Patents

Literature

75 results about "Xylidine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

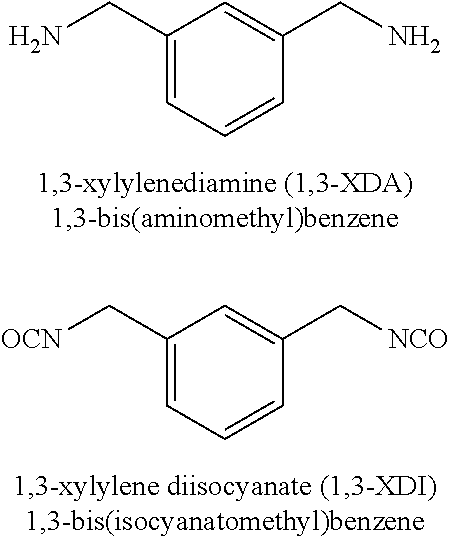

Xylidine can refer to any of the six isomers of xylene amine, or any mixture of them. The chemical formula of xylidines is C₈H₁₁N or, more descriptively, (CH₃)₂C₆H₃NH₂. The CAS number for the isomer mixture is 1300-73-8. They are colorless solids or liquids, although commercial samples can appear yellow or darker. They are miscible with ethanol and diethyl ether and slightly soluble in water. Xylidines are used in production of pigments and dyestuffs, and various antioxidants, agrochemicals, pharmaceuticals, hypergolic propellants, and many other organic chemicals.

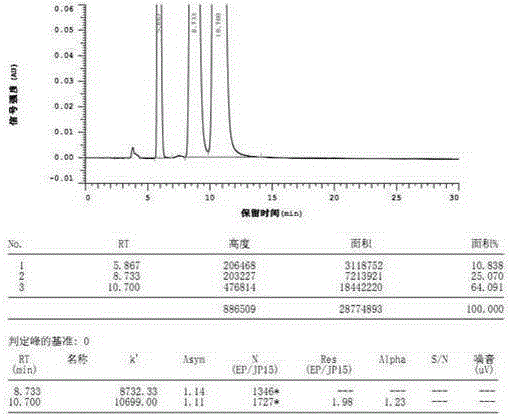

Separation method of edoxaban and isomers thereof

The invention provides a method for separating and purifying edoxaban by chromatography. The separation method is chromatography, and the chromatographic conditions are as follows: the filler is an amylose-tri(3,5-xylylcarbamate) bonded silica gel, and the mobile phase is selected from a mixed solution comprising a non-polar solvent and a polar solvent. By selecting the chromatographic conditions, the edoxaban and seven enantiomers and nonenantiomers thereof can be simultaneously separated, and thus, the method has the characteristics of high speed, high simpleness, high efficiency and the like.

Owner:北京康派森医药科技有限公司

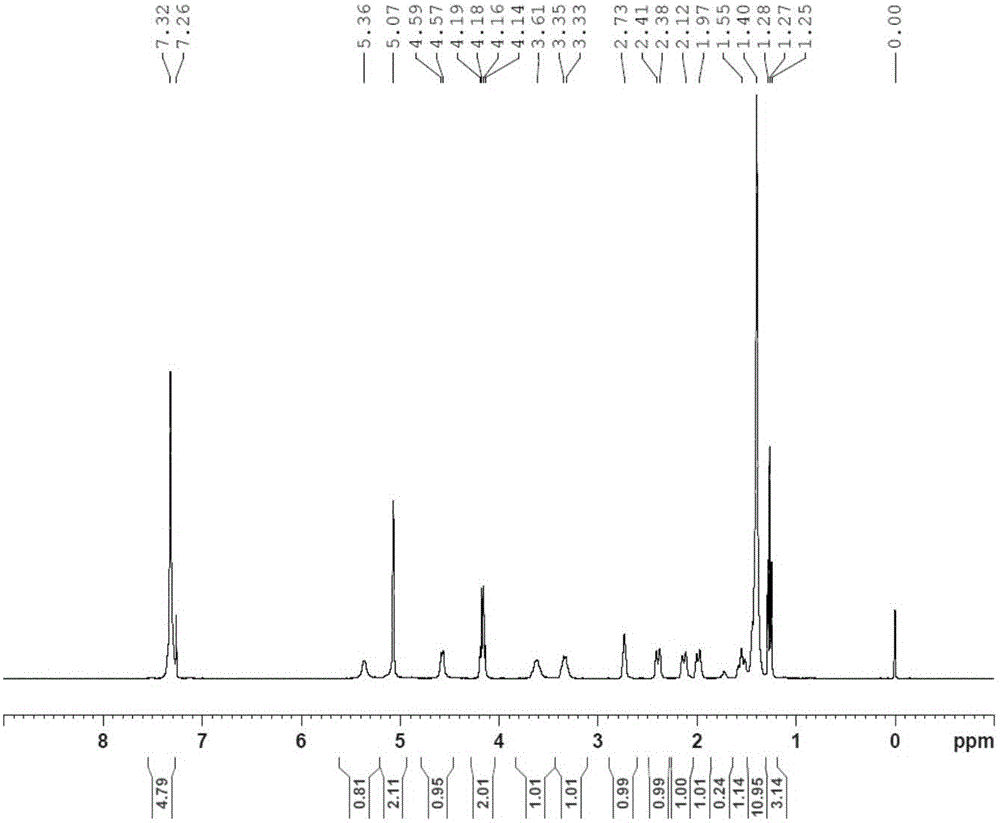

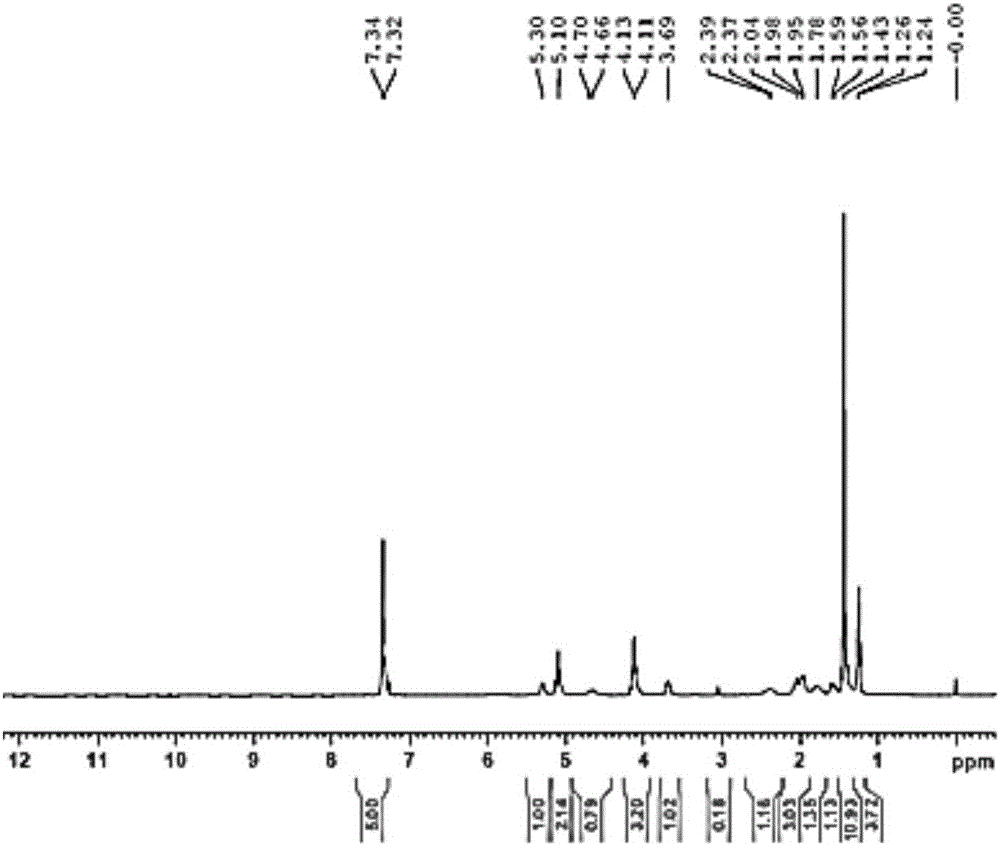

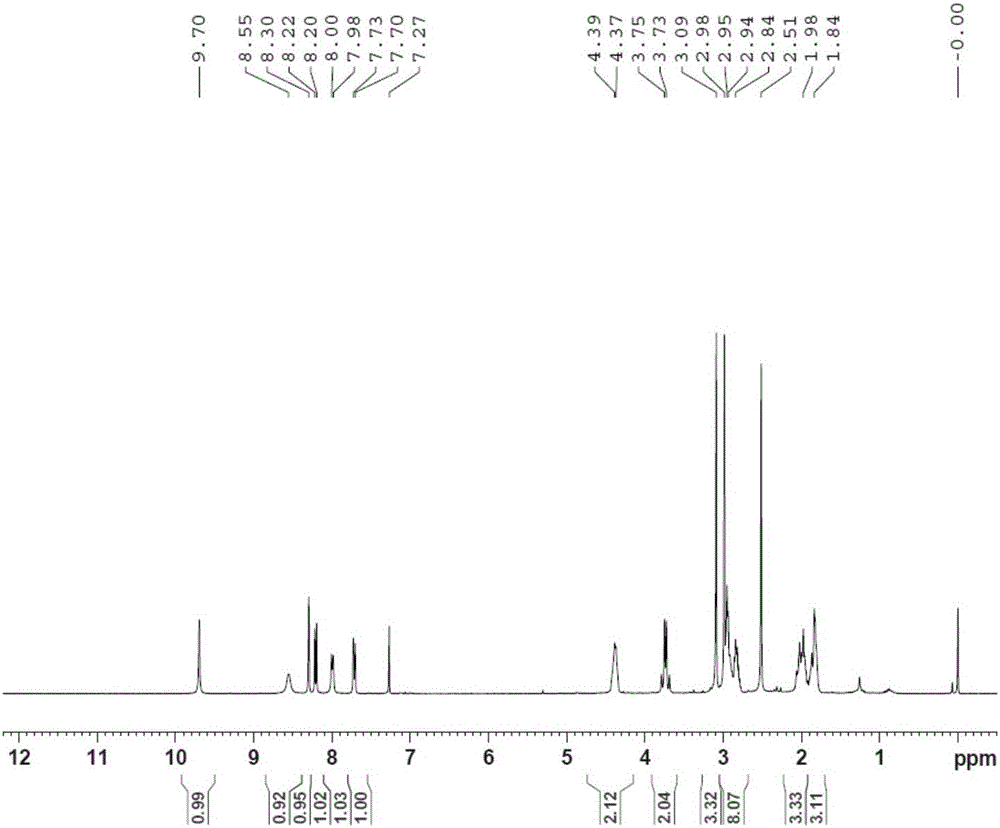

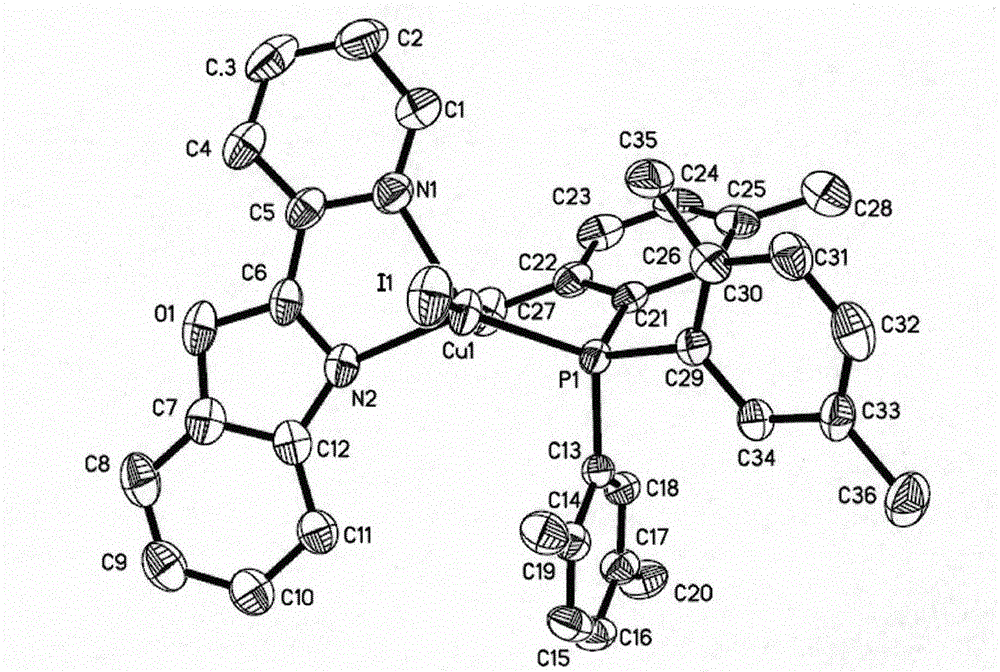

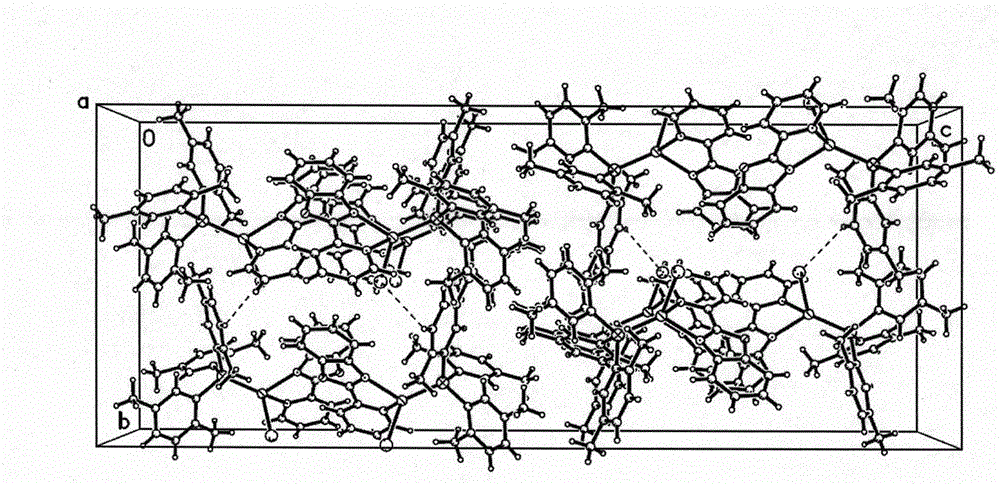

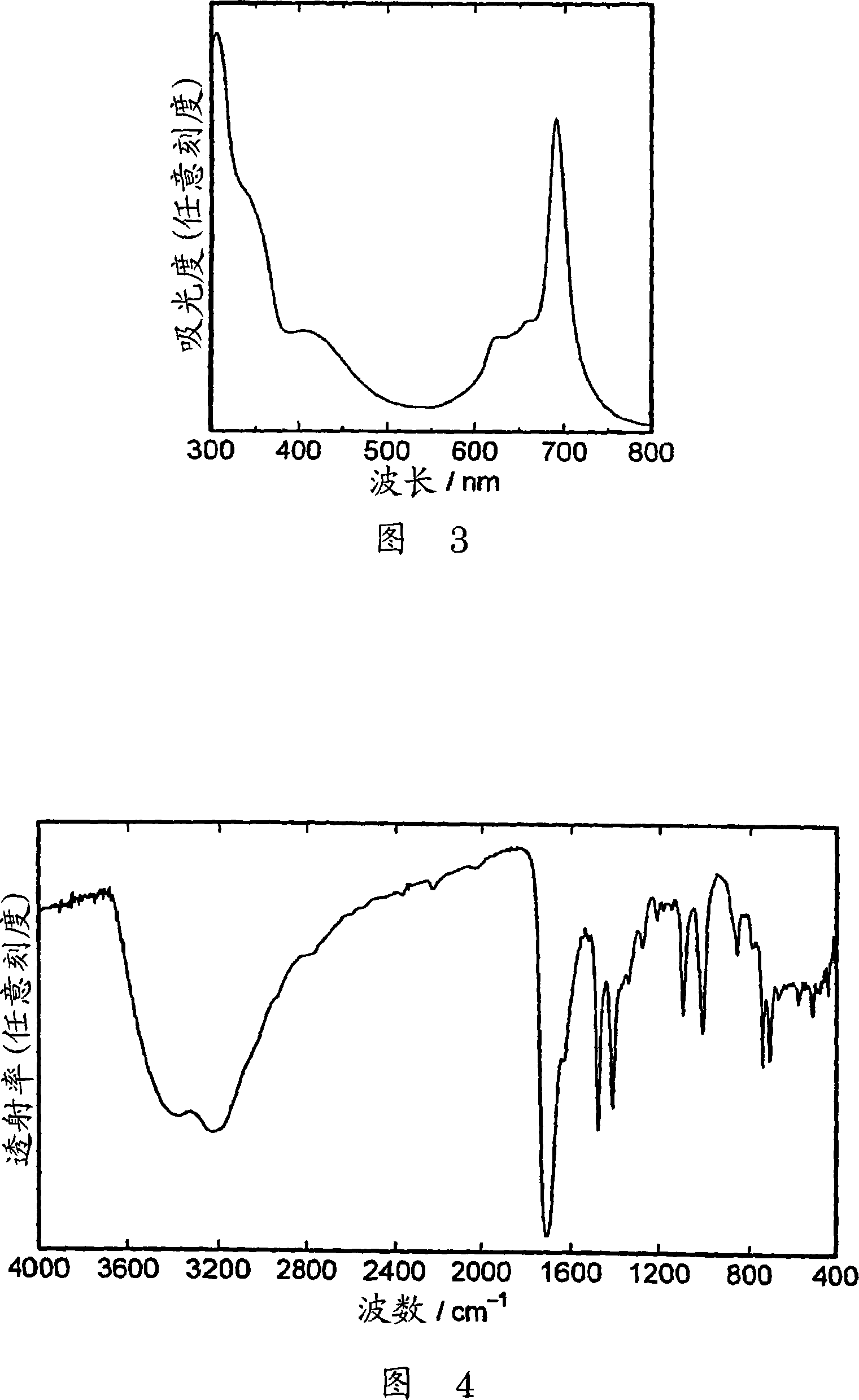

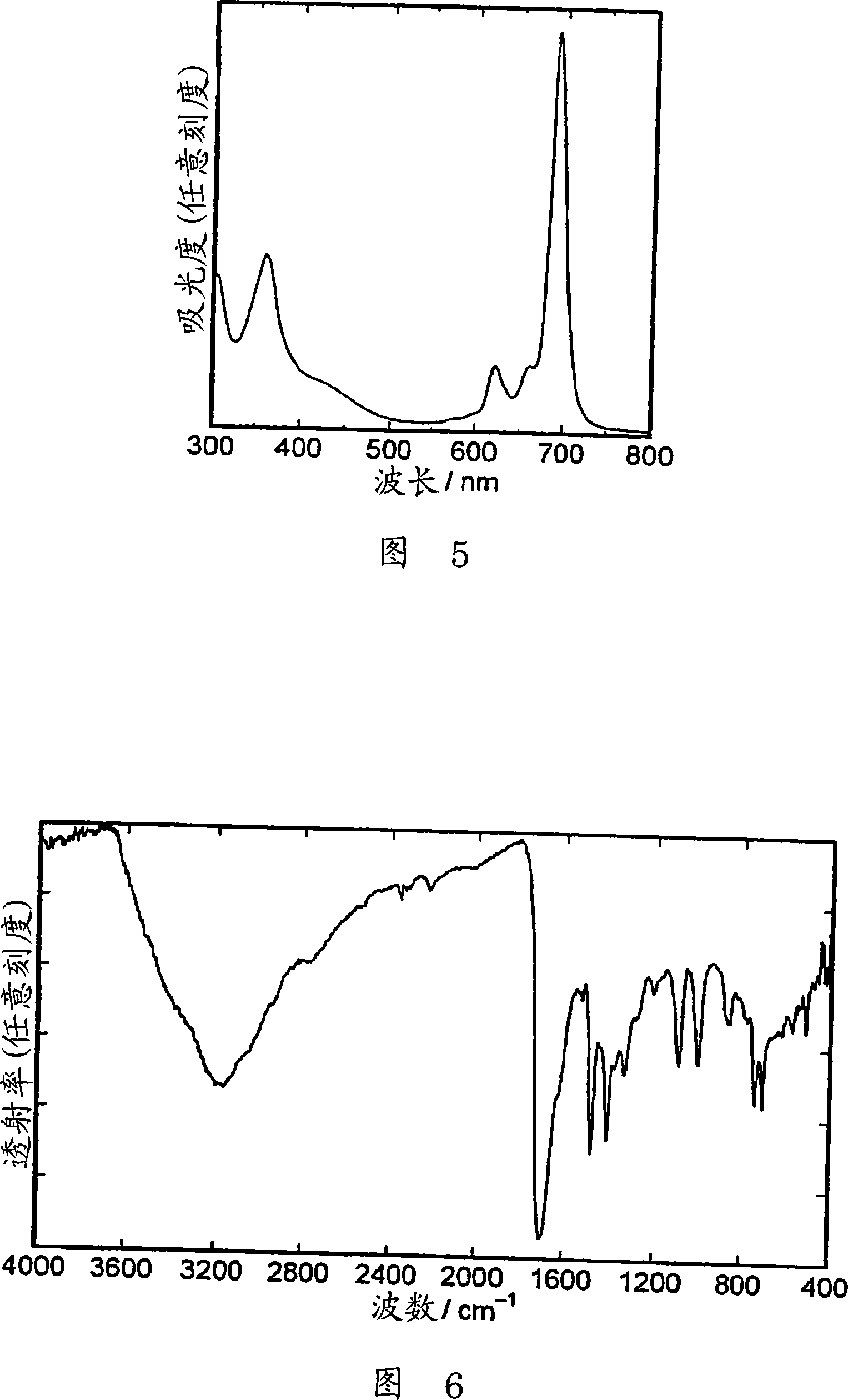

CuIN2P-type red light emitting material with cuprous complexes

InactiveCN104927842AIntersystem crossingSuppression of non-radiative decayCopper organic compoundsSolid-state devicesIodideChemistry

The invention discloses a red phosphorescence CuIN2P-type light emitting material with cuprous complexes and a method for manufacturing the red phosphorescence CuIN2P-type light emitting material. Cuprous iodide and ligands carry out coordination reaction to obtain the phosphorescence complexes of the red phosphorescence CuIN2P-type light emitting material. A molecular structural formula of the red phosphorescence CuIN2P-type light emitting material is CuI(2-PBO)(TXP-2, 5), and the 2-PBO and the TXP-2, 5 in the formula respectively represent electrically neutral ligand 2-(2-benzoxazole) pyridine and (2, 5-xylyl) triphosphine. The red phosphorescence CuIN2P-type light emitting material and the method have the advantages that small molecules of the complexes are easy to purify, and the complexes are high in light emitting efficiency and can be easily dissolved by organic solvents; liquor of the cuprous iodine and liquor of the ligands directly carry out mixed reaction to obtain the red phosphorescence CuIN2P-type light emitting material, accordingly processes are simple and convenient, equipment is simple, raw materials are easily available, and the red phosphorescence CuIN2P-type light emitting material is low in cost; the ed phosphorescence CuIN2P-type light emitting material not only can be used as a photoluminescence red light material, but also can be used as a phosphorescence material for a light emitting layer in an electroluminescence device with multiple layers of organic materials, and the like.

Owner:CHINA JILIANG UNIV

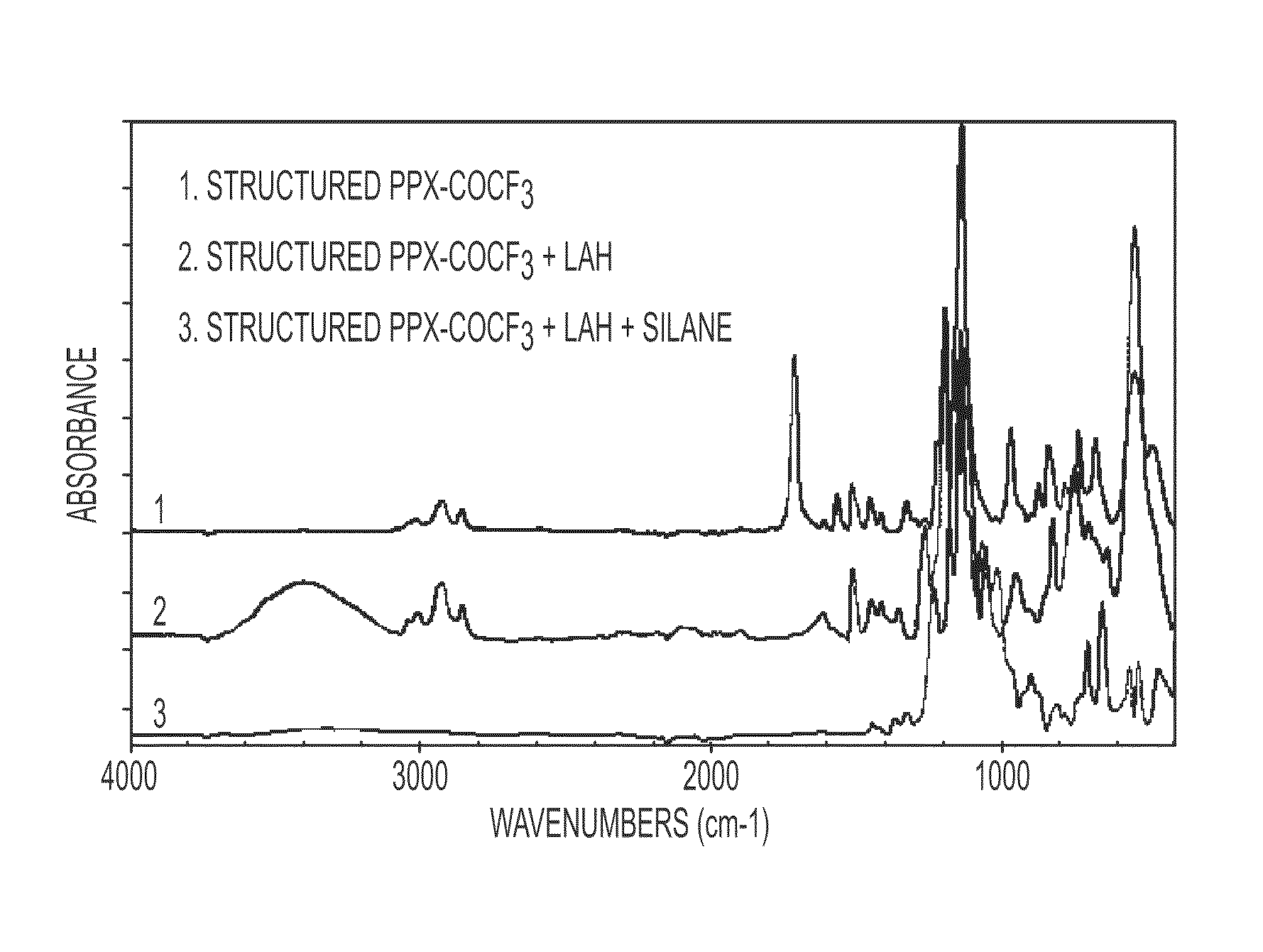

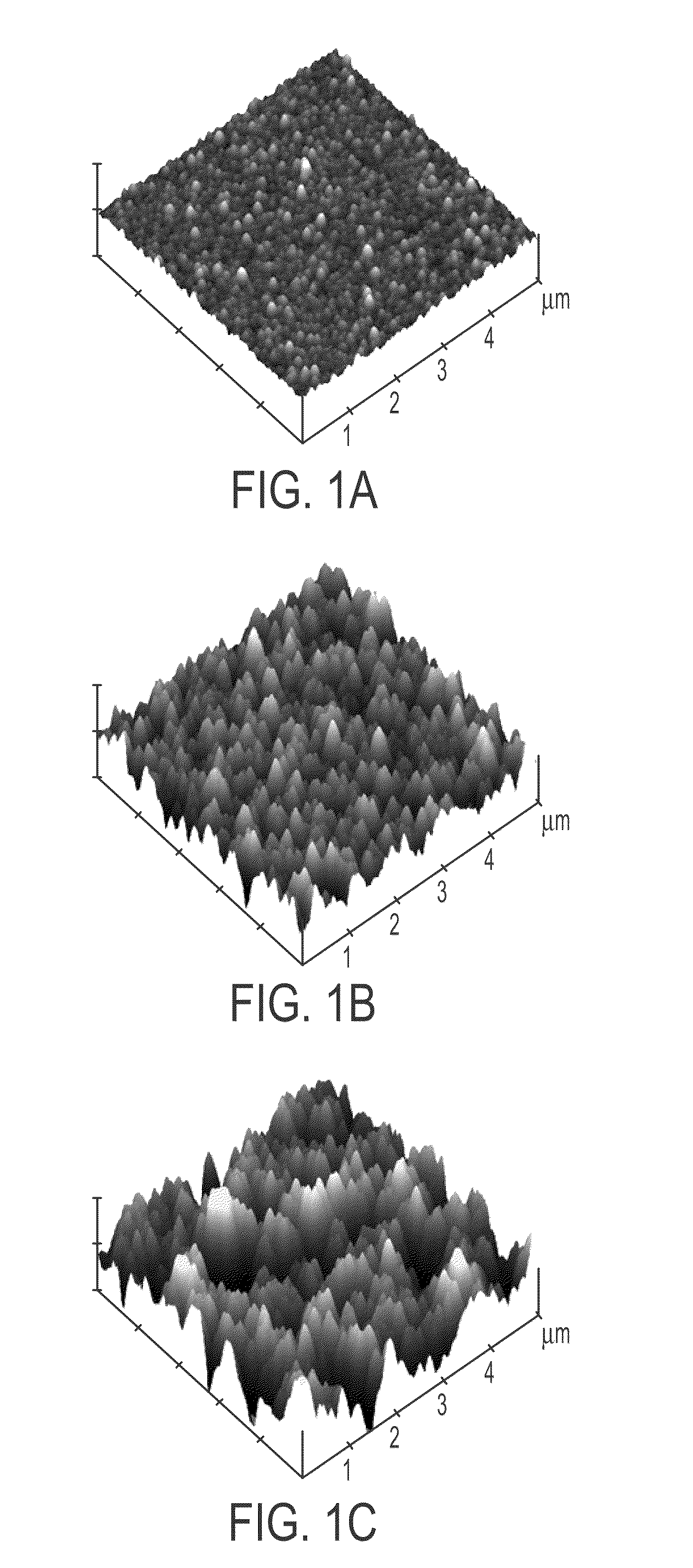

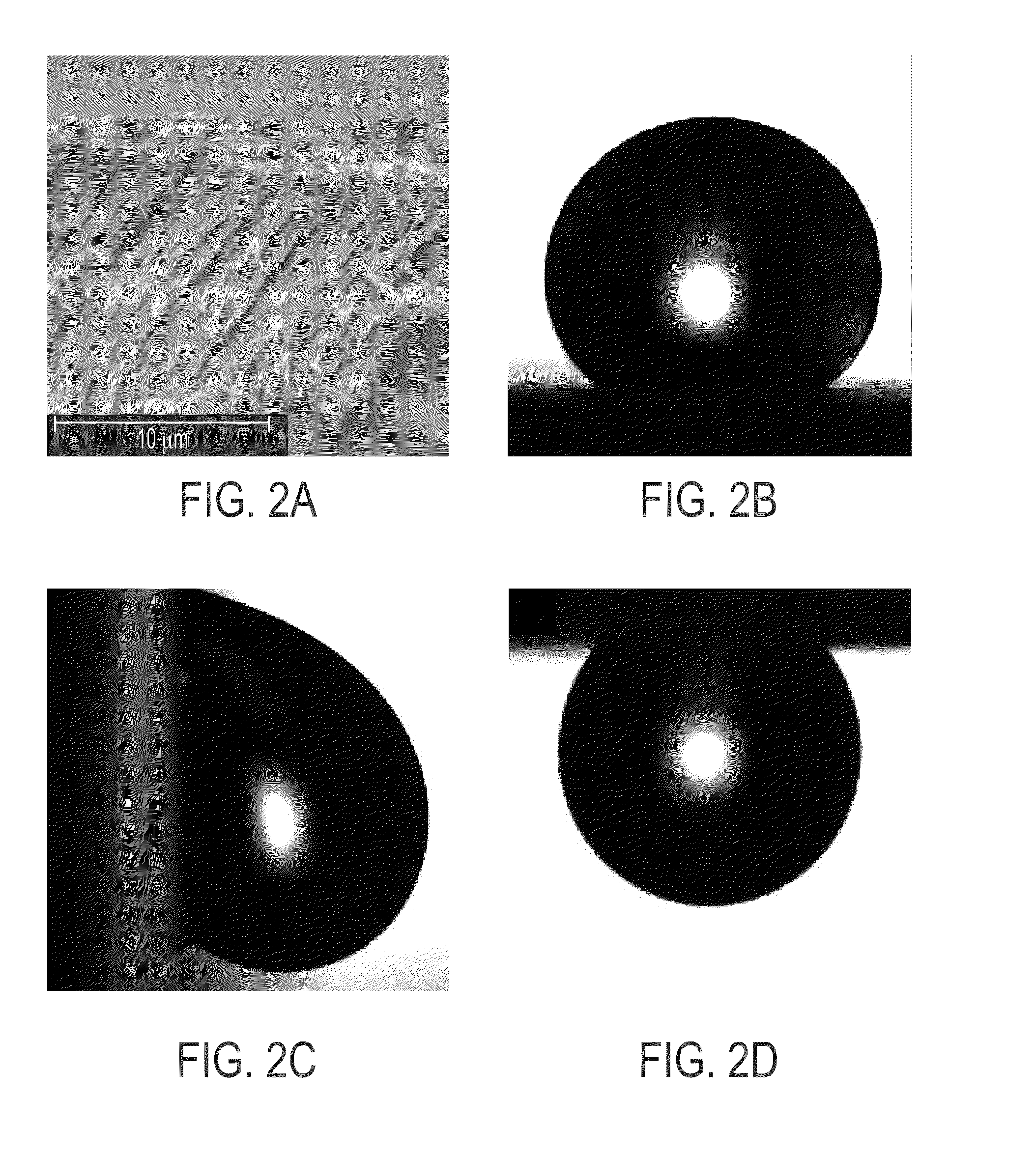

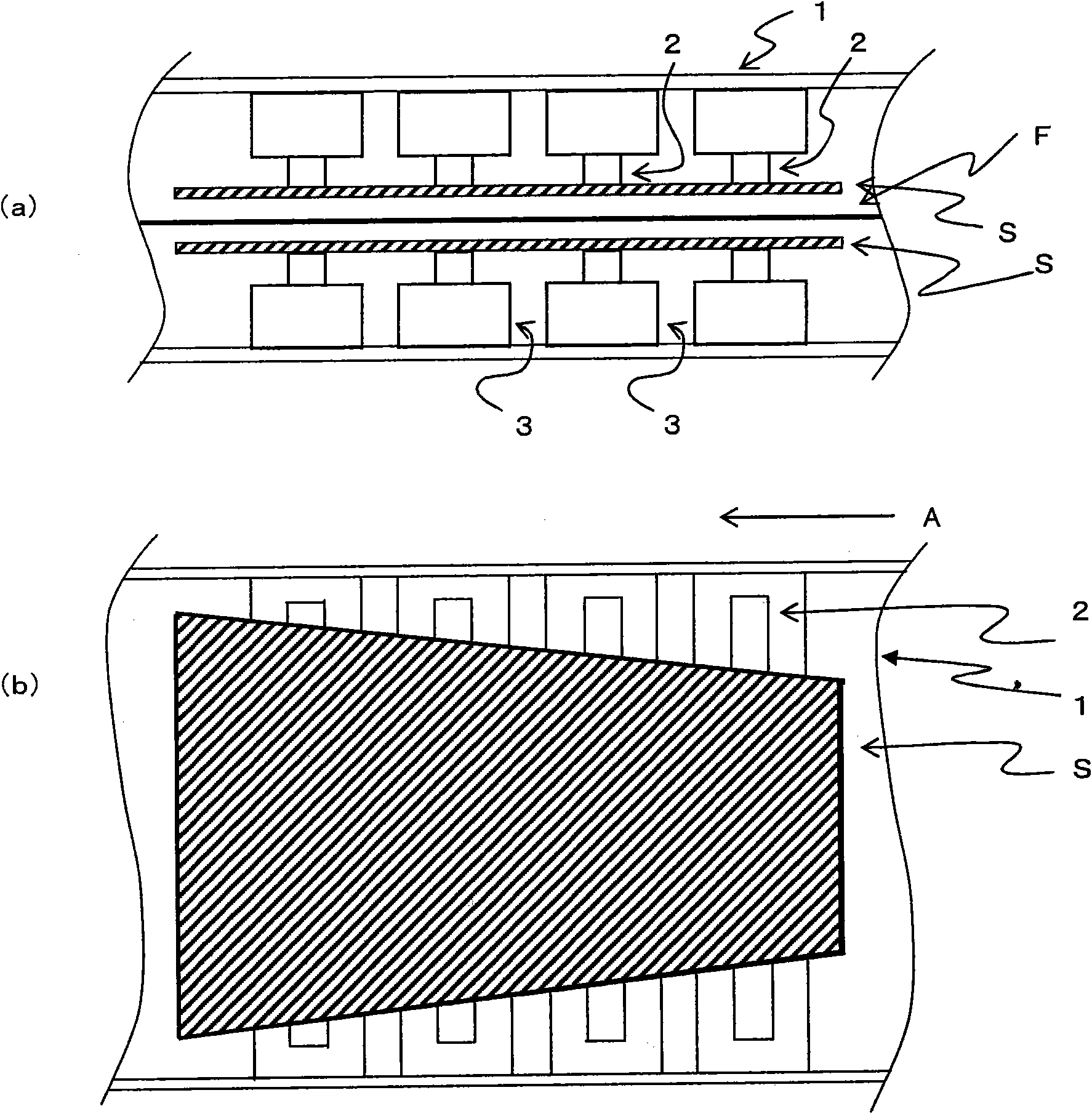

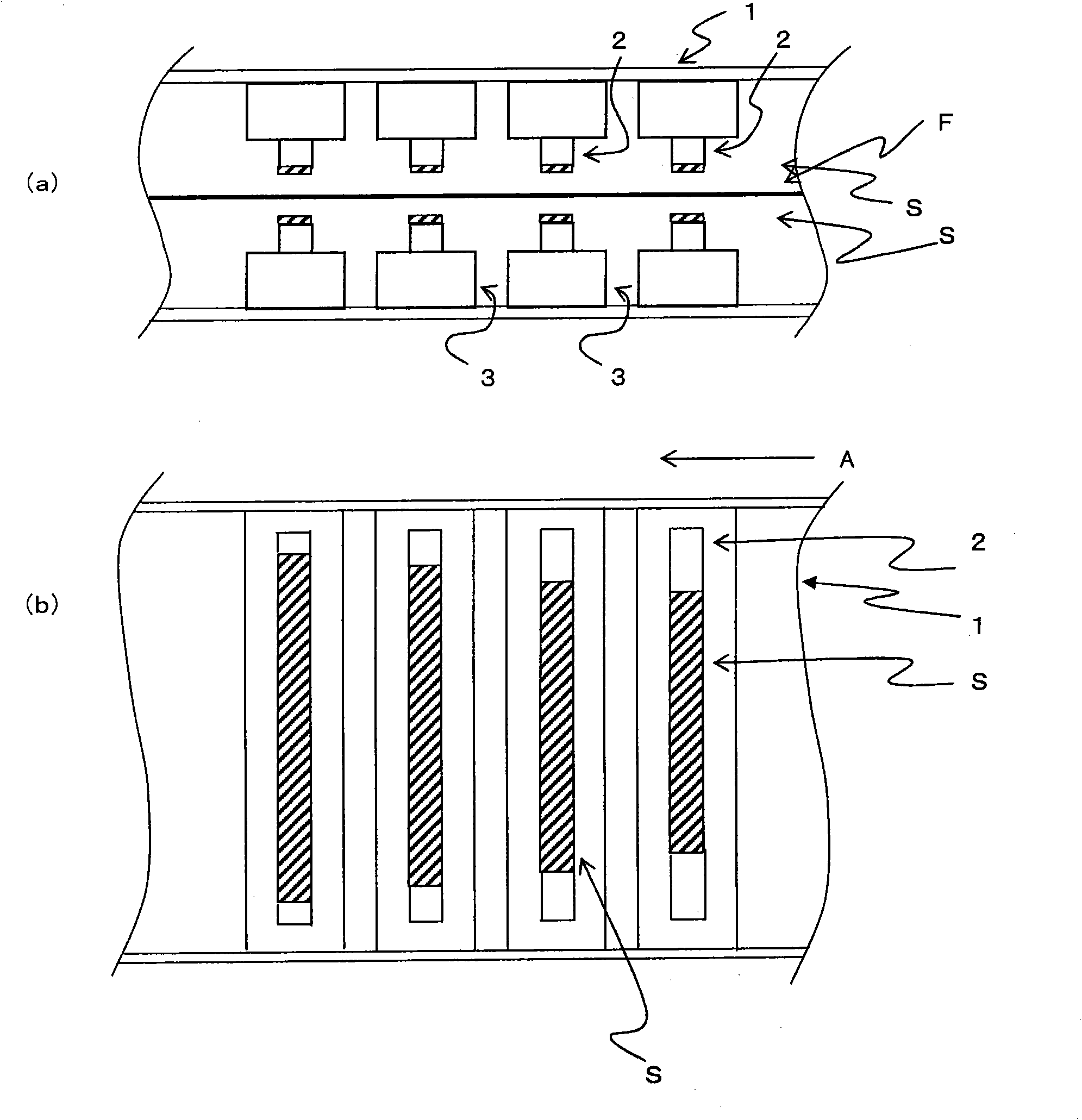

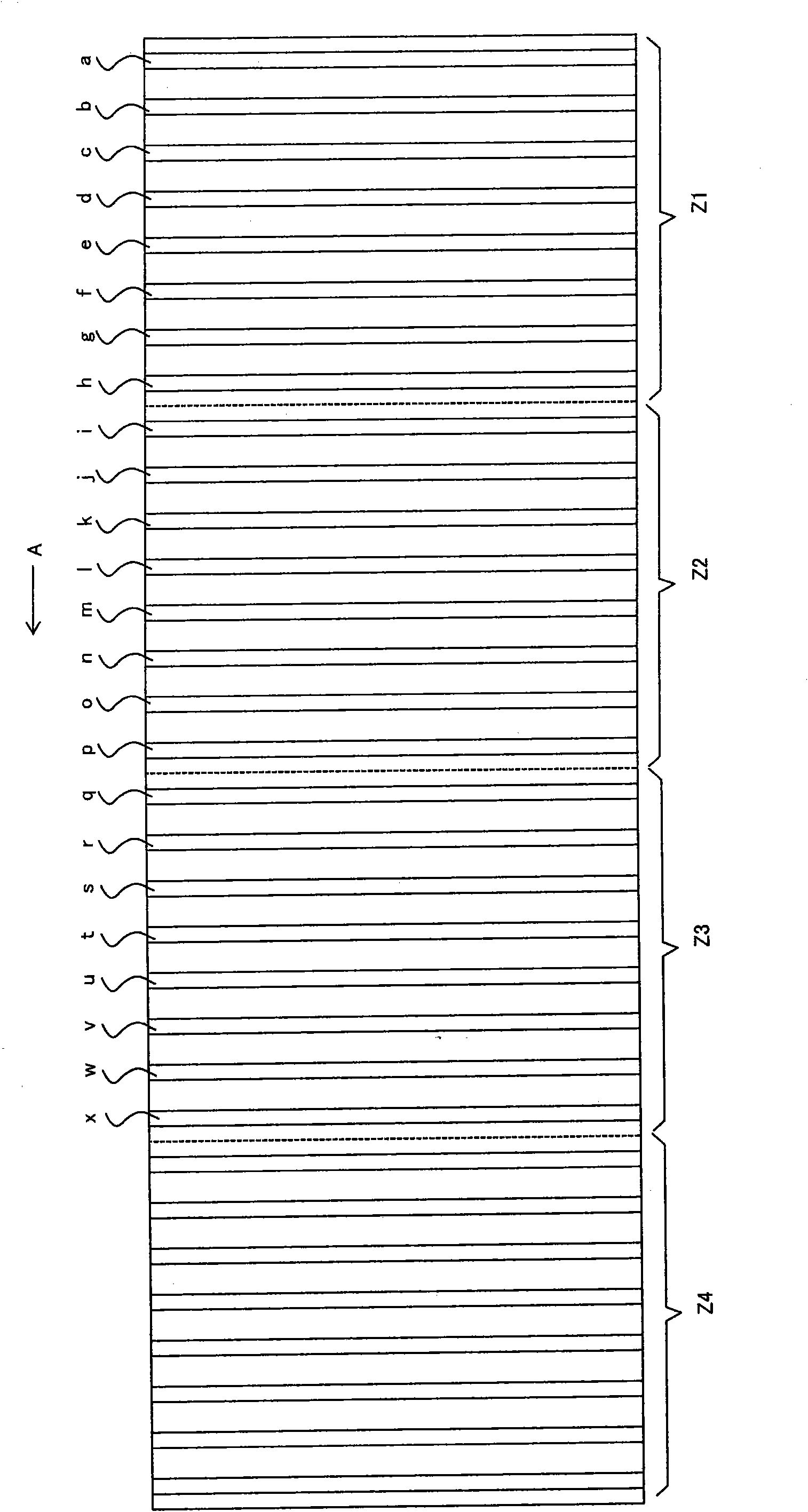

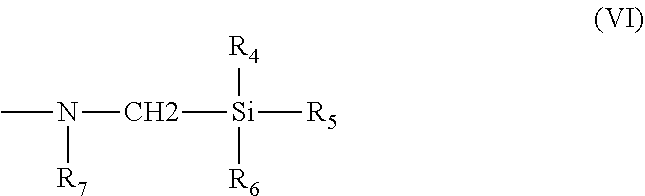

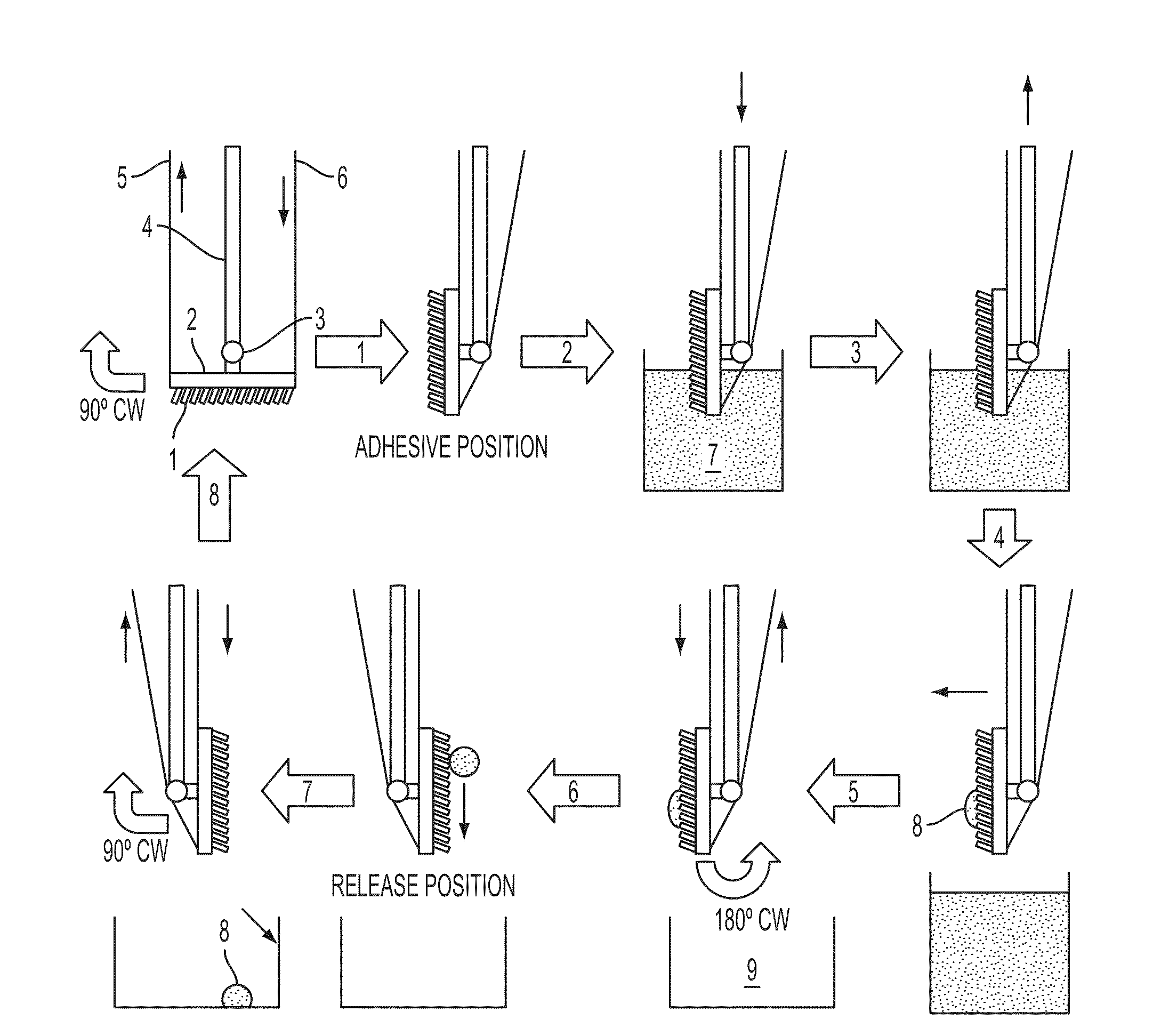

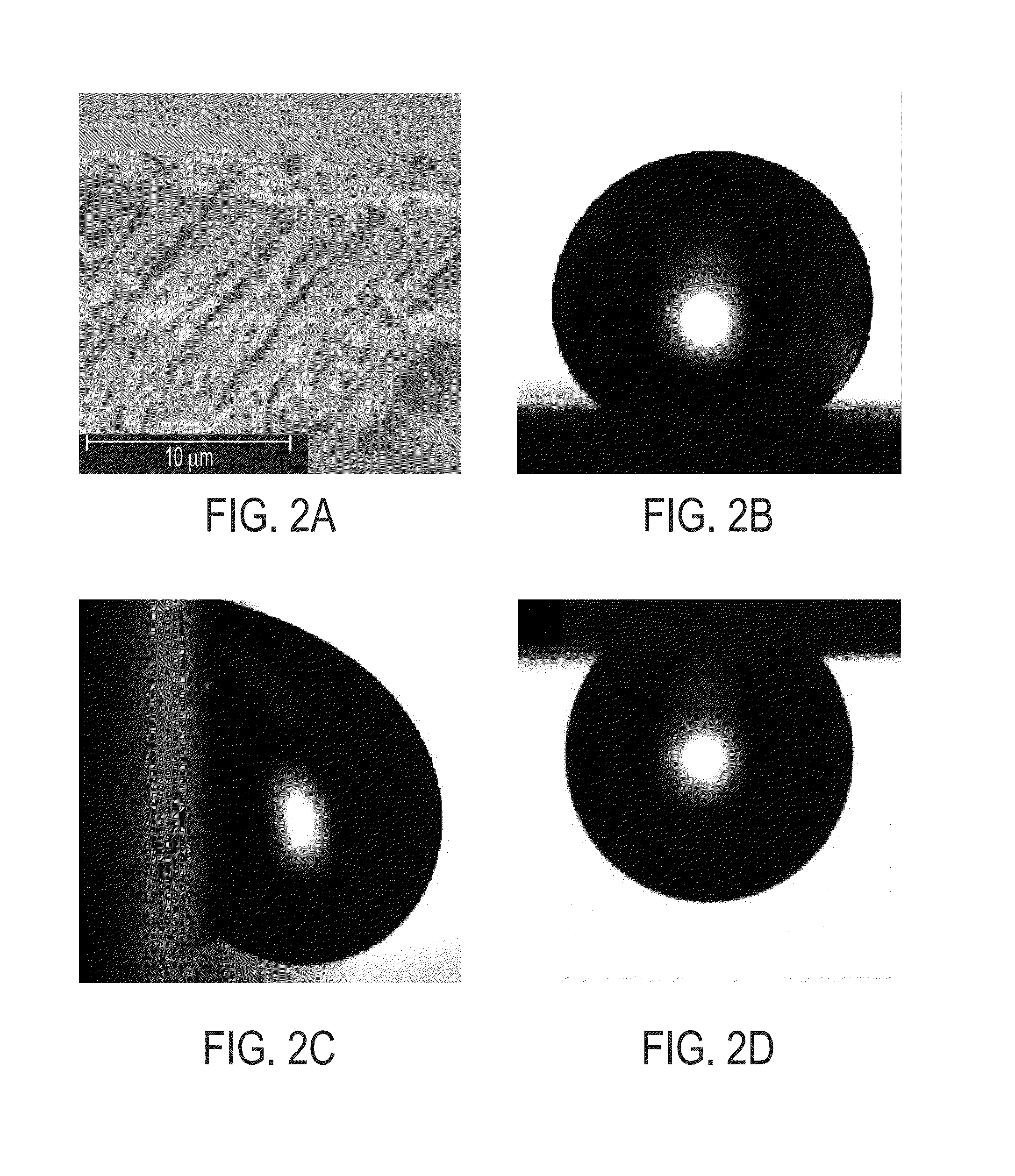

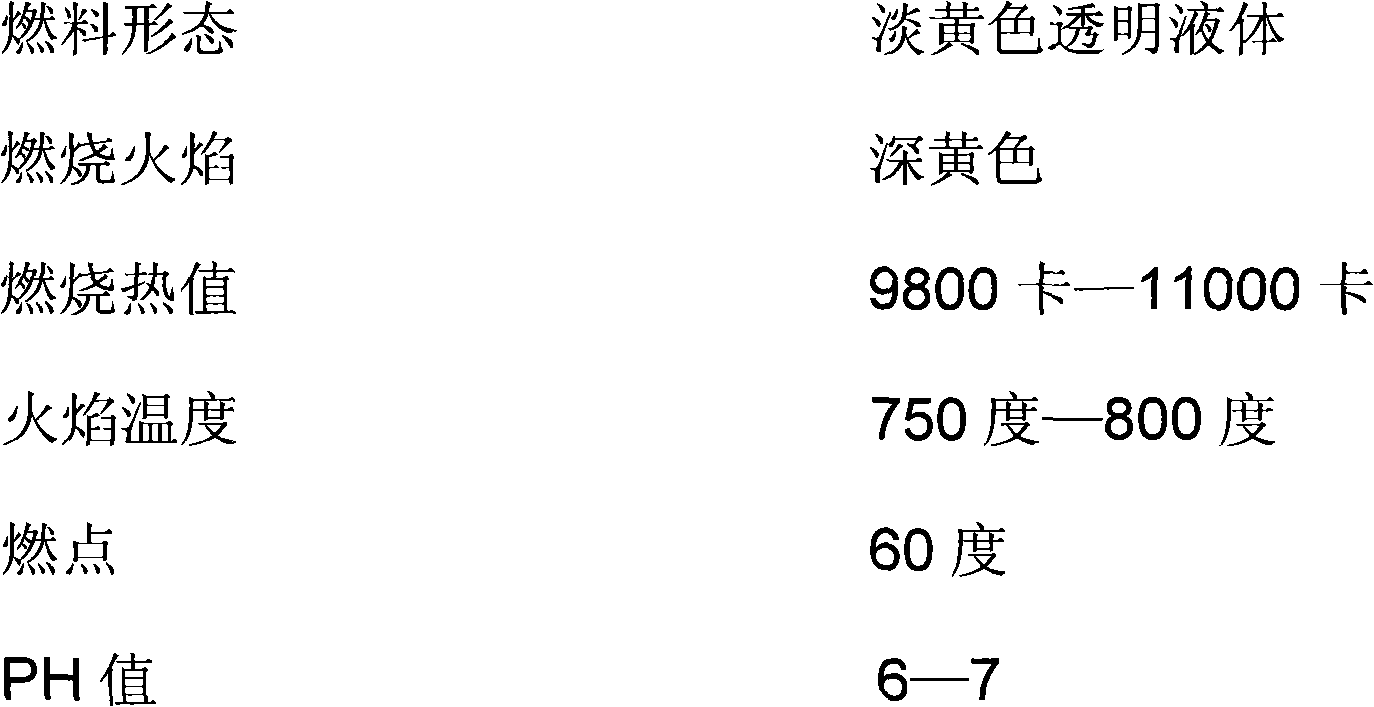

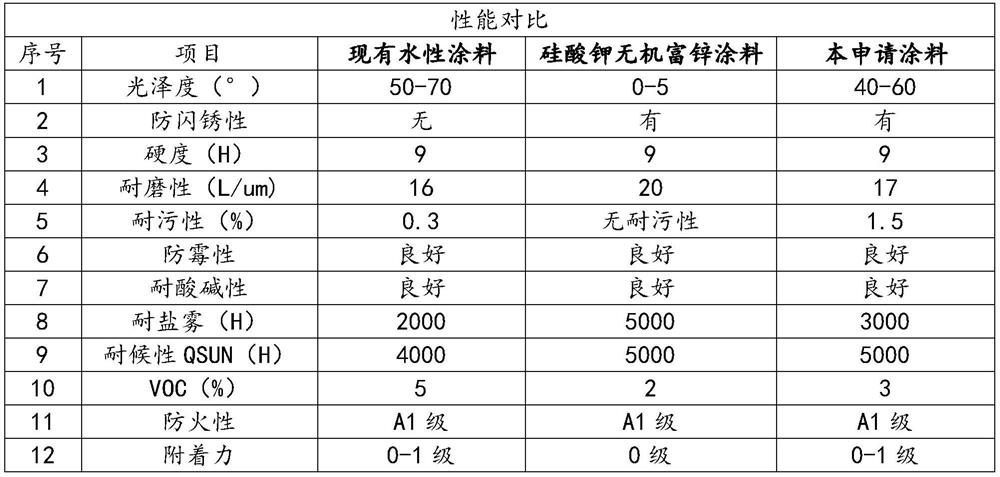

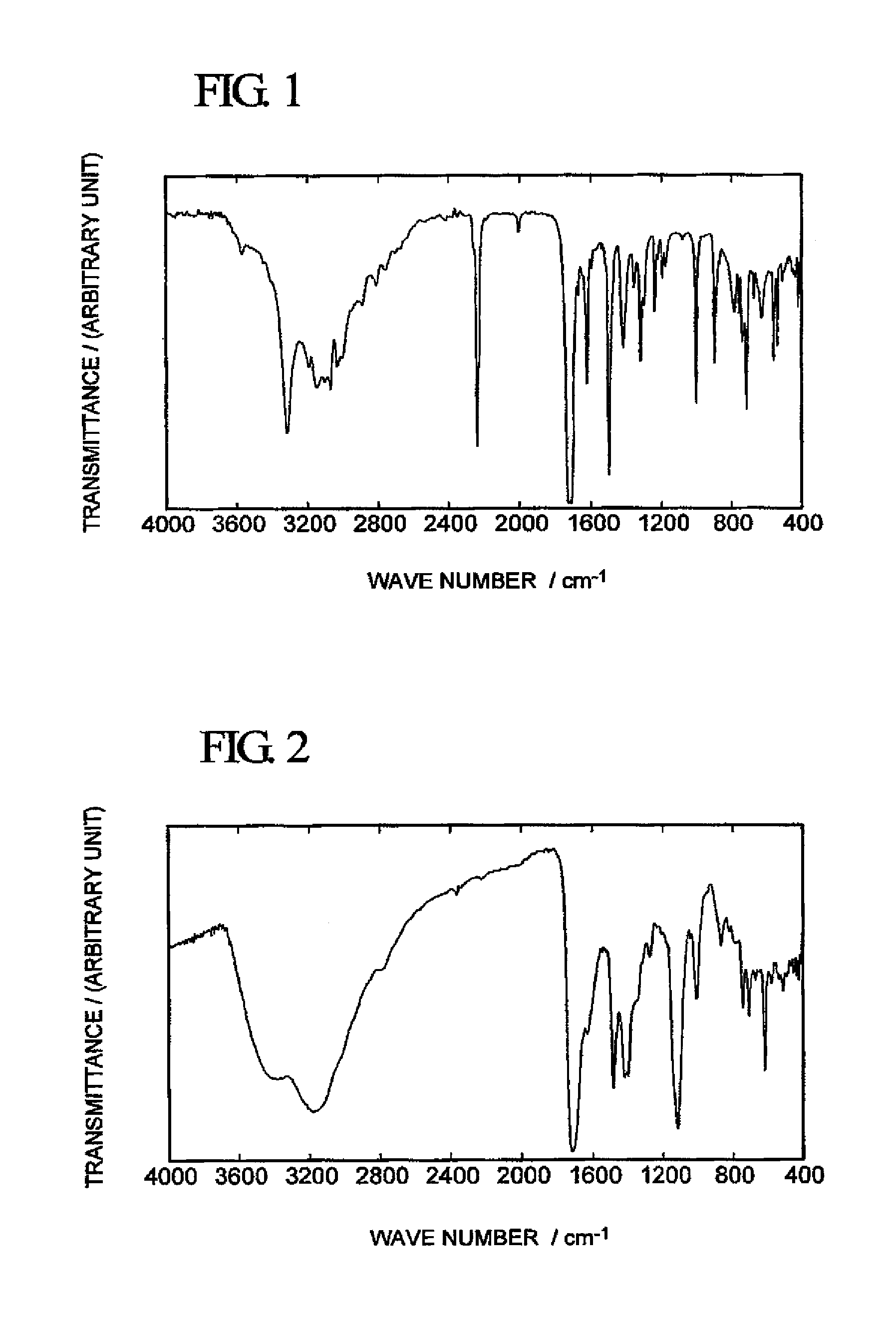

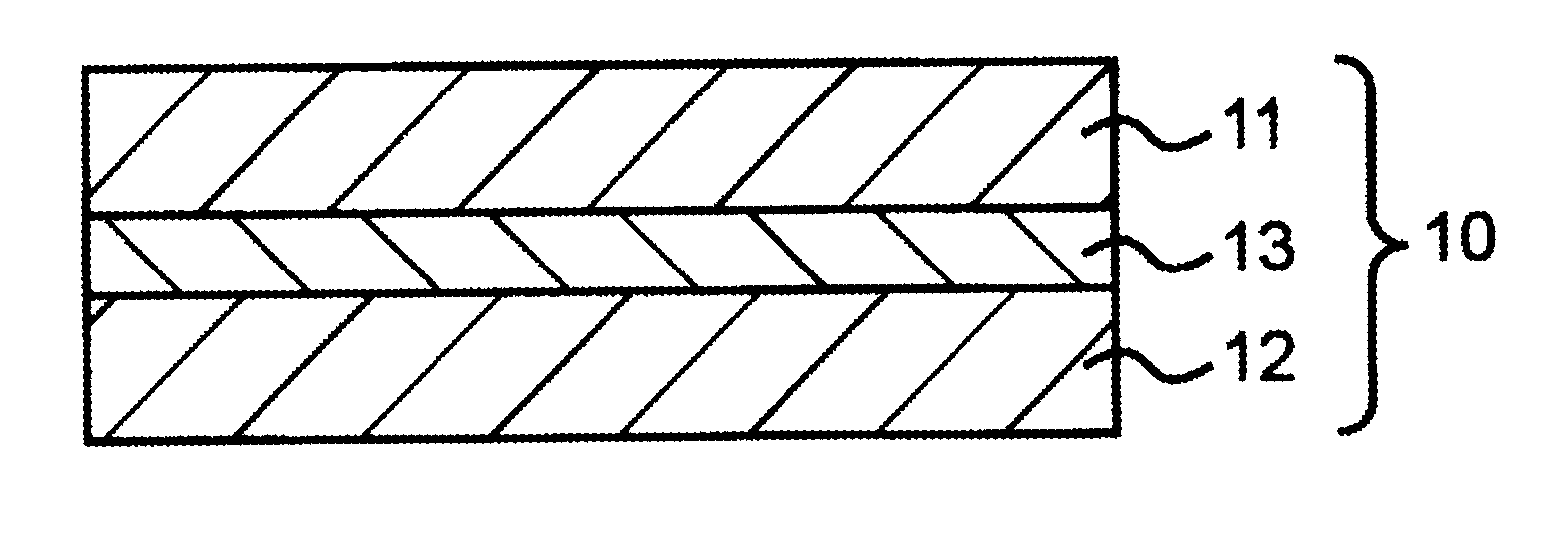

Hydrophobic nanostructured thin films

Provided herein are the polymers shown below. The value n is a positive integer. R1 is an organic group, and each R2 is H or a chemisorbed group, with at least one R2 being a chemisorbed group. The polymer may be a nanostructured film. Also provided herein is a method of: converting a di-p-xylylene paracyclophane dimer to a reactive vapor of monomers; depositing the reactive vapor onto a substrate held at an angle relative to the vapor flux to form nanostructured poly(p-xylylene) film; reacting the film with an agent to form hydrogen atoms that are reactive with a precursor of a chemisorbed group, if the film does not contain the hydrogen atoms; and reacting the hydrogen atoms with the precursor. Also provided herein is a device having a nanostructured poly(p-xylylene) film on a pivotable substrate. The film has directional hydrophobic or oleophobic properties and directional adhesive properties.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Polyamide-based laminated biaxially-stretched film, and vapor-deposited polyamide-based laminated resin film

Disclosed is a polyamide-based laminated biaxially-stretched film which comprises a resin layer (layer A) mainly composed of a polyamide polymer having a metaxylylene group and a resin layer (layer B) mainly composed of an aliphatic polyamide resin and laminated on at least one surface of the resin layer (layer A), and which has a specific small number of pinholes and a specific oxygen permeability, wherein the polyamide polymer having a metaxylylene group comprises metaxylylene diamine or a mixed xylylene diamine component composed of metaxylylene diamine and paraxylylene diamine as the main diamine component and an alpha, omega-aliphatic dicarboxylic acid having 6 to 12 carbon atoms as the main dicarboxylic acid component.

Owner:TOYO TOYOBO CO LTD

Polyamide resin moldings

Provided is a xylylenesebacamide resin molding which is excellent in mechanical strength such as elastic modulus and avoids the problem of mechanical strength loss during long-term use. This is a molding of a polyamide resin or a polyamide resin composition containing the polyamide resin, wherein 70 mol % or more of the diamine structural unit is derived from xylylenediamine (A) and 50 mol % or more of the dicarboxylic acid structural unit is derived from sebacic acid (B), and the molding has a crystallinity index of 0 to 50% and a moisture content of 0.1 to 2% by mass.

Owner:MITSUBISHI GAS CHEM CO INC

Electrical insulating oil composition having excellent low temperature properties

InactiveUS20140110643A1Improve low temperature performanceSimple compositionElectrolytic capacitorsLiquid organic insulatorsDiphenylmethaneEthyl group

The present invention provides an electric insulating oil composition that has excellent low temperature properties, hydrogen gas absorbability and giving less adverse effect on living bodies and comprises [A] 1,1-diphenylethane in an amount of 30 to 70 percent by mass, [B] at least one or more component selected from 4 components that are (a) 1-phenyl-1-methylphenylethane, (b) 1-phenyl-1-xylylethane, (c) 1-phenyl-1-ethylphenylethane and (d) benzyltoluene in a total amount of 30 to 70 percent by mass, and [C] 1,2-diphenylethane in an amount of 0.1 to 2 percent by mass and / or diphenylmethane in an amount of 0.1 to 13 percent by mass.

Owner:JX NIPPON OIL & ENERGY CORP

Method for preparing 3,3',4,4'-benzophenonetetracarboxylic dianhydride

The invention discloses a method for synthesizing 3,3',4,4'-benzophenonetetracarboxylic dianhydride by taking o-xylene and bis(trichloromethyl) carbonate as raw materials. The method comprises the steps of: by taking o-xylene and bis(trichloromethyl) carbonate as the raw materials, performing acylation reaction in catalysis of anhydrous lewis acid, thus obtaining bis(3,4-ditolyl)methanone; fully oxidizing bis(3,4-ditolyl)methanone in a potassium permanganate / hydrochloric acid system, and carrying out filtration, concentration, crystallization and the like to obtain 3,3',4,4'-benzophenonetetracarboxylic acid; performing vacuum high-temperature melting and dehydration to 3,3',4,4'-benzophenonetetracarboxylic acid to obtain the 3,3',4,4'-benzophenonetetracarboxylic dianhydride product. The preparation method has the advantages of being simple in technology, high in yield, fewer in three wastes, capable of recycling anhydrous lewis acid, low in production cost and easy for industrial implementation, and the like.

Owner:六安科瑞达新型材料有限公司

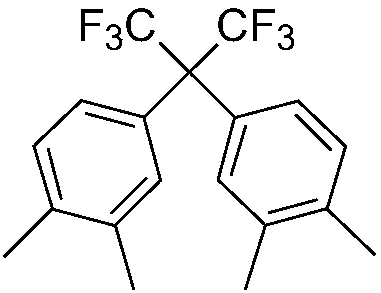

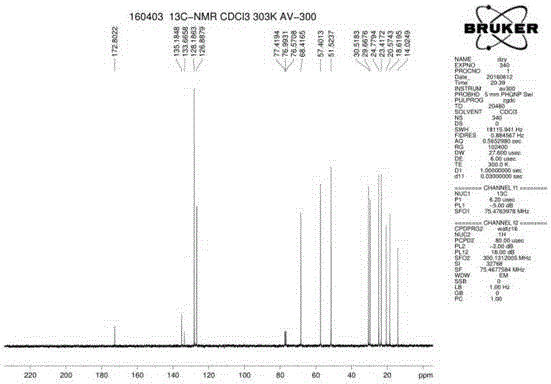

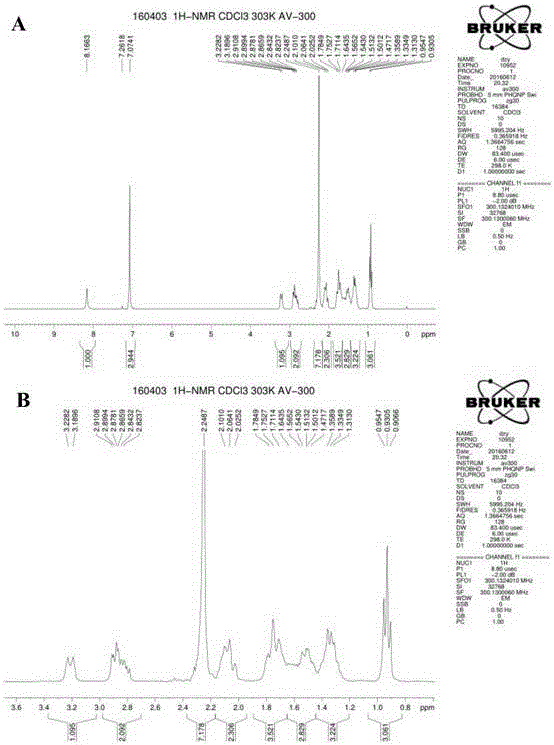

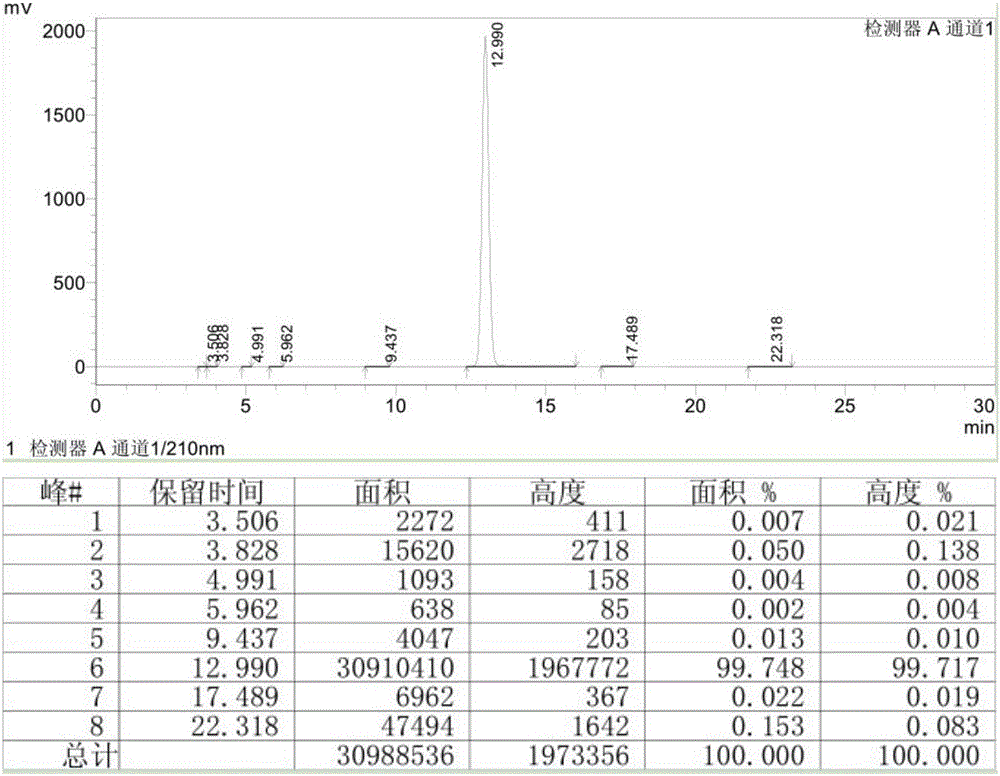

Preparation method of 2,2-bis(3,4-dimethylphenyl) hexafluoropropane

ActiveCN108395363AMild preparation conditionsReduce the risk factorHalogenated hydrocarbon preparationSolventSulfonic acid

The invention discloses a synthesis technology for taking sulfoacid as a catalyst to prepare 2,2-bis(3,4-dimethylphenyl) hexafluoropropane. The synthesis technology comprises the following operation steps that (1) ortho-xylene, sulfoacid and a solvent are mixed at the proportion, and a mixture is obtained; (2) hexafluoroacetone gas is injected into the mixture obtained in the step (1), a crude product is obtained at a reaction temperature and reaction pressure, the crude product is subjected to alkali washing, water washing and concentration, and then crystallization through the crystallization solvent, and vacuum drying, and 2,2-bis(3,4-dimethylphenyl) hexafluoropropane is obtained. The synthesis technology is novel, the condition is mild, and the obtained battery-level 2,2-bis(3,4-dimethylphenyl) hexafluoropropane has the high purity.

Owner:SHANGHAI ROLECHEM CO LTD

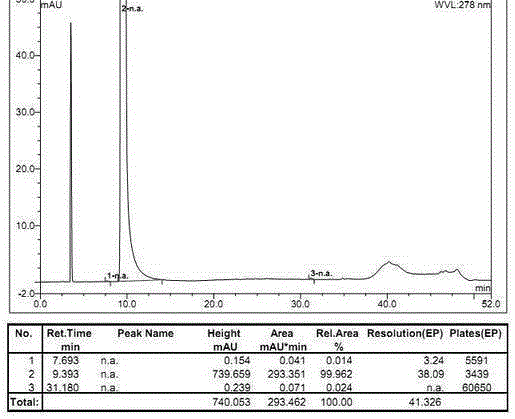

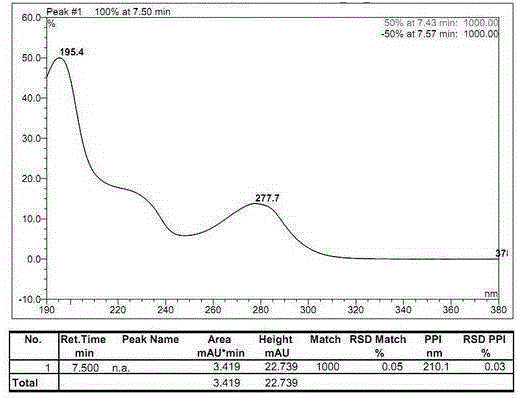

Method for measuring optical purity of R-alogliptin benzoate

The invention relates to a method for measuring the optical purity of R-alogliptin benzoate. The method is characterized in that a chromatographic system is a high performance liquid chromatograph; a chromatographic column filler is amylose-tris(3,5-dimethylphenyl carbamate); the flow velocity is 0.8 ml / min; the column temperature is 25 DEG C; the measurement wavelength is 278 nm; the sample introduction amount is 20 [mu]l; the chromatographic mobile phases are n-hexane and an ethanol solution which contains 0.2% trifluoroacetic acid and 0.1% diethyl amine; the ratio of n-hexane to the ethanol solution is 80:20; sample introduction is conducted on an R,S-alogliptin benzoate reference solution and an S-alogliptin benzoate reference solution respectively for system suitability analysis at first, and then the optical purity of an R-alogliptin benzoate test solution is measured and the optical purity of an R-alogliptin benzoate sample is calculated according to an area normalization method.

Owner:DISHA PHARMA GRP +1

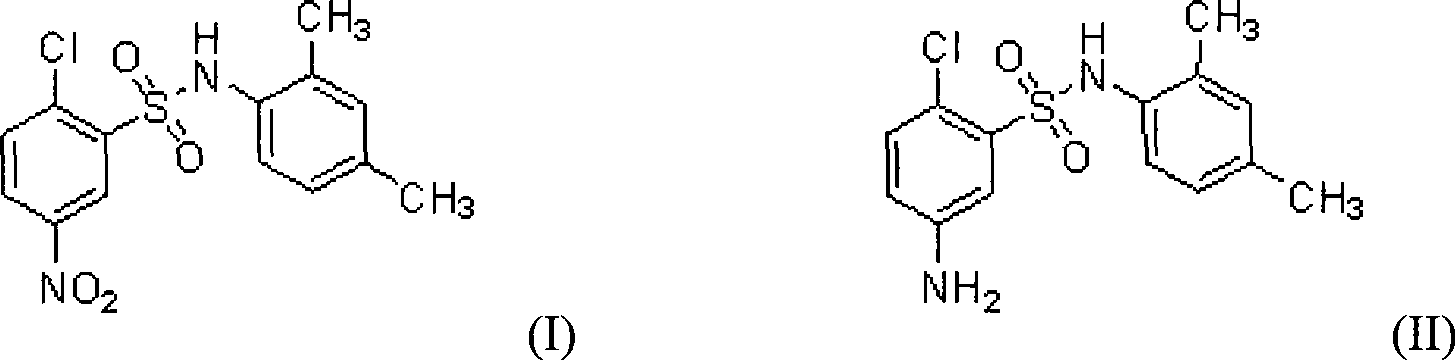

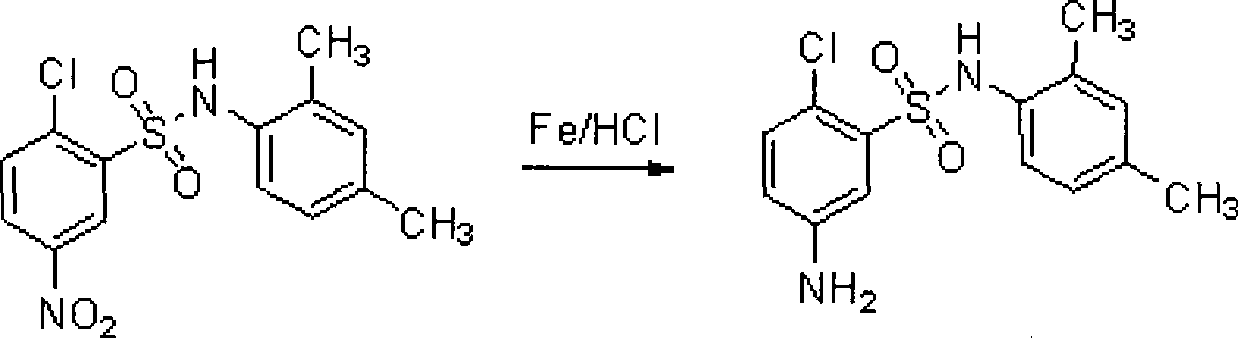

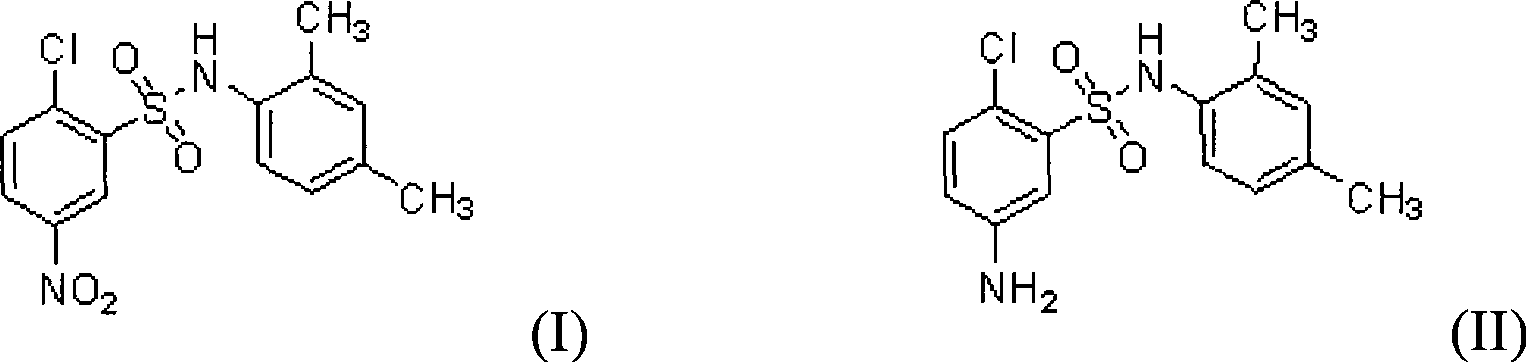

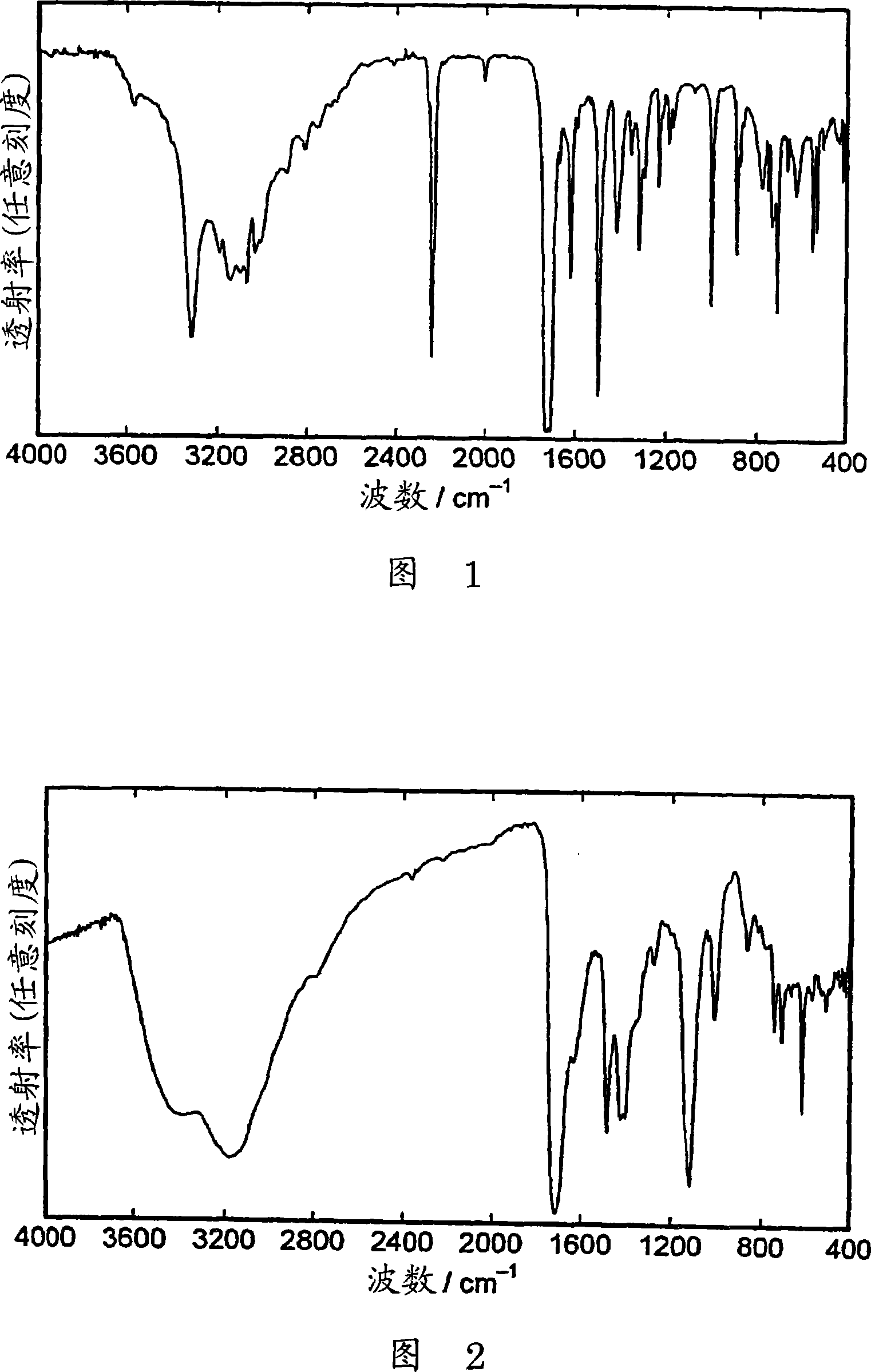

Method for preparing 5-amino-2-chloro-N-(2,4-xylyl)-benzene sulfonic amide in water phase

InactiveCN101475515AMild reaction conditionsSimple processSulfonic acid amide preparationBULK ACTIVE INGREDIENTSolvent

The invention discloses a method for preparing 5-amino-2-chlorine-N-(2,4-xylyl)-benzsulfamide of which the structure is as shown in a formula (II) in a water phase, which comprises: performing catalytic hydrogenation reaction on 5-nitryl-2-chlorine-N-(2,4-xylyl)-benzsulfamide of which the structure is as shown in a formula (I) in a water solvent in a closed reactor under the action of a supported catalyst under the condition of stirring, and preparing target products, wherein the temperature of the catalytic hydrogenation reaction is between 30 and 150 DEG C, and the pressure in the closed reactor is between 0.1 and 4.0 MPa; a supporter of the supported catalyst is gamma-Al2O3; and active ingredients of the gamma-Al2O3 are one or complexes of more than two of Pa, Ru, Pt, Ni, Fe, Co, Sn, Ge, Al, Zn, Ce and Au in any proportion, or complexes of non-metal B or P and metals in any proportion. The method is performed in the water phase, and has the advantages of high conversion rate, high selectivity, mild reaction conditions, simple technique, clean production and no pollution.

Owner:WENZHOU UNIVERSITY

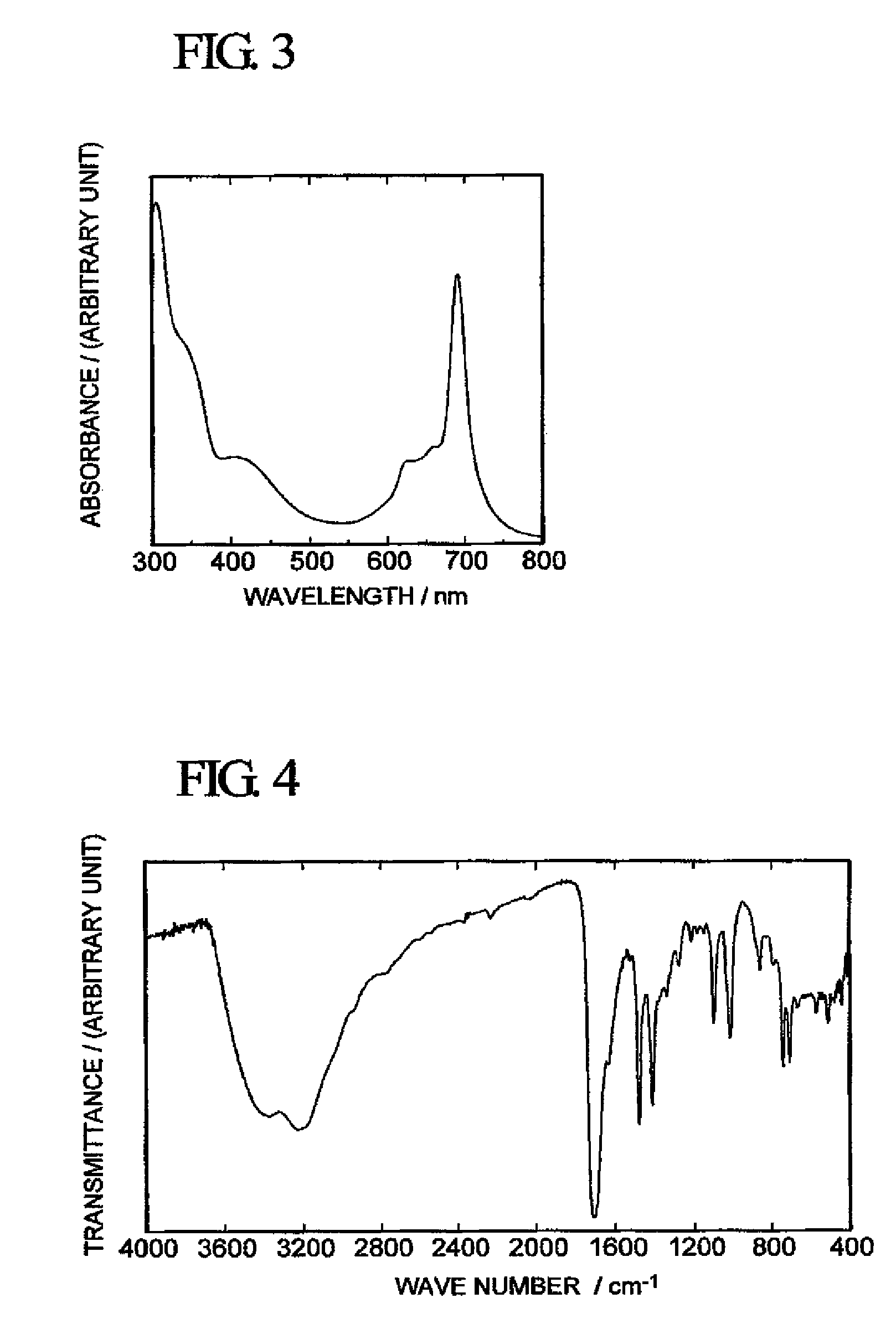

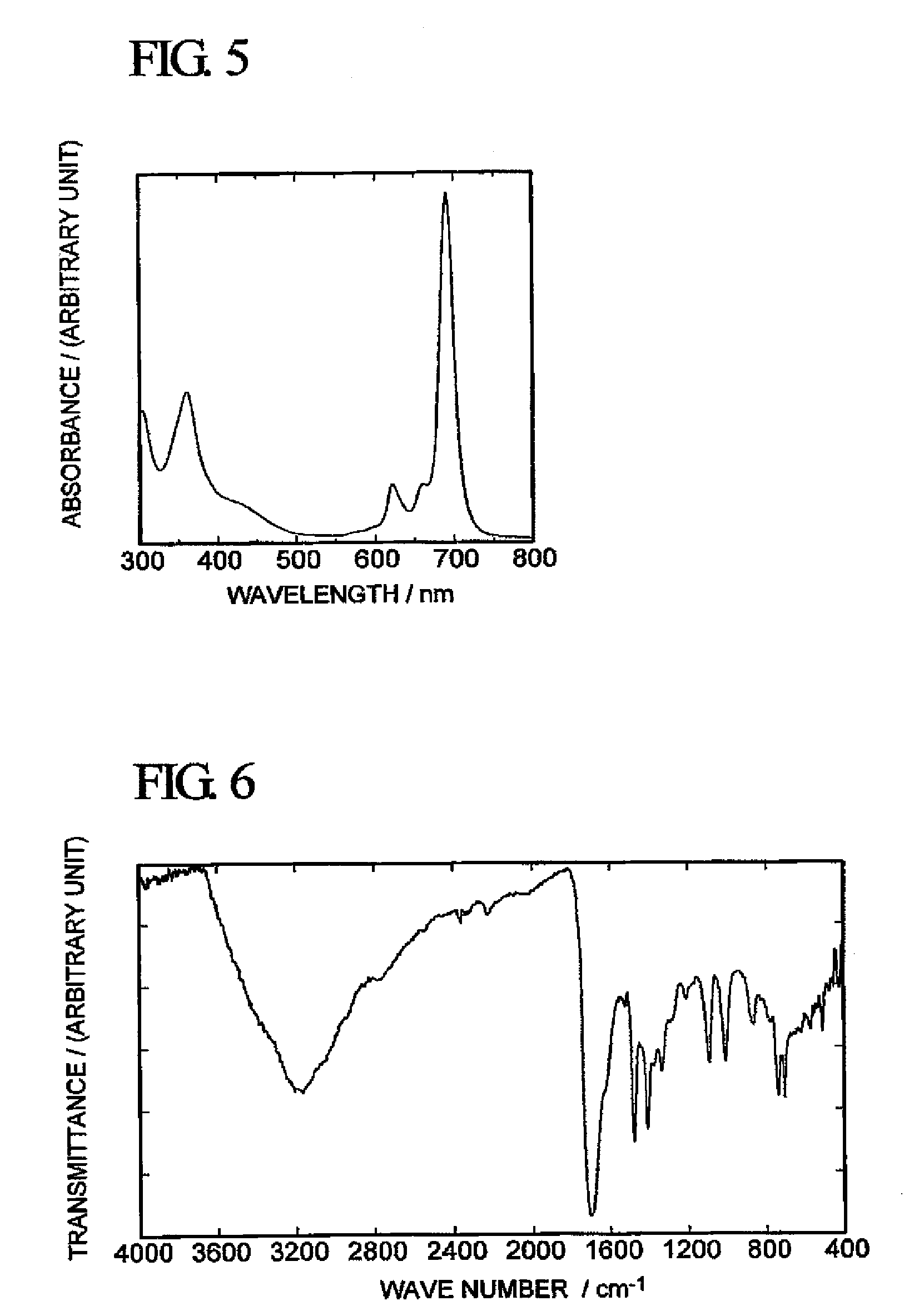

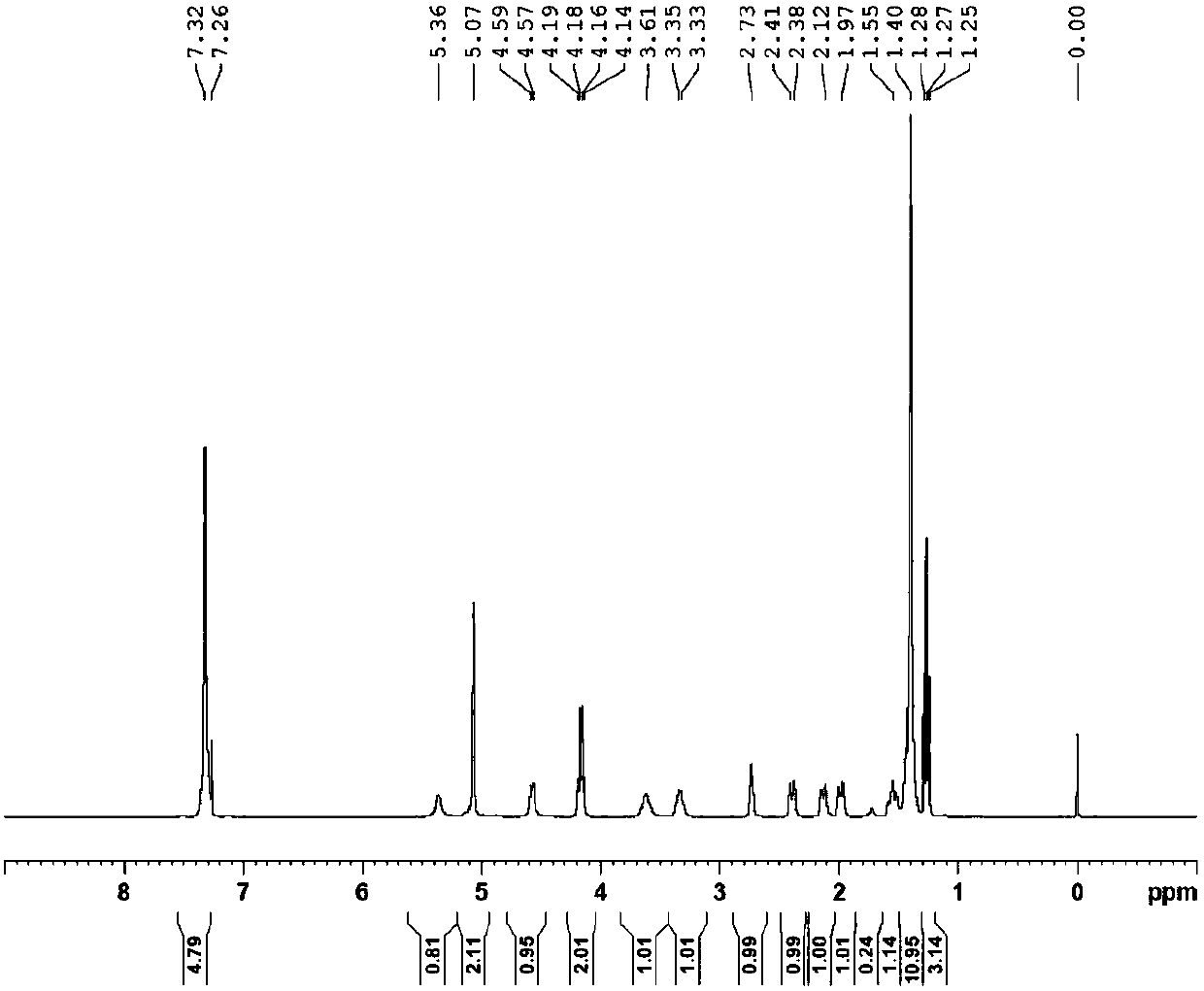

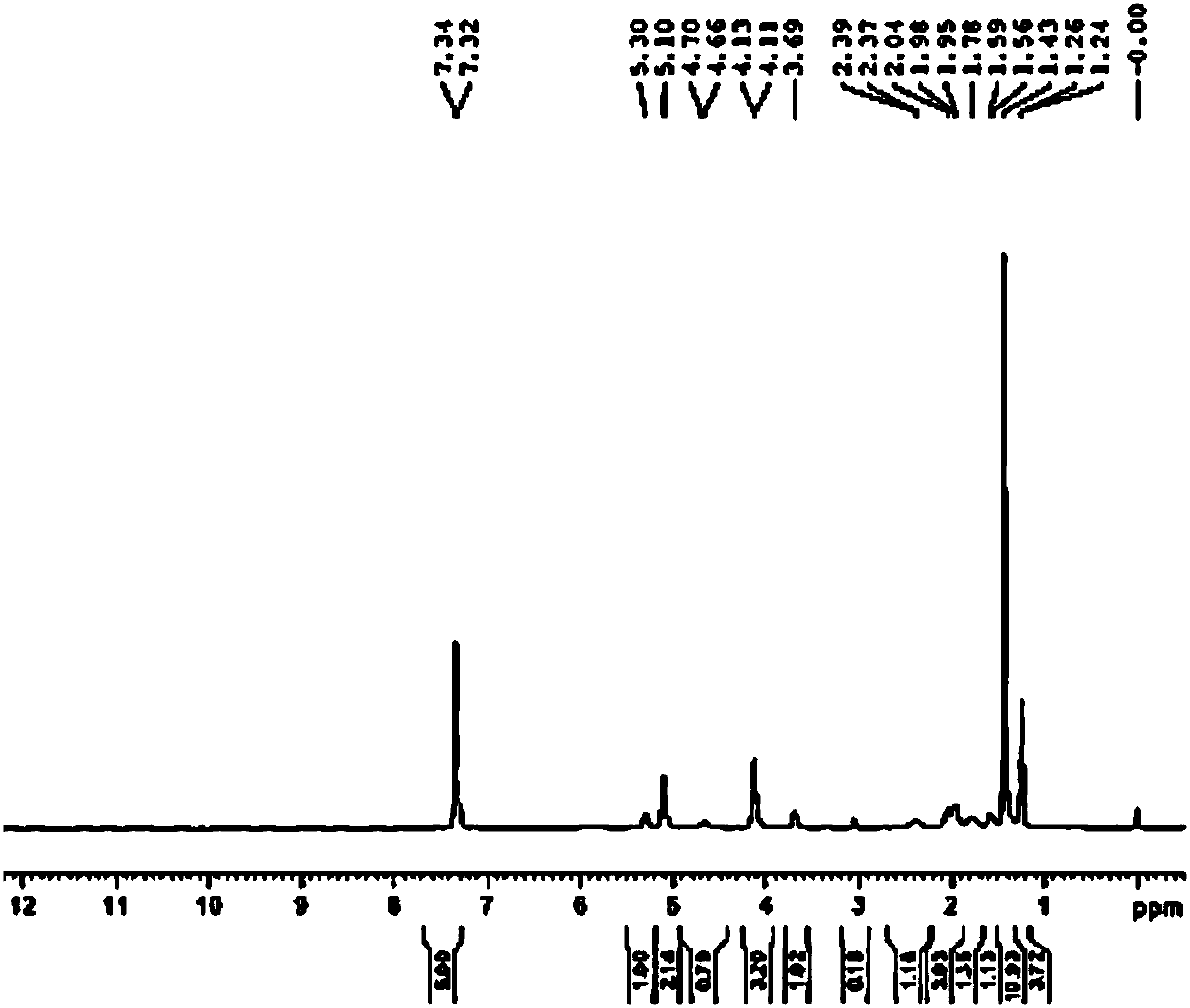

Phthalocyanine compound, process for producing the same and colored composition containing the phthalocyanine compound

InactiveCN101120057AToleratedImprove securityOrganic chemistryPorphines/azaporphinesOrganic solventPhthalocyanine

Provided is a phthalocyanine compound represented by the following general formula (1) which is halogen-free, has a green hue, and is resistant to organic solvents and acids (in the above general formula (1), M represents 2 to 4 valent A metal atom or two hydrogen atoms, rings A1, A2, A3 and A4 each independently represent a benzene ring or a structure represented by the above-mentioned general formula (2). Among them, at least one of the rings A1, A2, A3 and A4 is the above-mentioned A structure represented by general formula (2). In addition, in the above general formula (2), R represents a hydrogen atom, an alkyl group having 1 to 4 carbon atoms, a phenyl group, a tolyl group or a xylyl group).

Owner:DIC CORP

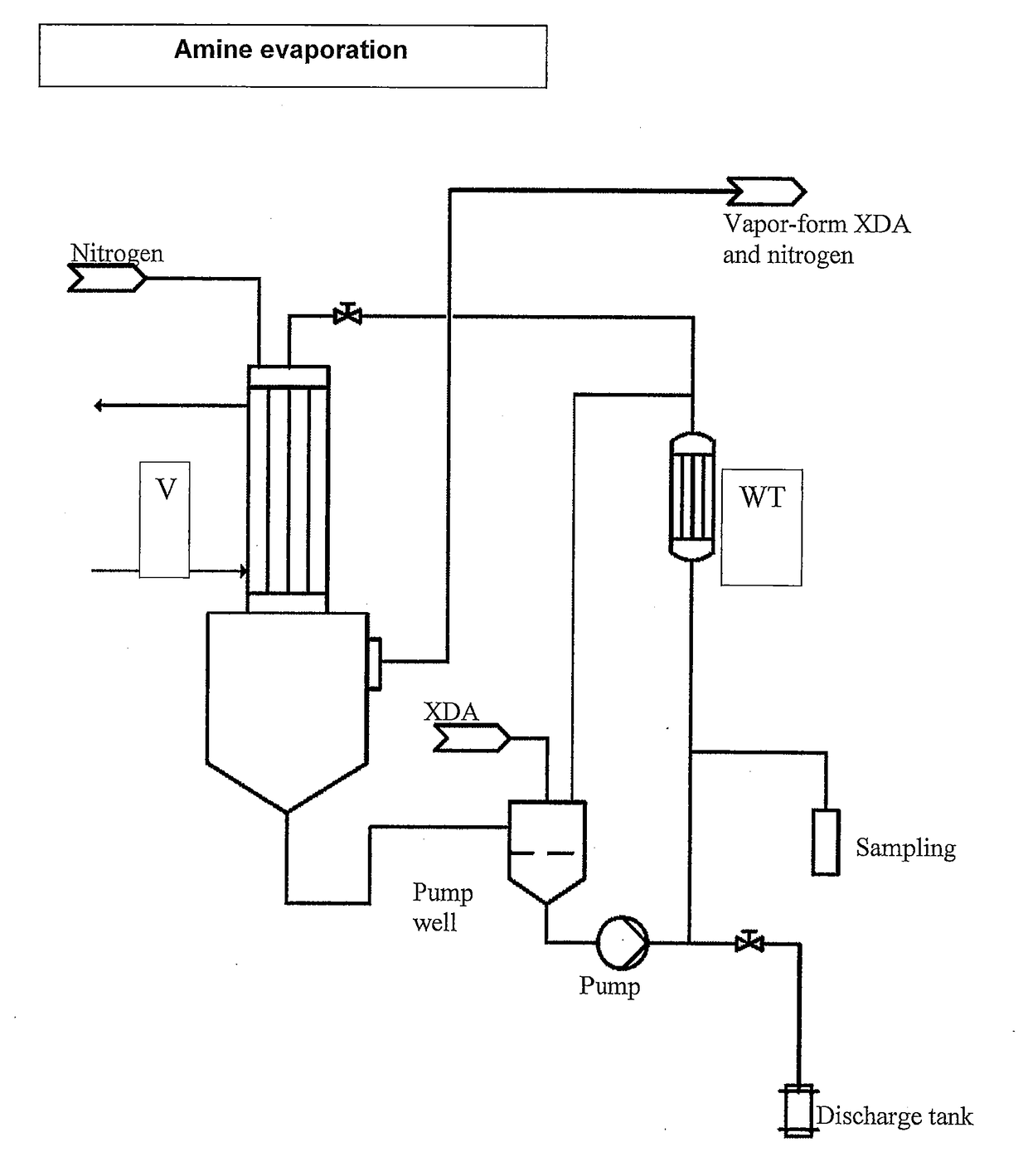

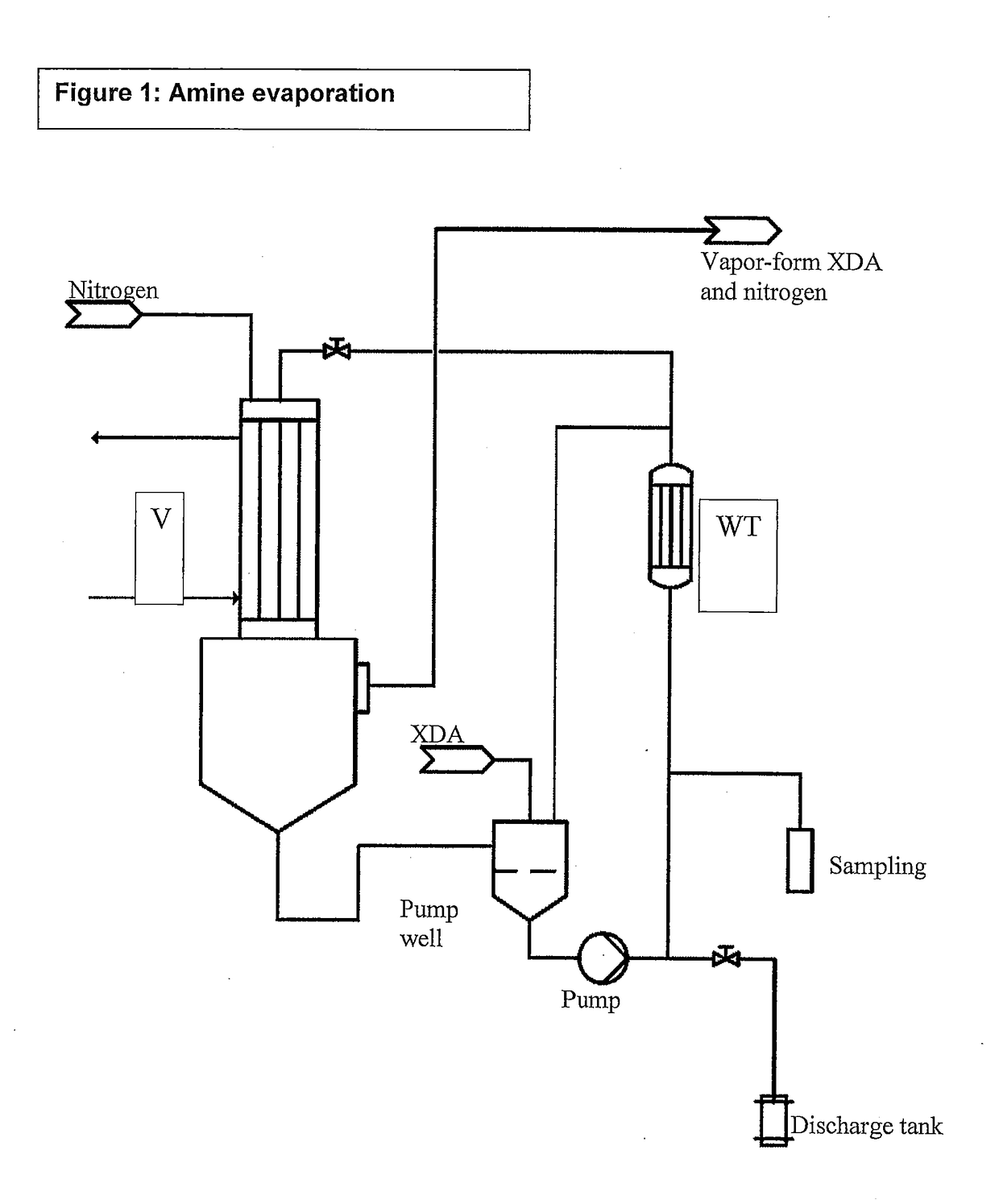

Method for producing xylylene diisocyanates in the gaseous phase

ActiveUS20170210702A1Long run timeKeep for a long timeIsocyanic acid derivatives preparationOrganic compound preparationChemistryIsocyanate compound

Owner:COVESTRO DEUTSCHLAND AG

Automobile synthetic diesel oil and preparation method thereof

InactiveCN101643671ALow costImprove securityLiquid carbonaceous fuelsFuel additivesChemical synthesisZinc peroxide

The invention relates to an automobile synthetic diesel oil and a preparation method thereof, belonging to the technical field of synthetic chemical fuel. The synthetic gasoline contains methyl alcohol, methylbenzene, stearic acid, fatty acid methyl ester, potassium chlorate, zinc peroxide, nitromethane, cyclohexane, glyceride, octane number regulator and xylidine. The automobile synthetic dieseloil has the characteristics of good volatility and stability, high calorific value, no carbon deposit, low cost, etc, thus completely achieving the properties of the existing diesel oil and being an ideal substitute product.

Owner:徐宏远

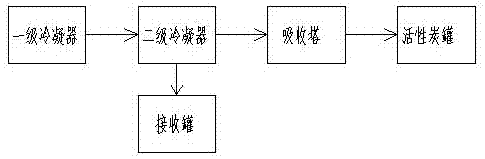

Novel xylidine and acetic acid waste gas recovery device and method

InactiveCN107511023AReduce and prevent frostingMeet the requirements of environmental indicatorsGas treatmentDispersed particle separationAcetic acidActivated carbon

The invention relates to a novel xylidine and acetic acid waste gas recovery device and method. The recovery device comprises a condensation type recovery device and an adsorption-type recovery device; the condensation type recovery device comprises a primary condenser and a secondary condenser which are communicated in sequence; the lower end of the secondary condenser is provided with a condensate recovery tank; the adsorption-type recovery device comprises an absorption tower and an activated carbon tank which are communicated in sequence; in a condensing period, a pre-condensation plus secondary condensation method is adopted, and meanwhile frosting of a condensation device are reduced and prevented as much as possible; xylidine and acetic acid mixed gas which is condensed and not recovered is subjected to cyclic spray settling by a tail gas absorber, and the gas running away to the upper part is subjected to adsorption treatment by the activated carbon tank. The novel xylidine and acetic acid waste gas recovery device and method have the advantages that the recovery utilization rate or organic matters such as acetic acid and xylidine is up to 99 percent or higher, activated carbon regeneration is thorough, the reuse rate is high, the service life is long, the operation cost is low, energy is saved, a process is simplified, and steam regeneration is not adopted.

Owner:NANTONG ITALMATCH CHEM

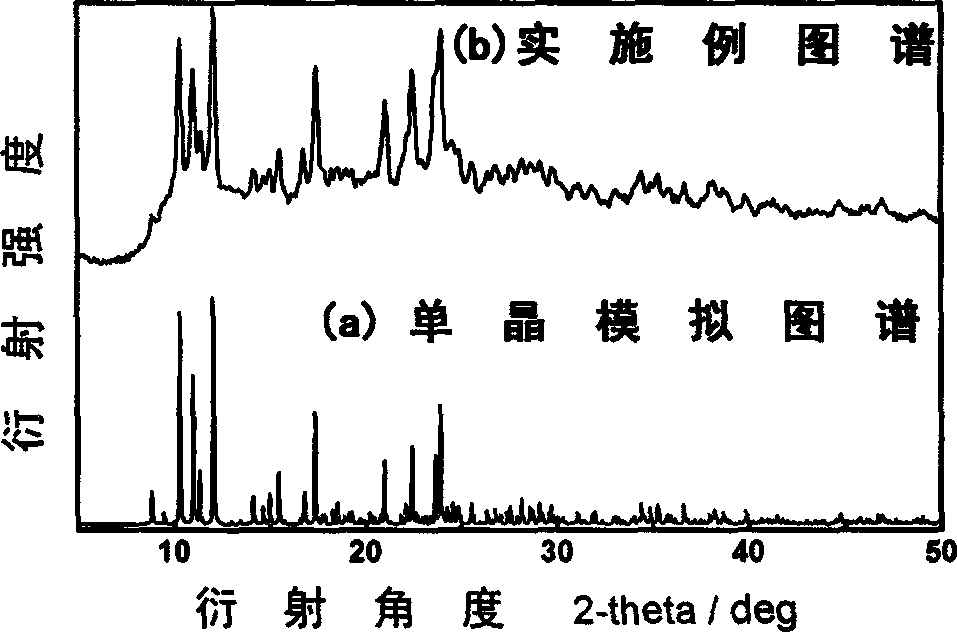

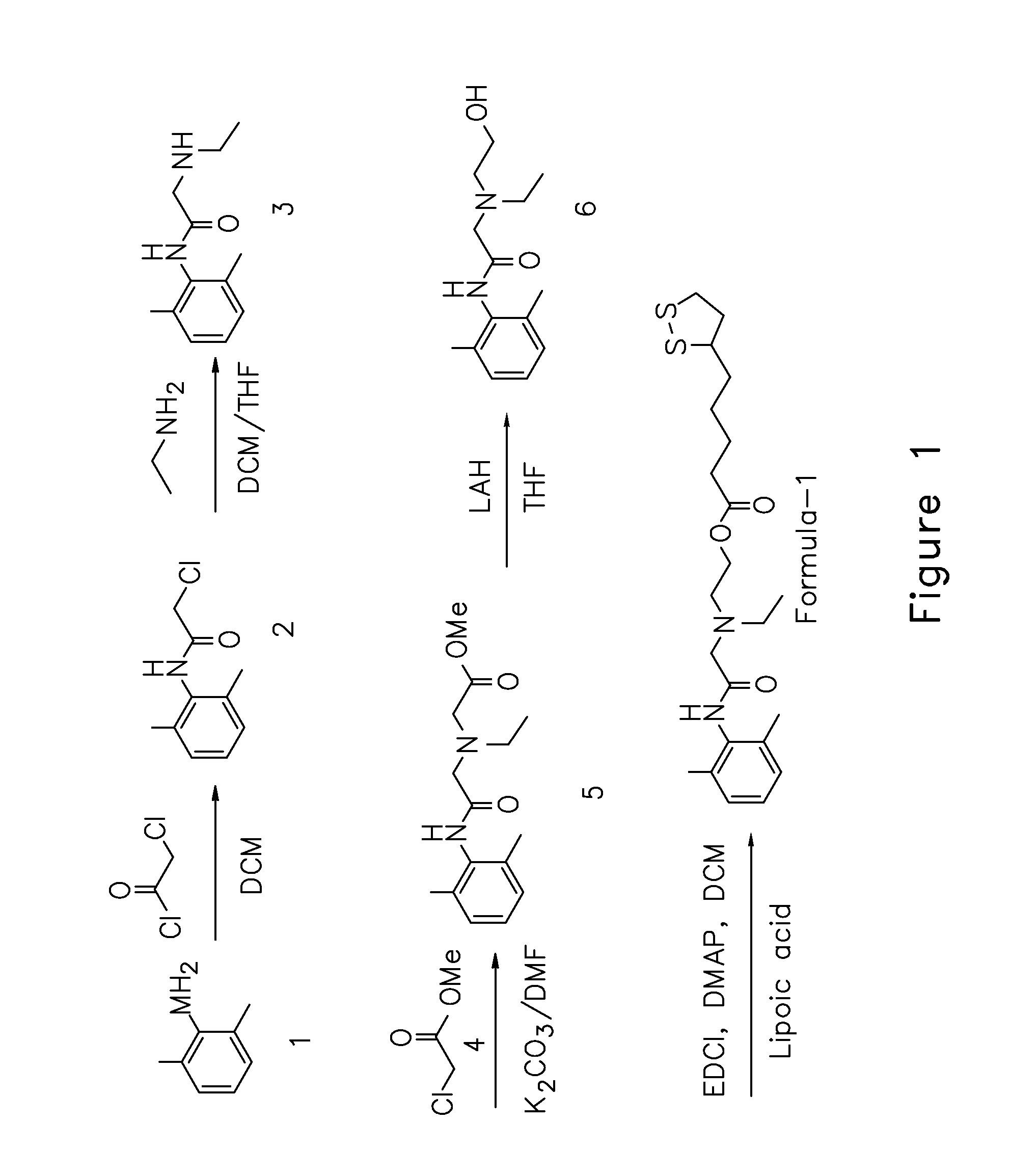

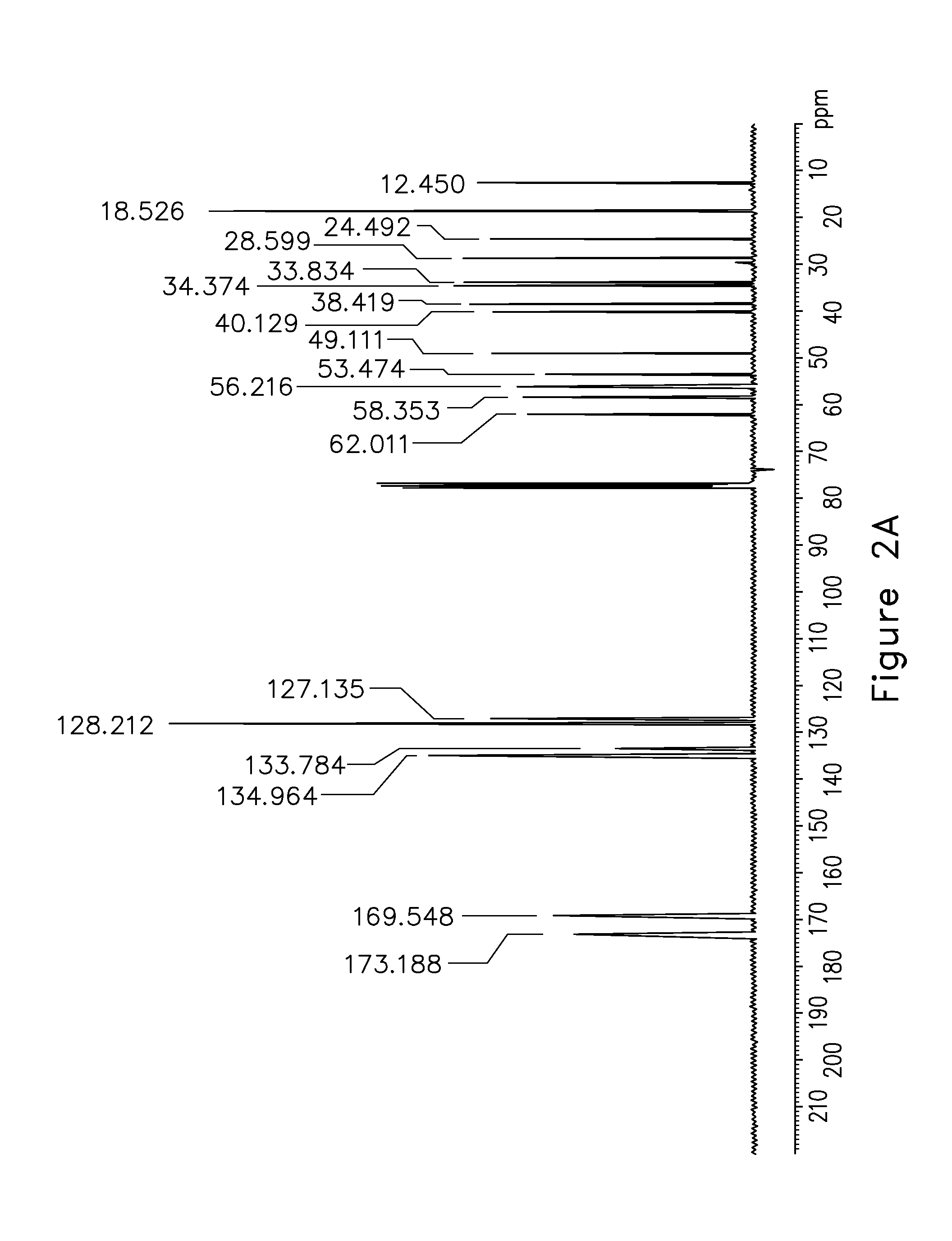

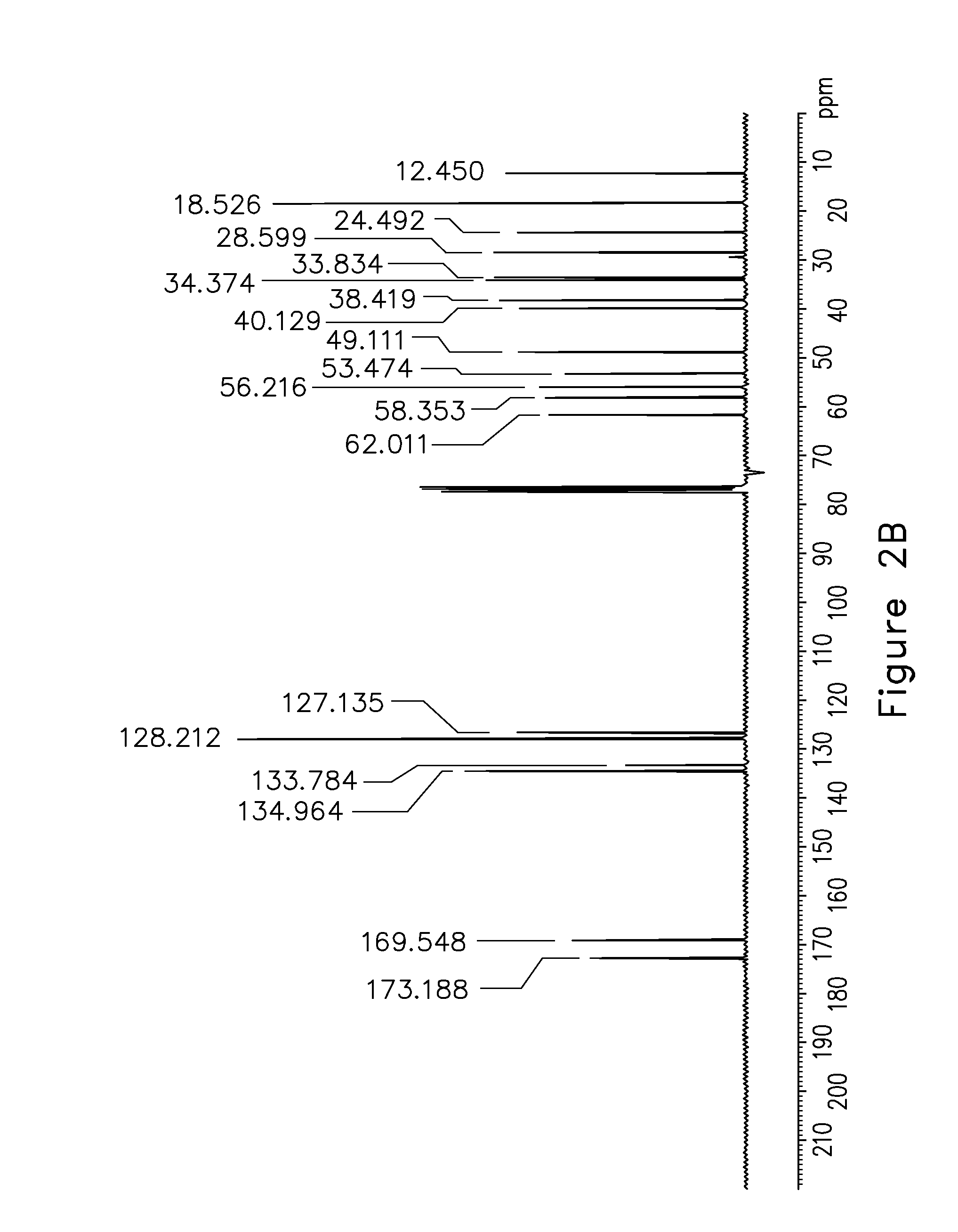

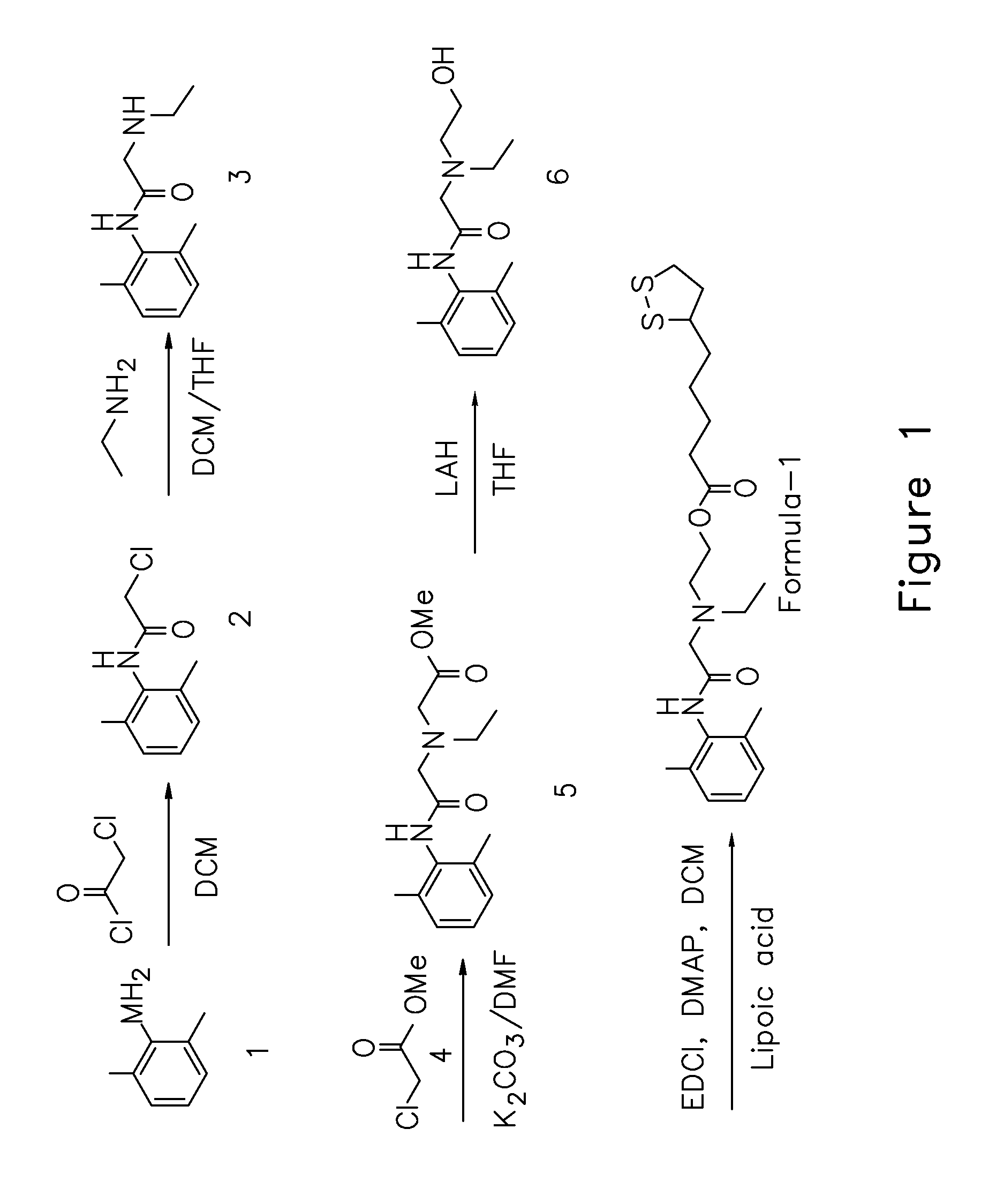

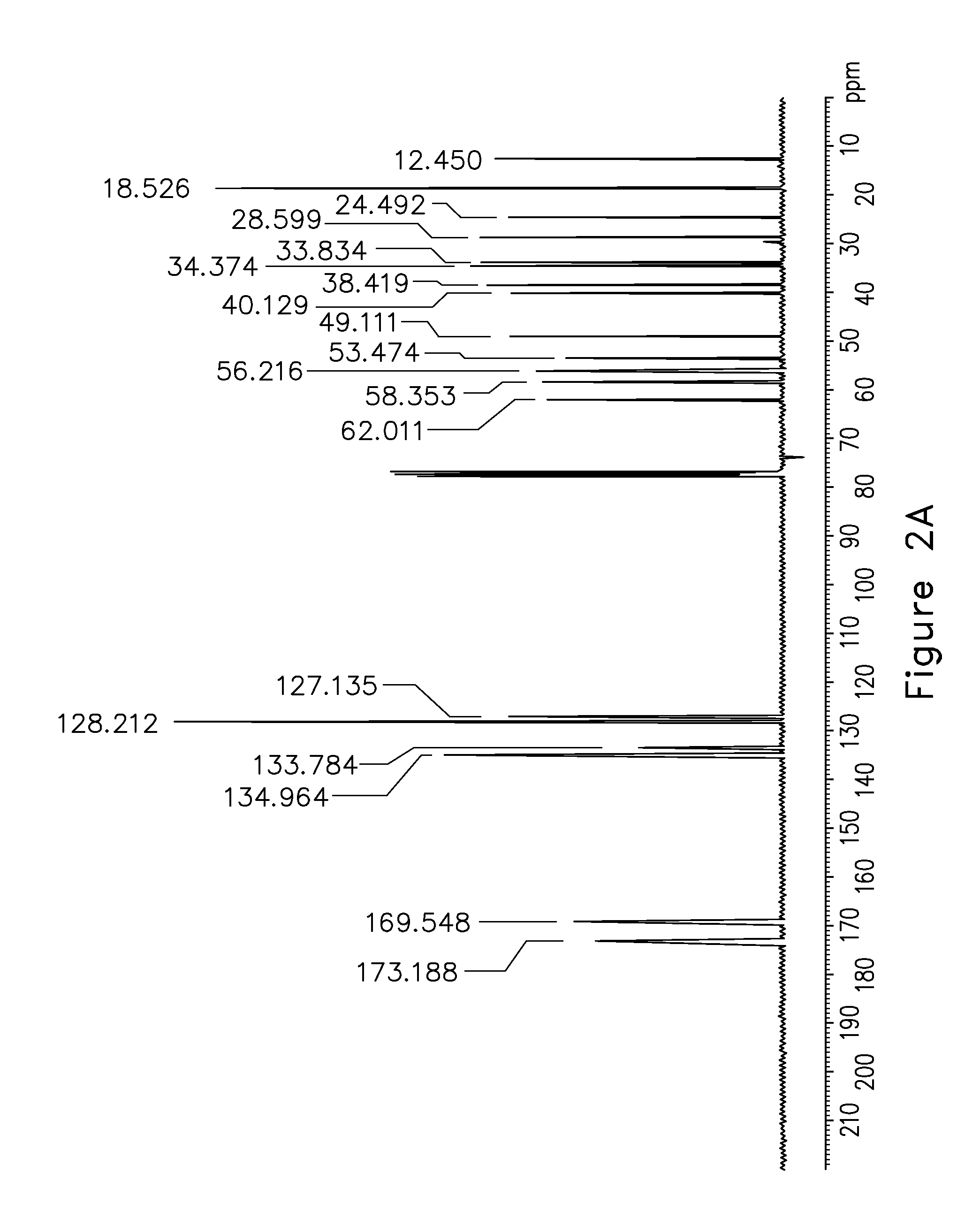

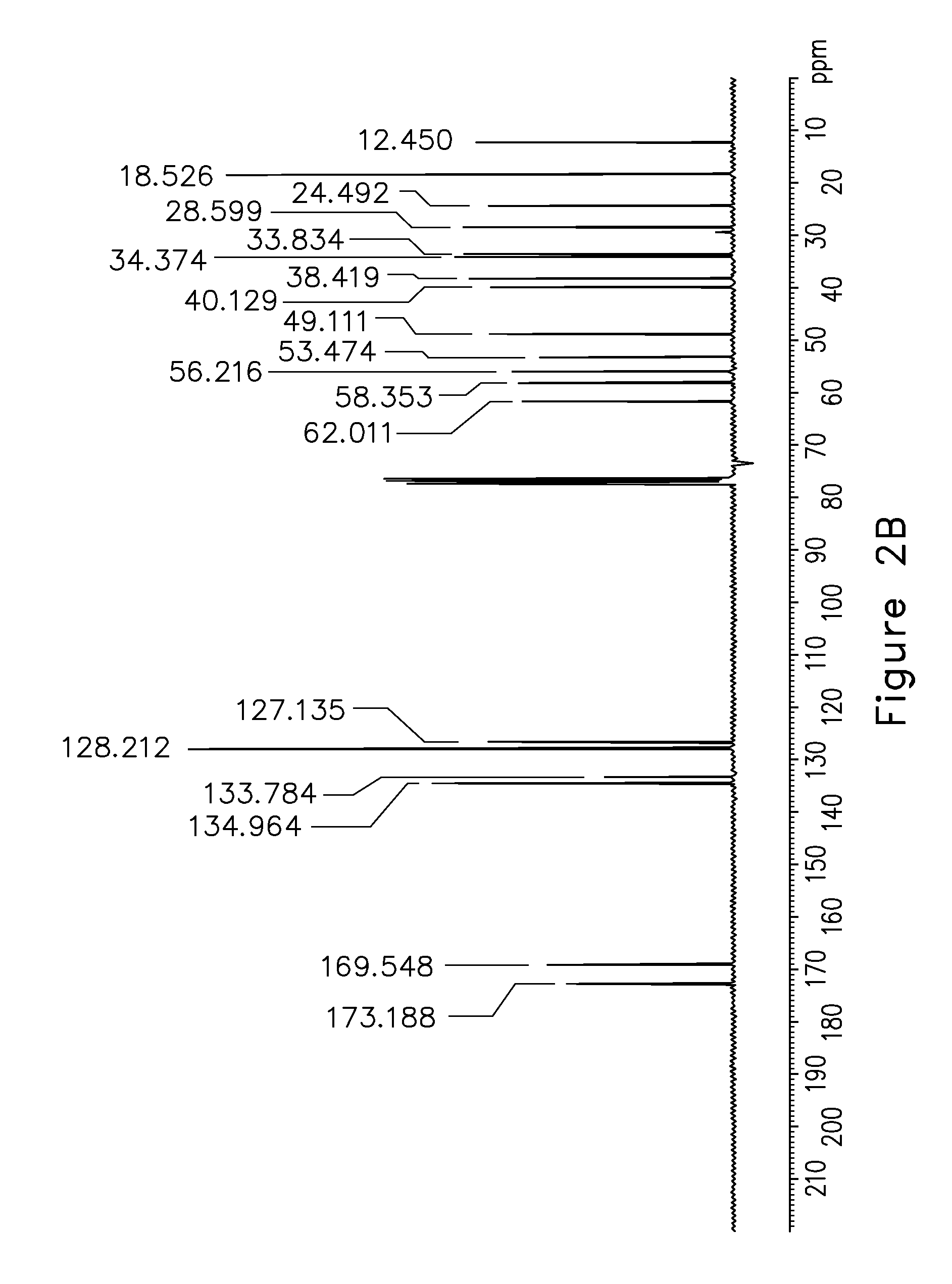

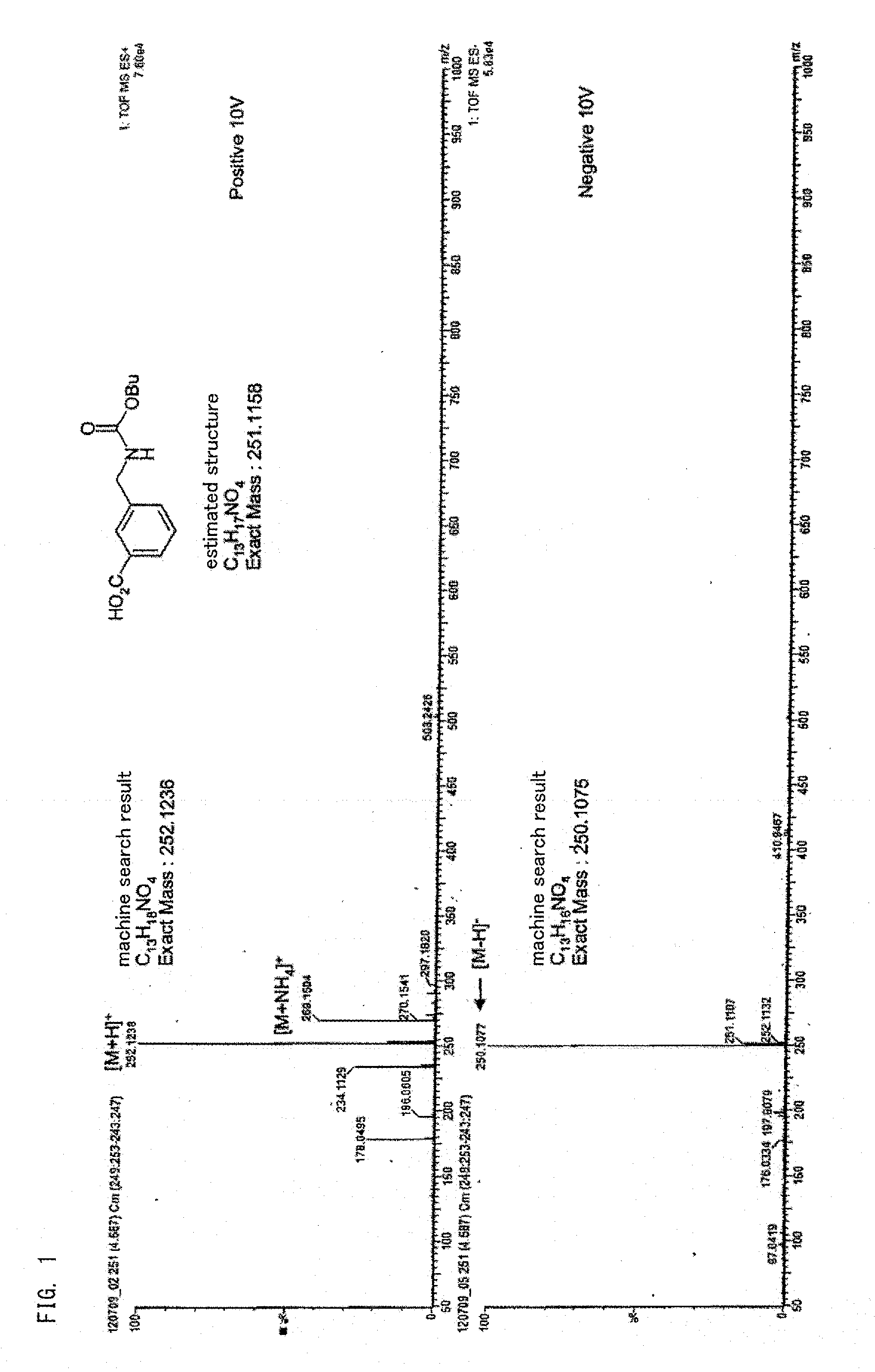

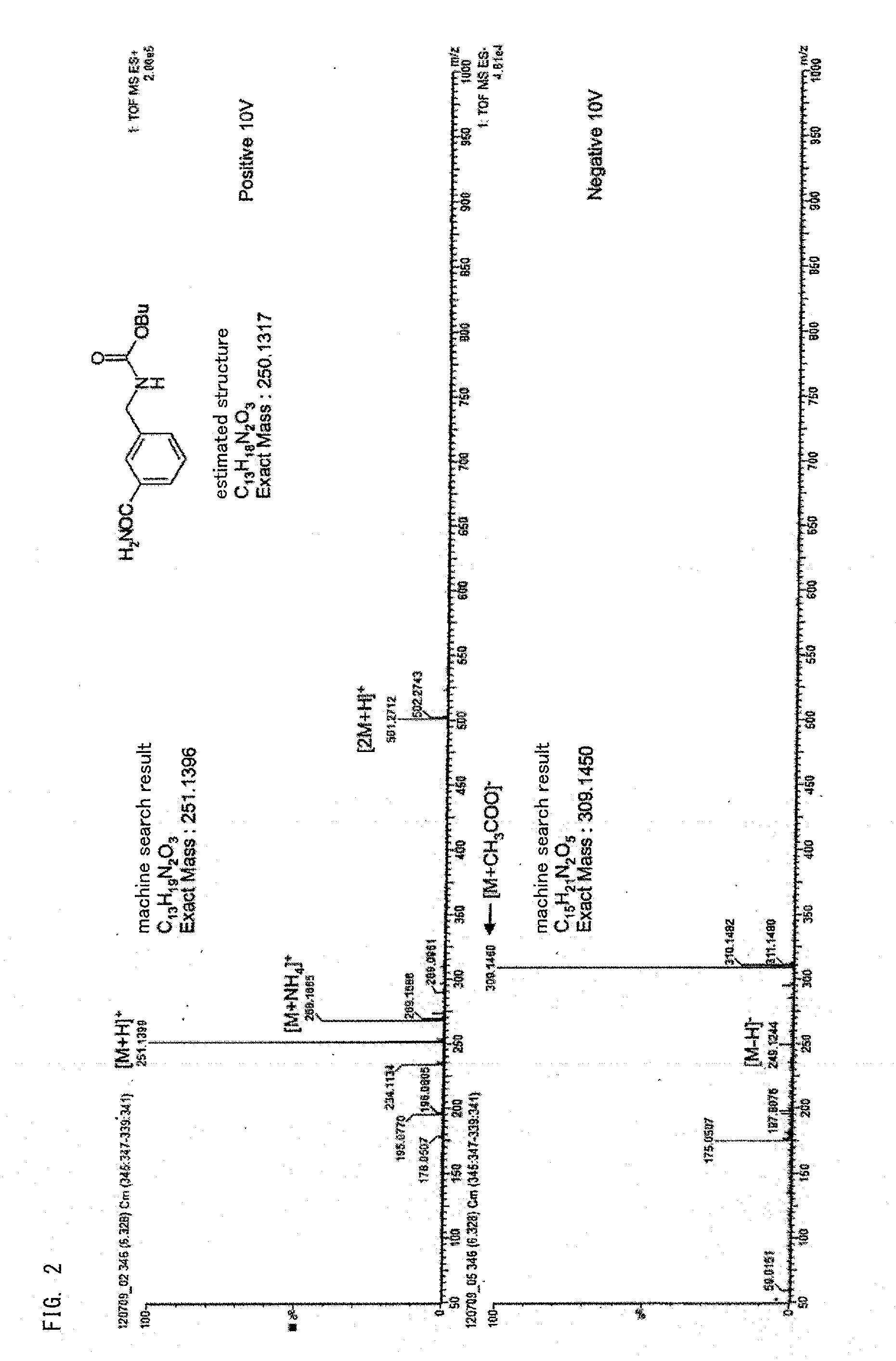

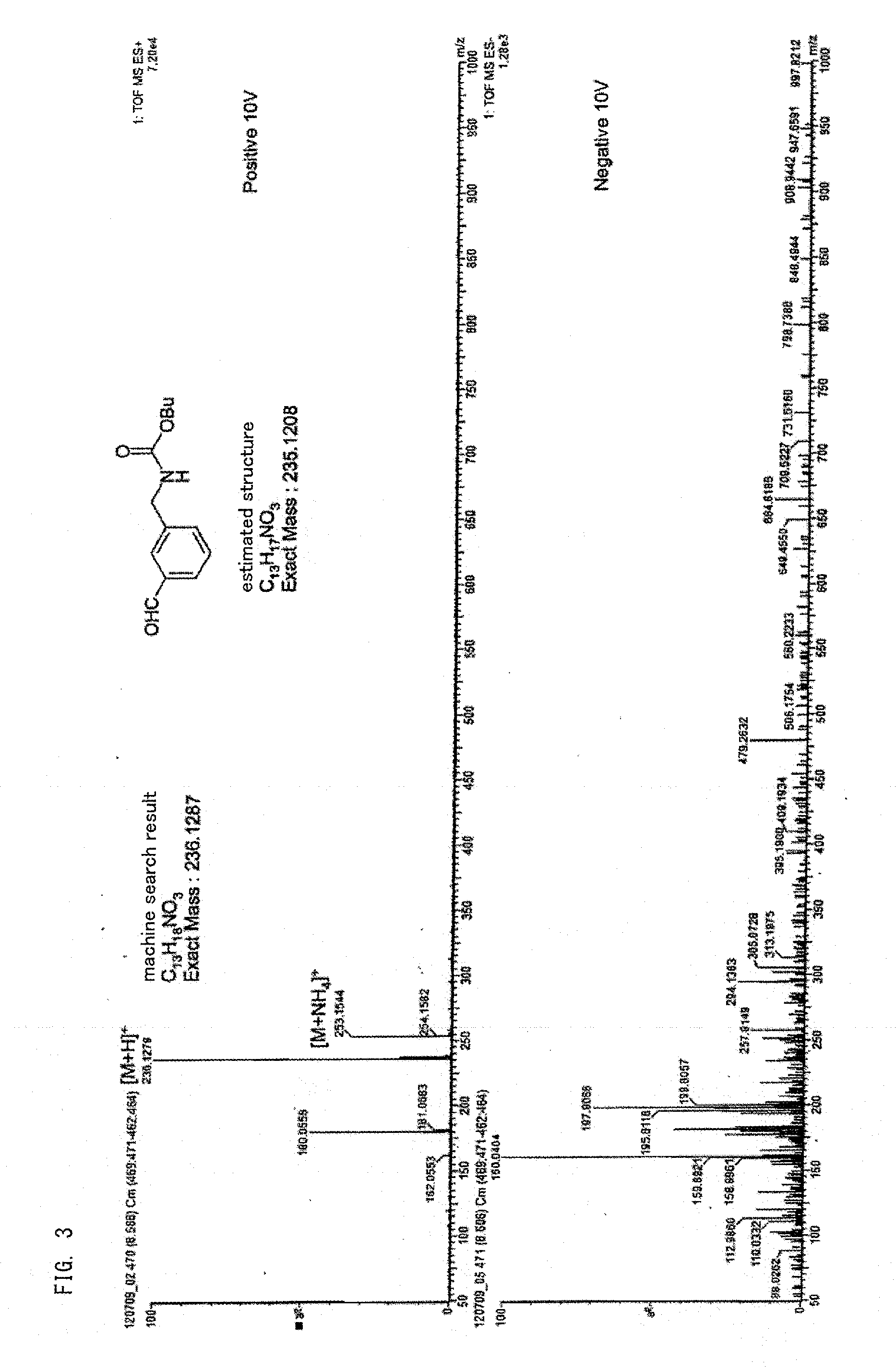

2, 6 xylidine derivatives for the treatment of pain

The disclosure herein provides a composition compound of formula 1. The disclosure also provides a method of synthesizing the compound of formula 1. The compound of formula 1 or its pharmaceutical acceptable salts, as well as polymorphs, solvates, and hydrates thereof may be formulated as pharmaceutical composition to be used for treatment of pain. The pharmaceutical composition of compound of formula 1 or the final compound may be formulated for non-invasive peroral, topical (example transdermal), enteral, transmucosal, targeted delivery, sustained release delivery, delayed release, pulsed release and parenteral methods. Such compositions may be used to treat chronic pain manifested with chronic diseases or its associated complications. The compound of formula 1 may also be offered as a kit.

Owner:KRISANI BIOSCI P

Method of preparing unsaturated polyester putty for automobile repair

InactiveCN102504641AAddress resilienceSolve the contradiction that the sandability is also poorFilling pastesBenzoyl peroxideDimethylaniline N-oxide

The invention discloses a method of preparing unsaturated polyester putty for automobile repair, which includes: firstly, proportionally adding air-dry water based unsaturated polyester resin into a reactor, mixing under rotation at speed of 350-450r / min, respectively adding cobalt iso-octoate, xylidine and 4-tert-butylcatechol prior to mixing for 10-15 minutes, then adding white carbon black and titanium dioxide prior to mixing under rotation at 600-650r / min for 10-15 minutes, adding -325-mesh pulvistalci, -325-mesh diatomite powder, gaseous SiO2 powder, palygouskite and ultramarine prior to mixing under rotation at 950-1000r / min for 35-45 minutes, and using a colloid mill to grind the mixture to obtain finished base stock; secondly, proportionally adding cyclohexanone peroxide, benzoyl peroxide, acetone and white carbon black into the reactor prior to mixing under rotation at 600-800r / min for 15-25 minutes, and grinding the product of mixing into paste to obtain finished curing agent; and thirdly, well mixing the prepared base stock and the curing agent according to a proportion 100:2.

Owner:TIANCHANG CITY TONGTIAN CHEM

Preparation method of eltrombopag medicine for treating idiopathic thrombocytopenic purpura

InactiveCN107915678AReduce usagePromote the development of economy and technologyOrganic chemistryBlood disorderHigh volume manufacturingThrombocytopenic purpura

The invention discloses a preparation method of Eltrombopag used for treating idiopathic thrombocytopenic purpura. The chemical name of Eltrombopag is 3‑{(2Z)‑2‑[1‑(3 ,4‑xylyl)‑3‑methyl‑5‑oxo‑1,5‑dihydro‑4H‑pyrazole‑4‑ylidene]hydrazino}‑2‑hydroxy‑3‑biphenylcarboxylic acid‑ 2-amino ethanol salt; the preparation process of the present invention is simple, the raw material is easy to get, avoids the use of highly toxic methyl iodide, is economical and environmentally friendly, is conducive to the realization of industrialization, can promote the economic and technological development of Eltrombopag raw material medicine, and reduces the production cost. cost, suitable for mass production.

Owner:孙婷婷

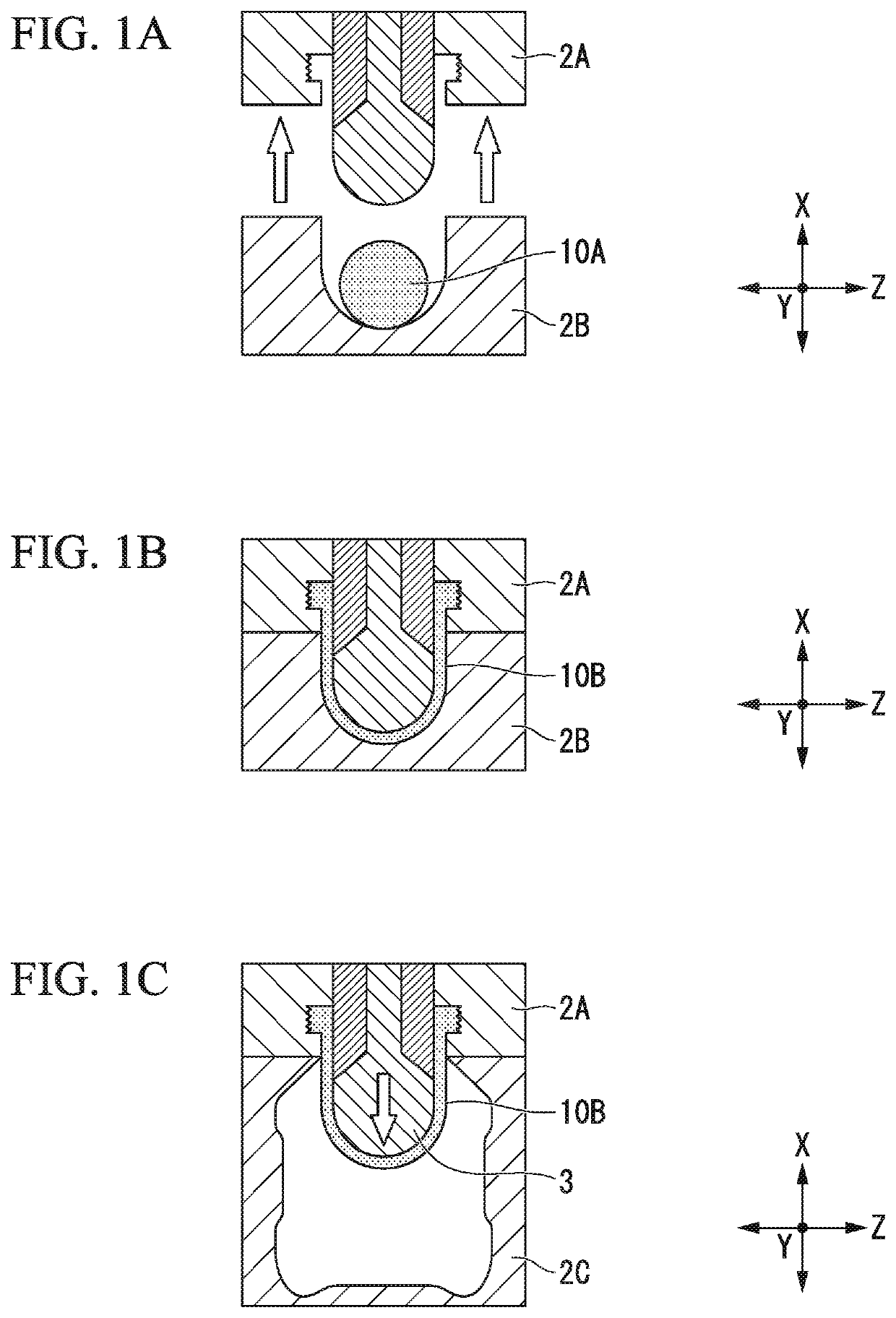

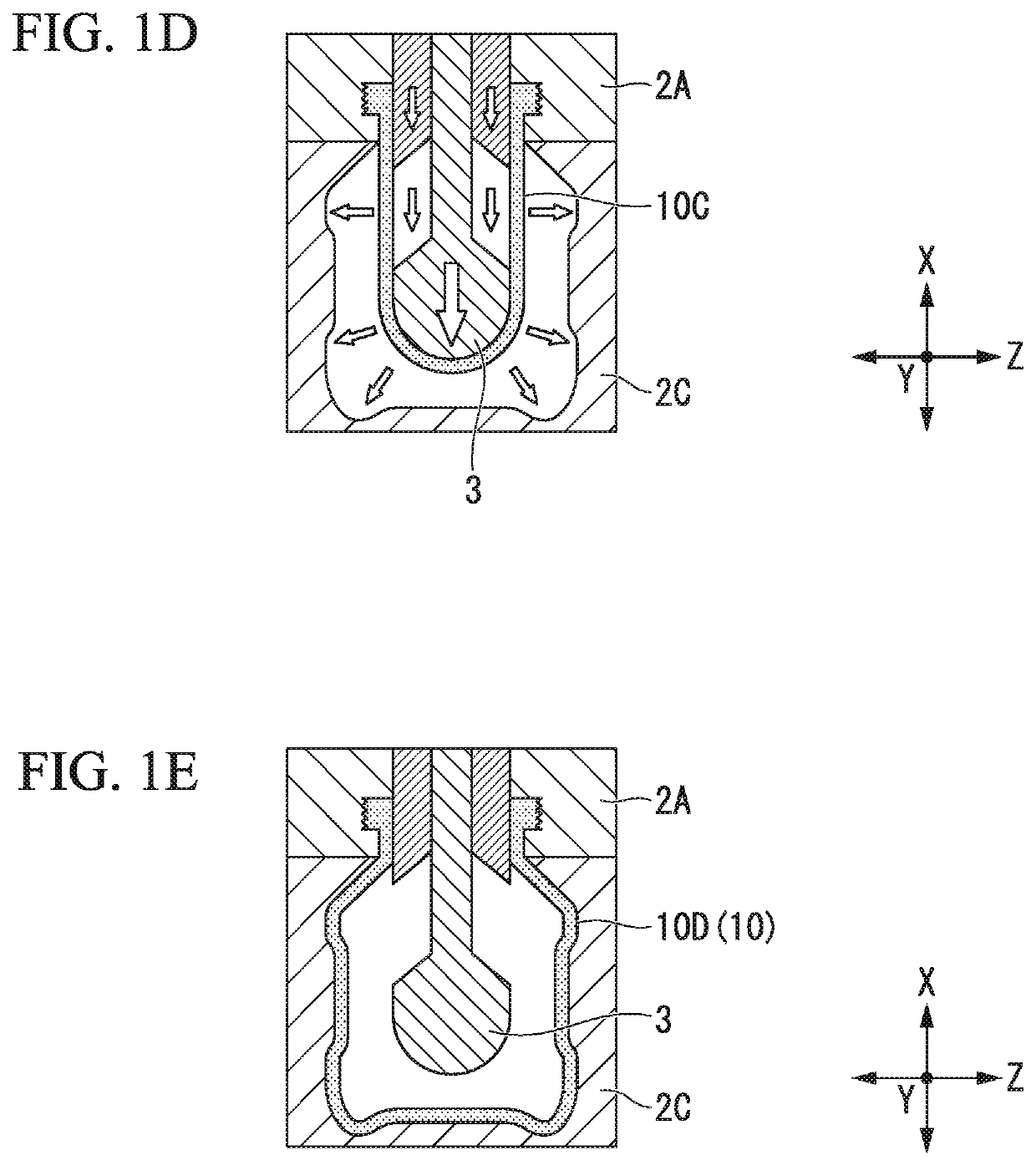

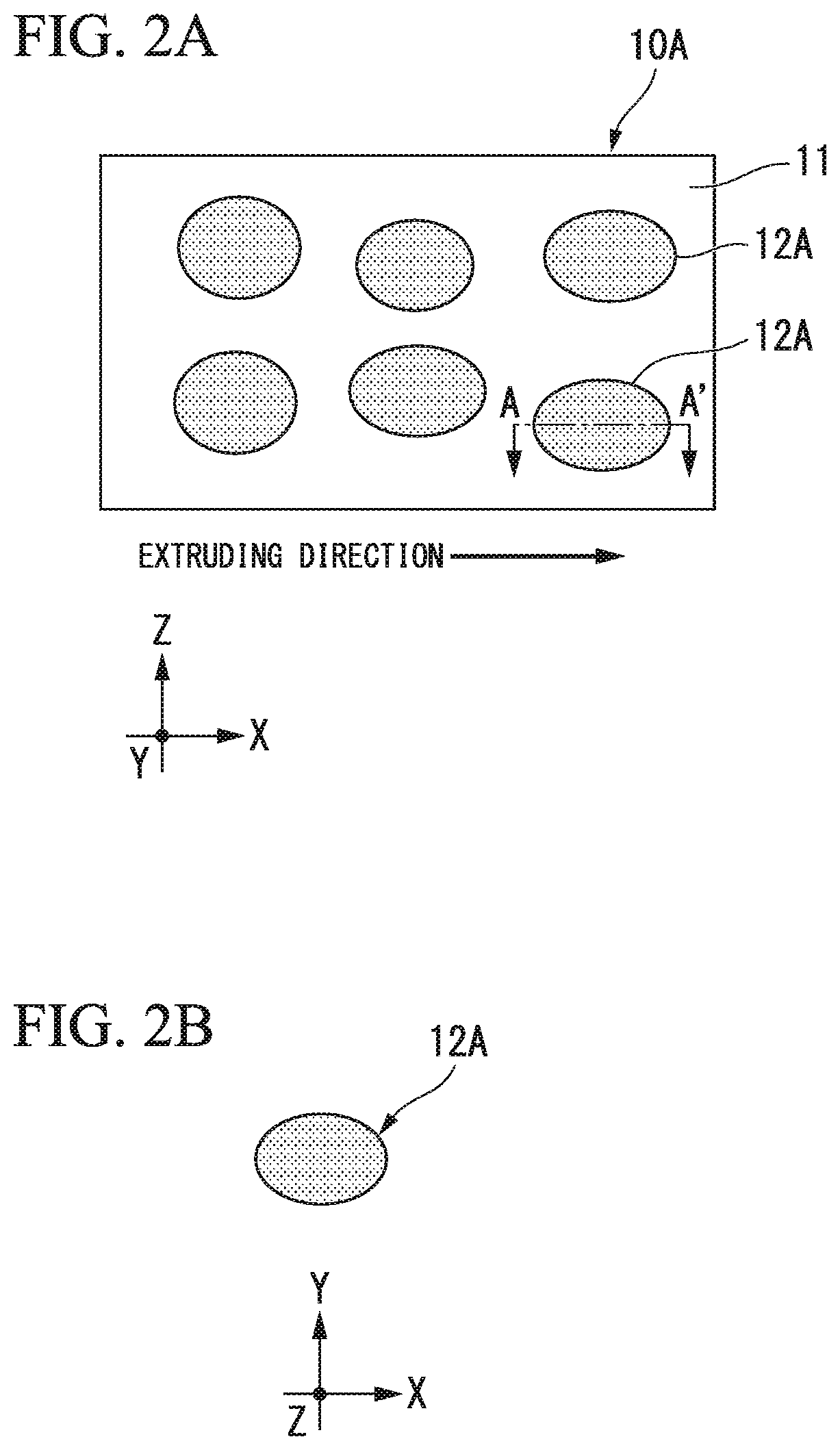

Hollow container and method for manufacturing hollow container

ActiveUS10781010B2Excellent oxygen barrier property and solvent barrier propertyImprove productivityLayered productsBottlesXylylenePolymer science

A single-layer hollow container includes: a resin composition that is formed of 60 to 90% by mass of polyolefin, 2 to 35% by mass of meta-xylylene group-containing polyamides, and 5 to 30% by mass of modified polyolefin. The meta-xylylene group-containing polyamides are dispersed insularly in the polyolefin, and in a case where each of a vertical length and a horizontal length of the meta-xylylene group-containing polyamide in an initial state is 1, the vertical length of the meta-xylylene group-containing polyamide in the hollow container ranges from 3.3 to 15.8 and the horizontal length ranges from 0.5 to 2.0.

Owner:TOPPAN PRINTING CO LTD

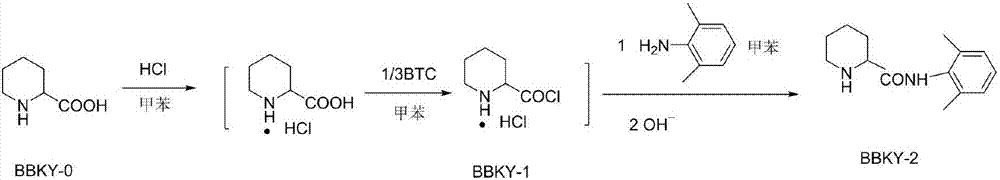

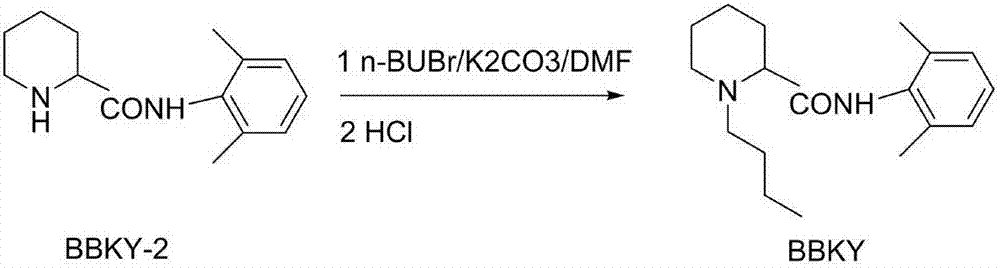

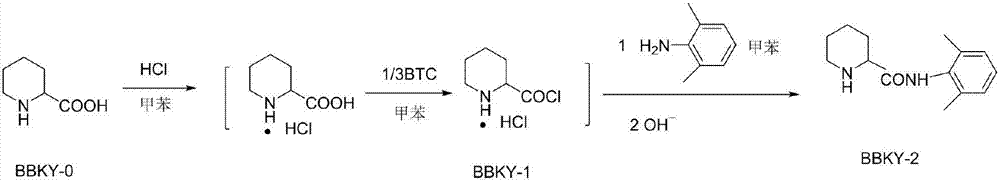

Preparation process of bupivacaine hydrochloride

InactiveCN106117118AEnables reusabilityAchieve reuseOrganic chemistryRoom temperatureBupivacaine hydrochloride

The invention discloses a preparation process of bupivacaine hydrochloride. According to the specific scheme, N-(2,6-xylyl)-2-piperidine formamide is adopted as a starting raw material and dissolved in methylbenzene, then a deacidification agent, a phase transfer catalyst and bromobutane are added, certain temperature is kept for reacting, and after the reaction is finished, filtering is carried out at room temperature, and a bupivacaine solution is obtained; the bupivacaine solution is acidized with an acidification agent, aftertreatment is carried out, and bupivacaine hydrochloride is obtained through drying. According to the preparation process, the solvent can be recycled, the production cost can be reduced, environmental pollution can be reduced, meanwhile, byproducts of other products of the company are fully utilized, refuse reclamation is achieved, and generated waste gas, waste water and industrial residues are reduced.

Owner:JIANGSU TIANHE PHARMA CO LTD

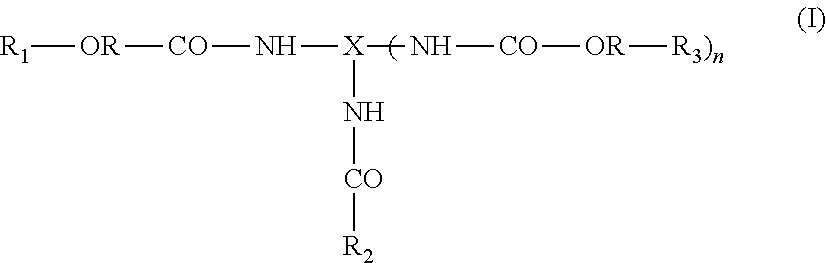

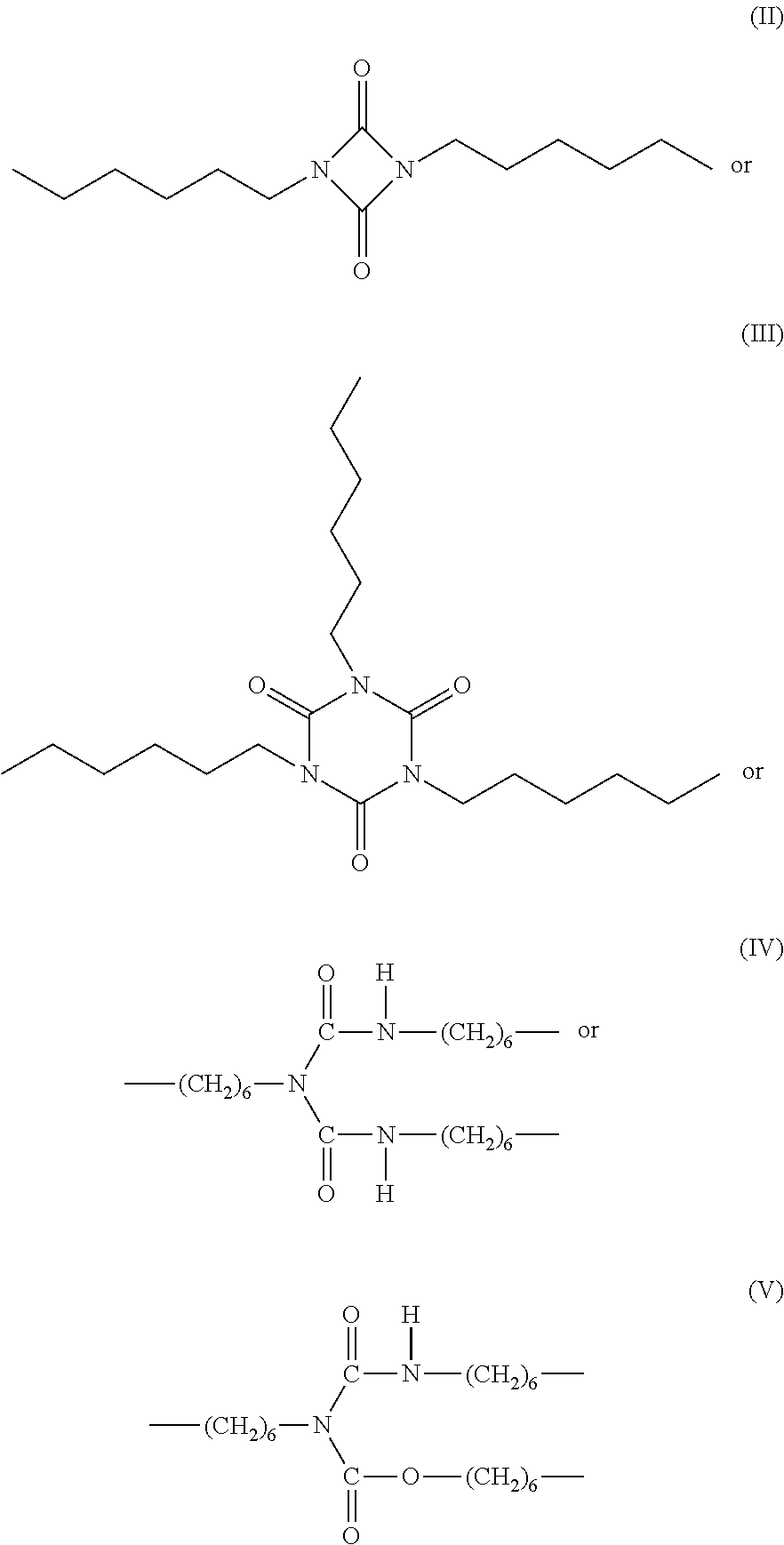

Compound for manufacturing watermark in a textile sheet material and the corresponding composition, material, method and use

InactiveUS20120295079A1High transparencyLow refractive indexSilicon organic compoundsSynthetic resin layered products1,4-ButanediolXylylene

The invention relates to a compound for manufacturing watermark in a textile sheet material and the corresponding composition, material, method and use. The compound for manufacturing a watermark in a textile sheet material of formulawhereinX is hexamethylene, trimethylhexamethylene, isophorone, dicyclohexylmethyl, tetramethylxylylene, tetramethylenexylene, xylylene, trimethylhexamethylene, hydrogenated 4,4′-diphenylmethylene, 1,12-dodecylene, 1,5-2-methylpentylene; 1,4-butylene; 1,4-cyclohexylene, or a compound of formula5R1 is a linear aliphatic C1-C12 alkyl radical or a branched aliphatic C3-C18 alkyl radicalR2 is a radical of formulawhereinR4 is methoxy or ethoxyR5 and R6 are H, methoxy, ethoxy, methyl or ethylR7 is cyclohexyl, phenyl or aliphatic C3-C6 alkylR3 is a linear aliphatic C1-C12 alkyl radical or a branched aliphatic C3-C18 alkyl radicaln is 0 or 1.

Owner:OLIVA GURGUI ANTONIO MR

Hydrophobic nanostructured thin films

Provided herein are the polymers shown below. The value n is a positive integer. R1 is an organic group, and each R2 is H or a chemisorbed group, with at least one R2 being a chemisorbed group. The polymer may be a nanostructured film. Also provided herein is a method of: converting a di-p-xylylene paracyclophane dimer to a reactive vapor of monomers; depositing the reactive vapor onto a substrate held at an angle relative to the vapor flux to form nanostructured poly(p-xylylene) film; reacting the film with an agent to form hydrogen atoms that are reactive with a precursor of a chemisorbed group, if the film does not contain the hydrogen atoms; and reacting the hydrogen atoms with the precursor. Also provided herein is a device having a nanostructured polyp-xylylene) film on a pivotable substrate. The film has directional hydrophobic or oleophobic properties and directional adhesive properties.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Composite clean liquid fuel and production method thereof

The invention discloses a composite clean liquid fuel and a production method thereof. The composite clean liquid fuel is prepared from methanol, water, alcohol, acetic acid, natron, aqua ammonia, xylidine, sodium nitrate, and dicyclic diolefine iron. The production method comprises the following steps:1, adding the methanol into the dicyclic diolefine iron, stirring uniformly and mixing fully; 2, adding the natron into the water and stirring uniformly; 3, enabling the two liquids produced in the step 1 and the step 2 to dissolve each other and stirring, and then adding the acetic acid into the liquids and stirring; 4, stirring to enable the aqua ammonia, the xylidine and the sodium nitrate to dissolve one another in sequence, adding the aqua ammonia, the xylidine and the sodium nitrate into the alcohol and stirring uniformly; 5, enabling the two liquids produced in the step 3 and the step 4 to dissolve each other, guiding the liquids into a reaction pot for reaction, and stirring; and 6, deeply filtering the liquid produced in the step 5 through a filter, then inputting the filtered liquid into a softening system for softening treatment, and finally pouring the softened liquid into a storage tank for settlement, so as to obtain the finished product. The composite clean liquid fuel has the advantages of safety, environmental protection, no undesirable odor, easiness in production, low cost and the like, and is suitable to be used as fuel oil for kitchens.

Owner:殷孟波

Water-based coating material for galvanized steel plate, and preparation method thereof

InactiveCN112480811ASolving Flash Rust ProblemsImprove impact resistanceAnti-corrosive paintsSilicic acidStearic acid

The invention discloses a water-based coating material for a galvanized steel plate, and a preparation method thereof. The water-based coating material comprises a component A, a component B and a component C, wherein the component A is composed of 15-20 parts by weight of methyltrimethoxysilane, 1-2 parts by weight of white carbon black and 1-2 parts by weight of stearate, the component B is prepared from 20-25 parts by weight of cation modified potassium silicate resin, 15-25 parts by weight of pigment, 6-16 parts by weight of filler, 0.5-1 part by weight of leveling agent, 0.5-1 part by weight of defoamer, 1-2 parts by weight of a film forming aid, 0.5-1 part by weight of dispersing agent, 3-8 parts by weight of photocatalyst and 20-30 parts by weight of water, and the component C is prepared from the following components in parts by weight: 1-2 parts of organic acid and 1-2 parts of xylylguanidine. According to the invention, by adding potassium silicate into the water-based coating material, the problem of flash rust of the existing water-based coating material for galvanized steel plates is solved, so that the coating material has favorable impact resistance; and the preparedwater-based coating material has excellent properties by further preferably selecting other components and reasonably compounding.

Owner:常州天瑞新材料科技有限公司

Phthalocyanine compound and method for producing the same, and coloring composition containing the phthalocyanine compound

InactiveUS7799911B2Improve securityLow environmental burdenReactive dyesPorphines/azaporphinesHydrogenHydrogen atom

To provide a phthalocyanine compound represented by the following general formula (1), which is halogen-free and has green hue, and also has resistance to an organic solvent and an acid:in the above general formula (1), M represents a divalent to tetravalent metal atom or two hydrogen atoms, and rings A1, A2, A3 and A4 each independently represents a benzene ring or a structure represented by the above general formula (2), provided that at least one of rings A1, A2, A3 and A4 is a structure represented by the general formula (2) and, in the above general formula (2), R represents a hydrogen atom, an alkyl group having 1 to 4 carbon atoms, a phenyl group, a tolyl group, or a xylyl group.

Owner:DAINIPPON INK & CHEM INC

Automobile synthetic gasoline and preparation method thereof

InactiveCN101643670ALow costReduce consumptionLiquid carbonaceous fuelsFuel additivesZinc peroxideAcetic acid

The invention relates to an automobile synthetic gasoline and a preparation method thereof, belonging to the technical field of synthetic chemical fuel. The synthetic gasoline contains methyl alcohol,methylbenzene, ethyl acetate, zinc peroxide, HMPA, glyceride, octane number regulator and xylidine. The automobile synthetic gasoline has the characteristics of good volatility and stability, high calorific value, no carbon deposit, low cost, etc.

Owner:徐宏远

Method for Separating Edoxaban and Its Isomers

The invention provides a method for separating and purifying edoxaban by chromatography. The separation method is chromatography, and the chromatographic conditions are as follows: the filler is an amylose-tri(3,5-xylylcarbamate) bonded silica gel, and the mobile phase is selected from a mixed solution comprising a non-polar solvent and a polar solvent. By selecting the chromatographic conditions, the edoxaban and seven enantiomers and nonenantiomers thereof can be simultaneously separated, and thus, the method has the characteristics of high speed, high simpleness, high efficiency and the like.

Owner:北京康派森医药科技有限公司

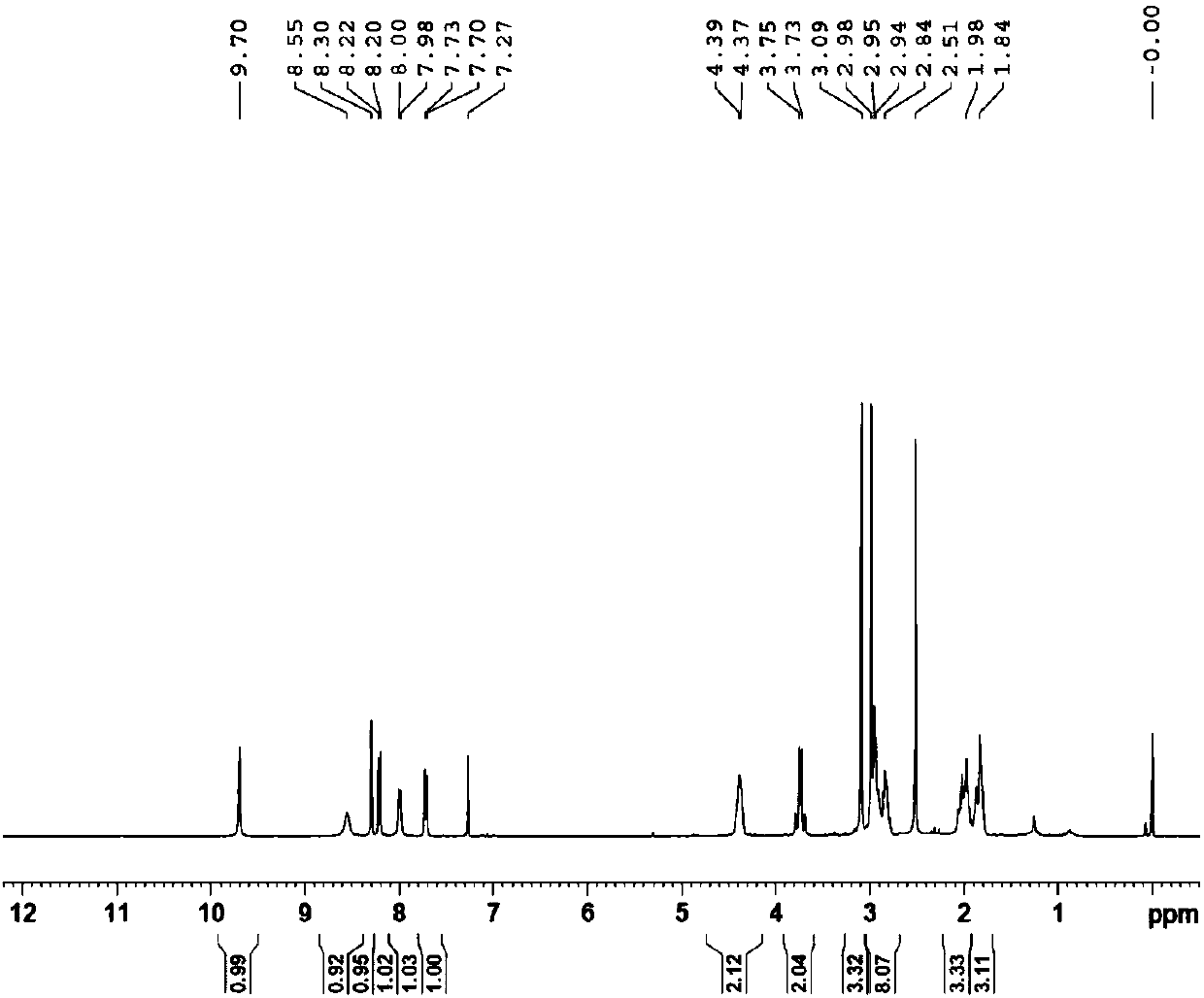

Preparation method of bupivacaine hydrochloride

InactiveCN107501167AHigh yieldImprove product qualityOrganic chemistryBupivacaine hydrochlorideAutomation

The invention discloses a preparation method of bupivacaine hydrochloride. The preparation method includes the steps of: 1) preparing N-(2,6-xylyl)-2-piperidineformamide; 2) preparing the bupivacaine hydrochloride. The reaction routes in the two steps are described in the specification. The method has high yield, high product quality and low operation cost, allows automation operation of equipment, has good stability, and can satisfy industrial demands.

Owner:JIANGXI YONGTONG TECH

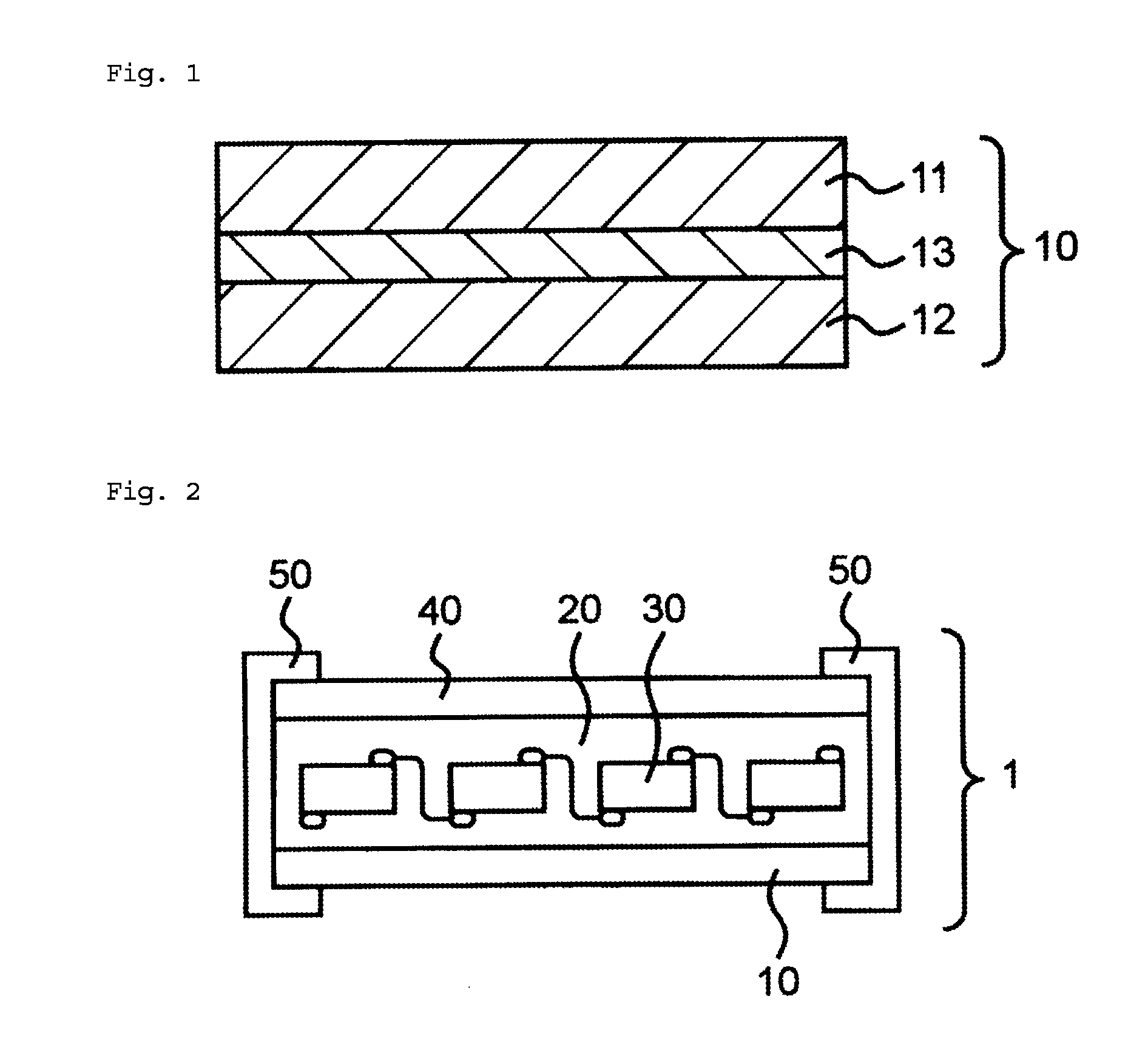

Protective sheet for rear surface of solar cell

ActiveUS20150263206A1High bonding strengthInhibitionPolyureas/polyurethane adhesivesPhotovoltaic energy generationXylylenePolymer science

This invention provides a solar cell rear surface protection sheet comprising two or more substrates laminated together by means of an adhesive, the adhesive comprising a urethane resin obtained by mixing an acrylic polyol, an isocyanate compound, 3-glycidoxypropyltriethoxysilane, and tin octylate, whereinthe acrylic polyol being obtained by polymerizing polymerizable monomers, the polymerizable monomers comprising a hydroxyl group-containing monomer and other monomers, the other monomers comprising acrylonitrile,the isocyanate compound comprising both a xylylene diisocyanate monomer and hexamethylene diisocyanate isocyanurate, the xylylene diisocyanate monomer being is present in an amount of 20 to 40 wt %, and the hexamethylene diisocyanate isocyanurate is present in an amount of 80 to 60 wt % andthe equivalent ratio of isocyanate groups of the xylylene diisocyanate monomer and the hexamethylene diisocyanate isocyanurate to hydroxyl groups of the acrylic polyol being 1.0 to 3.0.

Owner:TOYO ALUMINIUM KK

2, 6 xylidine derivatives for the treatment of pain

The disclosure herein provides a compound of formula 1. The disclosure also provides a method of synthesizing the compound of formula 1. The compound of formula 1 or its pharmaceutical acceptable salts, as well as polymorphs, solvates, and hydrates thereof may be formulated as pharmaceutical composition. The pharmaceutical composition of compound of formula 1 or the final compound may be formulated for non-invasive peroral, topical (example transdermal), enteral, transmucosal, targeted delivery, sustained release delivery, delayed release, pulsed release and parenteral methods. Such compositions may be used to treat chronic pain manifested with chronic diseases or its associated complications. The compound may also be offered as a kit.

Owner:KRISANI BIOSCI P

Xylylene dicarbamate, method for producing xylylene diisocyanate, xylylene diisocyanate, and method for reserving xylylene dicarbamate

ActiveUS20160046565A1Quality improvementHigh yieldCarbamic acid derivatives preparationOrganic compound preparationXylyleneXylidine

Xylylene dicarbamate contains impurities represented by formulas (1) to (4) below at a ratio of less than 100 ppm as a total amount thereof on a mass basis.(In the above-described formulas (1) to (4), R represents a monovalent hydrocarbon group.)

Owner:MITSUI CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com