Patents

Literature

71results about How to "Discharge cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

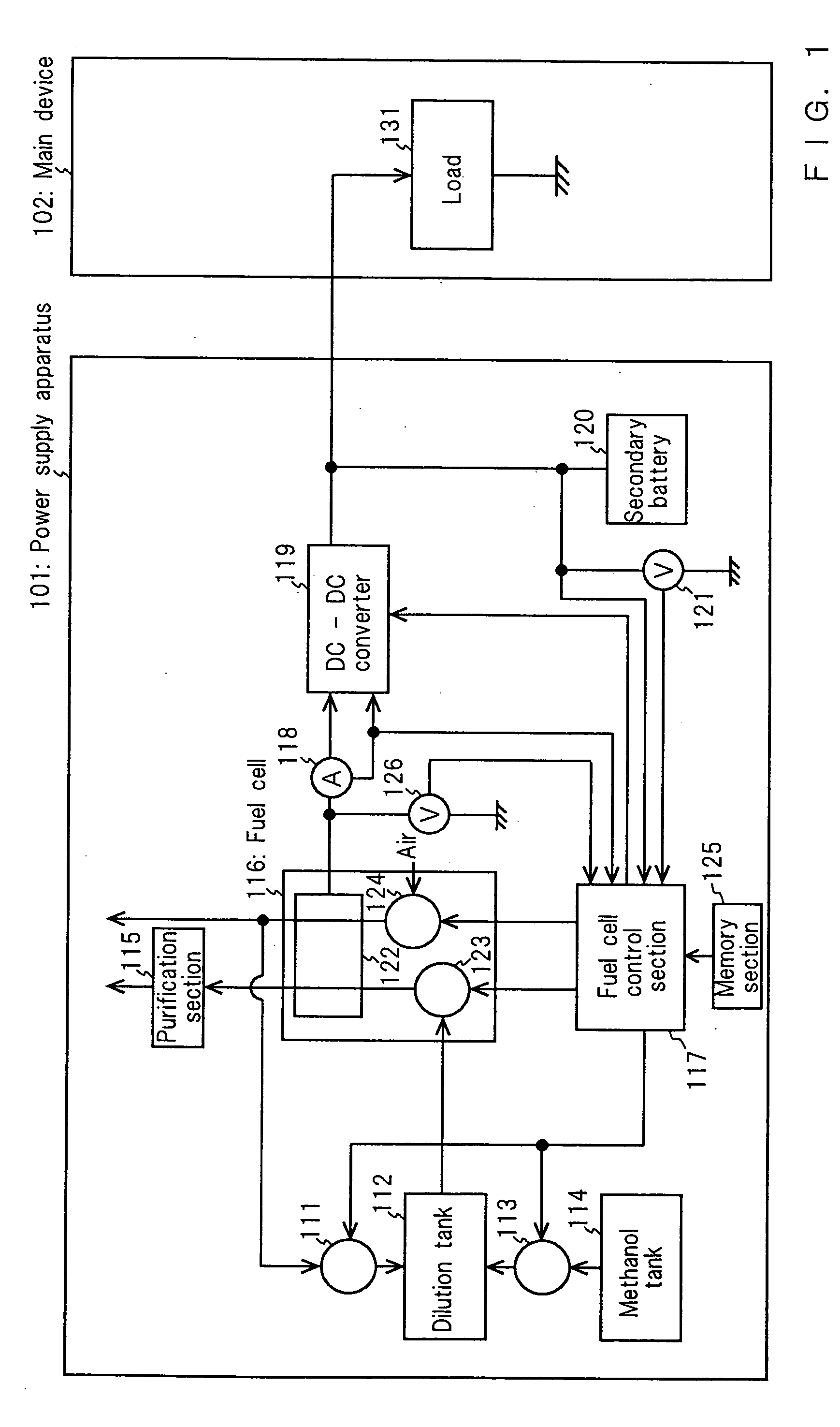

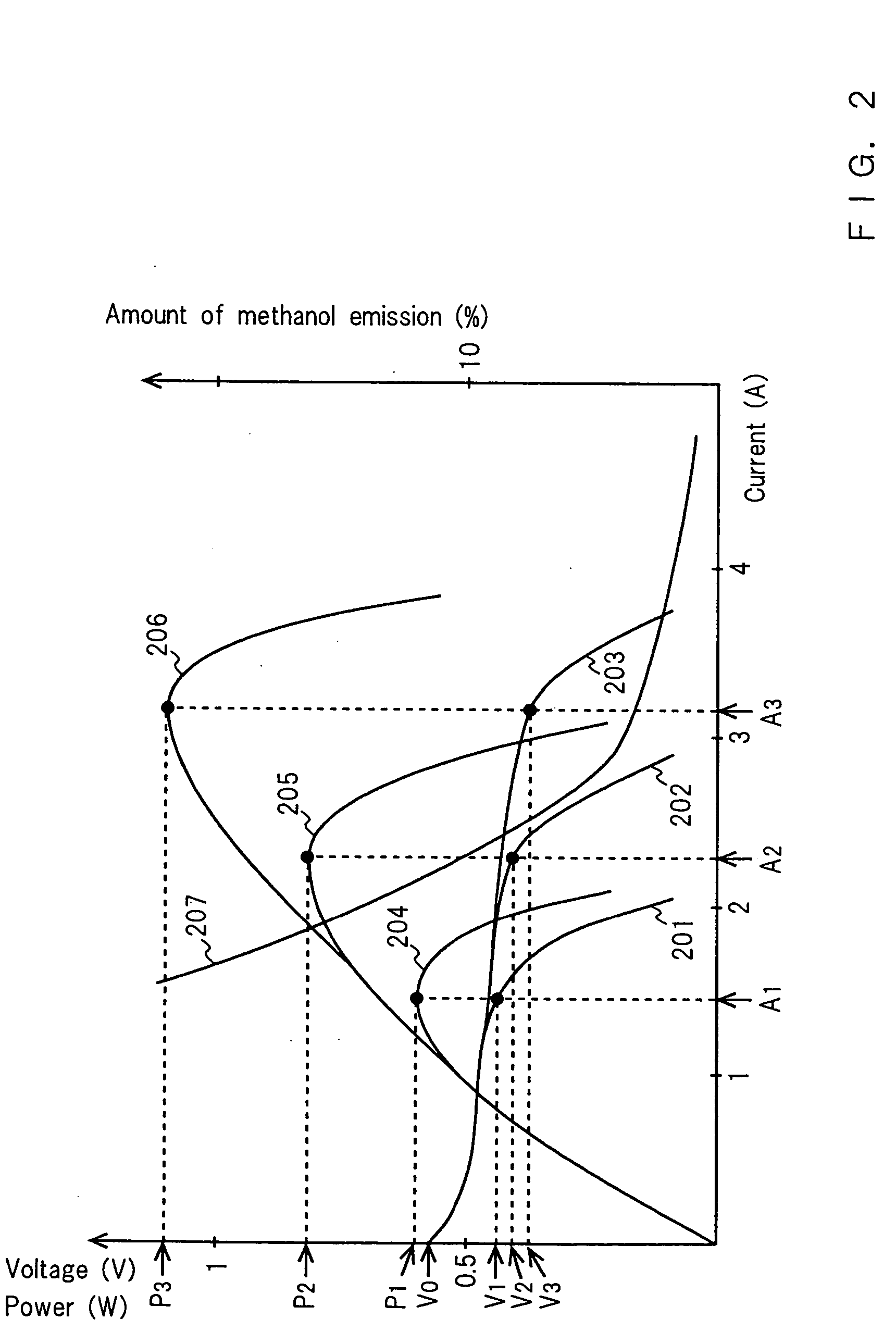

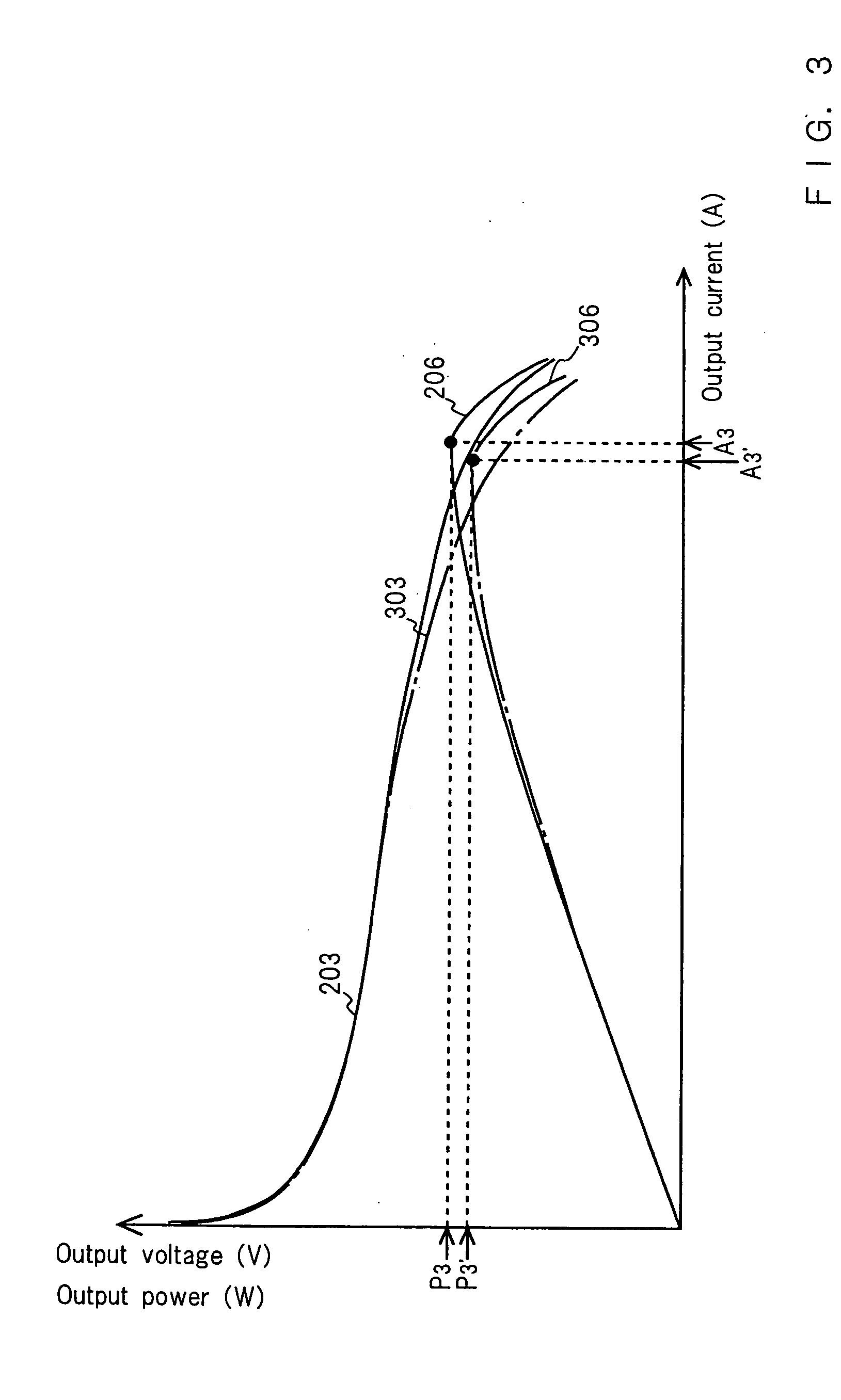

Power supply apparatus

InactiveUS20050040786A1Improve purification effectSmall and safeBatteries circuit arrangementsFuel cell auxillariesElectric forceFuel cells

The power supply apparatus of the present invention comprises a fuel cell, a secondary battery for supplying power to a load, a power measurement section for measuring the output power of the fuel cell, a power converter which inputs output of the fuel cell, controls the output power so that the input voltage or the input current approaches the operation target value, supplies the output power to the load and / or the secondary battery and conducts a power conversion, and a control section which controls quantity of fuel to be supplied to the fuel cell, and also indicates to the power converter of an operation target value that comes within predetermined range which includes the smallest quantity of fuel the fuel cell discharges, wherein the control section sequentially indicates a plurality of the target values for power measurement to the power converter, the power measurement section measures the output power of the fuel cell for each target value for power measurement, and the control section seeks the target value which gives the maximum power within a plurality of output powers, and updates the operation target value based on that value.

Owner:PANASONIC CORP

Apparatus and method of automatically regulating intake of air into heating unit

InactiveUS6041771ACounteracting forceDischarge cleaningCombustion-air/flue-gas circulation for stovesCheck valvesCombustion chamberGas pressure

This invention relates to a novel apparatus and method for automatically and dynamically regulating the intake of air into the combustion chamber of a heating unit such as a wood burning stove, furnace, or fireplace to ensure even and efficient burning of fuel. More particularly, this invention pertains to a method and apparatus that uses negative gas pressure in the heating unit's flue, and no additional temperature or pressure sensors, to automatically and dynamically control a damper regulating intake of air into the combustion chamber in inverse relation to changes in negative flue gas pressure. This method and apparatus are especially useful in combination with a heating unit having two combustion chambers, one chamber for combustion of solid fuel and a second chamber for further combustion of exhaust gases and other byproducts from combustion in the first chamber. The two-stage combustion in a dual chamber heating unit is an especially dynamic situation where traditional static controls are not very effective.

Owner:HAYES CECIL JOSEPH

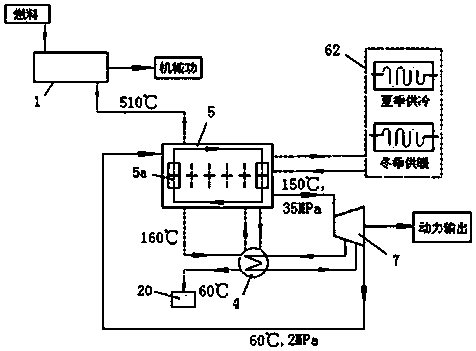

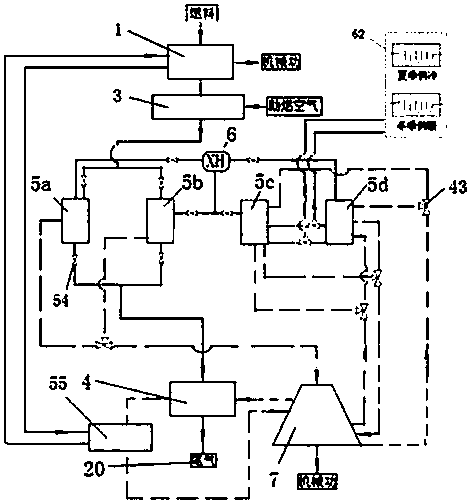

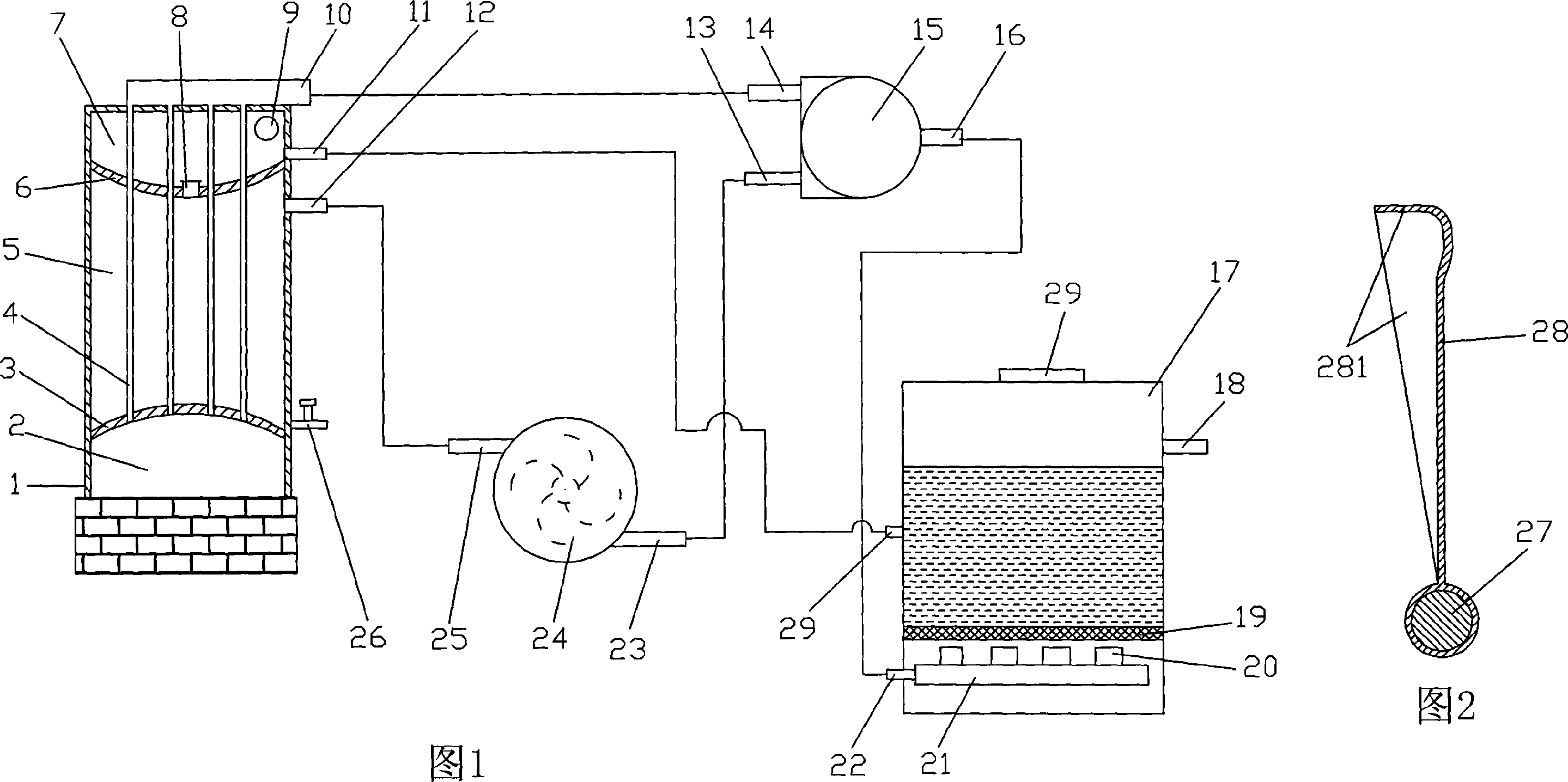

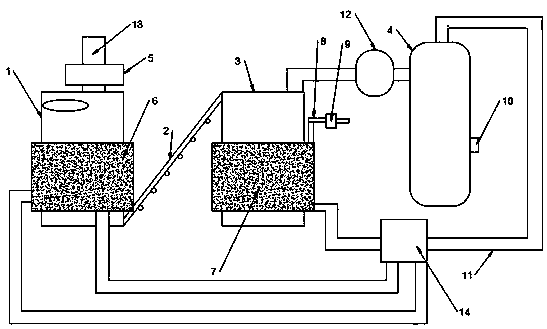

Heat engine-hydrogen reaction bed combined circulating system

ActiveCN107605559ADischarge cleaningImprove efficiencySteam engine plantsHigh pressure hydrogenExhaust gas

The invention relates to a heat engine-hydrogen reaction bed combined circulating system comprising a heat engine, a hydrogen compression unit, an intermediate reheater and an expansion machine. The hydrogen compression unit is provided with at least one set of hydrogen reaction beds, each set comprises the at least two hydrogen reaction beds, and the hydrogen reaction beds mutually communicate. The expansion machine adopts multiple stages, and a thermal medium outlet of the heat engine is connected to a tail gas discharging opening through the hydrogen reaction beds and the intermediate reheater. The hydrogen reaction beds of the hydrogen compression unit are connected to an inlet of the expansion machine, a first-stage outlet and / or a second-stage outlet of the expansion machine are / is connected with the intermediate reheater or the hydrogen compression unit, an outlet of the intermediate reheater or the hydrogen compression unit is connected with a next-stage inlet of the expansionmachine, and the outlets of the expansion machine are connected to the hydrogen reaction beds of the hydrogen compression unit. The heat engine and the hydrogen reaction beds of the hydrogen compression unit are combined, tail gas waste heat after the heat engine does work is fully utilized to heat metal hydride, high-pressure hydrogen is generated to promote the expansion machine to do work, andthus the thermal efficiency is advantageously improved.

Owner:SHANGHAI KELAIPU ENERGY TECH CO LTD

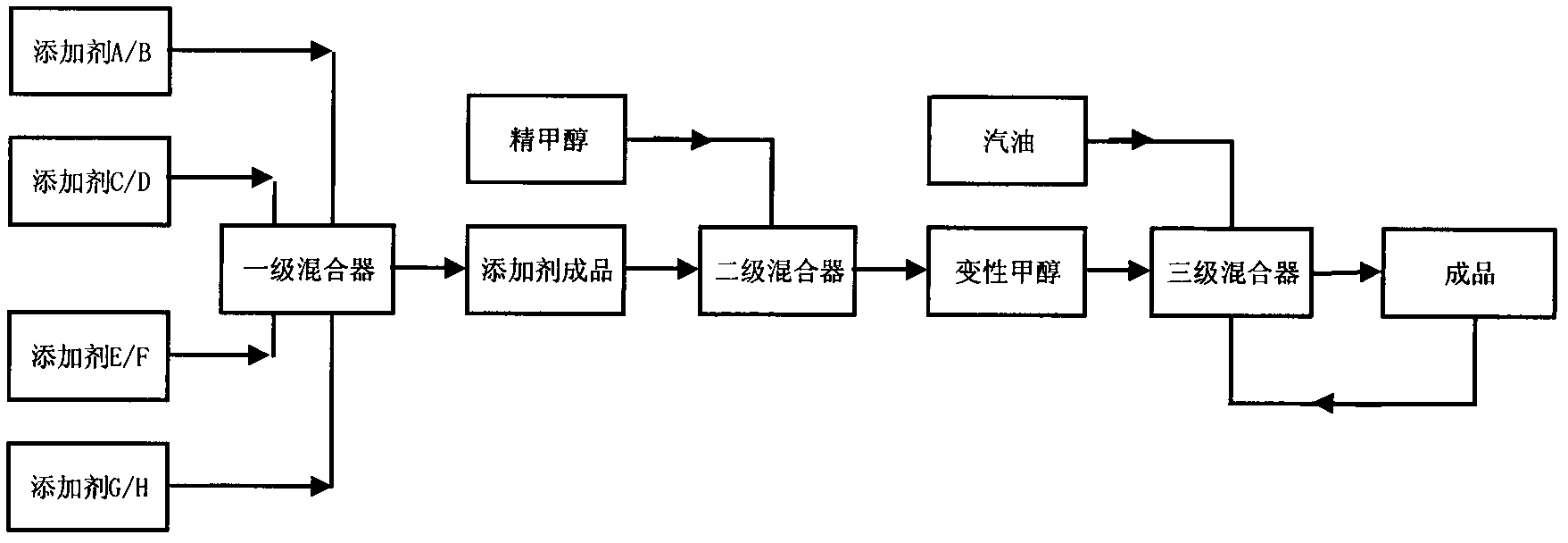

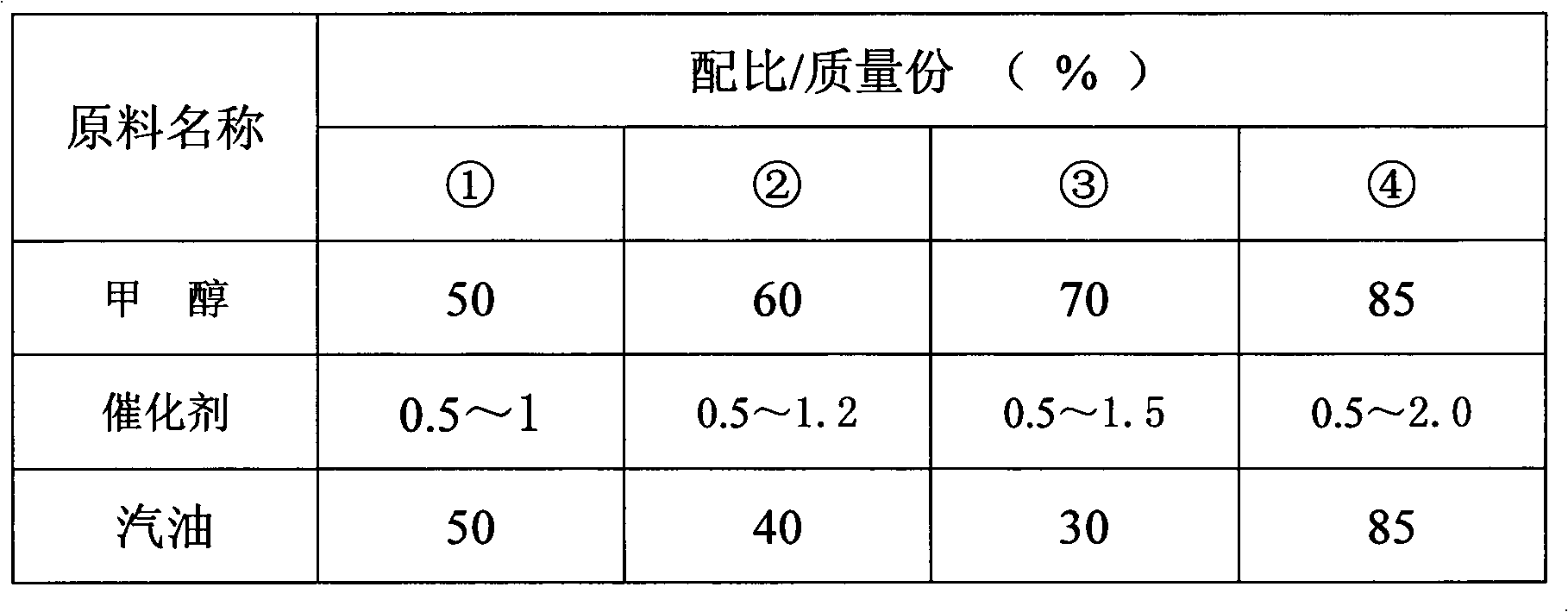

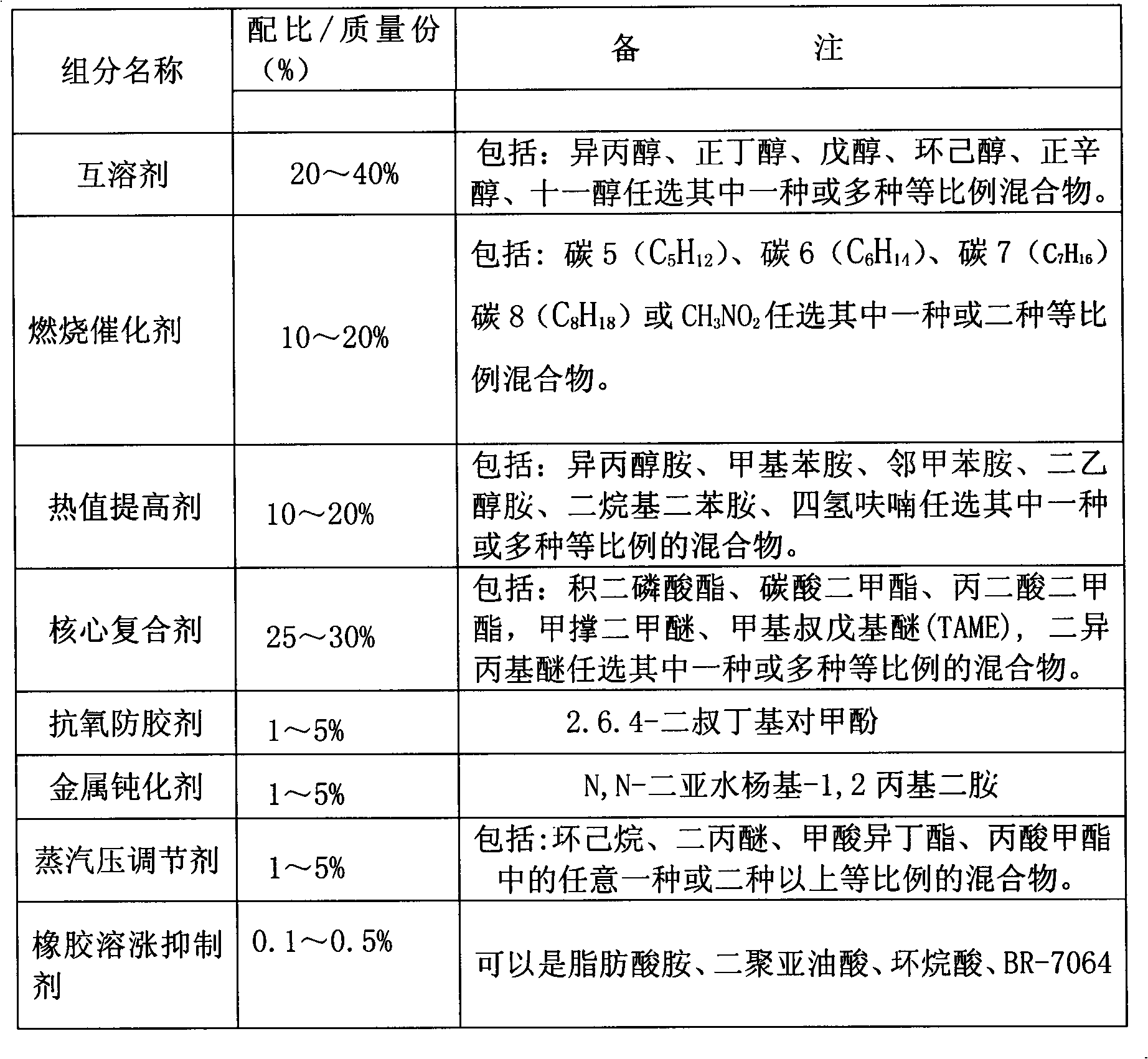

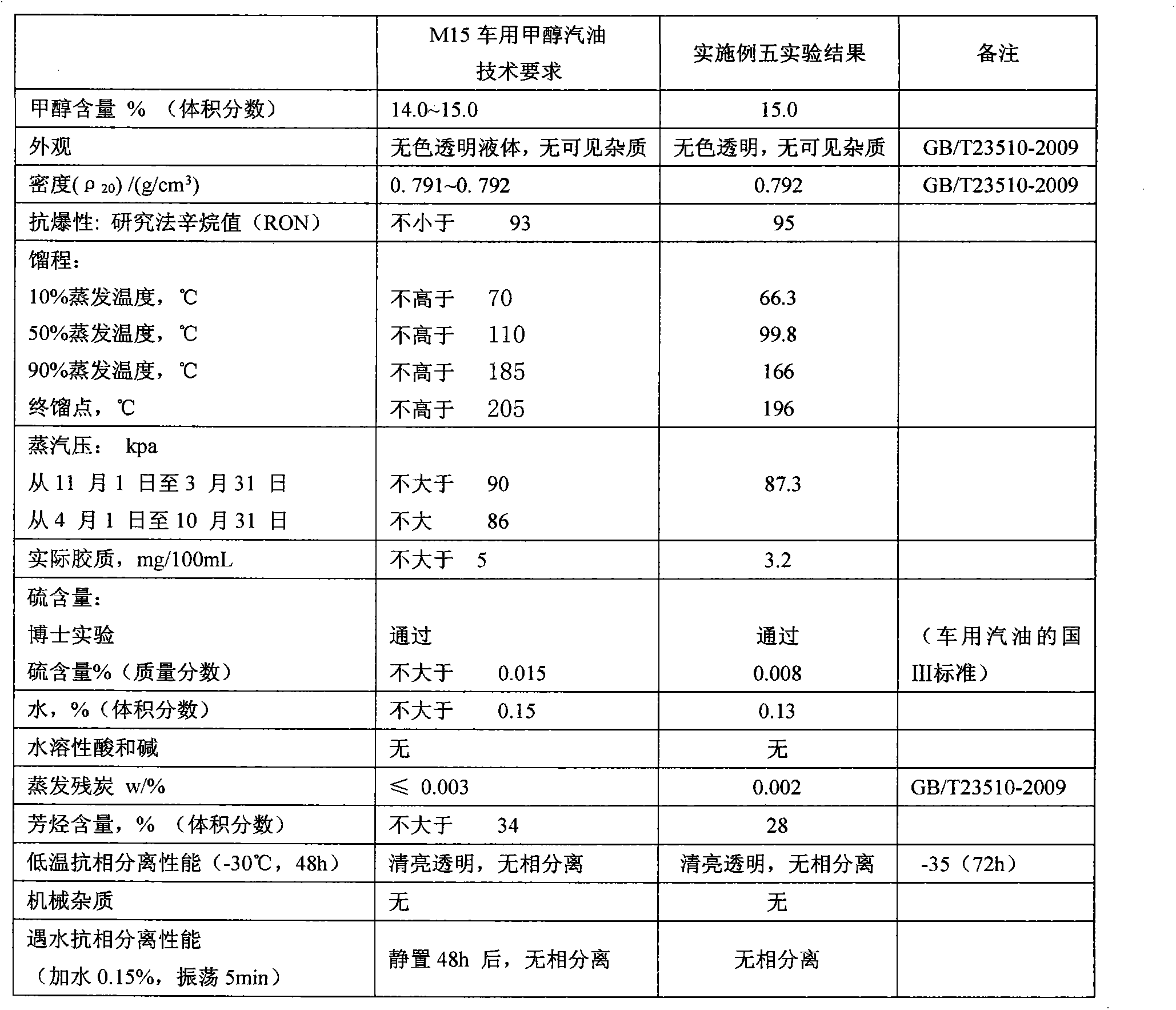

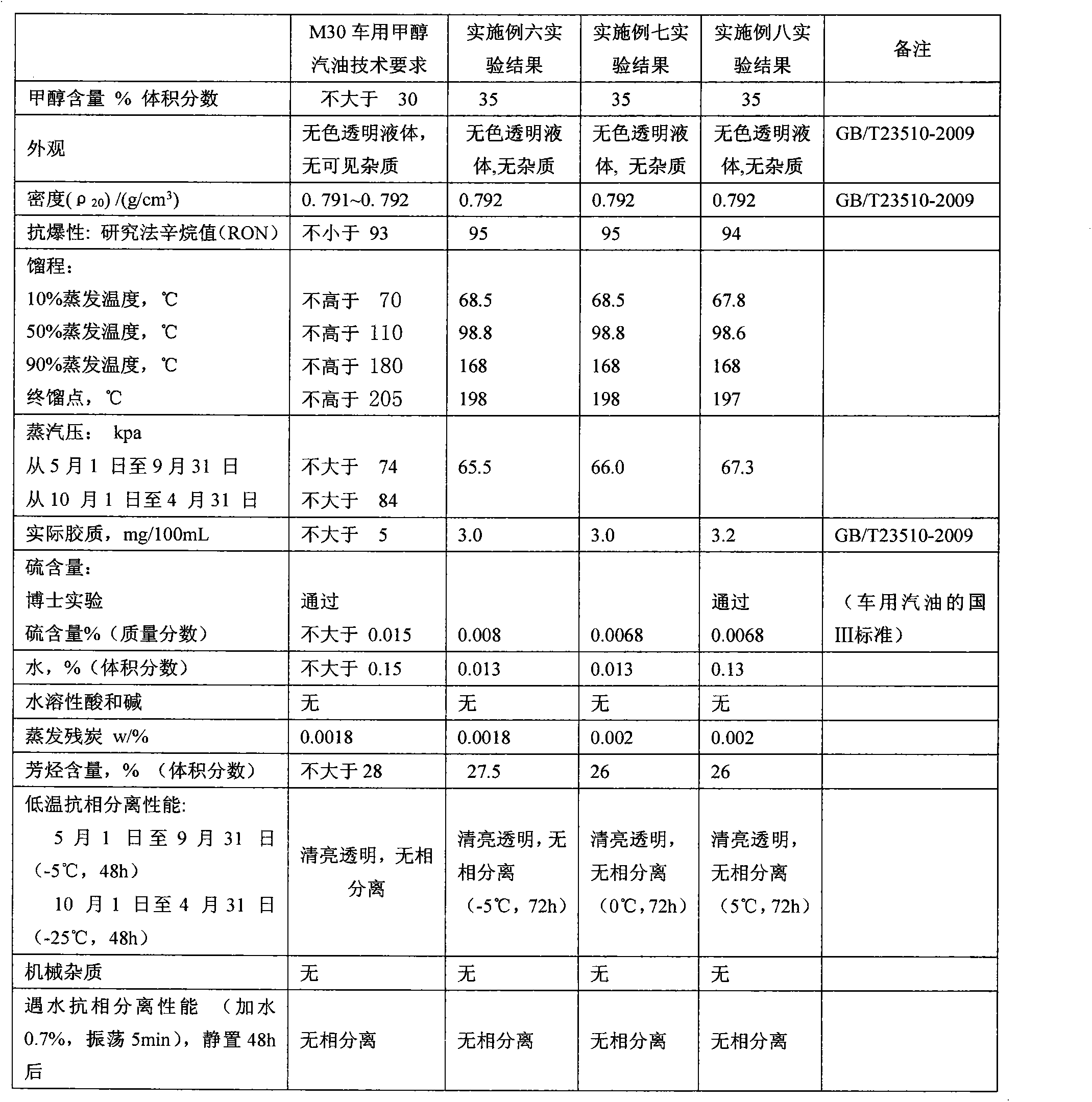

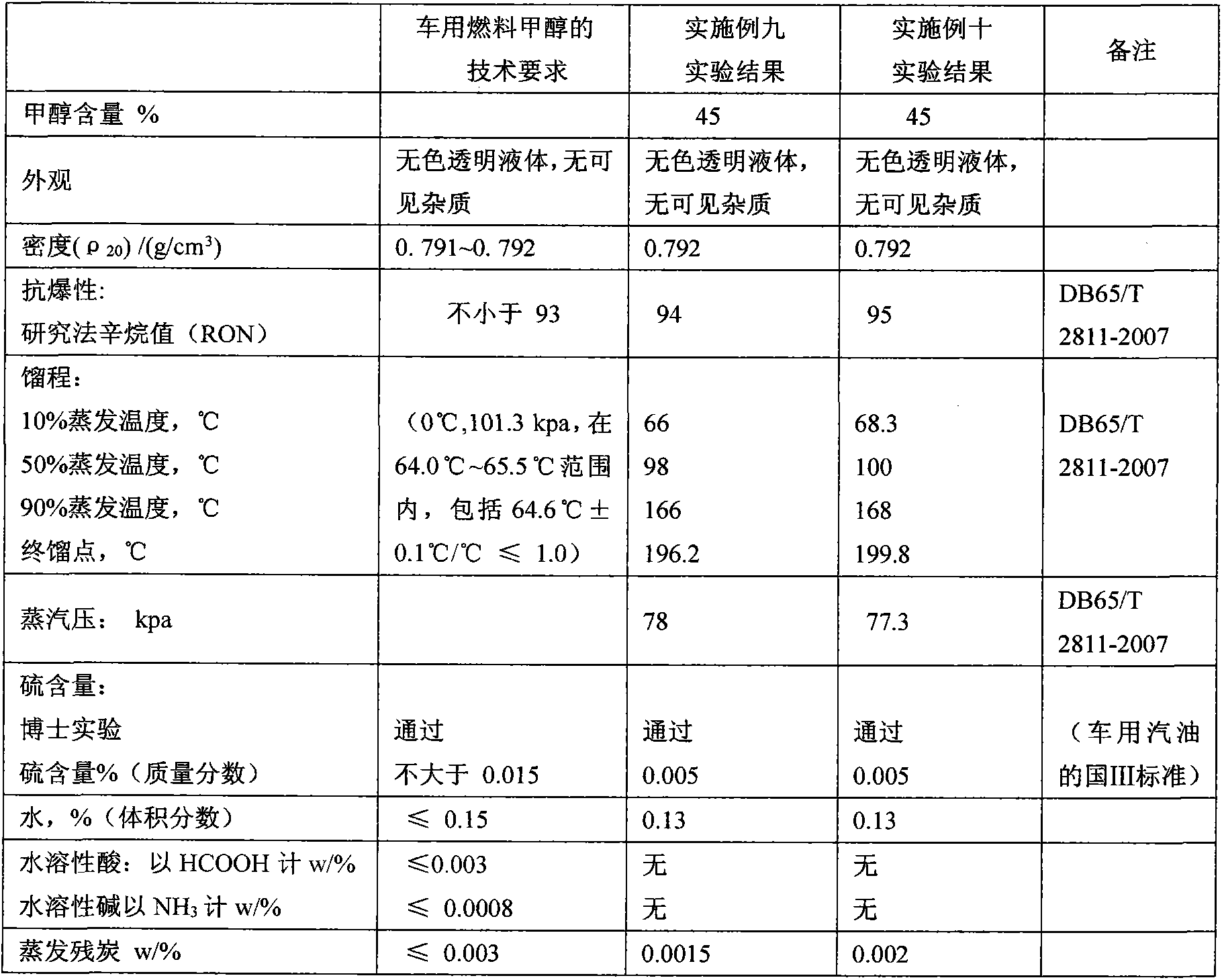

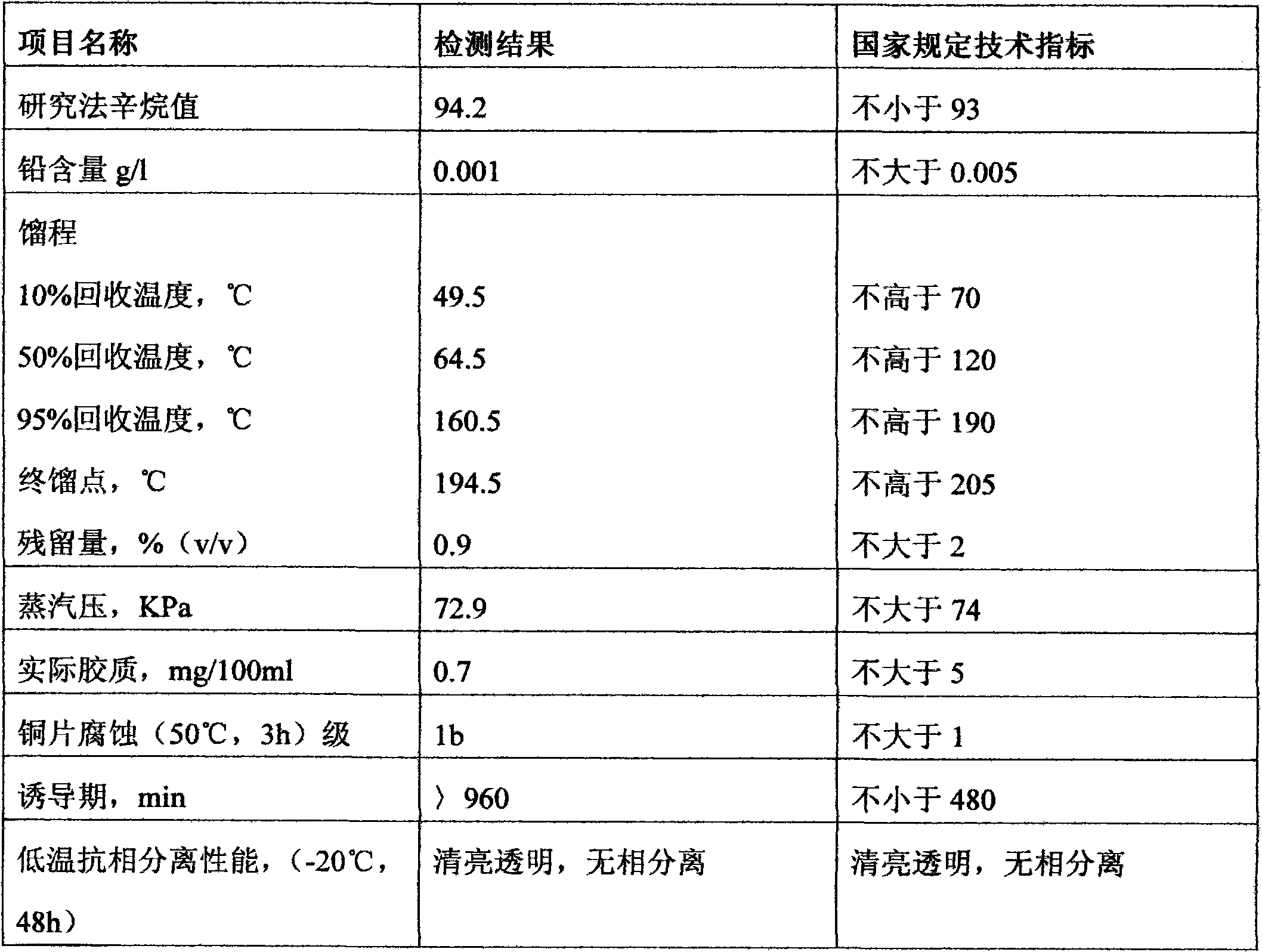

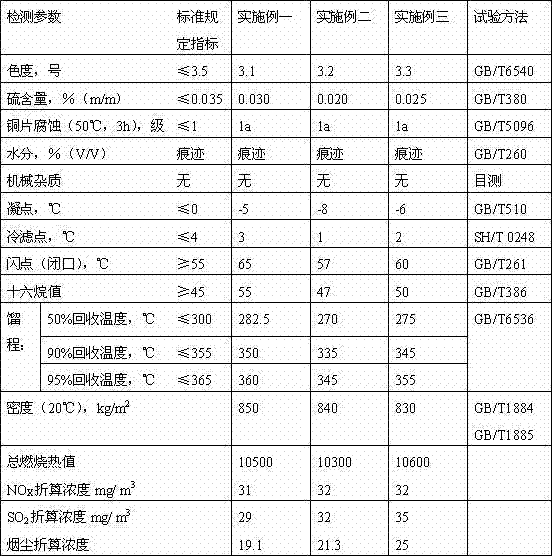

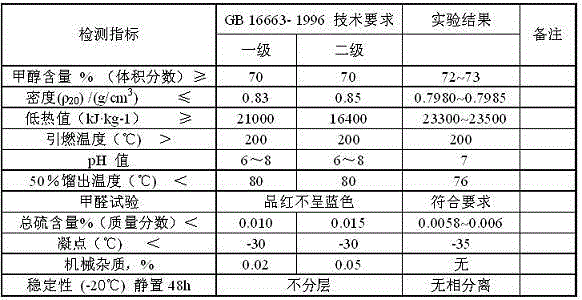

Large-proportion methanol gasoline catalyst and preparation method

InactiveCN103160344AGood miscibilityImprove water resistanceLiquid carbonaceous fuelsFuel additivesAlkaneNaphtha

The invention provides a large-proportion methanol gasoline catalyst and a preparation method thereof. A product mark of the large-proportion methanol gasoline can be expressed by M50 and M85, wherein M represents a first letter of methanol; 50 and 85 respectively represent 50% of methanol and 85% of methanol are added in the gasoline The large-proportion methanol gasoline catalyst is obtained by mixing refined methanol with a purity of 99.9% and national standard gasoline or naphtha and component oil in presence of a special catalyst. A preparation method of the special catalyst is composed of high alcohols (C3-C11), alkanes (C5(C5H12), C6(C6H14), C7(C7H16), C8(C8H18) or CH3NO2), an organic amine, a plurality of esters and auxiliary inhibitors. The large-proportion methanol gasoline produced by the invention passes through a road test longer than 10,000 KM, without changing an engine structure. The large-proportion methanol gasoline is powerful, can be easily started at a low temperature, has no gas block at a high temperature, is not stratified when being contacted with water, can resist rubber swelling, and is low in production cost and flexible in operations. Besides, all project technical indicators are superior to those of national standard gasoline for vehicles. Practice proves that the large-proportion methanol gasoline catalyst has the advantages in a plurality of aspects such as technology, economy, feasibility for large-scale application, and the like, and has obvious competitive advantages as alternative energy.

Owner:杨军

Composite gasoline

InactiveCN107267228ANo need to change the structureDischarge cleaningLiquid carbonaceous fuelsAnti oxidantMaterials science

A compound gasoline, related to the field of fuel technology, comprising the following component raw materials in weight percentage: methanol 15-35%, gasoline 50-80%, antiknock agent 0.6-3%, antioxidant 0.2-1%, alcohols 4-12% of substances, 3-9% of benzene substances, 3-10% of ether substances, 5-18% of surfactants, and 0.2-2% of corrosion inhibitors. The invention has the advantages that the composite gasoline has good starting performance, power performance, antiknock performance, corrosion resistance and stability, complete combustion, less harmful substances in tail gas emission, energy saving and environmental protection.

Owner:HUBEI UNIV OF ARTS & SCI +1

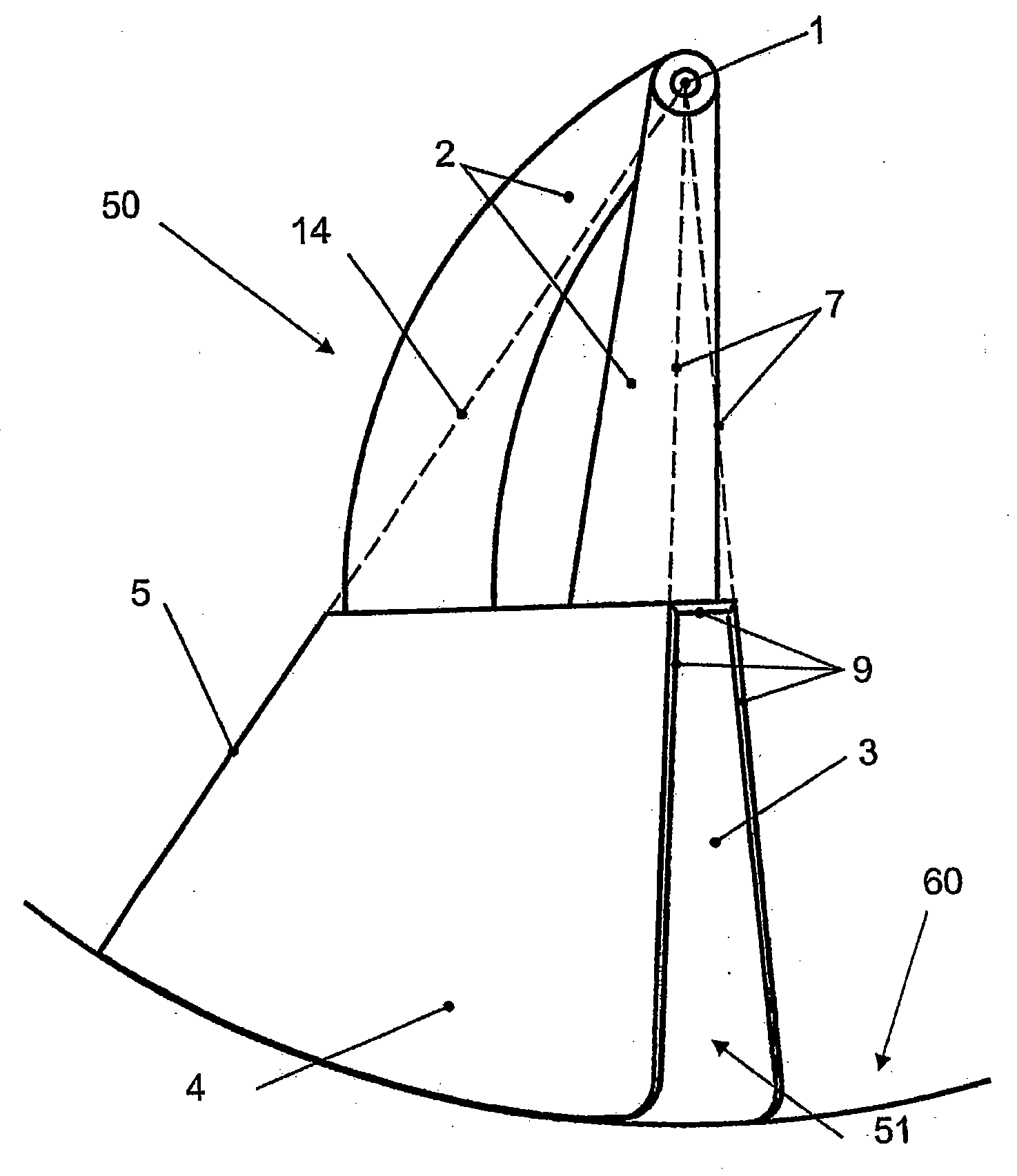

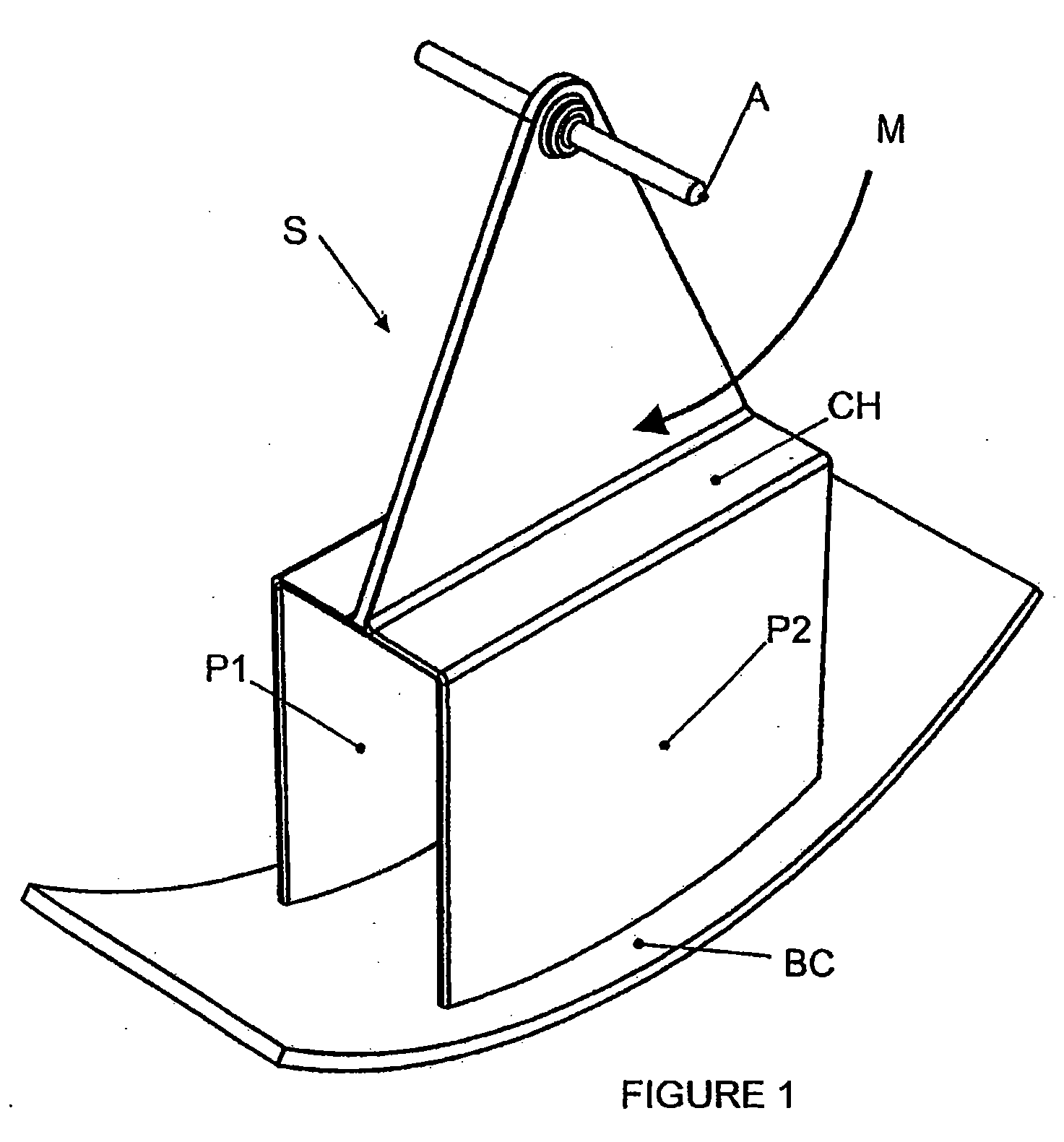

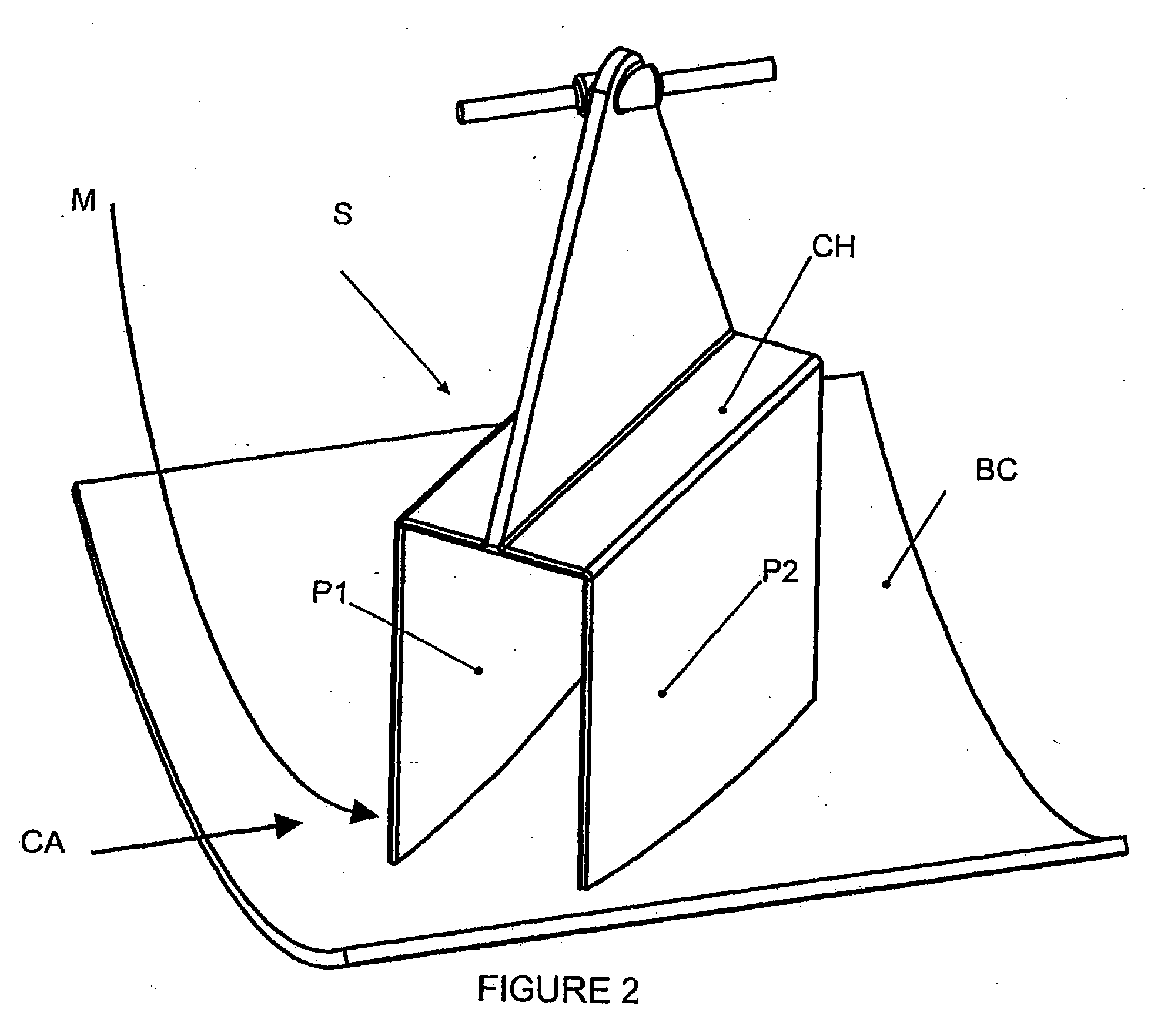

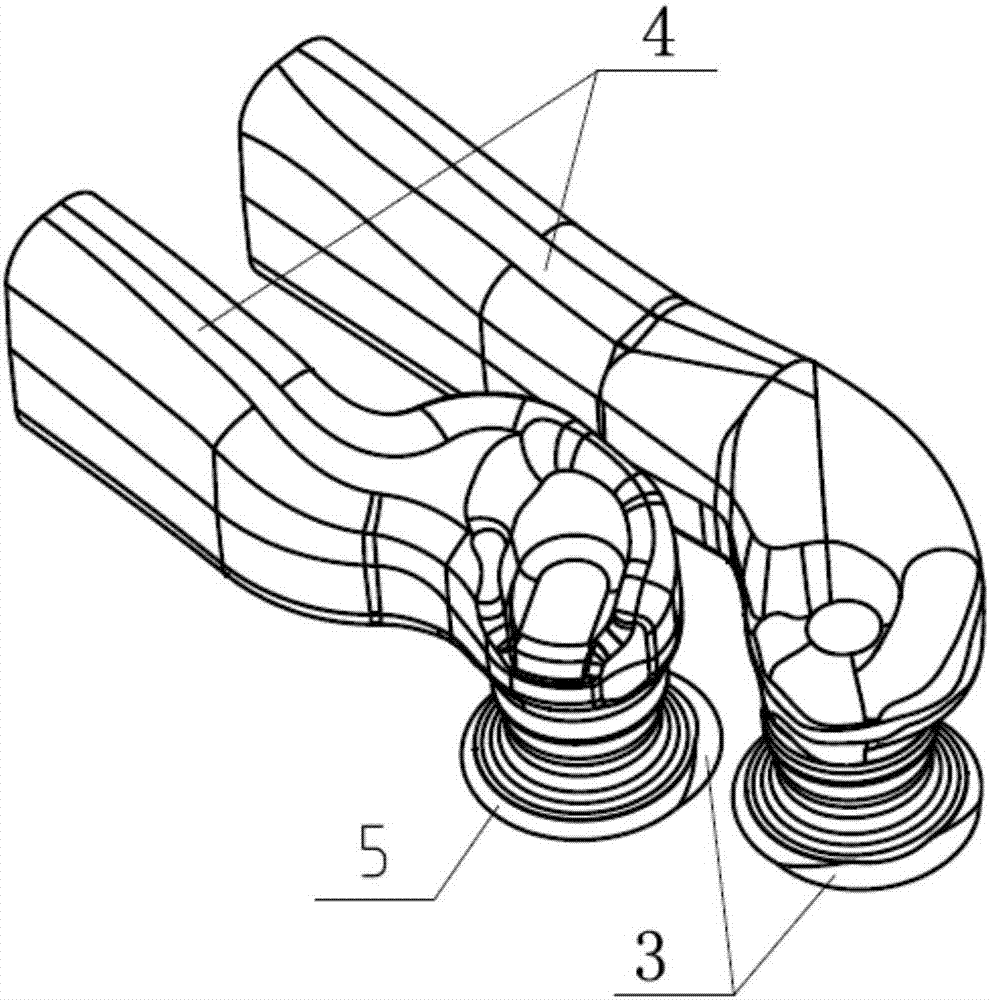

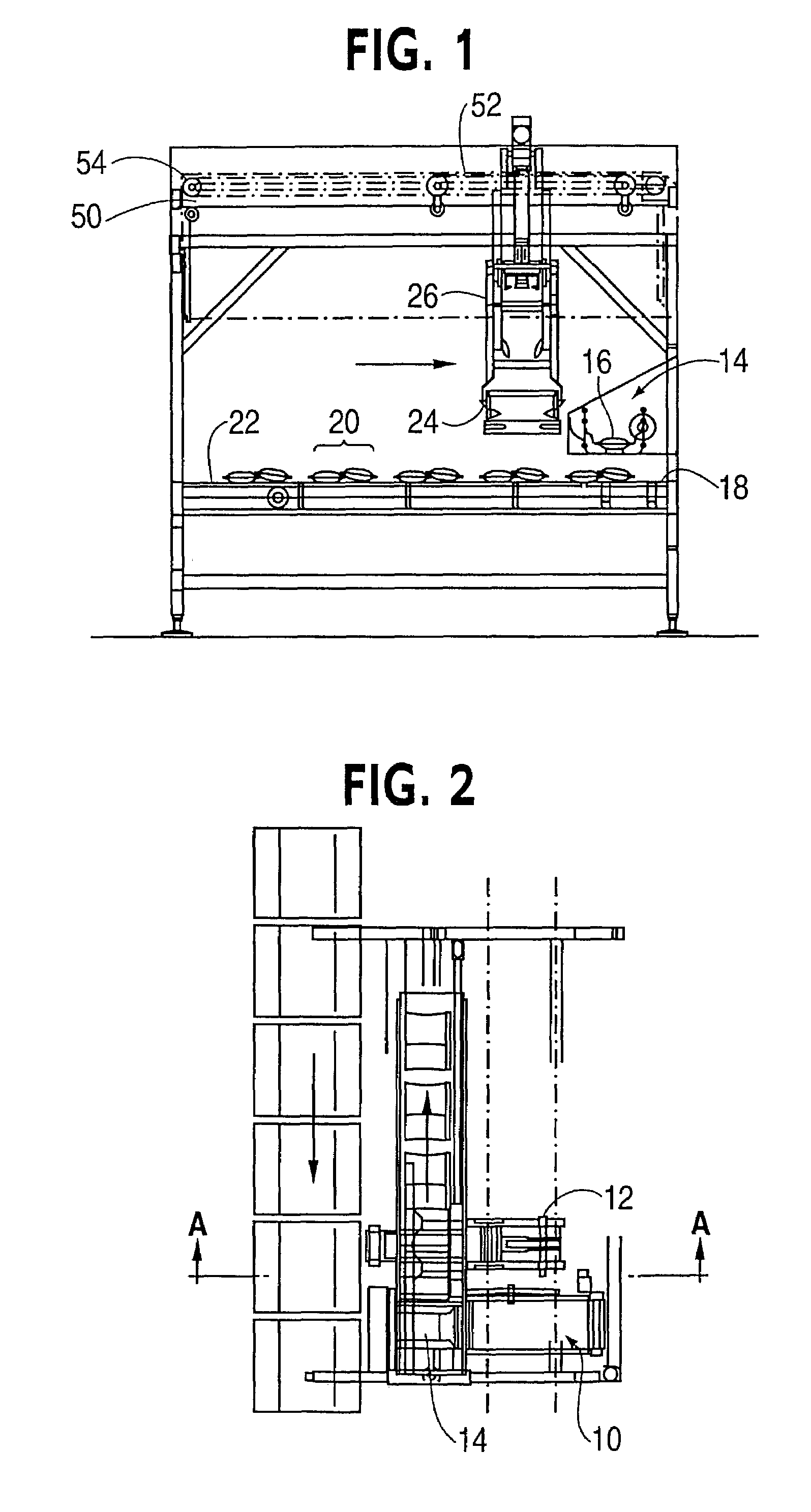

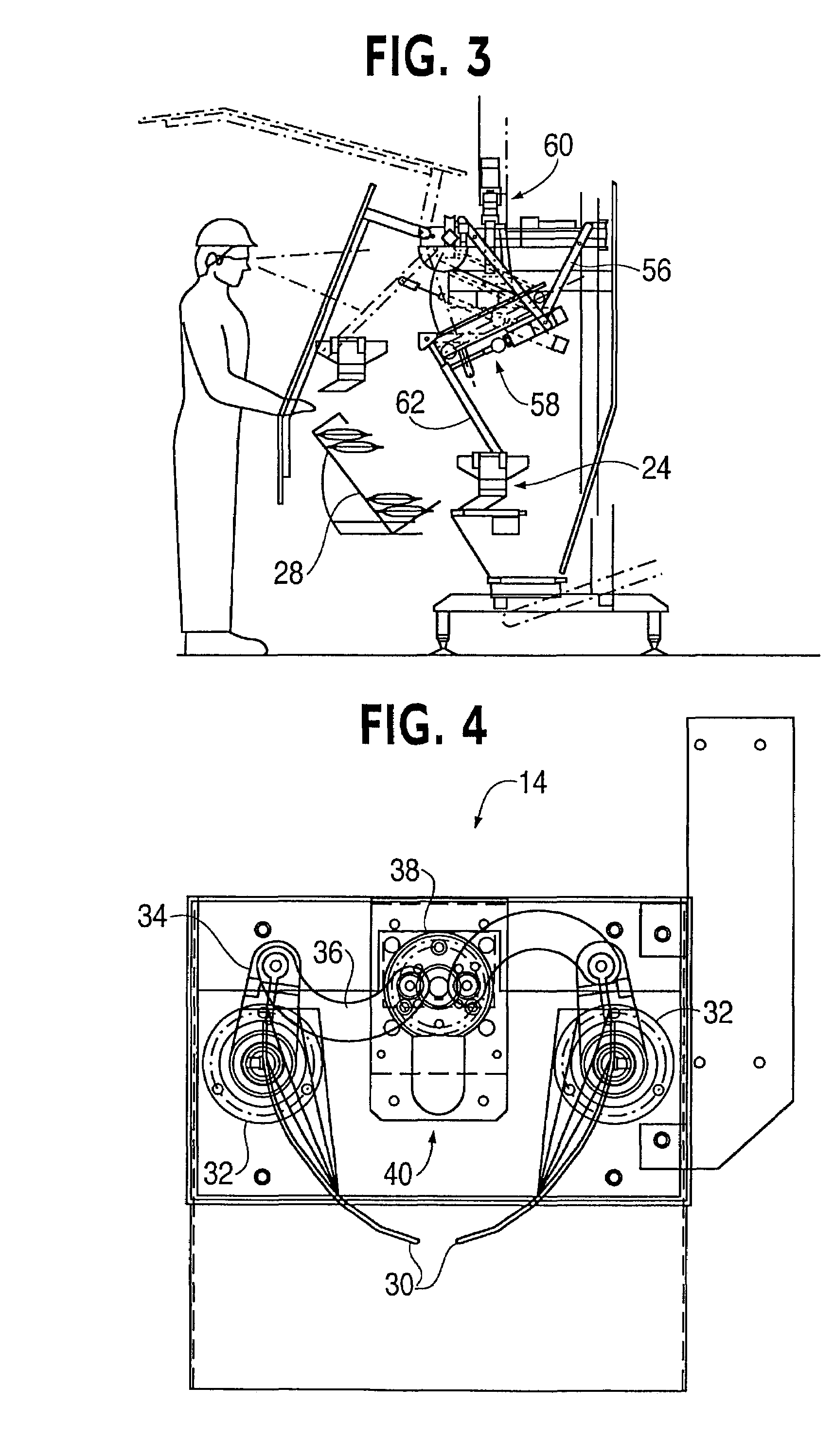

Cross-Belt Sampler for Materials Conveyed on a Belt Conveyor

ActiveUS20090205446A1Lower retention rateDischarge cleaningWithdrawing sample devicesEngineeringBelt conveyor

A cross-belt sampler (100) for material (70) on a belt-conveyor (60) has a cutter head (50), where the cutting edges (9) of the side plates (3, 4) lie on lines co-incident with the axis of rotation (1) of the cutter head (50). The rear plate (5) lies on a plane parallel to the axis of rotation (1) and a truncated plate (6) eliminates a sharp corner in which the material (70) may be compacted. The axis of rotation (1) of the cutter head (50) is offset a distance (28) relative to the longitudinal axis of the belt conveyor (60).

Owner:LYMAN GEOFFREY JOHN

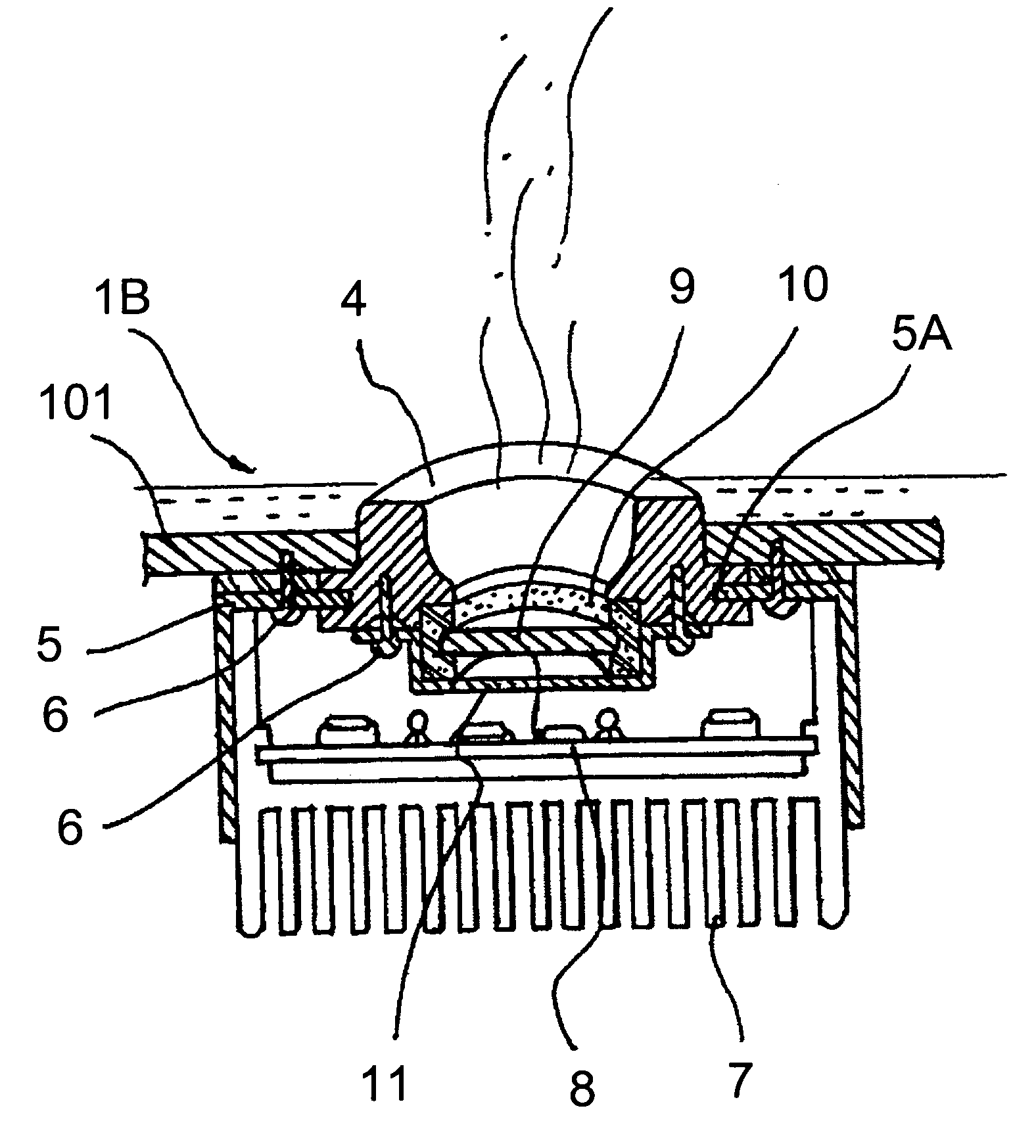

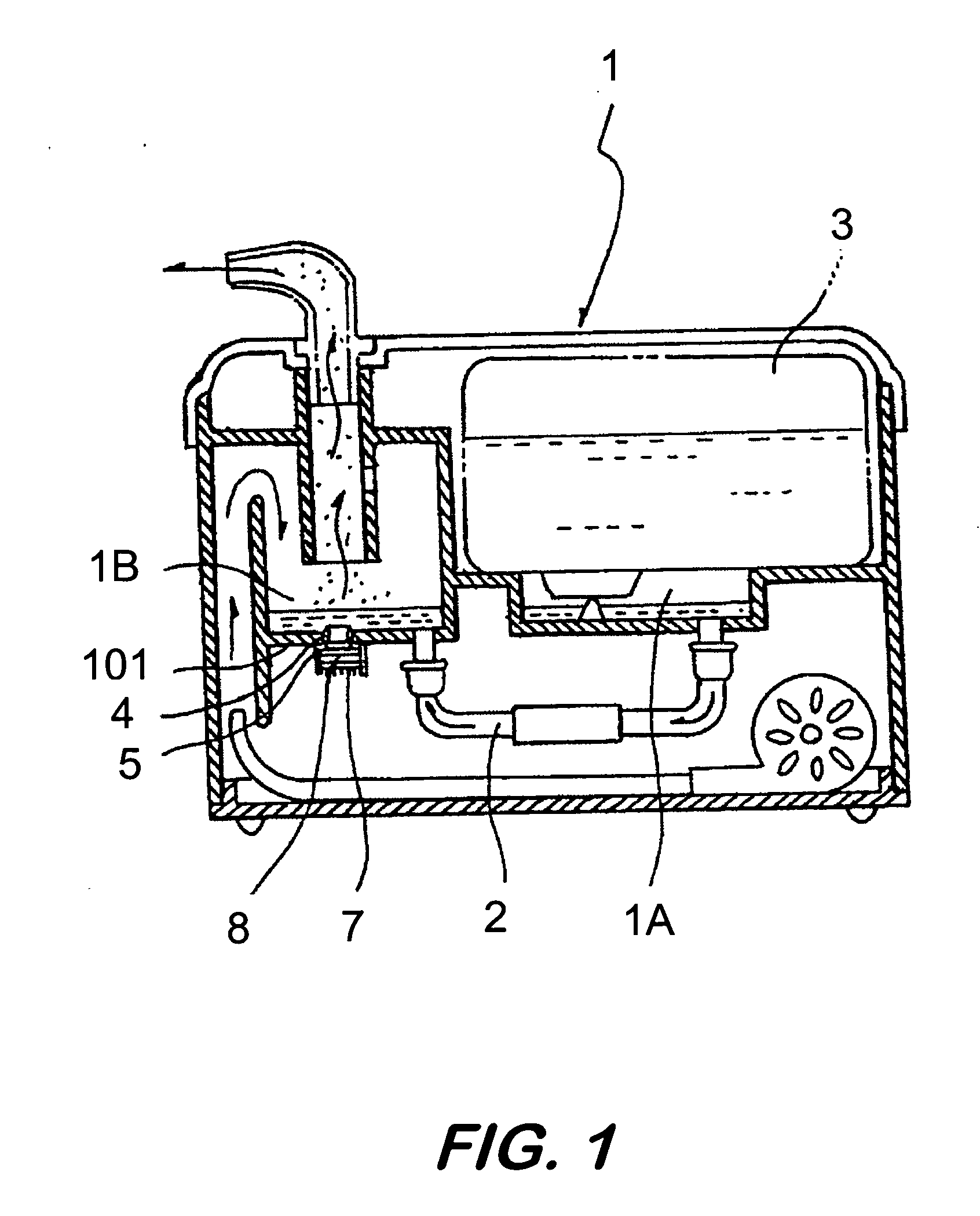

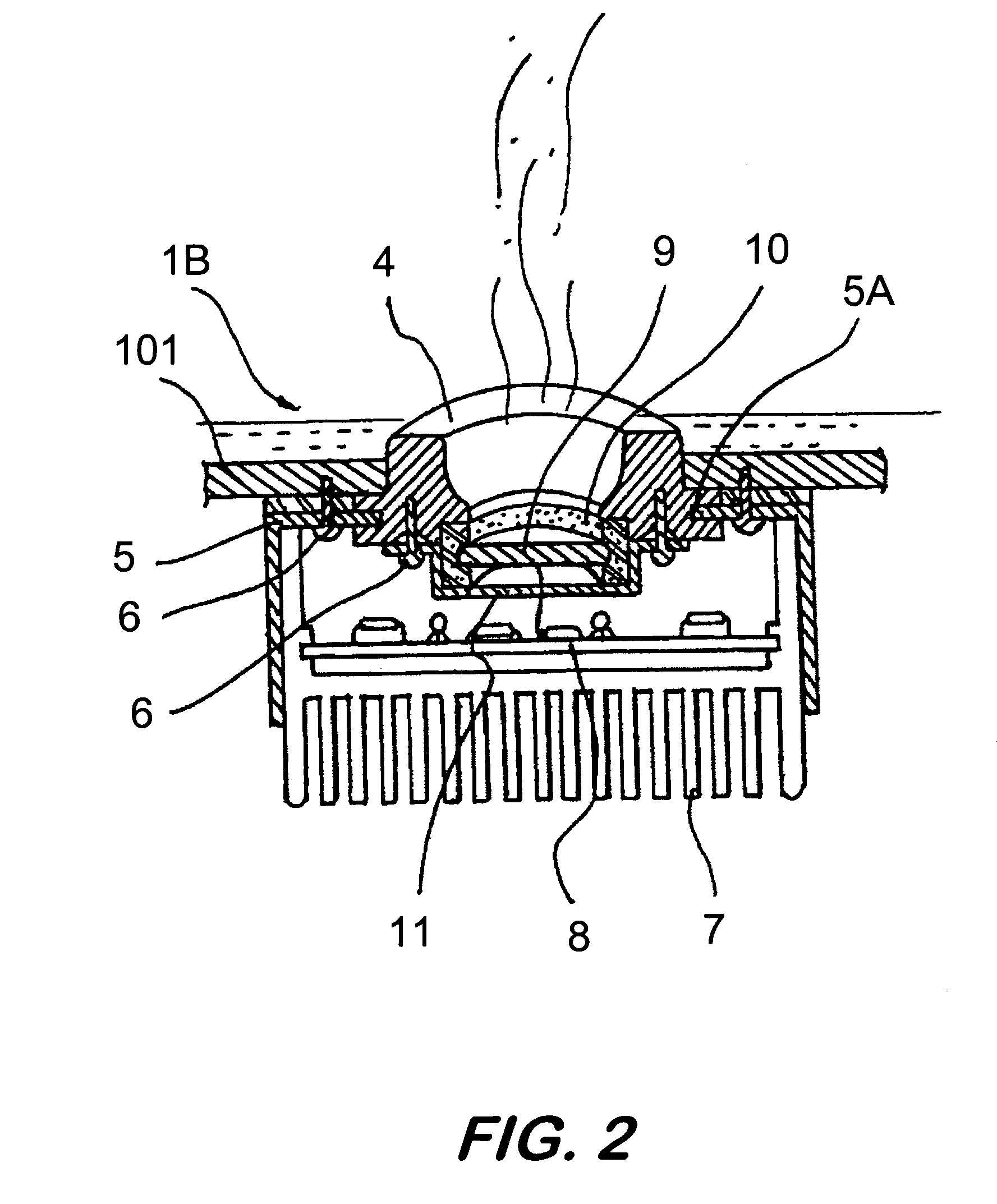

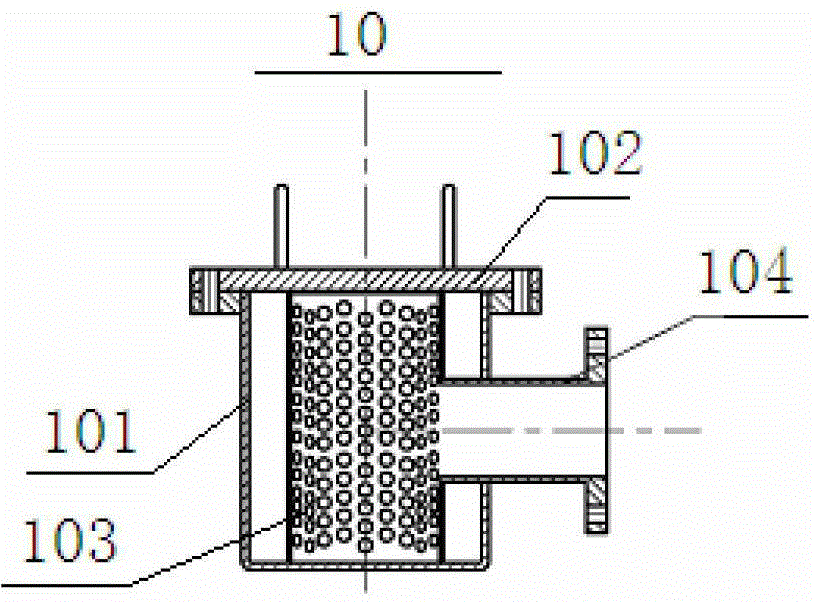

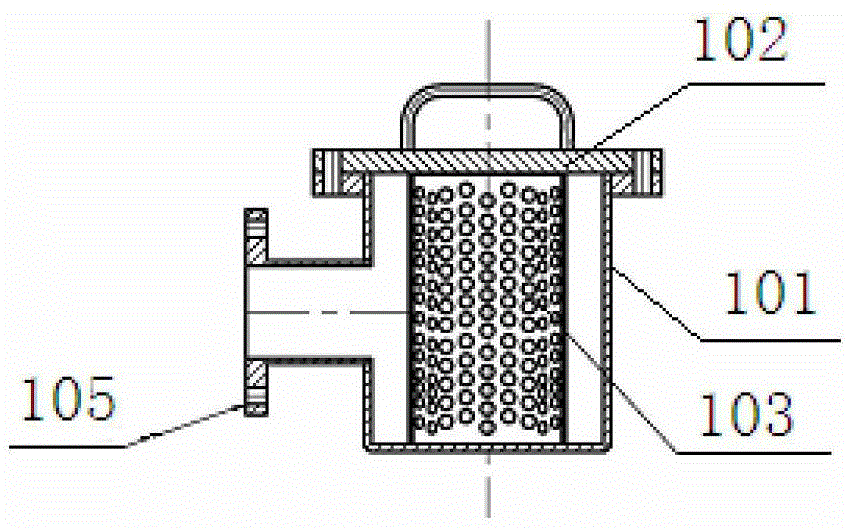

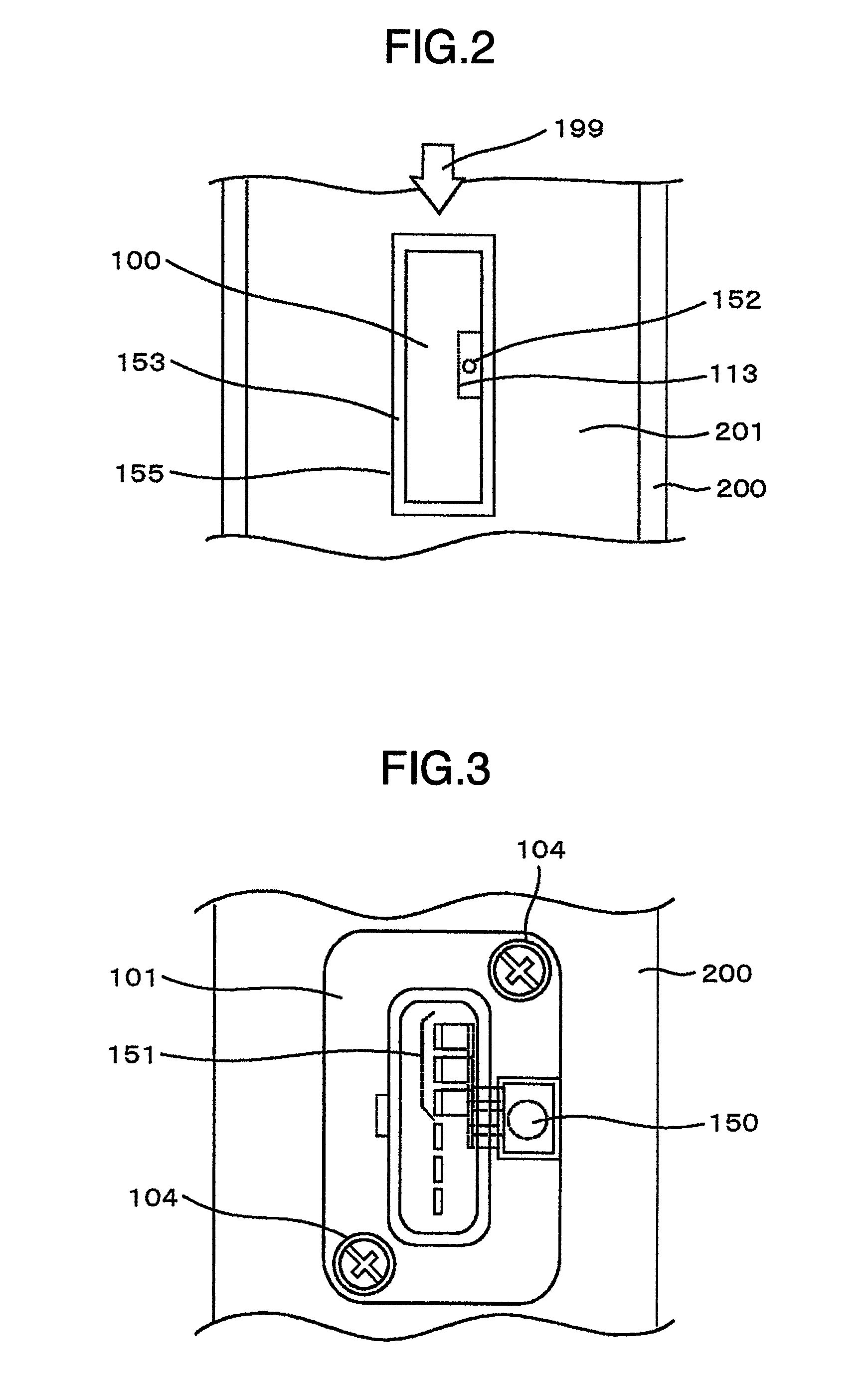

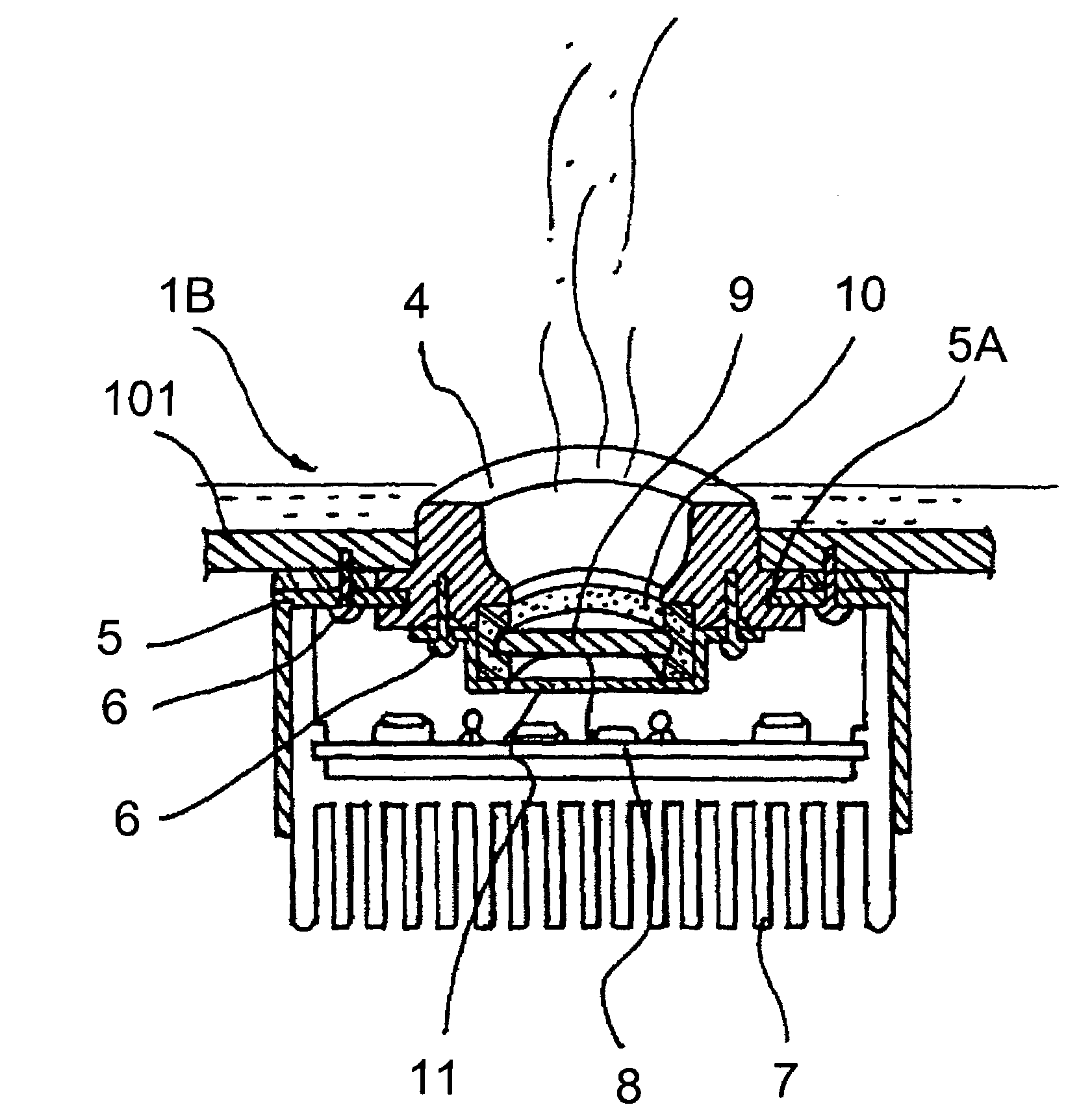

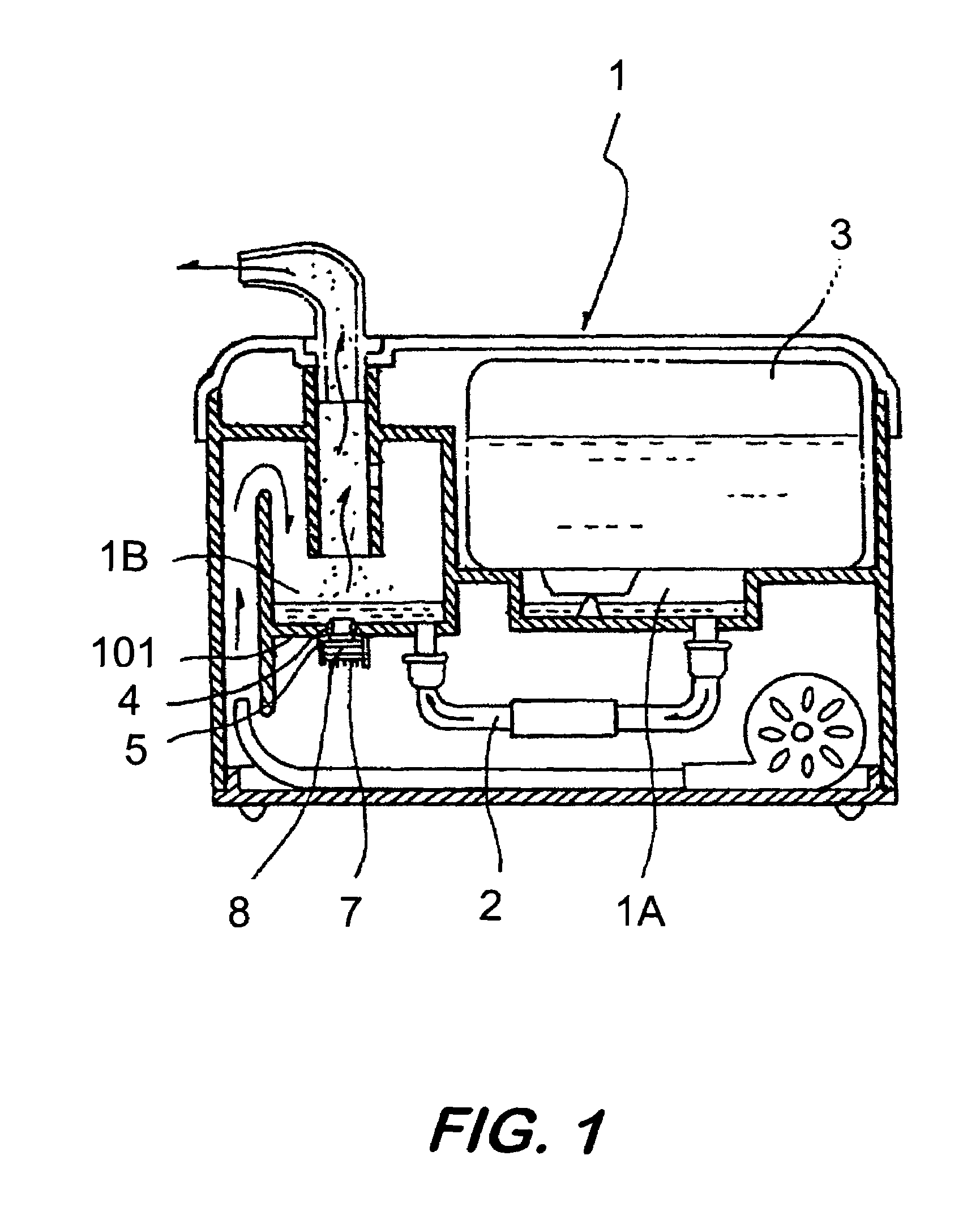

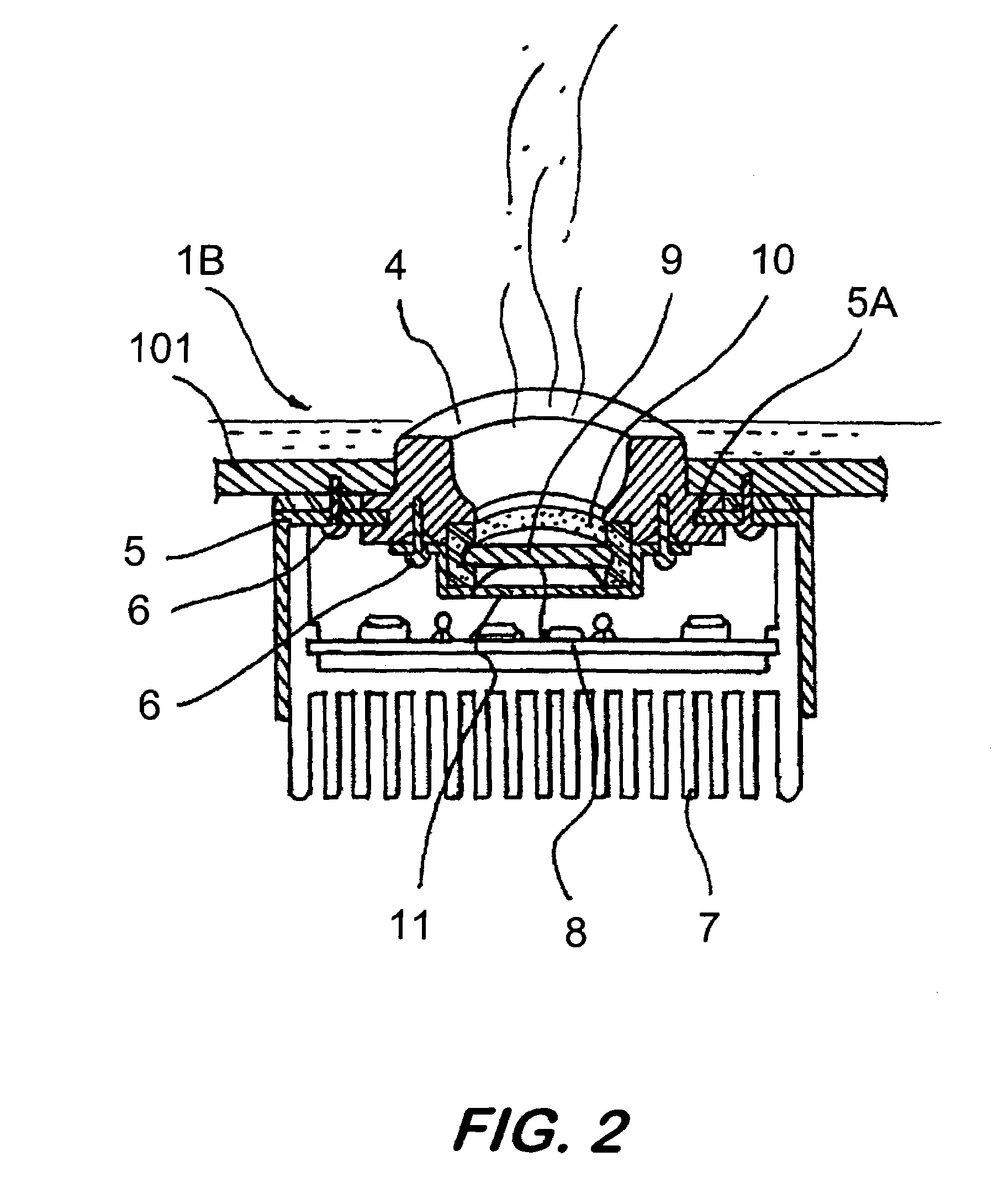

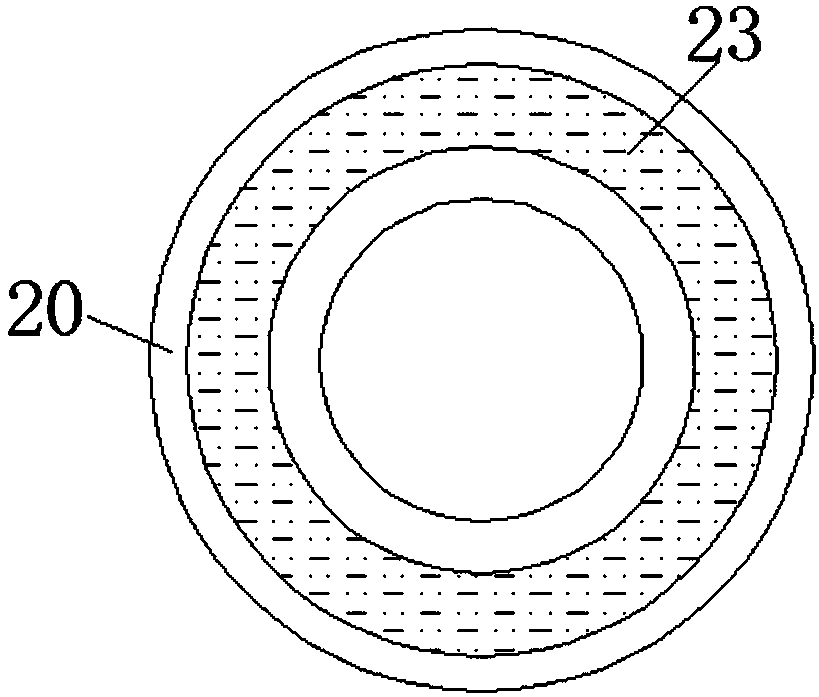

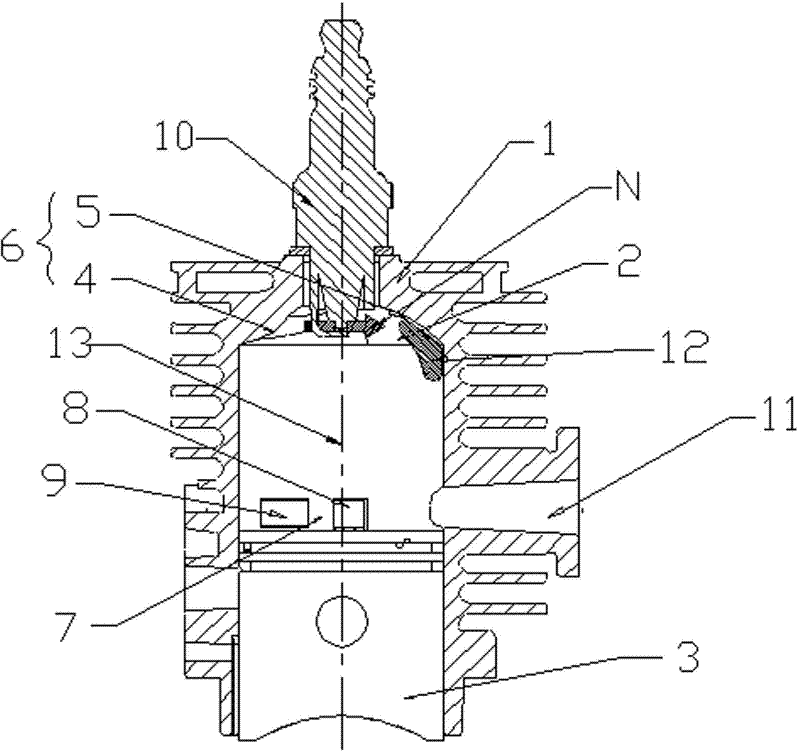

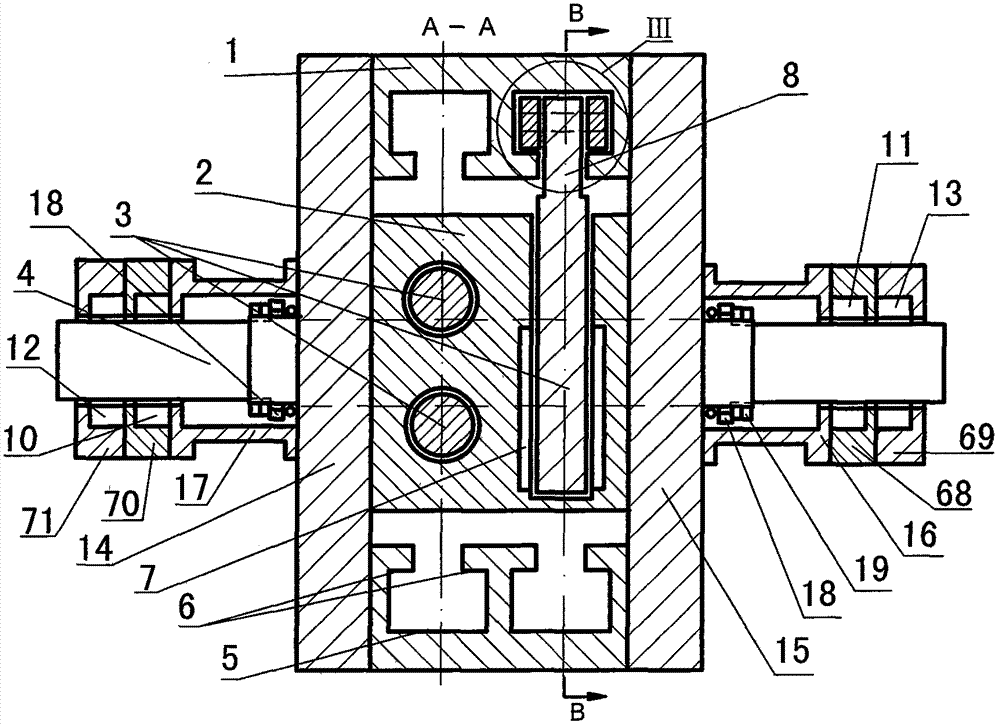

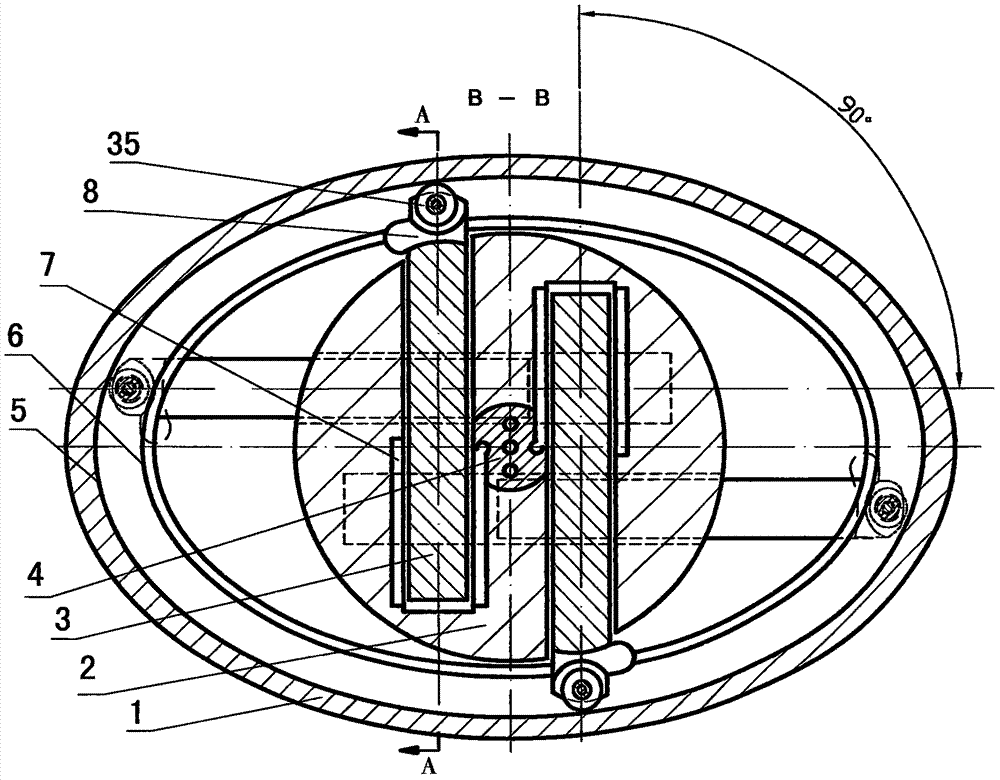

Ultrasonic transducer device for humidifier

InactiveUS20070216259A1Extended service lifeDischarge cleaningPiezoelectric/electrostriction/magnetostriction machinesLighting and heating apparatusUltrasonic sensorPlastic materials

An ultrasonic transducer device for a humidifier, the humidifier having a vaporizing chamber for producing water vapor or mist, the ultrasonic transducer device comprises: a transducer holder having a central opening formed in a longitudinal direction of the transducer holder and a flange portion disposed at a periphery of the transducer holder, the transducer formed of synthetic resin or plastic materials; an ultrasonic transducer disposed at the central opening of the transducer holder; a support member formed of metal and having an upper planar section and a side section extending vertically from the upper planar section, the upper planar section defining an opening therein for coupling with the flange portion of the transducer holder; and a heat discharge plate having heat discharging fins and coupled with the support member, the heat discharge plate coupled with a circuit board for discharging heat in the circuit board.

Owner:OHSUNG

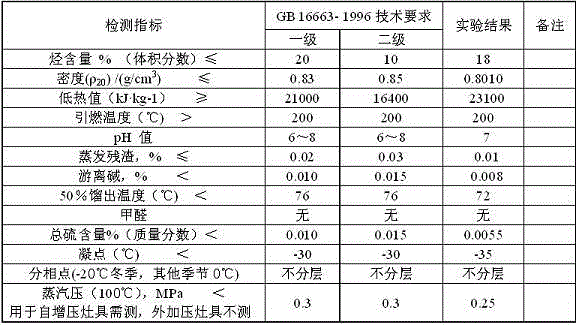

Methanol gasoline additive and methanol gasoline containing same

InactiveCN103710058AGood compatibilityLight colorOther chemical processesAluminium silicatesIsobutanolSolvent

The invention relates to a methanol gasoline additive and a methanol gasoline containing the same. The methanol gasoline additive comprises the following components in parts by mass: 4-32% of toluene, 4-42% of dimethylbenzene, 0.5-10% of C5H12 and C7H16, 3-43% of isobutanol, 4-33% of isopropanol, 0.8-15% of isoamyl alcohol, 1-8% of ethanol, 1-6% of antifreezing agent, 0.2-3% of antioxygen antigum inhibitor, 0.05-0.6% of metal passivator, 0.008-0.06% of detergent dispersant, 1-6% of preservative and 2-8% of emulsifier. The methanol gasoline is prepared by the following steps: uniformly mixing gasoline, naphtha, petroleum ether, 120# solvent oil, light hydrocarbon, methanol fuel and the methanol gasoline additive, and filtering through a modified attapulgite adsorption stabilizer. The methanol gasoline produced from the methanol gasoline additive is especially suitable for high altitude anoxia regions. The methanol gasoline has the advantages of quick cycling start, stable idle speed, low harmful substance emission during combustion, favorable dynamic performance in high altitude anoxia regions, high corrosion resistance, and no stratification at low temperature, and does not generate air resistance.

Owner:兰州市新城炼化厂

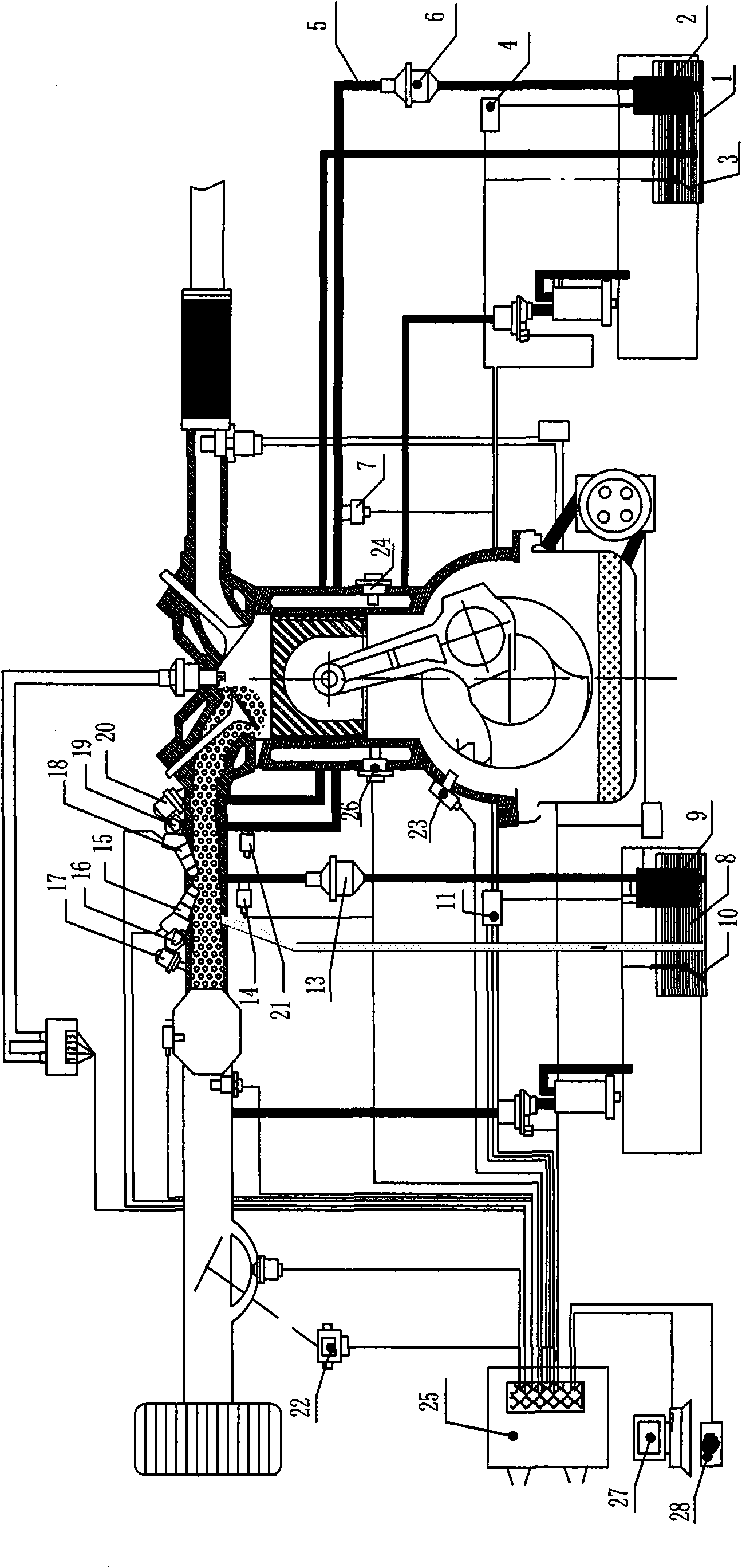

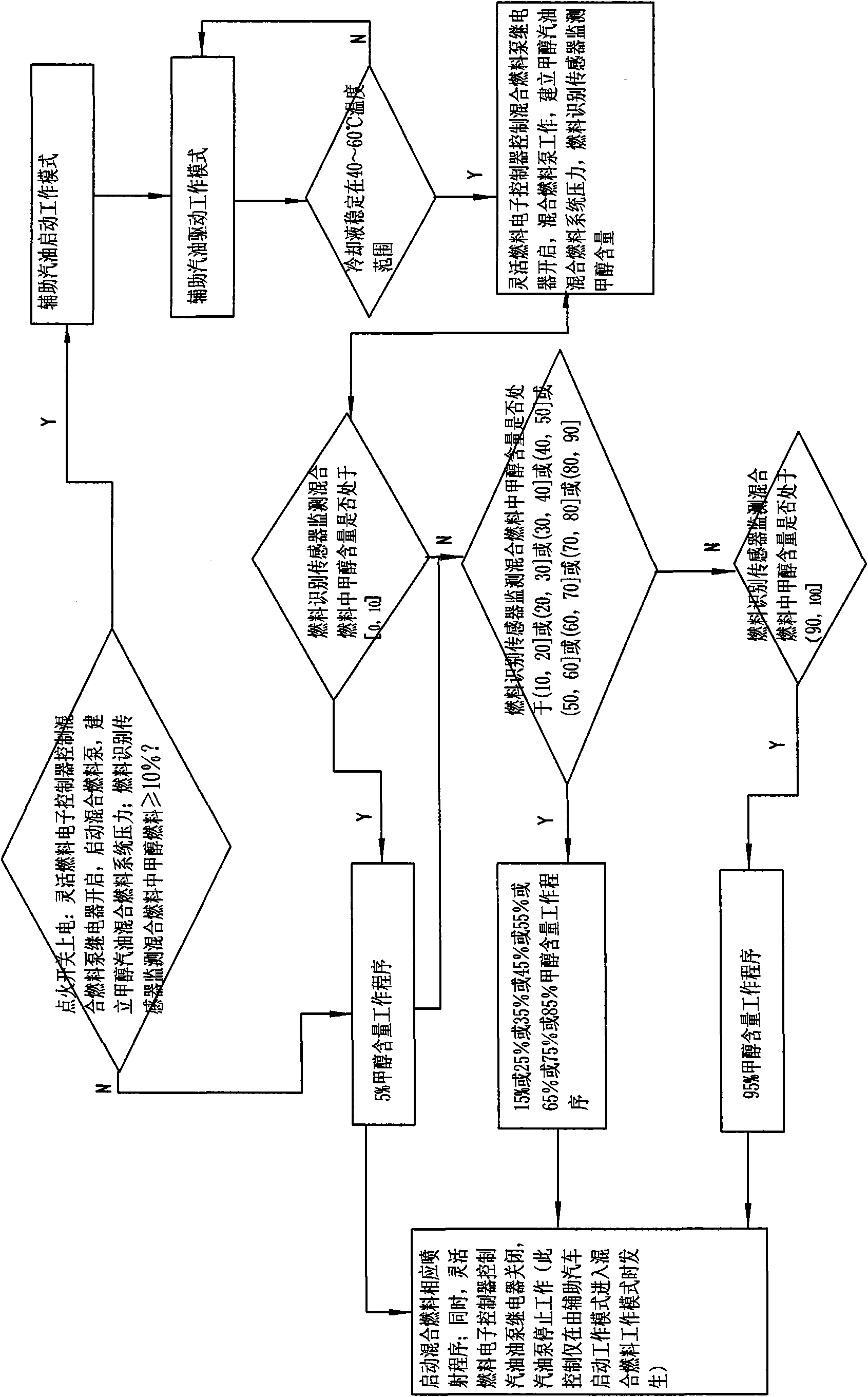

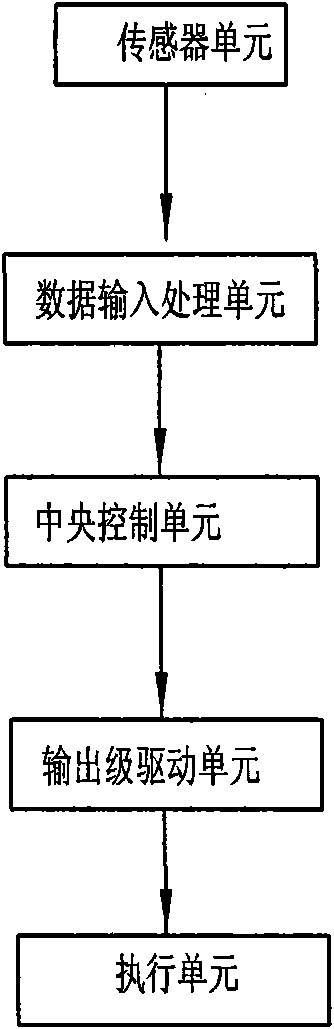

Control method of methyl alcohol flexible fuel vehicle and system thereof

ActiveCN101655037AGive full play to the high-efficiency combustion characteristicsBurn fullyElectrical controlMachines/enginesAlcohol contentElectronic control system

The invention relates to a control method of methyl alcohol flexible fuel vehicle and a system thereof. The system comprises a mixed fuel feeding system, an electronic control system and an engine, wherein, mixed fuel in a mixed fuel box comprises methyl alcohol and auxiliary fuel as the balance. A fuel recognition sensor is used for recognizing methyl alcohol content in fuel, corresponding data is transmitted to a data processing unit, the data processing unit analyzes the data and transmits a result to a central control unit, and the central control unit chooses a corresponding working module to adjust the corresponding control parameter, which ensures that the engine works at the optimum state. The invention mainly provides a control system of a methyl alcohol flexible fuel vehicle, which can add mixed fuel at any ratio to the mixed fuel box, needs no additives, has favorable starting performance and high dynamic property and discharges cleanly. The invention solves the technical problems that the fuel supply is out of control because of methyl alcohol-petrol mixed fuel delamination and vehicle starting performance is lowered in the prior art.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD

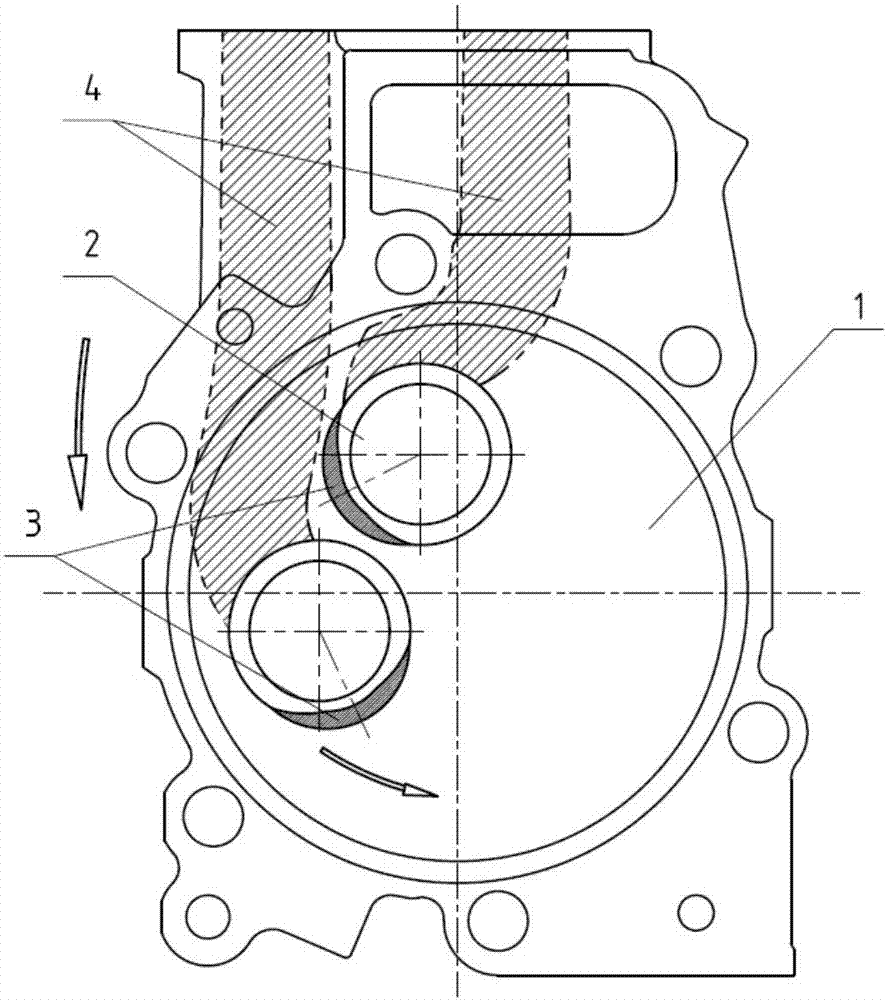

Air inlet guide structure for air inlet channels located on bottom face of cylinder cover

InactiveCN106884733AImprove combustion efficiencyIncrease vortexInternal combustion piston enginesCylinder headsInlet channelFlame propagation

The invention belongs to the technical field of internal combustion engine equipment and relates to an air inlet guide structure for air inlet channels. The air inlet guide structure for the air inlet channels comprises an air cylinder cover. The bottom face of the air cylinder cover is connected with the air inlet channels. Guide grooves are formed at the positions, corresponding to inlets of the air inlet channels, of the bottom face of the air cylinder cover. The direction of the guide grooves and the direction of spiral eddies in the air inlet channels are identical. The air inlet guide structure for the air inlet channels is simple and reasonable in structure, targeted improvement is conducted in order to overcome defects of an existing air cylinder cover, eddies in the air cylinder of an engine are enhanced, and it is guaranteed that fresh air and fuel in the air cylinder are more fully and evenly mixed; and tumbles in the air cylinder are enhanced, so that the flame propagation speed in the air cylinder is increased, the combustion efficiency of the engine is higher, and discharged tail gas is cleaner.

Owner:WUXI KIPOR POWER CO LTD

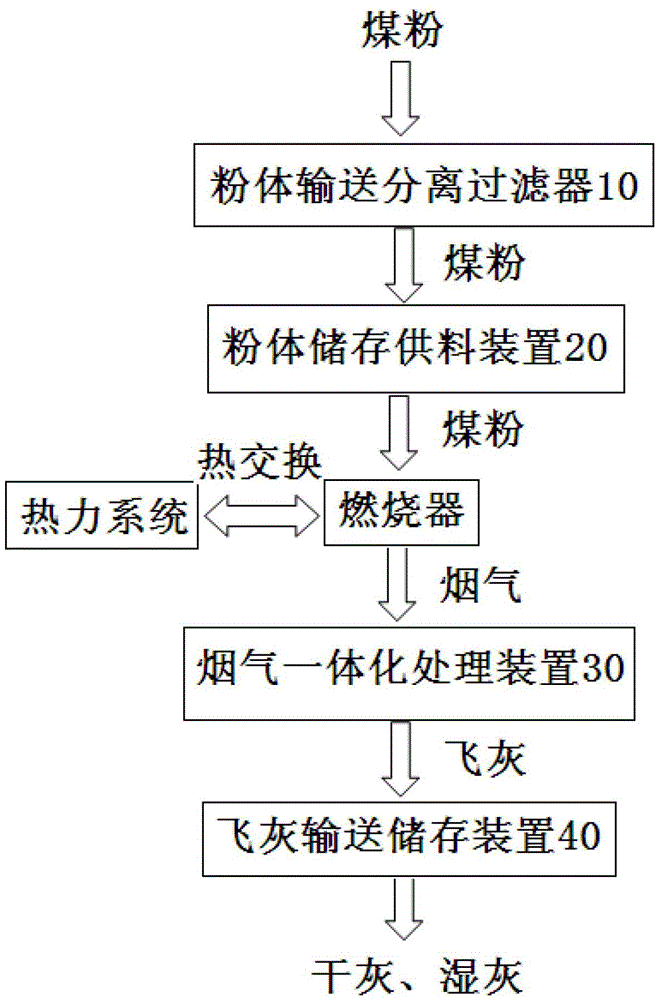

Pulverized coal industrial boiler system

ActiveCN102980200AStable deliveryDischarge cleaningSolid removalLump/pulverulent fuel feeder/distributionCombustorFlue gas

The invention relates to a pulverized coal industrial boiler system. The pulverized coal industrial boiler system is characterized by comprising a pulverized coal feeding and separating filter, a pulverized coal storing and feeding device, a boiler burner, a flue gas integrated treatment device, a fly ash delivering and storing device and an inert gas protecting device; the feeding and separating filter filters pulverized coal and then conveys the pulverized coal to the pulverized coal storing and feeding device, the pulverized coal storing and feeding device stores the pulverized coal and supplies the pulverized coal to the boiler burner, the boiler burner exchanges heat with a thermodynamic system during the burning process and supplies hot water or steam to users; and flue gas after the combustion of the boiler burner is treated through the flue gas integrated treatment device and is delivered to the fly ash delivering and storing device, wherein the pulverized coal in the pulverized coal storing and feeding device needs to be protected through inertia gases which are provided by the inert gas protecting device during the storing process. The system integrates pulverized coal delivering, storing, feeding, flue gas treating and recycling into a whole, has high function integration level, a small occupation area, low operation cost, high economy and no dust and flue gas leakage, cannot cause environmental pollution and can be widely used for a pulverized coal feeding process.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

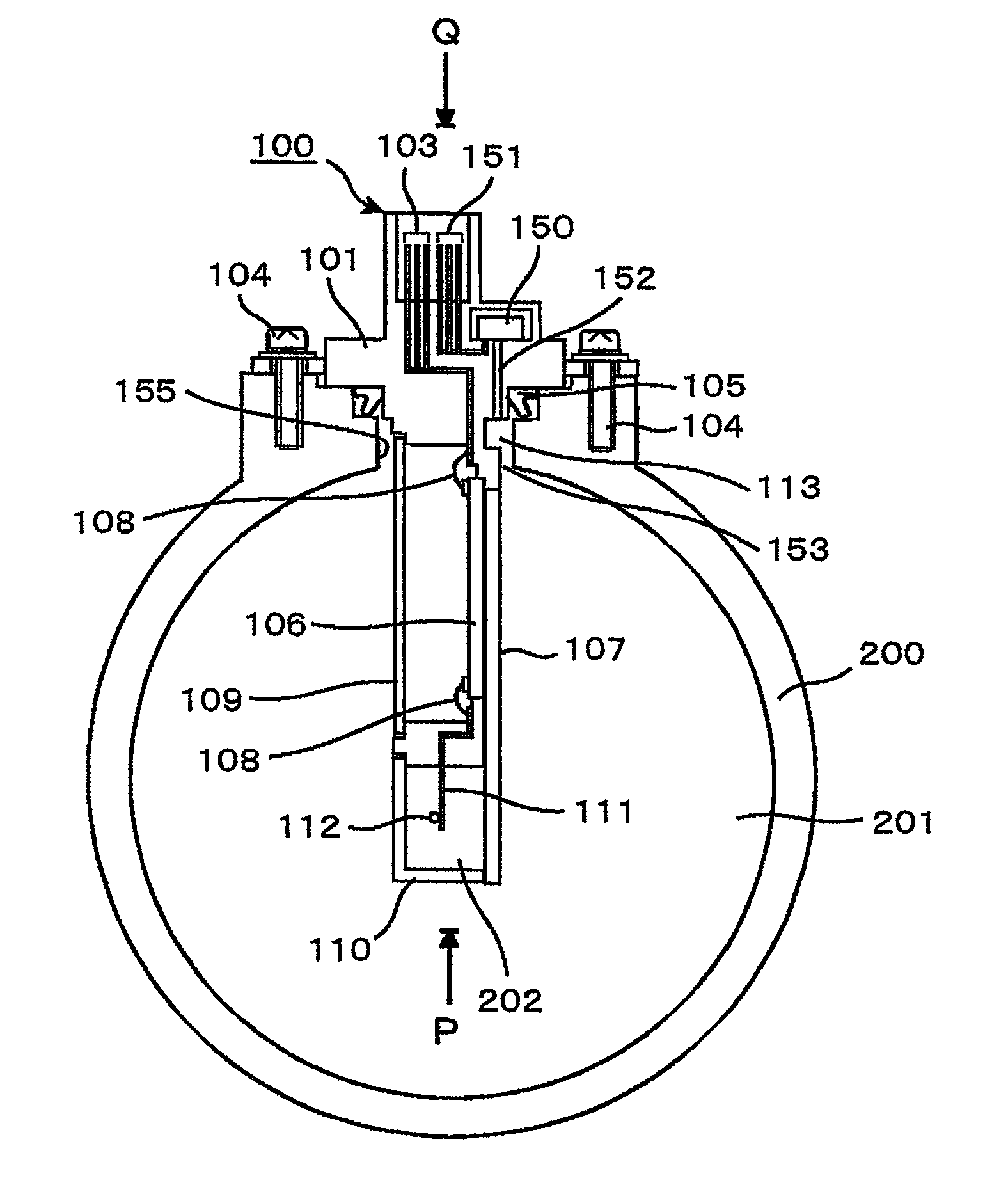

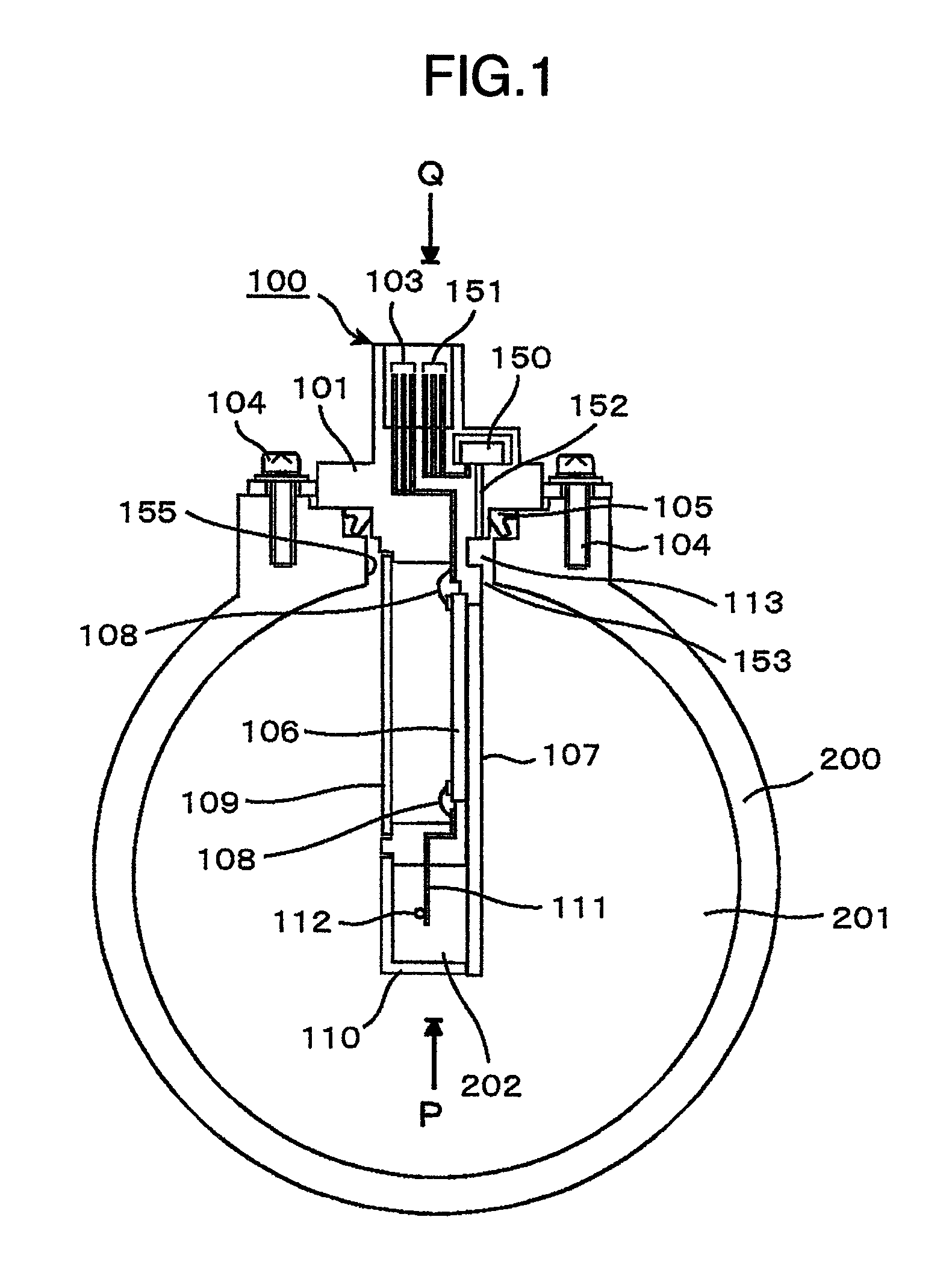

Intake air mass flow measurement device

ActiveUS7934419B2Reduce the amount requiredDischarge cleaningInternal-combustion engine testingVolume flow proportion measurementMeasurement devicePressure sense

In an intake air mass flow measurement device, for preventing clogging in a pressure intake tube due to water or the like entering the pressure intake tube in a device measuring a pressure in the intake air tube, the intake air mass flow measurement device includes a mass air flow measurement device for measuring an intake air mass flow in an intake air tube; and a pressure sensing device for sensing pressure in the intake air tube, the pressure sensing device being integrated with the mass air flow measurement device, and an aperture plane opened to the inside of a main air flow passage for detection of the pressure takes in pressure by using a gap generated between a main air flow passage constituting member and an insertion part of the mass air flow measurement device when a measurement part of the mass air flow measurement device is inserted into the main air flow passage. With this construction, it is possible to provide a structure in which water or the like can hardly clog the pressure intake port.

Owner:HITACHI ASTEMO LTD

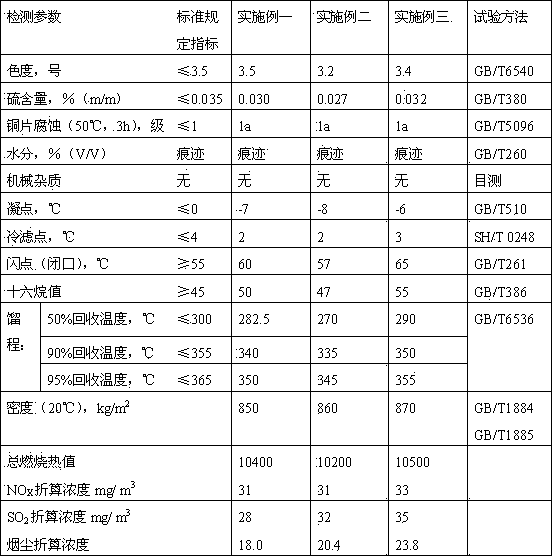

Energy-saving environment-friendly fuel oil and preparation method thereof

InactiveCN104099141AHigh calorific valueImprove performanceLiquid carbonaceous fuelsOil and greaseEnvironmental resistance

The invention discloses energy-saving environment-friendly fuel oil and a preparation method thereof. The energy-saving environment-friendly fuel oil comprises the following components in parts by mass: 10-20 parts of biodiesel, 10-40 parts of coal oil, 20-40 parts of vegetable fat, 5-10 parts of microbial oil, 3-6 parts of vegetable oleic acid or ethanolamine, 10-25 parts of methanol and 10-40 parts of distilled oil, wherein the distilled oil is obtained by distilling used oil, and / or diesel oil and / or drainage oil. The fuel oil disclosed by the invention is high in heat value, stable in performance, clean in discharge, not easy to volatilize, non-toxic, smokeless and tasteless, and can fully meet ignition temperature requirements during use, waste oil can be reasonably treated, and the existing energy sources are saved.

Owner:DONGGUAN XIANGYANG CENTURY ENERGY

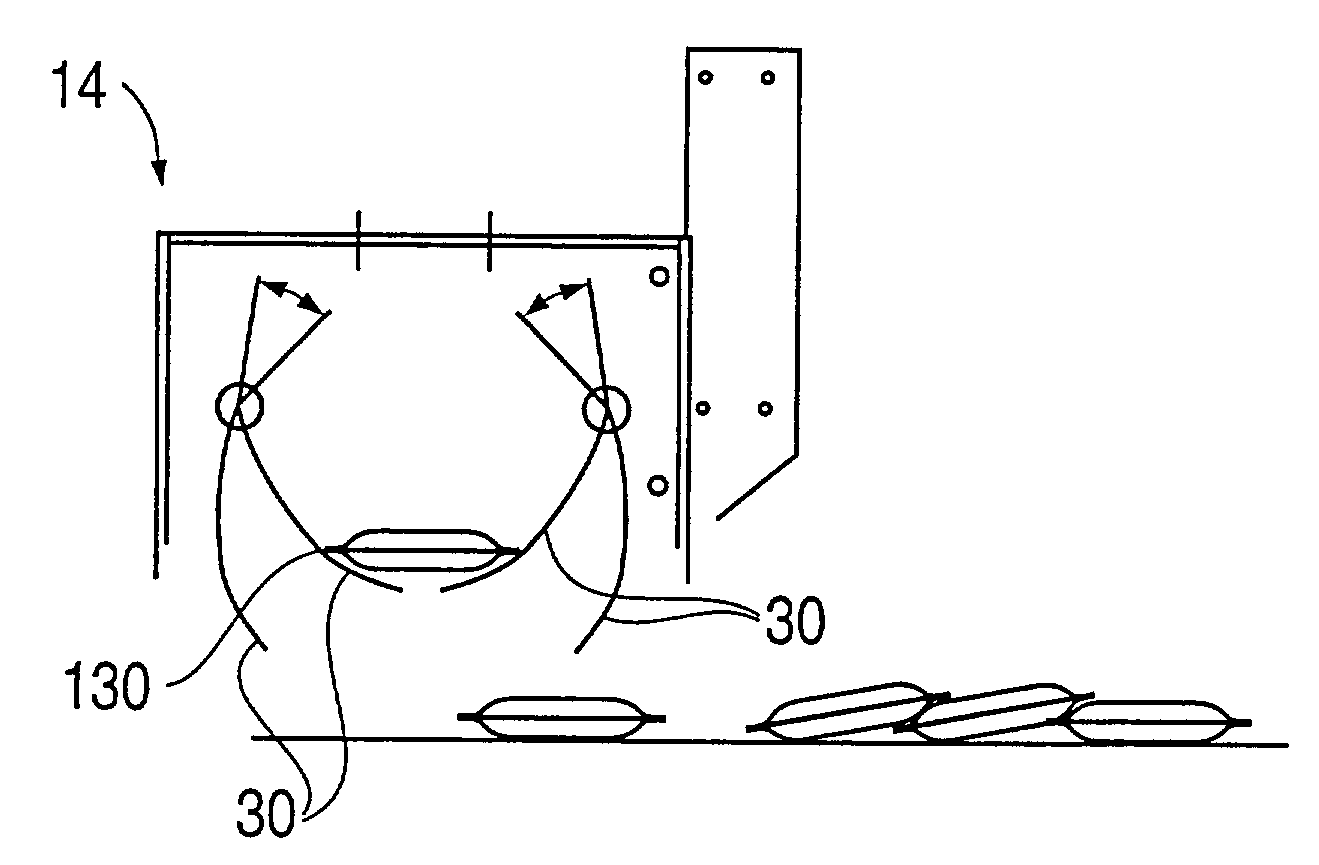

Packaging system

InactiveUS6988350B2Discharge cleaningHigh pickup rateProgramme-controlled manipulatorSolid materialLeading edgeRobotic systems

A packing system for articles. According to one embodiment of the invention, a receiving and dropping assembly comprising one or more doors that are displaceable between a holding configuration and a dropping configuration. The doors define a receptacle while in the holding configuration. The receptacle receives and holds an article, which is received by a leading edge of the article being guided by guide surfaces in the doors. The doors drop the article being held while in the dropping configuration. An output conveyor line receives the articles dropped by the receiving and dropping assembly. A controller controls the dropping and conveyance of the articles to convey the dropped articles along the output conveyor line in predetermined arrays. A pick-and-place robot system picks up the articles or arrays of articles from the output conveyor line and places the picked up articles in receptacles.

Owner:ISHIDA CO LTD

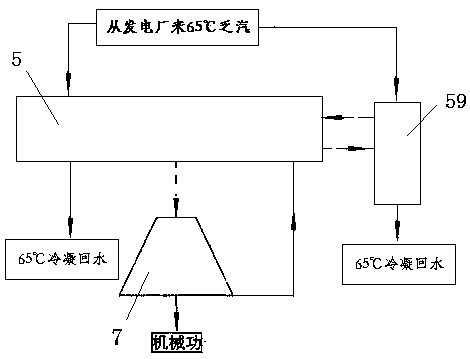

High efficiency energy-conserving environmental protecting power generating system

The present invention discloses a high-effective energy-saving environment-protecting power generation system. Said system includes the following several portions: boiler, turbine power generator, exhaust blower and heat-collecting water tank. The water vapour produced by boiler can be transferred into the turbine power generator by means of pipeline and can be used for driving said turbine power generator to make power generation. Besides, said invention also provides the concrete operation method of said power generation system.

Owner:赵文志

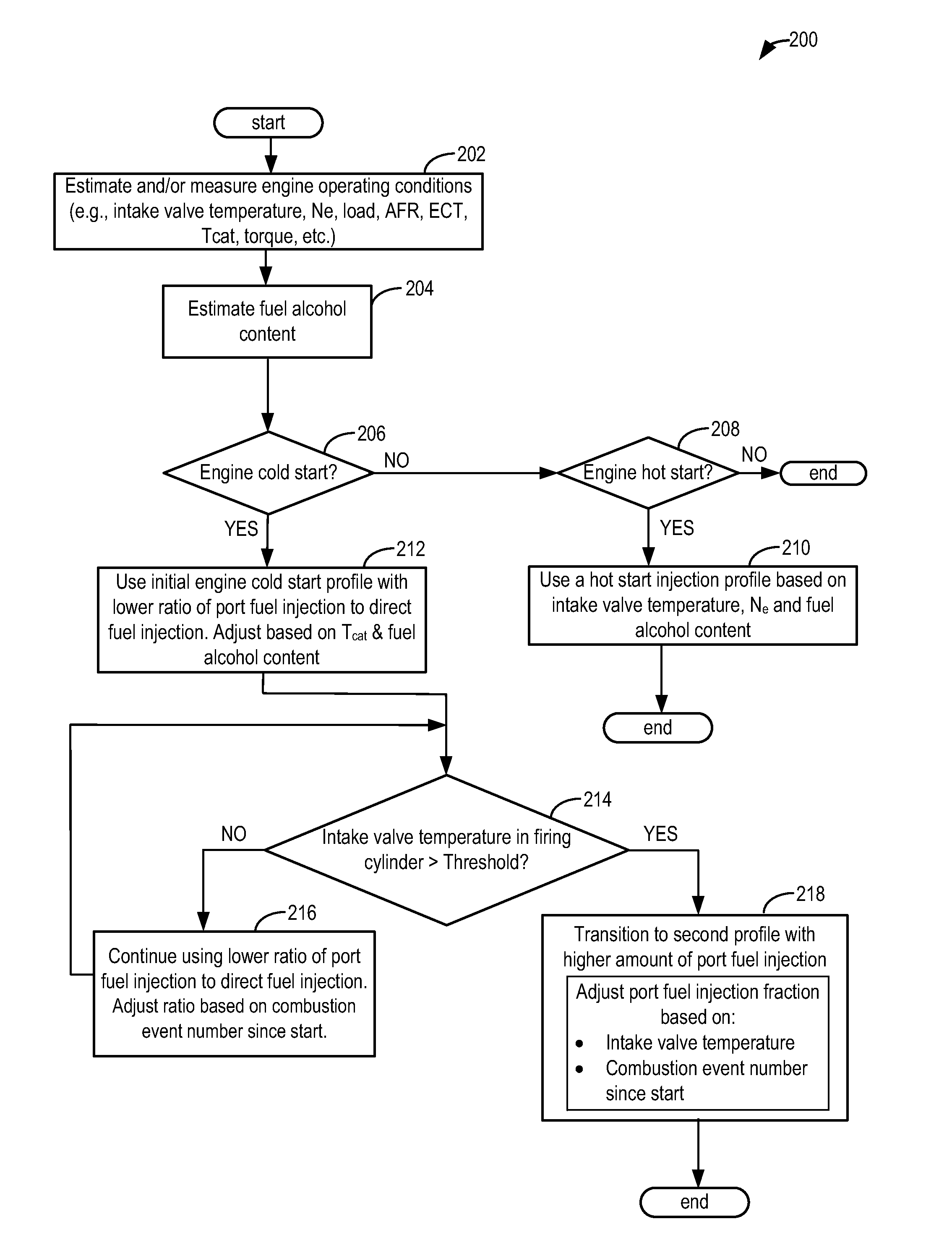

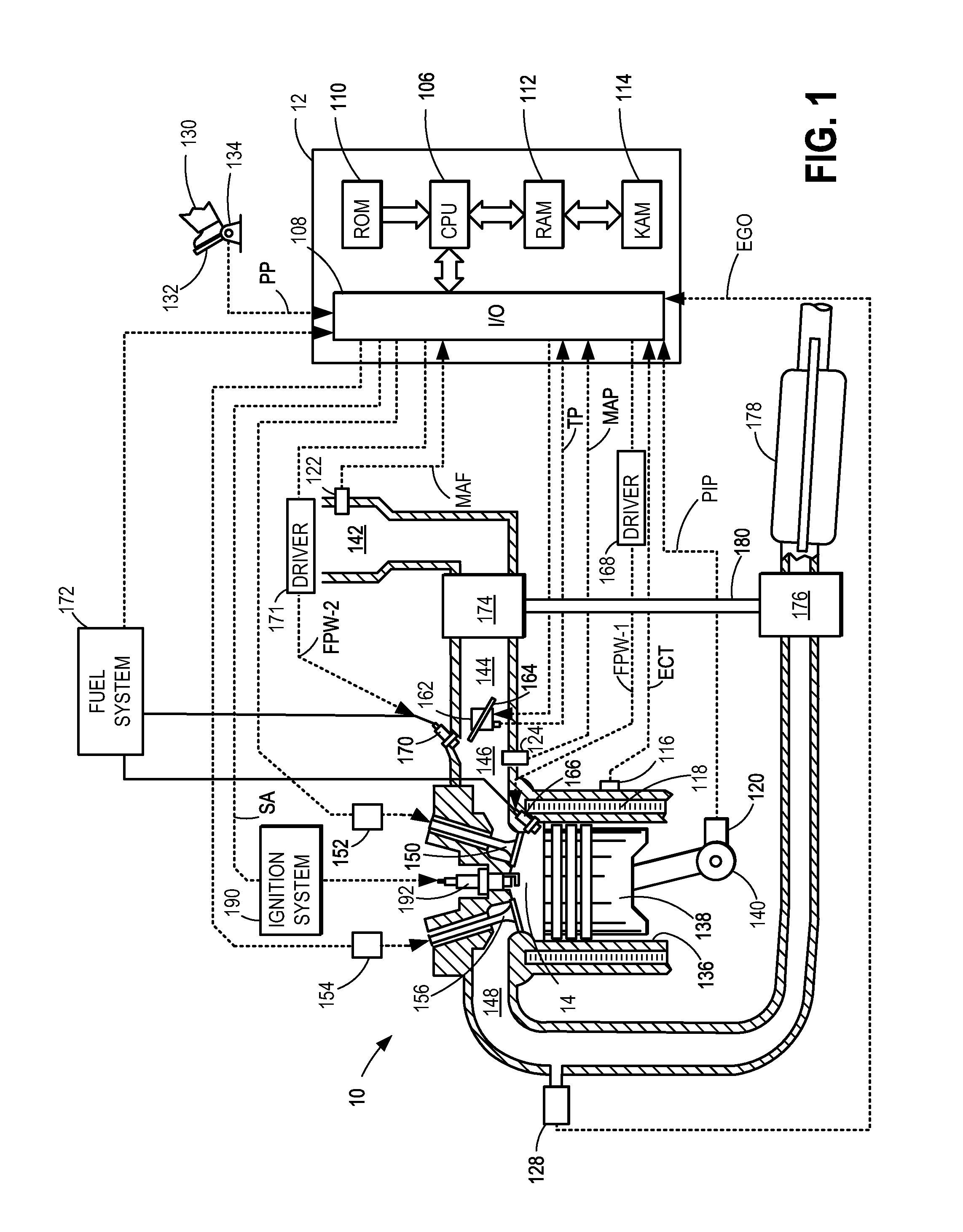

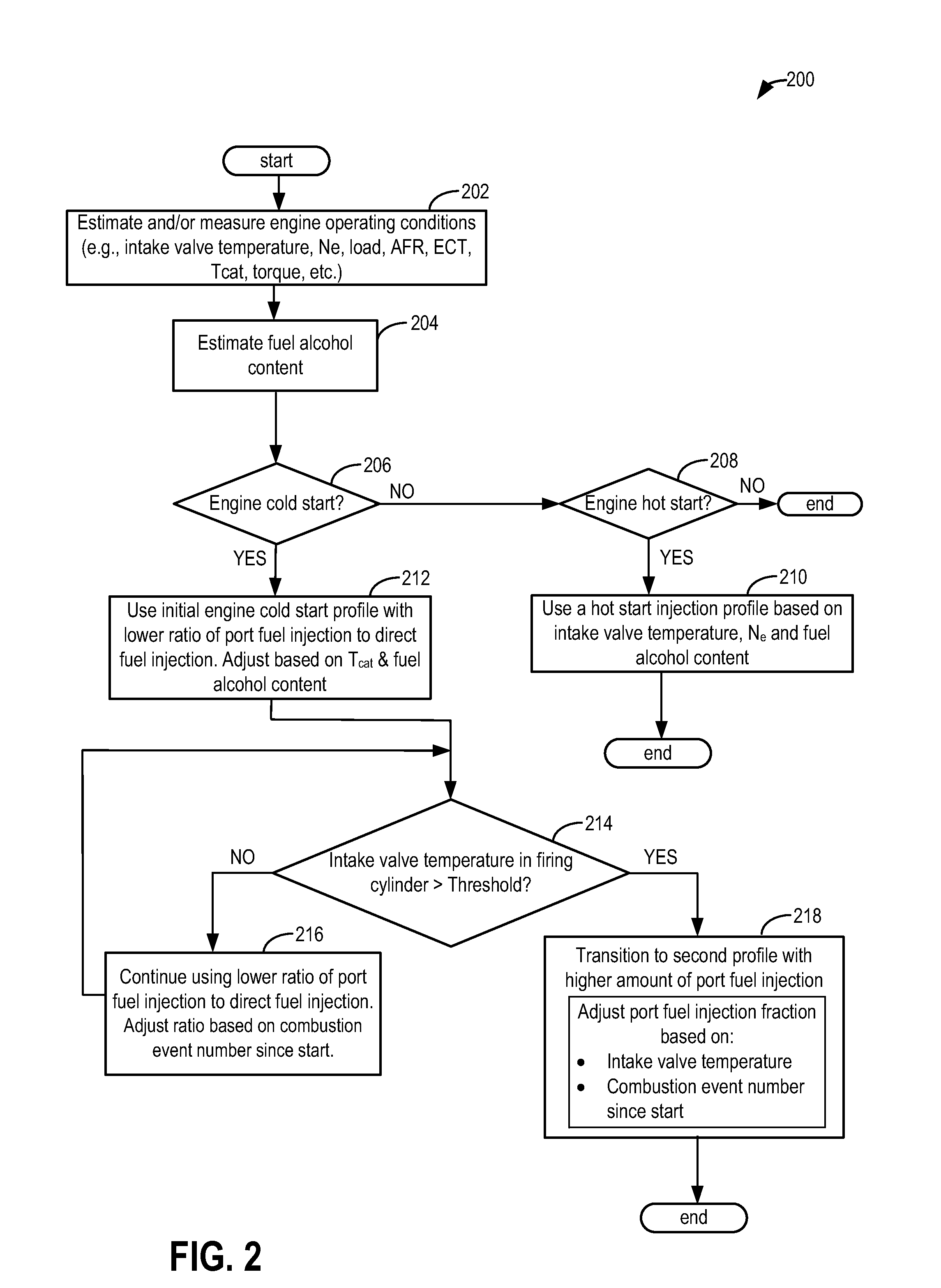

Method for fuel injection control

ActiveUS9435287B2Improve fuel efficiencyHigh power outputElectrical controlInternal combustion piston enginesInlet valveEngineering

Methods and systems are described for controlling fuel injection in an engine equipped with a dual injector system including a port injector and a direct injector. A ratio of port injected fuel to direct injected fuel is adjusted based at least on intake valve temperature. The proportion of fuel port injected into a cylinder is increased as the intake valve temperature for the given cylinder increases to improve fuel vaporization in the intake port.

Owner:FORD GLOBAL TECH LLC

High cleanness composite diesel oil

The invention relates to a high clean composite diesel. The raw materials adopted by the invention are waste materials after the coal, the timber and the bamboo are distilled and cooled. The invention is characterized in that: the invention consists of products after coal-tar oil, wood tar oil or bamboo tar oil are catalyzed and modified, aviation kerosene or kerosene, diesel and isooctyl nitrate; for more details about the preparation method, please refer to Instructions. The invention has the advantages of full combustion of fuel, strong power, clean tail gas discharge; abundant raw material source, low cost, simple production process, no use of any corrosive chemical components such as acid, alkali and so on, no pollution to the environment; convenient use, increased fuel variety, and being capable of solving the problem that the natural fuel is in short supply. The product can be directly used for various diesel engines.

Owner:于涛

Ultrasonic transducer device for humidifier

InactiveUS7362037B2Extended service lifeDischarge cleaningPiezoelectric/electrostriction/magnetostriction machinesLighting and heating apparatusUltrasonic sensorPlastic materials

An ultrasonic transducer device for a humidifier, the humidifier having a vaporizing chamber for producing water vapor or mist, the ultrasonic transducer device comprises: a transducer holder having a central opening formed in a longitudinal direction of the transducer holder and a flange portion disposed at a periphery of the transducer holder, the transducer formed of synthetic resin or plastic materials; an ultrasonic transducer disposed at the central opening of the transducer holder; a support member formed of metal and having an upper planar section and a side section extending vertically from the upper planar section, the upper planar section defining an opening therein for coupling with the flange portion of the transducer holder; and a heat discharge plate having heat discharging fins and coupled with the support member, the heat discharge plate coupled with a circuit board for discharging heat in the circuit board.

Owner:OHSUNG

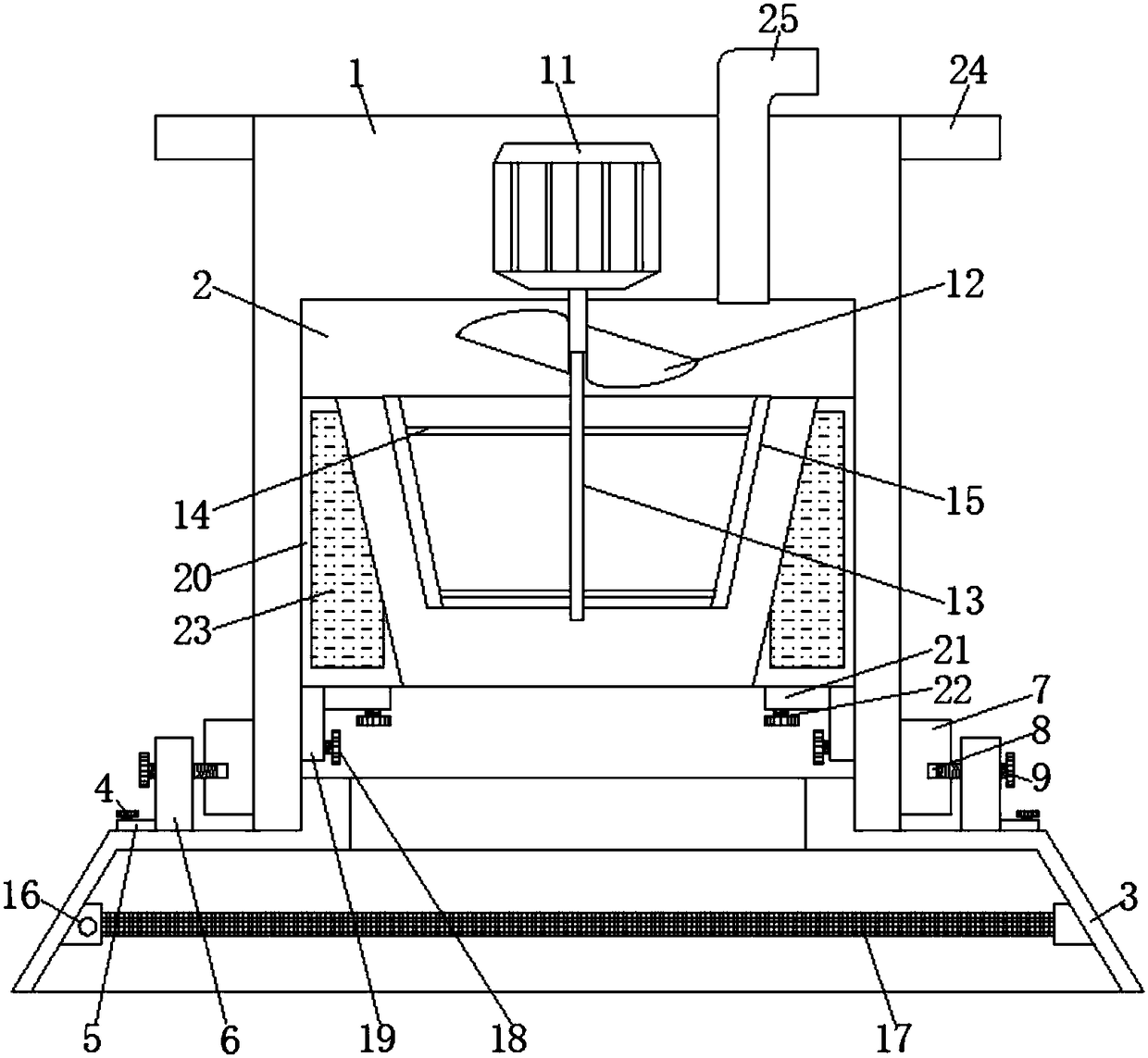

Clean type smoke exhaust ventilator for kitchen

InactiveCN108561926AEasy to disassembleEasy to cleanDomestic stoves or rangesLighting and heating apparatusButt jointPulp and paper industry

The invention provides a clean type smoke exhaust ventilator for a kitchen, and relates to the technical field of kitchen tools. The clean type smoke exhaust ventilator for the kitchen comprises a smoke exhaust ventilator body, wherein a smoke suction cavity is formed in the bottom of the smoke exhaust ventilator body; a smoke cover is inserted to the bottom of the smoke exhaust ventilator body; first fixing blocks are fixedly arranged at two sides of the top of the smoke cover through first screws; the mutually approaching sides of the two first fixing blocks are fixedly connected with side plates; butt joint blocks are fixedly connected onto two sides of the smoke exhaust ventilator body; a threaded groove is formed in one side, far away from the smoke exhaust ventilator body, of each butt joint block. The clean type smoke exhaust ventilator for the kitchen has the advantages that when a filtering screen is dismounted, a plug bolt post is backwards pressed; the plug bolt post extrudes a limiting plate; the limiting plate extrudes a reset spring; the reset spring is compressed, so that the insertion bolt post is disengaged from an extending hole and retracts into the inside of a stretching and retracting groove; a positioning block is downwards pulled, so that the positioning block is disengaged from a position clamping groove; the operation is simple; the structure is compact; the processing is easy, so that the filtering screen can be dismounted; the effect that the filtering screen can be conveniently cleaned is achieved.

Owner:WUHU LE CHUANG ELECTRONICS TECH CO LTD

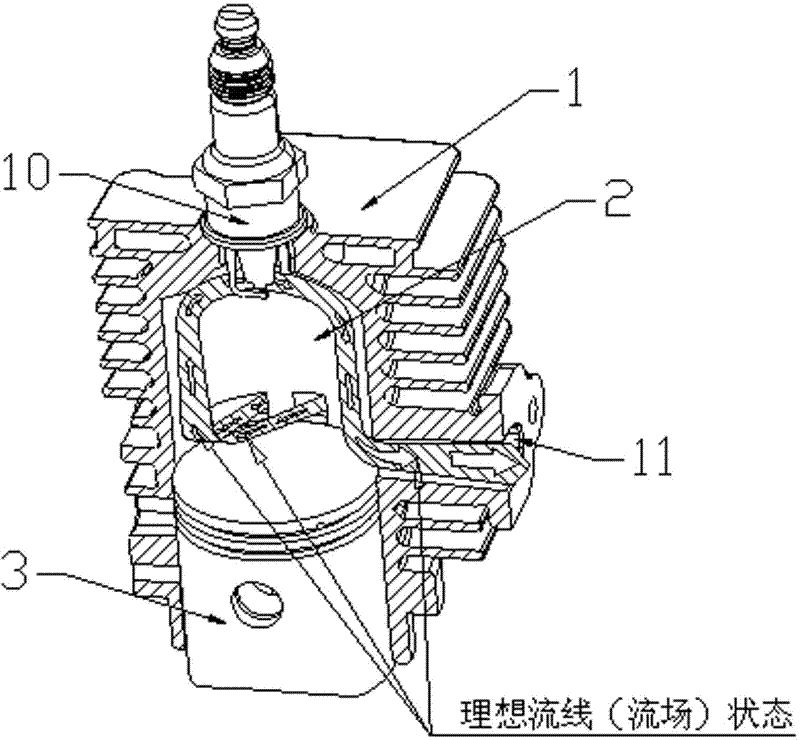

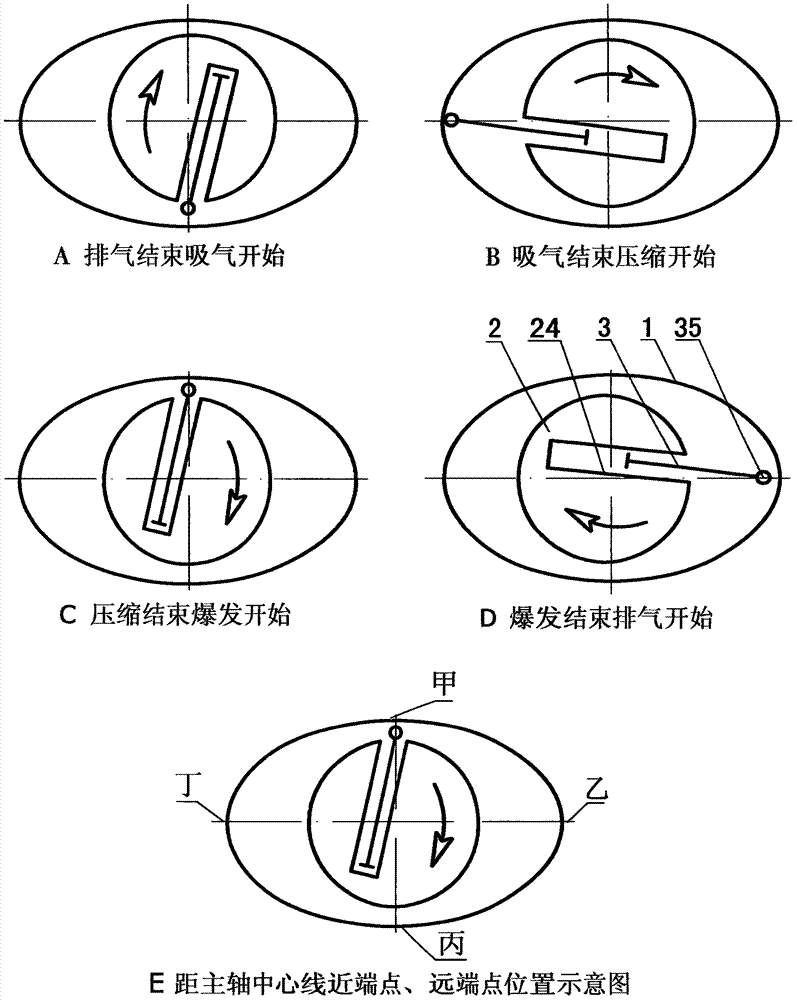

Combustion chamber for two-stroke engines

ActiveCN102392729AImprove combustion efficiencyReduce escapeInternal combustion piston enginesCylinder headsCombustion chamberCombustible gas

The invention discloses a combustion chamber for two-stroke engines, which is characterized in that in a cylinder body, the combustion chamber is composed of a sparking plug, a piston and the top part of the cylinder body; the top part of the cylinder body comprises a cylinder top (in the shape of a convex curved surface) away from the gas-outlet side and a cylinder top (in the shape of a concavecurved surface) close to the gas-outlet side; through selecting any point A on the convex curved surface and taking the axis of the piston as a symmetry axis, a point on the concave curved surface and symmetrical with the point A is a point B, and the distance between the point A and the top surface of the piston is less than the distance between the point B and the top surface of the piston; andbecause the point A is selected arbitrarily, any two points which are on the curved surfaces of the cylinder tops and symmetrical about the axis of the piston have the features. By using the structure, the combustion efficiency of combustible gas can be effectively improved, the escape of the combustible gas can be reduced, and emission gas is cleaner.

Owner:苏州圣雷动力机械有限公司

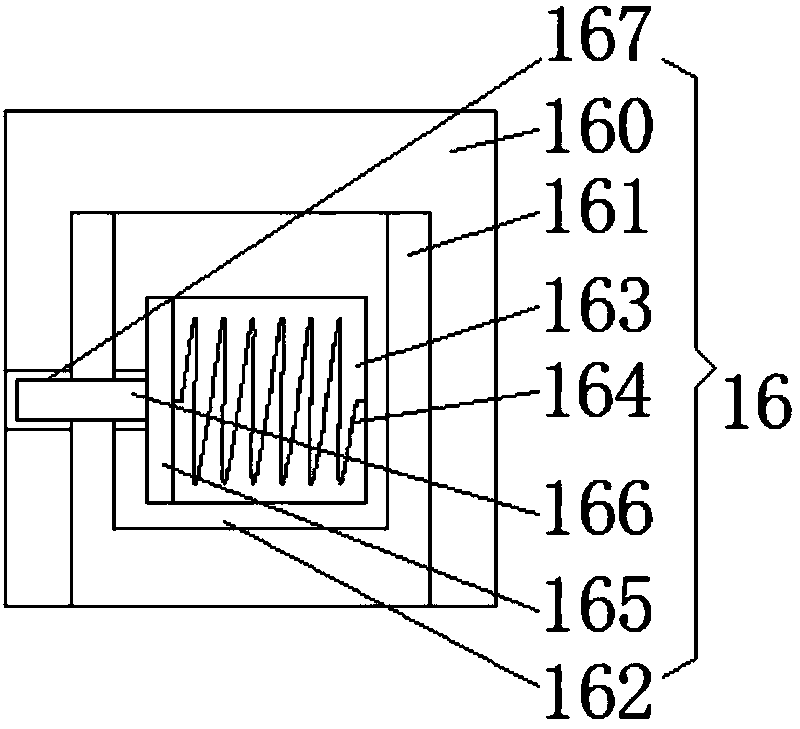

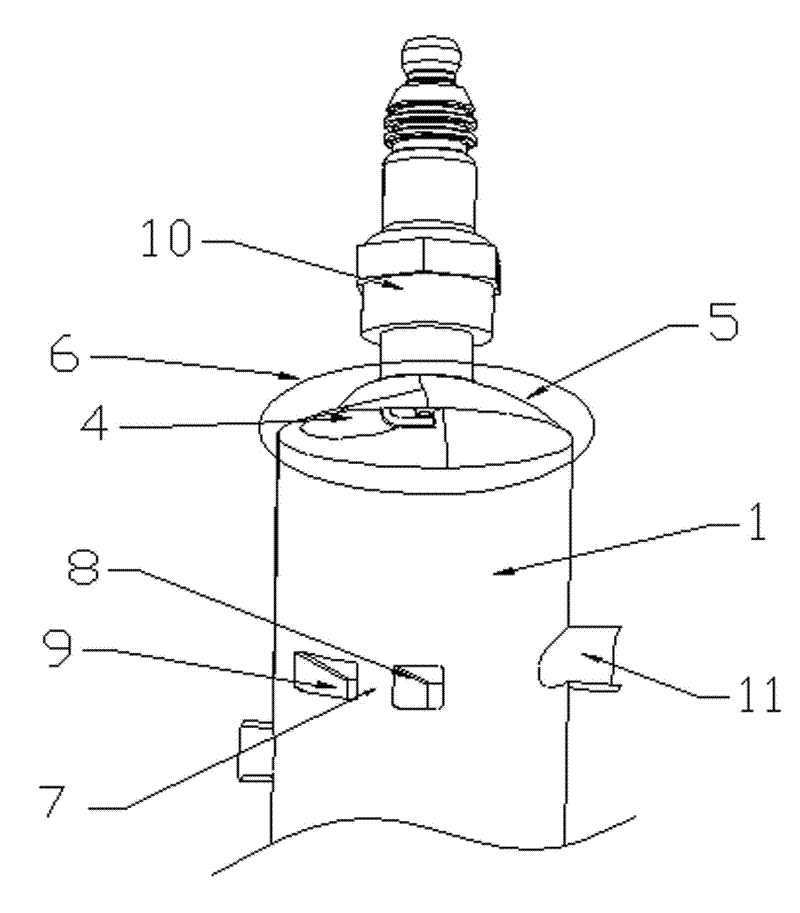

Energy-saving self-control system used for concentrated lampblack exhaust system

InactiveCN106369652ADischarge cleaningExtended service lifeDomestic stoves or rangesLighting and heating apparatusAir volumeEngineering

The invention discloses an energy-saving self-control system used for a concentrated lampblack exhaust system. The energy-saving self-control system comprises a user air volume requirement collector, a pipeline air volume collector, a data analysis and comparison device and a variable-frequency controller, wherein the user air volume requirement collector is used for receiving the air volume of a single requirement preset by a user and is in interlock switching with a lampblack exhausting motor switch of the user; the pipeline air volume collector is arranged on the straight pipe section, between a purification processor and a concentration fan, of a main pipeline; the data analysis and comparison device is used for receiving the air volume of the single requirements sent by users and the air volume information collected by the pipeline air volume collector, the air volume of the single requirements is counted, the required air volume is obtained through calculation, and the required air volume is compared with the collected air volume collected by the pipeline air volume collector; and the variable-frequency controller is used for controlling the operation frequency of the concentration fan according to the comparison result of the data analysis and the comparison device. According to the energy-saving self-control system, automatic lampblack exhaust control can be achieved according to the real-time lampblack exhaust required amount of the users, and energy saving and environment friendliness are facilitated.

Owner:奥意建筑工程设计有限公司

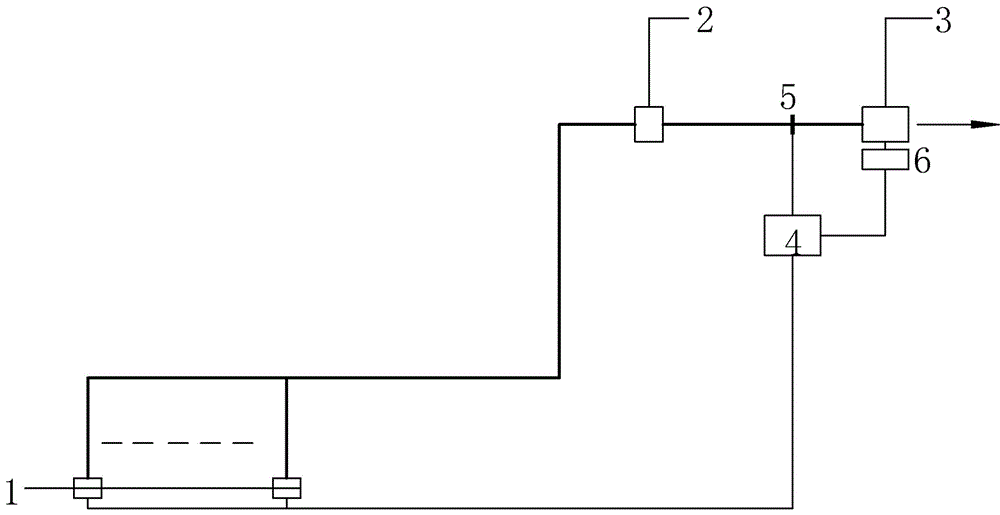

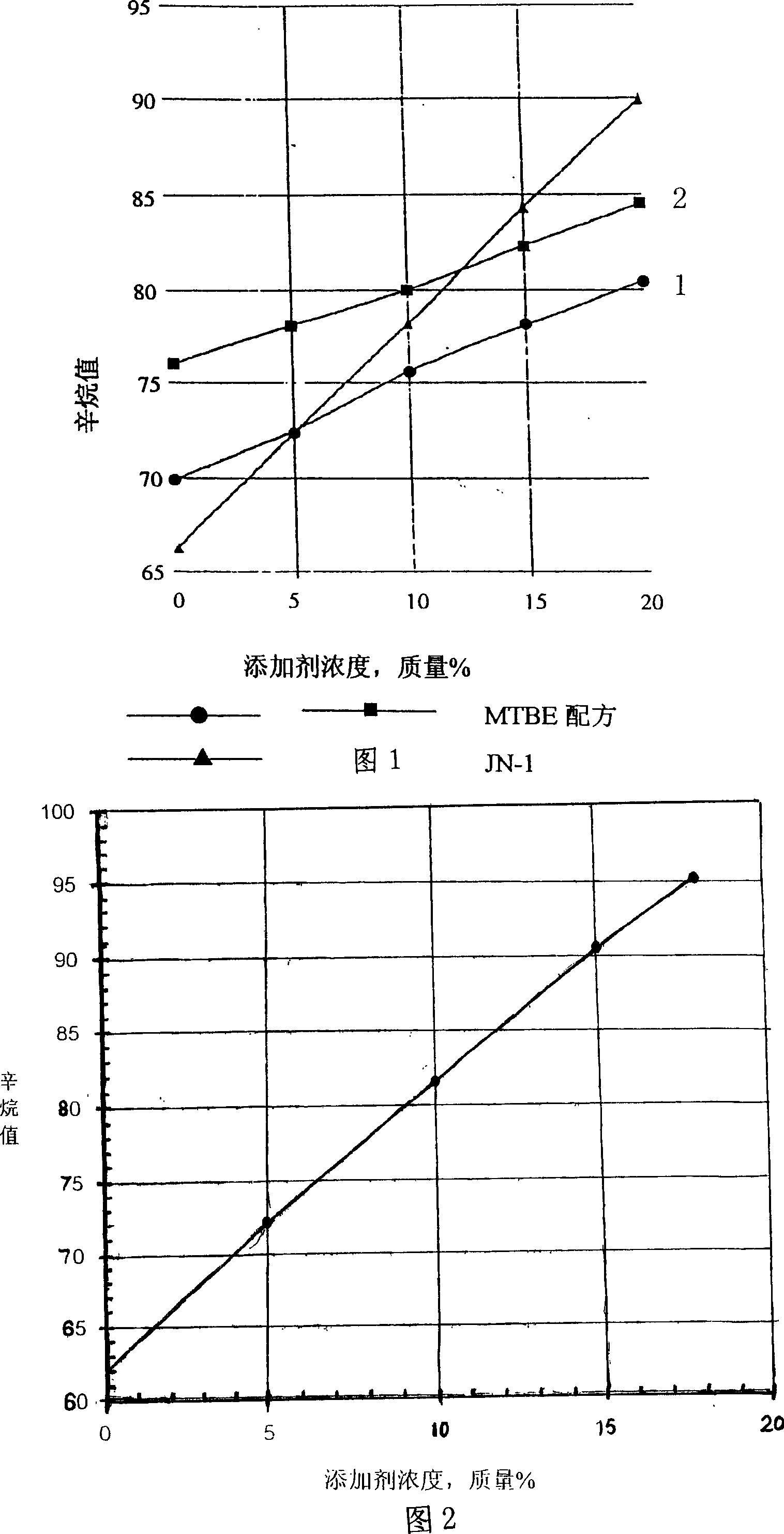

Environment protectional antiknock additive for high-effective and clean gasoline for vehicle, and method for manufacturing same

InactiveCN1730626AStrong antiknockPromote environmental protectionLiquid carbonaceous fuelsIsobutanolN-Methylaniline

The gasoline additive provided by the invention comprises methanol, ethanol, butanol, isobutanol, N,N-dimethylaniline, and N-methylaniline. Its preparing process consists of mixing the components proportionally with a metering valve, loading into sealed storage tank, stewing 10-20 minutes, finally mixing homogeneously.

Owner:XIAN JIANNENG TECH

High-cleaning composite gasoline and preparation method thereof

InactiveCN102002404AGood cold startStrong corrosion resistanceLiquid carbonaceous fuelsSolventChemistry

The invention relates to high-cleaning composite gasoline and a preparation method thereof. The high-cleaning composite gasoline comprises the following components in part by weight: 10 to 25 parts of methanol, 15 to 20 parts of naphtha, 52 to 74 parts of solvent gasoline and 1 to 3 parts of additive, wherein the additive is prepared from 10 weight percent of tridecyl alcohol, 10 weight percent of hexadecyl sodium sulfonate, 20 weight percent of hexadecyl calcium sulfonate, 50 weight percent of naphthenic acid, 2.5 weight percent of tertiary butanol, 2.5 weight percent of isobutanol and 5 weight percent of isopropanol. The preparation method comprises the following steps of: 1) preparing the additive; 2) preparing denatured methanol; and 3) blending the denatured methanol, the naphtha and the solvent gasoline to prepare the high-cleaning composite gasoline. The high-cleaning composite gasoline of the invention has good cold boot, strong anti-corrosion performance, full combustion, powerful motive power and clean discharged tail gas and abundant sources and low cost of raw materials, and can solve the problem that natural fuel is in short supply.

Owner:于涛

Environment-friendly fuel oil and preparation method thereof

The invention discloses environment-friendly fuel oil and a preparation method thereof. The environment-friendly fuel oil comprises the following components in parts by mass: 10-40 parts of coal oil, 20-40 parts of plant grease, 3-6 parts of vegetable oil acid or ethanol amine and 10-25 parts of methanol. The fuel oil is high in heat value, stable in property, environment-friendly in discharge, not easy to volatilize, free of toxicity and smoke or odor, the requirements of ignition temperature in use can be sufficiently met, waste oil products can reasonably treated, and the conventional energy is also saved.

Owner:DONGGUAN XIANGYANG CENTURY ENERGY

Methyl alcohol diesel fuel additive and methyl alcohol diesel fuel

InactiveCN103773516AAppearance is clear and transparentPromote combustionLiquid carbonaceous fuelsKetoneN-Butyl Alcohol

The invention relates to a methyl alcohol diesel fuel additive and methyl alcohol diesel fuel. The methyl alcohol diesel fuel additive is prepared from the following raw materials in volume ratio: 10-15% of methyl tertiary butyl ether, 5-10% of normal octane, 15-20% of isopropyl-ketone, 25-30% of n-butyl alcohol and 10-35% of methylcyclopentane. With adoption of the methyl alcohol diesel fuel, the technical problems about corrosivity, swelling property, cold boot difficulty, hot air resistance, layering in mixing with water, lowered power, flowability, emulsification and the like when the methyl alcohol diesel fuel is used are solved.

Owner:冯元淑

Multi-track rotor type internal combustion engine

InactiveCN107084043AMeet a wide range of needsFlexible designInternal combustion piston enginesElectric power transmissionExternal combustion engine

The invention discloses a multi-track rotor type internal combustion engine which is formed by combining a stator, a rotor, a main shaft, a front end cap, a back end cap and the like. The stator is provided with an inwards-concave or outwards-convex sliding way surrounding the main shaft, the sliding way is formed by combining an inner sliding rail and an outer sliding rail, and a path line of the sliding way is a special curve; air cylinders and pistons are installed on the rotor, the center line of each air cylinder is vertical to the center line of the main shaft, and an appropriate distance is kept between the center line of each air cylinder and the center line of the main shaft; a 90-degree angle is formed between the center line of the air cylinder at the front end and the center line of the air cylinder at the back end, when the internal combustion engine works, one air cylinder in the four air cylinders work when the rotor rotates by 90 degrees, and action is down four times when rotation by a circle is done; the front end cap and the back end cap are each provided with an exhaust passage, a scavenging hole and an inlet passage, compressed gas rapidly blows out residual gas in the air cylinders along the exhaust passages through the scavenging holes when exhausting is to be finished; the main shaft is provided with cooling water, lubricating oil and electric power channels to achieve cooling, lubrication and electric power transmission. The multi-track rotor type internal combustion engine is simple in structure, stable in running, large in torque, high in power and wide in application scope.

Owner:袁新文

Small waste incineration structure and method

The invention discloses a small waste incineration structure and method. The small waste incineration structure comprises a drying tank (1), wherein the drying tank (1) is connected with a pyrolysis tank (3) through a feeding device (2); and the pyrolysis tank (3) is connected with a combustor (4). The small waste incineration structure is characterized in that a plasma ozone processor (5) and a hot water sleeve (6) are separately arranged at the upper end and the lower part of the drying tank (1), wherein a smoke gas sleeve (7) is arranged on the lower part of the pyrolysis tank (3); a smokeoutlet tube (8) is arranged on the smoke gas sleeve (7); the smoke outlet tube (8) is connected with a smoke gas purifying device (9); a combustion-assisting inlet (10) and a smoke gas pipeline (11) which is connected with the smoke gas sleeve (7) are arranged on the combustor (4); a heat exchanger (14) is arranged on the smoke gas pipeline (11); and the heat exchanger (14) is connected with a hotwater sleeve (6) through a circulating pipeline. The small waste incineration structure has a relatively good drying and decomposing effect, can save energy throughout the process, and is good in index of exhausted smoke gas.

Owner:贵州富燃环保科技有限公司

High cleanness composite gasoline

InactiveCN101235326ADischarge cleaningRich sourcesLiquid carbonaceous fuelsPetroleum naphthaHazardous substance

The invention relates to high-cleanness compound gasoline, the gasoline source on the existing market is simpler, which has high production cost, the combination is not complete, and dynamic can not be completely released, exhaust emission contains more harmful substance, which has great pollution to environment. The main character of the high-cleanness compound gasoline is that the invention comprises three raw materials which are methanol, isopropanol and petroleum naphtha, which has the advantages of rich resource, low production cost and simple production technique, which does not contain any heavy metal iron such as plumbum, aluminum, manganese, zinc and the like, and has little pollution to environment. The high-cleanness compound gasoline can be used as fuel.

Owner:于涛

Composite catalyzing alcohol ether gasoline with no lead, and method of preparation

InactiveCN100462423CImprove catalytic combustion efficiencyEmission reductionLiquid carbonaceous fuelsZinc peroxideIsobutanol

This invention relates to a method for preparing leadless composite gasoline added with methanol and ethers. The leadless composite gasoline is composed of: methanol 50-80 parts, gasoline product 10-30 parts, naphtha 20-30 parts, isobutanol 0.5-14 parts, methyl-tert-butyl ether 1-8 parts, petroleum benzene 0.1-10 parts, petroleum ether 0.3-10 parts, additives 0.1-3 parts and assistant liquid 0.2-0.5 part. The additives are mixed from zinc peroxide, dimethyl carbonate, and vat yellow, cyclohexylamine and isooctyl nitrate. The assistant liquid is prepared from n-butanol, petroleum benzene and cyclohexylamine. The method comprises: (1) preparing the additives; (2) preparing the mother gasoline; (3) preparing modified methanol; (4) preparing modified naphtha; (5) preparing the synthetic liquid; (6) mixing with the assistant liquid to obtain leadless composite gasoline. The obtained leadless composite gasoline has high methanol content.

Owner:鲁希诺

Methanol fuel additive for cold plateau region and methanol fuel containing the additive

The invention relates to a methanol fuel additive for cold plateau region. The additive is prepped by adding 3-20 wt.% of an oxidant hydrogen peroxide with mass concentration of 30%, 1-6% of an antifreeze, 0.2-3% of an antioxidant antigum agent 2,6-butylated hydroxytoluene, 0.05-0.6% of a metal passivator N,N-bis(salicylidene)-1,2-propanediamine, 0.008-0.06% of a detergent dispersant, 1-6% of a preservative and 1-20% of a emulsifier into 10-83.742% of aqueous solution, mixing evenly by pump circulation, then successively adding 3-20% of naphtha, 3-10% of toluene, 2-10% of xylene, 2-10% of C5H12-C7H16 in weight ratio of 1:1, and mixing homogeneously by pump circulation. At the same time, the invention also discloses a ratio and a preparation method of a methanol fuel containing the methanol fuel additive for cold plateau region. The methanol fuel additive for cold plateau region provided by the invention has good and stable performance, and solves the problems of low temperature fluidity, high altitude hypoxia burning property, low sulfur, low nitrogen and dynamic stability.

Owner:GANSU ZHONGAO PETROCHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com