Patents

Literature

303 results about "Fat oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fat oxidation is a process by which the stored, giant lipid molecules are broken back down into their smaller parts, triglycerides and fatty acids. Why is the process necessary? Well, we eat more lipids at a given time than we need at that time. However, we don't eat constantly all day long.

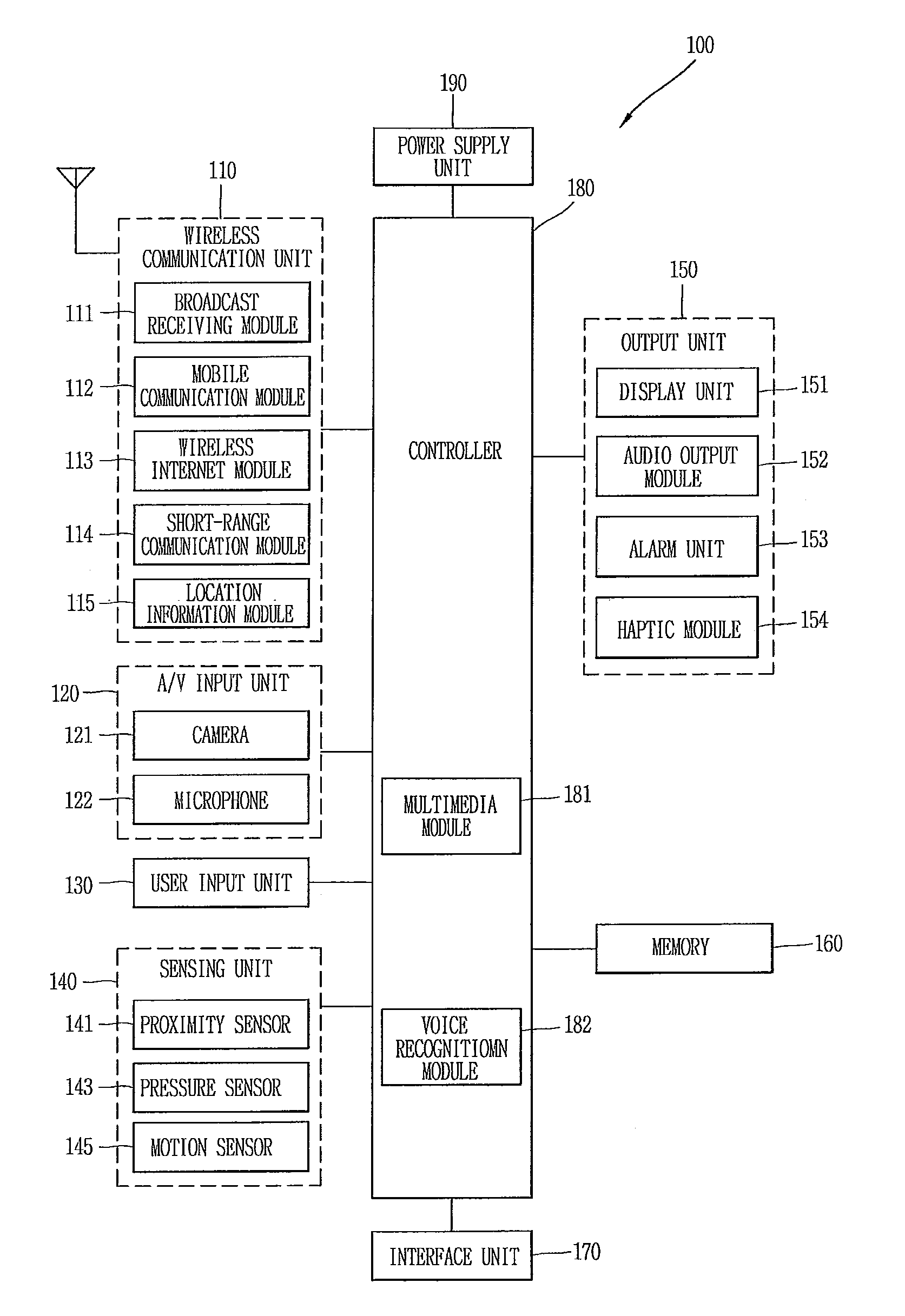

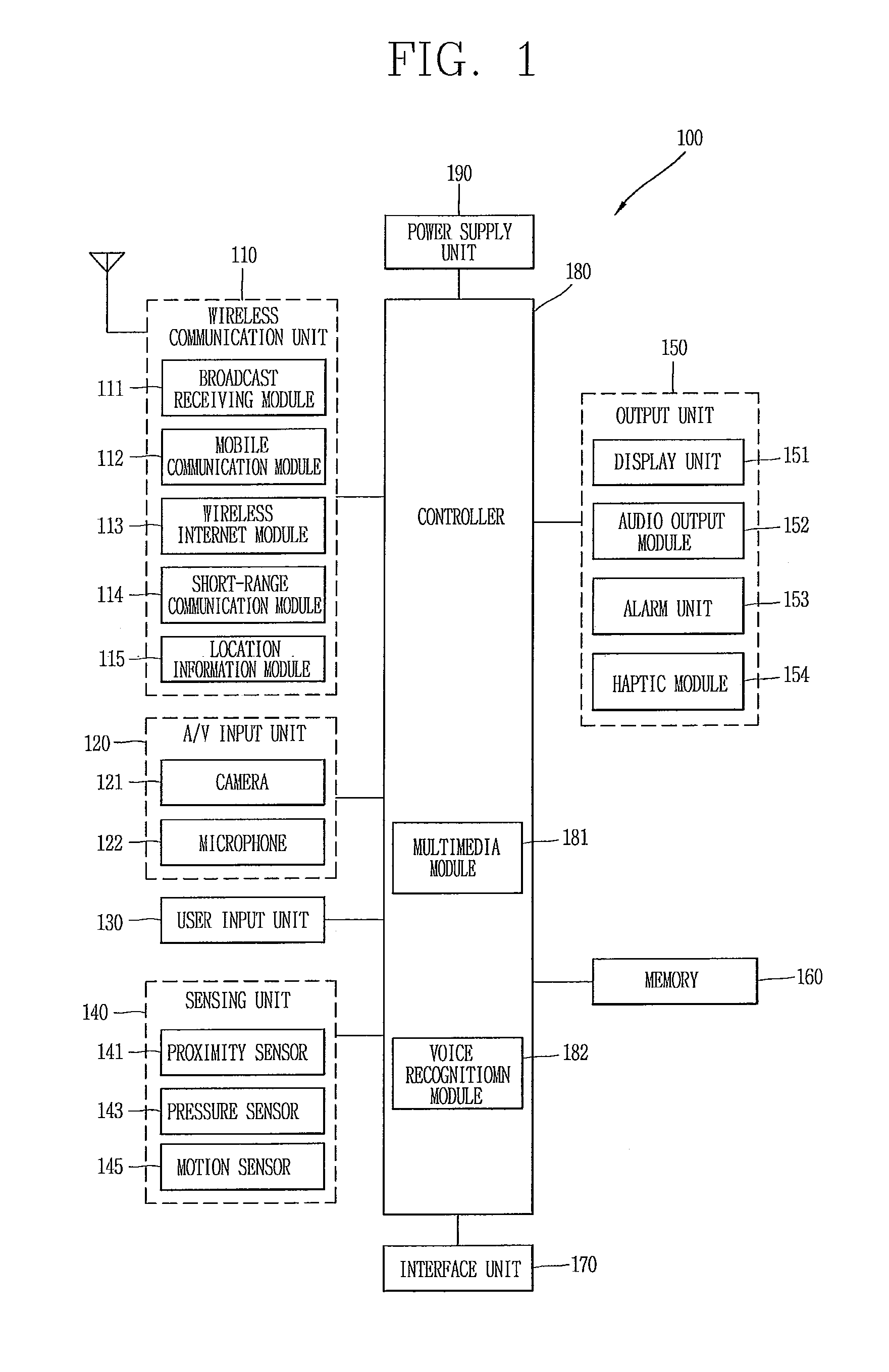

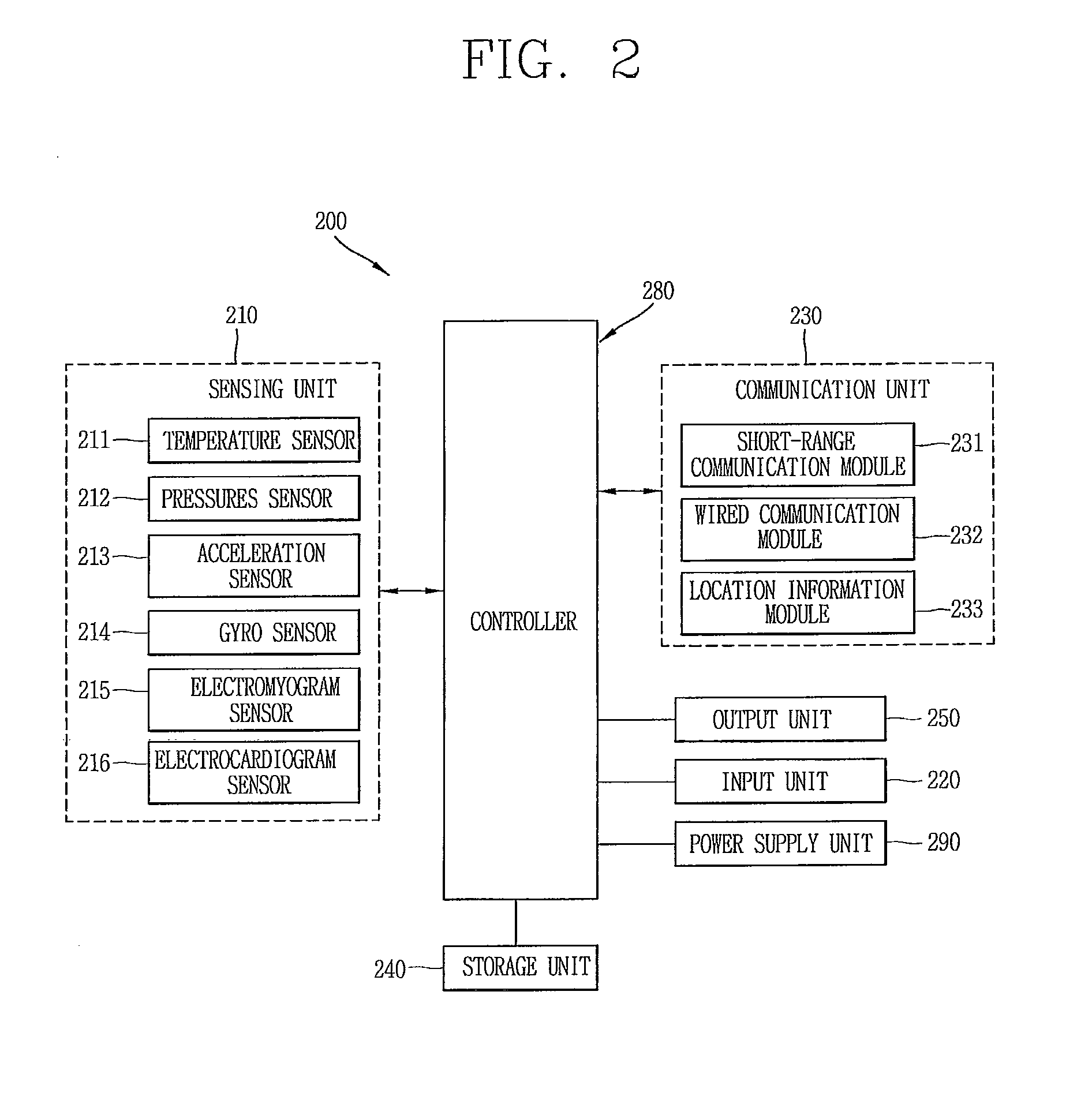

Guiding exercise based on fat oxidation rate

Disclosed is An exercise guide apparatus comprising: a sensing unit configured to obtain a heart rate of a subject; a strength determining unit configured to determine a maximal oxygen uptake of the subject; an exercise intensity measurement unit configured to determine a current exercise intensity of the subject based on the heart rate obtained by the sensing unit; and an exercise guide unit configured to estimate a fat oxidation rate of the subject, determine whether or not fat oxidation of the subject occurs, generate guide information according to a result of the determination of the occurrence of fat oxidation, and display the guide information generated, wherein the fat oxidation rate is estimated based on a ratio of fat being oxidized at the current exercise intensity to the maximal oxygen uptake, and wherein the occurrence of fat oxidation is determined by checking whether or not the fat oxidation rate estimated is greater than a threshold.

Owner:LG ELECTRONICS INC

Pickling method of preserved meat

InactiveCN101816434AGuaranteed to be moderately saltyKeep freshFood preparationBurned skinAbsorption capacity

The invention discloses a pickling method of preserved meat, which mainly comprises the following steps: cutting into strips-smearing seasonings-pickling-smoking-burning skin-cleaning-baking; the pickling steps of the method can lead a meat product to be tasty fast and have good tasting effect, the meat product is salty moderately and can avoid fat oxidation during the pickling process and preserve the fresh flavor of meat; the smoking temperature and the time are reasonably controlled during the smoking process, thereby leading the aroma of smog to be fully absorbed in the meat product and simultaneously avoiding meat stiffening due to excessive dehydration of cells; a condensing tube is adopted for condensing benzopyrene in the smog, thereby reducing the absorption capacity of the benzopyrene on the surface of the meat product and reducing the residual rate; the skin burning step can not only remove hair roots in the meat skin, but also lead the meat skin to be soft after boiling the preserved meat and facilitate the consumption; the cleaning step can clean dust particles on the surface of the meat product and further reduce the residue of the benzopyrene; and the meat product is dried at the specific temperature till the water content reaches 20%-25%, the meat product has good elasticity and high viscosity during the consumption, a consumer can not feel dry and astringent, and the taste is more comfortable.

Owner:巫溪县红池腊鲜食品有限公司

Pork-flavor essence

The invention relates to a pork-flavor essence. Mixed raw materials prepared by mixing amino acids, reducing sugar, proteins, spices, carrier, water, flavoring agents are added to a twin-screw extrusion-expansion machine set according to the value; the raw materials are conveyed from a hopper to an extruder for extrusion at a speed between 20 and 500 kg / hour; and the raw materials are allowed to undergo a series of maillard reaction, sugar degradation and fat oxidation and other changes at a high temperature under high pressure inside the extrusion machine, thus the pork essence with fuller flavor, natural harmonious aroma and strong pork-flavor characteristics can be produced.

Owner:TIANJIN CHUNFA BIO TECH GRP

Infant series yak milk formula milk powder and preparation method thereof

ActiveCN103621633APromote absorption and metabolismReduce stimulationMilk preparationBiotechnologyVegetable oil

The invention provides infant yak milk formula milk powder and a preparation method thereof. Raw materials for manufacturing products of one ton comprise 100-600 kg of yak milk, 2,000-4,500 kg of fresh milk, 200-500 kg of dried whey (D90), 20-120 kg of whey protein concentrate (WPC34), 0-110 kg of cream, 130-250 kg of refined vegetable oil and OPO structure grease, 15-65 g of lactose, and 0-50 kg of white granulated sugar. The infant yak milk formula milk powder facilitates infant absorption and metabolism, reduces stimulation to a gastrointestinal tract, can remove free radicals, enhances antioxidant ability and immunocompetence of bodies, promotes fat oxygenolysis, promotes human body protein synthesis, and has important function for promoting human body growth and development. The infant yak milk formula milk powder has the important functions for building normal gastrointestinal tract flora, adjusting the balance of various probiotics, stimulating immune cells, promoting intestinal tract movement, and preventing diarrhea and constipation.

Owner:甘南藏族自治州燎原乳业有限责任公司

Nutrient compositions and methods for sustenance and promotion of positive metabolic energy levels in a targeted manner

Nutrient compositions and methods that sustain and promote positive metabolic energy levels in a targeted manner are disclosed. Methods utilize endogenous energy stores (fat oxidation), increase use of those stores (increasing transport rate), increase available energy (increasing the ability to perform ADP to ATP phosphorylation,) as well as decrease catabolism and increase protein synthesis. Compositions are also disclosed, and include Mono- or Dicreatine-HMB salt; Putrescine Dihydrochloride; Alanine; L-Glutamine, which may be combined with Alanine in a 1:2 to 2:1 molecular ratio; Trimethylglycine; and Guanidinopropionic Acid.

Owner:SELLO AZUL

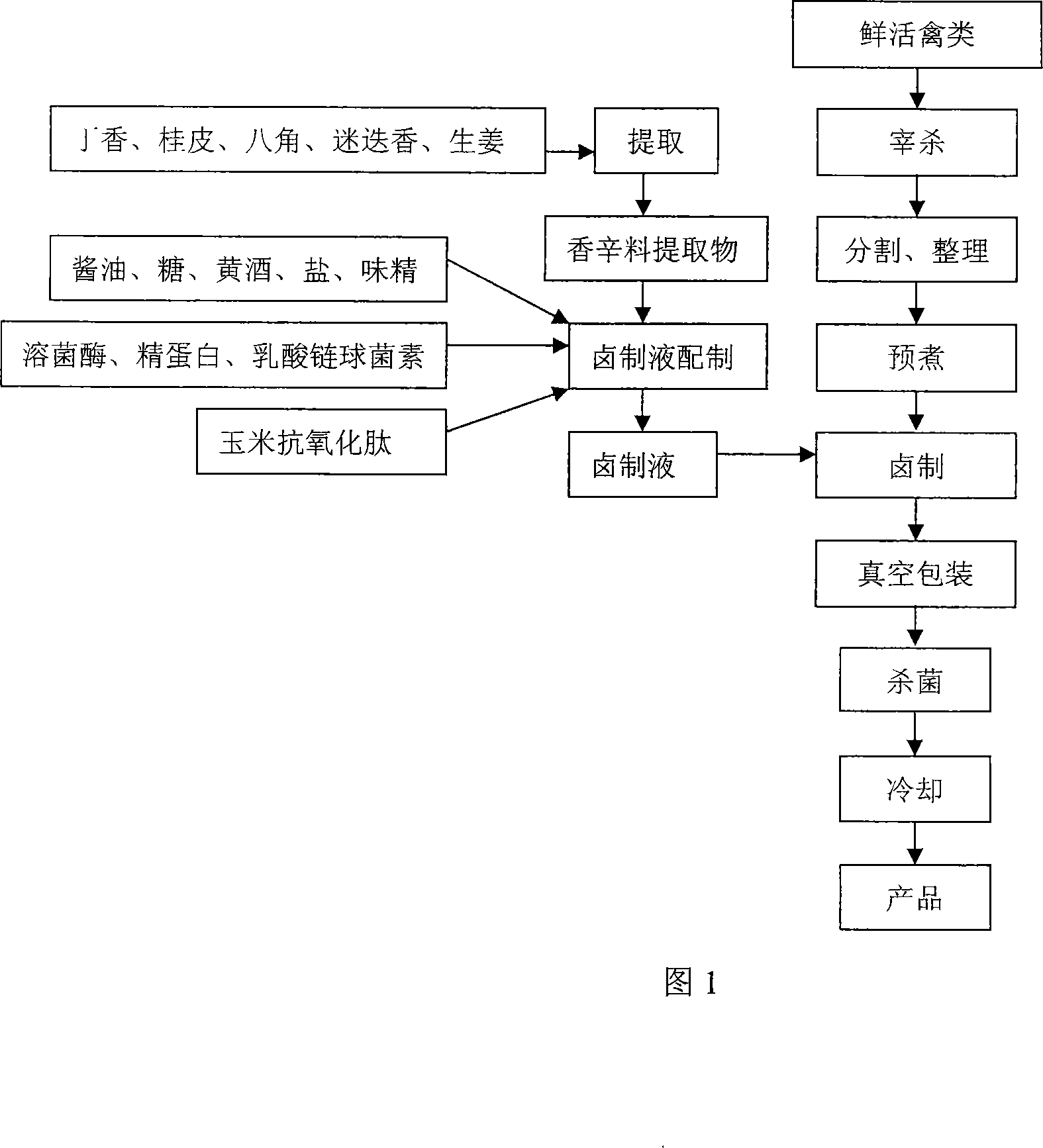

Processing method for high quality vacuum packaged poultry products

InactiveCN101053413AReduce the sterilizing strengthReduced Flavor VariationFood preparationHigh pressureTemperature and pressure

The patent relates to a processing method for high quality vacuum packaging poultry product, which belongs to food processing and storing technology field. The invention takes fresh poultry chicken, duck or goose as material, which is made into poultry product which can be preserved under room temperature through slaying, segmentation, finishing, precooking, braising, vacuum packaging, sterilization and cooling etc. The invention adds anti-oxidative bioactive peptides into bittern-making process for effectively controlling flavor deterioration problem caused by lipid oxidation in sterilization process and preserving process, thus the vacuum packaging product can keep remarkable traditional flavor characteristics. The invention adds antibacterial peptide, antibacterial protein and spice extracts having natural antibacterial effect into bittern-making process, which decrease sterilization strength of sterilization process, and avoids flavor and texture deterioration caused by high temperature and pressure sterilization, thus the shelf life of product can last 6 months under room temperature.

Owner:JIANGNAN UNIV

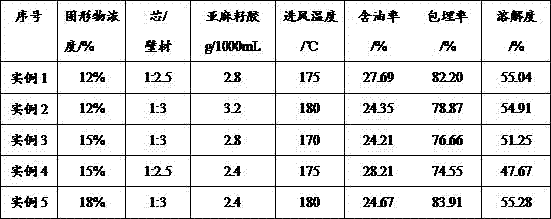

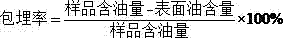

Linseed oil and linseed gum vegetable fat powder and preparation method thereof

The invention discloses linseed oil and linseed gum vegetable fat powder and a preparation method thereof. According to the vegetable fat powder, soy protein isolate (SPI) and maltodextrin (MD) are used as wall materials, linseed oil is used as a core material, linseed gum is used as an emulsifying agent, and a spray drying technology and a microcapsule technique are adopted, so that the vegetable fat powder is prepared. Compared with traditional vegetable fat powder using hydrogenated vegetable oil as a raw material, the vegetable fat powder prepared by the preparation method disclosed by the invention does not contain trans-fatty acid, so that the danger of the trans-fatty acid is greatly reduced; besides, the vegetable fat powder disclosed by the invention also has various health-care functions of preventing thrombosis, reducing blood lipid, regulating immunity, restraining cancer and the like; in addition, the microcapsule preparation technique is adopted, and liquid fat is converted into powdery solid, so that the fat oxidation risk is greatly reduced, the fat stability is strengthened, the storage period of the product is prolonged, and the special smell of the linseed oil is also concealed; and the vegetable fat powder has multiple advantages of being simple in technology, low in cost, easy to control and store, high in stability, high in water solubility and the like.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Green production method of chilled fillets

ActiveCN101983570AGuaranteed qualityReduce the initial bacterial countMeat/fish preservation by coatingMeat/fish preservation by freezing/coolingBiotechnologyChlorine dioxide

The invention provides a green production method of chilled fillets. The method mainly comprises the following steps: preparing raw material fish, temporarily cultivating fish in cold water, performing movement bloodletting in cold water, preprocessing (removing scales, heads, tails and internal organs), cleaning with cold water, cutting into slices, removing fish bones and repairing, grading, sterilizing with electrolyzed ozone water, dewatering, spraying for coating, drying the water on the surface of fish, sterilizing with ultraviolet, performing atmosphere packaging and transporting. The main characteristics of the method of the invention are as follows: 1) electrolyzed ozone water and ultraviolet are used to sterilize the fillets and reduce the initial microbial content of raw material, chlorine dioxide and preservative are not used so as to ensure that the production technology is green and environmentally friendly; 2) temporarily cultivating in cold water, low-temperature movement bloodletting and whole-process low temperature operation are adopted to effectively control the microbial spoilage of the chilled fillets, reduce fat oxidation and protein degradation and ensure the freshness of the product; and 3) the green composite film preservative is coated on the chilled and sterilized fillets, thus effectively prolonging the shelf life of the chilled fillets.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

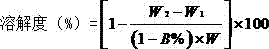

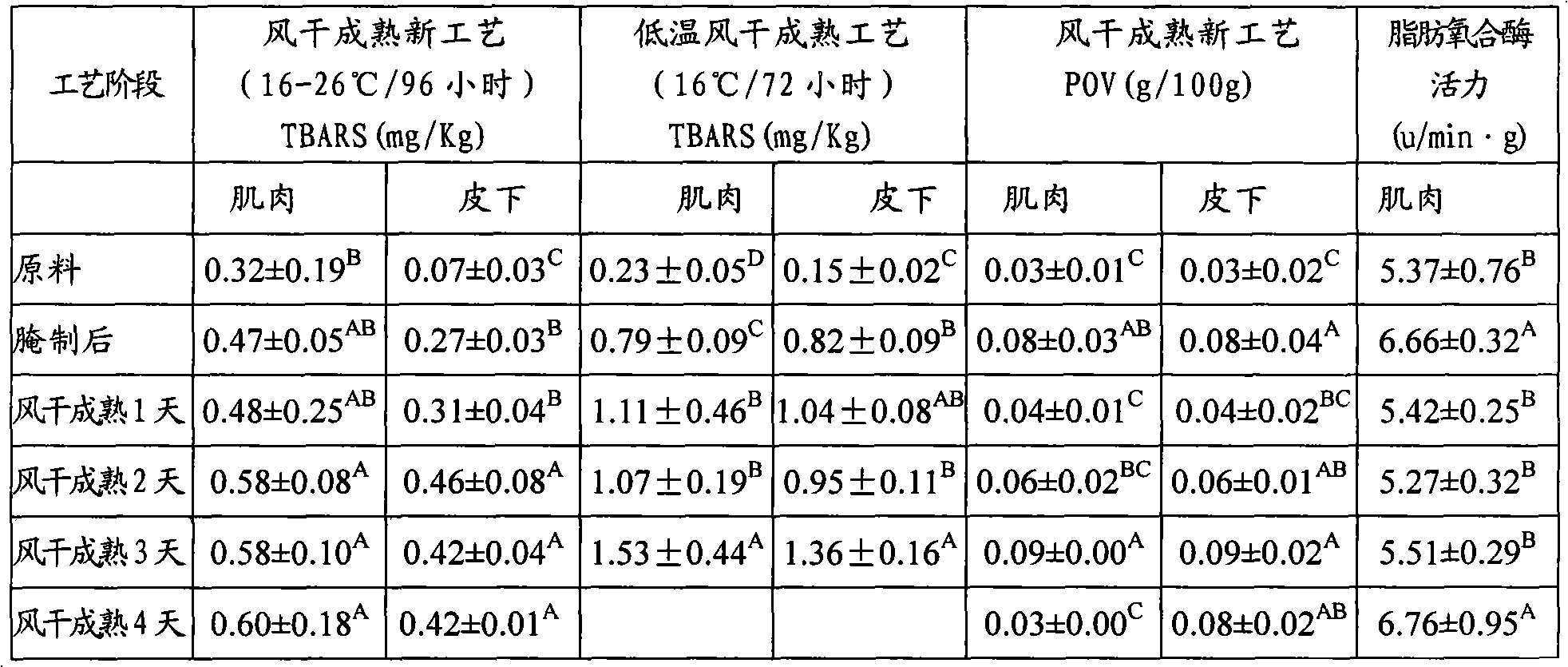

Air drying duck high-temperature maturation process

InactiveCN101254001AHigh activityImprove flavor qualityMeat/fish preservation using acidsFood preparationAdditive ingredientPeroxidase

The invention relates to a novel mature high-temperature air drying process of a dry duck, and belongs to the further processing technology field of animal products. The process includes the steps as follows: a raw ingredient duck is processed with the wet salting (in 3 to 8 DEG C for 18 to 24 hours) in salting liquor (that is NaCl of 10 to 13 percent); then the raw ingredient duck is air-dried to maturity for 3 to 4 days in a gradient temperature elevation way, wherein, the humidity is 55 to 63 percent RH, and the temperature is 13 to 28 DEG C, so that the finished product of the dry duck is obtained. The air drying maturing temperature adopted by the invention is obviously higher than the maturing temperature that is 8 to 10 DEG C in the industrial production of the dry duck at present; the endogenous peroxidase activity and the microbial growth in dry duck muscles can be adjusted through regulating the temperature and the humidity during the air drying maturing process; the decomposition and oxidation of the protein and the lipid in the product and the speed of flavor formation can be accelerated; the fat oxidation index is effectively lowered; based on retaining traditional characteristic flavor of the dry duck, the flavor quality of the dry duck product is effectively increased.

Owner:JIANGSU ZHONGNONG BIOTECH CO LTD

Cardiovascular therapy composition including transfer factor and therapeutic methods including use of the composition

ActiveUS7815943B2Avoid damageReduce inflammationBiocidePeptide/protein ingredientsAntioxidantCholesterol

A composition for use in cardiovascular therapy includes transfer factor. The transfer factor may be nonmammalian transfer factor, such as that derived from eggs, or mammalian transfer factor, such as that derived from colostrum. The composition may also include one or more of the following: an LDL receptor-binding element; a blood flow-enhancing element; a cholesterol reducing element; a fat oxidation prevention element, and an antioxidant. Treatment methods include enlisting the immune system of a subject receiving therapy to attack pathogens that cause inflammation of blood vessels or to otherwise reduce inflammation of blood vessels.

Owner:4LIFE PATENTS

Chinese air-dry fish fermented sausage and preparation method thereof

The invention provides a Chinese air-dry fish fermented sausage and a preparation method thereof. The Chinese air-dry fish fermented sausage comprises the following components in percentage by weight: 10 to 95 percent of fish, 0.1 to 18 percent of ferment agent, 1 to 25 percent of auxiliary flavouring, and the rest of water. The Chinese air-dry fish fermented sausage of the invention has special flavor. Mainly the enzymes generated by the metabolism of the histenzyme of the fish and the microorganism decompose carbohydrate, fat, protein and the like to form the flavor components. The substances have important effect on formation of the flavor, and particularly the fat and the protein provide precursor substances, i.e. non-esterified fatty acid and free amino acid, of mass flavor substrates. Moreover, the Maillard reaction, the non-enzyme reactions, such as fat oxidation and the like, and a plurality of flavouring substrates added manually also make an important contribution to the formation of the flavor of the fermented sausage.

Owner:青岛农博农食品科技有限公司

Beef flavor essence prepared by extrusion technology

The invention provides a beef flavor essence prepared by an extrusion technology. The preparation method of the essence comprises the following steps: mixing raw materials: adding the raw materials used to prepare the beef flavor essence according to a proportion of a formulation into an auto mixing machine to be mixed uniformly and obtaining a raw mix; extruding reaction materials: preheating a twin screw extruding machine to the following appointed temperatures: the temperature of a mixing zone is 60-130 DEG C, the temperature of a shear zone is 90-160 DEG C, the temperature of a melting zone is 120-190 DEG C; adding the raw mix into a loading hopper of the extruding machine, starting a screw and adjusting the rotation speed of the screw to be 100-400 rotation / minute; evenly adding the materials and controlling the speed of adding materials to be 20-500 kg / hour; transmitting and extruding the raw materials in the extruding machine and generating Maillard reaction and changes like sugar degradation, fat oxidation and the like in a high-temperature and high-pressure state; then squeezing out the raw materials from the port of a mould in the extruding machine, cooling extruded samples to room temperature and obtaining the powdered beef flavor essence after being pulverized by a pulverizer.

Owner:TIANJIN CHUNFA BIO TECH GRP

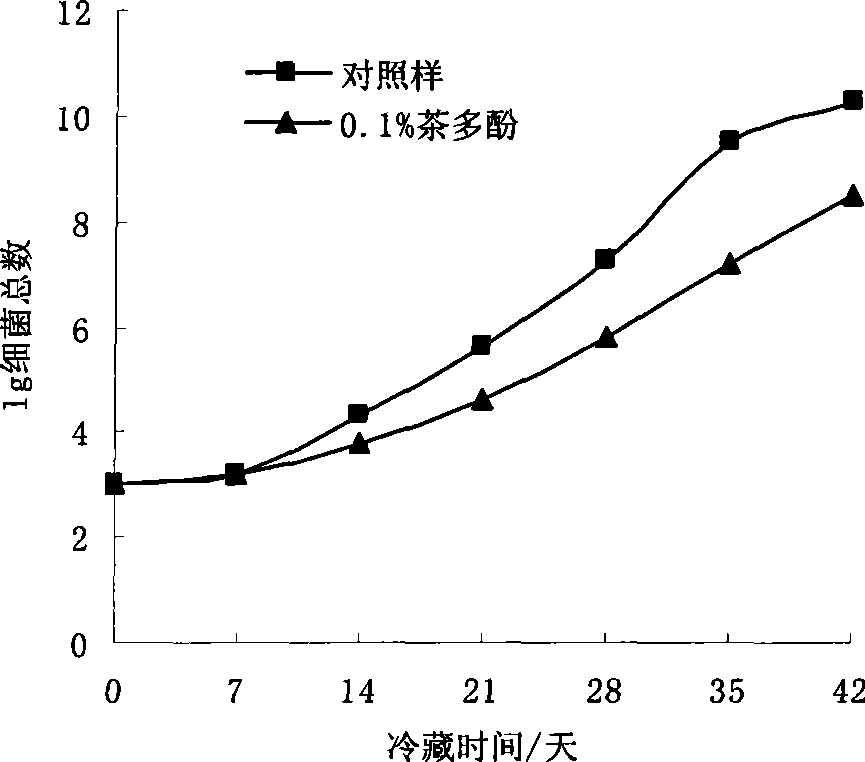

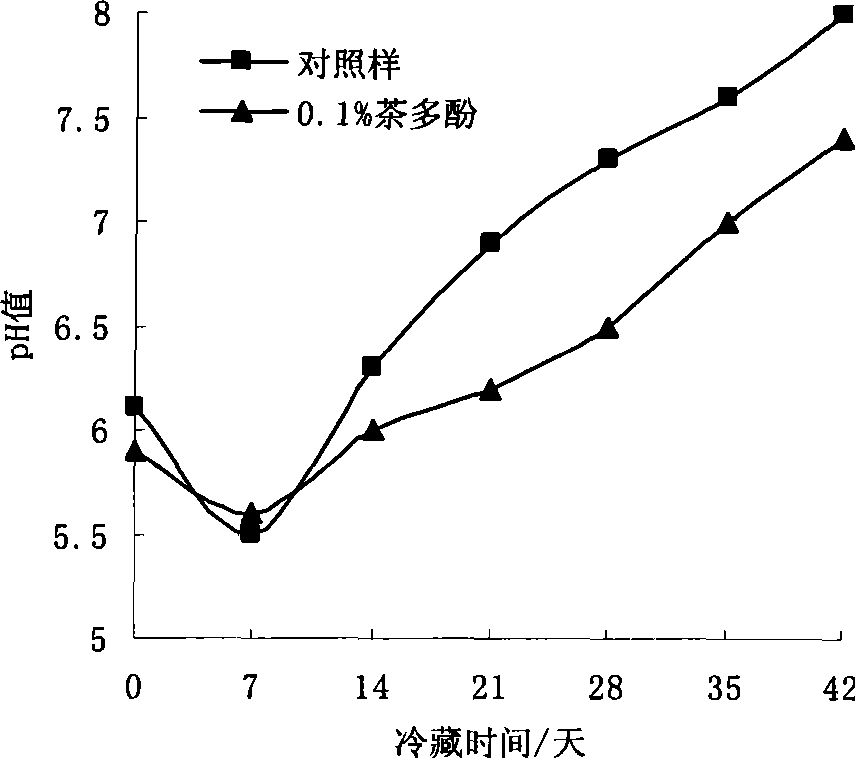

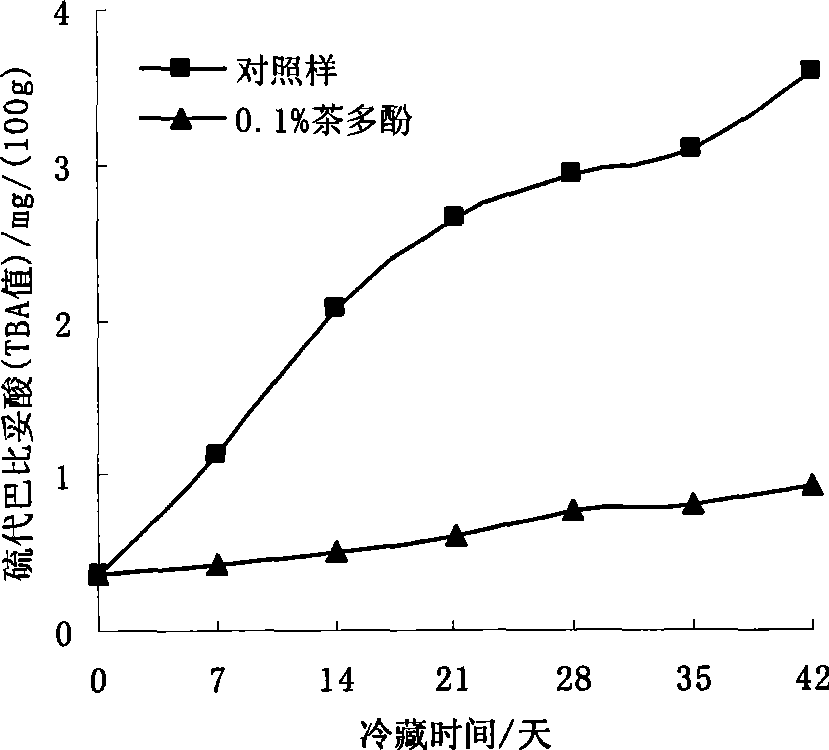

Fresh water fish cold-storage preservation method

InactiveCN101507447AReduce frost damageInhibition of reproductionMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsPolyphenolSeawater

The invention discloses a method for cold preservation and refreshment of freshwater fish, which comprises the following steps that: killed, cleaned and washed freshwater fish is soaked into a tea polyphenol acetic acid aqueous solution for 1.5 to 6 hours, drained and subjected to cold preservation and refreshment at the temperature of between 1 DEG C below zero and 8 DEG C below zero, wherein the tea polyphenol acetic acid aqueous solution contains the following materials in weight by percentage: 0.05 to 1.0 percent of tea polyphenol and 0.05 to 5.0 percent of acetic acid. The method not only has small freezing injury on the body of the freshwater fish, but also can further inhibit the propagation of body bacteria, retard the oxidation of fats, and increase the preserving effect on the basis of micro-freezing, and the storage period of the freshwater fish can reach 37 to 57 days. The method not only can be used for keeping freshwater fish products fresh, but also can be used in micro-freezing cold preservation technology for seawater fish and other meat products.

Owner:四川烹饪高等专科学校

Special medical infant formula milk powder with yak milk and preparation method thereof

ActiveCN103621685AGood absorption and metabolismReduce stimulationWhey manufactureChemistryWhey protein

The invention provides special medical infant formula milk powder with yak milk and a preparation method thereof. Each ton of infant formula milk powder comprises the following raw materials: 120-150 kg of yak milk, 80-300 kg of maltodextrin, 40-250 kg of glucose, 150-180 kg of anhydrous milk fat, 60-100 kg of refined vegetable fat, 100-140 kg of whey protein hydrolysate, 10-30 kg of milk protein isolate, and 200-260 kg of white granulated sugar. The yak milk is used as the main raw material to avoid the condition that in exclusive use of common milk, infants need to supplement a large quantity of organic and inorganic nutrients synthesized chemically, so that the yak milk can be absorbed and metabolized well by the infants, the stimulation to the gastrointestinal tract is reduced, the oxidation resistance and the immunocompetence of the human body are enhanced, the oxidative decomposition of fat is promoted, and the human protein synthesis is promoted, and the milk powder plays an important role in promoting the growth and development. The infant formula milk powder uses whey protein and milk protein isolate subjected to enzyme hydrolysis instead of lactose, and the infant formula milk powder is a nutrition specially prepared for infants who are 0-12 months old, lactose-intolerant, and are in diarrhea period and diarrhea recovery period.

Owner:甘南藏族自治州燎原乳业有限责任公司

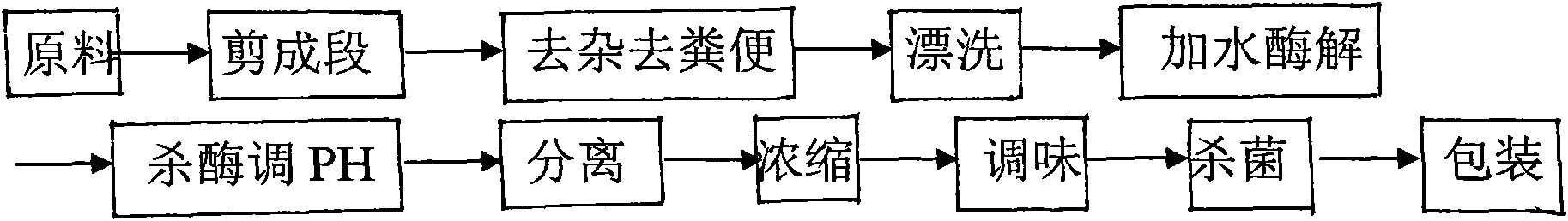

Chicken intestinal peptide and production process thereof

InactiveCN101601437AGood food attractantImprove digestion and absorption rateAnimal feeding stuffAccessory food factorsIntestinal structureAntioxidant

The invention discloses a chicken intestinal peptide extracted from chicken intestines by a method using an enzyme and a production process thereof. The chicken intestinal peptide is a straw yellow or brown pulpous state object, has the fragrance of a civet base, and comprises the following main components in percentage by weight: less than or equal to 45 percent of moisture content, more than orequal to 22 percent of crude protein, more than or equal to 25 percent of crude fat, and more than or equal to 19 percent of amino acid. The production process comprises the following steps: cutting chicken intestine raw materials into sections, extruding and rinsing the chicken intestine raw materials in clean water to remove impurities and feces; putting the intestine materials into an enzymolysis boiler, adding water, heating, adding an animal protease and a flavourzyme to perform hydrolysis; killing the enzymes, and adding an organic acid to adjust the PH value; separating and concentrating the reactants, and adding a flavoring agent to eliminate the bitterness generated in the process of the enzymolysis; adding an antioxidant to prevent fat oxidation; performing steam boiling and sterilization; and performing sealed package. The production process is simple, the obtained chicken intestinal peptide can be used as food for dog and cat pets, and a large number of the chicken intestines produced during chicken slaughtering can be utilized effectively so as to promote environmental protection.

Owner:陈道才

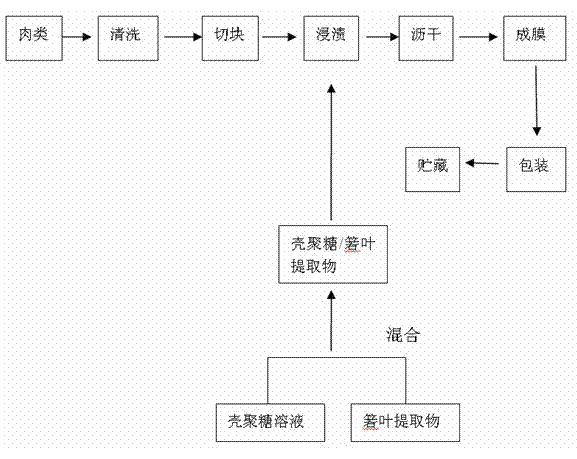

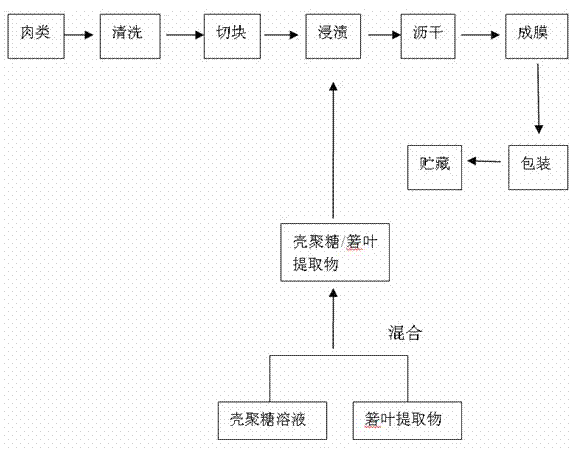

Method for preserving meat products

InactiveCN102511539AImprove sensory qualityExtended shelf lifeMeat/fish preservation by coatingAcetic acidNatural substance

The invention discloses a method for preserving meat products, comprising the following steps: dissolving chitosan with acetic acid, then mixing a chitosan solution with an Indocalamus leaf extract product to obtain a mixed solution, soaking the meat products to be preserved in the mixed solution and draining to form a film on the meat surface, and then packaging with a polyethylene film and storing in a 4 DEG C refrigerator. The method has the advantages of simple process and easy operation. The selected materials are obtained by processing natural substances and can be directly used for food preservation and have edible safety and good fresh-keeping effect. The method can solve the problem that the juice seeping from the meat products in the processes of storage, transportation and saleinfluences the product quality, can effectively control meat fat oxidation, color variation and microbial proliferation in the storage period, obviously raises the product sensory quality and prolongthe shelf-life, and provides a novel approach for meat preservation.

Owner:KUNMING UNIV OF SCI & TECH

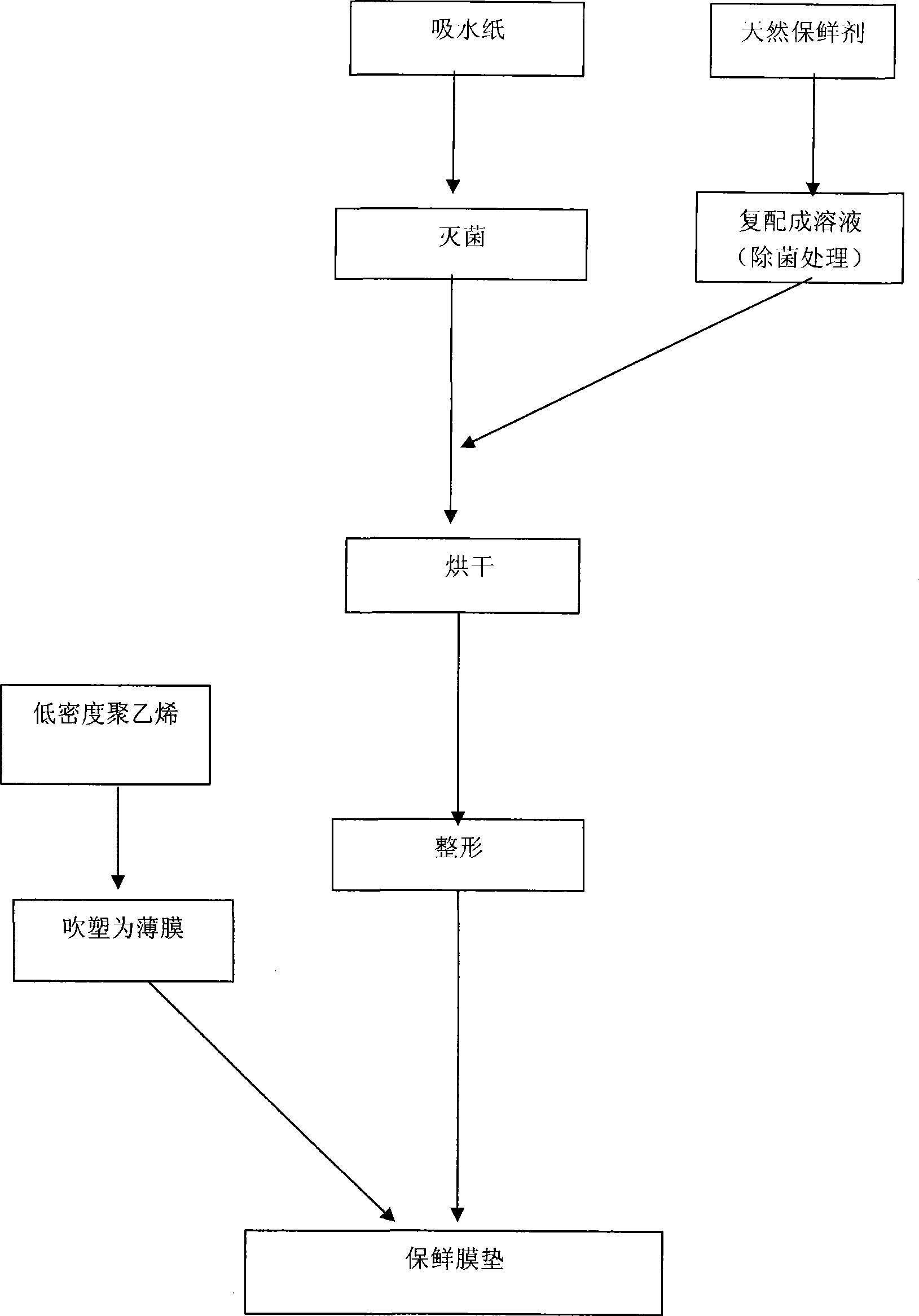

Preparation method of cooled meat plastic film mat

InactiveCN101385478AAvoid pollutionControlled reproductionMeat/fish preservation using chemicalsLow-density polyethyleneHigh pressure

The invention discloses a method for preparing a preservative film cushion of chilled meat, which is characterized in that low-density polyethylene is made into film by blow molding, puncturing is carried out on the film, the selected natural antistaling agent is dissolved in sterile distilled water to prepare solution that is sprayed on autoclaved absorbent paper, the paper is put in the film after being dried and shaped, and the preservative film cushion is prepared by sealing. The preparation method has simple technology and easy operation. The added natural antistaling agent used in the invention is safe and has good fresh-keeping effect. The prepared preservative film cushion is used for chilled meat with tray plastic package, thereby being capable of not only solving the influence on product quality caused by chilled meat juice dialysed in the processes of storage, transportation and selling, but also effectively controlling fat oxidation, color variation and microorganism propagation in the storage process of the chilled meat, obviously improving the product esthetic quality and prolonging the guarantee period, and developing a new way for meat fresh-keeping.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

Method for preparing meat flavor precursor by controlling enzymolysis-mild heating oxidation of fats

InactiveCN102246946AOutstanding characteristic aromaFull of flavorFood preparationMaillard reactionPhosphate

The invention discloses a method for preparing a meat flavor precursor by firstly utilizing lipase to carry out proper enzymolysis on fats and then regulating oxidation of enzymolysis products through mild heating. The method is characterized by comprising the following steps: firstly adding 10-50g of 0.05-0.2mol / L phosphate buffer with the pH value of 6-10 into 50-100g of fats and adding 1000-2500U / g of lipase of a substrate to carry out enzymolysis at 30-50 DEG C for 2-6 hours to obtain the fat enzymolysis products; and then pumping air into the enzymolysis products to carry out heating oxidation, wherein the concentration of the substrate is 50-90%; the air flow is 5-150L / 100g.h; the oxidation temperature is 50-100 DEG C; the oxidation time is 30 minutes to 4 hours; and the stirring speed is 100-500r / min (revolutions per minute). The method has the advantages of mild oxidation condition, easiness in regulation and oxidation, less byproducts, low energy consumption and easiness in realizing industrial enlargement. The prepared fat oxidation products are rich in the characteristic meat flavor precursor, and combined with the sensory evaluation of the Maillard reaction products, the selected oxidized fats can be used for producing the meat flavor with full flavor, prominent characteristic aroma, aromatic flavor and stable quality.

Owner:JIANGNAN UNIV

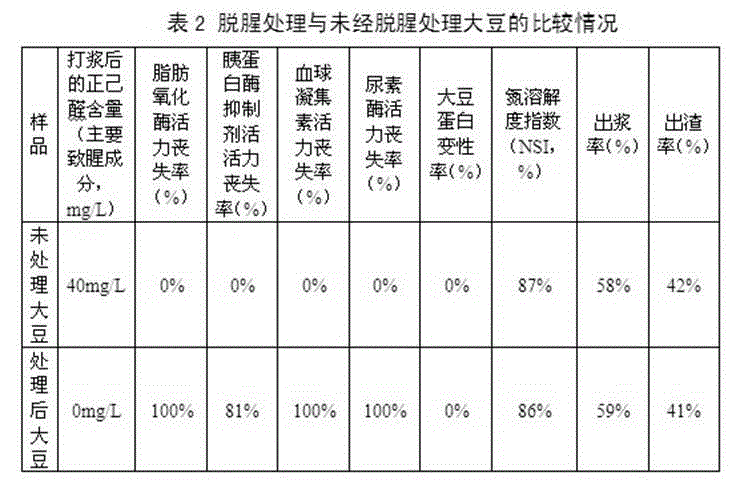

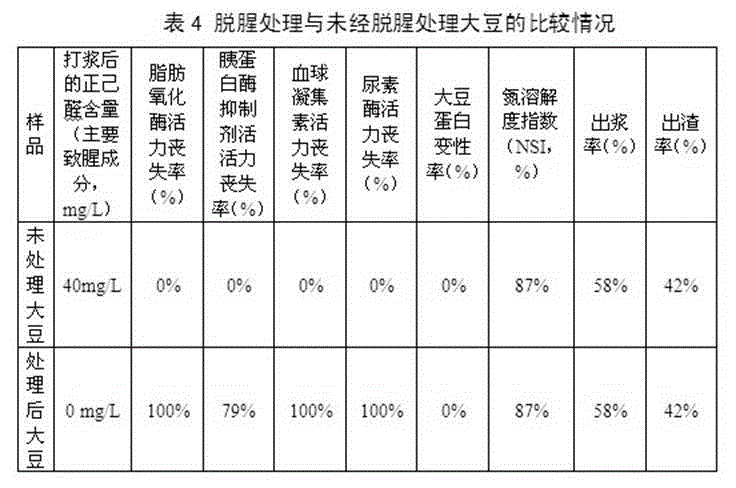

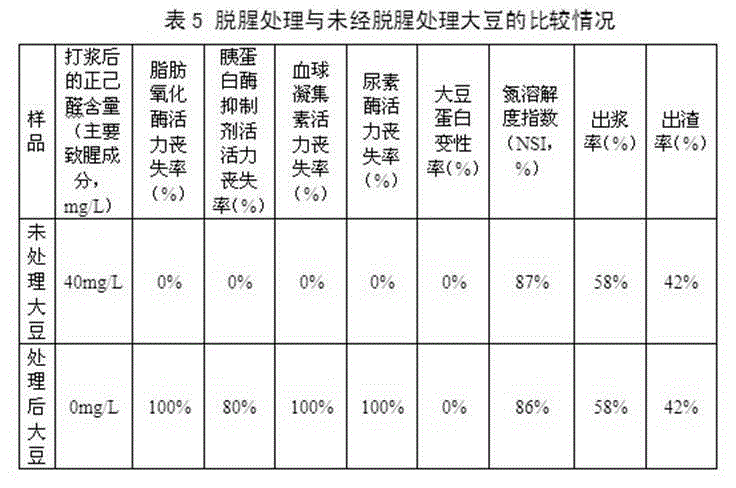

Preparation technique and application of non-odor soybean

InactiveCN102907627ANo beany smellEliminate anti-nutritional factorsFood preparationBiotechnologySodium bicarbonate

The invention relates to preparation technique and application of non-odor soybean. The preparation technique of non-odor soybean comprises cleaning, alkali treatment, microwave treatment, drainage and drying treatment and package, wherein the aqueous alkali comprises one or mixture of a plurality of sodium carbonate, sodium bicarbonate, potassium carbonate, potassium bicarbonate, sodium hydroxide and potassium hydroxide. The preparation technique combines the chemical treatment mode with the physical treatment mode to remove the beany flavor, the activity of the lipoxidase of the treated soybean is completely lost, and bean products prepared by the non-odor soybean do not generate n-hexylaldehyde or any beany flavor; besides, the preparation technique provided by the invention can eliminate the antinutritional factors in the soybean, the activity of the hemagglutinin and the urease of the treated soybean is completely lost, and the activity loss rate of the trypsin inhibitor is larger than 75%; and meanwhile, the nutritive value of the soybean is not being damaged at all.

Owner:桂仕林

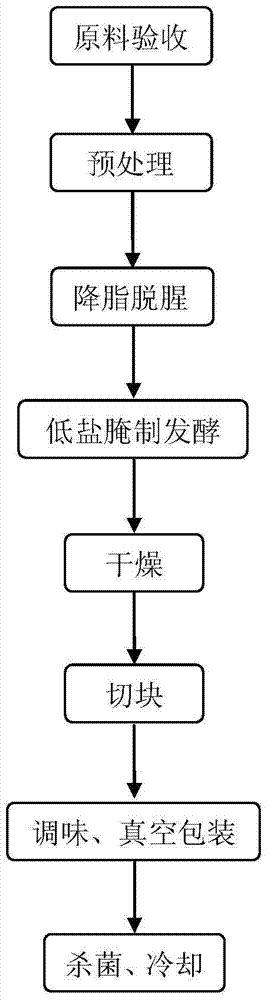

Method for improving flavor of liquor-marinated fish by utilizing biological flavor increasing technique

ActiveCN103932243AAchieving aroma enhancement by fermentationQuality improvementFood dryingFood preparationFish processingHigh fat

The invention discloses a method for improving flavor of liquor-marinated fish by utilizing a biological flavor increasing technique, belonging to the field of food processing and preservation. The method comprises the following steps: by taking fresh, alive or frozen freshwater fish as raw materials, pretreating, degreasing, deodorizing, pickling with low salt, fermenting, drying, slicing, carrying out seasoning and vacuum packaging, sterilizing and cooling, thereby preparing the instant liquor-marinated fish product with special flavor. According to the method, based on the traditional liquor-marinated fish processing technology, the earthy smell of freshwater fish is removed by utilizing a biological enzyme technique and a low-salt pickling and fermenting technique; the mellow flavor of the liquor-marinated fish is improved; leisure liquor-marinated fish food with low fat content and excellent flavor quality is produced; in the processing course, any chemical preservative is not added; the produced liquor-marinated fish is thick and mellow in flavor, and is stable in quality; due to the technique, the liquor-marinated fish production raw materials can also adopt high-fat fishes such as channel catfish; the production problems of difficulty of drying and dehydrating of high-fat fishes and serious oyster fat oxidation are solved; the liquor-marinated fish product quality and storage stability are improved; the industrialization production can be realized easily; the market prospect is wide.

Owner:JIANGNAN UNIV

Ketogenic energy bar containing high-quality fat and proteins and preparation method thereof

InactiveCN108936672AReduce oxidationReduce contentLipidic food ingredientsFood shapingVegetable oilHigh fat

The present invention provides a ketogenic energy bar containing high-quality fat and proteins and a preparation method thereof. The ketogenic energy bar is prepared by selecting high-quality fat andproteins. A microcapsule embedding technology is used to prepare fat microcapsule powder to delay fat oxidation. At the same time, hydrogenated-vegetable-oil-free and low-sugar chocolate is selected;a low-temperature production is used to minimize loss of nutrients; besides, the ketogenic energy bar has a reasonable ratio of the fat, proteins and carbohydrates, is excellent in flavor, fills a blank of high-quality ketogenic instant products, and helps people having a ketogenic diet to achieve the truly high-fat and low-carbon diet.

Owner:浙江衡美健康科技股份有限公司

Beef ball with pineapple and mung bean stuffing, and making method thereof

InactiveCN105166981AAdd flavorReduce greasy feelingFood ingredient as antioxidantFood ingredient as flavour affecting agentAnimal sciencePotato starch

The invention discloses a beef ball with a pineapple and mung bean stuffing. The beef ball with a pineapple and mung bean stuffing is made from, by weight, 100-120 parts of beef, 3-4 parts of edible salt, 20-24 parts of pineapple, 5-6 parts of grape wine, 8-10 parts of mung bean flour, 30-40 parts of fat meat, 4-5 parts of ginger, 3-4 parts of mycose, 2-3 parts of soybean protein isolate, 10-12 parts of sweet potato starch, 2-3 parts of rosemary, 1-2 parts of cinnamon bark, 1-2 parts of Syzygium aromaticum, 8-10 parts of egg liquid and a proper amount of ice water. Beef is preserved to make the beef have flavor, and the pineapple and mung bean stuffing contained in the beef ball reduces oiliness of meat balls and makes the meat balls have fruit flavor, mycose added in the invention can delay starch ageing in the beef ball, enhance the water retention of the beef ball and maintain the elasticity and the flavor of the beef ball in the long-term refrigeration process, and rosemary, cinnamon bark and Syzygium aromaticum with excellent oxidation properties added in the invention effectively inhibit the microbe growth and fat oxidation in the refrigeration process of meat balls, and have no untoward influences on the color, the sense and the quality of the meat balls.

Owner:高鹏

Preparation method of wheat germ short biscuit

InactiveCN102578189AHigh nutritional valueThe lack of lysine in biscuits improves the nutritional balance of biscuitsDough treatmentPre-baking dough treatmentCooking & bakingWheat germ

The invention discloses a processing method of wheat germ short biscuit, belonging to the field of food processing. The processing method comprises the following steps of: firstly weighing a certain amount of wheat germ, smashing and sieving, then placing the wheat germ in a high-pressure sterilizing device, heating at the temperature of 125 DEG C for 30 minutes to inactivate activity of lipoxidase in the wheat germ, and uniformly mixing with flour in a mass ratio of 1: (4-5) for later use; and secondly, adding white granulated sugar powder, grain blend oil, whey powder, edible salt, compound emulsifier, compound bulking agent and the like, then carrying out premixing, blending and preparing dough, moulding, baking, cooling and the like to finally obtain the wheat germ short biscuit. The wheat germ short biscuit obtained by adopting the invention has the characteristics of balanced nutrition, crisp taste, strong wheat fragrance and the like; milling by product is taken as raw material, thus cost is low; and the wheat germ short biscuit preparation process is simple, is convenient to control and popularize and has wide market prospect.

Owner:HEBEI AGRICULTURAL UNIV.

Microencapsulation fatty powder feed additives and preparation method thereof

ActiveCN105076723AImprove palatabilityMeeting nutritional needsAnimal feeding stuffFood shapingBiotechnologyAnimal science

The invention relates to the technical field of feed additives, and particularly discloses microencapsulation fatty powder feed additives and a preparation method thereof. Microencapsulation fatty powder consists of various kinds of fat, and is rich in medium and short chain fatty acids and long chain polyunsaturated fatty acids, effects of various fatty acids are sufficiently achieved, special nutrition requirements of animals are met, and growing performance of the animals is improved; the obtained feed additives have frankincense flavor, are sweet, are good in palatability, and have excellent attractiveness; the feed additives are prepared from fat, lactose and whey powder by a microencapsulation technology, fat and lactose contents are high, and the fat and the lactose are simultaneously provided for the animals, so that energy supply of the animals can be improved effectively; particles of the additives are small, and digestion rate of the animals is high; and moreover, the additives are treated by an antioxidant technology, fat oxidative rancidity can be prevented effectively, and stability performance of products is improved.

Owner:GUANGZHOU YOUBAITE FEED SCI & TECH

Yak milk formula milk powder for middle and old age, and preparation method thereof

ActiveCN103651940APromote absorption and metabolismReduce stimulationWhey manufactureBiotechnologyVegetable oil

The invention provides yak milk formula milk powder for middle and old age, and a preparation method thereof, wherein the main raw materials of the yak milk formula milk powder for middle and old age of per ton comprise: 100-800Kg of yak milk, 2000-4000Kg of fresh milk, 200-475Kg of whey powder (D90), 20-100Kg of whey protein concentrate (WPC34), 10-100Kg of refined plant oil, 15-150Kg of lactose, fructo-oligose, galactooligosaccharide, conjugated linoleic acid, phosphatidylserine, docosahexenoic acid, etc. The formula milk powder uses yak milk and fresh milk as milk raw materials, avoids the need of supplementing a lot of chemically synthesized organic and inorganic nutrients when common milk is individually used, can be better absorbed and metabolized for a consumer, reduces stimulation to gastrointestinal tracts, can enhance antioxidation and immunization capability of the body, promotes oxidation and decomposition of fat, promotes human protein synthesis, regulates balance of various beneficial bacteria, and prevents diarrhoea and constipation.

Owner:临夏州燎原乳业有限公司

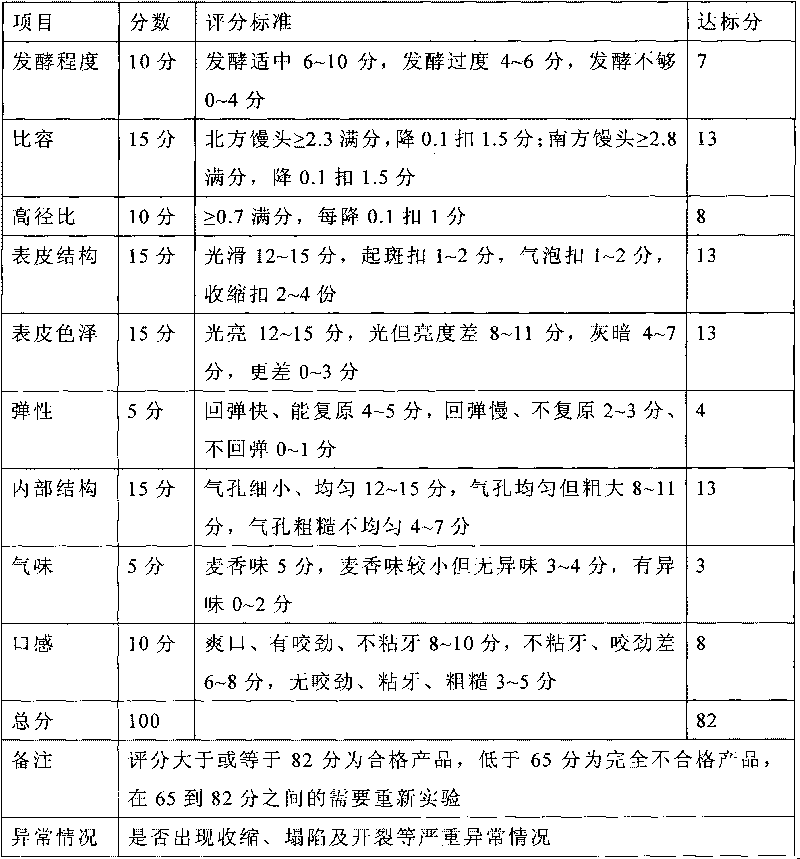

Domestic instantly-fermenting steamed bread modifier

InactiveCN101731299ANo yellowingNo retractionDough treatmentPre-baking dough treatmentSodium bicarbonateFood additive

The invention belongs to the technical field of compound food additives and in particular discloses a domestic instantly-fermenting bread modifier, which is mainly prepared by uniformly mixing the following raw materials in a certain weight ratio: yeast, emulsifier, sodium bicarbonate, citric acid, alpha-amylase, glucose oxidase, lipoxidase and modified starch. The modifier can be conveniently used without additional yeast and other additives, makes domestic operation more convenient, the skin the steamed bread smooth and the taste of the steamed bread fragrant and sweet, and delays ageing caused by water loss.

Owner:刘全卫

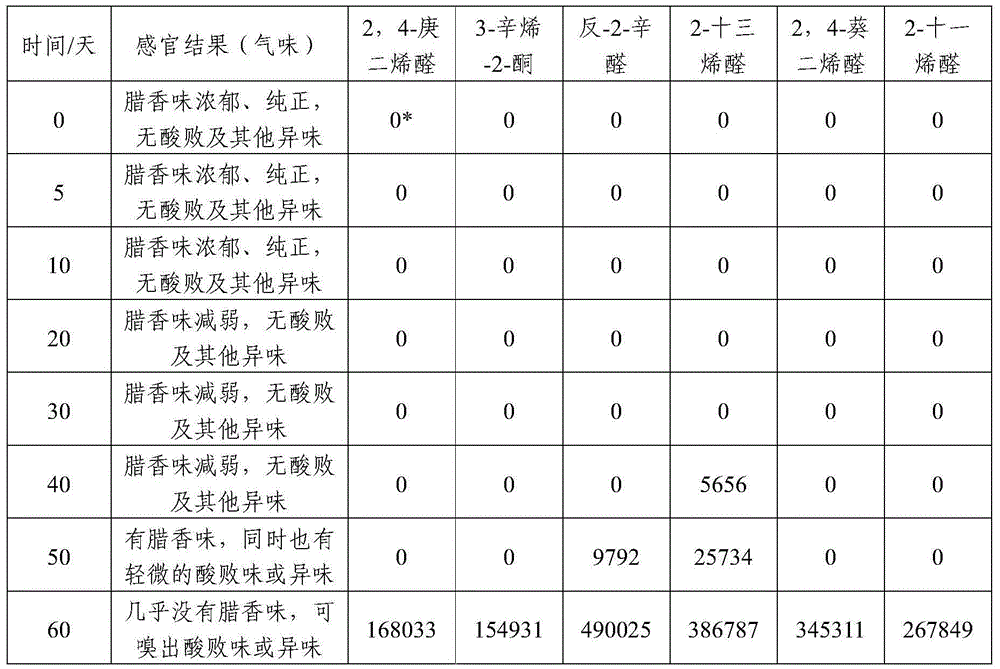

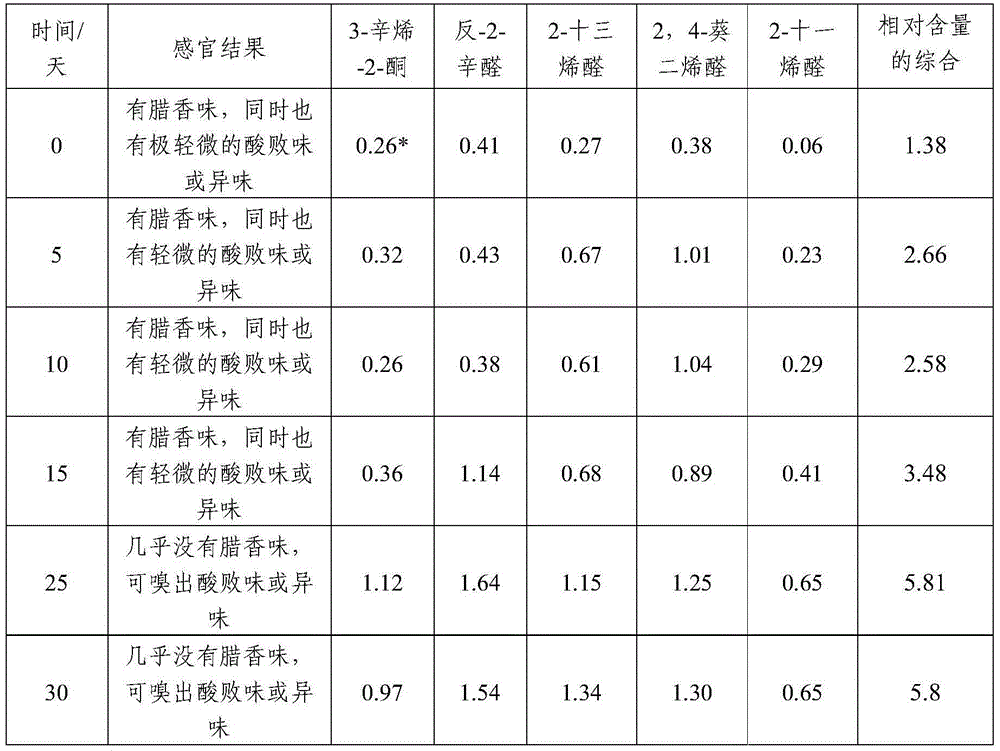

Method for detecting oxidative deterioration of cured meat product

ActiveCN104020224AExtended storage timeIncrease contentComponent separationSolid-phase microextractionKetone

The invention relates to a method for detecting oxidative deterioration of a cured meat product. The method adopts a headspace solid phase microextraction and GC-MS technique to analyze the kinds and change of smell substances of the cured meat product, and a detection result shows that after a rancid characteristic odor appears in the storage process, people find that one or more of six substances including 2,4-heptyl diene aldehyde, 3-octylene-2-ketone, anti-2-caprylic aldehyde, 2-tridecylene aldehyde, 2,4-decadienal and 2-hendecene exit in the cured meat product; one or more of the six substances corresponding to different products and sense and peroxide value indicators of the products are contrastively analyzed, people find that the six substances exist after the rancid odor appears and also in the early stage of oxidation, and the content of the six substances is gradually increased along with the prolonging of storage time. Further, the result proves that the six substances can be used as the indicator of the fat oxidative deterioration degree of the cured meat product in the storage process.

Owner:CHINA MEAT RES CENT

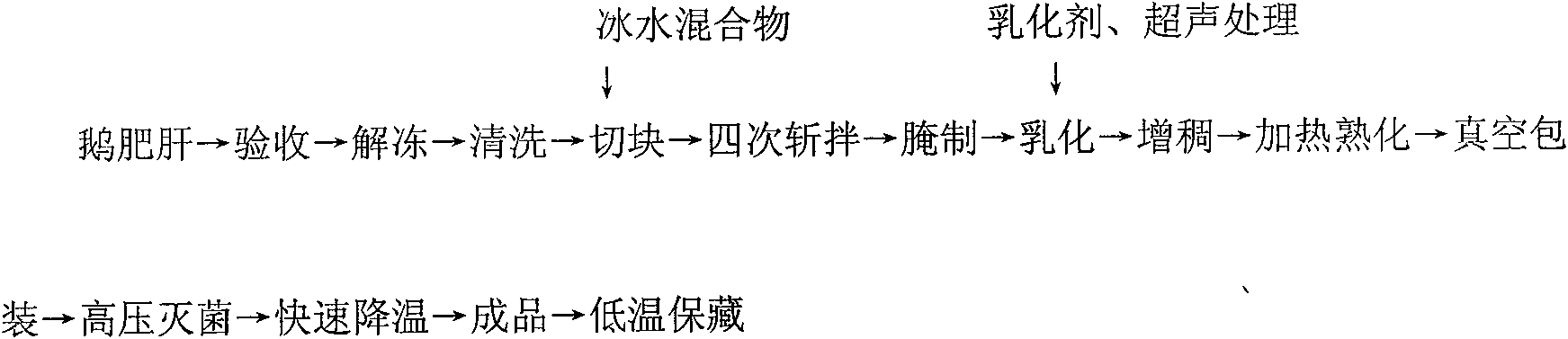

Process for stably processing foie gras without fat isolation and with low oxidation

InactiveCN101617807AAvoid churnAvoid breakingMeat/fish preservation by heatingMeat/fish preservation by freezing/coolingAdditive ingredientPickling Agents

The invention discloses a process for stably processing foie gras without fat isolation and with low oxidation, which comprises the following steps: slowly unfreezing goose livers serving as a raw material at a temperature of between 2 and 6 DEG C; cleaning the goose livers with a mixture of water and ice; mixing the goose livers under vacuum in a chopper for 10 to 15 minutes for four times; pickling the goose livers in a pickling agent for 24 hours at a temperature of between 0 and 4 DEG C; adding emulsifying agent; using 50 to 600w and 20 to 100 kHz ultrasonic waves to jointly process the goose livers to emulsify the pickled goose livers; thickening the emulsified goose livers and heating the goose livers at a temperature of between 90 and 100 DEG C to age the goose livers; canning the aged goose livers under vacuum; sterilizing the canned goose livers for 2 to 15 minutes at a temperature of between 100 and 120 DEG C; quickly decreasing the temperature to obtain the product; and storing the finished product in an environment at a temperature of 0 to 4 DEG C. The foie gras made by the process has rich nutrients, high quality, white color and luster, pure mouth feel, low fat oxidation, no fat isolation, little nutrient loss and long shelf life, and is widely applied to Chinese and western foods.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Porcini essential oil, essential oil seasoning and preparing method thereof

The present invention discloses a porcini essential oil and a essential oil seasoning, belonging to the field of food additives. The preparing method of the porcini essential oil comprises the following steps: adding porcini dry powder or porcine flavour dry powder to absolute ethyl alcohol by ratio, uniformly mixing, leaching at a temperature of 25 DEG C to 70 DEG C for 1 to 3 hours, and filtering to obtain alcohol extracting solution; concentrating under reduced pressure to obtain extract; dissolving the extract, standing, discarding deposits, and collecting superfacial solution to obtain porcini essential oil. Porcini powder essential oil and the essential oil seasoning can be obtained by adding other ingredients to the porcini essential oil. The porcini essential oil and the essential oil seasoning reserve the fragrance of porcini, and are ideal food additives. The yield of the porcini essential oil is improved by utilizing the endogenous lipoxidase of porcini with a biologic conversion method. The present invention can utilize porcini leftovers for production, so the cost is low, and porcini resources can be thoroughly utilized. The method is simple, safe and free of environmental pollution.

Owner:CHUXIONG HONGGUI GREEN FOOD

Phosphorus-free water-retaining agent for peeled squids and using method of phosphorous-free water-retaining agent

InactiveCN104222254AImprove water holding capacityExtended shelf lifeMeat/fish preservation by coatingMeat/fish preservation by freezing/coolingPhosphateSquid

The invention discloses a phosphorus-free water-retaining agent for peeled squids and a using method of the phosphorus-free water-retaining agent. The phosphorus-free water-retaining agent comprises the following components in parts by mass: 10-20 parts of sodium citrate, 10-20 parts of tea polyphenol, 5-10 parts of sodium D-isoascorbate, 30-35 parts of sorbitol and 25-30 parts of lactitol. The using method comprises the following steps: treating the squids, preparing a water-retaining agent solution, soaking the peeled squids and freezing and preserving the squids. The water-retaining agent has the characteristics of safety and effectiveness, the water retaining property of the peeled squids in the soaking process can be improved, squid fat oxidation and spoilage of fish can be effectively inhibited, and the storage period of the peeled squids is prolonged. Meanwhile, the water-retaining agent disclosed by the invention belongs to a non-phosphate water-retaining agent, and a series of problems caused by the reason that phosphate exceeds the standard can be effectively solved.

Owner:JIANGSU YOUYUAN BIOTIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com