Device for measuring casing diameter

A technology of casing and measuring tank, which is applied in the field of devices for measuring the diameter of casings, can solve the problems of high labor intensity, contact between hands and water, and worker's conflict, and achieves the effects of improving measurement accuracy, convenient operation and reducing influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

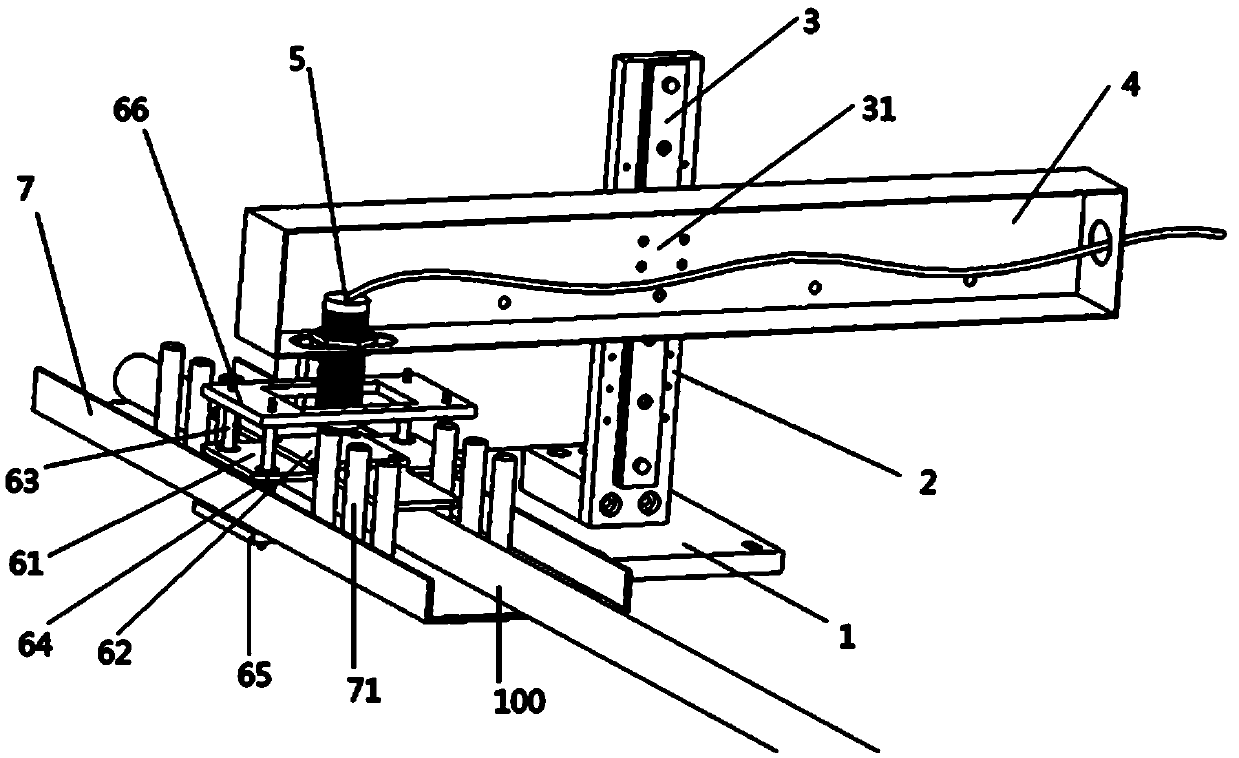

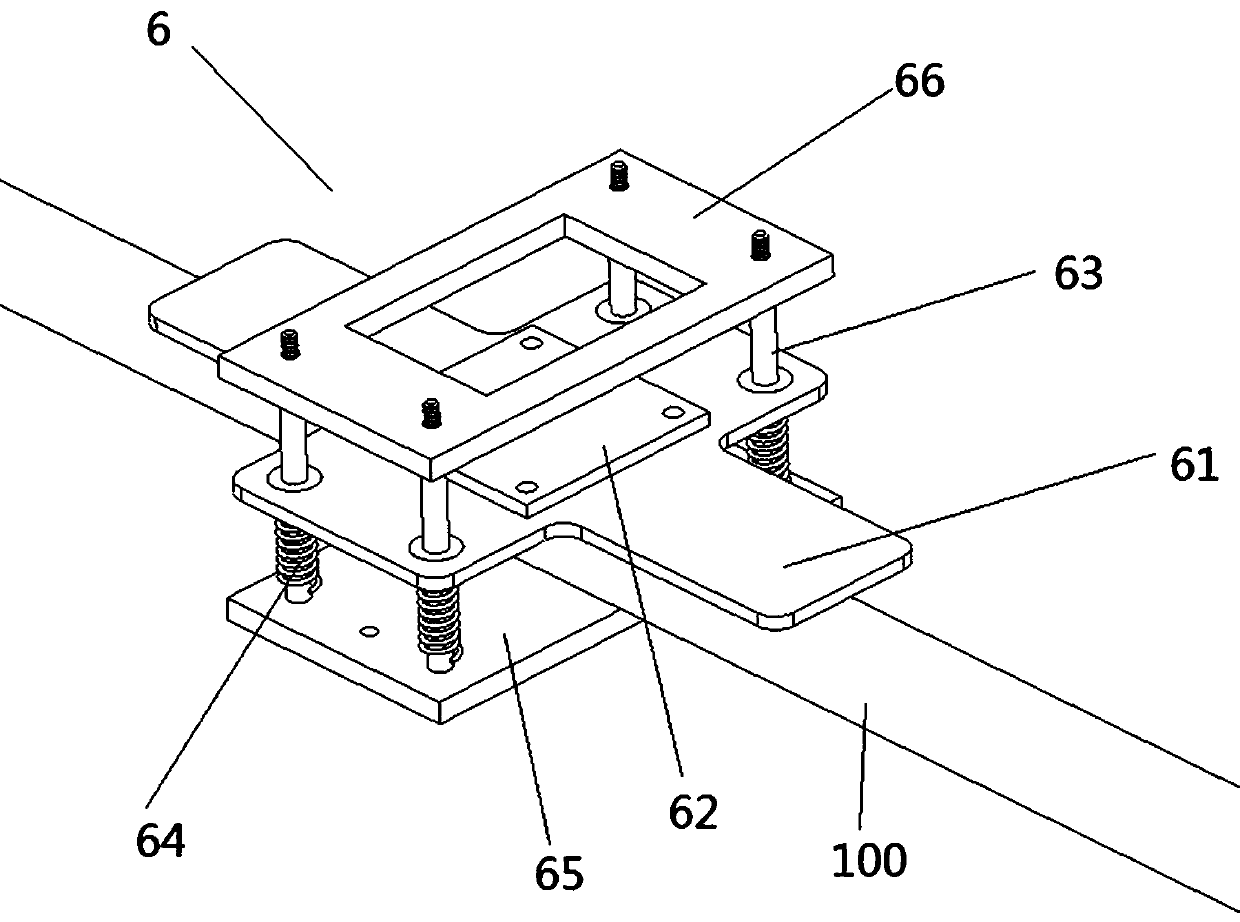

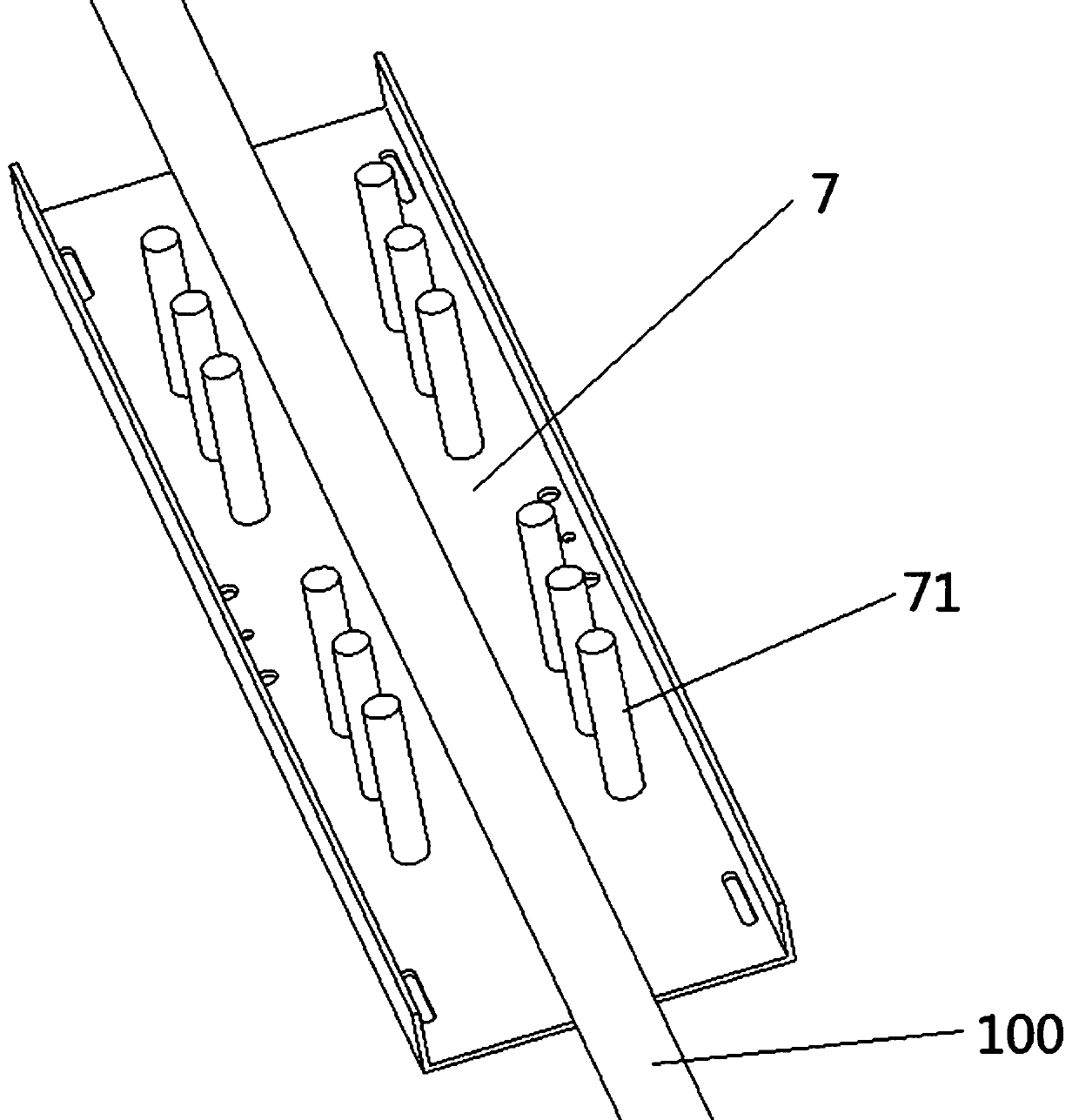

[0032] When the measurement work of this device starts, the horizontal plate 4 is fixed at a certain height to adapt to the measurement distance of the metal induction linear displacement sensor 5. The linear displacement sensor 5 is connected to the external display, and the casing 100 to be processed is put into the casing measuring tank and inflated after being filled with water. The change in the diameter of the casing 100 causes the reflection bottom plate 61 in the diameter reflection device 6 to move up and down, and synchronously drives the metal reflection sheet 62 Move together, and then the reading of metal induction linear displacement sensor 5 changes.

[0033] Assuming that the rising distance of the metal reflective flakes caused by casing expansion is H2, then the calculation module can know the diameter of the casing after expansion by adding H1 and H2, which can accurately measure the size change of the casing 100 diameter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com