Method for regenerating base oil by waste oil

A technology for waste oil regeneration and base oil, which is applied in the petroleum industry, hydrocarbon oil treatment, and multi-stage serial refining process treatment, etc. Protection, adjustable quality standards, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

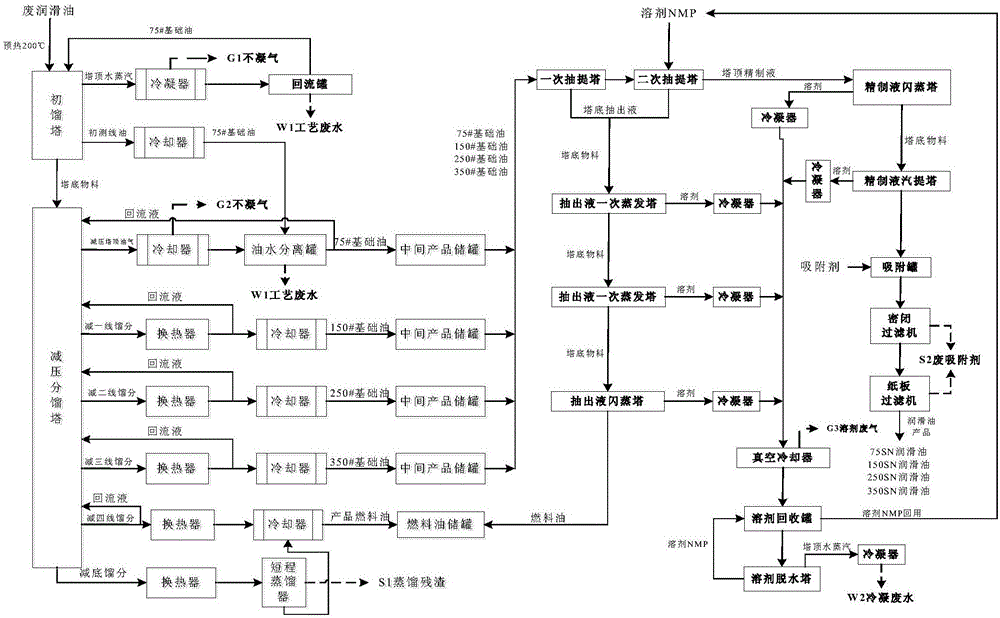

Image

Examples

Embodiment 1

[0030] The method for regenerating base oil from waste oil comprises the following steps:

[0031] 1. Raw material pretreatment part:

[0032] (1) Initial distillation:

[0033] The raw material of waste lubricating oil is heated to 180°C by a heat exchanger and then enters the initial distillation tower, and the pressure is reduced to -0.080MPa. The water in the raw material and 75# base oil are removed from the top of the tower, and the rest enters the vacuum tower for vacuum distillation cutting.

[0034] (2) vacuum distillation cutting:

[0035] Heat the bottom oil of the initial distillation tower to 350°C and send it to the vacuum distillation tower, and cut the raw oil sequentially under the condition of -0.095MPa:

[0036] The 75# base oil is fractionally distilled from the top of the tower, condensed by the condenser, enters the liquid separation tank at the top of the tower, and then pumped into the tank area or directly into the solvent refining system;

[0037]...

Embodiment 2

[0057] The method for regenerating base oil from waste oil comprises the following steps:

[0058] 1. Raw material pretreatment part:

[0059] (1) Initial distillation:

[0060] The raw material of waste lubricating oil is heated to 220°C by a heat exchanger and then enters the initial distillation tower, and the pressure is reduced to -0.080MPa. The water in the raw material and 75# base oil are removed from the top of the tower, and the remaining part enters the vacuum tower for vacuum distillation cutting.

[0061] (2) vacuum distillation cutting:

[0062] Heat the bottom oil of the initial distillation tower to 380°C and send it to the vacuum distillation tower, and cut the raw oil in sequence under the condition of -0.098MPa:

[0063] The 75# base oil is fractionally distilled from the top of the tower, condensed by the condenser, enters the liquid separation tank at the top of the tower, and then pumped into the tank area or directly into the solvent refining system; ...

Embodiment 3

[0084] The method for regenerating base oil from waste oil comprises the following steps:

[0085] 1. Raw material pretreatment part:

[0086] (1) Initial distillation:

[0087] The raw material of waste lubricating oil is heated to 200°C by a heat exchanger and then enters the initial distillation tower, and the pressure is reduced to -0.080MPa. The water in the raw material and 75# base oil are removed from the top of the tower, and the rest enters the vacuum tower for vacuum distillation cutting.

[0088] (2) vacuum distillation cutting:

[0089] Heat the bottom oil of the initial distillation tower to 360°C and send it to the vacuum distillation tower, and cut the raw oil in sequence under the condition of -0.096MPa:

[0090] The 75# base oil is fractionally distilled from the top of the tower, condensed by the condenser, enters the liquid separation tank at the top of the tower, and then pumped into the tank area or directly into the solvent refining system;

[0091] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com