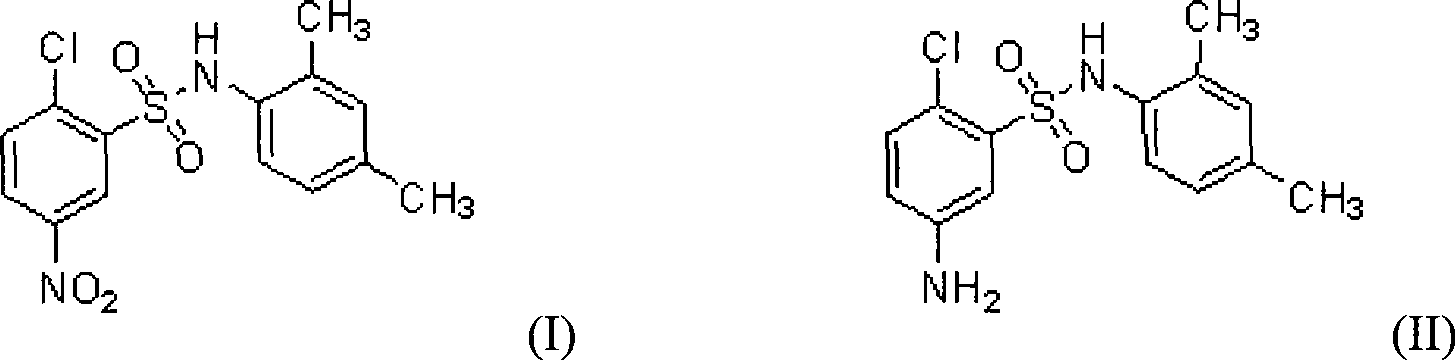

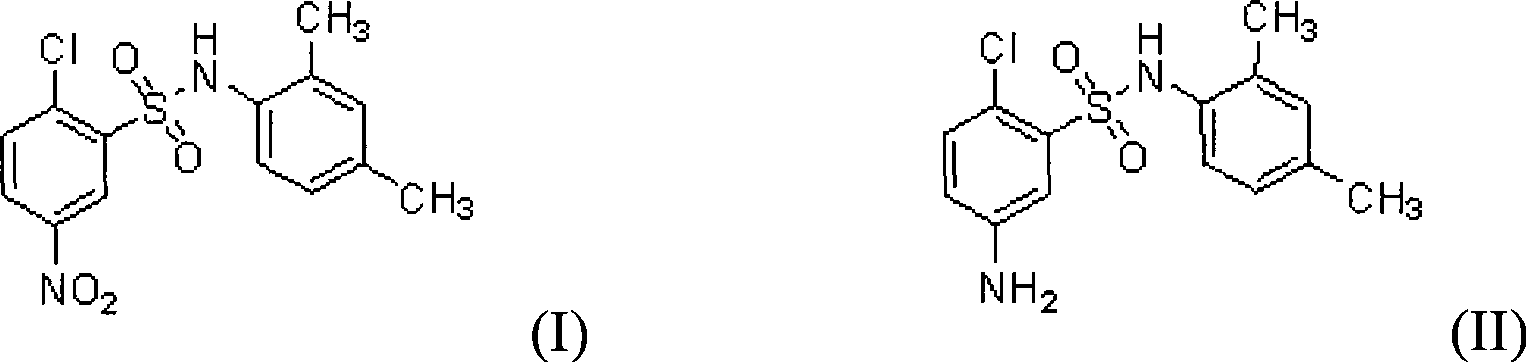

Method for preparing 5-amino-2-chloro-N-(2,4-xylyl)-benzene sulfonic amide in water phase

A technology of xylyl and benzenesulfonamide, applied in the preparation of sulfonic acid amide, organic chemistry and other directions, to achieve the effects of clean production, mild reaction conditions and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

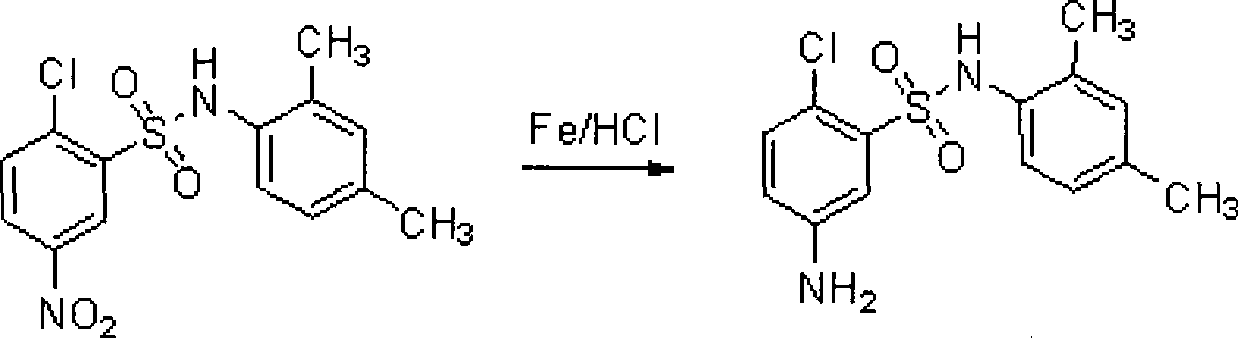

Method used

Image

Examples

Embodiment 1

[0026] Take 1.45g of palladium chloride and dissolve it in water, and use 5% dilute nitric acid to adjust the pH value of the solution to about 2~3, cool in an ice-salt bath to 0°C, and add 0.5mol / L of KBH dropwise under stirring 4 Until the solution is free of gas, adjust the pH value to 11 with 10mol / L NaOH solution to make a pre-prepared solution, and then spray the pre-prepared solution on 30g of γ-Al 2 o 3 on the carrier, let it stand for 2h, filter, wash the catalyst with deionized water until the pH value of the washing solution is 7, and then wash the catalyst 3 times with absolute ethanol to obtain Pa-B / Al 2 o 3 catalyst. Store the catalyst in absolute ethanol for later use. The total catalyst loading was 3%.

[0027] In a 50ml autoclave reactor, add 3g of 5-nitro-2-chloro-N-(2,4-xylyl)-benzenesulfonamide, dissolve in 30ml of water, 0.3g of Pa-B / al 2 o 3 Catalyst, close the autoclave reactor, put the reactor on an oil bath and fix it, replace the air in the re...

Embodiment 2

[0029] Dissolve 0.378g of palladium hydrochloride and 1.134g of ruthenium chloride in water, and use nitric acid to adjust the pH value of the solution to about 2 to 3, and then spray the prepared solution on 30g of γ-Al 2 o 3 On the carrier, let it stand for 3 hours, and turn it every 30 minutes. Dry it in an oven at 130°C for 10 hours, then put it into a muffle furnace, and roast it at a gradient temperature of 160-450°C. The roasting method is as follows: 160°C, 2h; 200°C, 2h; 300°C, 2h; 400°C, 2h; 450°C, 2h. After natural cooling, the catalyst is put into a closed container for use. The mass dosage of the active component is γ-Al based on the active component therein 2 o 3 3% of the mass of the carrier feed.

[0030] In a 50ml autoclave reactor, add 3g of 5-nitro-2-chloro-N-(2,4-xylyl)-benzenesulfonamide, dissolve in 30ml of water, 0.4g of Pa-Ru / al 2 o 3 Catalyst, airtight autoclave reactor, the reactor is placed on the oil bath and fixed, and the air in the react...

Embodiment 3

[0032] Dissolve 1.987g of nickel chloride in water, and use 5% dilute nitric acid to adjust the pH of the solution to about 2-3, and add 0.5mol / L of KBH dropwise under stirring 4 Until the solution has no gas generation, adjust the pH value to 12 with an aqueous alkali solution to make a pre-prepared solution, and then spray the pre-prepared solution on 30g of γ-Al 2 o 3 on the carrier, let it stand for 2 hours, cooled to 0°C in an ice-salt bath, filtered, washed the catalyst with deionized water until the pH value of the washing solution was 7, and then washed the filter cake with absolute ethanol 3 times to obtain Ni-B / Al 2 o 3 catalyst. Store the catalyst in absolute ethanol for later use. The catalyst loading was 3%.

[0033] In a 50ml autoclave reactor, 2.5g of 5-nitro-2-chloro-N-(2,4-xylyl)-benzenesulfonamide was added, dissolved in 30ml of water, 0.3g of Ni-B / Al 2 o 3 Catalyst, airtight autoclave reactor, the reactor is placed on the oil bath and fixed, the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com