Complete equipment for solving blockage and hardening of biological filter and matched system thereof and treatment process thereof

A technology of biological filter and complete set of devices is applied in the field of water pollution control to achieve the effect of strong resistance to load impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

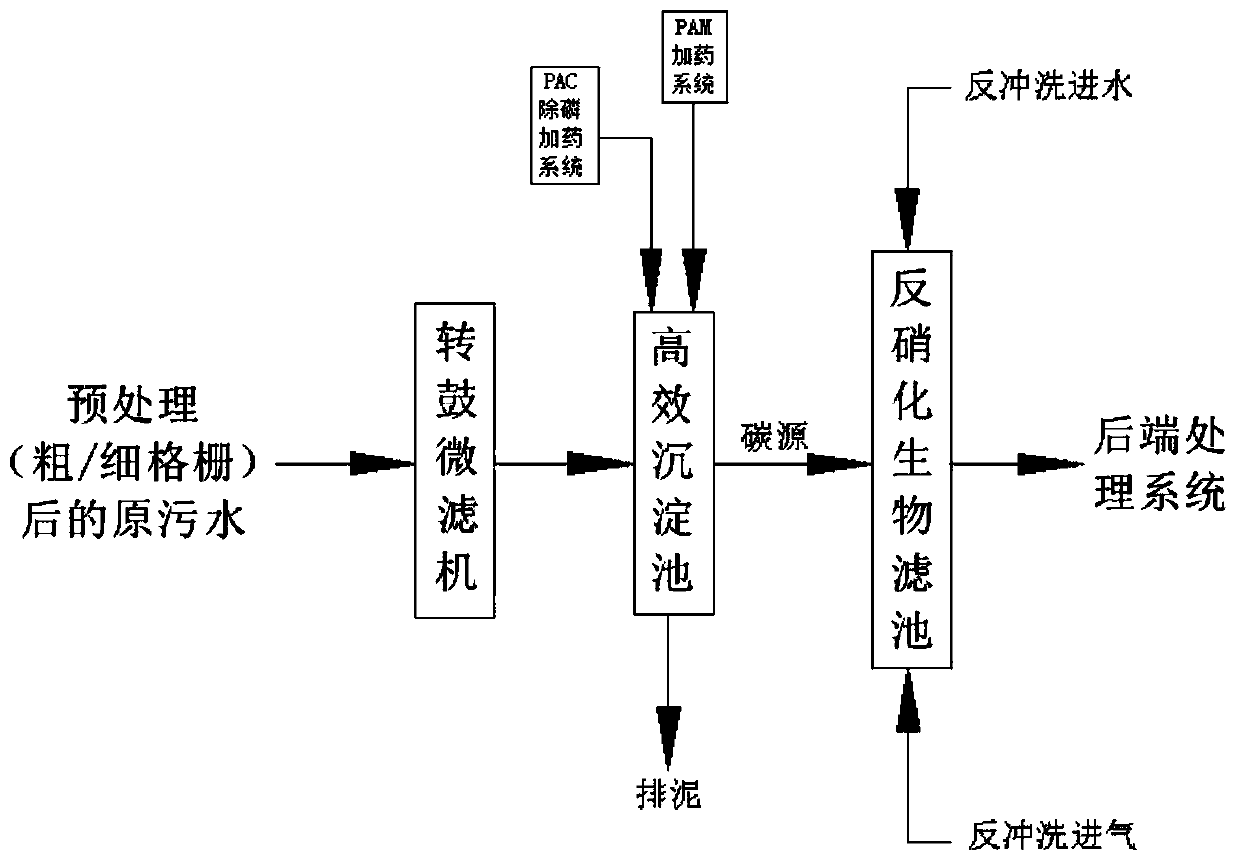

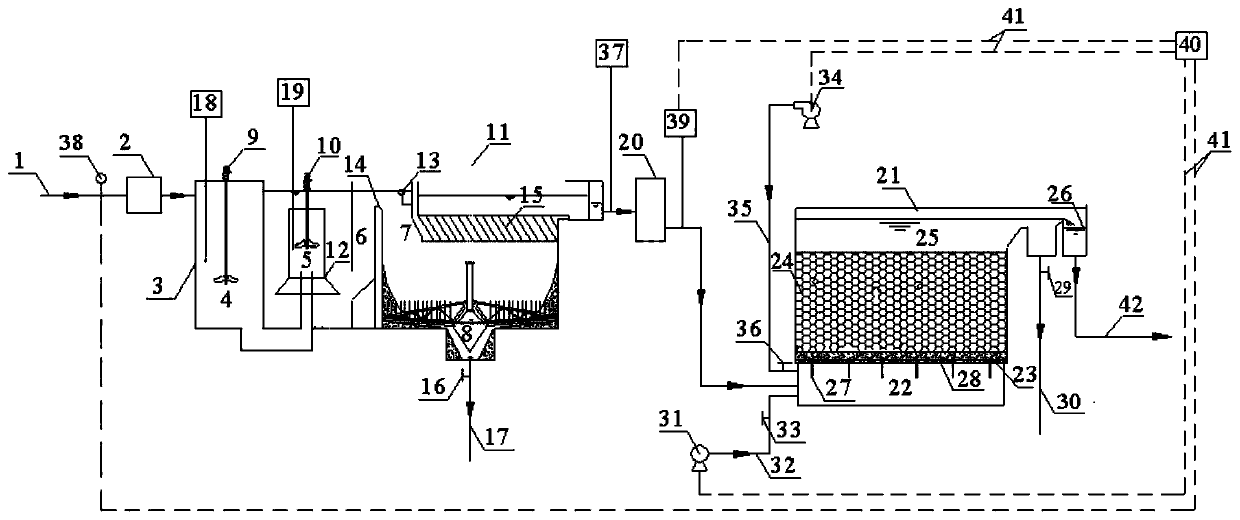

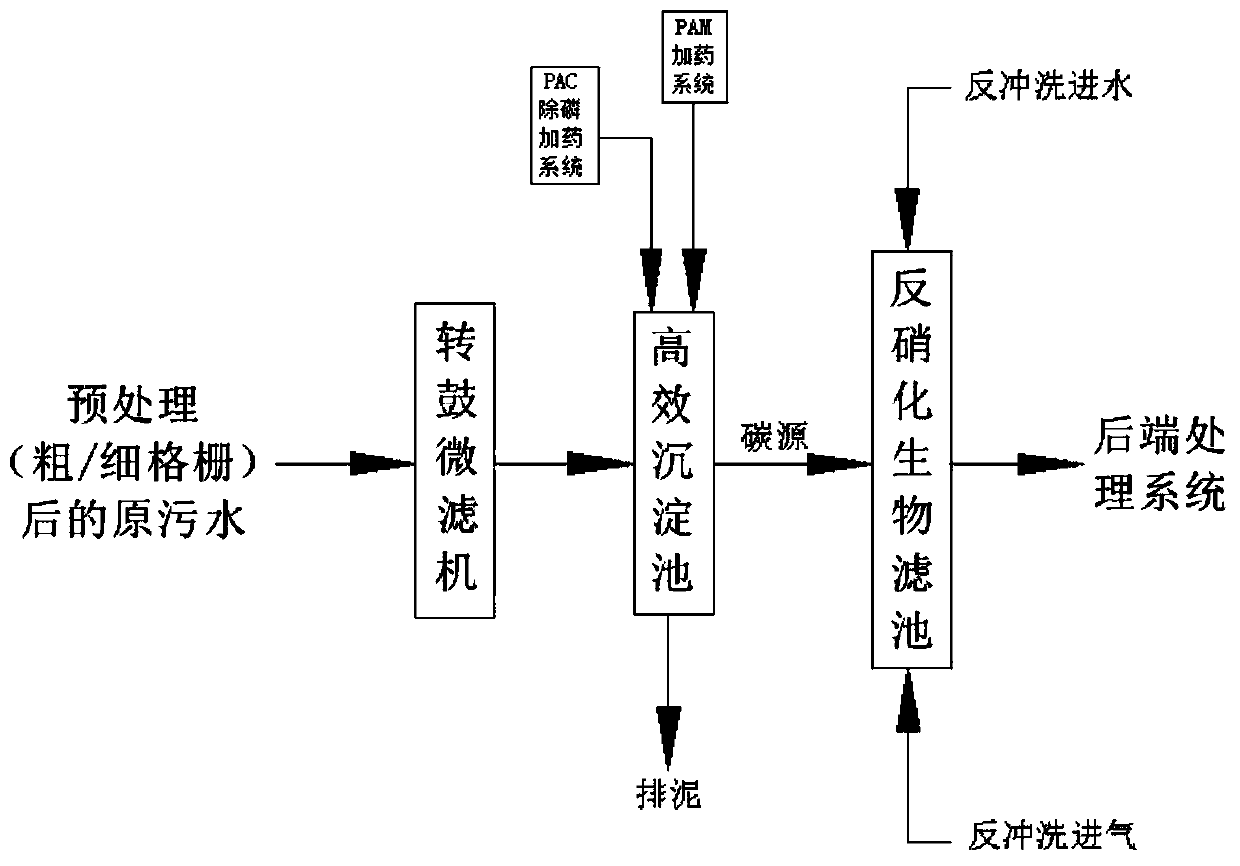

Method used

Image

Examples

Embodiment 1

[0036] A sewage treatment plant in Henan Province raised the standard wastewater, with a treatment flow of 50,000m 3 / d, the pollutant index before the raw sewage after pretreatment (coarse / fine grid) enters the process device is: COD=200mg / L, BOD 5 =100mg / L, TN=35mg / L, SS=150mg / L, TP=2.5mg / L, nitrate=27mg / L; after this process, the effluent water quality index is: COD=35mg / L, BOD 5 =15 mg / L, SS=10 mg / L, TN=11 mg / L, TP=0.2 mg / L.

Embodiment 2

[0038] A municipal sewage treatment plant in Lu'an City, Anhui Province, with a treatment flow of 100,000m 3 / d, the pollutant index before the raw sewage after pretreatment (coarse / fine grid) enters this process is: COD=300mg / L, BOD 5 =140mg / L, SS=210mg / L, TN=40mg / L, nitrate=30mg / L; after being treated by this process device, the effluent water quality index is: COD=35mg / L, BOD 5 =8 mg / L, SS=10 mg / L, TN=12 mg / L.

Embodiment 3

[0040] A municipal sewage treatment plant in Hefei, Anhui Province, with a treatment flow of 100,000m 3 / d, the pollutant index before the raw sewage after pretreatment (coarse / fine grid) enters this process is: COD=300mg / L, BOD 5 =140mg / L, SS=210mg / L, TN=40mg / L, ammonia nitrogen=20mg / L; after being treated by this process device, the effluent water quality index is: COD=35mg / L, BOD 5 =8 mg / L, SS=10 mg / L, TN=22 mg / L.

[0041] The invention adopts a drum microfilter to solve the problem that during the backwashing process of the biological filter system, the biological ceramsite filter material is lost to the high-efficiency sedimentation tank, and the water inlet pipe of the high-efficiency sedimentation tank is blocked, the rapid mixing area, the flocculation reaction area, etc. Problems with normal operation. The inner water inlet orifice grille is used to completely solve the problem that the filter head of the traditional denitrification biological filter is easily block...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com