Recovery method of medium oil in spent bleaching clay and preparation method of base oil for lubricating oil

A technology of lubricating base oil and recovery method, which is applied in the field of clay supplementing and refining waste clay, can solve the problems of high construction and use costs, and achieve the effects of improving the yield of extracted oil and the yield of base oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

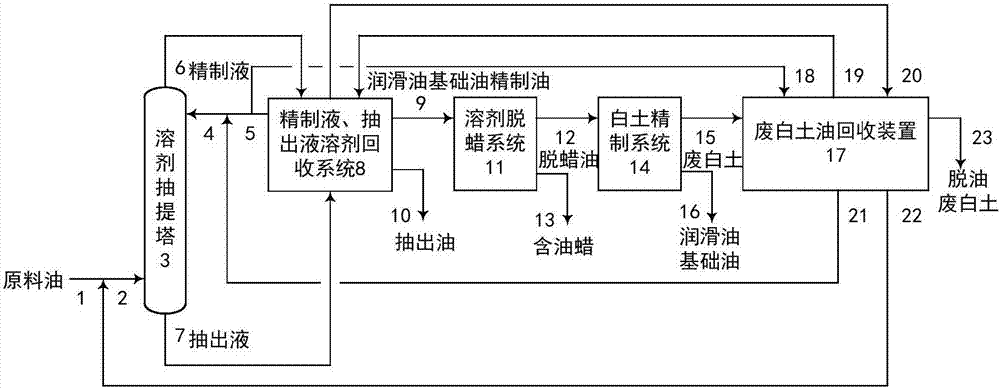

[0062] The present invention also provides a method for preparing lubricating base oil, wherein the preparation method comprises: contacting the raw material oil with an extraction solvent for solvent refining to obtain a refined liquid and an extracted liquid, and performing solvent recovery to obtain refined oil, Extract oil, recover solvent and water, contact refined oil with dewaxing dilution solvent for solvent dewaxing to obtain dewaxed oil and oily wax, contact dewaxed oil with clay for supplementary refining of clay to obtain lubricating oil base oil and waste clay , the waste clay contains lubricating oil base oil and non-ideal components, and the preparation method also includes:

[0063]Under the first contact condition, the waste clay to be treated is contacted with an organic solvent to desorb the lubricating oil base oil in the waste clay and separate the solid and liquid to obtain a mixture containing a lubricating oil base oil and an organic solvent and the firs...

Embodiment 1

[0093] This embodiment is used to illustrate the method for recovering oil from waste clay provided by the present invention.

[0094] Using the same raw materials, process flow and conditions as Comparative Example 1 to produce lubricating oil base oil, the difference is that according to figure 1 The process is to recover the oil in the waste clay obtained by supplementing and refining the clay.

[0095] The first experiment used the white clay obtained in Comparative Example 1 to refine the waste white clay, and the second experiment used the waste white clay obtained in the first experiment. Repeat the experiment many times. When the results of two consecutive experiments are the same, take the result of the last experiment , see Table 2 for details.

[0096] The formula for calculating the comprehensive yield of base oil in the table is:

[0097]Comprehensive base oil yield = (solvent refined oil yield / 100) x (dewaxed oil yield / 100) x (clay refined oil yield / 100) x 100....

Embodiment 2

[0110] This embodiment is used to illustrate the method for recovering oil from waste clay provided by the present invention.

[0111] Using the same raw materials, process and conditions as Comparative Example 2 to produce lubricating oil base oil, the difference is that according to figure 1 The process is to recover the oil in the waste clay obtained by supplementing and refining the clay. The first experiment used the white clay obtained in Comparative Example 2 to refine the waste white clay, and the second experiment used the waste white clay obtained in the first experiment. Repeat the experiment many times. When the results of two consecutive experiments are the same, take the result of the last experiment , see Table 2 for details.

[0112] The specific steps are as follows: step a, add organic solvent furfural to the waste clay, the mass ratio of furfural to waste clay is 4.3:1, the mixing temperature is 45°C, the mixing time is 15min, the mixture is settled at 45°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com