Patents

Literature

190results about How to "Clean manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

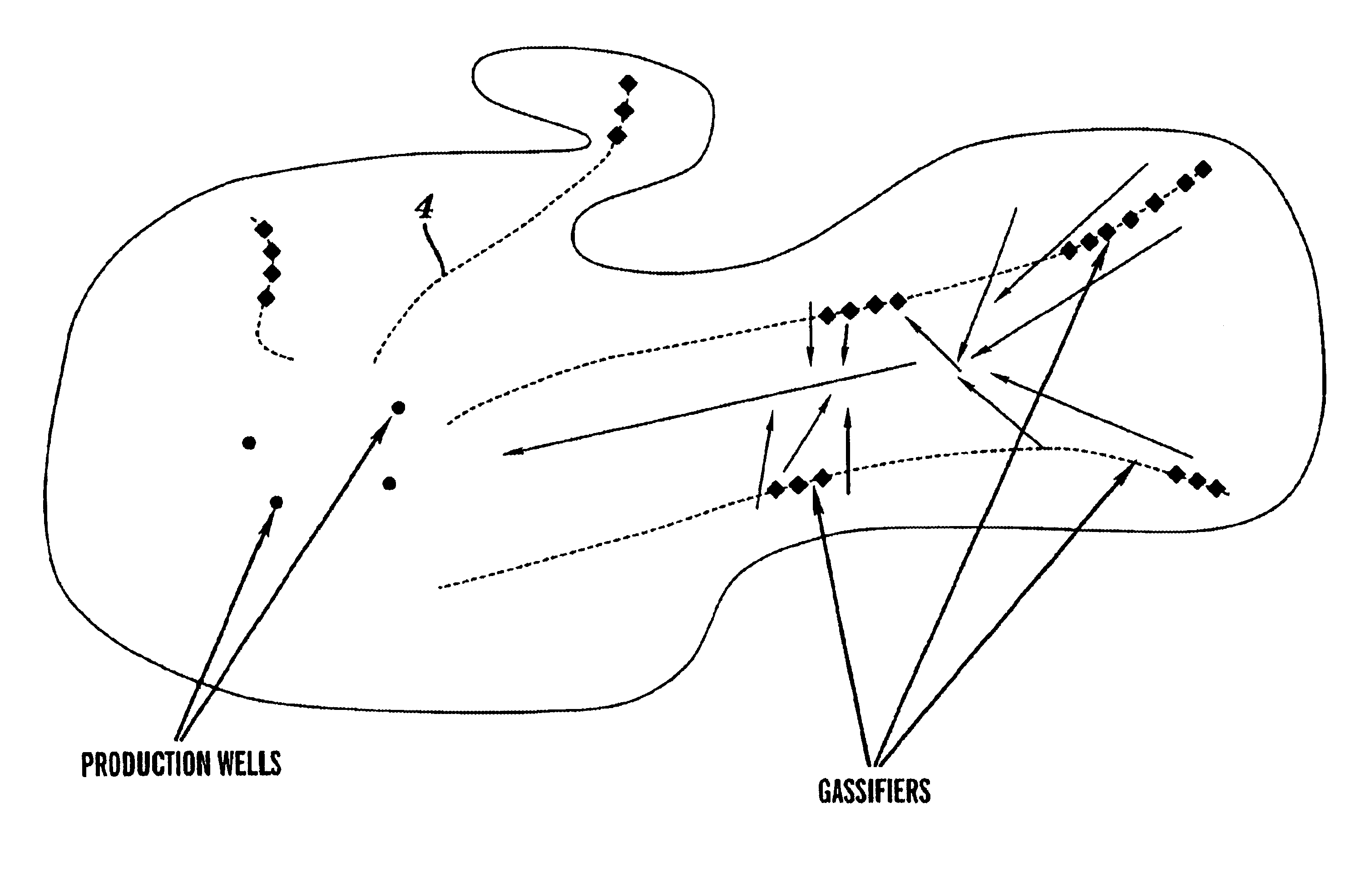

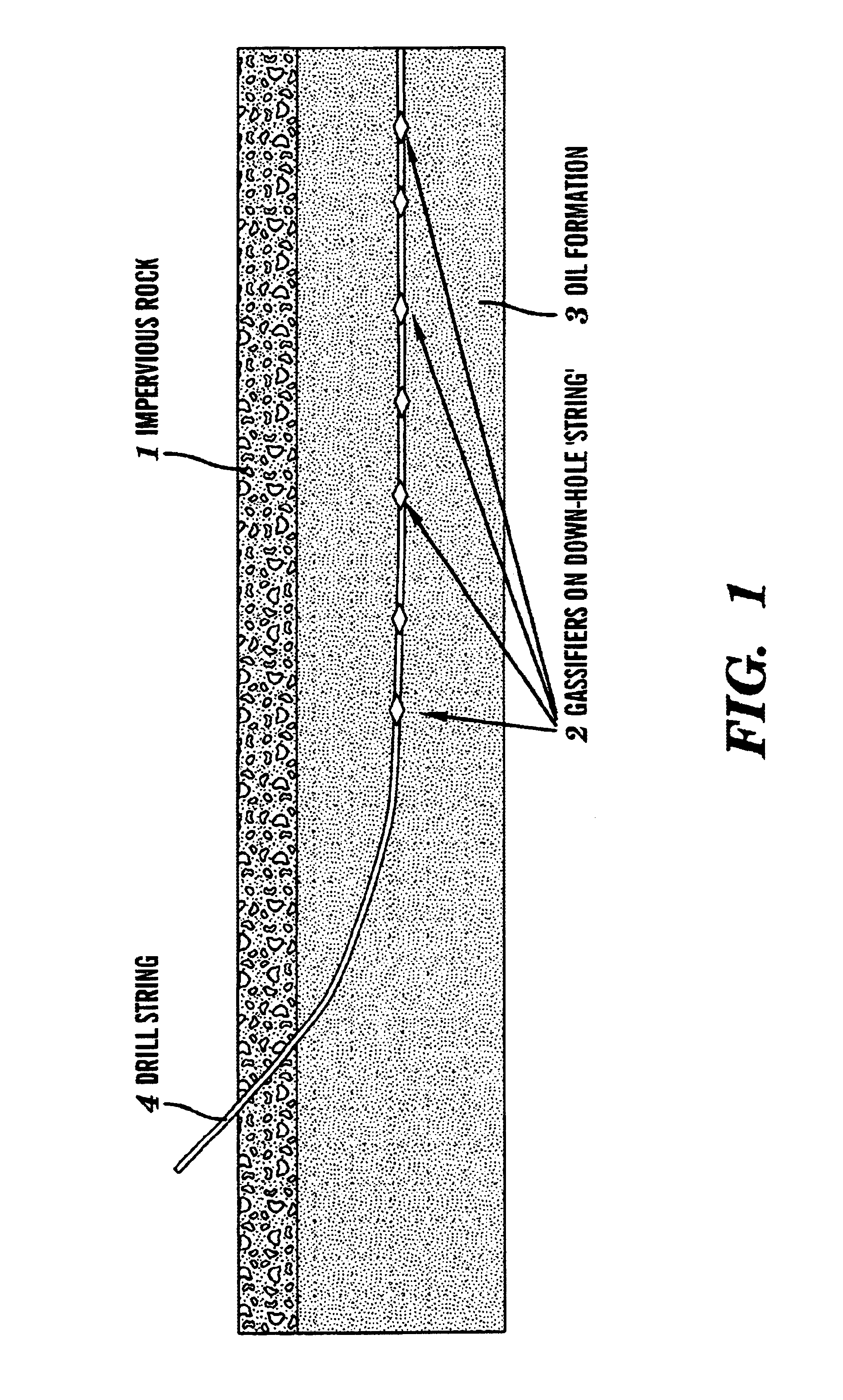

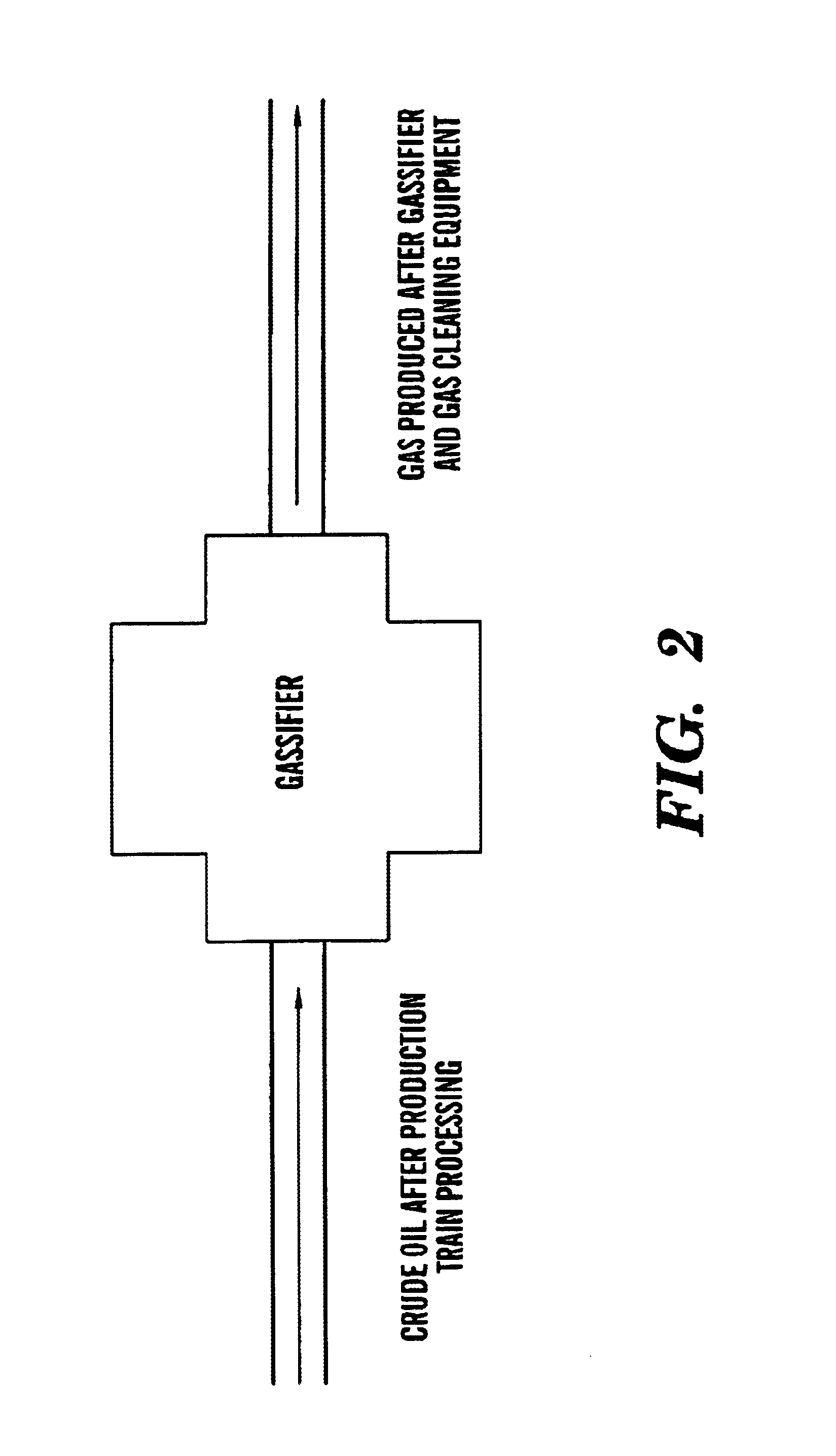

Gas and oil production

A process for in situ gasification of mineral oil in a subterranean formation comprises running a tool having a controllable thermal device therein from a surface production facility down to the subterranean formation, bringing said tool into operational proximity with the mineral oil in said subterranean formation, and activating the tool to operate the thermal device within a predetermined temperature range to generate gases or oily vapours from said mineral oil, which permits either an enhanced oil recovery (EOR) method with reduced water contamination, or a gas production process (GPP) which is useful in reducing environmental risks normally associated with transport of crude oil.

Owner:SCOTOIL SERVICES

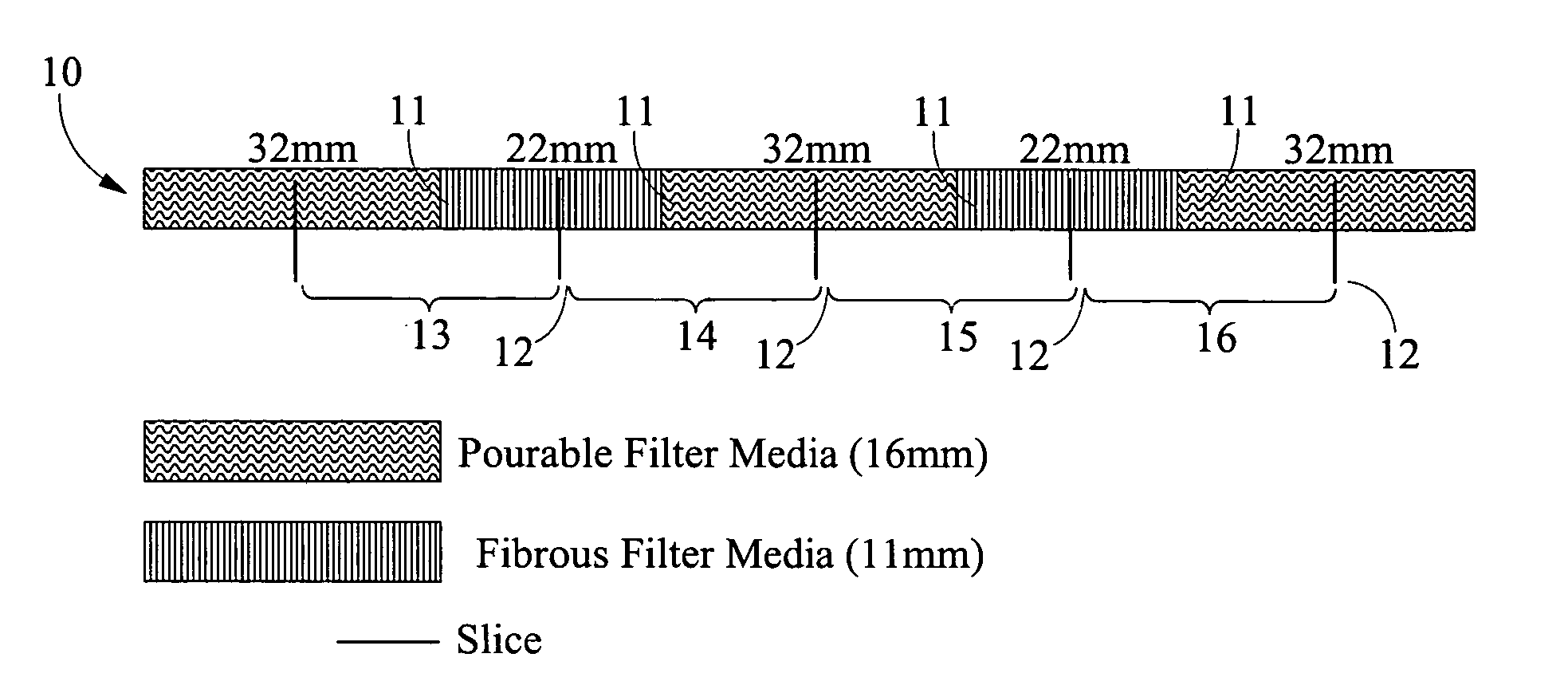

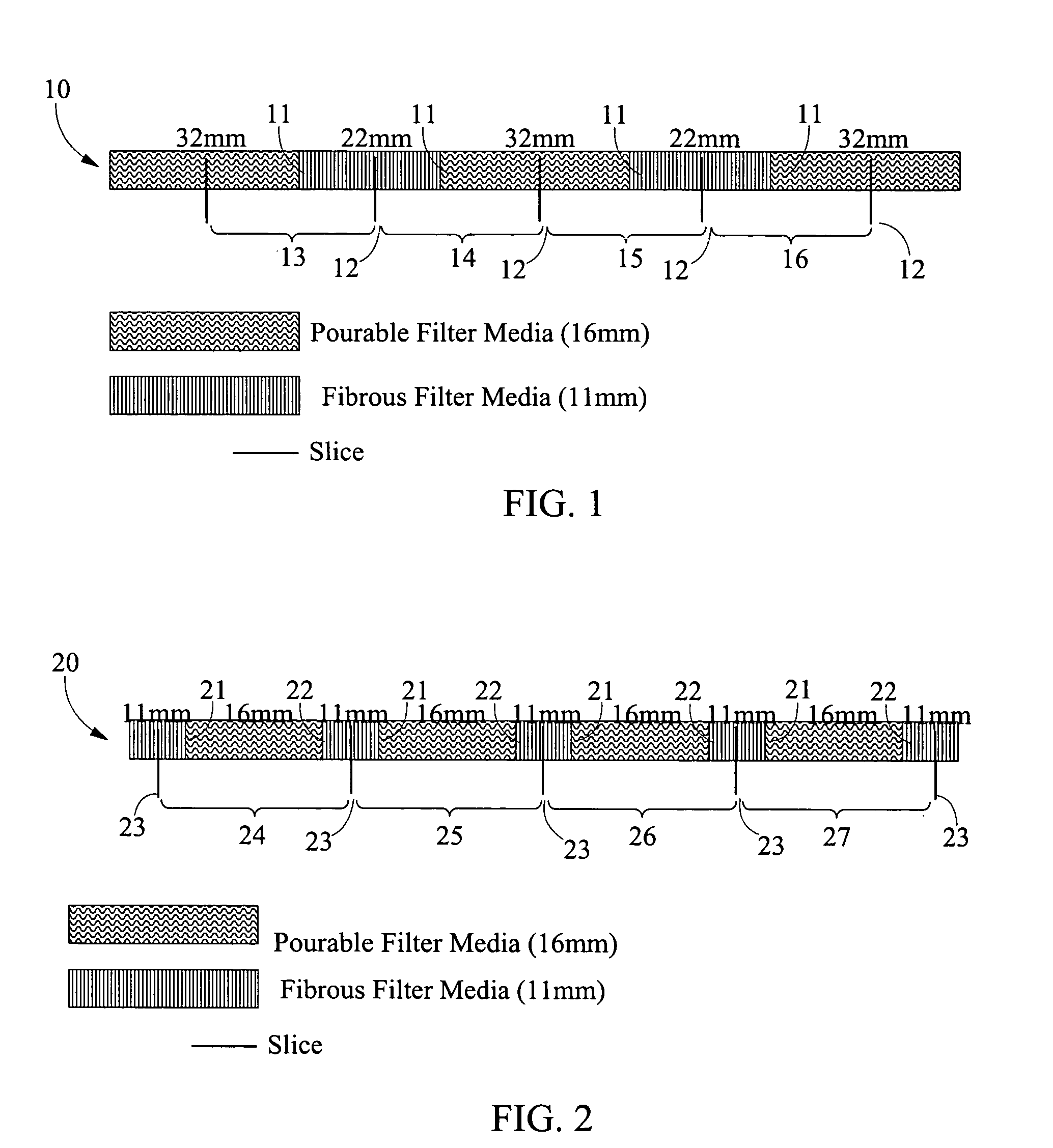

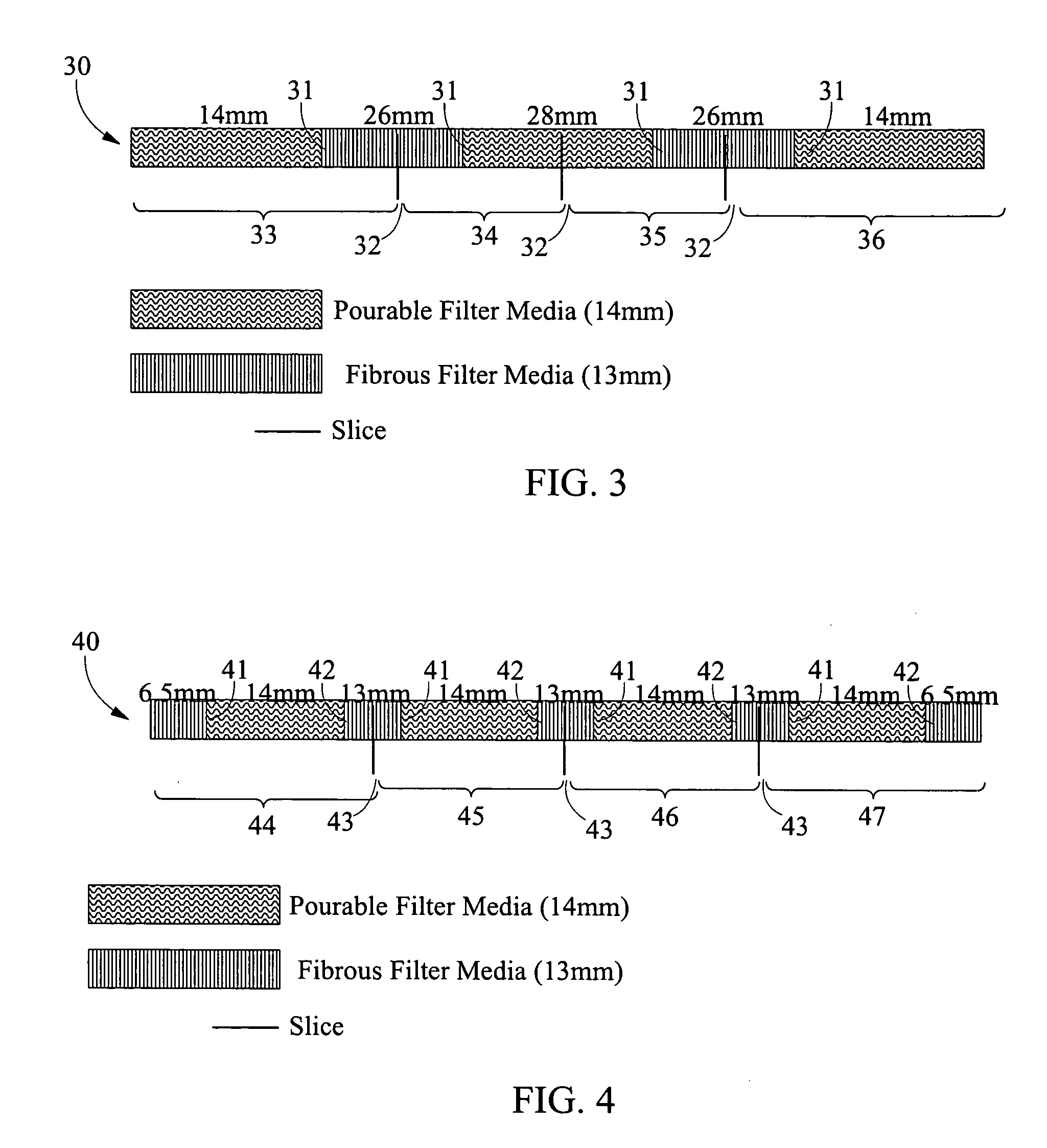

Producing triple section filters using a dual rod filter maker

InactiveUS20060025292A1Reduce switching costsSave stepsPaper/cardboard wound articlesTobacco smoke filtersEngineeringFour component

A method of producing a multi-component cigarette filter having one more filter component than the number of hoppers on the machine producing the cigarette filter rods. A dual hopper machine can produce two-component filters as well as three-component filters, and a three hopper machine can produce three-component filters as well as four-component filters.

Owner:BROWN & WILLIAMSON TOBACCO

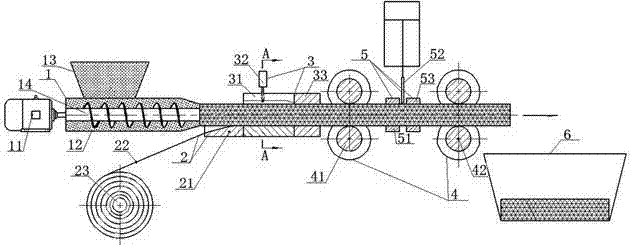

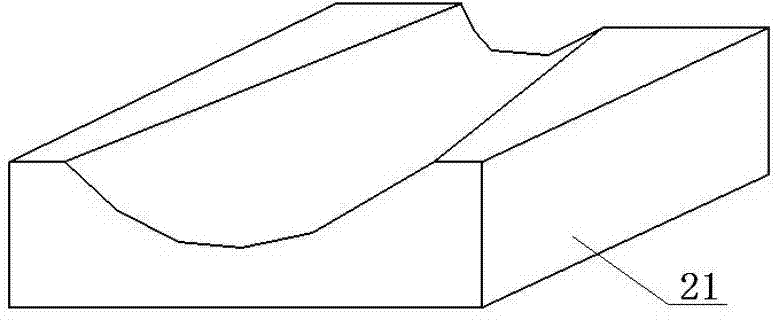

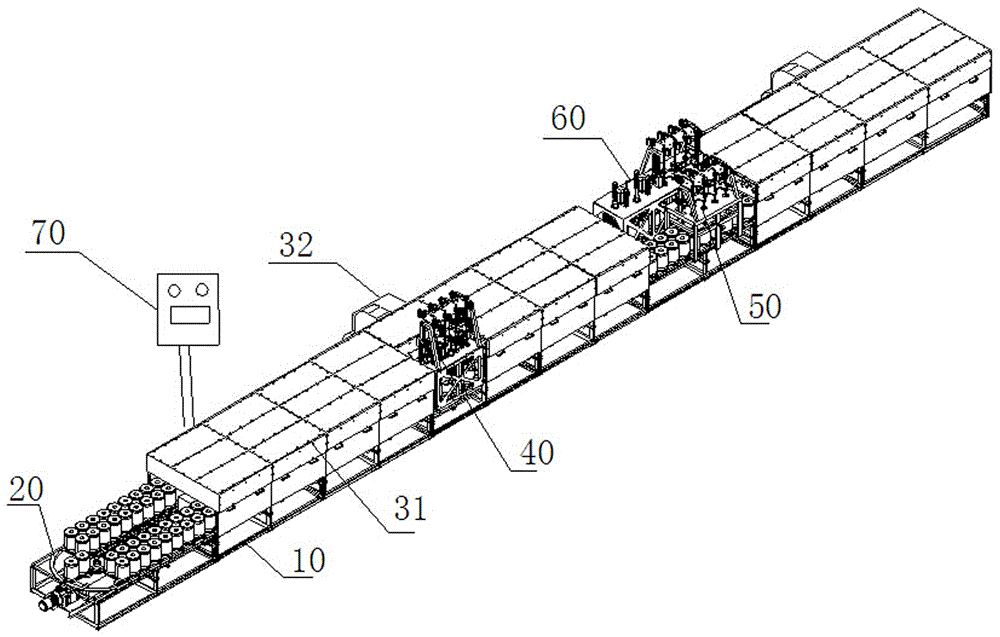

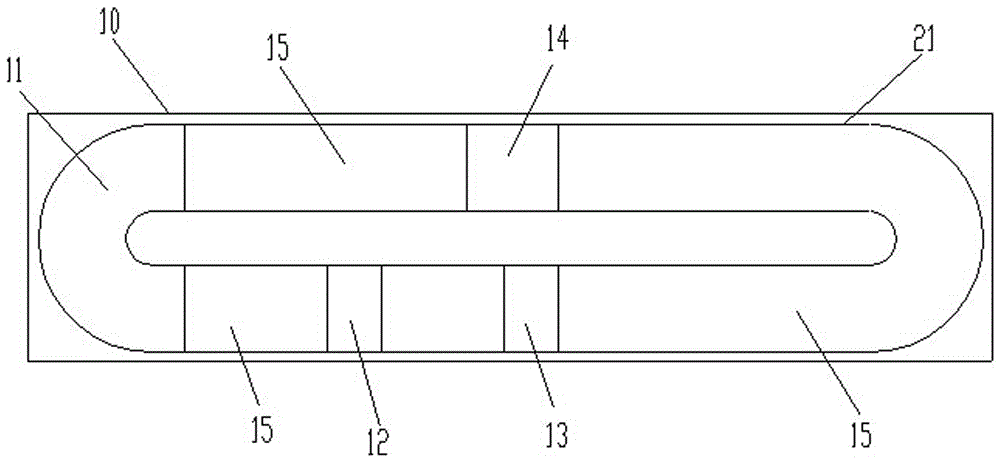

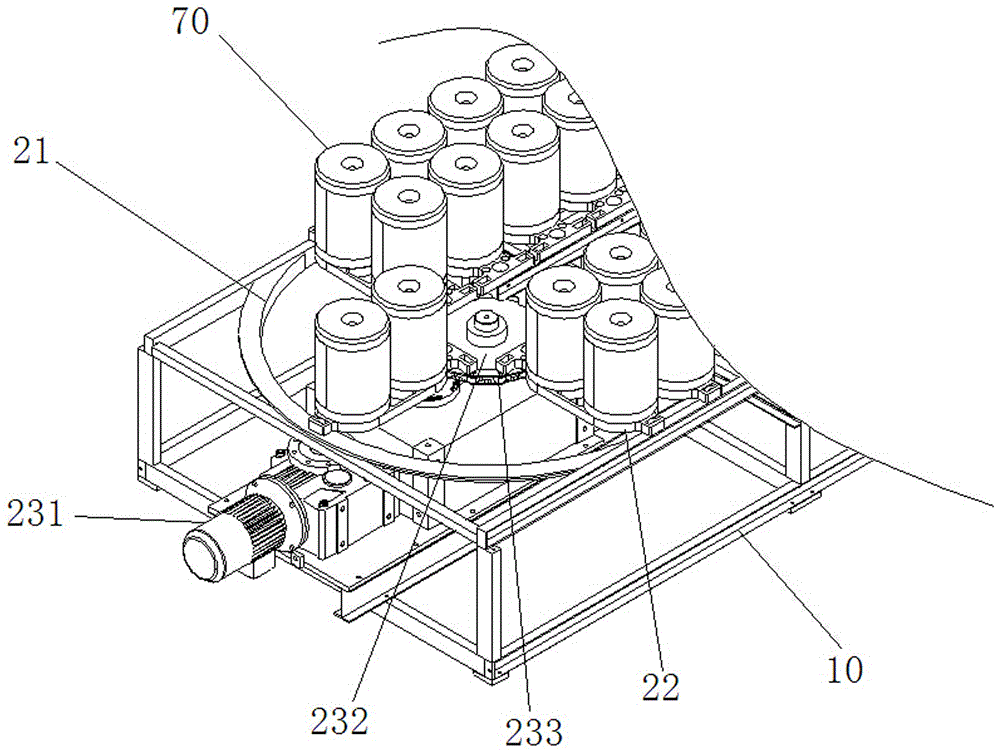

Moxa cone coiling forming machine

ActiveCN104490593AImprove medicinal qualityEasy to operateDevices for heating/cooling reflex pointsConveyorsRolling paperMolding machine

The invention discloses a moxa cone coiling forming machine which comprises a spiral conveying mechanism, a paper tape winding mechanism, a gluing and forming mechanism and a shearing mechanism which are arranged in sequence, wherein the spiral conveying mechanism is used for forming a naked moxa cone; the paper tape winding mechanism mainly consists of a paper coiling disc and a paper tape; a conical guide groove of which the front part is large and the rear part is small is formed in the paper coiling disc; the width of the paper tape is greater than the perimeter of the naked moxa cone; the paper tape is paved inside the conical guide groove in the paper coiling disc in a dynamic conveying manner; the gluing and forming mechanism mainly consists of a gluing machine and a sealing ring; the gluing machine is used for gluing the paper tape; the sealing ring is used for shifting, guiding and compacting the glued paper tape when the paper tape is dynamically conveyed, so as to coil and seal the paper tape; the shearing mechanism is used for shearing the coiled and formed moxa cone output from the gluing and forming mechanism. The moxa cone coiling forming machine is capable of automatically and continuously producing coiled paper moxa cones and is applicable to large-scale in-batch production, the whole production process is clean, sanitary, free of pollution, high in production efficiency and low in cost, and the formed moxa cones are high in medicinal quality.

Owner:SICHUAN ENG TECHN COLLEGE

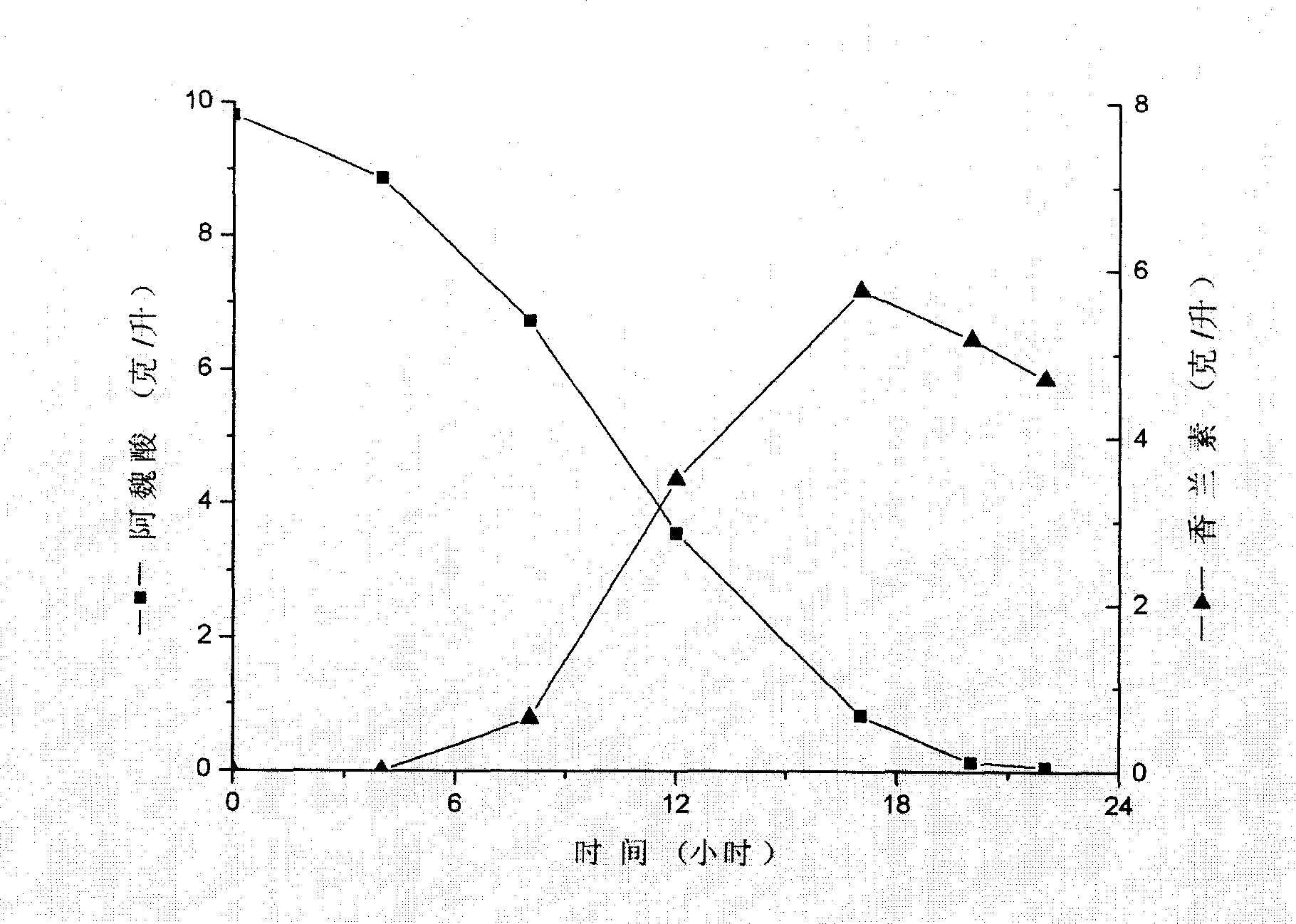

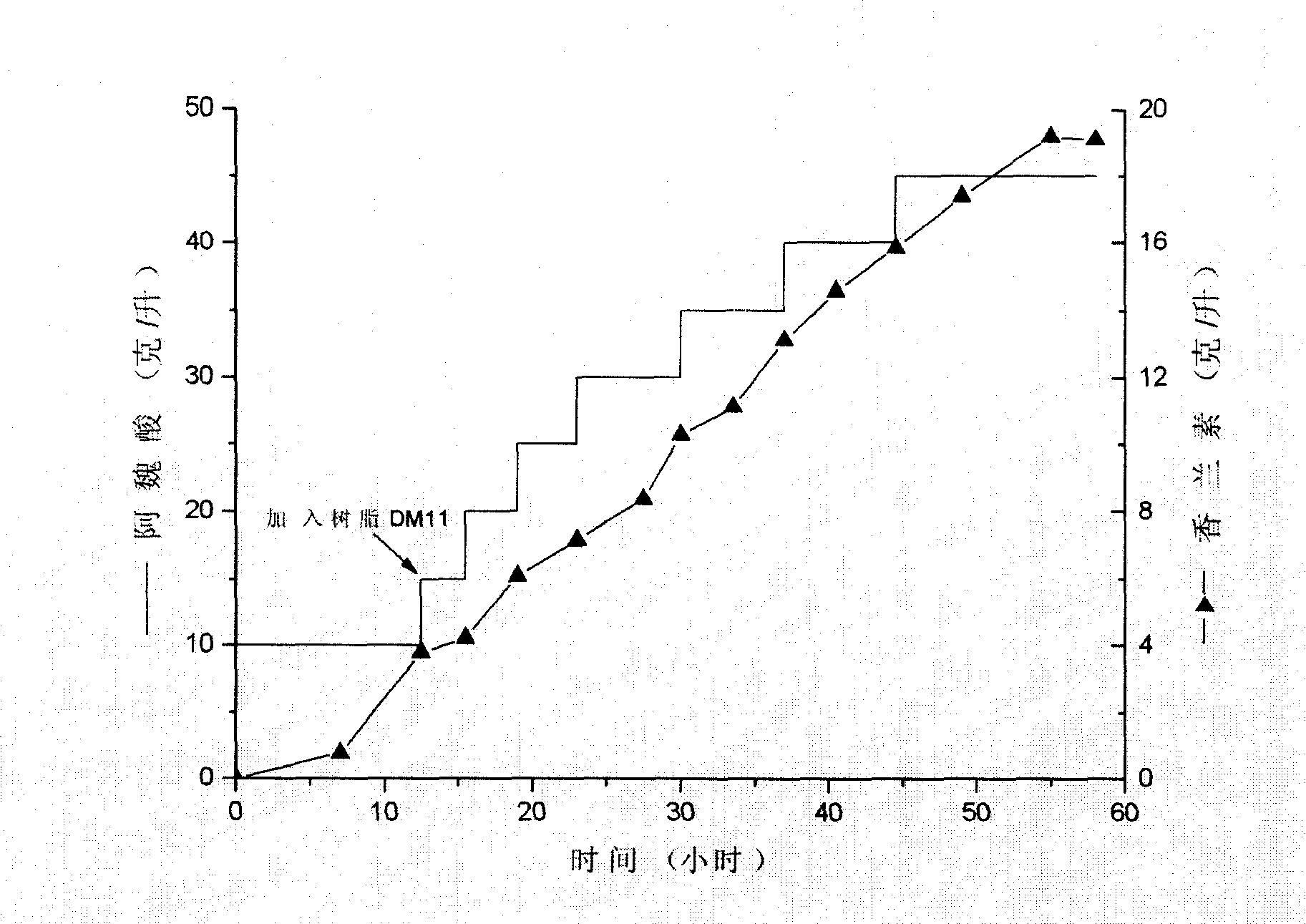

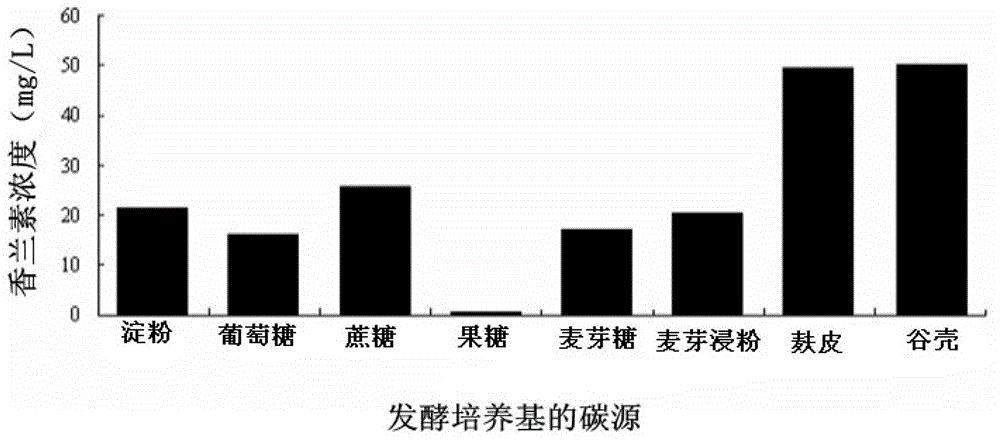

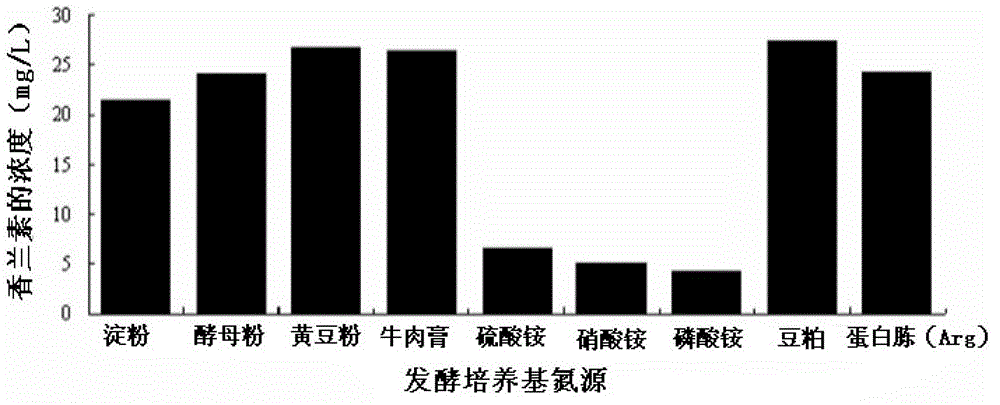

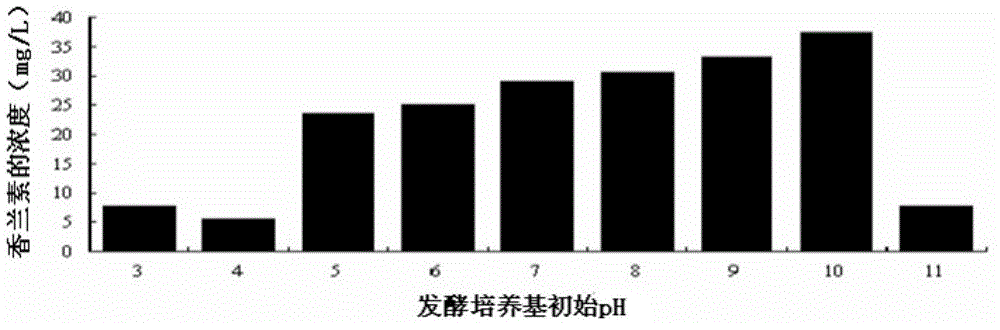

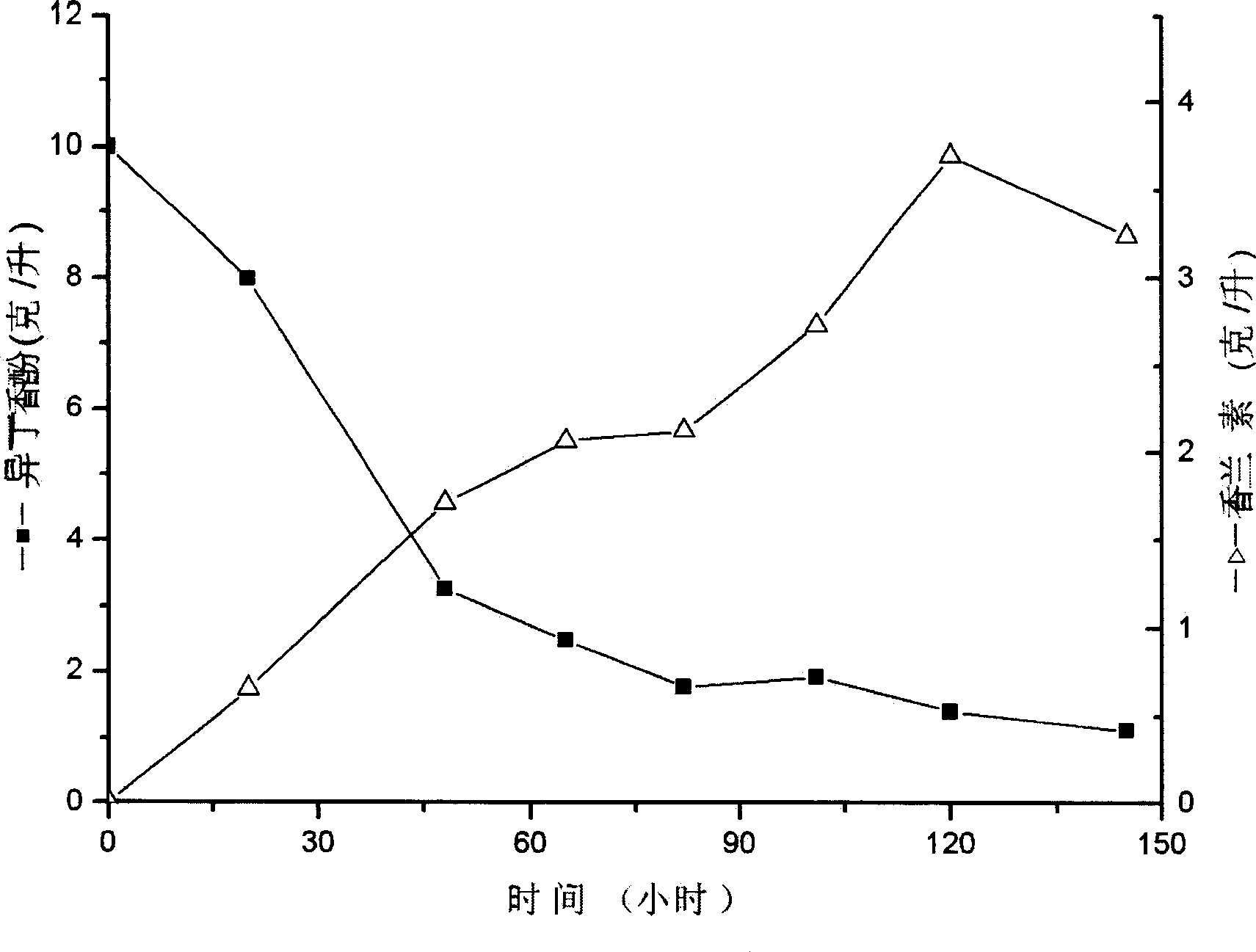

Streptomycete and method for producing vanillin by using the same to biologically transform ferulic acid

ActiveCN101165168AReduce pollutionMild reaction conditionsBacteriaMicroorganism based processesHigh concentrationChemical synthesis

The present invention is one Streptomyces strain and the process of utilizing the Streptomyces strain in converting ferulic acid to produce high concentration vanillin. The Streptomyces strain is Streptomyces sp.V-1 in the preservation number of CCTCC M 206065. In the GY converting culture medium with the Streptomyces strain, ferulic acid may be converted to produce high concentration vanillin fermenting liquid. Adding macroporous adsorption resin DM11 into the converting culture medium can increase the concentration of vanillin fermenting liquid greatly. The present invention has the advantages of less environmental pollution, high product concentration, less side products, short production period, low cost, etc.

Owner:APPLE FLAVOR & FRAGRANCE GRP +2

Solvent-free method for preparing non-ionic water-borne polyurethane

ActiveCN104530370AReduce adverse effectsSolve the problem that the viscosity is too high and need to add solvent to reduce the viscosity to emulsifyEmulsionPolyol

The invention relates to a solvent-free method for preparing non-ionic water-borne polyurethane. The method comprises the following steps: firstly, synthesizing a Y-shaped side chain nonionic hydrophilic chain extender containing two terminal hydroxyl groups; secondly, reacting poly(dihydric alcohol) with isocyanate, and adding the Y-shaped side chain nonionic hydrophilic chain extender for chain extending to generate a side chain prepolymer with a -NCO terminal-group; thirdly, adding one or mixture of two of small-molecular dihydric alcohol and oligomer polyol, uniformly stirring, and immediately adding a deionized water solution to disperse at high speed; and finally heating to react to obtain a stable solvent-free nonionic waterborne oligomer emulsion. Compared with the prior art, the method has the advantage that the stable solvent-free nonionic waterborne oligomer emulsion is prepared under conditions of no additional emulsifier and little co-stabilizer.

Owner:上海材料研究所靖江先进材料技术研究院 +1

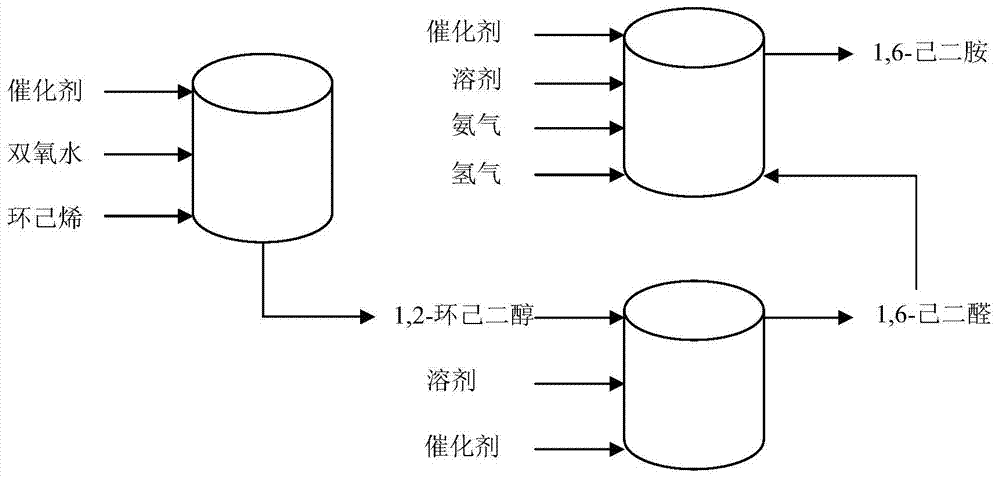

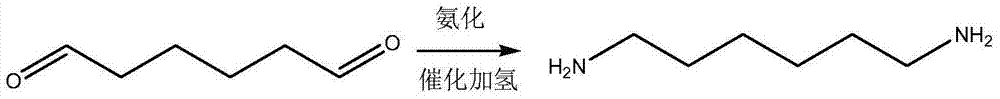

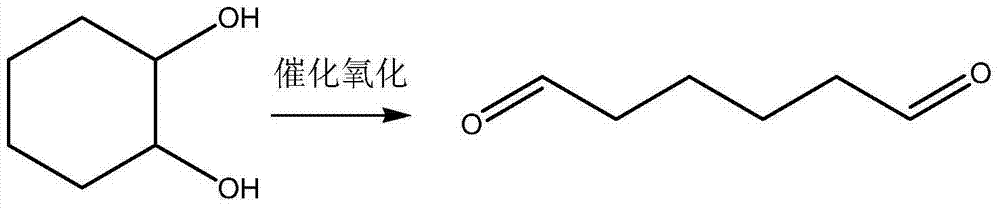

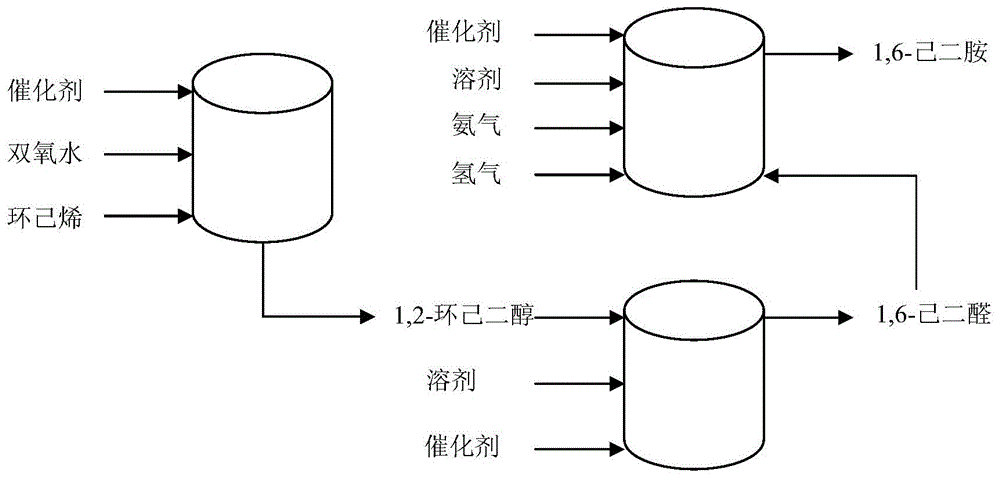

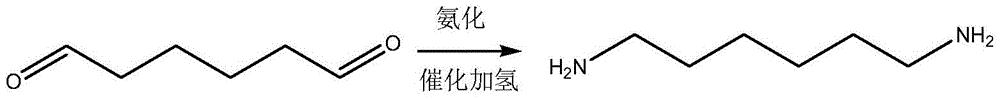

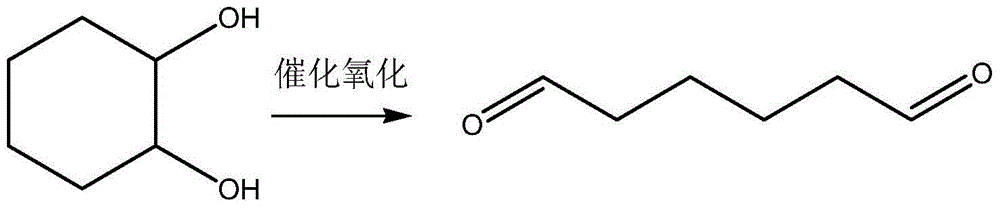

Preparation method of hexamethylenediamine

ActiveCN104262168AEasy to separateHigh catalytic activityPreparation by reductive alkylationHexamethylenediamineEnergy consumption

The invention discloses a preparation method of hexamethylenediamine. The method is used for preparing 1, 6-hexamethylenediamine by virtue of carrying out ammoniation and catalytic hydrogenation on 1, 6-adipaldehyde. The method is simple in process, low in cost, high in yield, low in energy consumption and free from industrial three wastes.

Owner:BEIJING RISUN TECH CO LTD

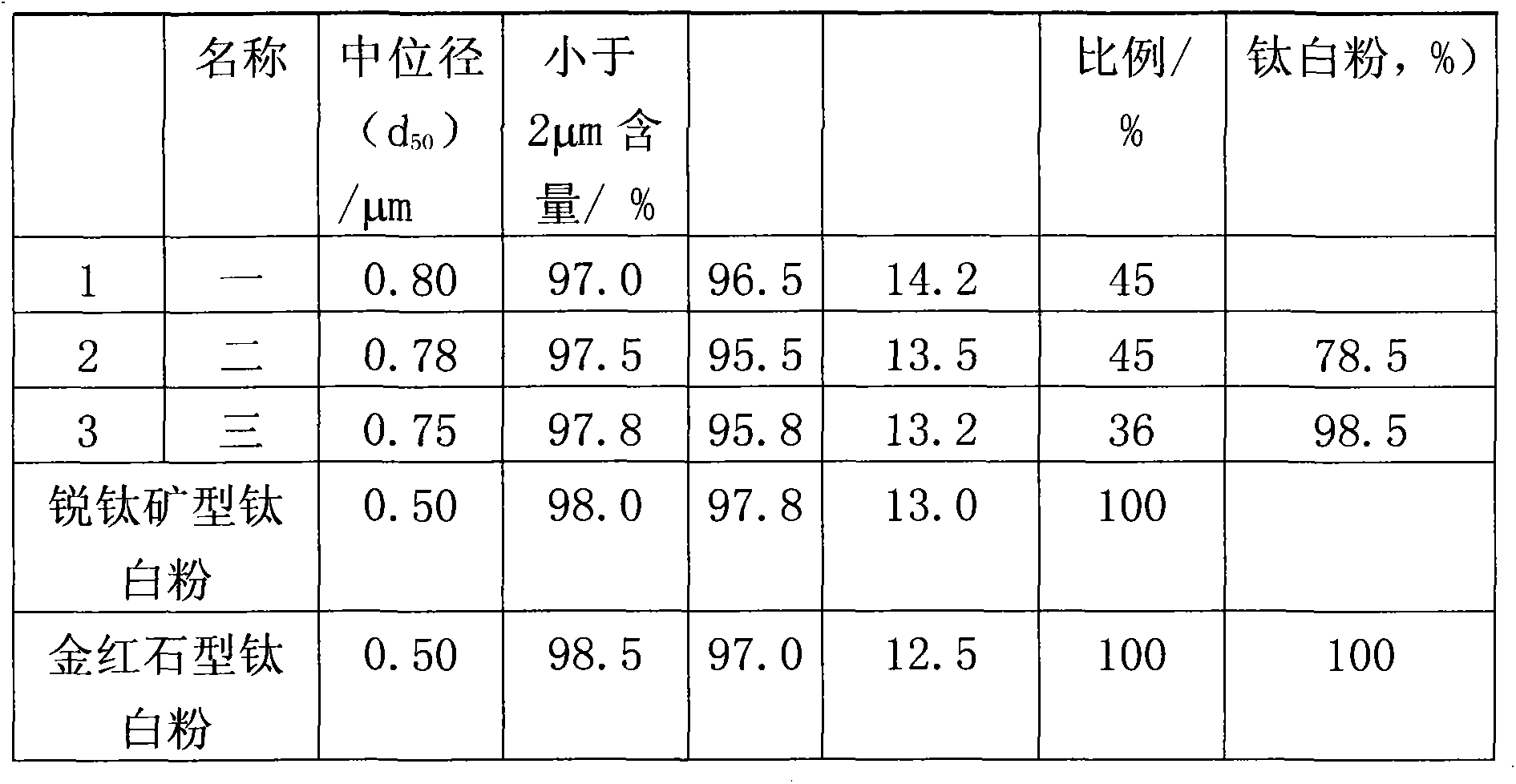

Preparation method for inorganic composite white pigment capable of replacing titanium dioxide at high proportion

InactiveCN104119701AReduce the dosage ratioNo emissionsPigment treatment with macromolecular organic compoundsPigment physical treatmentCalciteSODIUM SILICATE SOLN

The invention provides a preparation method for an inorganic composite white pigment capable of replacing titanium dioxide at a high proportion. The method employs calcite, barite or white carbon black as an inorganic white powder with the granularity less than 45 mu m, employs rutile type titanium dioxide or anatase type titanium dioxide as pigment-grade titanium dioxide, employs sodium polyacrylate with the concentration of 25% or a sodium silicate solution with the concentration of 15% as a surfactant, and employs diluted sulfuric acid as a pH regulator. The inorganic composite white pigment capable of replacing titanium dioxide at a high proportion is prepared by respectively pulping the white mineral powder and the pigment-grade titanium dioxide with water, employing an organic modifier to perform surface modification, regulating pH value, then uniformly mixing the prepared pulps, and performing intense agitation, press filtering and drying processing. Specifically, in the compositions, the inorganic white powder accounts for 55%-76% by weight and the pigment-grade titanium dioxide accounts for 24%-45%.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

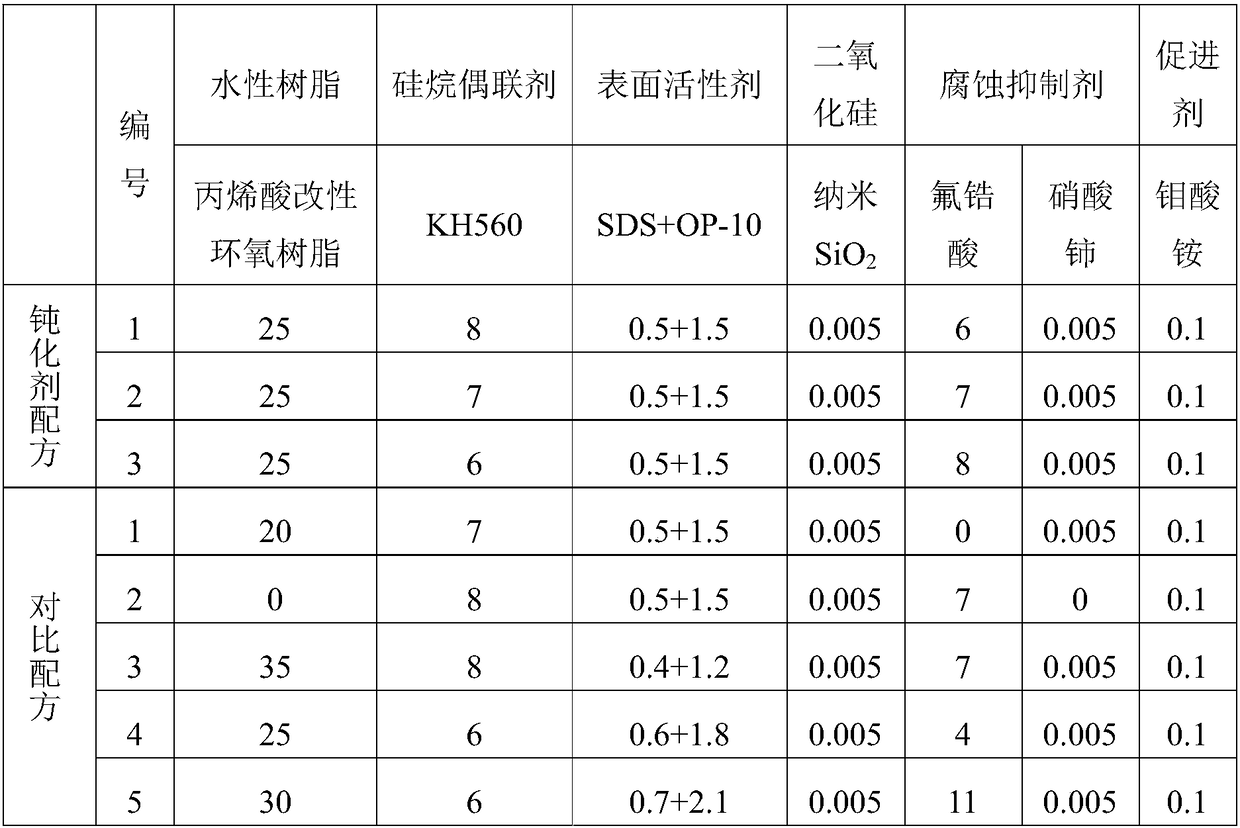

Compound chromate-free passivator capable of forming films rapidly and preparation method

InactiveCN108300988ANo pollution in the processClean manufacturingMetallic material coating processesCorrosion reactionPhosphoric acid

The invention provides a compound chromate-free passivator capable of forming films rapidly. The compound chromate-free passivator comprises water-dilutable resin, silicon dioxide, a surfactant, a corrosion inhibitor, an accelerant and water. The chromate-free passivator provided by the invention does not contain poisonous and harmful ingredients such as heavy metal, sodium nitrite, phosphoric acid and the like, is environment-friendly, pollution-free and clean in production, and is close to passivation effect of hexavalent chromate in the aspect of comprehensive performance such as corrosionresistance and reprocessing; and the passivator sufficiently utilizes the diversity of organic high-molecular polymers and the rapid forming characteristic of inorganic salt, so that a high-performance resin and zirconium-based oxide layer compound coating can be provided for metal surfaces, compound passivation film provides a double protection function for protection of metal surfaces, and the organic coating has a clear advantage of delaying initial-stage corrosion on the metal surfaces, so as to ensure that the metal surfaces have excellent corrosion resistance and then the adhesive forceof coating is improved.

Owner:长沙艾森设备维护技术有限公司

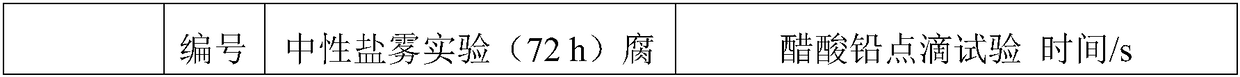

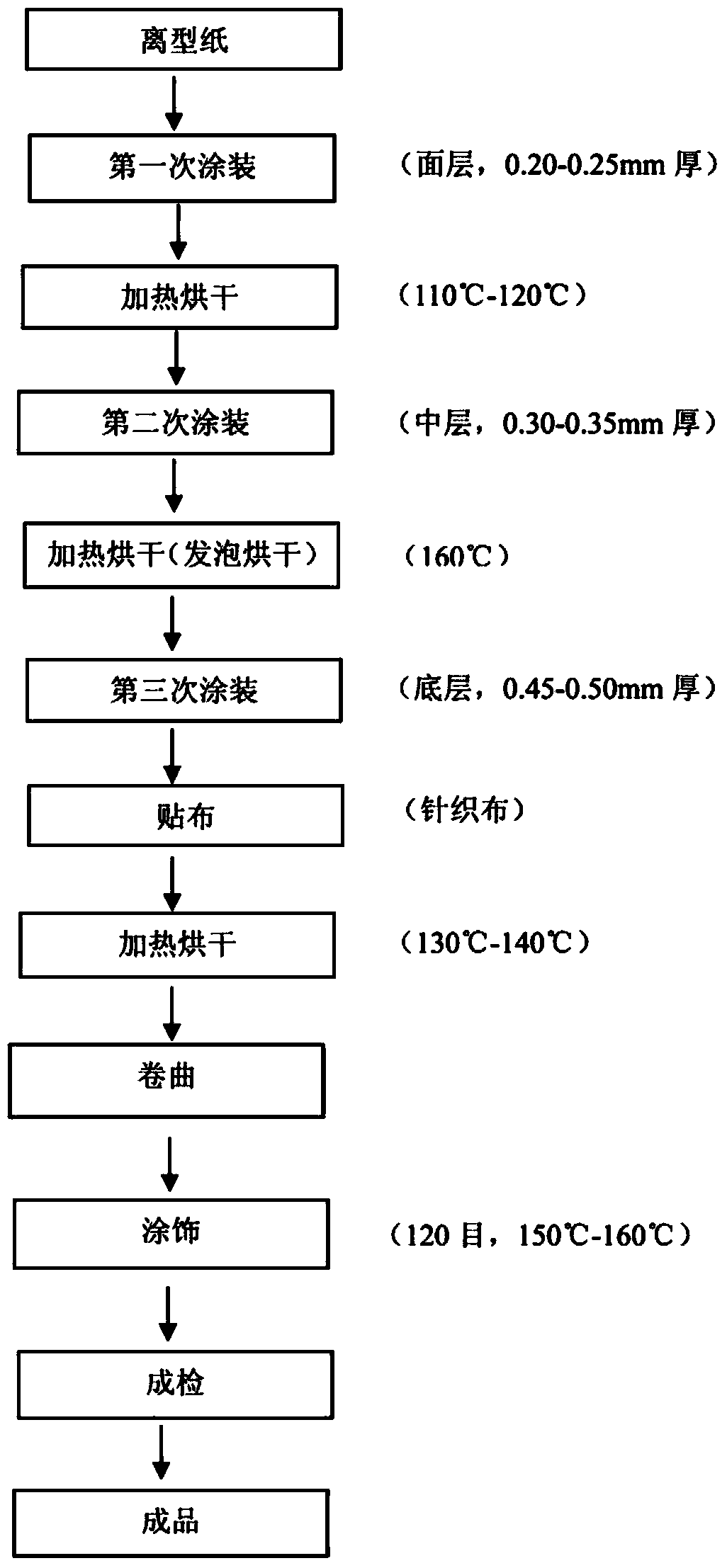

Preparation method of leather-imitating automobile leather

InactiveCN104313896AMeet needsClean manufacturingLamination ancillary operationsSynthetic resin layered productsFoaming agentSurface layer

The invention relates to a preparation method of leather-imitating automobile leather. The preparation method comprises the following steps: firstly designing a PU formula according to the purpose of the automobile leather, preparing slurry, coating the slurry on a piece of release paper to finish the coating process for the first time, and heating and drying the paper to obtain a surface layer of the automobile leather; secondly, adding a bridging agent, a leveling agent, a fire retardant and a microballoon foaming agent to high solid resin to be stirred uniformly, coating the prepared material on the surface layer of the automobile leather to finish the coating process for the second time, and foaming and drying to obtain an intermediate support foaming layer; coating the slurry prepared according to the PU formula on the obtained intermediate support foaming layer to finish the coating process for the third time; furthermore, adhering the formed coating to base cloth, heating and drying the cloth, and conducting separation and curling; finally, conducting postprocessing, finishing the surface, and heating and drying so as to obtain the leather-imitating automobile leather. The method disclosed by the invention is made from the environment-friendly materials during the production process, clean in production, soft and comfortable in product touch, easy to conduct post process, and capable of meeting requirements on automobile upholstery leather for customers.

Owner:HUALUN LEATHER & PLASTIC SUZHOU

A kind of preparation method of hexamethylenediamine

ActiveCN104262168BEasy to separateHigh catalytic activityPreparation by reductive alkylationHexamethylenediamineEnergy consumption

The invention discloses a preparation method of hexamethylenediamine. The method is used for preparing 1, 6-hexamethylenediamine by virtue of carrying out ammoniation and catalytic hydrogenation on 1, 6-adipaldehyde. The method is simple in process, low in cost, high in yield, low in energy consumption and free from industrial three wastes.

Owner:BEIJING RISUN TECH CO LTD

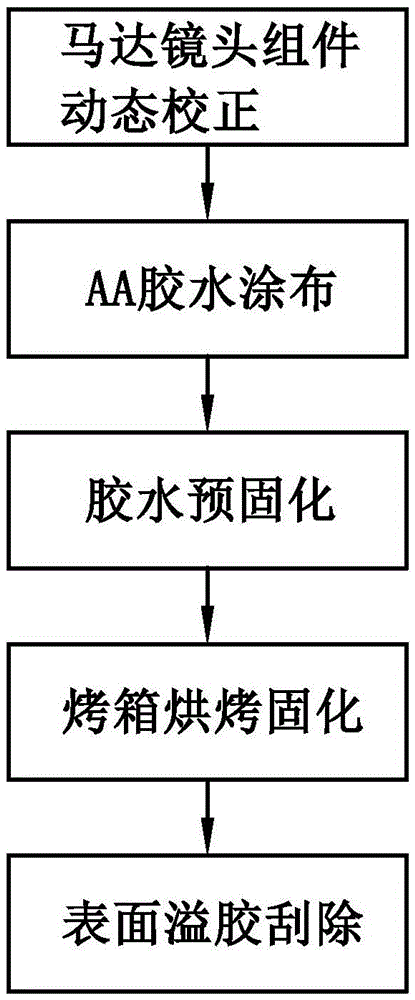

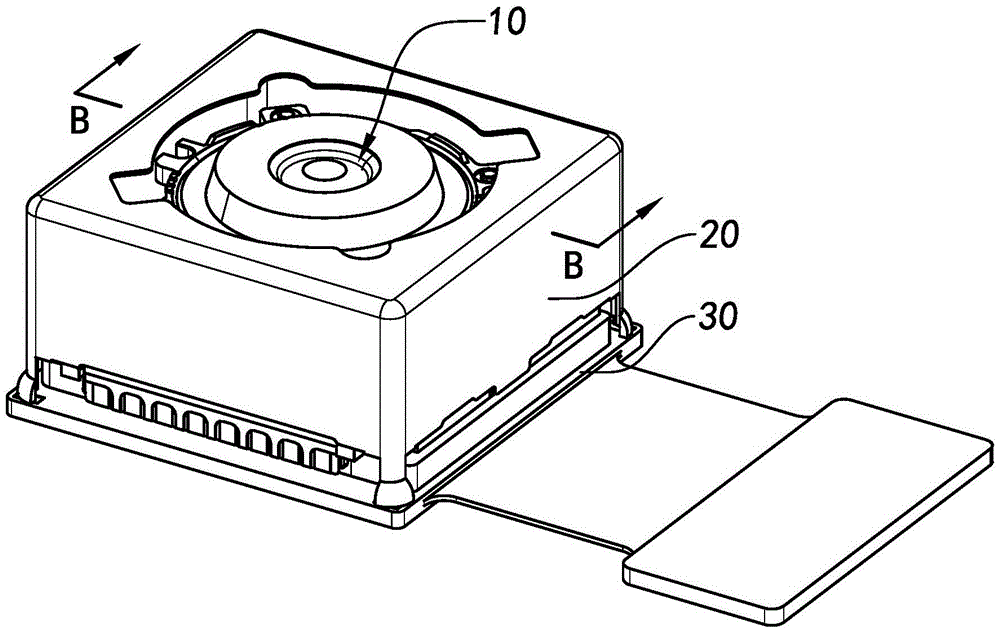

Camera module group, structure thereof, and assembly method thereof

ActiveCN106817515AImprove Design FeasibilityFast productionTelevision system detailsColor television detailsCamera moduleComputer science

The invention discloses a camera module group, a structure thereof, and an assembly method thereof. The camera module group comprises a first motor lens member and a circuit module. The motor lens member is located at a front side of the circuit module, so as to enable the light passing through the motor lens member to reach the circuit module. Moreover, the motor lens member is welded to the circuit module. The assembly method of the camera module group comprises the steps: (A), dynamically adjusting the motor lens member; (B), welding the motor lens member to the circuit module.

Owner:NINGBO SUNNY OPOTECH CO LTD

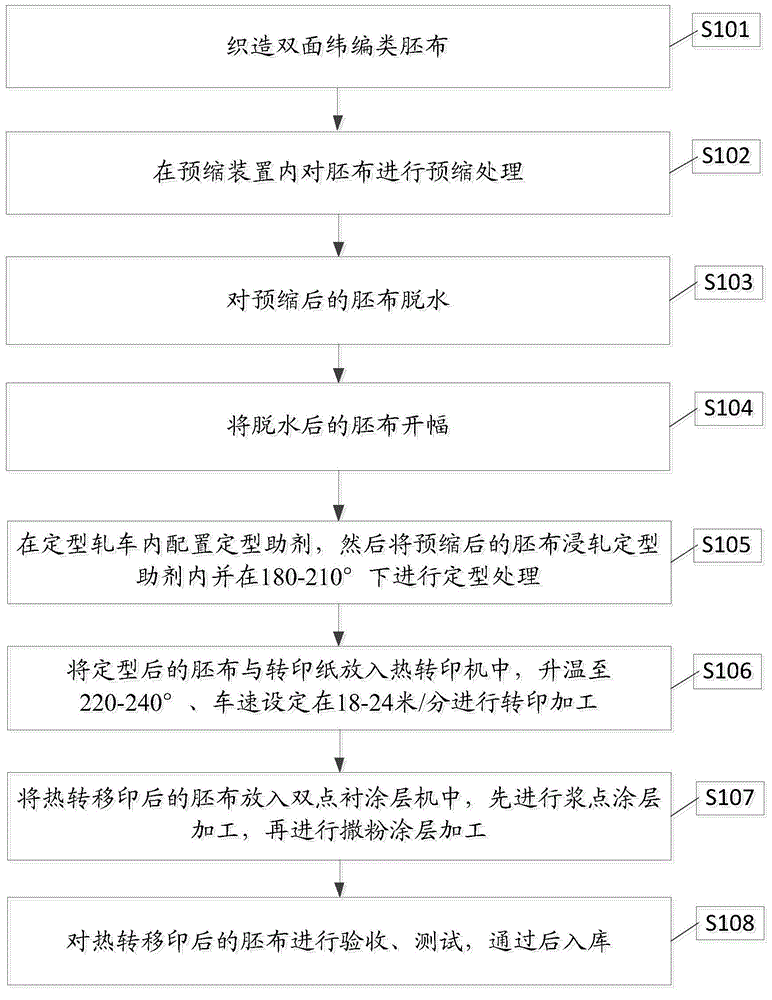

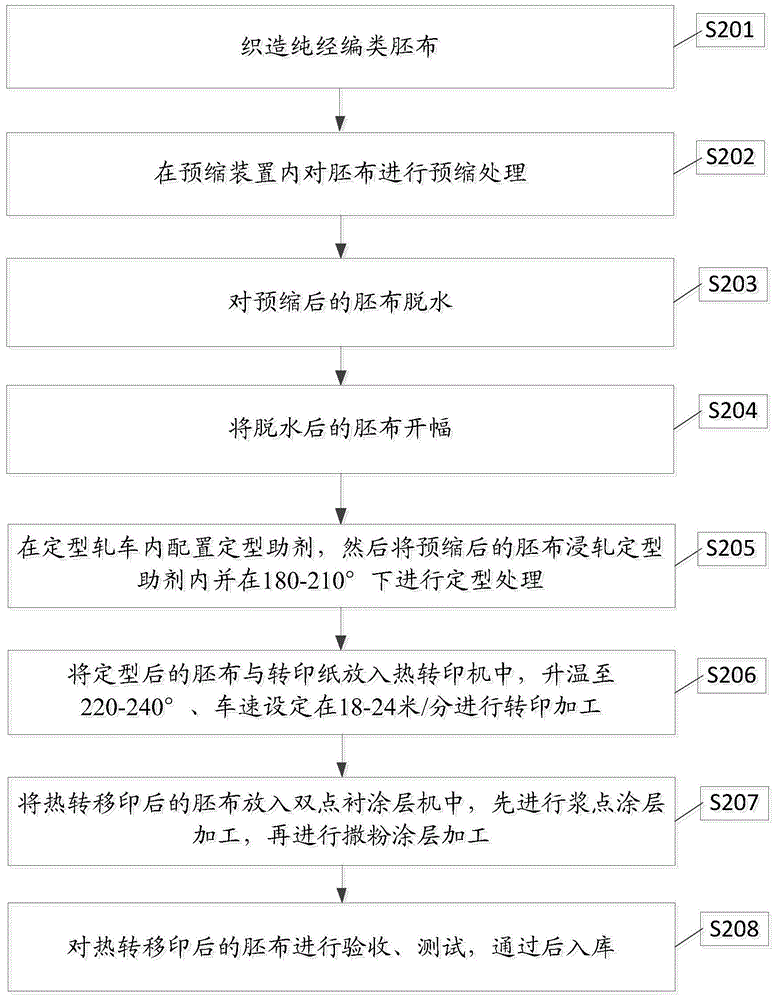

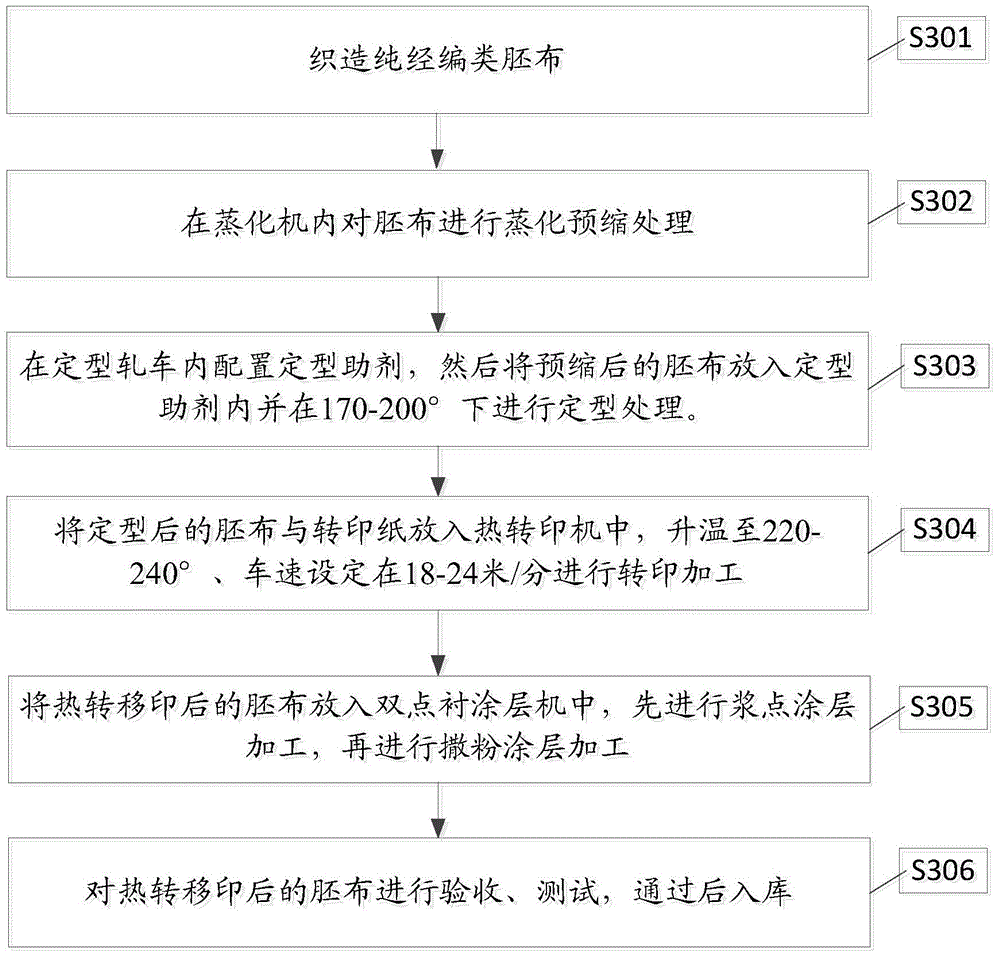

Production method of printing composite clothing material and printing composite clothing material

ActiveCN104522914AAdhesive fastnessGood compatibilityGarment special featuresWeft knittingEmulsionSizing

The invention provides a production method of a printing composite clothing material. The production method includes the following steps: preshrinking, wherein preshrinking on gray cloth is carried out in a preshrinking device; sizing, wherein a sizing auxiliary is arranged in a sizing rolling vehicle, then the preshrunk gray cloth is padded in the sizing auxiliary, and sizing is carried out at a first preset temperature; heat transferring printing, wherein the sized gray cloth and transfer printing paper are placed into a heat transferring printing machine, the temperature rises to range from 220 DEG C to 240 DEG C, and the vehicle speed is set to range from 18 meters per minute to 24 meters per minute for transferring printing; and gluing, wherein the gray cloth after heat transferring printing is placed into a two-point lining coating machine, paste dot coating machining is carried out, dusting coating machining is then carried out, a raw material of a paste dot coating is polyurethane emulsion, a raw material of a dusting coating is copolyamide, and the glue dot density ranges from 60 dots per square centimeter to 130 dots per square centimeter. The invention further provides the printing composite clothing material produced from the production method.

Owner:CPL NEW MATERIAL TECH CO LTD

Bacillus methylotrophicus VJ4-1 and method for producing natural vanillin by ferulic acid biotransformation with the same

InactiveCN102747008AIncrease concentrationReduce pollutionBacteriaMicroorganism based processesMicrobiologyDrug biotransformation

The present invention discloses a strain of Bacillus methylotrophicus VJ4-1, and a method for producing natural vanillin by ferulic acid biotransformation with the Bacillus methylotrophicus VJ4-1, wherein a name of the strain is Bacillus methylotrophicus VJ4-1, the strain is preserved in the China center for type culture collection (CCTCC) in Wuhan University on January 16, 2012, and a preservation number is CCTCC NO:M2012004. The method of the present invention has advantages of high yield, simple process, mild reaction conditions, less environmental pollution, high product concentration, simple extraction step, clean production, environmentally friendly products, safety, reliability, wide main raw material source, low cost, and natural property, and has an industrial production prospect.

Owner:HUBEI CHINA TOBACCO IND

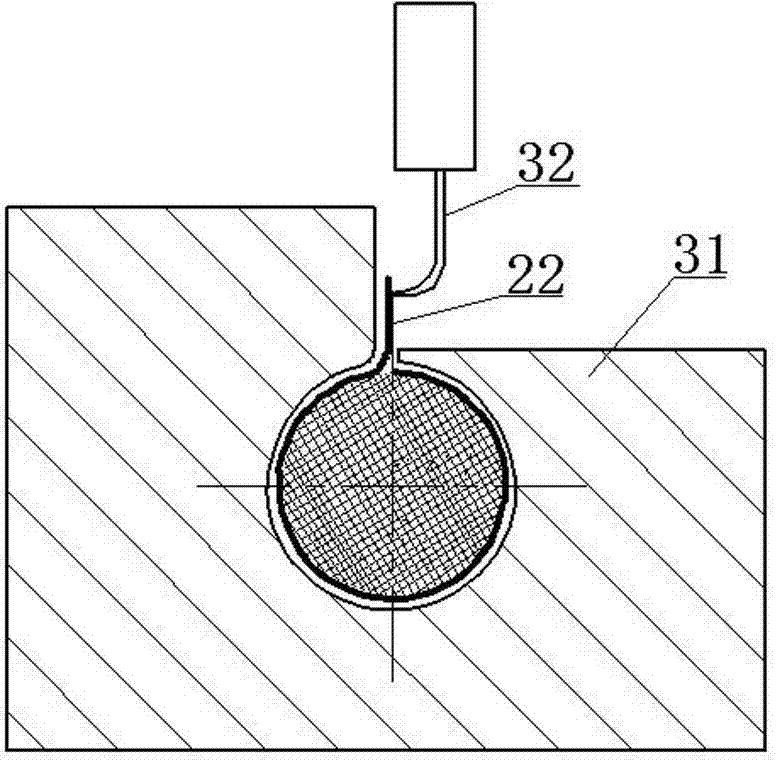

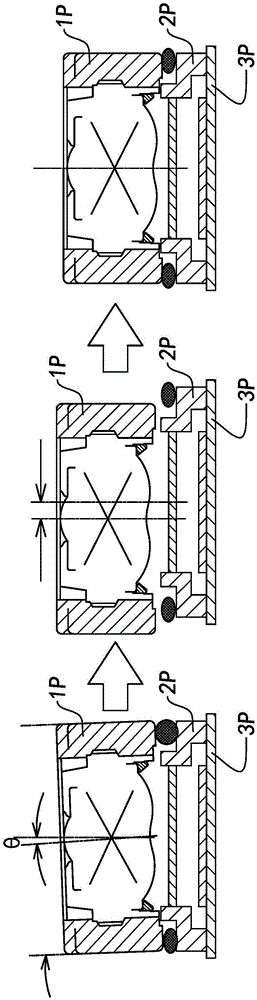

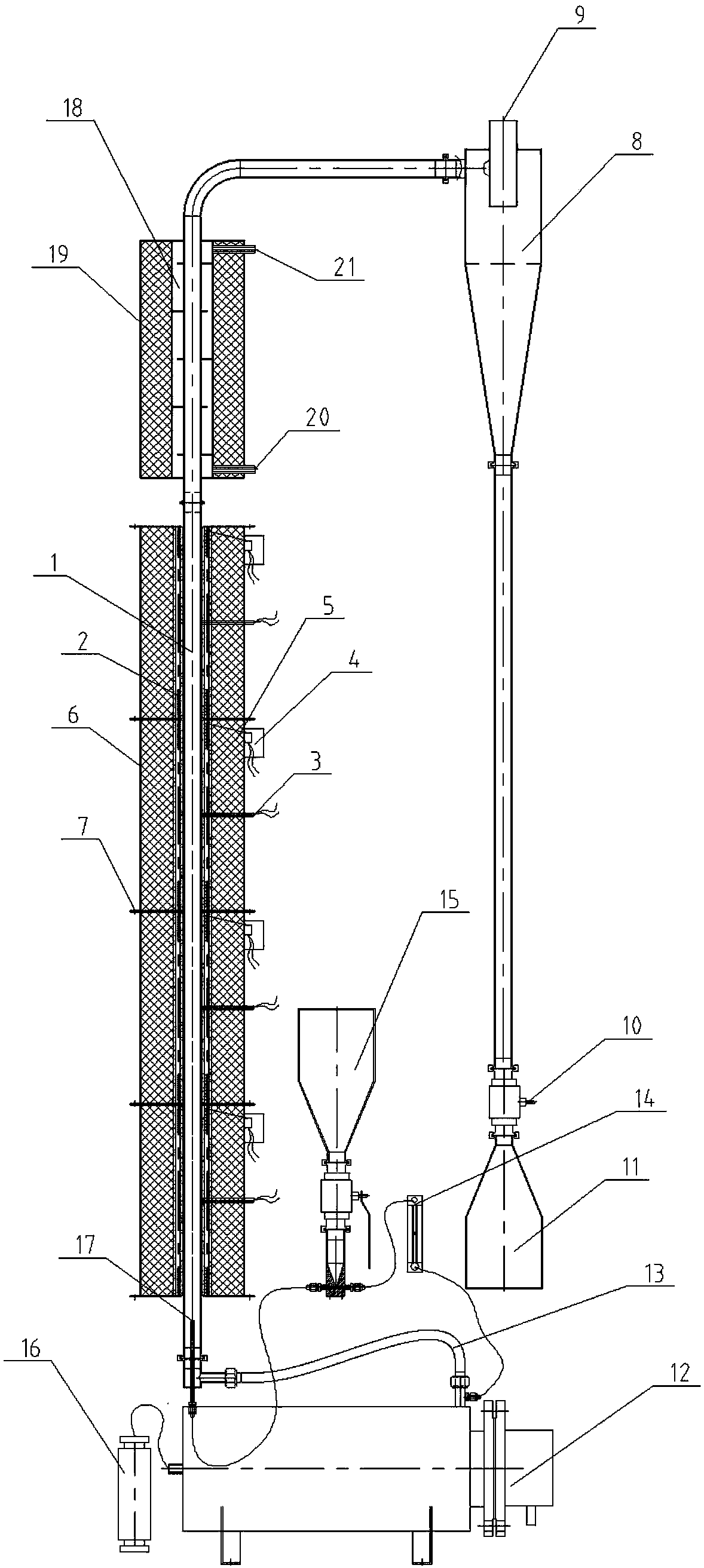

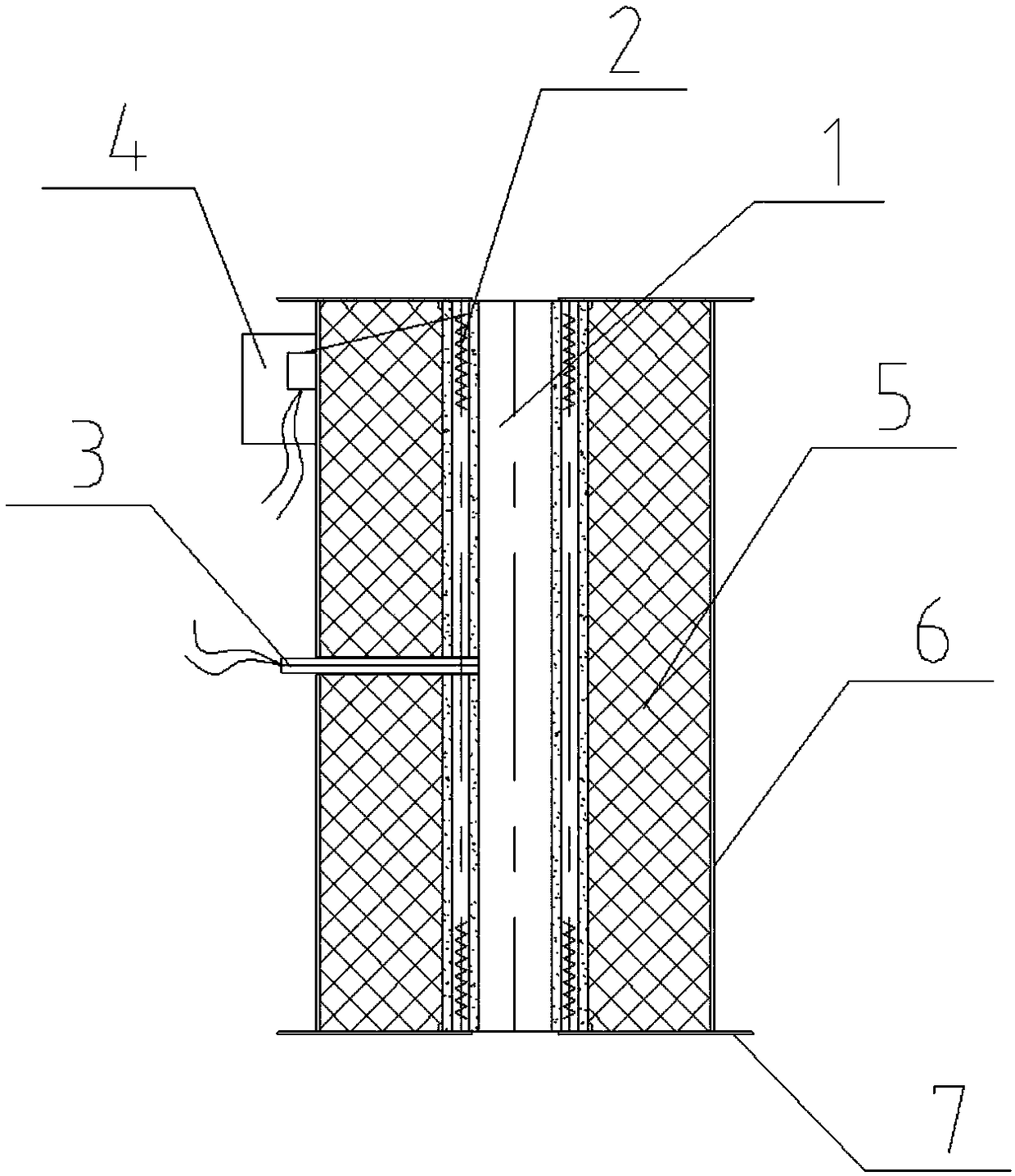

Ceramic slurry injection forming system

ActiveCN106313277AAvoid sizeAvoid stabilityCeramic shaping plantsAuxillary shaping apparatusSlurryVacuum pump

The invention provides a ceramic slurry injection forming system. When a slurry injection device injects slurry into a plaster mold, a movable supporting pipe rises up from the bottom of the plaster mold while being subjected to slurry injection, so that the phenomenon that air is mixed in slurry due to mutual collision of the slurry can be avoided during slurry injection; meanwhile, a rotating part drives the plaster mold to rotate to enable the slurry in the plaster mold to be uniformly distributed; a slurry supplementation device supplements the slurry to the plaster mold, so that the phenomenon of unstable size and thickness of a product due to the fact that the plaster mold is not full of the slurry because of various reasons in the slurry injection device is avoided; a drying device enables the plaster mold to absorb the slurry for forming; a main pipe in a slurry extraction part is connected with a vacuum pump, so that residual slurry in the plaster mold can be extracted; a slurry throwing part drives the plaster mold to move, so that a little of slurry extracted from the bottom of the plaster mold is thrown to the inner wall of the plaster mold so as to be absorbed by the inner wall; and therefore, the ceramic slurry injection forming system provided by the invention is high in automation degree and high in product quality, and is relatively clean in production and high in production efficiency.

Owner:QUANZHOU KUNTAI MACHINERY PRECISION MFG CO LTD

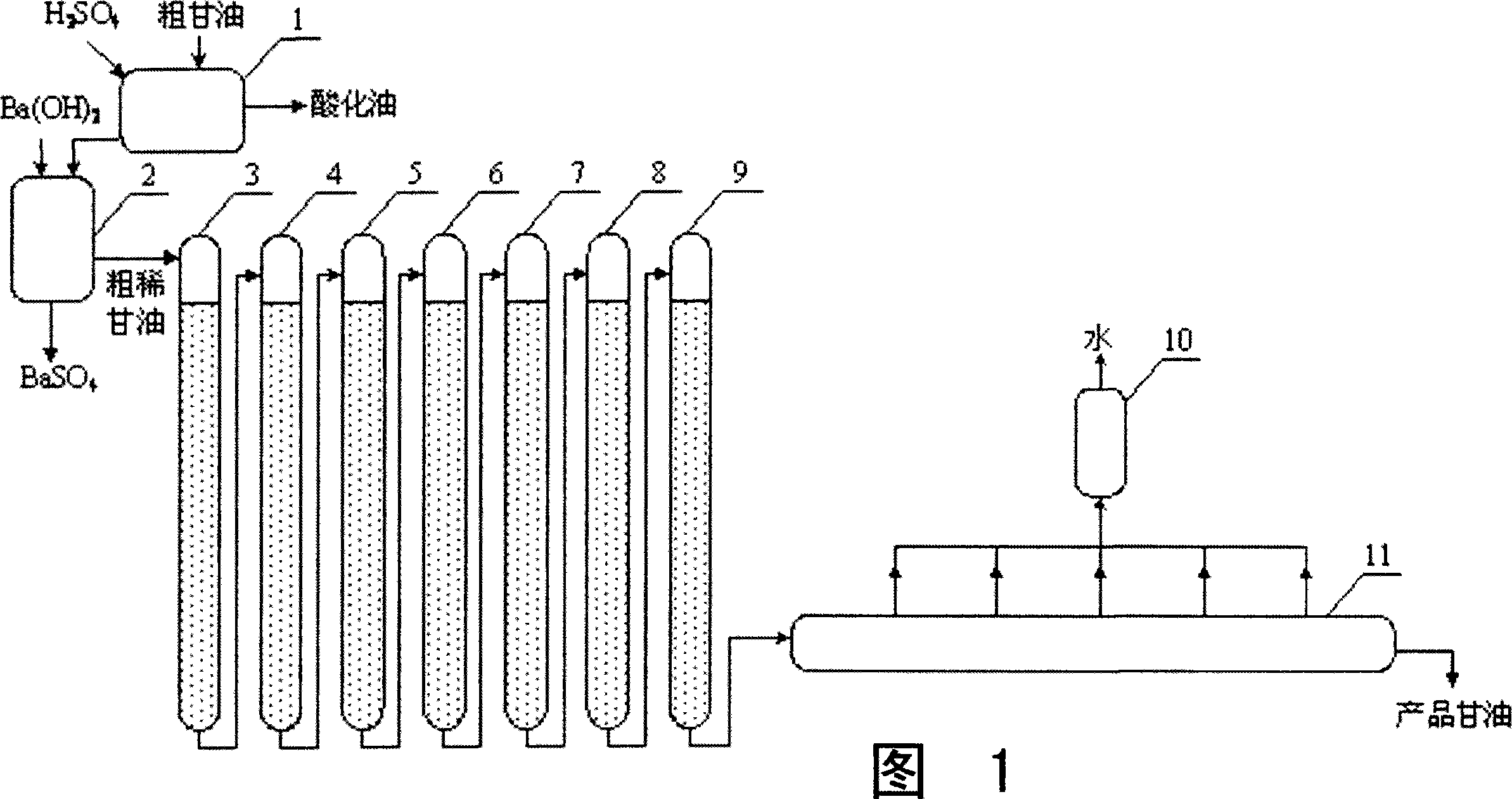

Method for refining biodiesel byproduct glycerin

InactiveCN101182281ASimple processImprove efficiencyHydroxy compound separation/purificationChemical industryBiodiesel

The invention provides a method of refining a biological diesel oil by-product of glycerol. The invention relates to the technical field of the oil and fat chemical industry and more particularly a method of refining the biological diesel oil by-product of the glycerol. The steps of the method are that crude glycerol produced during the production process of the biological diesel oil is added into a acidification reactor for the acidification treatment; acidified oil at the upper layer is returned to a biological diesel oil production system as the production materials of the biological diesel oil, and the glycerol at the lower layer is put into a neutralization reactor for the neutralization reaction; the glycerol layer is put into an ion exchange column for impurity removal to obtain the dilute solution of glycerol which contains water; the dilute solution of glycerol is put into a short-stroke pipeline evaporator for continuous evaporation and concentration to obtain the refined glycerol product. The technical process of the invention is simple; the efficiency is high; the investment is less; the quality of the obtained product is uniform; the invention can reduce the recycle cost of the glycerol and the production cost of the biological diesel oil.

Owner:KUNMING UNIV OF SCI & TECH

Method for regenerating corrugated paper by paper mill sludge cracking

InactiveCN108729281AEmission reductionImprove bindingWaste product additionPaper recyclingPapermakingPre treatment

The invention discloses a method for regenerating corrugated paper by paper mill sludge cracking. By means of a papermaking process in which paper mill sludge is subjected to pressurized liquefying, low-temperature cracking, separating and dewatering, filter pressing and the like to be suitable for regenerating corrugated medium paper in a paper mill, the paper mill sludge is better recycled; besides, a low-temperature cracking technology is adopted in the paper mill sludge pretreating process, and no chemical agent is needed; meanwhile, waste gas generated in the paper mill sludge treating process is centralizedly treated, secondary pollution is avoided, and the paper mill sludge treating process further reduces the cost and has higher environmental friendliness.

Owner:DONGGUAN TAICHANG PAPER CO LTD

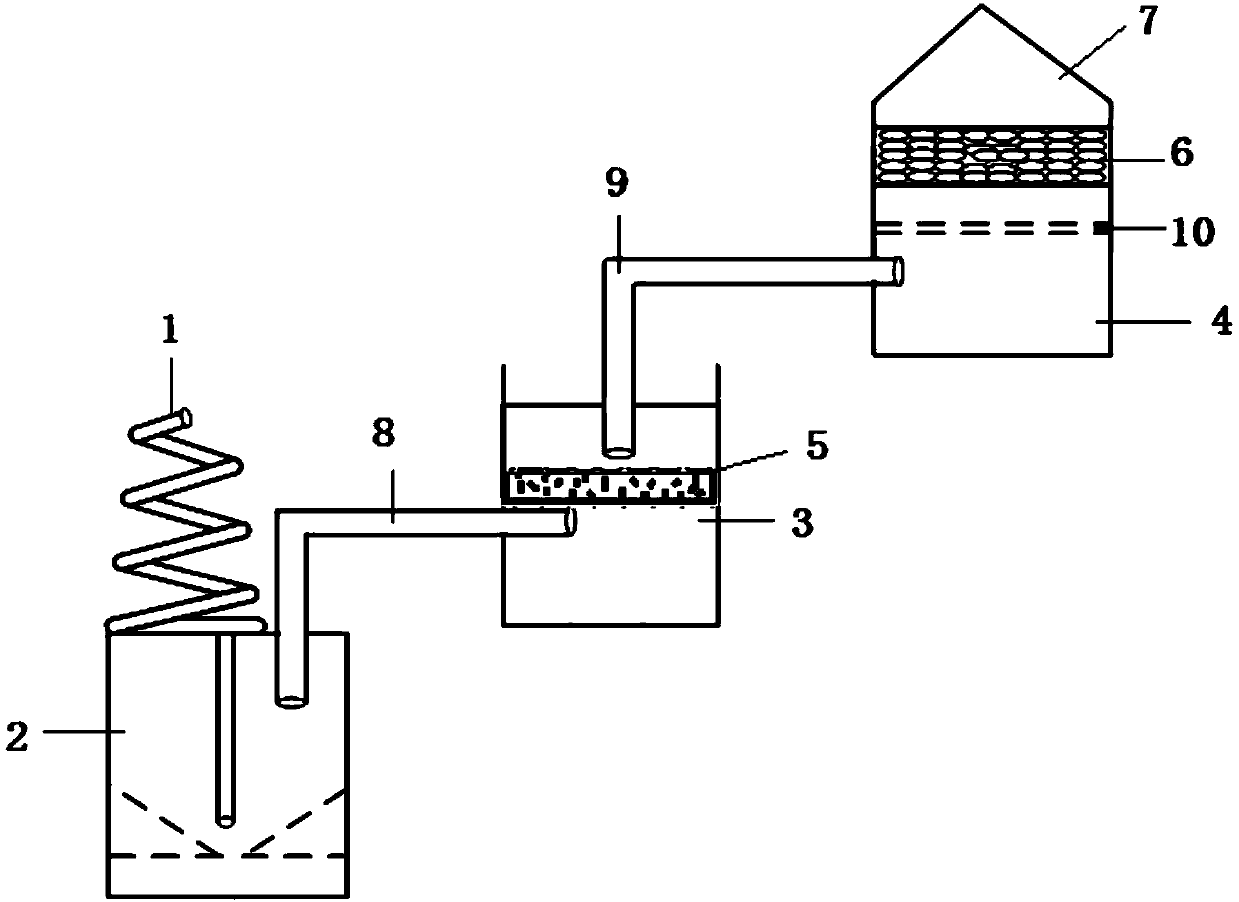

Equipment for directly producing arsenic by utilizing high-arsenic dust and production method

PendingCN107779608AEfficient productionAvoid harm from toxic substancesProcess efficiency improvementArsenicDirect production

The invention discloses equipment for directly producing arsenic by utilizing high-arsenic dust and a production method. The equipment comprises a closed direct current furnace (2), a closed deoxidizing device (3) and a closed arsenic reduction-condensation integrated device (4) connected in sequence by virtue of pipelines, as well as a screw feeding device (1) communicated with the interior of the direct current furnace, wherein the deoxidizing device (3) is characterized in that a carbon powder layer (5) is arranged in a deoxidizing tank; the arsenic reduction-condensation integrated device(4) comprises a tank body, a reduced carbon layer (6) arranged in the tank body, and a condensation cover (7) arranged on the top of the tank body; two ends of a first connecting pipe (8) are respectively communicated with the top of the direct current furnace and the lower part of the deoxidizing device; and a second connecting pipe (9) is communicated with the top of the deoxidizing device and the lower part of the arsenic reduction-condensation integrated device. The equipment disclosed by the invention is capable of producing arsenic in a fully closed environment, and is safe, reliable, high in yield, simple and low in investment.

Owner:红河砷业有限责任公司

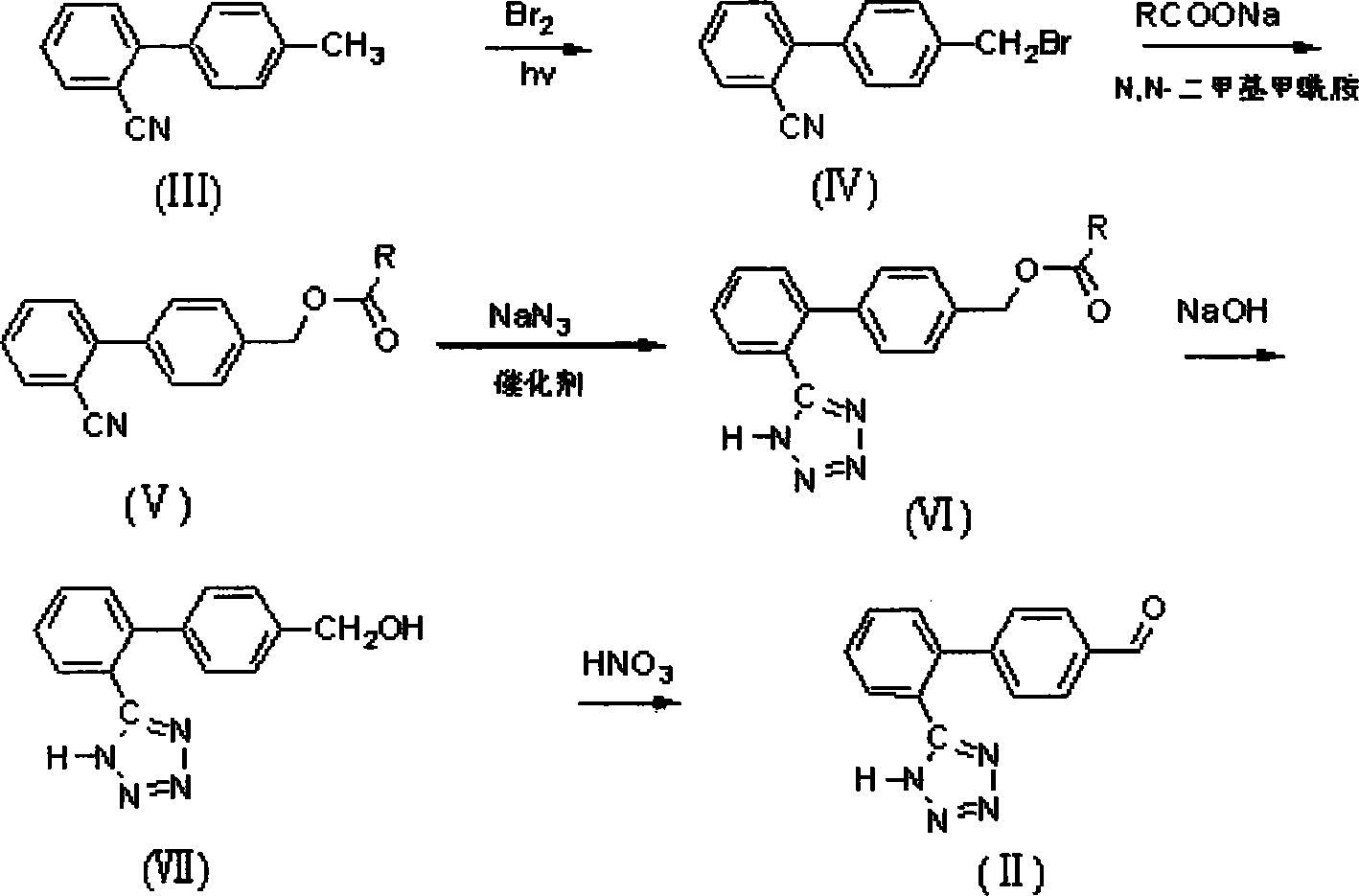

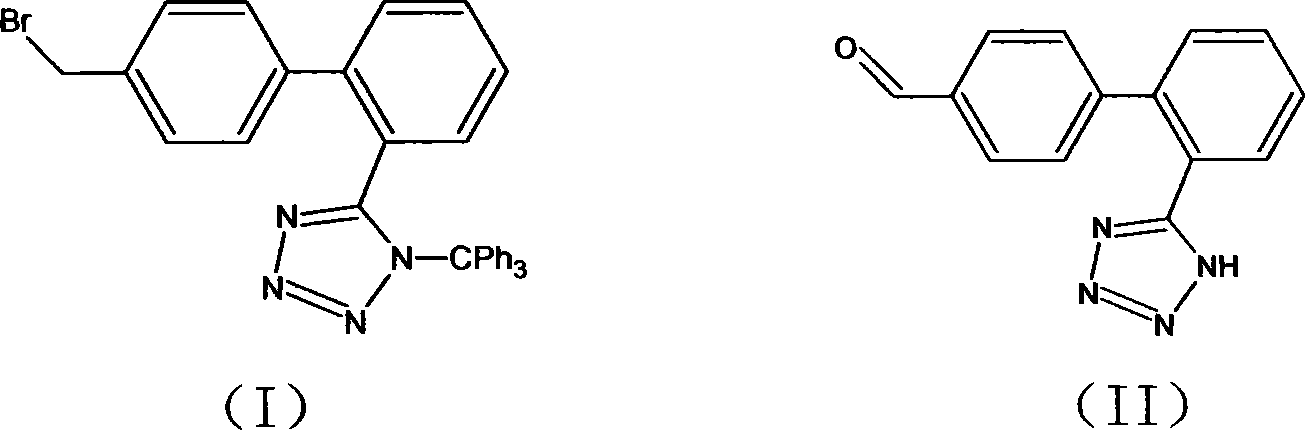

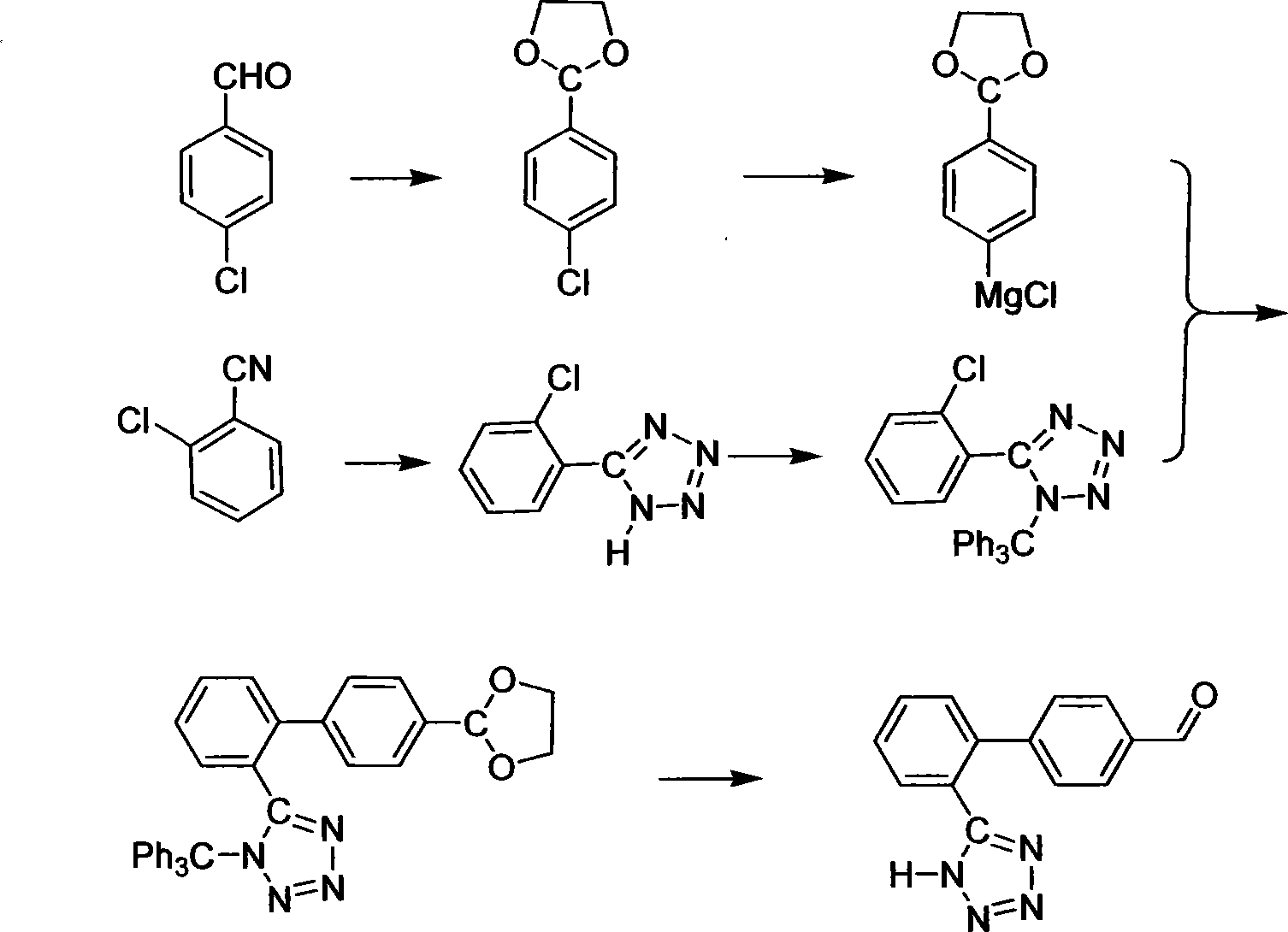

Method for preparing sartan drug main ring 5-(4'-formyl biphenyl-2-group)-1H-tetrazole treating hypertension

The invention belongs to drug synthesis, particularly relates to the main ring of Sartan drug for the treatment of the hypertension i.e. 5-(4'-formyl biphenyl-2-base)-1H-tetrazole. The preparation method comprises the following procedures, bromination, esterification, cyclization, hydrolysis and oxidation. Utilizing the triethylamine hydrochloride to serve as the catalyst, the method of the invention inhibits the side reaction, promotes the purity and the yield of the product, avoids the residue of the poisonous matter in the drug intermediate, reduces the waste discharge, realizes the clean production and protects the environment.

Owner:NANTONG SHIMEIKANG PHARMA CHEM

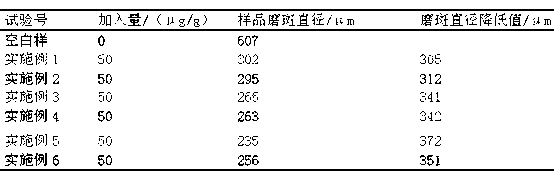

Ultra-low-sulfur diesel lubricating property improver and preparation method thereof

InactiveCN103173254AImprove conversion rateReduce lubricationLiquid carbonaceous fuelsFuel additivesBiodieselMonoglyceride

The invention relates to an ultra-low-sulfur diesel lubricating property improver and a preparation method thereof. The improver is a mixture of monoglyceride, fatty acid and low-molecular-weight alcohol. The improver has acid value being lower than 30.0mgKOH / g and a condensation point being lower than -1 DEG C. according to the preparation method, biodiesel co-product glycerin and low-molecular-weight alcohols serving as the raw materials have esterification reaction with the fatty acid in the presence of an ionic liquid catalyst to generate the mixture of monoglyceride, fatty acid and low-molecular-weight alcohols, namely the ultra-low-sulfur diesel lubricating property improver, wherein the addition of the improver relative to low-sulfur diesel is 50mu g / g, the temperature is 100-170 DEG C, the pressure is 0.1-0.2MPa and the time is 1-2 hours. The detailed preparation method refers to the specification. The low-sulfur diesel lubricating property improver has low acid value and high lubrication improvement property, can be directly used without use of antioxidants and cleaning agents; production cost is low, the production process is clean and the production flow is short.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

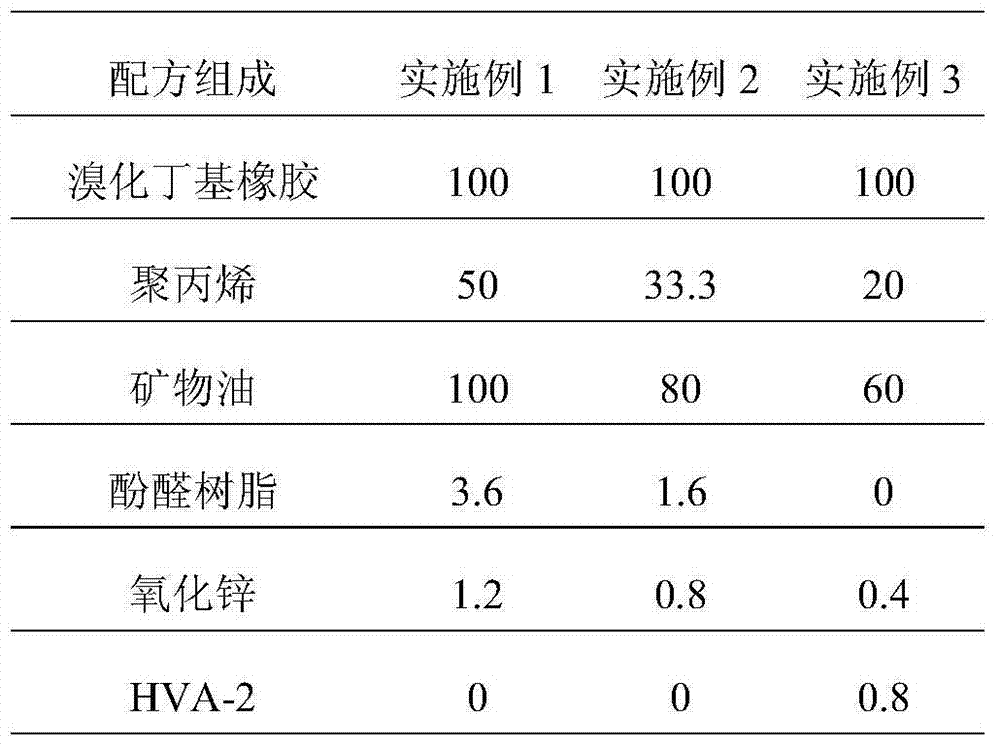

Low-hardness medical thermoplastic brominated butyl rubber and preparation method thereof

The invention provides low-hardness medical thermoplastic brominated butyl rubber and a preparation method thereof, and belongs to the technical field of polymer materials. The low-hardness medical thermoplastic brominated butyl rubber is prepared from a rubber-plastic blend of brominated butyl rubber and polypropylene by a complete pre-dispersion two-step method and dynamic vulcanization technology, can be thermoplastically processed and has the application performance of thermoplastic brominated butyl rubber, the material composition is simple, clean and sulfur-free, or antioxidant or stabilizer is added, the safety and sealing property of an elastomer material in pharmaceutical package application, the low-hardness medical thermoplastic brominated butyl rubber can be directly injection molded into gaskets of rubber plugs, combined covers and infusion bags (bottles), the production process is cleaner, the energy consumption is greatly reduced, and the product cost is greatly reduced.

Owner:SHANDONG DAWN POLYMER CO LTD

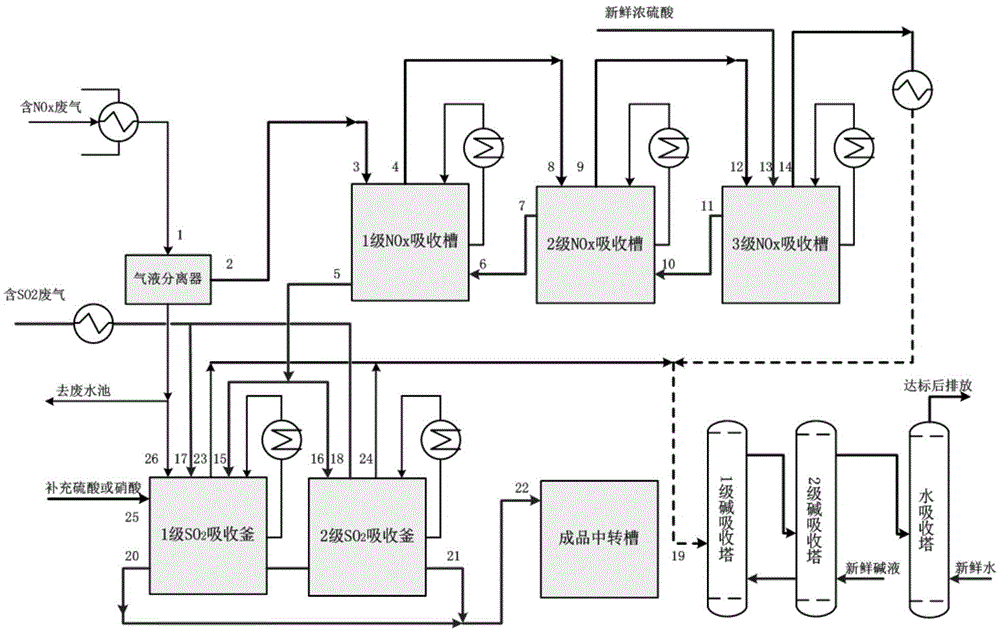

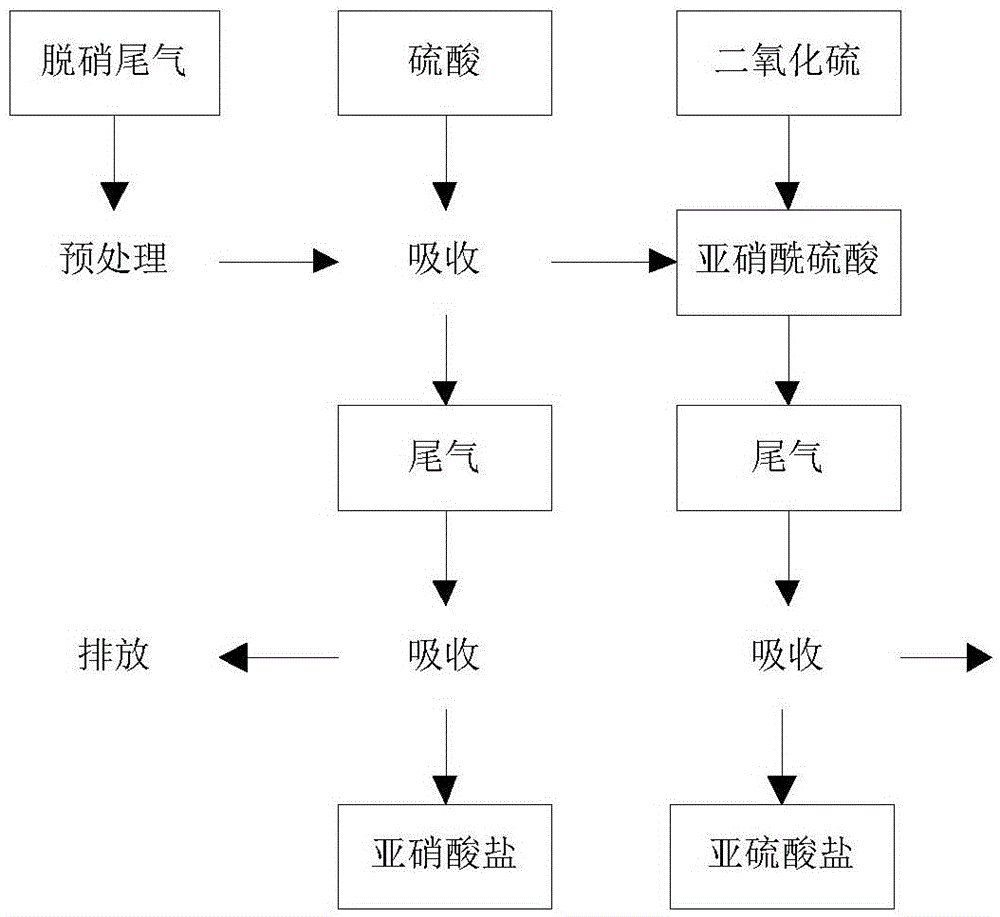

Resourceful treatment method and system for H acid production tail gas

ActiveCN105536478AMake the most ofIncrease secondary valueGas treatmentNitrogen compoundsSulfite saltSodium sulfite

The invention relates to a resourceful treatment method and system for H acid production tail gas. The method comprises the steps that a sulfuric acid solution is used for absorbing denitration exhaust gas, the obtained absorption liquid is used for absorbing acidification exhaust gas, a nitrosyl sulfuric acid product is obtained, the excessive amount of NOx or SO2 is absorbed through alkali, and finally sodium nitrite or sodium sulfite is recycled. According to the method, the NOx or SO2 is recycled in the H acid production process, the exhaust gas is purified, and meanwhile the nitrosyl sulfuric acid product with the high added value is obtained. According to the treatment system, H acid production exhaust gas is treated, the nitrosyl sulfuric acid is obtained, and the product can be used as a diazotization reagent commonly used in the dye synthesis process for sale.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

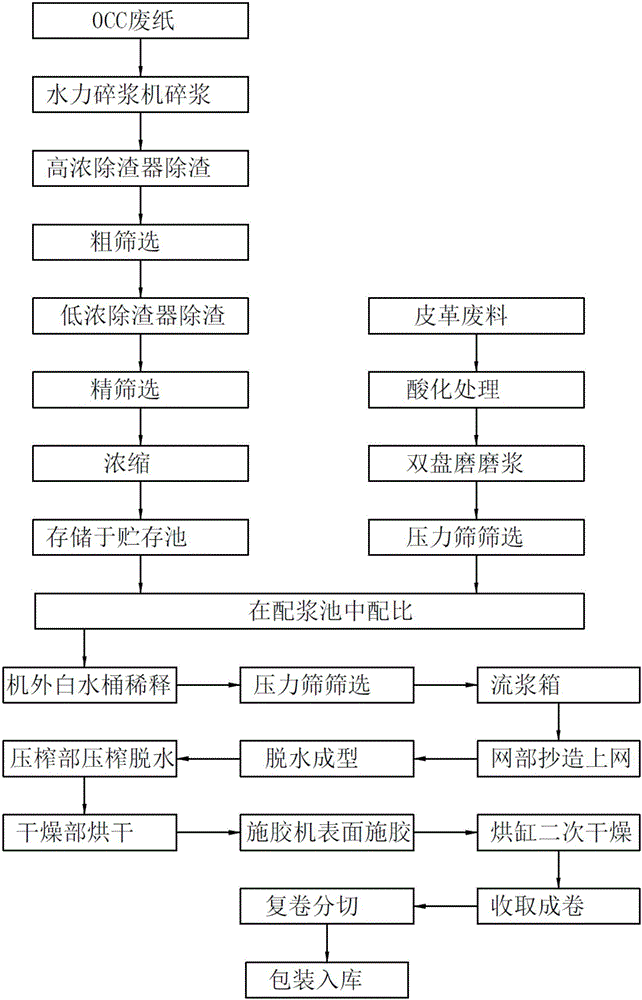

Method for producing high-strength corrugating medium paper through blending of leather waste and OCC waste paper

ActiveCN106256953ARealize comprehensive utilizationReduce paper production costsMechanical working/deformationPre-tanning chemical treatmentPapermakingSingle fiber

The invention discloses a method for producing high-strength corrugating medium paper through blending of leather waste and OCC waste paper. The leather waste is treated to obtain clean collagen fibers existing in a single fiber form, the OCC waste paper is pulped to be prepared into OCC pulp suitable for papermaking, 15-20% by weight of collagen fibers and 80-85% by weight of OCC pulp are matched into mixed pulp, the mixed pulp is used for papermaking, and the finished high-strength corrugating medium paper is obtained. Comprehensive utilization of resources is achieved, leather waste of shoe factories and leather factories is recycled to serve as production raw materials of the high-strength corrugating medium paper, a brand-new treating method is provided for the leather waste, and waste is turned into wealth; the production process is environmentally friendly, clean and free of pollution, environmental pollution is avoided, and the papermaking cost of the high-strength corrugating medium paper is reduced. According to the high-strength corrugating medium paper produced through the process, the collagen fibers from the leather waste and plant fibers from the OCC waste paper are interwoven and combined, and the higher-quality high-strength corrugating medium paper is obtained.

Owner:东莞顺裕纸业有限公司

Bacillus pumilus and application of the same in producing natural vanillin by biologically converting iso-eugenol

ActiveCN101078005AWide variety of sourcesLow priceBacteriaMicroorganism based processesBiotechnologyHigh concentration

The invention discloses Bacillus pumilis and its application of biotransformation of iso-eugenol into natural vanillin. The name of bacterial stripe is Bacillus pumilus S-1, preserved in China Center for Type Culture Collection on 3rd, January, 2006 and its serial number is CCTCC M 205165. The procedure of transforming iso-eugenol into natural vanillin includes: (1)cultivation, (2)preparation of seed culture fluid, (3)culture of transforming cell, (4) transformation.The invention exists in field of biology and technology. It can improve the transformating rate of vanillin with high concentration, solving problems of low concentration and low yield of vanillin by biological method.

Owner:SHANGHAI KAIXIN BIOTECH +2

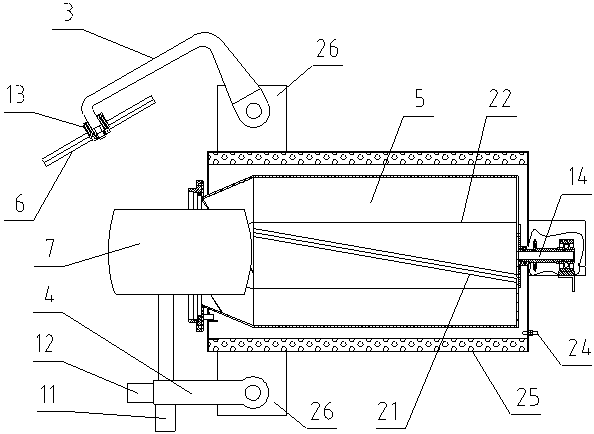

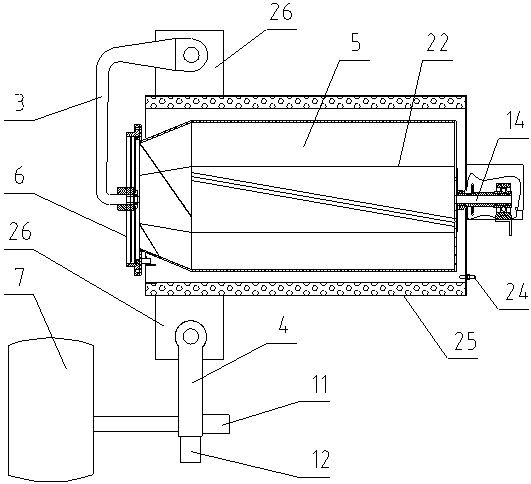

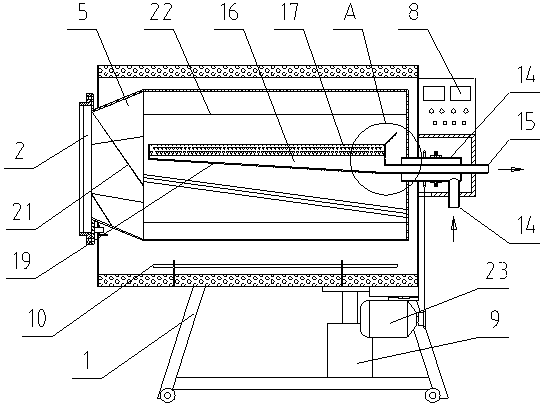

Drum-type automatic final-panning aroma raising machine and processing method thereof

InactiveCN102754705ACompact and smooth shapeColor emerald greenPre-extraction tea treatmentProduction lineAutomatic control

The invention discloses a drum-type automatic final-panning aroma raising machine. The drum-type automatic final-panning aroma raising machine comprises a frame, a drum, a drum heater and a drum dumping mechanism, wherein the drum, the drum heater and the drum dumping mechanism are disposed on the frame. One end of the drum is provided with a tea leaf access hole, and the other end of the drum isclosed and is connected with an air heating device through a hot air pipe. A door opening and closing manipulator and a feeding and discharging manipulator are arranged on two sides of the drum on the frame. A moving door is disposed at the tail end of the door opening and closing manipulator. A tea leaf chute is arranged at the tail end of the feeding and discharging manipulator. The drum-type automatic final-panning aroma raising machine is further provided with an automatic control system. By the drum-type automatic final-panning aroma raising machine, the problem that an existing drum-type tea leaf final-panning machine is unavailable for an automatic tea leaf production line is solved effectively, and the problem that dustiness of the drum-type tea leaf final-panning machine endangers physical health of workers and possibly causes dust explosion is also solved. The drum-type automatic final-panning aroma raising machine is ingenious in structure, suitable for automatic tea leaf production lines, clean and safe and has broad market prospect.

Owner:苏和生

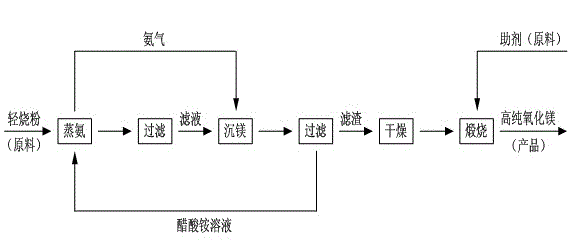

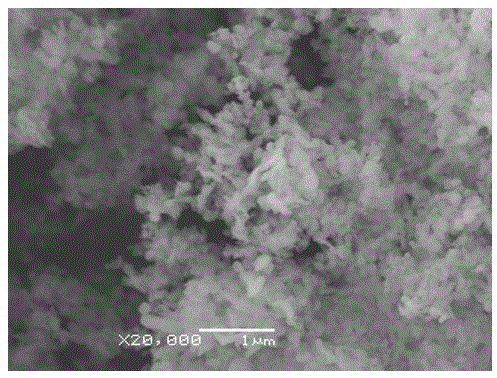

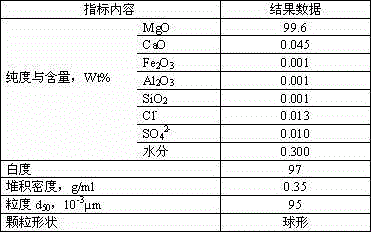

Method for producing high-purity magnesium oxide by using light calcined powder as raw material

A method for producing high-purity magnesium oxide by using light calcined powder as a raw material relates to a production method of magnesium oxide; ammonia gas and ammonia distilled liquid are obtained by the raw material of light calcined powder and an ammonium acetate solution through an ammonia distillation process; the ammonia distilled liquid is filtered to remove solids so as to obtain magnesium salt refined liquid; a magnesium precipitation reaction is performed by the refined liquid and the ammonia gas released in the ammonia distillation process to obtain magnesium hydroxide mother liquor; the magnesium hydroxide mother liquor is filtered to separate magnesium hydroxide filter residues and an ammonium acetate filtrate, and the filter residues are dried to obtain magnesium hydroxide; the dried magnesium hydroxide is calcined with a raw material additive to obtain the high-purity magnesium oxide product whose purity, whiteness, granularity, and bulk density meet requirements. The method produces high-purity magnesium oxide by using light calcined powder as a raw material, realizes ammonia (ammonium) circulation; not only the ammonia distillation time is shortened to less than 1 hour, but also the Mg2+ concentration of the magnesium salt liquid obtained after ammonia distillation is increased to above 2.5 mol / L; production energy consumption per unit product is reduced by 30-50%; the production cost is reduced and the economic benefit is improved.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Airflow spherification reactor and method for preparing polymer-based spherical powder material by same

ActiveCN108501250APrevent disorderAvoid accumulationAdditive manufacturing apparatusAirflowPhencyclone

The invention discloses an airflow spherification reactor and a method for preparing a polymer-based spherical powder material by the same. The reactor comprises a powder material conveying system, aheating reactor body, a condensing system and a cyclone separator which are connected in sequence, wherein the powder material conveying system is used for uniformly dispersing the powder material andenabling the powder material to enter the reactor with temperature higher than the melting point of the powder material, so that the solid powder material is molten and changes into spheres under theaction of surface tension, the spheres then enter the condensing system to be cooled and shaped, gas-solid separation is realized by the cyclone separator, and the polymer-based powder material withhigh sphericity is prepared finally. The reactor has the advantages of simple structure, low cost, high production efficiency and wide application range. Aftertreatment is not needed with adoption ofair as a dispersion medium, and the method is convenient and quick, can achieve continuous mass production and can be applied to various thermoplastic polymers such as nylon, polyetheretherketone, polystyrene and composite materials of the polymers. The prepared powder material has the advantages of high sphericity, good fluidity, narrow particle size distribution and the like.

Owner:SICHUAN UNIV

Preparation method of fine graphite

The invention relates to a preparation method of fine graphite, belonging to the technical field of graphite material. The method comprises the following steps: performing dry mixing to coke fine powder and asphalt fine powder in a weight ratio of 10:1-7:3, heating the mixed powders for 4-8h in a sealed environment with the temperature of 250-350 DEG C and the vacuum degree of no less than 0.005 MPa while vibrating the mixed material to ensure that the density is not less than 1.8g / cm<3>; then adding 30-50t of pressure to the sealed environment, and gradually heating to 900-1200 DEG C to sinter and obtain fine graphite. The preparation method of the invention has simple process, convenient operation, short production cycle and low production cost; the prepared product has better overall volume density, asphalt coking value and qualification rate of the finished products; in addition, the production process is cleaner, the production environment is better and the influence of the production to the dust, atmosphere and water body can be effectively controlled.

Owner:李公成

Brucite composite heavy metal adsorption granules and preparation method thereof

InactiveCN105148872ALarge specific surface areaImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionBruciteStearic acid

The invention discloses brucite composite heavy metal adsorption granules. The brucite composite heavy metal adsorption granules are characterized by being prepared from raw materials in parts by weight as follows: 10-15 parts of brucite powder, 5-10 parts of plant ash, 2-4 parts of stearic acid, 1-2 parts of carboxymethyl cellulose, 5-10 parts of light calcium carbonate, 0.1-0.2 parts of sodium dodecyl benzene sulfonate, 0.1-0.2 parts of sodium benzoate, 1-2 parts of tartaric acid, 0.5-1 part of boric acid and 5-10 parts of bonding auxiliary materials. The adsorption granules have high adsorption capacity, not only can effectively absorb and remove heavy metal ions in water, but also has certain adsorption and removal effects on nitrogen and phosphorus organic matters in water and has high water purification capacity, the production process is clean and safe, and no secondary pollution is caused during wastewater treatment.

Owner:安徽省中日农业环保科技有限公司

Preparation method of barium hydroxide

InactiveCN1962451ASimple methodClean manufacturingCalcium/strontium/barium oxides/hydroxidesBarium sulphideSlag

The invention discloses a preparing method of barium hydroxide, which comprises the following steps: (1) reducing barite into barium sulphide through coal; (2) immersing barium sulphide through washing water to obtain mother liquid of barium sulphide; adjusting the temperature of mother liquid of barium sulphide to 30-70 Deg C and density at 50-150g / L; washing filter slag through water; immersing barium sulphide through washing water; (3) oxidizing barium sulphide to produce barium hydroxide, sulfur and manganese monoxide through manganese dioxide; filtering to obtain barium hydroxide mother liquid; obtaining the filter slag with sulfur and manganese monoxide; (4) condensing barium hydroxide; crystallizing; centrifuging; separating to obtain barium hydroxide octahydrate; (5) separating filter slag in the step (3); recycling sulfur; oxidizing manganese monoxide into manganese dioxide through air to circulate in the step (3).

Owner:李守德

Two-step method for preparing biodiesel

ActiveCN102260596ASimple post-processingAdaptableFatty acid esterificationBiofuelsBiodieselAfter treatment

The invention relates to a method for preparing biodiesel by a two-step process, which comprises the following steps: (1) supplying grease and fatty alcohol to a reactor, reacting at 190-300 DEG C under the pressure of 3-11 MPa, and separating fatty alcohol and glycerol from the crude product after reaction to obtain the crude ester phase; and (2) supplying the crude ester phase and fatty alcoholto the reactor, adding ethers, carbonates and / or carboxylates containing methoxy or oxyethyl functional groups, reacting at 190-300 DEG C under the pressure of 3-11 MPa, and collecting the biodiesel from the mixture after reaction. The invention has the advantages of simple technique, strong adaptability of raw materials, high biodiesel purity, simple after-treatment, clean production process andhigh concentration of the byproduct glycerol, and the grease utilization ratio approaches to 100%.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com