Patents

Literature

118 results about "Zinc peroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

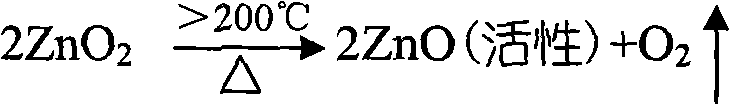

Zinc peroxide (ZnO₂) appears as a bright yellow powder at room temperature. It was historically used as a surgical antiseptic. More recently zinc peroxide has also been used as an oxidant in explosives and pyrotechnic mixtures. Its properties have been described as a transition between ionic and covalent peroxides. Zinc peroxide can be synthesized through the reaction of zinc chloride and hydrogen peroxide.

Method and composition for preventing tooth hypersensitivity when using passive bleaching agents

InactiveUS20060013778A1Avoid allergiesLonger contact/coating periodCosmetic preparationsGum massageZinc peroxidePotassium nitrate

Dental bleaching compositions, for example in the form of liquids, gels, creams, pastes and ointments, comprising a peroxide releasing compound and from 1% to 35% by weight of a potassium-containing compound such as potassium nitrate, wherein the potassium nitrate is present in a safe and effective amount to prevent tooth hypersensitivity in the patient during the bleaching process. The potassium nitrate contemplated by the invention is compatible with peroxide yielding bleaching compounds such as peroxide, carbamide peroxide, calcium peroxide, zinc peroxide, magnesium peroxide and sodium perborate. Potassium nitrate is complimentary and synergistic with the peroxide bleaching agents contemplated by the invention and enhances the release of oxygen to the tooth enamel. Also contemplated are methods of bleaching teeth comprising application of the dental bleaching compositions of the invention.

Owner:HODOSH MILTON

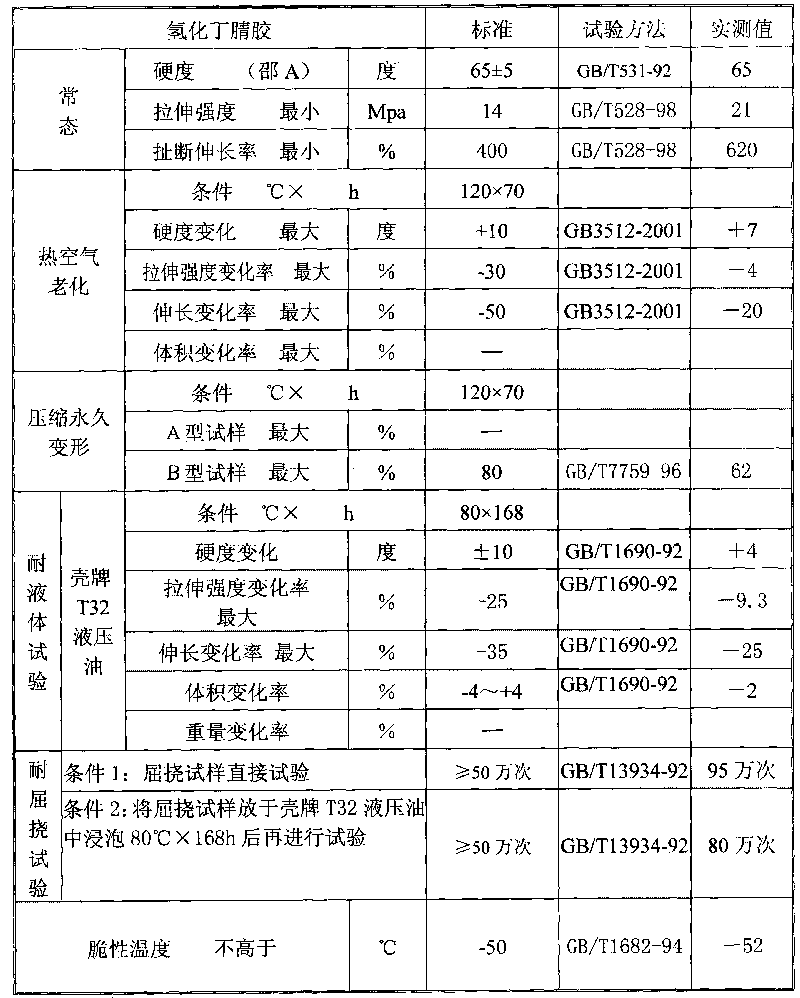

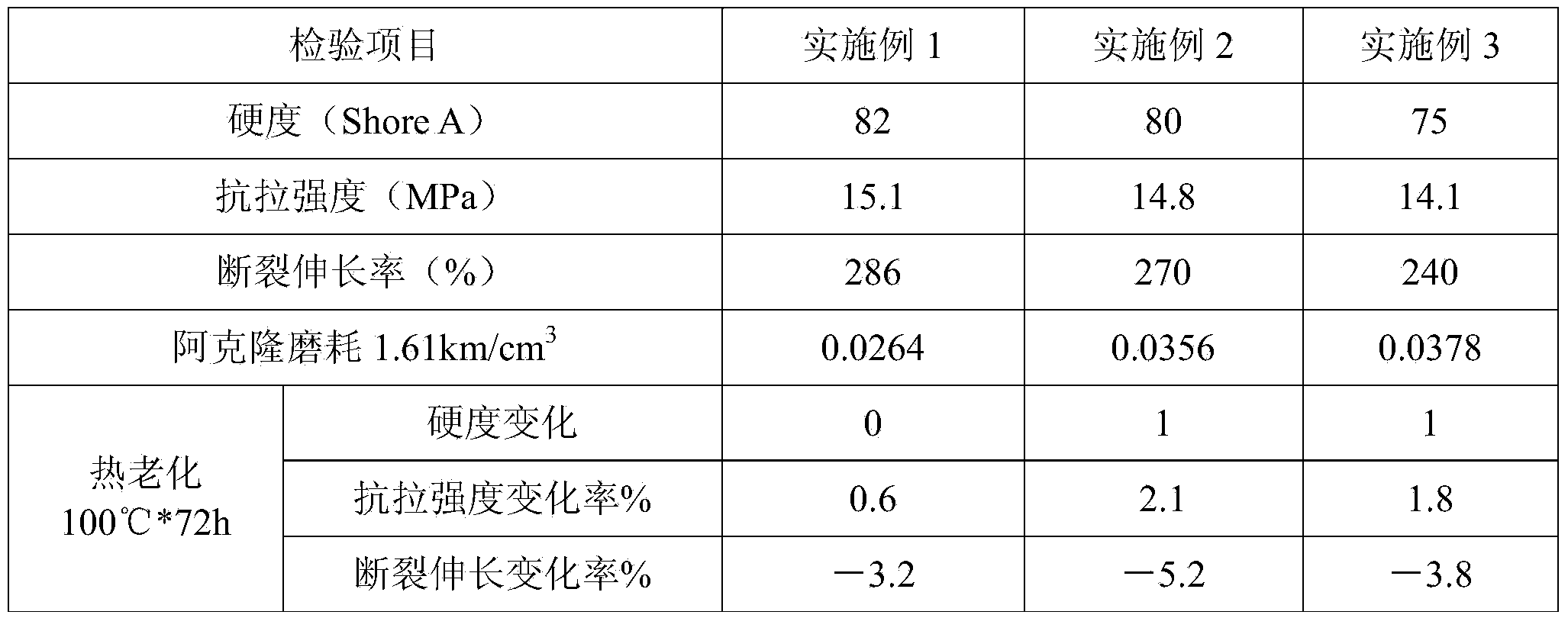

Sealing sleeve for locomotive damper and preparation method thereof

The invention relates to a sealing sleeve for a locomotive damper, which is prepared from the following raw materials in parts by weight: 80-120 parts of hydrogenated nitrile butadiene rubber, 4-10 parts of zinc peroxide, 1-4 parts of antioxidant 445, 10-40 parts of semi-reinforced carbon black, 5-20 parts of white carbon black, 5-25 parts of plasticizer TP759, 0-1 part of sulfur, 0.5-3 parts of accelerant CZ and 1-4 parts of accelerant TMTD. The sealing sleeve which is produced by adopting the raw materials and processes of the invention and used for the locomotive damper has the advantages of excellent performance, high flex property, T32 hydraulic oil resistance, high temperature aging resistance, and favorable low temperature resistant performance, and the product can keep excellent performance under hostile use environment and greatly meets usage requirements. The invention has simple and reasonable processes as well as unique and novel raw material proportioning.

Owner:QINGDAO TKS SEALING IND

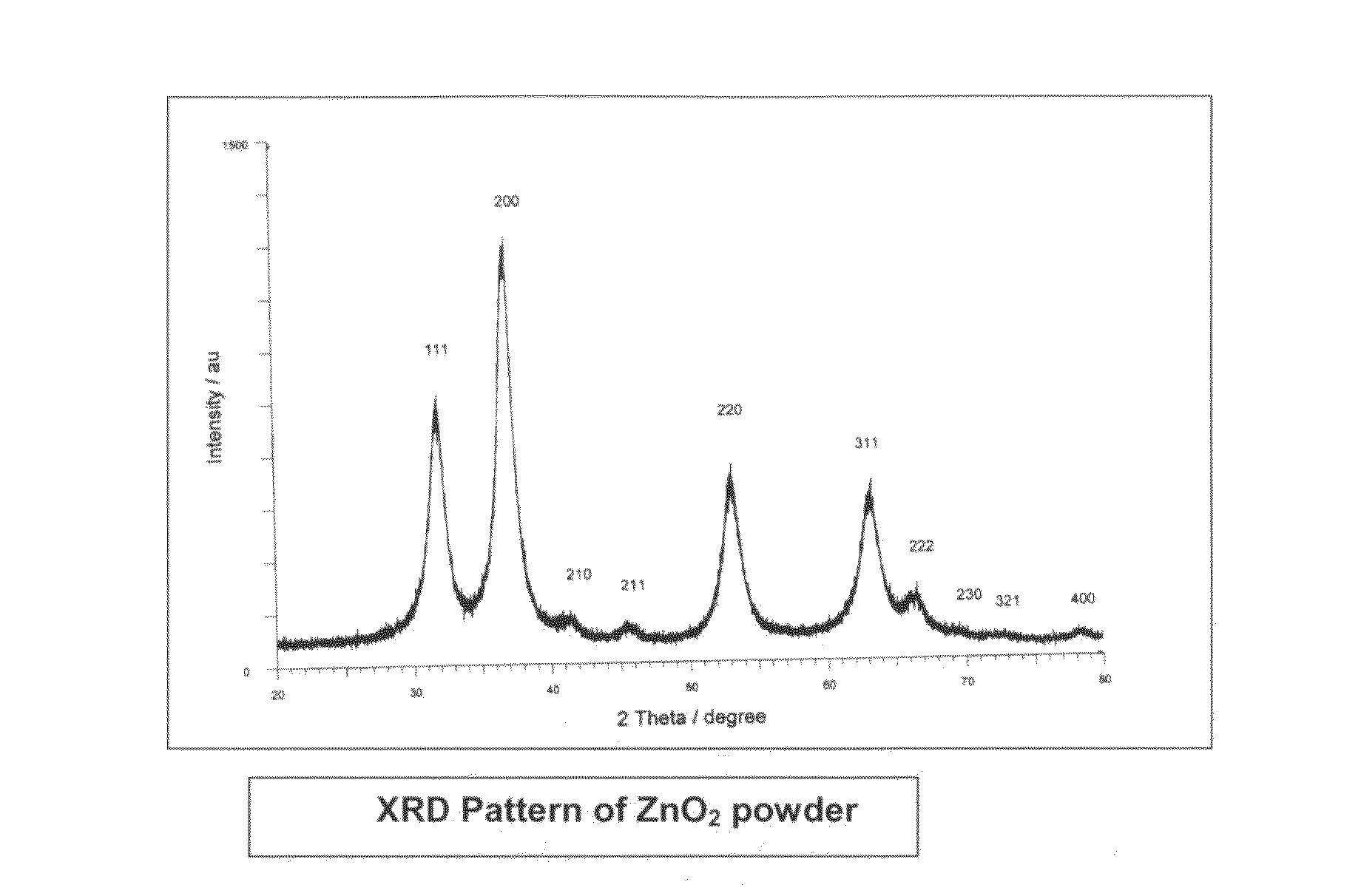

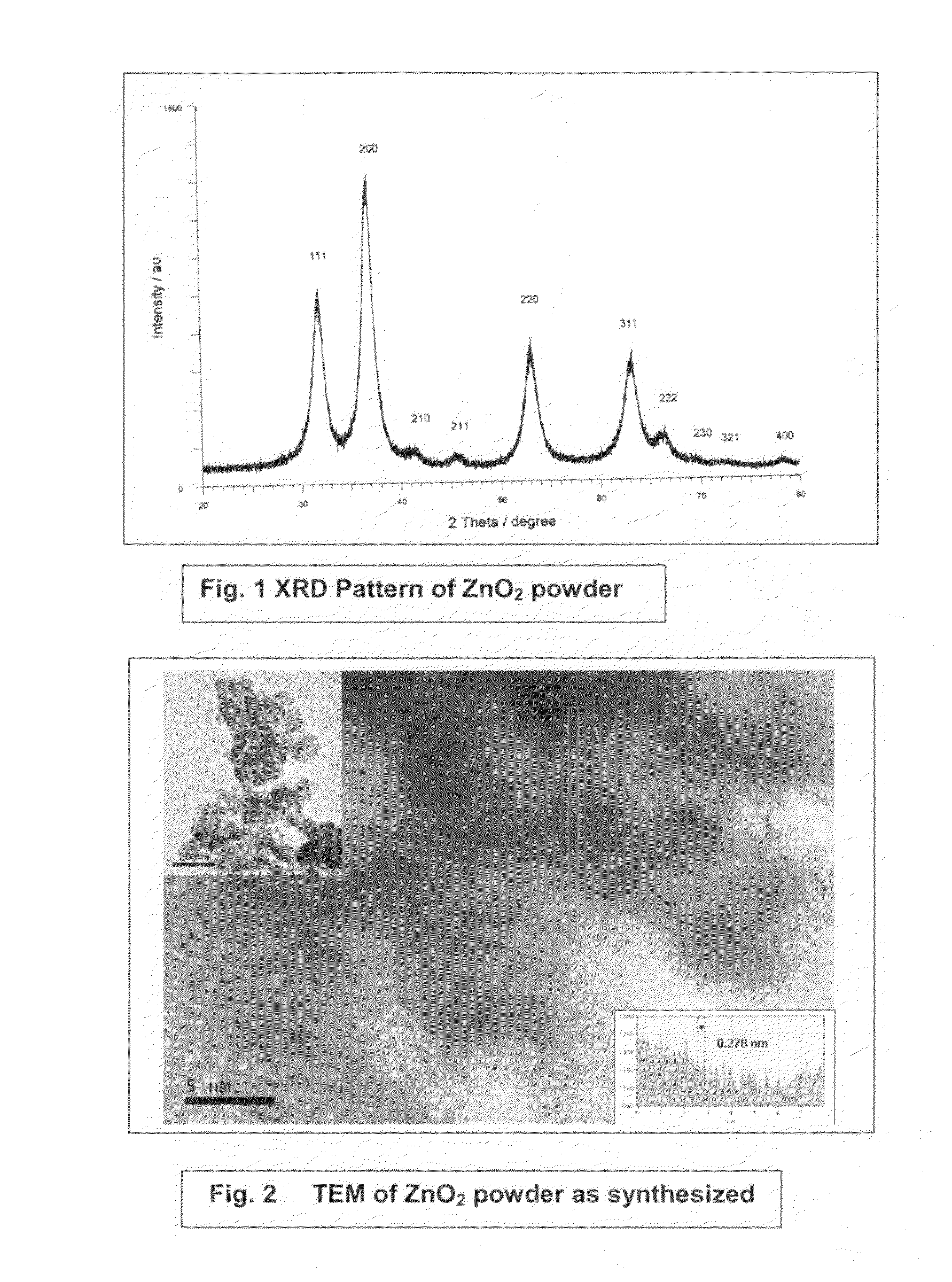

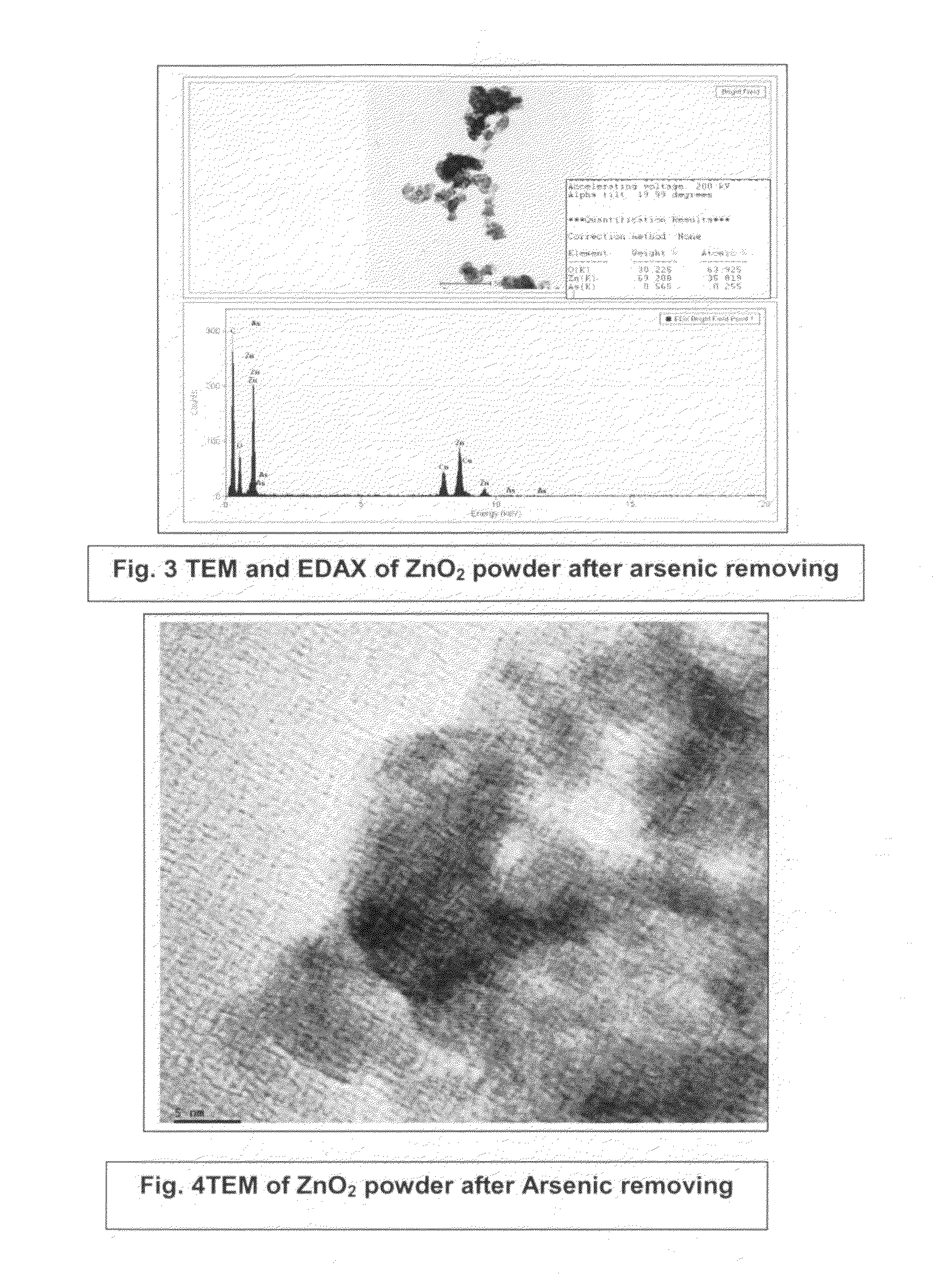

Process for the removal of arsenic and chromium from water

InactiveUS20110220577A1Low costSmall sizeMaterial nanotechnologyWater treatment compoundsZinc peroxideGlycerol

The present invention provides low cost and highly effective method for the removal of arsenic and Cr(III&VI) from contaminated water using zinc peroxide nanoparticles (20±5 nm) capped with glycerol / PVP / TEA upto the permissible range of drinking water. As Arsenic and chromium occurs naturally in the earth's crust. When rocks, minerals, and soil erode, they release arsenic and chromium into groundwater. Arsenic and chromium occurs naturally in varying amounts in groundwater in various parts of country from ppb level to ppm level. The average concentration of arsenic and chromium as per USEPA standard in drinking water it is 10 parts per billion and 0.05 ppm (50 ppb) respectively. In drinking water the level of chromium is usually low as well, but contaminated water may contain the dangerous Cr(III&VI). Although Cr(III) is an essential nutrient for humans and shortages may cause heart problems, disruptions of metabolisms and diabetes. But the uptake of too much Cr(III) can cause health effects as well, for instance skin rashes. Cr(VI) is known to cause various health effects Skin rashes, upset stomachs, respiratory problems, weakened immune systems, kidney and liver damage and lung cancer The persons who are drinking water having upto 50 ppb of arsenic and 0.05 ppm chromium over for many years could experience skin damage or problems with their circulatory system, and may have an increased risk of getting cancer. Keeping the above facts we developed a cost effective nanoparticles for the removal of Arsenic and Cr(III&VI) from potable water upto potable range.

Owner:COUNCIL OF SCI & IND RES

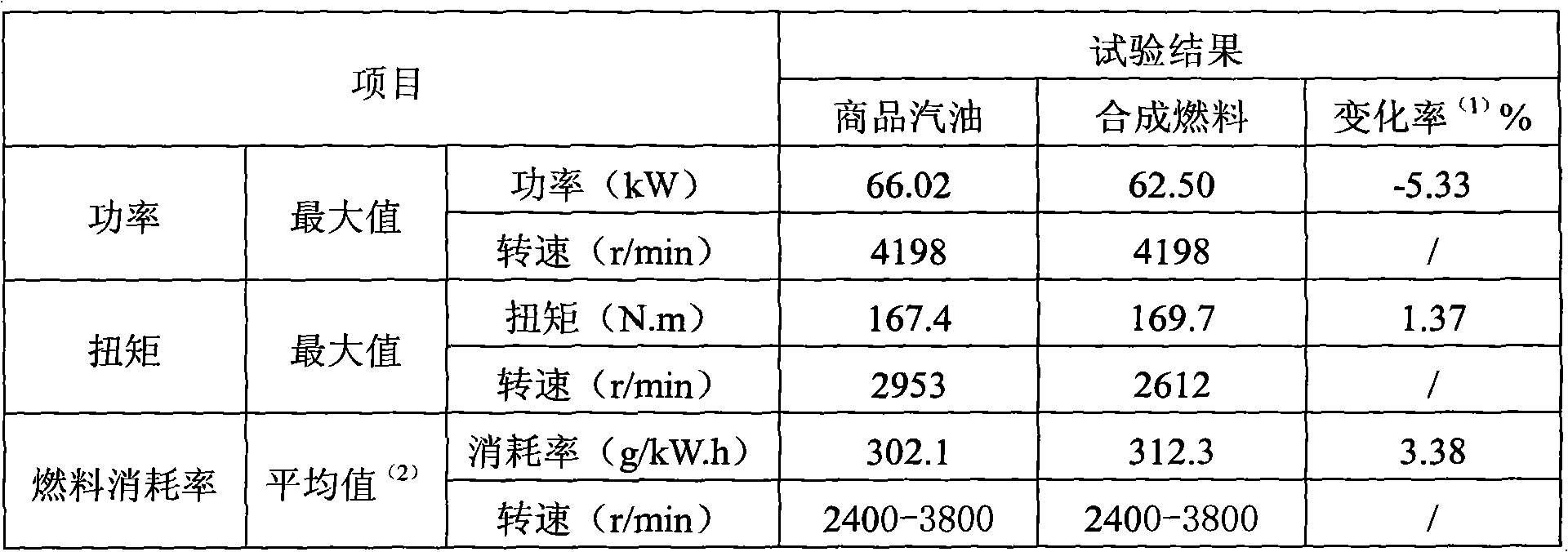

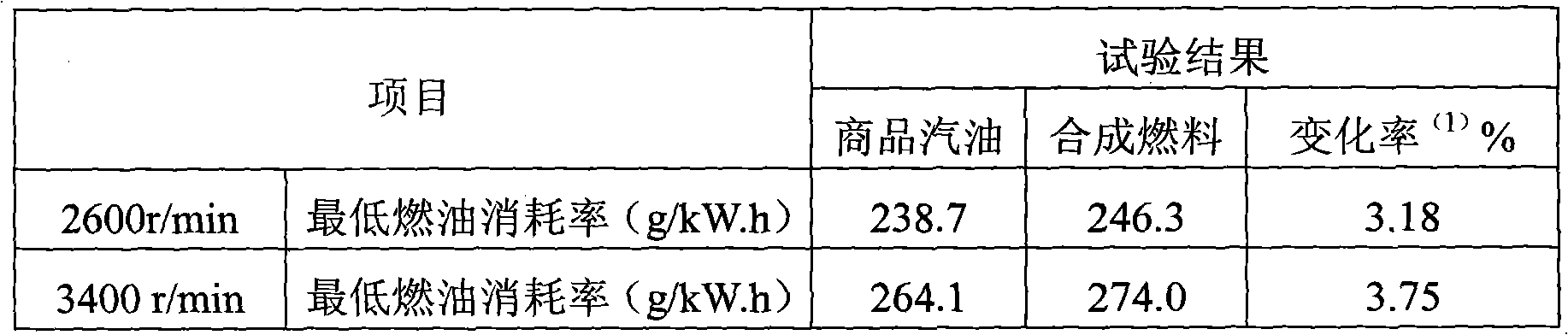

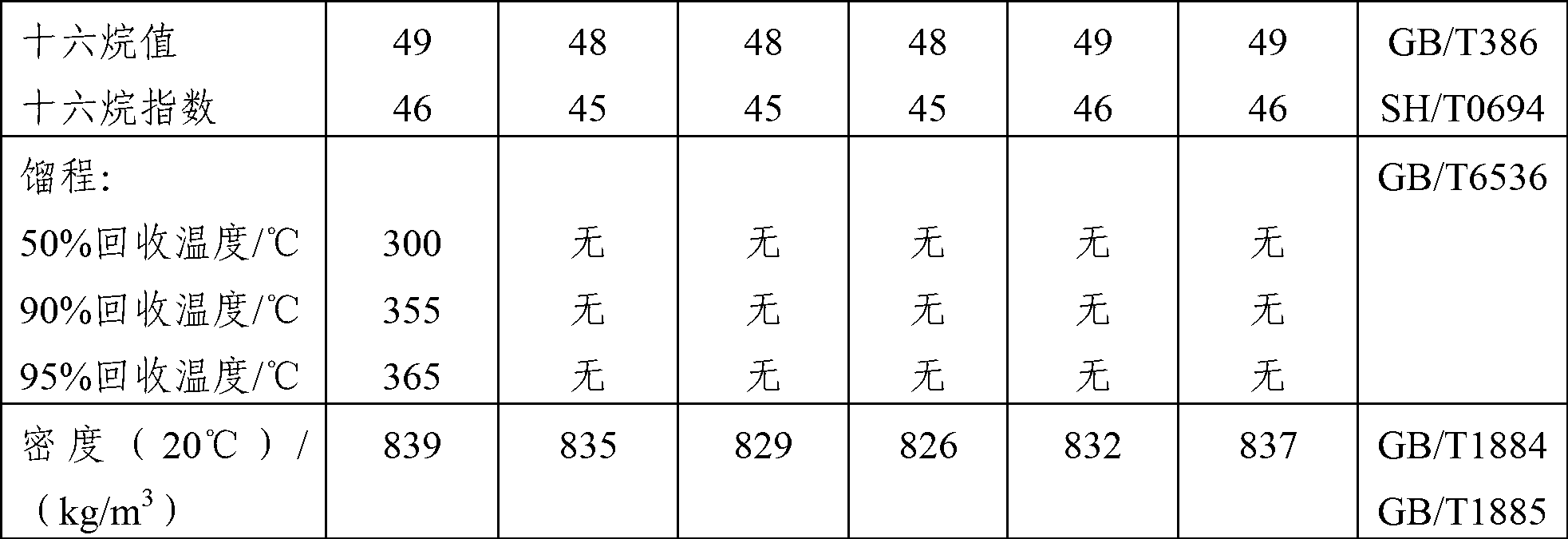

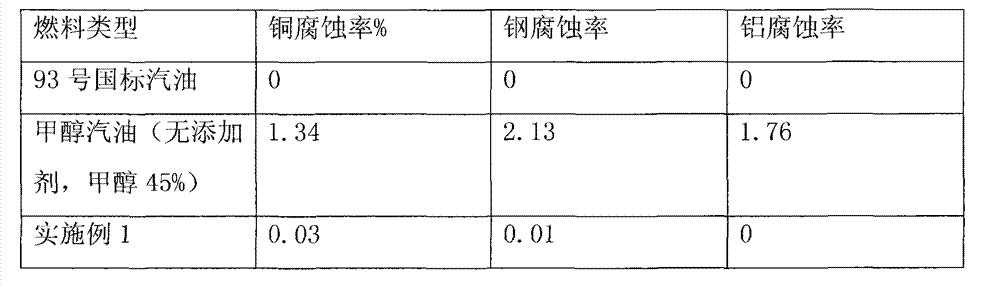

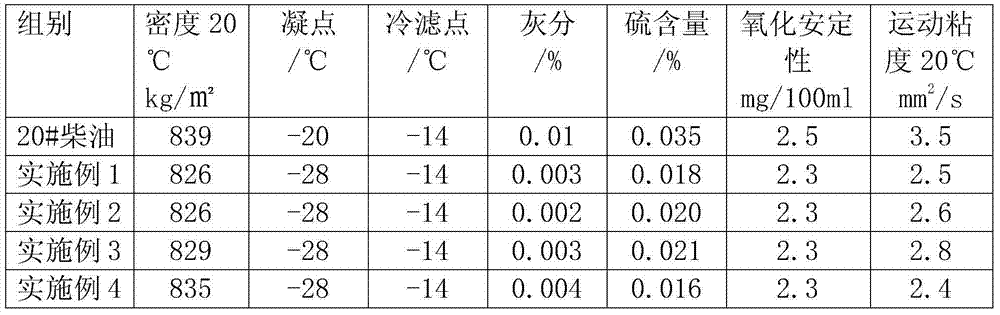

Synthetized diesel oil

This invention relates to synthetic diesel oil, which is produced by: (1) mixing isooctyl nitrate 30 wt.%, cyclohexylamine 30 wt.%, ferrocene 30 wt.%, and zinc peroxide 10 wt.% to obtain composite additive; (2) mixing fossil-grade diesel oil 10-40 parts and the composite additive 0.3-2 parts to obtain mother diesel oil; (3) mixing 200# solvent oil 10-30 parts and lightweight aviation kerosene 5-20 parts to obtain modified 200# solvent oil; (4) mixing fatty acid methyl ester or C9 10-60 parts, the mother diesel oil and the modified 200# solvent oil to obtain the synthetic diesel oil. The synthetic diesel oil has such advantages as low cost, simple process and abundant raw materials, and can be used for replacing standard fossil-grade diesel oil.

Owner:固安中德利华石油化学有限公司

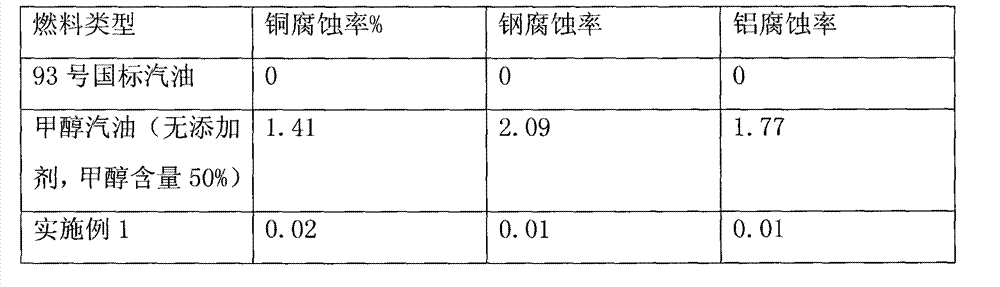

Methanol gasoline modified alcohol additive

InactiveCN101024788ASolve the problem of easy water absorptionDoes not reduce the use effectLiquid carbonaceous fuelsBenzoic acidZinc peroxide

The invention relates to a methanol gas oil modification alcohol additive that uses acetone, toluol, isobutyl alcohol, benzoic acid, ferrocene and zinc peroxide as raw material, and whisking equal in the volume under room temperature and normal pressure to gain the product. It adds 1-3% additive into methanol to gain modified mellow after whisking, and adding the mellow into naphtha or 90# diesel oil to gain the 90#, 93#, 97# and 98# methanol gas oil. The gas oil condensation point would be decreased by adjusting the methanol gas oil and the pollution would be sharply decreased. It has great social benefits and economic benefits.

Owner:北京福众金源环保科技有限公司

Viscosity Breaker for Polyacrylamide Friction Reducers

A well treating fluid useful in slickwater fracturing processes contains polyacrylamide friction reducer and a viscosity breaker capable of reducing the viscosity of the well treating fluid to about the viscosity of water at ambient temperatures of typical underground formations. The viscosity breaker is selected from the group consisting of hydrogen peroxide, calcium peroxide, magnesium peroxide, and zinc peroxide and is present in an amount above about 0.002% by weight.

Owner:SOLVAY USA

Methanol gasoline and its compounding process

InactiveCN1487060AReduce usageSolve the problem that mechanical stirring cannot be usedLiquid carbonaceous fuelsZinc peroxideMethyl tert-butyl ether

Methanol gasoline is compounded with lead-free gasoline 15-80 wt%, methanol 15-80 wt%, and acetone 1-10 wt%, and some of the following material(s) may be also added: zinc peroxide, ethyl ether, fat activitor, dimethoxy methane, methyl tert-butyl ether, ocatne and light gasoline. Methanol and gasoline are miscible, and using the methanol gasoline can obtain ever high driving force and 0.7-3.6% lowered oil consumption, and reduce CO in tail gas by over 95% and oxycarbide by over 85%. In addition, the methanol gasoline may be used with gasoline alternately.

Owner:季子善

Composite modifying alcohol ether fuel and catalytic fuel agent

InactiveCN1944596AImprove catalytic combustion efficiencyEmission reductionLiquid carbonaceous fuelsZinc peroxideCombustion

The composite modifying catalyst for alcohol-ether fuel is compounded with zinc peroxide 5-15 weigh portions, dimethyl carbonate 15-35 weigh portions, vat yellow GCN 5-15 weigh portions, cyclohexylamine 3-10 weigh portions, and isooctyl nitrate 15-30 weigh portions, and through mixing at normal temperature. The alcohol-ether fuel with the composite modifying catalyst may have great methanol adding ratio while ensuring the combustion efficiency, fuel consumption, dynamic performance and other indexes.

Owner:BEIJING QINGYANLIHUA GASOLINEEUM CHEM

Viscosity breaker for polyacrylamide friction reducers

A well treating fluid useful in slickwater fracturing processes contains polyacrylamide friction reducer and a viscosity breaker capable of reducing the viscosity of the well treating fluid to about the viscosity of water at ambient temperatures of typical underground formations. The viscosity breaker is selected from the group consisting of hydrogen peroxide, calcium peroxide, magnesium peroxide, and zinc peroxide and is present in an amount above about 0.002% by weight.

Owner:SOLVAY USA

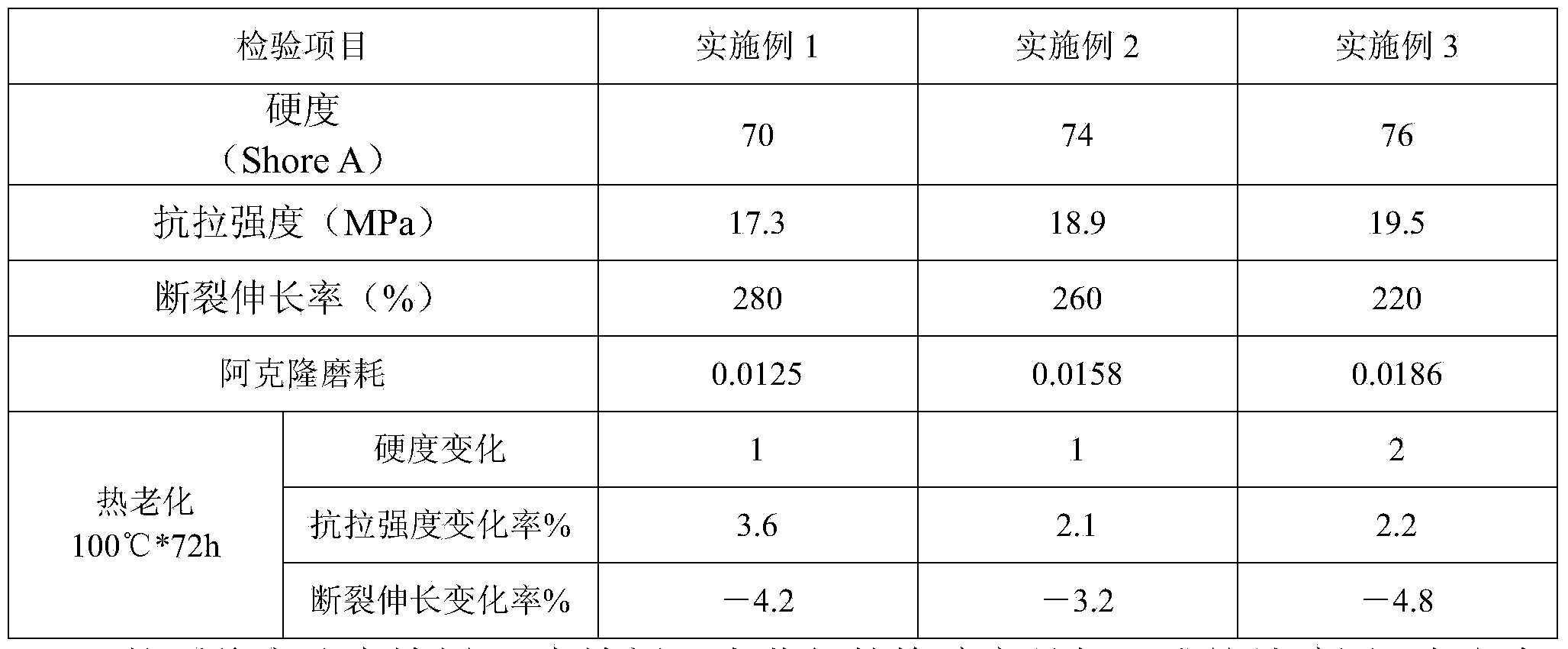

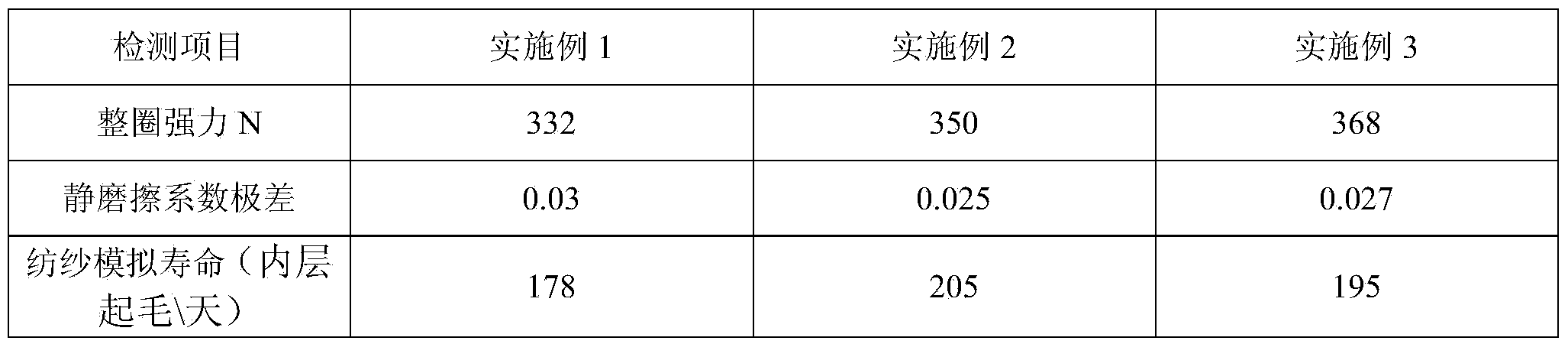

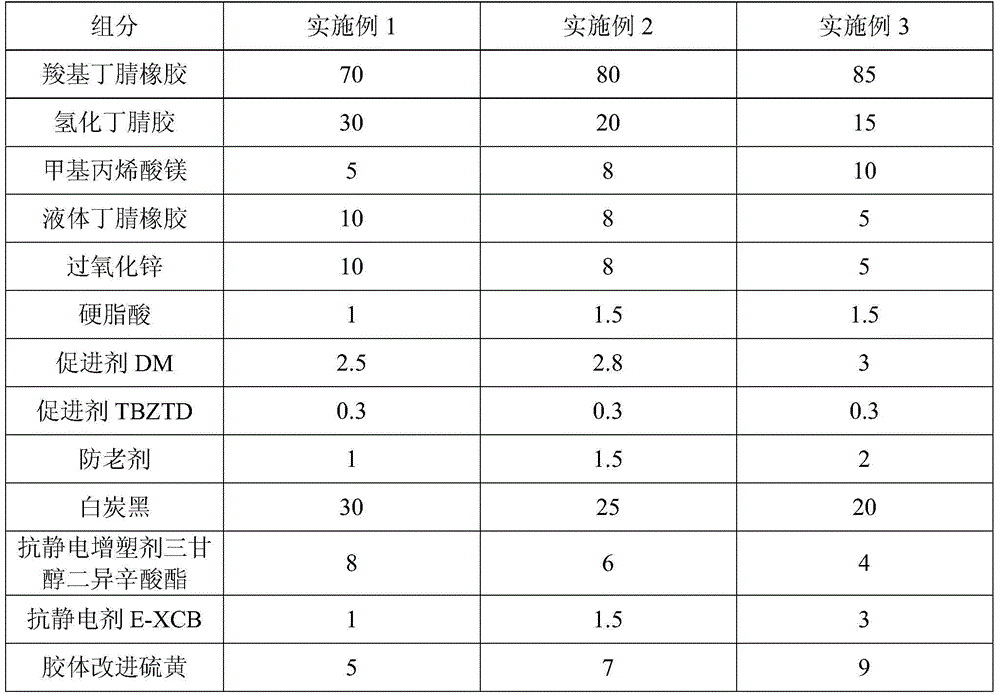

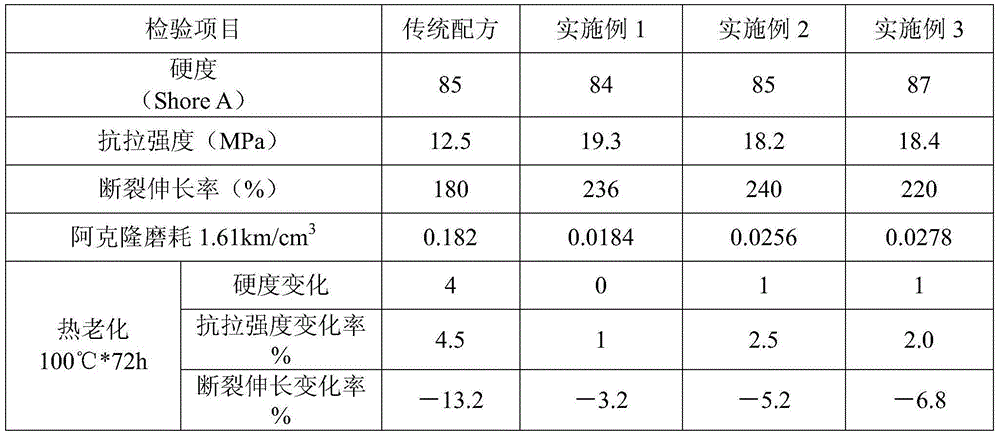

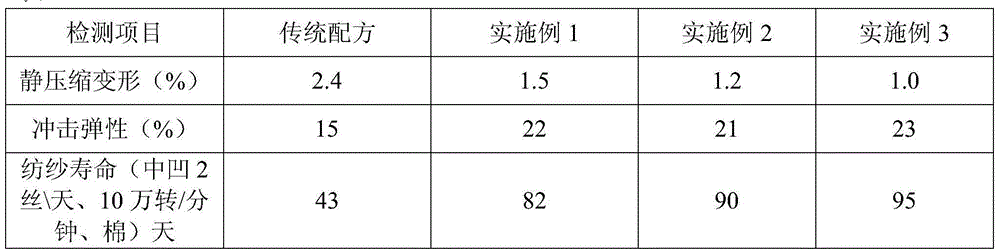

Vortex spinning rubber roll

ActiveCN103819770AImprove wear resistanceExtended service lifeDrafting machinesZinc peroxideNitrile rubber

The invention relates to a vortex spinning rubber roll; the spinning rubber roll comprises a roll core and a rubber composite material layer coating the roll core; the rubber composite material layer comprises the following raw constituent in parts by weight: 50-70 parts of hydrogenated nitrile-butadiene rubber, 30-50 parts of carboxy terminated nitrile rubber, 5-10 parts of phenolic resin, 8-15 parts of liquid nitrilo rubber, 1.5-2 parts of an accelerating agent H, 2.5 to 3 parts of an accelerating agent CZ, 0.3 part of an accelerating agent TMTD, 5-10 parts of zinc peroxide, 1-1.5 parts of stearic acid, 1-2 parts of an anti-aging agent, 4-10 parts of an antistatic plasticizer, 6-18 parts of a reinforcing agent, 1-2 parts of an antistatic agent, and 5-9 parts of a vulcanizing agent. The spinning rubber roll made by the formula provided by the invention can be applied to conditions of super draft and high-speed running; the spinning rubber roll has high wearing resistance and oil resistance, is antistatic at a high temperature and has a small rate of hardness change and a long service life.

Owner:WUXI NO 2 RUBBER

Production formula of high-abrasion high-draft high-speed spinning rubber ring

ActiveCN103819769AImprove wear resistanceImprove the lack of low strengthDrafting machinesRubber layered productsZinc peroxideRubber ring

The invention relates to a production formula of a high-abrasion high-draft high-speed spinning rubber ring which comprises an inner rubber composite material layer, an outer rubber composite material layer and a middle framework layer. the spinning rubber ring is characterized in that the inner and outer rubber composite materials are prepared from components of, by weight, 50-80 parts of carboxylated nitrile rubber, 20-50 parts of nitrile rubber, 30-60 parts of polyvinyl chloride 2500, 20-40 parts of EVM, 1.5-3 parts of a promoter MDB, 5-10 parts of zinc peroxide, 5 parts of titanium dioxide, 1.5 parts of stearic acid, 1-2 parts of an anti-aging agent, 10-15 parts of an antistatic plasticizer, 10-20 parts of a reinforcing agent and 4-8 parts of a vulcanizing agent. The spinning rubber ring prepared by the production formula can be applied under high-draft, high-pressure and high-speed running conditions, is oil resistant, has high abrasion resistance and has long service life.

Owner:WUXI NO 2 RUBBER

M50 clean environment-friendly petrol

The invention belongs to the technical field of fuels and discloses M50 clean environment-friendly petrol. The M50 clean environment-friendly petrol is formed by mixing the following components in percentage by weight: 50% of methanol, 0.5% of cerous nitrate, 0.5% of oleic acid, 0.5% of caster oil, 0.8% of isobutanol, 1% of n-butyl alcohol, 1% of alcohol, 1.5% of tributyl phosphate, 2% of methyl tert-butyl ether, 0.6% of borneol, 1.2% of ethyl nitroacetate, 0.2% of aluminum phosphate,, 1.2% of tetrahydrofuran, 1.5% of polyvinyl alcohol, 0.8% of acetone, 0.6% of butanone, 1.0% of benzene, 0.5% of 2,4-dimethyl aniline, 0.3% of zinc peroxide, 0.8% of alkanolamide, 1% of cyclohexane, 32.375% of 93# petrol, 0.05% of benzotriazole and 0.075% of T501 antioxidant. The M50 clean environment-friendly petrol disclosed by the invention is better in performance parameters, and environment-friendly and clean.

Owner:QIDONG CHUANGLYU GREENING ENG CO LTD

Preparation method of long-acting, anti-bacterial and mould-proof cotton fabric

InactiveCN107354716AImprove bindingImprove bonding fastnessVegetal fibresZinc peroxideAntibacterial activity

The invention relates to a preparation method of long-acting, anti-bacterial and mould-proof cotton fabric. The preparation method is implemented through steps as follows: firstly, aminated modified nano-ZnO is prepared from nano-ZnO and a silane coupling agent KH-550 as raw materials with a chemical modification method, a silver nitrate and trisodium citrate aqueous solution is added to the system, and an Ag / ZnO nano-composite antibacterial agent is prepared with a chemical reduction method; cotton fabric is subjected to epoxidation pretreatment with alkali liquor with concentration being 5%-8% and epichlorohydrin; finally, the Ag / ZnO nano-composite antibacterial agent is applied to anti-bacterial and mould-proof finish of the cotton fabric. Under the synergistic effect of Zn ion dissolution of ZnO, photocatalytic activity and broad-spectrum antibacterial activity of nano-Ag, broad-spectrum efficiency of the antibacterial agent is improved, certain mould-proof performance on aspergillus niger is realized, and long-lasting action of anti-bacterial and mould-proof performance of the cotton fabric is improved through covalent bonding between amino groups on the surface of the nano-composite antibacterial agent and epoxy groups on the surface of the pretreated cotton fabric. The preparation method of the long-acting, anti-bacterial and mould-proof textiles is simple and environment-friendly.

Owner:SHAANXI UNIV OF SCI & TECH

Modified methanol and preparation method thereof

InactiveCN102051236AImprove catalytic combustion efficiencyEmission reductionLiquid carbonaceous fuelsZinc peroxideCresol

The invention relates to modified methanol. The modified methanol is prepared from the following components in part by weight: 80 to 90 parts of methanol and 3.16 to 15.38 parts of methanol modified additive; and the methanol modified additive is prepared from the following components in part by weight: 50 to 90 parts of isopropanol, 3 to 20 parts of cyclohexane, 5 to 10 parts of aviation kerosene No.1, 0.1 to 0.9 part of zinc peroxide, 1 to 10 parts of dimetyl carbonate, 4 to 15 parts of isooctyl nitrate, 3 to 10 parts of fatty acid methyl ester, and 0.1 to 0.9 part of 2,6-di-tert-butyl-4-methylpenol. The invention has the advantages that: the cyclohexane and the 2,6-di-tert-butyl-4-methylpenol are compounded, so that the modified methanol has high corrosion resistance and swelling resistance; the isopropanol and the fatty acid methyl ester are compounded, so that the water resistance of vehicle methanol gasoline is improved by more than two times; surfactant fatty acid methyl ester, the fatty acid methyl ester and the isopropanol are compounded, so that the added methanol and fossil gasoline can be mutually dissolved according to any proportion, and the problems of low-temperature layering and emulsification layering of the methanol gasoline are solved thoroughly; and the aviation kerosene No.1 is added so as to solve the problem of low-temperature cold boot of the methanol gasoline.

Owner:北京校产企联科技有限公司

Method and composition for preventing tooth hypersensitivity when using passive bleaching agents

InactiveUS20070065376A1Avoid allergiesLonger contact/coating periodCosmetic preparationsToilet preparationsZinc peroxidePotassium nitrate

Dental bleaching compositions, for example in the form of liquids, gels, creams, pastes and ointments, comprising a peroxide releasing compound and from 1% to 35% by weight of a potassium-containing compound such as potassium nitrate, wherein the potassium nitrate is present in a safe and effective amount to prevent tooth hypersensitivity in the patient during the bleaching process. The potassium nitrate contemplated by the invention is compatible with peroxide yielding bleaching compounds such as peroxide, carbamide peroxide, calcium peroxide, zinc peroxide, magnesium peroxide and sodium perborate. Potassium nitrate is complimentary and synergistic with the peroxide bleaching agents contemplated by the invention and enhances the release of oxygen to the tooth enamel. Also contemplated are methods of bleaching teeth comprising application of the dental bleaching compositions of the invention.

Owner:HODOSH MILTON

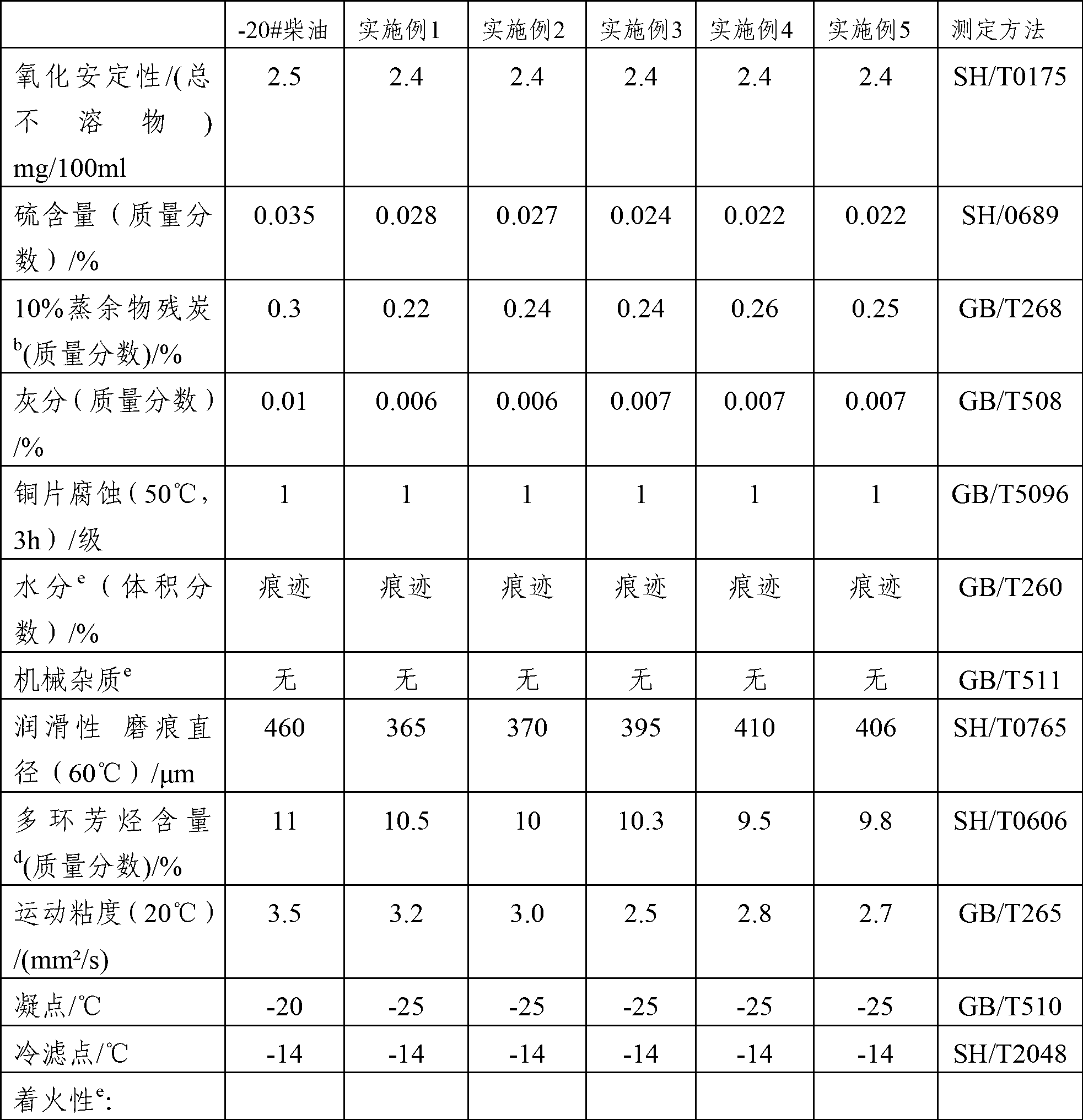

Methanol diesel oil and preparation method thereof

InactiveCN103013590APromote mutual solubilityEnhancement of miscible propertiesLiquid carbonaceous fuelsZinc peroxideSolvent

The invention relates to methanol diesel oil which comprises methanol, diesel oil, fatty acid, petroleum acid, cosolvent, aviation kerosene, a cetane number improver and zinc peroxide. The invention further relates to a preparation method of the methanol diesel oil. According to the methanol diesel oil, the content of methanol in a system is greater, the methanol diesel oil has better mutual solubility with fossil diesel oil, the performance of the methanol diesel oil is improved obviously, and the methanol diesel oil can serve as -20# diesel oil for use, and is safe, environment-friendly and low in raw materials cost. The preparation method is simple in step, mild in condition and suitable for large-scale industrial production.

Owner:BEIJING QINGYANLIHUA GASOLINEEUM CHEM

M45 novel energy high-cleanness environment-friendly petrol

The invention belongs to the technical field of fuels and discloses M45 novel energy high-cleanness environment-friendly petrol. The M45 novel energy high-cleanness environment-friendly petrol is prepared from the following components: methanol, 93# national-standard petrol, oleic acid, tea oil, isobutanol, n-butyl alcohol, alcohol, tributyl phosphate, methyl tert-butyl ether, borneol, ethyl nitroacetate, aluminum phosphate, tetrahydrofuran, polyvinyl alcohol, acetone, butanone, benzene, 2,4-dimethyl aniline, zinc peroxide, alkanolamide, cyclohexane, benzotriazole and T501 antioxidant. The environment-friendly petrol disclosed by the invention is high in octane number, environment-friendly and clean, and low in tail gas pollutant.

Owner:色彩传奇(北京)国际日化有限公司

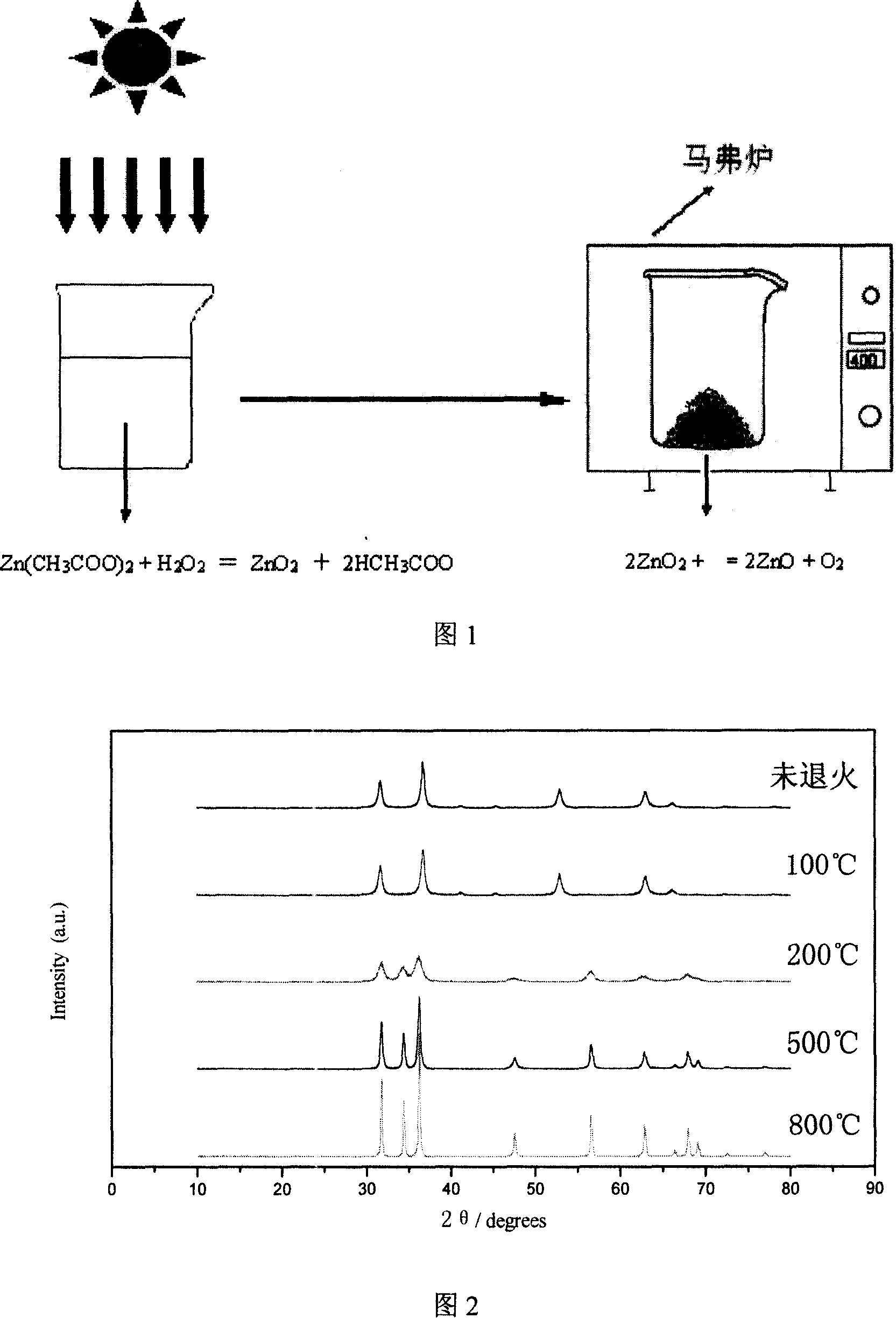

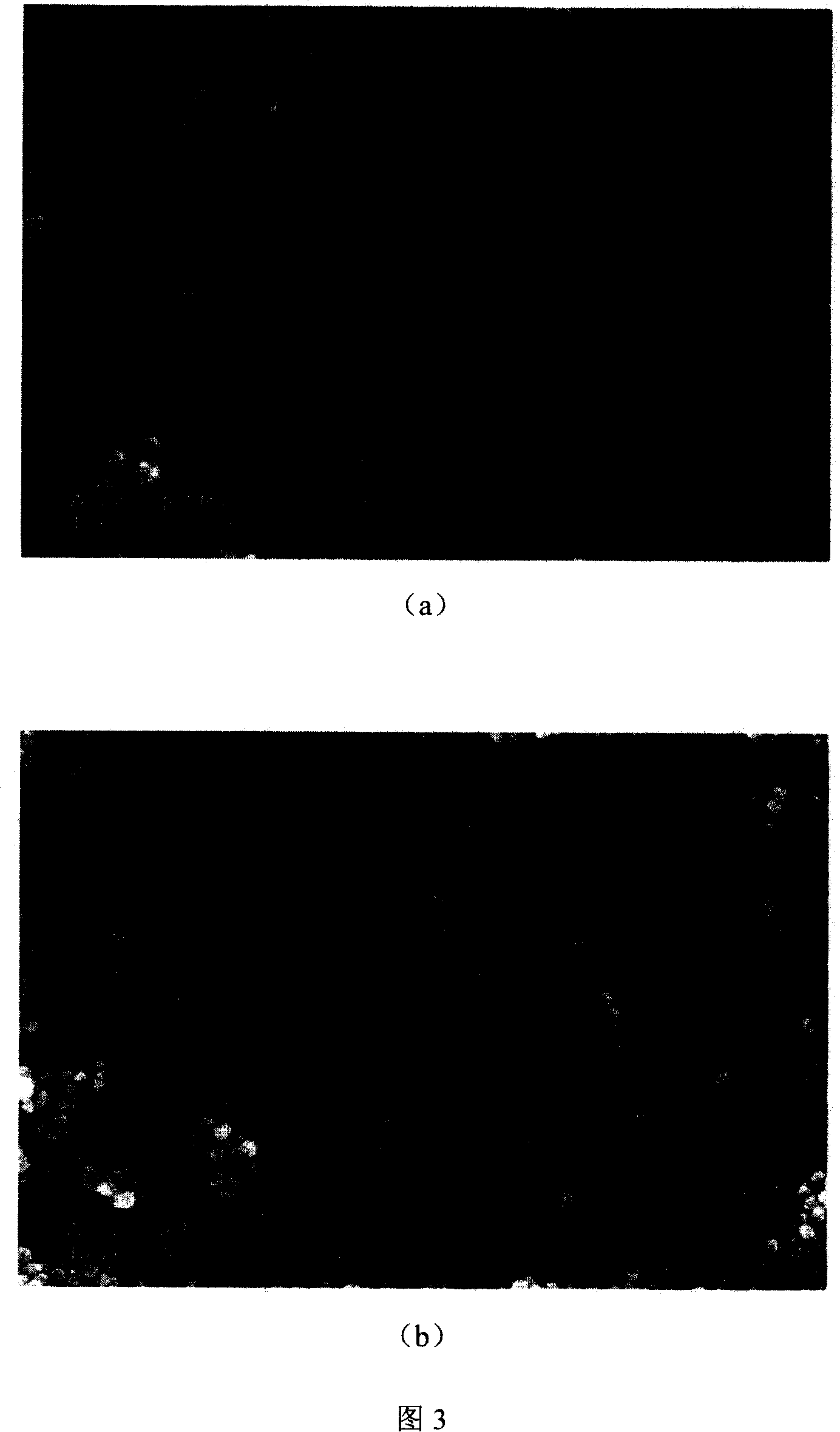

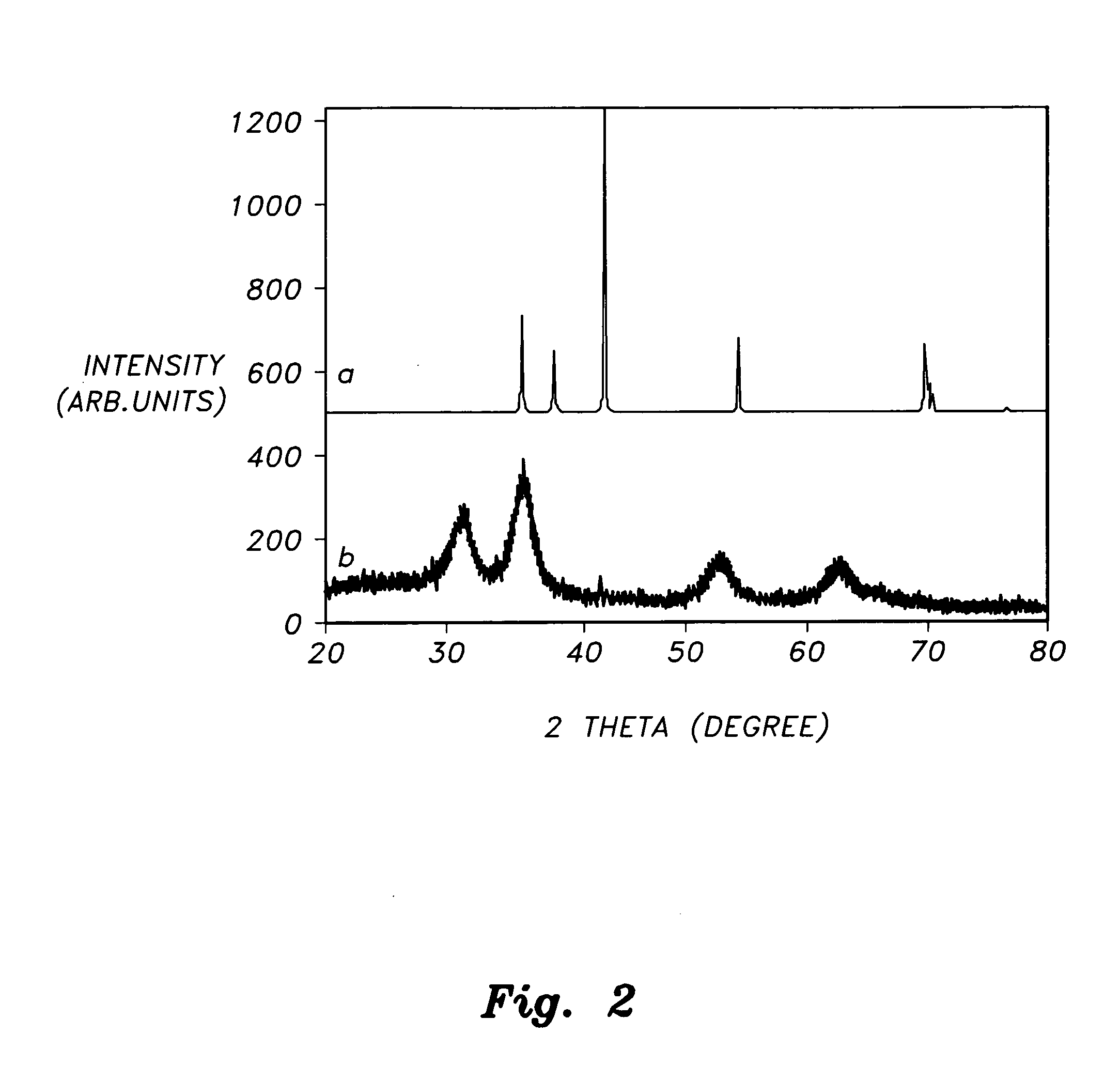

Method for producing nano zinc peroxide and zinc oxide by using solar

InactiveCN101152957AImprove stabilityHigh purityZinc oxides/hydroxidesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesZinc peroxideRoom temperature

The present invention provides a method preparing zinc peroxide and zinc oxide using solar energy. The zinc acetate and hydrogen peroxide are chosen to be material. The zinc acetate is dissolved in a mixture of hydrogen peroxide and deionized water. A white sol is obtained by reaction under sunlight illumination. The white sol is dried and a buff powder which is zinc peroxide powder is obtained. Then the powder is annealed in high temperature and a white zinc oxide powder is obtained. Through controlling pH value of the sol and reaction time, nanometer grain of zinc peroxide and zinc oxide which are provided with grain-controlled, good dispersivity, high purity and high crystallinity are obtained. Preparation method of the present invention is simple in process, easy in operating, mild in reaction condition and can be completed at room temperature, which has the advantages of energy-saving and environmental friendly.

Owner:BEIHANG UNIV

Water-based inorganic negative ion coating and preparation method thereof

ActiveCN105602302AHigh generation of negative ionsHigh hardnessAlkali metal silicate coatingsZinc peroxideOrganic solvent

The invention provides an inorganic negative ion coating and a preparation method thereof. Special mica powder is added to a coating formula, so that the aims of releasing negative ions and not generating radiological hazards are achieved. Meanwhile, a sodium silicate solution is modified through zinc oxide and an organic silicon solution, so that a coating film has super-strong adhesion and hardness, fireproof and flame-retardant properties, water resistance, stability and high temperature resistance. The obtained coating does not contain an organic solvent or other toxic or harmful substance and is an environment-friendly product.

Owner:四川弘达瑞涂料科技有限公司

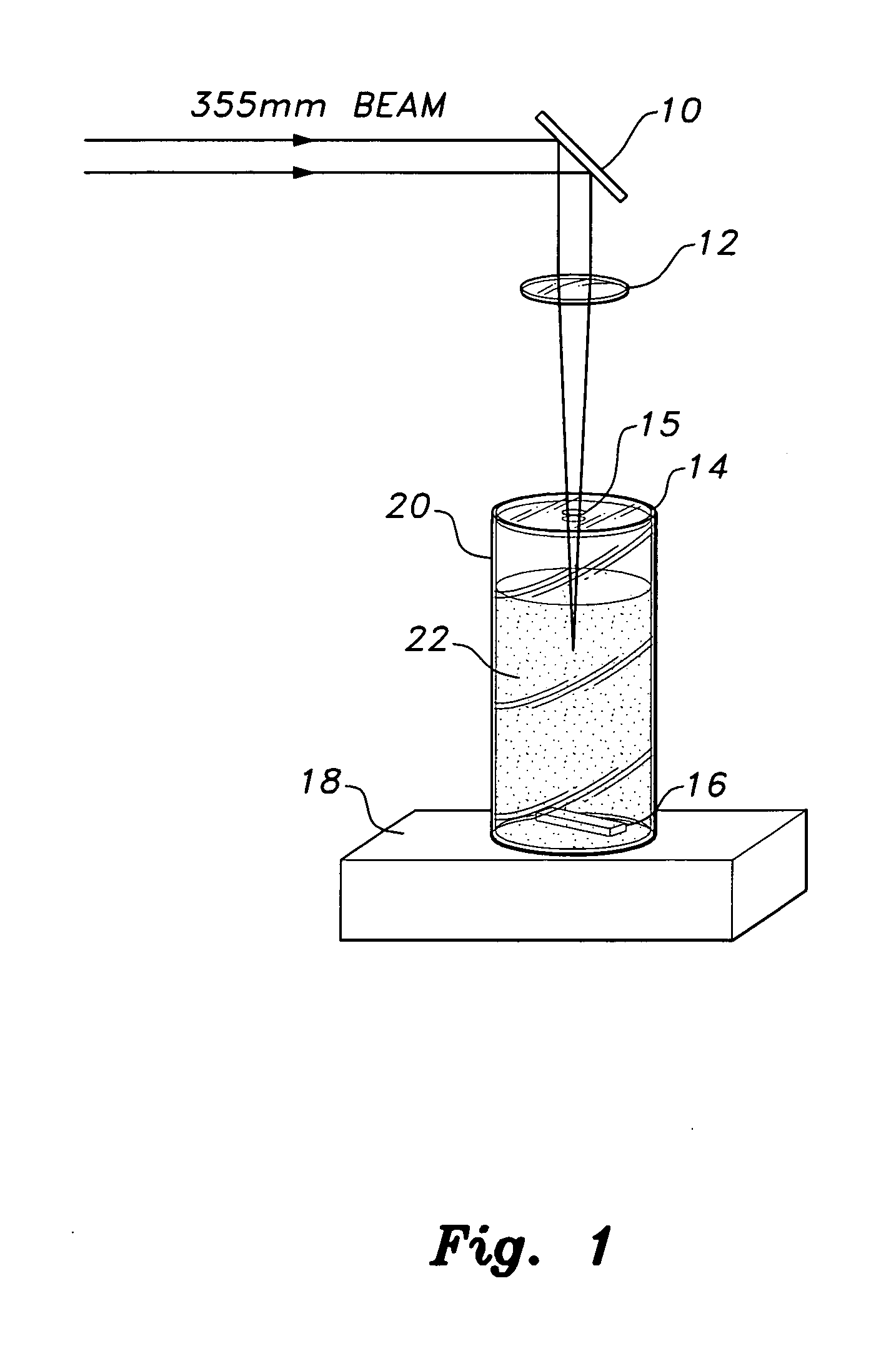

Method of forming zinc peroxide nanoparticles

The method for detection of cyanide in water is a method for the detection of a highly toxic pollutant, cyanide, in water using ZnO2 nanoparticles synthesized locally by an elegant Pulsed Laser Ablation technique. ZnO2 nanoparticles having a median size of 4 nm are synthesized from pure zinc metal target under UV laser irradiation in a 1-10% H2O2 environment in deionized water. The synthesized ZnO2 nanoparticles are suspended in dimethyl formamide in the presence of Nafion, and then ultrasonicated to create a homogenous suspension, which is used to prepare a thin film of ZnO2 nanoparticles on a metal electrode. The electrode is used for cyanide detection.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Diesel cetane number improver

InactiveCN102876425AReduce fuel consumptionAlleviate resource constraintsLiquid carbonaceous fuelsFuel additivesZinc peroxideNitrate

The invention relates to a diesel cetane number improver which comprises 5-20% of zinc peroxide, 15-40% of dimethyl carbonate, 5-20% of vat yellow, 3-15% of cyclohexylamine and 15-45% of isooctyl nitrate. The product provided by the invention can enhance the cetane number of petrochemical diesel, and add the catalytic combustion function to the diesel, thereby implementing the dual purposes of car power enhancement and fuel saving.

Owner:ZHENGZHOU GUOCHUANG ENERGY TECH

Coating additive for waterborne coating

InactiveCN106280666AImprove thixotropyHigh glossAntifouling/underwater paintsPaints with biocidesZinc peroxideUltraviolet

The invention discloses a coating additive for a waterborne coating. A formula of the coating additive for the waterborne coating comprises raw materials as follows: 20-25 parts of a substrate wetting agent, 5-15 parts of a dispersing agent, 10-25 parts of a defoaming agent, 6-12 parts of a thickening agent, 5-10 parts of a coalescing agent, 10-15 parts of nano zinc peroxide, 8-15 parts of an ultraviolet absorbent agent, 10-22 parts of an inorganic antibacterial agent, 12-16 parts of a mold inhibitor and 2-10 parts of a surfactant. The coating additive for the waterborne coating adopts a simple formula and has effects of mold prevention, bacteria killing, oxidation resistance and ultraviolet resistance; besides, the prepared finished product has a good anti-corrosion effect, and the thixotropy and the glossiness of the coating are improved.

Owner:WUHAN ZHIFU ENTERPRISE MANAGEMENT CONSULTING CO LTD

Methanol diesel fuel

InactiveCN104232180ANo stratificationStrong resistance to water phaseLiquid carbonaceous fuelsZinc peroxideFatty acid glycerol esters

The invention discloses methanol diesel fuel. The methanol diesel fuel comprises the following components in parts by weight: 10 to 30 parts of methanol, 40 to 70 parts of diesel fuel meeting national standard, and 15 to 30 parts of diesel fuel additive; the diesel fuel additive comprises the following components in parts by weight: 5 to 13 parts of diethyl phthalate, 1 to 10 parts of zinc peroxide, 0.01 to 0.03 part of ferrocene, 5 to 15 parts of polyoxymethylene dimethyl ethers, 15 to 35 parts of petroleum acid, 3 to 9 parts of ethyl formate, 5 to 15 parts of isooctyl nitrate, and 10 to 25 parts of fatty acid glyceri. The methanol diesel fuel is stable in performance, high in resistance to water phase, free of emulsifying and layering, relatively high in cetane number, full of power when in use, low in sulphur content, and meets the environmental protection by exhaust emission.

Owner:东奇能源技术有限公司

Anti-aging sunshine fabric

InactiveCN106400155ANot easy to ageProtective fabricsMonocomponent halogenated hydrocarbon artificial filamentGlass fiberZinc peroxide

The invention relates to an anti-aging sunshine fabric. The anti-aging sunshine fabric is prepared from, by weight, 100 to 150 parts of PVC, 1 to 10 parts of a plasticizer, 20 to 30 parts of glass fiber, 10 to 20 parts of an anti-aging agent, 1 to 5 parts of zinc peroxide, 1 to 10 parts of a surfactant, and 10 to 30 parts of a filling agent.

Owner:PHIFER INC

Automobile synthetic diesel oil and preparation method thereof

InactiveCN101643671ALow costImprove securityLiquid carbonaceous fuelsFuel additivesChemical synthesisZinc peroxide

The invention relates to an automobile synthetic diesel oil and a preparation method thereof, belonging to the technical field of synthetic chemical fuel. The synthetic gasoline contains methyl alcohol, methylbenzene, stearic acid, fatty acid methyl ester, potassium chlorate, zinc peroxide, nitromethane, cyclohexane, glyceride, octane number regulator and xylidine. The automobile synthetic dieseloil has the characteristics of good volatility and stability, high calorific value, no carbon deposit, low cost, etc, thus completely achieving the properties of the existing diesel oil and being an ideal substitute product.

Owner:徐宏远

Rotor spinning rubber roller

ActiveCN104448448AImproved anti-static winding effectImprove quality stabilityDrafting machinesChemical treatmentZinc peroxide

The invention relates to a rotor spinning rubber roller which comprises a roller core and a rubber composite material layer wrapping the roller core. The rubber composite material layer comprises, by weight, 70-80 parts of carboxyl acrylonitrile-butadiene rubber, 15-30 parts of hydrogenated acrylonitrile-butadiene rubber, 5-10 parts of magnesium methylacrylate, 5-10 parts of liquid acrylonitrile-butadiene rubber, 4-8 parts of antistatic plasticizing agents, 2-3 parts of promoting agent DM, 0.2-0.4 part of promoting agent, 5-10 parts of zinc peroxide, 1-1.5 parts of stearic acid, 1-2 parts of anti-aging agents, 20-30 parts of reinforcing agents, 1-3 parts of functional aids and 5-9 parts of vulcanizing agent. The manufactured rotor spinning rubber roller can be applied to high-speed operation conditions larger than one hundred thousand revolutions per minute, the surface of the rotor spinning rubber roller does not need to be chemically treated, and the rotor spinning rubber roller can be used and is antistatic under high-speed and high-temperature conditions, small in hardness change rate, resistant to abrasion and oil and long in service life.

Owner:WUXI NO 2 RUBBER

Antibacterial fabric and production method thereof

The invention discloses an antibacterial fabric and a production method thereof. The antibacterial fabric is made from, by weight, 20-30 parts of polyethylene, 50-80 parts of ethyl acrylate, 20-30 parts of glass fiber, 10-20 parts of zinc peroxide, 5-10 parts of nano-montmorillonite, 13-18 parts of vinyl acetate, 20-30 parts of methyl acrylate, and 10-20 parts of surfactant. The production method includes: mixing well and heating to melt the polyethylene, the ethyl acrylate, the glass fiber, the zinc peroxide, the nano-montmorillonite, the vinyl acetate and the methyl acrylate, adding the surfactant, mixing well, extruding with a spinneret plate to form fibers, and weaving the fibers into the fabric. Total bacterial count of the antibacterial fabric is 40-58 / cm<2>, while the total bacterial count of the prior fabric is up to 210-220 / cm<2>; accordingly, the antibacterial fabric has good antibacterial property.

Owner:JOES HOME TEXTILE CO LTD

High-performance formaldehyde adsorbent and preparation method thereof

InactiveCN108745293ALarge specific surface areaImprove purification efficiencyGas treatmentOther chemical processesZinc peroxideThermal insulation

A high-performance formaldehyde adsorbent is prepared from components in parts by weight as follows: 60-80 parts of modified activated carbon, 15-30 parts of sepiolite, 10-20 parts of zeolite, 5-10 parts of microcrystalline cellulose, 10-20 parts of diatomaceous earth, 15-30 parts of a polyethylene polyamine polymer, 1-4 parts of polyethylene glycol, 0.5-2 parts of nano-titania and 0.5-2 parts ofnano-zinc peroxide. A preparation method of the high-performance formaldehyde adsorbent comprises the following steps: the polyethylene polyamine polymer and polyethylene glycol are mixed, deionized water is added for dilution, and a solution a is obtained; then the modified activated carbon, the sepiolite, the zeolite, microcrystalline cellulose, the diatomaceous earth, nano-titania and nano-zincperoxide are added to the solution a, and a thermal insulation reaction is performed; vacuum drying is performed, and the adsorbent is obtained. The prepared high-performance formaldehyde adsorbent has excellent formaldehyde removal performance, and tests prove that formaldehyde degradation rate of the formaldehyde adsorbent within 24 h reaches 99% or higher.

Owner:ANHUI KEPU ENVIRONMENT TECH CO LTD

A metal cleaning agent and a preparation method thereof

The invention discloses a metal cleaning agent and a preparation method thereof. The metal cleaning agent comprises following raw materials by weight: 8-10 parts of sodium dodecylbenzenesulfonate, 2-6 parts of sodium hydrogen carbonate, 10-12 parts of magnesium carbonate, 4-6 parts of trisodium phosphate, 2-9 parts of zirconium oxychloride, 5-10 parts of butyl stearate, 10-15 parts of propylene glycol, 20-22 parts of ethylene oxide, 10-20 parts of zinc peroxide and 30-40 parts of water. Dirt on metal surfaces and other dirt difficult to remove can be easily removed by the metal cleaning agent provided by the invention. Cleaned metals can maintain rustless for 30 days when being exposed in the air. In addition, the metal cleaning agent is low in cost.

Owner:上海兆立纸业发展有限公司

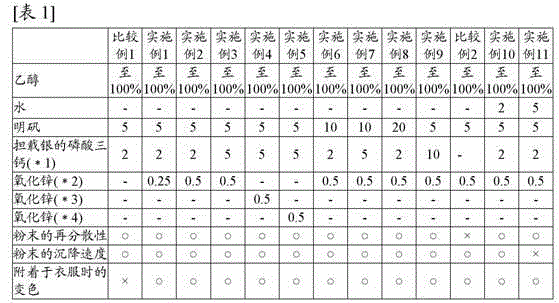

External preparation for skin

ActiveCN104968322APrevent discolorationReduce discolorationCosmetic preparationsToilet preparationsZinc peroxideDeodorant

The present invention is an external preparation for the skin, which is characterized by containing silver-supported tricalcium phosphate, alum and zinc oxide. The purpose of the present invention is to provide an external preparation for the skin, which is capable of suppressing discoloration of clothes by means of zinc oxide in cases where the external preparation for the skin gets on the clothes, said external preparation for the skin being obtained by combining silver-supported tricalcium phosphate that serves as a deodorant and alum that serves as an antiperspirant.

Owner:SHISEIDO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com