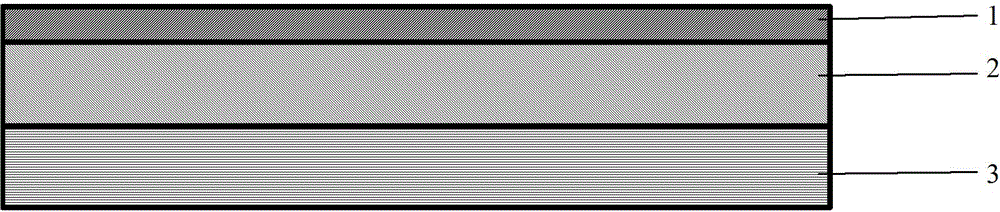

Multilayer composite positive pole piece, method for preparing pole piece and lithium ion battery applying multilayer composite positive pole piece

A positive electrode, multi-layer composite technology, used in battery electrodes, secondary batteries, battery pack components, etc., can solve problems such as low ionic conductivity, improve battery capacity, increase safety tolerance temperature, and increase reaction. Effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

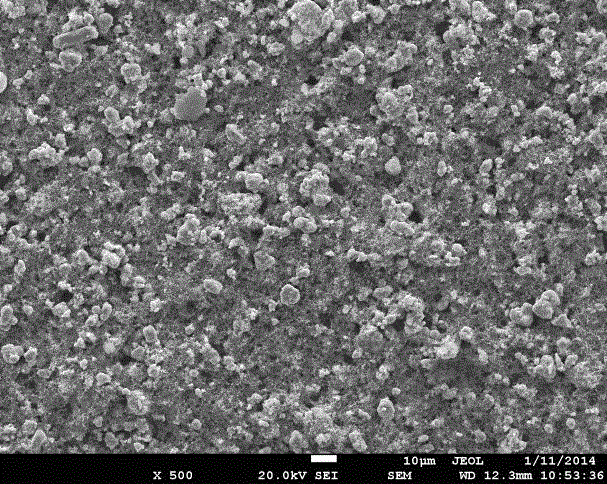

[0030] Example 1: Al2O3 multilayer composite positive pole piece S1

[0031] (1) Dissolve 2.0g of aluminum nitrate in 20g of deionized water, then add 20g of polyvinyl alcohol aqueous solution with a mass concentration of 10%, and stir thoroughly to obtain a precursor solution; add the above precursor solution into the syringe of the electrospinning equipment, Obtain precursor fibers by electrospinning (spinning conditions: spinning voltage 30KV, extrusion speed 2.0ml / min); after repeating the above steps several times, obtain multiple precursor fibers; remove all fibers from the receiving plate , calcined in a medium-temperature furnace at 1000°C for 10 hours, and collected a total of 50.5 g of aluminum oxide fiber powder obtained. The average length of the aluminum oxide fiber was 0.5 microns, and the average diameter was 50 nanometers; The aluminum fiber powder is evenly dispersed in water, and under the condition of heating in a water bath at 80 degrees Celsius, add the si...

Embodiment 2

[0033] Example 2: Magnesium oxide, titanium dioxide multilayer composite positive pole piece S2

[0034] (1) Dissolve 2.0g of magnesium nitrate in 20g of deionized water, then add 20g of 10% polyvinyl alcohol solution in mass concentration, and stir thoroughly to obtain a precursor solution; add the above precursor solution into the syringe of the electrospinning equipment, and pass Electrospinning method to obtain precursor fibers (spinning conditions: spinning voltage 30KV, extrusion speed 2.0ml / min); after repeating the above steps several times, multiple precursor magnesium oxide fibers were obtained; all magnesium oxide fibers were obtained from The receiving plate was removed, and calcined at 1200° C. for 10 hours in a high-temperature furnace, and a total of 40.5 g of magnesium oxide and titanium dioxide fiber powders obtained were collected. The average length of the magnesium oxide fibers was 3 microns, and the average diameter was 300 nanometers; the magnesium oxide ...

Embodiment 3

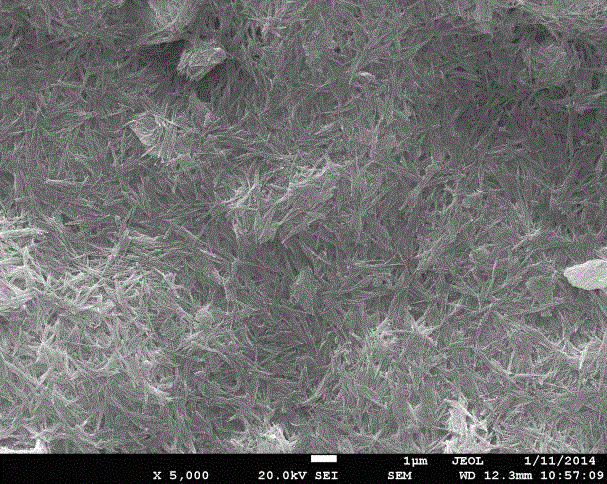

[0036] Example 3: Attapulgite clay multilayer composite positive electrode sheet S3

[0037] (1) Attapulgite clay is selected from samples that have been purified by physical flotation (purchased from Jiangsu Jiuchuan Nano Material Technology Co., Ltd.), produced in Jiangsu-Anhui area, with a rod-like microscopic appearance, an average length of 1 micron, and an average 2:1 type clay mineral with a diameter of 0.05 microns; uniformly disperse the attapulgite clay fiber powder in water, add the silane coupling agent KH570 solution under the condition of heating in a water bath at 80 degrees Celsius, soak for 2 hours, and then filter , dry, and complete surface lipophilic treatment; weigh 28.0g of pretreated mineral fiber powder, 11.6g of polyvinylidene fluoride, and 0.4g of polyethylene glycol, dissolve in 30g of ethanol, and fully stir to form a protective layer slurry material;

[0038] (2) Dissolve 20g of lithium cobaltate, 1g of conductive carbon black, and 1g of polyvinyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com