Patents

Literature

616 results about "Rapid mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Disposable pipette extraction

Owner:BREWER WILLIAM E

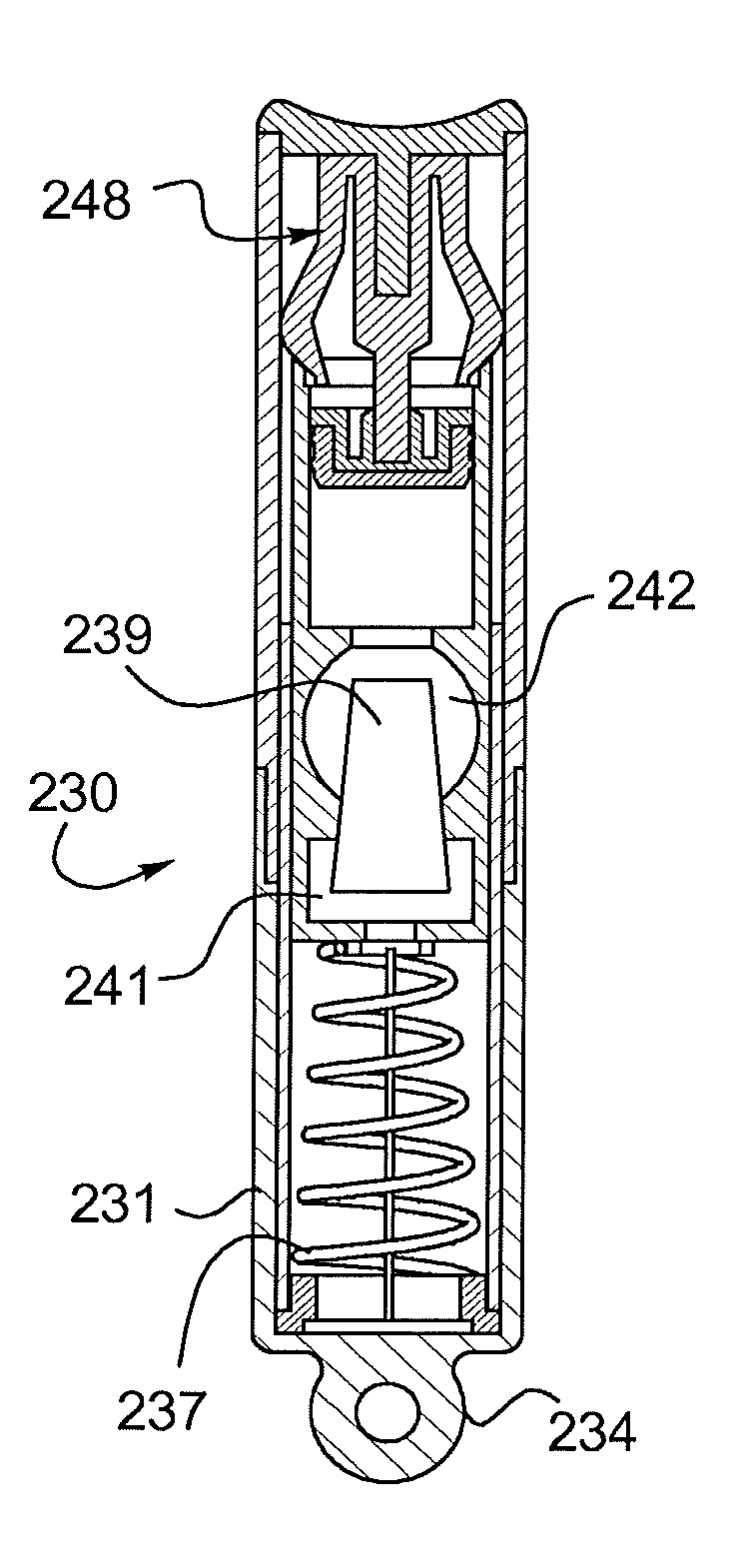

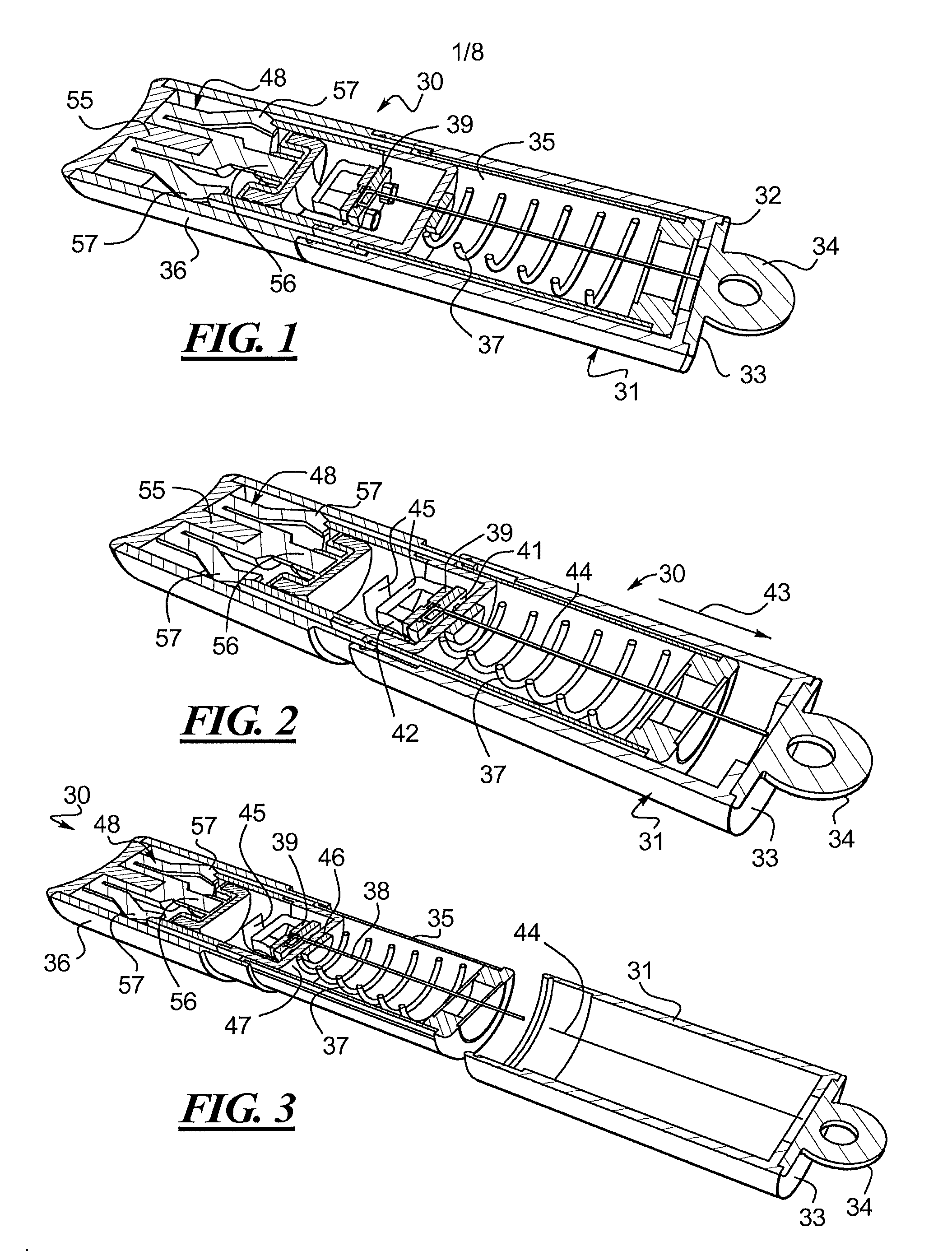

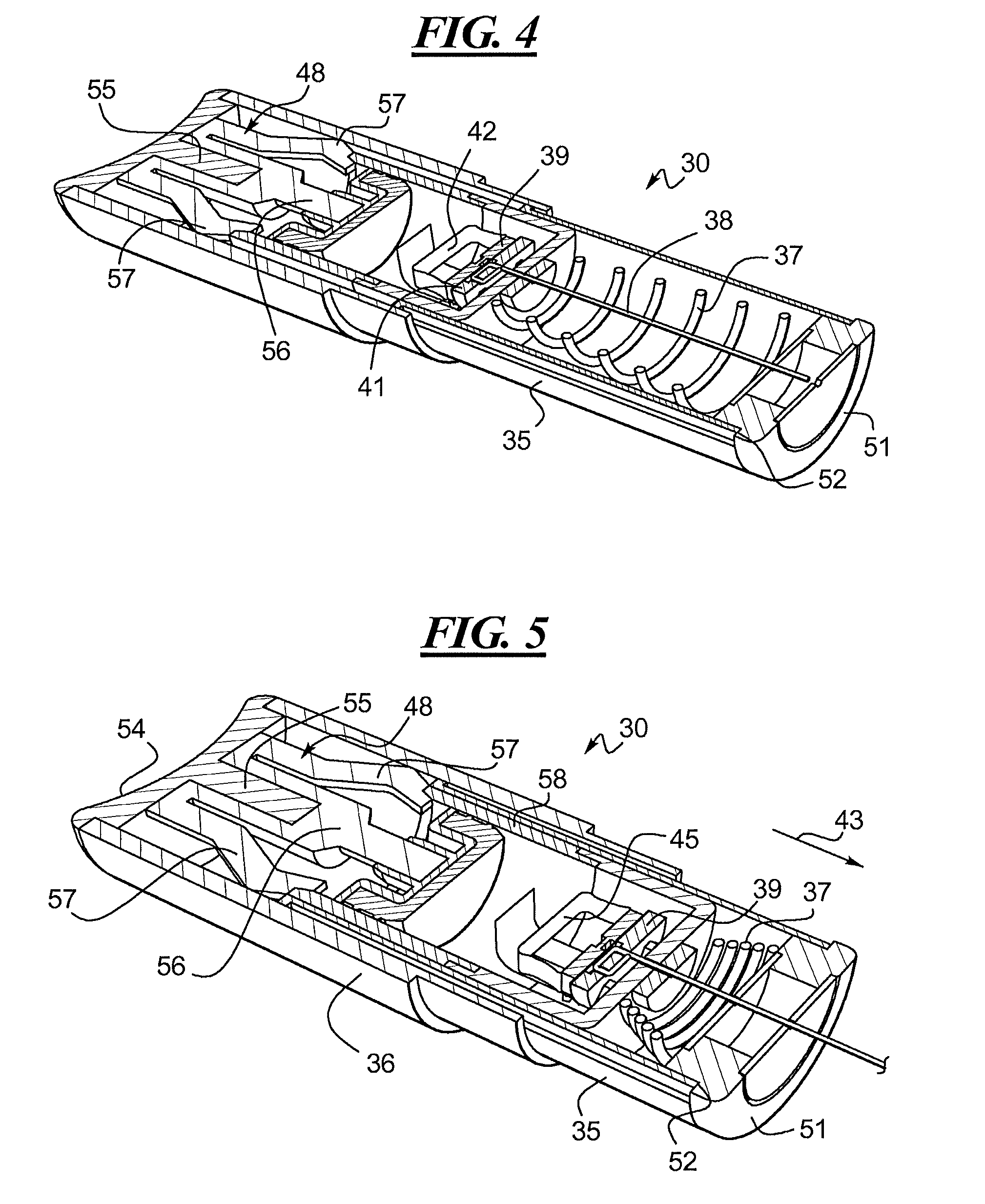

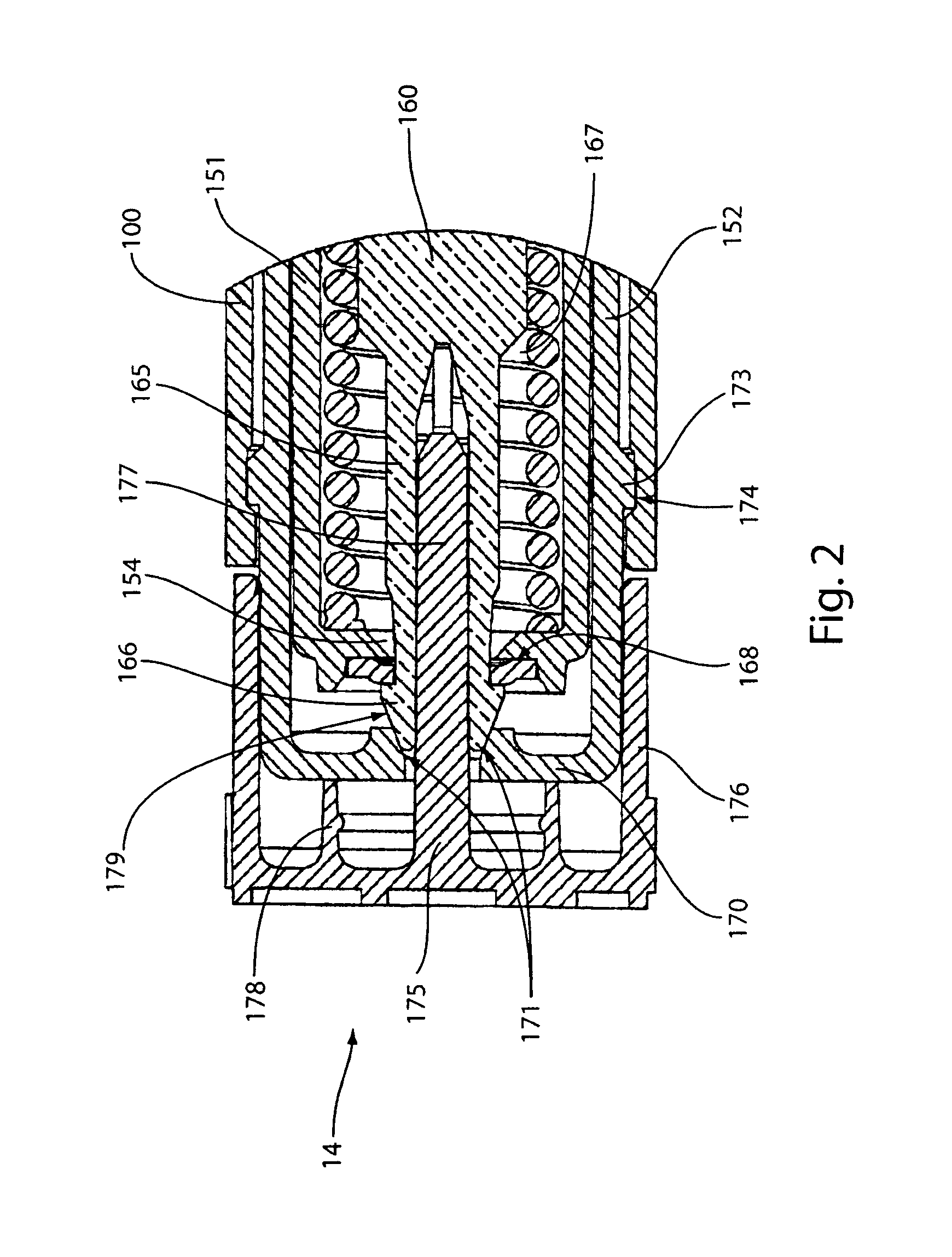

Compact Device That Rapidly Mixing and Deliverings Substances To a Patient

InactiveUS20120179137A1Minimal interactionSimplify the management processInfusion syringesMedical devicesBiological activationBiomedical engineering

Injection devices are disclosed for injections of substances. The disclosed devices separately may hold two separate substances, e.g., solid, liquid or gas substances, in separate compartments which are interrupted so that the separate substances come into contact during the activation of the device. One disclosed device includes a needle for injection and two substances that are mixed with only a few actions by the operator of the device. The device may or may not activate mixing by the removal of a sleeve which triggers compartment interaction through movement of pins, pegs, springs, wires, string, or other mechanisms which allow the materials held in separate chambers to come into contact with each other. Operator error during mixing and checking the dosage of substances to be injected is avoided with the disclosed devices. Also, the needle is maintained in a sterile state because the needle is held internally of the device until the sleeve is removed and the device begins to activate.

Owner:GLUCAGO

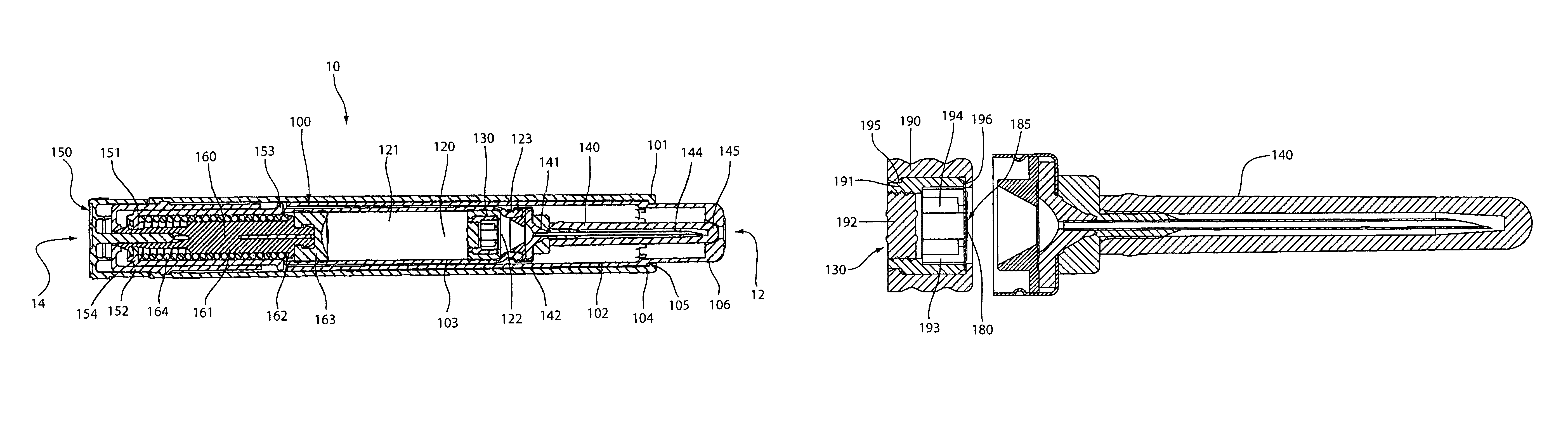

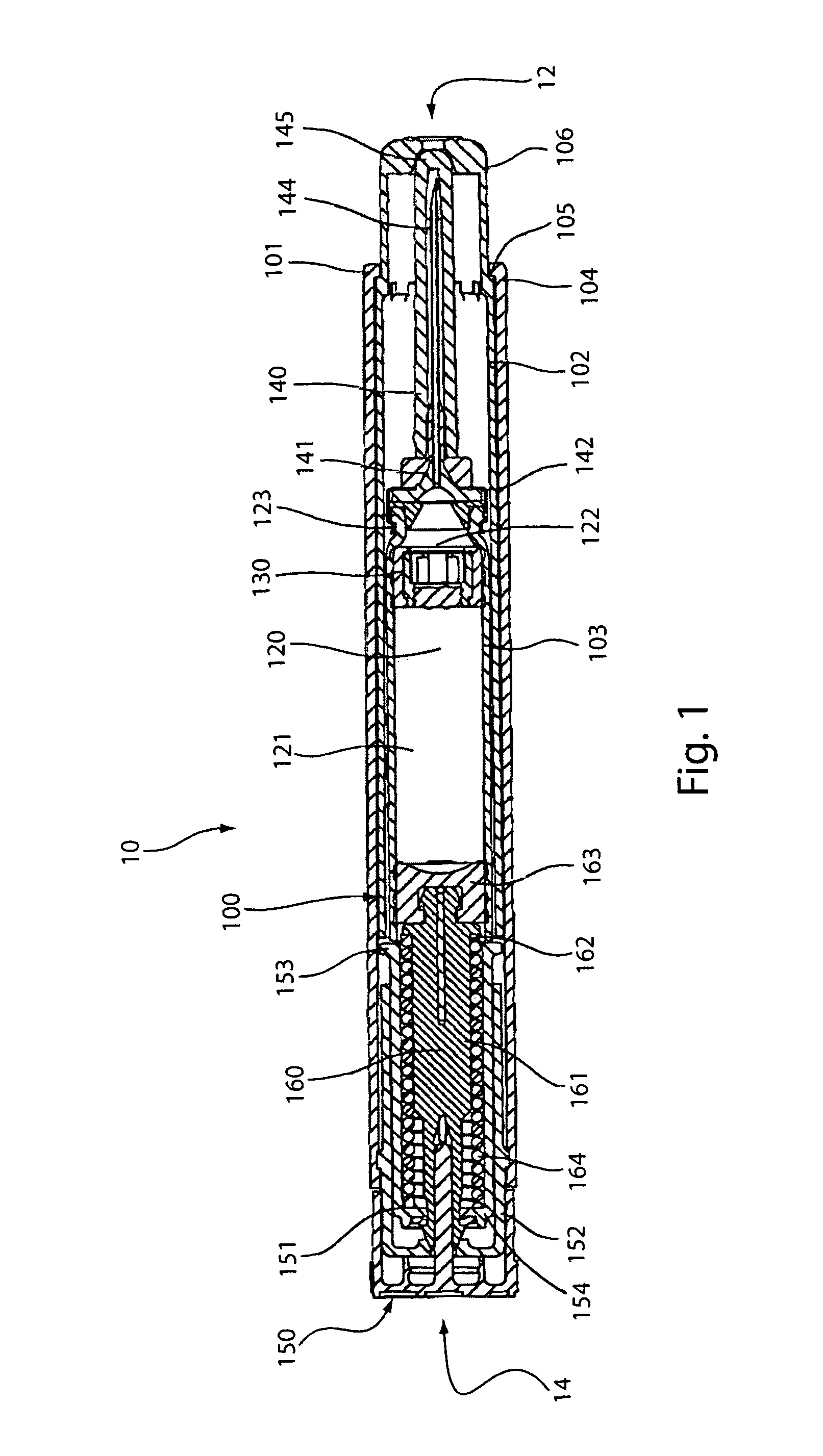

Drug delivery system with a small amount of a therapeutic agent

ActiveUS8057427B2Cost-effectiveSmall and precise amountAmpoule syringesAutomatic syringesBiological activationBiomedical engineering

A drug delivery system includes an automatic injector that can deliver a small, precise amount of a therapeutic agent. The automatic injector includes a chamber for containing a liquid component and a thin porous member that carries thereon and / or therein the small, precise amount of therapeutic agent. Upon activation of the automatic injector, a flow path opens from the chamber through the porous member, enabling the liquid component to rapidly mix with the therapeutic agent before being injected.

Owner:MERIDIAN MEDICAL TECH

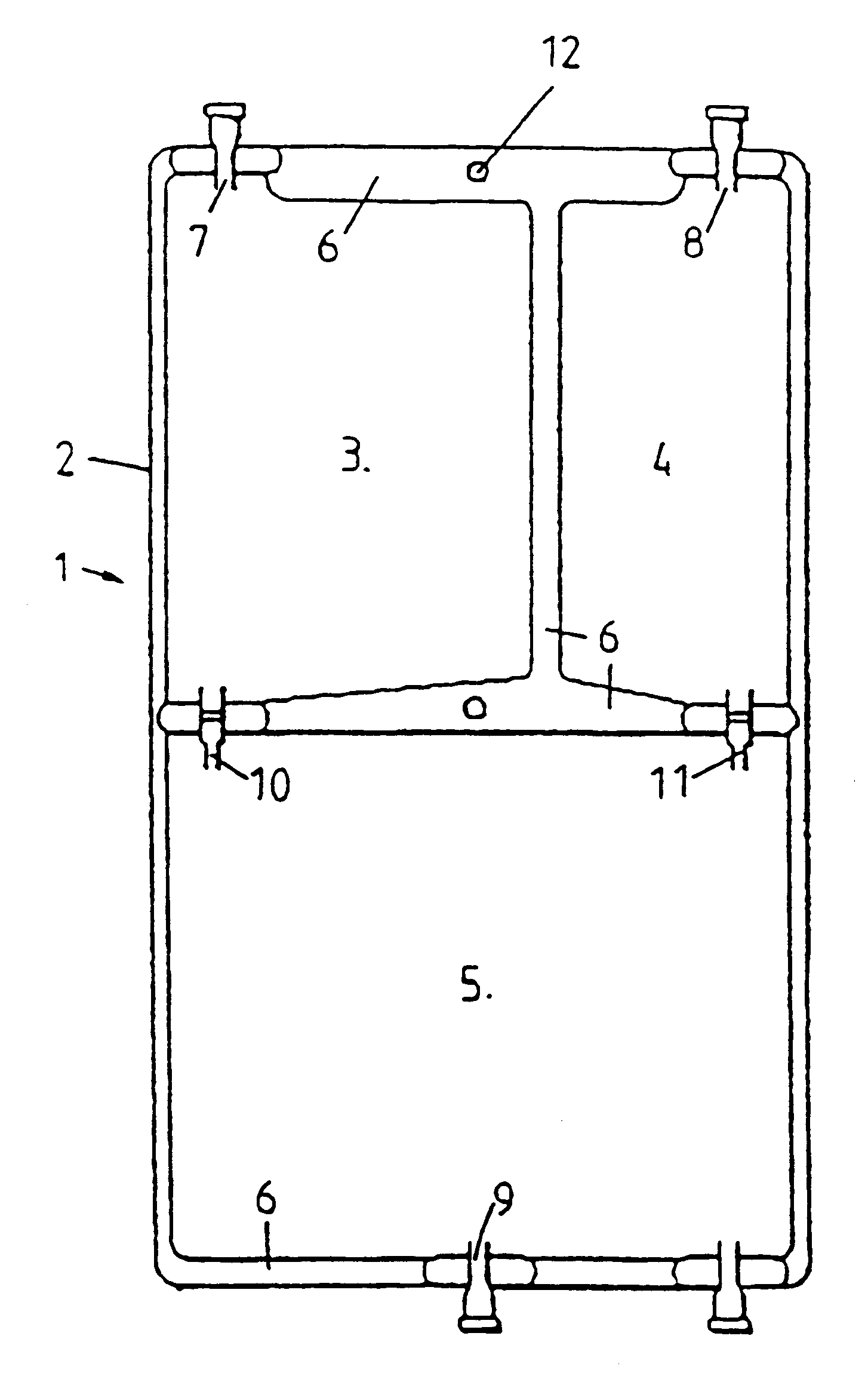

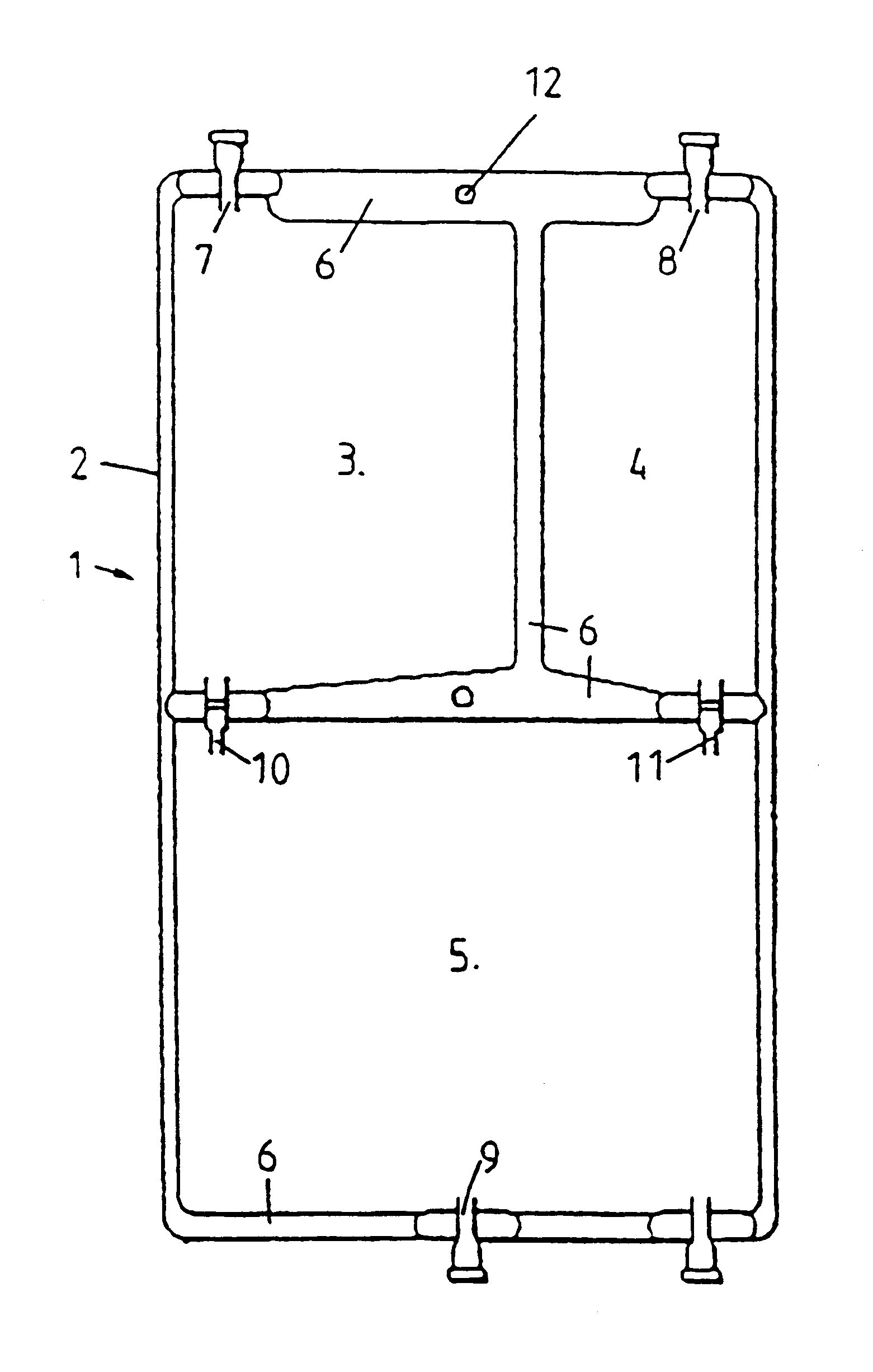

Flexible plastic container with three chambers

InactiveUS6231559B1Keep for a long timeRapid and still safer mixingDiagnosticsSurgeryAdditive ingredientTime-Consuming

The object of the invention is a flexible plastic container for the spatially separated storage and, optionally, selective sterilization of the ingredients of preparations for parenteral or enteral use. The container comprises three compartments being suited for taking up the ingredients, namely carbohydrates within compartment 3, lipids within compartment 4, and amino acids within compartment 5 as well as connections between the compartments which can be opened sterilely from the outside. The proportions by volume of the compartments are selected such that rapid mixing of all ingredients without time-consuming pressing and kneading operations by the hospital personnel is possible within compartment 5.

Owner:B BRAUN MELSUNGEN AG

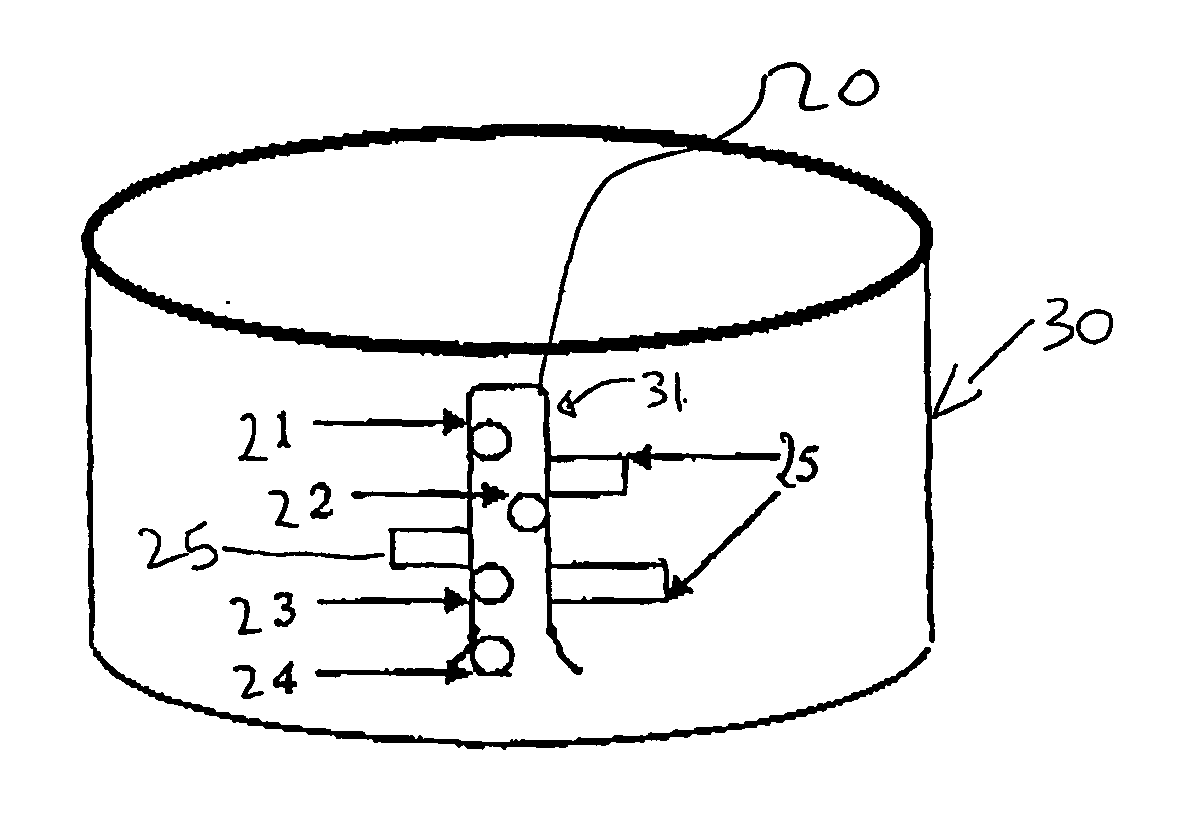

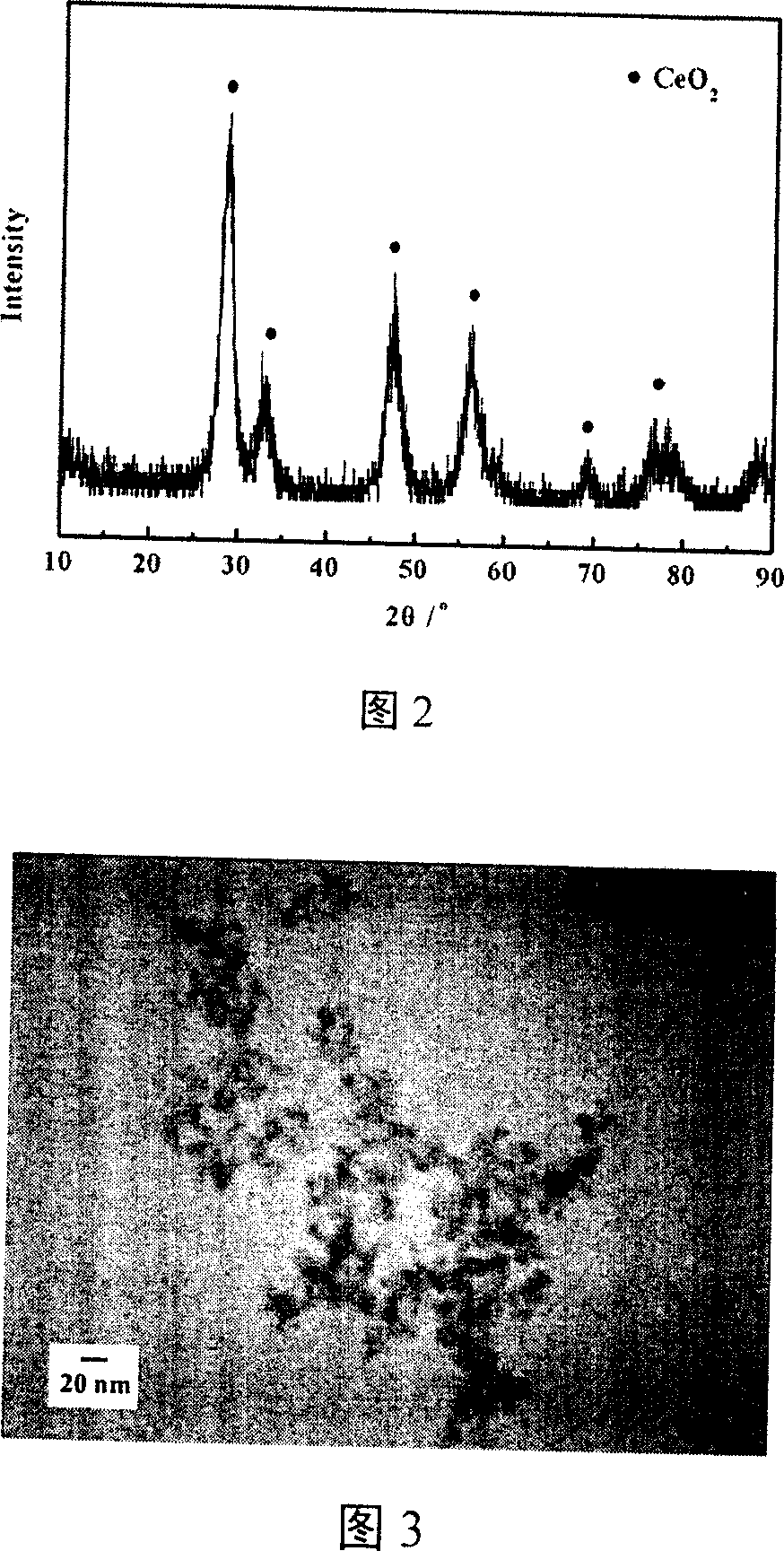

Apparatus and method for preparing cerium oxide nanoparticles

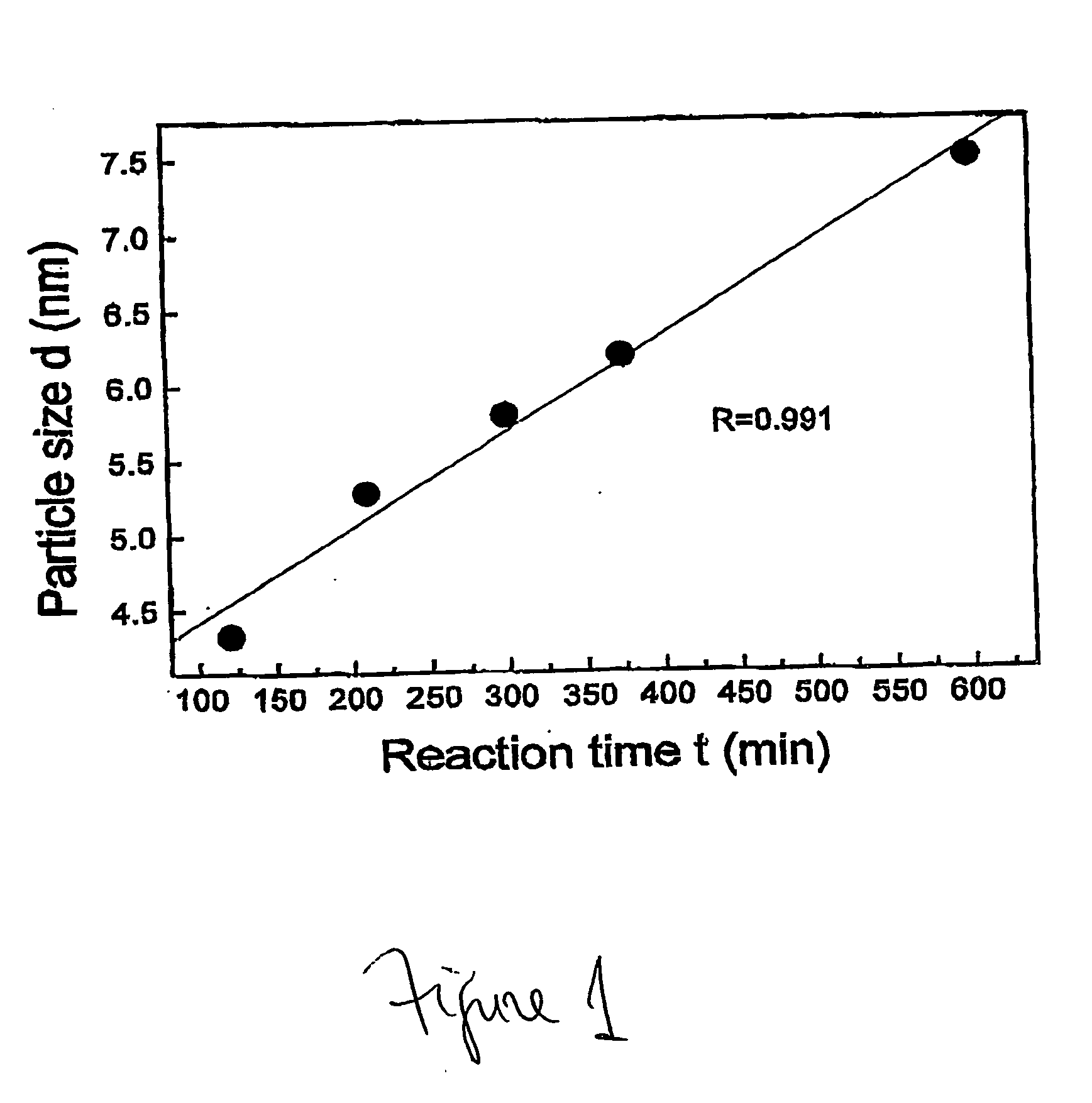

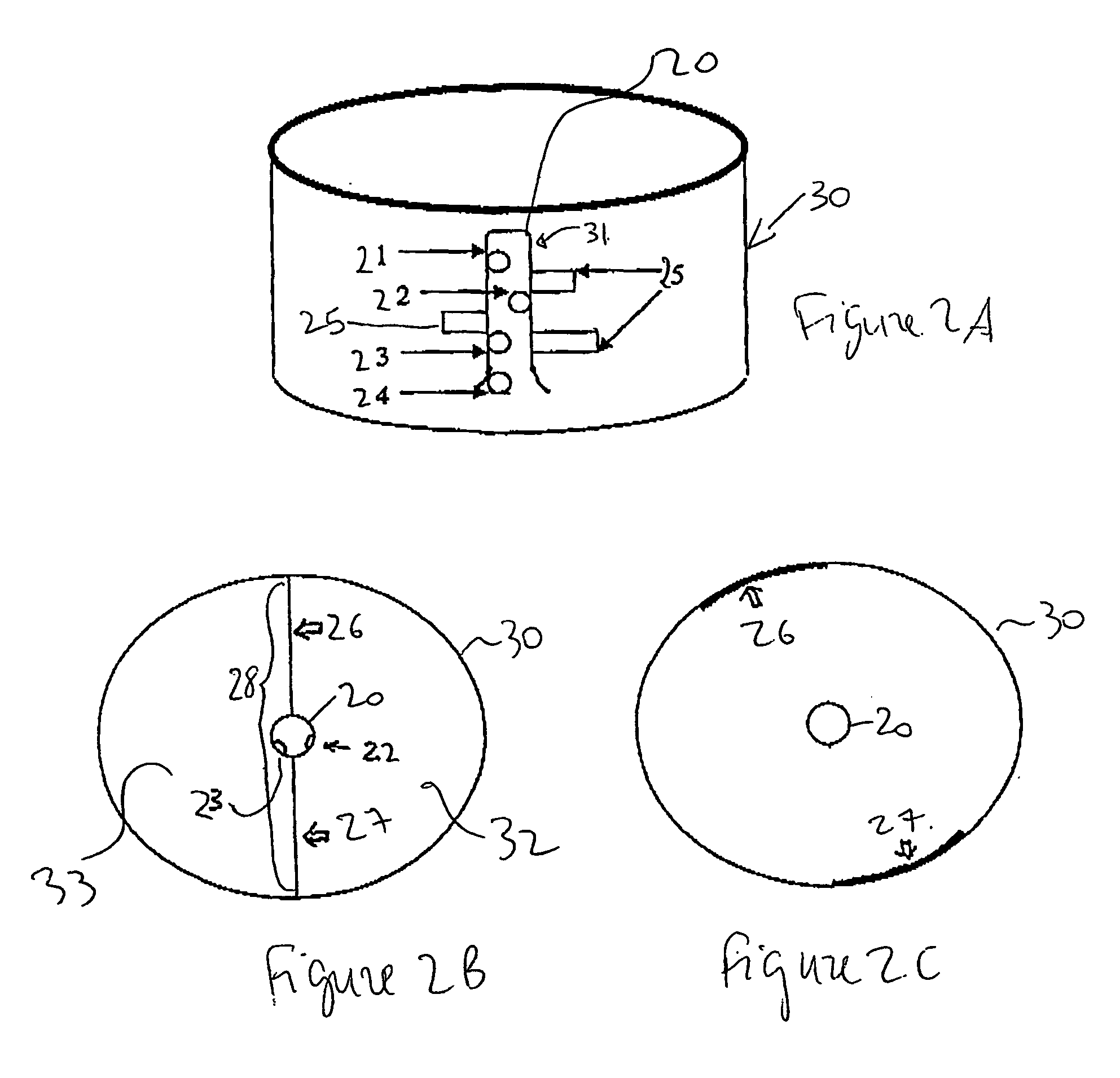

InactiveUS20050031517A1Quick responseReaction time is thus limitedMaterial nanotechnologyMixing methodsCerium nitrateNanoparticle

This invention provides a method for preparing cerium oxide nanoparticles with a narrow size distribution. The cerium oxide nanoparticles obtained by the method of the invention are nearly all crystalline. The method comprises providing a first aqueous solution comprising cerium nitrate and providing a second aqueous solution comprising hexamethylenetetramine. The first and second aqueous solutions are mixed to form a mixture, and the mixture is maintained at a temperature no higher than about 320° K to form nanoparticles. The nanoparticles that are formed are then separated from the mixture. A further aspect of the present invention is an apparatus for preparing cerium oxide nanoparticles. The apparatus comprises a mixing vessel having a first compartment for holding a first aqueous solution comprising cerium nitrate and a second compartment for holding a second aqueous solution comprising hexamethylenetetramine. The mixing vessel has a retractable partition separating the first and second compartments. When the retractable partition is retracted, rapid mixing of the first aqueous solution with the second aqueous solution takes place to form a mixture, and the mixture is maintained at a temperature no higher than about 320° K to form nanoparticles therein.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Continuous hydrothermal synthetic method for lithium ion cell nano anode material

InactiveCN101016150ASimple processImprove economyNanostructure manufactureElectrode manufacturing processesConductive materialsSolid particle

The invention discloses a continual hydrothermal synthesizing method of lithium ion battery nanometer anode, which comprises the following steps: adopting continual hyper (sub) clinical hydrothermal synthetic technique to make nanometer graded LiFePO4 particle through hypercritical flow transfer mass and crystallizing elementary; adding conductive material to make electrode material; spraying the product liquid into low-pressure flashing room with cyclone separator directly; gasifying water in the flashing room into steam; draining out from the top of cyclone separator; sedimenting solid particle on the bottom of flashing room; collecting dry powder as product.

Owner:SHANGHAI JIAO TONG UNIV

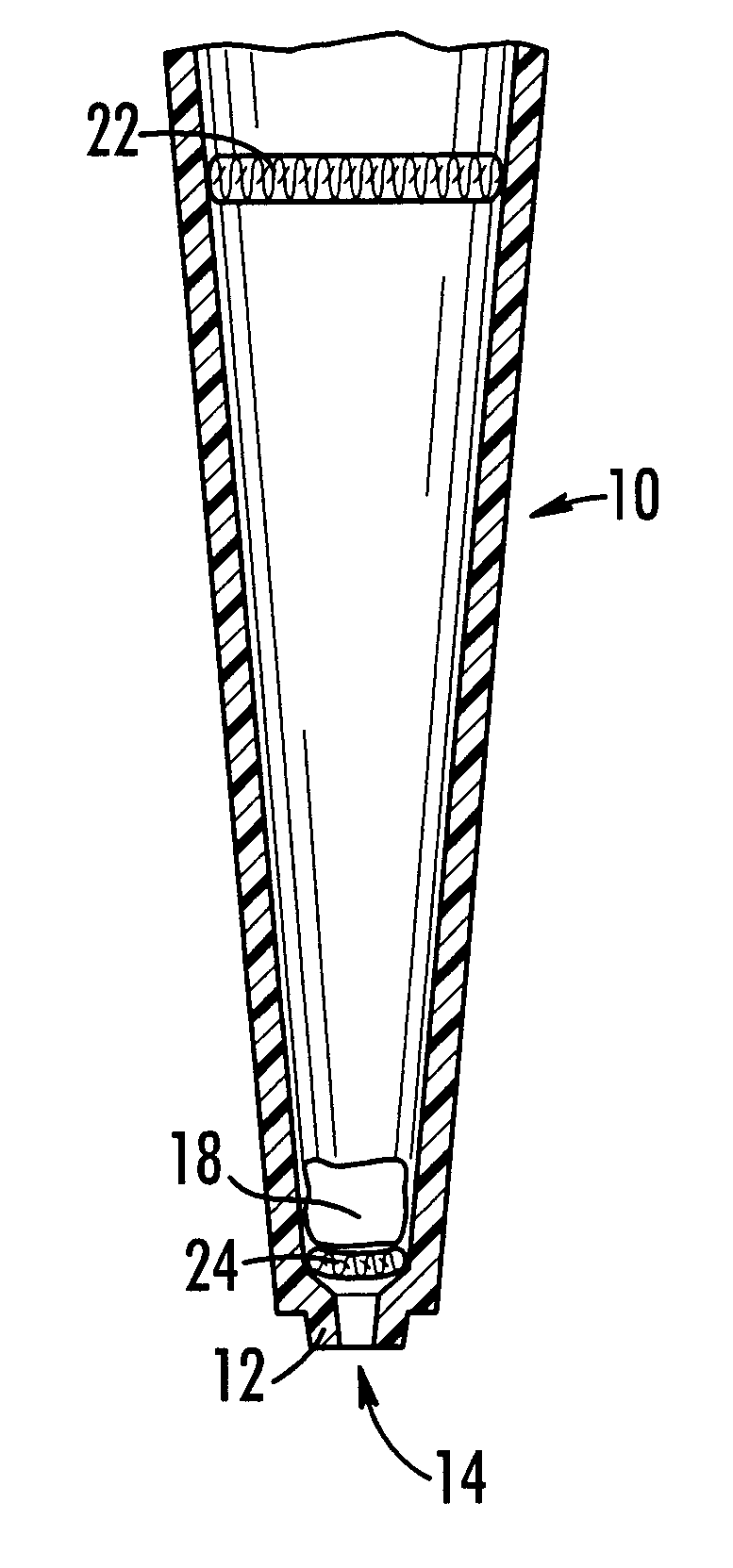

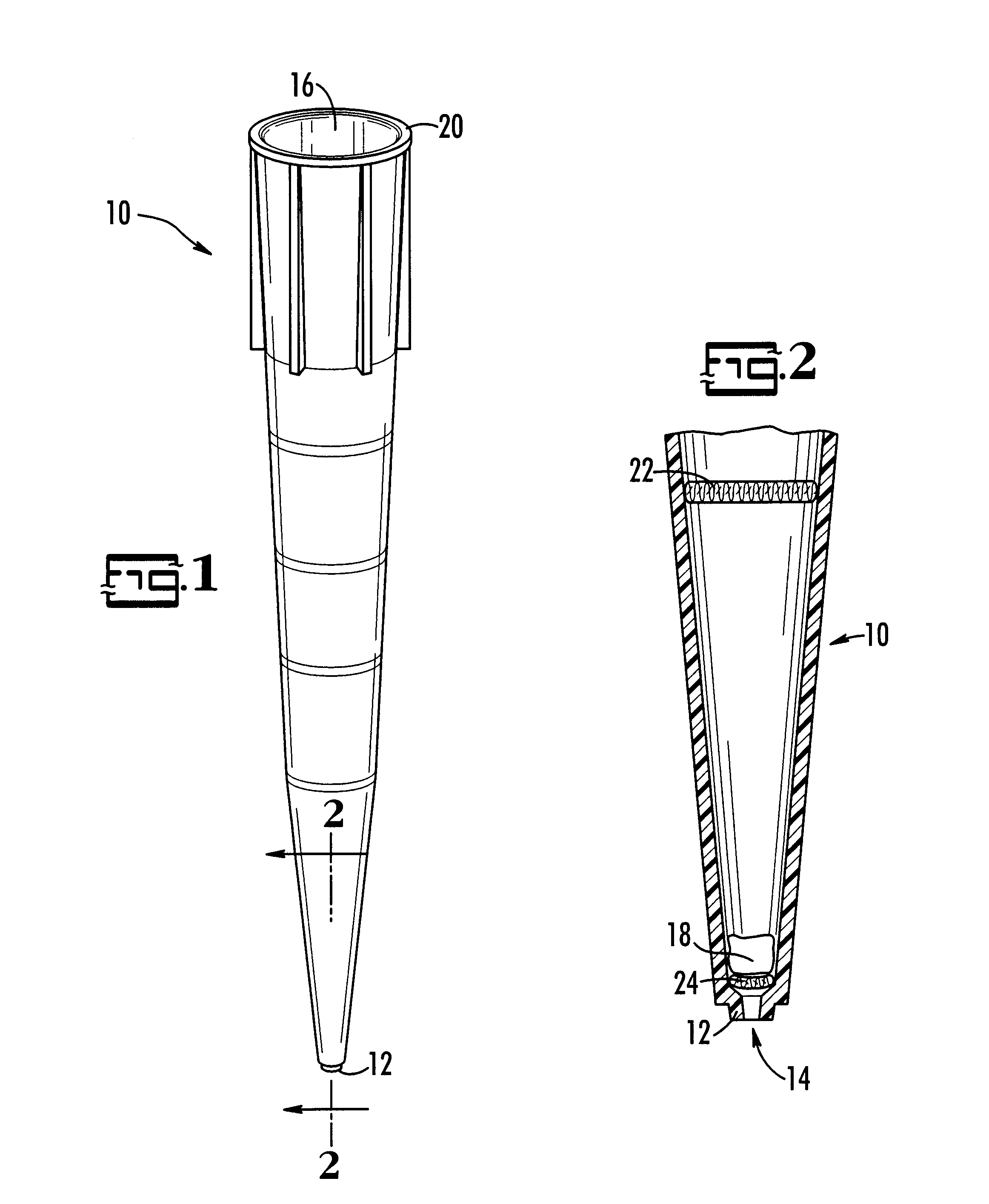

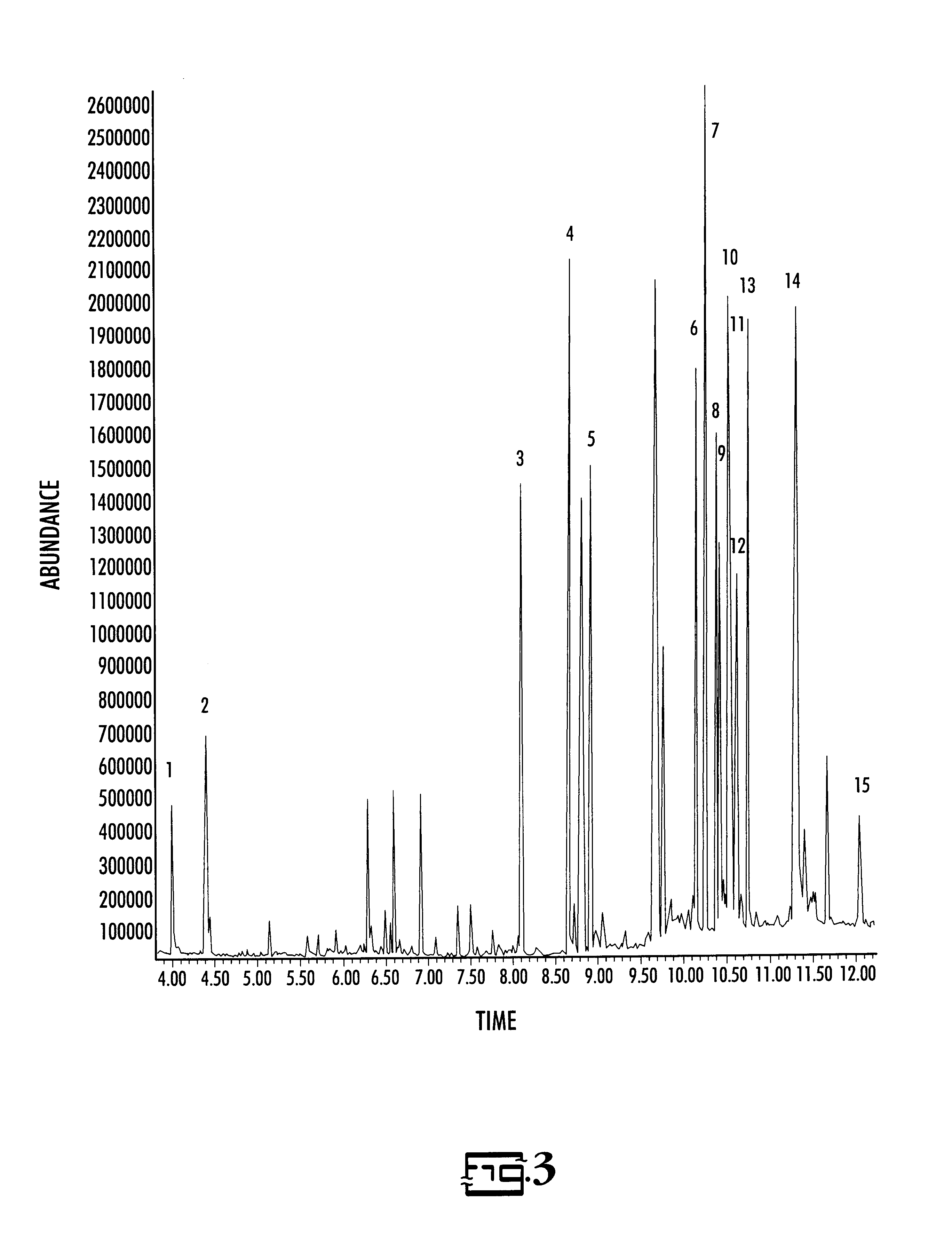

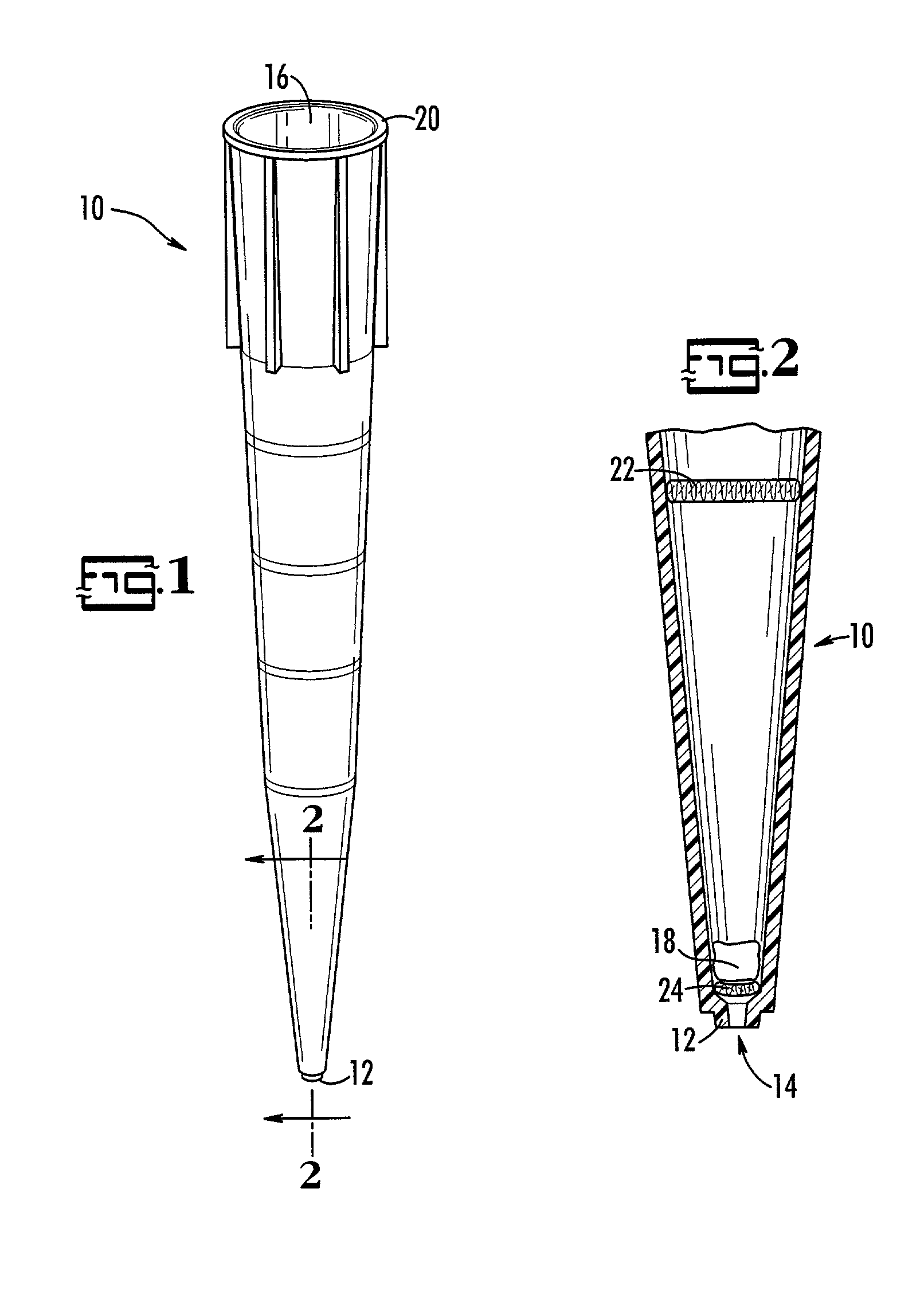

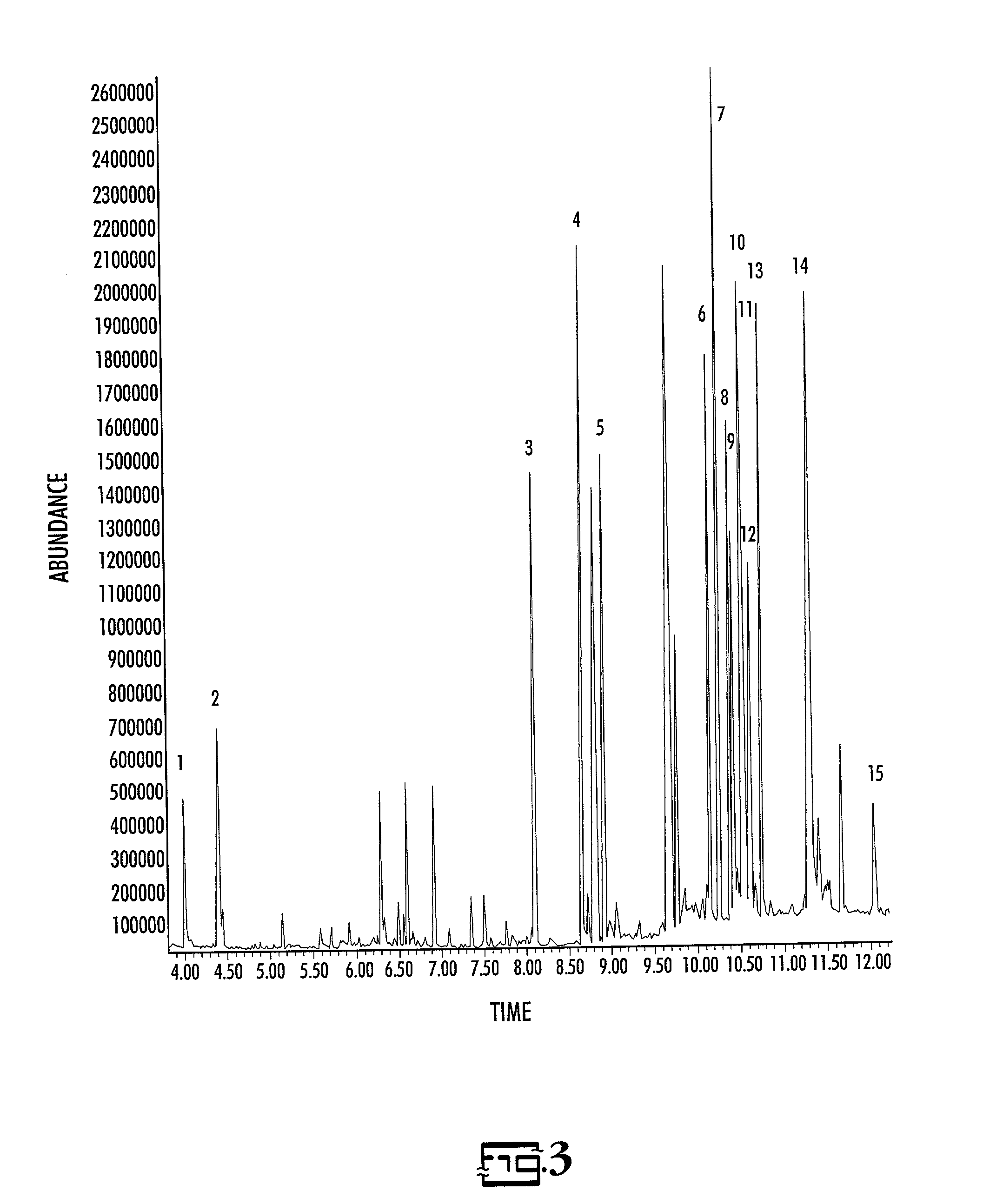

Disposable pipette extraction

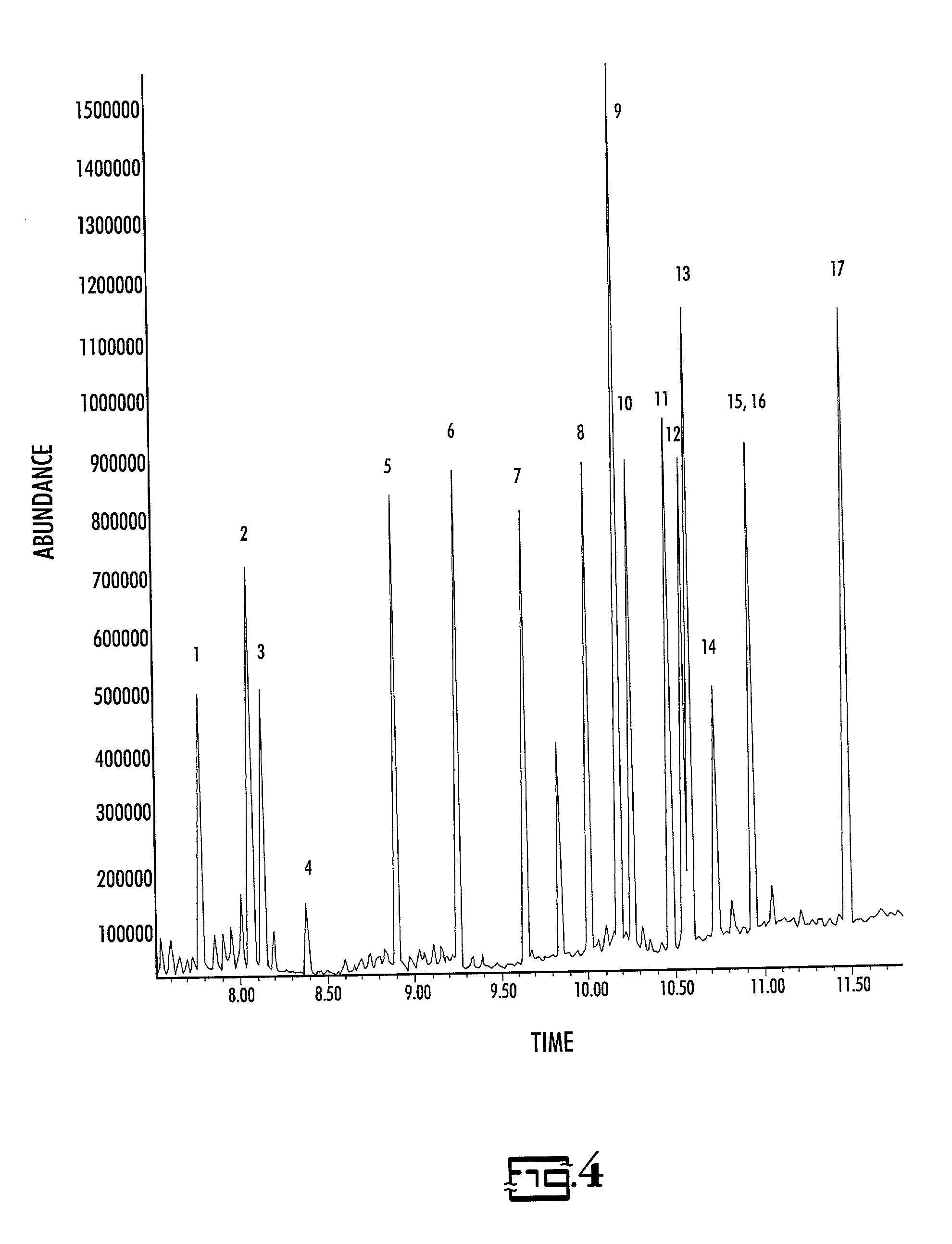

The present invention is a disposable apparatus for the rapid, low-volume solid phase extraction of analytes from a variety of sources. The apparatus of the present invention is configured as a pipette tip and contains a loosely confined stationary phase. The mobility of the stationary phase particles enables rapid mixing and equilibration with a sample solution during agitation. The analyte may thereby be extracted in less time with less solvent, removing the need for a separate concentration step.

Owner:BREWER WILLIAM E

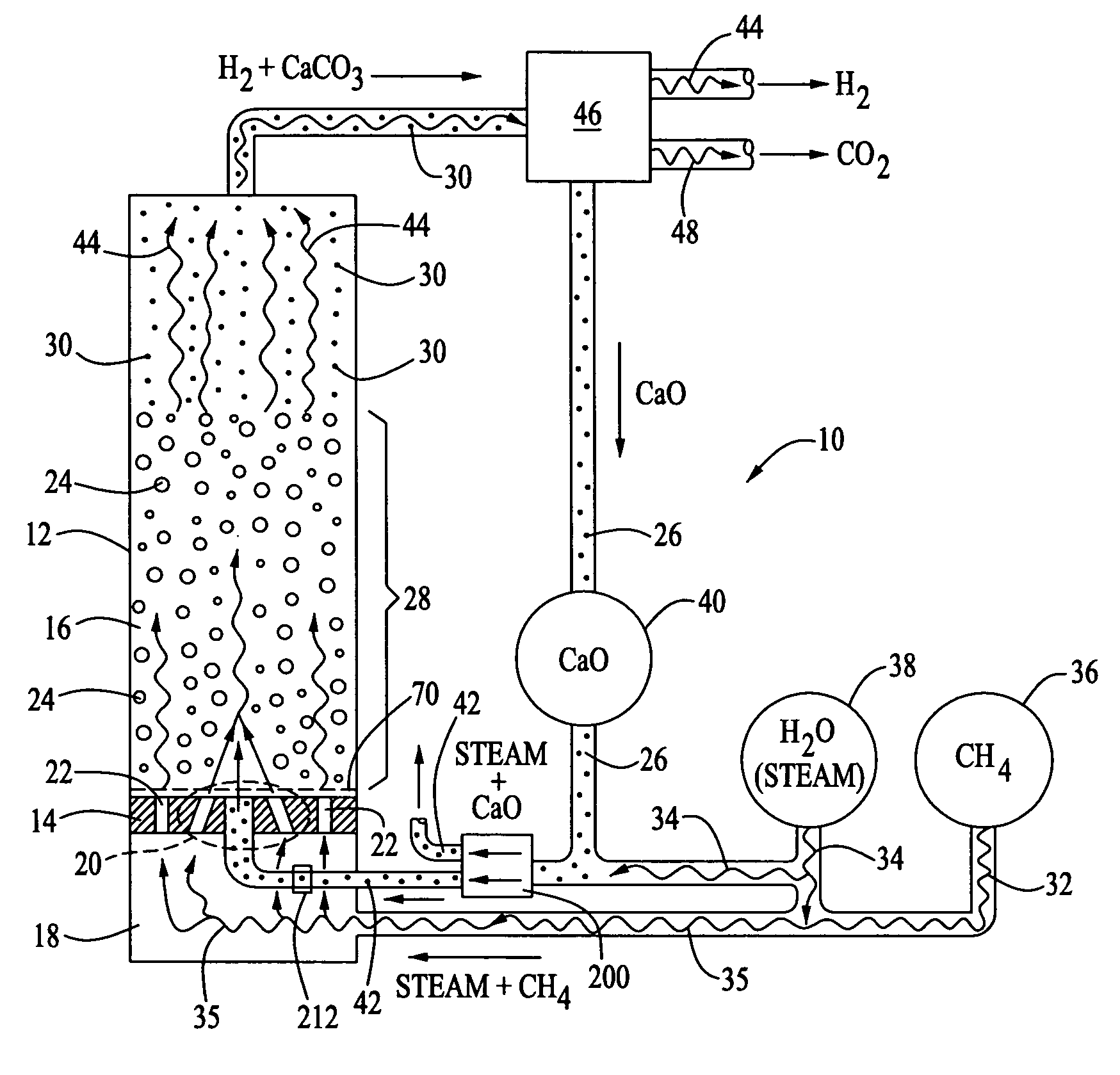

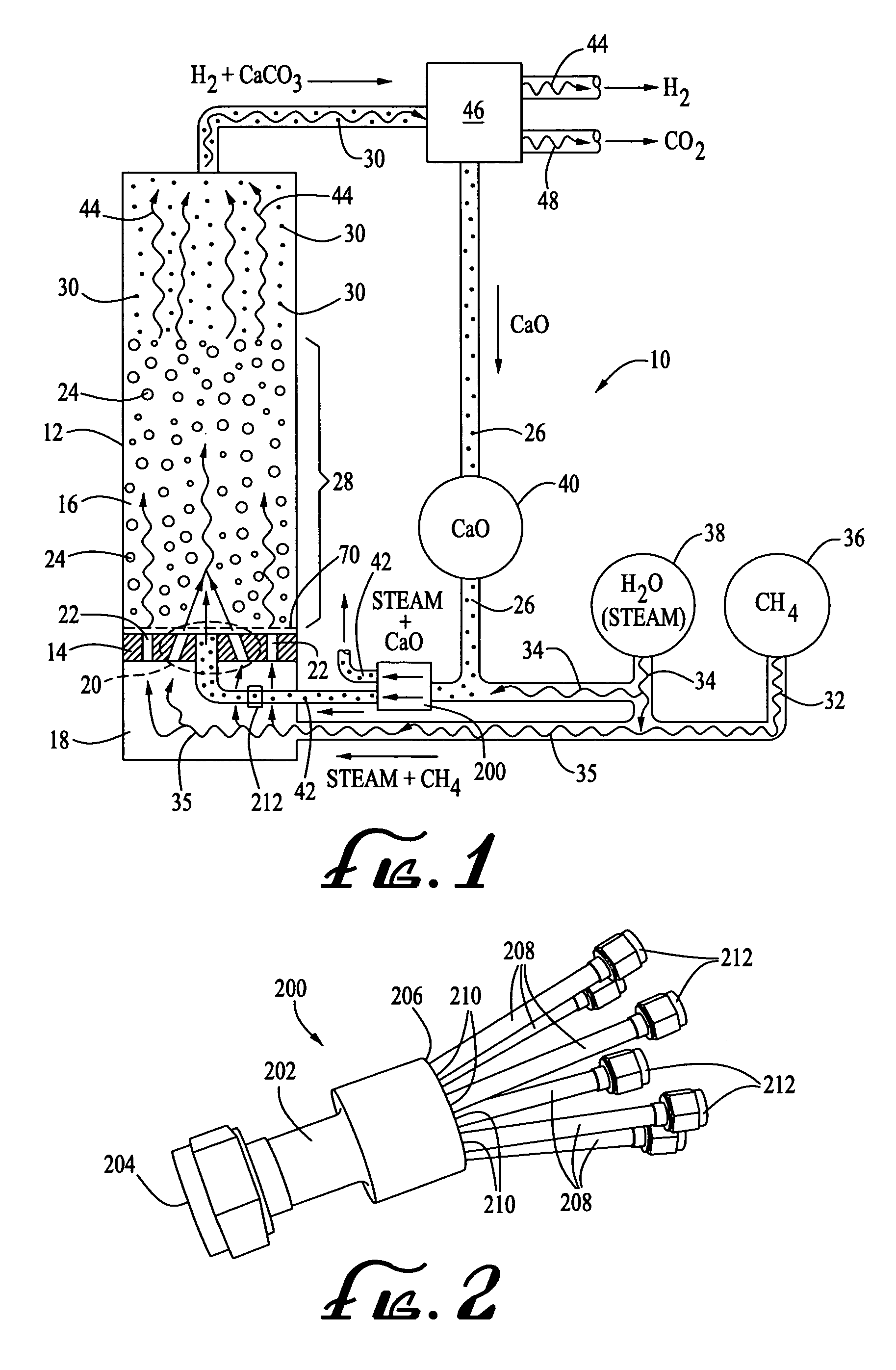

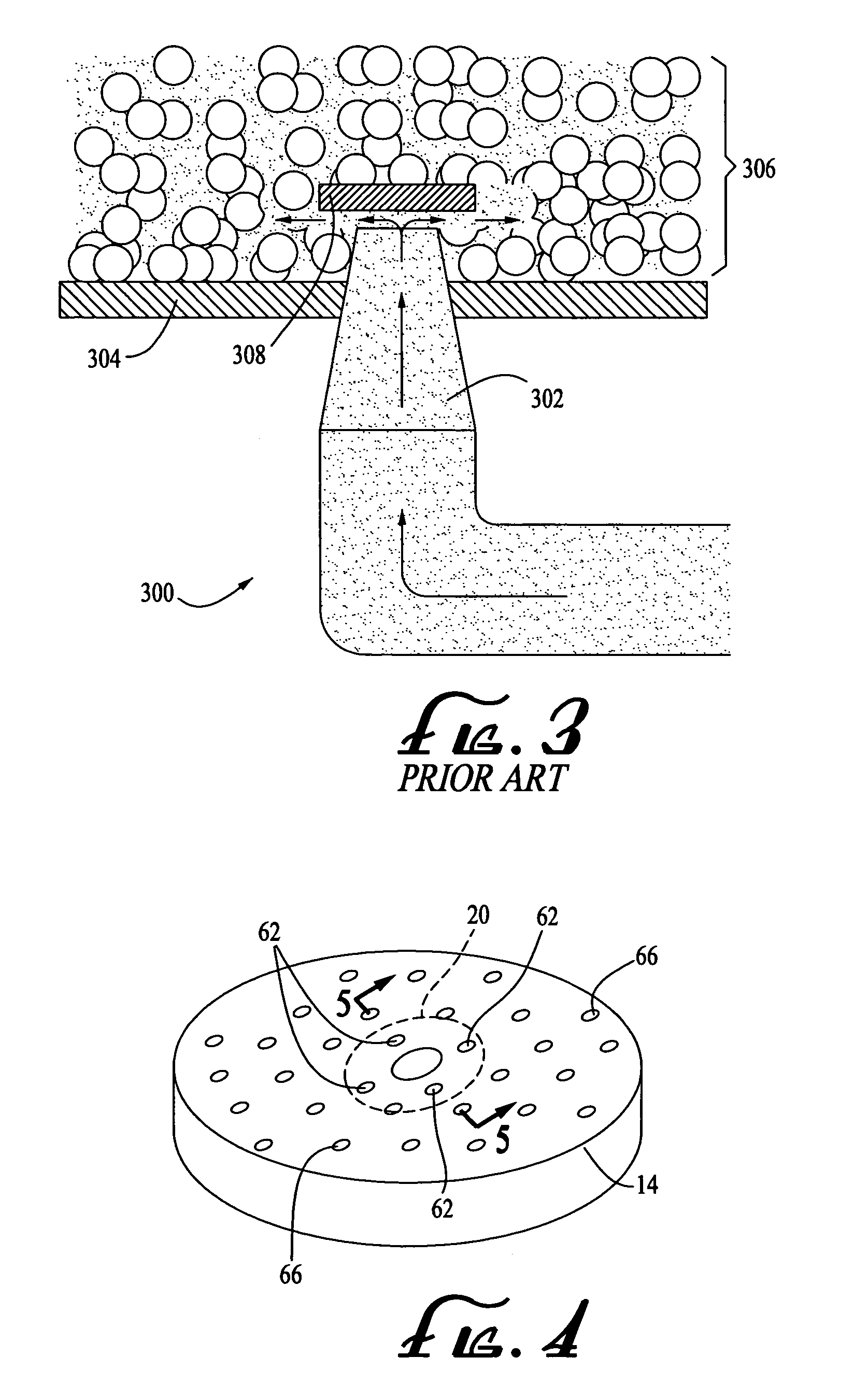

Two phase injector for fluidized bed reactor

A fluidized-bed reactor for producing hydrogen from methane by steam reforming includes a flow splitter that splits a dense-phase flow of a gas having entrained calcium oxide particles into a plurality of equal flow streams. The reactor also incorporates an orifice plate having at least one high-velocity, rocket-style impinging injector for injecting reactants into the reactor bed. The injector includes a central orifice extending perpendicularly through the plate, and one or more adjacent peripheral orifices that extend through the plate at such an angle that respective streams of reactants injected into the reactor bed through the peripheral orifices impinge on a stream of reactants injected vertically into the reactor bed through the central orifice. The injector cooperates with adjacent base-bleed orifices in the plate to provide a uniform distribution and rapid mixing of the calcium oxide particles with a steam / methane gas mixture across the entire bottom of the reactor bed.

Owner:THE BOEING CO +2

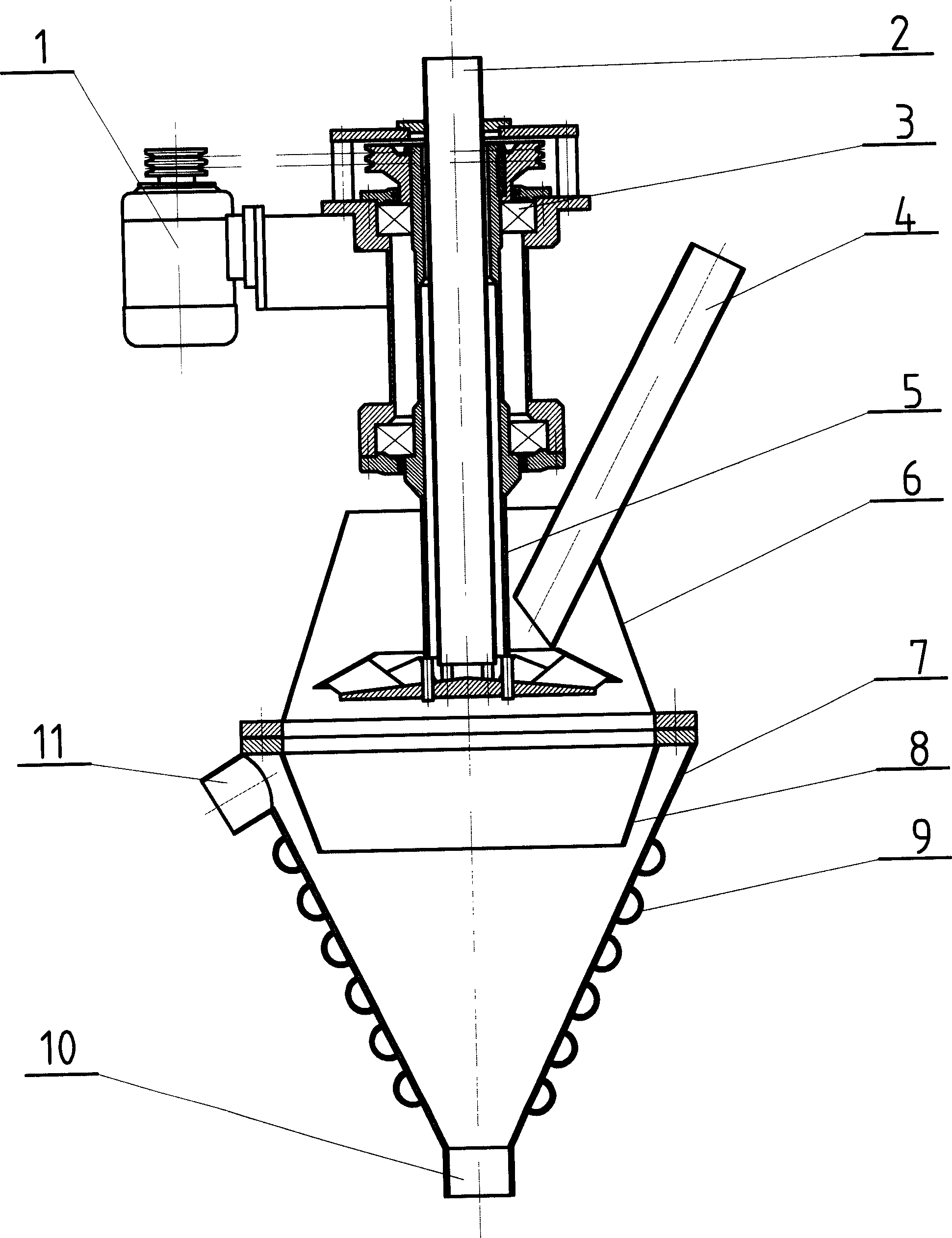

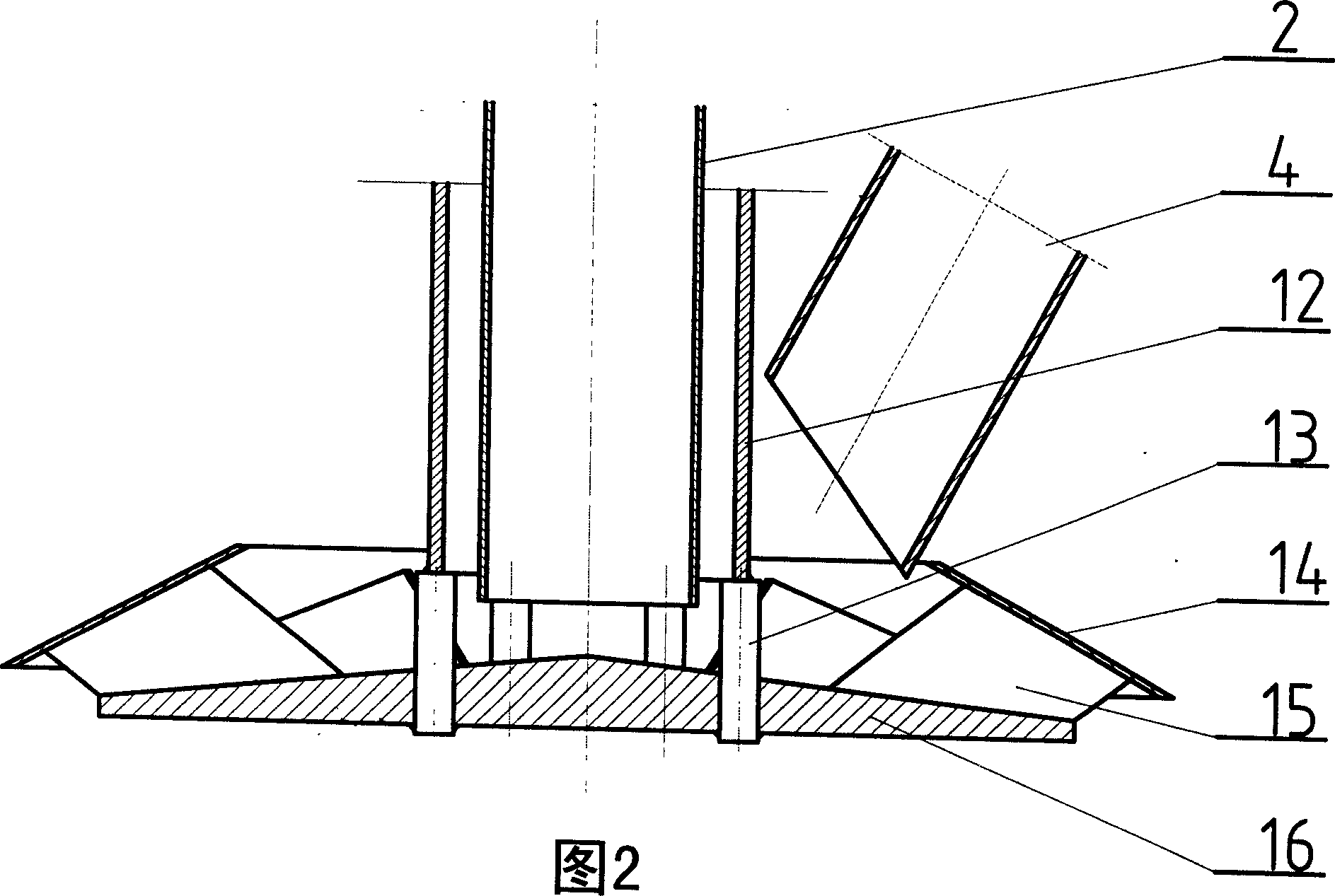

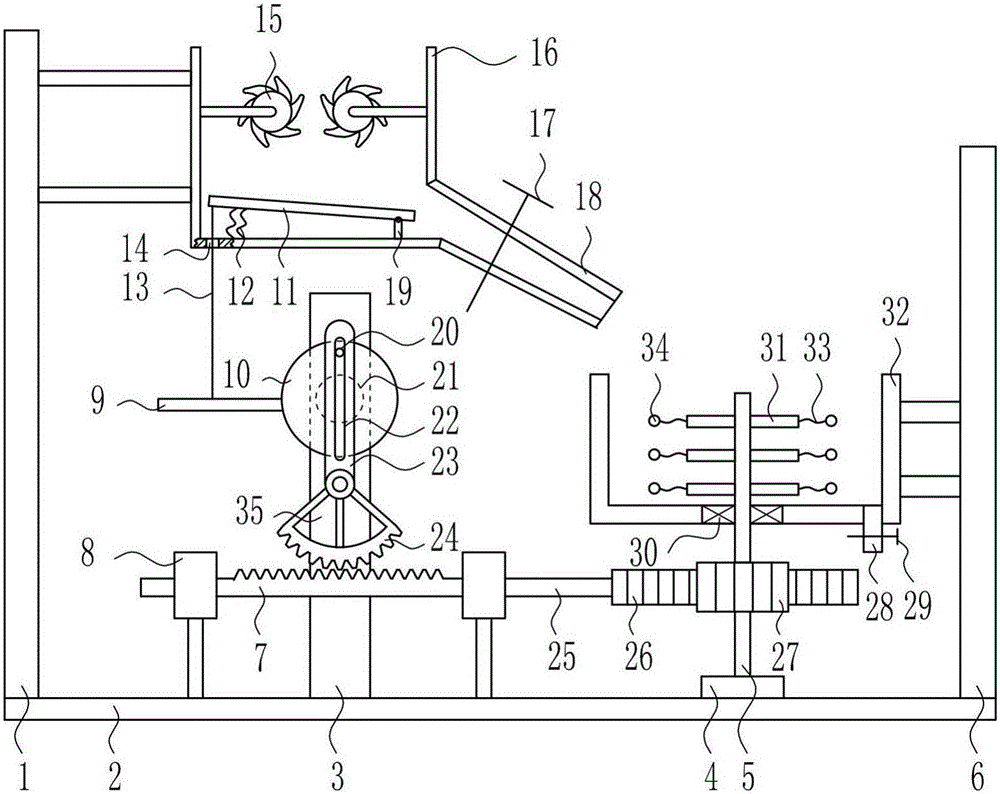

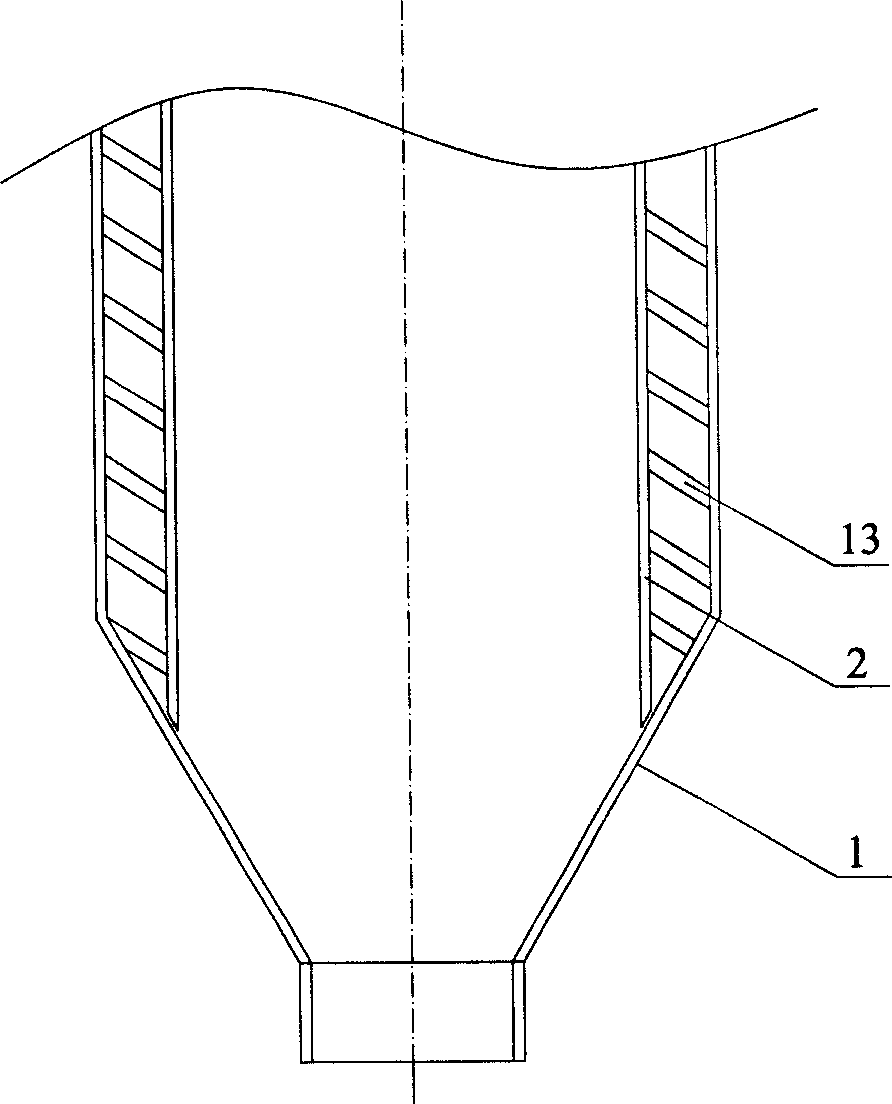

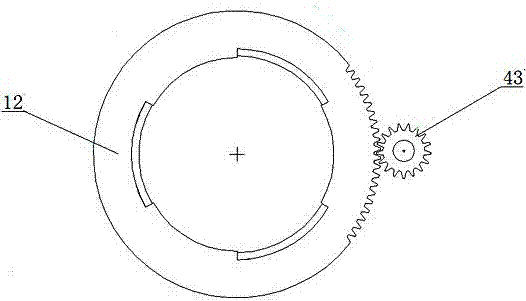

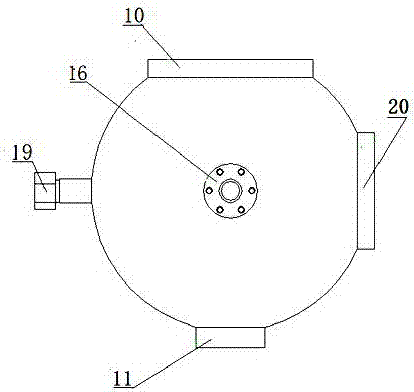

Apparatus for quickly mixing chemical melt and solid powder

InactiveCN1721051AAvoiding Agglomerate ProblemsParticle cavitation containmentFlow mixersTransportation and packagingEngineeringBlend time

Quick mixture device for chemical fuse-elements and solid power comprises mixture slot composed with fixed truncated cone upper mixed cone table laid narrow-end-up and lower mixed cone table laid narrow-end-down, and mixture impeller expended into and connected with the mixture table; discharge port; shaft extended into slot and drove by motor and gear mechanism; and inlet pipes for liquid and power expended and feed raw material into mixture impeller to make it rotate and finish the forced mixture depended on centrifuging motion. This invention can mix the raw material quickly and fully, and avoid the generation of new solid suspended matter.

Owner:SHANDONG HOLLY PHARM CO LTD

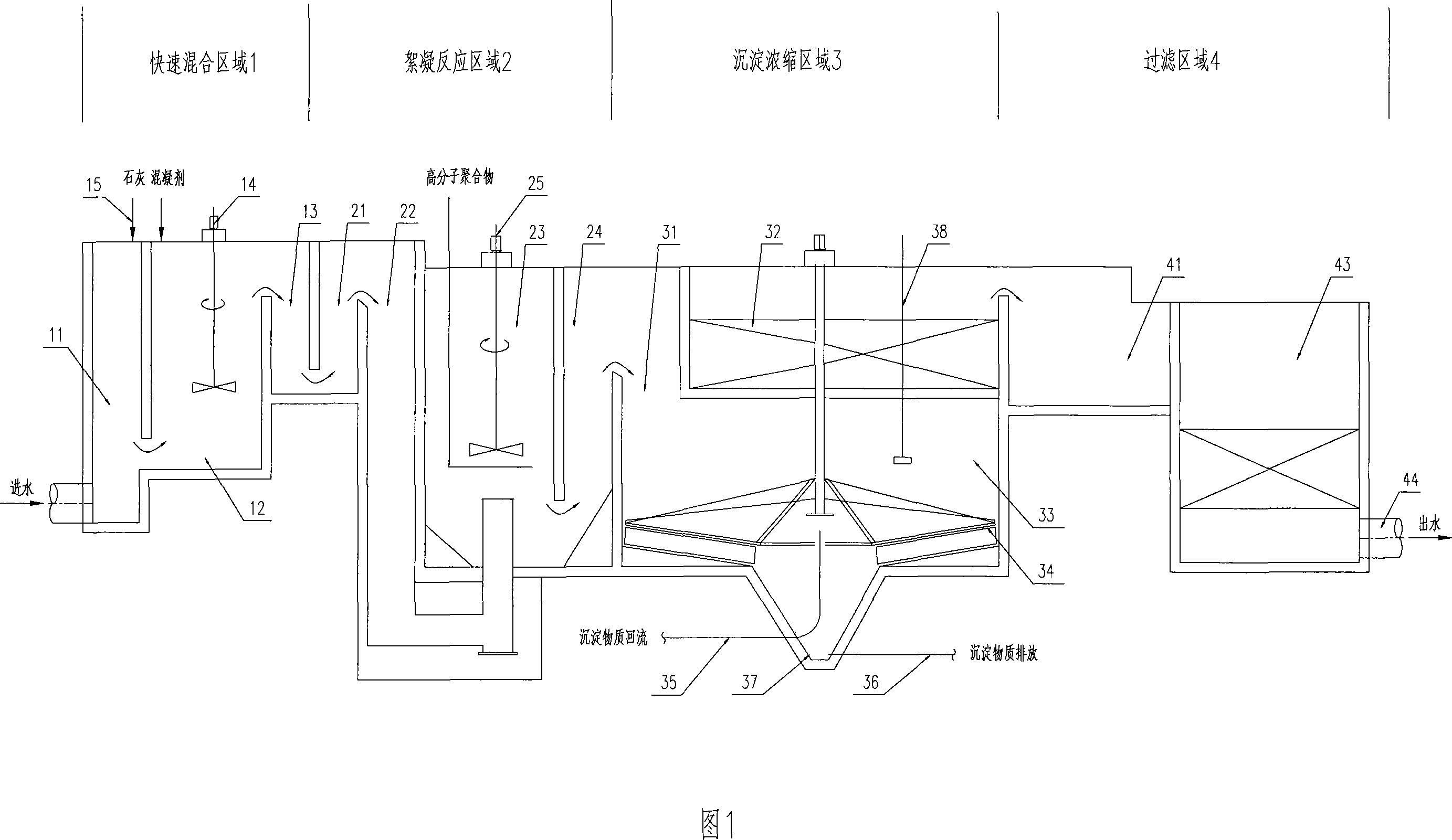

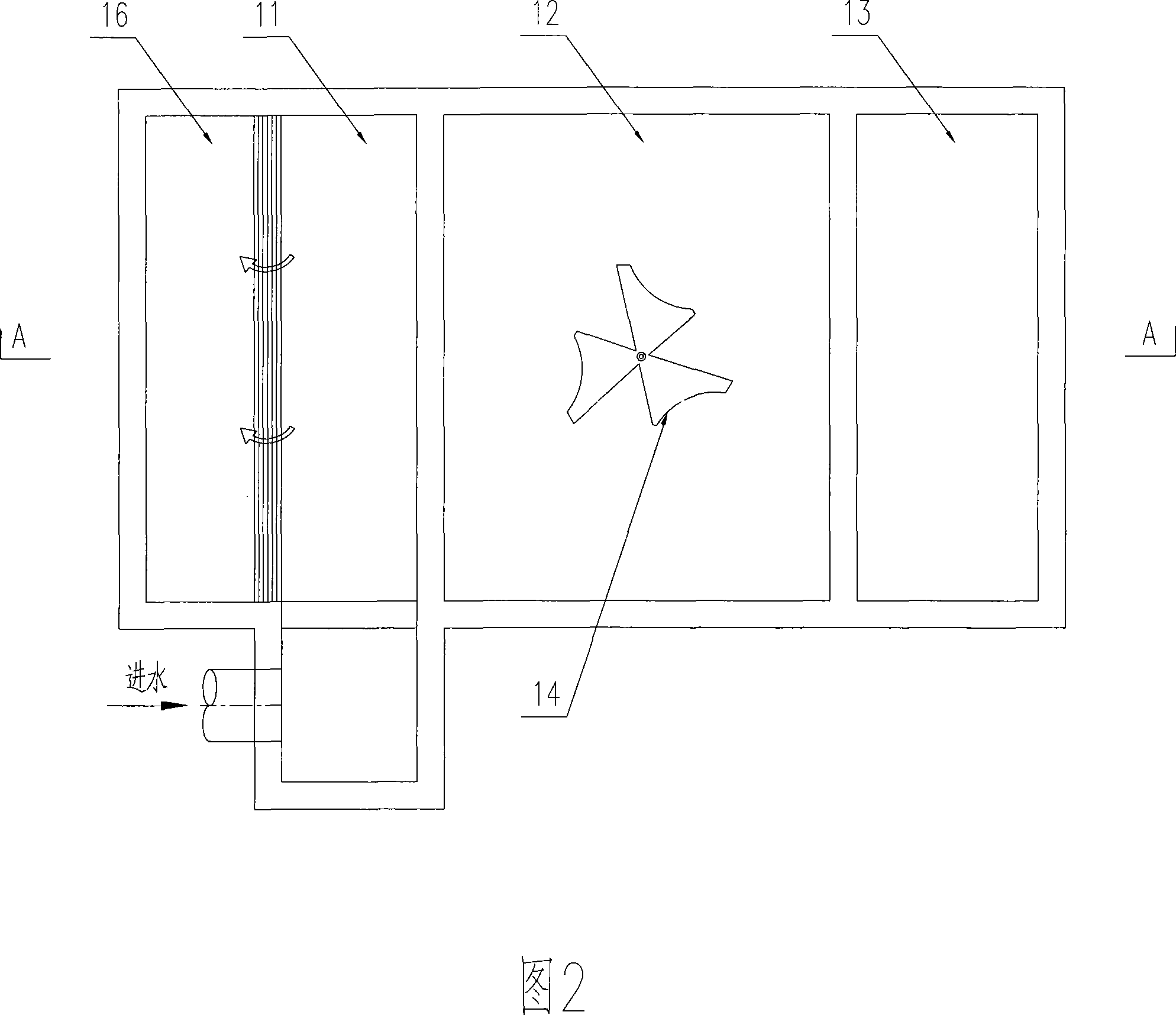

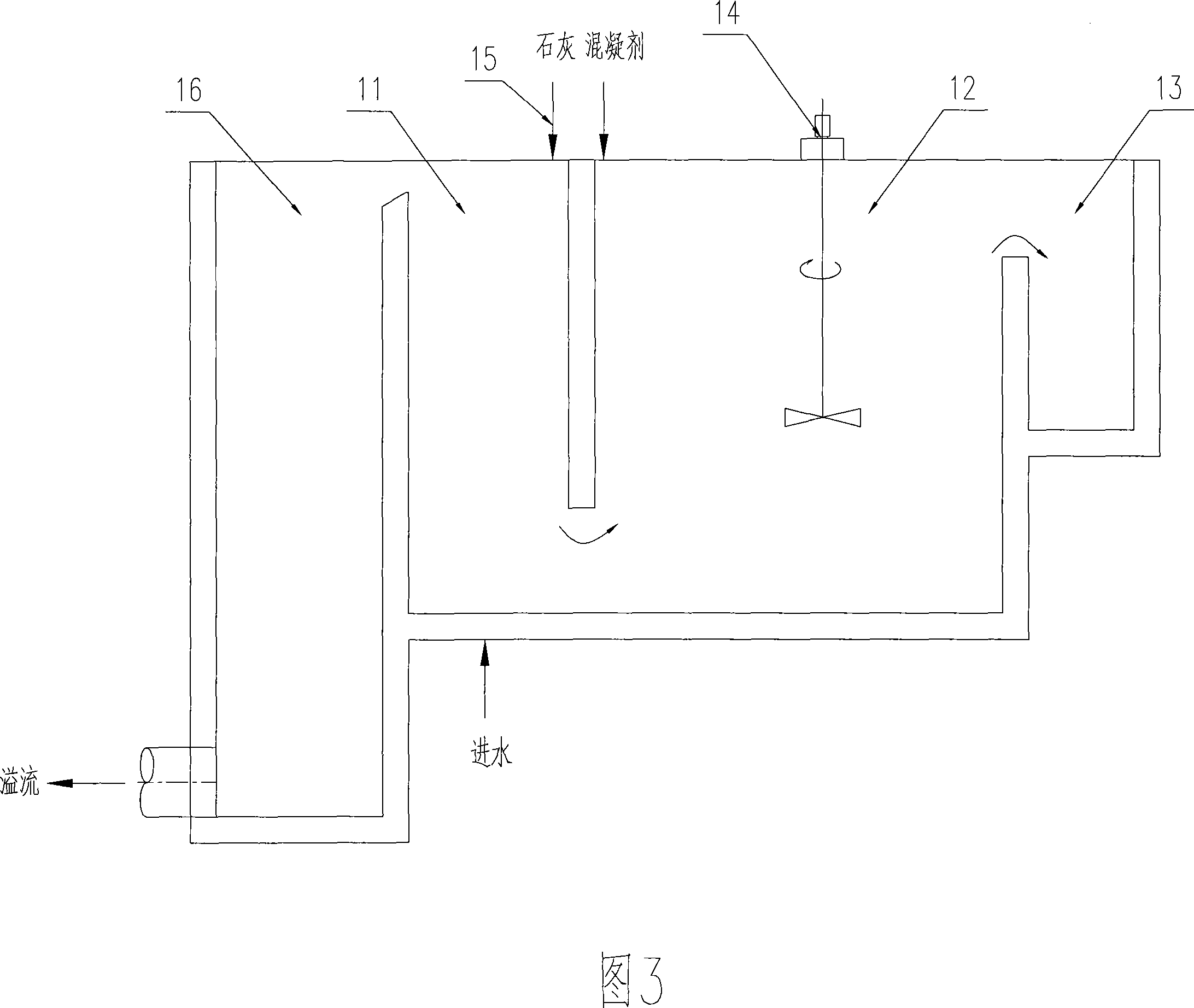

Method and equipment for purifying recirculated cooling water or town B-grade sewage

ActiveCN101117250APromote productionEasy to quantifyWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationPurification methodsWater quality

The invention relates to a purification method and equipment for cool circulating water or town secondary sewage water, and is characterized in that the invention has the following steps: a quick mixing zone 1 for mixing a ready treated liquid and a mixing medicament, a flocculating reaction zone 2 for mixing and flocculating a mixed liquid with a backflow deposit substance to get a compact alum at an outlet of the zone, a depositing and concentrating zone 3 for separating a supernatant liquor and a suspension solid and for returning and draining a deposit substance, and a filtering facility zone 4 for purifying the supernatant liquor; the equipment of the invention mainly comprises the quick mixing zone, a high efficient clarification tank and a filtering zone; the invention designs the purification method and equipment for liquid and water; the water quality from the invention is stable, the cost is lower, which changes the prior purification method for liquid and water.

Owner:华电水务(天津)有限公司

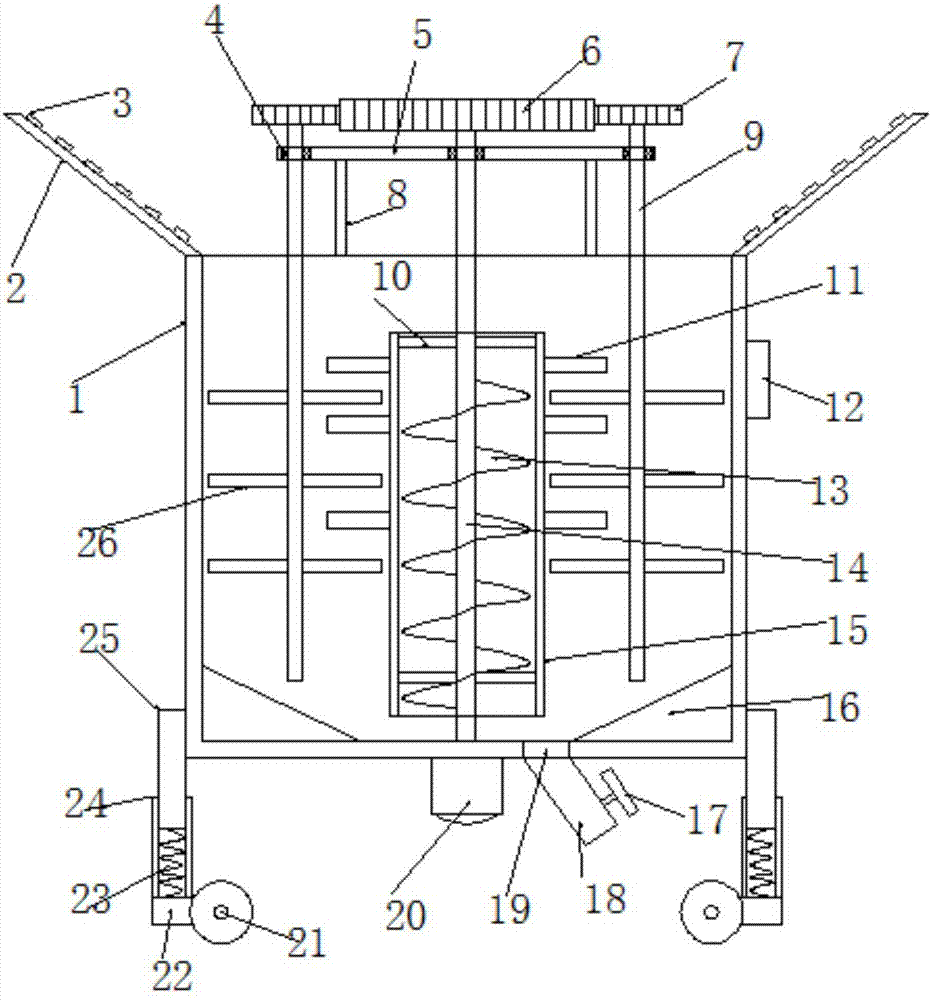

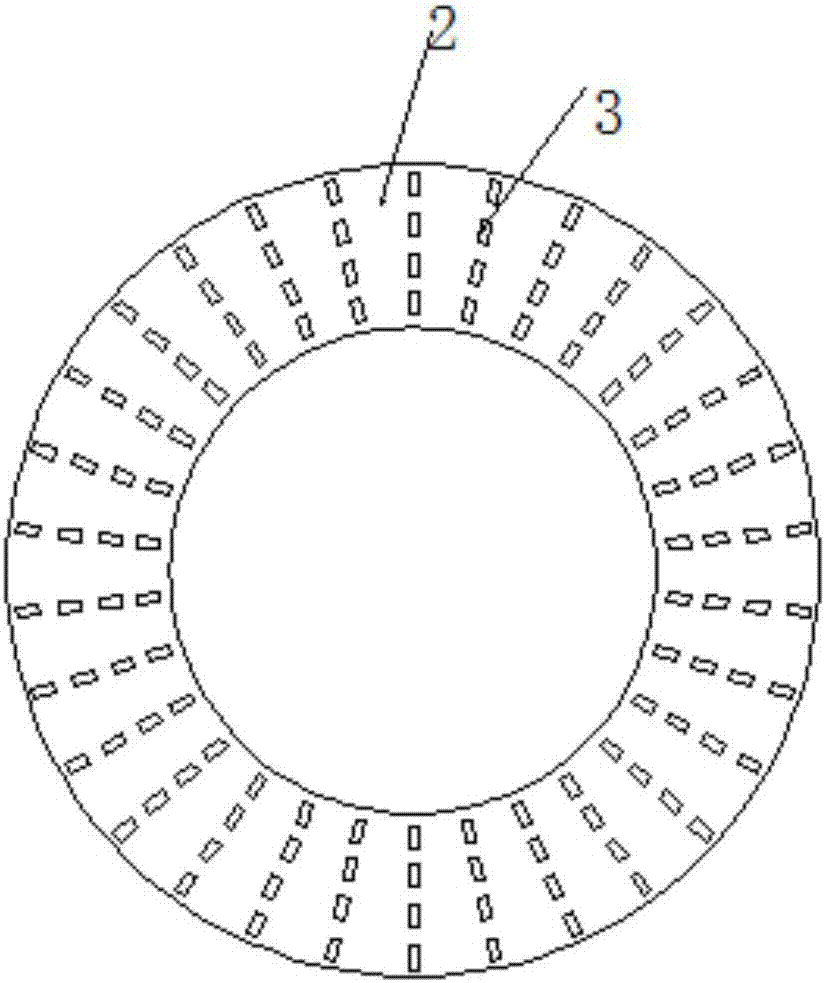

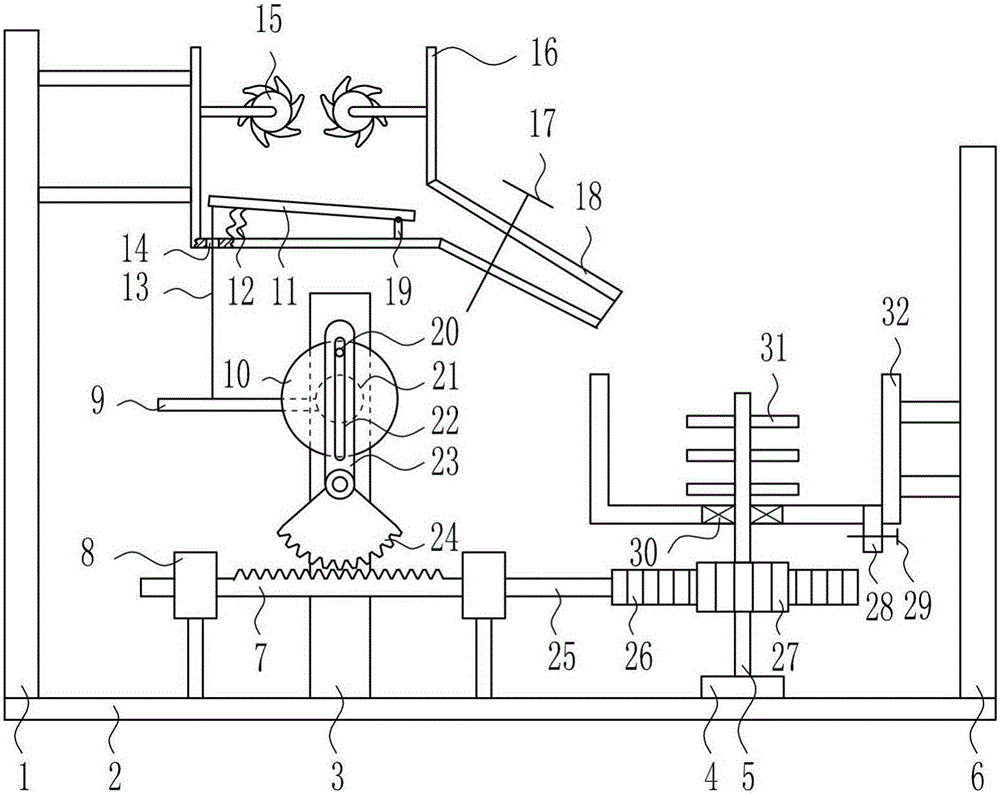

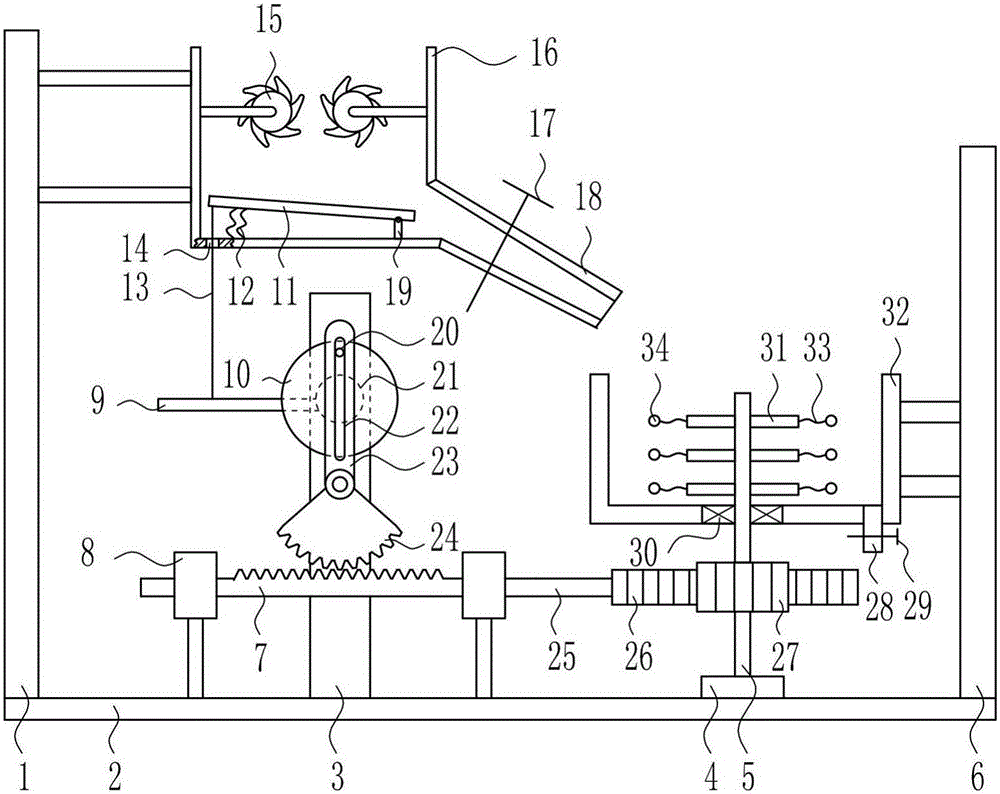

Agitator used for livestock feed processing

PendingCN107321223AImprove the mixing effectQuick mixTransportation and packagingRotary stirring mixersHelical bladeDrive motor

The invention discloses an agitator used for livestock feed processing. The agitator used for livestock feed processing comprises a stirring box; the stirring box is a cylinder with an opening on the upper end; the opening on the upper end of the stirring box is provided with a feed hopper; dispersing blocks are uniformly arranged in the feed hopper; a driving motor is fixedly arranged at the middle part of the lower end of the stirring box; an output terminal of the driving motor is provided with a material pushing shaft; the material pushing shaft in the stirring box is sleeved by a lifting barrel; the upper end and the lower end of the lifting barrel are fixedly connected with the material pushing shaft via fixing rods; a helical blade is arranged on the material pushing shaft in the lifting barrel; No.1 stirring rods are symmetrically arranged on the outside of the lifting barrel; the upper end of the material pushing shaft is fixedly provided with a driving gear. The agitator is simple and reasonable in structure design, is convenient to move, possesses buffer performance, is capable of realizing convection stirring of upper layer material with lower layer material in stirring, realizing reverse stirring of the materials in convection stirring, and improving material stirring effect greatly, is convenient for material rapid mixing, and is high in practicality.

Owner:ZHENGZHOU UNIV

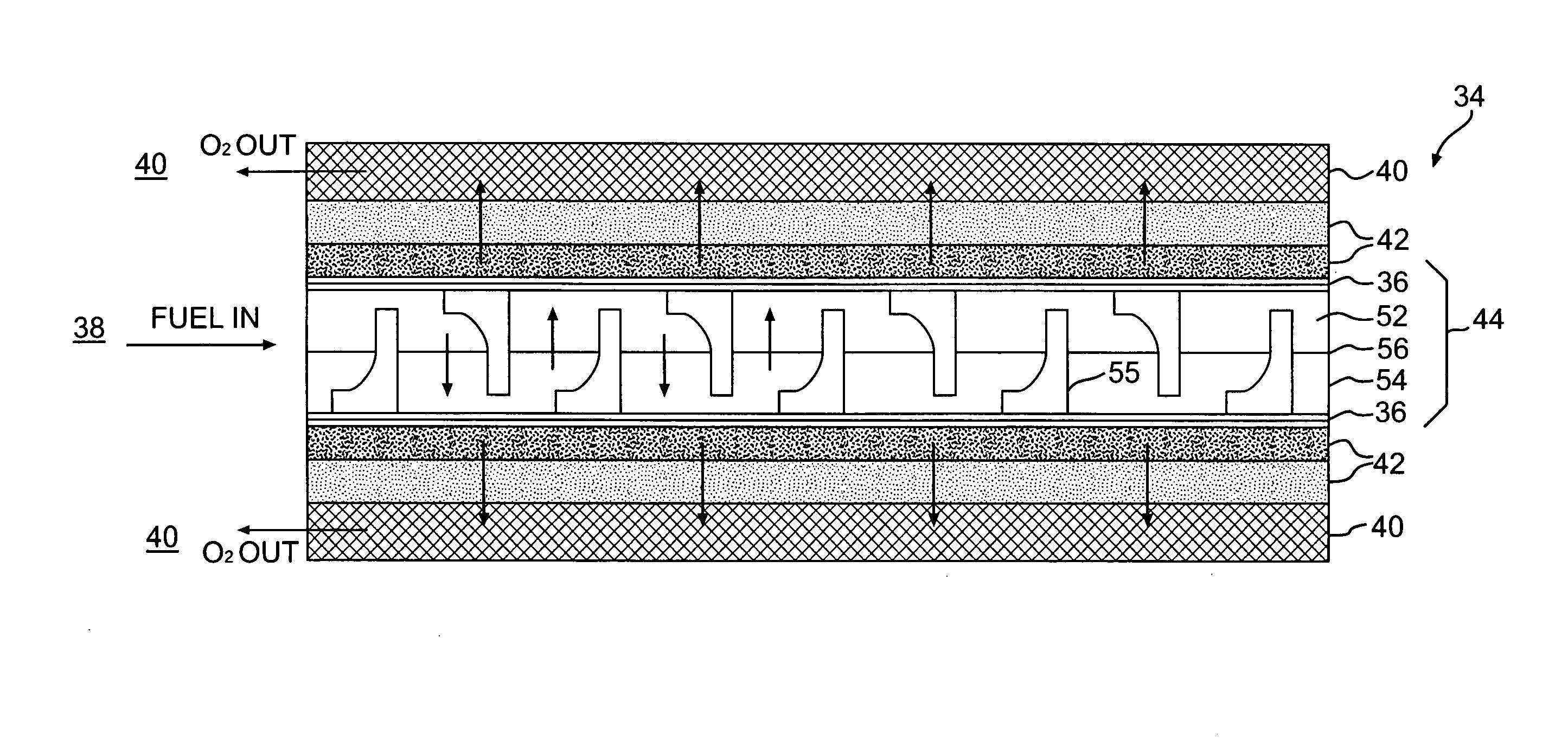

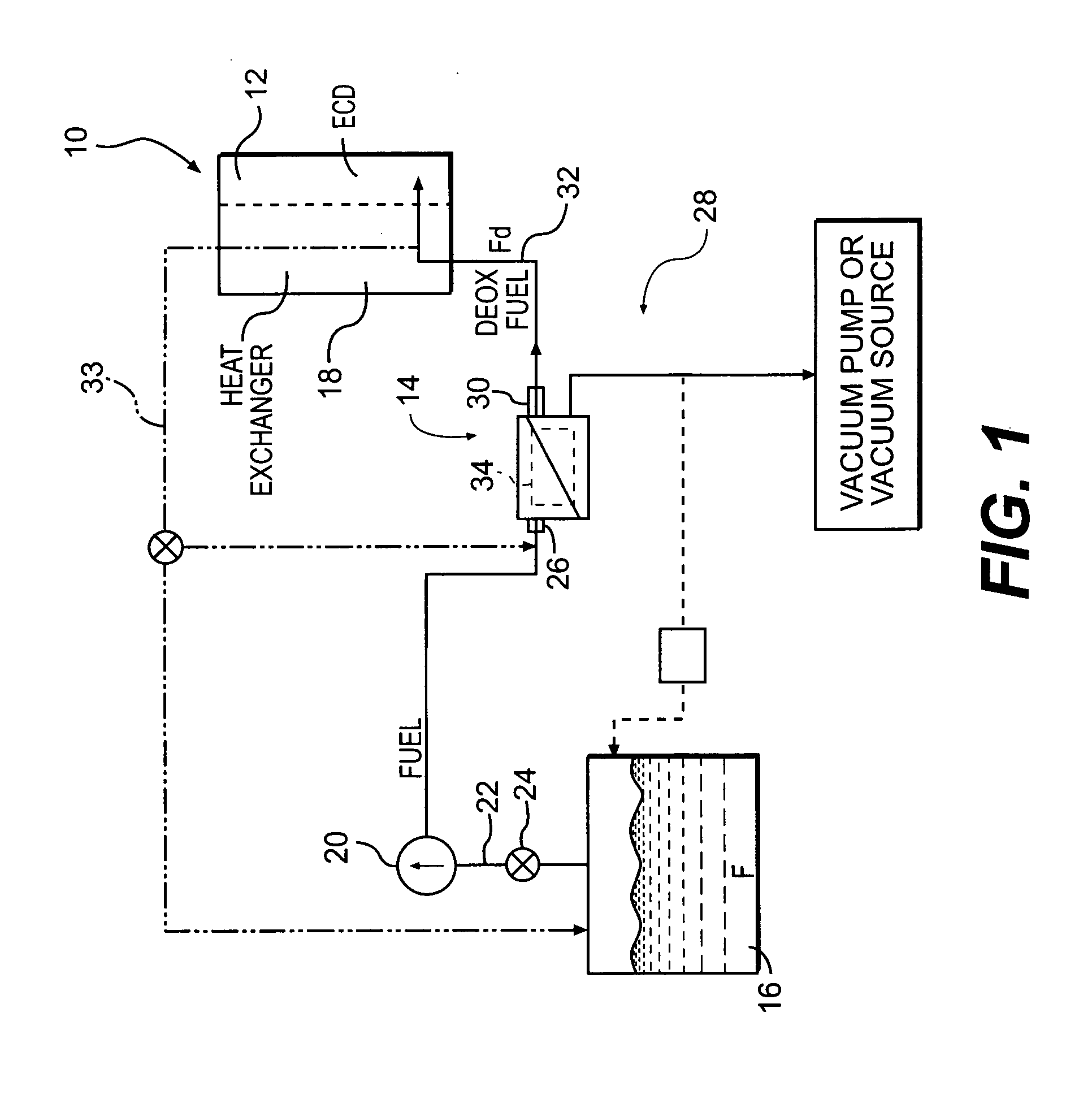

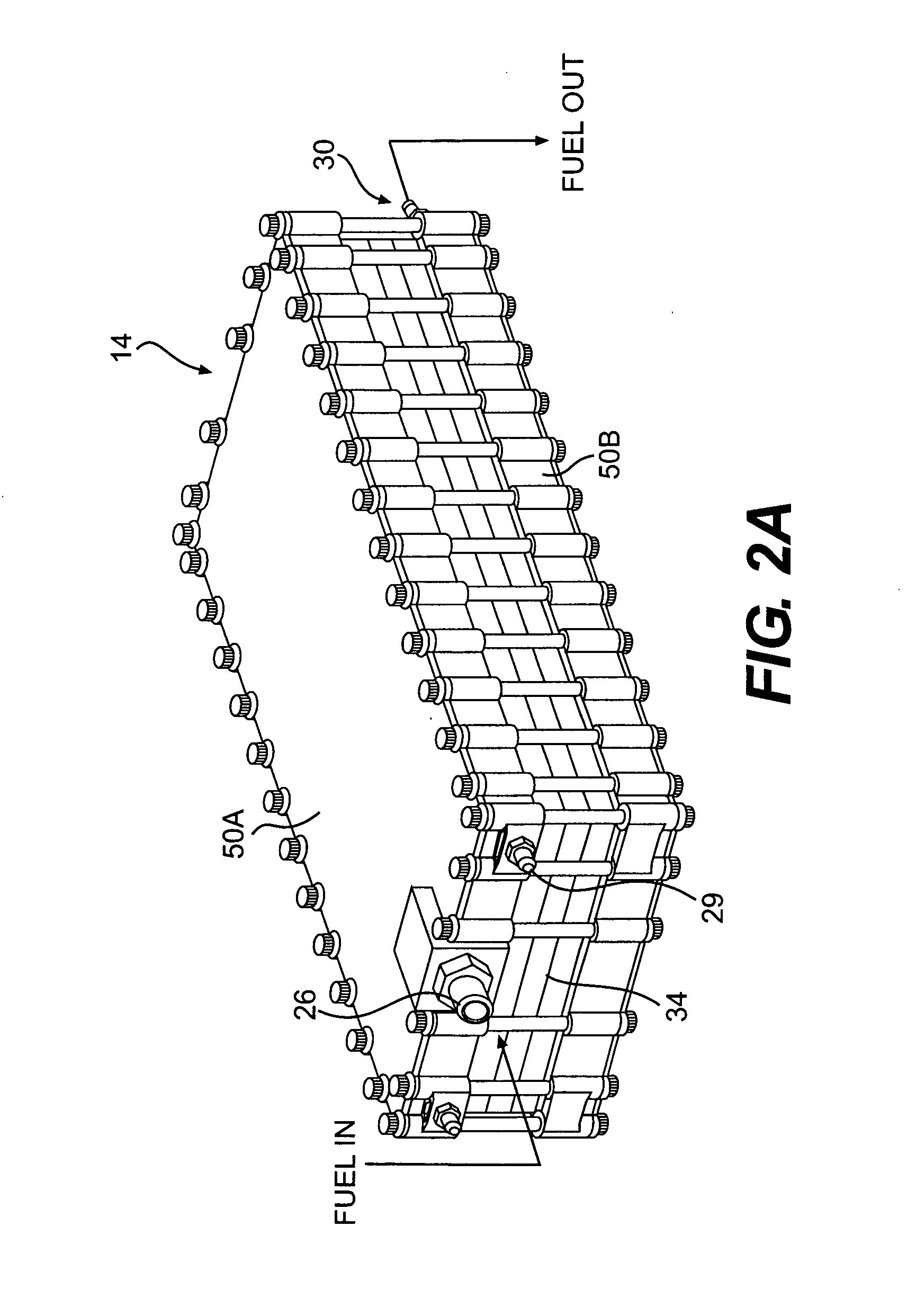

Method for enhancing mass transport in fuel deoxygenation systems

ActiveUS7824470B2Increase mass transportEasy to transportSemi-permeable membranesFlow mixersMembrane surfaceEngineering

A fuel system for an energy conversion device includes a deoxygenator system with a multitude of flow impingement elements which are interleaved to provide a fuel channel with intricate two-dimensional flow characteristics. The flow impingement elements break up the boundary layers and enhance the transport of oxygen from the core of the of the fuel flow within the fuel channel to the oxygen permeable membrane surfaces by directing the fuel flow in a direction normal to the oxygen permeable membrane. The rapid mixing of the relatively rich oxygen core of the fuel with the relatively oxygen-poor flow near the oxygen permeable membrane enhances the overall removal rate of oxygen from the fuel. Because this process can be accomplished in fuel channels of relatively larger flow areas while maintaining laminar flow, the pressure drop sustained is relatively low.

Owner:RTX CORP

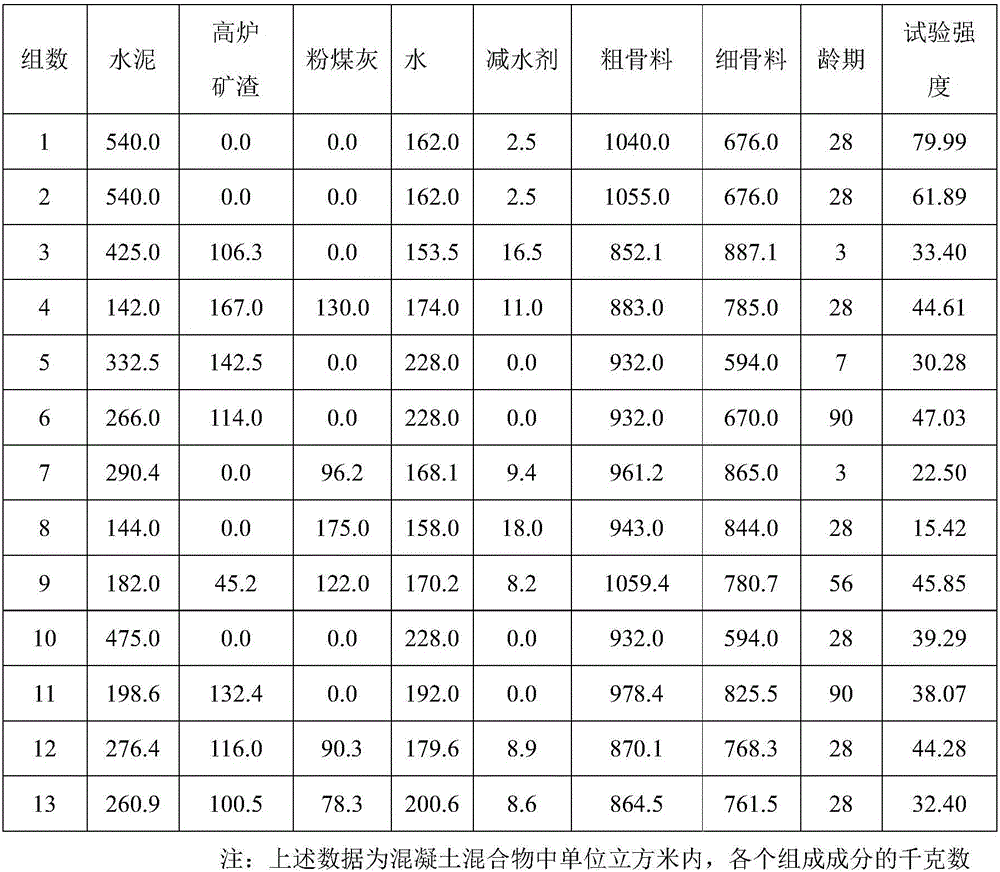

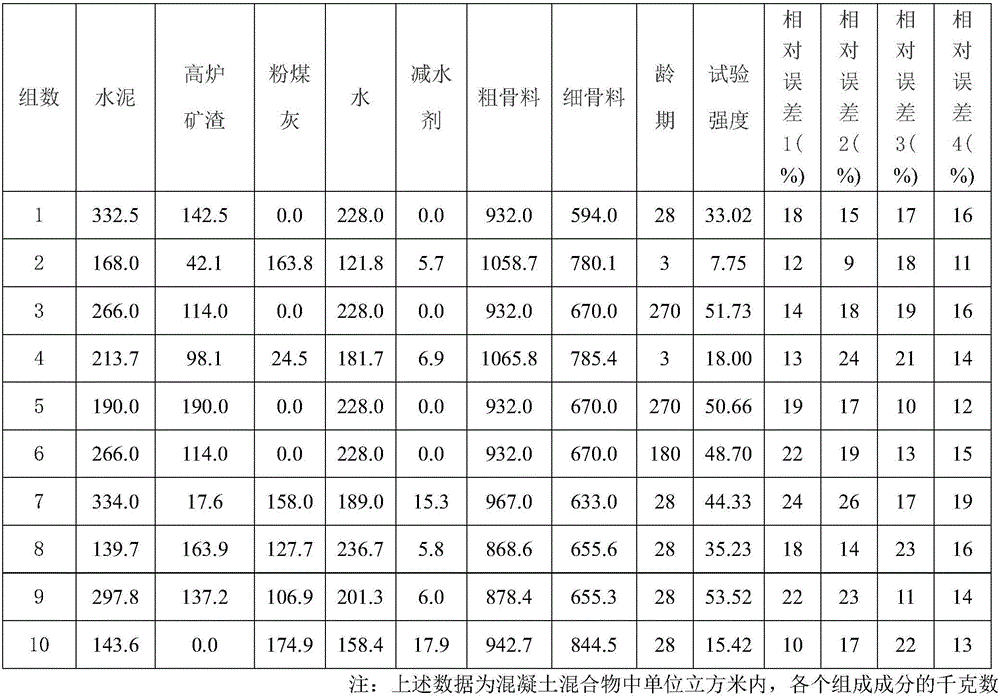

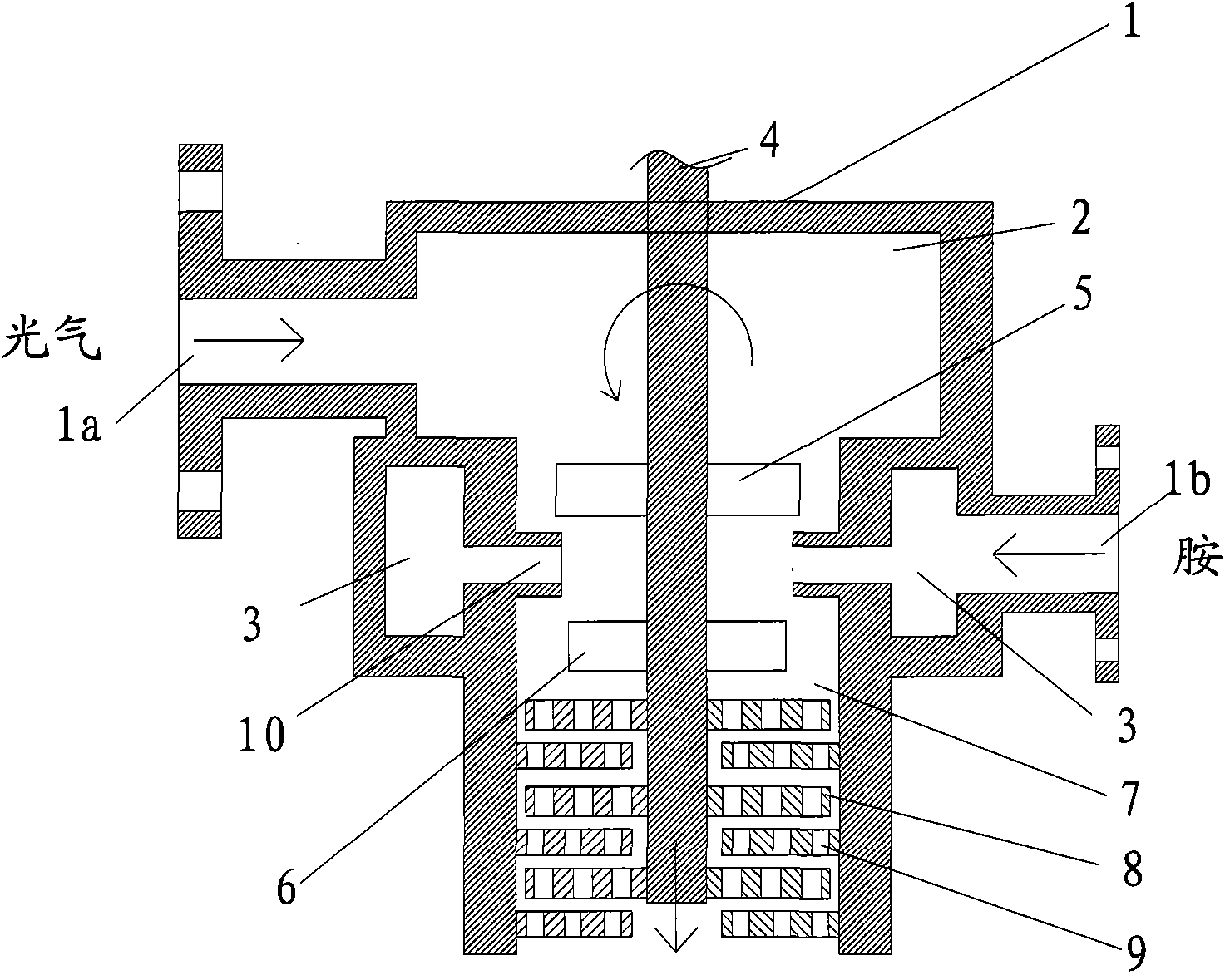

Method for predicting concrete strength based on hybrid model

ActiveCN104991051ASolve the problem that strength testing requires cumbersome, time-consuming, labor-intensive, and labor-intensive manual testingSolve the problem of cumbersome and time-consuming consumables and labor-intensive manual test detectionMaterial testing goodsSlagMixing ratio

The invention discloses a method for predicting the concrete strength based on a hybrid model. The method comprises the following steps: conducting strength experiments on concrete at different mixing ratios on site according to a standard concrete strength detection method, thereby obtaining a plurality of learning samples about the function relationships between cement x1, blast-furnace slag powder x2, fly ash x3, water x4, a water reducing agent x5, a coarse aggregate x6, a fine aggregate x7, a curing period x8 and other concrete component mixing information as well as the concrete strength y; training extreme learning machines, artificial neural networks and support vector machines in the hybrid model, and confirming the optimal extreme learning machine, artificial neural network and support vector machine according to the optimization goal of minimized relative errors; on the basis of the optimal extreme learning machine, artificial neural network and support vector machine, confirming the optimally predicted concrete strength y with a decision function based on adaptive weight according to the predicted values of three modeling methods, wherein the optimally predicted concrete strength y can be utilized for judging whether concrete component input information meets the engineering design requirements or not. Through adoption of the method, the advantages of the three modeling methods are enhanced while the disadvantages of the three modeling methods are avoided, and the comprehensive predicting effect is better, so that the adaptability to different actual work conditions, namely the robustness, can be improved, and important significance is provided for rapid mixing ratio design and quality control for concrete.

Owner:HUAQIAO UNIVERSITY

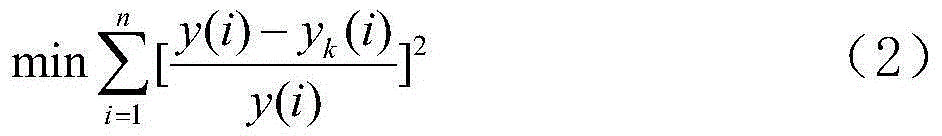

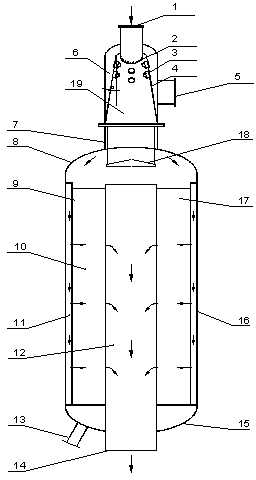

Biomass supercritical and subcritical combined continuous type pretreatment and hydrolysis equipment and method

InactiveCN101613377AAchieving processing powerAchieve hydrolysis conversionSugar derivativesSugar derivatives preparationFiberElectronic temperature

The invention relates to biomass supercritical and subcritical combined continuous type pretreatment and hydrolysis equipment and a method. The equipment comprises a water storage tank, a material storage tank with a stirring device, a preheating system, a supercritical reaction system, a primary cooling system, a subcritical reaction system, a final cooling system, a product collection system and an electronic temperature controlling system. The method comprises the following processing steps: water reaching preheat temperature and biomass material paste are rapidly mixed and then injected into the supercritical reaction system to be pretreated under supercritical condition; the reaction product is cooled through the primary cooling system and depressurized through a pressure reducing valve and then enters into the subcritical reaction system to be hydrolyzed sequentially, therefore fermentable sugars are continuously generated and collected. The invention utilizes the advantages of the supercritical method that the reaction is rapid, activator is not required and product inhibition does not exit, realizes that the continuous hydrolysis conversion of wood fiber biomass can generate fermentable sugars, is the foundation of subsequent resource recovery technologies, such as ethanol production by fermentation and the like, and has wide application prospect.

Owner:TSINGHUA UNIV

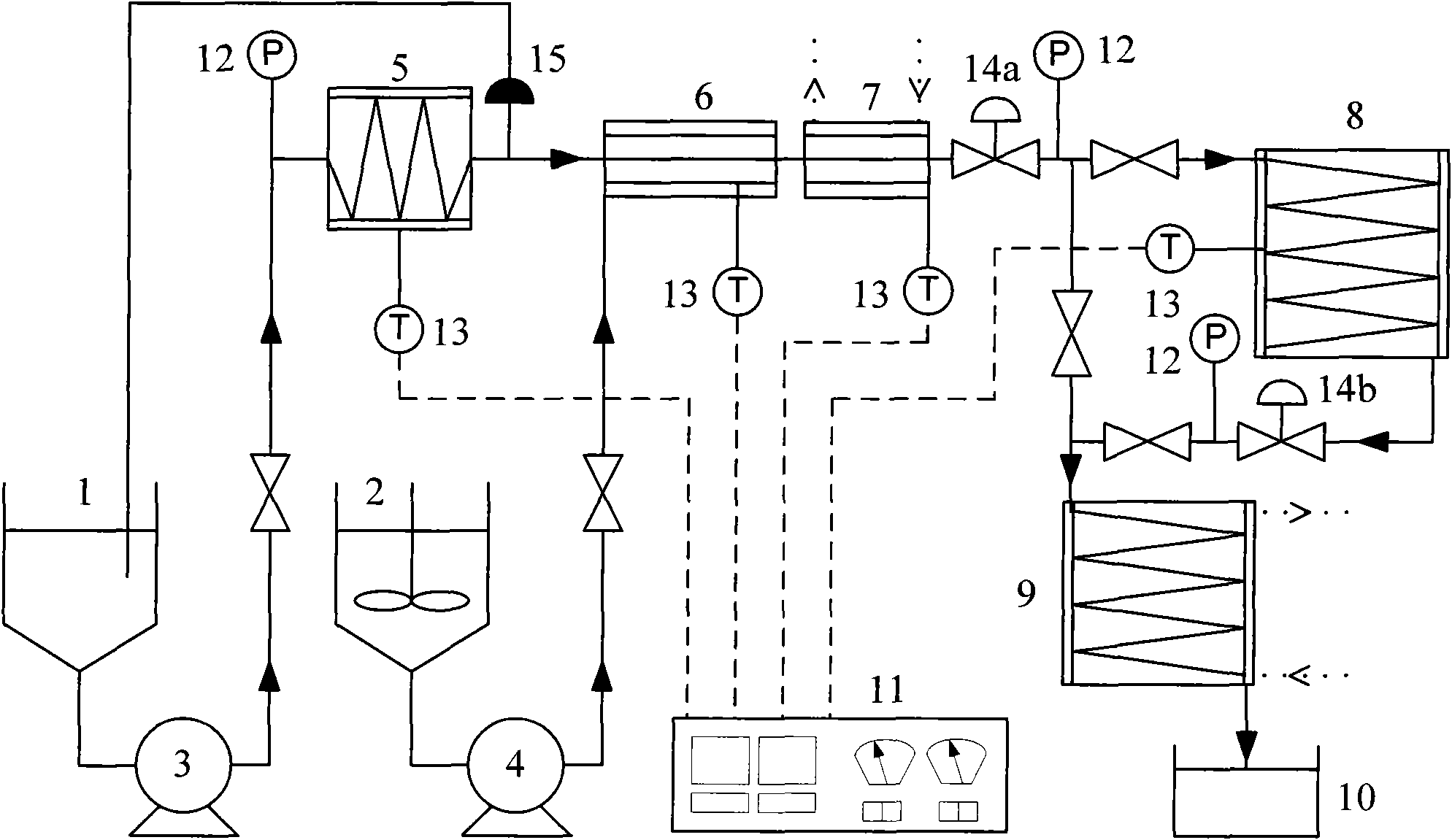

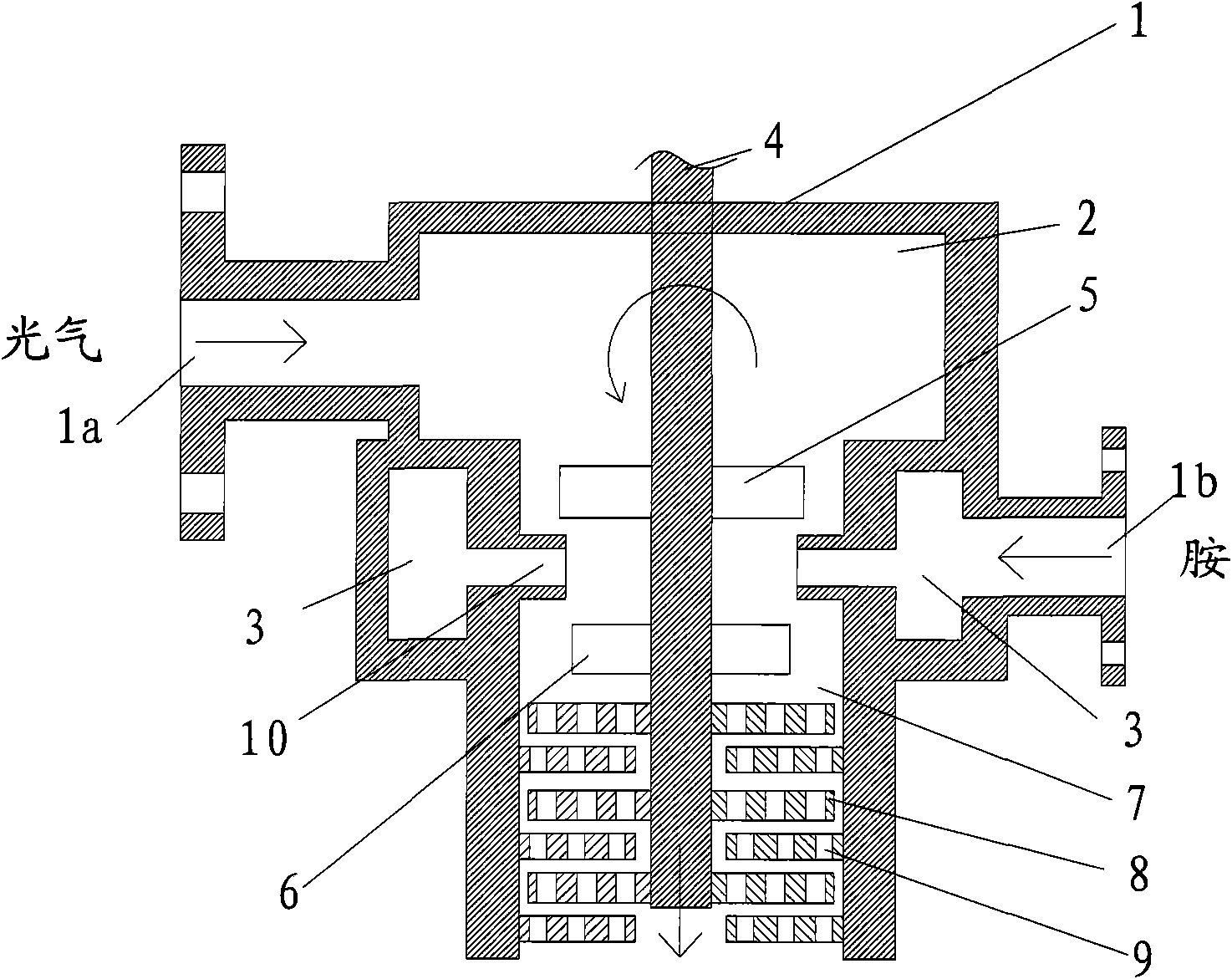

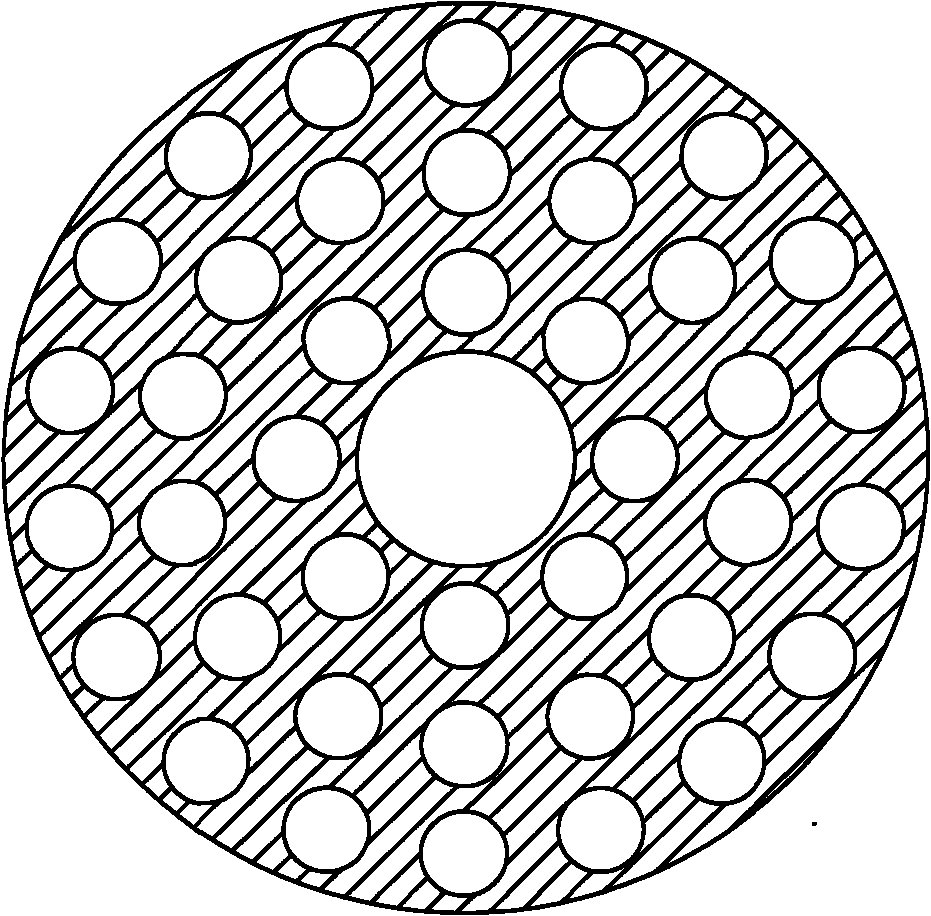

Stirring and grinding reactor and method for preparing isocyanate with same

ActiveCN101811017AIncreased initial mixingRapid responseIsocyanic acid derivatives preparationOrganic compound preparationSolid reactionEngineering

The invention relates to a stirring and grinding integrated reactor and a method for preparing isocyanate by using the reactor. The reactor comprises a reactor shell, a first reactant feeding hole, a first reactant distributing tray, a second reactant main feeding hole, an annular second reactant distributing tray, a stirring shaft, an axial stirring paddle, a radial stirring paddle, a dynamic grinding sheet, a static grinding sheet and at least one second reactant sub feeding hole, wherein the dynamic and static grinding sheets are provided with a plurality of passage holes. Quick mixing and quick reaction between the raw materials are realized by axial and radial strong stirring and a feeding method of a strongest mixing area, and the solid reaction product is further pulverized by hole passage type quick grinding combined through multilayer dynamic and static grinding trays so as to enhance the reaction effect, improve the yield and quality of the isocyanate, reduce the using amount of a solvent and the excess ratio of phosgene, improve the yield of the device, improve the quality of the product and reduce the energy consumption.

Owner:WANHUA CHEM GRP CO LTD +1

Rapid mixing and stirring device for fodder used for animal husbandry

InactiveCN106334477AEasy to useImprove work efficiencyRotary stirring mixersTransportation and packagingEngineeringAnimal husbandry

The invention relates to a mixing and stirring device for fodder used for animal husbandry, in particular to a rapid mixing and stirring device for fodder used for animal husbandry. In order to solve technical problems, the rapid mixing and stirring device for the fodder used for animal husbandry is high in stirring speed, even in stirring and convenient to operate. The rapid mixing and stirring device for the fodder used for animal husbandry comprises a left support, a bottom plate, a fixing plate, a first bearing pedestal, a rotating shaft, a right support, a second gear rack, a guide bush, a swinging rod, a rotating disc, a supporting plate, a first spring, a stay wire and others; the first bearing pedestal and the right support are arranged on the right side of the top of the bottom plate, the right support is located at the right of the first bearing pedestal, a stirring box is arranged in the middle of the left side of the right support, and a second bearing pedestal is arranged in the middle of the bottom of the stirring box. The rapid mixing and stirring device achieves the effects of high stirring speed, even stirring and convenient operation, and is novel in structure, high in practicability and capable of improving the using effect of the fodder after evenly stirring the fodder.

Owner:邵鹏程

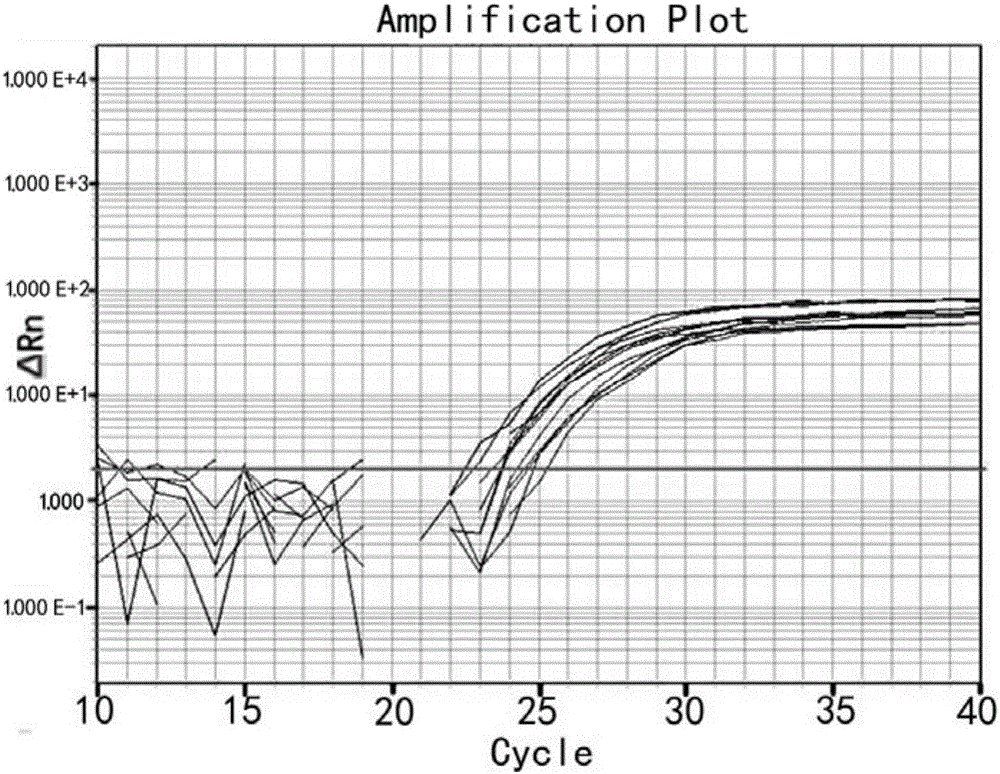

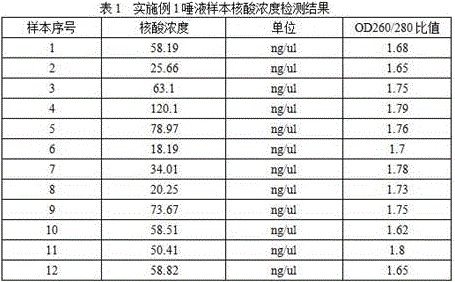

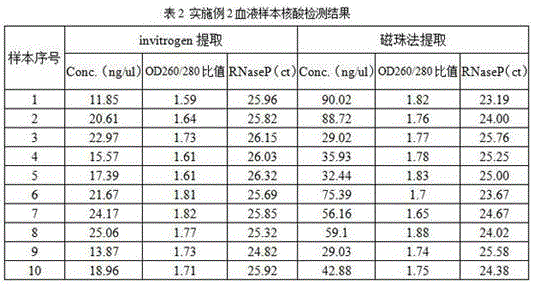

Nucleic acid extraction method by virtue of paramagnetic particle method

The invention discloses a nucleic acid extraction method by virtue of a paramagnetic particle method. The nucleic acid extraction method comprises the following steps: sub-packaging 'N' [mu]M (M refers to mol / L) of sample ('N' is less than or equal to 300 and greater than or equal to 50), 'N' [mu]M of lysate and '0.1N' [mu]M of protease K in a No.1 nucleic acid extraction plate, conducting a cracking reaction at 70 DEG C for 10-60min, and then adding '1.1N' [mu]M of magnetic particle-binding buffer; sub-packaging '2.5N' [mu]M of washing solution A, '2.5N' [mu]M of washing solution B and '0.25-0.5N' [mu]M of TE solution in No.2, No.3 and No.4 nucleic acid extraction plates; and under the action of magnetic force, adsorbing magnetic particles in the No.1 nucleic acid extraction plate by virtue of a magnetic bar, conducting transferring, releasing, rapid mixing and magnetic absorption and sequentially processing the magnetic particles by virtue of the No.2, No.3 and No.4 nucleic acid extraction plates, so as to obtain extracted nucleic acid. With the application of the method disclosed by the invention, the influence of impurities on nucleic acid extraction from saliva and other biological samples is effectively reduced, so that nucleic acid extraction efficiency and nucleic acid purity are improved.

Owner:广东国盛医学科技有限公司

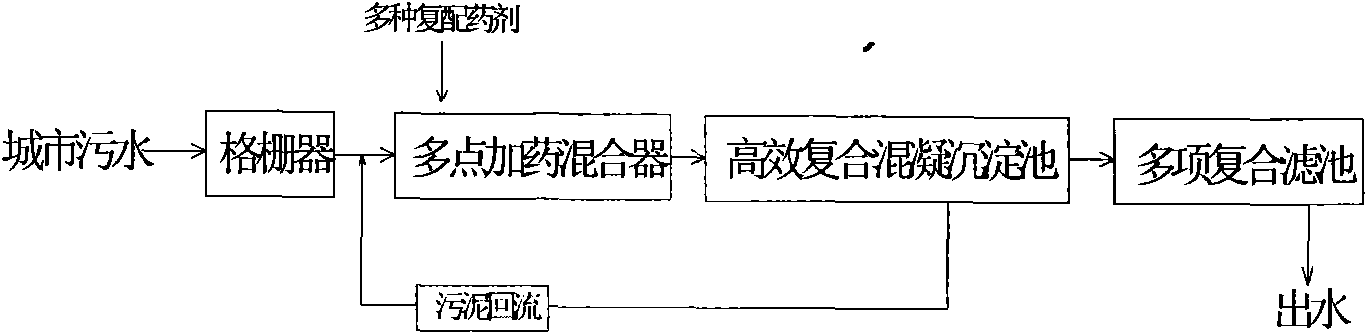

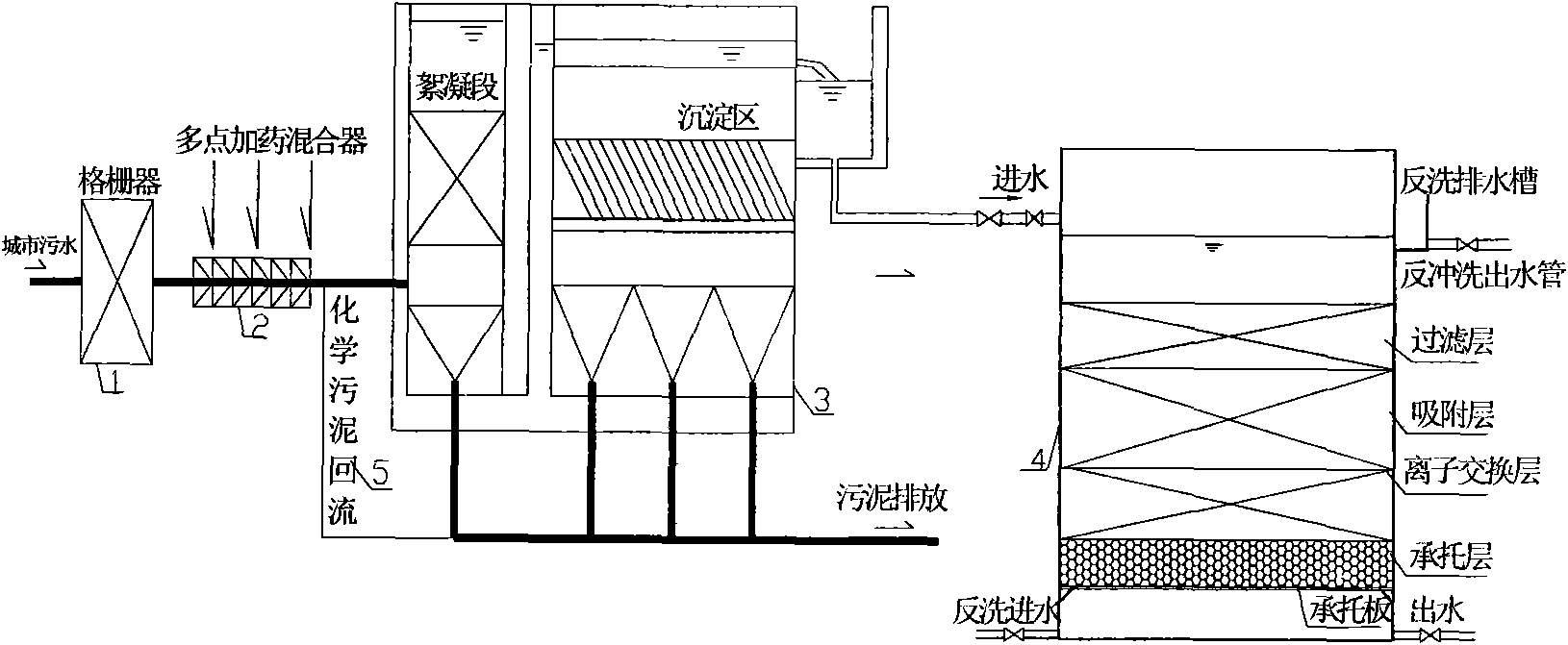

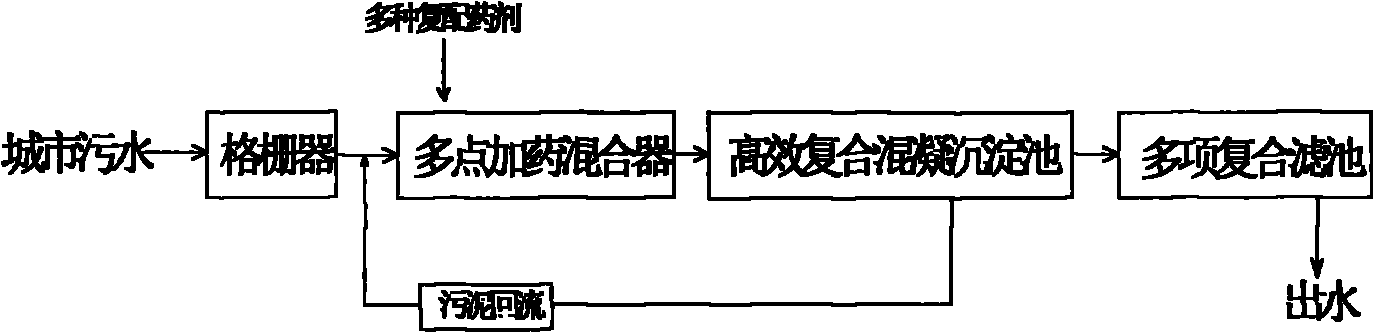

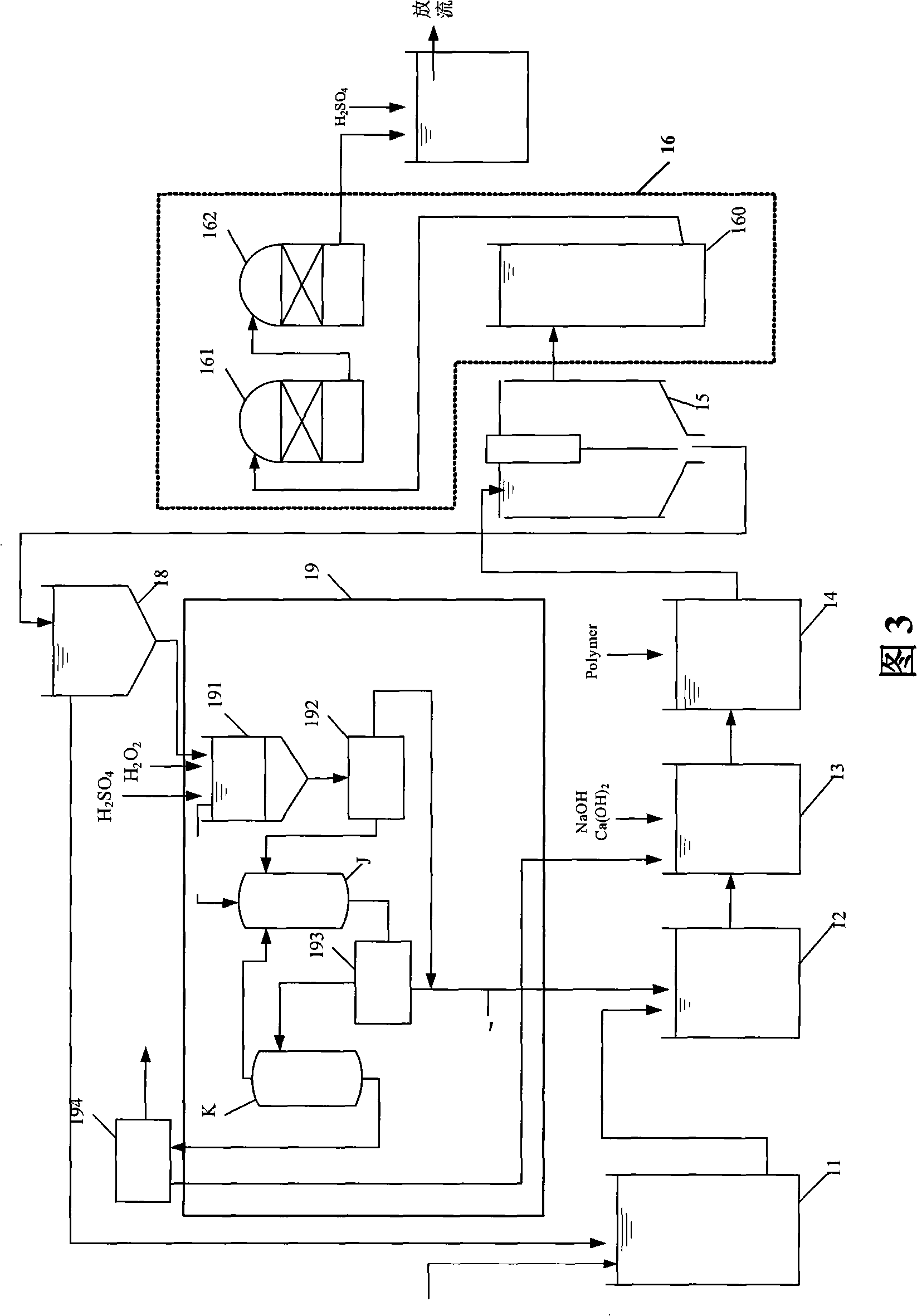

Composite technology for treatment of urban wastewater in complete set of physical and chemical methods

InactiveCN101880101AEnhanced mass transferAchieve efficiencyWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentFiltrationSludge

The invention provides a composite technology for treatment of urban wastewater in a complete set of physical and chemical methods. When the urban wastewater flows into the system, large-particle impurities are basically removed through a grille, the wastewater is then rapidly mixed with a plurality of compound medical preparations and returning chemical sludge in a multi-point dosing mixer and then flows into an efficient complex coagulation-precipitation system for flocculation and precipitation, the supernate after precipitation flows into a multi-phase composite filter, and water is finally discharged after filtration, ion exchange and adsorption. The chemical sludge can be further used for processing building materials after stabilization, acidification, alkalization and chemical phosphorus recovery, thereby realizing the utilization of the sludge resource. The invention has the advantages of low requirements for the ambient temperature and flexible starting and operation. Compared with the complex process for advanced treatment with serial combination of the traditional secondary biological treatment, coagulation, precipitation and filtration, the invention shortens the overall treatment flow, and effectively reduces the infrastructure investment cost.

Owner:王鹤立

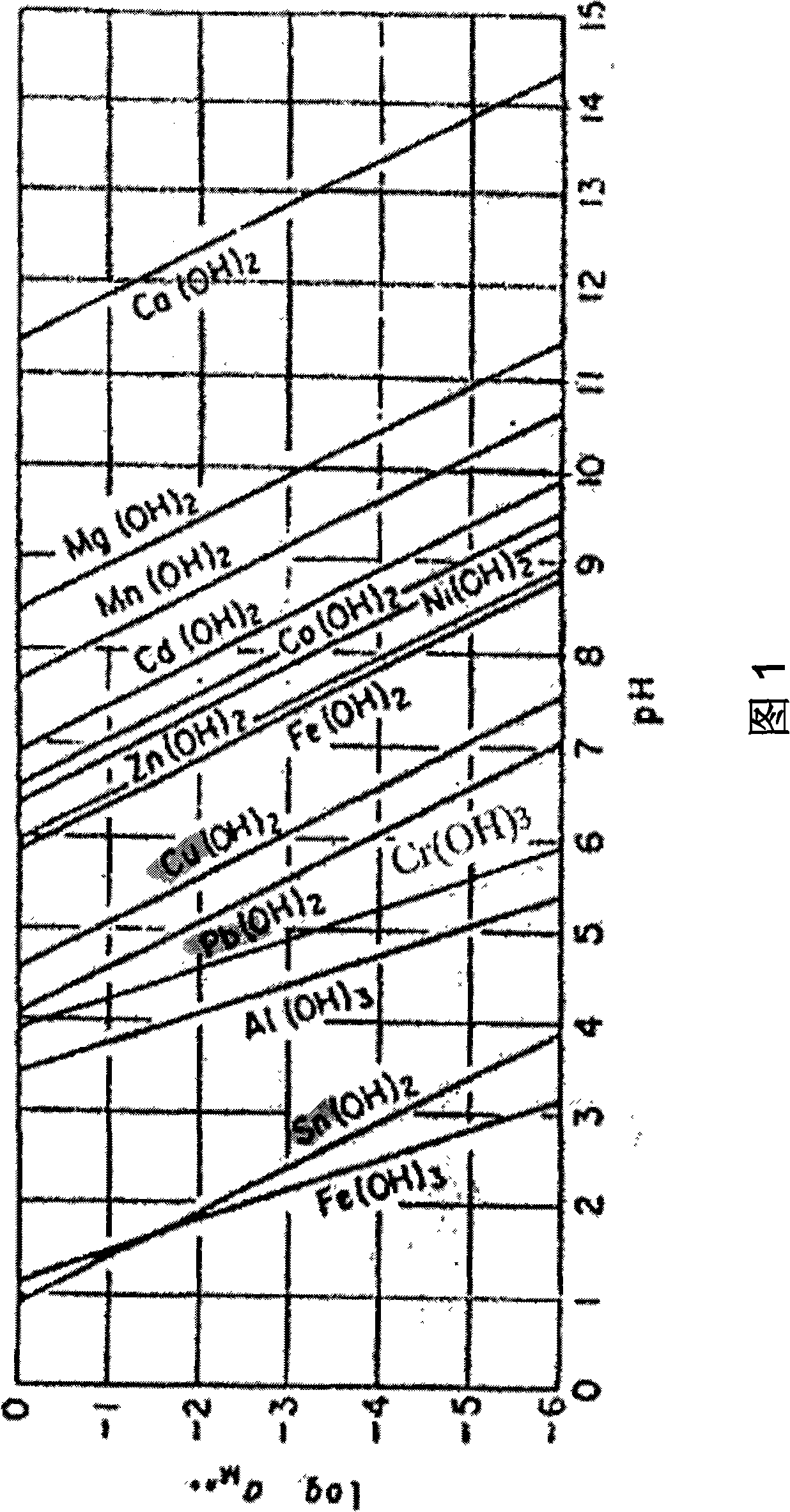

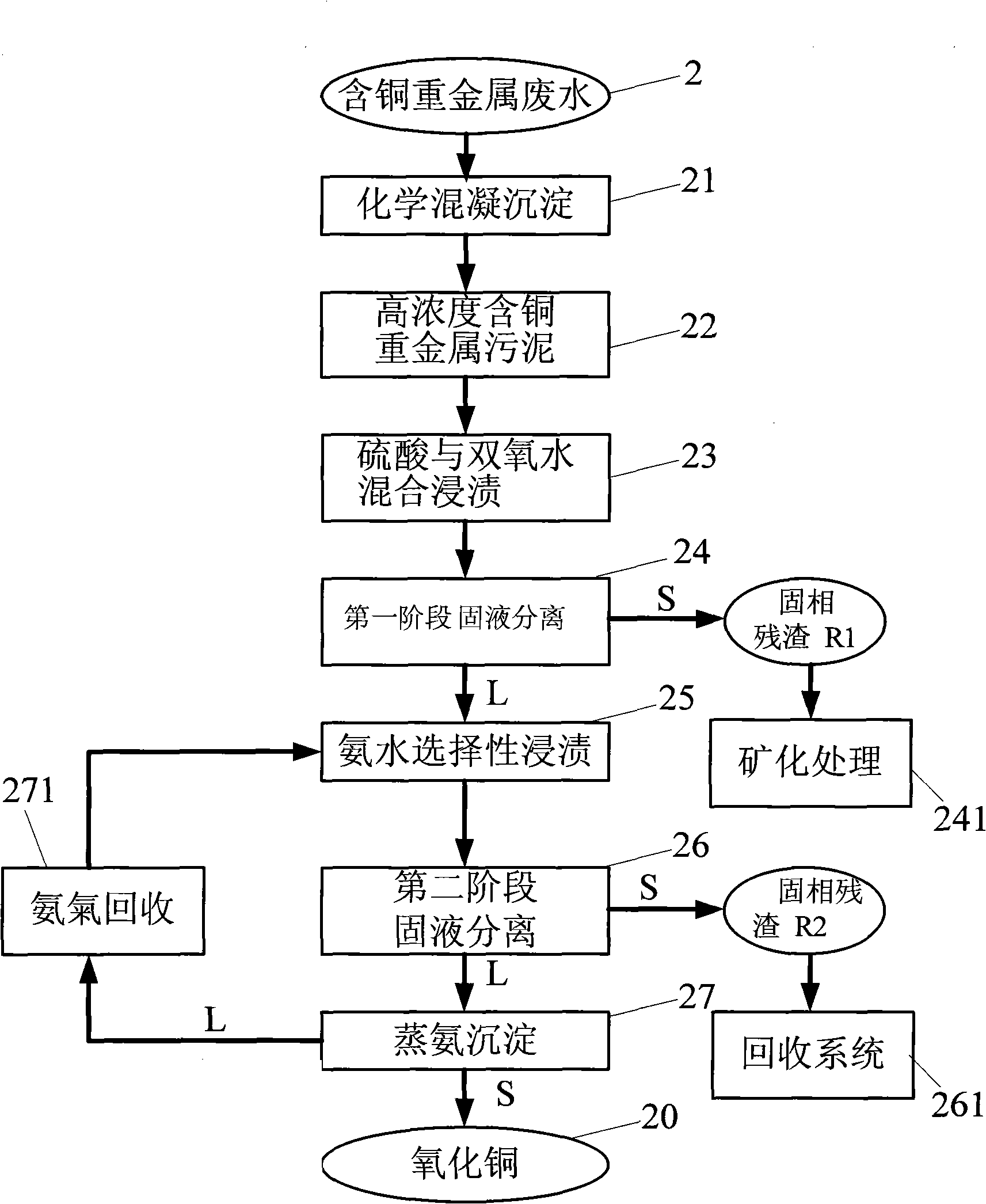

Zero sludge and resource handling arrangement and recovery method of heavy metal waste water

InactiveCN101357809AZero wasteZero pollutionMultistage water/sewage treatmentCopper oxides/halidesRecovery methodHigh concentration

The invention relates to a treatment device and a recovery method for zero sludge resource recovery of heavy metal wastewater, the heavy metal wastewater which mainly contains copper is coagulated and sedimented chemically, after that, sludge with high-concentration copper ions is formed by concentration, the heavy metal sludge is dipped in mixed liquid of sulfuric acid and hydrogen peroxide, thereby obtaining impregnation liquid with the high-concentration copper ions; ammonia water is further used for adjusting the pH value of the impregnation liquid, the selective impregnation is carried out, ammonia copper solution and residues which are rich in iron or aluminium can be obtained after the solid-liquid separation, the ammonia copper solution is done with the procedure of heating and ammonia distillation, then copper oxide and ammonia with very high utilization values can be obtained by recovery, wherein, the generated residues are recovered to be directly added in a rapid mixing tank during the wastewater treatment process as a coagulating agent, the harmless treatment is carried out by wet treatment, or the resource recovery is carried out by using the dry smelting method to recover the iron or the aluminium, and the generated ammonia during the procedure of heating and ammonia distillation can be recovered and reused. The purposes of zero sludge, zero waste and zero emission output can be achieved.

Owner:蔡敏行

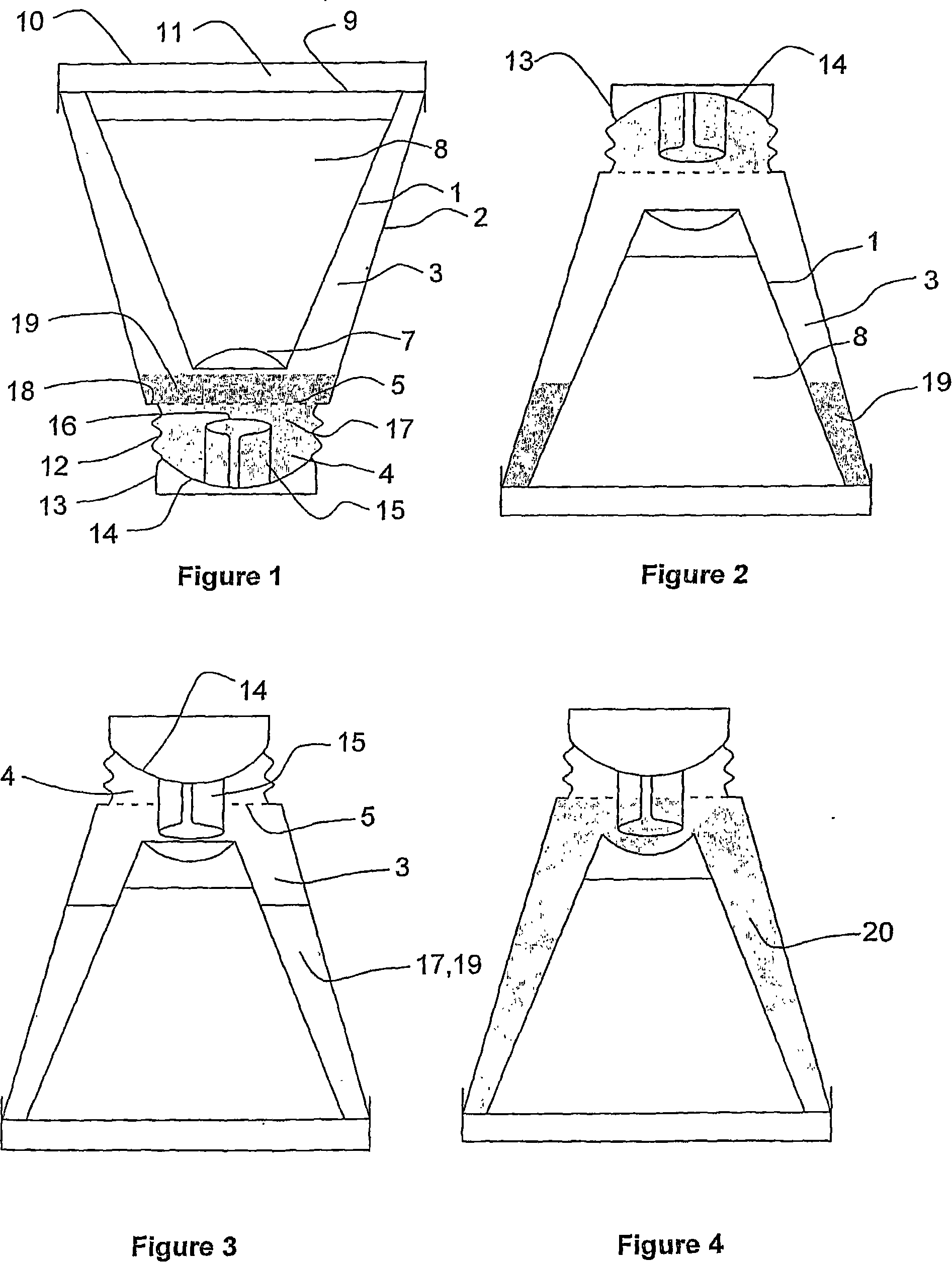

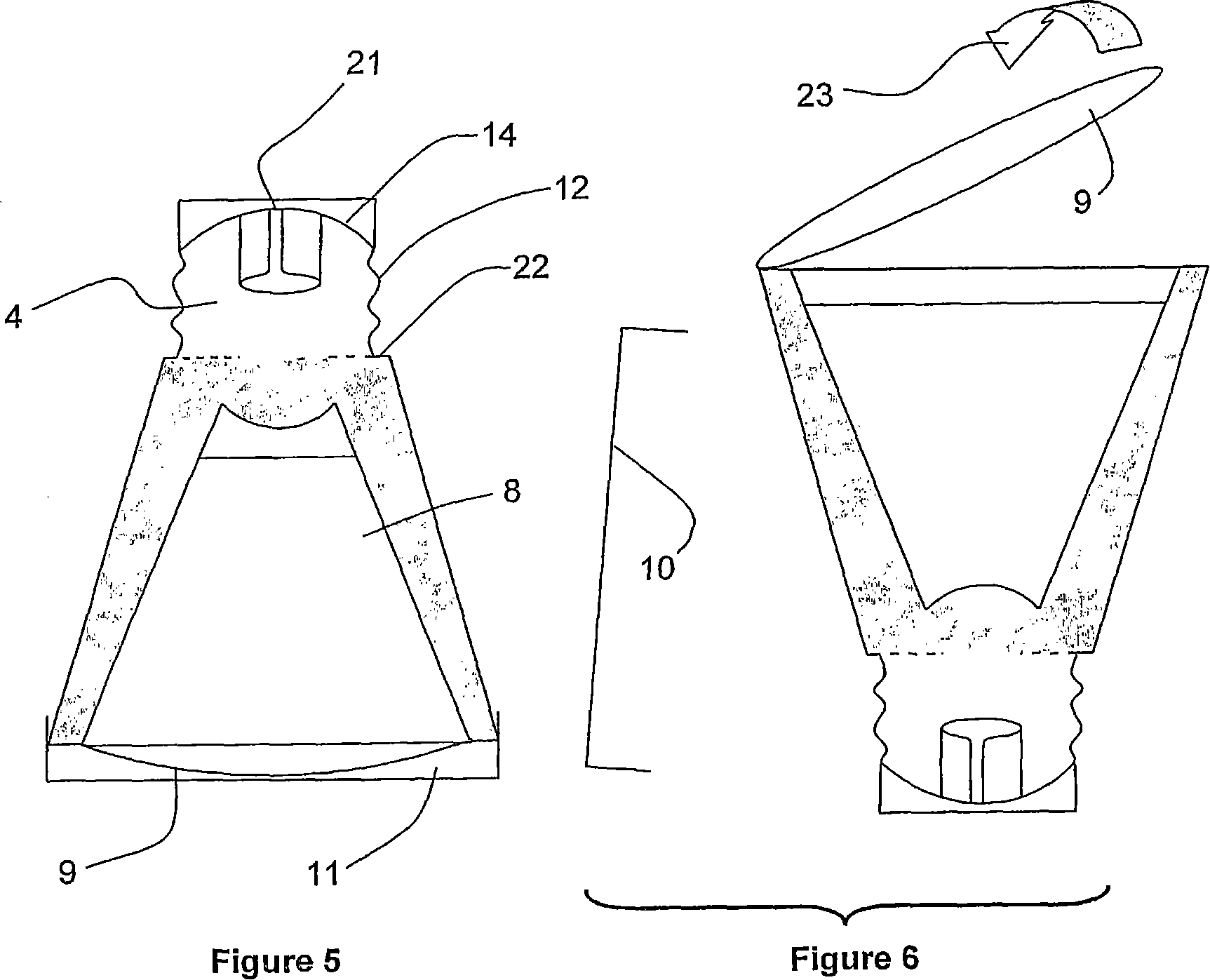

Heating or cooling containers

InactiveCN101175678AReduce the temperatureExothermal chemical reaction heat productionDomestic cooling apparatusAmbient pressureCompound (substance)

A self-heating or self-cooling container for food or drink comprises inner and outer vessels (1 ,2) defining a reaction cell between their mutually facing walls. The reaction cell is divided into first and second chambers (3,4) by a rupturable membrane (5). A liquid chemical reagent (17) is filled into the second chamber (4) which is at ambient pressure, and a solid chemical reagent (19) is placed in the first chamber (3) which is at sub-atmospheric pressure. The chemicals are chosen for their exothermic or endothermic heats of reaction after rupture of the membrane, and preferably result in a solid or semi-solid porous residue. The sub-atmospheric pressure in the first chamber (3) causes a rapid and thorough mixing of the chemical reagents, and shaking the container after the initial rupture of the membrane assists that rapid mixing. Preferably the second chamber (4) is elastically deformable to increase its internal volume, for example being formed with corrugated walls. That makes it possible to form the reaction cell as a totally sealed volume. Alternatively the reaction cell may be provided with pressure relief valve means. The use of a sub-atmospheric pressure in the first chamber permits the design of the container so that the contents of the inner vessel can be raised from ambient to 85 DEG C to 90 DEG C within three minutes, or alternatively cooled from ambient to 5 DEG C within the same or a shorter time.

Owner:萨博·阿哈默德·博翰姆 +1

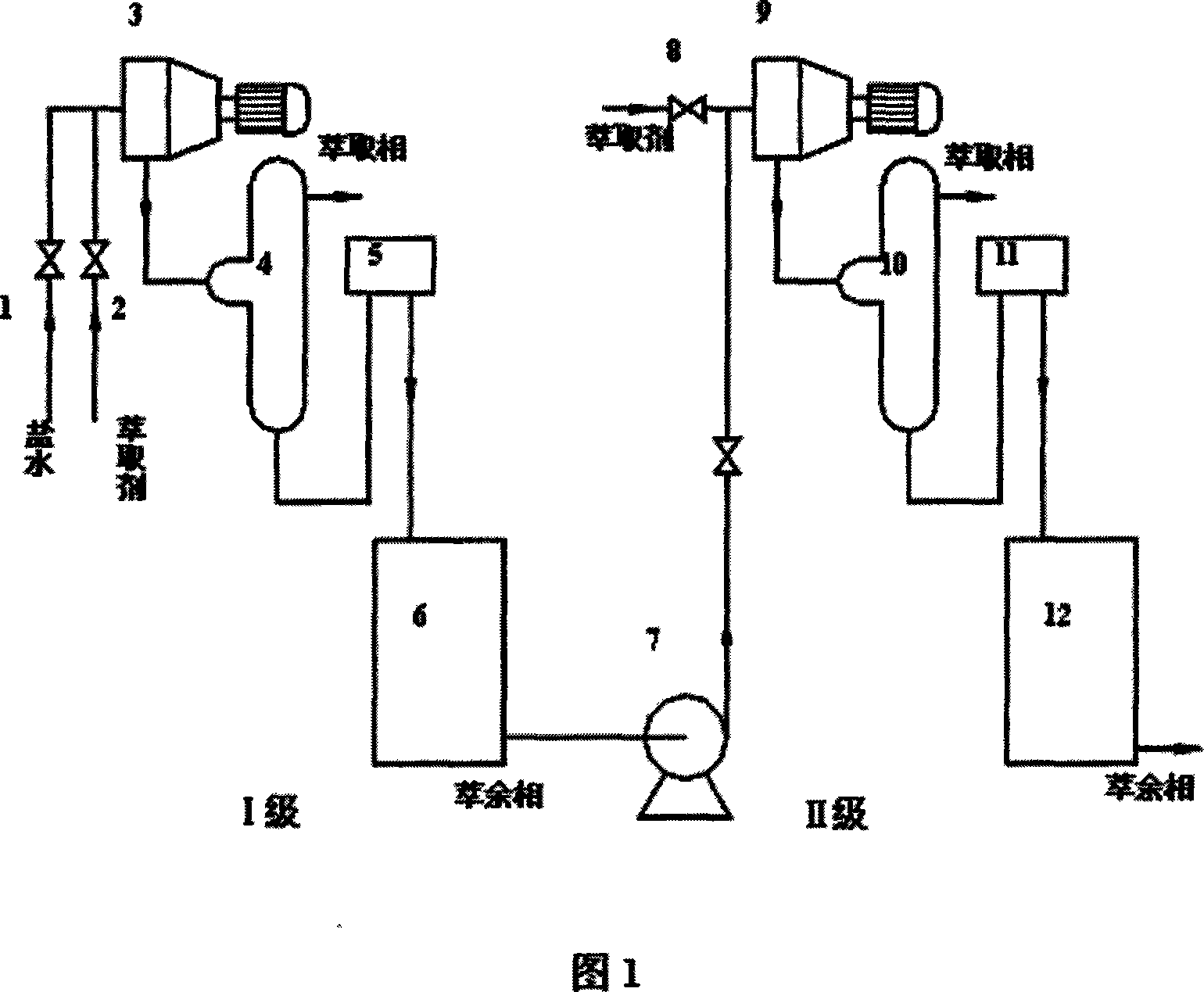

Process of extracting polymethylene polyphenyl polyamine from its salt water solution

ActiveCN101020642AReduced polyamine contentAchieving a circular economyAmino compound purification/separationSolvent extractionSaline waterElectrolysis

The present invention relates to salt solution treating technology, and is especially process of extracting polymethylene polyphenyl polyamine from its salt water solution. The process includes two steps, extraction and separation. In the extraction step, salt water solution and extractant are mixed fast in a hypergravital rotation bed as the extractor, and polymethylene polyphenyl polyamine is extracted from the salt water phase to extracted liquid phase. In the separation step, the extracted liquid phase is separated from the salt water phase in separating apparatus. One stage of extraction can reduce the concentration of polymethylene polyphenyl polyamine in salt water from about 1000 mg / L to below 20 mg / L, and two stages of extraction can reduce to below 1 mg / L. The present invention has greatly raised extraction efficiency and reuse of the waste salt solution.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +1

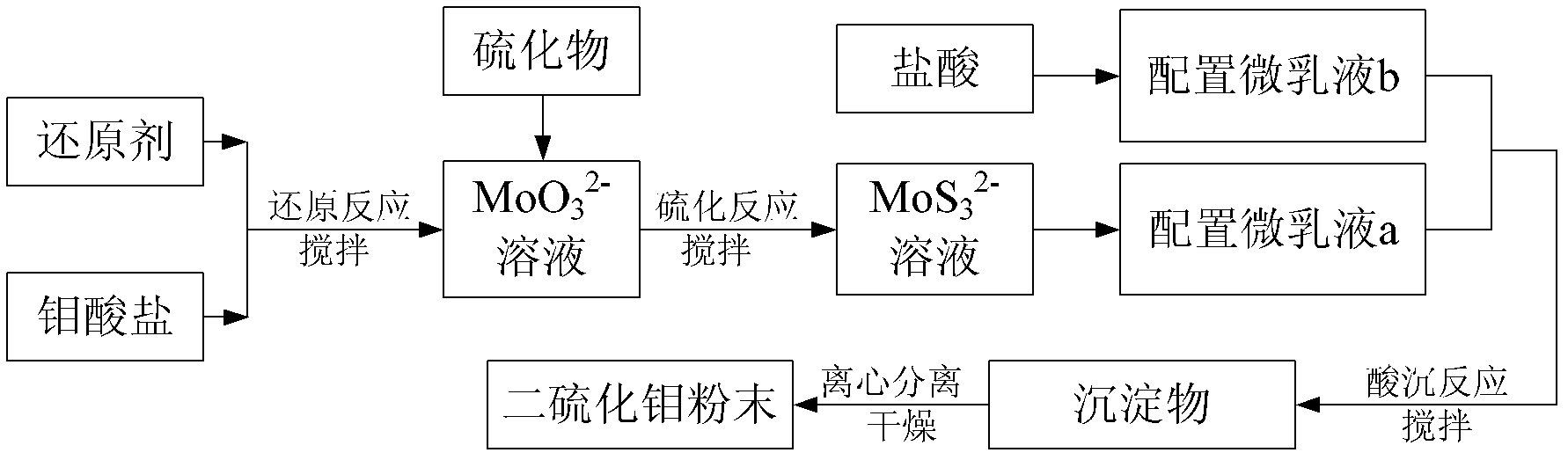

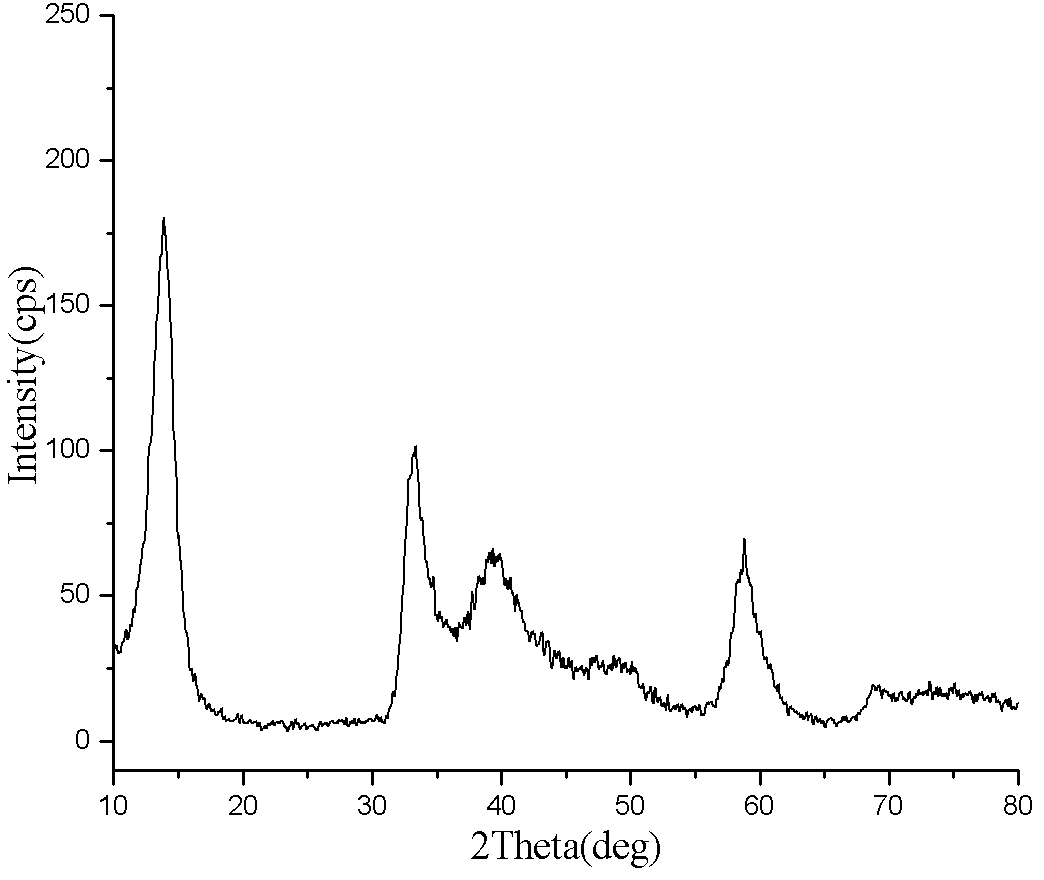

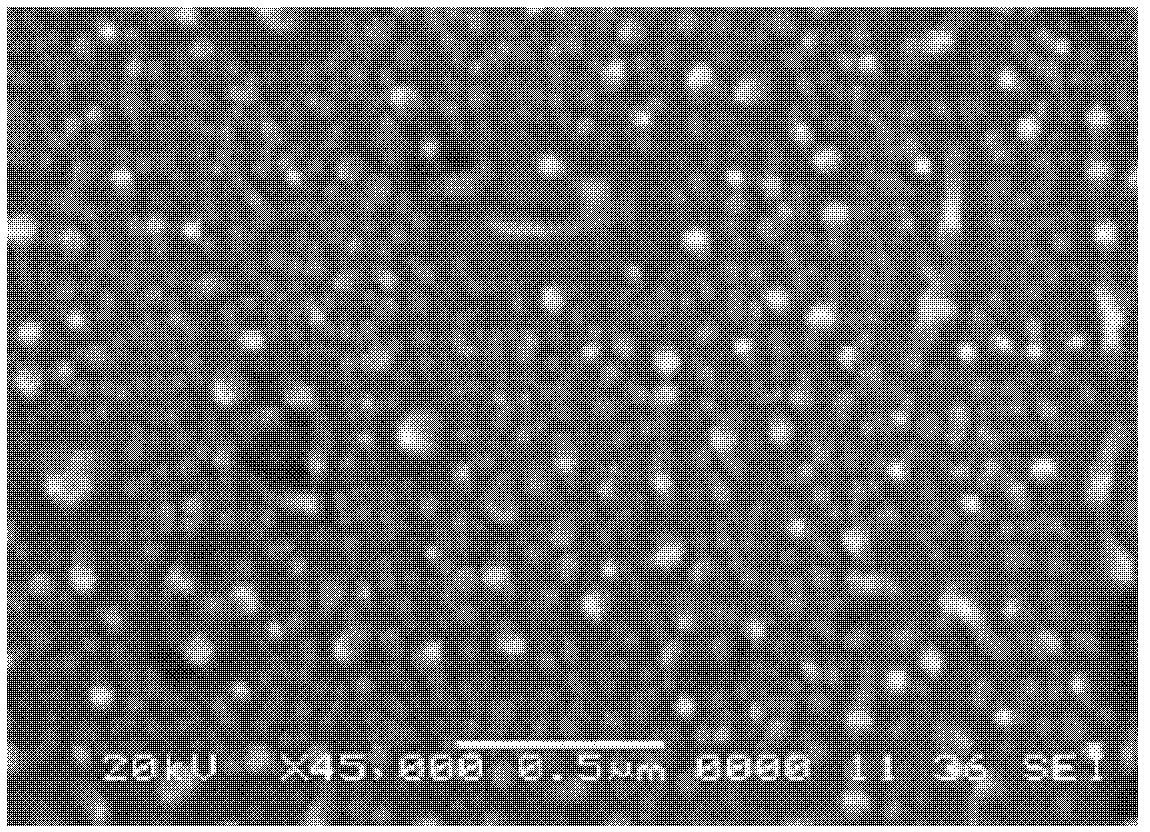

Method for preparing nanometer molybdenum disulfide by aid of microemulsion system

InactiveCN102616855AImprove stabilityUniform particlesNanotechnologyMolybdenum sulfidesIsoamyl alcoholSulfidation

The invention provides a method for preparing nanometer molybdenum disulfide by the aid of a microemulsion system. The method includes steps of chemically reducing hexamolybdate, then adding sulfide into the hexamolybdate to perform sulfidation reaction so as to generate thiomolybdate sulfite; adding the thiomolybdate sulfite into TritonX100, isoamyl alcohol, normal heptane and secondary deionized water to form microemulsion a; adding hydrochloric acid into TritonX100, soamyl alcohol, normal heptane and secondary deionized water to form microemulsion b; adding the microemulsion b into the microemulsion a; fast mixing and stirring; leading acid sinking reaction to be thorough to obtain a product; and obtaining the nanometer molybdenum disulfide after the product is separated centrifugally, washed and dried in a vacuum manner. The preparation method is simple, reaction conditions are easy to be controlled, stability is good, generated particles are uniform, appearances are neat, and the nanometer molybdenum disulfide is expectably prepared on a large scale.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

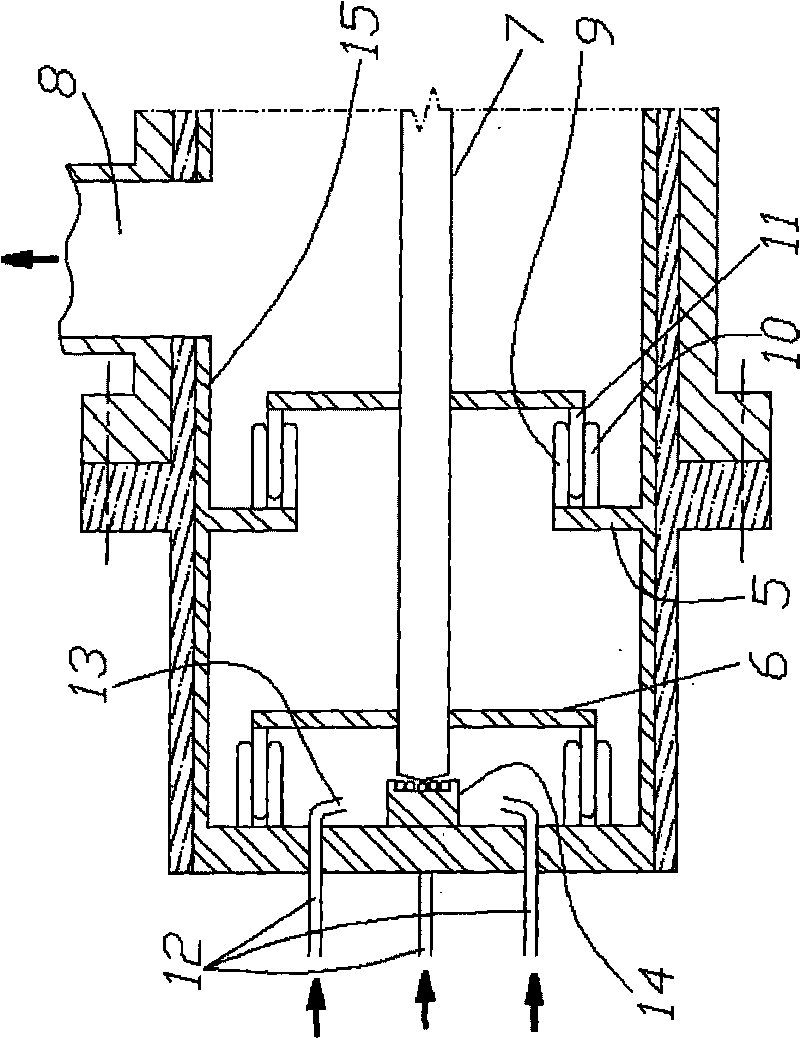

Impinging stream high-shear reactor for liquid-liquid quick mixing and reaction

ActiveCN101716486AReduce incidenceWell mixedChemical/physical/physico-chemical stationary reactorsLiquid-liquid reaction processesDrive shaftProcess engineering

The invention discloses an impinging stream high-shear reactor for liquid-liquid quick mixing and reaction, which comprises a cylindrical reactor shell, a rotor, a stator and a main drive shaft, wherein the center of an end wall at one end of the reactor shell is provided with a first feed pipe; the end of the first feed pipe, which is positioned in the reactor shell, is a dead end; a discharge port of the feed pipe is arranged near the dead end; a second feed pipe is arranged around the first feed pipe; the discharge port of the second feed pipe is positioned in the reactor shell and opposite to the discharge port of the first feed pipe; the dead end of the first feed pipe is movably connected with the main drive shaft through a bearing; the main drive shaft is provided with a rotor base connected with the rotor; the stator is arranged on the internal surface of the reactor shell or arranged on the internal surface of the reactor shell through the stator base; the stator meshes with the rotor; and a discharge port of the reactor is arranged on the other end of the reactor shell. The reactor of the invention has the advantages of favorable mixing effect, low equipment investment and convenient heat exchange, and can not easily produce blocking.

Owner:TIANJIN UNIV +1

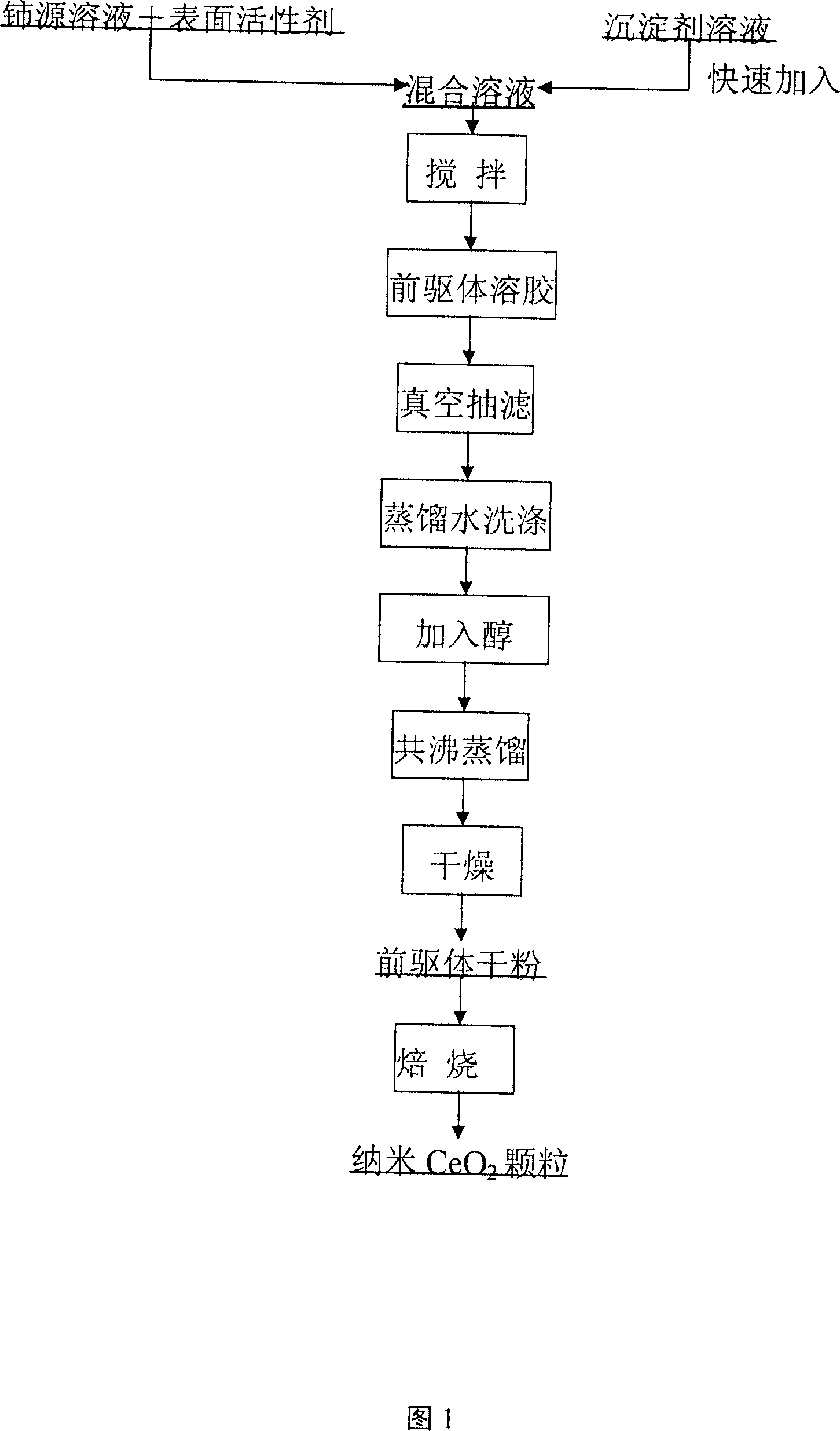

Process for preparing nanometer cerium dioxide

InactiveCN101104524AGood dispersionAvoid reunionNanostructure manufactureRare earth metal compoundsAlcoholBoiling point

Disclosed is a method for nano-cerium oxide preparation. The azeotropic mechanism will be introduced to the precipitation method; surfactant is added to 0.1-0.5 mol / L cerium salt solution and precipitator is rapidly added for reaction, then the gel produced after the reaction is washed by ionic water and mixed with a certain amount of organic alcohol under rapid mixing; then the mixture is poured into an azeotropic device to be slowly heated above the alcohol boiling point; through refluxing, the gel is taken out and dried to obtain precursor powder; through the baking of the precursor powder, high-purity active CeO2 is obtained. The nano-CeO2 prepared by the present invention is within 5 to 19 nm in grain size, which is smaller and more uniformly, with better dispersibility and greater activity. The organic alcohol used in the azeotropic distillation process is recyclable and is low in cost and can prevent environmental pollution.

Owner:CENT SOUTH UNIV

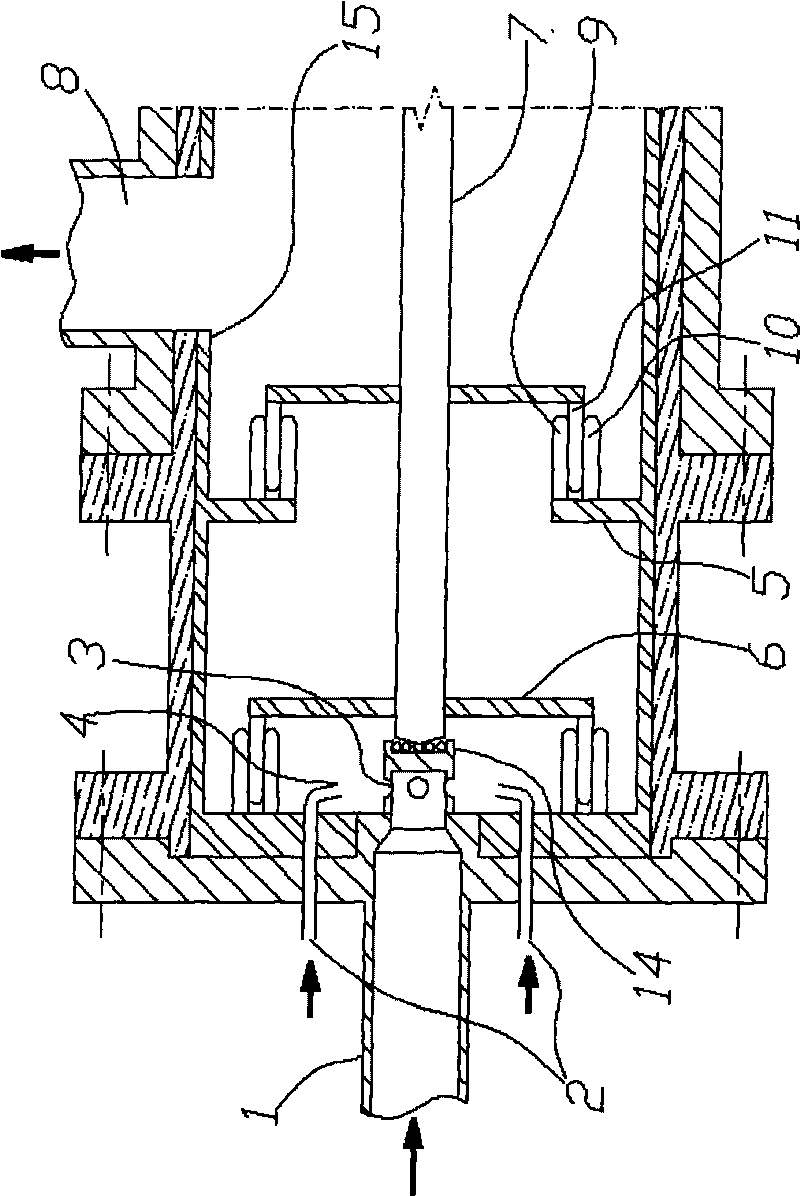

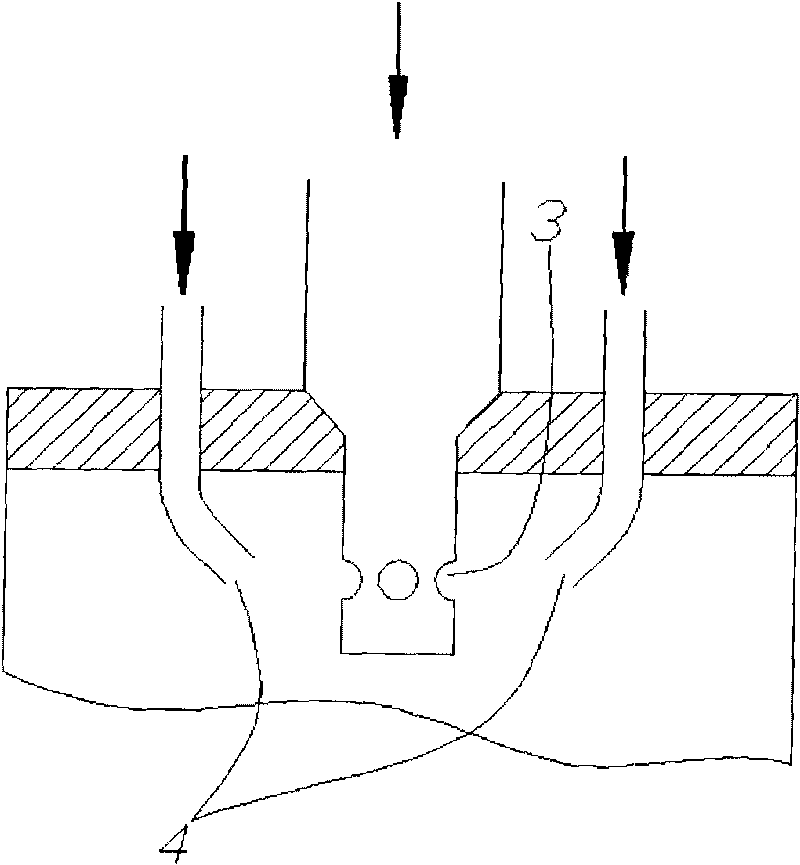

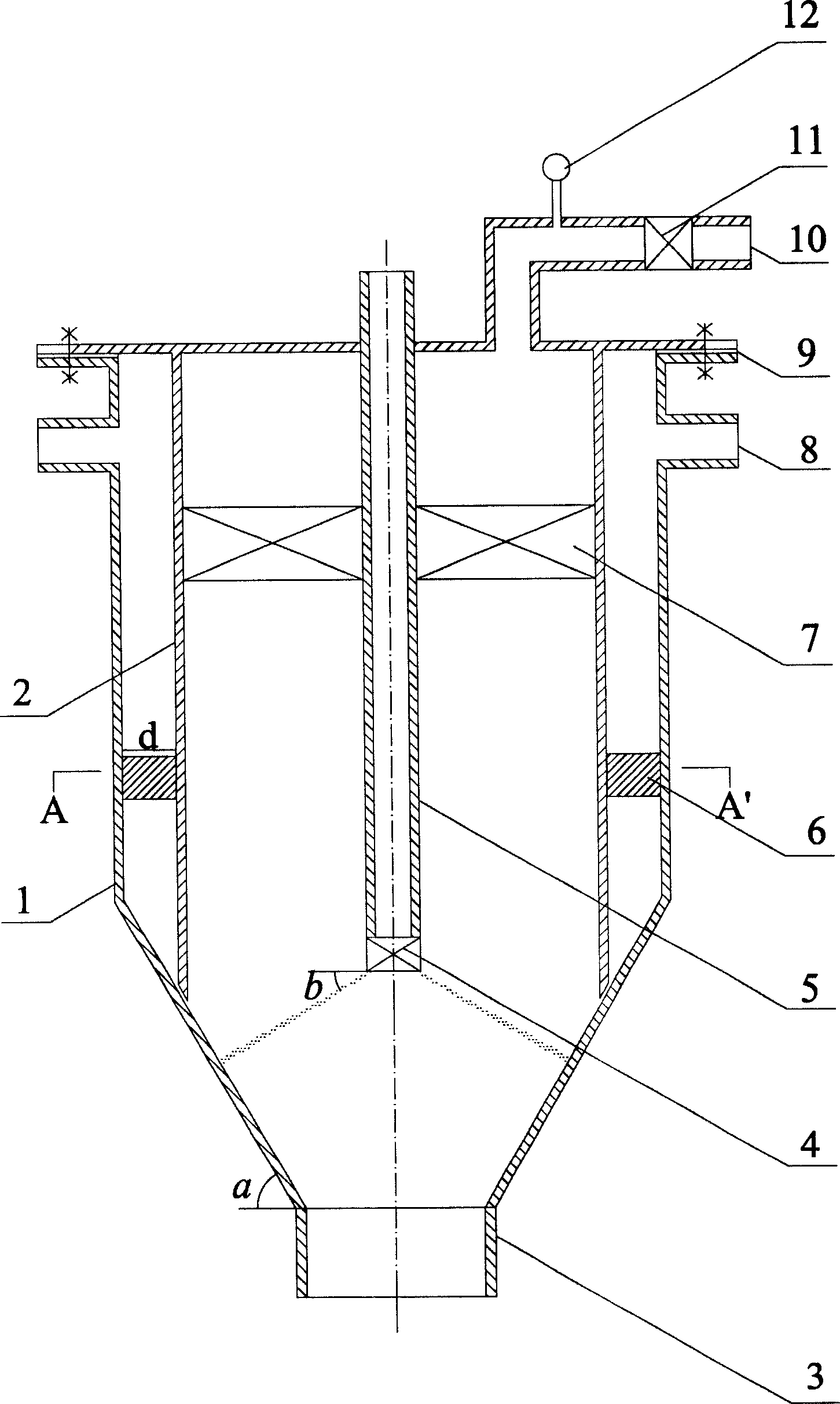

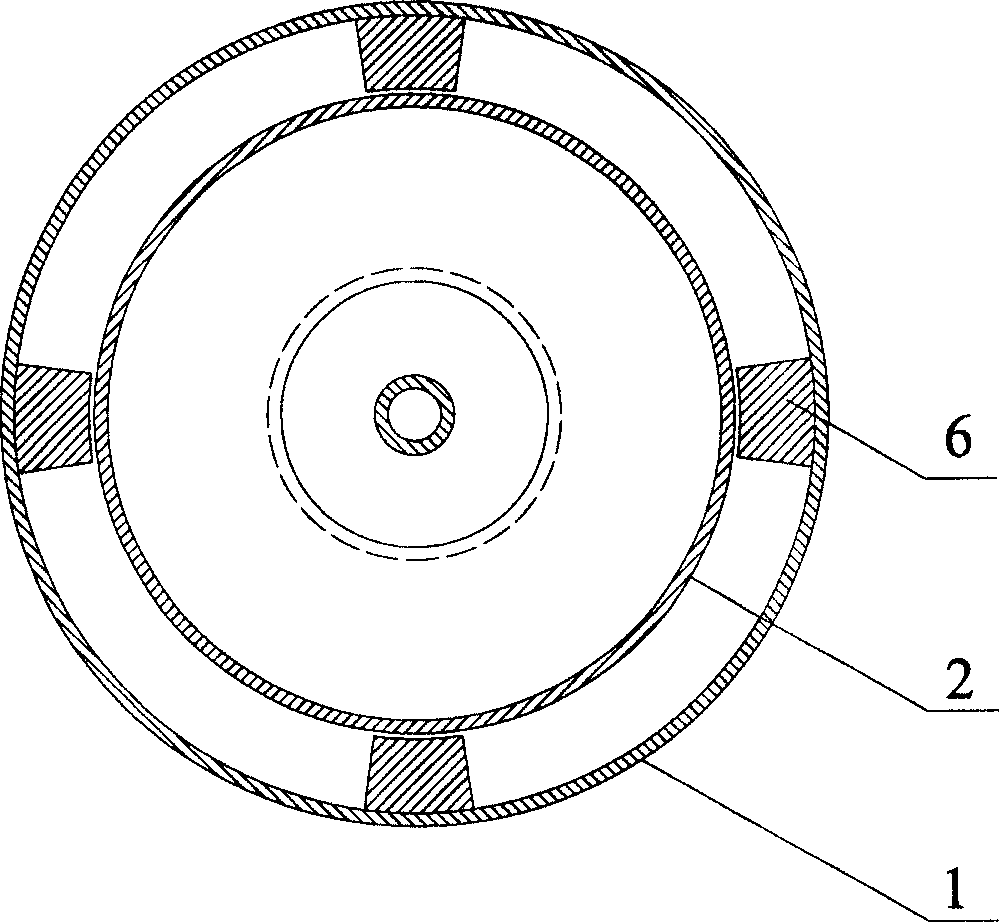

Liquid-liquid fast-mixing reactor

InactiveCN1669631AGuaranteed to proceed normallyEfficient mixingChemical/physical/physico-chemical nozzle-type rreactorsLiquid-liquid reaction processesCycloneSpray nozzle

The invention relates to a liquid-liquid fast-mixing reactor, which comprises a housing, an inner casing, a liquid conducting tube, an injector, a demister, a backing sheet, a pad, an adjusting valve, a manometer, wherein the housing (1) has a liquid feed inlet (8), the necked-in parts, and a liquid outlet (3); the inner casing (2) has the liquid conducting tube (5), the injector (4), the air outlet (10), the adjusting valve (11) and the manometer (12) inside. The space between the inwall of the housing (1) and the inner casing (2) forms a channel cyclone or non-cyclone through which a fold of liquid inlets, and another liquid passes the liquid conducting tube and the injector and forms the droplet distributed circlewise, the droplet connects with the film formed when the first fold of liquid passing the chine, and the two folds of liquid mix in the meeting point rapidly, then the product will be discharged from the liquid outlet (3).

Owner:TSINGHUA UNIV

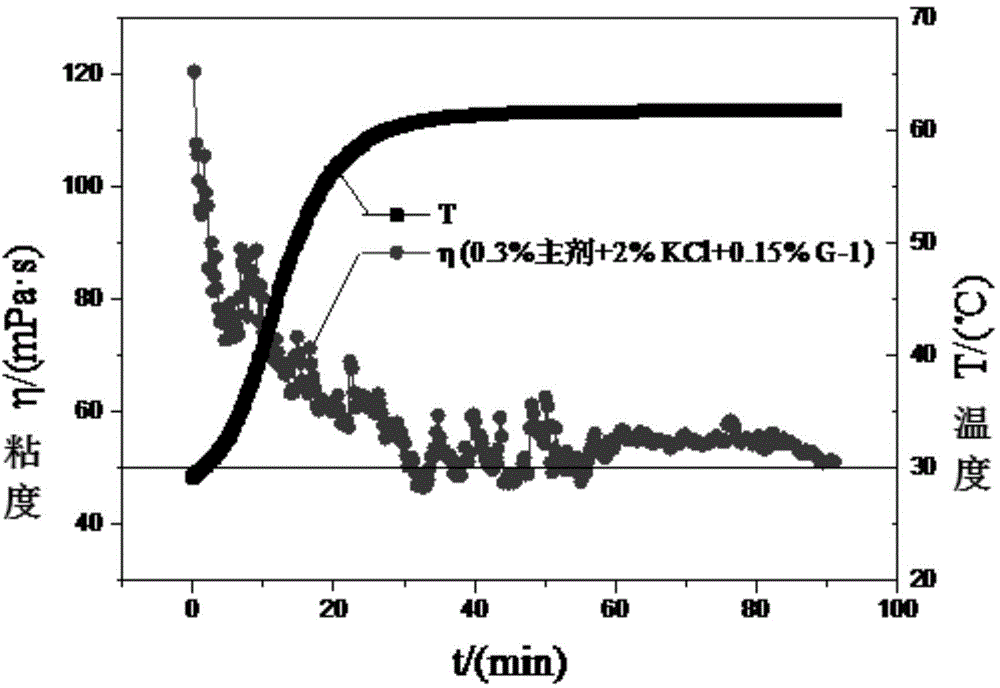

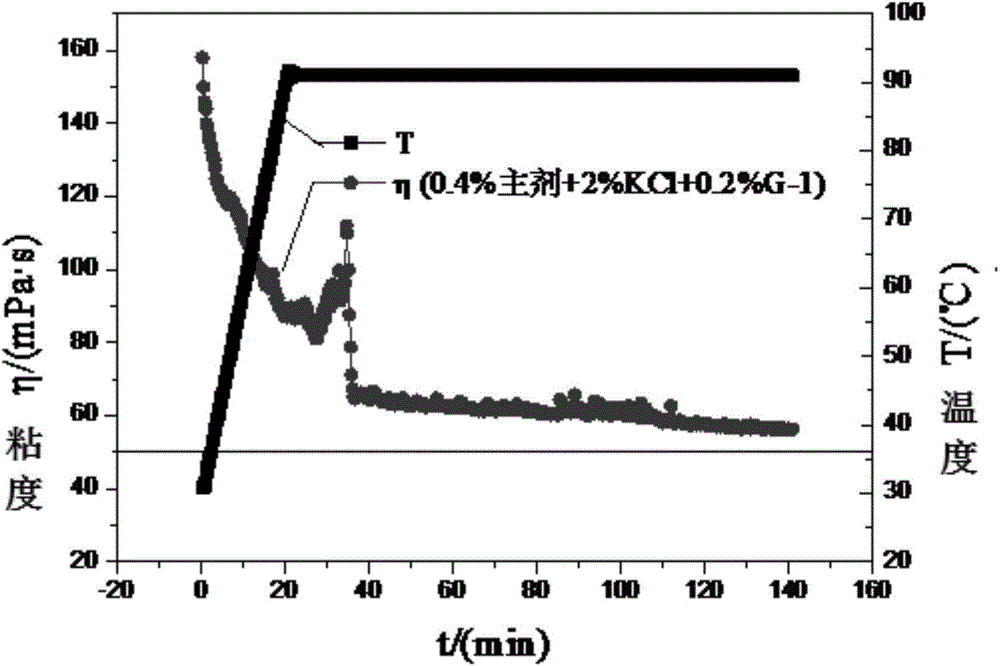

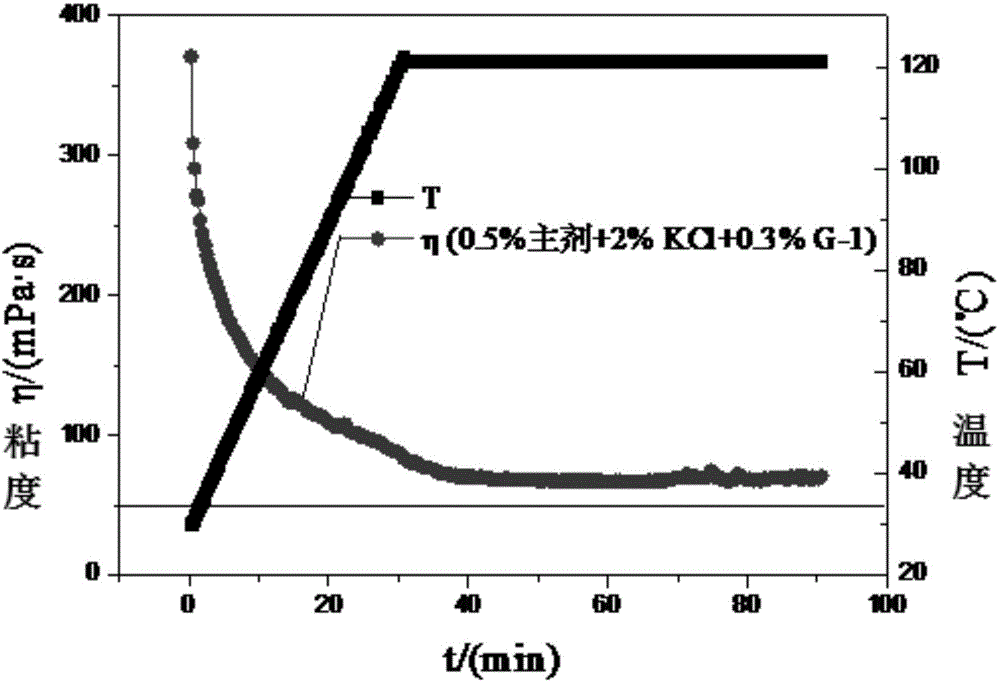

High-concentration water-in-oil emulsion-state associating polymer fracturing fluid and preparation method thereof

ActiveCN104449649AImprove rheologyEnhanced pumpabilityDrilling compositionHigh concentrationPolymer science

The invention relates to a high-concentration water-in-oil emulsion-state associating polymer fracturing fluid and a preparation method thereof. The fracturing fluid comprises the following components in mass fraction: 38.7-45.18% of water, 25.30-28.67% of diesel oil, 25-30% of a fracturing fluid thickening agent and 2.53-2.88% of an emulsifier. The high-concentration water-in-oil emulsion-state associating polymer fracturing fluid disclosed by the invention has a stable time greater than 15 days at 0 DEG C-40 DEG C and has the characteristics that the fracturing fluid is easy to prepare, dissolve and disperse and the like, and rapid mixing, construction and fracturing on the spot can be achieved.

Owner:RES INST OF PETROLEUM ENG SHENGLI OIL FIELD SINOPEC

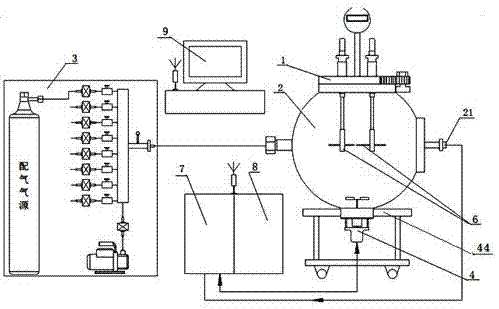

Device for measuring limit oxygen concentration parameter of combustible gas and operating method

The invention relates to a device for measuring a limit oxygen concentration parameter of combustible gas and an operating method. The device comprises a quick sealing screw cover, an explosion experiment container tank, a multi-path precision proportional gas distribution device, a gas stirrer device, an oxygen concentration detection device, an igniting device, a control unit, a data acquisition unit, a computer wireless monitoring system and a base, wherein the multi-path precision proportional gas distribution system achieves gas distribution and sample injection so as to achieve measurement of the limit oxygen concentration of the combustible gas at normal temperature and under normal pressure; the gas stirring system is mounted at the inner bottom of the explosion container so as to achieve rapid uniform mixing of the combustible gas in the explosion experiment container tank; the quick sealing screw cover achieves rapid sealing; through increase of the volume fraction of inert gas, the limit air concentration LAC of the combustible gas is measured, and the limit oxygen concentration LOC of the combustible gas to be measured is calculated. The device has the technical effects as follows: the device adopts a modular design, is stable in performance, reasonable in structure, convenient and fast to operate, safe and reliable, and can simultaneously achieve measurement of a variety of explosion parameters.

Owner:应急管理部天津消防研究所 +1

Radial fixed bed reactor for oxydehydrogenation of butylene

InactiveCN103071430AWell mixedIncrease profitHydrocarbonsChemical recyclingPtru catalystButadiene Dioxide

The invention relates to a radial fixed bed reactor for oxydehydrogenation of butylene. The radial fixed bed reactor adopts the technical scheme that the radial fixed bed reactor is a cylindrical vessel with a catalyst bed, a rapid mixing device is arranged at the top of the reactor and consists of a tapered tube and a straight tube, nozzles are mounted on a side wall of the tapered tube, a mixing cavity is formed in the tapered tube, a distribution cavity is formed between the tapered tube and the straight tube, a porous distribution plate is arranged at the top of the tapered tube, an inlet distributor is connected with the downside of the mixing device, the catalyst bed of the reactor consists of a fan-shaped cylinder distributor positioned at an outer ring and a center porous wall cylinder positioned at an inner ring, a catalyst is filled in the middle of the catalyst bed, and a cover plate sealing structure is arranged at the top of the catalyst, so that the problems existing in the prior art that a reactor is subjected to partial carbon deposition easily and a catalyst regeneration period is short due to the fact that butylene, water steam and air are not mixed uniformly are better solved, and the radial fixed bed reactor can be used for industrial production for preparing butadiene through the oxydehydrogenation of butylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

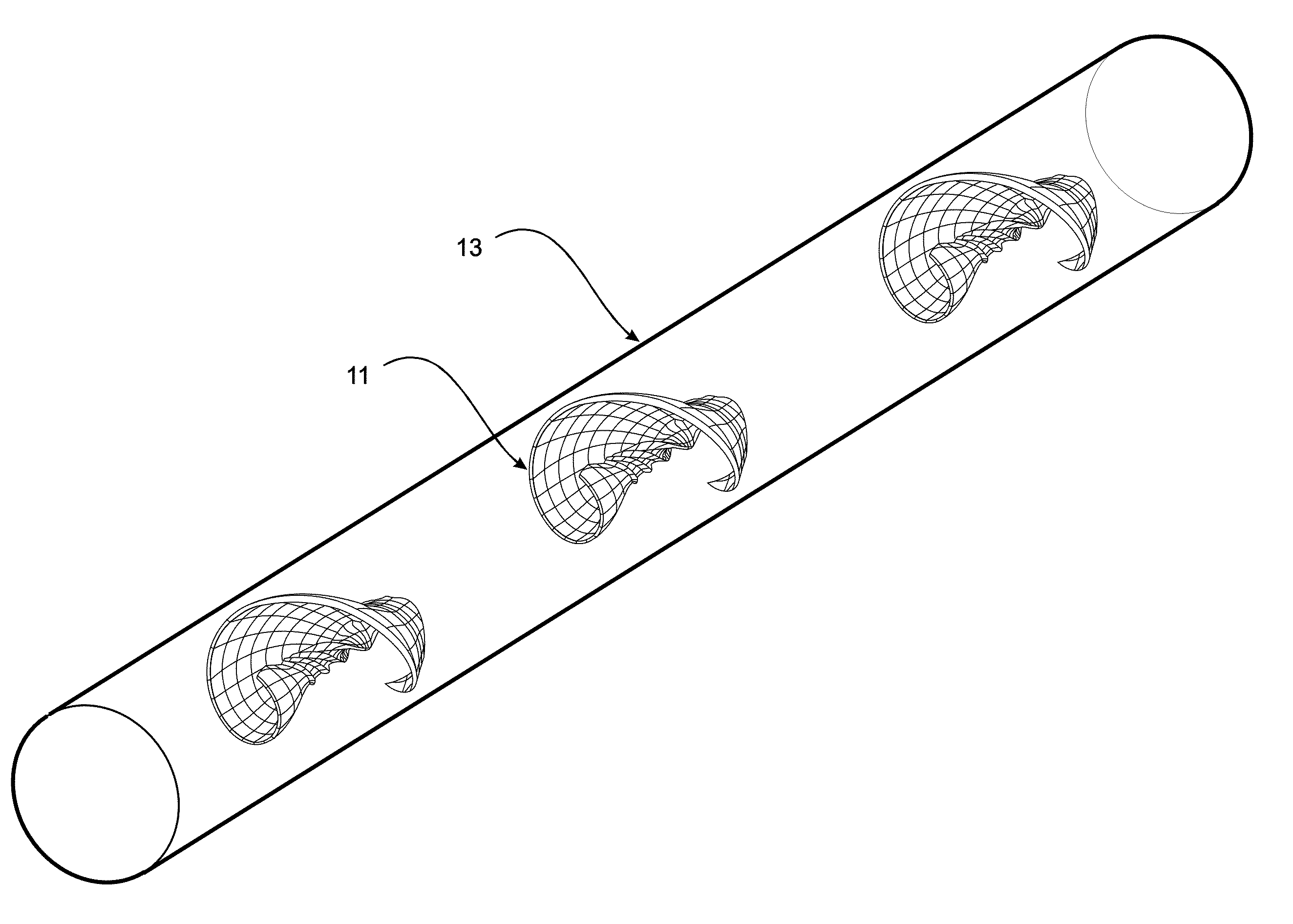

Swirl Inducer

A swirl inducer or mixer for location within a tube or duct. The swirl inducer may extend within the tube or duct and has an active surface over which a fluid flows to induce a swirling vortical flow within the fluid. The swirl inducer induces vortical flow in the tube or duct, which conforms with the path of least resistance and minimizes the amount of energy that is applied to the fluid to cause it to flow through the tube or duct and that causes the greatest, most rapid mixing of fluids passing through the tube or duct.

Owner:PAX STREAMLINE +1

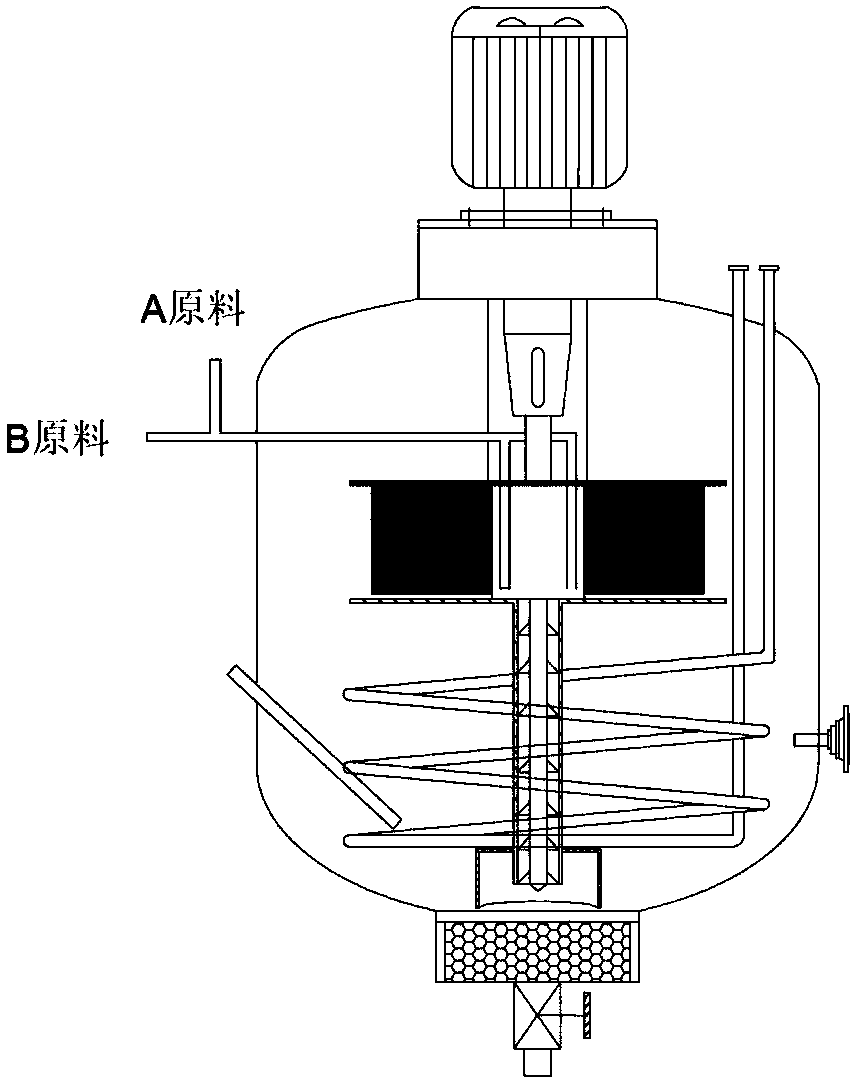

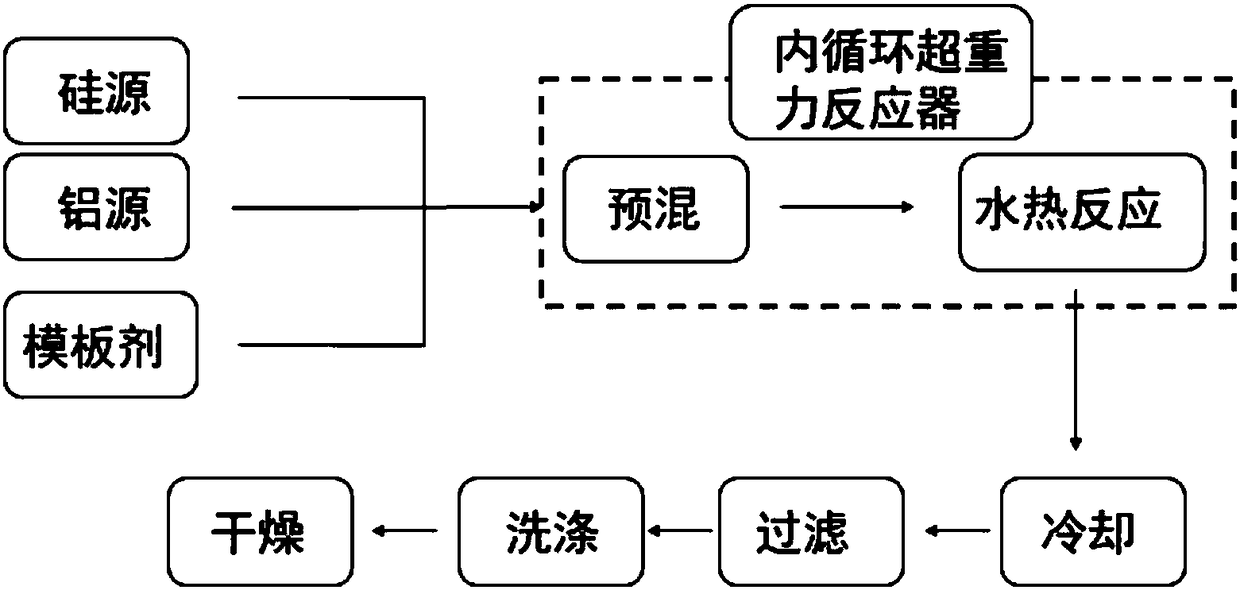

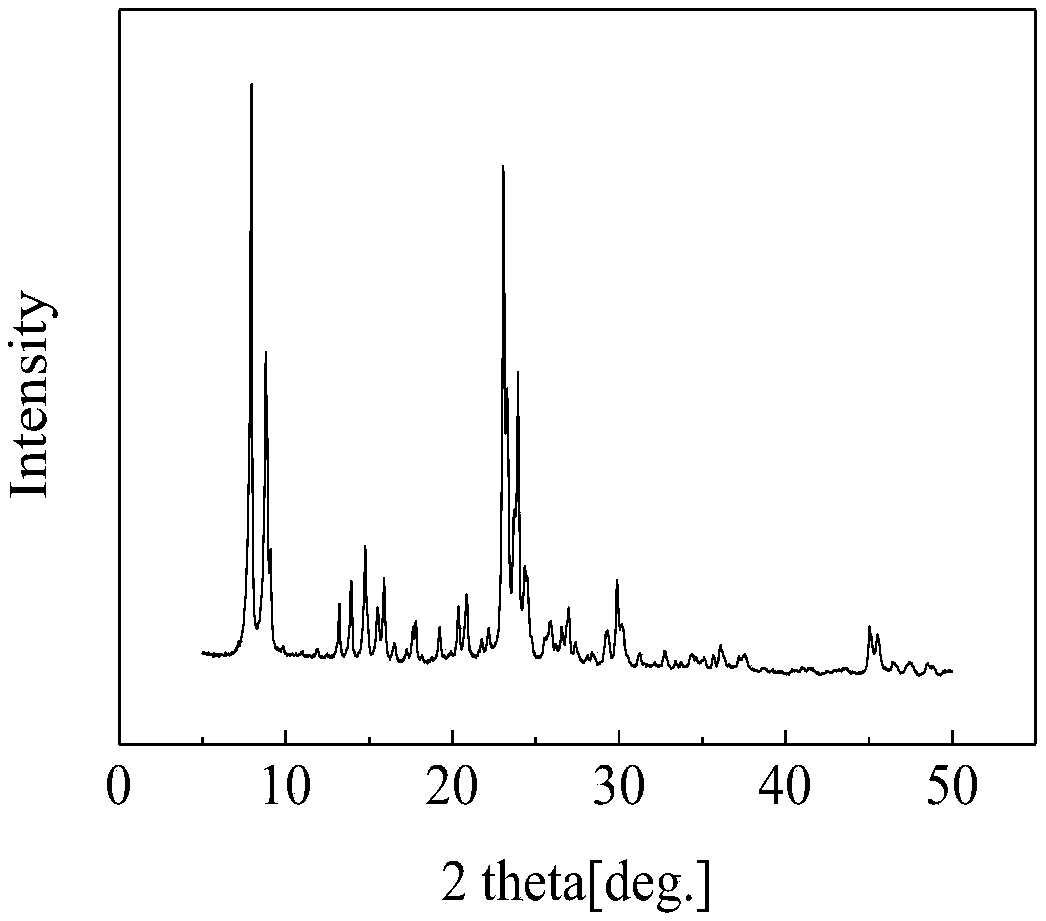

A supergravity method for preparing an aluminosilicate molecular sieve

InactiveCN108217674APrecise control of ratioControllable growth processChemical/physical/physico-chemical stationary reactorsCrystalline aluminosilicate zeolitesMolecular sieveProcess conditions

The invention provides a supergravity method for preparing an aluminosilicate molecular sieve, and belongs to the field of catalyst preparation. An internal-circulating supergravity reactor is adoptedas a reaction device. A silicon source and an aluminum source are pumped into the reactor at the same time through a liquid feeding pipe, and initial gel is obtained after the two raw materials are premixed. A rapid mixing characteristic of supergravity is utilized by a reaction system so that a raw material ratio under a microcosmic condition is accurately controlled and regulated, and crystallization is performed in a microcosmic and uniform environment, and therefore nucleating and growing processes are uniform and controllable, crystals grow uniformly, and particle size distribution is narrowed. Proper process conditions for preparing the molecular sieve are obtained through influences of process condition changes on the synthesized molecular sieve.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com