Patents

Literature

40results about How to "Production process hygiene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

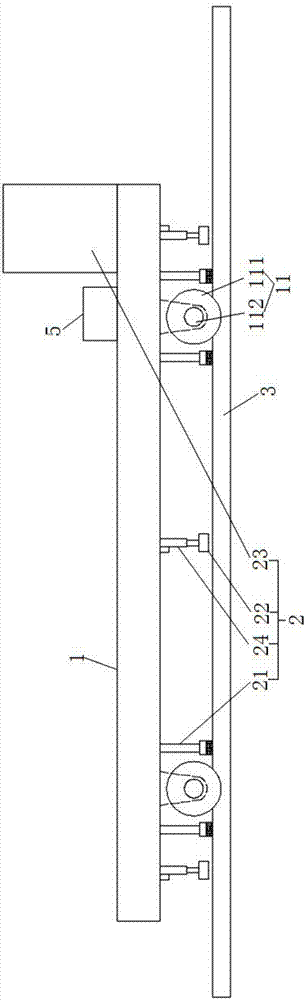

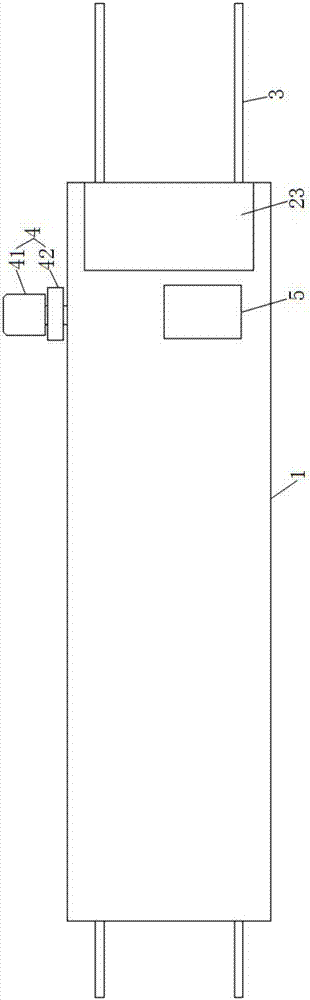

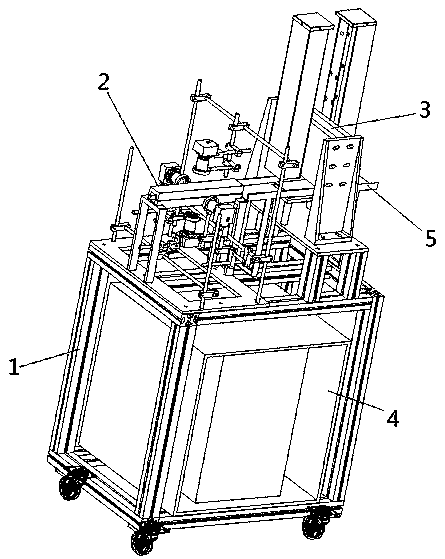

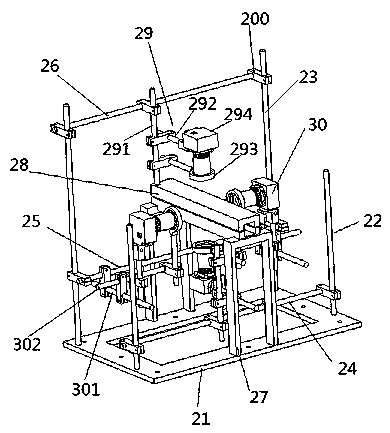

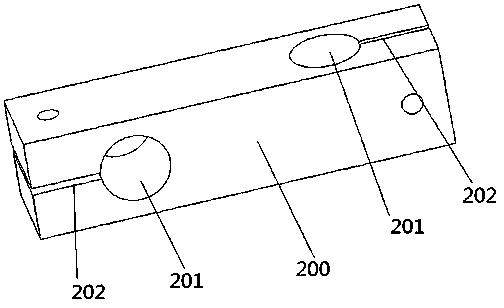

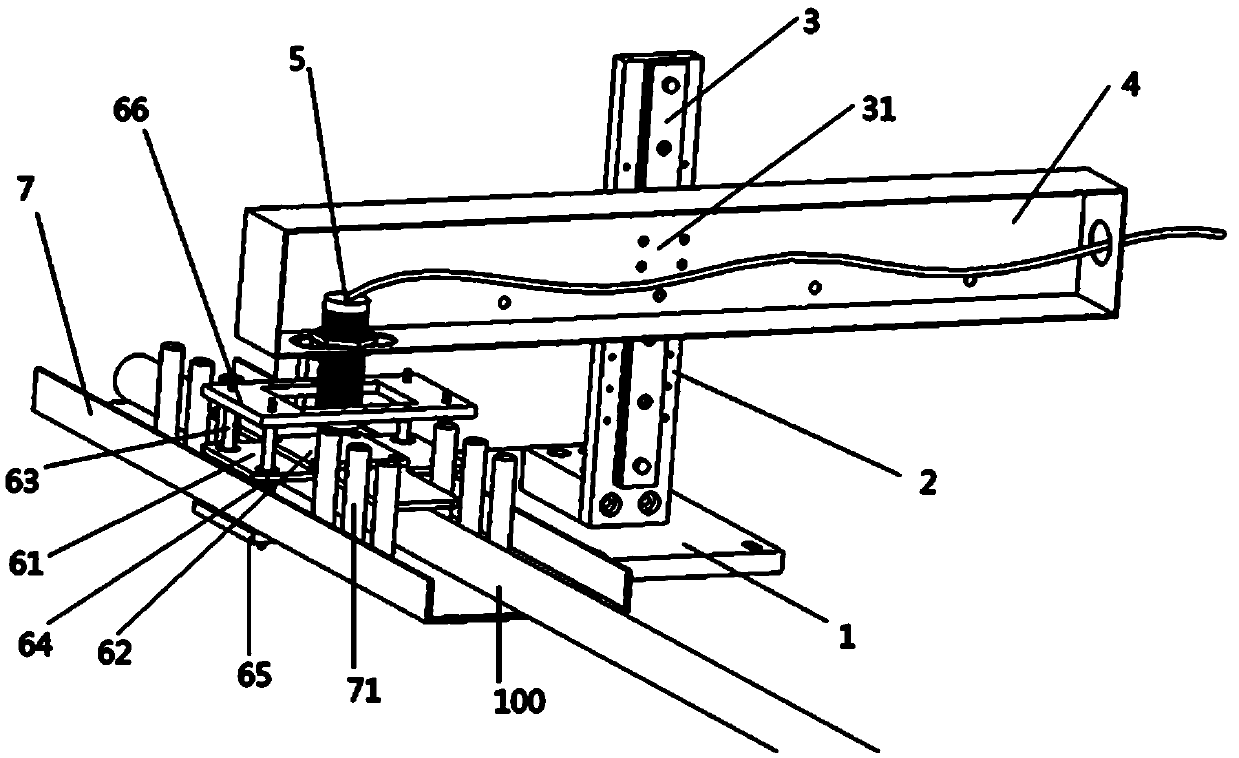

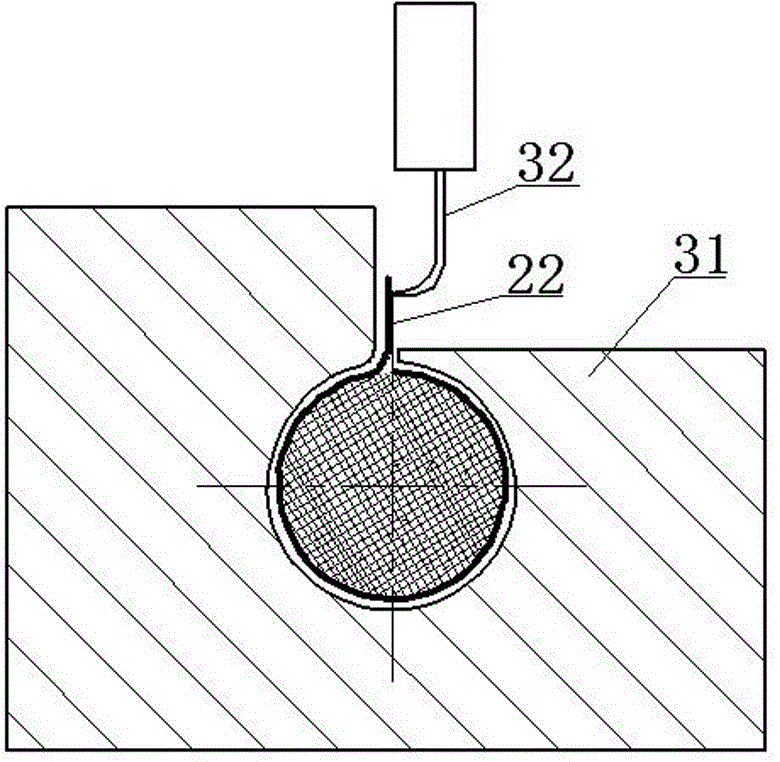

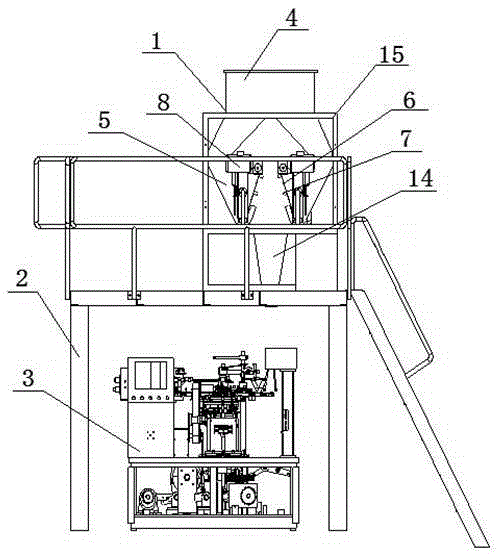

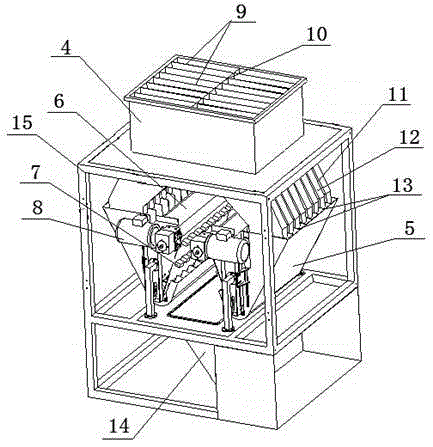

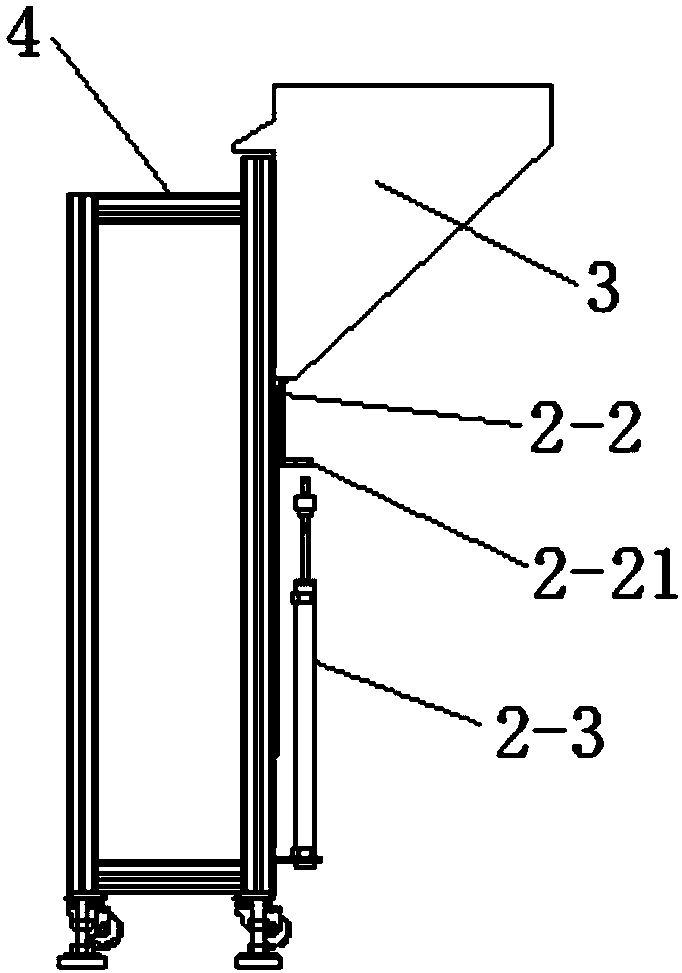

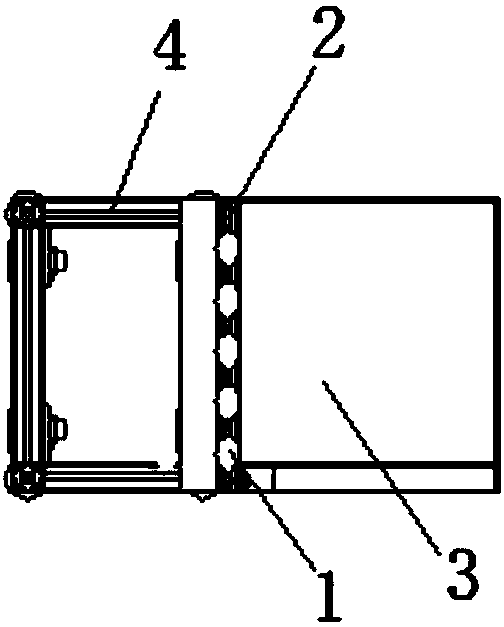

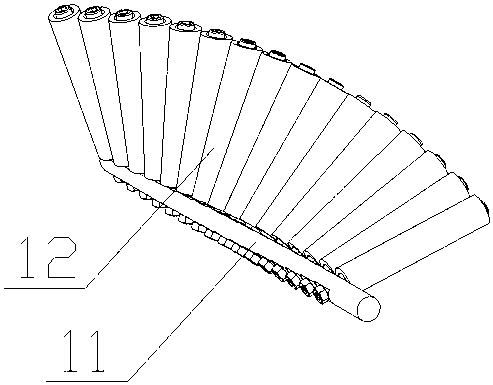

Moxa cone coiling forming machine

ActiveCN104490593AImprove medicinal qualityEasy to operateDevices for heating/cooling reflex pointsConveyorsRolling paperMolding machine

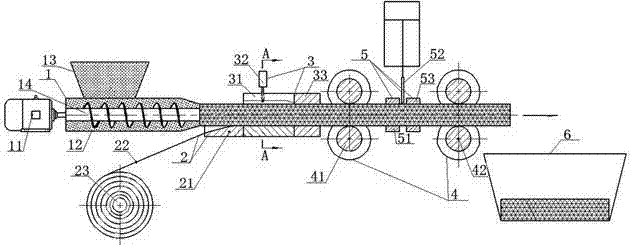

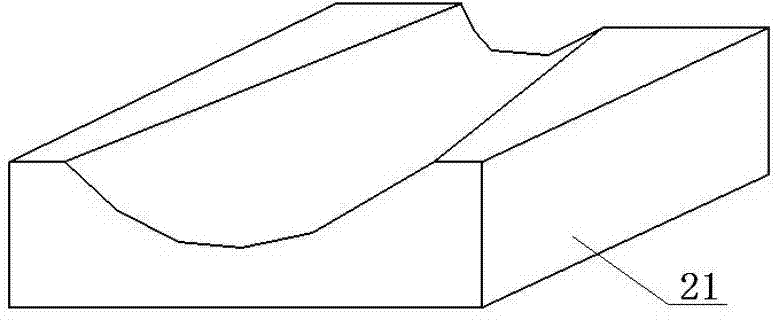

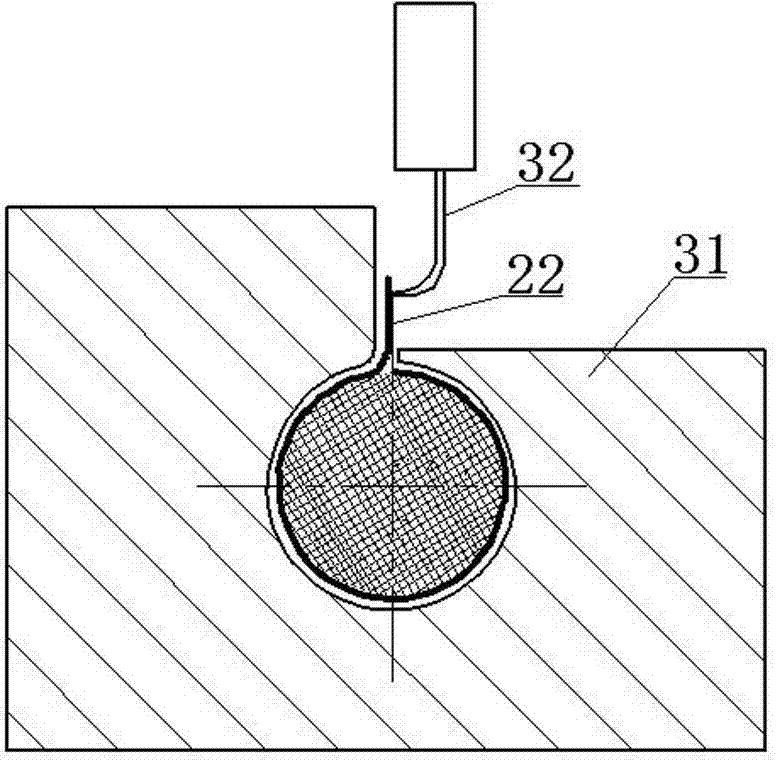

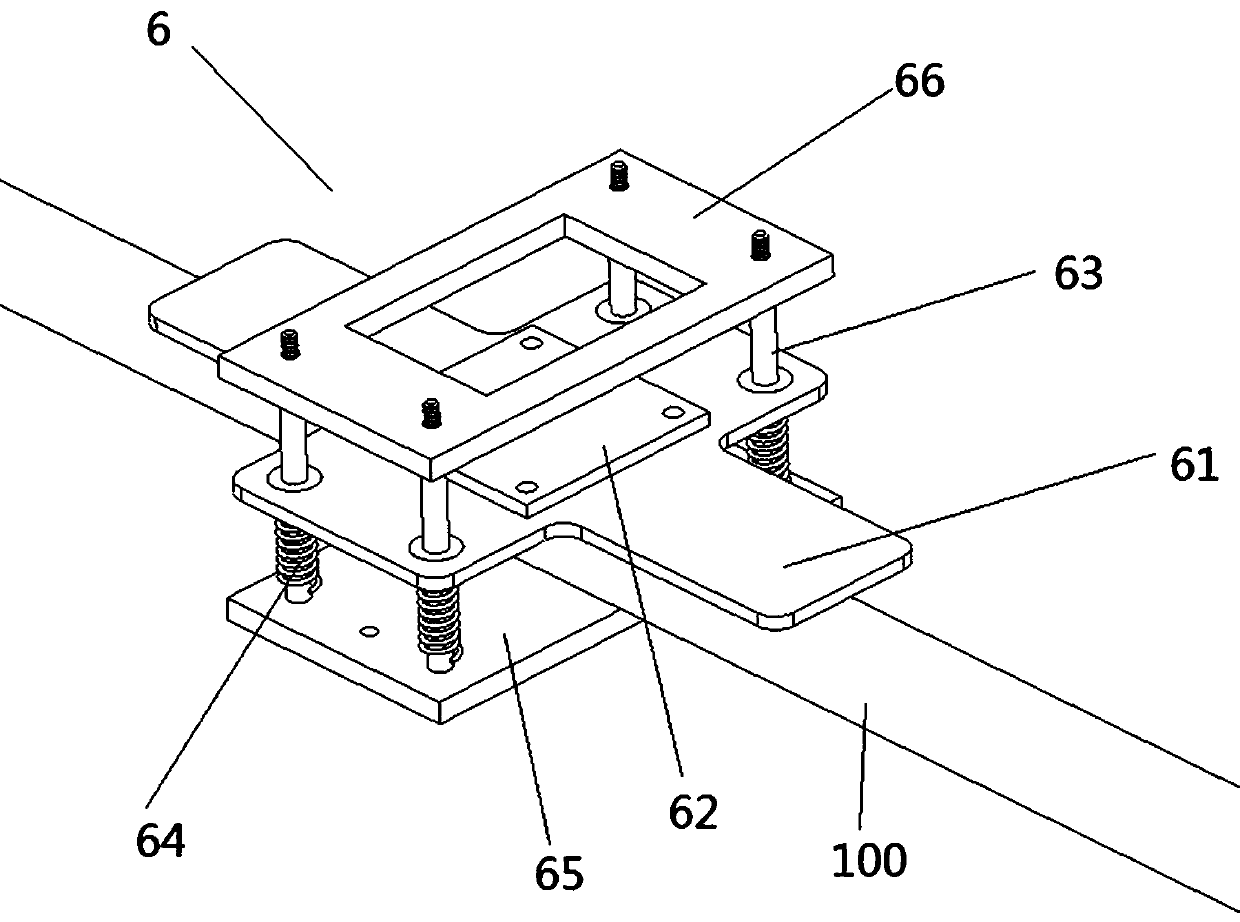

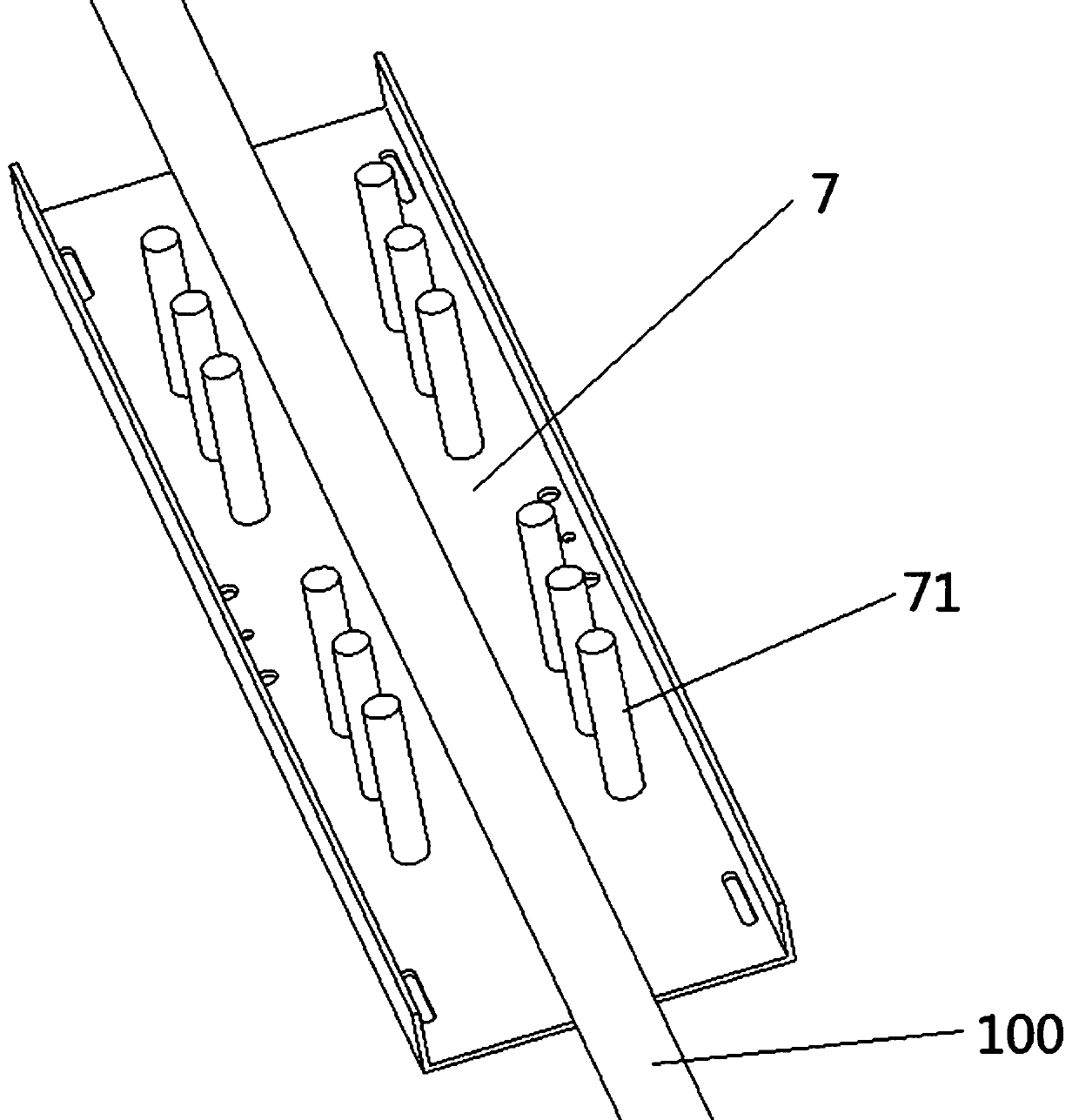

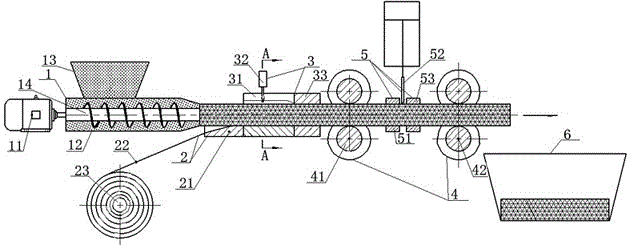

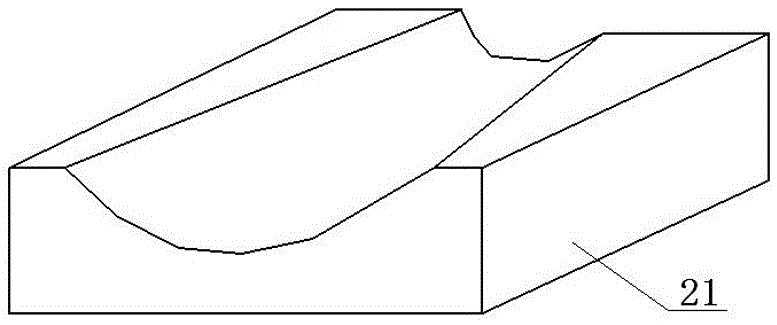

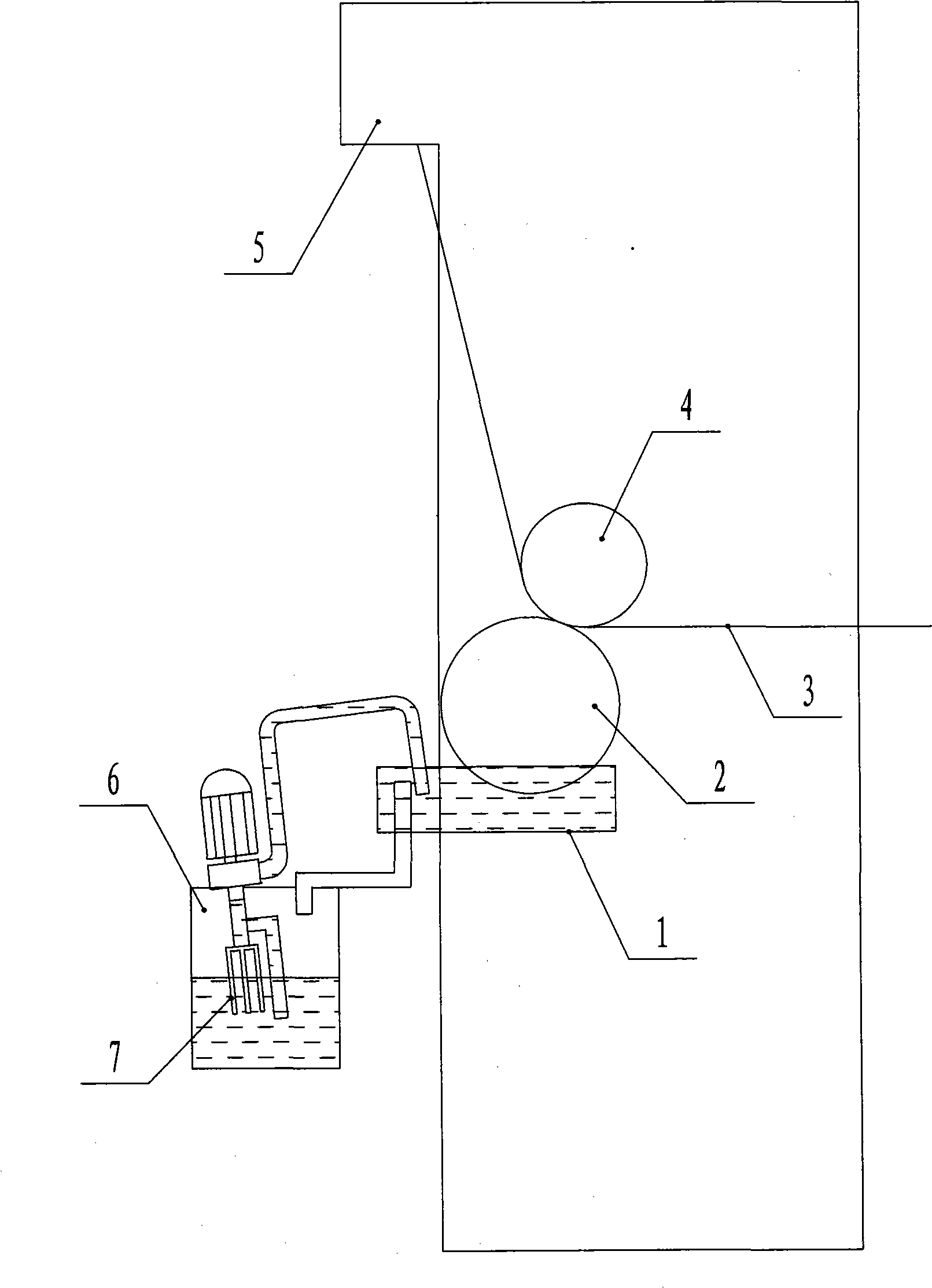

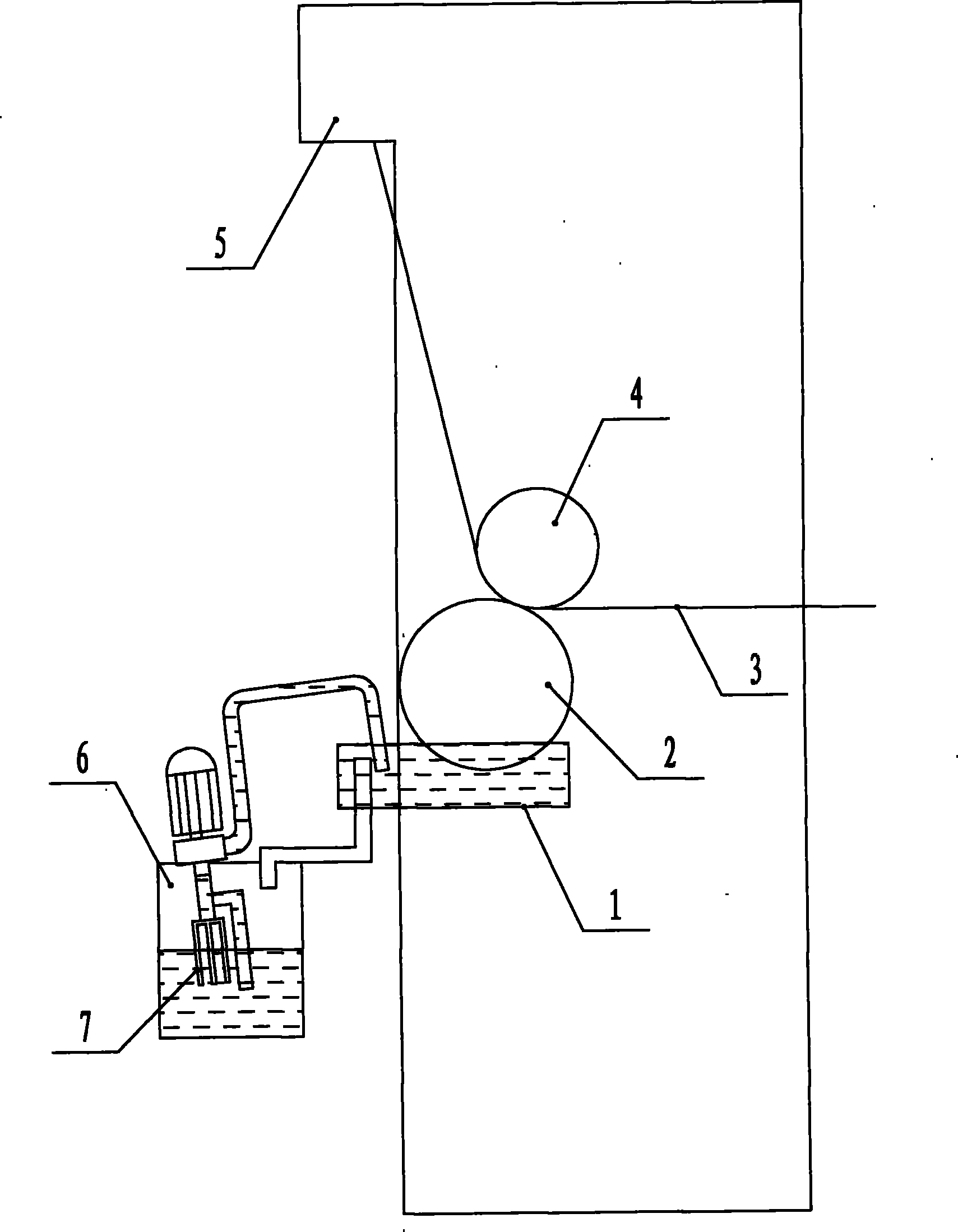

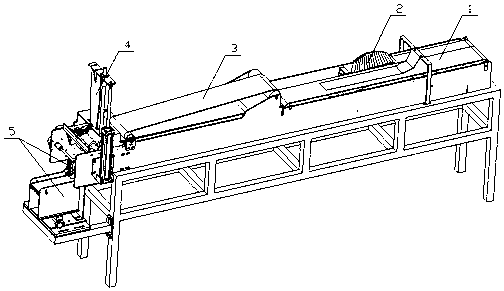

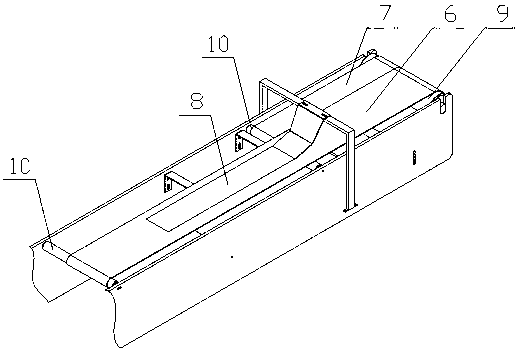

The invention discloses a moxa cone coiling forming machine which comprises a spiral conveying mechanism, a paper tape winding mechanism, a gluing and forming mechanism and a shearing mechanism which are arranged in sequence, wherein the spiral conveying mechanism is used for forming a naked moxa cone; the paper tape winding mechanism mainly consists of a paper coiling disc and a paper tape; a conical guide groove of which the front part is large and the rear part is small is formed in the paper coiling disc; the width of the paper tape is greater than the perimeter of the naked moxa cone; the paper tape is paved inside the conical guide groove in the paper coiling disc in a dynamic conveying manner; the gluing and forming mechanism mainly consists of a gluing machine and a sealing ring; the gluing machine is used for gluing the paper tape; the sealing ring is used for shifting, guiding and compacting the glued paper tape when the paper tape is dynamically conveyed, so as to coil and seal the paper tape; the shearing mechanism is used for shearing the coiled and formed moxa cone output from the gluing and forming mechanism. The moxa cone coiling forming machine is capable of automatically and continuously producing coiled paper moxa cones and is applicable to large-scale in-batch production, the whole production process is clean, sanitary, free of pollution, high in production efficiency and low in cost, and the formed moxa cones are high in medicinal quality.

Owner:SICHUAN ENG TECHN COLLEGE

Frozen instant noodles and processing method thereof

InactiveCN102178171AStrong fresh-keeping abilityNot subject to storage conditionsFood preparationMixed materialsInstant noodle

The invention relates to frozen instant noodles and a processing method thereof. The frozen instant noodles comprise raw materials of flour, starch, wheat gluten, albumen powder, vegetable jelly, alkali, common salt, food dye and water. During processing, the mixed materials are synchronously placed in dough kneading equipment, vacuum stirred and then are let stand; the dough is subjected to rolling and pulling type composite calendaring for multiple times, is cured and is subjected to rolling and pulling type continuous calendaring and is chopped into short noodles; and finally, the noodles are boiled, washed and sub-packaged into boxes and refrigerated at a temperature of -18DEG C.

Owner:牛选欣

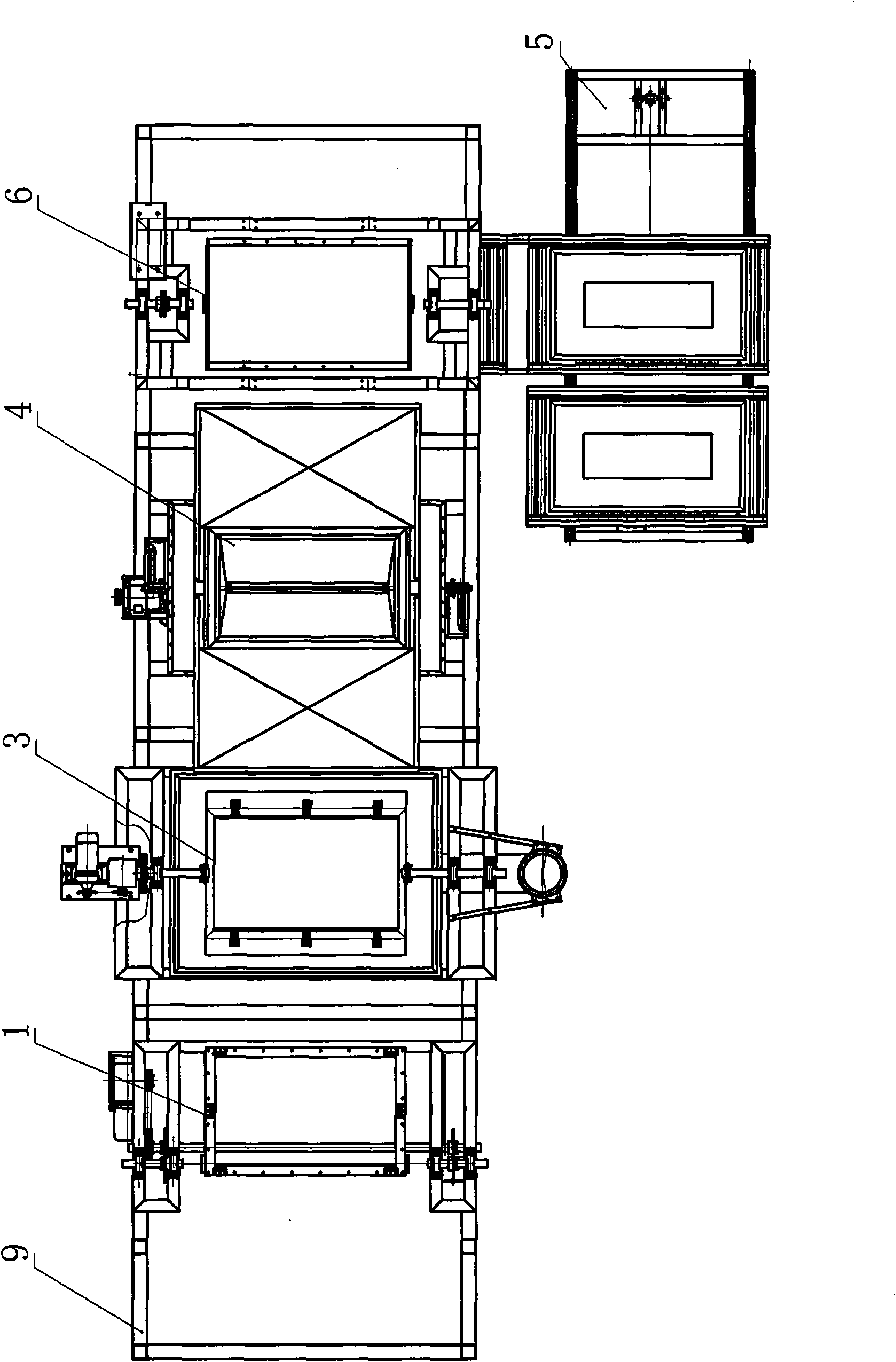

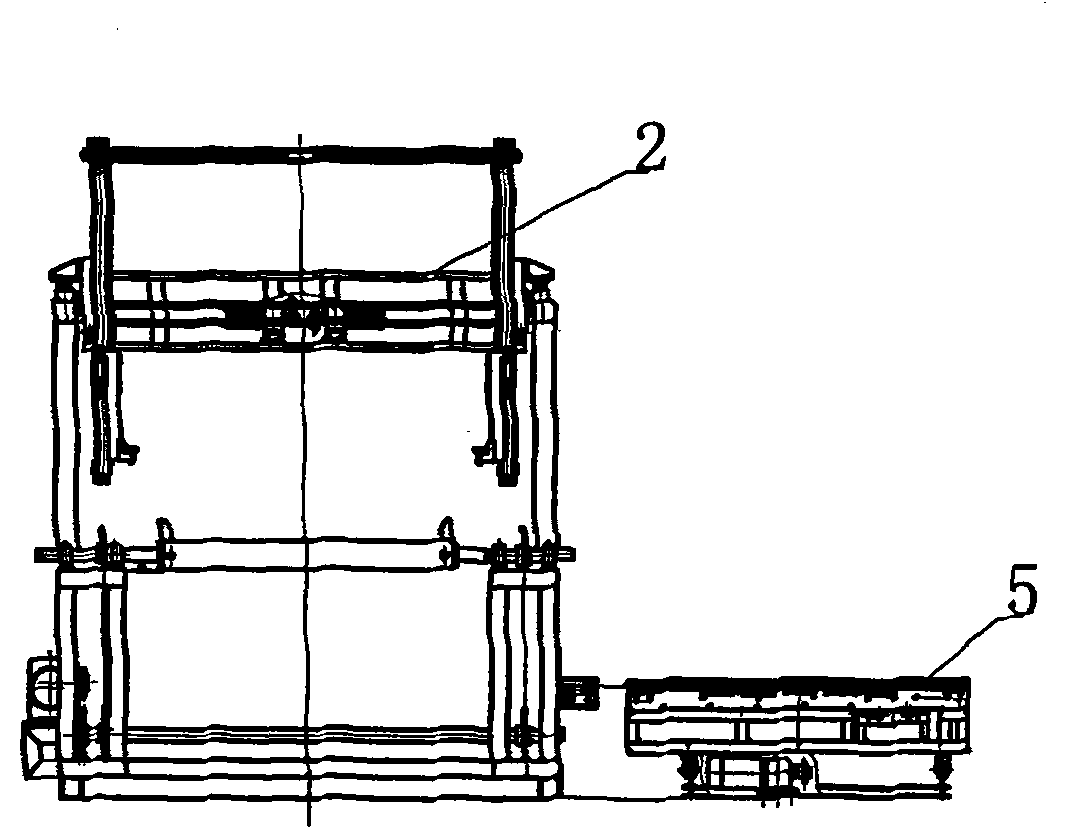

Slush molding machine

InactiveCN102001146AShorten the processing cycleNo need for manual feedingCoatingsMolding machineCooling chamber

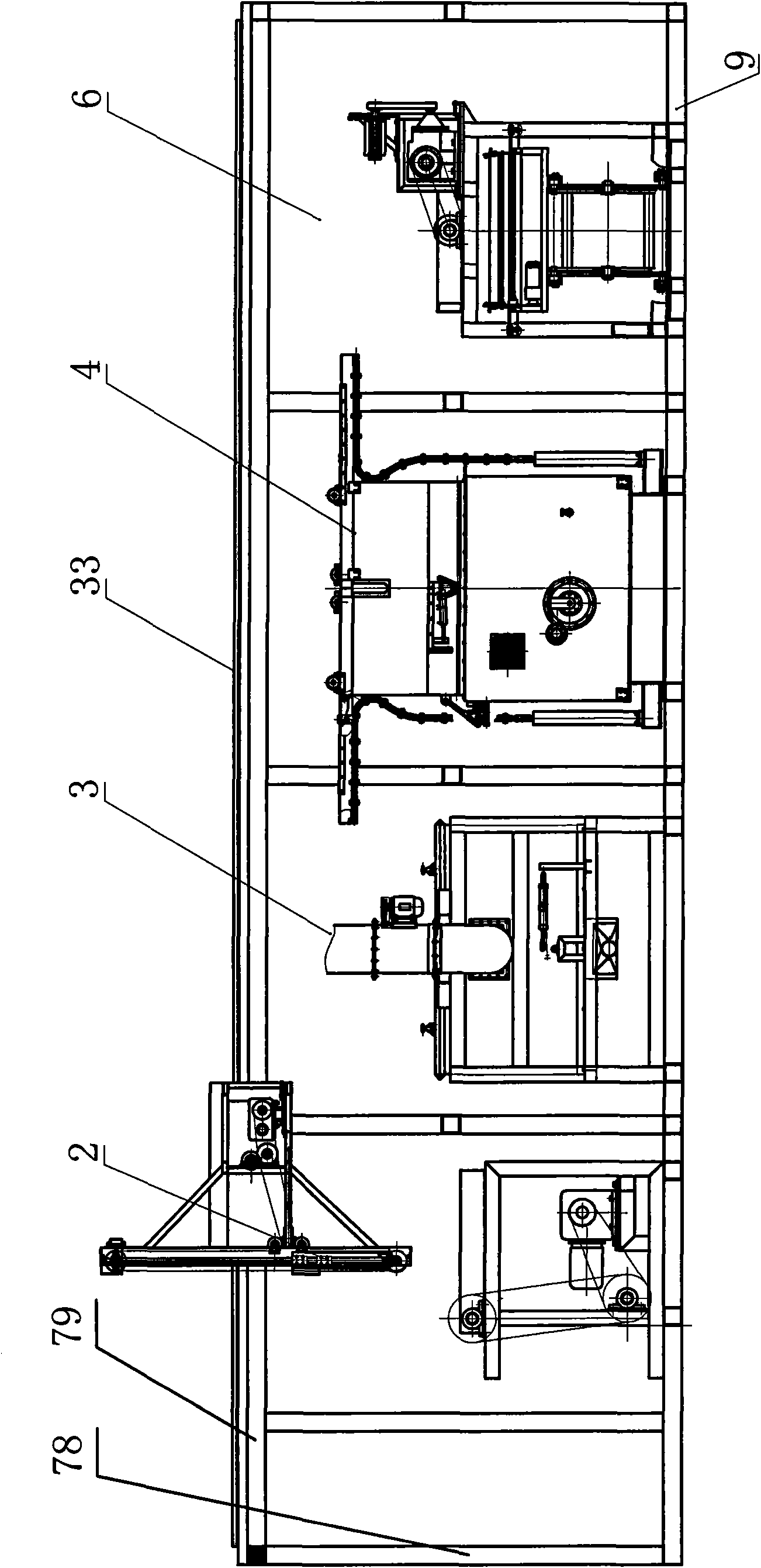

The invention discloses a slush molding machine, which consists of 9 units including a powder exchange chamber, a molding roll-over stand, an air heater, a cooling chamber, a piece-taking roll-over stand, a manipulator, a mold frame, a powder box and a main machine frame, wherein the powder exchange chamber, the molding roll-over frame, the air heater, the cooling chamber, the piece-taking roll-over stand and the manipulator are arranged side by side in turn from one end in the main machine frame and fixedly connected with the main machine frame; the main machine frame consists of a plurality of symmetric beams on two sides and vertical sides, the beams on the two sides of the main machine frame are provided with linear sliding rails, and a slider on the manipulator is slidably connected with linear sliding rails on the main machine frame; the mold frame, the powder box and the powder exchange chamber are positioned on one side of the main machine frame and arranged in parallel to the main machine frame; and the mold frame, the powder box and the powder exchange chamber are moveably connected with the main machine frame through chain wheels or rollers. The slush molding machine is scientifically, rationally and creatively designed, completely solves the problem of localization of the slush molding machine, has the advantages of convenience of use, high practicability and the like and has a bright market prospect.

Owner:JINXING AUTOMOTIVE INTERIOR DECORATION

Frozen and cooked noodle capable of being heated through microwave

InactiveCN102396670AImprove stretchSpeed up coolingDough treatmentFood preparationWater contentConvenience food

The invention discloses frozen and cooked noodles capable of being heated through microwave, which belong to the technical field of frozen instant foods. The frozen and cooked noodles are prepared mainly by the following raw materials in part by weight: 40-50 parts of water, 115-124 parts of flour, 12-17 parts of cassava modified starch, 4-7 parts of cassava starch, 1-3 parts of duck egg pulp, 2-4 parts of table salt, 0.3-0.7 part of dietary alkali and 0.5-0.8 part of composite phosphate. The invention improves the quality of the frozen and cooked noodles by adopting a reasonable frozen and cooked noodle prescription, contains 70+ / -5 percent of water and can be cooked by adopting microwave heating or cooked by heating with a common stove. The cooked noodles cooked by adopting microwave heating have higher quality, smooth edible taste, even color and complete shapes and can not generate the phenomenon of breakage or soup mixture.

Owner:云鹤食品有限公司

Preparation method of dietary fibers from peanuts

The invention relates to a preparation method of dietary fibers from peanuts, which comprises the following steps: wet peanut residues are taken as raw materials and proper amount of process water and accessories are added to prepare peanut residue pulps through hardening and tempering process; under certain conditions of temperature, time and environment, the peanut residue pulps respectively pass through various procedures to undergo chemical reaction and processing; the peanut residue pulps pass through a filter pressing procedure and are prepared into filter cakes with thickness of 20-40mm; the filter cakes are subjected to flash drying process and the dried filter cakes have moisture content of 15-20%; the filter cakes are broken up and are coarsely ground by flour mills to uniform powder; the powder is sterilized by microwave sterilizers and then is conveyed to a super micron mill for micronization to prepare the dietary fibers from peanuts; the dietary fibers have protein content more than or equal to 35%, moisture content less than or equal to 12%, ash content less than or equal to 6%, total content of dietary fibers more than or equal to 60%, water-holding capacity more than or equal to 20%, swelling coefficient more than or equal to 13ml / g and fineness of 100-380 meshes. The dietary fibers from peanuts can fully extract the nutritions in the peanut residues and have good quality, wide application, high added-value of products, high production efficiency, low production cost and good economic benefits.

Owner:SHANDONG GAOTANG LANSHAN GRP CORP

Chicken paste and its production method

The invention relates to a chicken paste, which comprises the following raw materials by weight ratio: 80-90 parts of chicken reactant, 0.5-1.5 parts of chicken essence, 1-3 parts of edible ethanol, 10-20 parts of purified water, 0.5-1 part of thickening agent and 0.1-0.2 parts of potassium sorbate. The whole production process of the chicken paste is carried out in a reaction kettle, and the production process is simple, safe and healthy. The produced chicken paste has the characteristics of pure color, soysauce-like flavor, delicious taste and abundant nutrition, and reduces the salt proportion for achieving the diet requirement for people health.

Owner:TIANJIN LANSHI SEASONING

Lip gloss

The invention provides a lip gloss. The lip gloss contains 80% to 100% by weight of honey. Compared to the prior art, the lip gloss provided by the invention mainly contains honey, which not only can brighten the lip color, but also can nourish the lips so as to effectively prevent lip from chapping. The lip gloss contains no chemical additives and preservatives harmful to the human body, and the production process is obviously sanitary, so that the lip gloss is eatable and has no damage to the human body even after long-term use.

Owner:张文博

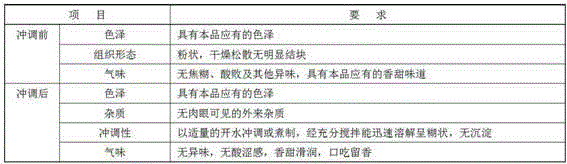

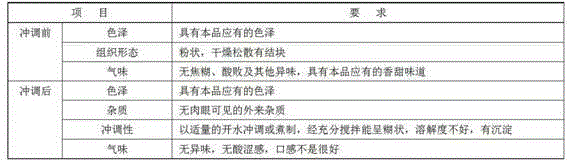

Composite nutrition powder containing black corn and preparation method thereof

InactiveCN105212040AAvoid churnSolve problems that cannot be fully absorbedFood scienceBiotechnologyAnimal science

The invention discloses a composite nutrition powder containing black corn and a preparation method thereof, and belongs to the food field. The nutrition powder is composed of the following components in percentage by weight: walnut kernel, wolfberry, black sesame, black corn, grape seed oil, black rice, kudzu vine root starch, and auxiliary materials; wherein black rice accounts for 50 to 68% of the total weight of nutrition powder, walnut kernel, black sesame, and grape seed oil account for 10 to 15% of the total weight of nutrition powder, black corn accounts for 2 to 5% of the total weight of nutrition powder, wolfberry accounts for 2 to 5% of the total weight of nutrition powder, kudzu vine root starch accounts for 3 to 5% of the total weight of nutrition powder, and the balance is auxiliary materials. The provided nutrition powder is delicious, can be used as breakfast or a beverage after meal, has a healthcare function, and is capable of improving the immunity, preventing cancer and osteoporosis, preventing and treating arteriosclerosis, protecting heart and cerebral vessels, tonifying kidney and liver, nourishing internal organs, and boosting essence and blood, if people eat the nutrition powder regularly.

Owner:SHIJIAZHUANG YILING PHARMA

Seafood sauce, seafood essence cream and preparation method thereof

The invention relates to a seafood sauce and seafood essence cream, which are prepared by the following raw materials by weight: 80-90 parts of seafood reactant, 0.5-1.5 parts of seafood essence, 1-3 parts of edible ethanol, 10-20 parts of purified water, 0.5-1 part of a thickening agent, and 0.1 part of potassium sorbate. The whole preparation process of the seafood sauce in the invention is carried out in a reaction vessel, and the production process is simple, safety and sanitary. And the produced seafood sauce has pure color, sauce flavor, fresh and mellow taste, abundant nutrition, and has the salt proportion lowered so as to meet the dietary needs of modern people for low salt and health.

Owner:TIANJIN LANSHI SEASONING

Carriage band sawing machine body with self-cleaning function

PendingCN107984549AEasy to cleanReduce resistanceBand sawsBark-zones/chip/dust/waste removalEngineeringMachine tool

The invention relates to a carriage band sawing machine body with a self-cleaning function. The carriage band sawing machine body comprises a machine frame and a cleaning mechanism, and walking wheelgroups are transversely rotationally arranged on the front side and the rear side of the lower end of the machine frame respectively. Two parallel tracks are arranged under the machine frame, and thewalking wheels of the two ends of each walking wheel group are respectively arranged on the two tracks in a rolling mode. One walking wheel group is connected with a driving mechanism used for drivingthe walking wheel group to rotate in a transmitting mode. The cleaning mechanism is arranged on the machine frame and is used for respectively clearing away wood chips attached to the two tracks in the sawing process. The carriage band sawing machine body has the advantages of simple structure and convenience in operation and use, can effectively clear the wood chips attached to the tracks in thesawing process, and reduces the resistance of the walking wheels rolling along the tracks so as to enable the whole machine frame to walk smoothly. The production process is sanitary and environment-friendly.

Owner:湖北金成光电科技股份有限公司

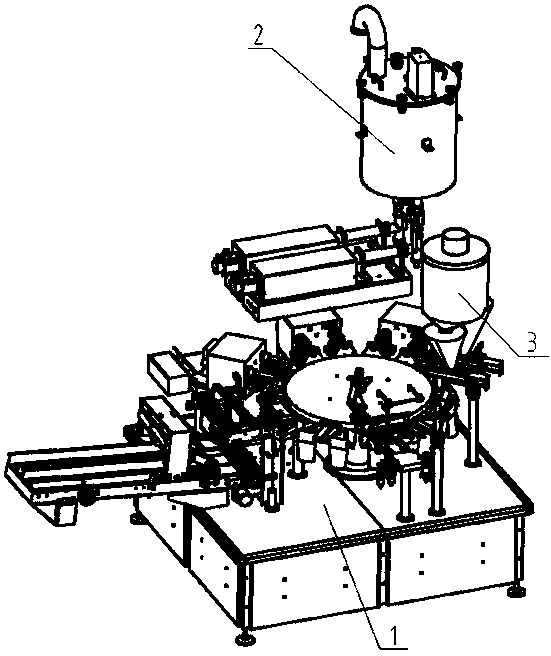

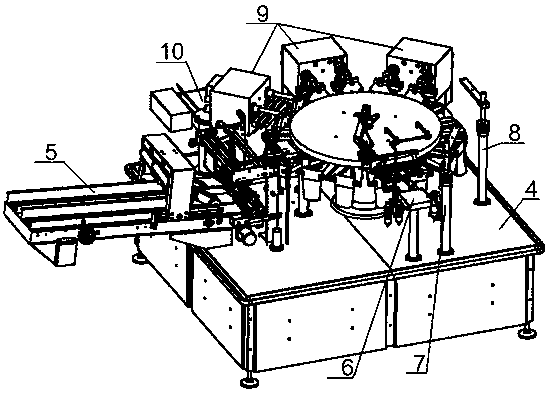

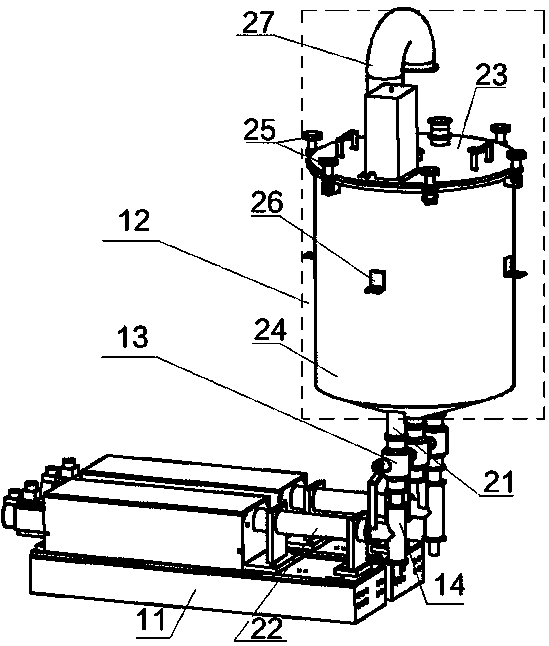

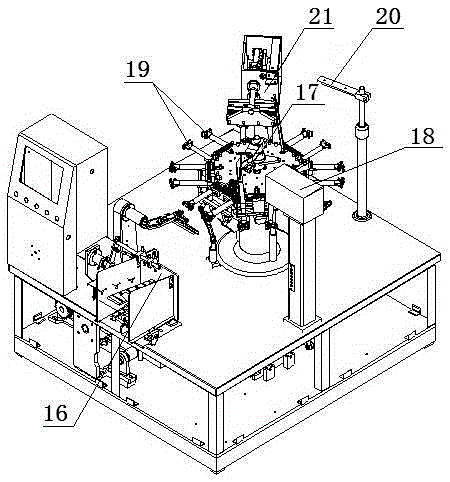

Packaging machine for mixed filling

PendingCN108438336AAvoiding the Drawbacks of PremixingFully automatedLiquid materialLiquid storage tankEngineering

The invention discloses a packaging machine for mixed filling. The packaging machine comprises a double-row packaging machine main body, a supporting frame, a liquid filling system and a fragment containing cup filling system, wherein the supporting framework is fixed on the double-row packaging machine main body, and the liquid filling system and the fragment containing cup filling system are fixed on the supporting frame side by side; and the liquid filling system comprises a filling machine, a liquid storage tank, a control valve and a filling tee joint, and the liquid storage tank is connected with the filling machine through a conveying pipe. The packaging machine for mixing filling has the beneficial effect that materials with different forms are mixed and filled into a packaging bag, the materials are not required to be mixed in advance, so that the defect existing in the pre-mixing process is avoided, full automation is realized, the labor force is saved, the production cycle is shortened, the production efficiency is greatly improved, and the whole production process is more sanitary, safe and reliable.

Owner:QINGDAO YILONG PACKAGING MACHINERY

Pork paste and its production method

The invention relates to a pork paste, which comprises the following raw materials by weight: 80-90 parts of pork reactant, 0.5-1.5 parts of pork essence, 1-3 parts of edible ethanol, 5-10 parts of purified water, 0.5-1 part of thickening agent and 0.1-0.2 parts of potassium sorbate. The whole production process of the pork paste is carried out in a reaction kettle, and the production process is simple, safe and healthy. The produced pork paste has the characteristics of pure color, soy sauce-like flavor, delicious taste and abundant nutrition, and can achieve the diet requirement for people health.

Owner:TIANJIN LANSHI SEASONING

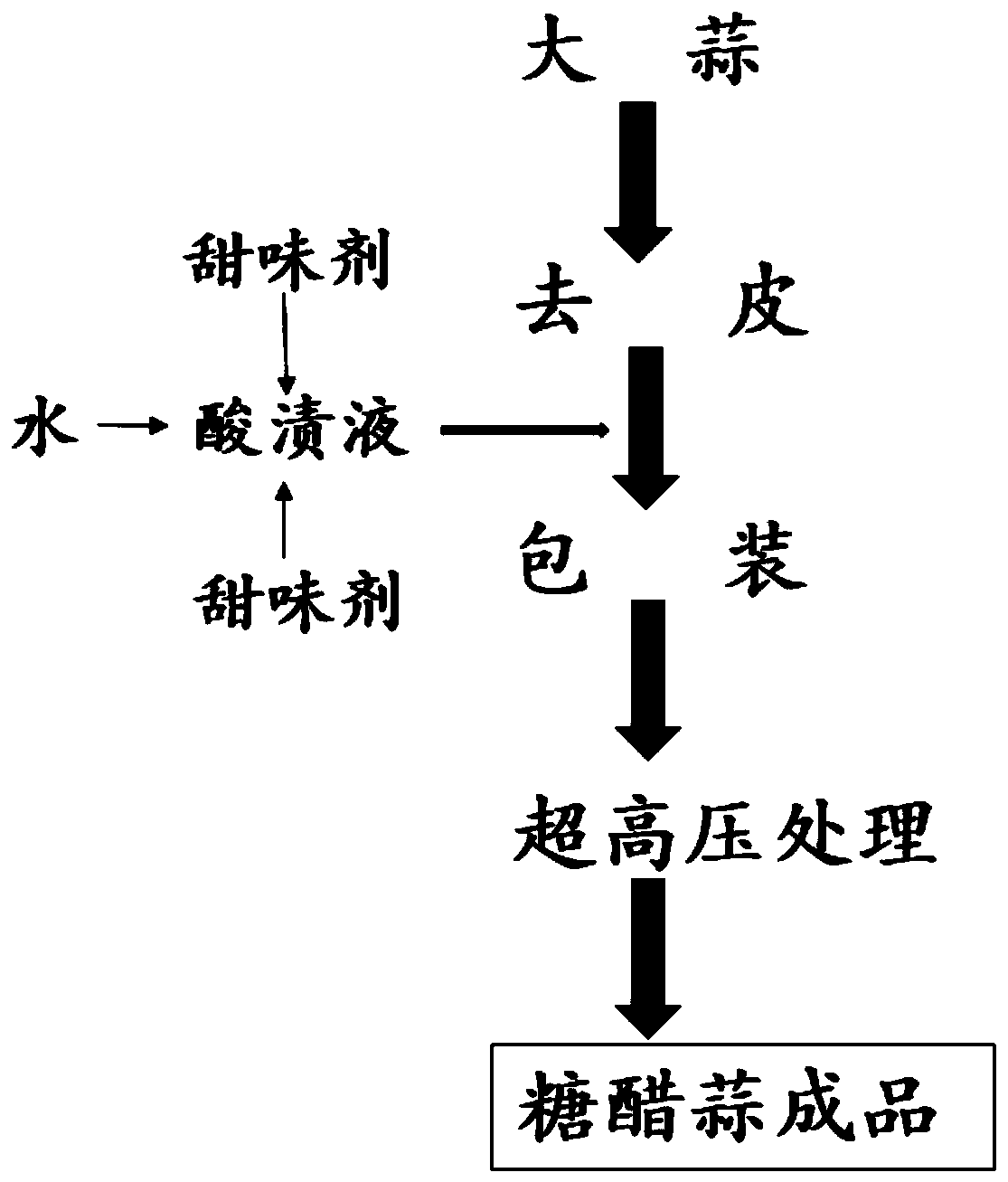

Method for rapidly producing sweet and sour garlic by ultra-high pressure

InactiveCN109717430AShorten the production cycleGo green no worriesFood scienceUltra high pressureHigh pressure

The present invention belongs to the field of deep processing of agricultural products and particularly relates to a method for rapidly producing sweet and sour garlic by ultra-high pressure. The method comprises the following steps: garlic cloves are prepared from a garlic raw material, bagging is conducted, sour pickling liquid is added, and treating at 400-1,000 MPa is conducted for 1-20 minutes to obtain the sweet and sour garlic. The method is short in production cycle and the sweet and sour garlic can be produced in 1 hour in a case of the pretreated garlic cloves. The dormancy-breakingraw material can be used and the raw material is not restricted by production season. The production processes are simple and save manpower, energy and water, raw material and production costs are greatly reduced. The production processes are hygienic and free of nutrient loss and environmental pollution. All in all, the method basically overcomes related shortcomings of traditional sweet and sourgarlic production technology.

Owner:JINAN UNIVERSITY

A kind of konjac bait and preparation method thereof

InactiveCN102257998AImprove quality stabilityImprove plasticityAnimal feeding stuffOther angling devicesBiotechnologyChemical synthesis

The invention relates to a preparation method of a konjac bait. The method comprises the steps of preparation of a modified konjac powder sol product, gelatinization of konjac powder, gelatinization of starch, gelatinization of gelatin, raw material preparation, stirring and filtration, and airing, sterilization and packaging. The preparation method has the following beneficial effects: the raw materials of the konjac bait are vegetative and have convenient sources and low price; the preparation process is simple, omits the link of chemical reaction of chemical compounds and is environmentally-friendly, thus solving the long-standing environmental issue of the baits; the prepared bait has rich nutriments, moderate viscosity and elasticity, strong allure to fishes and good fishing effect; the modified konjac powder sol product can serve as various additives, thus further saving the cost; the konjac bait does not have any toxic or side effect on the fish bodies and human bodies after long-term use; and the preparation course has the advantages of hygiene and quickness and the nutrient components are not damaged and are durably stored.

Owner:FUJIAN AGRI & FORESTRY UNIV

Device for detecting and excising loopholes of casing automatically and method thereof

PendingCN110278986AFacilitates automatic detectionSimple structureMeat/sausages markingSausage casingsEngineeringPortal frame

The invention provides a device for detecting and excising loopholes of a casing automatically and a method thereof. The device comprises a supporting platform device which is provided with a casing loophole detection device and a loophole excising device. The casing loophole detection device comprises a camera supporting rack, a hollow rectangular outer frame is fixed to the middle of the camera supporting rack, cameras are arranged around the hollow rectangular outer frame, a transmitting area arranged corresponding to a camera photographing area is arranged on the hollow rectangular outer frame, the loophole excising device comprises a portal frame mechanism located behind the hollow rectangular outer frame and fixed to the supporting platform device, a slicer supporting table is arranged on the lower part of a portal frame, and a slicer is arranged on the upper part of the slicer supporting table. The device is simple in structure, and can achieve a hardware foundation for automatically detecting the frame of the casing conveniently. The inner condition of the irrigated casing can be observed through the cameras on the hollow rectangular outer frame and the periphery, so that the loophole condition on the surface of the casing is judged favorably by means of related software subsequently. The production process is more efficient, safe and sanitary.

Owner:FUZHOU UNIV +1

Device for measuring casing diameter

PendingCN109916290ASimple structureEasy to operateElectrical/magnetic diameter measurementsNuclear energy generationEngineeringTransverse dimension

The invention provides a device for measuring a casing diameter. The device comprises a calculating module, a casing measurement groove, and a casing inflation device. The casing measurement groove can be put into a casing. A transverse dimension of the casing measurement groove is not less than the transverse dimension of the expanded casing in the groove, and a vertical dimension is less than the vertical dimension of the expanded casing in the groove. A top of the casing measurement groove is provided with a diameter reflecting device capable of moving up and down. The casing inflation device is connected to an inner cavity of the casing in the casing measurement groove. The calculating module stores a height of the casing measurement groove. When the casing inflation device fills a working medium into the casing in the groove at preset pressure so as to expand the casing and push the diameter reflecting device to rise, the calculation module can calculate the diameter of the casingat the preset pressure according to a rising distance of the diameter reflecting device and the height of the measurement groove. In the invention, the diameter of the casing after watering can be conveniently measured.

Owner:FUZHOU UNIV +1

Sauce-stewed flavored compound seasoning oil and preparation method thereof

Owner:洛阳味之泉调味技术有限公司

A kind of moxa roll forming machine

ActiveCN104490593BImprove medicinal qualityEasy to operateDevices for heating/cooling reflex pointsConveyorsRolling paperMolding machine

Owner:SICHUAN ENG TECHN COLLEGE

Soft-shelled turtle wine

InactiveCN1164729CThe wine is clear and transparentAromatic and mellow wineAlcoholic beverage preparationYeastHusk

Owner:范海庭

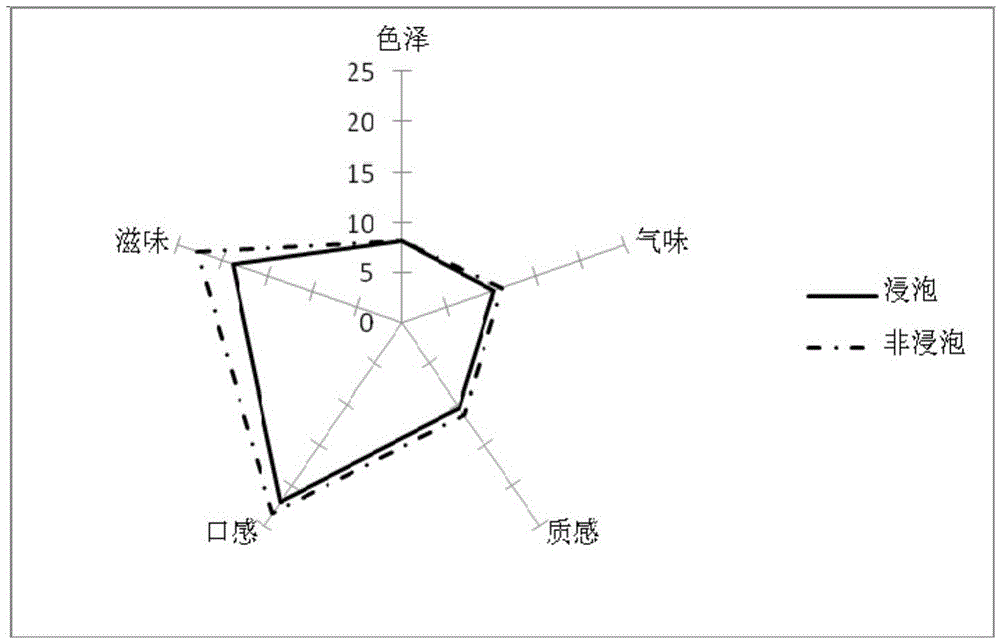

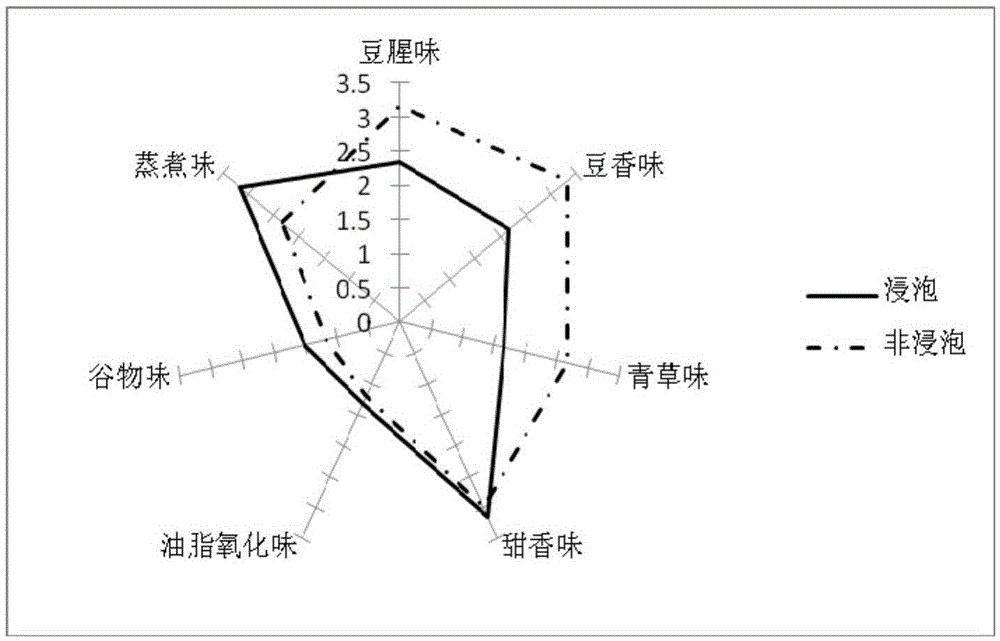

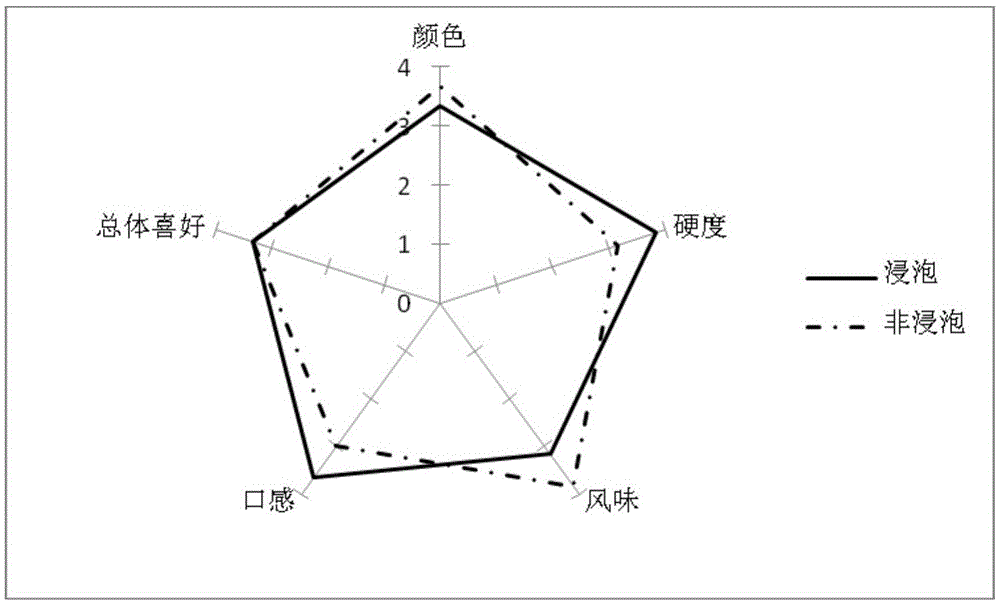

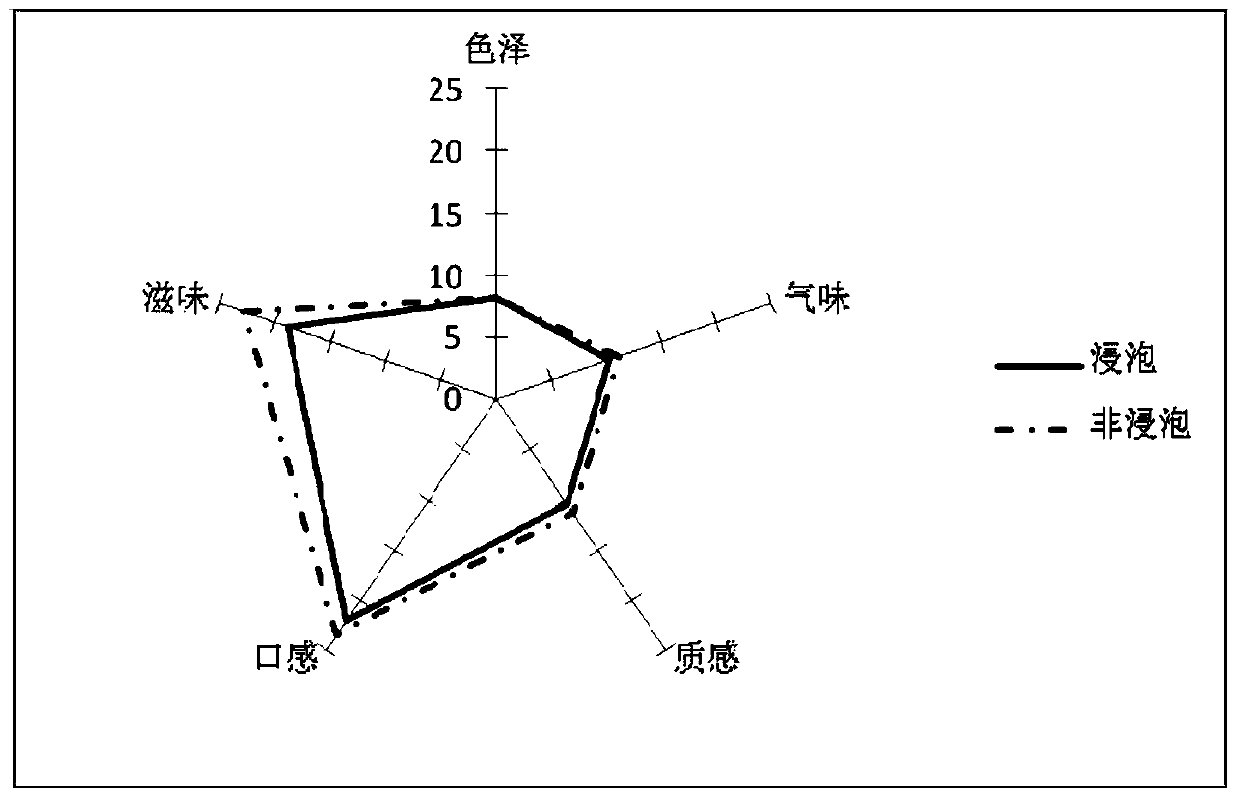

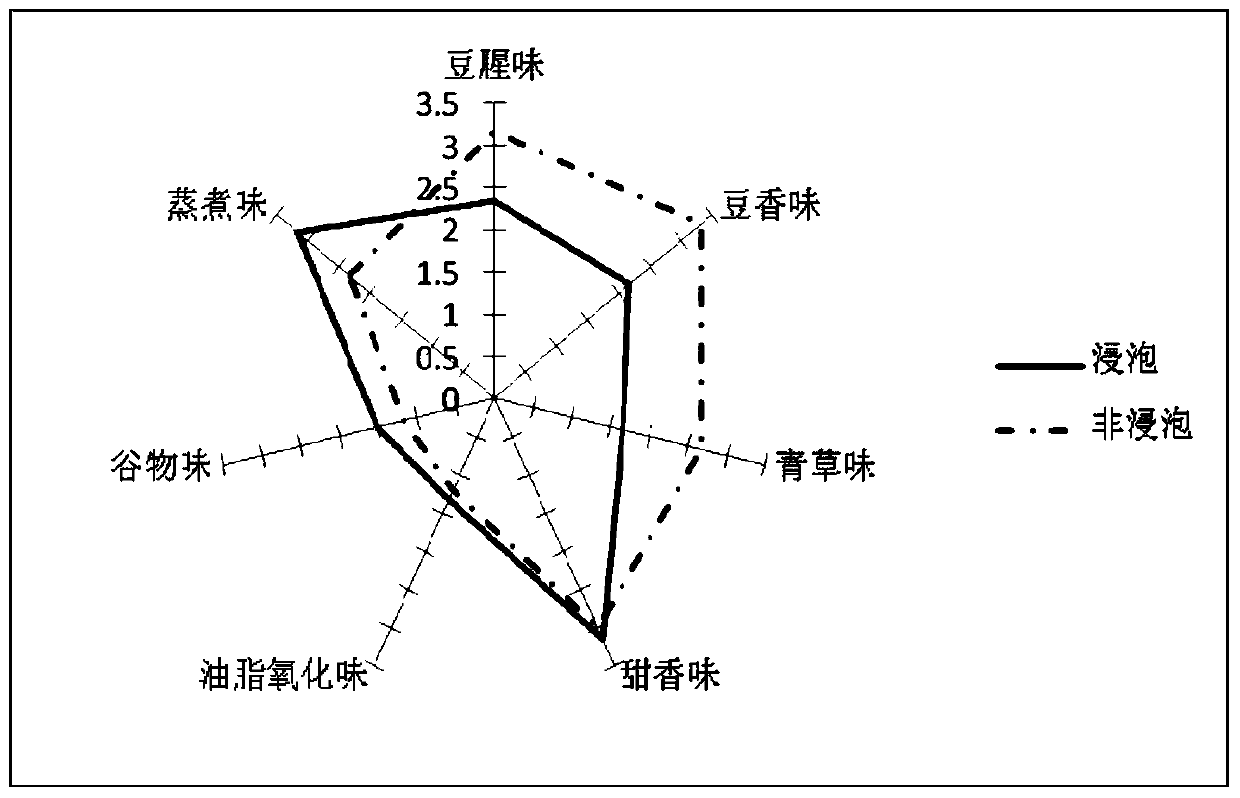

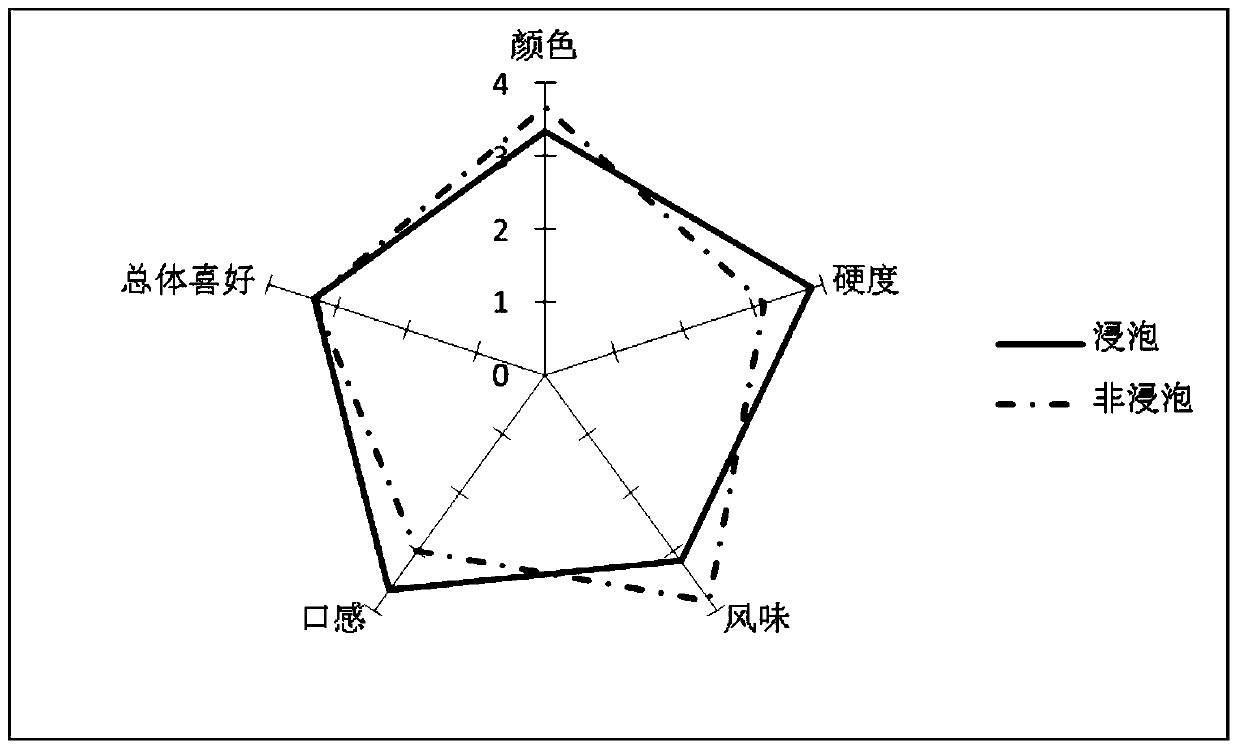

Preparation method of non-soaking soybean milk suitable for industrialized bean curd production

ActiveCN105532897AHigh yieldImprove protein dissolution rateCheese manufactureMilk substitutesFlavorLipid oxidation

The invention discloses a preparation method of non-soaking soybean milk suitable for industrialized bean curd production. The preparation method comprises the followings steps: step (1), first pulp-grinding, namely mixing the crushed soybeans with aqueous solution of small-molecule substances and carrying out the first pulp-grinding, so that a mixture of pulp and residue is obtained; step (2), mixed extraction, namely keeping the mixture of pulp and residue mixed during extracting; step (3), second pulp-grinding, namely performing the second pulp-grinding on the mixture of pulp and residue treated in step (2), so that a soybean paste is obtained; and step (4), carrying out the following process (1) or process (2) to the soybean paste obtained in the step (3), so that the soybean milk suitable for industrialized bean curd production is obtained. The process (1) comprises the following procedures: separating the residue from the pulp, namely removing the soybean residues from the soybean paste so as to obtain raw soybean milk; and then cooking the pulp, namely heating the raw soybean milk. The process (2) comprises the following procedures: cooking the pulp, namely heating the soybean paste; and then separating the residue from the pulp, namely removing the soybean residues. The preparation method solves the problem of eliminating smell of lipid oxidation in the soybean milk, so that the obtained soybean milk is suitable for industrialized bean curd production; and the preparation method is also capable of improving gelatin property of the bean curd. Moreover, the bean curd prepared by the preparation method is free of any bad flavor.

Owner:CHINA AGRI UNIV

Beef paste and producing method thereof

The present invention discloses beef paste and a producing method thereof. The producing method comprises the following steps: 1, 8% of glucose, 8% of MSG, 0.2% of Vc, 0.4% of L-acid, 1.2% of L-salt, 10% of plant hydrolyzed protein, 6% of soy sauce, 6% of salt, 5% of white sugar, 5% of green onions and water are poured into a reaction kettle, and heated until all the powdered materials are dissolved, then 14% of beef tallow, 5% of lard and 4 % of beef are added, and water is added to 100%; 2, the temperature is raised to 100-105 DEG C, and kept for 1-2 hours; 3, after completion of the reaction, the reaction kettle is rapidly cooled or the beef reactant is discharged from the reaction kettle; 4, the beef reactant is passed through a colloid mill twice; and 5, when the beef reactant temperature is dropped to 50-60 DEG C, the beef reactant, beef flavor, edible ethanol, purified water, a thickener and potassium sorbate are placed into a stirrer for stirring for 10-30 minutes, again passed through the colloid mill twice, and caned.

Owner:徐小芹

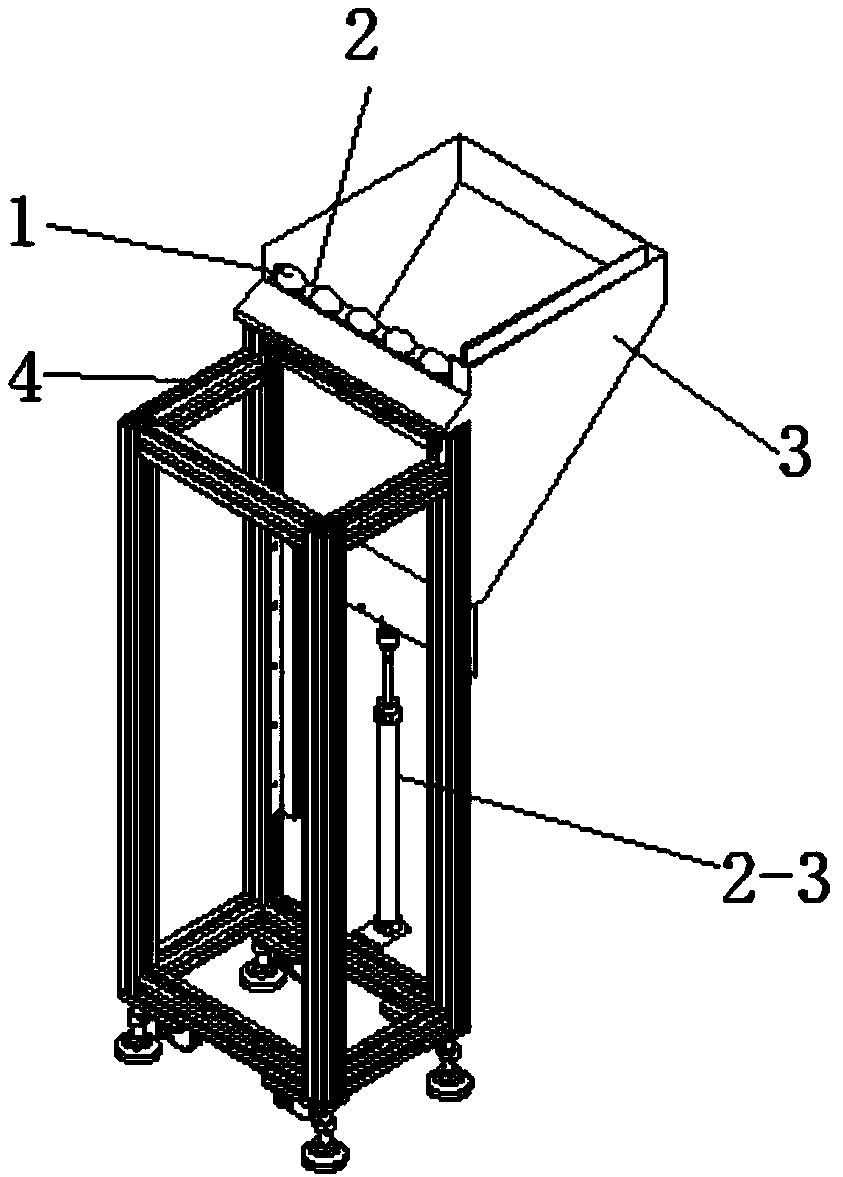

Multi-material packaging machine

ActiveCN103950560BRealize mechanized automationLabor savingSolid materialMulti materialPulp and paper industry

The invention discloses a multi-material packing machine. The multi-material packing machine comprises a multi-material metering machine, a support machine frame and packing equipment, wherein the multi-material metering machine is fixedly mounted at the upper part of the support machine frame; the packing equipment is arranged at the lower part of the support machine frame and is matched with the multi-material metering machine; the multi-material metering machine comprises a material storage tank, a lower storage tank and a fetching mechanism; the bottom of the storage tank is connected with the top of the lower storage tank in a sleeving manner; the fetching mechanism is arranged on the fetching side of the lower storage tank. Mechanization and automation of multi-material metering packing are realized; the labor force is saved; the production cycle is shortened; the production efficiency is greatly improved; the metering is more accurate; the overall production process is more sanitary, safer and more reliable.

Owner:QINGDAO YILONG PACKAGING MACHINERY

A salted egg quantitative distribution device

The invention discloses a salted egg rationing device, comprising a rack, a salted egg box for containing salted eggs and a rationing mechanism, wherein the rationing mechanism comprises a moving plate, a first driving mechanism driving the moving plate to move up and down, an overturning plate rotatably connected on the upper end of the moving plate and a second driving mechanism driving the overturning plate to perform overturning movement; the salted egg box is fixed at one side of the rack, the moving plate is disposed at one side in the salted egg box close to the rack and a distance between the moving plate and a side plate close to the rack in the salted egg box is smaller than diameters of salted eggs. The salted eggs can be automatically rationed to the next processing working station, processing efficiency is improved, labor is saved, and production cost is reduced; and in addition, no manual operation is required in a salted egg dispensing process, and a production process is more sanitary.

Owner:GAOYOU QINYOU EGG PROD

A kind of preparation method of non-soaked soybean milk suitable for industrialized tofu production

ActiveCN105532897BHigh yieldImprove protein dissolution rateCheese manufactureMilk substitutesBiotechnologyEngineering

The invention discloses a method for preparing non-soaked soybean milk suitable for industrialized tofu production. The preparation method comprises the following steps: (1) primary refining: mixing crushed soybeans with an aqueous solution of small molecular substances and then conducting the first refining to obtain a mixture of pulp and residue; (2) mixing and extraction: mixing the pulp and residue The mixture is kept mixed and leached; (3) secondary refining: the slurry residue mixture treated in step 2) is subjected to secondary refining to obtain soybean paste; (4) the soybean paste described in step (3) is After the following steps of 1) or 2), soybean milk suitable for industrialized tofu production can be obtained; 1) separation of dregs and slurry: removing the bean dregs from the soybean paste to obtain raw soybean milk; boiling: heating the raw soybean milk; 2) Boiling: heating the bean paste; then separating the bean paste and removing the bean dregs. The invention overcomes the elimination of the fat oxidation smell of soybean milk, is suitable for the production of industrialized tofu, improves the gelatinity of the tofu, and the prepared tofu has no bad flavor.

Owner:CHINA AGRI UNIV

Bio-organic fertilizer produced from edible fungus slag as main material and preparation method thereof

ActiveCN105175153BNutritional diversityPromote growthBio-organic fraction processingOrganic fertiliser preparationFecesShoot

The invention discloses a bio-organic fertilizer produced by using edible fungus residues as a main material and a preparation method thereof. The bio-organic fertilizer uses the edible fungus residues as the main material and is supplemented by durian shells, Chinese herbal medicines, lobster shells, livestock and poultry dung, locust tree leaves, chenopodium album linn, scales and the like, trichoderma and enzyme bacteria are sequentially fermented step by step according to characteristics of the raw materials, the Chinese herbal medicines include duckweed, camphor tree leaves, astragalus membranaceus, acorus calamus and mint, the trichoderma includes trichoderma viride, long-shoot trichoderma and trichoderma harveyi, and the preferable portion of the trichoderma viride, the long-shoot trichoderma and the trichoderma harveyi is 1:1:1. The bio-organic fertilizer has the advantages that the bio-organic fertilizer is comprehensive in nutrition, contains major elements and trace elements required by crop growth and a large number of active substance produced through fermentation, is high in plant absorption and utilization rate and can promote plant growth, increase production and income and improve soil texture, raw material sources are wide, the price is low, the production process is environmentally friendly and hygienic and the like.

Owner:WUHAN RUIZE SOURCE BIOLOGICAL ENVIRONMENTAL PROTECTION TECH

Method for producing crystal decorative paper

ActiveCN101838954AWon't raiseHigh continuous performance in automationSpecial paperPaper coatingOrganic solventPrinting ink

The invention provides a method for producing crystal decorative paper and relates to the method for printing and producing a new product of the decorative paper, which aims to solve the problems of low production efficiency and high processing cost of the conventional method for producing a laser powder decorative plate. The invention provides the method for producing the crystal decorative paper, which comprises the following steps of: dissolving an adhesive resin into an organic solvent; adding laser powder into the solvent with uniform stirring to prepare a laser powder coating material; printing an ink bottom layer on paper; and transferring the laser powder coating material onto the ink bottom layer of the paper with a coating roll and a pressing roll, and then drying and cooling the paper. The method for producing the crystal decorative paper can realize production automation, and has sanitary and healthy production process. In addition, the product produced by the method is the soft paper product, can be stuck onto surfaces of various decorative materials and is widely used.

Owner:YUNNAN TONGPRINT

Inline Folding Machine

The invention discloses a straight mask folding machine. The straight mask folding machine comprises a machine frame, a mask conveying belt, a turning roller way, an opposite conveying and mask pressing belt, a pneumatic mask punching device and a bag feeding and opening mechanism. The mask conveying belt, the opposite conveying and mask pressing belt, the pneumatic mask punching device and the bag feeding and opening mechanism are sequentially arranged on the machine frame from back to front. The turning roller way is arranged on the mask conveying belt. The mask conveying belt and the opposite conveying and mask pressing belt are coplanar. The bag feeding and opening mechanism is located below the pneumatic mask punching device. A mask is folded and placed in a mask bag mechanically, full automation is achieved, labor is saved, the production cycle is shortened, the production efficiency is greatly improved, the whole production process is more sanitary, safer and more reliable.

Owner:QINGDAO YILONG PACKAGING MACHINERY

Method for producing crystal decorative paper

ActiveCN101838954BWon't raiseHigh continuous performance in automationSpecial paperPaper coatingOrganic solventPrinting ink

Owner:YUNNAN TONGPRINT

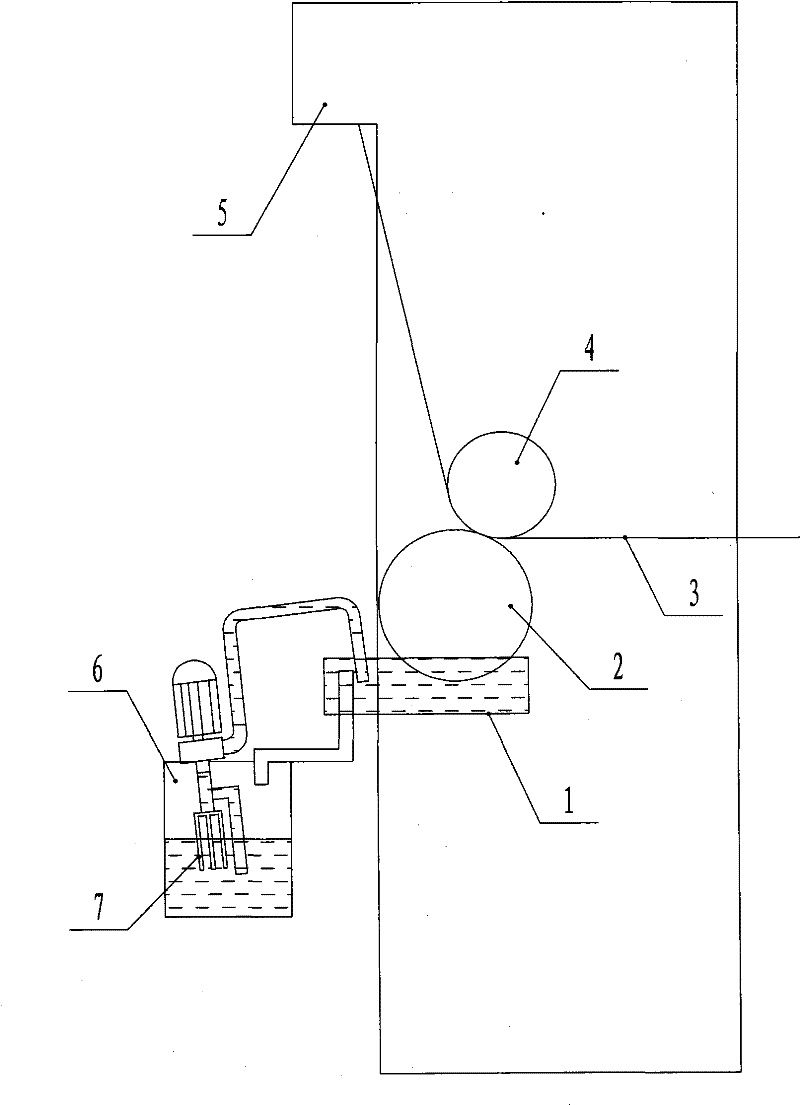

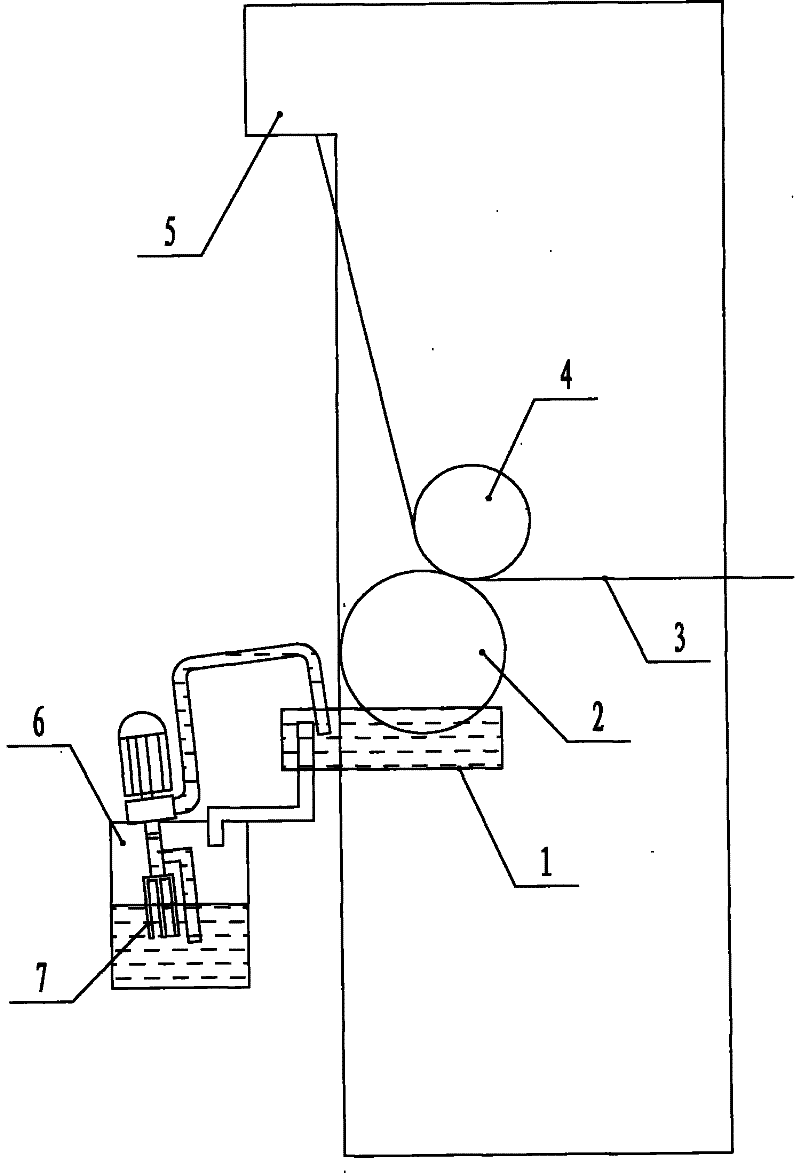

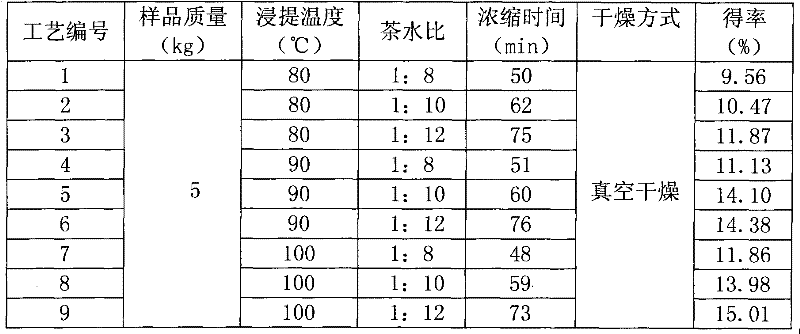

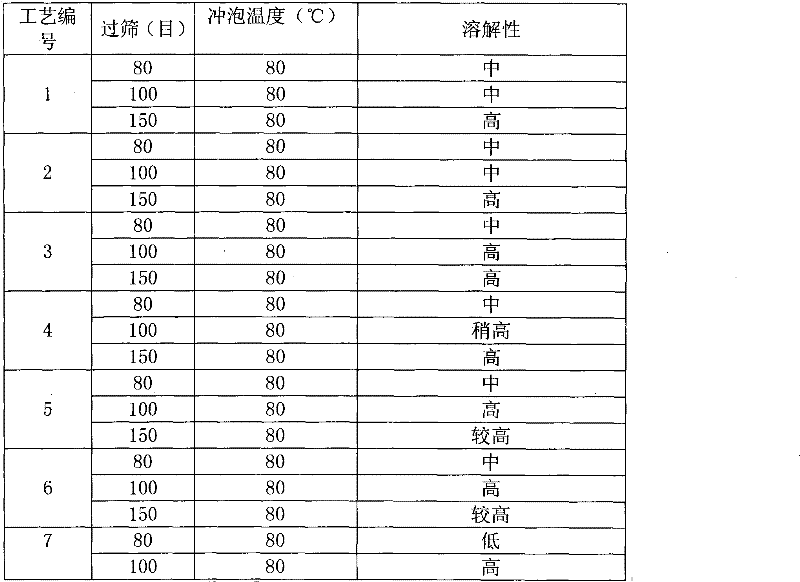

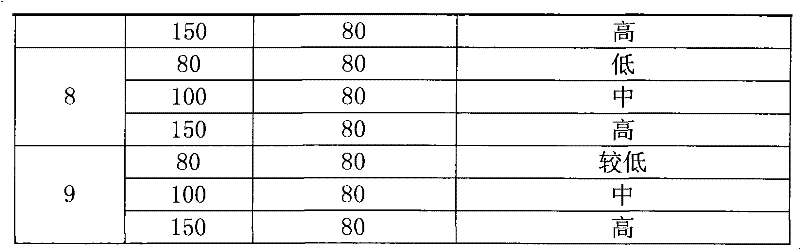

Process for extracting Pu'er tea paste by heated refluxing method

ActiveCN101695329BKeep the color and fragrancePreparation scienceTea extractionFiltrationVacuum drying

The invention relates to a process for extracting Pu'er tea paste by a heated refluxing method, which comprises the following steps of: taking Pu'er tea as a raw material, drying and pulverizing to obtain tea leaf powder with 60 meshes, wrapping the tea powder by a gauze, putting into a vacuum condensation refluxing extraction tank according to a certain tea-water ratio, heating, refluxing and leaching for 15min at the temperature of 80-100 DEG C; filtering an extracting liquid in an extraction tank, sucking into a concentration tank, carrying out vacuum concentration, concentrating into a concentrated liquid with the dry substance content of 30-40%, drying the concentrated liquid into a tea paste block with the water content of 16% and molding and pressing by a mould to obtain the Pu'er tea paste after pulverizing the tea paste. The Pu'er tea paste is extracted by utilizing the advanced techniques of heated refluxing leaching, decompressing filtration, vacuum concentration, vacuum drying and the like, thereby enabling the preparation process of the modern Pu'er tea paste to be more scientific, simpler, more convenient and more sanitary and being beneficial to increasing the valueof a tea leaf product and saving resources; and the quality of the obtained product can be better guaranteed, and the process is easy for industrialized production.

Owner:YUNNAN GONGRUNXIANG TEA IND DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com