvent, and the main solvent has greater dissolvability of aromatic hydrocarbons than of alkane. According to the invention, the preparation method has high extraction efficiency; the extraction solvent used has good selectivity; DAE prepared by the method has high yield; the content of benzo(a)pyrene and the total content of 8 PAHs, namely, benzo(a)anthracene, chrysene, benzo(b)fluoranthene, benzo(k)fluoranthene, benzo(j)fluoranthene, benzo(a)pyrene, benzo(e)pyrene and dibenzo(a,h)anthracene, are low, which is in accordance with the European Union 2005 / 69 / EC instruction; the content of polycyclicaromatics is less than 3%.

Owner:CHINA PETROLEUM & CHEM CORP +1

Refining technique of base oil regenerated from used lubrication oil

Disclosed is a refining technique of base oil regenerated from used lubrication oil, and the refining technique comprises the following steps of 1, removing solid waste, which includes removing solid waste from used lubrication oil by centrifugation; 2, solvent pretreatment, which includes extracting mixed impurities and moisture through a solvent and obtaining raw oil after removing upper oil; 3, flocculation treatment, which includes turning mixtures obtained from step 2 into a mixture of flocculation; 4, atomospheric distillation; 5, carrying out reduced pressure distillation; 6, carrying out rectification; 7, solvent refining: putting oil produced from a rectifying column into a treatment tank and when the height of the oil level in the treatment tank reaches 65%-75% of the height of the treatment tank, adding by mass 10%-40% of 1-Methyl-2-pyrrolidinone, and carrying out solvent refining. The refining technique of base oil regenerated from used lubrication oil has the advantages of low investment and high yield efficiency, meanwhile, the refining technique accords with the requirement of environmental protection, reduces vacuum residuum by 15%, improves product yield, facilitates the overhauling of equipment, prolongs the production period, largely improves production efficiency and appearance quality of minus line oil, and helps to obtain high quality regenerated base oil.

Owner:济南亿诺再生资源有限公司

Preparation method and application of trichloroacetone with high purity

ActiveCN101768066ASimple processEasy to operateOrganic compound preparationCarbonyl compound preparationSolvent refiningCrystallization

The invention discloses a preparation method of trichloroacetone with high purity, which uses a solvent refining method to prepare the trichloroacetone with high purity and comprises the following two steps: step one, using mixed solvent of varsol and polar solvent for recrystallization; and step two, using mixed solvent and fatty acid ester and varsol for recrystallization to improve the purity of the trichloroacetone with low purity to above 80-98%.

Owner:ZHEJIANG SHENGDA BIO PHARM +1

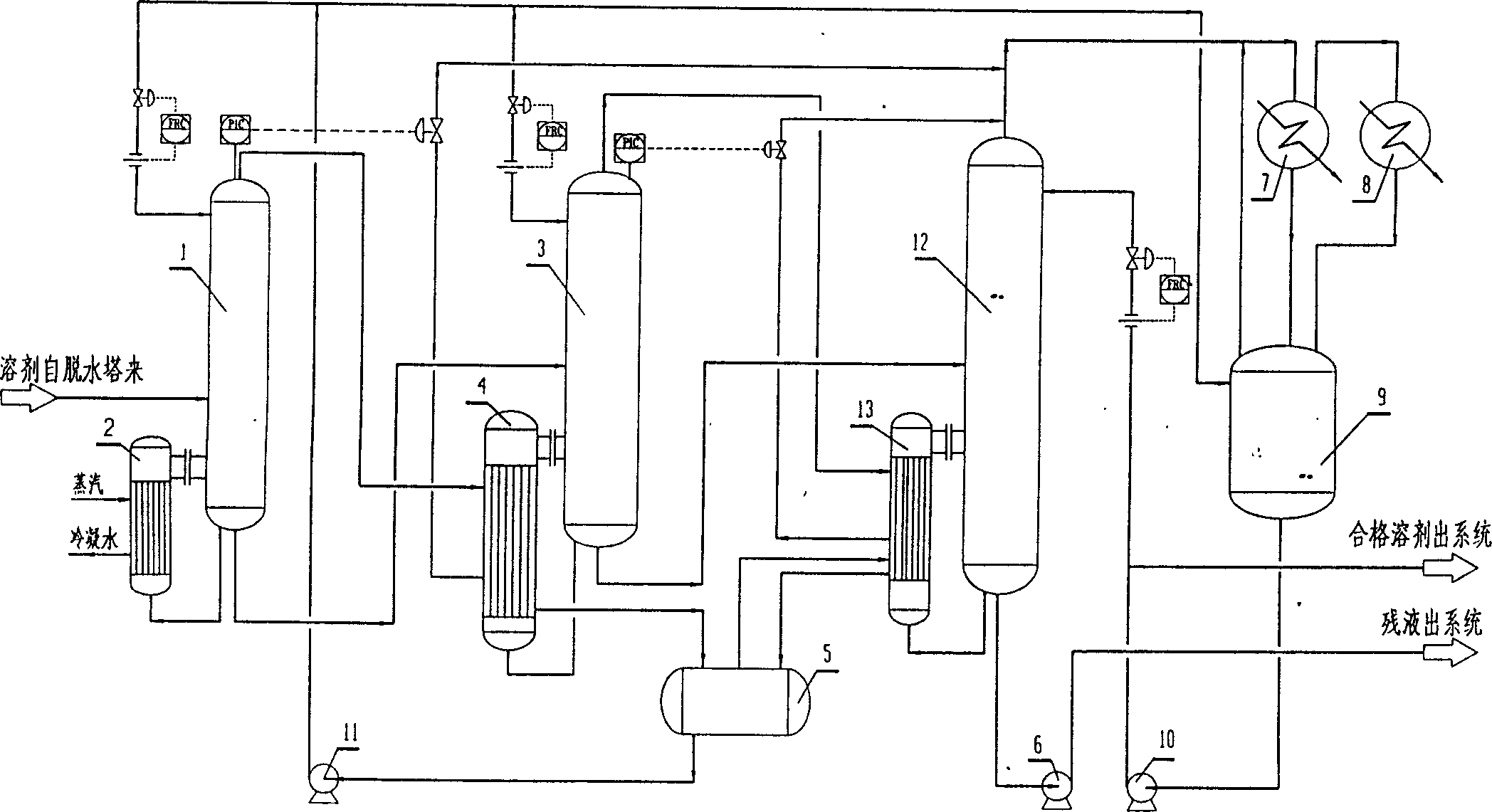

Technique of refining solvent in process of producing synthetic rubber

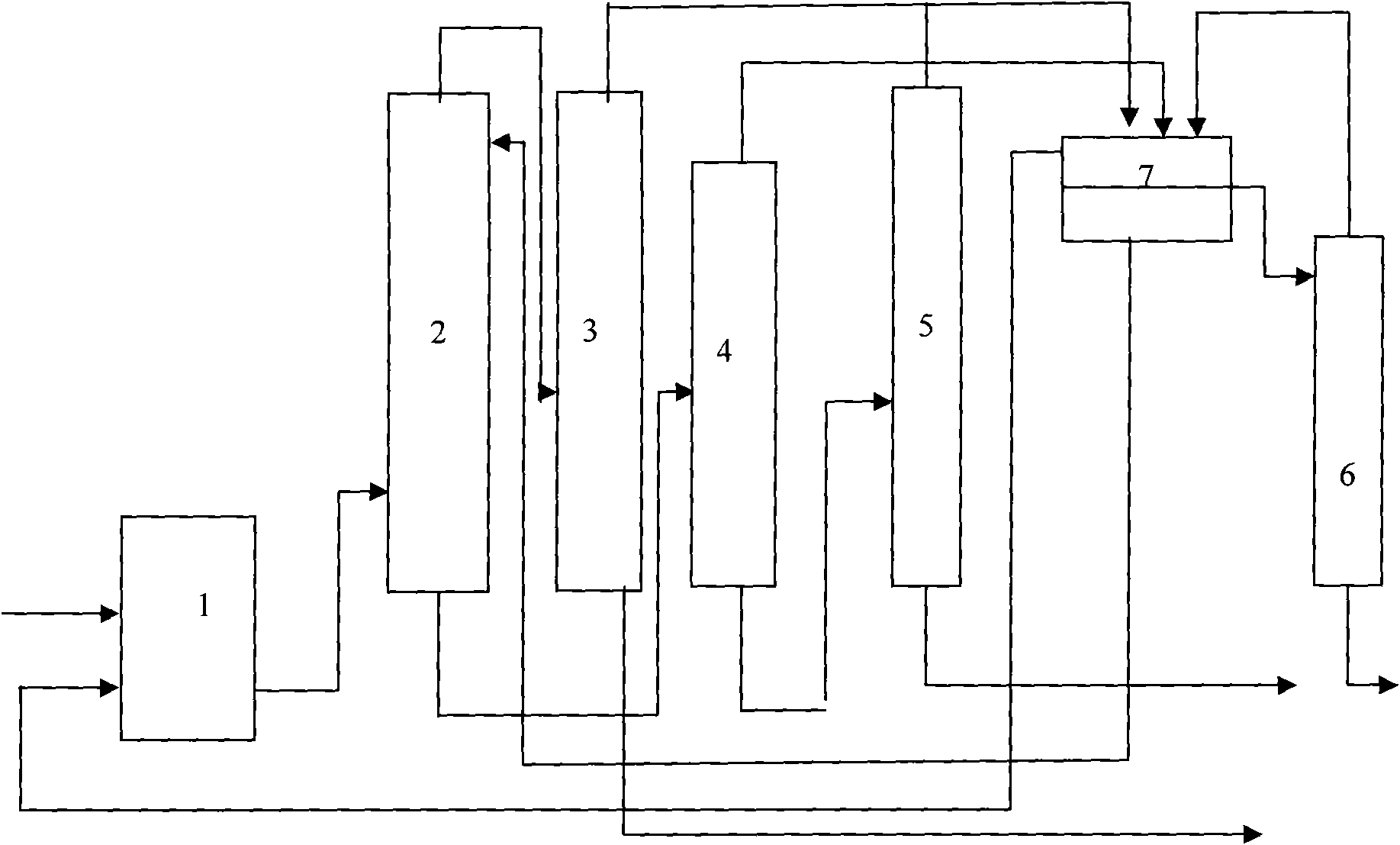

the invention discloses a solvent refining technology of rubber synthetic manufacturing course, which is characterized by the following: adopting multiple rectifying towers to replace present single rectifying tower to reduce steam by about 60-50%; adopting cooled heat of last rectifying top gas as heat source of next tower through improving operational pressure of one tower to utilize pressure difference and temperature difference of each tower; adopting two-effective paralleling combination, two-effective cascading combination or three-effective cascading combination in the course.

Owner:HUNAN BAILI ENGINEERING SCIENCE AND TECHNOLOGY CO LTD

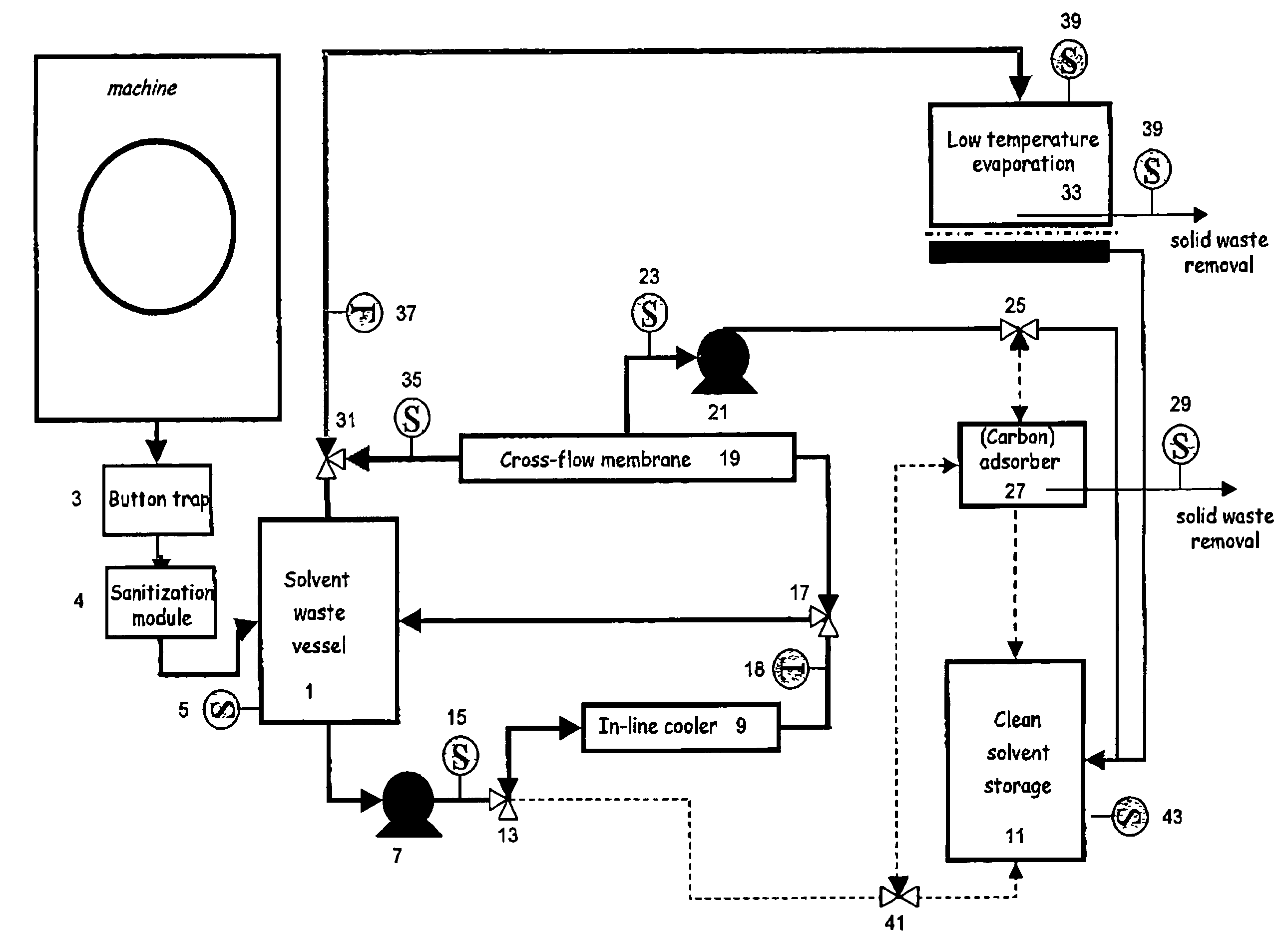

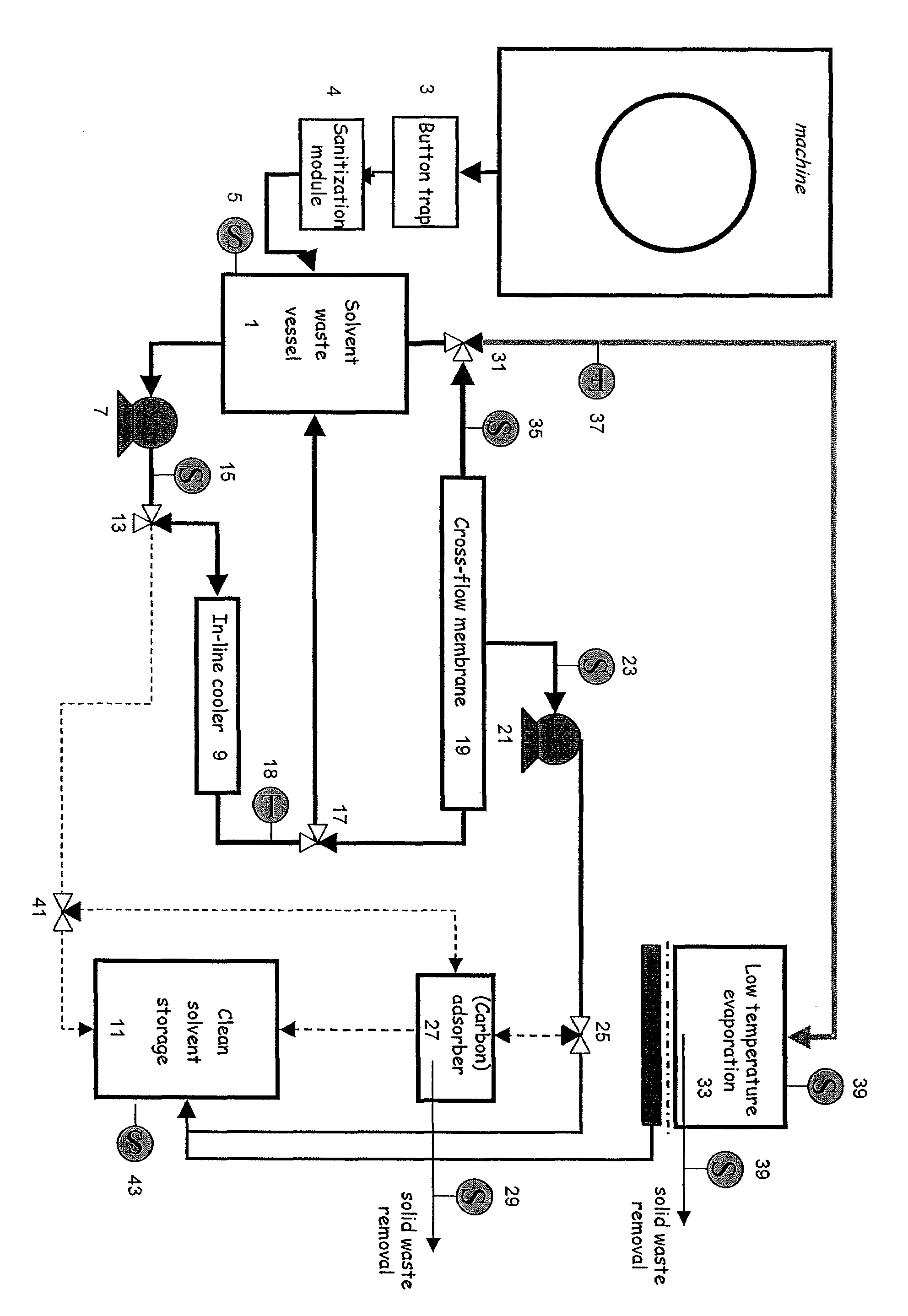

Solvent cleaning process

InactiveUS7497877B2Small apertureDegrade solventDry-cleaning apparatusSolid sorbent liquid separationSolvent refiningDry cleaning

An improved solvent cleaning process of cleaning a non-aqueous solvent used in a dry cleaning process for fabrics including consecutive wash cycles for washing respective fabrics batches, including a basic solvent refining cycle and a first advanced solvent refining cycle, the basic solvent refining cycle including a step of separating solvent into a first solvent fraction and a second solvent fraction which is less clean than the first fraction, wherein the basic and first advanced solvent refining cycles are independently effected when solvent to be cleaned fulfils a respective predetermined condition.

Owner:WHIRLPOOL CORP

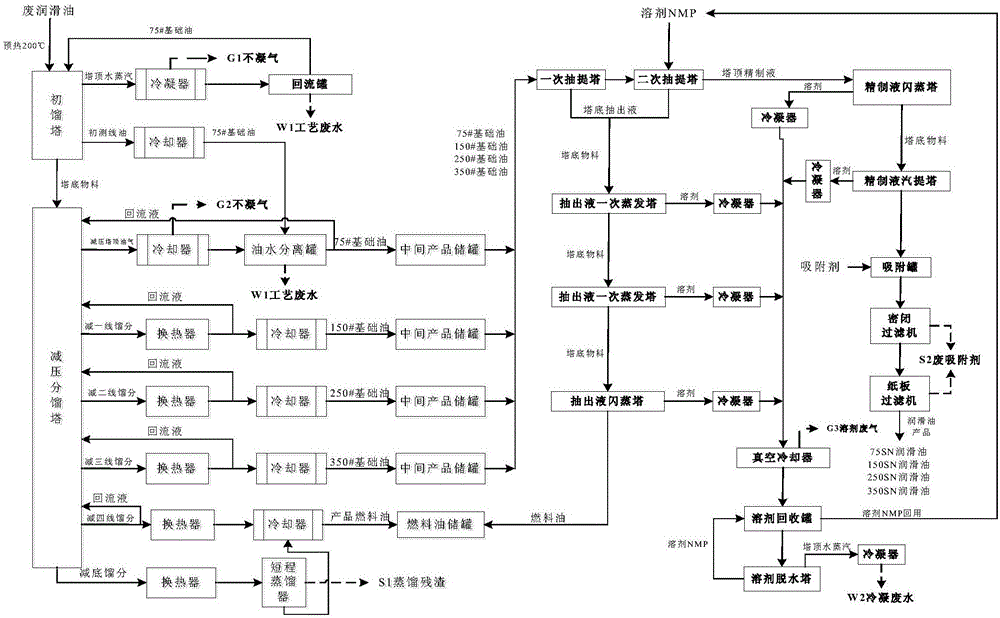

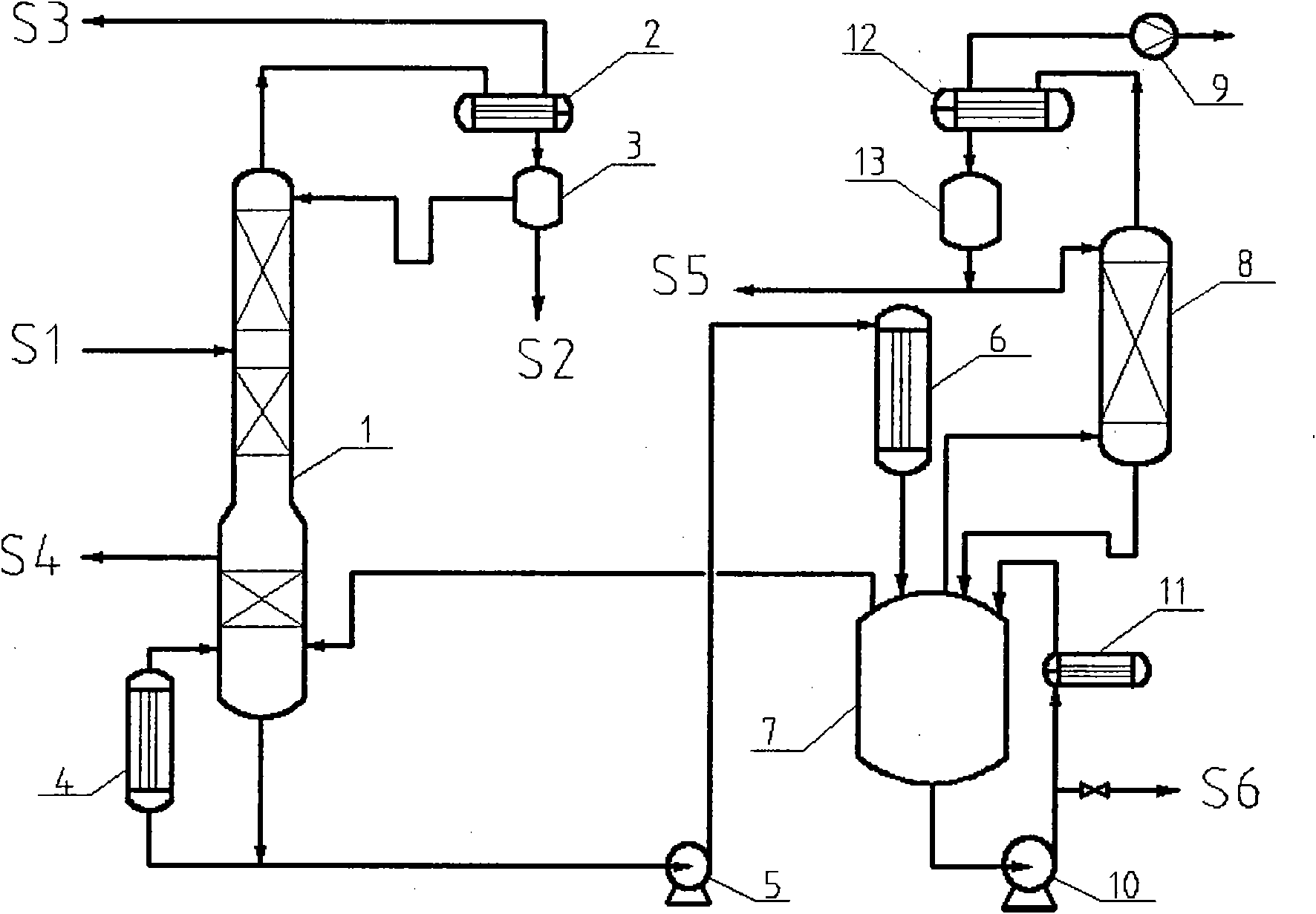

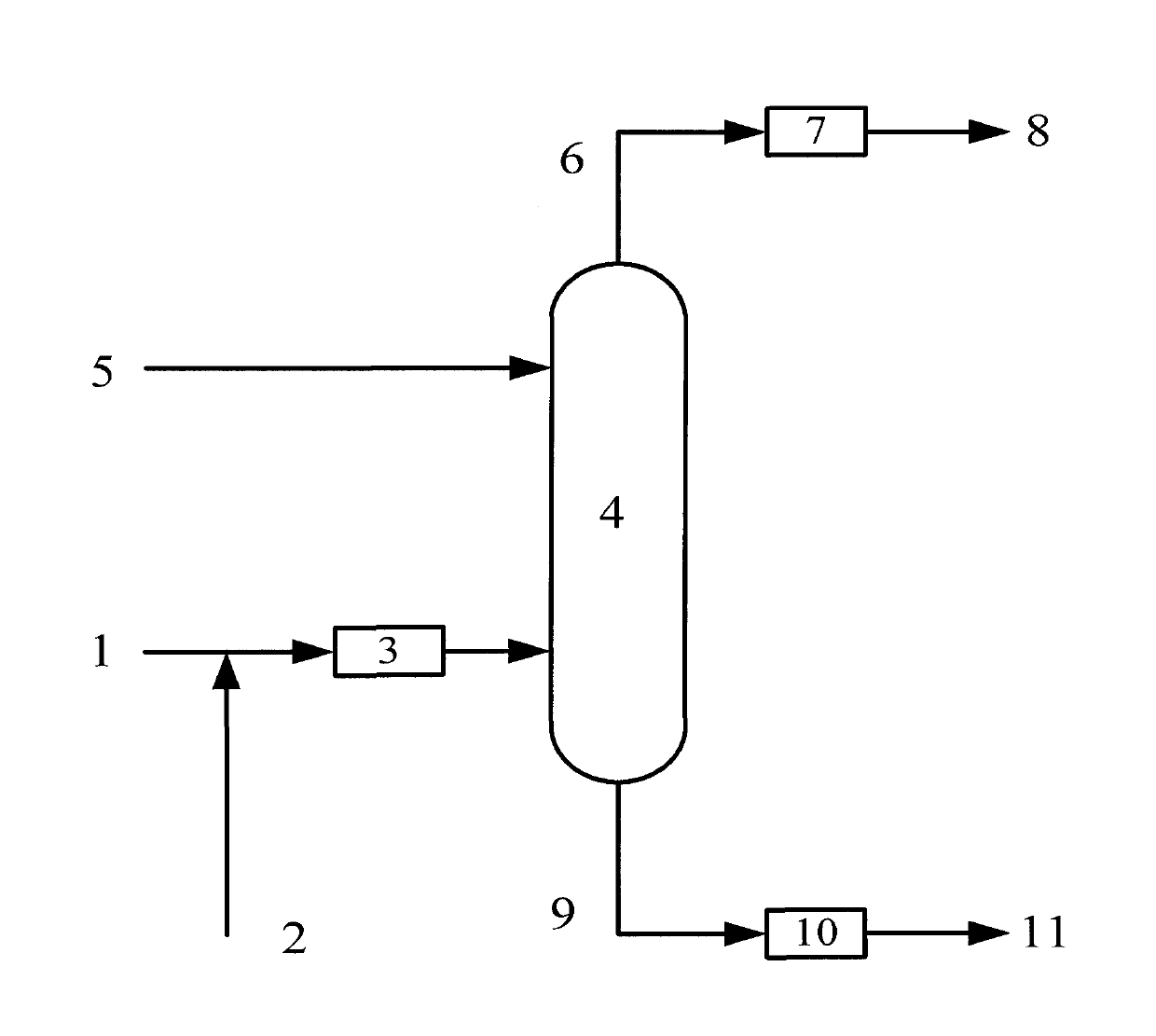

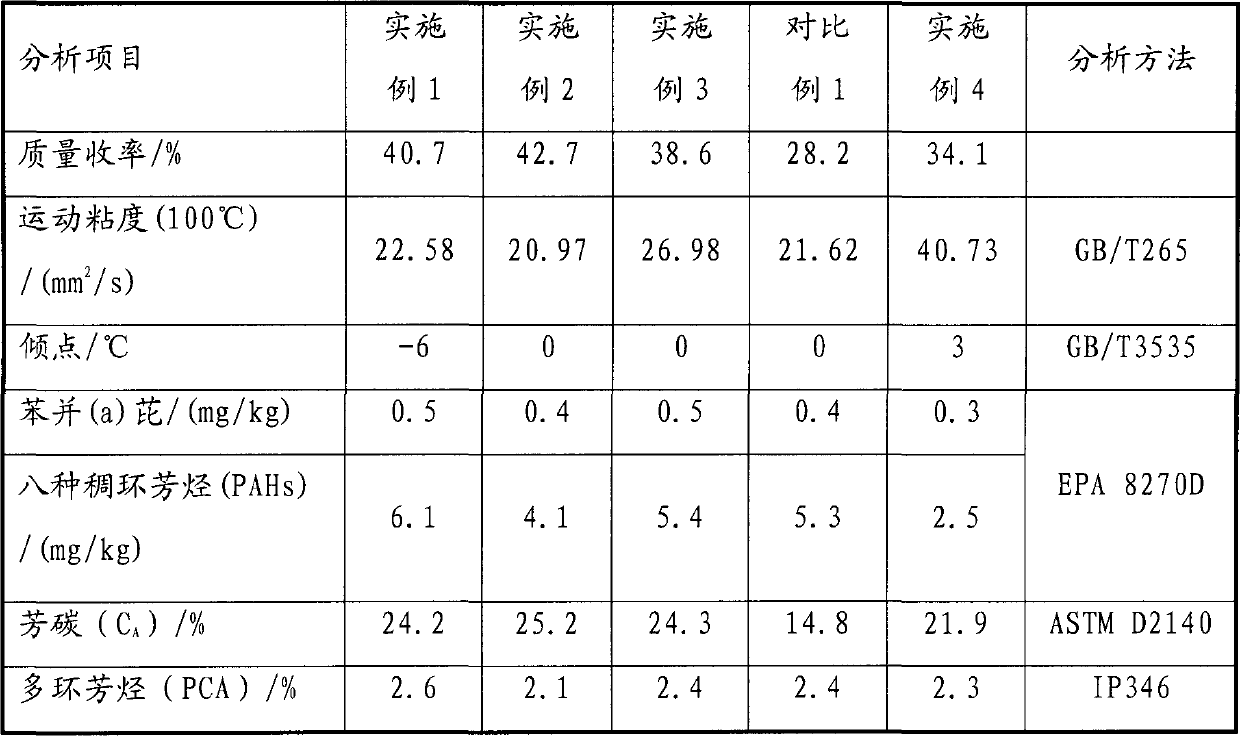

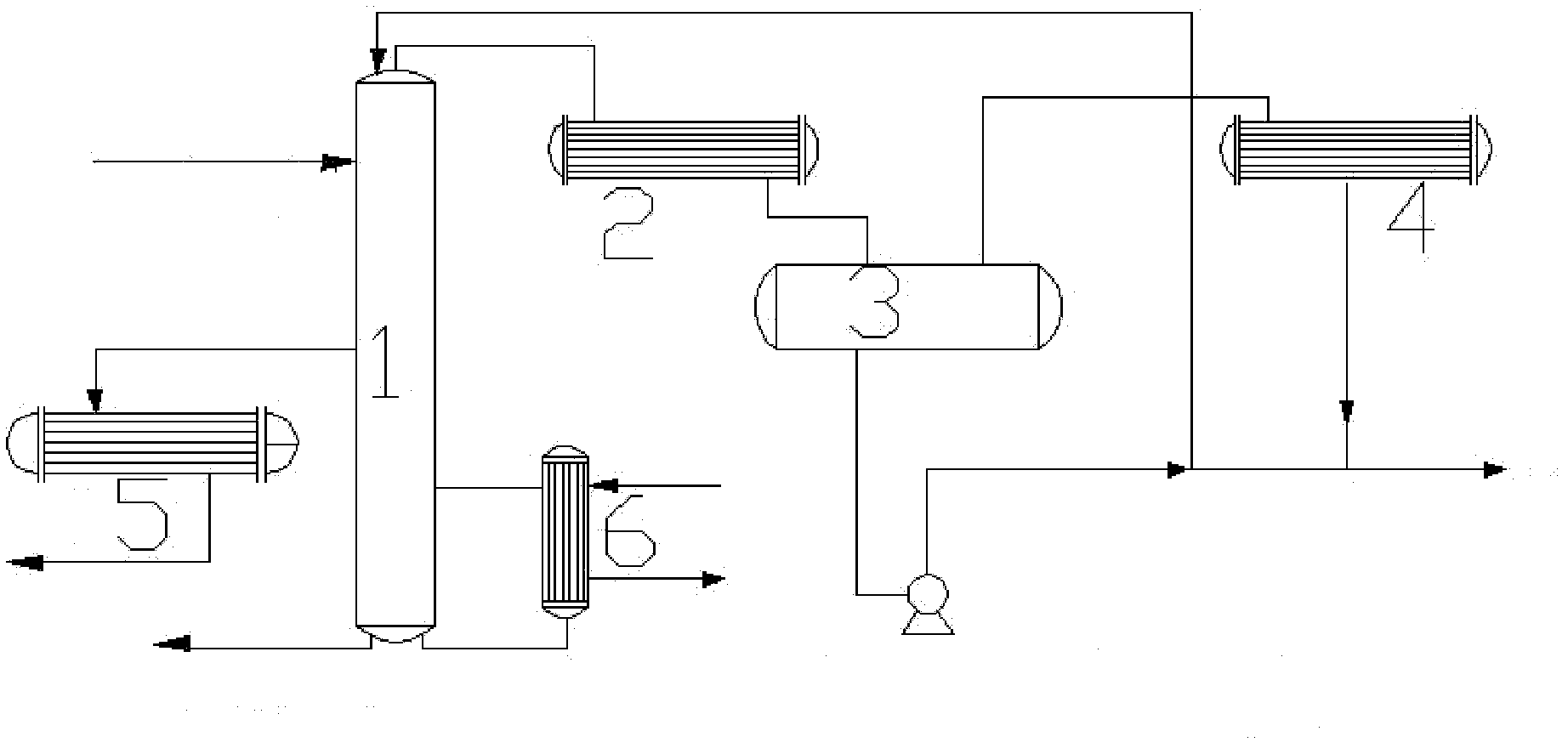

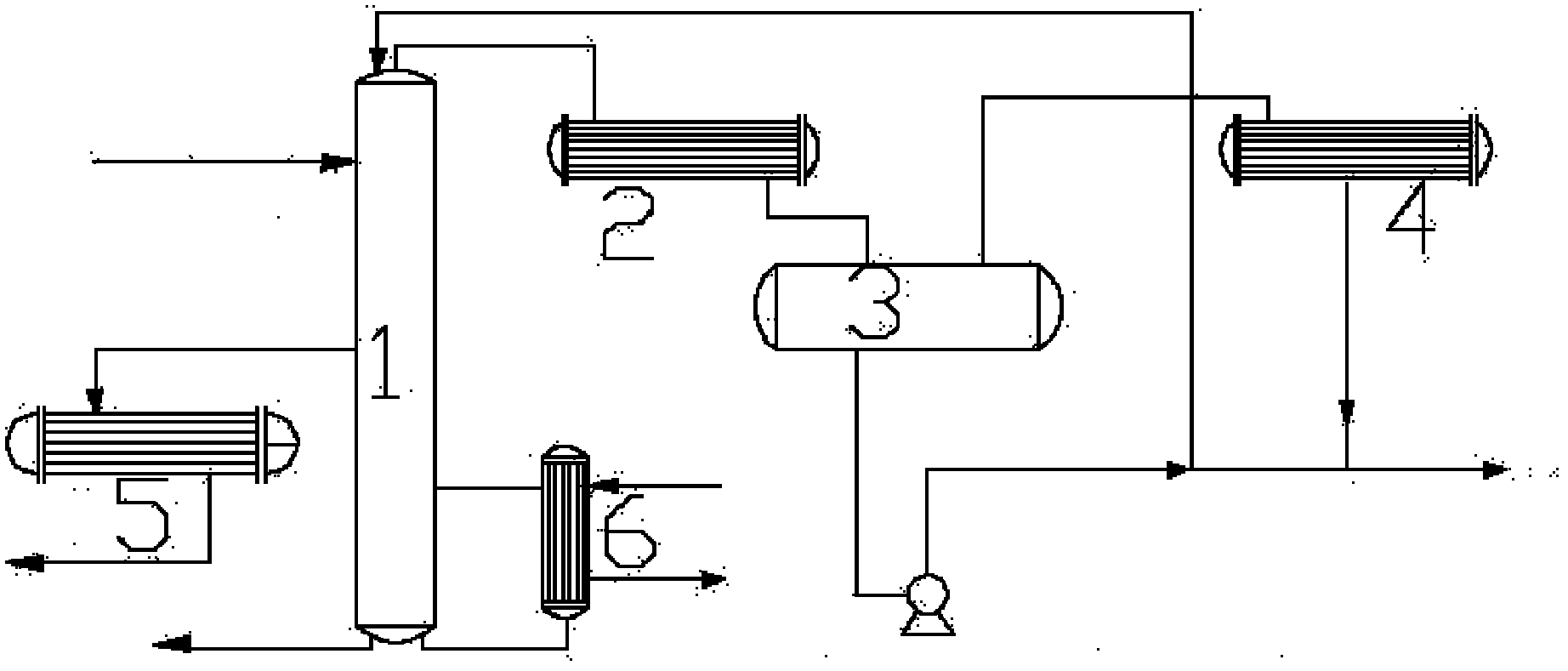

Raw oil optimization method for improving environment-friendly rubber filling oil aromatic hydrocarbon content and equipment

The invention belongs to the technical field of petrochemical engineering and discloses a raw oil optimization method for improving environment-friendly rubber filling oil aromatic hydrocarbon content and equipment. The method includes: performing solvent refining in a counter-current extraction tower by taking heavy lubricating oil solvent extract oil as raw oil, recovering solvent from tower top raffinate liquid by means of steam stripping so that environment-friendly high-aromatic-hydrocarbon rubber filling oil is obtained, and enabling part of raffinate oil or raffinate liquid to enter the extraction tower from a raw oil inlet to the lower portion of a solvent inlet, wherein the mass ratio of the raffinate oil or the raffinate liquid to the raw oil is 0.1 to 2.0:1.0; and recovering solvent from extraction tower bottom extract by means of evaporation and steam stripping so that extract oil is obtained, enabling part of the extract oil to mix with the extract at a bottom circulation extraction outlet of the extraction tower, and enabling the mixture to enter the extraction tower from a bottom circulation inlet of the extraction tower after cooling, wherein the mass ratio of the extract oil entering bottom circulation to the raw oil is 0.2 to 2.0:1.0.

Owner:PETROCHINA CO LTD

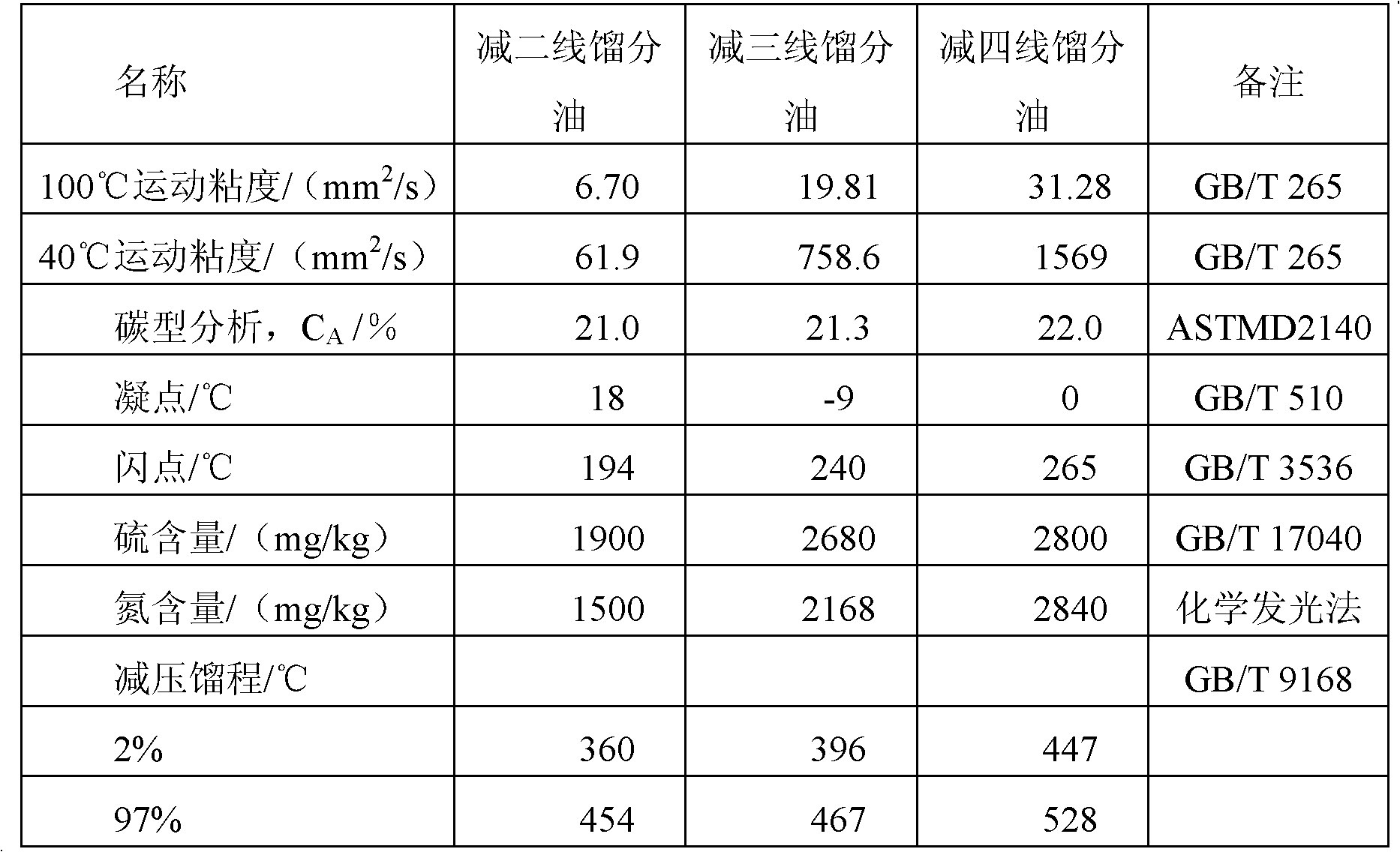

Rubber oil with low aromatic hydrocarbon content and preparation method thereof

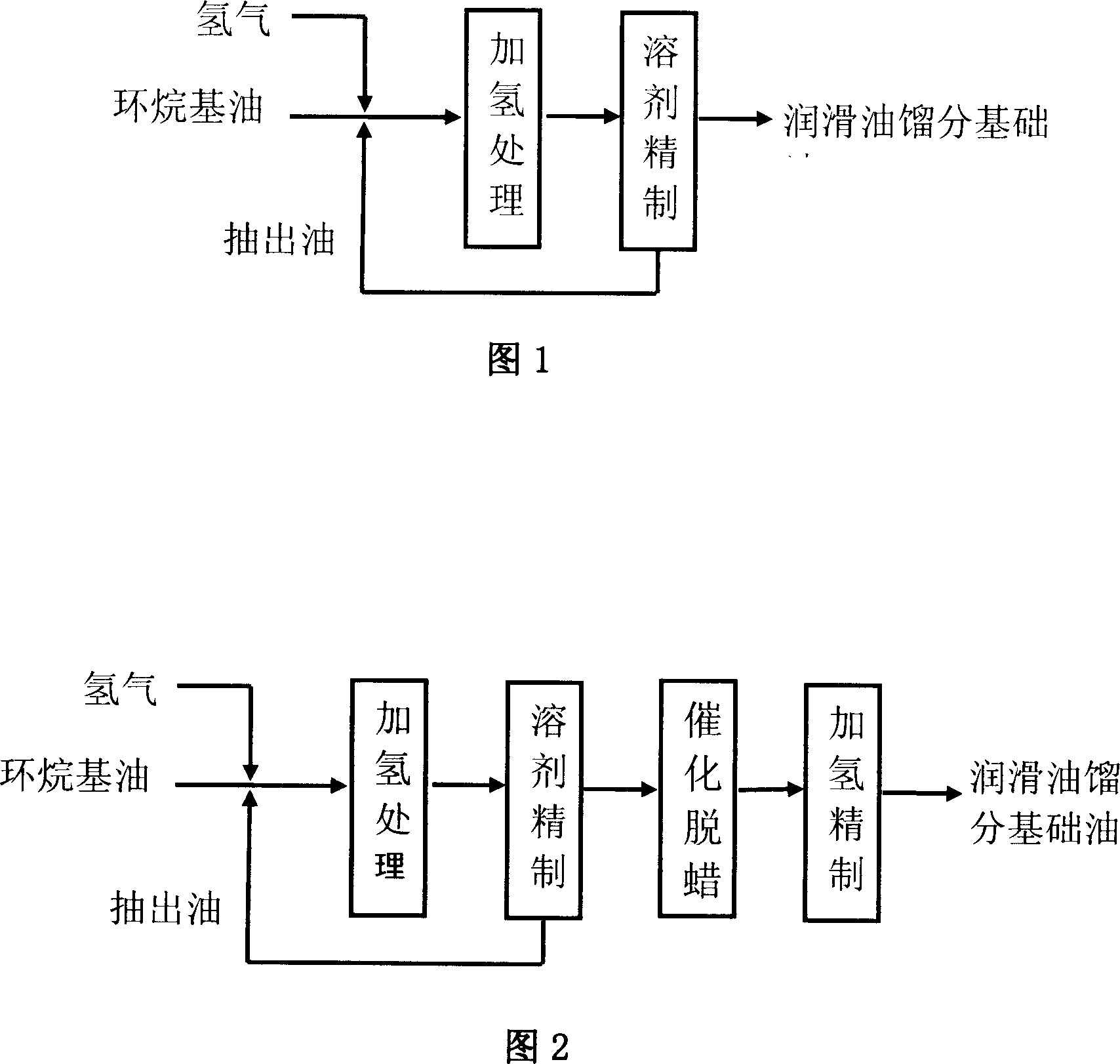

ActiveCN102585901ALess resource reservesHigh freezing pointTreatment with hydrotreatment processesHydrogenTower

The invention discloses rubber oil with low aromatic hydrocarbon content and a preparation method thereof. The method comprises the following steps of: (1) placing naphthenic base distillate oil in a solvent refining tower to perform solvent refining, obtaining refined liquid on the tower top of the solvent refining tower and recovering solvent to obtain refined oil, and obtaining extract at the tower bottom and recovering solvent to obtain extract oil; and (2) performing hydrotreating, hydrodewaxing and hydro-finishing on the refined oil in sequence to obtain hydrogenation full distillate oil, distilling the hydrogenation full distillate oil, and removing light fraction to obtain the rubber oil with low aromatic hydrocarbon content. The rubber oil produced by the invention has extremely low aromatic hydrocarbon content, extremely high naphthenic hydrocarbon content, high solvability, product CN value of greater than 48 percent and even greater than 50 percent and saybolt color of reaching or exceeding +30; and the extract oil refined from the solvent obtained by the preparation method has high aromatic hydrocarbon content and is a high-grade raw material for producing environmentally-friendly rubber oil with high aromatic hydrocarbon content.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Tractor five-purpose lubricating oil composition

The invention relates to a tractor five-purpose lubricating oil composition comprising the following components in percentage by weight: 3.5-5.5% of high-temperature detergent, 3.5-5.0% of ashless dispersant, 1.0-1.7% of oxidation and corrosion inhibitor, 0.4-2.5% of oiliness agent, 0.03-0.1% of metal deactivator, 5.0-12.0% of viscosity index improving agent, 0.3-0.8% of pour point depressant, 0.001-0.005% of kilfoam, and the balance of solvent refining base oil or hydrogenated base oil. The lubricating oil composition has easy availability of raw materials, simple production process and highperformance price ratio, and can meet the oil consumption requirements of a whole oil consumption system, namely engine, hydraulic pressure, driving, braking and speed changing of large-medium sized tractors, thereby effectively simplifying oil varieties and avoiding mechanical failures caused by wrong use of oil products; and by using the lubricating oil composition, each lubricating system of the large-medium sized tractors can be kept in a good working state to avoid failures caused by insufficient lubrication, thereby prolonging the service life of the whole machine.

Owner:PETROCHINA CO LTD

Production of naphthenic lube oil and base oil

ActiveCN1982417AHigh yieldImprove Oxidation StabilityTreatment with hydrotreatment processesBase oilSolvent refining

Production of naphthenic lube oil and base oil is carried out by feeding for naphthenic base oil, hydrogenation treating, contacting with catalyst, separating to obtain hydrogenated oil in hydrogenation reactive area, contacting it with solvent in solvent refining area, extracting partial or solvent as feed and mixing it with naphthenic base oil. It has more yield and better performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

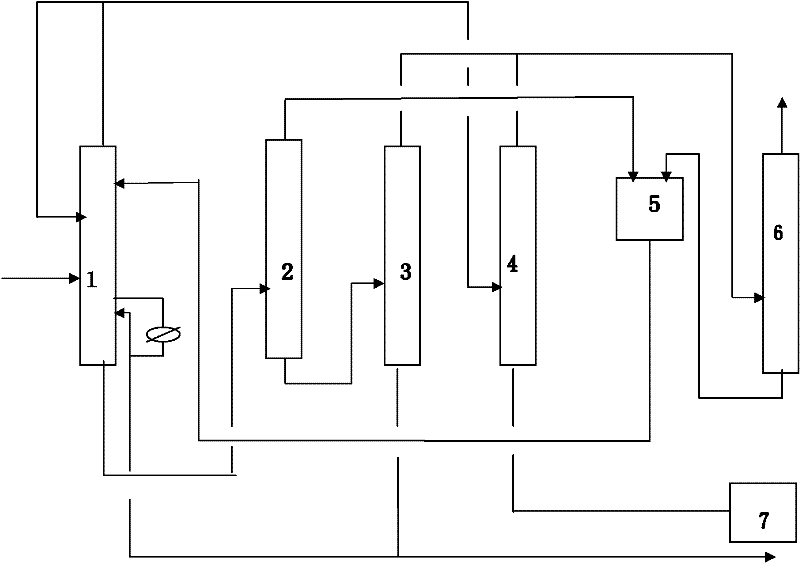

Method for solvent refining during isoprene rubber production

InactiveCN102504066APrecise control of operating pressurePrecise temperature controlRefluxDistillation

The invention relates to a method for solvent refining during isoprene rubber production. According to the method, the solvent recovered from a self-condensation process is conveyed into a distillation tower from the top of the tower; light components on the top of the tower are subjected to a total reflux operation through a tower top condenser and a reflux tank, or are subjected to small amount continuous recovery under the operation with a large reflux ratio more than 20, and the free water is separated from the reflux tank, and a small amount of uncondensed gases on the top of the tower are discharged to a tail gas condenser; the tower kettle liquid containing weight components is subjected to intermittent or continuous small flow rate recovery; the treated solvent is recovered from the side stream through the middle part of the tower in a vapor phase form, and is condensed by a side stream condenser, and the resulting solvent is conveyed to a polymerization process to directly use, wherein the treated solvent is the qualified solvent through the refining. According to the present invention, only a distillation tower is adopted in the method, the removal works of the water and other light components, and the heavy components are achieved in the single tower, the process is simple, the equipment investment is low, and the energy consumption is small, such that the production and operation cost can be effectively reduced.

Owner:广东鲁众华新材料有限公司

Pretreatment process for regenerating high-quality base oil by using waste lubricating oil

The invention provides a pretreatment process for regenerating high-quality base oil by using waste lubricating oil. The process comprises the steps of chemical reaction dechlorination, hydrocatalyticthermal decomposition, atmospheric flashing, propane refining and NMP or furfural extraction. The chemical reaction dechlorination solves the problems of corrosion, pipeline blockage, catalyst poisoning and the like caused by organic chlorine to a reaction device in the regeneration process by using the waste lubricating oil. The hydrocatalytic thermal decomposition destroys metal-salt additivesin the waste lubricating oil and solves the problem of difficult separation during solvent refining. The waste lubricating oil is subjected to atmospheric flashing, water and light fuel oil are removed, then topped residual oil is subjected to propane refining, additives, metal salt, oxidized condensate, colloid, asphaltene and other impurities in the waste lubricating oil are removed, and the ashcontent can be reduced to 0.02% or below. NMP or furfural is a solvent with high selectivity and low solubility, by utilizing the property, refined oil with less metal, carbon residues, colloid and aromatic hydrocarbon can be obtained, and high-quality raw materials are provided for hydrogenation.

Owner:湖北科润石化科技有限公司

Preparation method of 3-methyl-4-isopropylphenol

InactiveCN103044205AMild reaction conditionsHigh yieldOrganic chemistryOrganic compound preparationHigh pressure4-isopropylphenol

The invention discloses a preparation method of 3-methyl-4-isopropylphenol. The method comprises the following steps of: (1) dissolving m-toluidine into sulfuric acid to react with an isopropylation reagent to obtain 3-methyl-4-isopropylaniline, wherein the isopropylation reagent is isopropanol, propylene or 2-chloropropane; (2) hydrolyzing the 3-methyl-4-isopropylaniline to obtain a reaction solution containing the 3-methyl-4-isopropylphenol, wherein the hydrolysis is diazo hydrolysis or high-temperature high-pressure hydrolysis by using the sulfuric acid as a solvent; and (3) distilling the reaction solution containing the 3-methyl-4-isopropylphenol and performing solvent refining to obtain needle-like crystalline 3-methyl-4-isopropylphenol. The method disclosed by the invention has the characteristics of mild reaction condition, high yield, few by-products and little pollution; and the preparation method effectively solves difficulties such as many by-products, severe condition and great pollution in the existing preparation process of the 3-methyl-4-isopropylphenol.

Owner:ZHEJIANG DINGLONG TECH

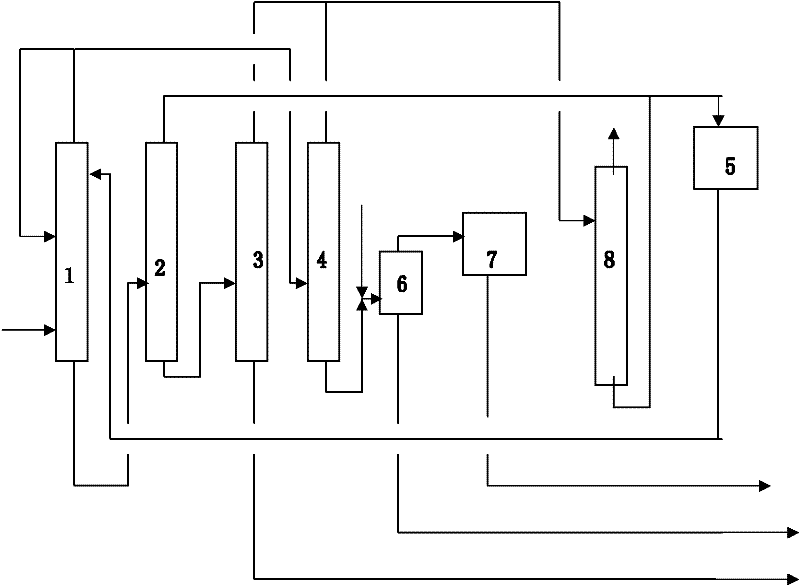

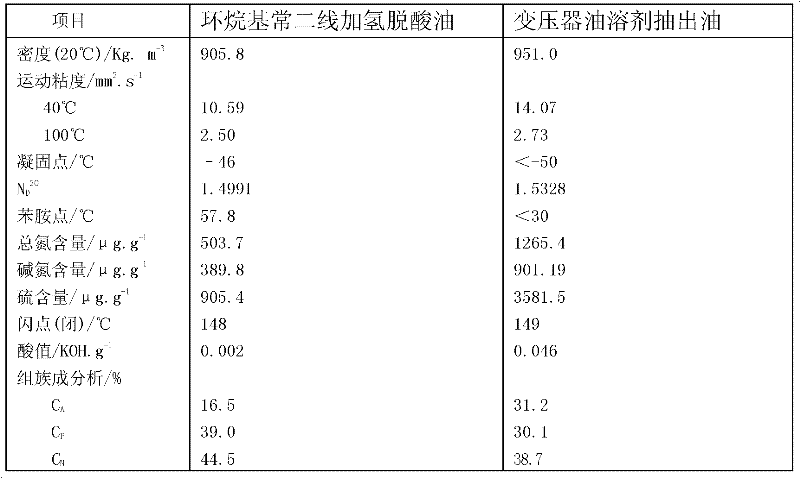

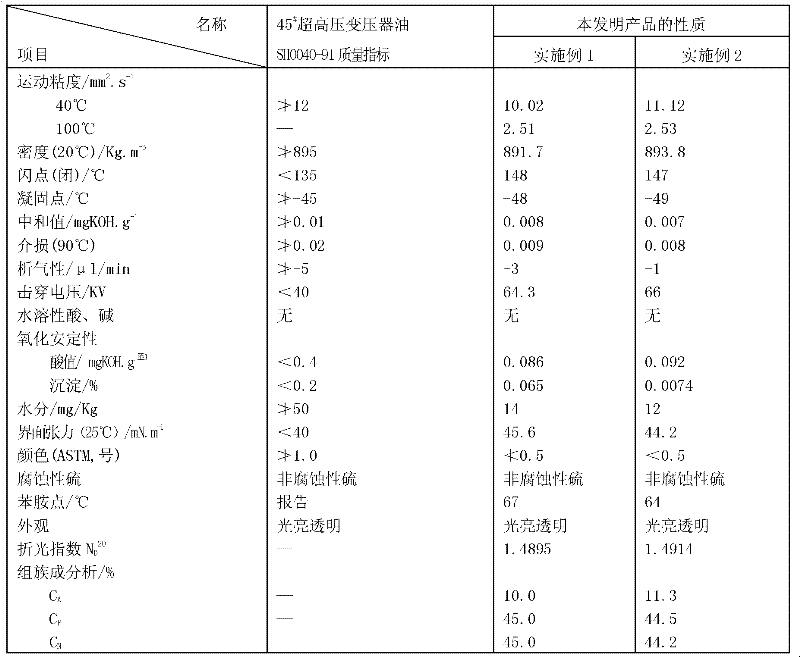

Method for improving gassing resistance of transformer oil and equipment for producing transformer oil

The invention belongs to the technical field of petrochemical engineering and discloses a method for improving the gassing resistance of transformer oil and equipment for producing the transformer oil. The equipment is a piece of solvent refining equipment. According to the method, solvent refined extract oil of the transformer oil or a mixture of the solvent refined extract oil of the transformer oil with fraction hydrogenation deacidified oil of naphthenic crude transformer oil is taken as raw oil, a solvent is fed from the upper part of an extraction tower, the raw oil is fed from the lower part of the extraction tower, partial raffinate oil or raffinate liquid returns to the extraction tower from the lower parts of a raw oil inlet and a solvent inlet for solvent refining, refined oil is obtained after the raffinate liquid at the tower top is subjected to steam stripping to recover the solvent, liquid phase denitrification and clay refining are then carried out to obtain base oil or gassing resistant components of extra-high-voltage transformer oil, and finally, the base oil of the extra-high-voltage transformer oil is obtained after the gassing resistant components of the extra-high-voltage transformer oil are mixed with the base oil of common transformer oil. By blending the base oil of the extra-high-voltage transformer oil, the extra-high-voltage transformer oil meeting the requirements of SH0040-91 is produced.

Owner:PETROCHINA CO LTD

Environment-friendly rubber oil and preparation method thereof

ActiveCN102585902ALow aromatic contentHigh content of saturated hydrocarbonsTreatment with hydrotreatment processesEnvironmental resistanceEconomic benefits

The invention discloses environment-friendly rubber oil and a preparation method thereof. The preparation method comprises the following steps of: (1) placing naphthenic-base distillate oil in a solvent refining tower to carry out solvent refining to obtain refined liquid at the top of the solvent refining tower and extracted liquid at the bottom of the solvent refining tower, recovering the solvent from the refined liquid to obtain refined oil and receiving the solvent from the extracted liquid to obtain extracted oil; and (2) hydrogenating the extracted oil to obtain hydrogenated oil; and distilling the hydrogenated oil for removing light fraction to obtain the environment-friendly rubber oil. The preparation method has the following beneficial effects: after raw material oil is refined with the solvent, the refined oil has the characteristics of low aromatic hydrocarbon content, high saturated hydrocarbon content and light color and is a high-quality naphthenic-base basic oil with a wide application scope; in addition, the non-environment-friendly extracted oil with low additional value is further subjected to the hydrogenation treatment and then is converted to be the environment-friendly rubber oil with high additional value, thus the integral economic benefits of the naphthenic-base distillate oil are greatly improved.

Owner:CHINA NAT OFFSHORE OIL CORP +3

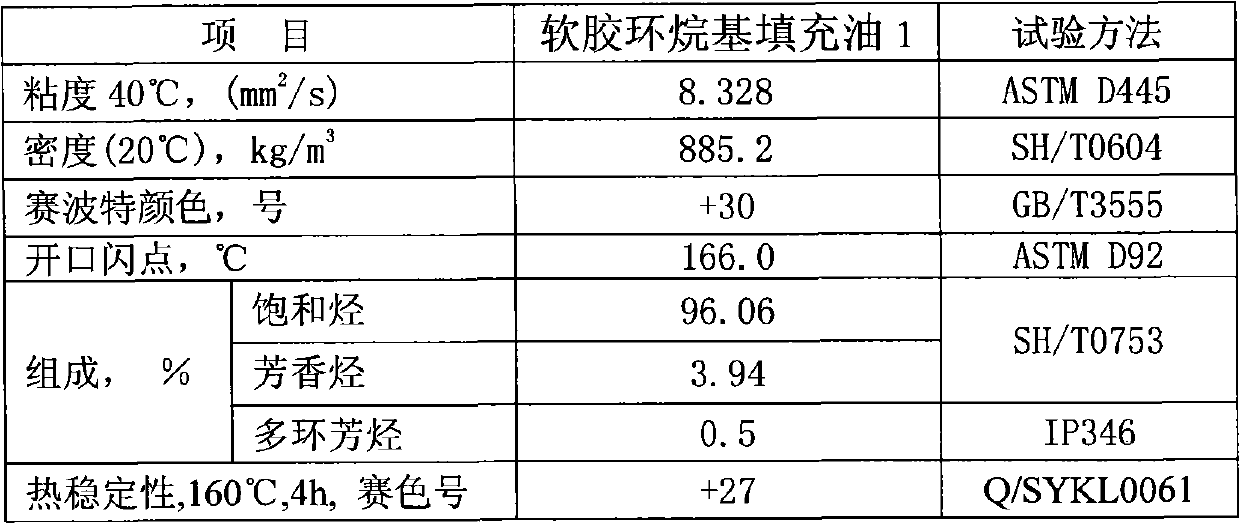

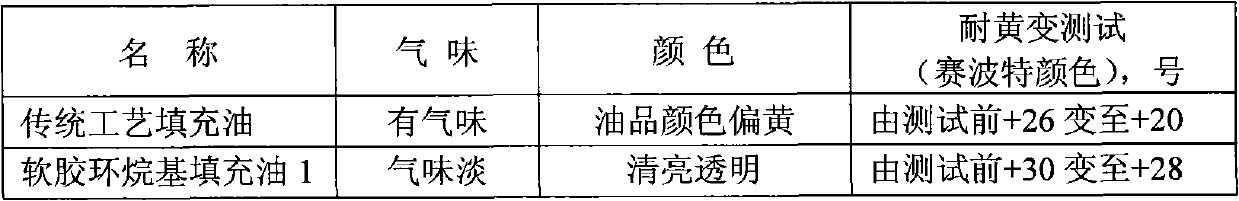

Naphthenic filling oil for soft plastic toys and preparation method thereof

ActiveCN102021032AGood yellowing resistanceReduce PAH contentTreatment with hydrotreatment processesDistillationPolyaromatic hydrocarbon

The invention relates to naphthenic filling oil for soft plastic toys and a preparation method thereof. The preparation method comprises the following steps of: distilling naphthenic crude under the normal and reduced pressure to cut distillate oil of which the acid value is less than 0.5 mgKOH / g and of which the distillation range is between 350 and 500 DEG C; hydrotreating the distillate oil, adding a molecular sieve-containing bifunctional catalyst with active nickel and tungsten components or cobalt and molybdenum components to obtain a hydrogenated component of which the distillation range is between 300 and 400 DEG C, wherein the catalyst takes Al2O3 as a carrier; performing solvent refining on the hydrogenated component to obtain raffinate oil, wherein a solvent ratio is 1:1-2:1, and the extraction temperature is between 45 and 70 DEG C; performing hydrofinishing on the raffinate oil by adopting the refining catalyst which takes a nickel-tungsten or cobalt-molybdenum system as an active component and the Al2O3 as the carrier; and obtaining the naphthenic filling oil with polyaromatic hydrocarbon content less than 0.5 percent, Saybolt color of appearance more than +30 number, the Saybolt color of thermal stability more than +20 number and opening flash point more than 160 DEG C.

Owner:PETROCHINA CO LTD +1

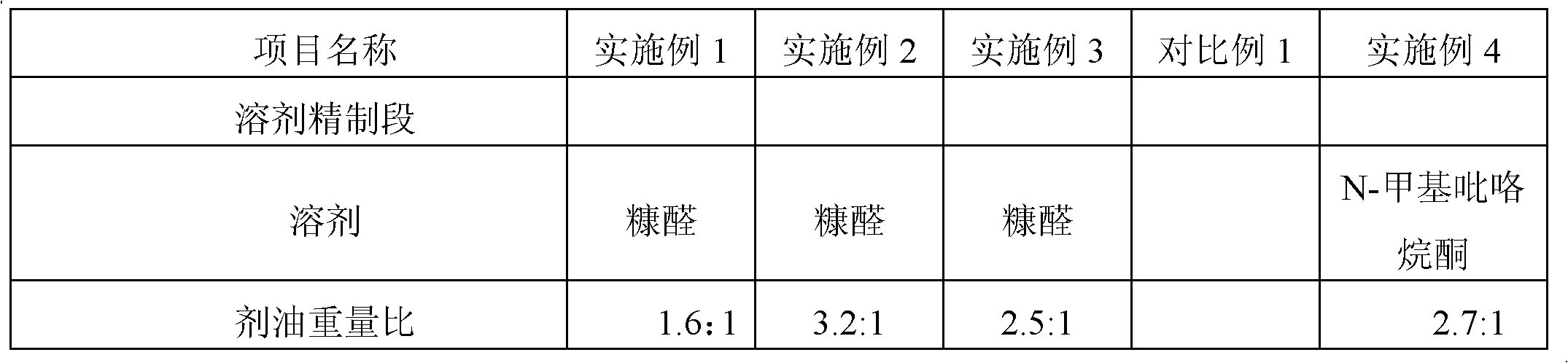

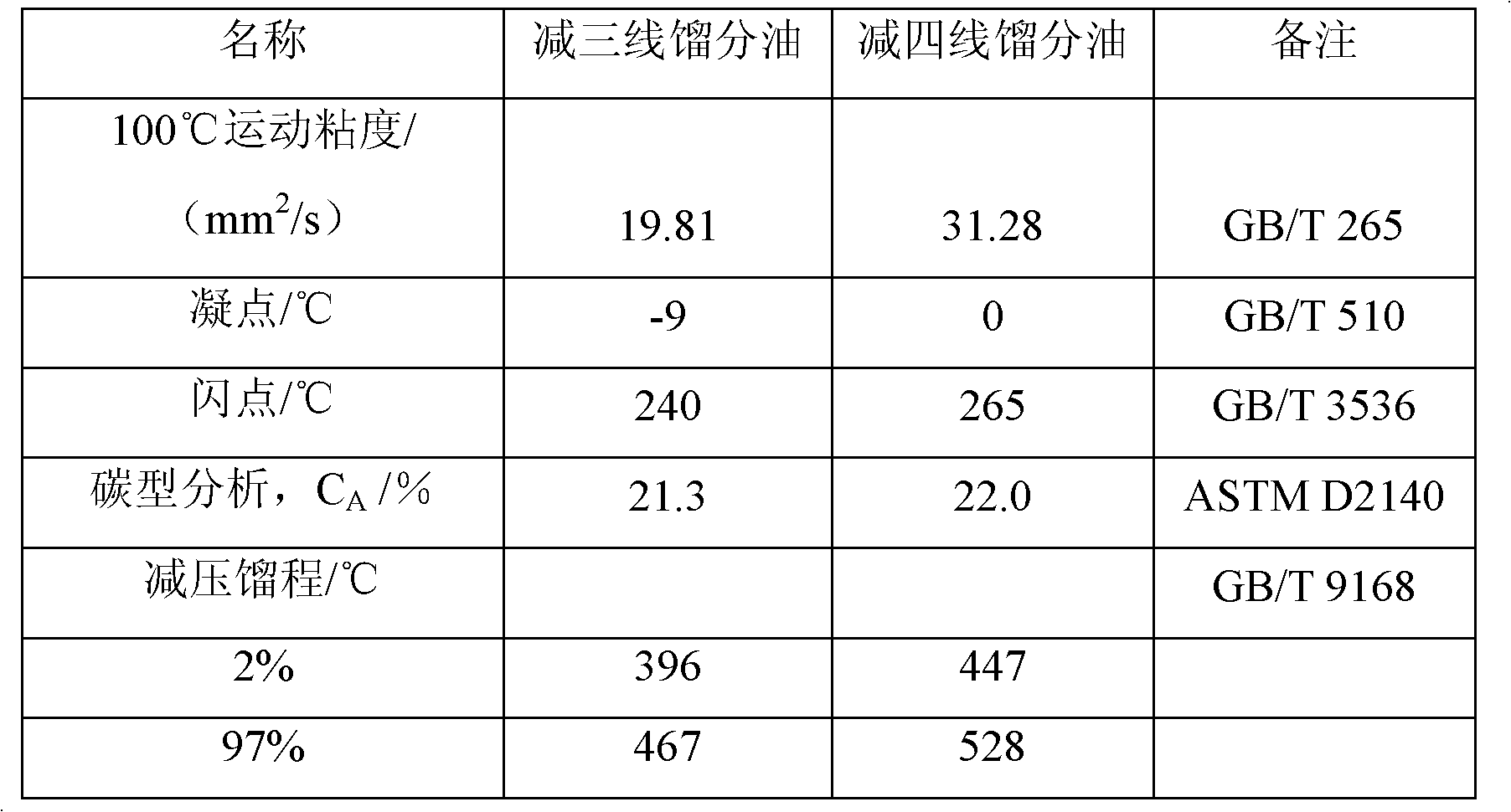

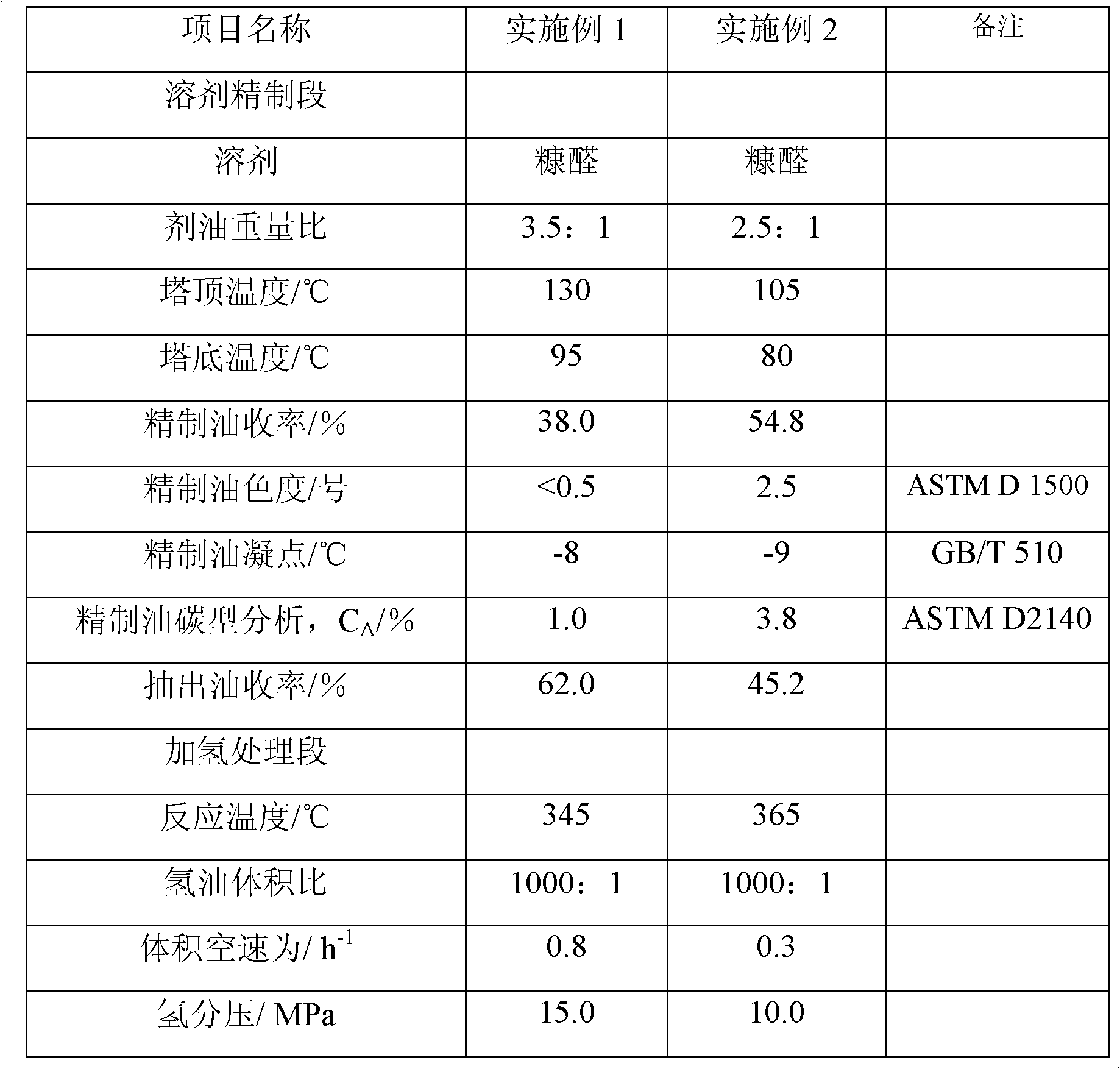

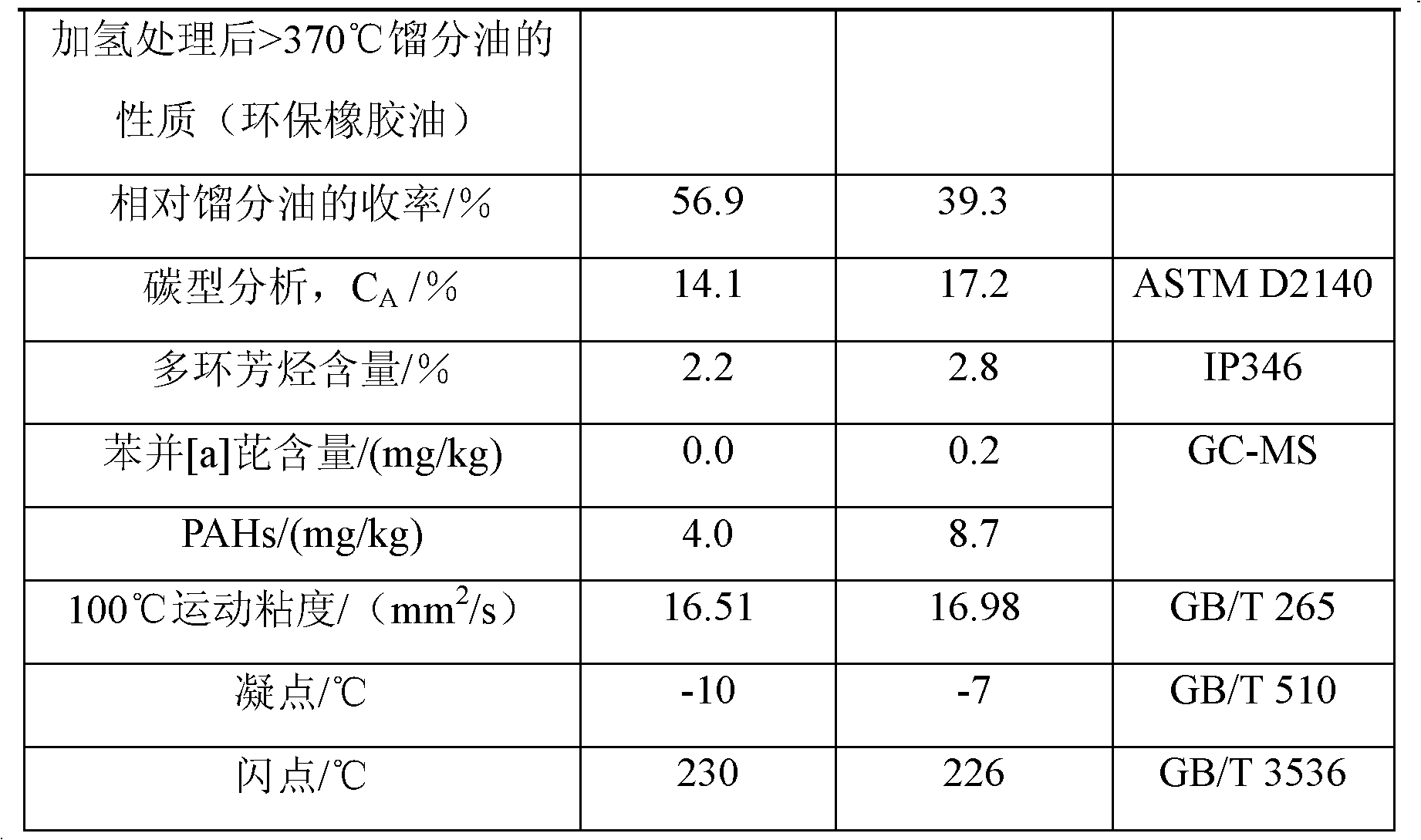

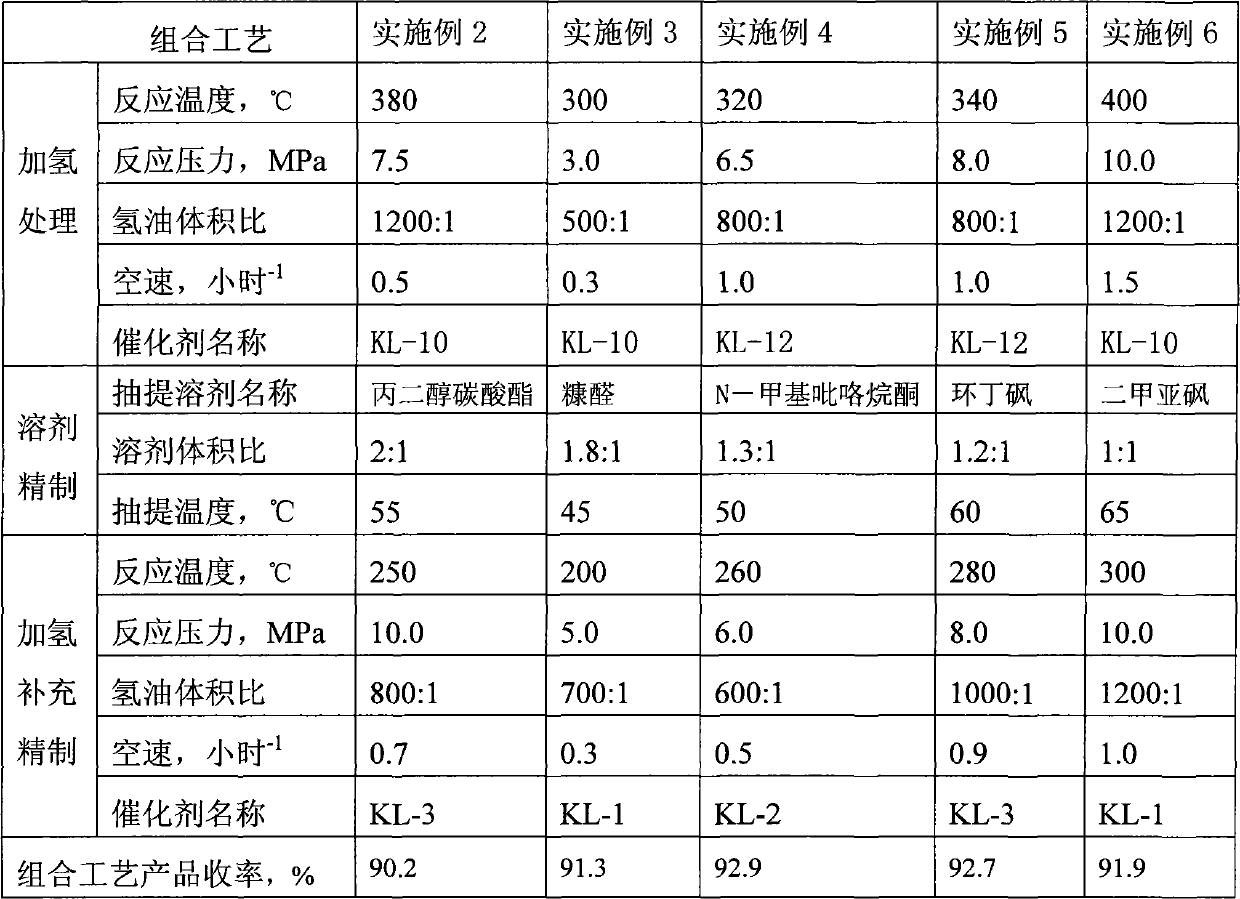

Method for preparing environmentally-friendly rubber oil through solvent refining and hydrofining combination technology

ActiveCN102952582AReduce carbon residueTreatment with hydrotreatment processesReaction temperatureHigh pressure

The invention relates to a method for preparing environmentally-friendly rubber oil through a solvent refining and hydrofining combination technology. Aromatic hydrocarbon extract oil in a vacuum fraction is adopted as a raw material, a ternary composite solvent comprising 60-75% by volume of furfural, 20-35% by volume of a polyhydroxy alcohol or a polyhydroxy alcohol ester, and the balance an aqueous NaCl solution is adopted as a solvent in a solvent extraction segment, and extraction oil is obtained under operation conditions comprising that the top temperature of an extraction tower is 50-100DEG C, wherein the oil-solvent volume ratio is 0.5-3.0:1; and then the extraction oil is hydrofined under a high pressure, wherein the high-pressure hydrogenation treatment conditions comprise that the reaction pressure is 15.0Mpa, the reaction temperature is 330-350DEG C, the reaction air speed is 0.3-1.0h<-1> and the hydrogen-oil ratio is 500-1000:1, and a catalyst is a non-precious metal sulfide hydrogenation treatment catalyst treating Ni-W as a hydrogenation active component. Environmentally-friendly rubber oil with the CA percentage characterizing the aromatic hydrocarbon content of above 16 can be prepared through the method, the content of the polycyclic aromatic hydrocarbons (PCAs) in the rubber oil is less than 3%, and the sum of eight PAHs is less than 10mg / kg.

Owner:PETROCHINA CO LTD +1

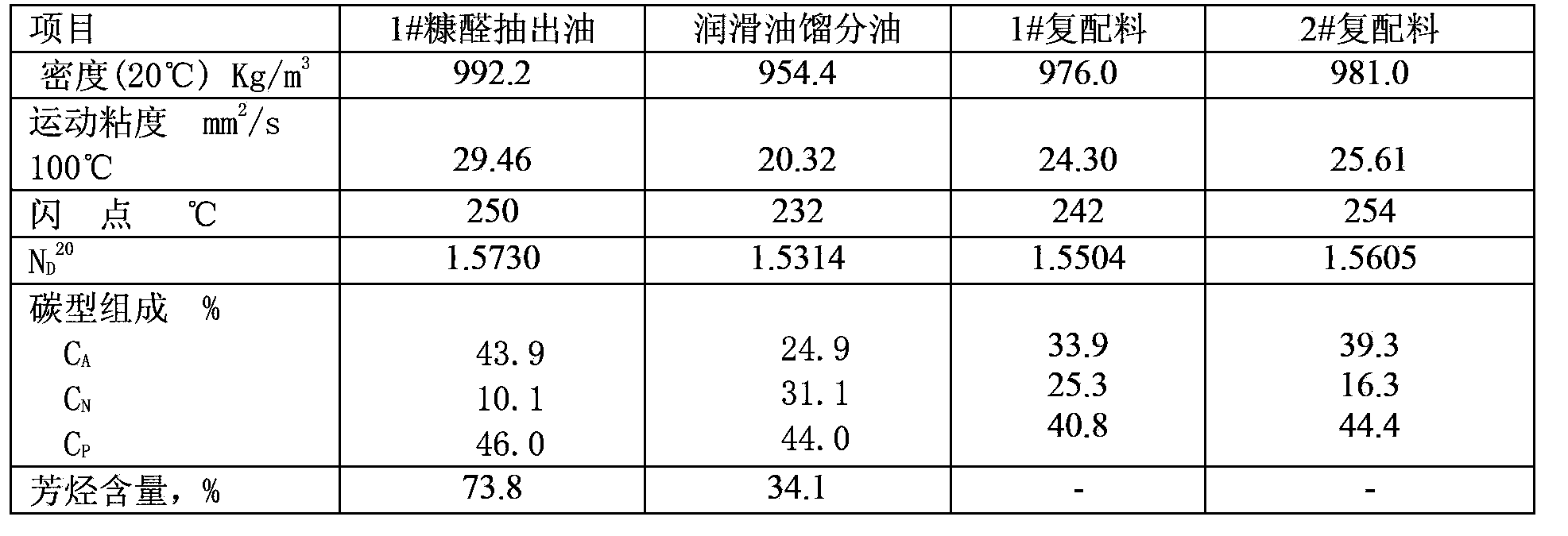

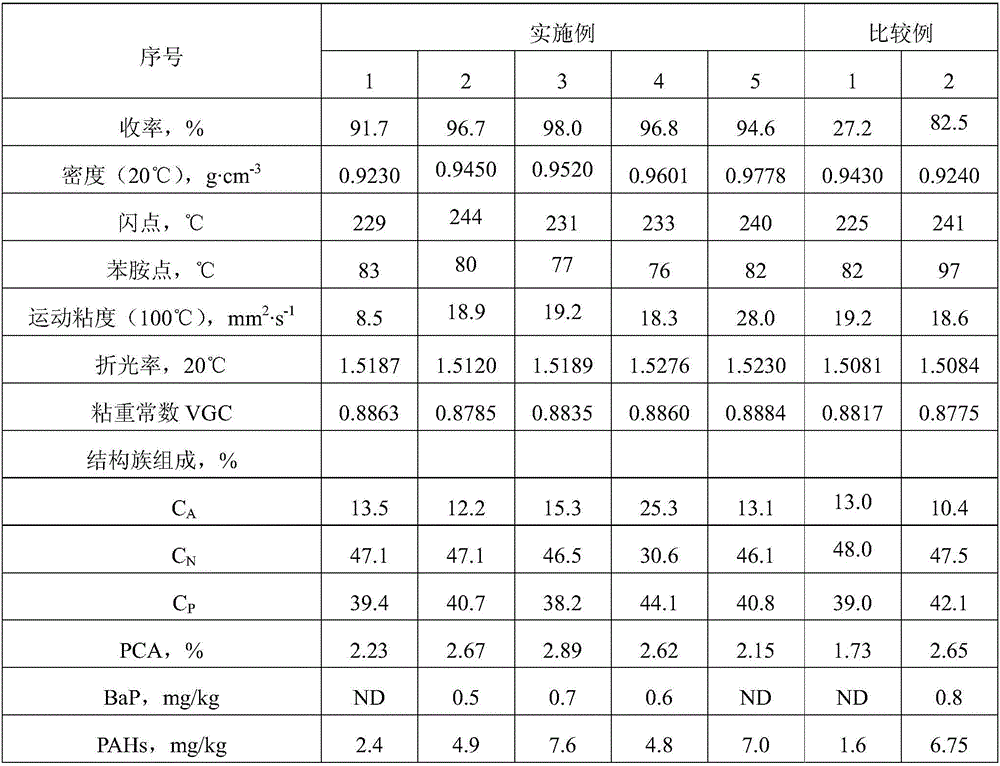

Production method of high-performance environment-friendly rubber oil

ActiveCN103382399AHigh yieldImprove compositionHydrocarbon oils refiningPolycyclic aromatic hydrocarbonPetroleum product

The invention relates to a production method of high-performance environment-friendly rubber oil. The raw materials for producing the environment-friendly rubber oil are two combinations of petroleum products, one is lubricating-oil solvent refining extract oil with suitable viscosity and flash point and a higher aromatic content, and the other is a lubricating-oil distillate oil with suitable viscosity and flash point and a higher cyclane content and a higher aromatic hydrocarbon content. By taking the combined raw materials as raw materials for production of the environment-friendly rubber oil, and employing a conventional lubricating oil refining technology, the environment-friendly rubber oil, which has a CA value of 15.0-25%, the aromatic content of 40.0-55% , a benzopyrene concentration of less than 1 mu g / g and the total content of eight specific polycyclic aromatic hydrocarbons of less than 10 mu g / g, and completely reaches environment-protecting index requirements of EU environment-protecting directives 2005 / 69 / EC, can be trial-produced; and the environment-friendly rubber oil of the invention is higher in yield by 20-30 percent points than an environment-friendly rubber oil prepared by taking pure lubricating oil refining extract oil as a raw material.

Owner:PETROCHINA CO LTD

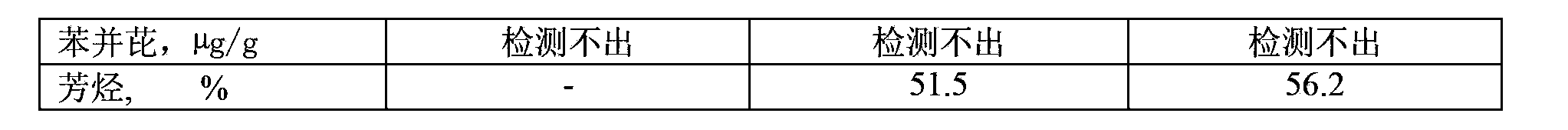

Novel high-performance cooperative system flame retarding asphalt

ActiveCN102942795AImprove temperature sensitivityImprove aging resistanceBuilding insulationsLead phosphateSlurry

The invention discloses novel high-performance cooperative system flame retarding asphalt which is characterized by comprising the following components in parts by weight: 100 parts of asphalt, 1-30 parts of flame retardant, 1-20 parts of synergist, 2-15 parts of compatilizer and 2-4 parts of modifier, wherein the asphalt is one or more of coal tar asphalt, shale asphalt and petroleum asphalt; the flame retardant is an organic silicon flame retardant; the organic silicon flame retardant is reacted with a small amount of zinc borate at a temperature of 90 DEG C for 1.5 hours to obtain a smoke suppression organic silicon flame retardant; the synergist is one or more of stearate, potassium silicate, dibasic lead phosphate, tribasic lead sulfate and calcium carbonate; the compatilizer is one or more of catalytic cracking slurry, de-asphalted oil, solvent refining extract oil, naphthenic oil, white oil and coal tar fraction; and the modifier is powdered butadiene styrene rubber added with anti-aging agent and parting agent. According to the method, the flame retarding effect of the organic silicon flame retardant is improved and the applicability of the organic silicon flame retardant is improved.

Owner:CHINA ROAD & BRIDGE

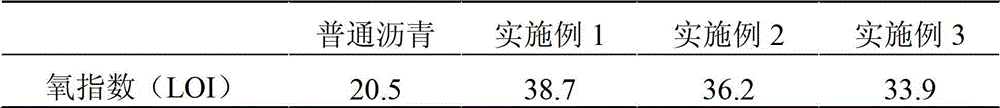

Recovery method of medium oil in spent bleaching clay and preparation method of base oil for lubricating oil

ActiveCN107286973AHigh yieldHydrocarbon oils refiningLubricant compositionRecovery methodOrganic solvent

The invention relates to the field of a petrochemical industry and discloses a recovery method of medium oil in spent bleaching clay and a preparation method of base oil for lubricating oil. The recovery method comprises the following steps: contacting the spent bleaching clay with an organic solvent under a first contact condition, so as to desorb base oil for the lubricating oil in the spent bleaching clay; contacting the first-treated spent bleaching clay with an organic solven under a second contact condition, so as to dissolve non-ideal components in the spent bleaching clay; contacting the second-treated spent bleaching clay with water under a third contact condition, so as to dissolve the organic solvent in the spent bleaching clay, wherein both the organic solvents used in the first contact and the second contact are from extraction solvents for solvent refining of raw oil; returning an oil-contained solvent mixture which is obtained by first contact separation, and using as one part of the extraction solvents for solvent refining; returning oil-contained solution which is obtained by second contact separation, and using as one part of the raw oil. According to the method, the base oil for the lubricating oil in the spent bleaching clay can be effectively recovered.

Owner:CHINA PETROLEUM & CHEM CORP +1

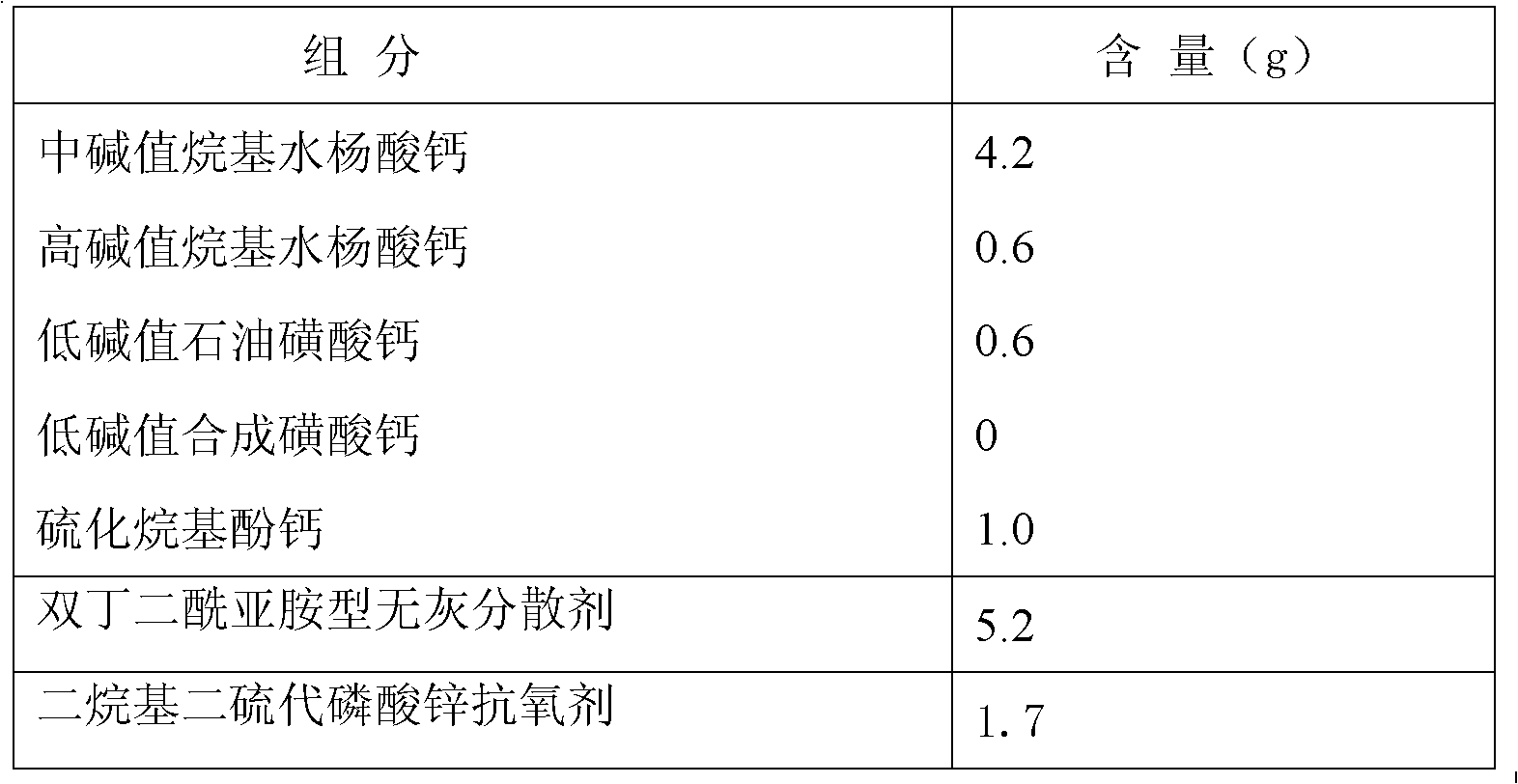

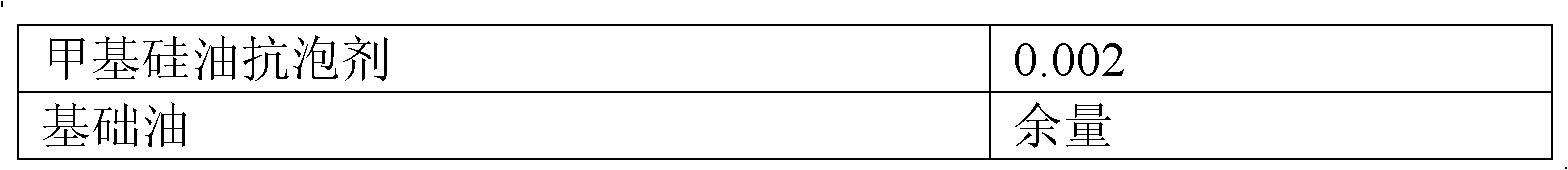

Ship universal type diesel engine lubricating oil composition

The invention relates to a lubricating oil composition used for a ship universal type diesel engine, which comprises the following components by weight: 5.2-7.4% of high temperature clearing agent, 2.6-5.2% of ash-free dispersant, 0.6-1.7% of zinc dialkyl dithiophosphate anti-oxidant, 0.0015-0.0050% of methylsilicone oil anti-foaming agent and the balance of base oil, the base oil is composed of paraffin-based solvent refining neutral base oil and 20-5% of solvent refining heavy component base oil, the high temperature clearing agent is composed of 15-25% of salt of alkylphenol sulfide, 14-25% of calcium sulfonate with low base number and the balance of alkyl-based salicylate; the lubricating oil composition can simultaneously satisfy the requirements of vessel two stroke and four stroke, and a middle-speed diesel engine and a high-speed diesel engine, and has excellent water diversion performance, high temperature cleanliness performance, good lubrication, antiwear and antirust performances, the lubricating oil composition can satisfy the usage requirement of the ship universal type diesel engine, and can prolong the usage life of the engine.

Owner:PETROCHINA CO LTD

Process for producing soybean isoflavone by waste water of bean products factory

The invention relates to a method of producing soybean isoflavone by using waste water in bean products factories, extracting highly pure isoflavone by the process curse of alkali treatment, neutralization, column chromatography, alcohol recycle, solvent refining, solvent recycling, drying, etc, and it can make the obtained soybean isoflavone has a content higher than 40%. It is also applied to producing soybean insolfavone by whey in producing soybean protein and yellow seriflux in producing bean curd products.

Owner:杨爱平

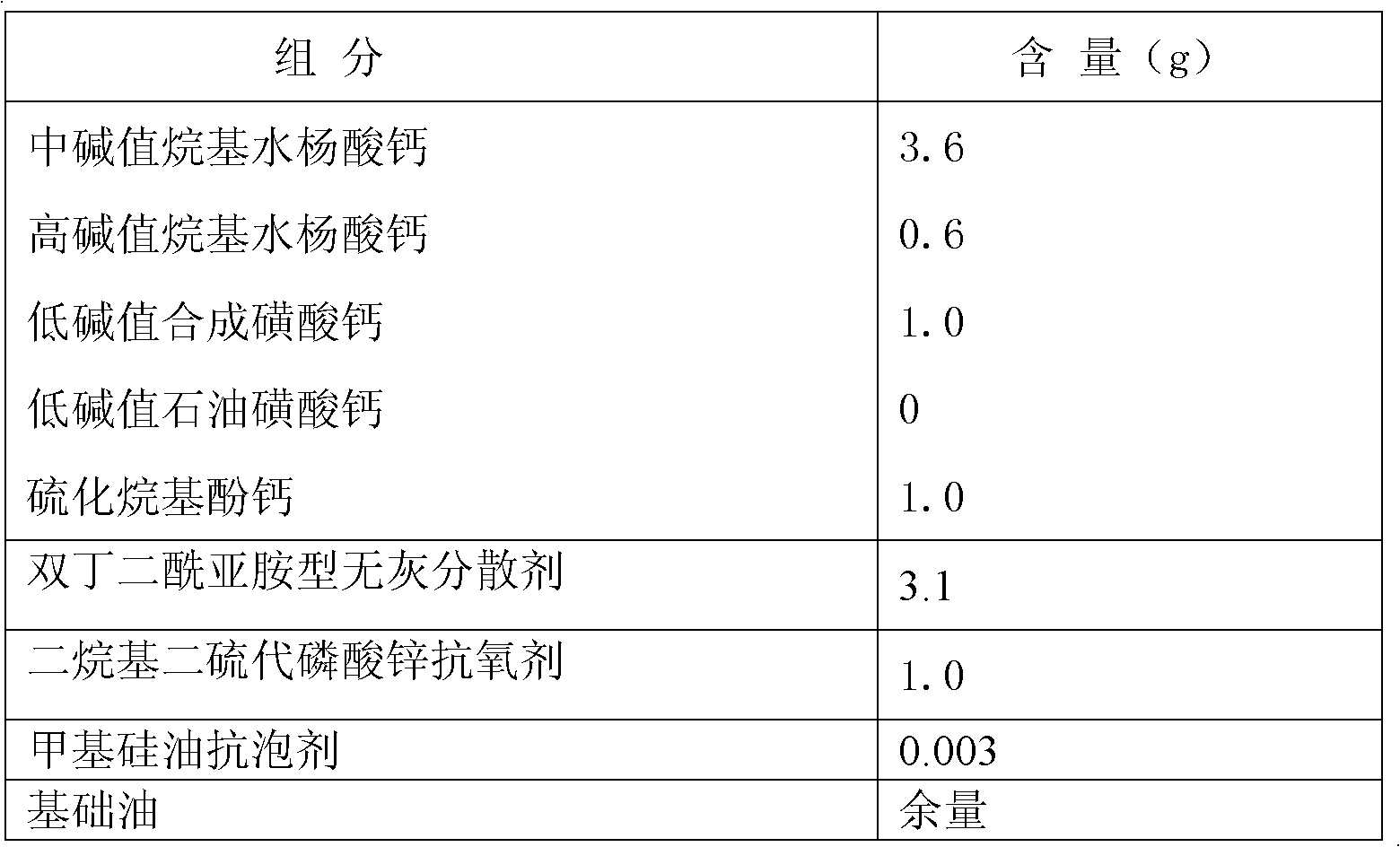

Refining method of long chain dicarboxylic acid

ActiveCN110002992ASimple preparation stepsScalable productionCarboxylic compound separation/purificationAcetic acidThermal insulation

The invention provides a refining method of long chain dicarboxylic acid. The long chain dicarboxylic acid is refined with a long chain dicarboxylic acid crude product prepared with a biological method as a raw material and low-concentration acetic acid as a solvent. Specifically, the long chain dicarboxylic acid crude product and the low-concentration acetic acid are mixed firstly, stirred, heated and decolorized in a normal pressure environment, filtration is performed with thermal insulation, filtrate is cooled slowly, crystallization and separation are performed, a dicarboxylic acid intermediate is obtained and suspended with water with melting point temperature higher than that of monoacid with chain length corresponding to that of the long chain dicarboxylic acid, thermal insulation,cooling, separation and drying are performed in a negative pressure environment, and a long chain dicarboxylic acid refined product is obtained. The defects that existing solvent refining methods arelow in yield and the content of solvent residues in products is high are overcome. The refined long chain dicarboxylic acid completely meets the raw material quality requirement of polymer material synthesis.

Owner:张艾琳

Preparation method of rubber plasticizer with low content of polycyclic aromatic hydrocarbons

ActiveCN105969420AHigh yieldImprove adaptabilityHydrocarbon oils refiningHydrocarbon oils treatmentAniline pointFluoranthene

The invention discloses a preparation method of a rubber plasticizer with low content of polycyclic aromatic hydrocarbons. The preparation method comprises the following steps: vacuum distillate oil is mixed with aromatic hydrocarbon oil to obtain raw oil; the raw oil enters an extraction tower from the lower part of the extraction tower and is subjected to solvent refining with the solvent entering from the upper part of the extraction tower through countercurrent contact; and refined liquid is obtained from the top of the extraction tower, and the solvent is recycled to obtain refined oil which is the rubber plasticizer. The physical and chemical parameters of the rubber plasticizer are as follows: the aniline point is lower than 92 DEG C; the CA value is higher than 12%; the content of benzo(a)pyrene is lower than 1mg / kg; the content of polycyclic aromatic hydrocarbons is not higher than 3%; the total content of carcinogenic polycyclic aromatic hydrocarbons is lower than 10mg / kg; and the carcinogenic polycyclic aromatic hydrocarbons include benzo[a]pyrene, benzo[e]pyrene, benzo[a]anthracene, chrysene, benzo[b]fluoranthene, benzo[j]fluoranthene, benzo[k]fluoranthene and dibenzo[a, h]anthracene. The method disclosed by the invention has remarkably obvious advantage in yield; and compared with the hydrotreatment technology, in the method disclosed by the invention, by adopting the solvent refining, the equipment investment is small, the operation cost is low, and the adaptability of the raw materials is better.

Owner:CHINA OFFSHORE BITUMEN

Method for separating isoprene by front-end hydrogenation one-stage extraction

ActiveCN101302135ALower levelReduce trafficDistillation purification/separationHydrocarbonsHigh energyHeat energy

The invention discloses a method for separating isoprene by front-end hydrogenation one-section extraction, which belongs to the C5 fraction separation technical field. The invention aims to solve the problems that: during the prior C5 separation flow, a second extraction unit has high energy consumption, complicated operation and strict operation requirement, and large loss of extracting solvent and so on, and provides a method for separating isoprene fractions by one-section extraction rectification. The method removes cyclopentadiene by a rectification method and removes acetylene hydrocarbon by an azeotropic rectification method, can obtain a polymerization grade isoprene product without secondary extraction, and save the second extraction unit and a solvent refining column. The method has simple and easy operation, and reduces production cost. Under the same raw material treatment load, the heat energy consumption of a polymerization grade isoprene unit is about 20 percent of the prior second extraction unit, m-pentadien is extracted from a pre-deheavy fractionator without entering an extraction rectification unit, the treatment capacity of an extraction rectification column, an absorption tower and a de-heavy fractionator is reduced by 50 percent, and the energy consumption is correspondingly reduced by 50 percent, so the construction cost and the production cost are greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com