Large-proportion methanol gasoline catalyst and preparation method

A methanol gasoline and catalyst technology, which is applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of metal corrosion and rubber swelling, restricting the development of methanol gasoline, and small replacement ratio, and achieves overcoming high temperature non-air resistance, Overcome swelling and metal corrosion problems, clean exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

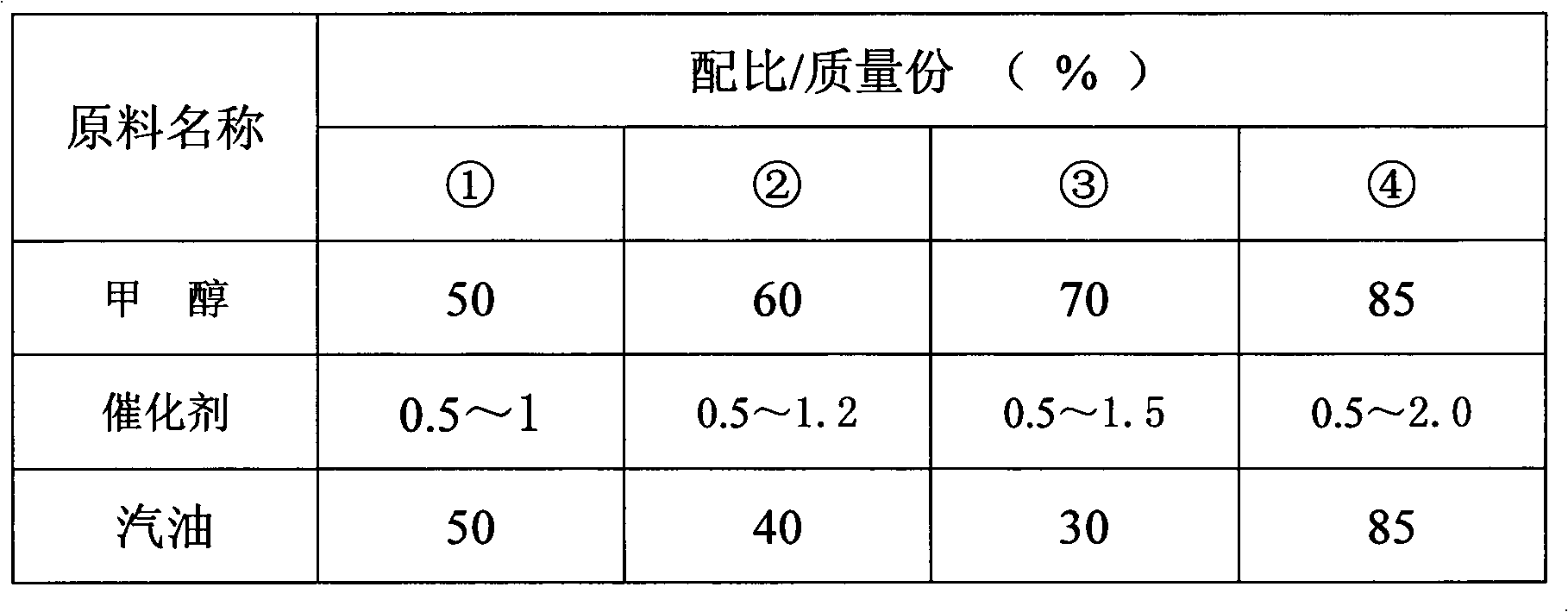

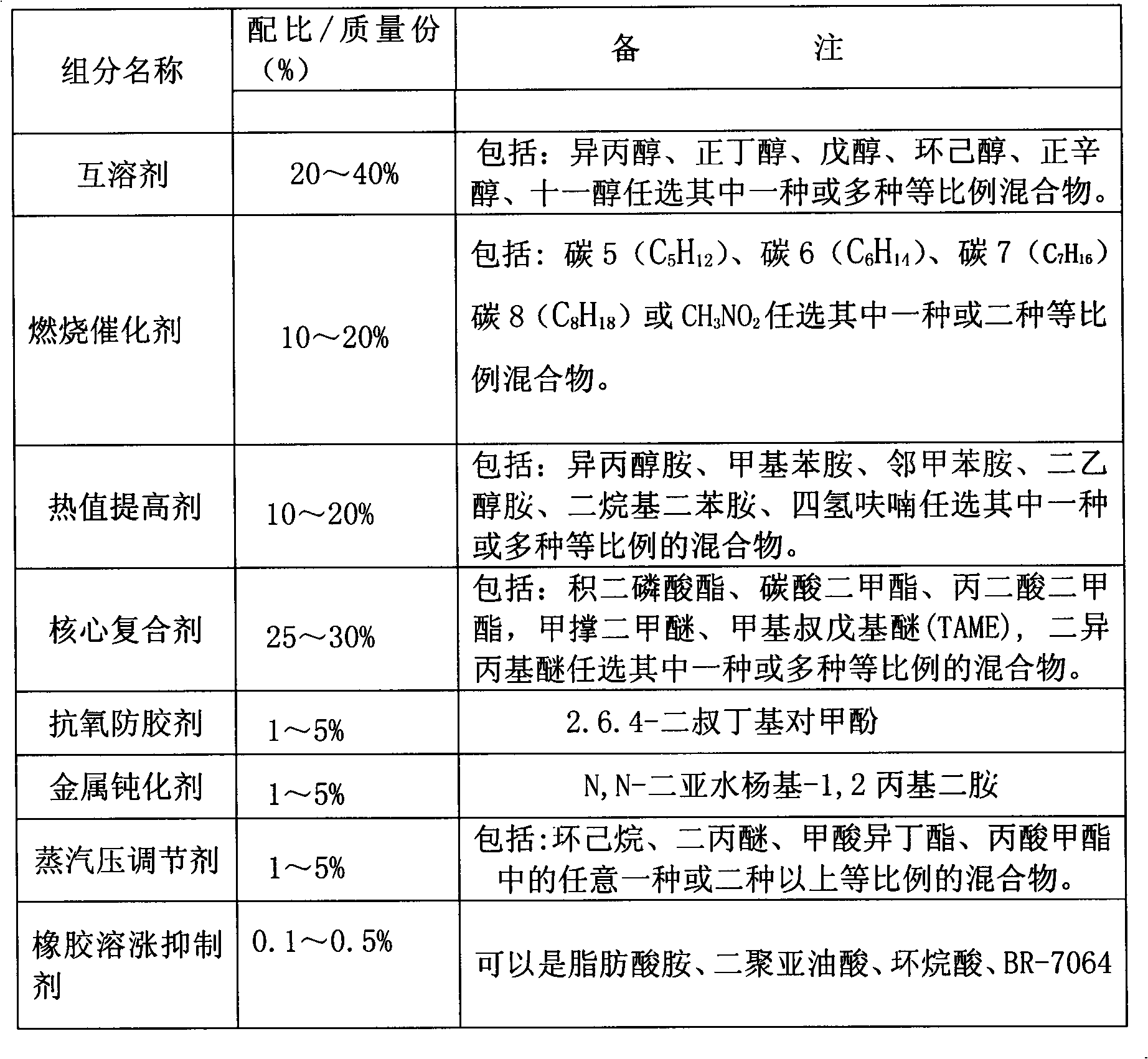

[0040] A kind of large-scale methanol gasoline catalyst, its volume percent composition is as follows:

[0041] A. Mutual solvent: 20-40% (isopropanol, n-butanol)

[0042] B. Combustion catalyst: 10-20% carbon 5 (C 5 h 12 )

[0043] C. Calorific value enhancer: 10-20% (isopropanolamine)

[0044] D. Core complex agent: 25-30% (diphosphate, dimethyl carbonate)

[0045] E. Antioxidant anti-adhesive agent: 1~5% (T-501)

[0046] F. Metal passivation agent: 1~5% (T1201)

[0047] G. Vapor pressure regulator: 1-5% (cyclohexane)

[0048] H. Rubber swelling inhibitor: 0.1~0.5%

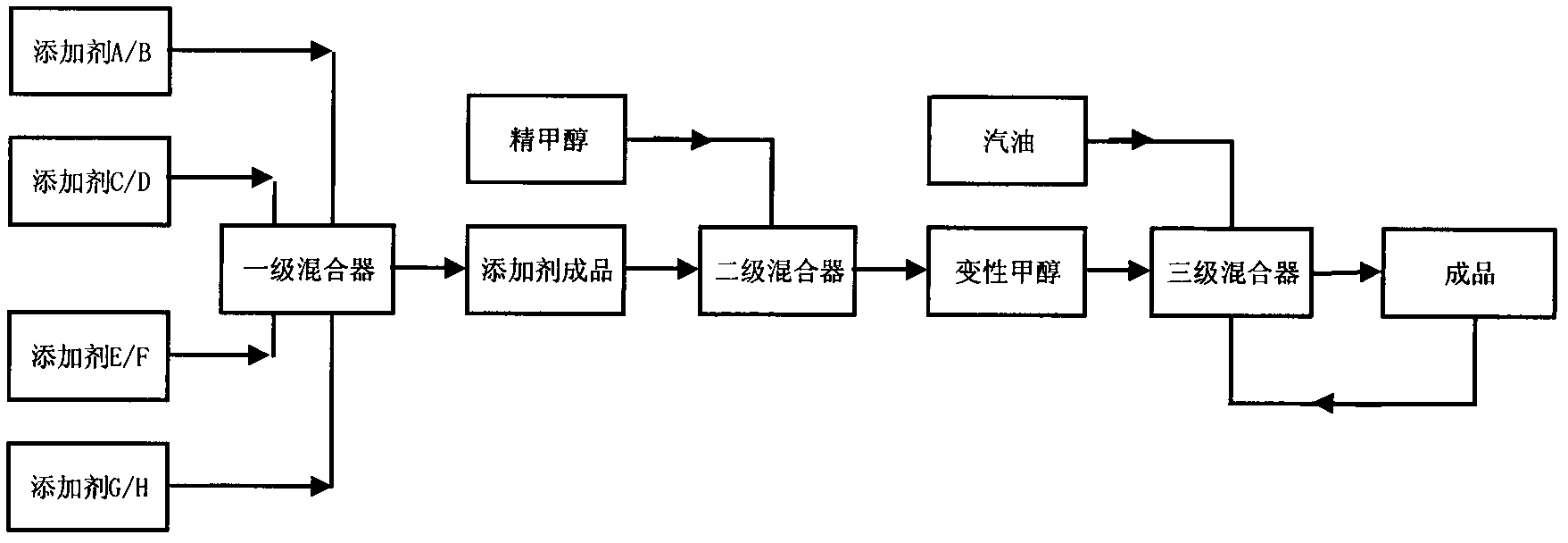

[0049] Preparation method of the present invention:

[0050] (1) First, the diphosphate solution and the dimethyl carbonate solution are mixed in a primary mixer in a ratio of 1:1 and then mixed with isopropanol and n-butanol in an equal ratio of 1:1;

[0051] (2) carbon 5 (C 5 h 12 ) into the primary mixer;

[0052] (3) isopropanolamine is added in the primary mixer;

[0053] (4) Add T-50 in the pr...

Embodiment 2

[0059] A kind of large-scale methanol gasoline catalyst, its volume percent composition is as follows:

[0060] A. Mutual solvent: 20-40% (isopropanol, cyclohexanol)

[0061] B. Combustion catalyst: 10-20% carbon 6 (C 6 h 14 )

[0062] C. Calorific value enhancer: 10-20% (methylaniline, o-toluidine)

[0063] D. Core compounding agent: 25-30% (methyl tert-amyl ether, diisopropyl ether)

[0064] E. Antioxidant anti-adhesive agent: 1~5% (T-501)

[0065] F. Metal passivation agent: 1~5% (T1201)

[0066] G. Vapor pressure regulator: 1-5% (methyl propionate)

[0067] H. Rubber swelling inhibitor: 0.1~0.5%

[0068] Preparation method of the present invention:

[0069] (1) First, the methyl tert-amyl ether solution and the diisopropyl ether solution are mixed in a primary mixer in a ratio of 1:1 and then mixed with isopropanol and cyclohexanol in an equal ratio of 1:1;

[0070] (2) carbon 6 (C 6 h 14 ) into the primary mixer;

[0071] (3) Add methylaniline and o-toluidine ...

Embodiment 3

[0078] A kind of large-scale methanol gasoline catalyst, its volume percent composition is as follows:

[0079] A. Mutual solvent: 20-40% (isopropanol, undecyl alcohol)

[0080] B. Combustion catalyst: 10-20% carbon 8 (C 8 h 18 )

[0081] C. Calorific value enhancer: 10-20% (tetrahydrofuran)

[0082] D. Core complex agent: 25-30% (dimethyl malonate, methylene dimethyl ether)

[0083] E. Antioxidant anti-adhesive agent: 1~5% (T-501)

[0084] F. Metal passivation agent: 1~5% (T1201)

[0085] G. Vapor pressure regulator: 1 to 5% (ethylene glycol monomethyl ether)

[0086] H. Rubber swelling inhibitor: 0.1~0.5%

[0087] Preparation method of the present invention:

[0088] (1) First, the dimethyl malonate solution and the methylene dimethyl ether solution are mixed in a primary mixer in a ratio of 1:1, and then mixed with isopropanol and undecyl alcohol in an equal ratio of 1:1;

[0089] (2) carbon 8 (C 8 h 18 ) into the primary mixer;

[0090] (3) tetrahydrofuran is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com