Volute of centrifugal fan and method for manufacturing volute

A centrifugal fan and manufacturing method technology, applied in the field of pump parts, can solve problems such as noise, airflow collision, and limited housing space, and achieve the effects of reducing frictional noise, reducing overall flow resistance, and reducing obstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

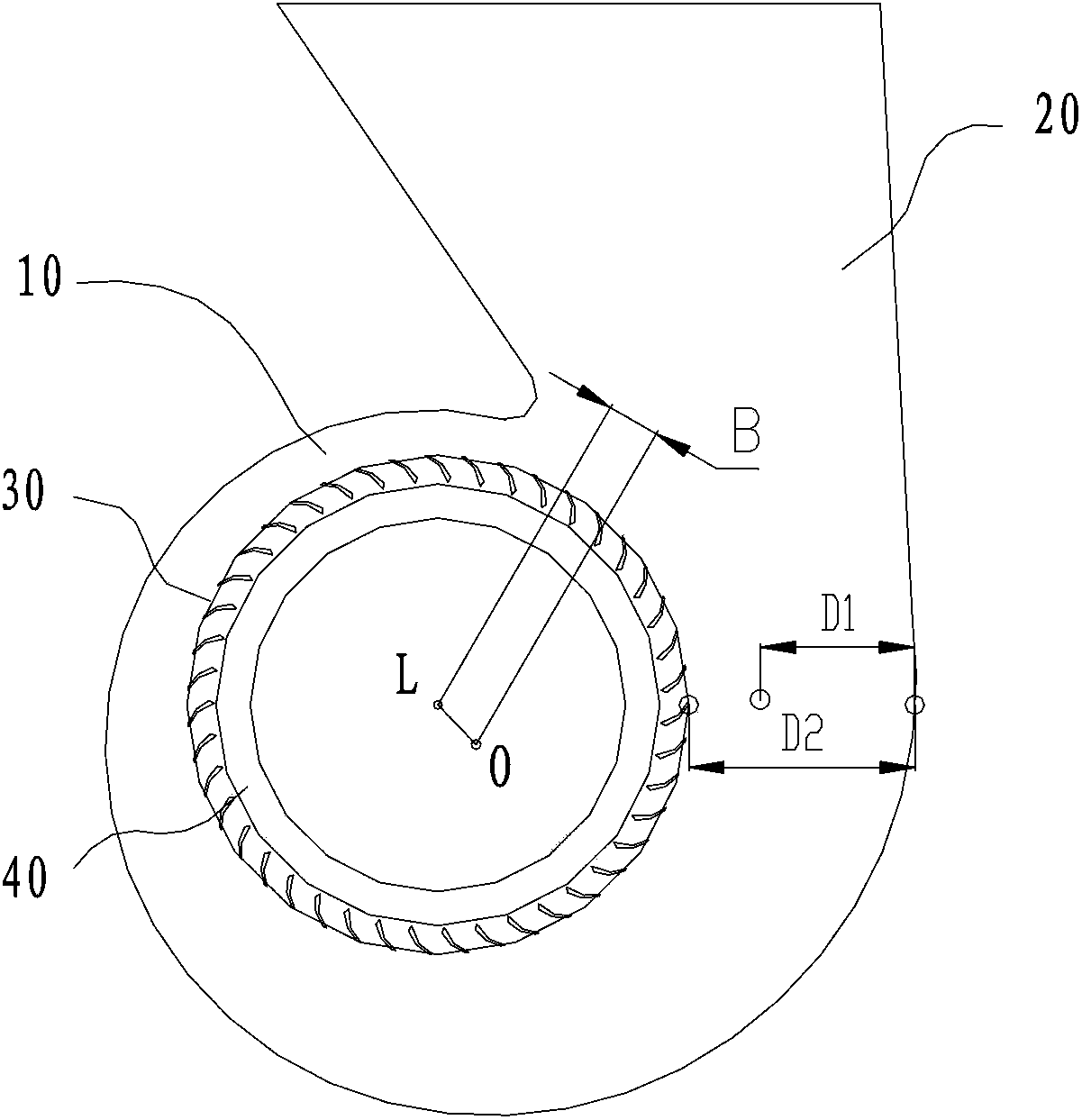

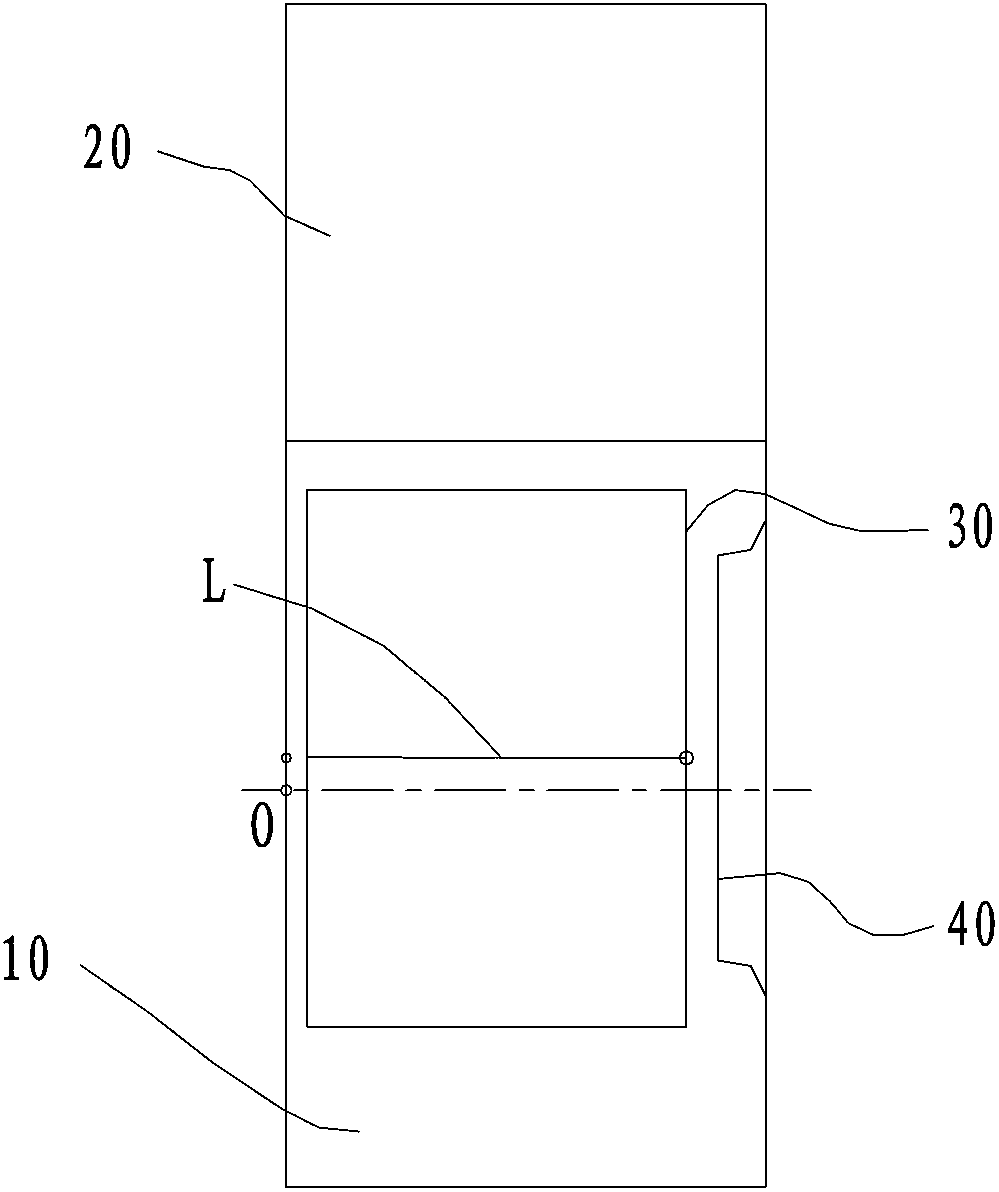

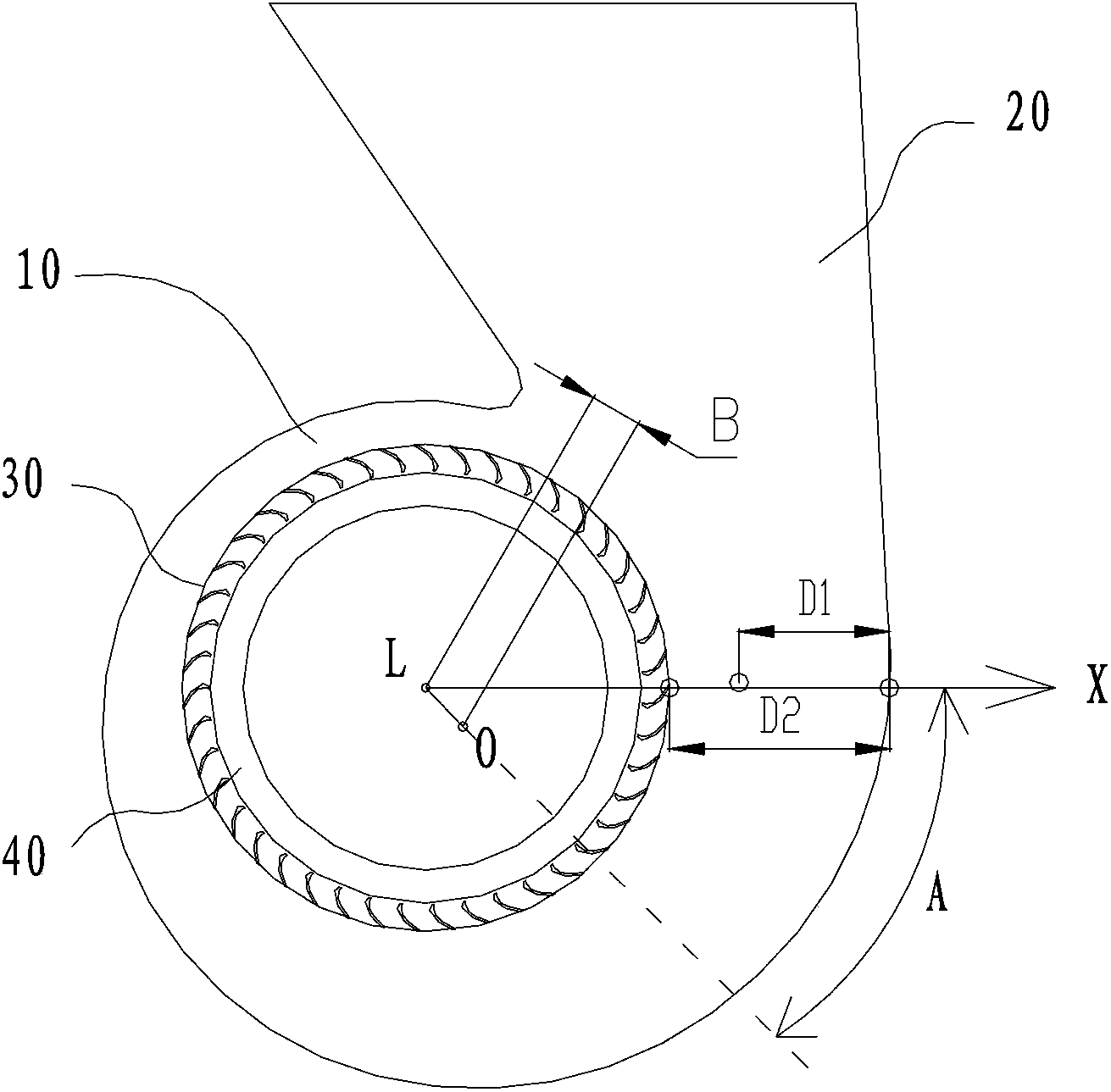

[0030] Such as figure 1 , figure 2 As shown, a centrifugal fan volute includes a volute body 10 designed with an Archimedes spiral or a logarithmic spiral, a diffuser chamber 20 connected to the volute body 10 and a volute inside the volute body 10 Centrifugal wind impeller 30. The profile line drawing center O of the volute body 10 is set eccentrically relative to the central axis L of the centrifugal wind impeller 30, so that the distance D1 between the centrifugal wind impeller 30 and the inner wall of the diffuser cavity 20 is enlarged to D2, wherein D1

[0031] In this embodiment, the range of the distance B between the drawing center O of the volute body 10 and the central axis L of the centrifugal wind impeller 30 is 0 mm

[0032] In this embodiment, the diameter of the diffuser cavity 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com