Patents

Literature

77results about How to "Continuous and stable discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

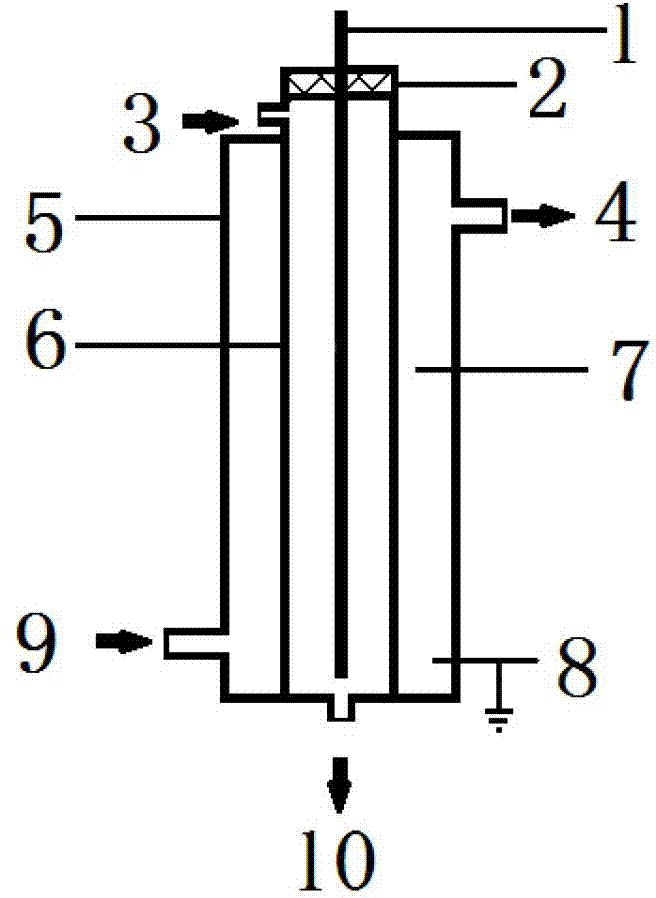

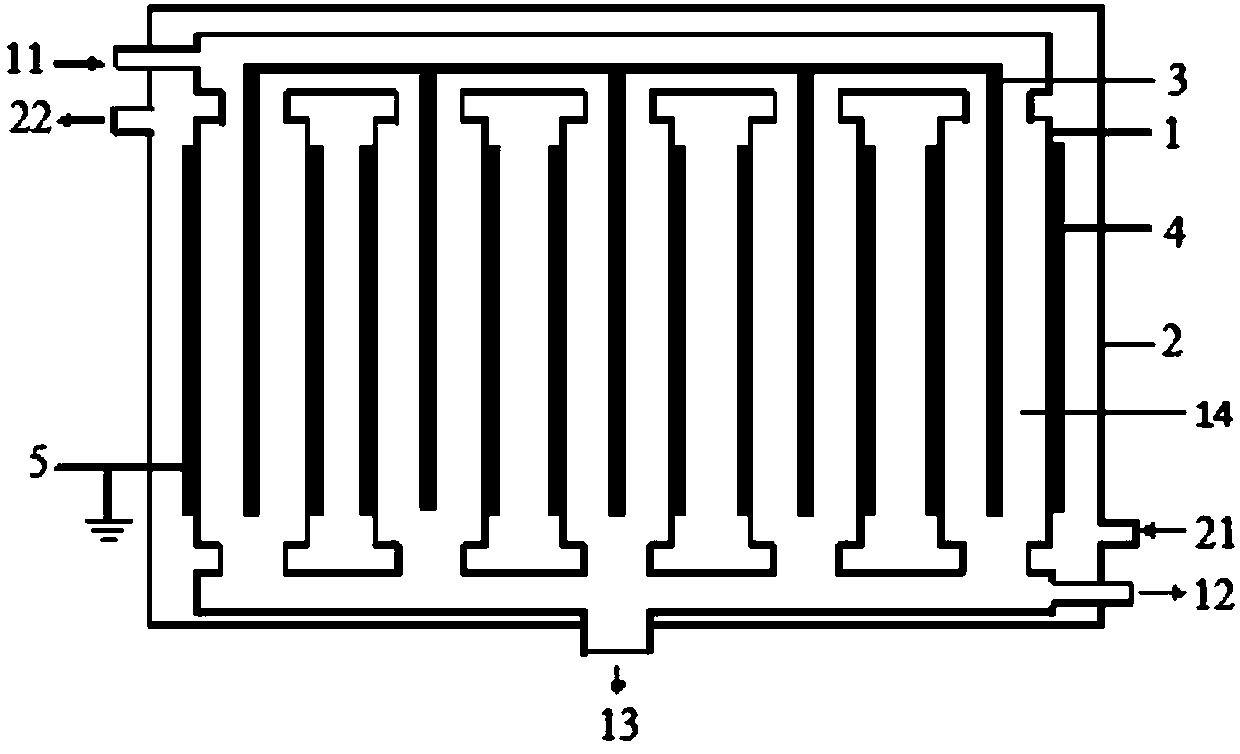

Device and method for preparing hydrogen through temperature controlled continuous decomposition of hydrogen sulfide

InactiveCN103204466AImprove uniformityContinuous and stable dischargeHydrogen productionChemical industryTemperature control

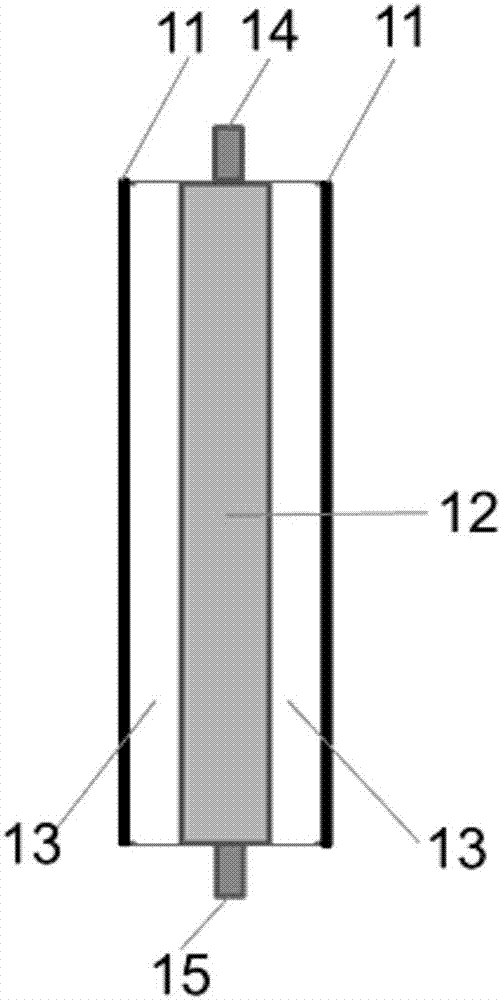

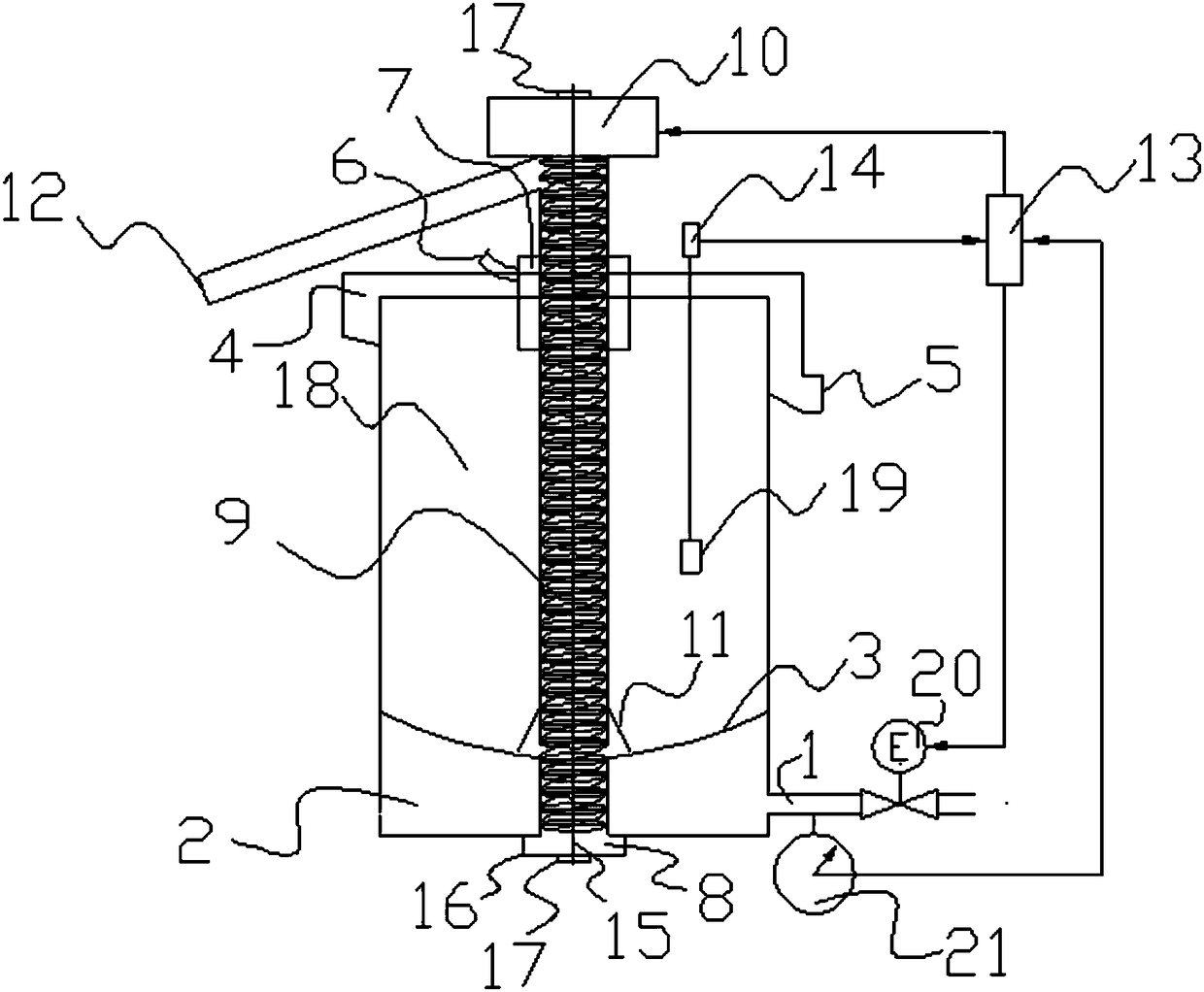

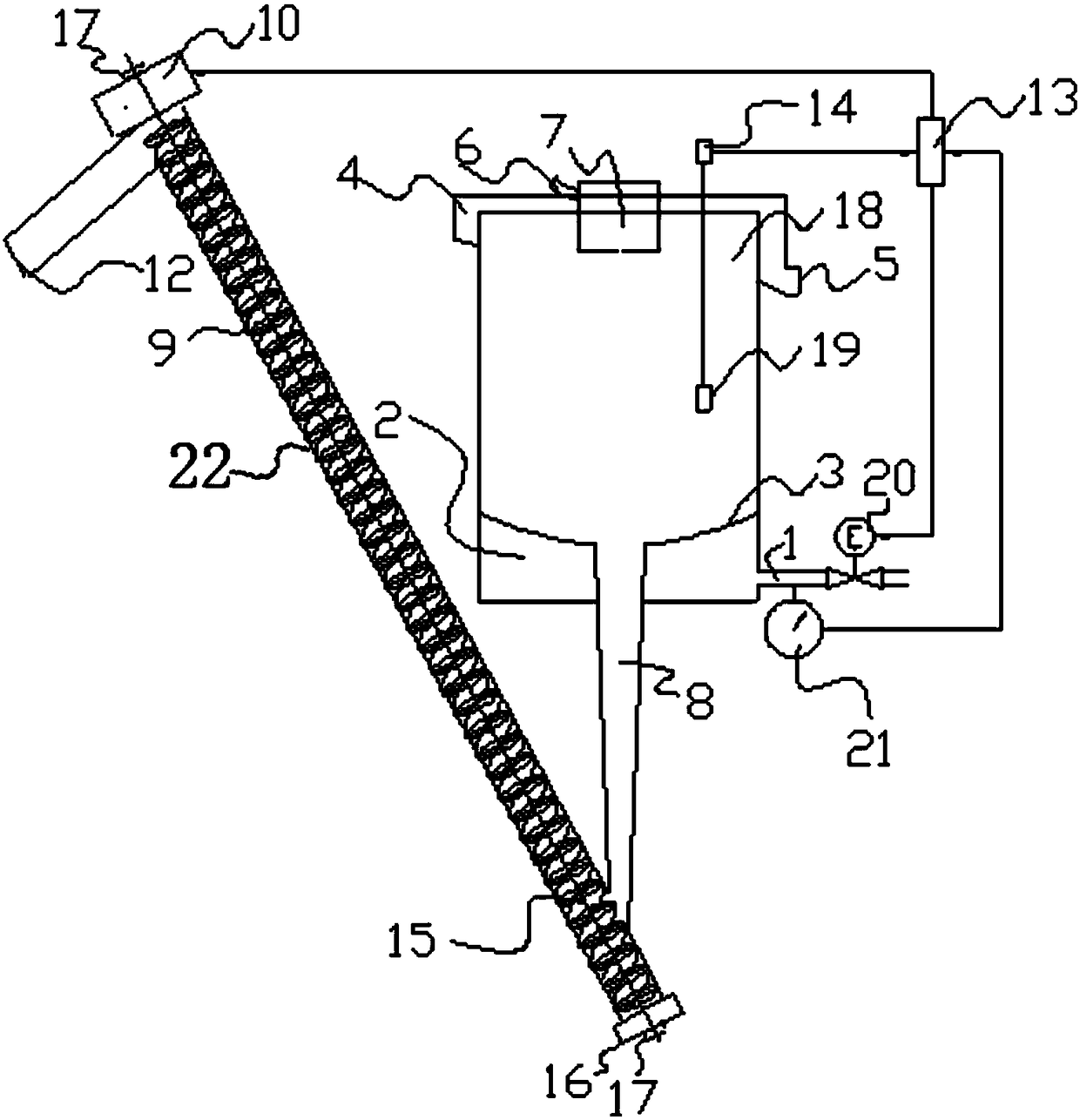

The invention discloses a device and a method for preparing hydrogen through temperature controlled continuous decomposition of hydrogen sulfide, belongs to the technical field of hydrogen preparation and gas purification, and relates to a dielectric barrier discharge temperature controllable plasma generating device and a method for preparing hydrogen through continuous and stable ionizing decomposition of a hydrogen sulfide gas or a gas containing hydrogen sulfide by using the device. The device is characterized in that a reactor has a coaxial sleeve type structure, a cylinder of the reactor is made of an insulating medium, a central electrode is formed by a metal, a grounding electrode is formed by a temperature controllable circulating liquid, and decomposed sulfur is separated through temperature control, so that continuous and stable operation of preparing the hydrogen through the decomposition of the hydrogen sulfide is ensured. The invention has the advantages that the method is suitable for preparing the hydrogen and elemental sulfur by dissociating the gases containing the hydrogen sulfide in chemical industries of natural gas, petroleum and coal; and the method does not have special requirement or limitation for the source and the composition of the gases, so the method has universal applicability for preparing the hydrogen and the elemental sulfur through the decomposition of the hydrogen sulfide.

Owner:BINZHOU UNIV

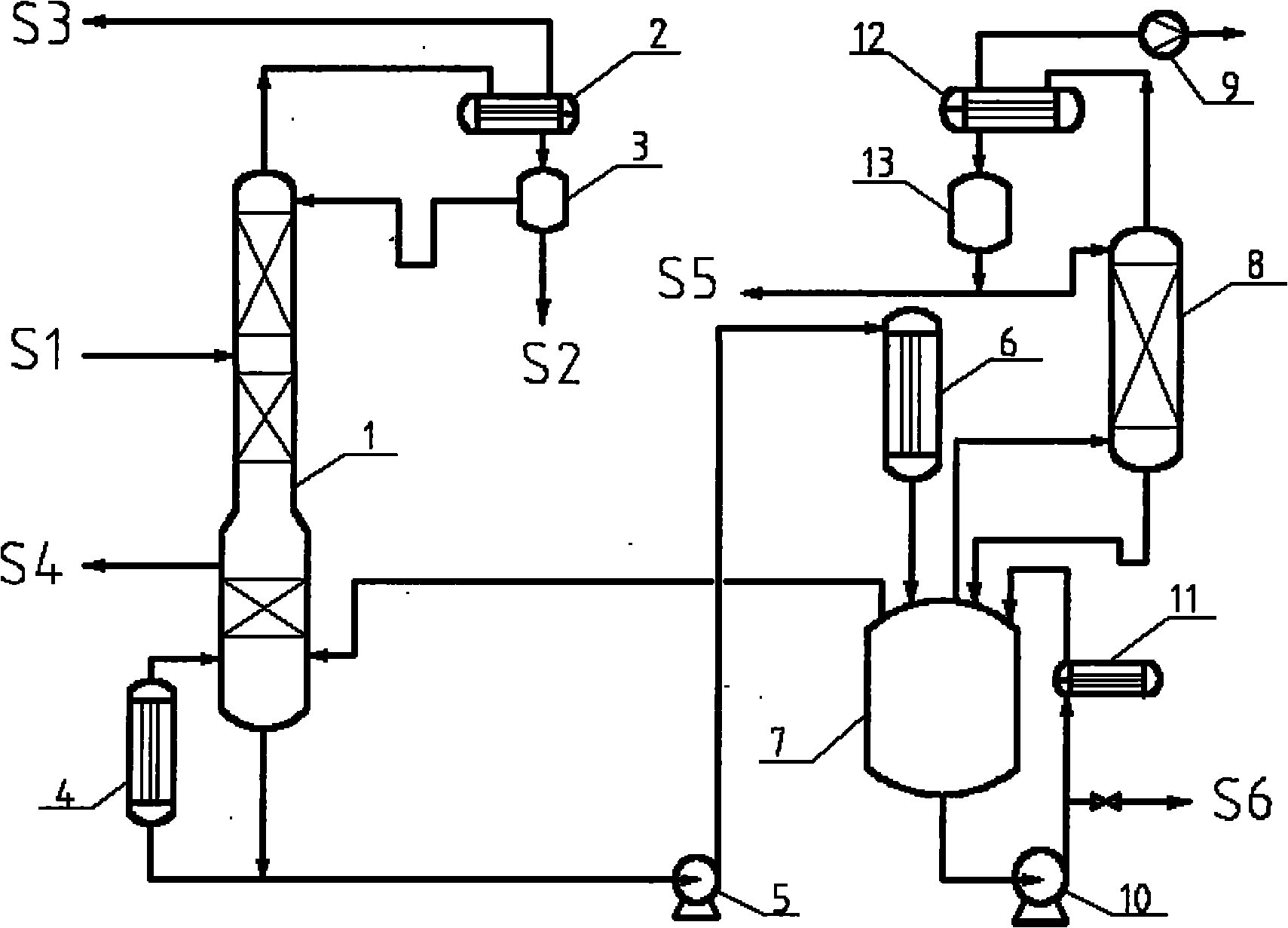

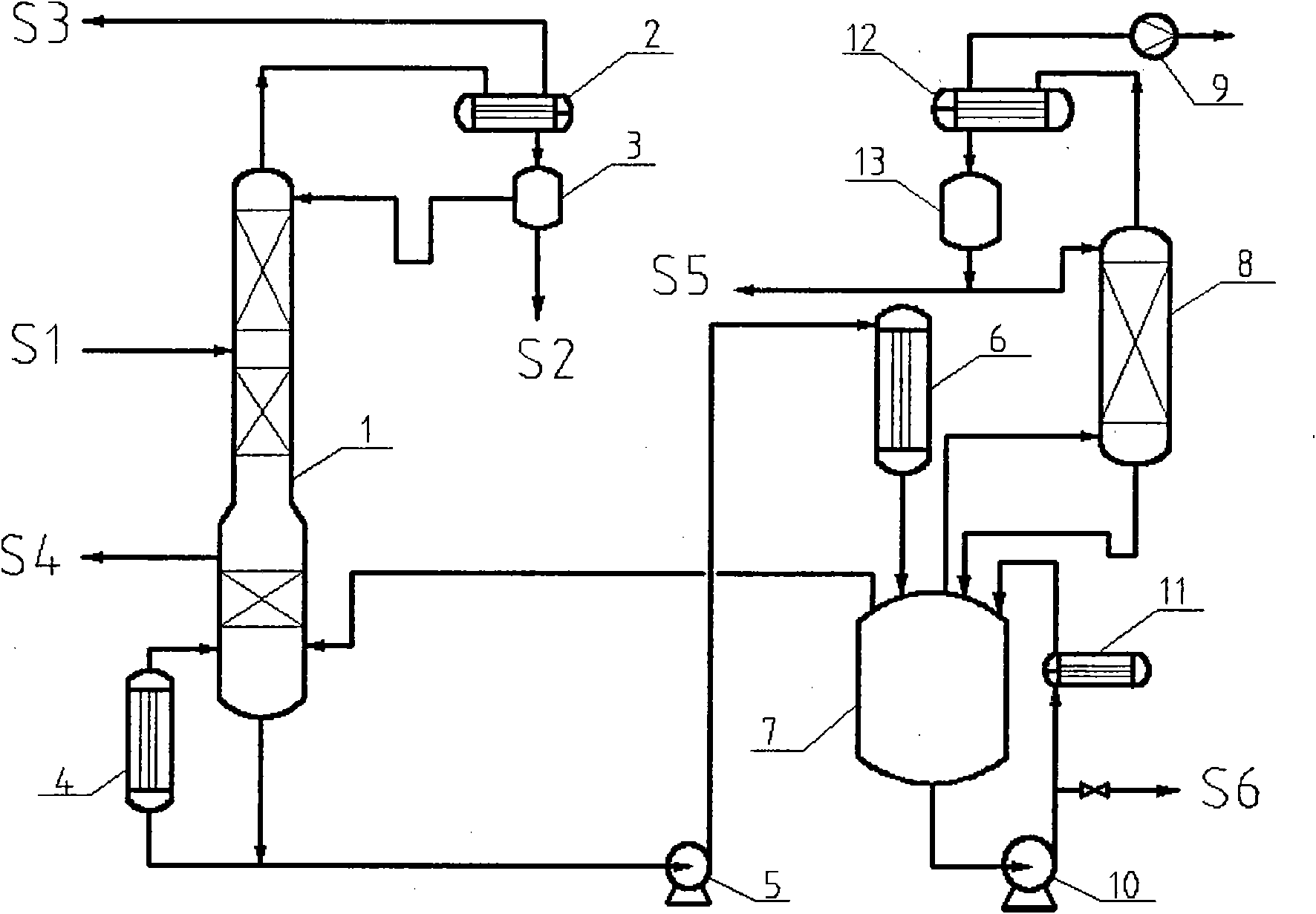

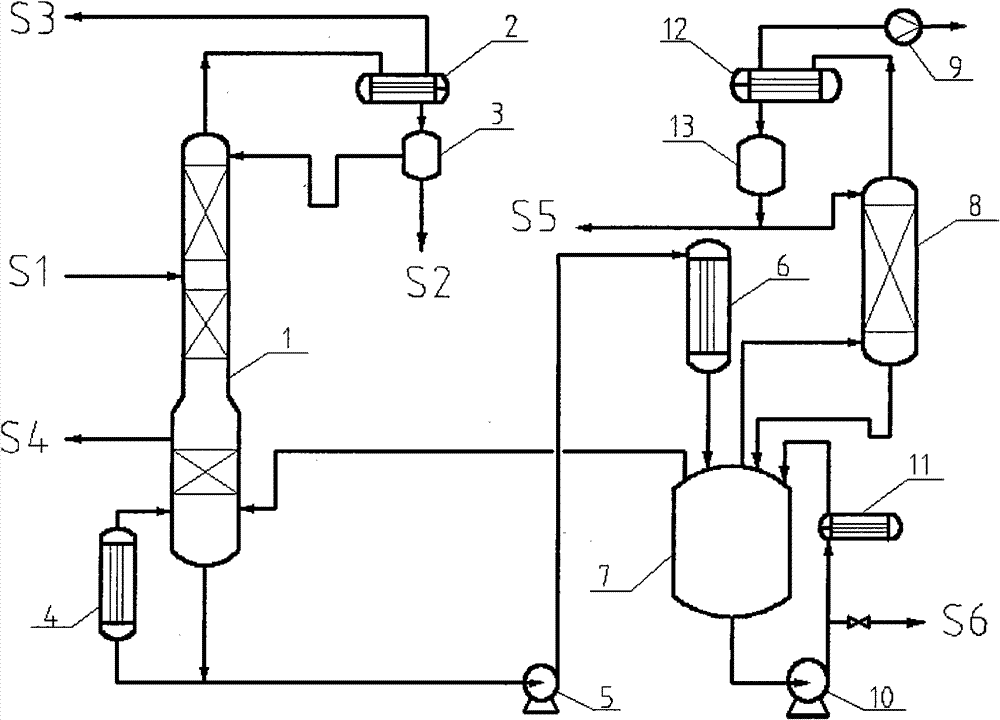

Refining and reclaiming technology of tail gas absorption solvent in production of toluene diisocyanate

InactiveCN101870666AContinuous and stable feedingContinuous and stable dischargeDispersed particle separationDistillation purification/separationToluene diisocyanateGas phase

The invention relates to a refining and reclaiming technology of a tail gas absorption solvent in the production of toluene diisocyanate (TDI). The solvent containing little phosgene, toluene diisocyanate and di-Et-1,3-benzenedicarboxylate (DEIP) performs two-stage refinement in an atmospheric refining tower and a vacuum refining tower, and a falling-film evaporator and a storage tank are arranged between the two towers. The overhead non-condensable gas phase of the atmospheric refining tower is returned to a phosgene absorption tower to recycle phosgene, the refined solvent is drawn from theside of the atmospheric refining tower, the temperature of the tower bottom is controlled to be 3-8 DEG C higher than the boiling point of the solvent, the discharged material of the tower bottom enters the falling-film evaporator, the evaporating temperature is 20-30 DEG C higher than the boiling point of the solvent, the unevaporated material enters the storage tank for storage, the material inthe storage tank performs batch vacuum rectification under the absolute pressure of 0.1-0.25bar, and the unevaporated residual material enters the residue evaporator of a TDI device to recycle TDI and DEIP. By using the solvent refining technology provided by the invention, the useful components in the solvent can be completely recycled, and the technology has the advantages of simple and stable operation and lower cost and energy consumption.

Owner:QINGDAO UNIV OF SCI & TECH +1

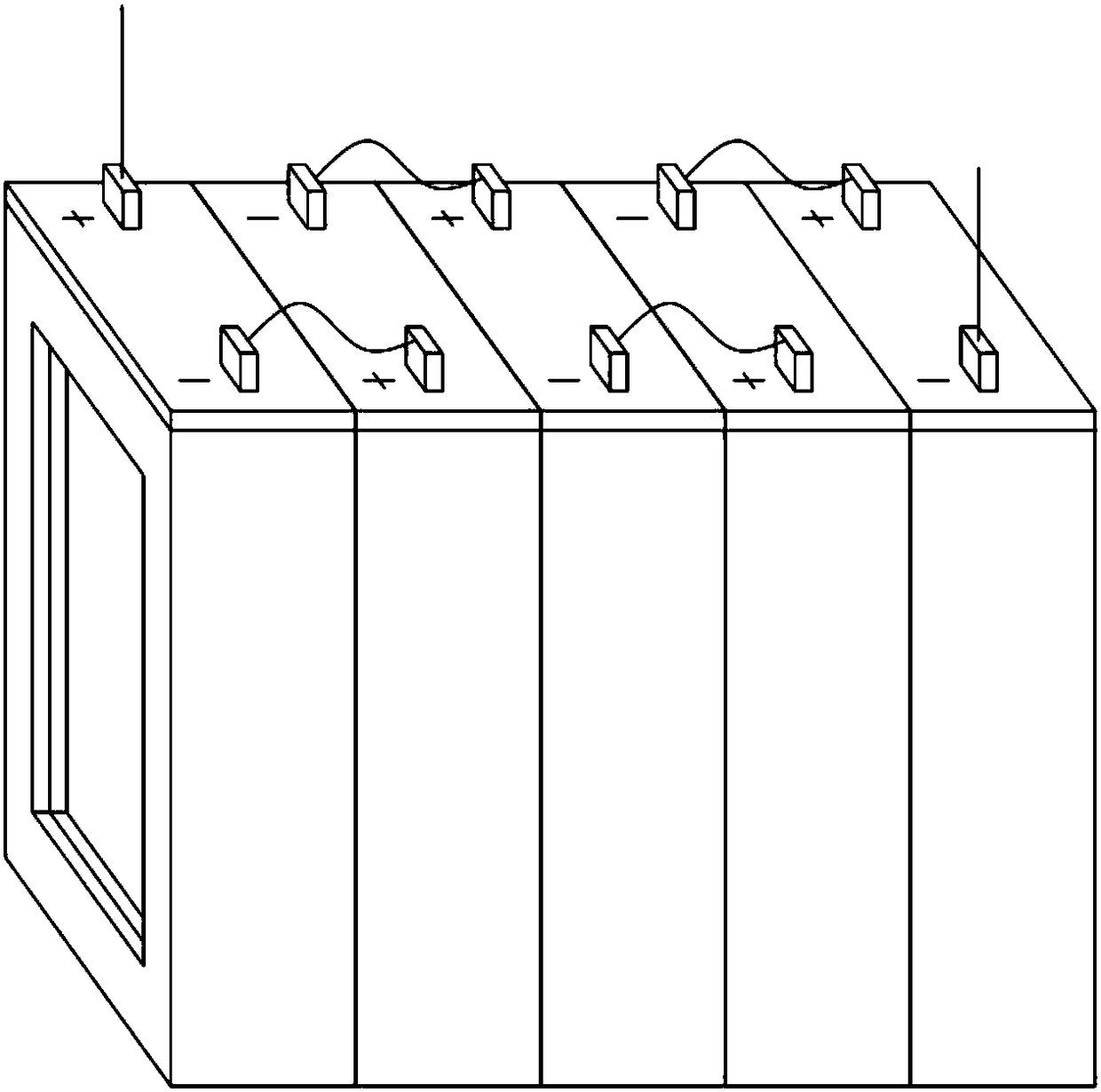

Al-air battery system

ActiveCN107492603AContinuous and stable dischargeDoes not affect the sealing stateFuel and secondary cellsSmall-sized cells cases/jacketsInjection portBattery system

In one embodiment, an Al-air battery single body is provided and includes: a sealed housing, and the following units that are installed in the sealed housing: a battery positive pole; a battery negative pole being an aluminum plate; and a connection slot for fixing the aluminum plate. The sealed housing comprises a sealing cap, which provides an opening for replacing the aluminum plate; the sealed housing also includes an electrolyte injection port and an electrolyte discharge port, which are respectively used for receiving and discharging an electrolyte. In the Al-air battery system, the aluminum plate is easy to replace, so that continuous and stable discharge is achieved for a long time; due to the sealing structure, the system is free of instant power failure when single battery cell in the system is in failure, so that driving safety is improved; due to the single battery cells, integration and detachment of the battery are convenient, so that recovery and gradient utilization of the battery are convenient.

Owner:MATERIAL & IND TECH RES INST BEIJING

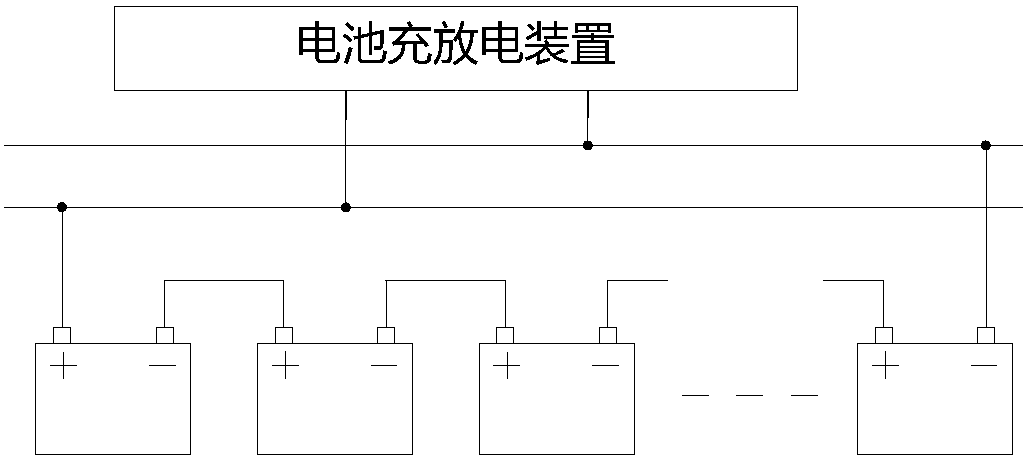

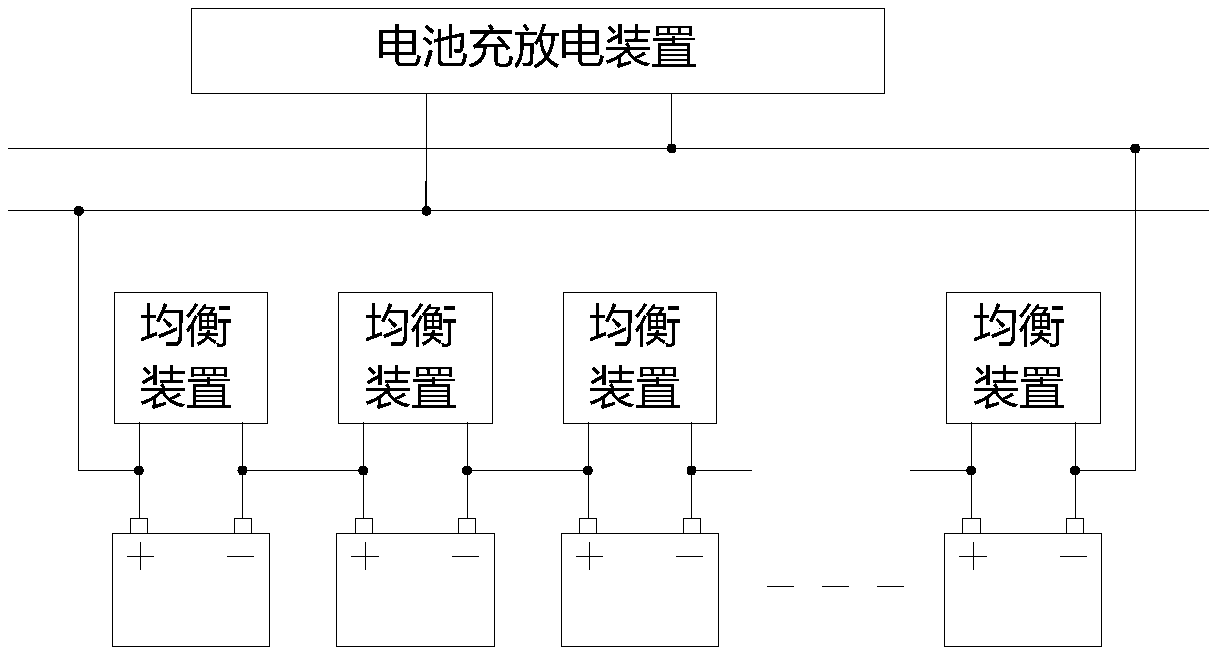

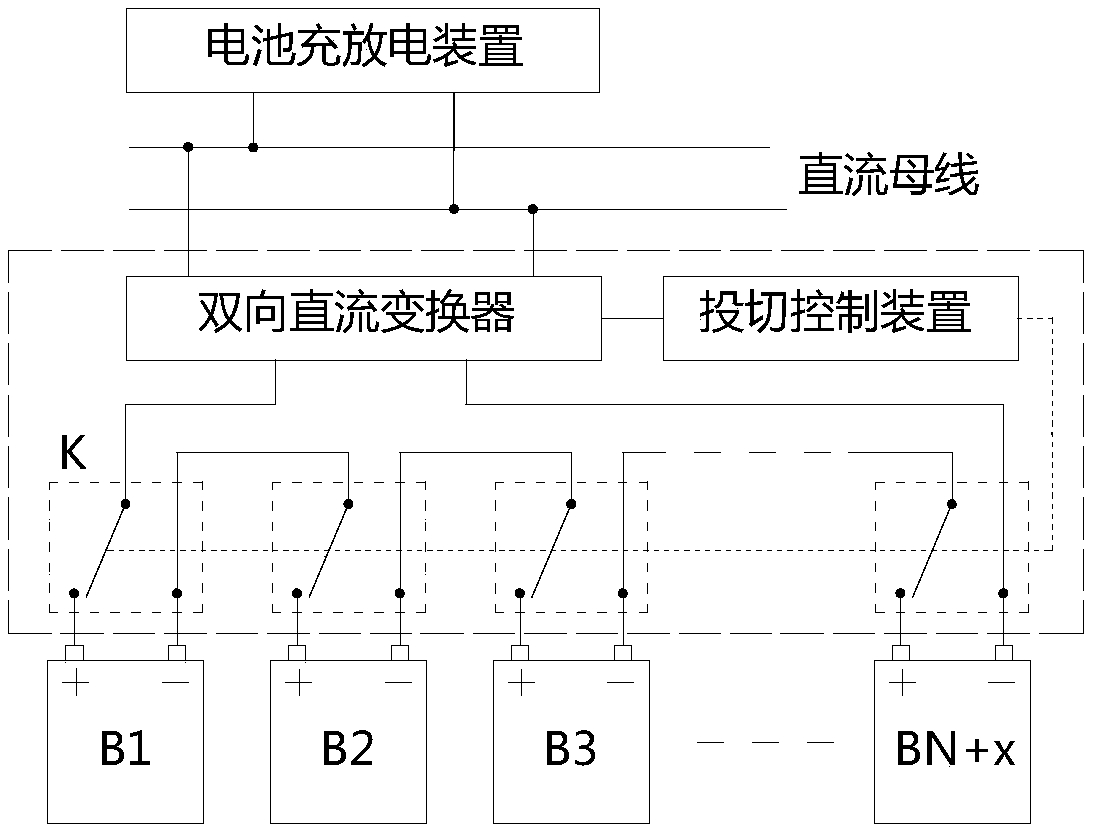

Battery pack charging and discharging management system and method

ActiveCN108400636AGuaranteed performanceGuaranteed uptimeCharge equalisation circuitSafety/protection battery circuitsEngineeringEqualization

A battery pack charging and discharging management system and a method thereof relate to charging and discharging control technology of storage batteries and belong to the technical field of control for storage batteries, for solving the problem that the adoption of the equalization technology in the existing charge and discharge management system still cannot effectively solve the problem of inconsistency caused by the deterioration of the battery. The management method adopts a multi-stage, intermittent charging or discharging method. In the charging / discharging process, a progressive charging method is adopted, different charging / discharging conditions are set in each stage, and the conditions are switched to the next stage until the condition is reached until the conditions of the laststage are satisfied. The switching time between adjacent stages is less than 10ms, and the charging / discharging duration of each stage is between 20 and 100s. The management system includes a switching control device for switching the unit cells and a bidirectional direct current converter for adjusting the charging / discharging circuit voltage. The invention overcomes bias in the prior art, ensures that each unit cell in the battery pack is fully charged or vented, and is capable of saving energy.

Owner:刘铭新

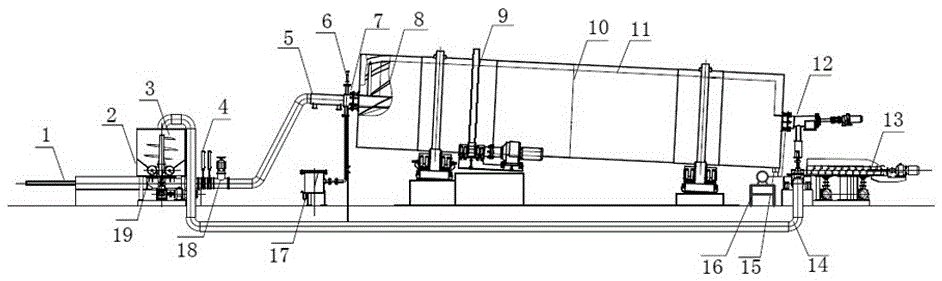

Continuous horizontal dry-process anaerobic fermentation system

InactiveCN105602843AImprove airtightnessRealize high-value utilizationBioreactor/fermenter combinationsBiological substance pretreatmentsRefluxAutomatic control

The invention provides a continuous horizontal dry-process anaerobic fermentation system, belonging to the technical field of fermentation plants. The continuous horizontal dry-process anaerobic fermentation system comprises a horizontal fermentation tank capable of rotating along the axis, wherein a biogas slurry reflux spray system is fixedly arranged in the fermentation tank; one end of the fermentation tank is a feed end, and the other end is a discharge end; the height of the feed end is greater than that of the discharge end; the feed end is connected with a mixing bin through a feed system; the feed end is provided with a biogas pipe; the discharge end is provided with a fermentation leftover discharge system; and a temperature measuring device is arranged inside the fermentation tank. Both ends of the obliquely-arranged horizontal fermentation tank are respectively connected with the automatic feed system and automatic discharge system, and the reflux spray system is arranged in the fermentation tank, thereby implementing continuous stable feed and discharge; and thus, the biogas slurry can implement circulating spray, and the marsh slag can implement circulating mixing. The continuous horizontal dry-process anaerobic fermentation system has the advantages of simple structure, reasonable design, high operation smoothness and low energy consumption, and can implement full-automatic control. The capacity aerogenesis rate is 1.0-1.5 m<3> / m<3>.d.

Owner:QINGDAO TIANREN ENVIRONMENT

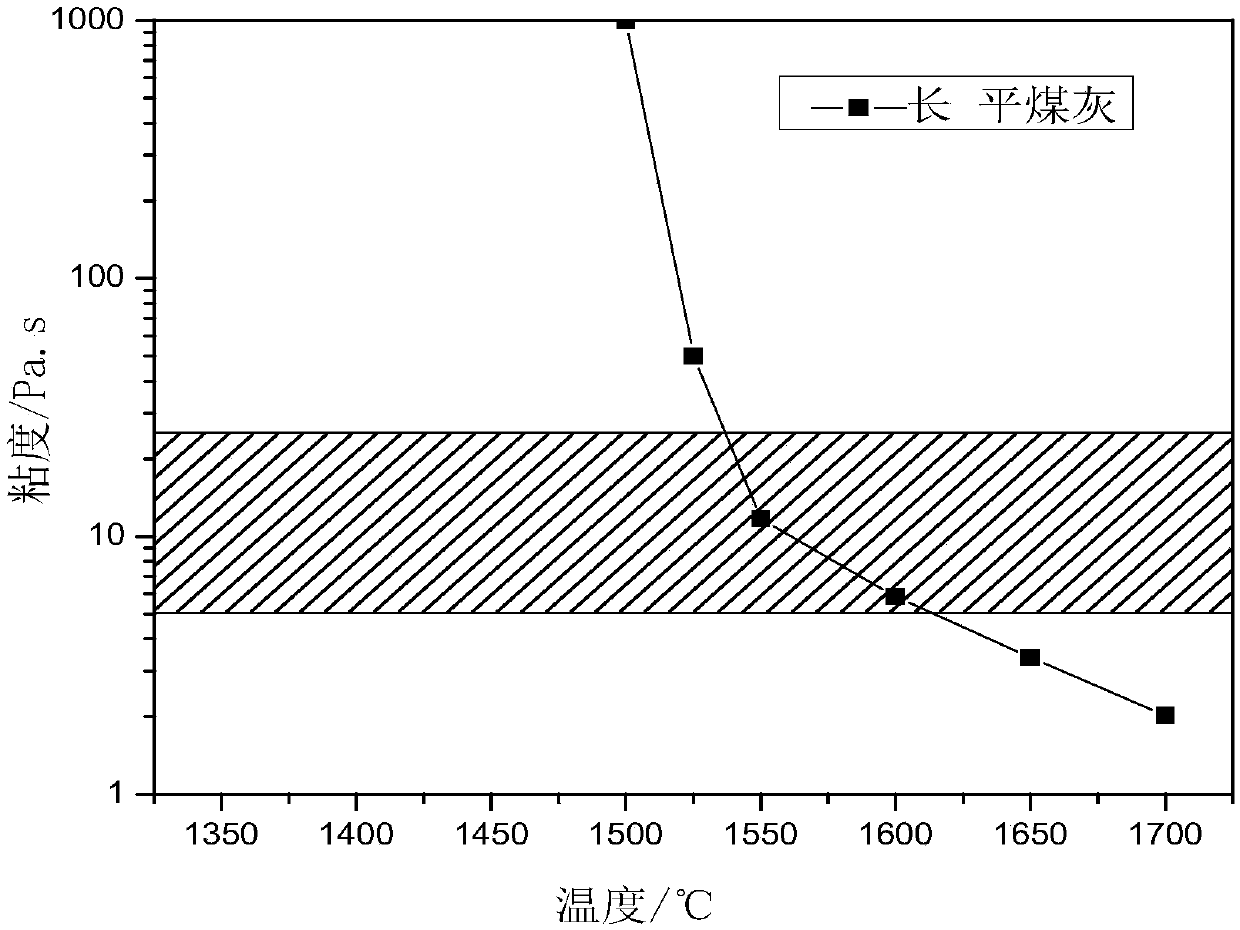

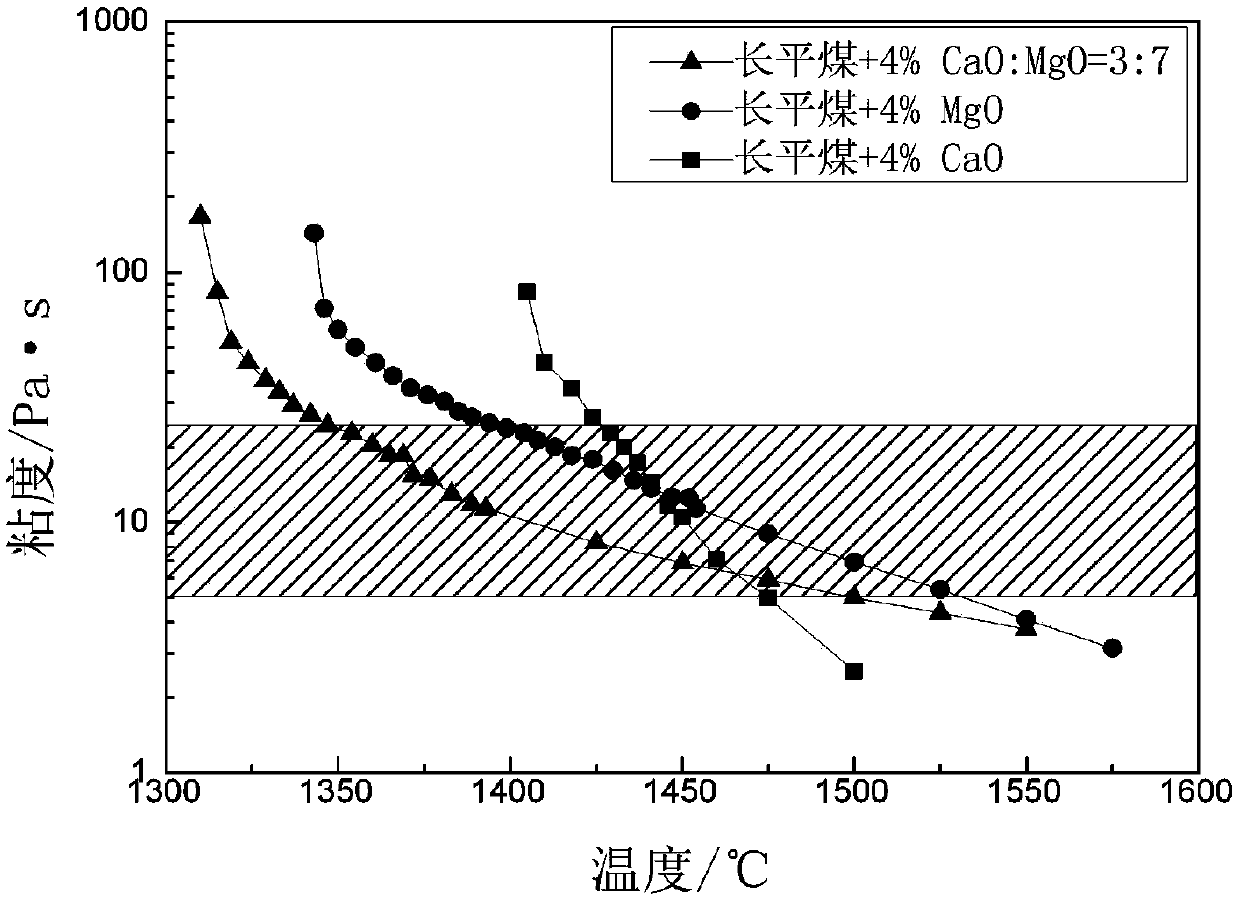

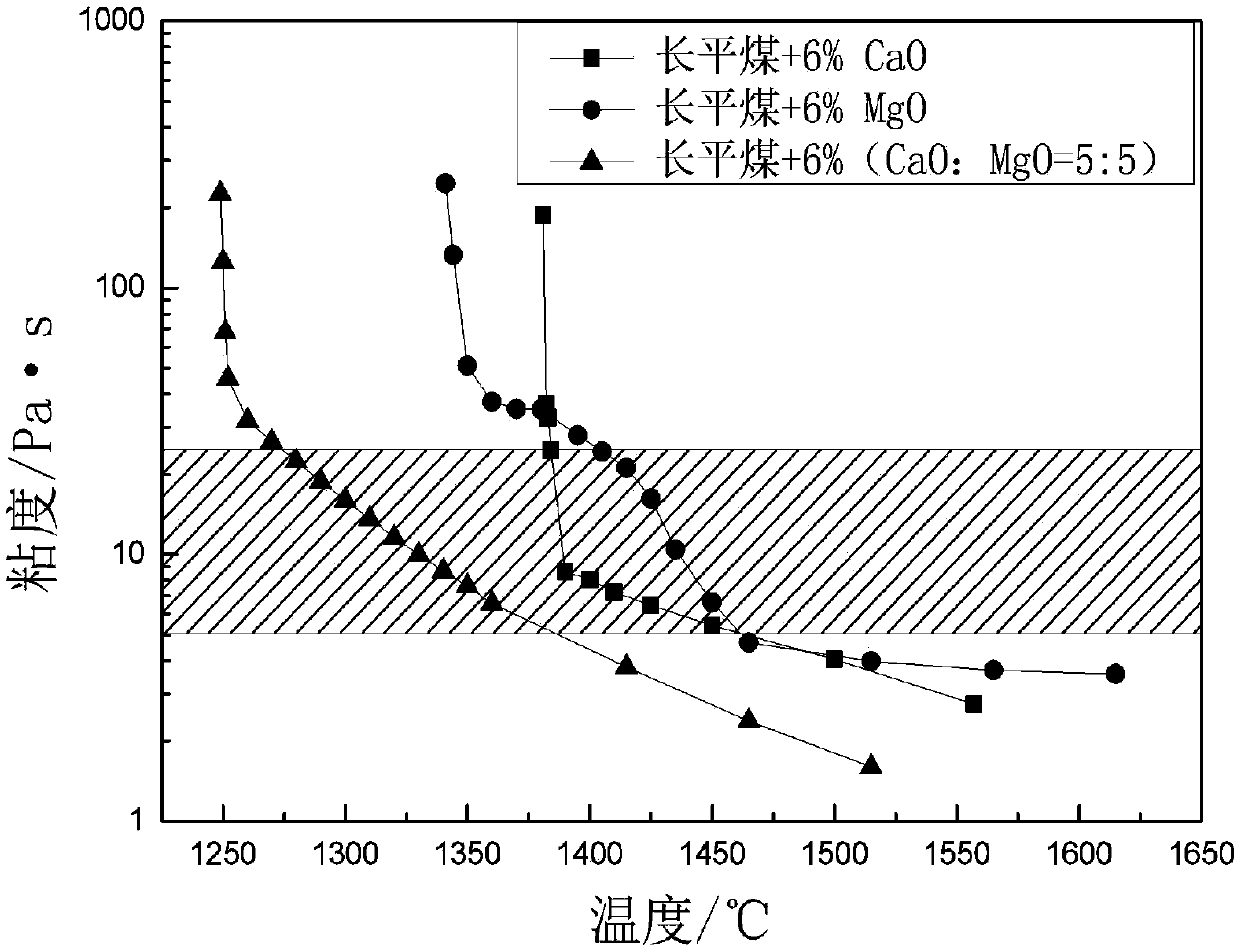

Auxiliary for improving pulverized coal gasification ash slag viscosity-temperature characteristics and preparation method

InactiveCN109576036AImprove viscosity-temperature characteristicsContinuous and stable dischargeFuel additivesSlagMaceral

The invention discloses an auxiliary for improving pulverized coal gasification ash slag viscosity-temperature characteristics. The auxiliary is characterized in that the adding amount and the mixtureratio of raw materials of the auxiliary are determined according to raw coal ash content and coal ash chemical composition, the adding amount ranges from 3% to 6%, the ash content of coal ash added with the auxiliary is lower than 25%, and the coal ash composition is characterized by CaO+MgO=13%-26%, CaO / MgO=0.6-2.6, SiO2+Al2O3=65%-78%, SiO2 / Al2O3=1.25-2.6. The coal ash composition is changed byadding the auxiliary, the auxiliary participates in coal ash mineral transformation, diopside remarkably melted acid oxide is generated at high temperature, low-temperature co-melting of calcium and magnesium minerals is promoted, the auxiliary varies from raw coal ash composition to raw coal ash composition and has strong pertinence, the viscosity-temperature characteristics of pulverized coal gasification ash slag can be remarkably improved, and coal with poor fusibility can effectively adapt to a liquid slagging gasifier.

Owner:ANHUI UNIV OF SCI & TECH

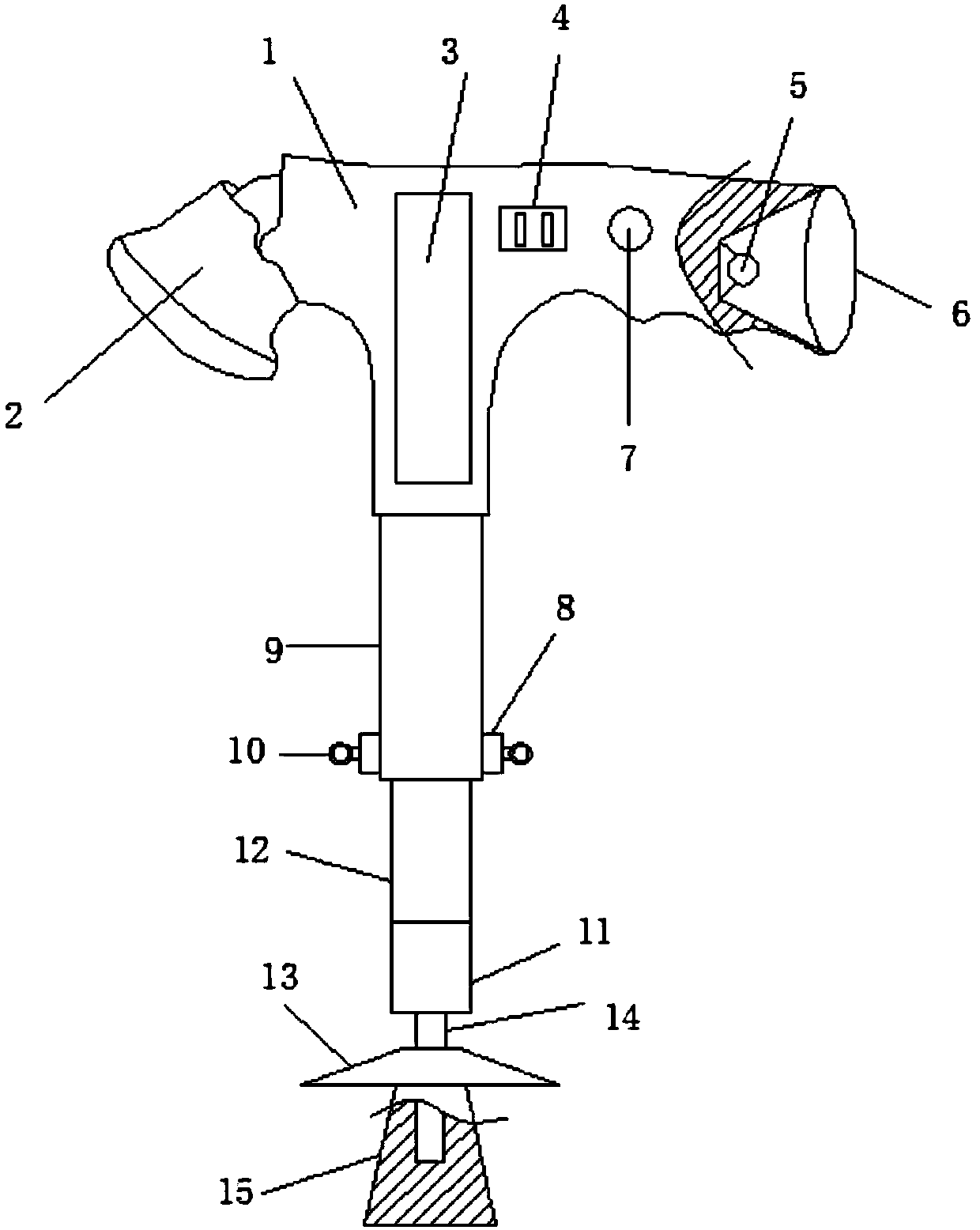

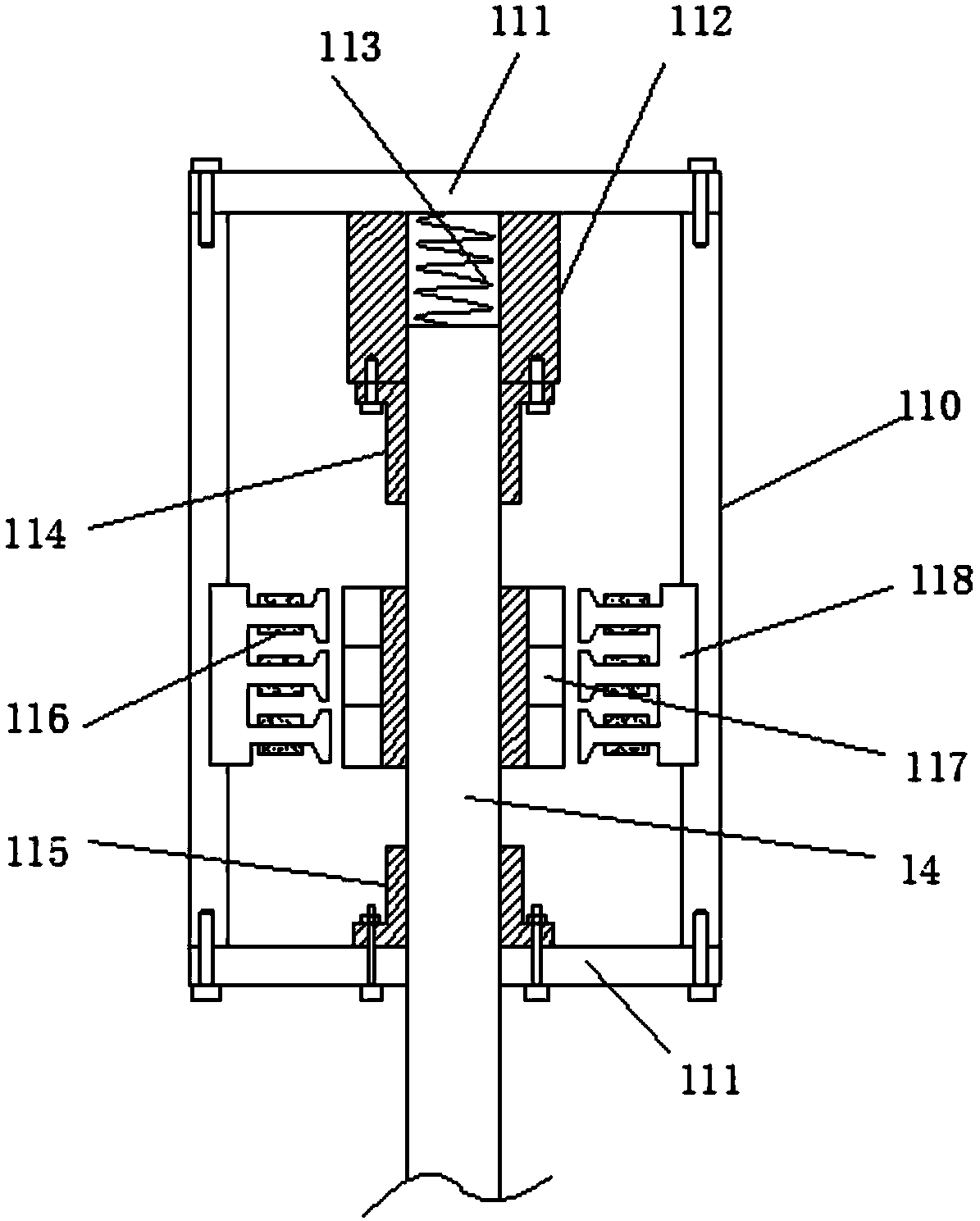

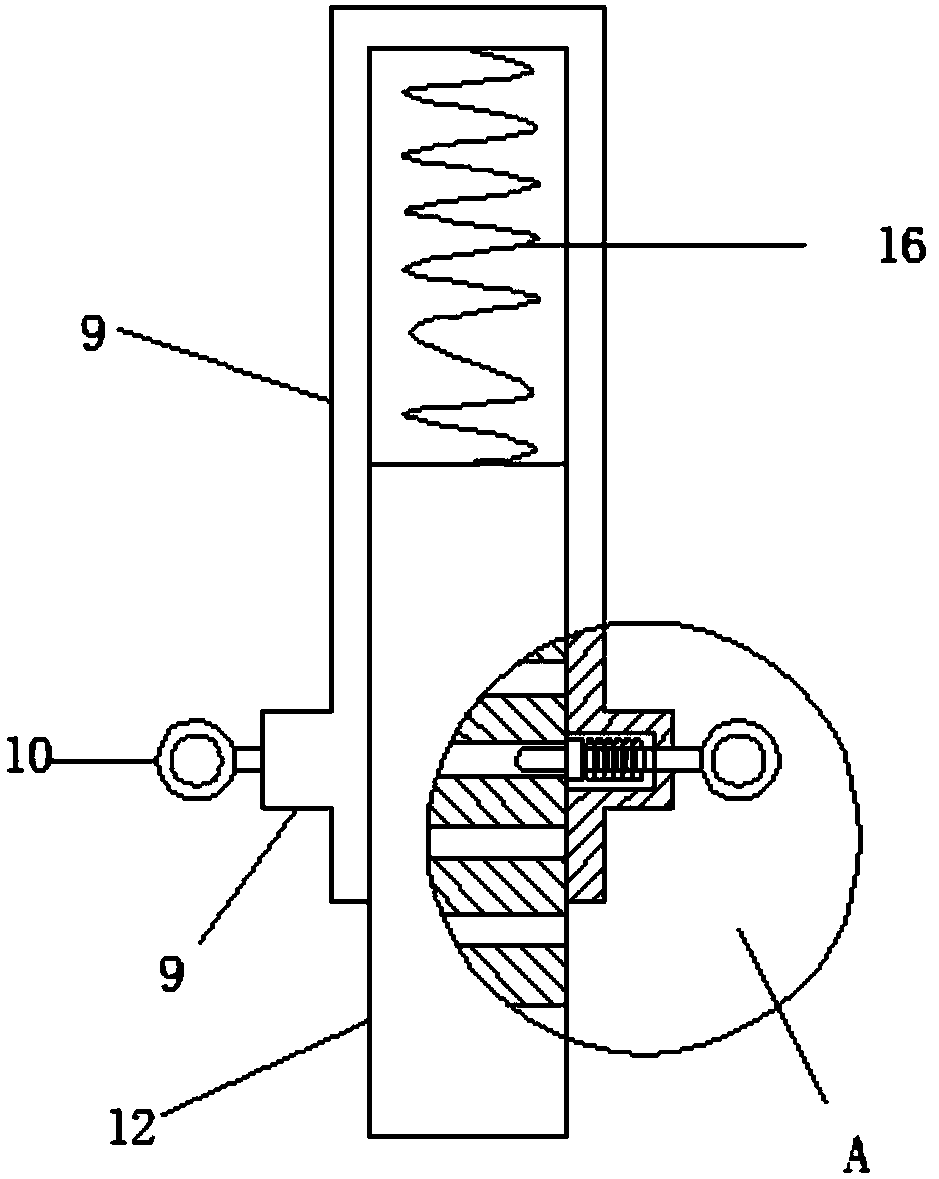

Self-generating electricity type adjustable climbing stick for outdoor travel

InactiveCN108031080AReasonable structureContinuous and stable dischargeWalking sticksMountaineeringElectricityEngineering

The invention discloses a self-generating electricity type adjustable climbing stick for outdoor travel. The climbing stick comprises a handle. An illumination cover is installed in the middle of theright end of the handle. An illumination lamp bead is installed inside the illumination cover, a storage battery piece is installed in the middle of the handle, a fixing column is installed in the middle of the lower end of the handle, fixing cavities are formed in the two sides of the lower end of the fixing column, stretchable rods are installed inside the fixing cavities, the stretchable rods are sleeved with stretchable springs, stretchable blocks are installed at the left ends of the stretchable rods, fixing heads are installed at the left ends of the stretchable blocks, a fixing spring is installed inside the fixing column, a lifting column is installed at the lower end of the fixing spring, a self-generating electricity device is installed at the bottom end of the lifting column, the self-generating electricity device comprises a fixing plate, top plates are installed at the upper and lower ends of the fixing plate through fixing bolts, and a limiting base is installed in the middle of the top plate on the upper side. The self-generating electricity effect is achieved, it is ensured that the whole climbing stick continues to discharge stably, meanwhile, the buffer effect ofa buffer column is enhanced in the whole walking stick climbing process, and the climbing comfort is ensured.

Owner:WUXI X RES PROD DESIGN & RES

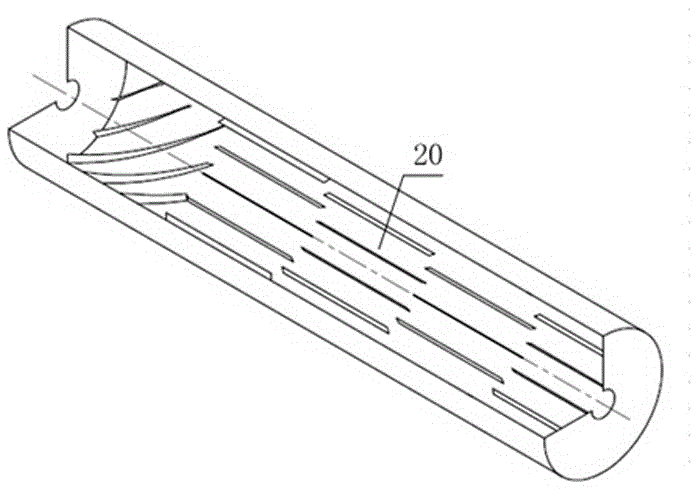

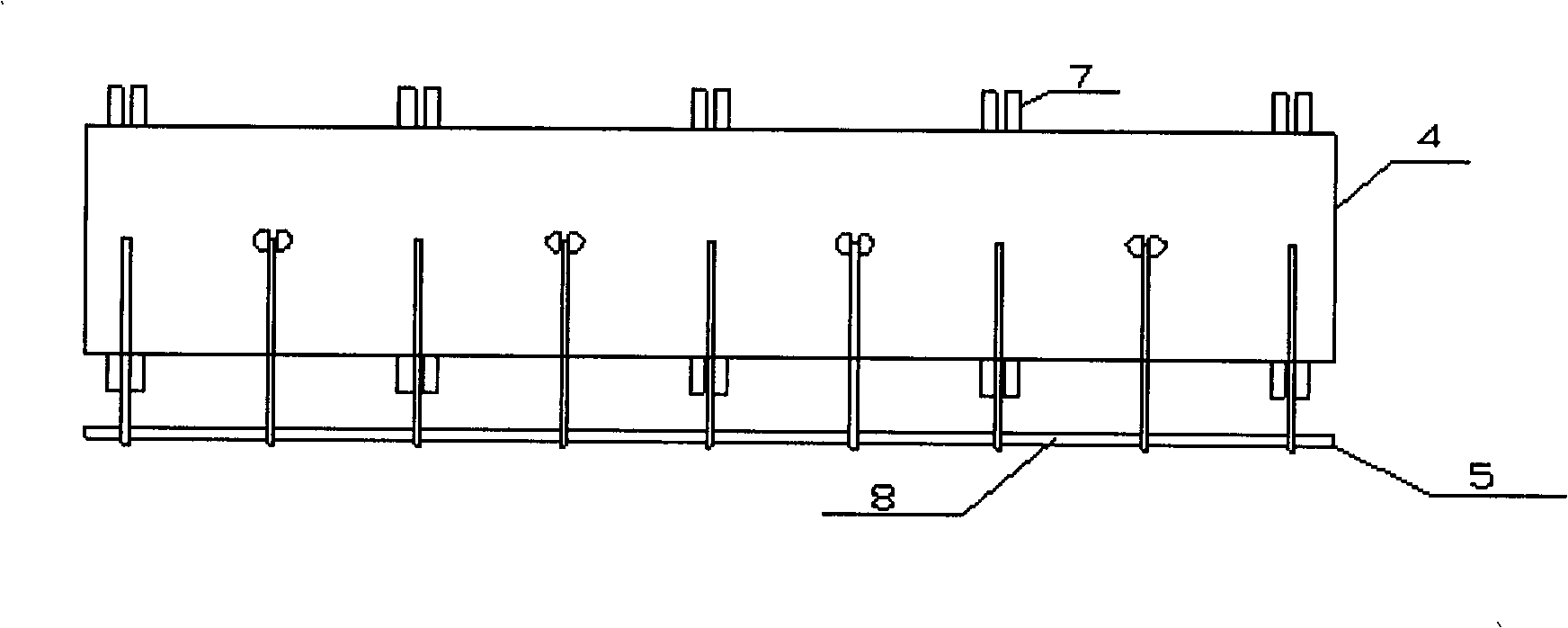

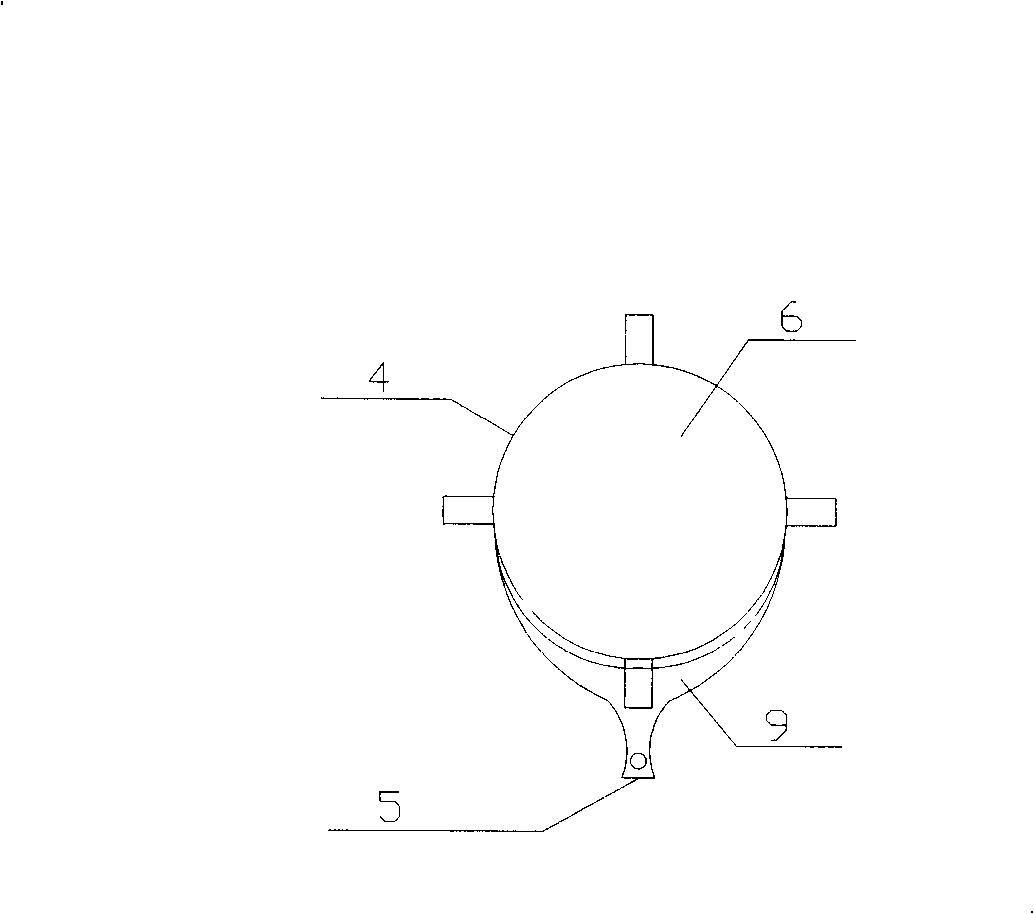

Feeding apparatus of biomass silo

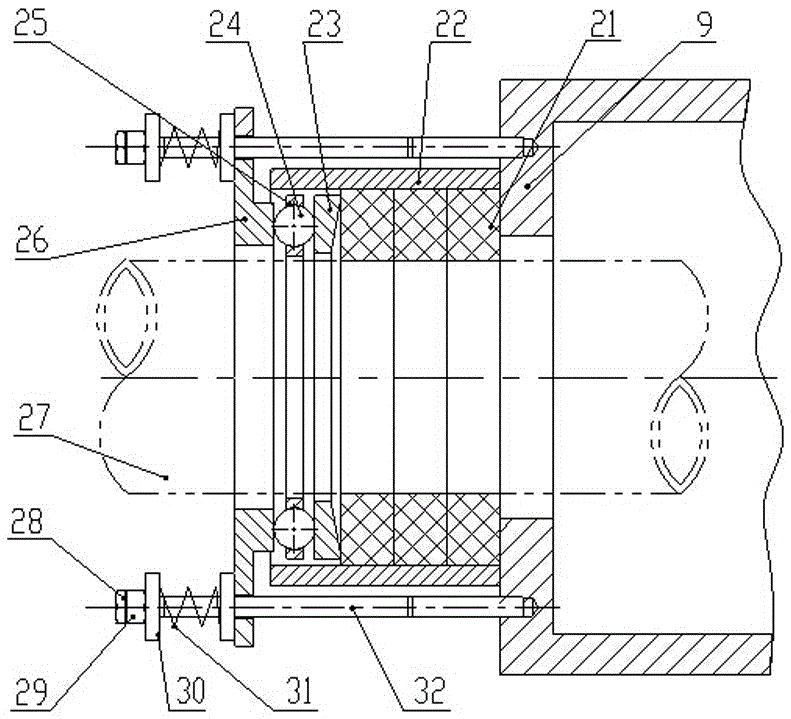

InactiveCN101353117AStrong targetingContinuous and stable dischargeLarge containersLoading/unloadingEngineeringSilo

The invention discloses a feeding device used in biomass storage hopper, comprising a storage hopper, a switching device and a transporting device; the switching device is arranged at the lower part of the storage hopper; the transporting device is arranged at the bottom of the storage hopper; the switching device comprises a plurality of switchers and enwinding breakers which are laid in parallel; the switchers are provided with a switching shaft; a plurality of bar sets are arranged on the switching shaft along the axial direction with equal distance; 1 to 6 switching bar pairs are arranged in each bar set along axial direction of the switching shaft; the enwinding breakers are provided with a fixed shaft; doctor bars matched with the switching bars are arranged on the fixed shaft. The feeding device used in the biomass storage hopper of the invention can break bridging or scaffolding of the biomass material in the storage hoppers, can also break the enwinding of biomass stalks on the switching shaft during the rotation of the switcher, thus realizing continuous, stable and adjustable material discharging of the biomass material piled in the storage hopper, and forming strong direction on soft stalks. The feeding device realizes the separation of switching and transporting and becomes more flexible on feeding control.

Owner:ZHEJIANG UNIV

Metal fuel battery

ActiveCN108346844AImprove performanceStable current and voltageFuel and primary cellsCell electrodesFuel cellsEngineering

The present invention provides a metal fuel battery comprising a plurality of battery cells connected in turn in series, the battery cell comprises a battery casing, air electrode sheets, a zinc sheetand an electrolyte; the battery casing is hollow structure, the zinc sheet is disposed inside the battery casing, the air electrode sheets are disposed inside the battery casing and on both sides orone side of the zinc sheet, and one sides, facing away from the side of the zinc sheet, of the air electrode sheets are connected with the outside, the electrolyte is filled between the air electrodesheets and the zinc sheet, and the air electrode sheets and the zinc sheet are respectively connected with wires. The metal fuel battery has stable performance and is capable of stably discharging byarrangement of the zinc sheet as a battery negative electrode. Through arrangement of the air electrode sheets as a positive electrode of the battery, the cost is low, the overall structure is simple,voltage and current are stable, and the metal fuel battery t is environmentally friendly and non-pollution.

Owner:YUNAN JINGCHUANG LIQUID METAL THERMAL CONTROL TECH RES & DEV CO LTD

Effective slurry thick and stable discharging device and method

PendingCN109260774ASettling thickening time shortenedSingle consumption saturation point dropSettling tanks feed/dischargeSedimentation settling tanksUltrasonic generatorEngineering

The invention provides an effective slurry thick and stable discharging device and method and belongs to the technical field of flocculation settling. The device comprises a cabin body, transducer carrier tubes, sound / ultrasonic transducers, a digital controller, a rotation driving device, a mixing helix tube, a flocculant tube, an overflow pipe, a barretter, a carrier tube stabilizer and a sand outlet, wherein the transducer carrier tubes are arranged inside the cabin body, the rotation drive device is arranged at the upper end of the cabin body, and thus a rotation blind-less scanning systemis formed; the sound / ultrasonic transducers are respectively arranged at a settling section, a thickening section and a discharging section in each transducer carrier tube to form a sound field destabilization granulating active region, a sound field resonant draining thickening active region and a sound field excitation liquefying discharge active region respectively, and are connected with thesound / ultrasonic transducers through transducer connecting wires; the mixing helix tube is connected with the flocculant tube and is communicated with the barretter. The device has simple structure and process, and can realize quickly thick and stable discharging of slurry.

Owner:UNIV OF SCI & TECH BEIJING

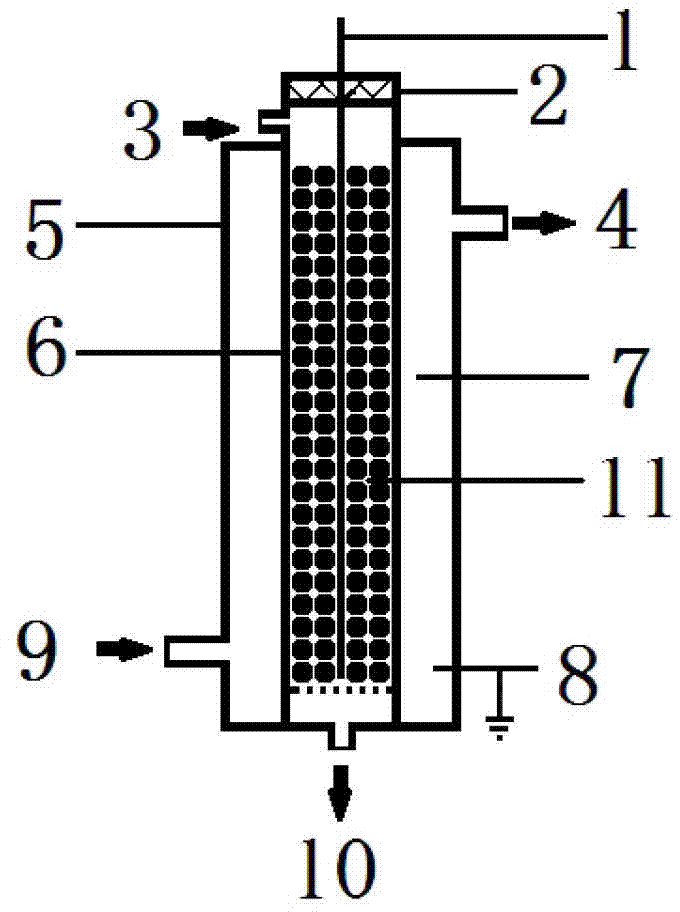

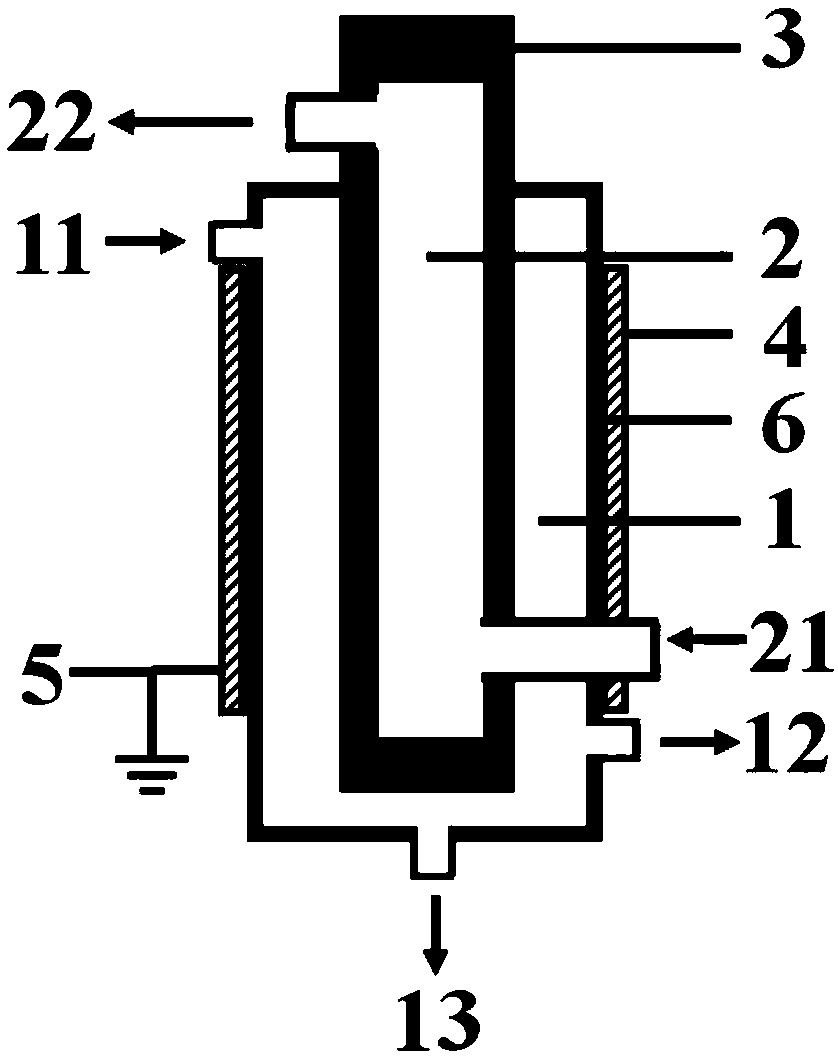

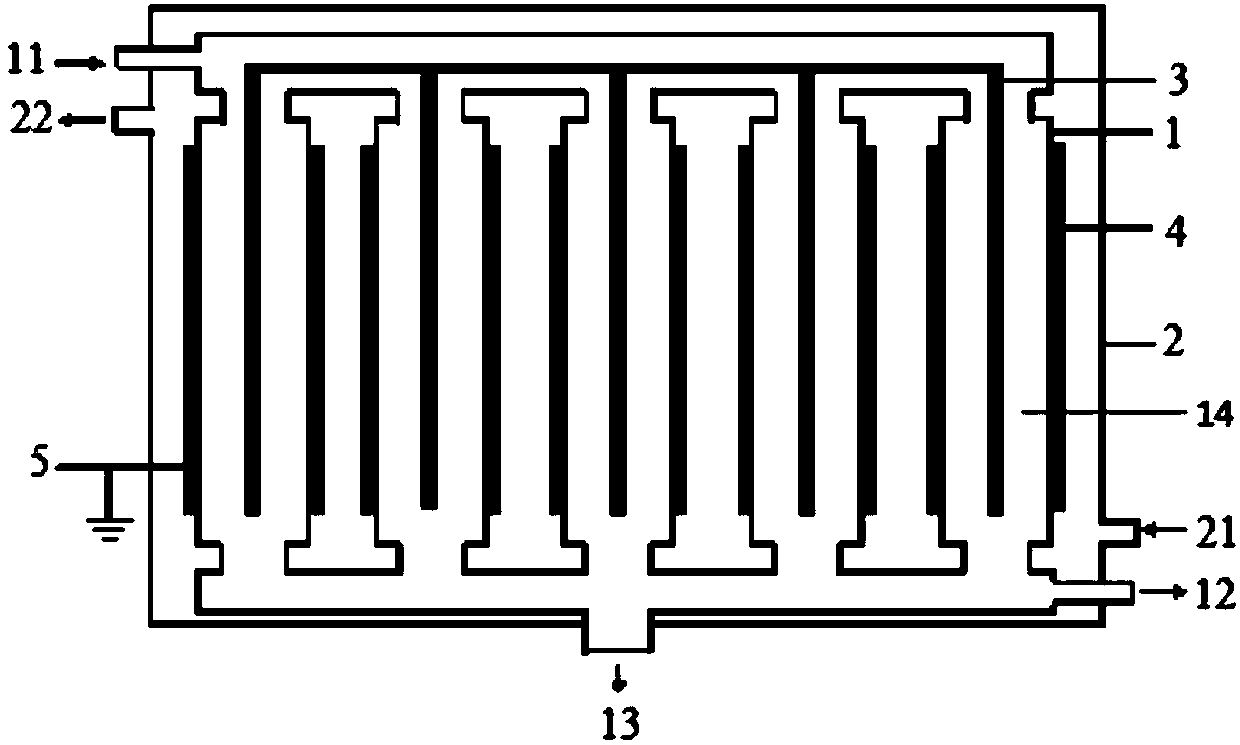

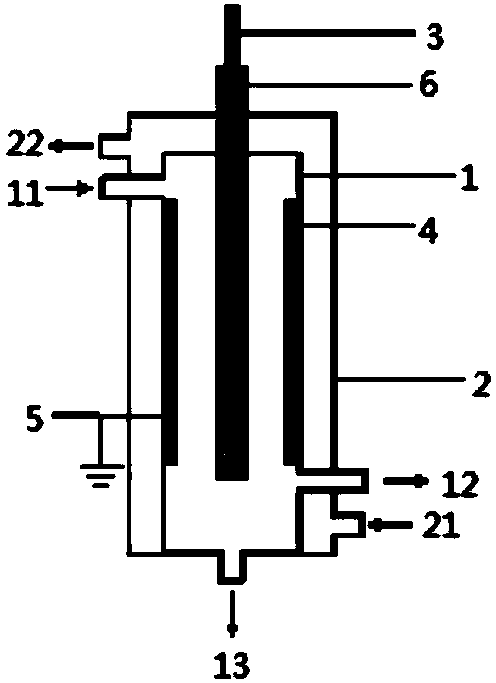

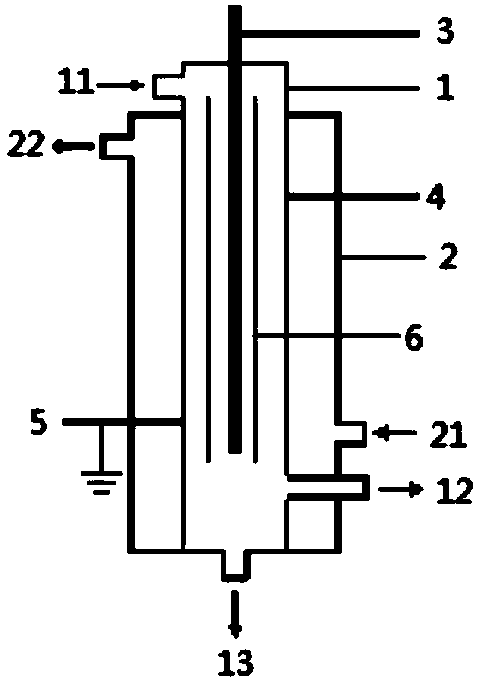

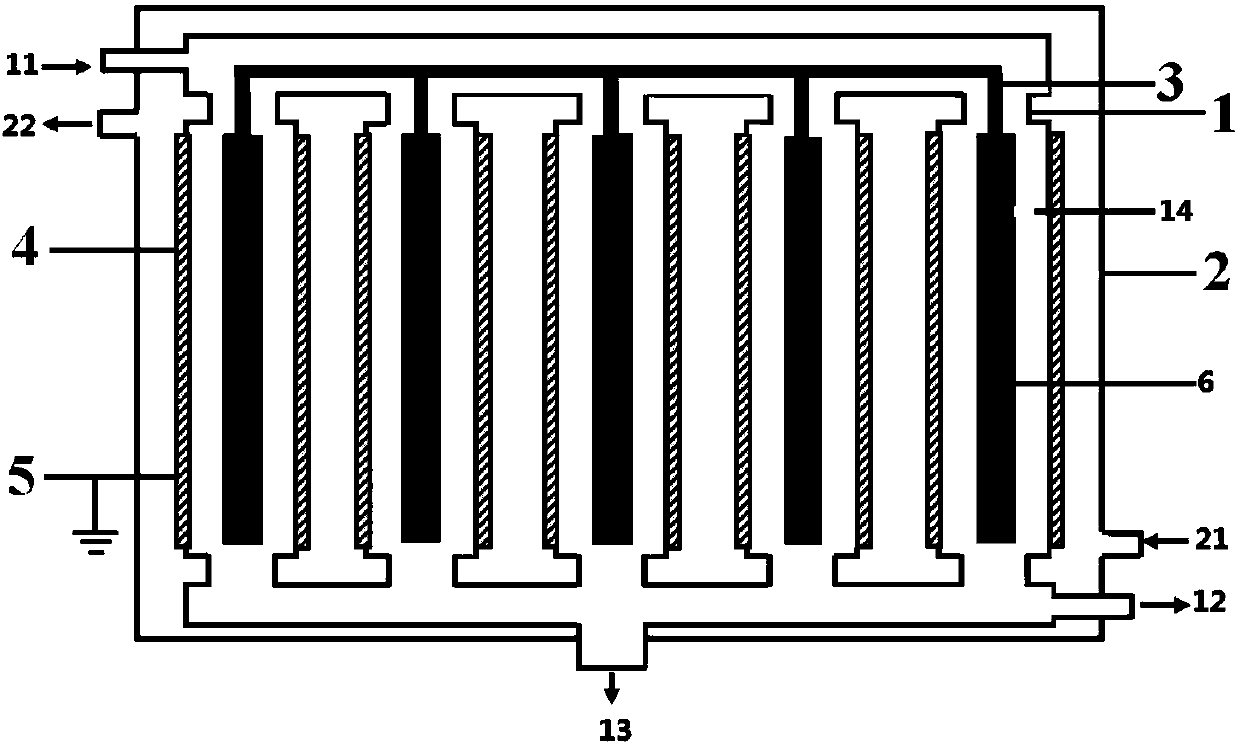

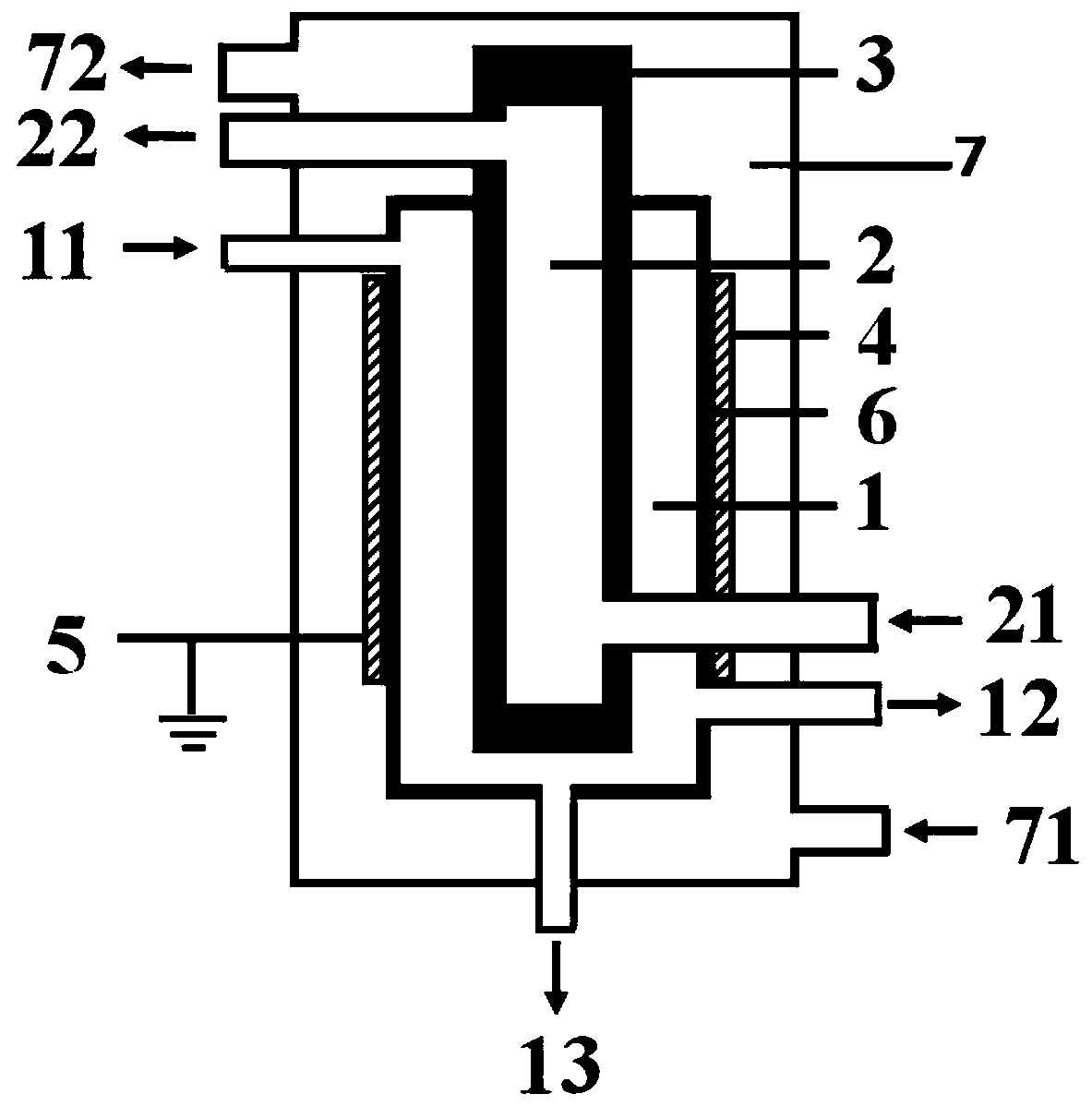

Plasma device and method for decomposing hydrogen sulfide

PendingCN111377409AFacilitate discharge decomposition reactionLarge micro discharge currentSulfur preparation/purificationHydrogen productionLow temperature plasmaPlasma chemistry

The invention relates to the field of plasma chemistry, and discloses a plasma device and a method for decomposing hydrogen sulfide; the device comprises a first cavity (1), a second cavity (2), an inner electrode (3), an outer electrode (4) and a blocking medium (6), wherein the inner electrode (3) and the outer electrode (4) are both solid electrodes, and the shapes of the inner electrode (3) and the outer electrode (4) are mutually matched to form an equal-diameter structure. The low-temperature plasma reactor provided by the invention can realize continuous and stable operation of a hydrogen sulfide decomposition process under an obviously high hydrogen sulfide conversion rate, and the device can realize long-period operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

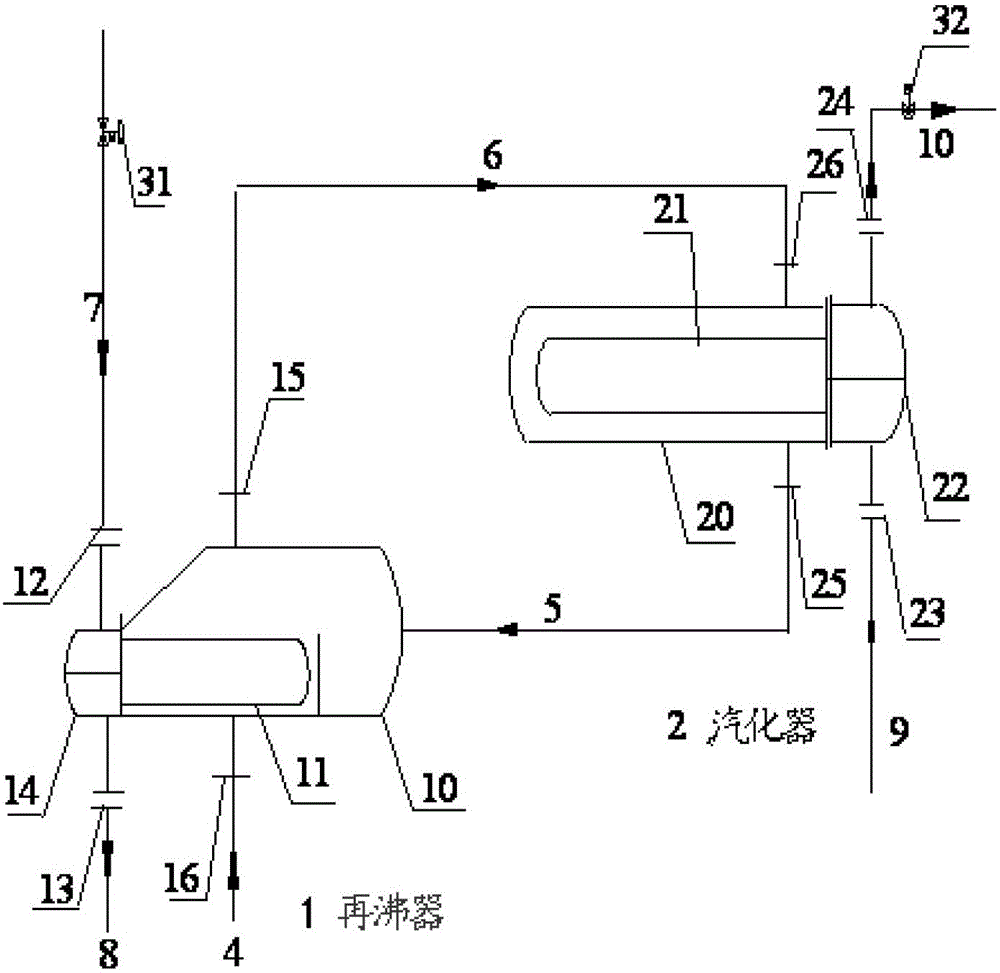

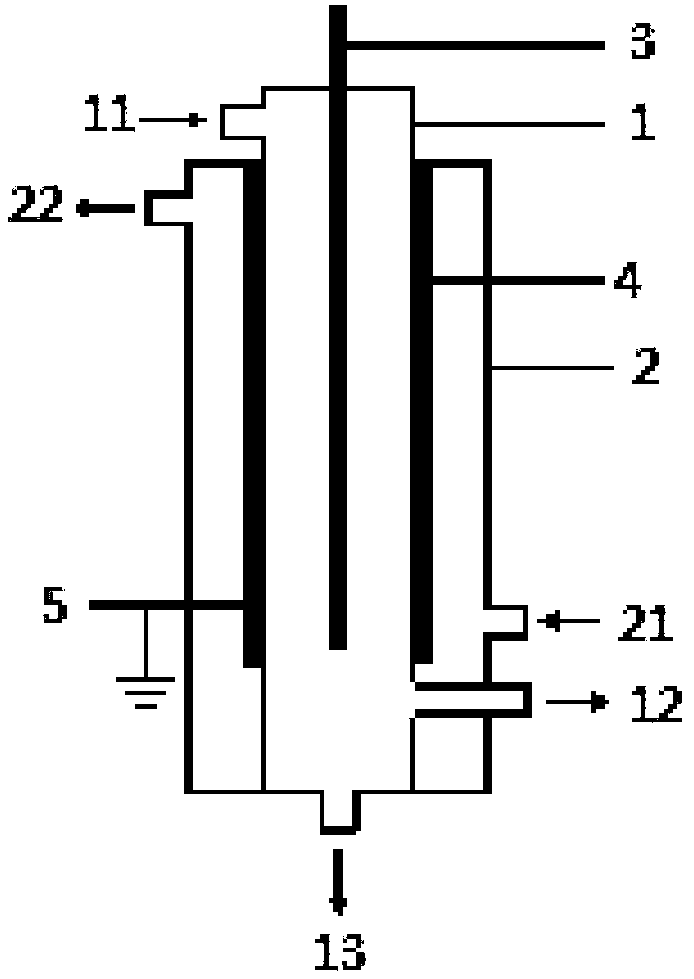

Liquid ammonia vaporization method

ActiveCN102980023AEliminate liquid shockMake full use of heat exchange efficiencyPressure vesselsContainer discharging from pressure vesselsSteam condensationReboiler

The invention discloses a liquid ammonia vaporization method. The liquid ammonia vaporization method is mainly used for solving the problems that equipment is subjected to water attack, the surface of a heat exchange pipe is frosted and the heat exchange efficiency is reduced due to the vaporization of liquid ammonia. The liquid ammonia vaporization method comprises the following steps: heating vapor enters a reboiler tube pass from a vapor port and heats a heat medium in a reboiler after being subjected to heat exchange with the heat exchange pipe, and water produced through vapor condensation flows out of the reboiler; the heat medium is heated to vaporize and becomes heat medium gas after being subjected to heat exchange, the heat medium gas rises into an vaporizer, heats a vaporizer tube pass and is condensed into heat medium liquid after being subjected to heat exchange with ammonia in the vaporizer tube pass, and the heat medium liquid flows into the reboiler; and liquid ammonia enters the vaporizer tube pass and is vaporized into gaseous ammonia after receiving heat supplied by the heat medium gas, and the gaseous ammonia is discharged from the outlet of the vaporizer tube pass.

Owner:XIAN MODERN CHEM RES INST

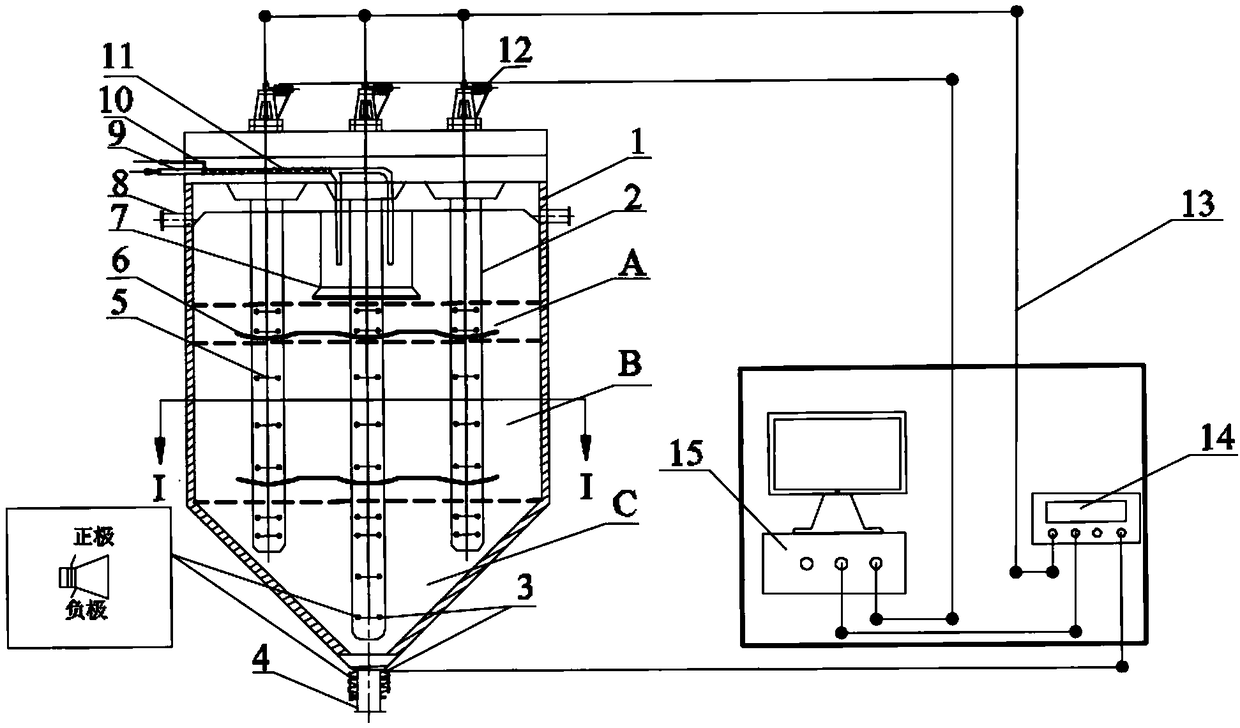

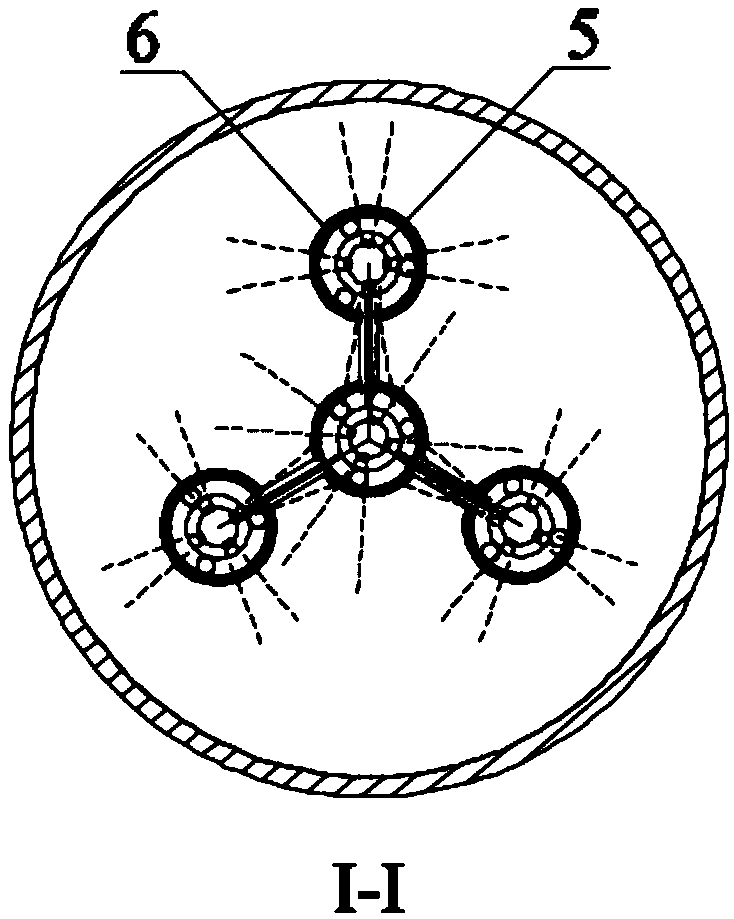

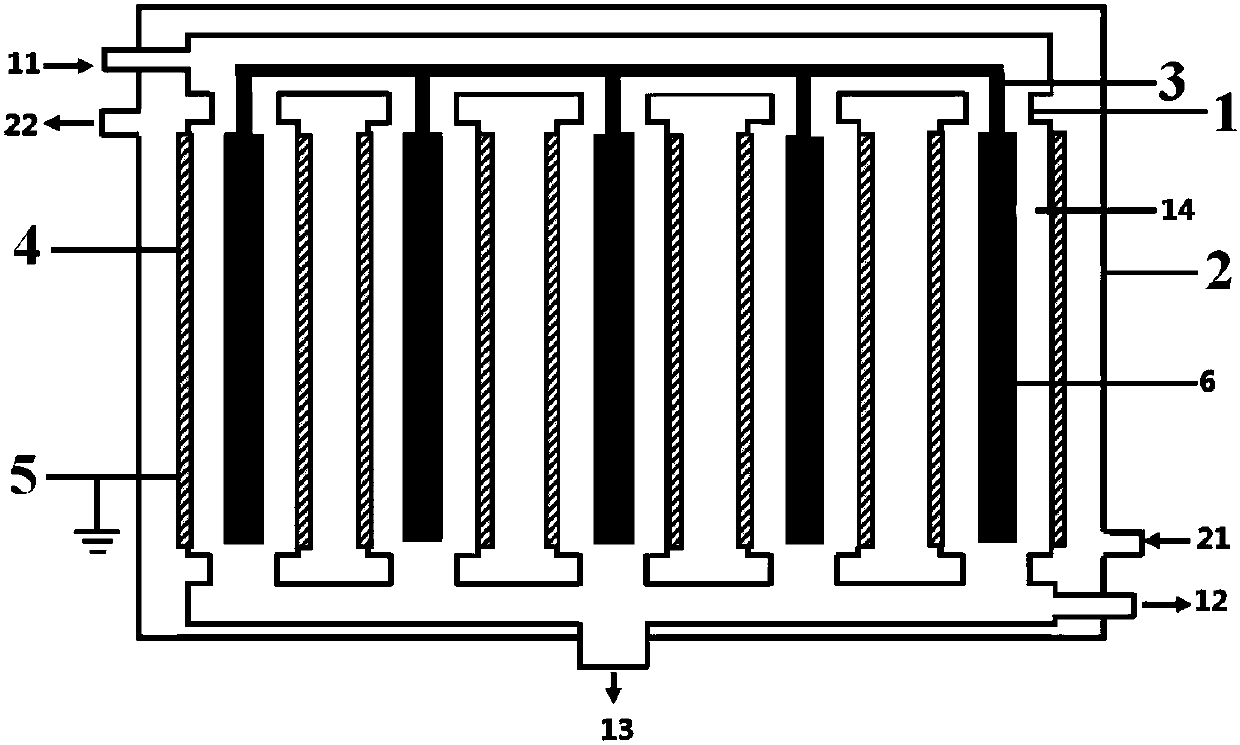

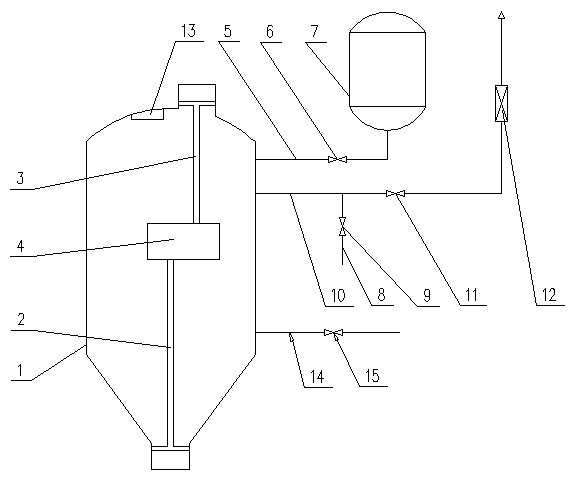

Low temperature plasma reactor and method for decomposing hydrogen sulfide

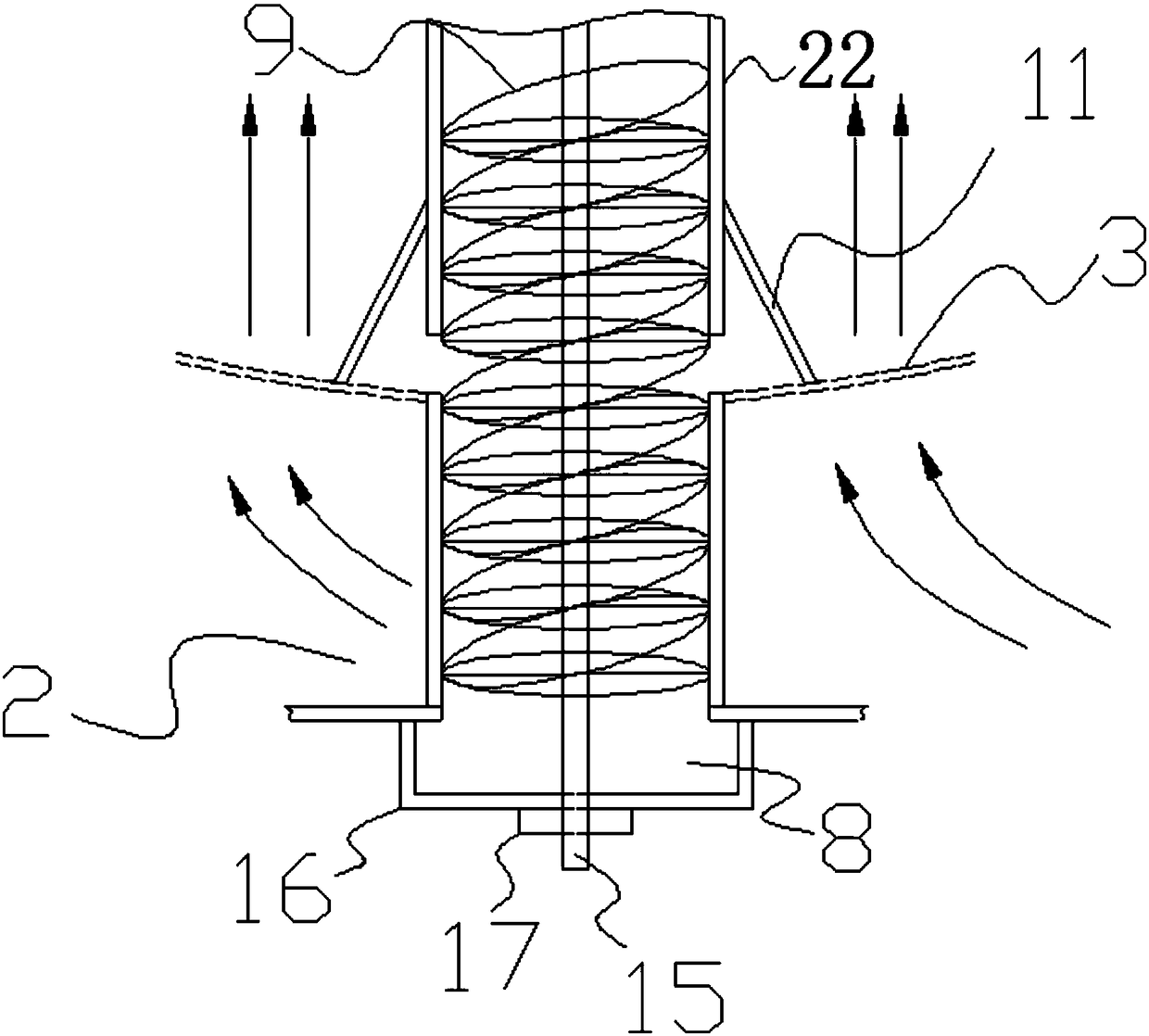

PendingCN110124482AFlexible temperature controlImprove conversion rateGas treatmentDispersed particle separationDecompositionEngineering

The invention relates to the field of plasma chemistry, and discloses a low temperature plasma reactor and a method for decomposing hydrogen sulfide. The reactor comprises: an inner cylinder (1); an outer cylinder (2) nested in the outer portion of the inner cylinder (1); a center electrode (3) arranged in the inner cylinder (1); a grounding electrode (4) formed by a solid electric-conduction material, wherein the grounding electrode forms at least part of the side wall of the inner cylinder or is arranged around the outer side wall of the inner cylinder; and a barrier medium, wherein the barrier medium forms at least part of the side wall of the inner cylinder or is arranged around the inner side wall of the inner cylinder. According to the present invention, the low temperature plasma reactor can achieve the continuous and stable performing of the hydrogen sulfide decomposition process at a significantly high hydrogen sulfide conversion rate, and can achieve long-cycle operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

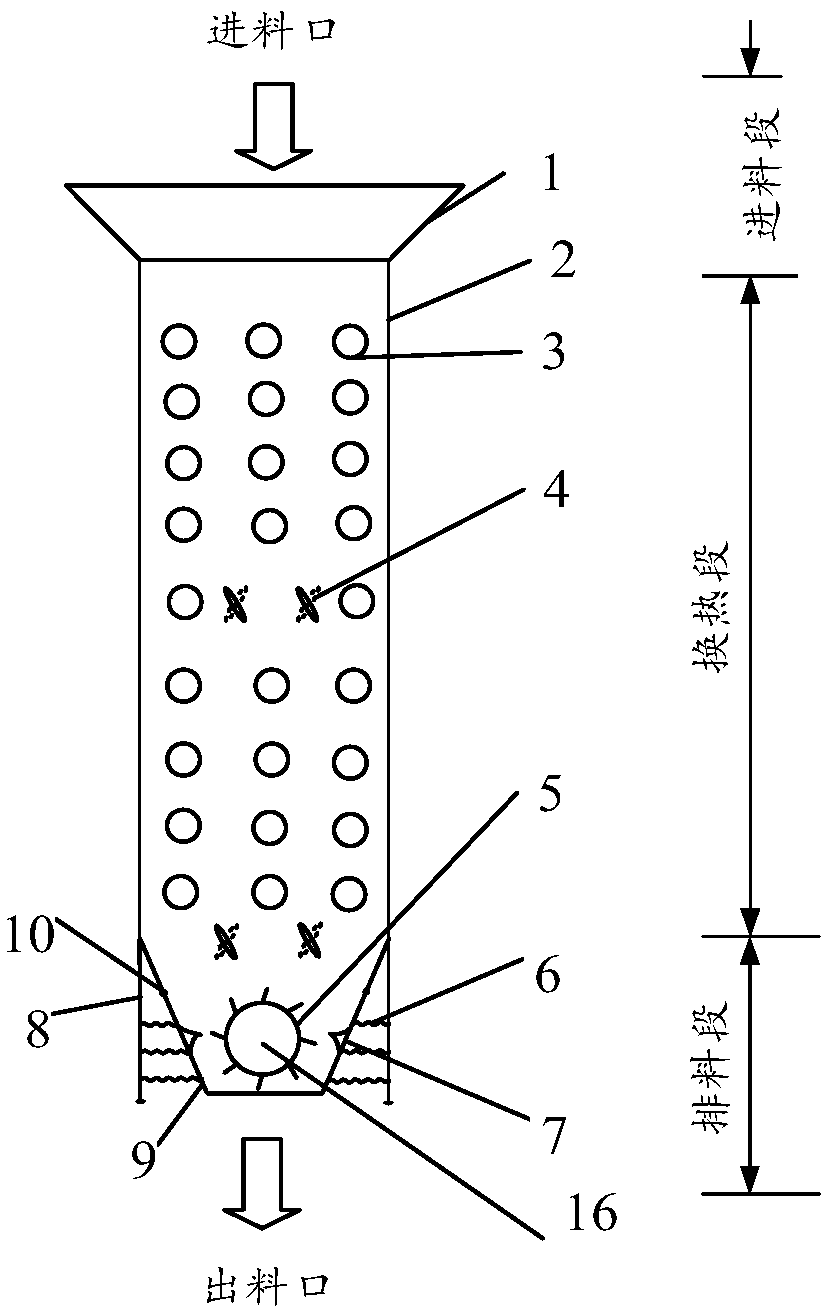

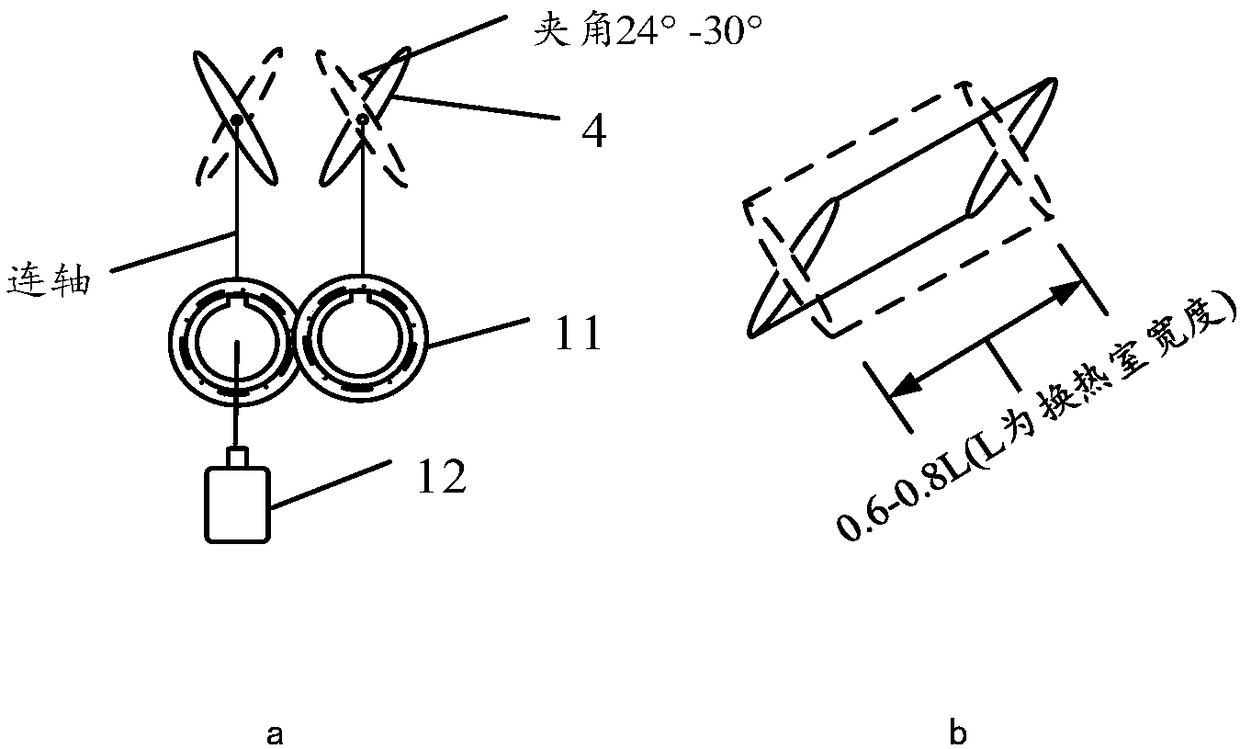

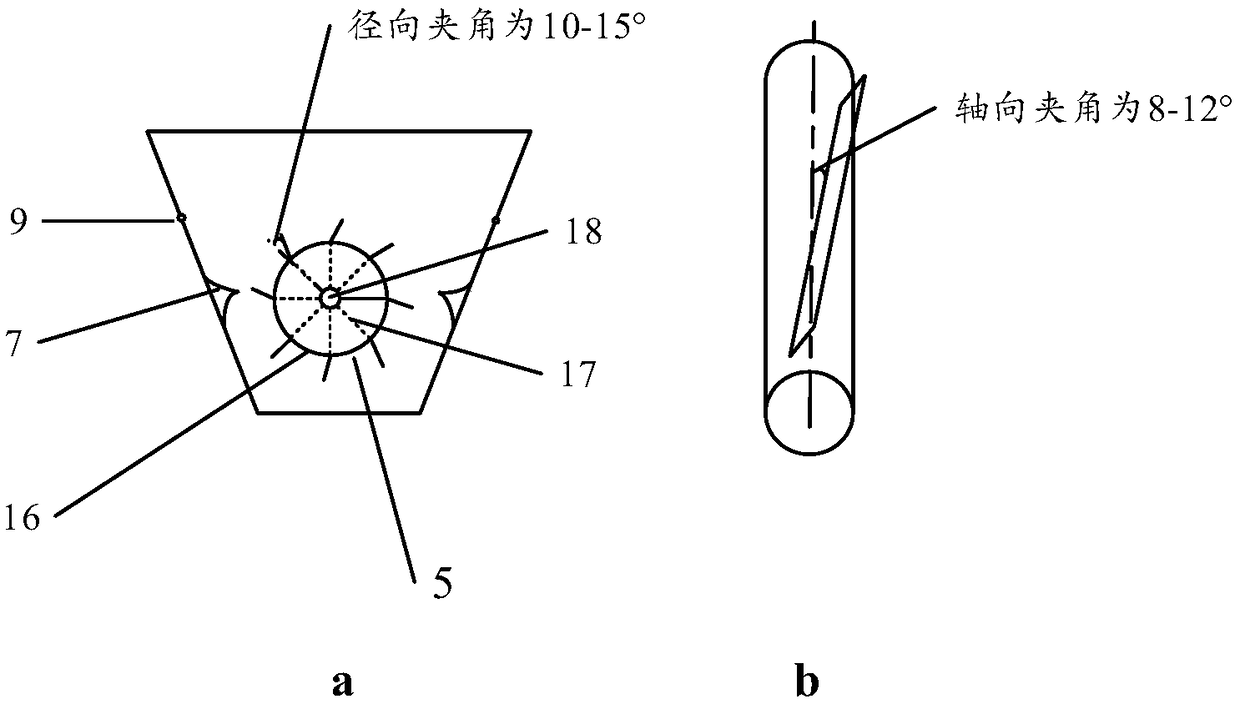

Stable continuous discharging device of high temperature bulk material heat exchanger

ActiveCN109029041ASimple structureGuaranteed uptimeRecuperative heat exchangersHeat exchanger casingsFusiform shapeEngineering

The invention provides a stable continuous discharging device of a high temperature bulk material heat exchanger, and belongs to the field of optimal design of heat exchangers. A method comprises thesteps that a group of fusiform spoiler plates is arranged at the upper part of a discharging section, so that synchronous low-amplitude disturbance is generated; for bulk materials with extremely lowfluidity, the spoiler plates can be further arranged at the central area of multilayer pipe racks of a heat exchange section at intervals; the spoiler plates are driven by gears engaged with each other and arranged at the exterior of heat exchange equipment; improved starlike discharging devices are arranged at the discharging section, the radial included angle between blades and a drum is set tobe 10-15 DEG, and the axial included angle between the blades and the drum is set to be 8-12 DEG; and side plates at the lower part of a discharging port of the heat exchange equipment are connected flexibly, and connected to the right and left side wall surfaces through compression springs. The device is simple, and flexible in operation, and is applicable for the heat exchange conditions of hightemperature bulk materials which are low in fluidity and easily result in blockage of an outlet; and the problems that the bulk materials are liable to accumulate at the discharging port and result in blockage of the discharging port, and consequently are hard to discharge stably and continuously are solved.

Owner:UNIV OF SCI & TECH BEIJING

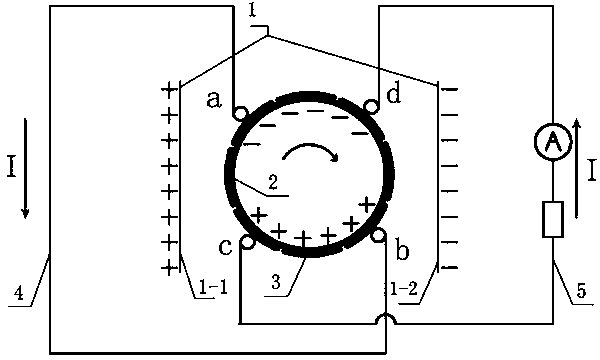

Capacitive electrizer

InactiveCN103401469AConvenient power supplyThe principle is novelInfluence generatorsElectricityMetal sheet

The invention relates to a capacitive electrizer which comprises plate electrodes (1), a roller and a periphery circuit. The electrizer is characterized in that the roller is positioned between the plate electrodes, the roller can roll around a roller shaft, the periphery of the roller is equipped with sheet metals (3) which are not connected, and the periphery circuit is connected with the sheet metals. In the rolling process of the roller, negative electrons move from a sheet metal whose electromotive force is relatively low to a connected sheet metal whose electromotive force is relatively high due to effect of electric field force, so that the two sheet metals are separated from each other. Driven by external force, the sheet metal with the negative electrons moves to a position in the lower electromotive force, and when the other sheet metal which is separated from the metal sheet and has positive electricity characteristics moves to a position in the higher electromotive force, the periphery circuit is connected, the live sheet metals discharges, and output is formed.

Owner:程龙

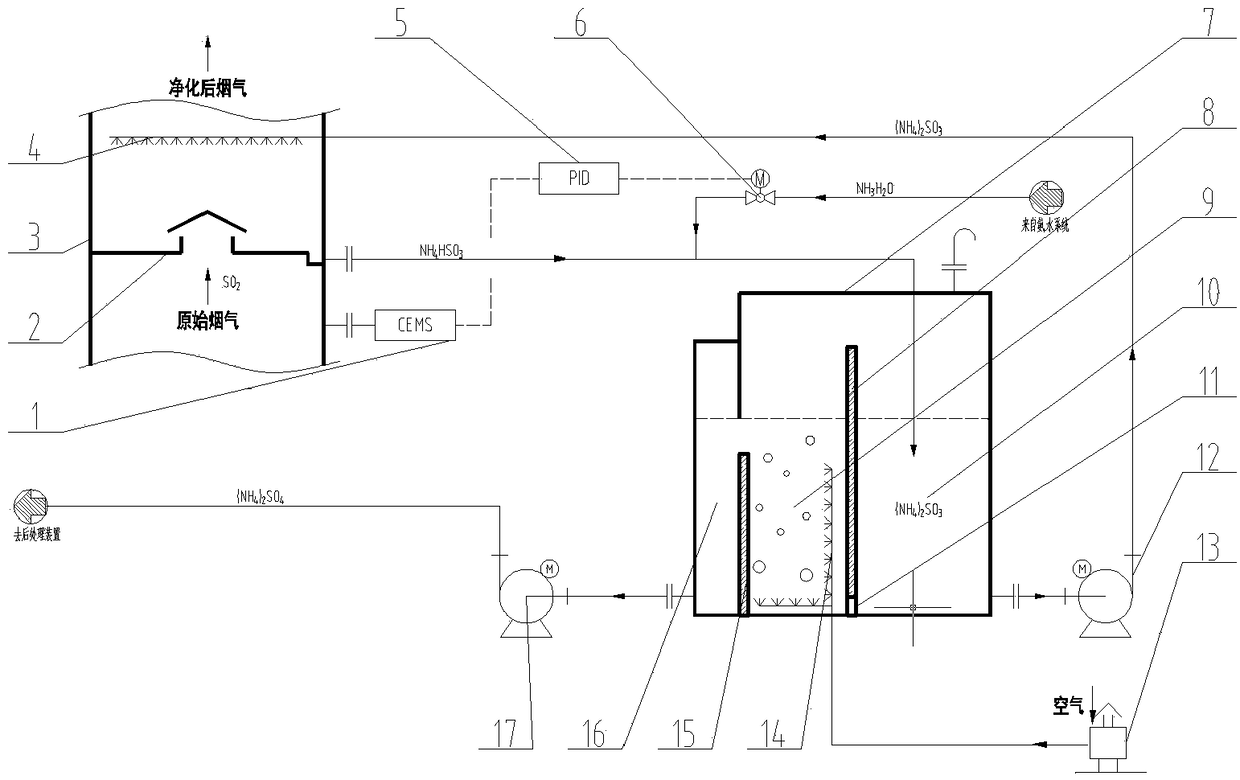

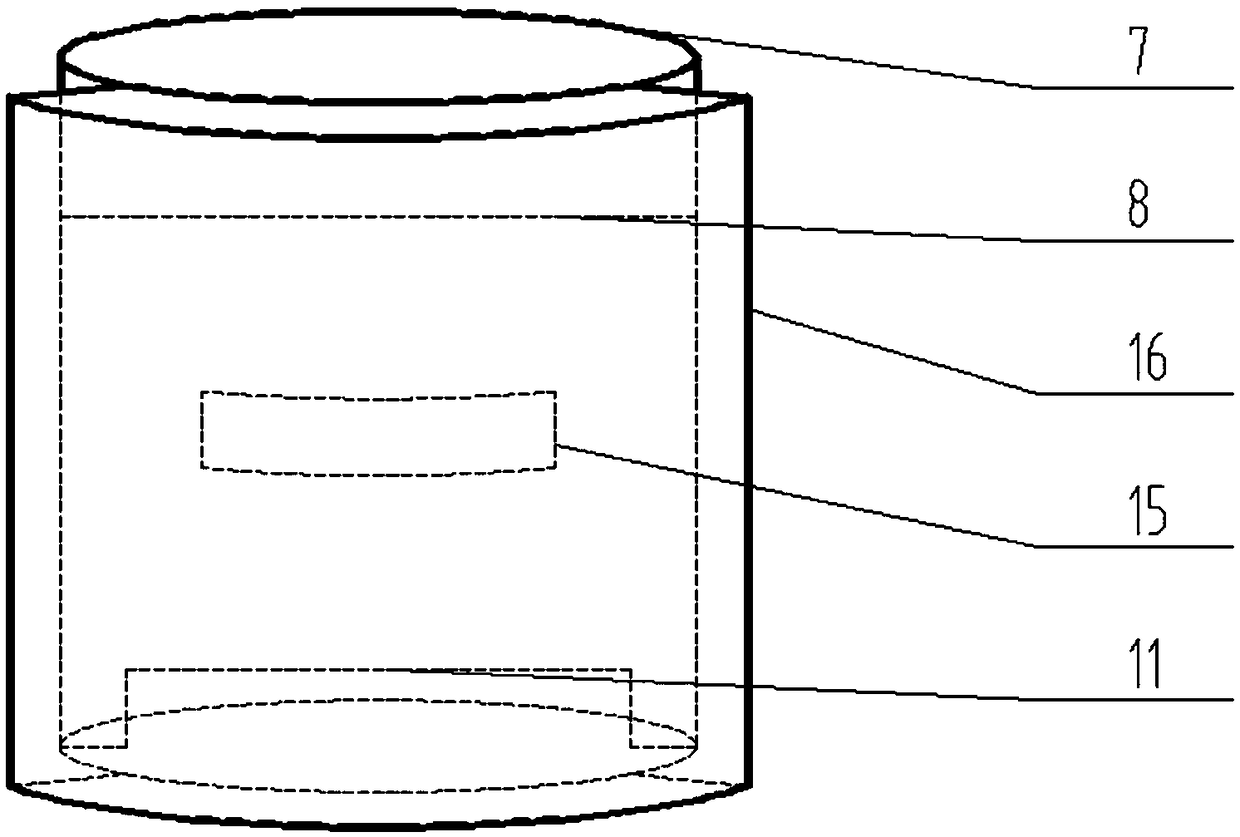

Function guidance product partition ammonia process desulfurization oxidation circulation tank device and method

PendingCN109260895AImprove desulfurization effectWon't happenGas treatmentDispersed particle separationOxidation zoneSlurry

The invention belongs to the technical field of ammonia process smoke gas desulfurization, and particularly relates to a function guidance product partition ammonia process desulfurization oxidation circulation tank device and method. The device comprises a desulfurization tower absorption section and an oxidation circulation tank, wherein the desulfurization tower absorption section and the oxidation circulation tank are connected through a pipeline; the oxidation circulation tank is separated into three regions including a single phase liquid region, an oxidation region and a reduction region by tank wall plates and separation plates; one side of the reduction region is communicated with the oxidation region; the other side of the reduction region is communicated with a desulfurization circulation pump through a pipeline; the oxidation region is communicated with the single phase liquid region; the single phase liquid region is communicated with an ammonium sulfate material transferpump through a pipeline; an oxidation aeration layer is arranged inside the oxidation region, and is communicated with an oxidation fan through a pipeline. The absorbing capacity of absorption slurryon SO2 is greatly improved; the smoke gas desulfurization effect is enhanced; the field operation environment is greatly improved; the continuous and stable discharging of ammonium sulfate by-productsis ensured.

Owner:XIAN AEROSPACE SOURCE POWER ENG CO LTD

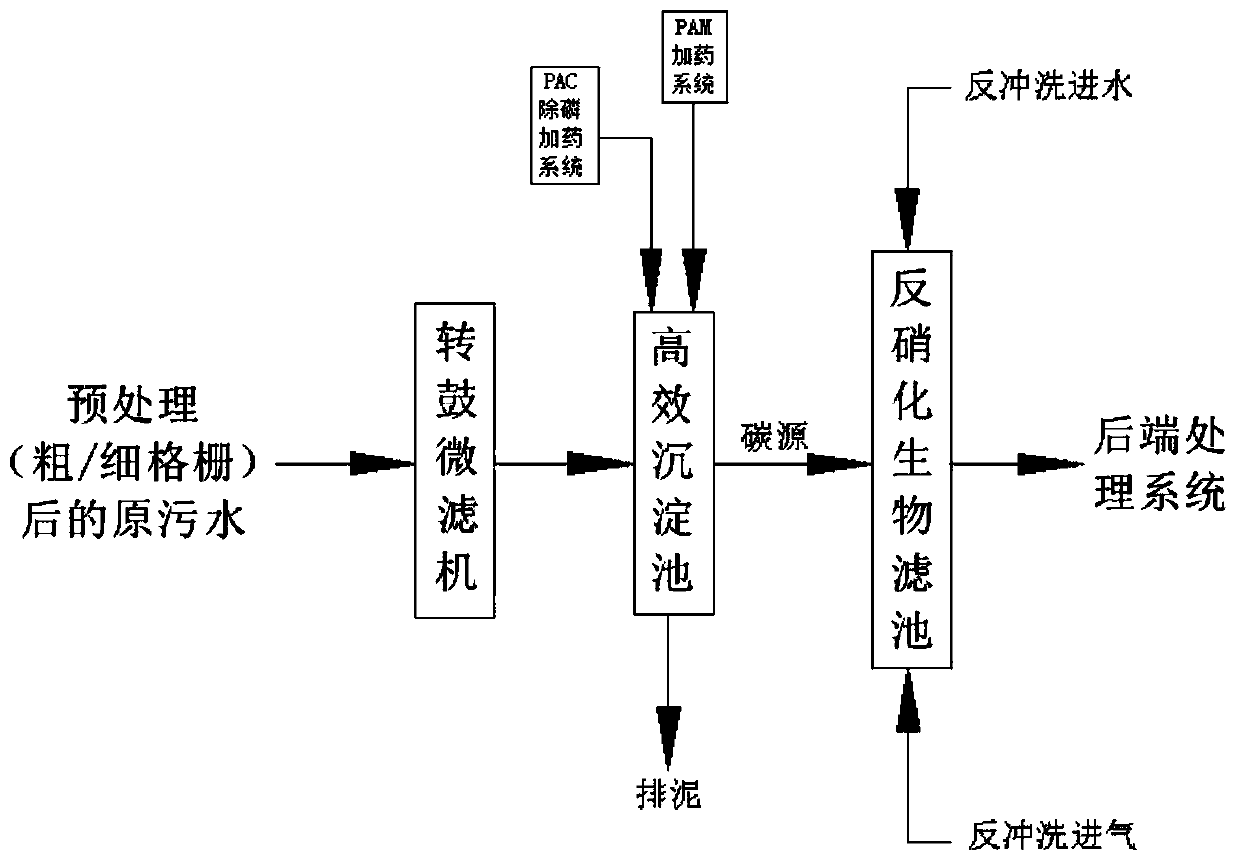

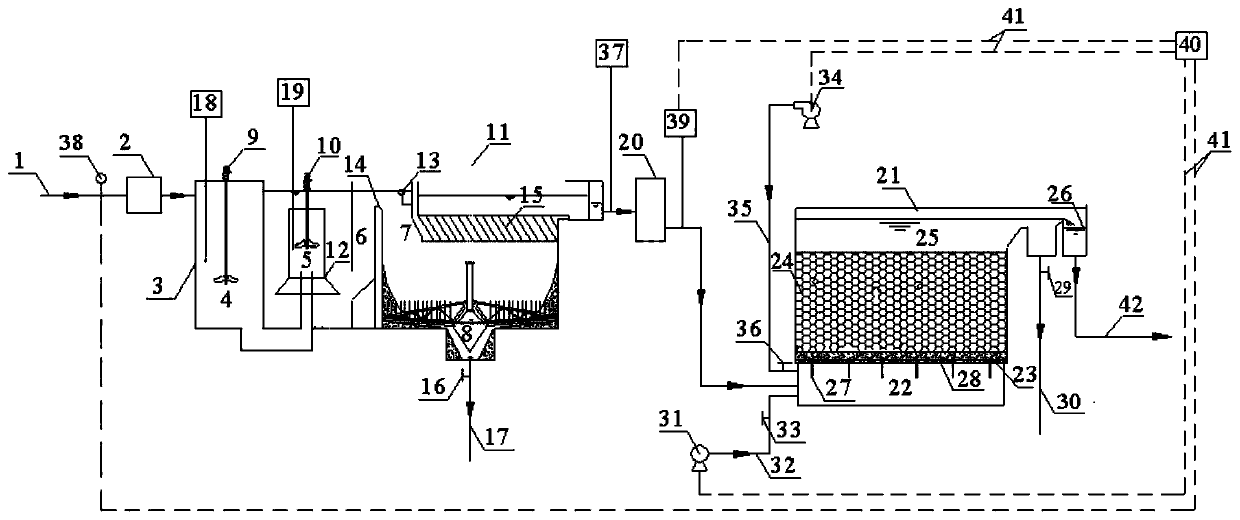

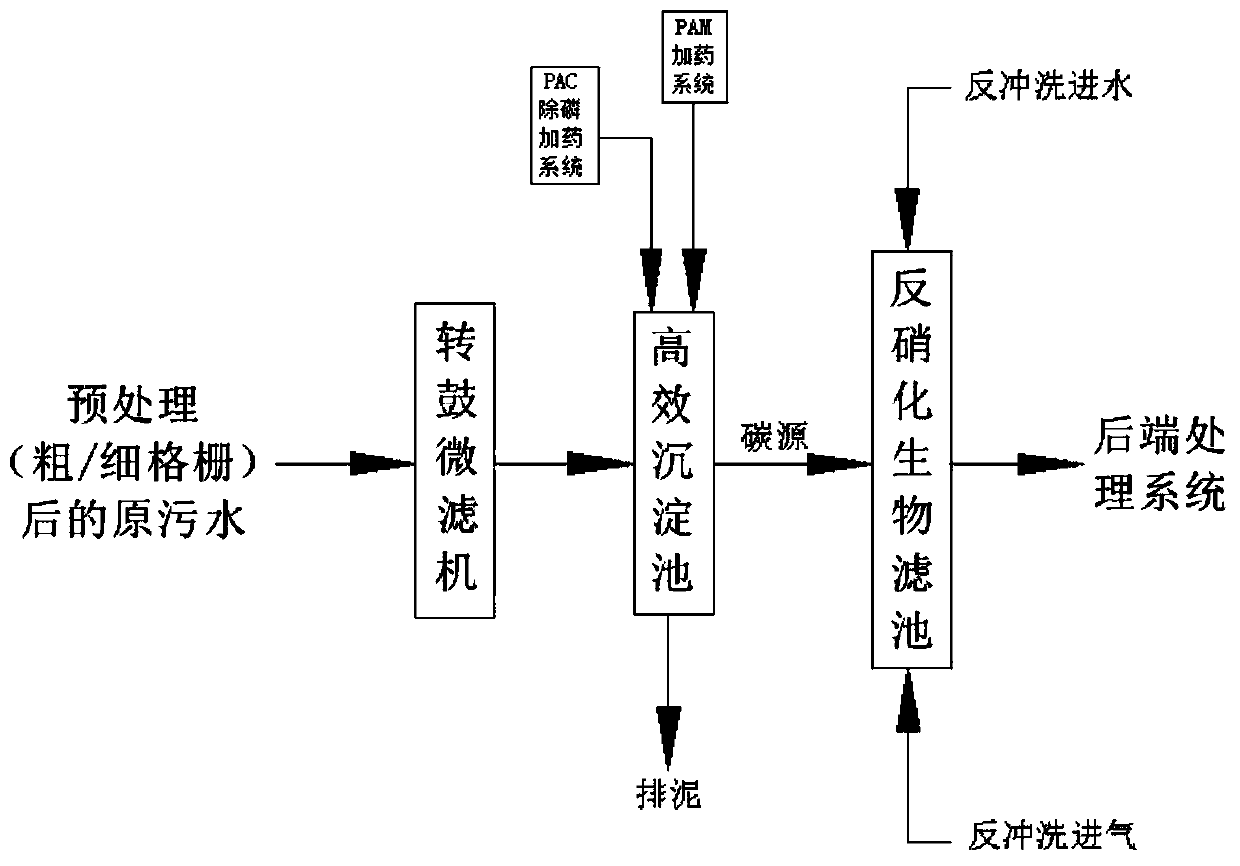

Complete equipment for solving blockage and hardening of biological filter and matched system thereof and treatment process thereof

PendingCN111170591AAvoid churnSolve easy blockageWater contaminantsTreatment involving filtrationFlocculationBiological filter

The invention discloses complete equipment for solving blockage and hardening of a biological filter and a matched system thereof and a treatment process of the complete equipment. The complete equipment is formed by sequentially connecting a rotary drum micro-filter, an efficient sedimentation tank, an inner water inlet pore plate grid and a denitrification biological filter in series. By adopting the complete equipment for treatment, the problem that in the backwashing process of a biological filter system, biological ceramsite filter materials run off to an efficient sedimentation tank, a water inlet pipeline, a rapid mixing area, a flocculation reaction area and the like of the efficient sedimentation tank are blocked, and consequently normal operation cannot be achieved is solved. Theinner water inlet pore plate grid is adopted, so that the problem that a filter head of a traditional denitrification biological filter is easy to block due to fibrous impurities is thoroughly solved. An inflow water flow meter, the denitrification biological filter and an online COD, nitrate nitrogen and total nitrogen multifunctional monitoring instruments are fully utilized to realize accurateaddition of a carbon source agent, the load impact resistance is higher, continuous and stable operation of the efficient sedimentation tank is guaranteed, stable and up-to-standard discharge of effluent water of the system is economically realized, and the complete equipment has great popularization and application values.

Owner:安徽绿衡环保科技有限公司

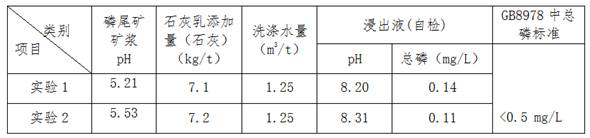

Method for treating goaf by harmlessly filling phosphate tailings

PendingCN114517679AEliminate potential safety hazardsReduce storage costsSolid waste managementUnderground miningPhosphoriteSlurry

The invention relates to a method for treating a goaf by harmlessly filling phosphate tailings, which comprises the following steps of: treating the phosphate tailings into general industrial solid wastes I, thickening tailing slurry generated by a phosphate ore flotation plant as a raw material, adding quick lime or lime milk to adjust the pH value to be neutral, and filtering twice to obtain filtrate I; and adding the filtrate subjected to secondary filtration into the obtained filter cake, and adjusting to a paste state to obtain the phosphate tailing paste for filling the open pit to realize treatment and ecological restoration of the open pit. According to the method, the tailing pulp generated by the phosphorite flotation plant can be treated into the I-type solid waste, tailing stockpiling can be carried out without newly building a tailing pond, under the condition that the state does not approve the newly building of the tailing pond, the treated tailings reaching the I-type solid waste discharge standard can be used for carrying out filling treatment on an open pit, and the economic benefit is high. And the potential safety hazard of the open pit is eliminated on the premise of innocent treatment of the phosphate tailings.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

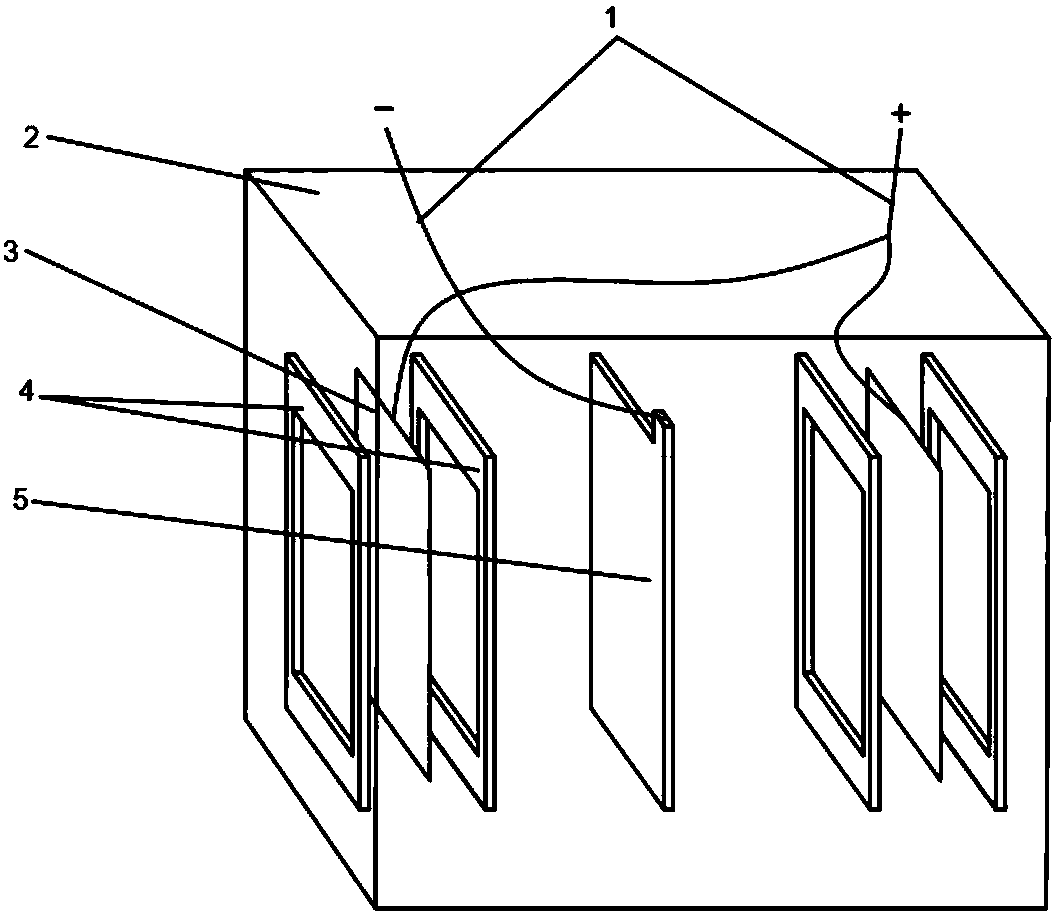

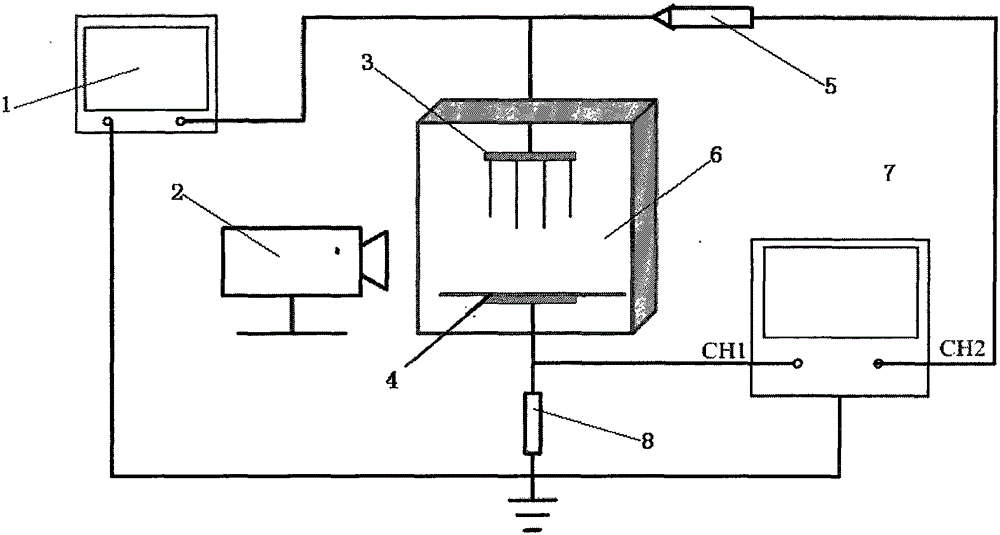

Magnetic control type tapered needle array diffuse discharge system in atmospheric pressure air

InactiveCN106470521AInhibition of movement speedUniform dischargePlasma techniqueMagnetDiffuse discharge

The invention discloses a magnetic control type tapered needle array diffuse discharge system in the atmospheric pressure air, which comprises a power supply (1), a discharge air chamber (6) and a measuring device (7), wherein the center of the discharge air chamber (6) is provided with a tapered needle array (3), and the tampered needle array (3) is connected with a positive electrode of the power supply (1) through a wire; the lower end, which is opposite to the tapered needle array (3), of the discharge air chamber (6) is provided with a permanent magnet (4); the measuring device is provided with a voltage measuring terminal CH2 and a current measuring terminal CH1, the voltage measuring terminal CH2 is connected with the positive electrode of the power supply (1) through a high-voltage probe (5), and the current measuring terminal CH1 is connected with the permanent magnet (4) through a wire; and a negative electrode of the power supply (1) and the measuring device (7) are connected with a grounding terminal together. The system disclosed by the invention adopts the high-voltage DC power supply, thereby being capable of providing stable and persistent current so as to acquire diffuse discharge in the atmospheric pressure air.

Owner:吴勇峰

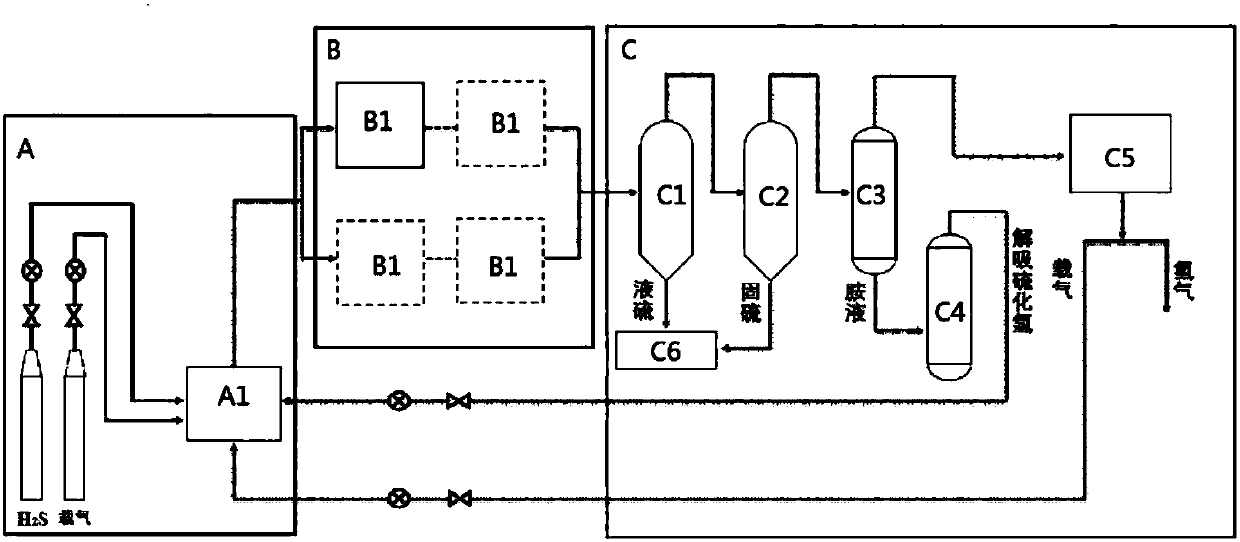

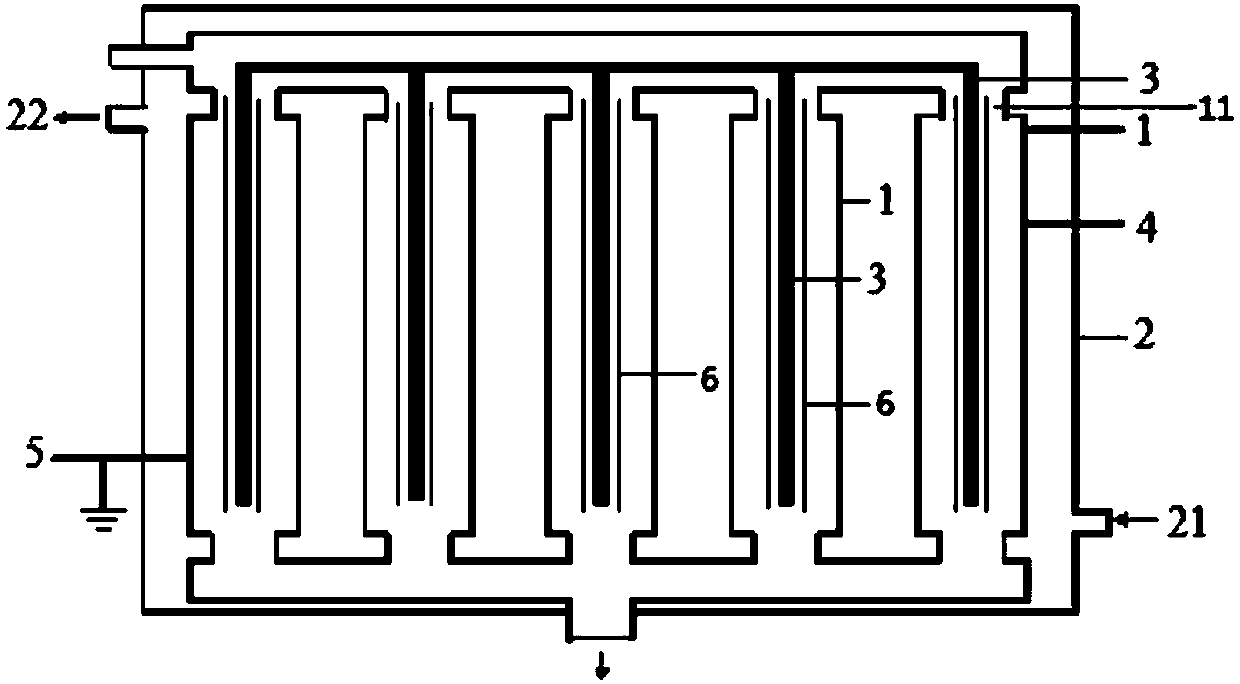

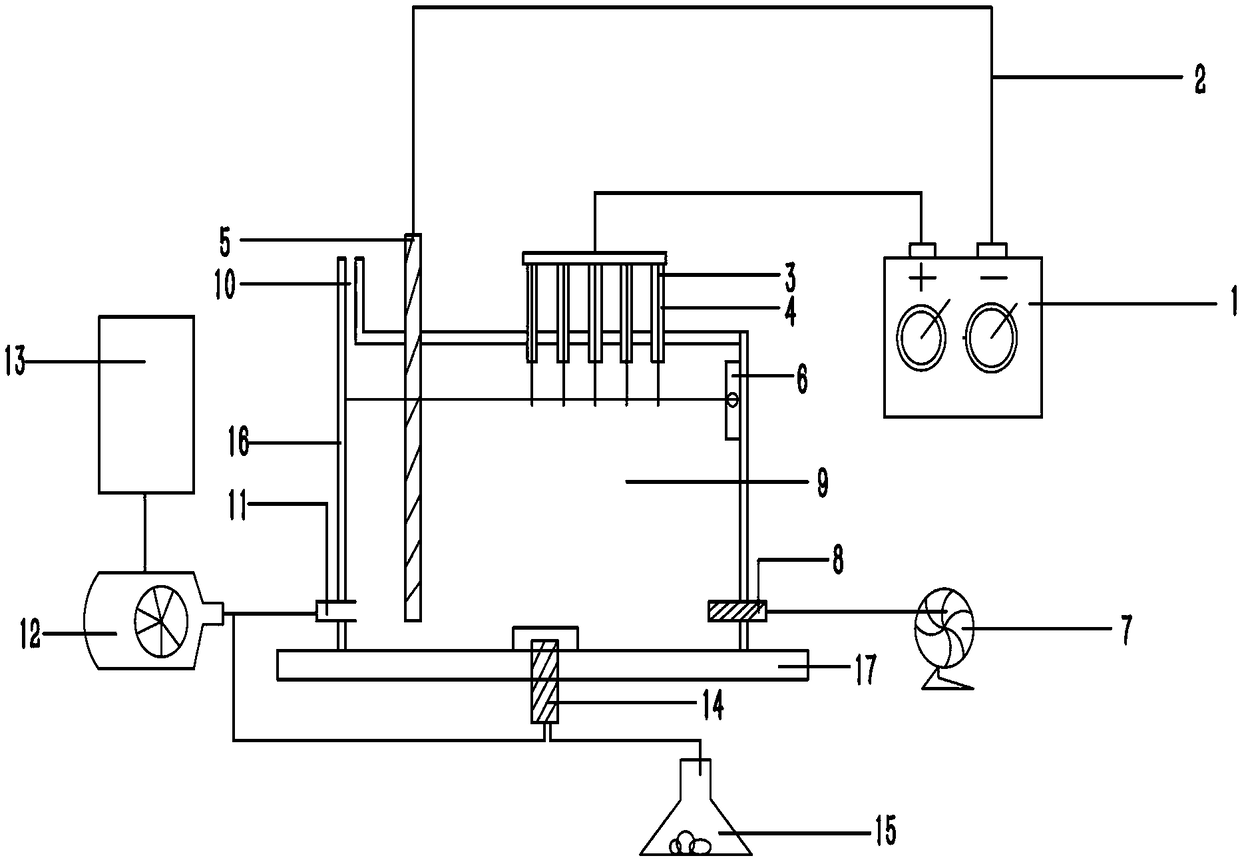

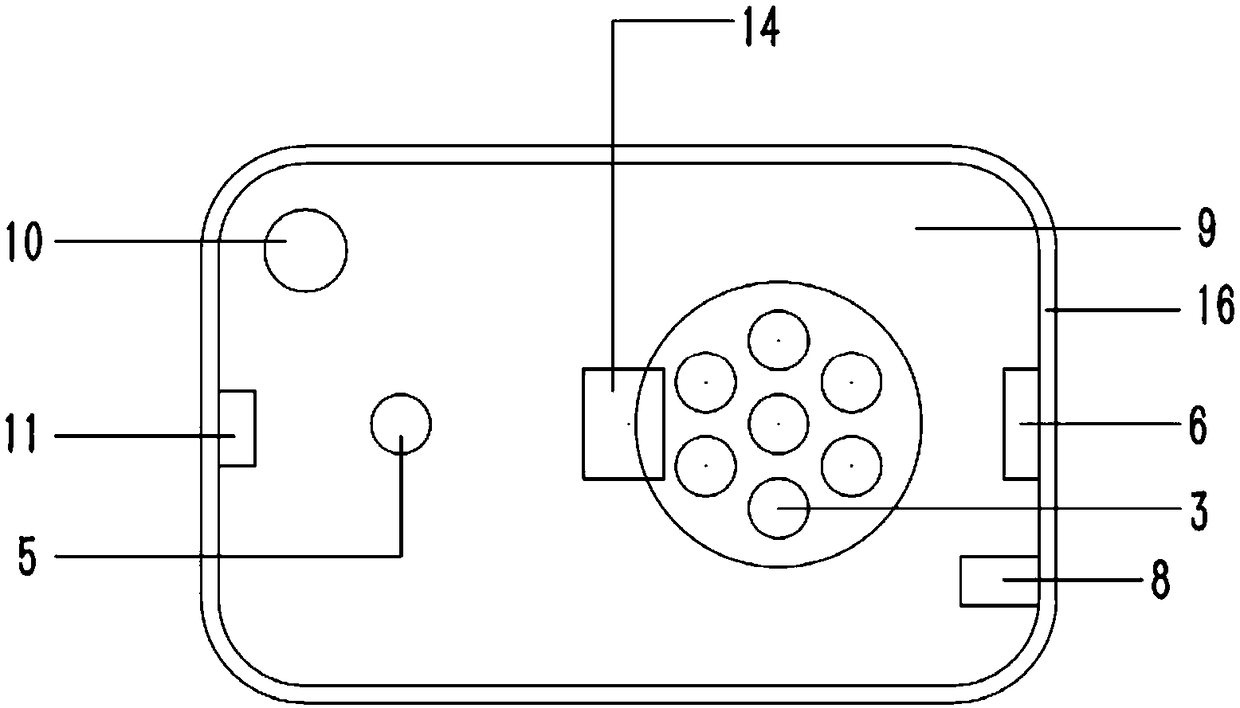

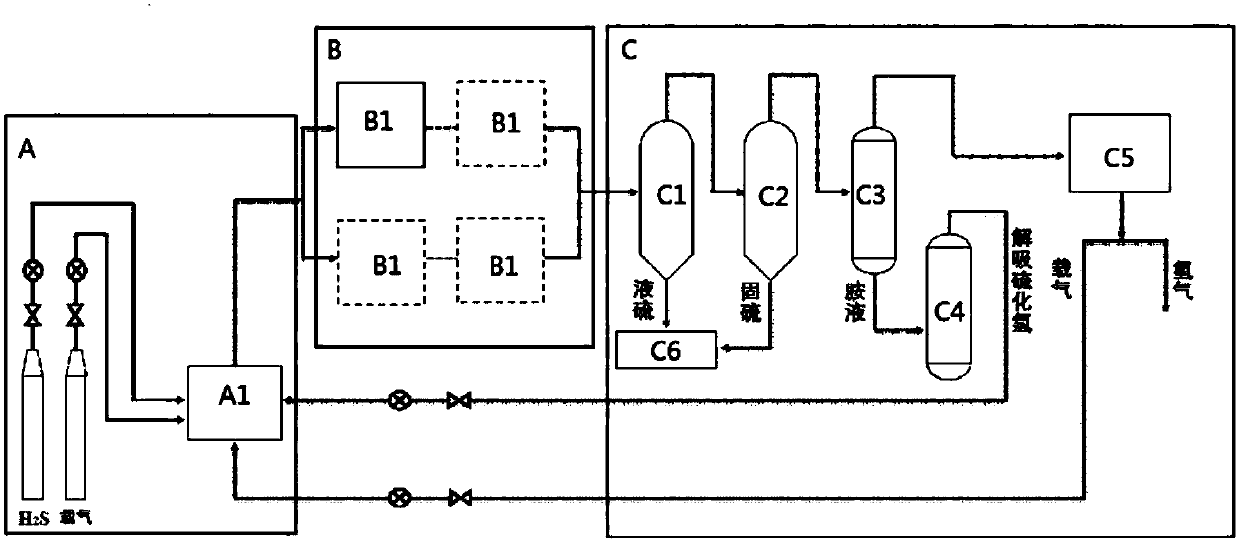

High-flux low-temperature plasma system for decomposing hydrogen sulfide, and method for decomposing hydrogen sulfide

ActiveCN110124471AImprove conversion rateHigh purityGas treatmentDispersed particle separationHigh fluxLow temperature plasma

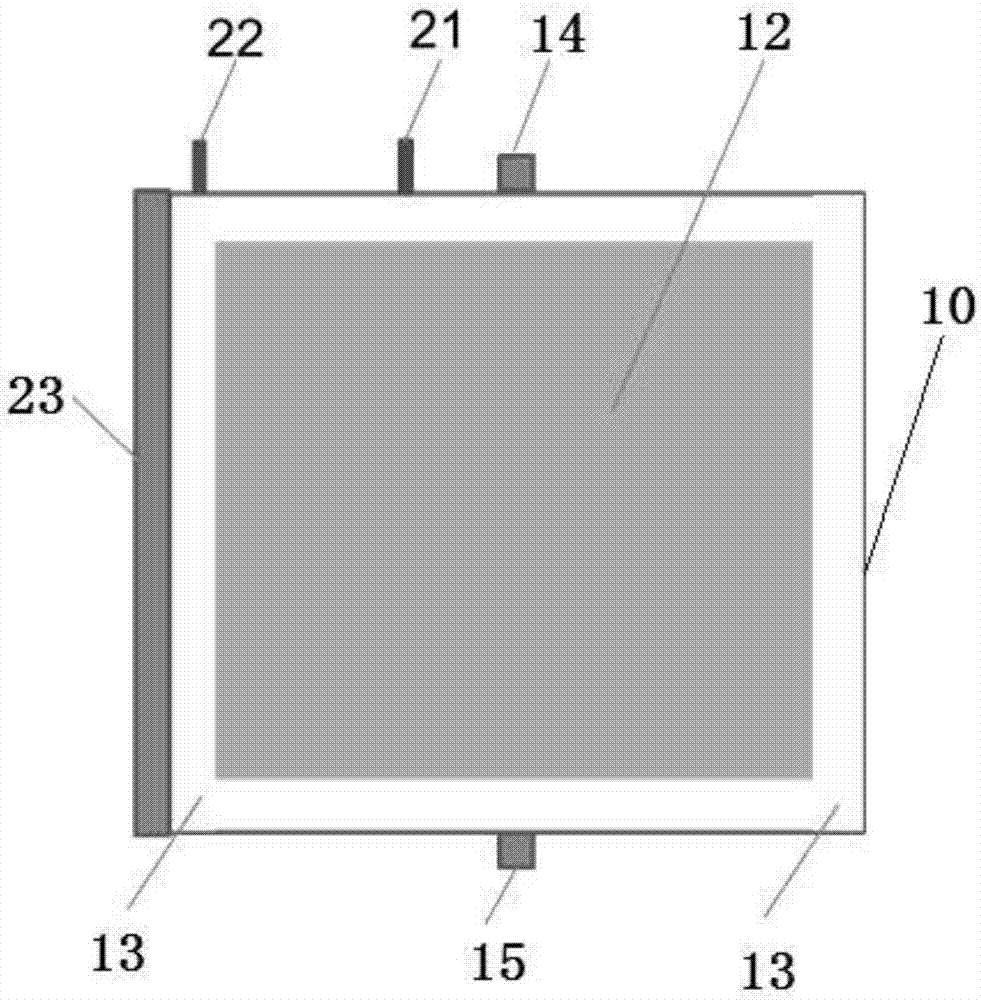

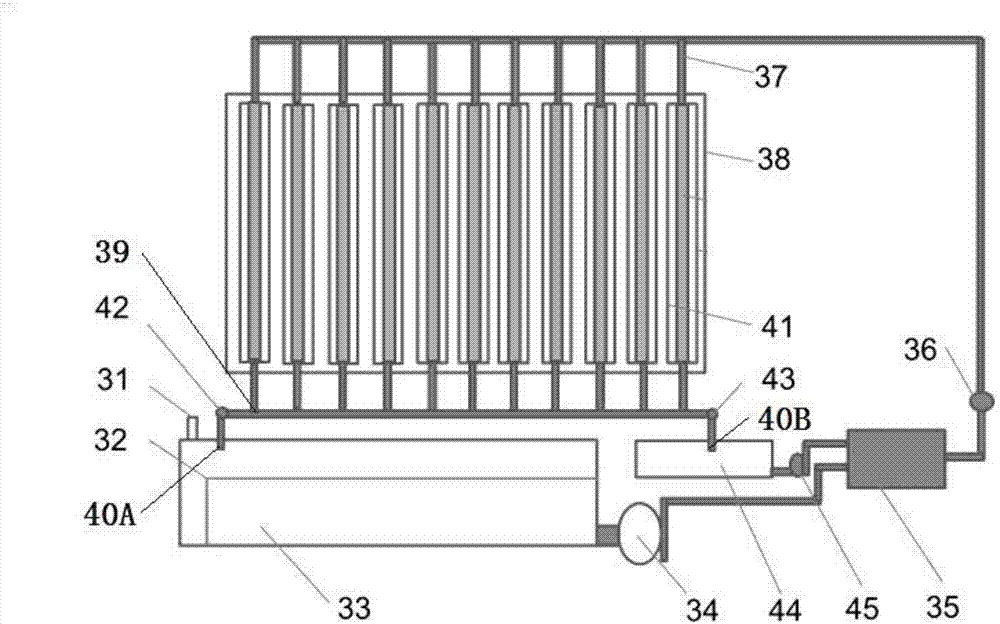

The invention relates to the field of plasma chemistry, and discloses a high-flux low-temperature plasma system for decomposing hydrogen sulfide, and a method for decomposing hydrogen sulfide. The system comprises a gas supply-gas distribution unit, a plasma reaction unit and a product separation unit, wherein the plasma reaction unit comprises a low temperature plasma reactor, the reactor comprises an inner cylinder (1) containing a reaction pipe (14), an outer cylinder (2) nested in the outer portion of the inner cylinder, a center high-voltage electrode (3) arranged in the reaction pipe, agrounding electrode (4) arranged on the side wall of the reaction pipe or forming the side wall of the reaction pipe, and a barrier medium (6), and the barrier medium forms the side wall of the reaction pipe, or is arranged around the side wall of the reaction pipe, or is arranged on the outer surface of the center high-voltage electrode (3). According to the present invention, the system and themethod have high hydrogen sulfide conversion rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

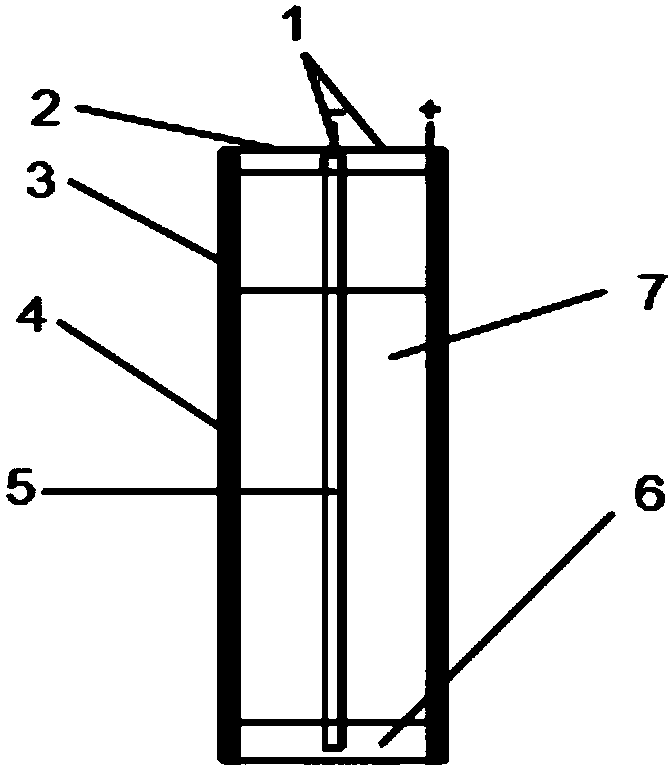

Low temperature plasma reaction apparatus and method for decomposing hydrogen sulfide

PendingCN110127605AFlexible temperature controlImprove conversion rateSulfur preparation/purificationHydrogen productionDecompositionEngineering

The present invention relates to the field of plasma chemistry, and discloses a low temperature plasma reaction apparatus and a method for decomposing hydrogen sulfide. The low temperature plasma reaction apparatus comprises: an inner cylinder (1); an outer cylinder (2) nested in the outer portion of the inner cylinder (1); a center electrode (3) arranged in the inner cylinder (1); a grounding electrode (4) arranged around the side wall of the inner cylinder (1); and a barrier medium (6) arranged on at least part of the outer surface of the center electrode (3), wherein a ratio (L1:L2) of thedistance L1 between the outer side wall of the barrier medium and the inner side wall of the grounding electrode to the length L2 of a discharge region is 1:(0.5-6000). According to the present invention, the low temperature plasma reaction apparatus can achieve the continuous and stable performing of the hydrogen sulfide decomposition process at a significantly high hydrogen sulfide conversion rate, and can achieve long-cycle operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low temperature plasma reaction equipment and hydrogen sulfide decomposing method

PendingCN110127601AFacilitate discharge decomposition reactionLarge micro discharge currentSulfur preparation/purificationHydrogen productionDecompositionEngineering

The present invention relates to the field of plasma chemistry, and discloses low temperature plasma reaction equipment and a hydrogen sulfide decomposing method. The reaction equipment comprises: aninner cylinder (1); an outer cylinder (2) nested on the outer portion of the inner cylinder (1); a center electrode (3) arranged in the inner cylinder (1); a grounding electrode (4) formed by a solidelectric-conduction material, wherein the grounding electrode forms at least part of the side wall of the inner cylinder or is arranged around the inner side wall of the inner cylinder; and a barriermedium arranged between the grounding electrode and the center electrode. According to the present invention, the low temperature plasma reaction equipment can achieve the continuous and stable performing of the hydrogen sulfide decomposition process at a significantly high hydrogen sulfide conversion rate, and can achieve long-cycle operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

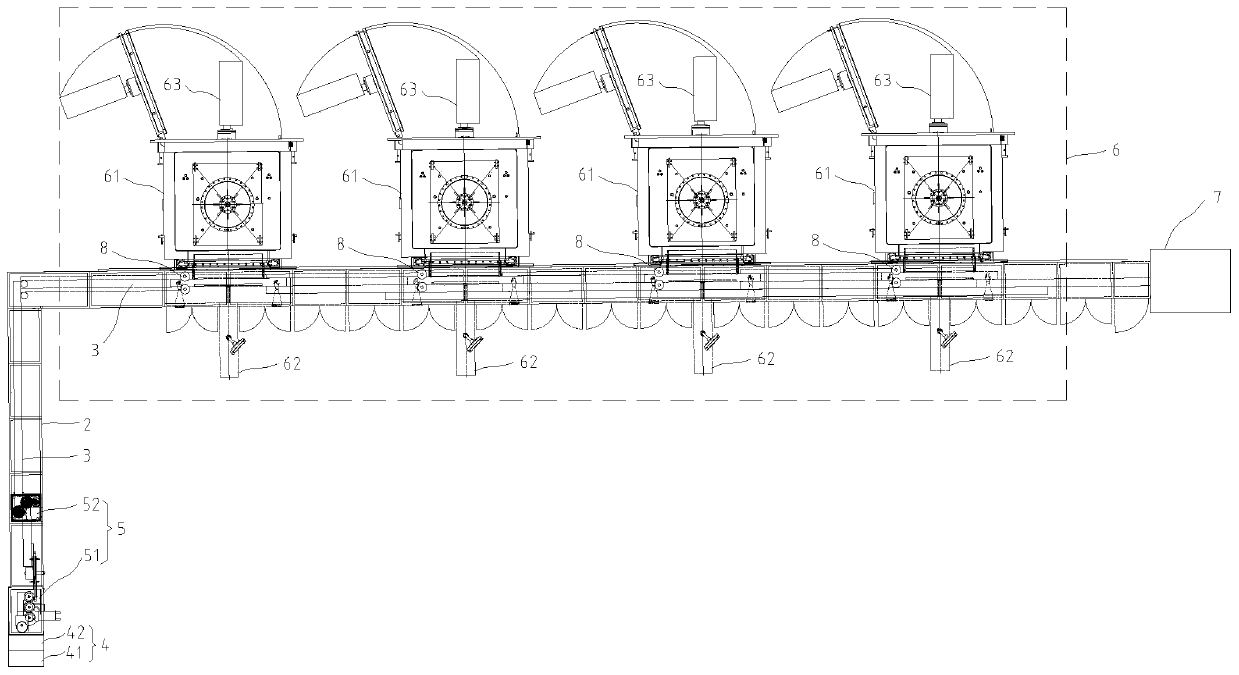

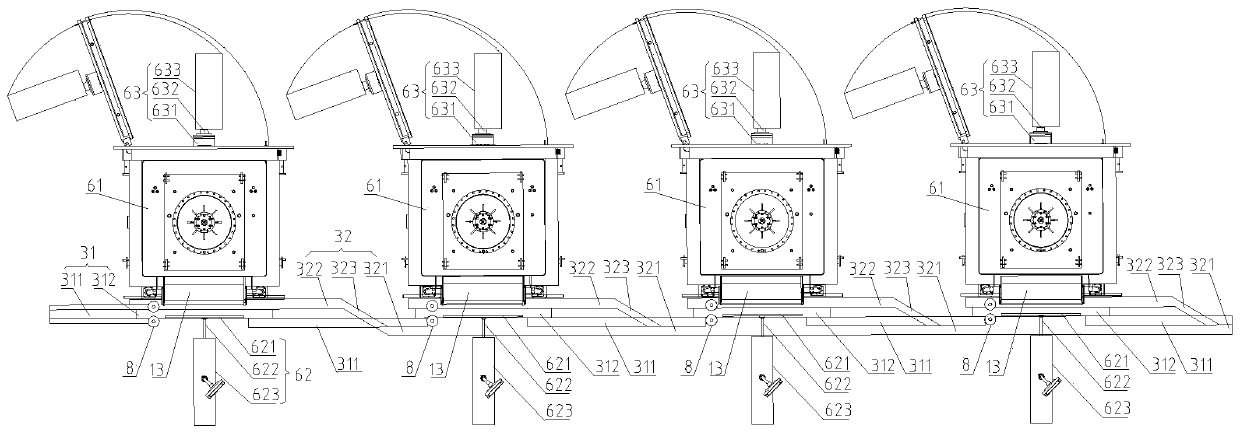

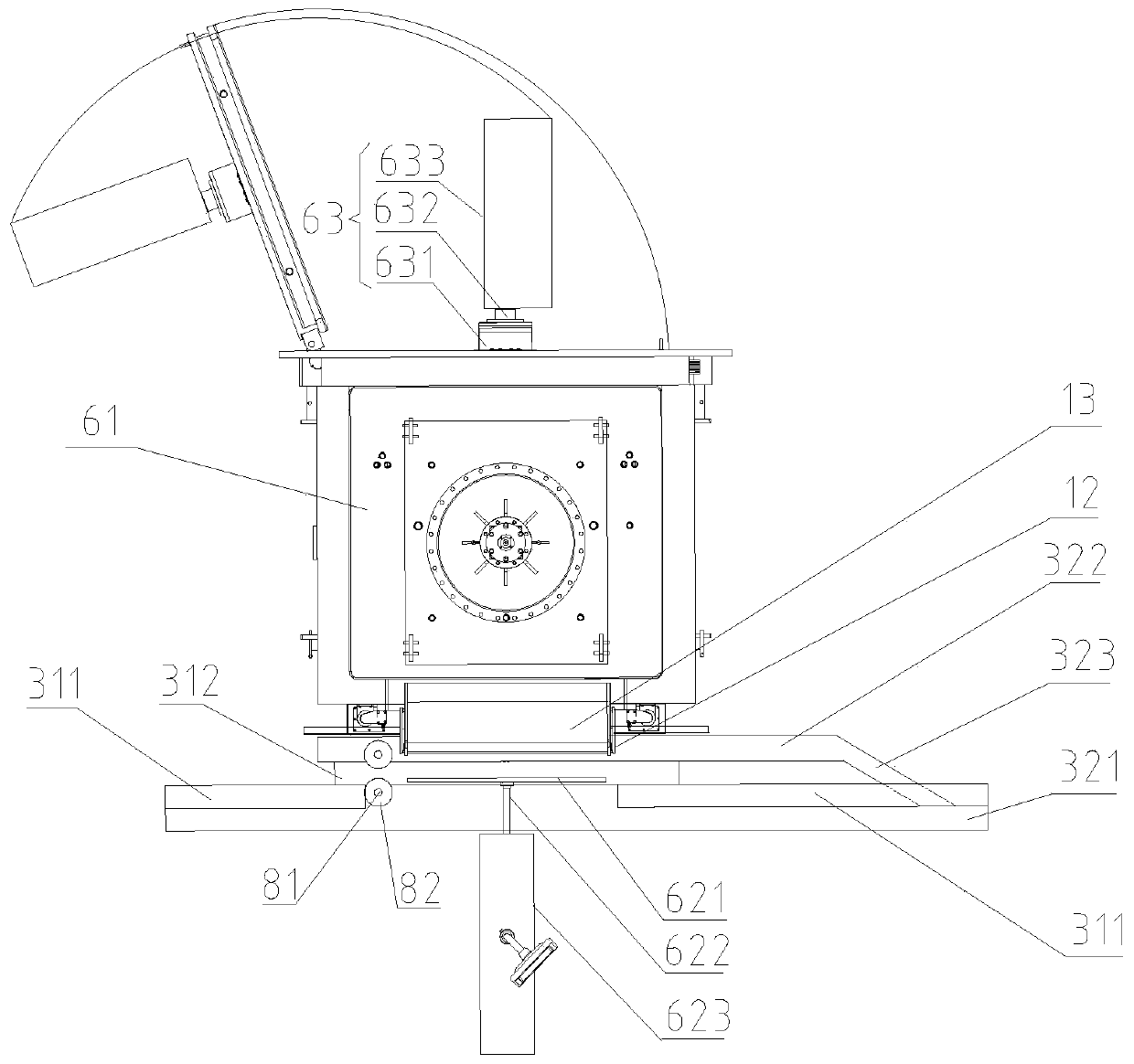

Automatic production line of freeze-dried products

PendingCN109879030AContinuous and stable automatic feedingContinuous and stable dischargeConveyorsLiquid fillingFreeze dryControl system

The invention discloses an automatic production line of freeze-dried products. The automatic production line comprises a control system, a sterile isolator, a conveying mesh belt, a bottle washing system, a filling system, a freeze-drying system and a capping system, wherein the bottle washing system, the filling system, the freeze-drying system and the capping system are sequentially arranged inthe conveying direction of the conveying mesh belt, the conveying mesh belt, the filling system, the freeze-drying system and the capping system are all arranged in the sterile isolator, the conveyingmesh belt comprises a feeding transportation assembly and a discharging transportation assembly, the freeze-drying system comprises a freeze-drying cabinet, a feed front push device and a discharge rear push device, and the control system is correspondingly connected with the sterile isolator, the bottle washing system, the filling system, the freeze-drying system, the capping system and the conveying mesh belt. According to the automatic production line of the freeze-dried products, the aseptic requirement is met, automatic feeding and discharging of the freeze-drying cabinet can be realizedcontinuously and stably, feeding and discharging of the freeze-dried products are independent, discharging can be carried out while feeding is carried out, the structure is simple, and use is convenient.

Owner:GUANGXI WUZHOU PHARMA GRP

Integrated biogas desulfurizing device and method

The invention discloses an integrated biogas desulfurizing device and method, and belongs to the technical field of biogas desulfurizing. The integrated biogas desulfurizing device comprises a reaction tank, wherein the reaction tank is used for accommodating absorbing liquid; the upper side of the reaction tank is provided with a gas outlet, and the lower side of the reaction tank is provided with a gas collection and distribution port; the gas collection and distribution port is connected with a fan at the exterior of the reaction tank; a high-voltage electrode and a low-voltage end are arranged in the reaction tank; one end, without being immersed under the liquid level, of the high-voltage electrode is connected with a positive electrode of a high-voltage direct current power source control console through a high-voltage conducting wire; one end, without extending under the liquid level, of the low-voltage end is connected with a negative electrode of the high-voltage direct current power source control console. The integrated biogas desulfurizing device has the advantages that a technology route and device combining direct current glow discharge and wet desulfurization are proposed; after reaction, the sulfur element with higher purity can be collected for recycling; the investment cost and running cost are low, and the treatment, regeneration and recycling are integratedtogether.

Owner:XI AN JIAOTONG UNIV

Method for decomposing hydrogen sulfide through plasma

ActiveCN110127623AImprove conversion rateLow energy consumption for decompositionSulfur preparation/purificationHydrogen productionDecompositionReaction temperature

The invention relates to the field of plasma chemistry, and discloses a method for decomposing hydrogen sulfide through plasma. The method comprises: introducing a hydrogen sulfide-containing raw material gas into a plasma system containing a plasma reactor under dielectric barrier discharge conditions, and carrying out a hydrogen sulfide decomposition reaction, wherein the dielectric barrier discharge conditions comprise a discharge voltage of 5-30 kV and a discharge frequency of 200-30000 Hz, the hydrogen sulfide decomposition reaction conditions comprise a reaction temperature of 0-800 DEGC and a reaction pressure of -0.06-0.6 MPa, and the residence time of the reactant in the plasma reactor is 1*10<-5>-120 s. According to the present invention, with the method, by using the specific discharge conditions and the hydrogen sulfide decomposition reaction conditions, the high hydrogen sulfide conversion rate under the dielectric barrier discharge conditions can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Biomass material lock and working method

ActiveCN108980883AThe system is stable and reliableFeed stableLump/pulverulent fuel feeder/distributionBiomassFlue gas

The invention provides a biomass material lock and a working method. Blockage, high temperature flue gas backflow and other problems of a biomass feeding system appear, not only are the operation of abiomass incinerator or a biomass gasifier influenced, but also feeding system catching fire, even explosion, and other safety accidents are caused. The biomass feeding lock includes a shell (1), a discharge valve (2) is installed in the shell, and the discharge valve is connected with a feeding valve (3) through a drive mechanism (4); the shell is correspondingly connected with a primary pressurecharging and relief pipeline (5), a secondary pressure relief pipeline (10), an air seal pipeline (14), wherein the primary pressure charging and relief pipeline is connected with a buffer tank (7),the secondary pressure relief pipeline is correspondingly connected with a dust remover (12), and a secondary pressure charging pipeline (8); and the feeding valve and a material level monitor (13) are installed in the shell, the material level is located at the top of the interior of the shell, the feeding valve is connected with the discharge valve (2) through the drive mechanism (4), and the material level monitor is installed at the top of the interior of the shell. The biomass material lock and the working method are used in a feeding system of biomass power generation.

Owner:HARBIN BOILER

Continuous and stable coarse slime sorting machine heavy product discharging device and method

ActiveCN108057512AContinuous and stable dischargeImprove sorting efficiencyWet separationAutomatic controlControl system

The invention discloses a continuous and stable coarse slime sorting machine heavy product discharging device and method. The device comprises a sorting machine body, a water feeding system, a feedingsystem, a light product overflow system, a heavy product discharging system and an automatic control system. The water feeding system comprises a water tank arranged at the bottom of the sorting machine body. A water flow distributor is arranged at the upper portion of the water tank and provided with a plurality of holes. The feeding system is arranged at the center position of the top of the sorting machine body. The light product overflow system is arranged on the outer side of the upper portion of the sorting machine body .The heavy product discharging system comprises a heavy product collecting tank, a heavy product outlet and a spiral elevating device. The automatic control system comprises an automatic controller, a density measurer, a density sensor, a control valve, a water feeding pressure intensity meter and a control circuit. By means of the continuous and stable coarse slime sorting machine heavy product discharging device and method, disturbance on sorting from discharging is reduced, the sorting efficiency is greatly improved, the property of heavy products is stable, the water content is low, and the heavy product water removal treatment is reduced.

Owner:CHINA UNIV OF MINING & TECH

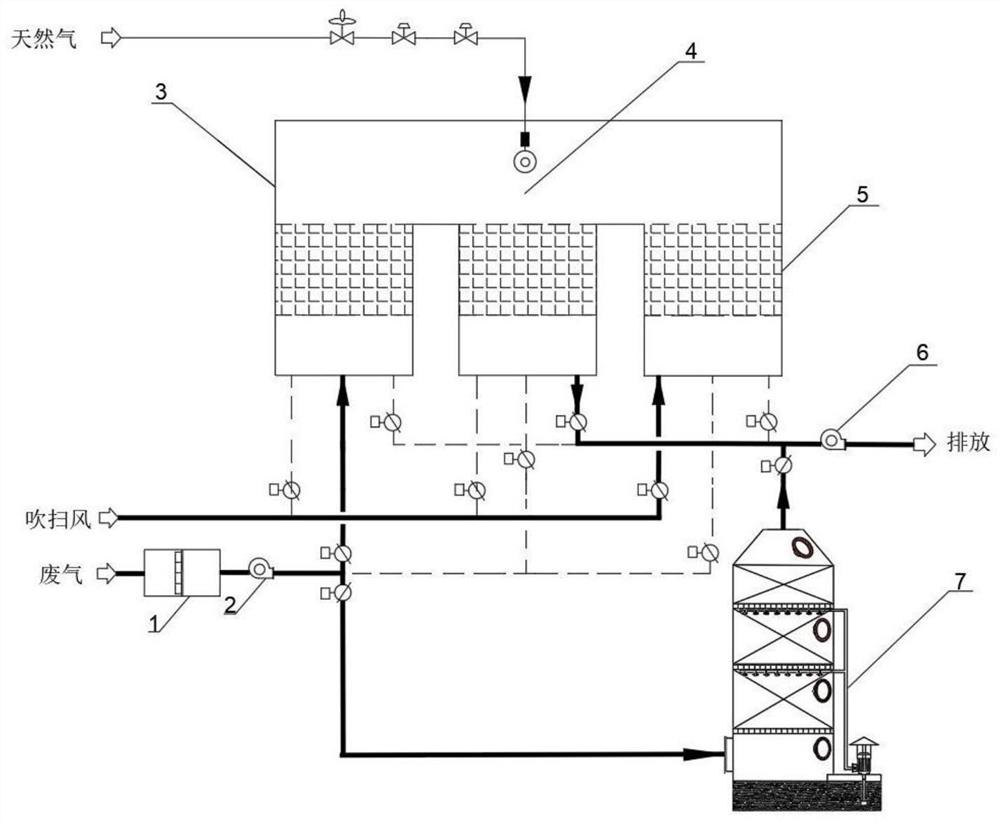

Purification method for PAN-based carbon fiber production waste gas

PendingCN113813771AReduce concentrationGuaranteed uptimeDispersed particle filtrationIncinerator apparatusFiberParticulates

The invention discloses a purification method for PAN-based carbon fiber production waste gas. The method comprises the following steps: the PAN-based carbon fiber production waste gas is pretreated; the pretreated PAN-based carbon fiber production waste gas is introduced into a heat storage type thermal incineration system through a waste gas fan; the temperature of the waste gas is increased to 800 DEG C, so pollutants in the PAN-based carbon fiber production waste gas in the heat storage chamber are oxidized; and gas fully oxidized in the heat storage type thermal incineration system is induced by an induced draft fan and is exhausted through an exhaust funnel. According to the invention, a filter filled with a filtering material is used for filtering, so the concentration of particulate matters such as tar can be reduced, and normal operation of the heat storage type thermal incineration system is guaranteed; and the heat storage type thermal incineration system of a fixed three-chamber structure is utilized, main components in the waste gas are removed through thermal oxidation, generation of thermal nitric oxide is reduced, and a heat accumulator can recover heat generated by combustion to guarantee the temperature of the thermal oxidation chamber, thereby achieving energy-saving effect.

Owner:JILIN INST OF CHEM TECH

Low temperature plasma device and method of decomposing hydrogen sulfide

PendingCN111377410AFacilitate discharge decomposition reactionLarge micro discharge currentSulfur preparation/purificationHydrogen productionLow temperature plasmaPlasma reaction

The invention relates to the field of plasma chemistry, and discloses a low temperature plasma device and a method of decomposing hydrogen sulfide, the device comprising: a first cavity (1), a secondcavity (2), a third cavity (7), an inner electrode (3), an outer electrode (4), and a barrier medium (6), wherein the inner electrode (3) and the outer electrode (4) being both solid electrodes and the shapes of which cooperate with each other to form an isodiametric structure. The low-temperature plasma reaction device provided by the invention can realize continuous and stable operation of a hydrogen sulfide decomposition process under an obviously high hydrogen sulfide conversion rate, and the device can realize long-period operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Refining and reclaiming technology of tail gas absorption solvent in production of toluene diisocyanate

InactiveCN101870666BContinuous and stable feedingContinuous and stable dischargeDispersed particle separationDistillation purification/separationToluene diisocyanateGas phase

Owner:QINGDAO UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com