Patents

Literature

232 results about "Logarithmic spiral" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A logarithmic spiral, equiangular spiral, or growth spiral is a self-similar spiral curve which often appears in nature. The logarithmic spiral was first described by Descartes and later extensively investigated by Jacob Bernoulli, who called it Spira mirabilis, "the marvelous spiral".

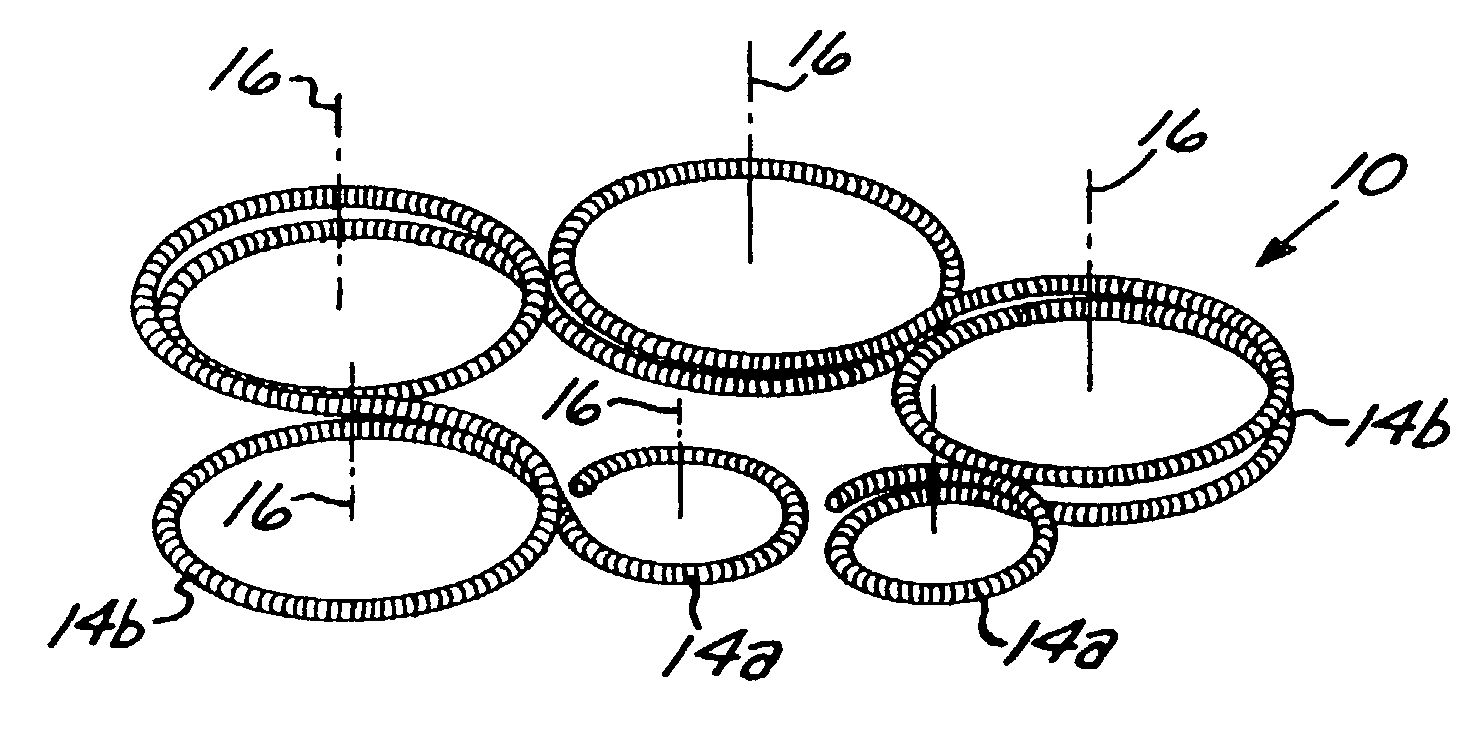

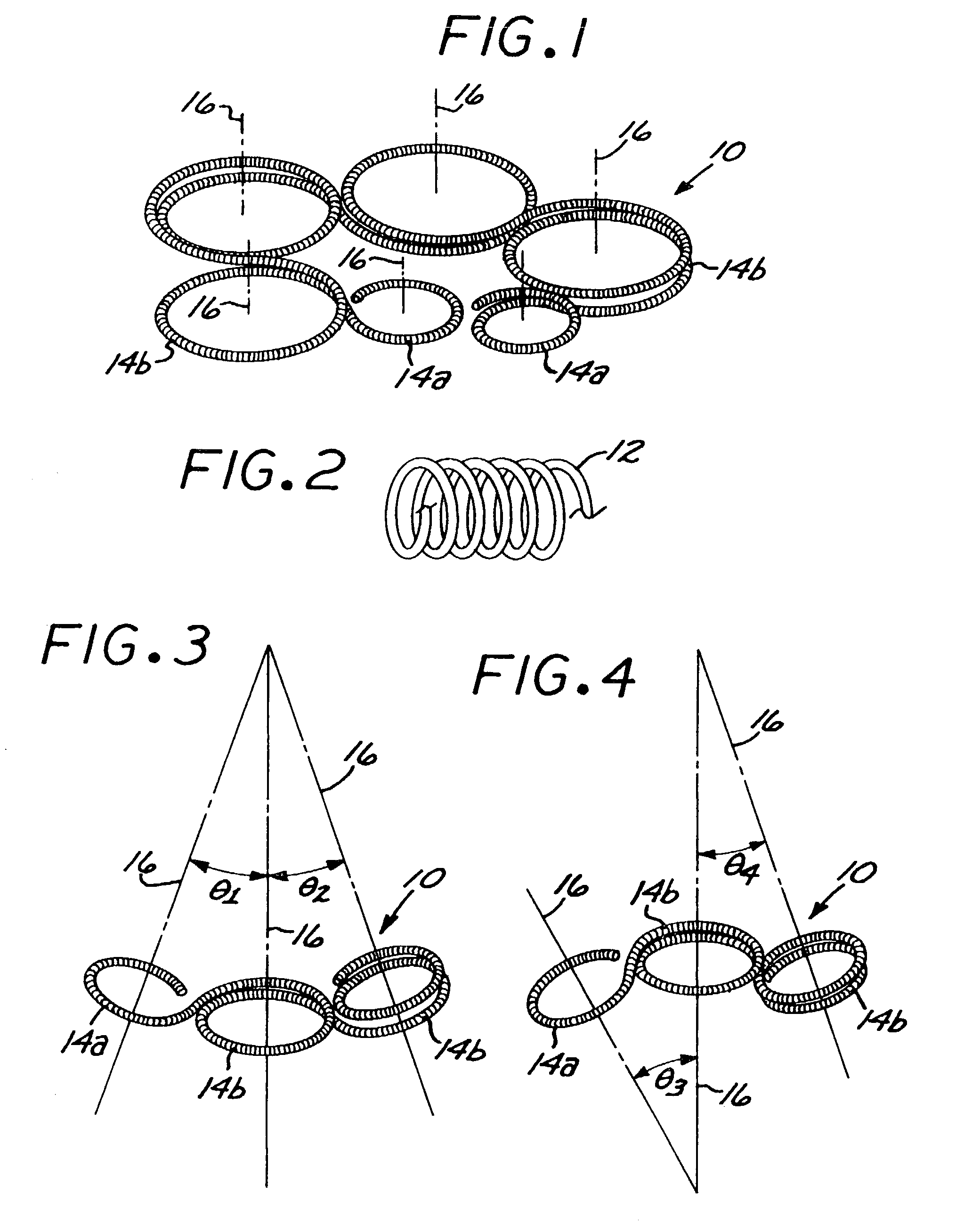

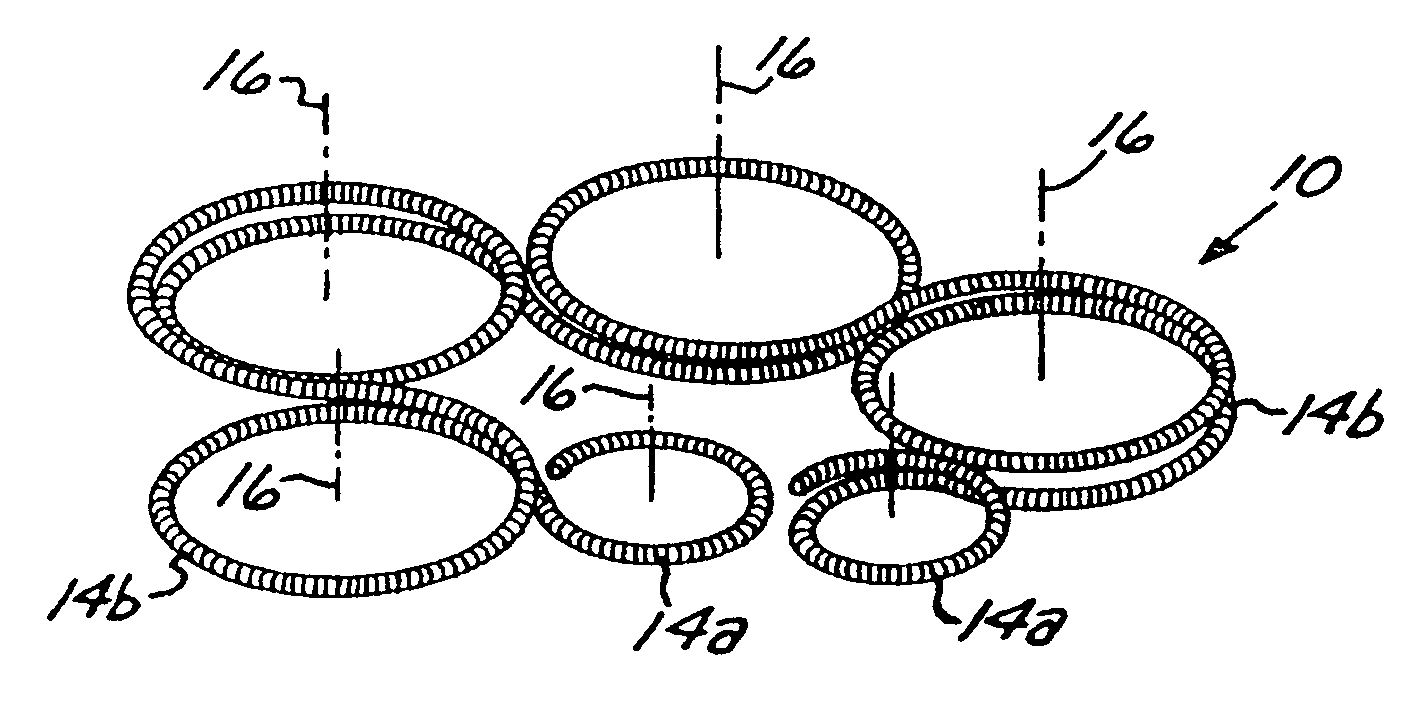

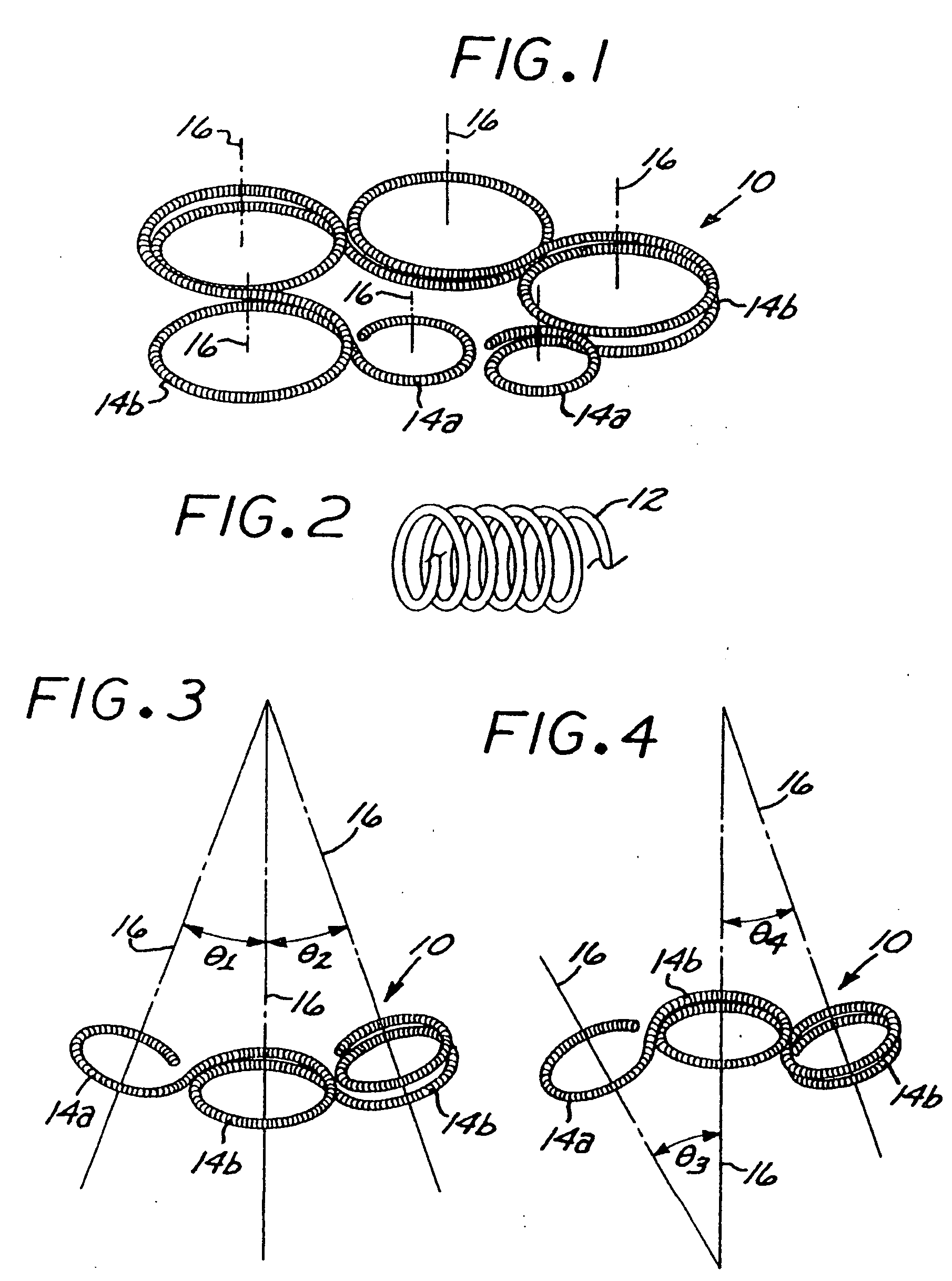

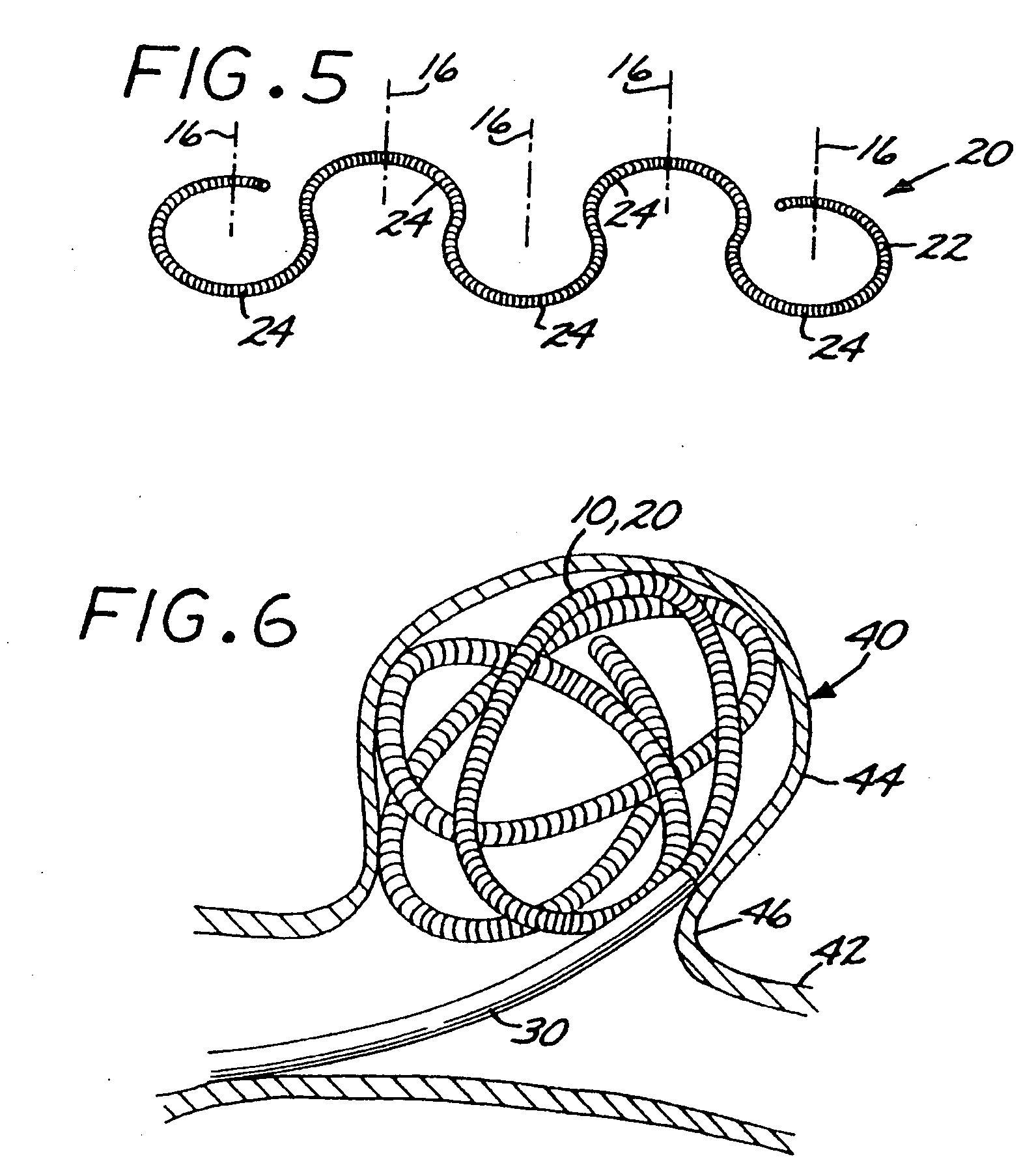

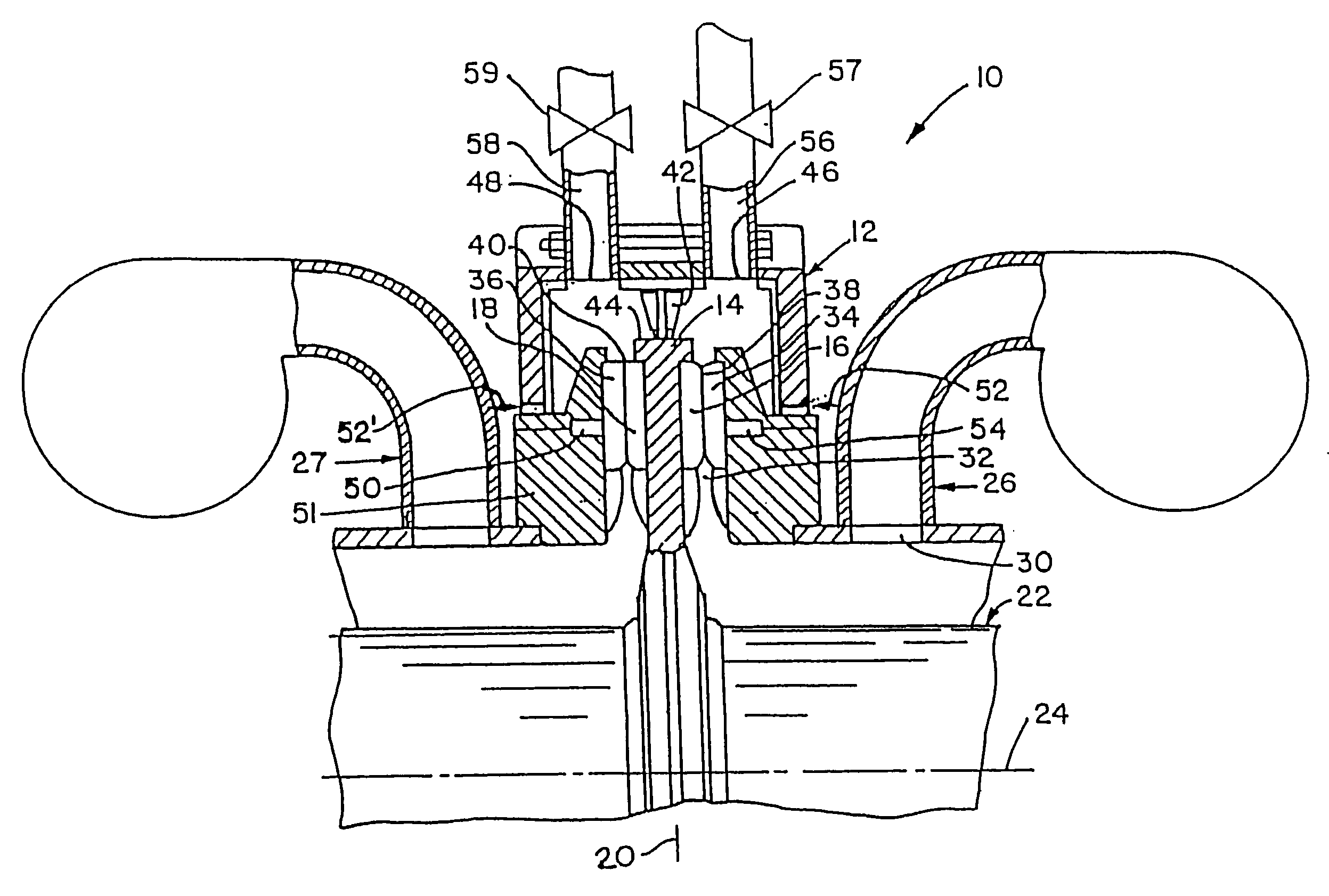

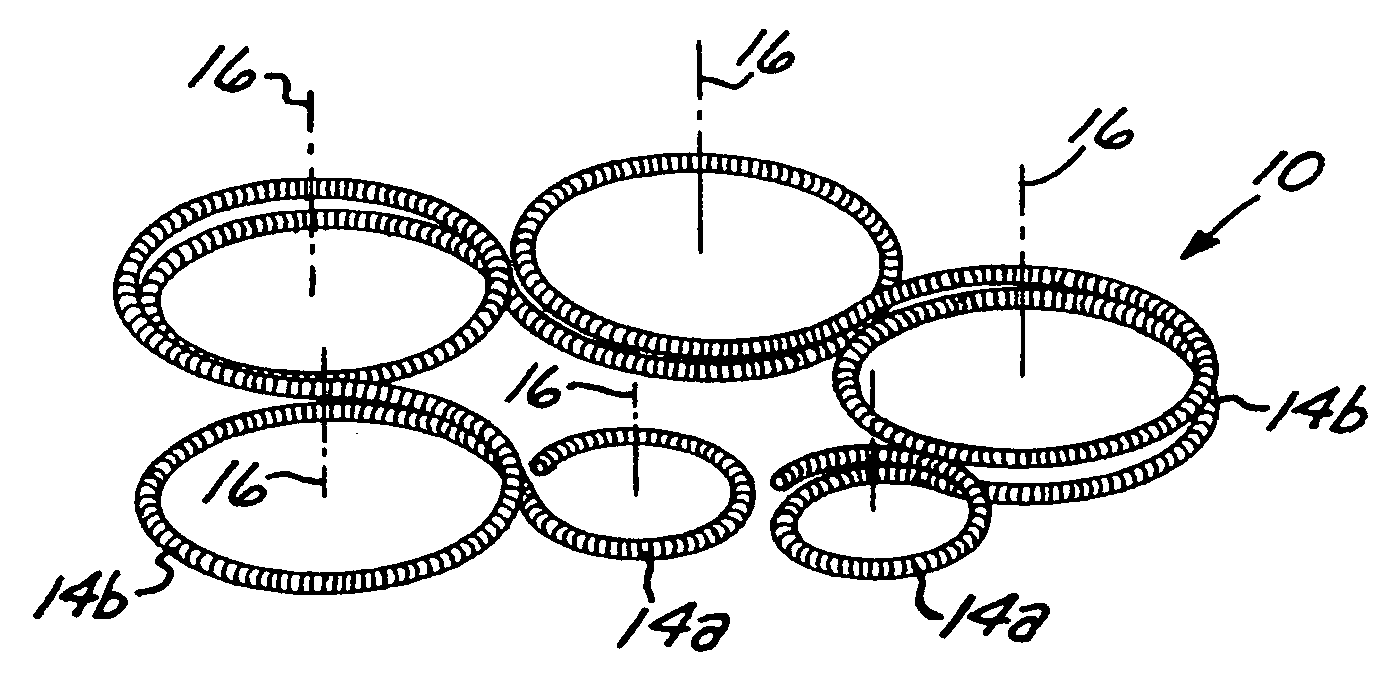

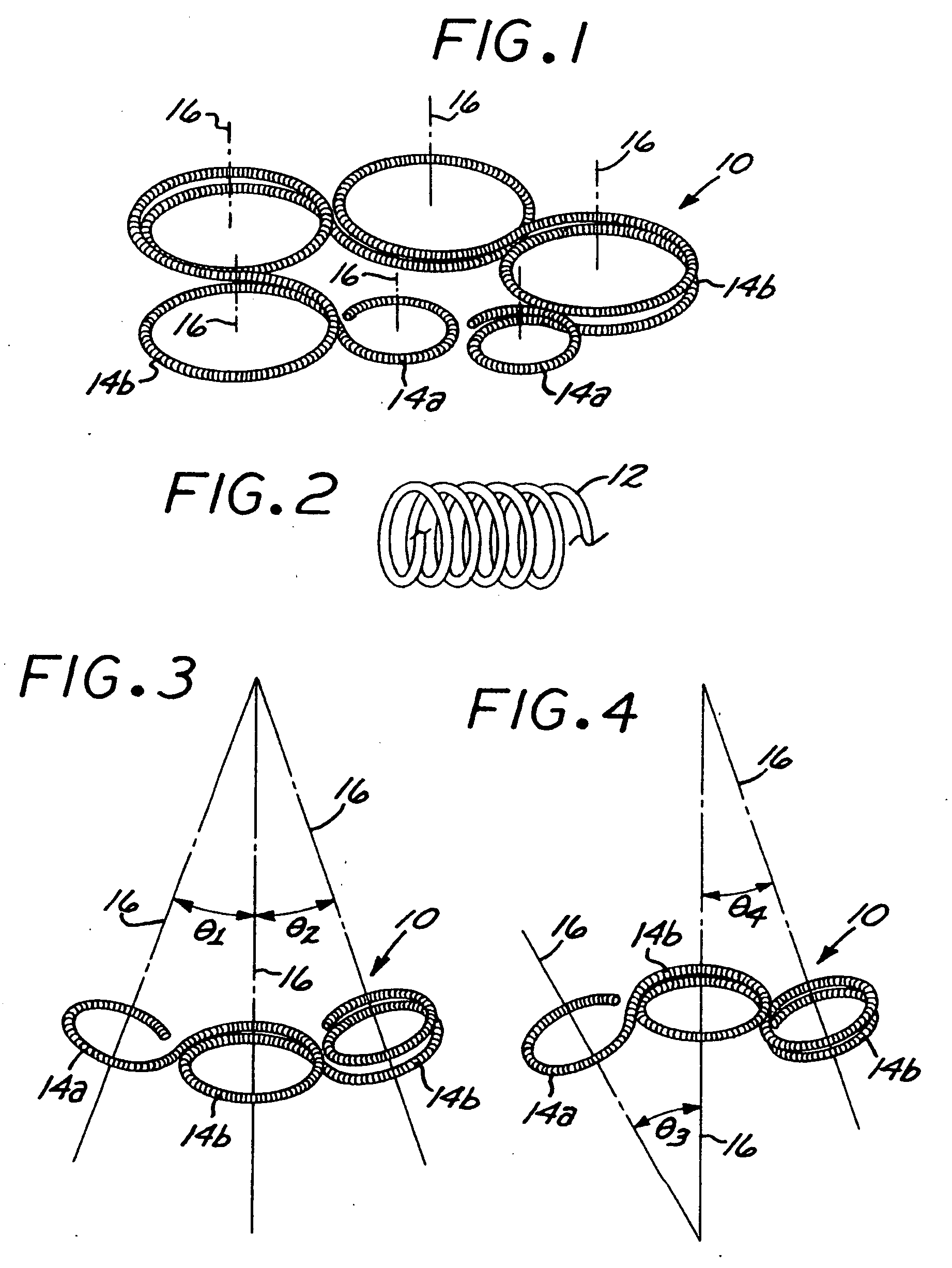

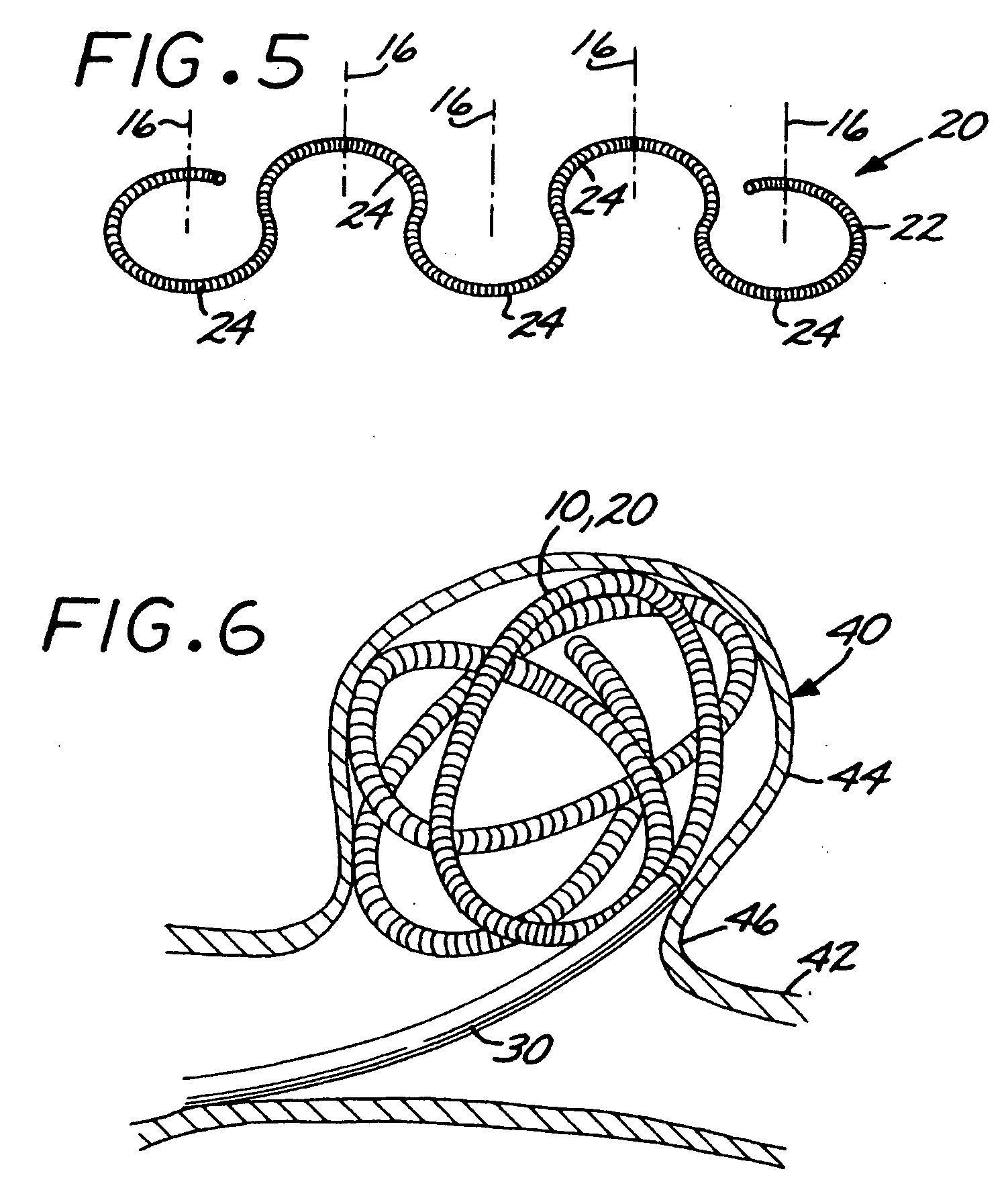

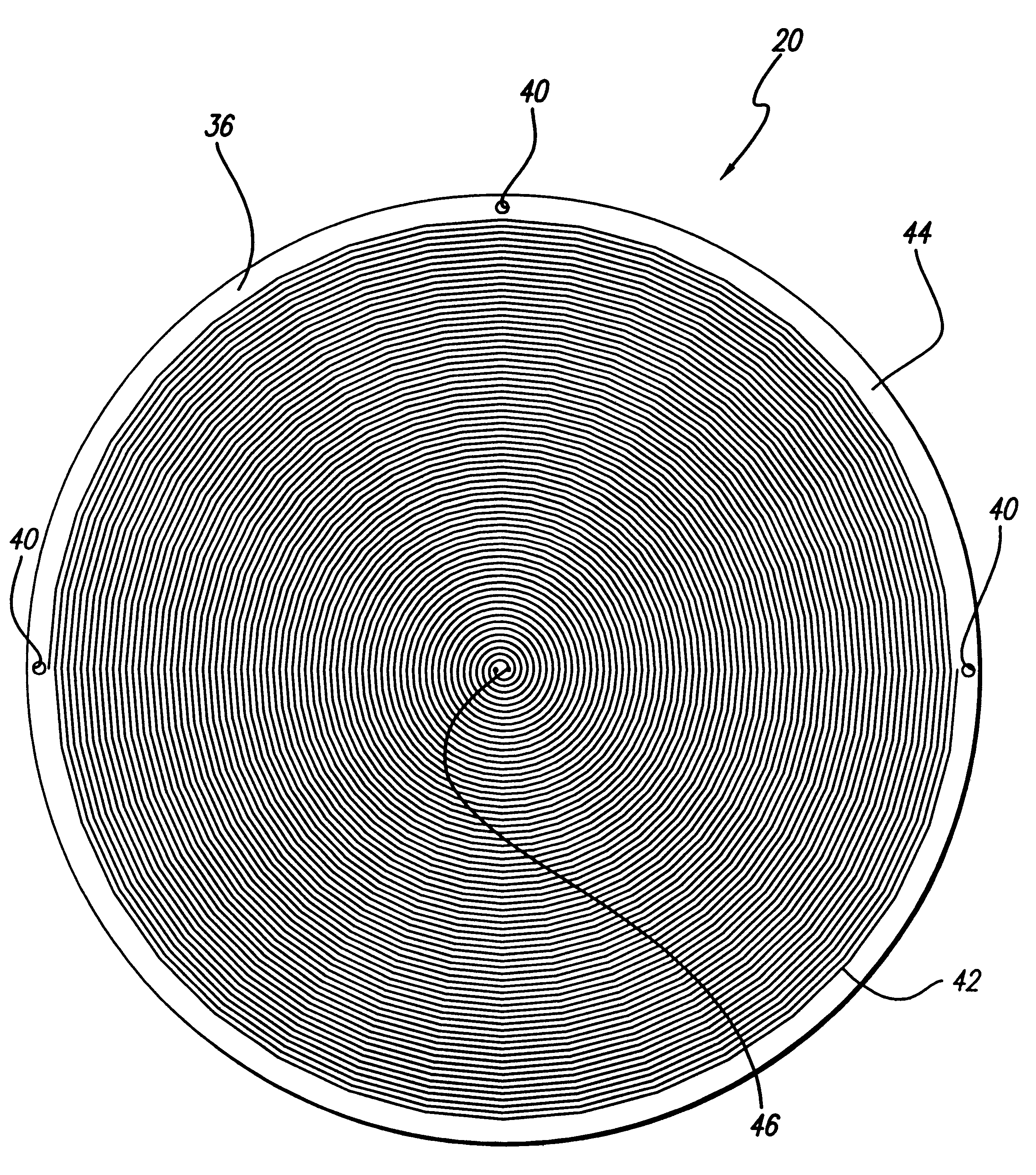

Microcoil vaso-occlusive device with multi-axis secondary configuration

InactiveUS7033374B2Minimizing shifting and tumblingMinimizing degree of compactionDilatorsOcculdersHigh energyClosed loop

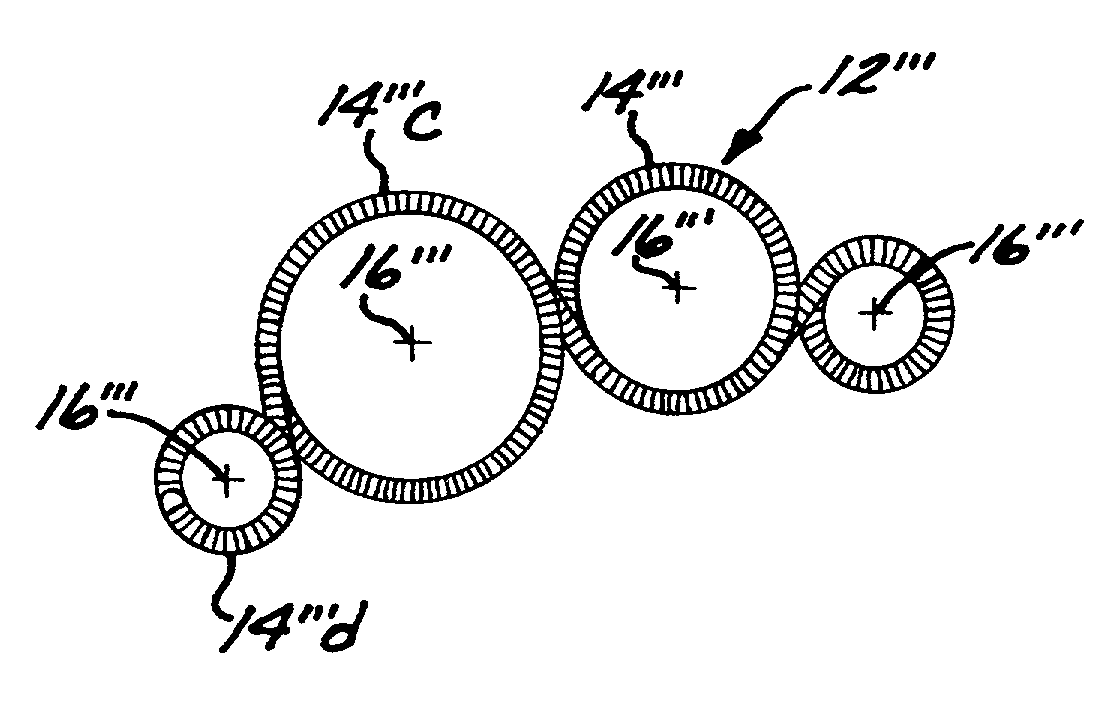

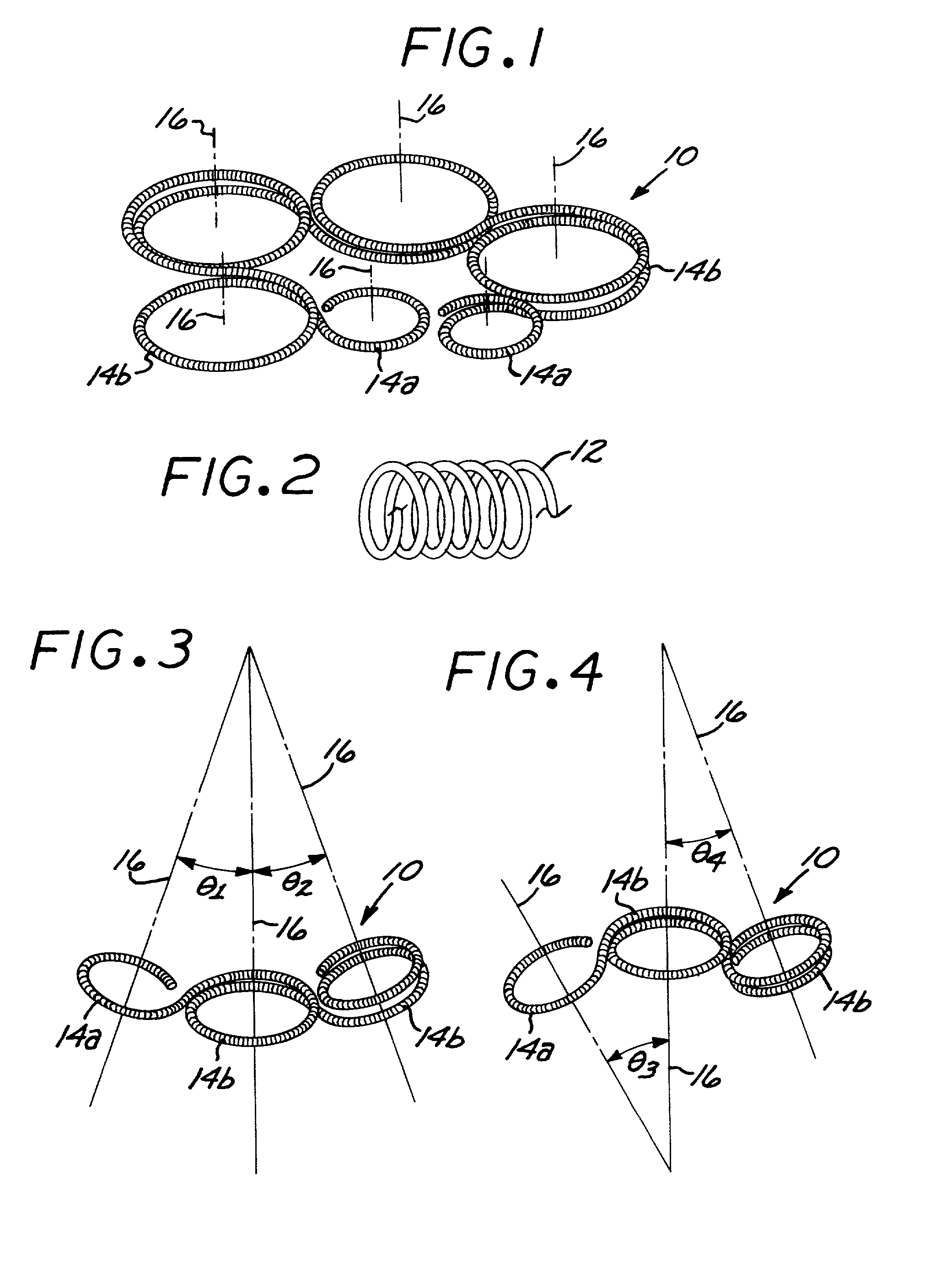

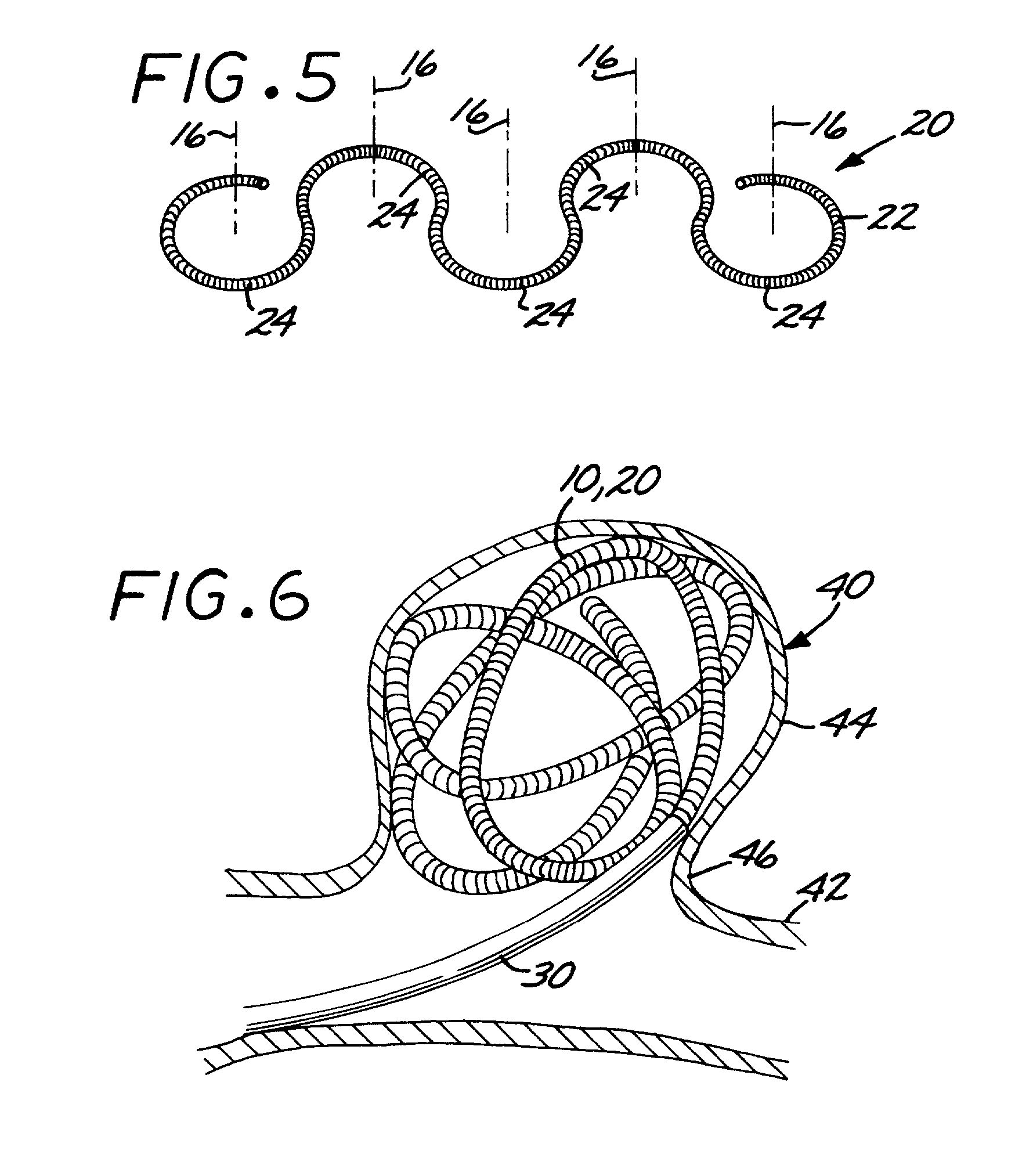

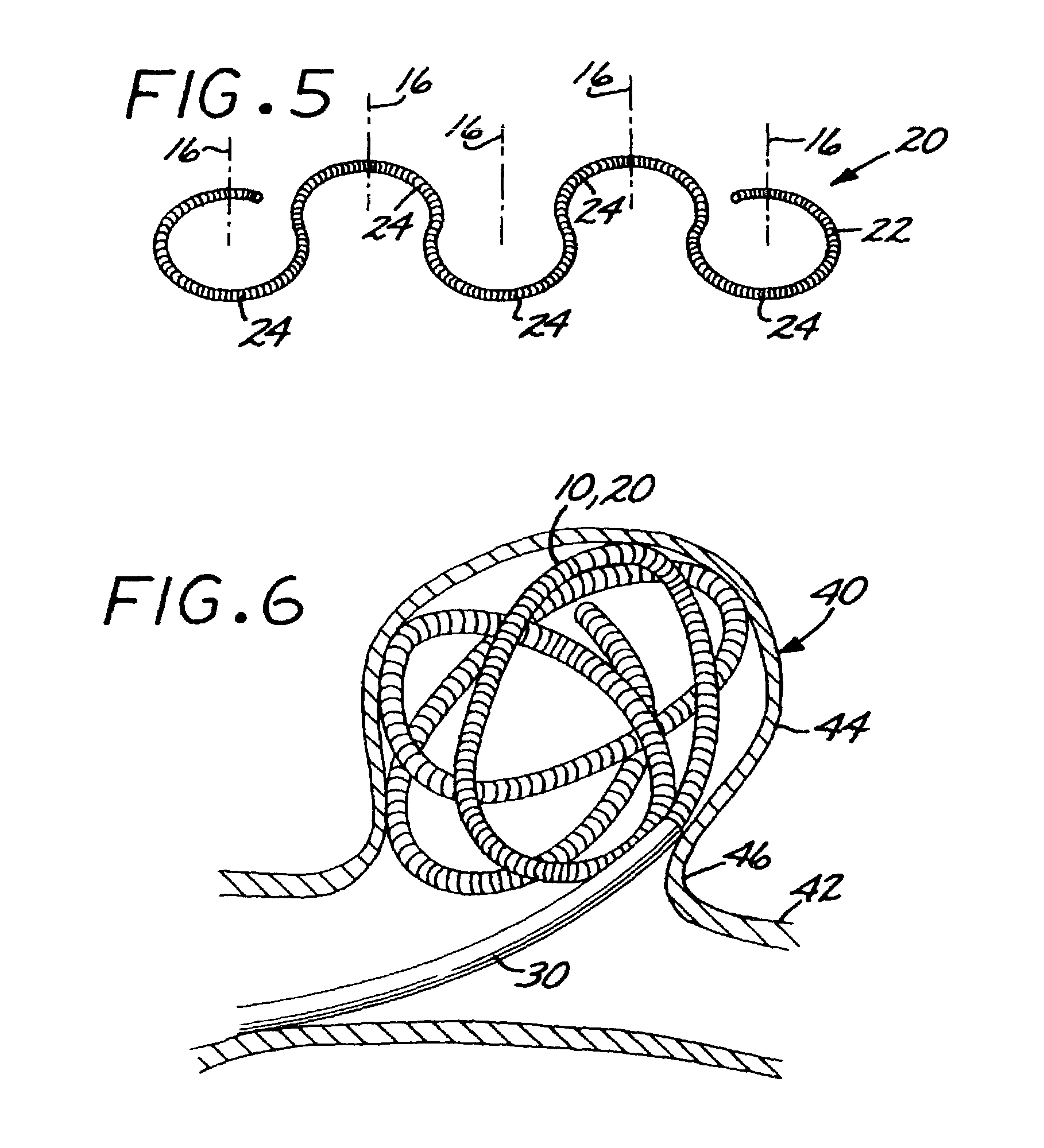

A vaso-occlusive device includes a microcoil formed into a minimum energy state secondary configuration comprising a plurality of curved segments, each defining a discrete axis, whereby the device, in its minimum energy state configuration, defines multiple axes. In a preferred embodiment, the secondary configuration-comprises a plurality of interconnected closed loops defining a plurality of discrete axes. In a second embodiment, the secondary configuration defines a wave-form like structure comprising an array of laterally-alternating open loops defining a plurality of separate axes. In a third embodiment, the secondary configuration forms a series of tangential closed loops, wherein the entire structure subtends a first angle of arc, and wherein each adjacent pair of loops defines a second angle of arc. In a fourth embodiment, the secondary configuration forms a logarithmic spiral. In all embodiments, the device, in its secondary configuration, has a dimension that is substantially larger than the largest dimension of the vascular site (i.e., aneurysm) in which it is to be deployed. Thus, confinement of the device within an aneurysm causes it to assume a three-dimensional configuration with a higher energy state than the minimum energy state. Because the minimum energy state configuration of the device is larger (in at least one dimension) than the aneurysm, the deployed device is constrained by its contact with the walls of the aneurysm from returning to its minimum energy state configuration. The engagement of the device with the aneurysm wall minimizes shifting or tumbling due to blood flow. Furthermore, the secondary configuration is not conducive to “coin stacking,” thereby minimizing the compaction experienced.

Owner:MICROVENTION INC

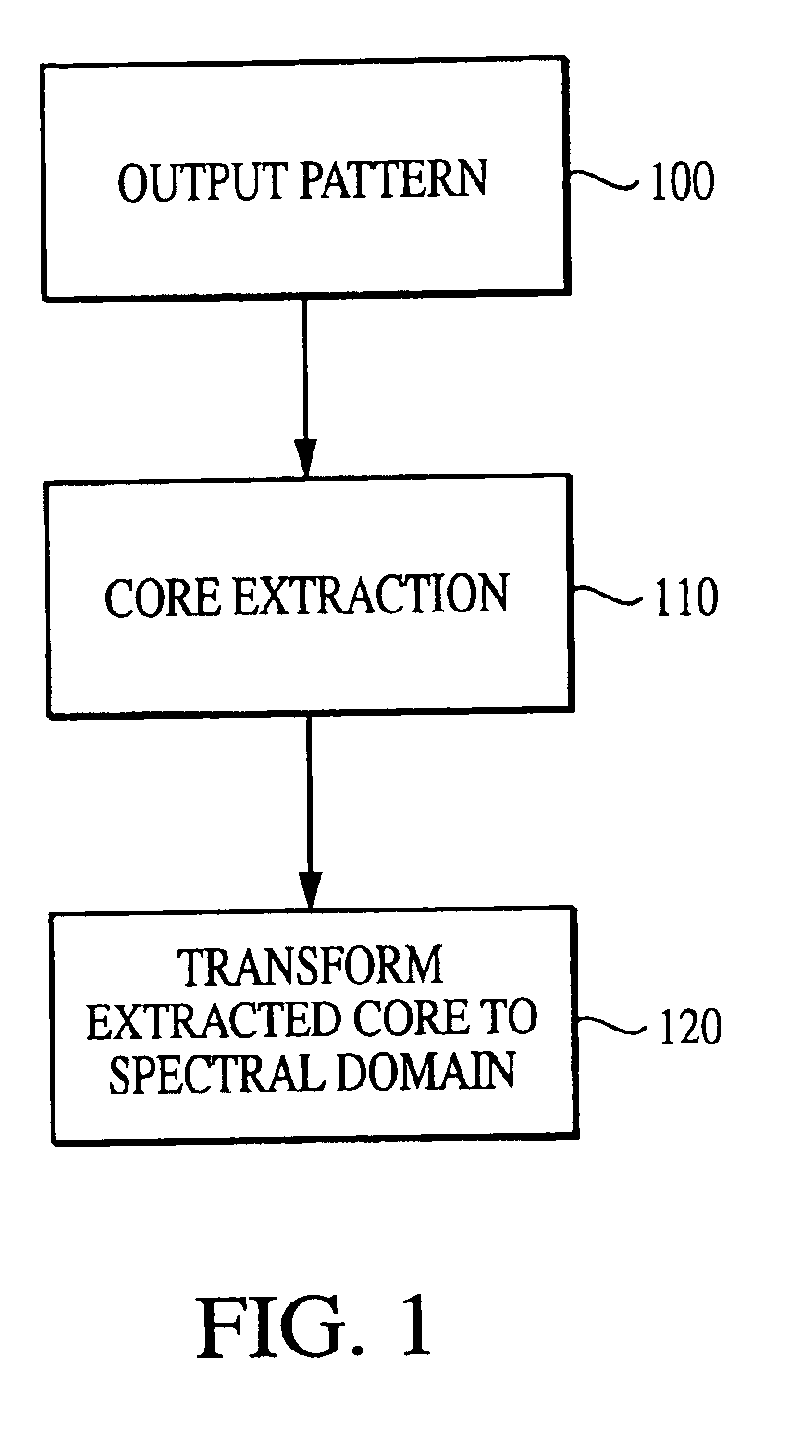

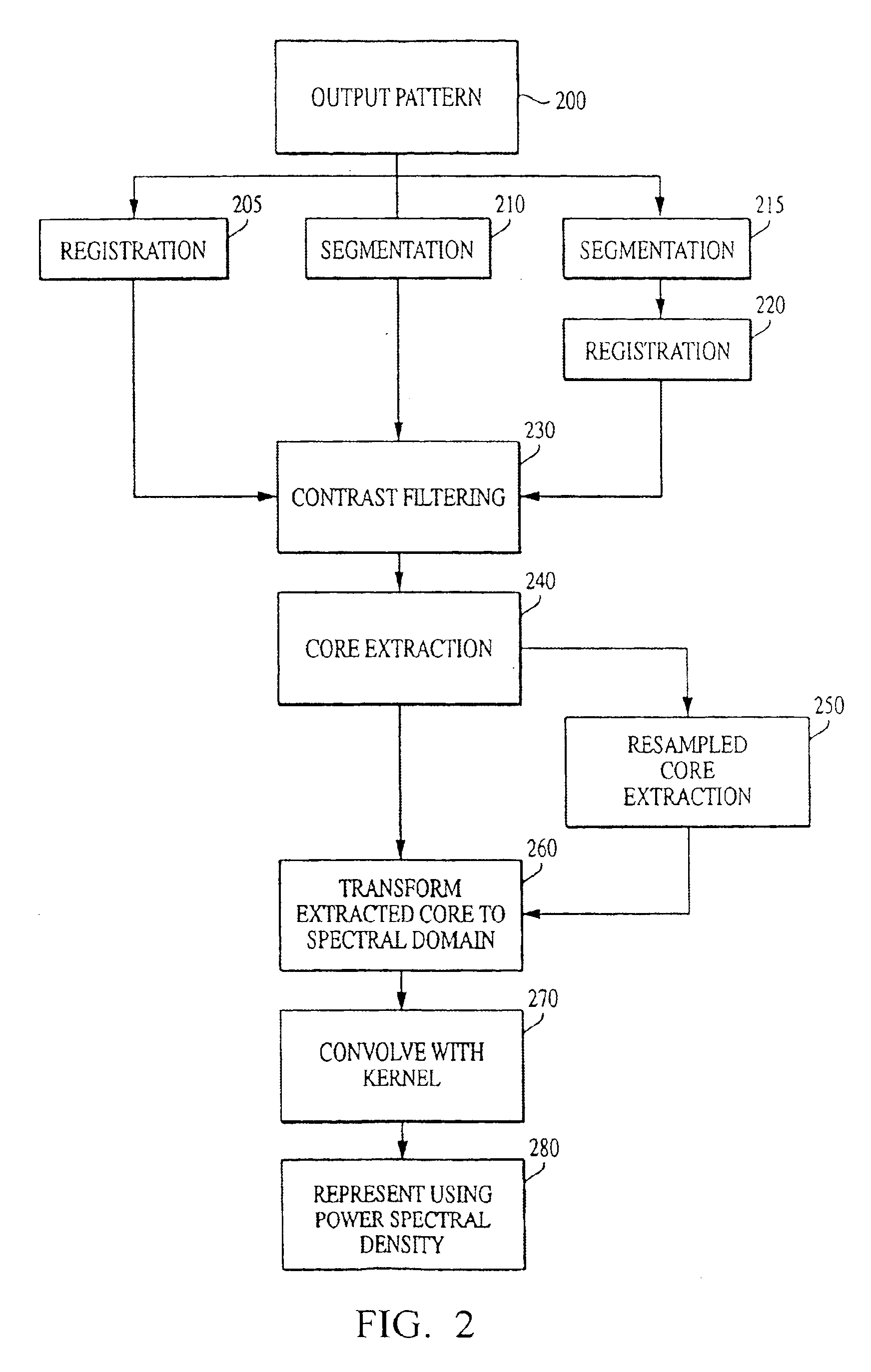

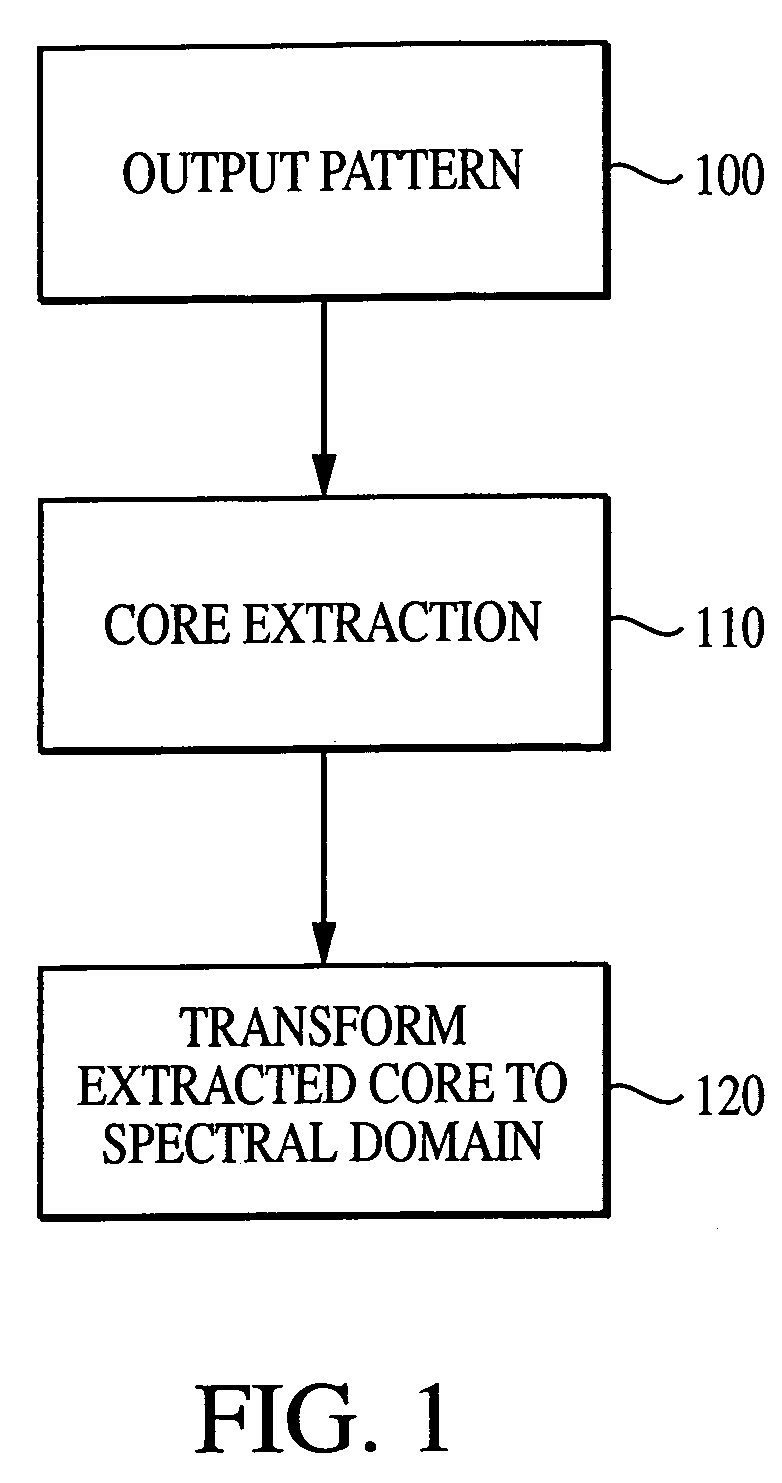

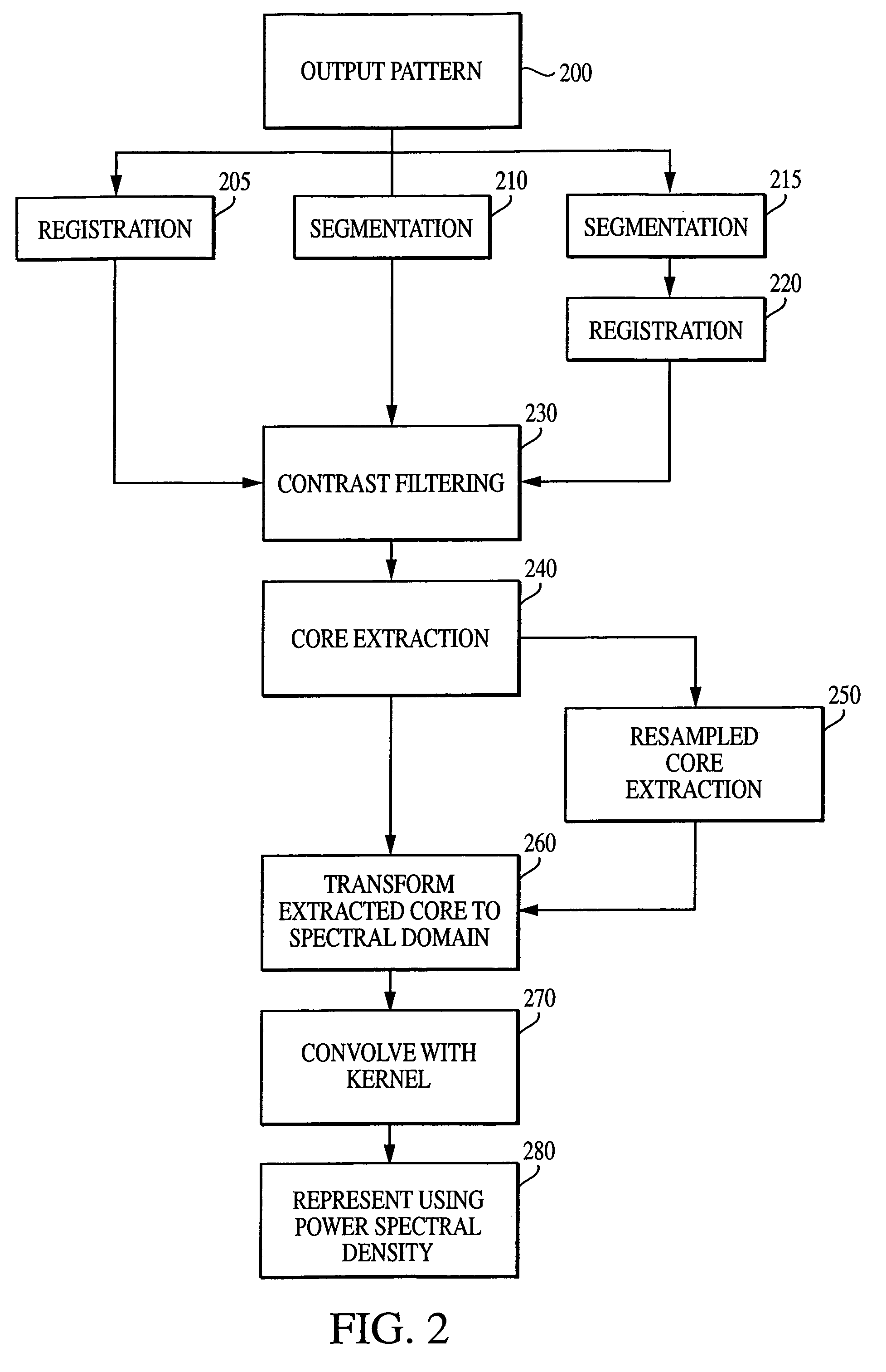

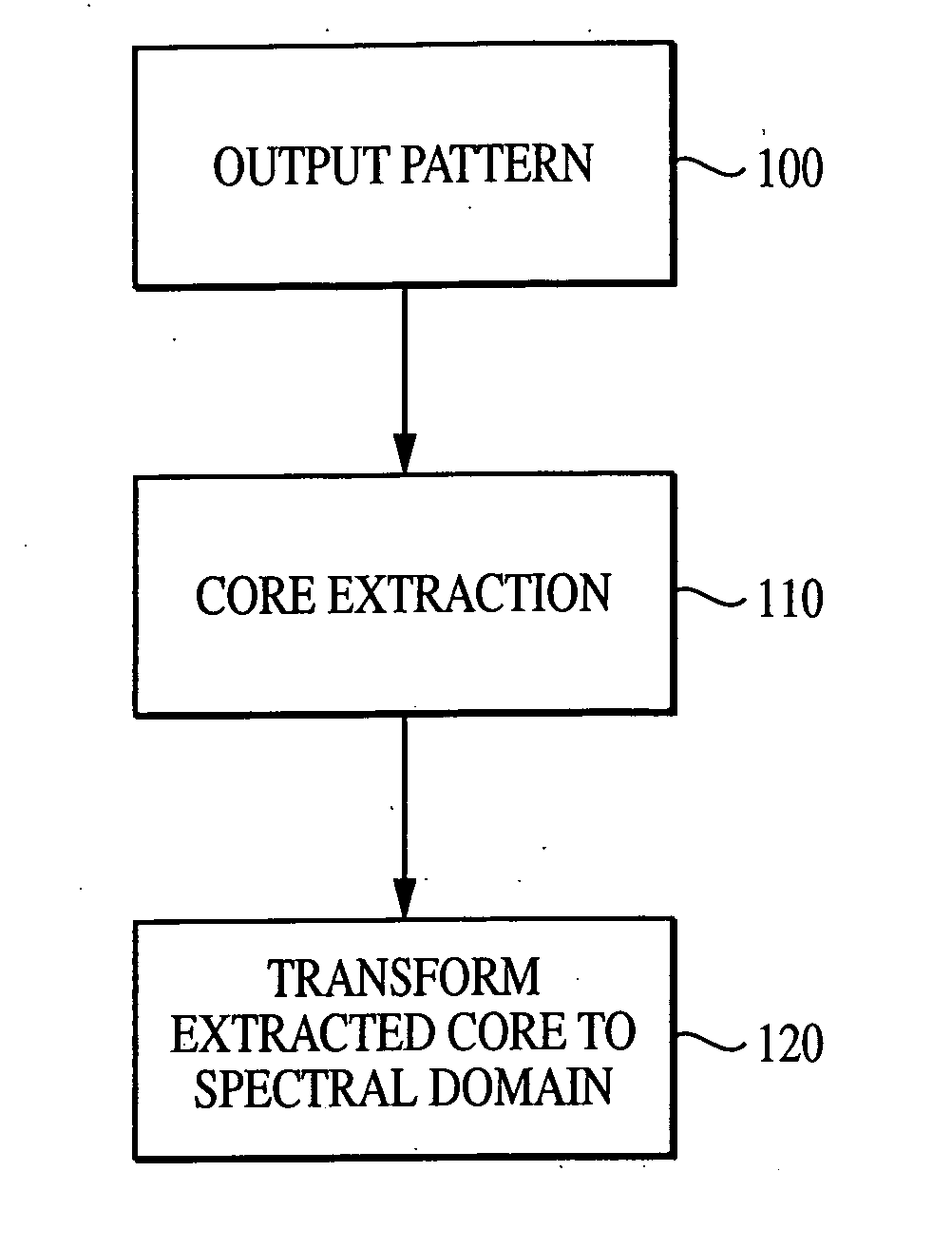

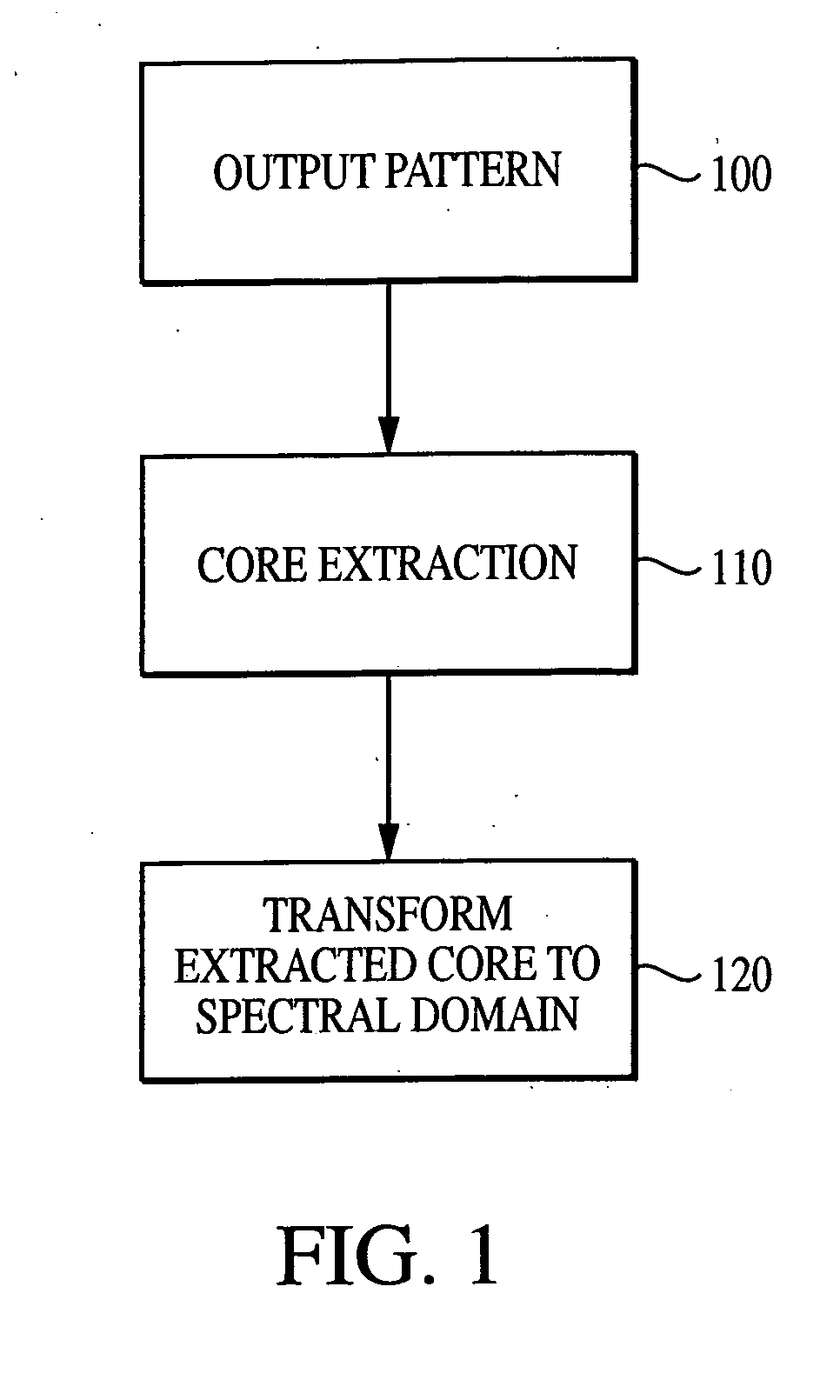

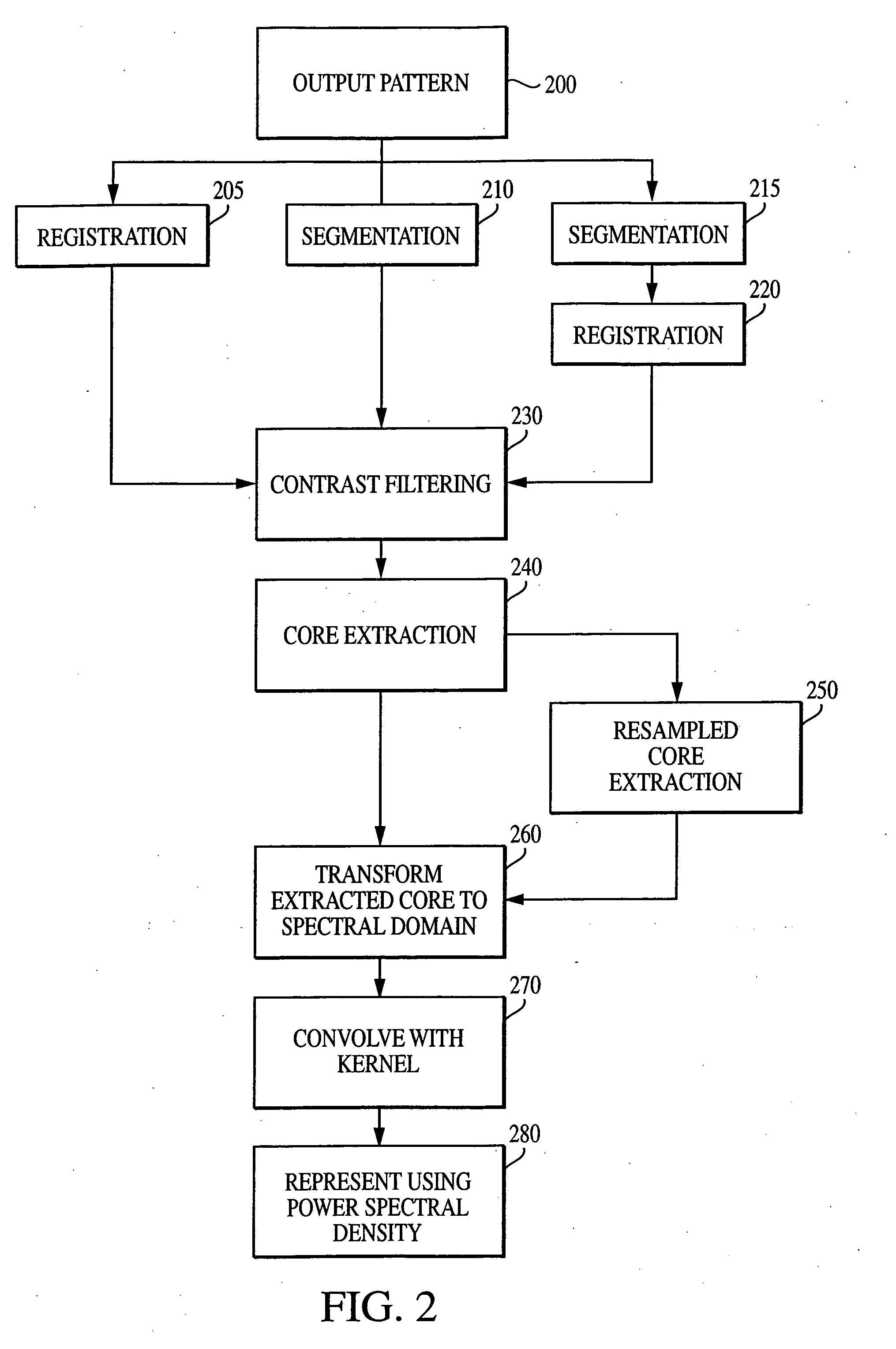

System and method for characterizing microarray output data

InactiveUS7006680B2Increase contrastImprove spatial resolutionImage enhancementImage analysisFrequency spectrumSpectral transformation

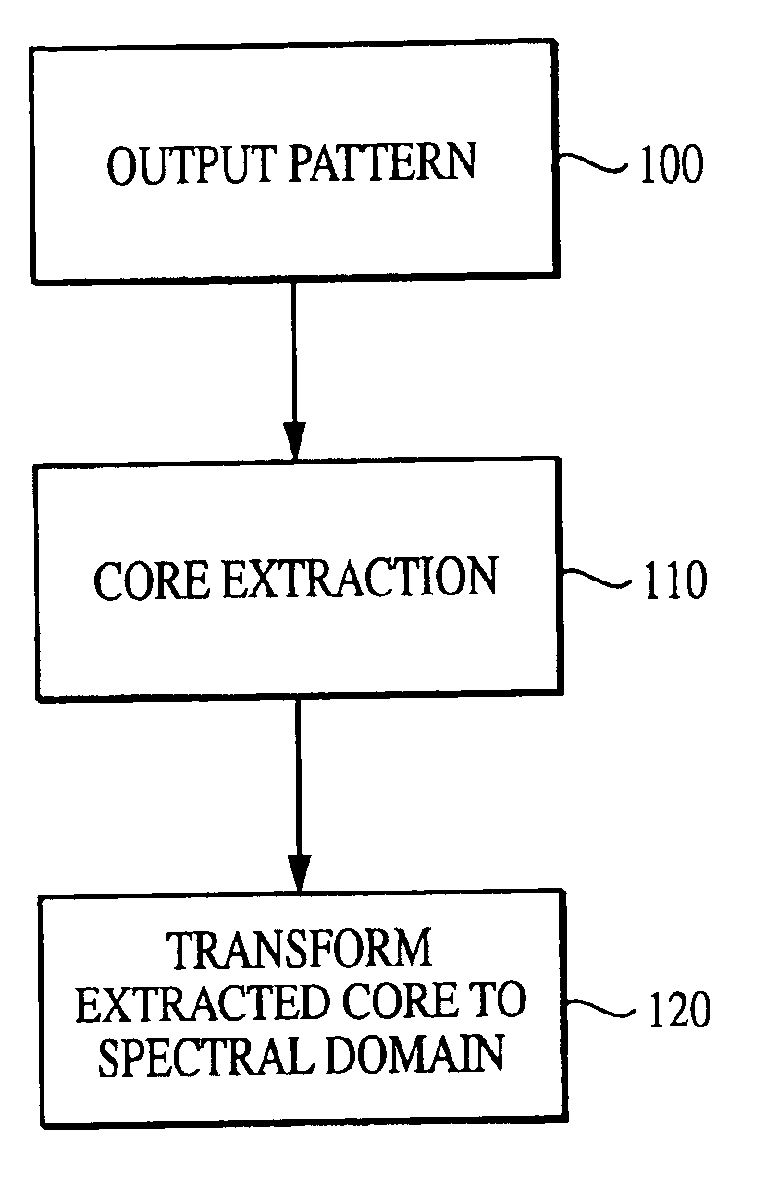

The current invention discloses a novel spectral transformation technique for characterizing digitized intensity output patterns from microarrays. This method yields improved sensitivity with reduced false positives and false negatives. Current microarray methods are overly sensitive to the detection of a visible distinction between pixels associated with probes and pixels associated with background. In one embodiment, a technique is disclosed that comprises the steps of: extracting pixels associated with an object of interest and transforming such pixels from an intensity representation to a spectral representation. In some embodiments, the extraction is based on a tessellated logarithmic spiral extraction that may yield a pixel core with a sampling of both foreground and background pixels. This core may then be computationally rescaled by 10×-10,000× to enhance spatial resolution. Once the extracted pixels are represented in the spectral regime, convolution with resolution-enhancement kernels may be used to accentuate morphological features capturing platform specific phenomenology.

Owner:VIALOGY

Microcoil vaso-occlusive device with multi-axis secondary configuration

InactiveUS7029486B2Minimizing shifting and tumblingMinimizing degree of compactionDilatorsOcculdersHigh energyClosed loop

A microcoil vaso-occlusive device has a minimum energy state secondary configuration having a plurality of curved segments, each defining a discrete axis. The secondary configuration may be a plurality of interconnected closed loops; an array of laterally-alternating open loops; a series of tangential closed loops; or a logarithmic spiral. The device, in its secondary cofiguration, has a dimension that is substantially larger than the largest dimension of the vascular site in which it is to be deployed. Thus, confinement of the device within the site causes it to assume a configuration with a higher energy state than the minimum energy state. Because the secondary configuration is larger (in at least one dimension) than the site, the device is constrained, by contact with the walls of the site, from returning to its secondary configuration, and shifting of the device due to blood flow is minimized.

Owner:MICROVENTION INC

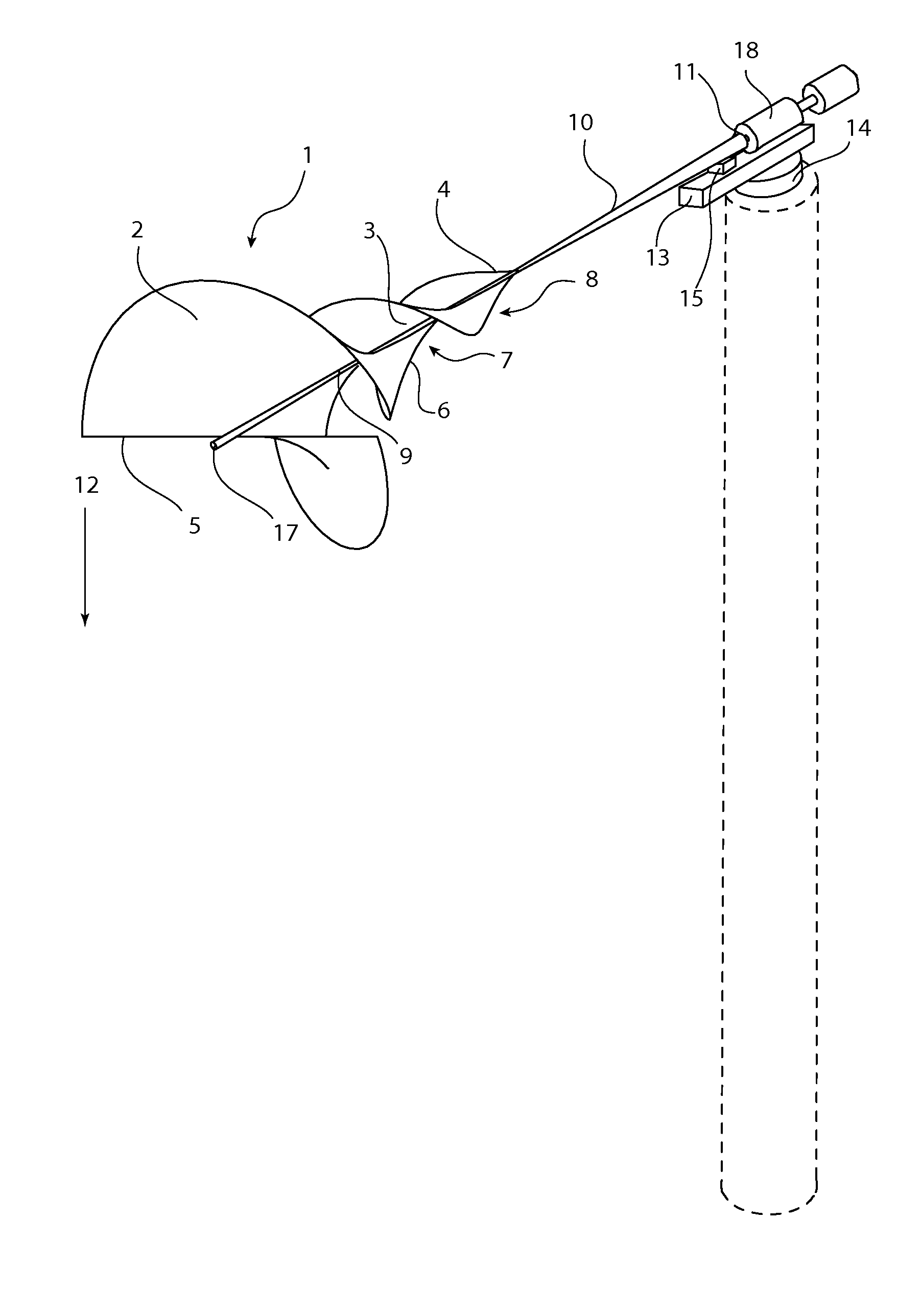

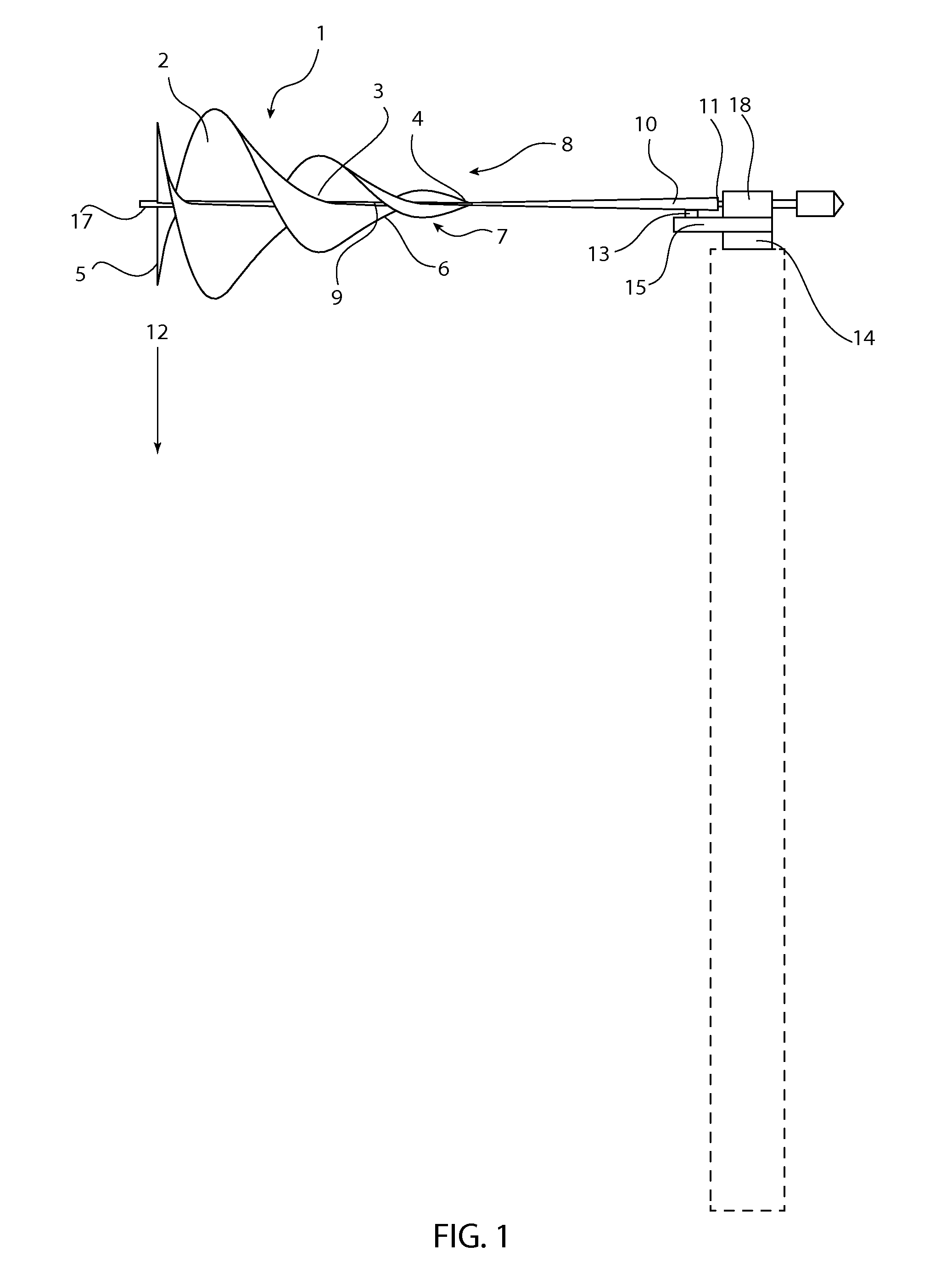

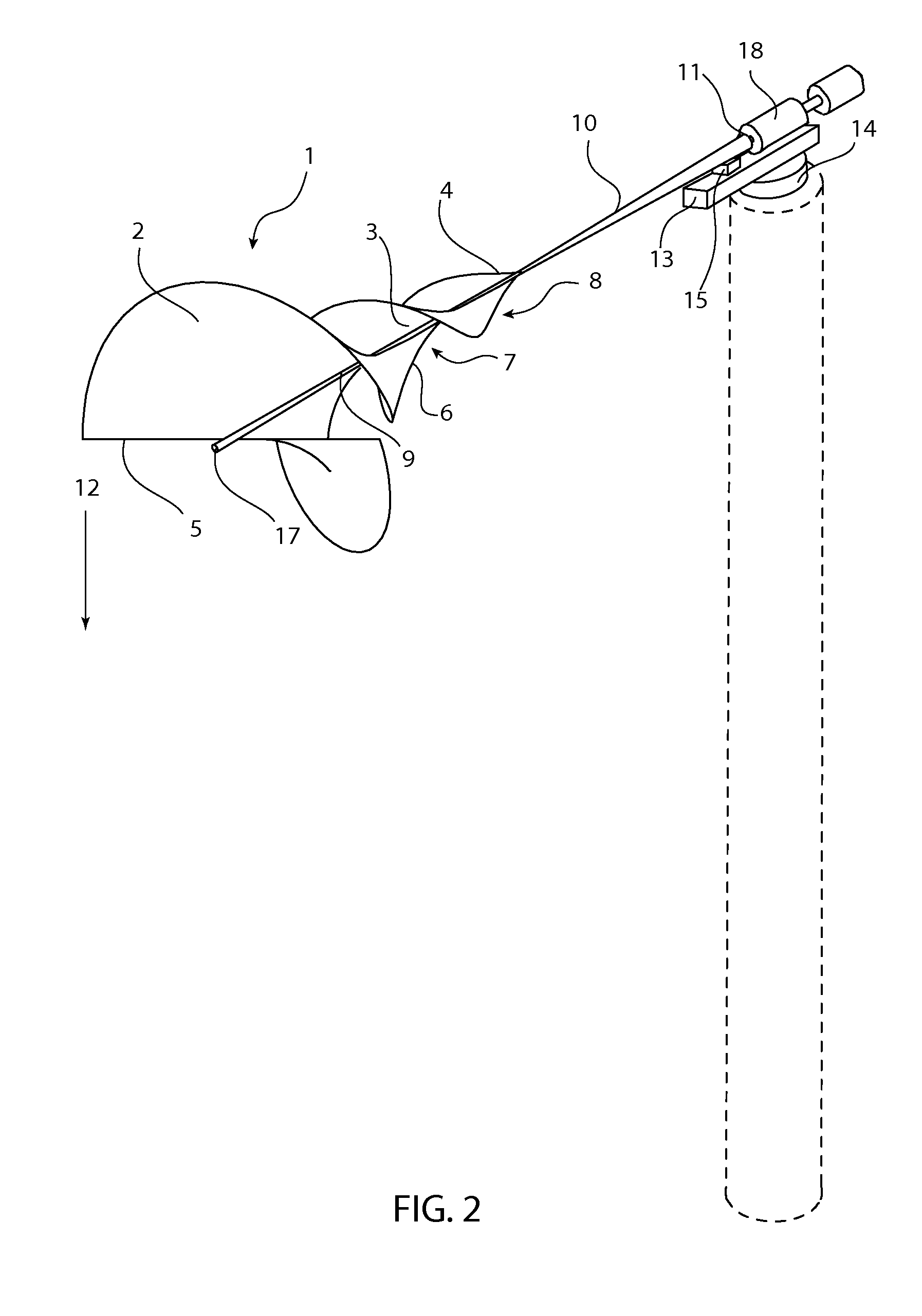

Horizontal Axis Logarithmic Spiral Fluid Turbine

InactiveUS20120076656A1More kinetic energyEfficient collectionPropellersPump componentsForms of energyHorizontal axis

The present invention is a more simplified and efficient design of a turbine. The use of a logarithmic curve pattern for blade design and an aerodynamic profile allows the present invention to not only be versatile in its uses, but also much more efficient at gathering forms of energy for different purposes.

Owner:ABASS OMAR NABIL

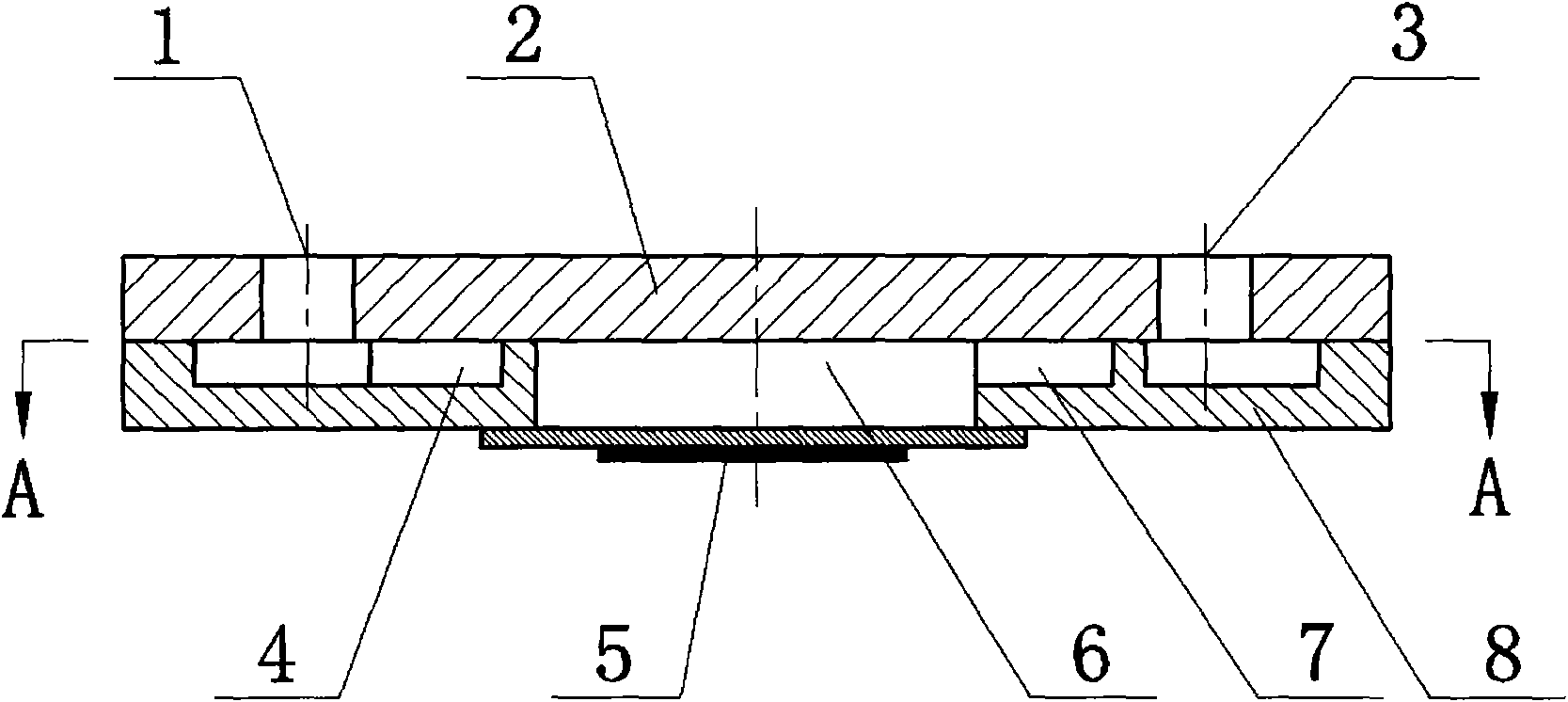

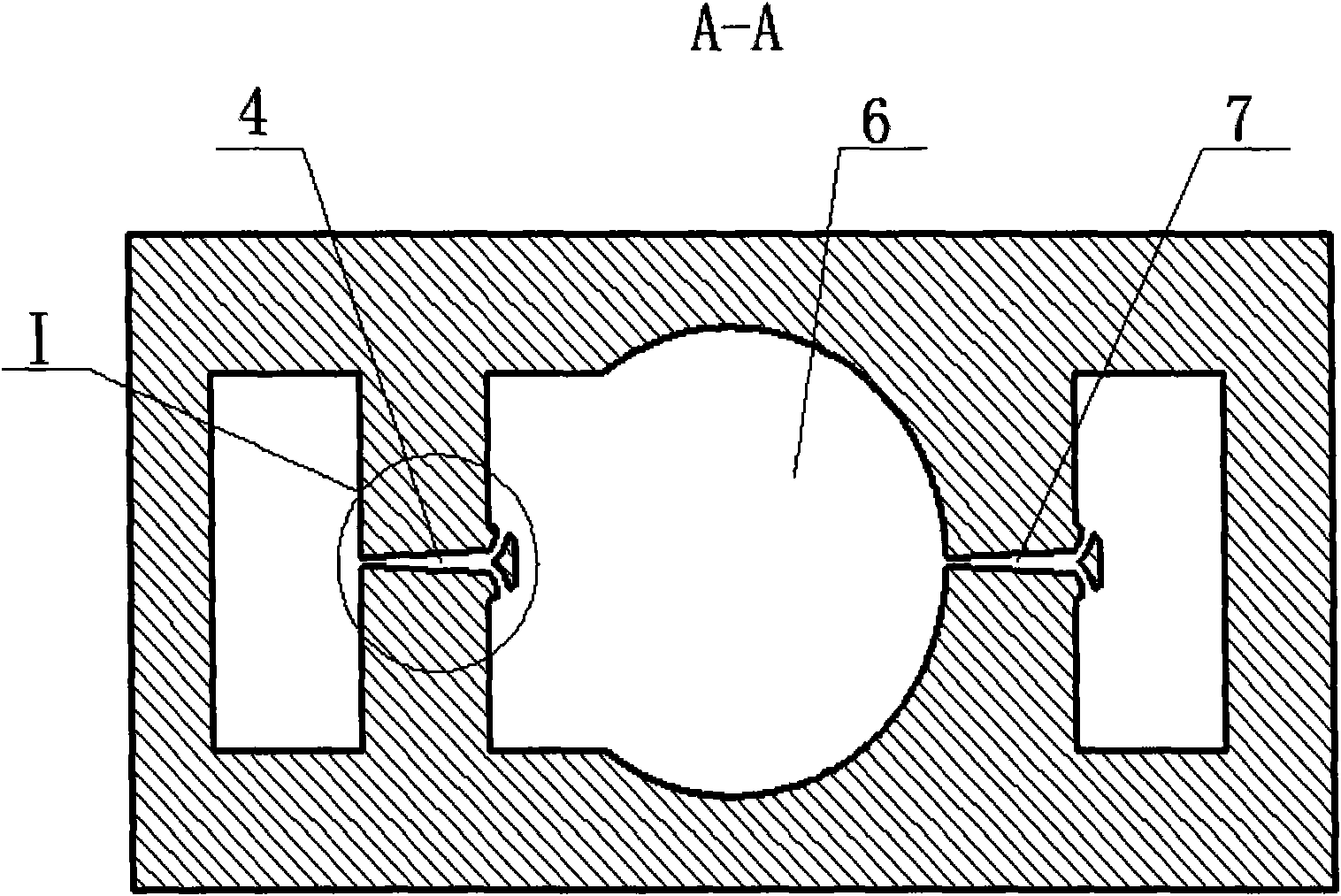

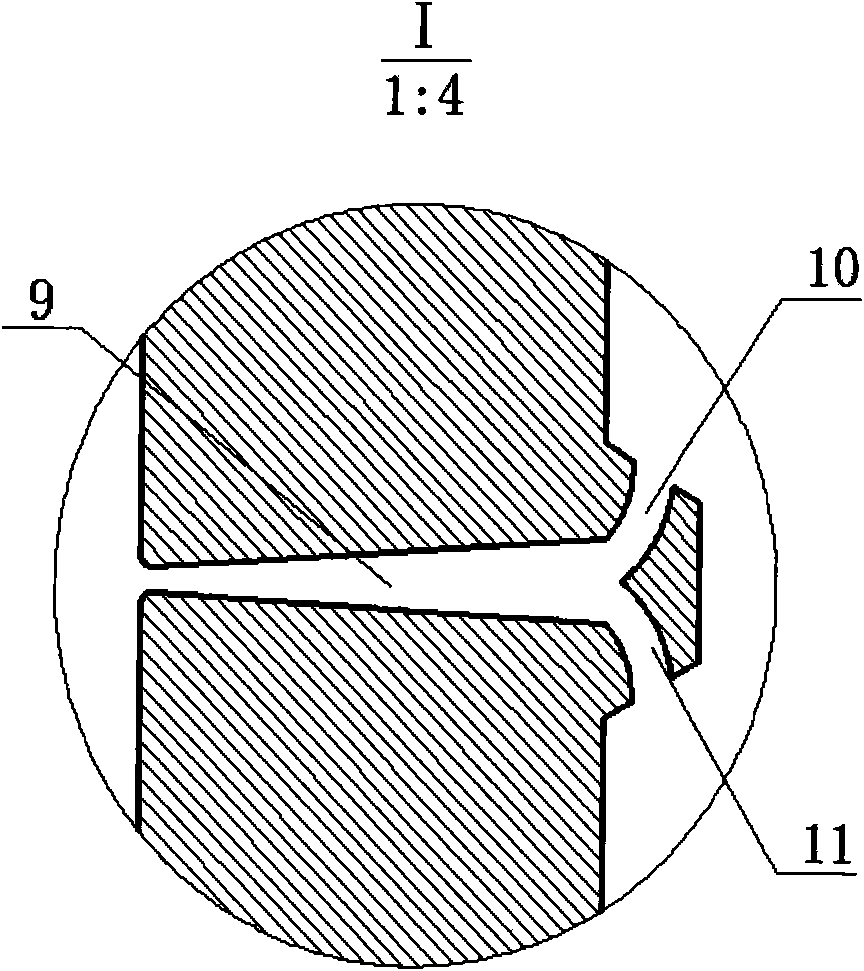

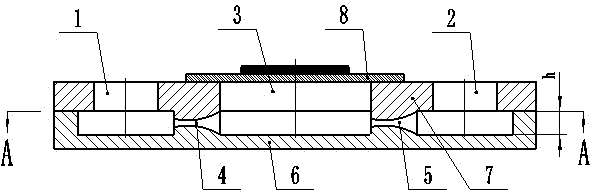

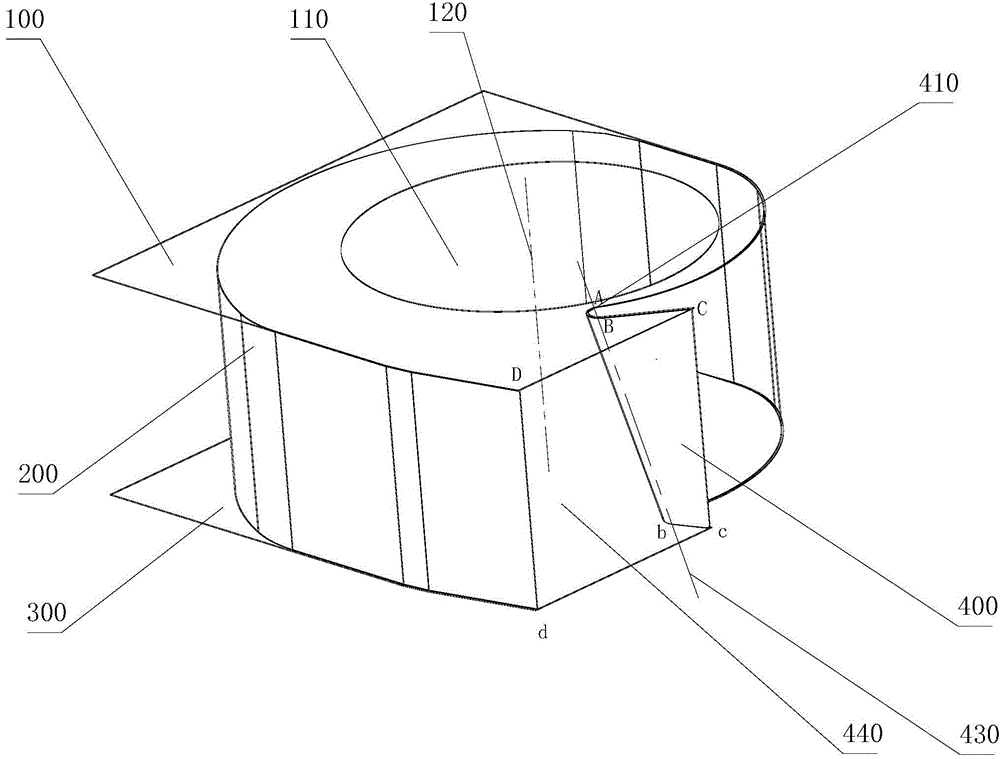

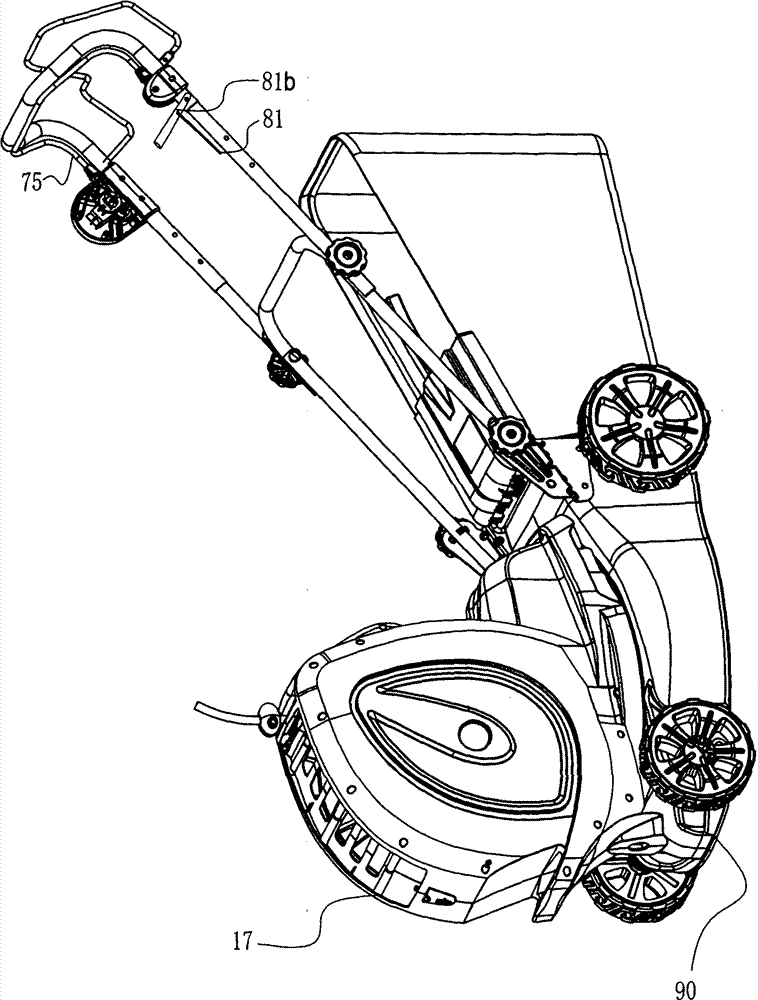

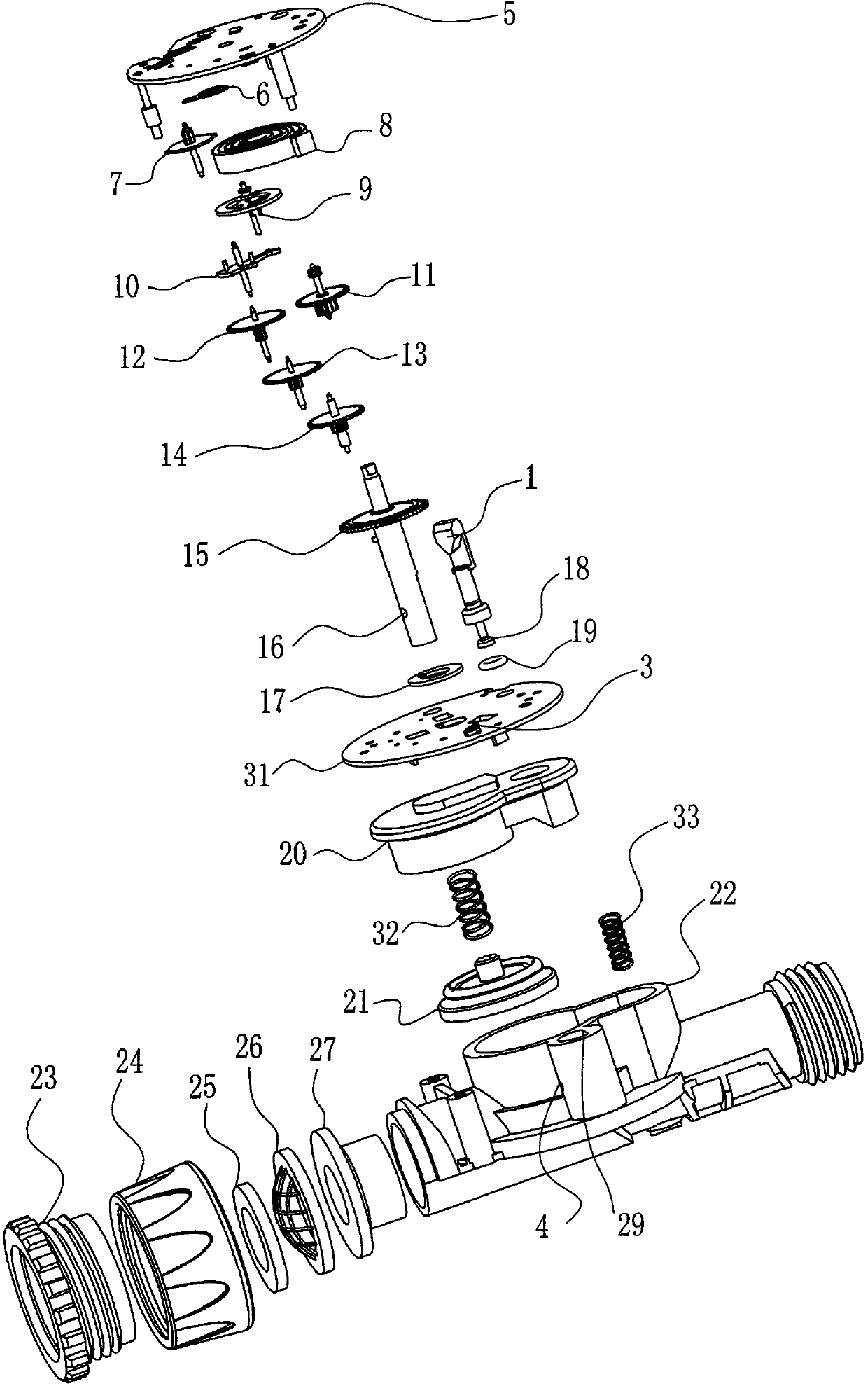

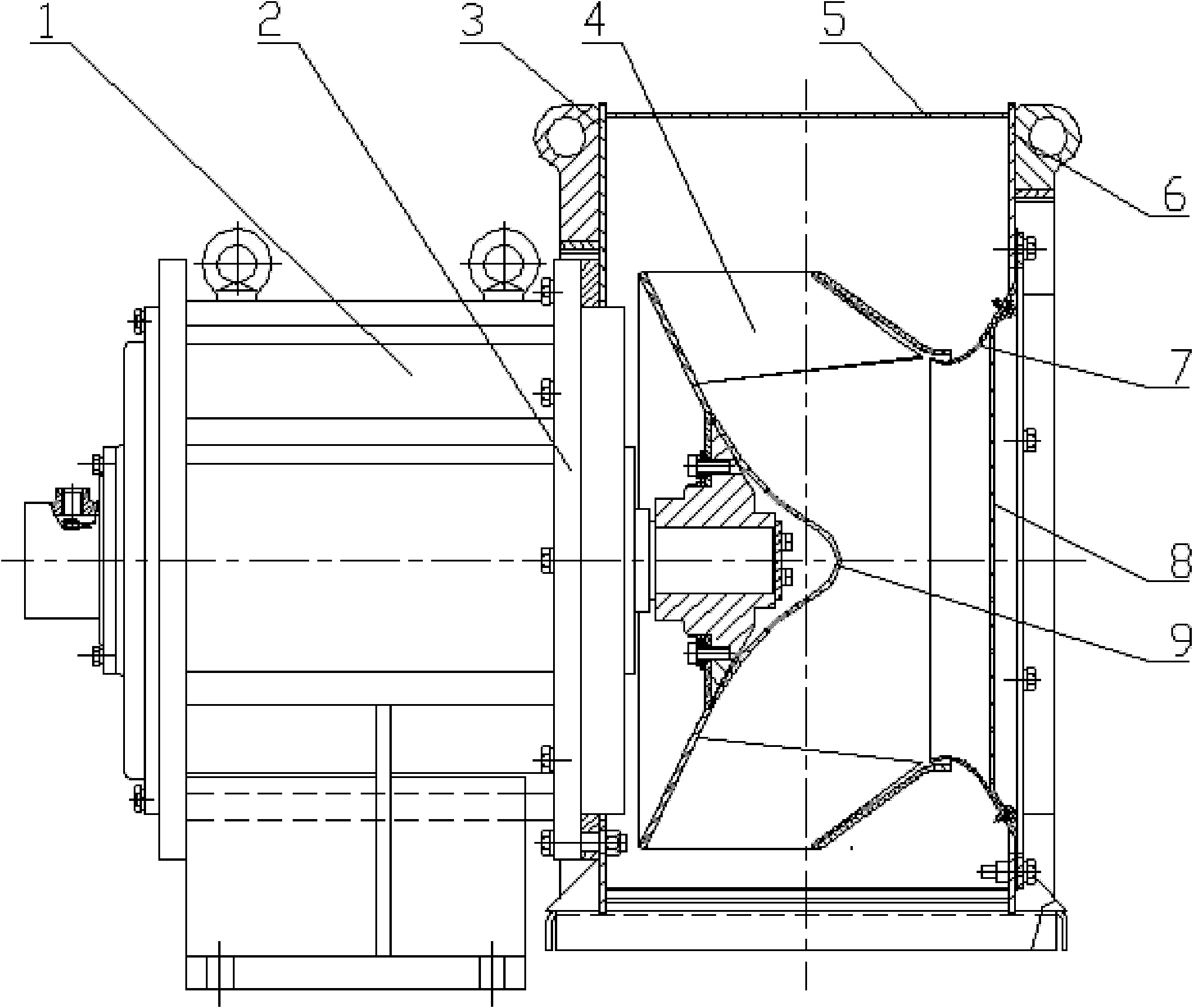

Valve-free piezoelectric pump of logarithmic spiral combined tube

InactiveCN101975154ANo damageSmall scalePositive displacement pump componentsFlexible member pumpsEngineeringInlet flow

The invention discloses a valve-free piezoelectric pump of a logarithmic spiral combined tube in the field of microfluid transmission and control, comprising a pump body, a pump cover and a piezoelectric vibrator, wherein the pump body is provided with an inlet flow pipe, an outlet flow pipe and a pump cavity; the inlet flow pipe and the outlet flow pipe have the same structure, are coaxially arranged, have the equal distance with the circle center of the pump cavity and comprise confluence taper tubes and two shunt logarithmic spiral tube communicated with the large ends of the confluence taper tubes respectively; the included angle of center lines of the two shunt logarithmic spiral tubes is 120 degrees; the center lines of the two shunt logarithmic spiral tube are symmetrical to the center lines of the confluence taper tubes; and the contour lines of the shunt logarithmic spiral tube are two adjacent logarithmic spiral lines with a wrap angle of 45 degrees, which are determined by the logarithmic spiral equation of rho=rho0*ek theta. The valve-free piezoelectric pump has small size and high flow resistance coefficient ratio; the flow vortex in the pump is extremely small and has no damage to the transported medium; compared with the valve-free piezoelectric with other structure, the unidirectional flow resistivity is reduced greatly, so that the energy consumption is low and the energy-saving effect is remarkable; and the valve pressure free electric pump has simple structure and controls the flow rate more easily.

Owner:JIANGSU UNIV

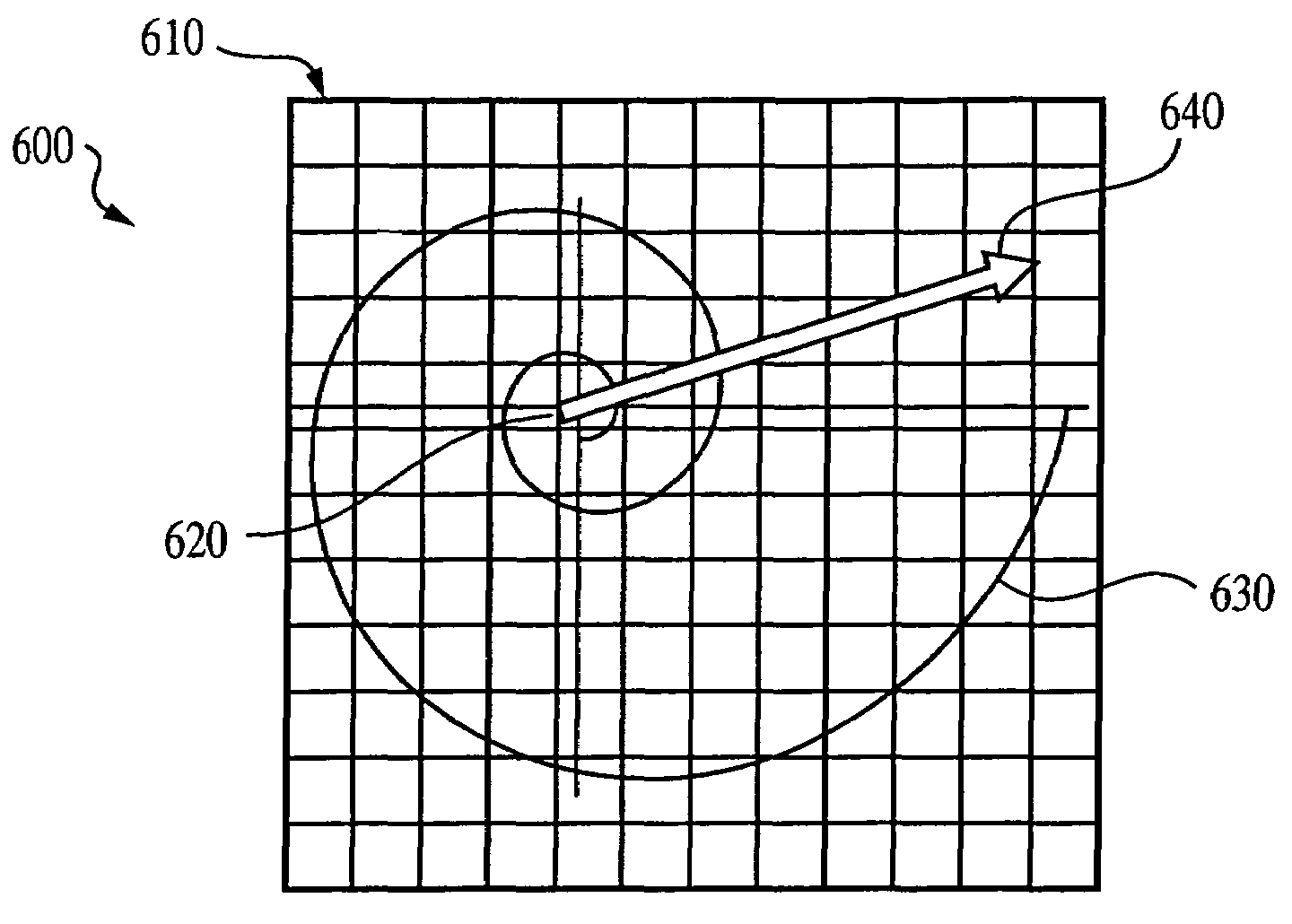

Technique for extracting arrayed data

InactiveUS7466851B2Increase contrastImprove spatial resolutionImage enhancementImage analysisFrequency spectrumImage resolution

The current invention discloses a novel spectral transformation technique for characterizing digitized intensity output patterns from microarrays. This method yields improved sensitivity with reduced false positives and false negatives. Current microarray methods are overly sensitive to the detection of a visible distinction between pixels associated with probes and pixels associated with background. In one embodiment, a technique is disclosed that comprises the steps of: extracting pixels associated with an object of interest and transforming such pixels from an intensity representation to a spectral representation. In some embodiments, the extraction is based on a tessellated logarithmic spiral extraction that may yield a pixel core with a sampling of both foreground and background pixels. This core may then be computationally rescaled by 10×-10,000× to enhance spatial resolution. Once the extracted pixels are represented in the spectral regime, convolution with resolution-enhancement kernels may be used to accentuate morphological features capturing platform specific phenomenology.

Owner:VIALOGY

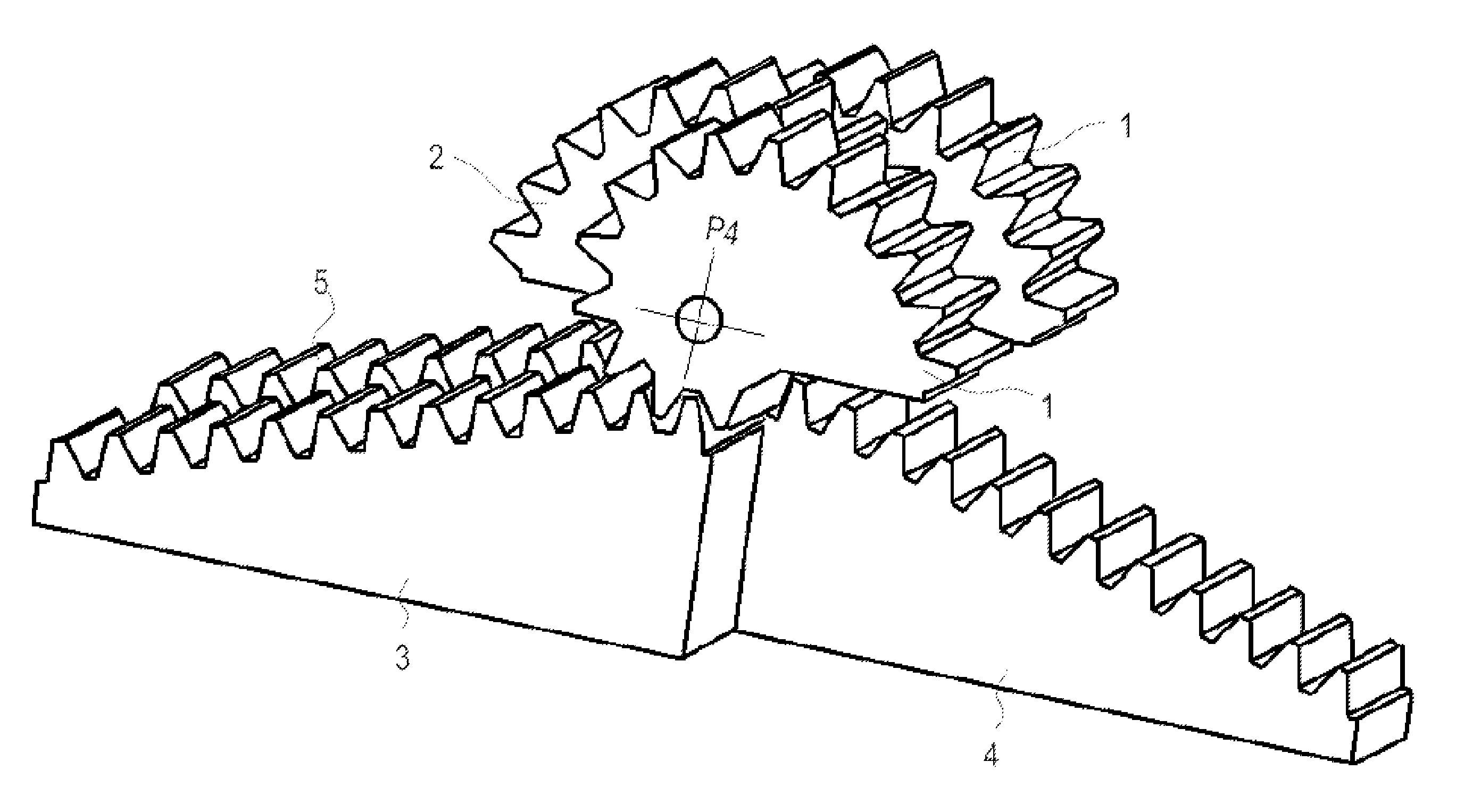

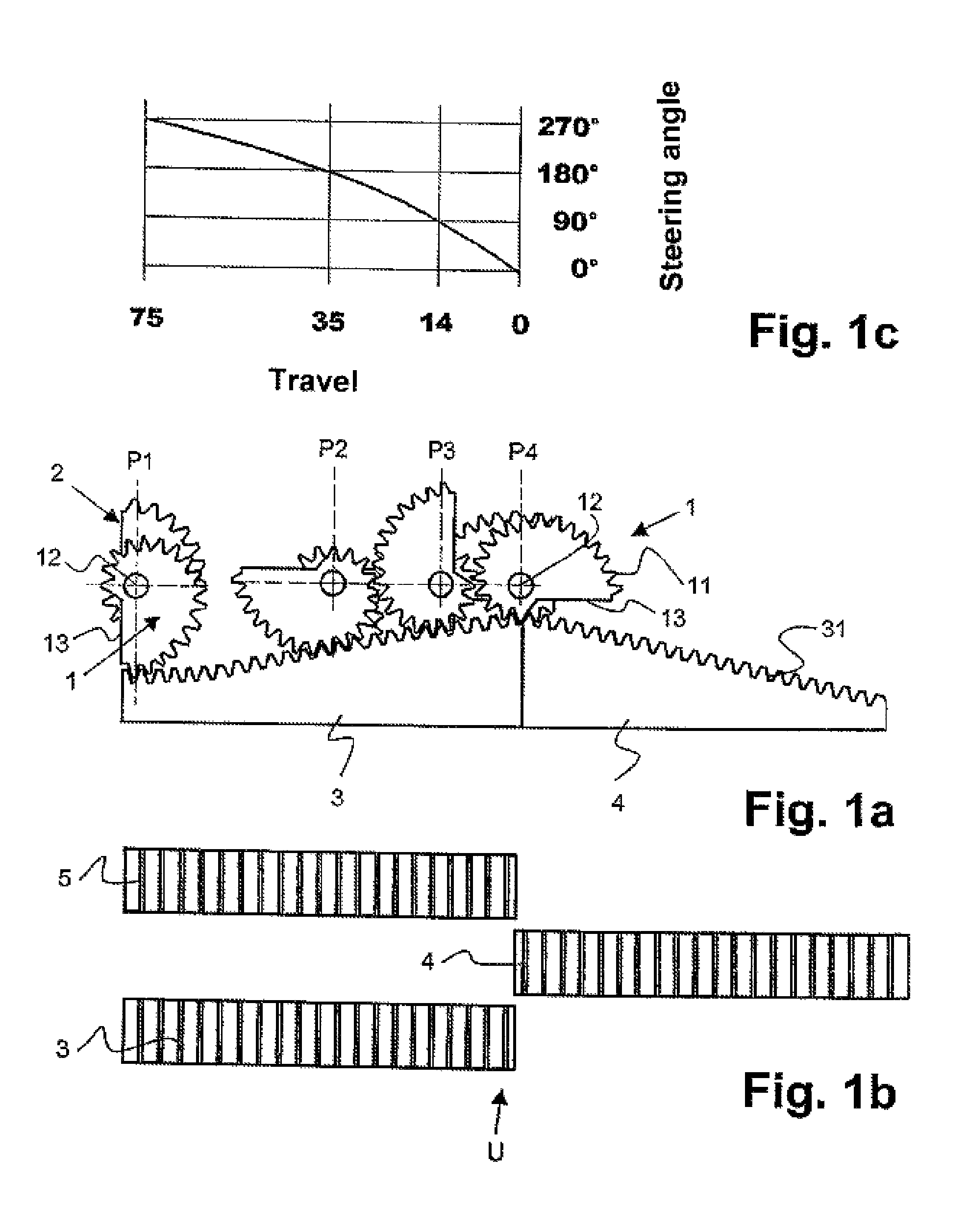

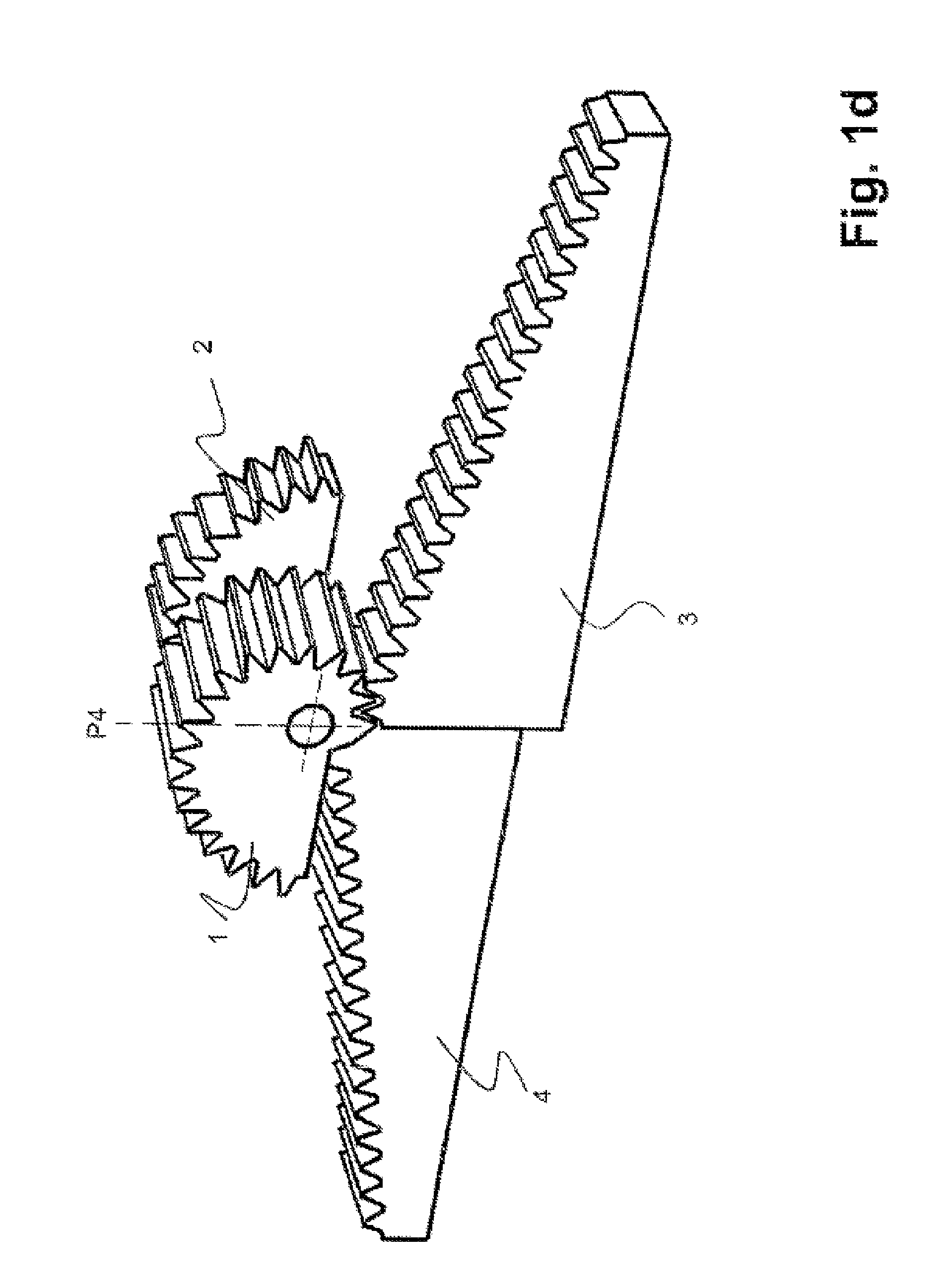

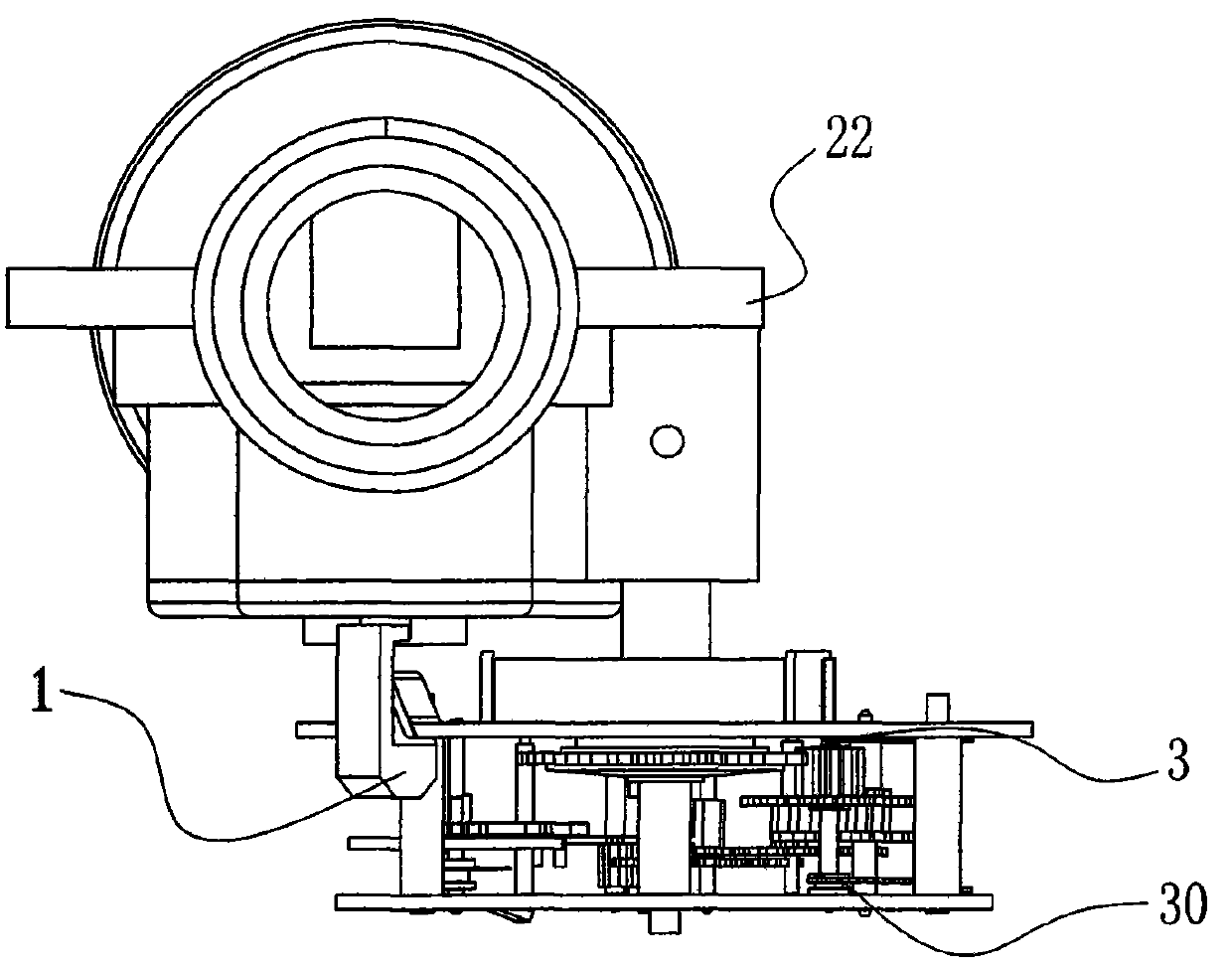

Progressive gearing

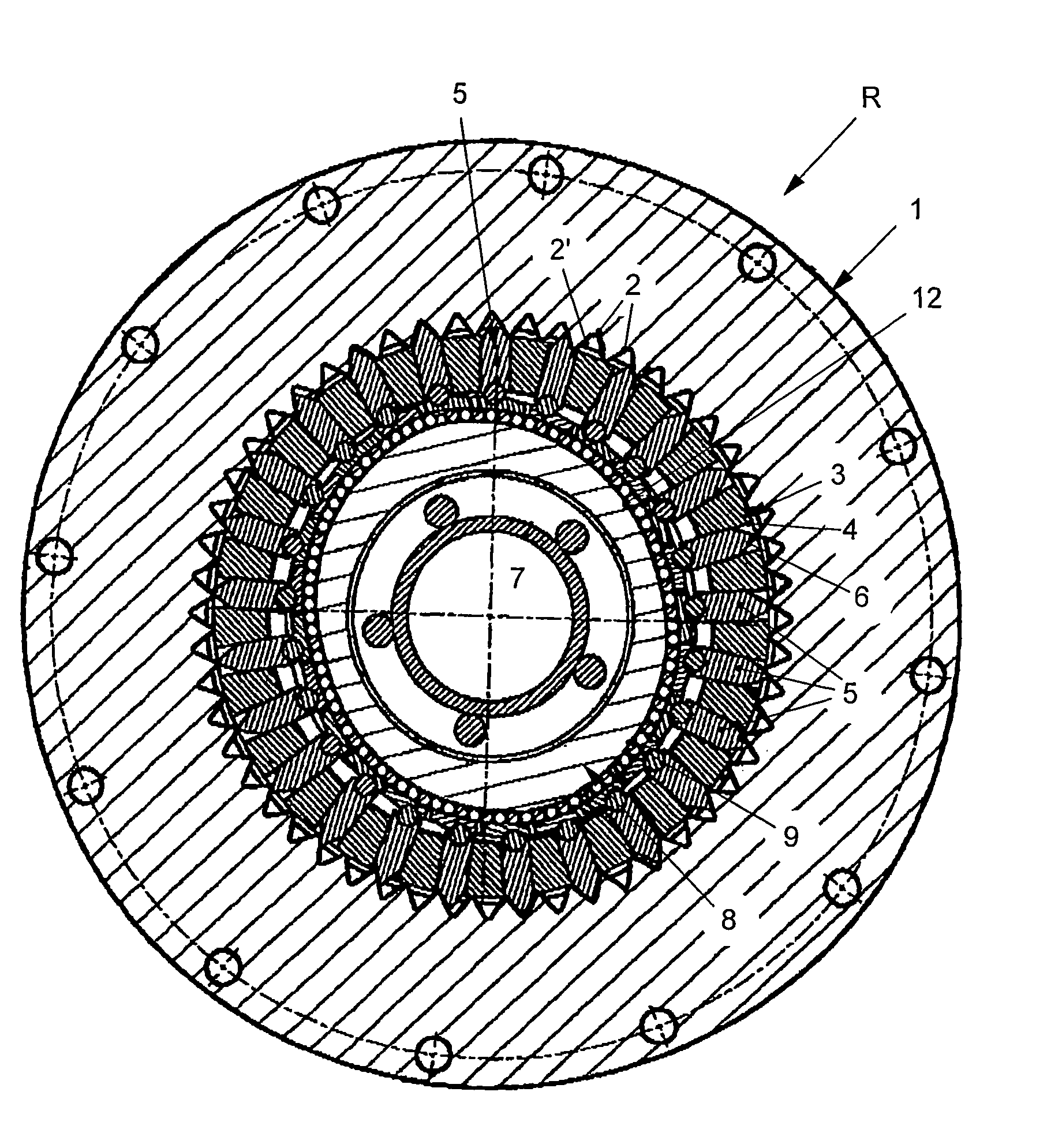

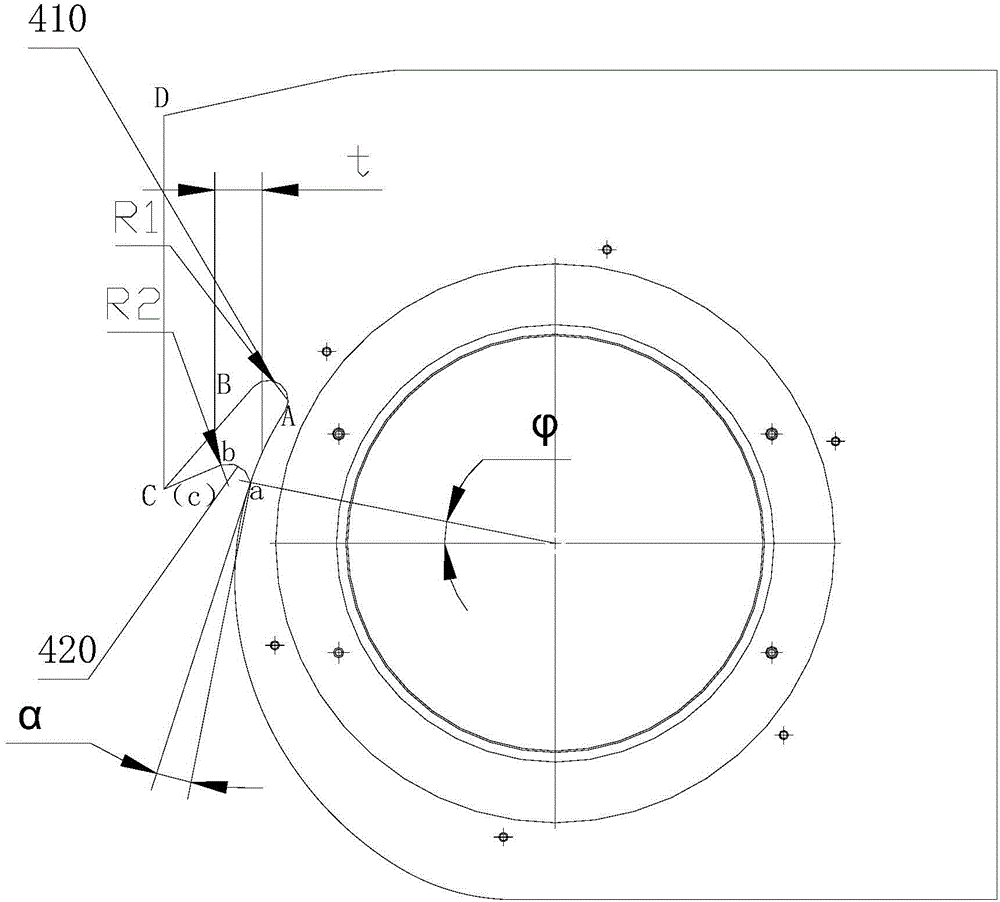

ActiveUS8196487B2No fluctuation in torqueZero backlashPortable liftingToothed gearingsEngineeringSpur gear

Owner:BLESS WERNER M

Technique for extracting arrayed data

InactiveUS20050105787A1Increase contrastImprove spatial resolutionImage enhancementImage analysisHigh spatial resolutionImage resolution

The current invention discloses a novel spectral transformation technique for characterizing digitized intensity output patterns from microarrays. This method yields improved sensitivity with reduced false positives and false negatives. Current microarray methods are overly sensitive to the detection of a visible distinction between pixels associated with probes and pixels associated with background. In one embodiment, a technique is disclosed that comprises the steps of: extracting pixels associated with an object of interest and transforming such pixels from an intensity representation to a spectral representation. In some embodiments, the extraction is based on a tessellated logarithmic spiral extraction that may yield a pixel core with a sampling of both foreground and background pixels. This core may then be computationally rescaled by 10×-10,000× to enhance spatial resolution. Once the extracted pixels are represented in the spectral regime, convolution with resolution-enhancement kernels may be used to accentuate morphological features capturing platform specific phenomenology.

Owner:VIALOGY

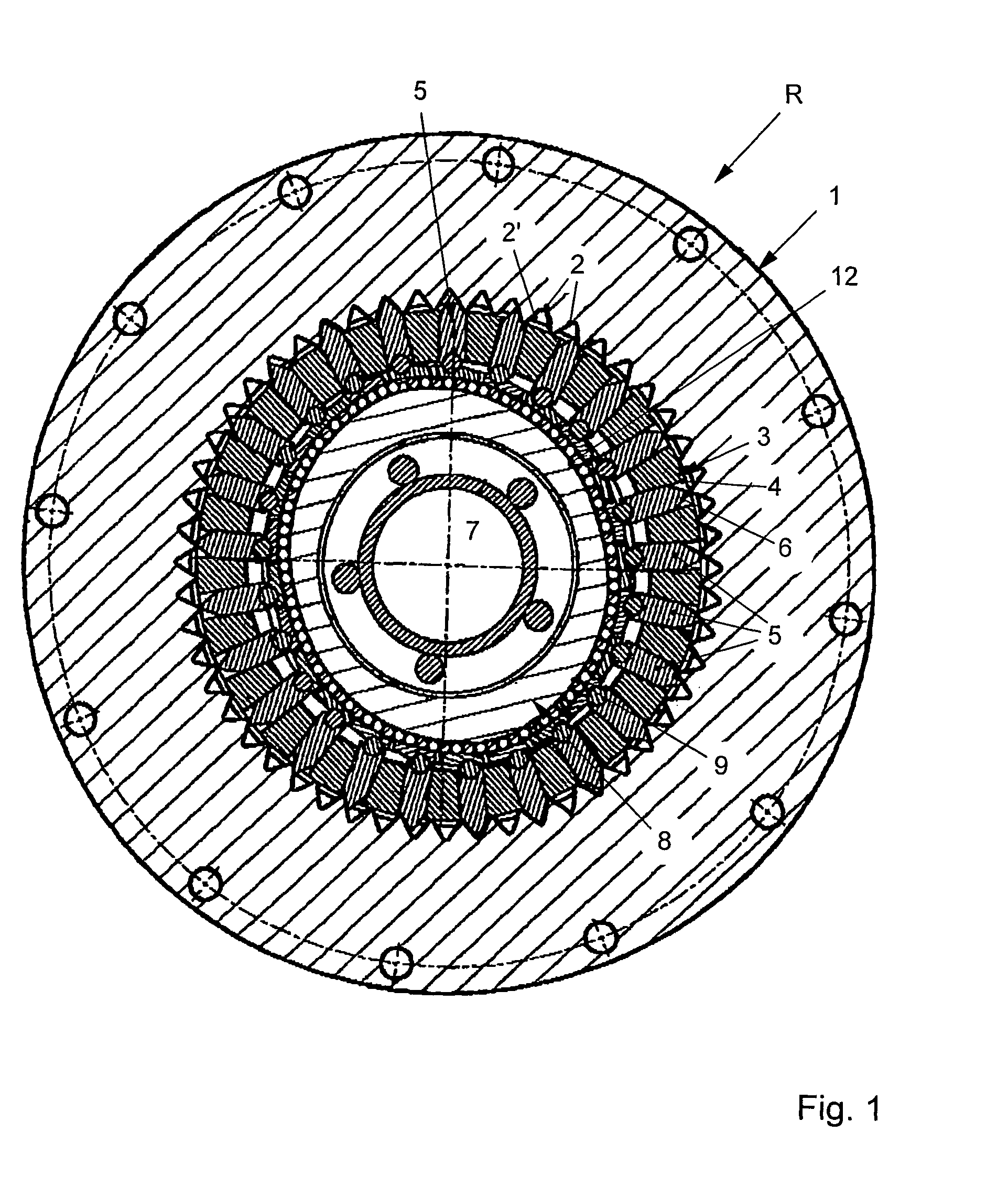

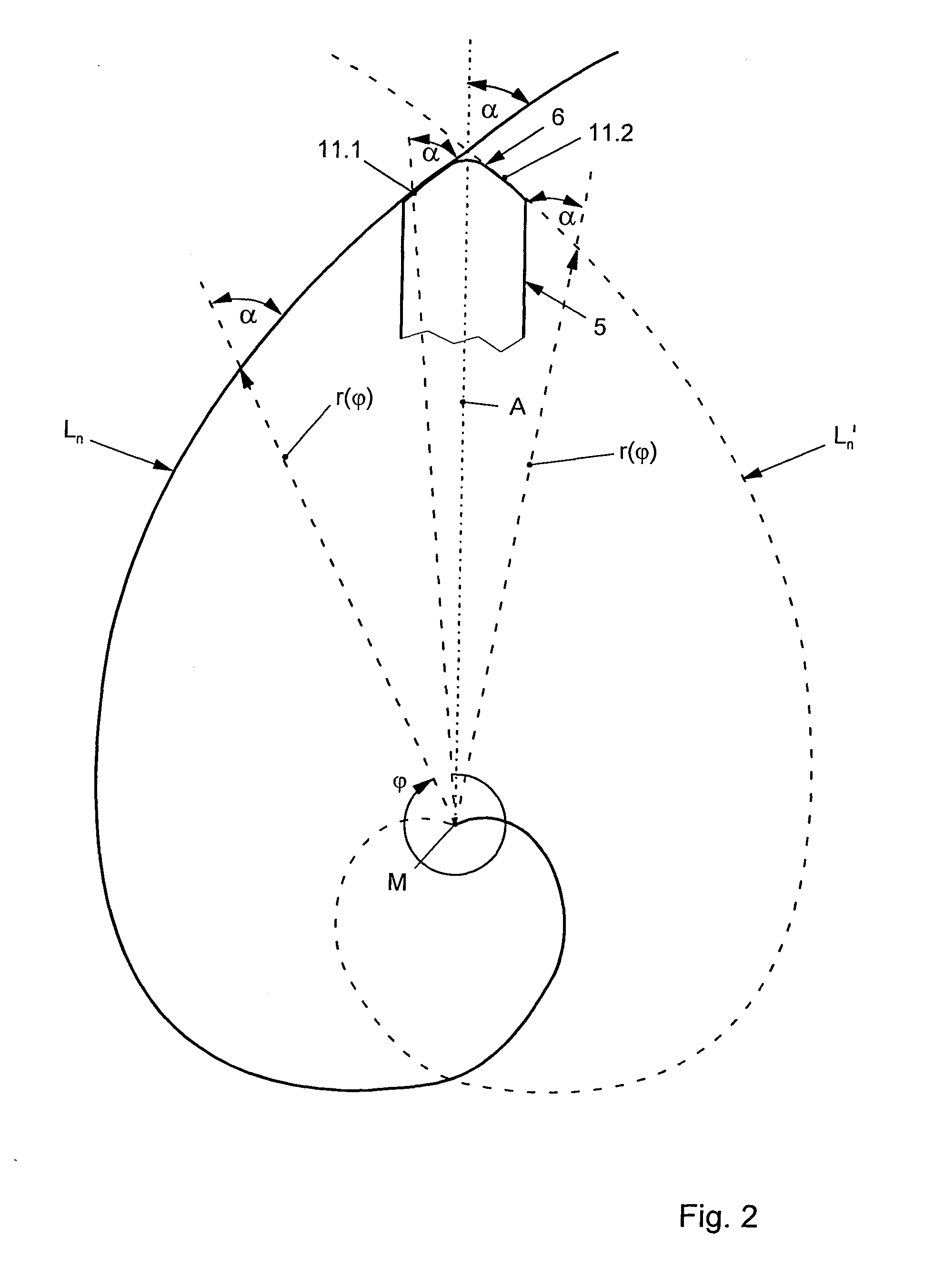

Coaxial gear set

ActiveUS8256327B2Service lifeExtended service lifePortable liftingToothed gearingsGear wheelEngineering

A coaxial gear set, in particular a hollow shaft gear set for industrial drive technology, having high power density, comprising a drive element (7), an element (3), and an output element, with a gear ratio and a transmission of a drive torque occurring between the drive element (7) and the output element via a plurality of radially movable tooth segments (5), an outer tooth flank contour (11.1, 11.2) of the tooth contour (6) of the tooth segments (5) and / or a flank contour (12.1, 12.2) of a gearing (13) of an inner gearing (15) of an internal wheel (1), relative to a gear axis (M), a tooth contour that allows surface contact in the engagement area comprising a logarithmic spiral.

Owner:WITTENSTEIN SE

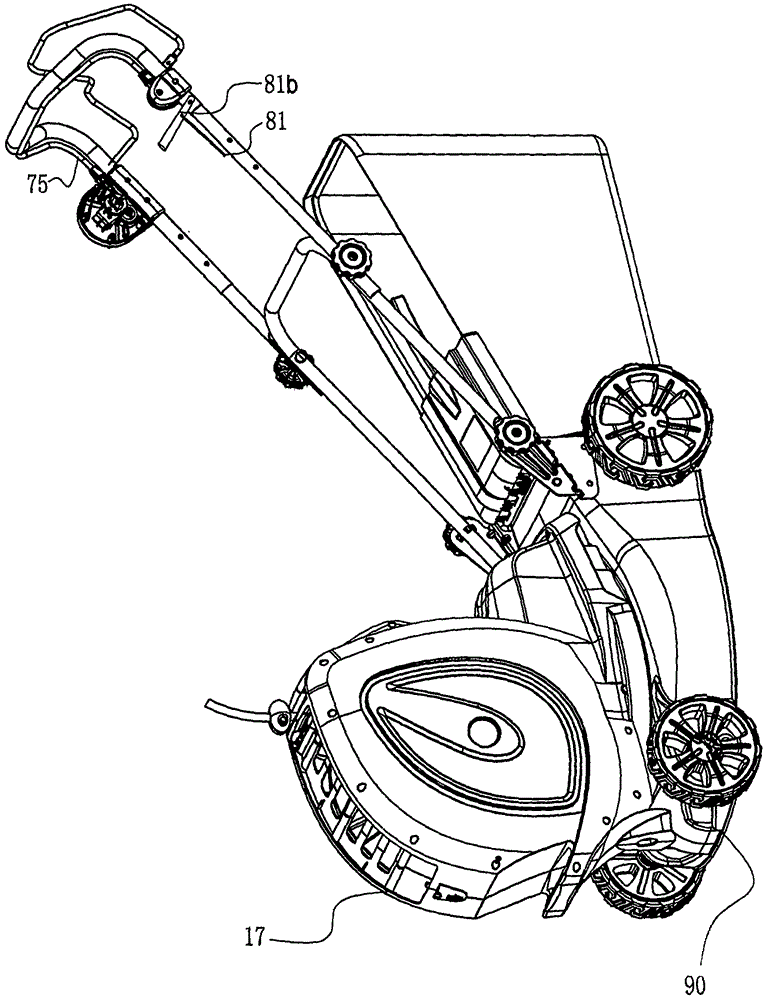

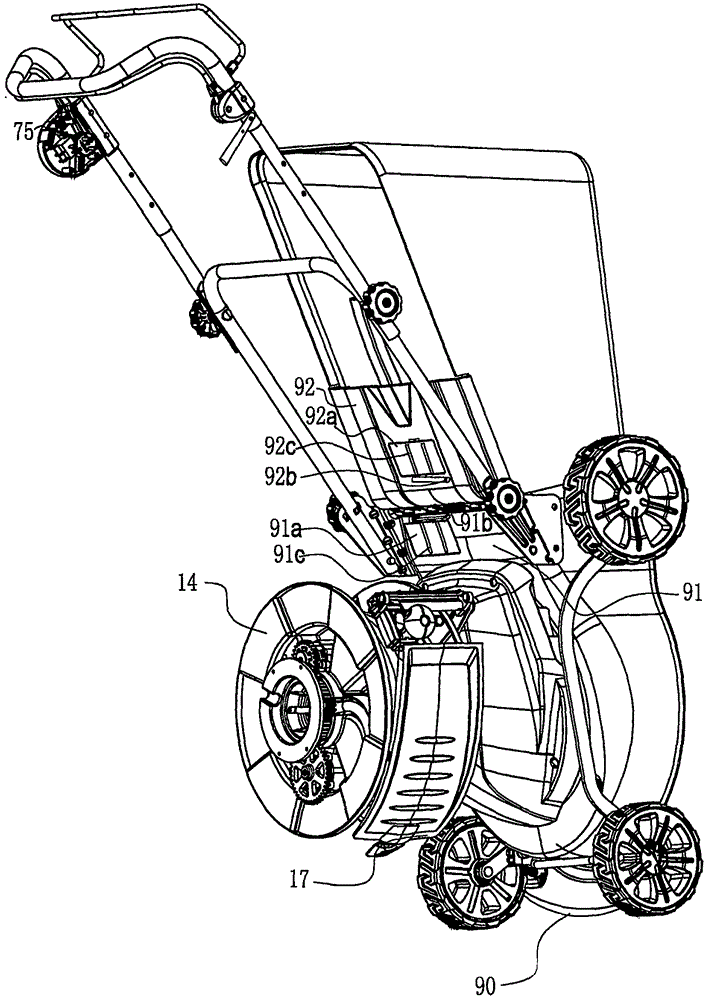

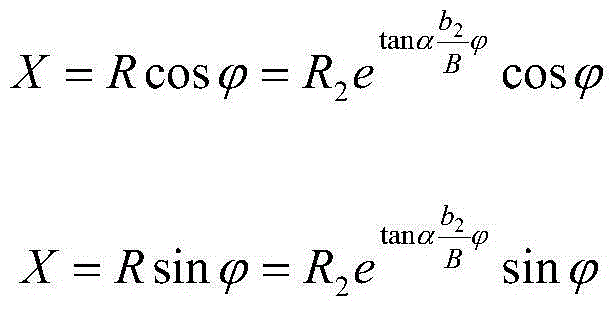

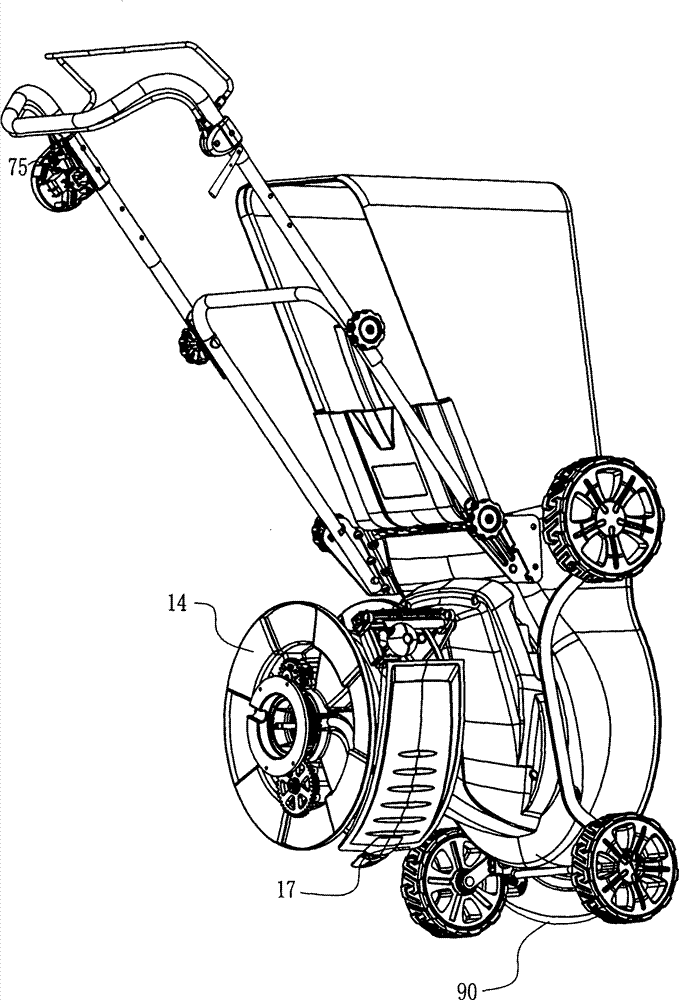

Blocked-grass lower-poking and upper-cutting mechanism for cleaning grass discharging passage of hand mower

InactiveCN106034538ASolve the problem of weed blockingSolving Worldwide Problems of MalfunctionMowersAgricultural undercarriagesLogarithmic spiralMower

The invention relates to a blocked-grass lower-poking and upper-cutting mechanism for cleaning a grass discharging passage of a hand mower. According to the blocked-grass lower-poking and upper-cutting mechanism, a lower poking mechanism is mounted on a rear shaft of the bottom of the mower, and meanwhile, an upper cutting mechanism is mounted at a grass discharging port of the grass discharging passage of the mower; the lower poking mechanism contains grass discharging blades (j1) and direction-changing bevel gears (j2), the rotating direction of a third direction-changing bevel gear is reverse to that of a first direction-changing bevel gear and that of the rear shaft, and thus, the rotating and direction changing of the grass discharging blades (j1), which are connected with the third direction-changing bevel gear and sleeve the rear shaft, are achieved; and the upper cutting mechanism contains upper cutting blades (j3) and a belt-pulley belt (j4), and a rotating shaft of the upper cutting blades (j3) is driven by the belt-pulley belt (j4). The direction-changing bevel gears are Klingen-Berg cycloidal-tooth hypoid gears. At least one of the upper cutting blades (j3) of the upper cutting mechanism of the blocked-grass lower-poking and upper-cutting mechanism for cleaning the grass discharging passage of the hand mower has a bent segment, and a curve of the bent segment is a logarithmic spiral which has the characteristic that pressure angles are equal everywhere.

Owner:NINGBO DAYE GARDEN EQUIP

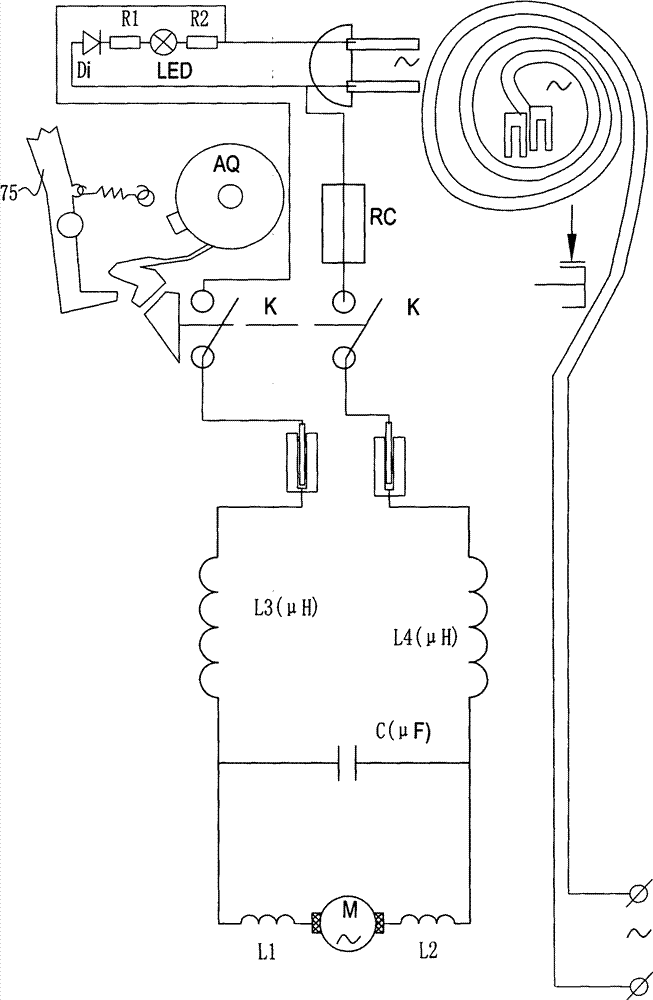

Embattling method of logarithmic spiral array antennas

InactiveCN101931124AIncrease cell spacingLarge apertureLogperiodic antennasHelical antennasPhase differenceArray element

The invention discloses an embattling method of logarithmic spiral array antennas. An antenna array uses N logarithmic spirals to embattle; a single logarithmic spiral line function is as follows: r=e, and an antenna unit is displaced on the logarithmic spiral line function r=e, wherein (r, phi) is a position coordinate of any point on the logarithmic spiral line under polar coordinates, r is a distance from the point to an original point (unit: wavelength), namely a relative wavelength number, phi is an angle relative to a polar axis (0 degree), and a is a parameter of the logarithmic spiral line function and is an optimizable constant for designing the array; the antenna unit n on each logarithmic spiral is arranged at the position of phi n along the spiral line function; the phase difference between adjacent units is delta phi; N spiral lines rotate 360 degrees / N rounding a rotating shaft in turn; r of the initial starting point of each logarithmic spiral line is the same; the phase position of the initial starting point of the first starting point on each spiral line is phi0; m array elements are respectively arranged on each spiral line from the initial starting point at an interval of delta phi; one array element can be placed at the center of the array, namely original point, or not; when the parameter a, delta phi and phi0 are determined, an array manifold is determined; and the total antenna unit number of N logarithmic spiral arrays is Nm+1.

Owner:SOUTHEAST UNIV

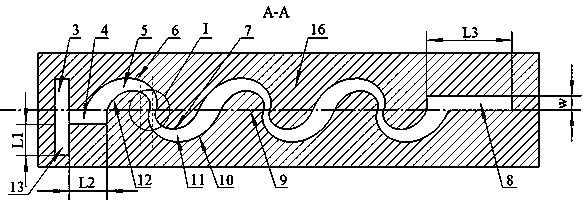

S-type passive micro-mixer

InactiveCN103638853APromote formationIncrease contact areaMixersLaboratory glasswaresHelical lineMain channel

Owner:JIANGSU UNIV

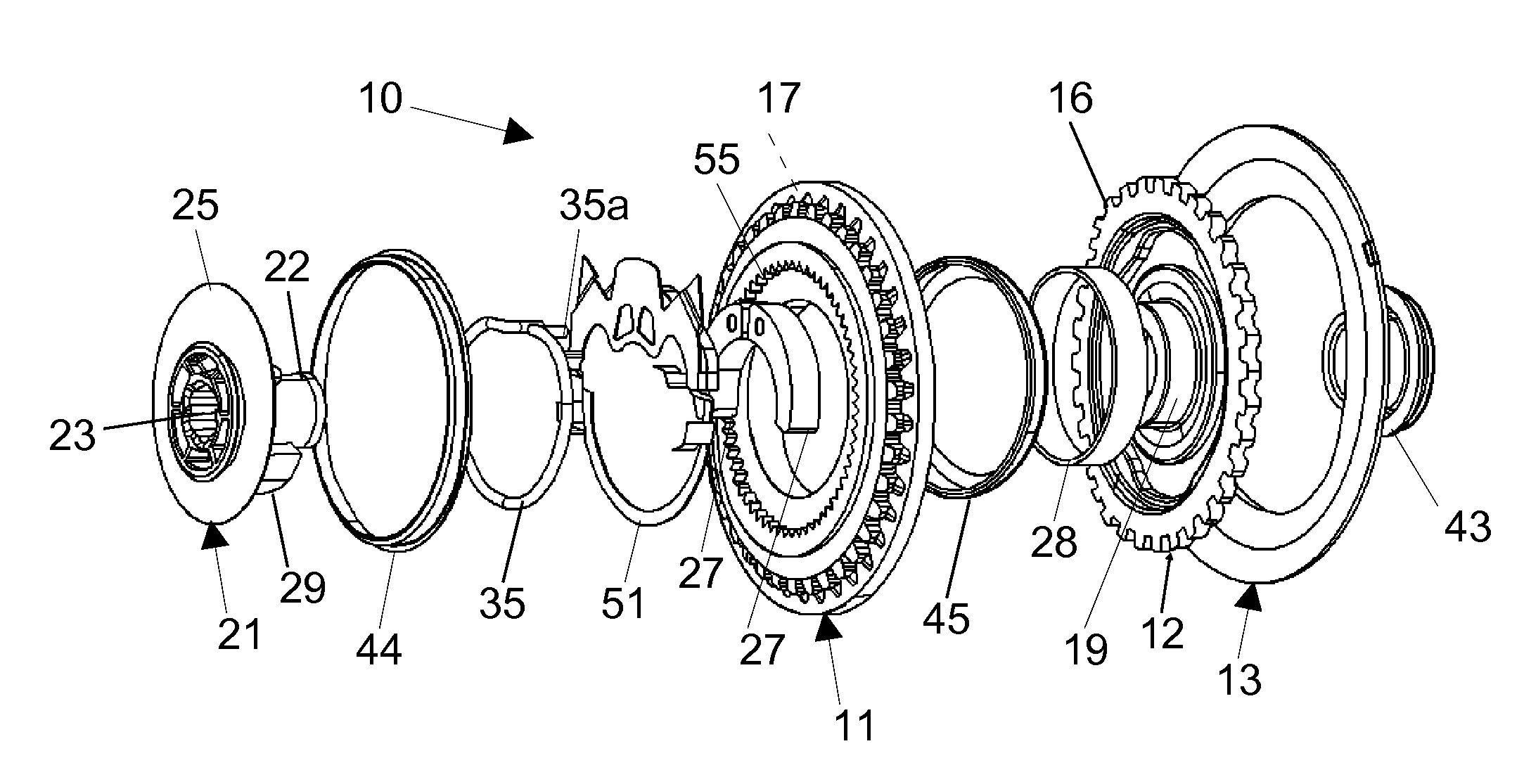

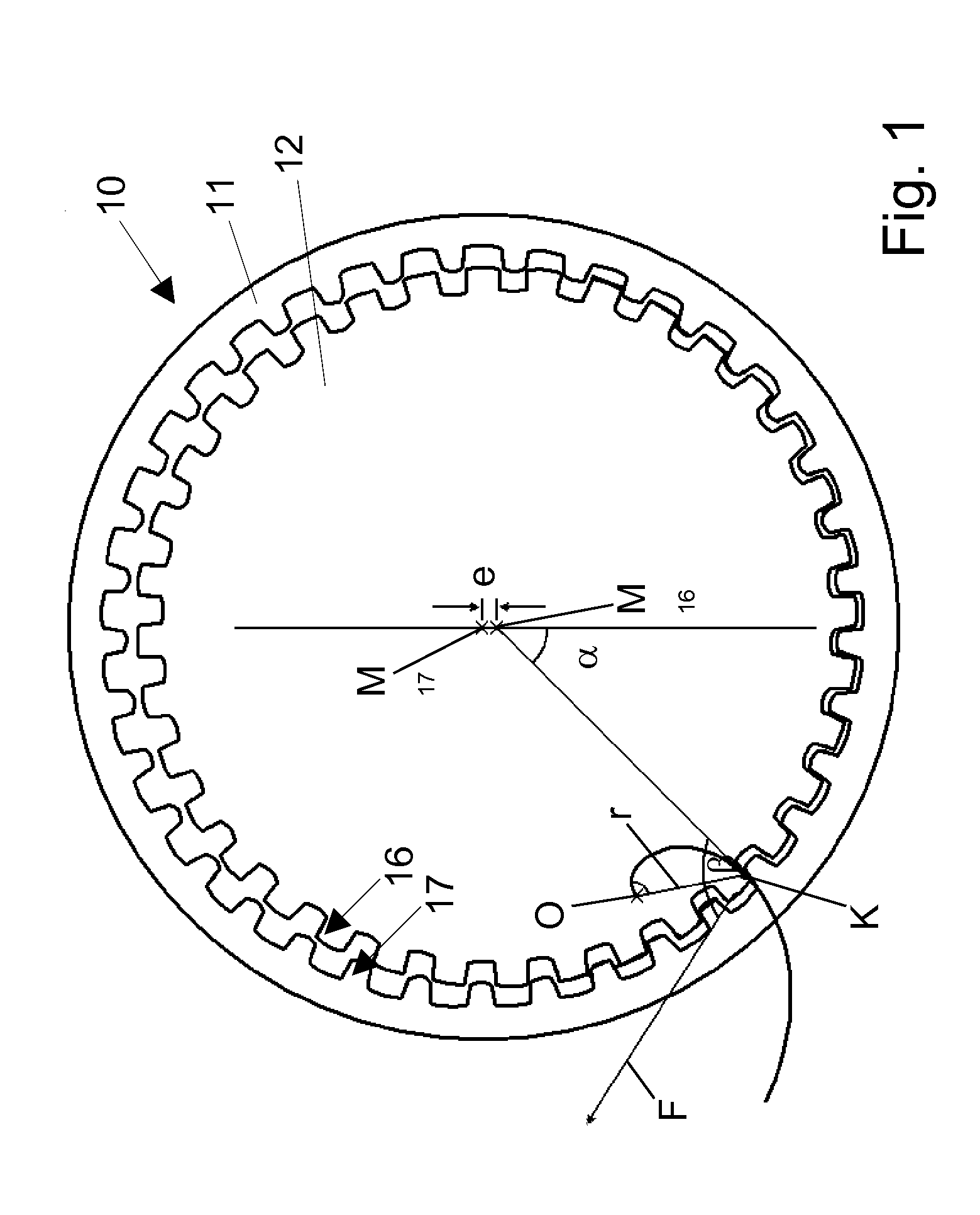

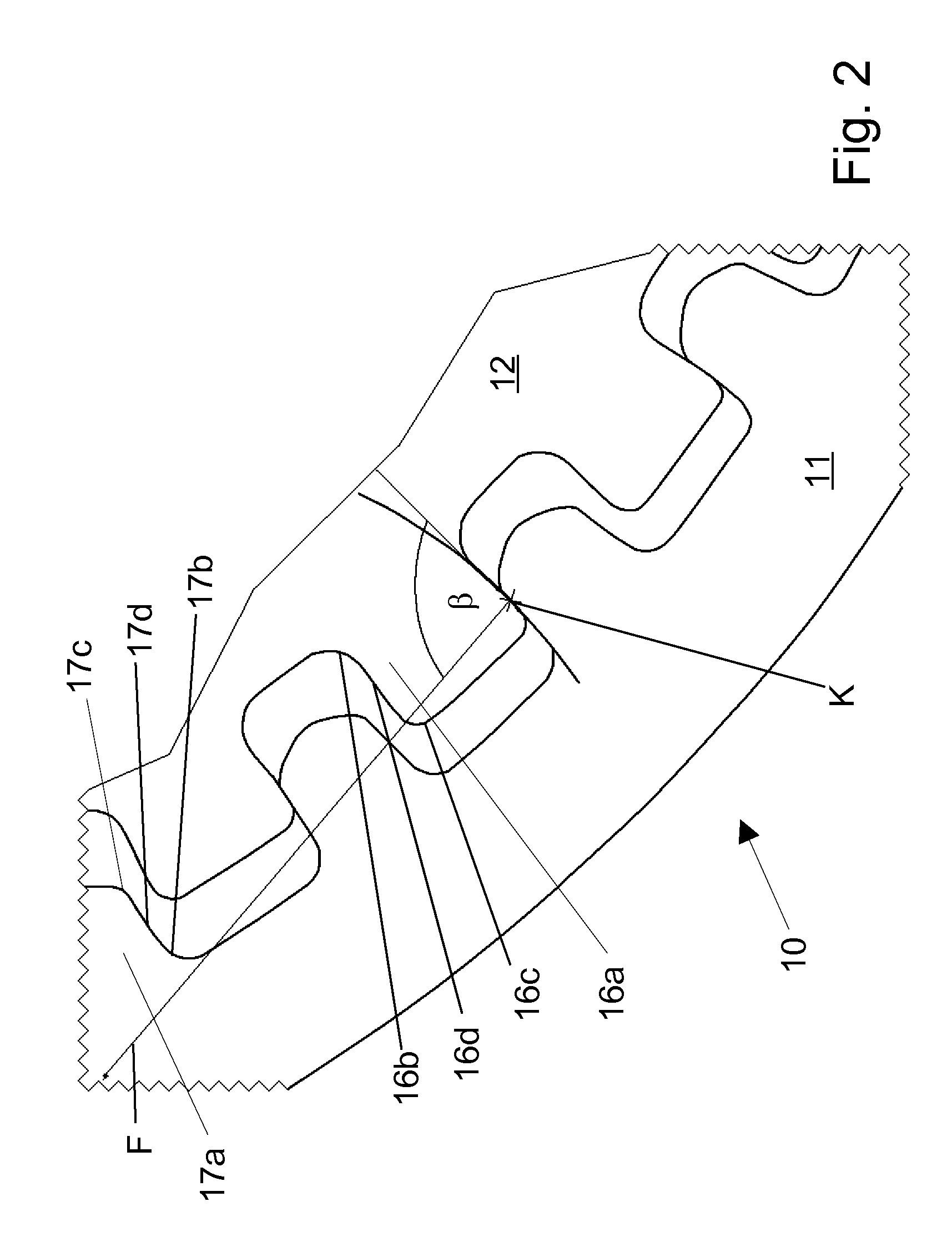

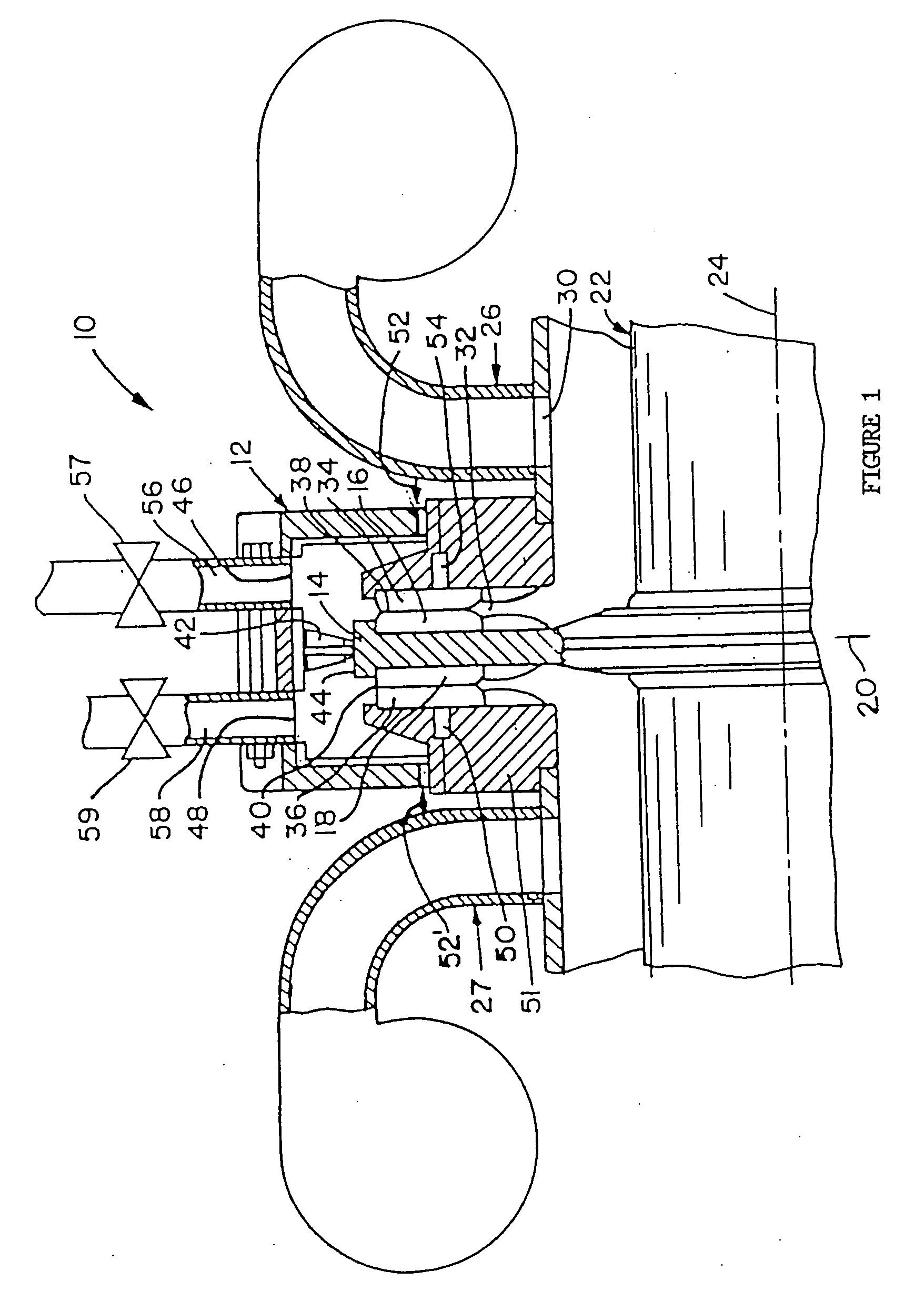

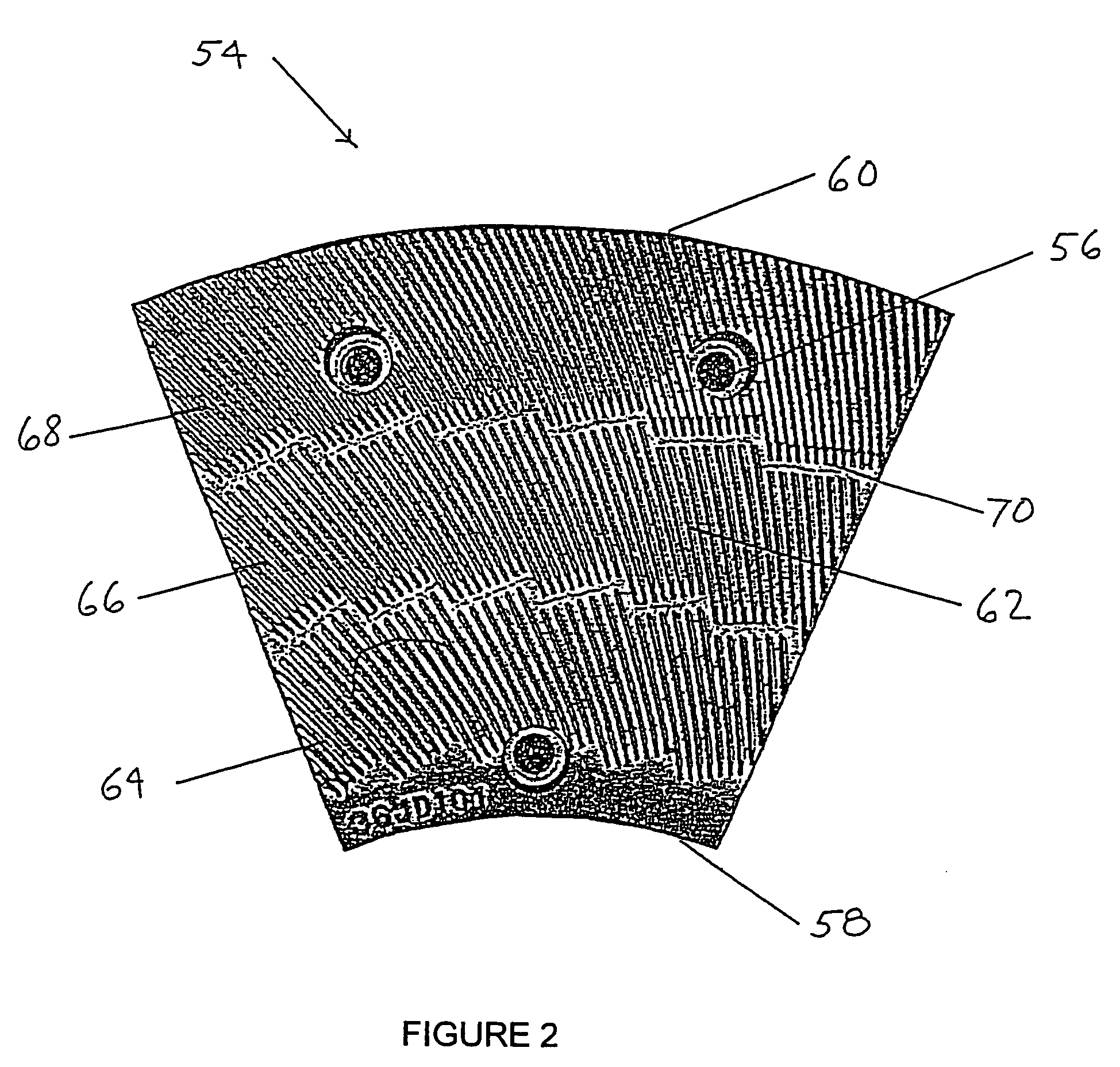

Fitting for a vehicle seat

A fitting (10), in particular for a motor vehicle seat, having a first fitting part (11), on which a gear rim (17) is formed and a second fitting part (12) on which a gearwheel (16) is formed. The gearwheel meshes with the gear rim (17), whereby the two fitting parts (11, 12) are in geared connection with each other. The fitting also has a rotatably mounted, revolving eccentric driven by a driving element for driving a relative rolling motion of gearwheel (16) and gear rim (17). During this rolling motion a tooth flank (16d) of a tooth (16a) of the gearwheel (16) rests against a tooth flank (17d) of a tooth (17a) of the gear rim (17) at a contact point (K). The tooth flanks (16d, 17d) of the teeth (16a, 17a) of the gearwheel (16) and gear rim (17) resting against each other at the contact point (K) each follow the course of a portion of a respective logarithmic spiral.

Owner:KEIPER SEATING MECHANISMS CO LTD

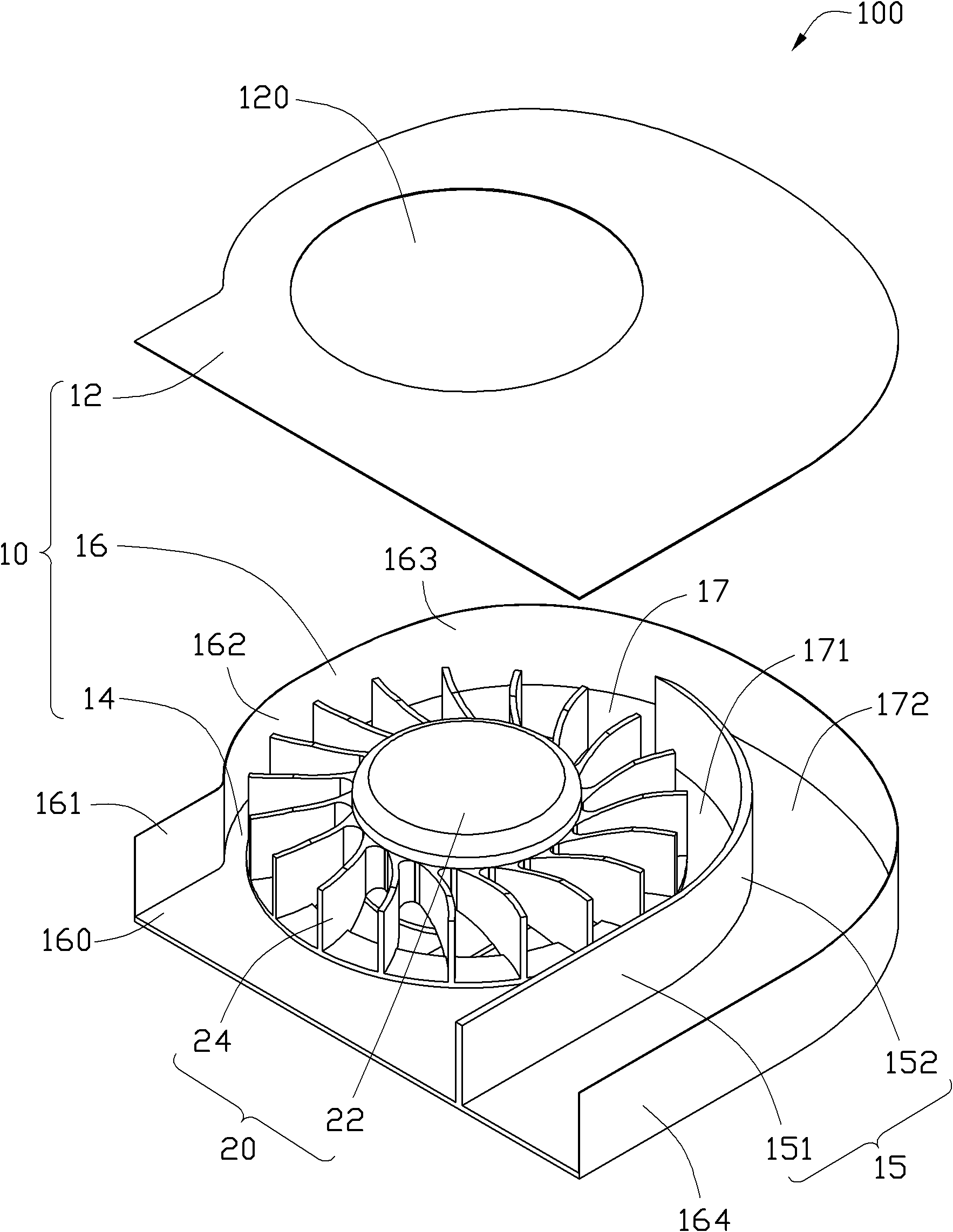

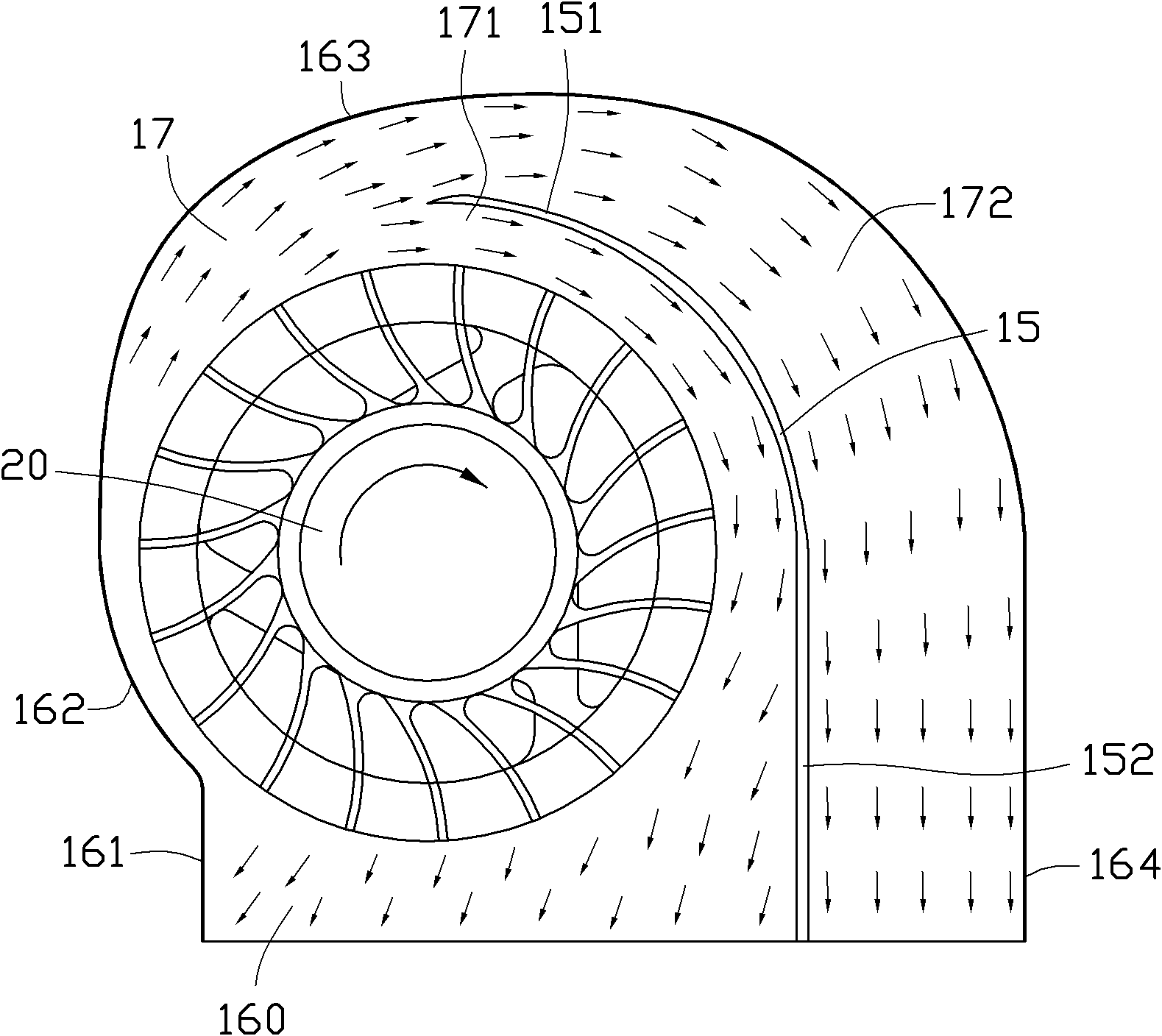

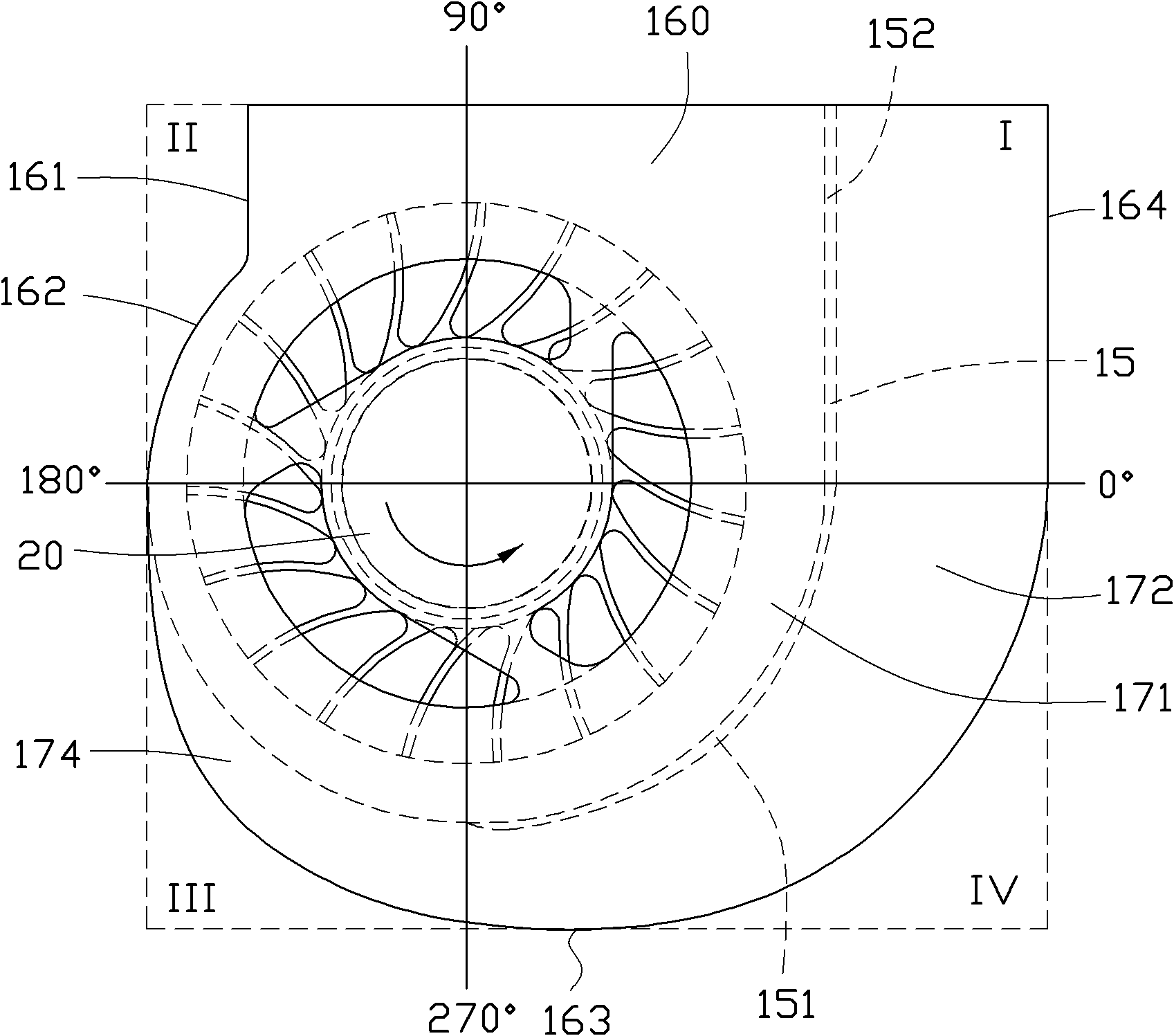

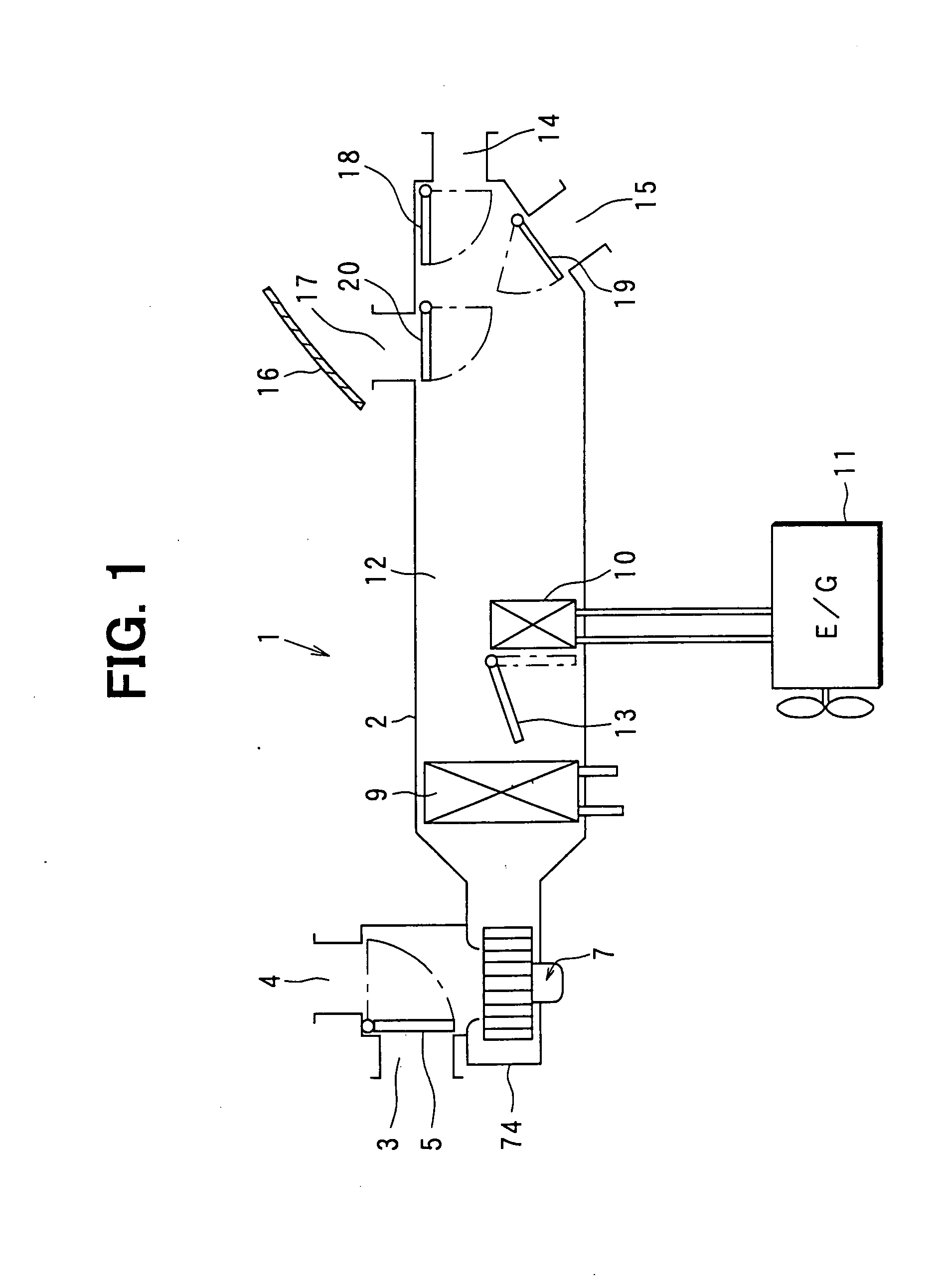

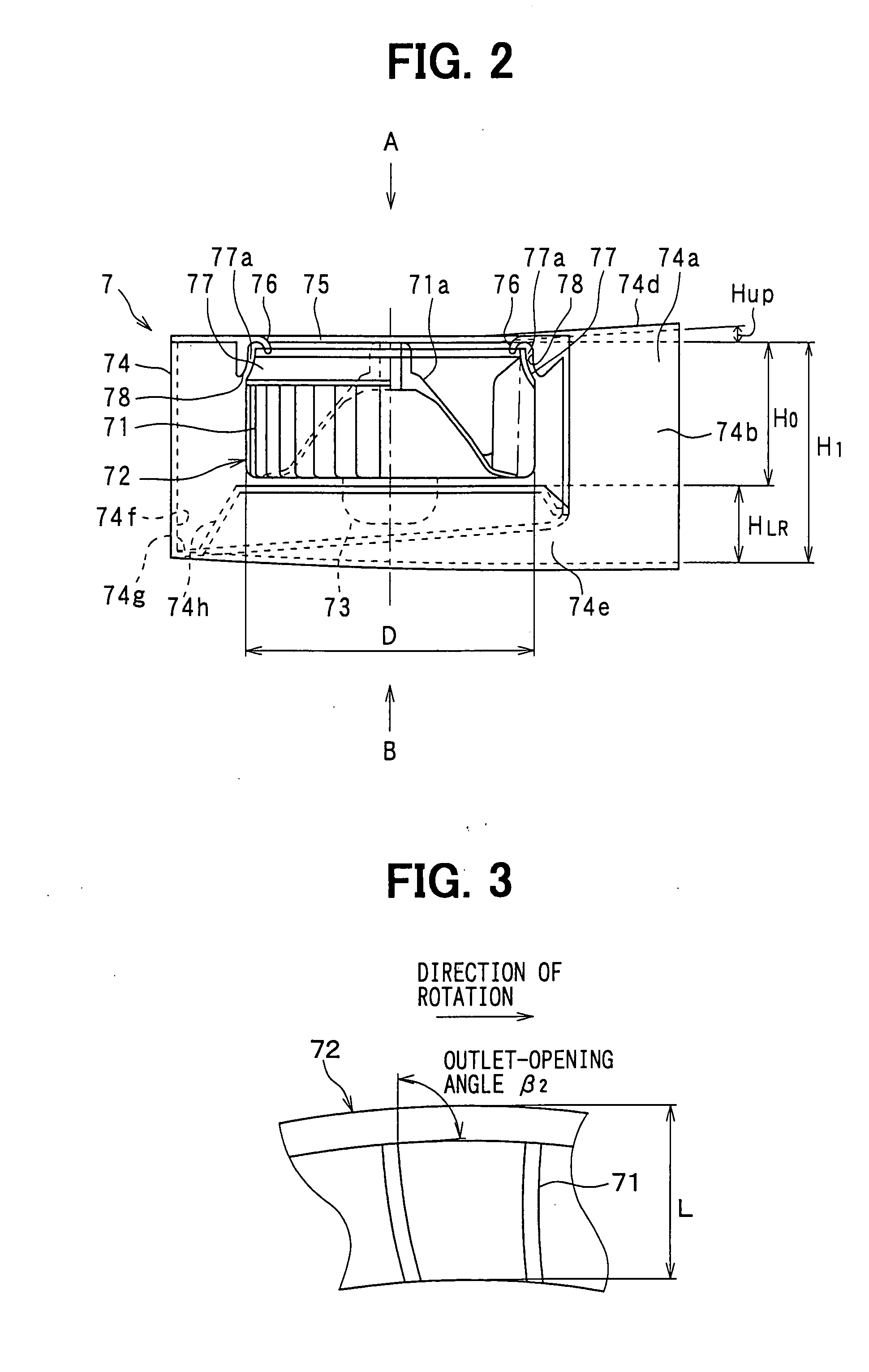

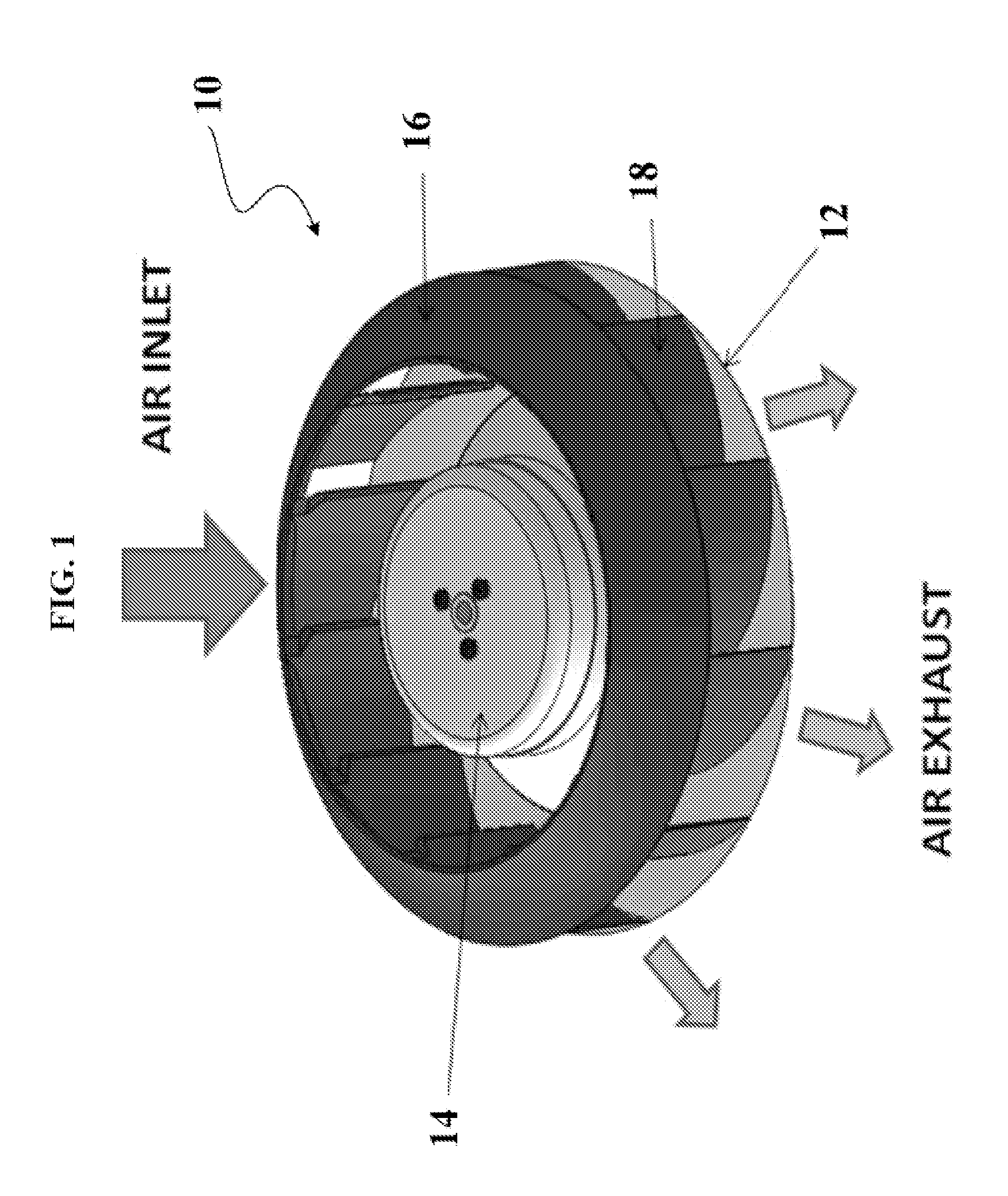

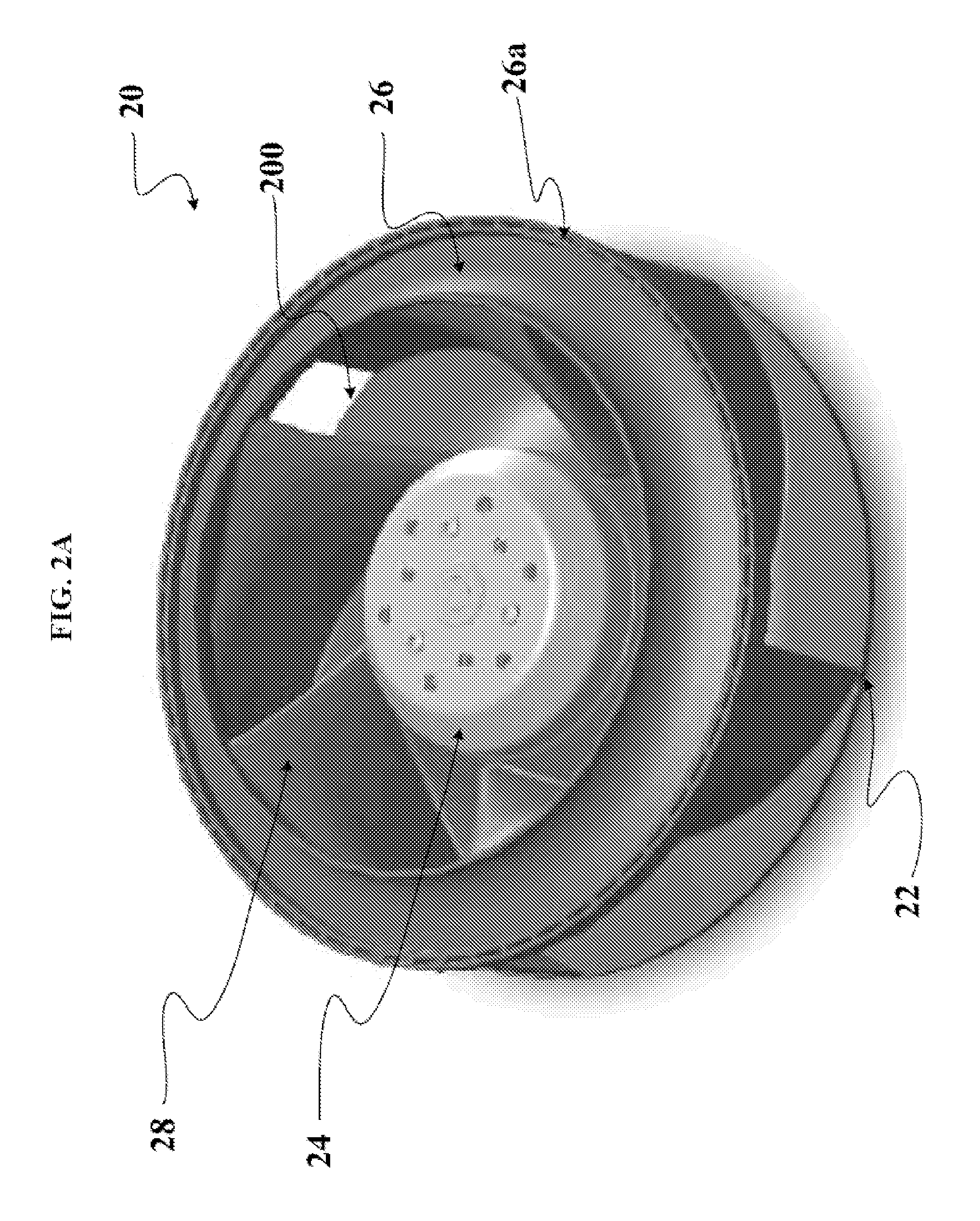

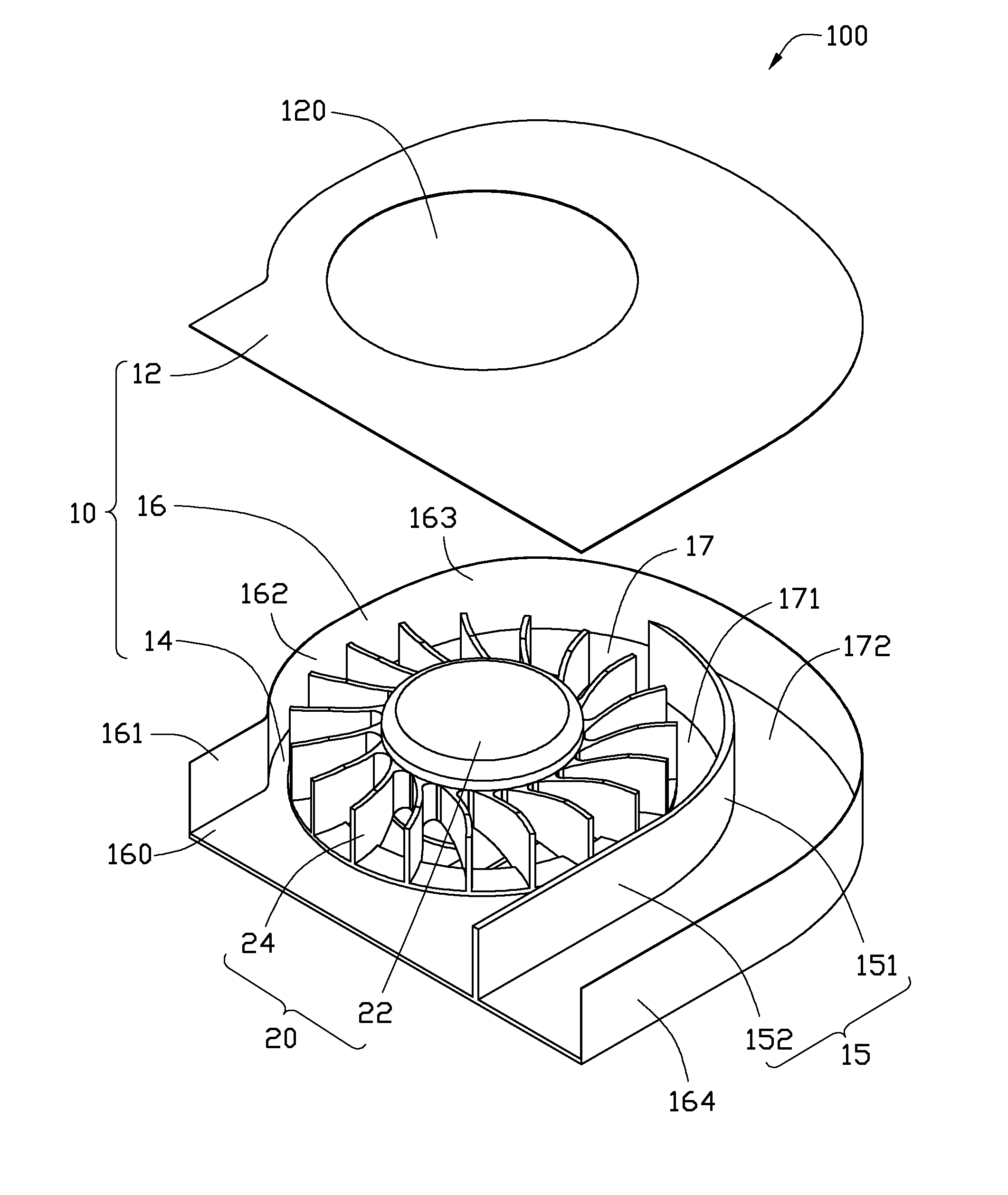

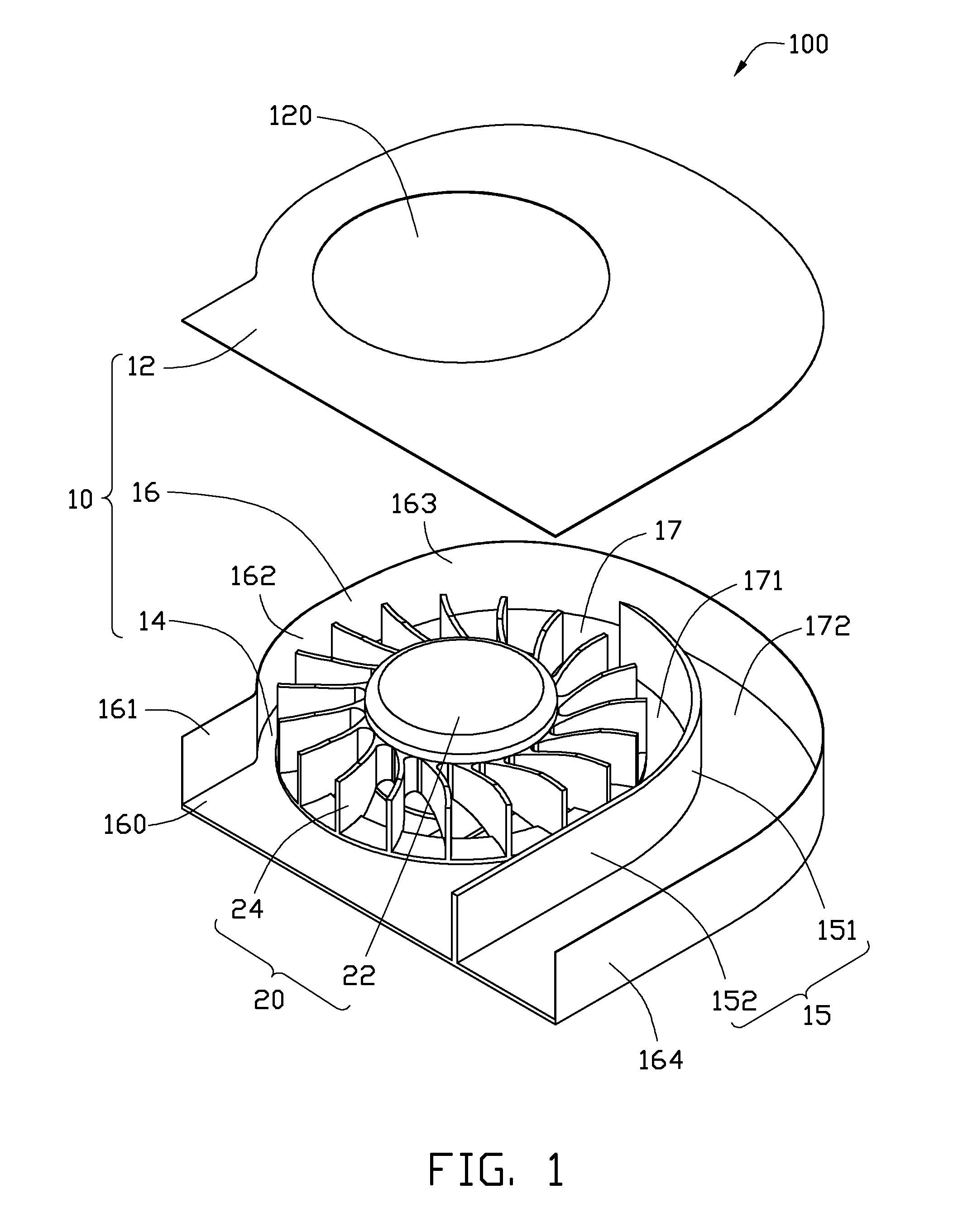

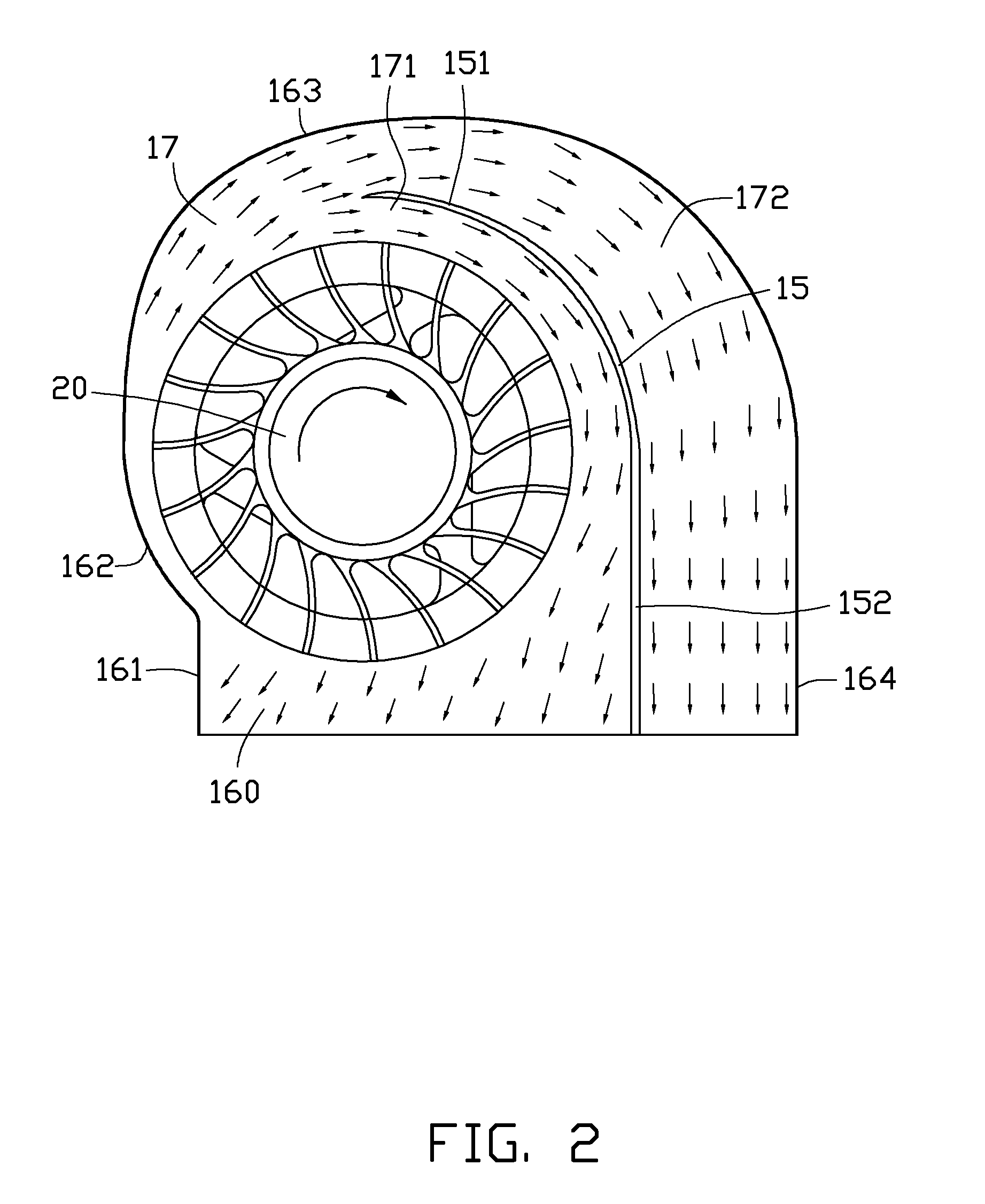

Centrifugal fan

InactiveCN102213236ALarge air volumeReduce curvaturePump componentsPump installationsImpellerEngineering

The invention relates to a centrifugal fan which comprises a fan frame and an impeller which is accommodated in the fan frame, wherein a channel is formed at the periphery of the impeller in the fan frame, one side of the fan frame is provided with an air outlet, the periphery of the fan frame is provided with an initial curve part and an expanded curve part connected with the initial curve part, the expanded curve part is placed at the rear side of the initial curve part along the direction of rotation of the impeller, the initial curve part extends along an Archimedean spiral or logarithmic spiral, the expanded curve part is placed on the outboard of the extended line obtained by extending the started curve part along the Archimedean spiral or logarithmic spiral, a guide plate is arranged in the fan frame, the guide plate extends from the air outlet to the channel, and the guide plate divides the channel into two airflow channels.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

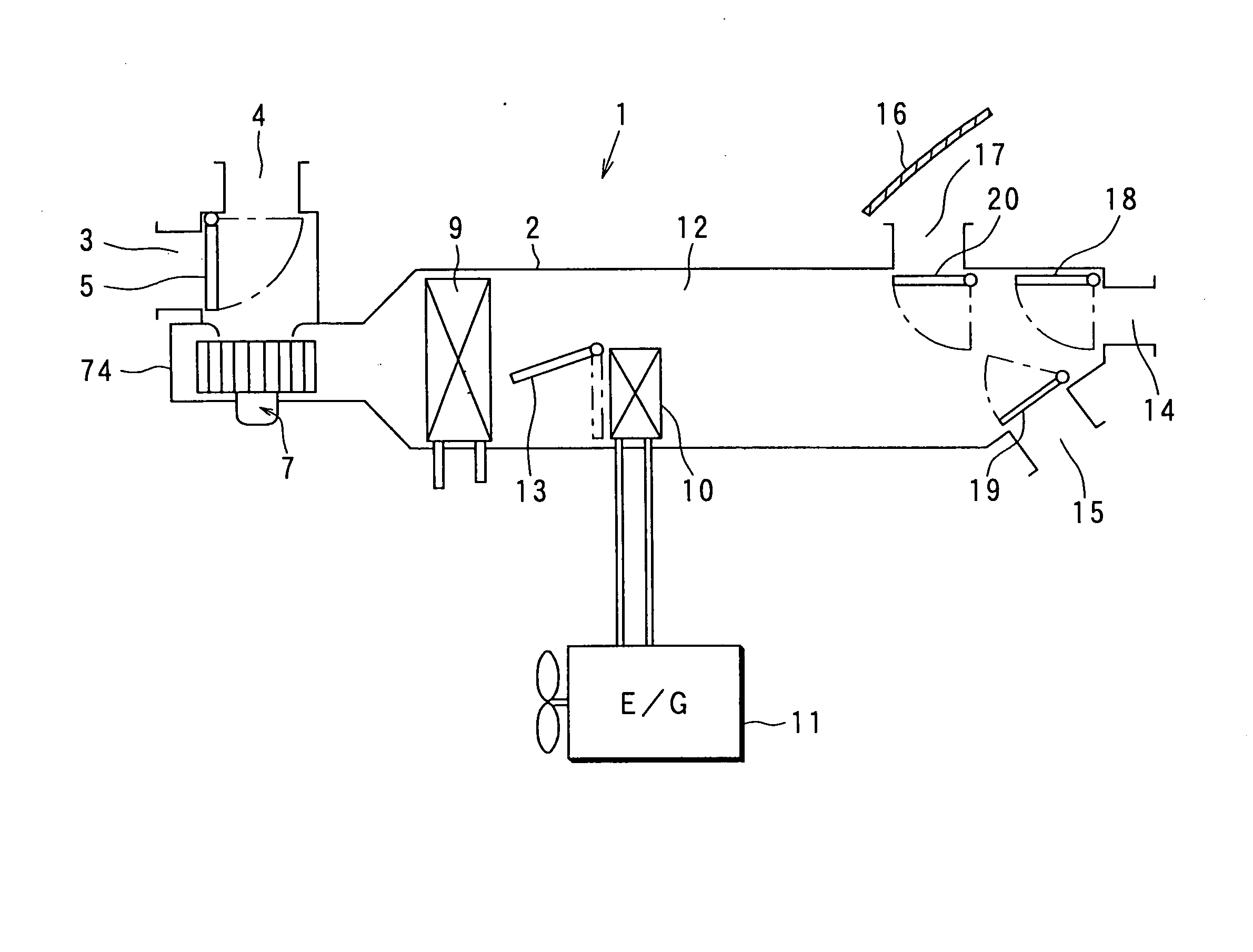

Centrifugal blower

InactiveUS20070274833A1Reduce wind noiseReduce noisePropellersPump componentsRotational axisEngineering

A centrifugal multi-blade fan has multiple blades about a rotational shaft and draws in air along the rotational shaft and then blows the air approximately perpendicular to the rotational shaft to reduce wind noise. A scroll casing encloses the multi-blade fan and defines a scroll-shaped airflow passage for directing the air blown from the multi-blade fan. The scroll casing has an intake opening and an outlet opening at a scroll end, in a downstream scroll casing portion. The scroll casing expands such that a flow passage cross-sectional area on the airflow downstream side is larger than that on an airflow upstream side. A ratio of a blade length to a diameter of the multi-blade fan is greater than or equal to 0.12, and an outer scroll casing radius, relative to the rotational axis, increases as a logarithmic spiral, its expansion angle being from 3.3° to 4.8°.

Owner:SAKAI MASAHARU +2

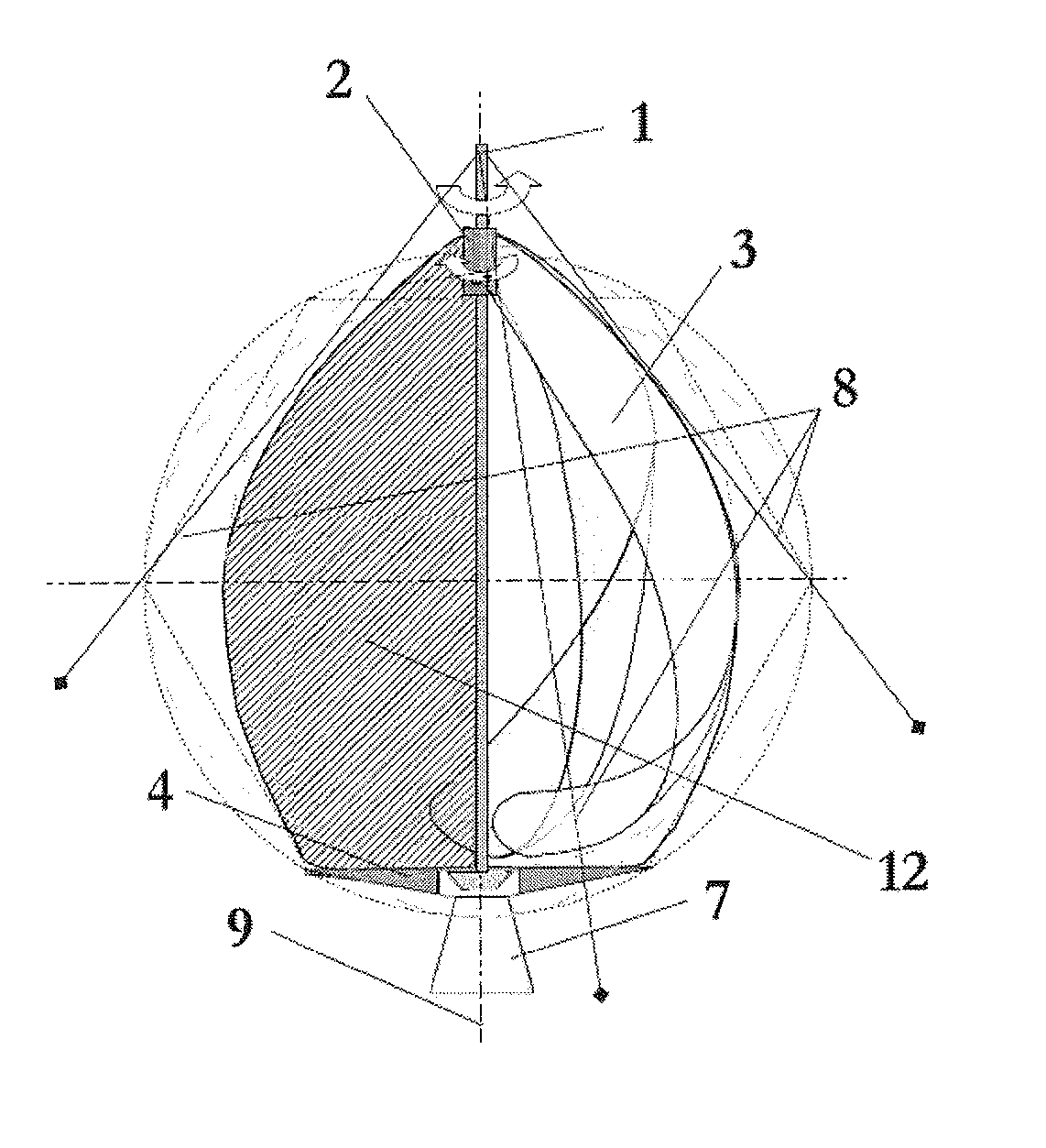

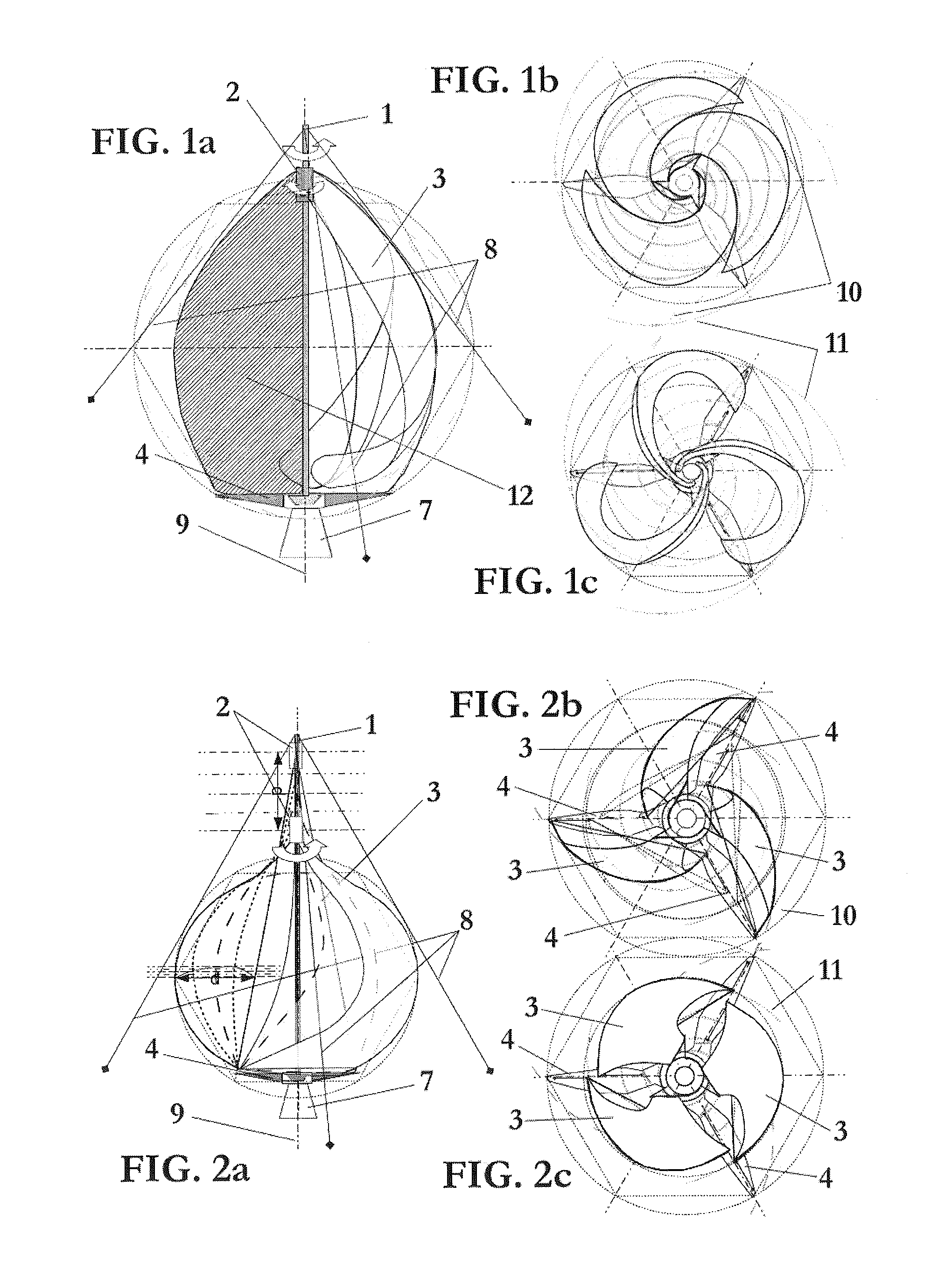

Driving force generating device

InactiveUS20100215492A1Drag minimizationReduce impactPropellersPump componentsEngineeringCentrifugal force

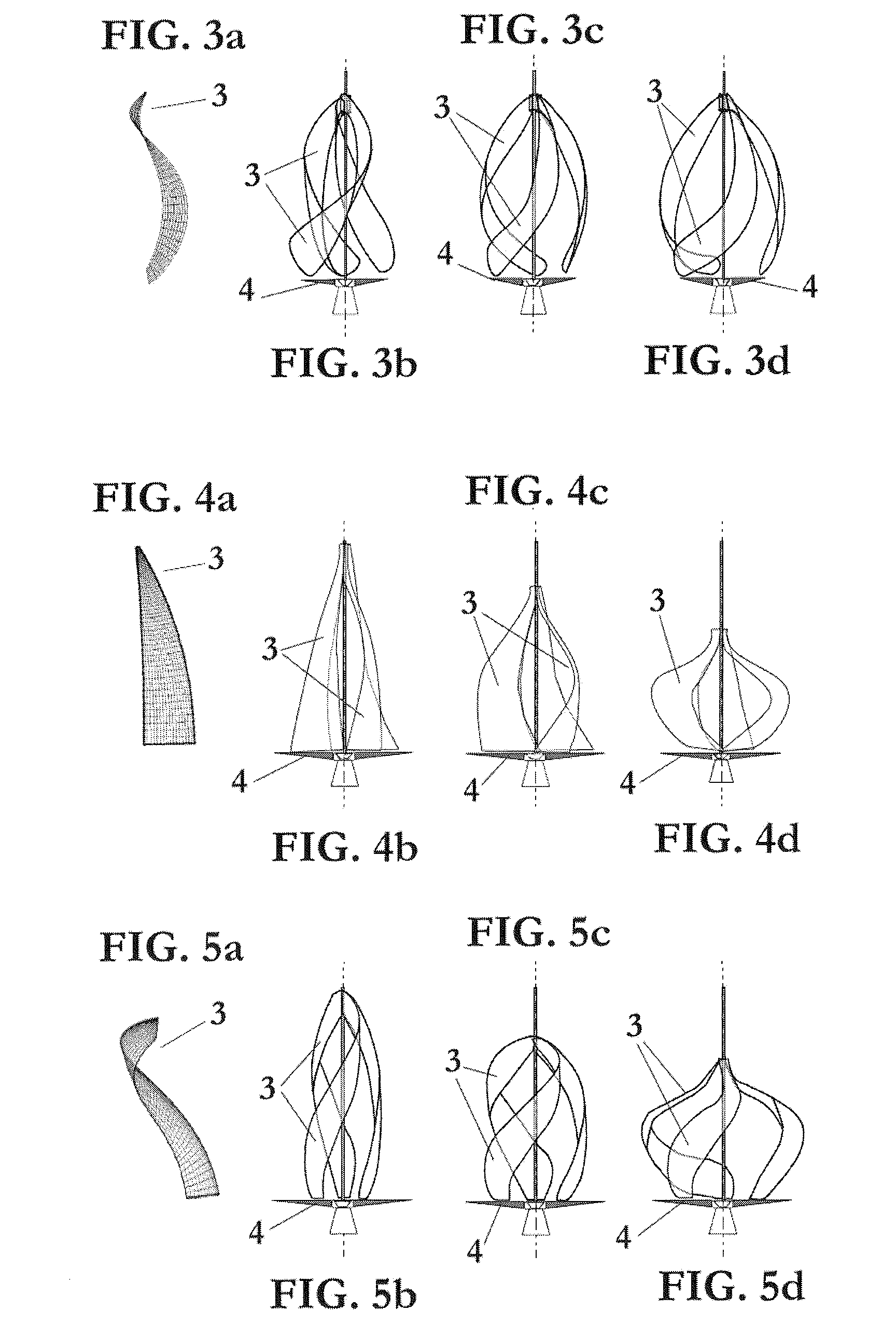

The invention relates to a driving force generating device including a column (1) provided with a plurality of flexible elements (3) positioned around the column (1), which react in response to the flow by rotating positively in the same direction. The invention is characterised in that the flexible elements take the form of aerodynamic membranes (3), the arrangement and shape of which correlate with logarithmic spiral patterns. The invention is also characterised in that it includes a movable head (2) positioned in the upper part of the central column (1) and a base (4) positioned in the lower part of said column (1), the upper part of each membrane (3) being secured to the movable head (1) and the lower part of each membrane being secured to the base (4). The invention can be used to balance kinetic, gravitational and centrifugal forces, thereby minimising resistance.

Owner:DOMENECH BARCONS SALVADOR

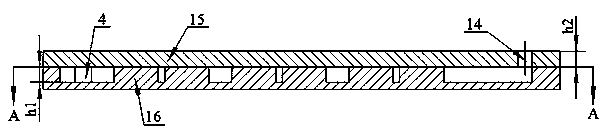

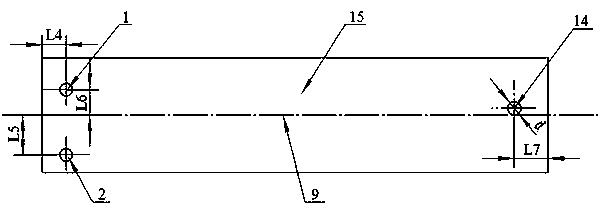

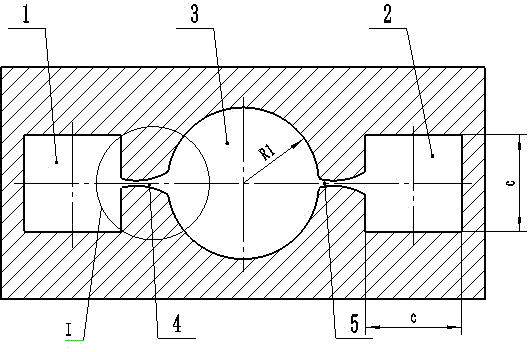

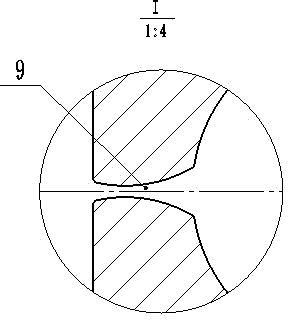

Valveless piezoelectric pump with axisymmetric logarithmic spiral pipe

InactiveCN102691648AImprove volumetric efficiencyReduced one-way pressure lossPositive displacement pump componentsFlexible member pumpsPump chamberEngineering

The invention relates to a valveless piezoelectric pump, more particularly to a valveless piezoelectric pump with axisymmetric logarithmic spiral pipes. The valveless piezoelectric pump with axisymmetric logarithmic spiral pipes comprises a pump body, a pump cover and a piezoelectric vibrator. An inlet flow tube, an outlet flow tube and a pump chamber are provided on the pump body. The inlet flow tube and the outlet flow tube have the same structure, are arranged coaxially, and are concentric and equidistant with the pump chamber center. The inlet flow tube and the outlet flow tube are both axisymmetric logarithmic spiral pipes. Profiles of the axisymmetric logarithmic spiral pipes are logarithmic spiral lines defined by a logarithmic spiral curve equation: rho = rho0 * e<k theta>. The pump of the invention has the main advantages of small scale, simple structure, easy miniaturization, capability of acquiring stable pressure, steady flow inside the pump with almost no eddy, and no damage to a transmission medium. Compared with valveless piezoelectric pumps with other structures, the valveless piezoelectric pump with axisymmetric logarithmic spiral pipes has lower unidirectional flow resistance and higher forward and reverse flow resistance coefficient ratio. Thus, the pump has higher volumetric efficiency, more stable flow can be obtained, and energy loss is significantly reduced.

Owner:JIANGSU UNIV

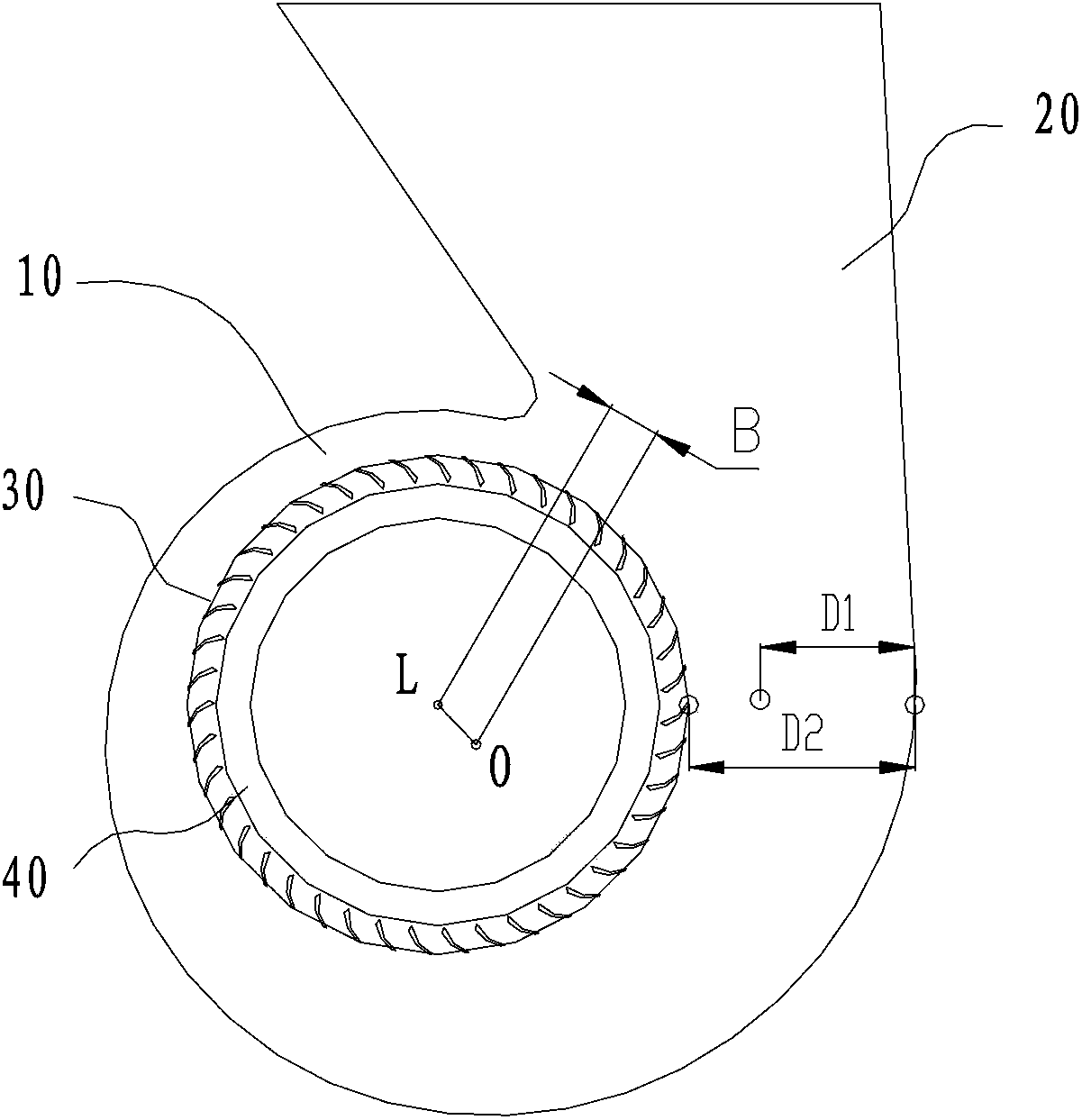

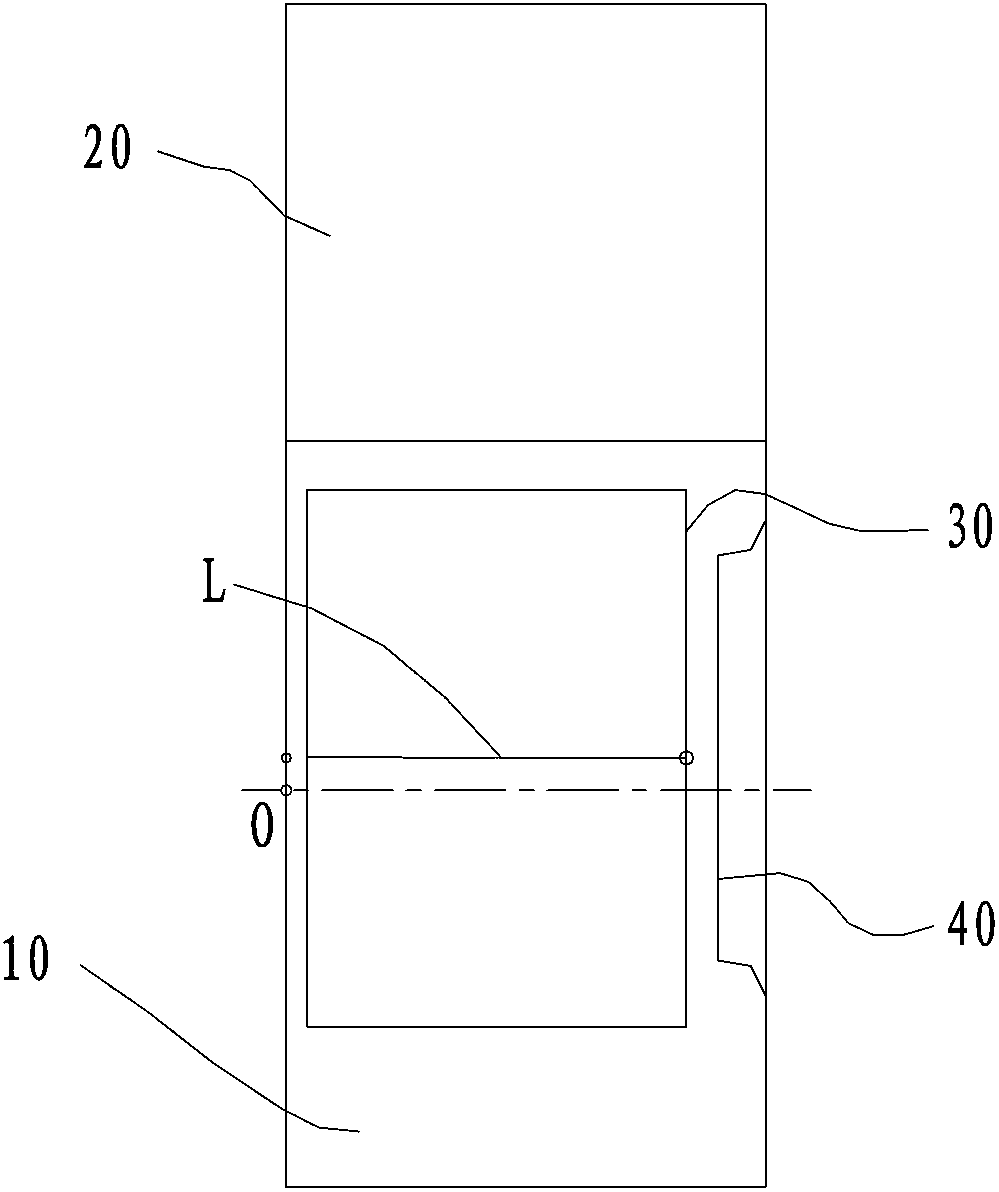

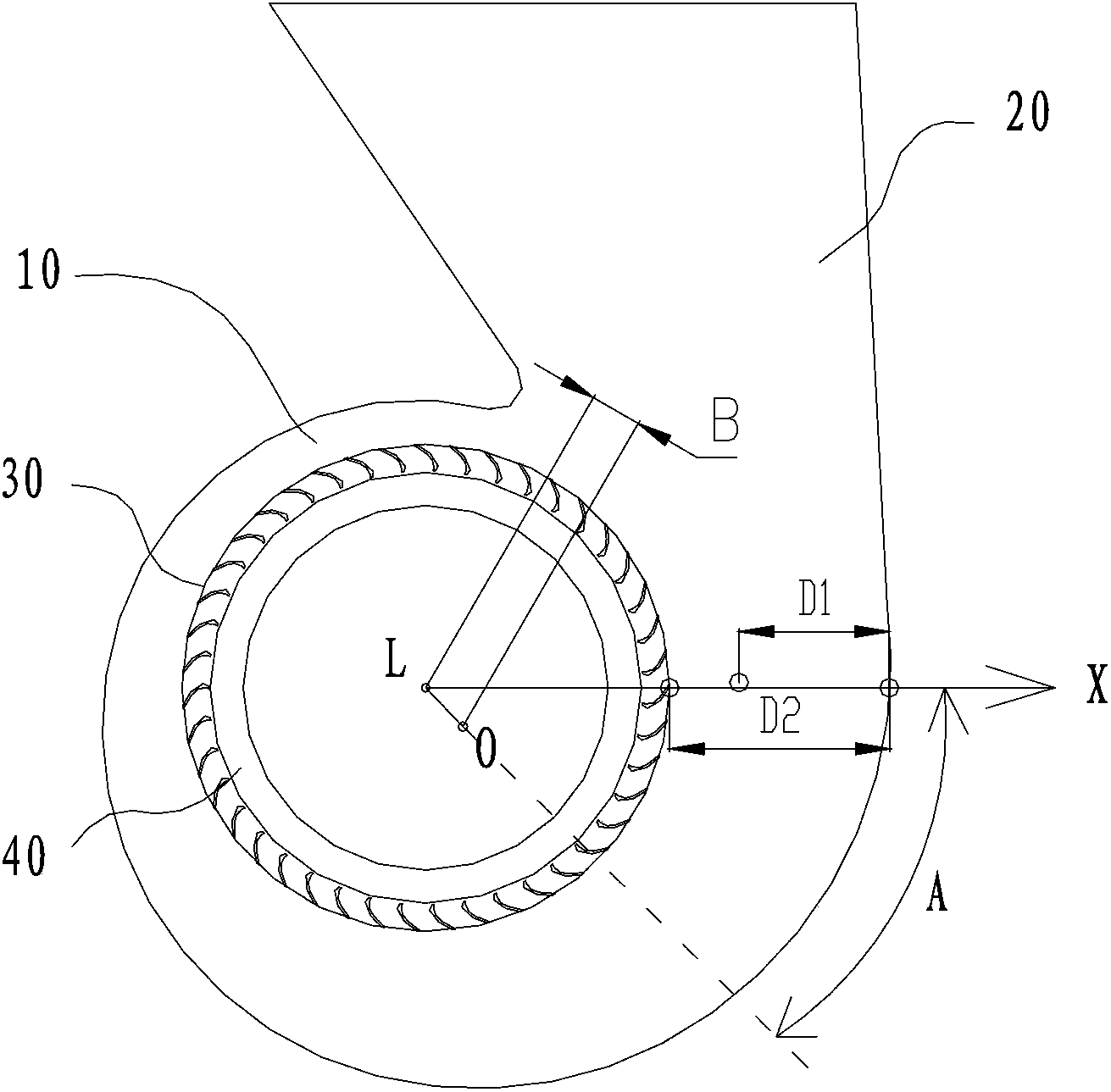

Volute of centrifugal fan and method for manufacturing volute

The invention discloses a volute of a centrifugal fan. The volute comprises a volute body, a diffusion cavity and a centrifugal blade impeller. The volute body is in an Archimedean spiral design or a logarithmic spiral design, the diffusion cavity is connected with the volute body, the centrifugal blade impeller is arranged inside the volute body, and a profile drawing center O of the volute body is deviated relative to the central axis of the centrifugal blade impeller, so that the distance D1 from the centrifugal blade impeller to the inner wall of the diffusion cavity is increased. The invention further discloses a method for manufacturing the volute of the centrifugal fan. The volute and the method have the advantages that airflow diffusion space can be reasonably arranged according to the distribution condition of the air speed of an outlet of the centrifugal fan, and main airflow can be smoothly accelerated from the centrifugal blade impeller, and then flows through the volute body to be transmitted to a diffusion opening of the diffusion cavity; obstacles to the main airflow are reduced, and accordingly integral flow resistance of an air channel of the fan and friction-induced noise of the air channel of the fan are reduced; purposes of preventing the airflow from being collided with the inner wall surface of the volute, increasing the quantity of air and reducing the noise are achieved; the quantity of the air generated by the fan is increased.

Owner:GREE ELECTRIC APPLIANCES INC

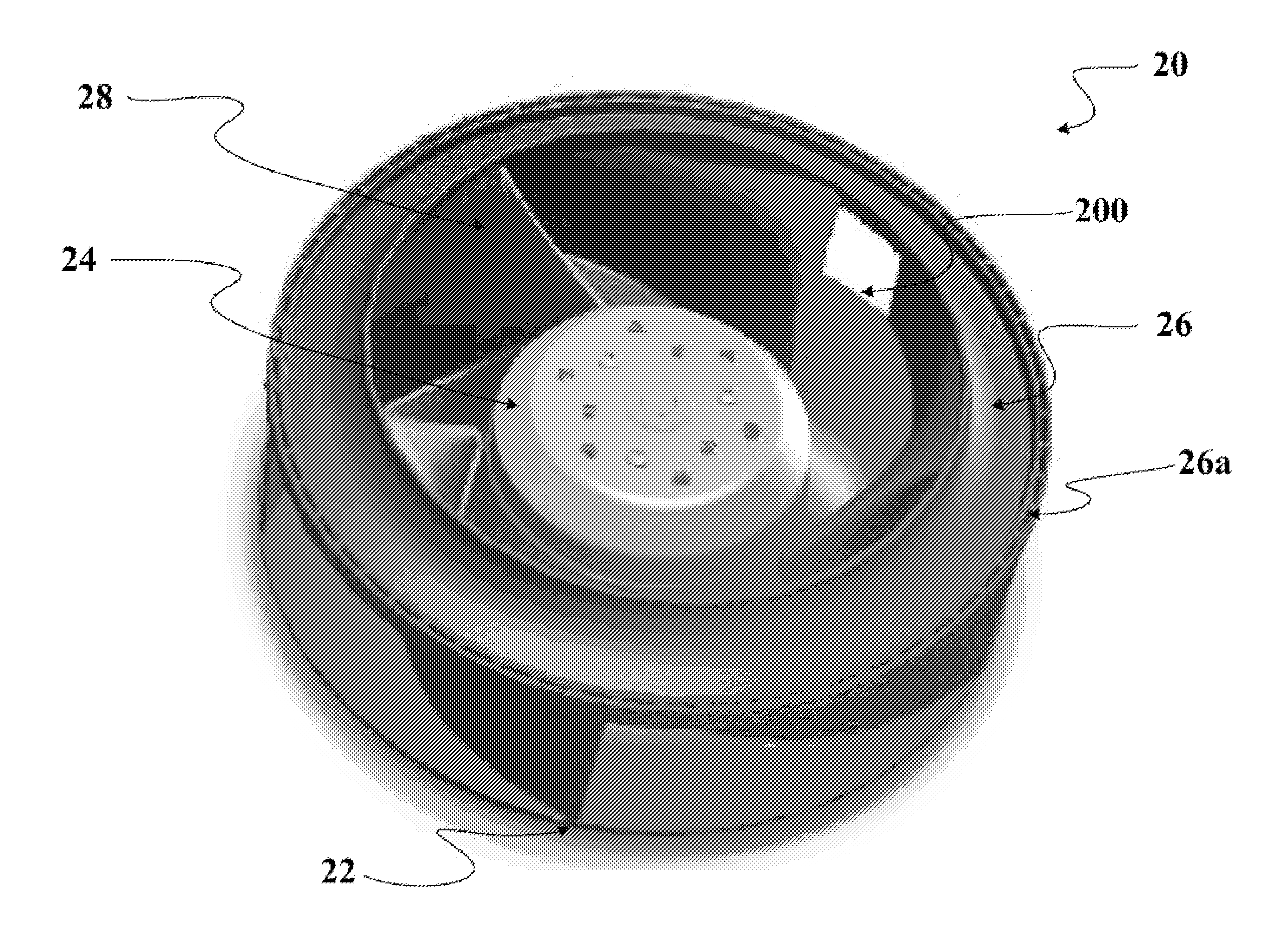

Boundary layer controlled logarithmic spiral blade

An impeller structure for a centrifugal fan apparatus includes a circular back plate, a ring-shaped shroud, and a tubular hub. The ring-shaped shroud and the tubular hub are respectively located a predetermined distance above and at the center of said circular back plate. The impeller structure further includes a plurality of blades which are annularly disposed around the tubular hub between the circular back plate and the ring-shaped shroud. Each of the plurality of blades includes a chord with a logarithmic spiral shape, and a mean camber line with an angle of return against the chord.

Owner:MCAFEE INC +1

Microcoil vaso-occlusive device with multi-axis secondary configuration

InactiveUS20060184195A1Minimizing shifting and tumblingMinimizing degree of compactionDilatorsOcculdersBlood flowHigh energy

A vaso-occlusive device includes a microcoil formed into a minimum energy state secondary configuration comprising a plurality of curved segments, each defining a discrete axis, whereby the device, in its minimum energy state configuration, defines multiple axes. In a preferred embodiment, the secondary configuration comprises a plurality of interconnected closed loops defining a plurality of discrete axes. In a second embodiment, the secondary configuration defines a wave-form like structure comprising an array of laterally-alternating open loops defining a plurality of separate axes. In a third embodiment, the secondary configuration forms a series of tangential closed loops, wherein the entire structure subtends a first angle of arc, and wherein each adjacent pair of loops defines a second angle of arc. In a fourth embodiment, the secondary configuration forms a logarithmic spiral. In all embodiments, the device, in its secondary configuration, has a dimension that is substantially larger than the largest dimension of the vascular site (i.e., aneurysm) in which it is to be deployed. Thus, confinement of the device within an aneurysm causes it to assume a three-dimensional configuration with a higher energy state than the minimum energy state. Because the minimum energy state configuration of the device is larger (in at least one dimension) than the aneurysm, the deployed device is constrained by its contact with the walls of the aneurysm from returning to its minimum energy state configuration. The engagement of the device with the aneurysm wall minimizes shifting or tumbling due to blood flow. Furthermore, the secondary configuration is not conducive to “coin stacking,” thereby minimizing the compaction experienced.

Owner:MICROVENTION INC

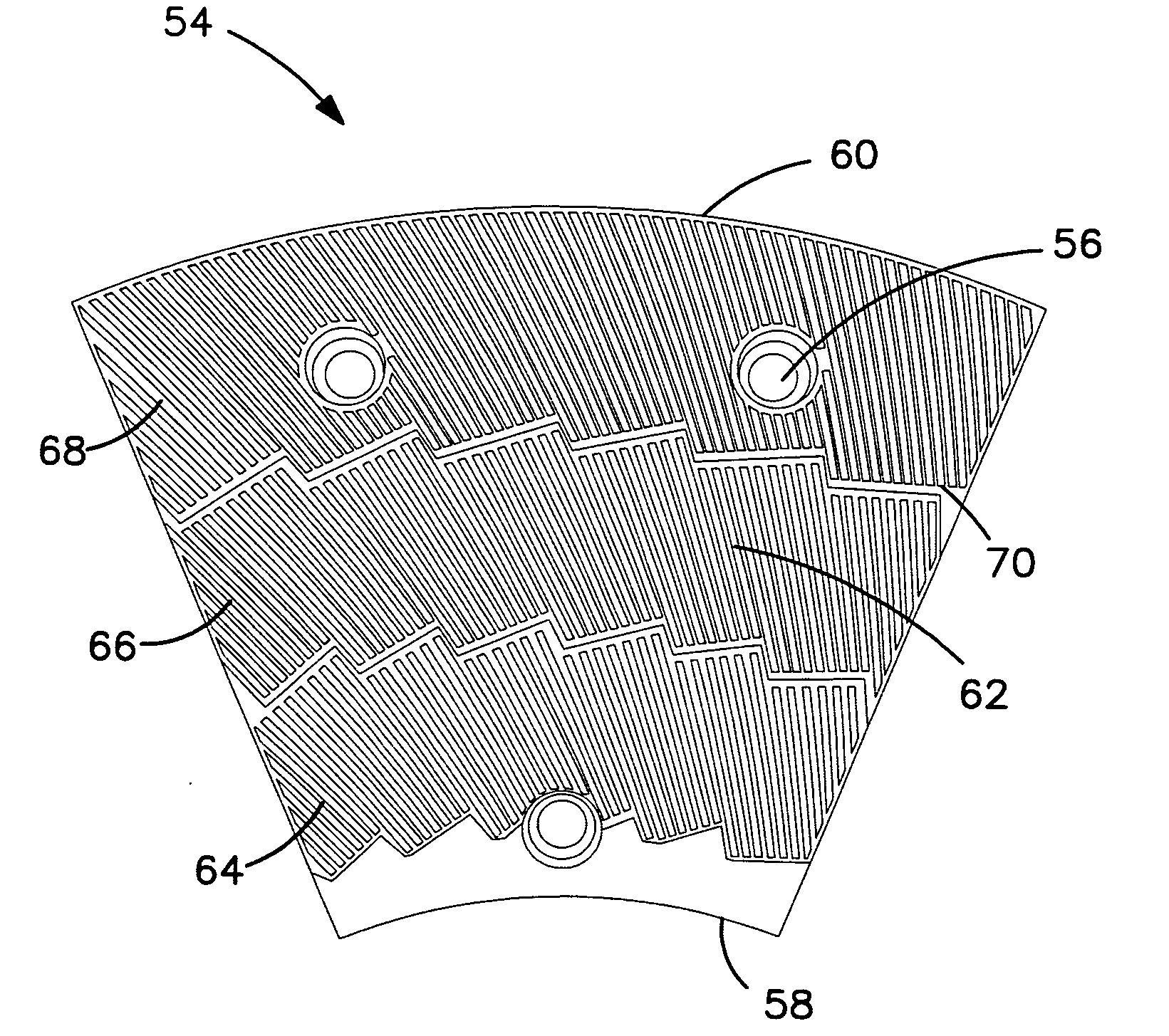

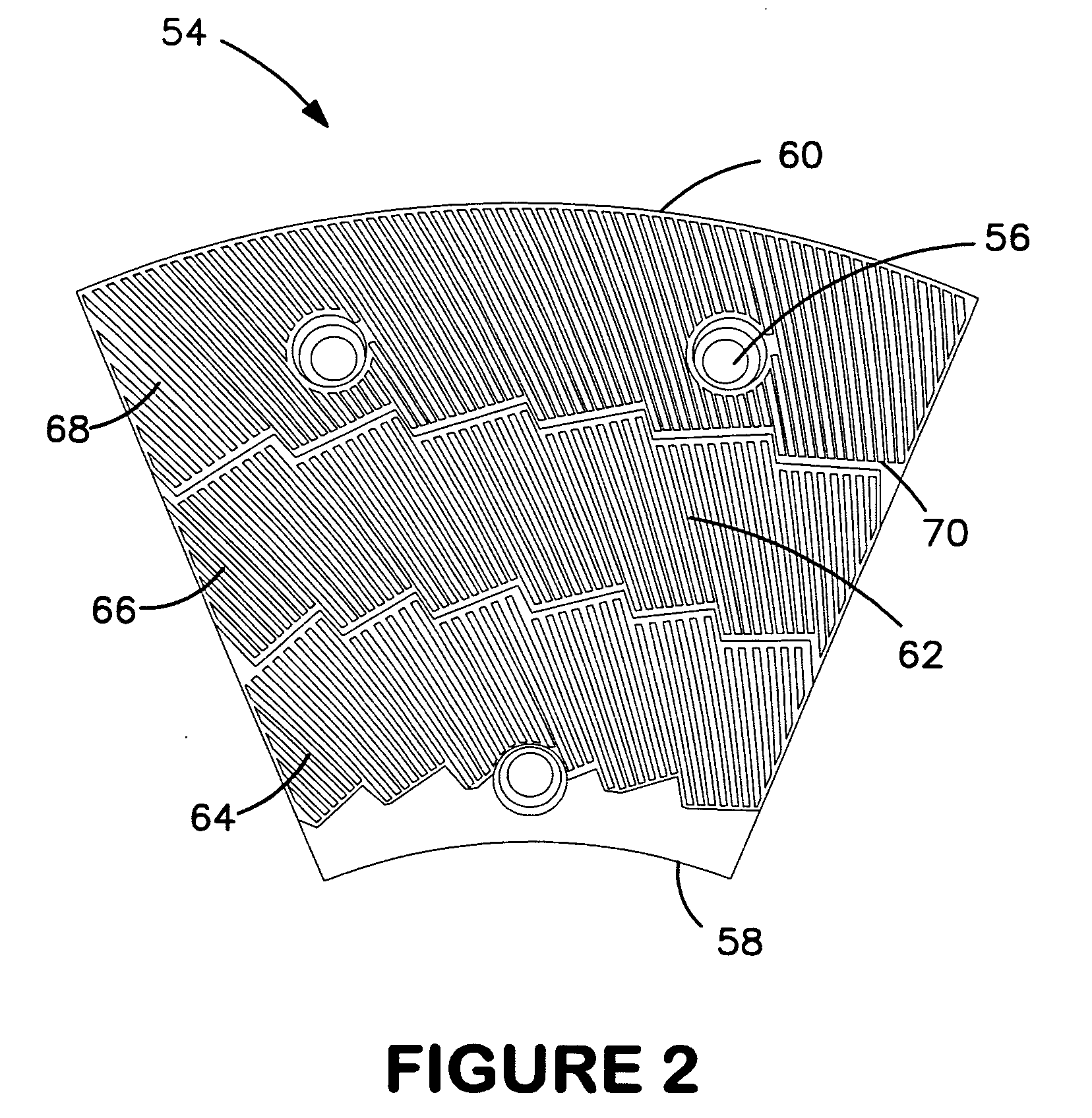

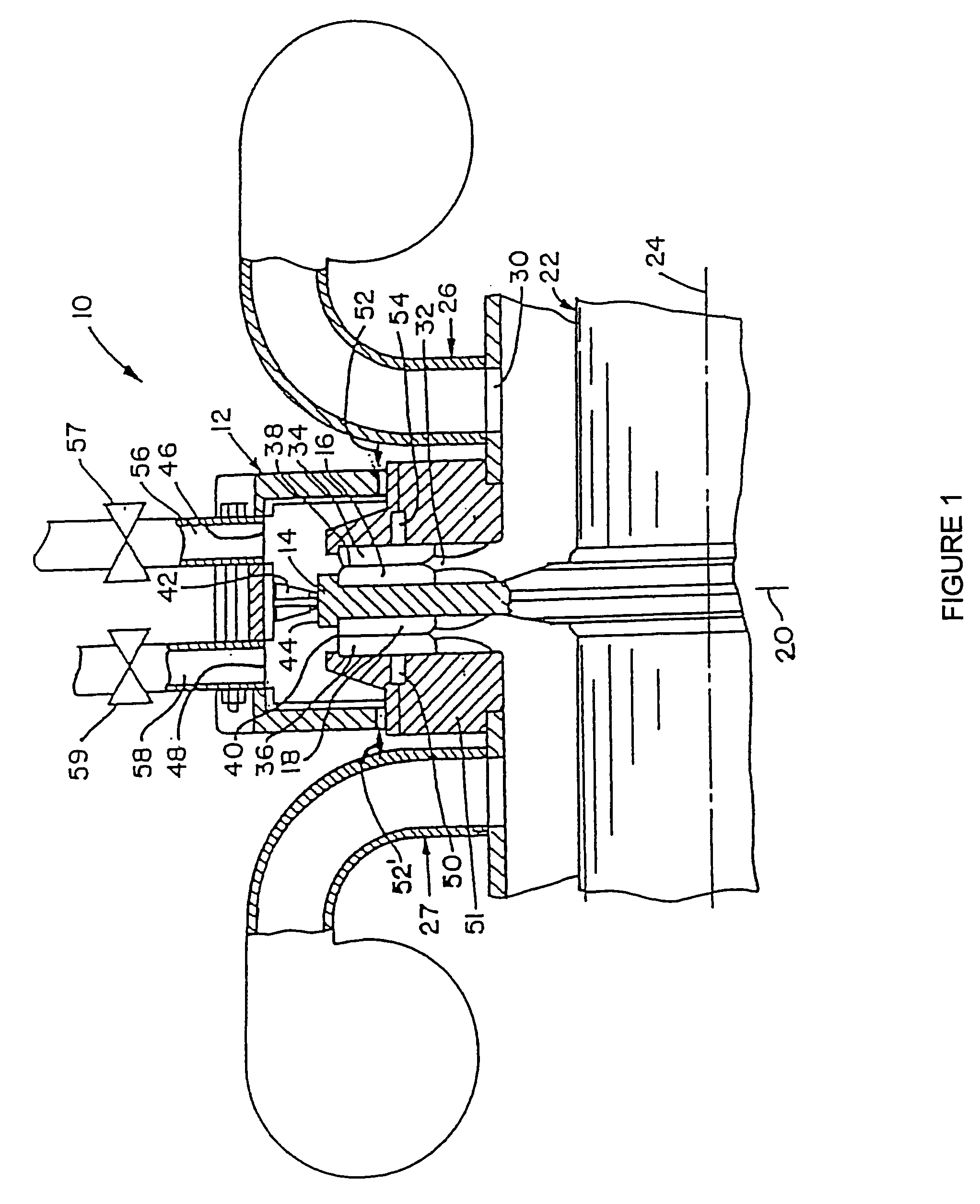

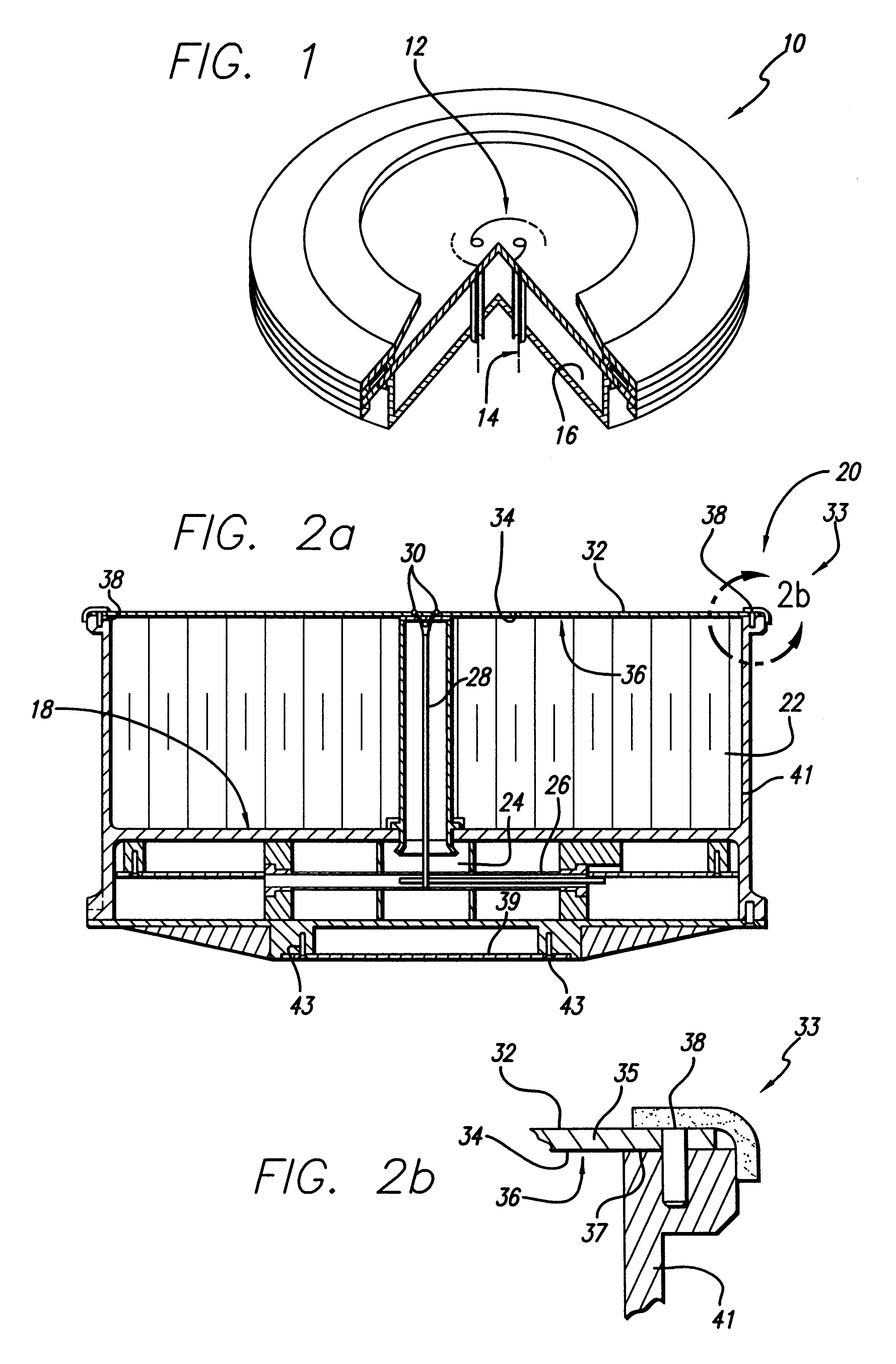

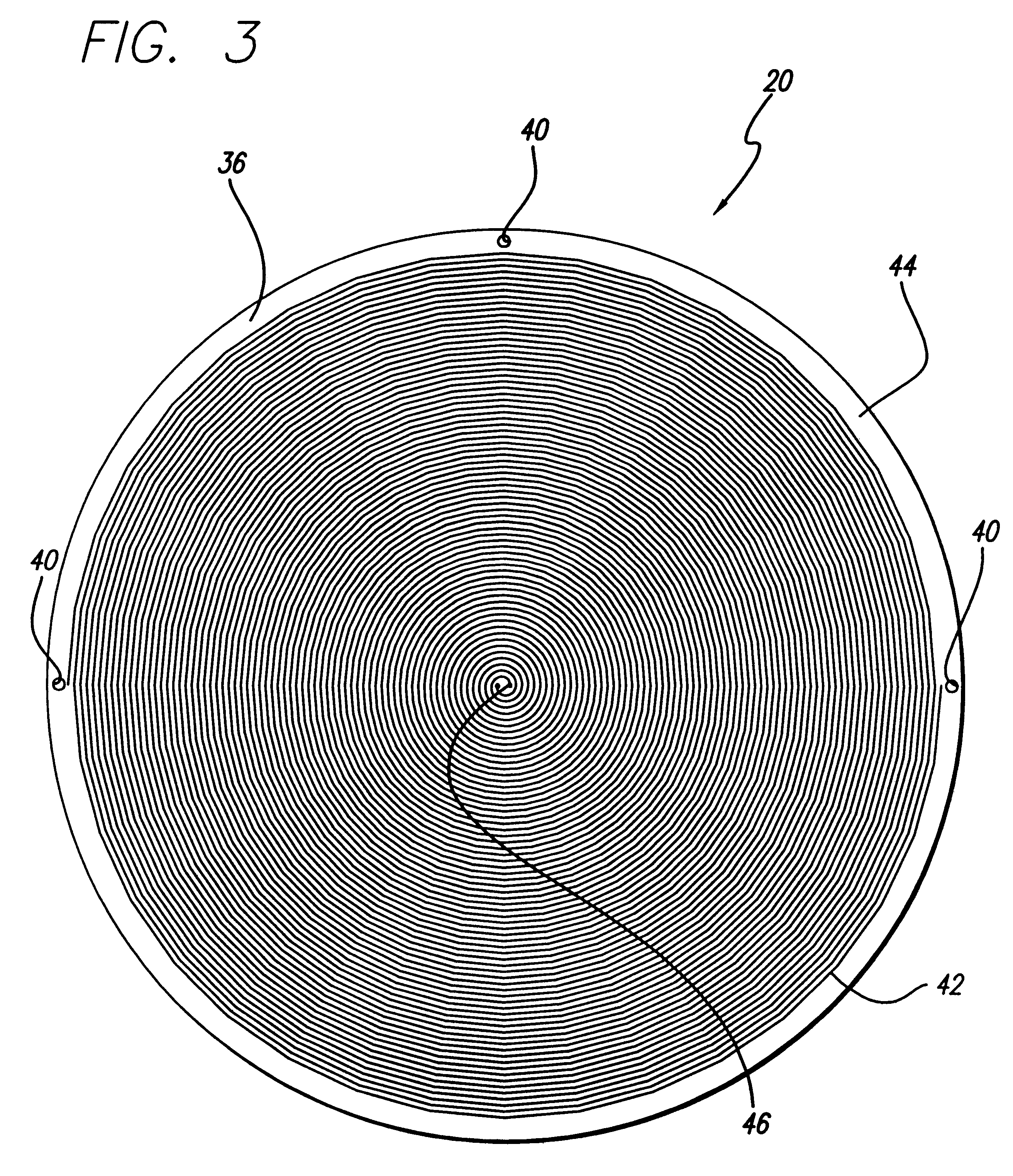

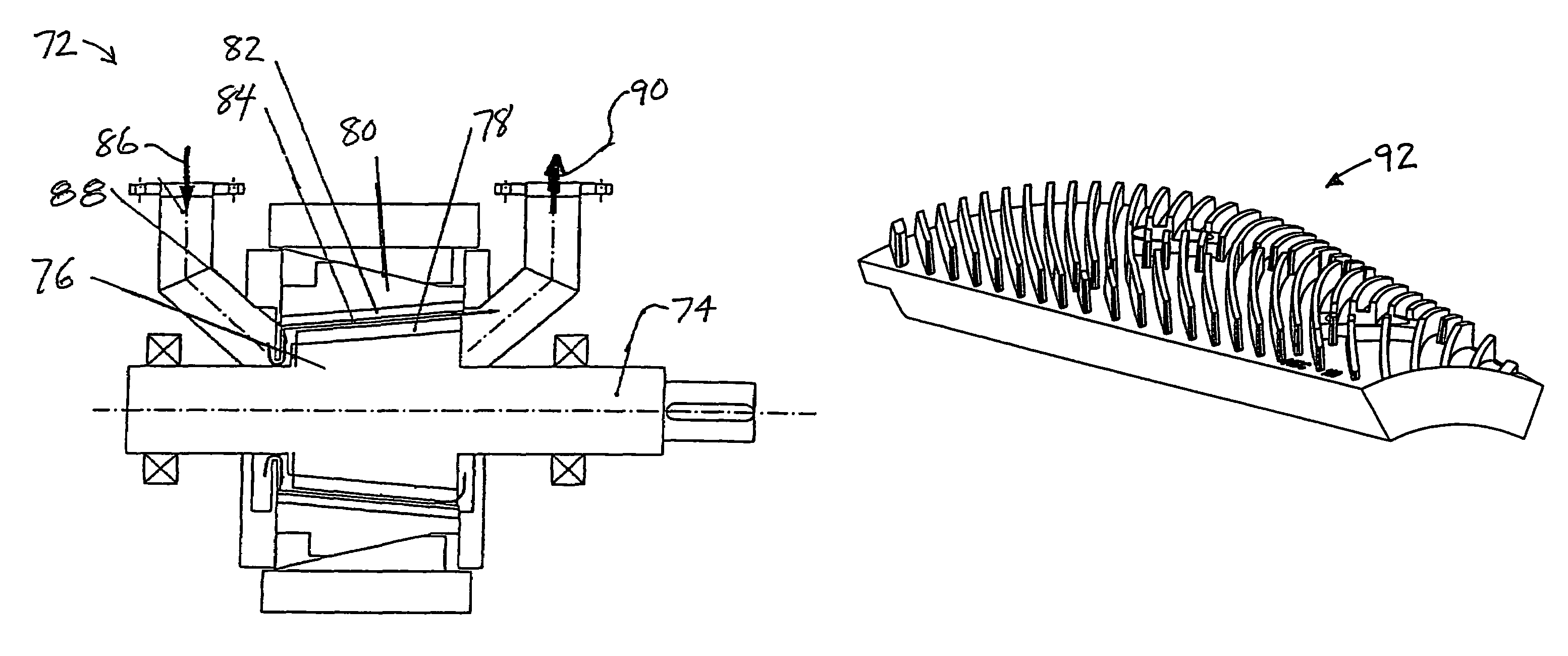

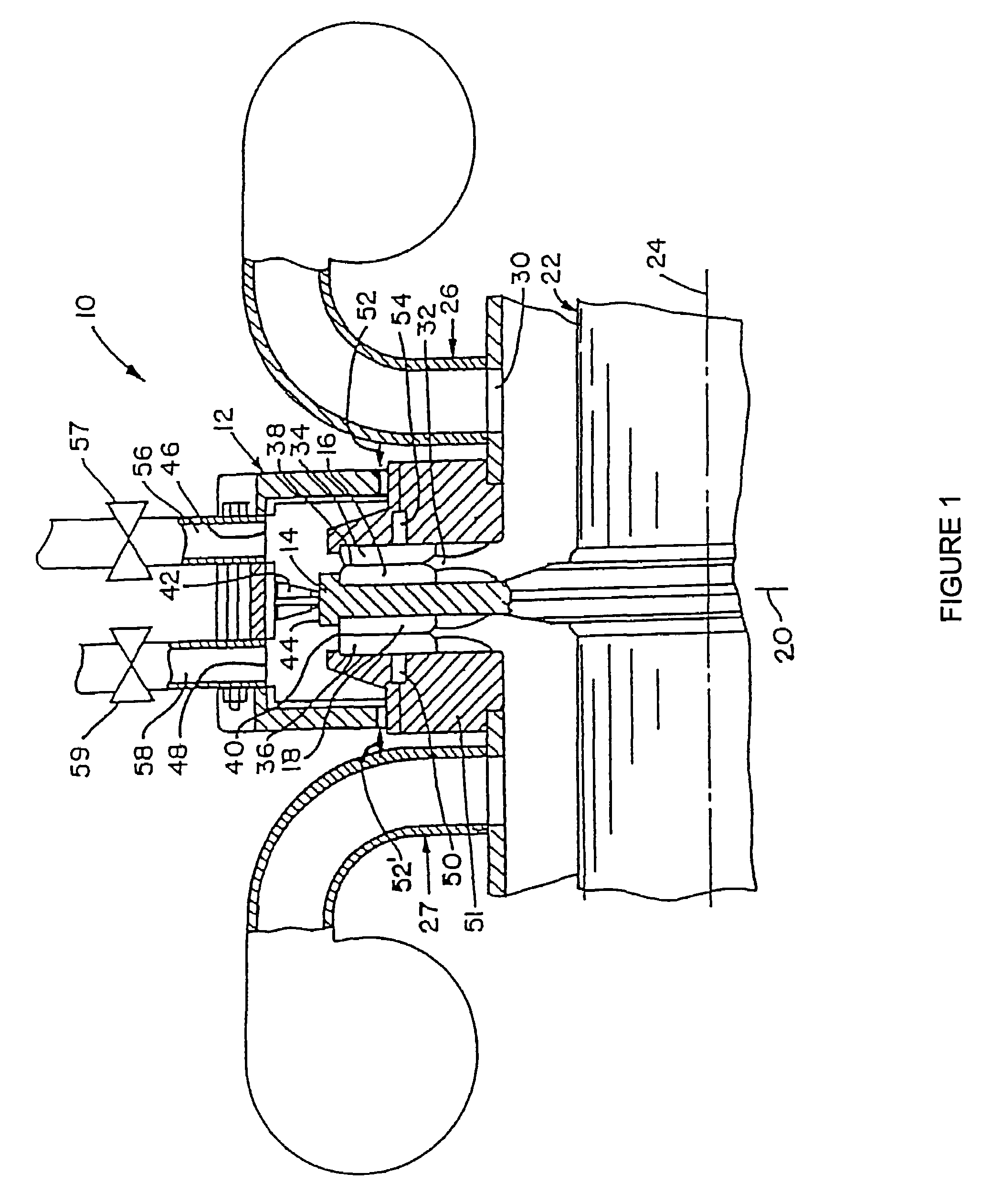

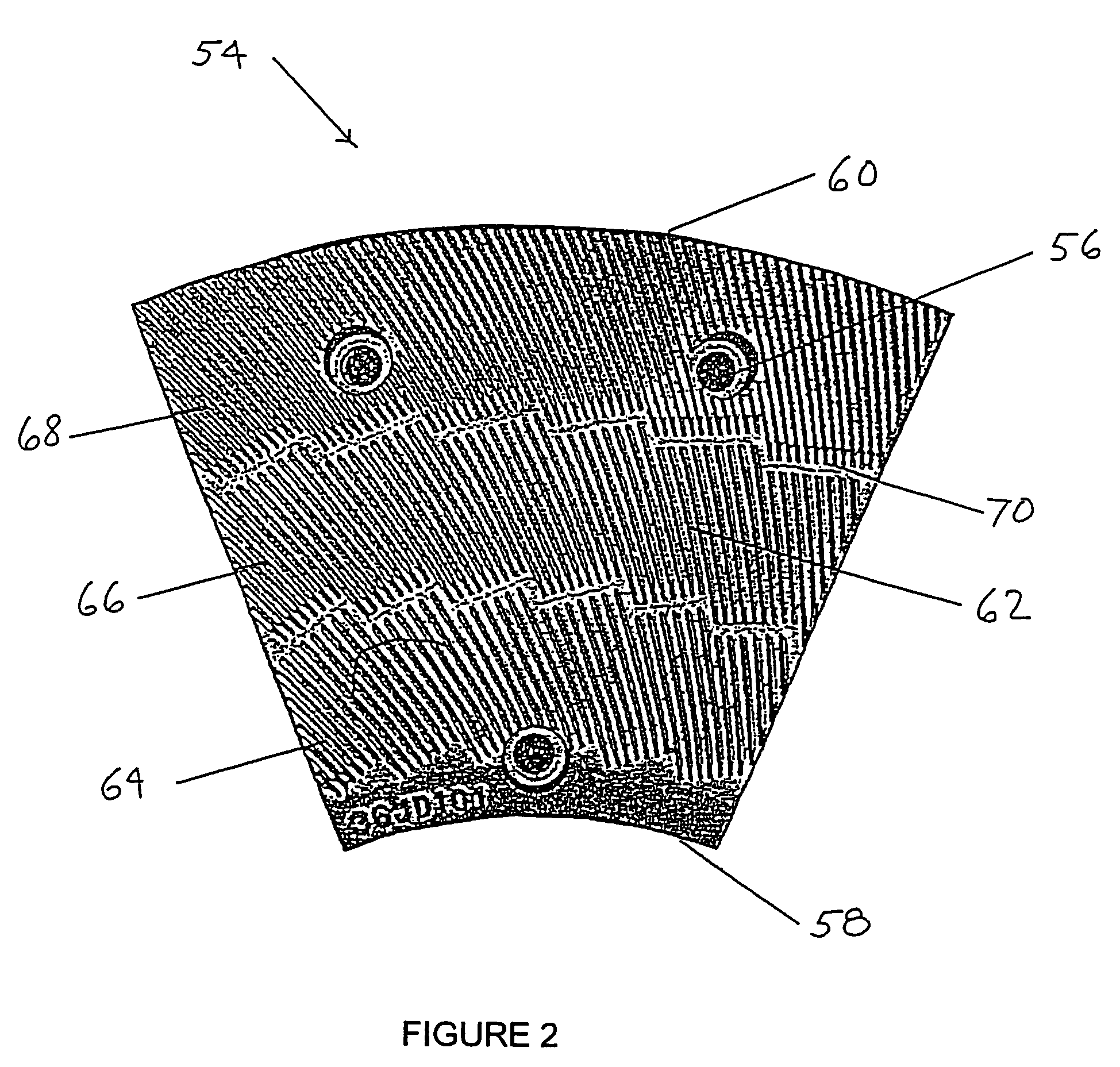

Disc refiner with plates having logarithmic spiral bars

InactiveUS20090001204A1More refining actionAvoid cloggingCocoaGrain treatmentsEngineeringLogarithmic spiral

A special shape of bars on refining discs or plate segments of a rotating disc refiner is disclosed including a plurality of bars generally extending outwards towards the outer end of the disk across its surface, arranged in a single, two or more radial zones, the plurality of the bars within a zone being curved with the shape of a logarithmic spiral. Disc refiners including such refining discs are also disclosed.

Owner:DURAMETAL CORP

Conical refiner plates with logarithmic spiral type bars

InactiveUS20060113415A1Avoid cloggingMore refining actionCocoaPulp beating/refining methodsMechanical engineeringConoid

Owner:ANDRITZ INC

Volute, centrifugal fan volute and range hood

InactiveCN104005996AIncrease air volumeReduce flow lossDomestic stoves or rangesPump componentsHelical lineAir volume

The invention provides a volute, a centrifugal fan volute and a range hood. The volute comprises a front plate, a side wall plate, a bottom plate and a volute tongue, an air inlet is formed in the front plate, the front plate and the bottom plate are respectively connected with the side wall plate, the edges of the side wall plate are logarithmic spiral lines, a hollow cavity is formed by the side wall plate, the edge line of the volute tongue comprises an arc segment and a straight line segment, the arc segment and the straight line segment are in smooth transition, the arc segment is connected with the side wall plate, and extending lines of the logarithmic spiral lines of the side wall plate are tangent to the arc segment. The volute tongue is different from the traditional design, the arc segment of the volute tongue is tangent to the extending lines of the logarithmic spiral lines of the side wall plate, and therefore air flows more smoothly in the flowing process, flowing losses are reduced, the air volume of the volute is high at the same rotating speed, and the high air volume requirement is met.

Owner:GREE ELECTRIC APPLIANCES INC

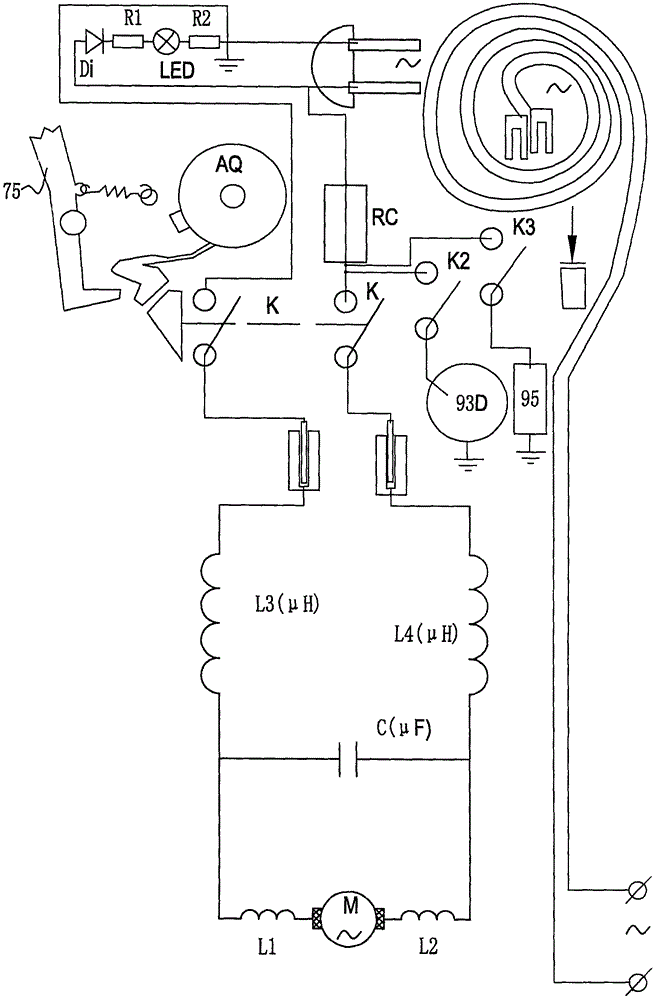

Mower comprising chassis blade broom and having blowing/suction, irrigation, fertilization, pesticide spreading and braking functions

PendingCN104838799ASolve the problem of double failureImprove braking performanceMowersEngineeringFan blade

The invention provides a mower comprising a chassis blade broom and having blowing / suction, irrigation, fertilization, pesticide spreading and braking functions. The mower is a multifunctional mower comprising a logarithmic spiral brake with an anti-corrosion guard and a pipe winder with liquid pipelines for irrigation, fertilization and pesticide spreading; four major assemblies, namely a support assembly with a charger and an inverter for a storage battery, a cutting device assembly dragged by a series excitation motor, a pipe winder assembly for irrigation, fertilization and pesticide spreading, and a brake assembly and a cutting device assembly, are additionally arranged on a common lawn mower; due to the addition of the irrigation, fertilization and pesticide spreading functions, the mower is wide in application range and large in movement area; a liquid fertilizer for fertilization in the pipe of the pipe winder is formed by adding a soluble fertilizer or pesticide to water in percentage. The dust collection bag support (35) of a blowing / suction unit arranged on the mower is connected with a dust collection bag (36) and a pipeline is connected with a grass collection arranged on the rear part of the mower. A blowing / suction fan blade (231) is arranged on a mowing cutter arranged on the chassis of the mower and a broom (232) is arranged to realize direct blowing, suction and sweeping.

Owner:NINGBO DAYE GARDEN EQUIP

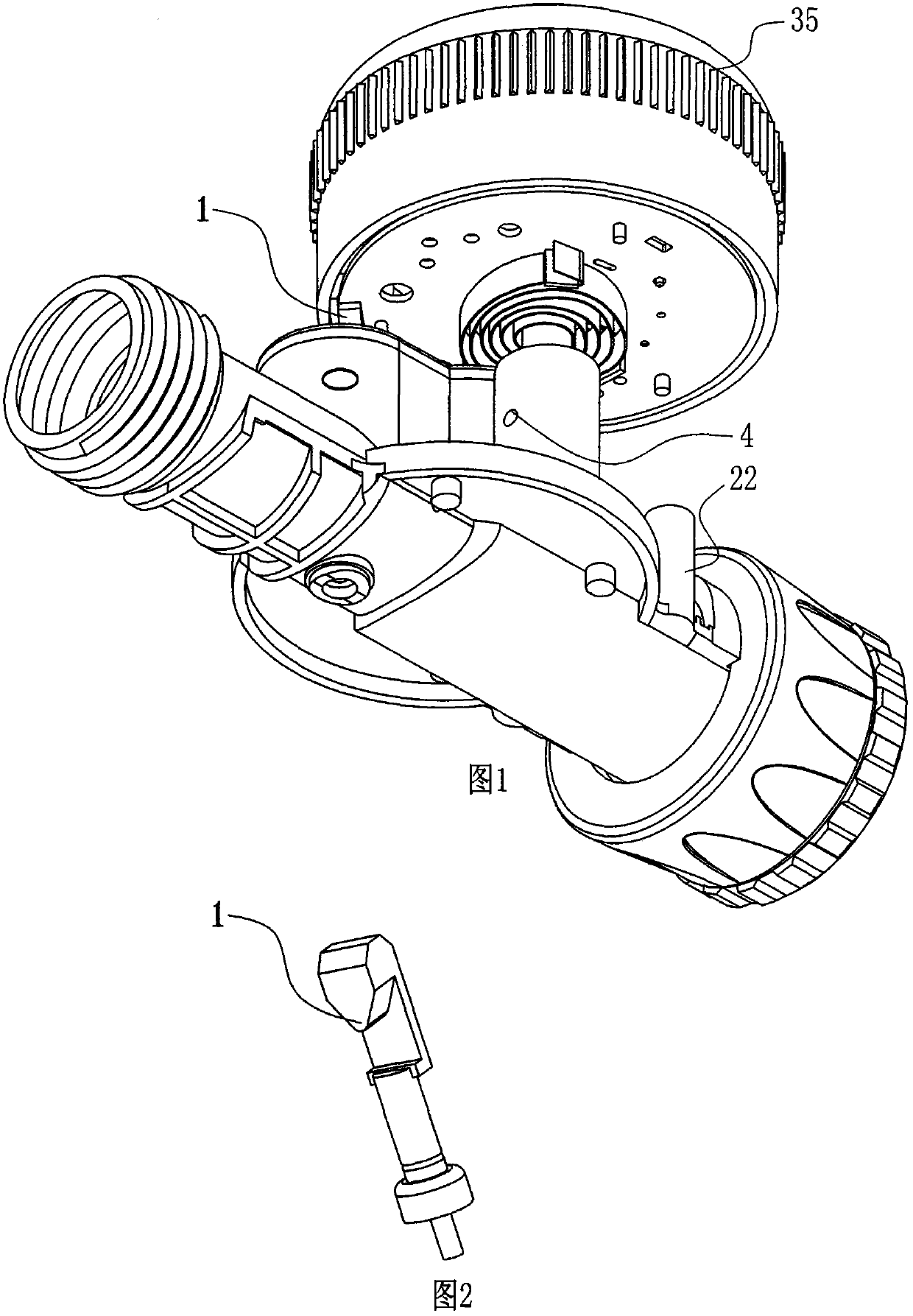

Water saving method for rotary water sprayer with wide range

The invention relates to a water saving method for a rotary water sprayer with a wide range. The method is characterized by comprising a rotary water sprayer (59), a spraying head of the rotary water sprayer is rotary, and the heights from bottom to top of the groove bottoms of a right water spraying groove and a left water spraying groove in water spraying grooves of the rotary water sprayer are different to form the rotary water sprayer with the wide range. Arc grooves of the rotary water sprayer are respectively contour line grooves of which the parabolas are smoothly connected in a central arc equation manner and the cross sections are in wing shapes, the heights of the two groove bottoms are different, and the distance between two water throwing grooves is different, so that the rotary water spraying with axial flow and wide range is convenient. Function curves are adopted in multiple positions, so that the product quality is improved; an inner wall which is provided with a plurality of through holes and is arranged at the side part of a spraying head cap adopts a cube curve with the function of a buffering curve in the middles of a straight passage and a circular arc-shaped water passage, and the impact is alleviated when water flow turns; a rib is arranged between every two through holes, the rib is in an equal angle spiral shape, i.e. a logarithmic spiral shape, and the water can be uniformly sprayed because pressure angles are the same in any place; the batched quality of the product is further improved by the spraying head cap with a cube curve water passage and the equal angles spiral rib and a spraying head seat with a hyperbolic curve pipeline or a logarithmic spiral pipeline.

Owner:NINGBO DAYE GARDEN IND

Microcoil vaso-occlusive device with multi-axis secondary configuration

InactiveUS20060184196A1Minimizing shifting and tumblingMinimizing degree of compactionDilatorsOcculdersBlood flowHigh energy

A vaso-occlusive device includes a microcoil formed into a minimum energy state secondary configuration comprising a plurality of curved segments, each defining a discrete axis, whereby the device, in its minimum energy state configuration, defines multiple axes. In a preferred embodiment, the secondary configuration-comprises a plurality of interconnected closed loops defining a plurality of discrete axes. In a second embodiment, the secondary configuration defines a wave-form like structure comprising an array of laterally-alternating open loops defining a plurality of separate axes. In a third embodiment, the secondary configuration forms a series of tangential closed loops, wherein the entire structure subtends a first angle of arc, and wherein each adjacent pair of loops defines a second angle of arc. In a fourth embodiment, the secondary configuration forms a logarithmic spiral. In all embodiments, the device, in its secondary configuration, has a dimension that is substantially larger than the largest dimension of the vascular site (i.e., aneurysm) in which it is to be deployed. Thus, confinement of the device within an aneurysm causes it to assume a three-dimensional configuration with a higher energy state than the minimum energy state. Because the minimum energy state configuration of the device is larger (in at least one dimension) than the aneurysm, the deployed device is constrained by its contact with the walls of the aneurysm from returning to its minimum energy state configuration. The engagement of the device with the aneurysm wall minimizes shifting or tumbling due to blood flow. Furthermore, the secondary configuration is not conducive to “coin stacking,” thereby minimizing the compaction experienced.

Owner:MICROVENTION INC

Compact low phase error antenna for the global positioning system

InactiveUS6201513B1Logperiodic antennasRadiating elements structural formsElectromagnetic shieldingLength wave

A low phase error antenna. The antenna is adapted for use with the Global Positioning System and includes a spiral antenna for receiving electromagnetic energy at a first standard frequency (L1) and a second standard frequency (L2). The spiral antenna has a spiral element with a circumference greater than approximately one and a half times the wavelength of electromagnetic energy at the lowest frequency (L2). The cavity of the antenna is unloaded and includes a balun adjusted for zero squint. The antenna element is either a logarithmic spiral or an archimedian spiral. In the illustrative embodiment, the spiral antenna includes a cavity having a depth which varies in accordance with the received electromagnetic energy. The cavity is approximately ¼ of a wavelength deep at the positions along spiral that receive electromagnetic energy.

Owner:MICROPULSE INCORPORATED

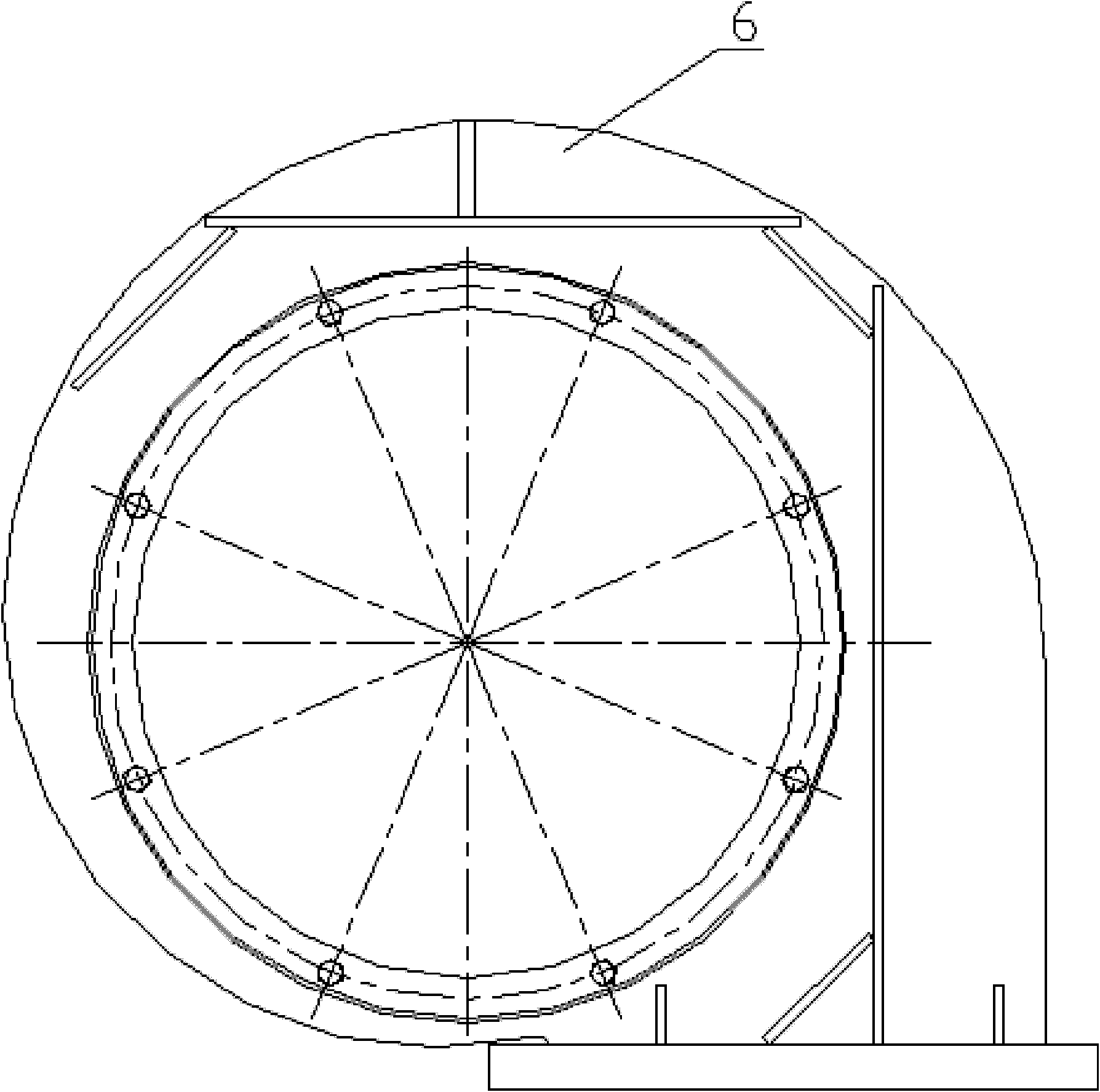

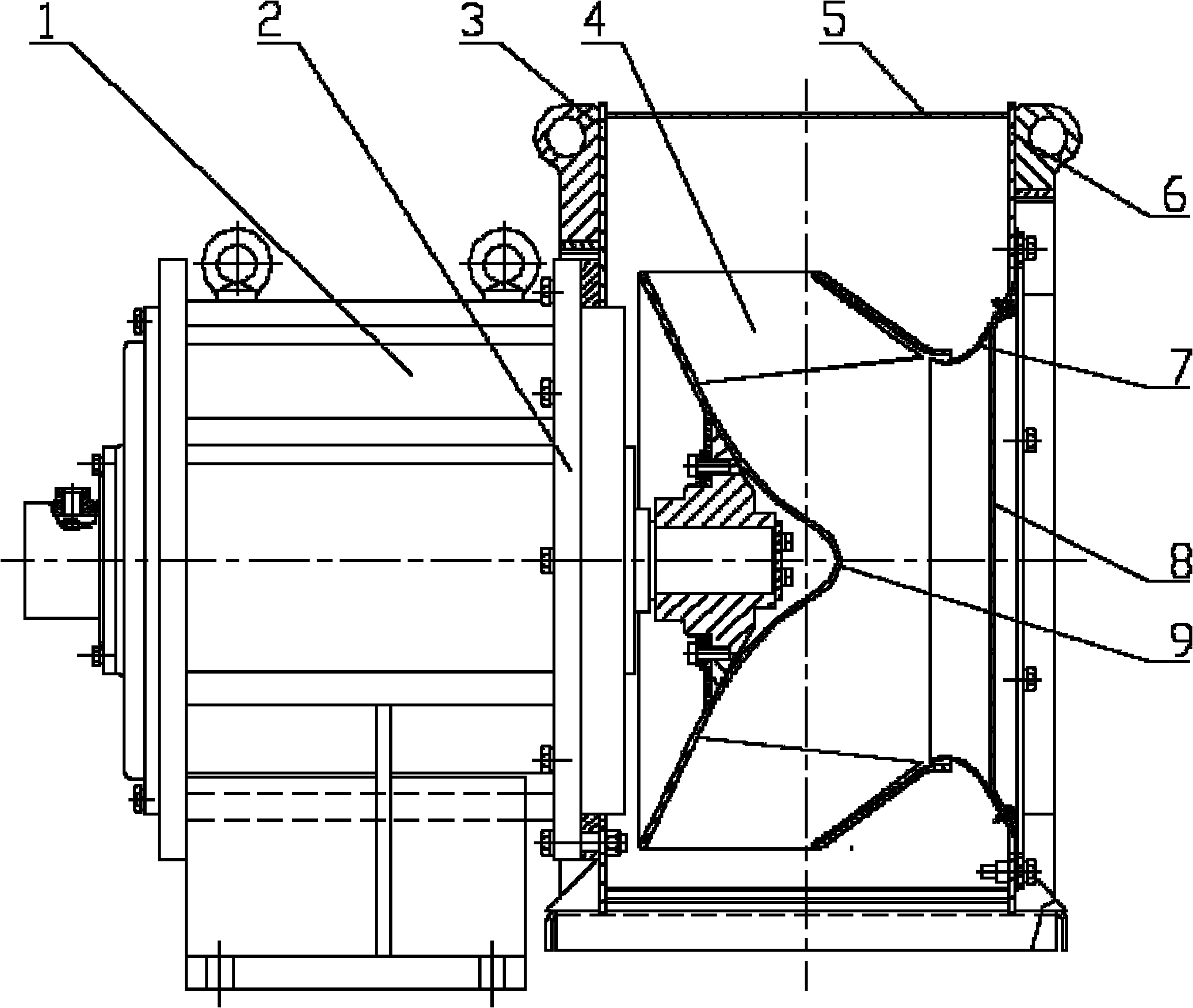

Centrifugal fan

Owner:CHAMP TECH OPTICAL FOSHAN

High full-voltage large-flow centrifugal blower with slant-wheel disk front-bent impeller

InactiveCN101818740AConform to flow characteristicsReduce flow lossPump componentsRadial flow pumpsImpellerMotor shaft

The invention discloses a high full-voltage large-flow centrifugal blower with a slant-wheel disk front-bent impeller, and belongs to the technical field of blowers. The high full-voltage large-flow centrifugal blower is characterized in that: the high full-voltage large-flow centrifugal blower consists of a motor, a support, a rear side plate, the impeller, an exhaust volute, a front side plate, a conical arc inlet guide pipe, a protective screen and an inlet fairing, wherein the impeller has the slant wheel disk structure; the slant wheel disk is that the wheel disk is not vertical to a motor shaft in a front view; the inlet fairing is arranged on a hub; the impeller adopts 36 circular arc long blades; the mold line of the exhaust volute adopts a logarithmic spiral form; the front side plate is provided with a large hole; and the rear side plate is provided with a small hole. The centrifugal blower meets the running requirements of a cooling fan on high full-voltage and large flow; the special slant wheel disk also improves the air flowing condition inside a ventilator, so the flow loss and noise are all reduced; and compared with the traditional similar ventilators, the centrifugal blower has the advantage of simpler processing and manufacturing due to a small number of the blades of the impeller.

Owner:DALIAN UNIV OF TECH

Conical refiner plates with logarithmic spiral type bars

InactiveUS7398938B2More refining actionAvoid cloggingCocoaGrain treatmentsEngineeringMechanical engineering

Owner:ANDRITZ INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com