Linseed oil and linseed gum vegetable fat powder and preparation method thereof

The technology of linseed oil and linseed gum is applied in the field of food science, which can solve the problems of limited application space and easy oxidation, and achieve the effects of good suspension, harm reduction, and blood lipid reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh 45 g of soybean protein isolate and 40 g of maltodextrin, dissolve them in 1000 mL of distilled water at 60 °C, add 2.8 g of linseed gum, stir with a stirrer until fully dissolved, then add 35 g of linseed oil, Stir well to obtain an emulsion.

[0028] (2) The emulsion prepared in the above step (1) was sheared and emulsified for 3 min at 8000 r / min, then added to the high-pressure homogenizer, and homogenized twice under the condition of 30 MPa, Afterwards, spray drying is carried out at an air inlet temperature of 175°C, and the non-dairy creamer product is obtained after collection.

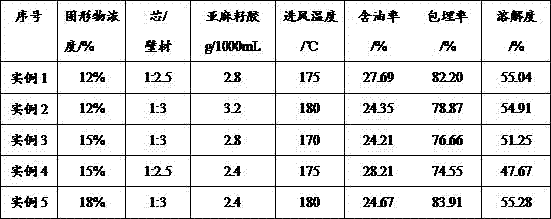

[0029] (3) Testing the oil content, embedding rate and solubility of the non-dairy creamer products obtained above are shown in Table 1.

Embodiment 2

[0031] (1) Weigh 45 g soybean protein isolate and 45 g maltodextrin, dissolve in 1000 mL distilled water at 60 °C, add 3.2 g linseed gum, stir with a stirrer until fully dissolved, then add 30 g linseed oil, Stir well to obtain an emulsion.

[0032] (2) The emulsion prepared in the above step (1) was sheared and emulsified for 3 minutes under the condition of 10000 r / min, and then the emulsion was added to a high-pressure homogenizer, and homogenized twice under the condition of 30 MPa, Afterwards, spray drying is carried out at an air inlet temperature of 180°C, and the non-dairy creamer product is obtained after collection.

[0033] (3) Testing the oil content, embedding rate and solubility of the non-dairy creamer products obtained above are shown in Table 1.

Embodiment 3

[0035] (1) Take 57 g of soybean protein isolate and 55 g of maltodextrin, dissolve them in 1000 mL of distilled water at 60 °C, add 2.8 g of linseed gum, stir with a stirrer until fully dissolved, then add 38 g of linseed oil, and stir Evenly, an emulsion is obtained.

[0036] (2) The emulsion prepared in the above step (1) was sheared and emulsified for 3 minutes under the condition of 10000 r / min, and then the emulsion was added to a high-pressure homogenizer, and homogenized twice under the condition of 30 MPa, Afterwards, spray drying is carried out at an air inlet temperature of 170°C, and the non-dairy creamer product is obtained after collection.

[0037] (3) Testing the oil content, embedding rate and solubility of the non-dairy creamer products obtained above are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com