Swirl Inducer

a technology of inducing structure and swirl, which is applied in the field of swirl inducing structure, can solve the problems of reducing the overall efficiency of fluid flow through requiring additional force, and stagnant fluid contained by the tube or du

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

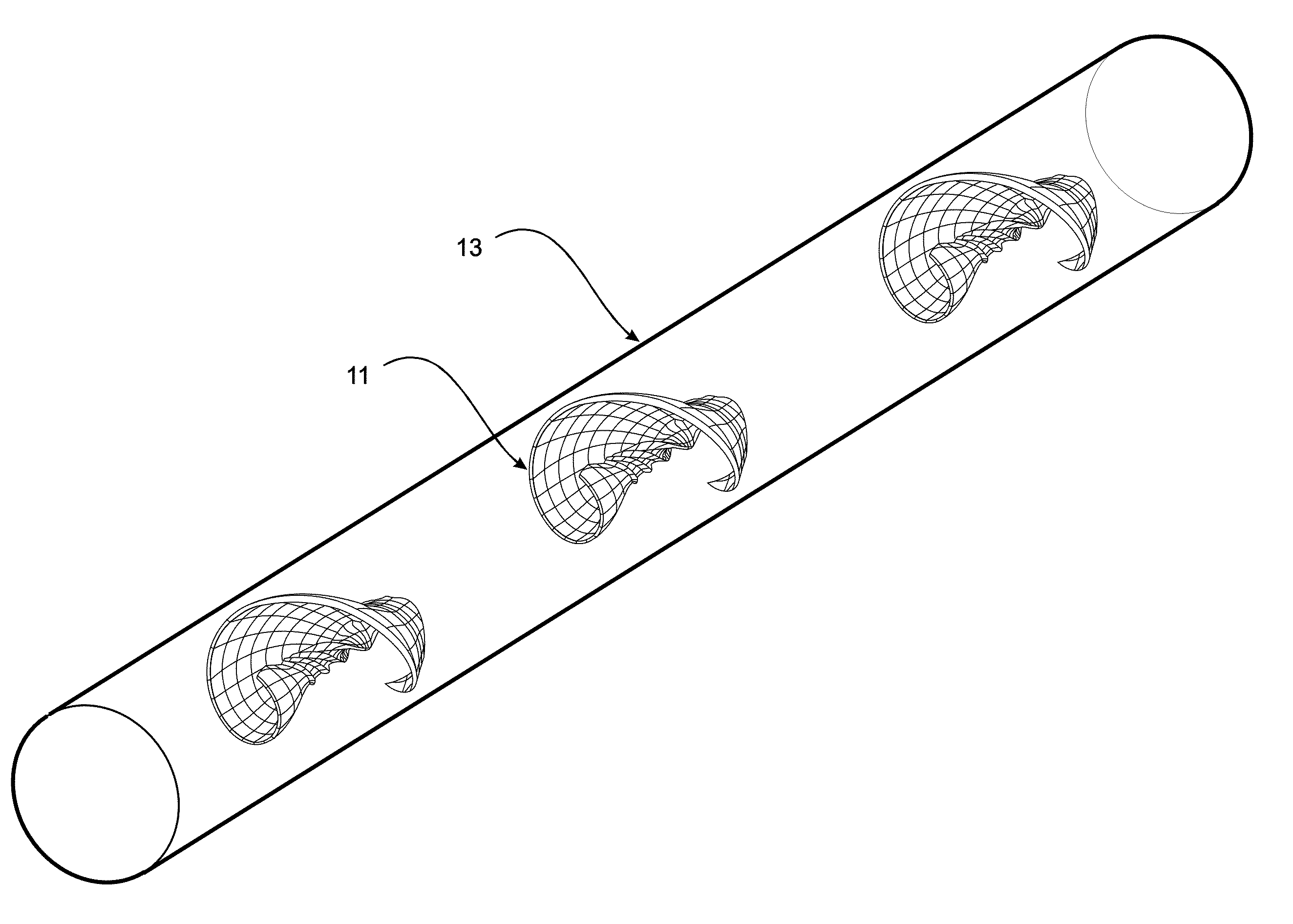

Image

Examples

Embodiment Construction

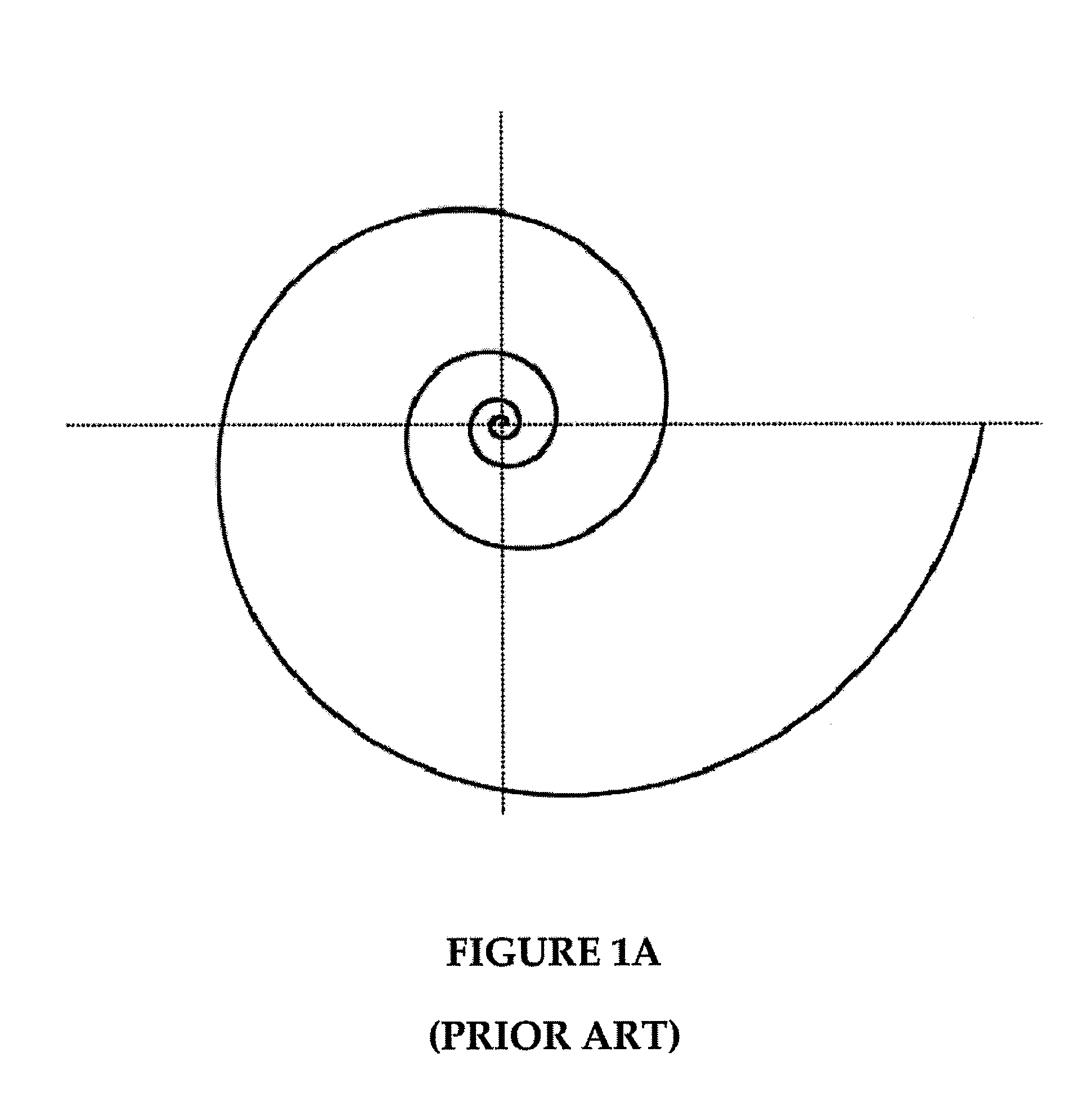

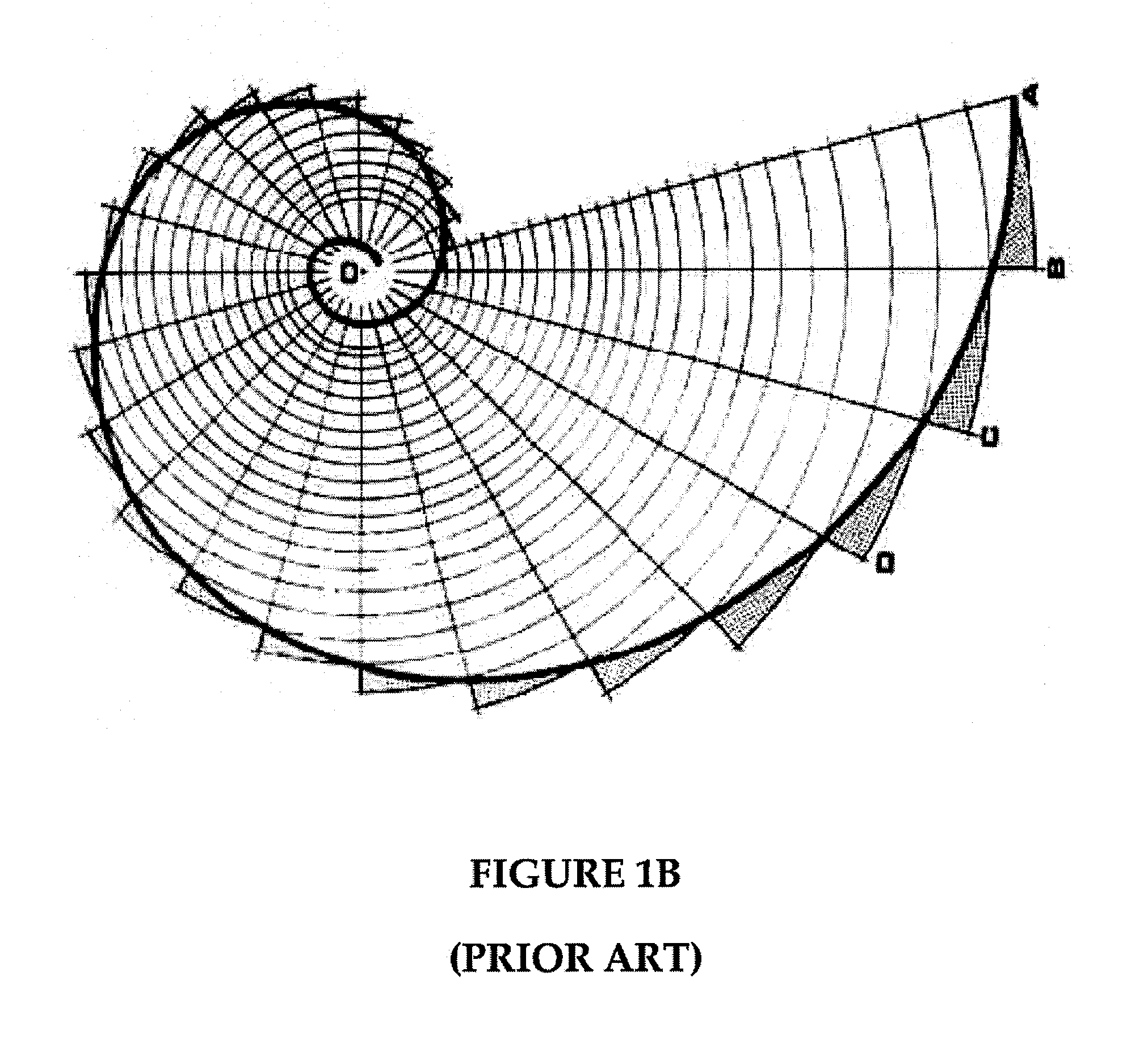

[0025]FIG. 1A illustrates a logarithmic spiral, as known in the prior art. FIG. 1B, however, illustrates a particular type of logarithmic spiral, also known in the art, wherein the radius of the logarithmic spiral measured at equiangular radii unfolds at a constant order of growth. A logarithmic spiral (sometimes referred to as an equiangular spiral or growth spiral) like that of FIG. 1A is a special kind of spiral curve that often appears in nature. A Golden Spiral—a spiral in accord with the Golden Section or Golden Ratio—like that depicted in FIG. 1B is a type of logarithmic spiral where two quantities are in golden ratio. Two quantities are in golden ratio or embody the Golden Ratio if the ratio of the sum of the quantities to the larger one equals the ratio of the larger one to the smaller. The golden ratio is an irrational mathematical constant, which approximates 1.6180339887 and is often denoted by the Greek letter phi (φ).

[0026]This constant, when expressed algebraically re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com